SERVICE MANUAL

CAUTION:

Before servicing this chassis, it is important that the service technician read the “Safety

Precautions” and “Product Safety Notices” in this service manual.

No. 0415

CM821FET

CM823FET

CM827ET

CM828ET

Data contained within this Service

manual is subject to alteration for

improvement.

Les données fournies dans le présent

manuel d’entretien peuvent faire l’objet

de modifications en vue de perfectionner

le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen können sich

zwecks Verbesserungen ändern.

ATTENTION:

Avant d’effectuer l’entretien du châassis, le technicien doit lire les «Précautions de sécurité»

et les «Notices de sécurité du produit» présentés dans le présent manuel.

VORSICHT:

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „Sicherheitshinweise“ und „Hinweise

zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

COLOUR MONITOR

DECEMBER 1999

FEATURES

1. Flat screen CRT with anti-glare, dynamic focus circuit,

dark glass, and INVAR shadow mask give the

sharpest focus and highest contrast.

2. Automatic scanning and automatic adjustment to

conform to a wide range of scanning frequencies and

user requirements.

3. Signal input allows D-Sub Mini 15-pin cable.

4. Power Save Mode automatically puts the monitor into

a standby mode (power consumption less than 15W)

when the H.sync. signal is not detected, and a power off mode (less than 5W) when the V.sync. signal is not

detected. Normal mode is restored immediately when

the H. sync. signal and the V.sync. signal are detected.

This feature prolongs monitor life and reduces energy

consumption by up to about 75 %.

SAFETY PRECAUTIONS

NOTICE: Comply with all cautions and safety related

notes located on or inside the cabinet and on the chassis

or picture tube.

The following precautions must be observed.

1. Do not install, remove, or handle the picture tube in

any manner unless shatterproof goggles are worn.

People not so equipped should be kept away while

picture tubes are handled.

2. When replacing a chassis in the monitor, all the

protective devices must be put back in place, such as,

barriers, non-metallic knobs, adjustment and compartment

shields, and isolation resistor-capacitor, etc.

3. When service is required, observe the original lead

dress. Extra precaution should be taken to assure

correct lead dress in the high voltage circuitry area.

4 Always use the manufacturer’s replacement components.

Especially critical components as indicated on the

circuit diagram should not be replaced by other

manufacturer’s one. Furthermore where a short circuit

has occurred, replace those components that

indicate evidence of overheating.

5. Before returning a serviced monitor to the customer,

the service personnel must thoroughly test unit to be

certain that it is completely safe to operate without

danger of electrical shock, and be sure that no

protective device built into the monitor by the

manufacturer has become defective, or inadvertently

defeated during servicing.

Therefore, the following checks should be performed

for continued protection of the customer and service

technician.

6. In the case of the microprocessor unit, shop

adjustment is necessary after exchange of the

microprocessor unit.

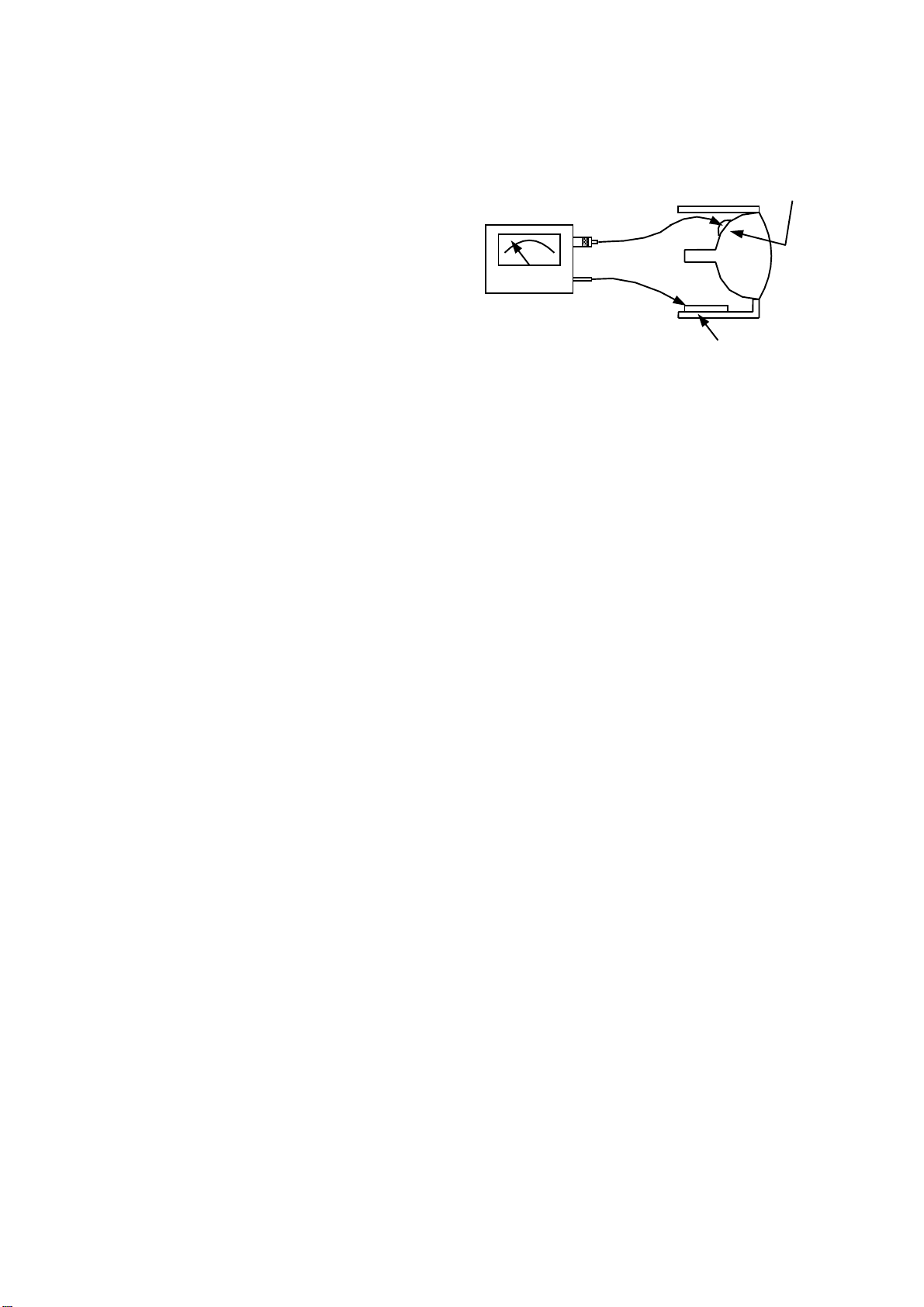

High Voltage

This monitor is provided with a high voltage hold down

circuit for clearly indicating that voltage has increased in

excess of a predetermined value.

Comply with notes described in this Service Manual

regarding this hold down circuit when servicing, so that

this hold down circuit may function correctly.

Service Warning

With minimum Brightness and Contrast the operating

high voltage in this display is lower than 30 kV.

If any component having influence on the high voltage is

replaced, confirm that the high voltage with minimum

Brightness and Contrast is lower than 30 kV.

To measure high voltage use a high impedance

high-voltage meter. (SENSITIVE RESEARCH Model:

ESH or Equivalent)

Connect (-) to chassis earth and (+) to the CDT anode

button. (See the following connection diagram Fig. 1.)

NOTE: Turn power switch off without fail before making

the connection to the Anode button

CDT ANODE

(+)

(-)

HIGH IMPEDANCE

H.V. METER

SENSITIVE RESEARCH

Model: ESH or equivalent. CHASSIS GROUND

FIG. 1

X-radiation

TUBE: The source of X-radiation in this monitor is the

picture tube. The tube utilized in this chassis is specially

constructed to limit X-radiation emissions.

For continued X-radiation protection, the replacement

tube must be the same type as the original, manufacturer

approved type.

When troubleshooting and making test measurements in

a monitor with a problem of excessive high voltage, avoid

being unnecessarily close to the picture tube and the high

voltage components.

Do not operate the chassis longer than is necessary to

locate the cause of excessive voltage.

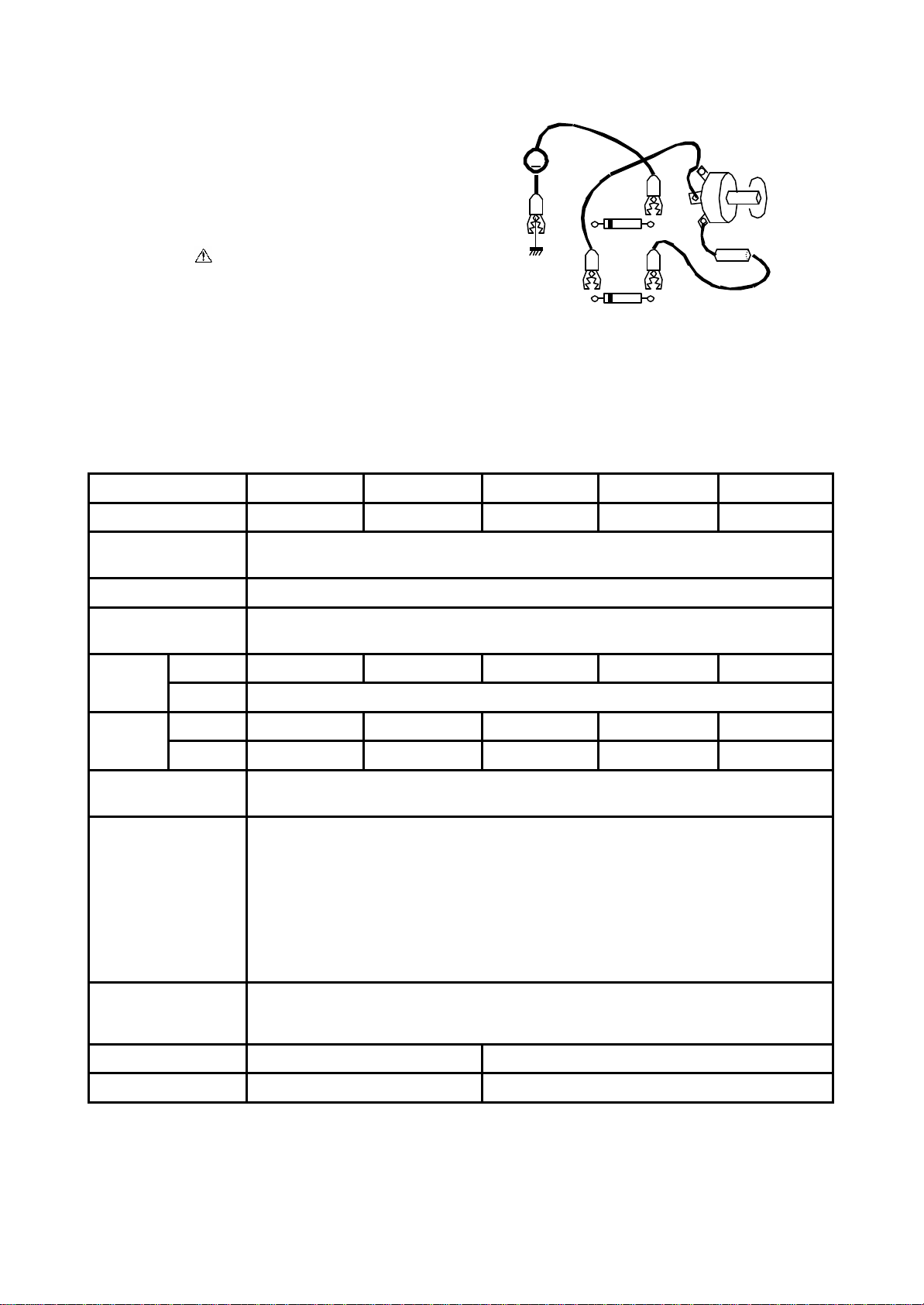

CHECK OF HIGH VOLTAGE HOLD DOWN

CIRCUIT

Checking of the high Voltage hold down circuit operation.

1. Turn the switch of the unit ON, and set the Brightness

and Contrast controls to max.

2. Turn the switch of the unit OFF.

3. Connect a DC Voltmeter and an adjustment jig as

shown in Fig. 2.

4. Set the adjustment VR to fully counterclockwise.

5. Turn the switch of the unit ON and gradually rotate the

adjustment VR clockwise.

6. Check that a reading of DC voltage-meter is less-than

0.6±0.1 V when picture disappears.

7. Turn the switch of the unit OFF immediately after

checking that the picture disappears.

8. Remove the adjusting jig and the DC voltmeter.

NOTE:

Reading of 0.6 V is approximately equivalent to

30 kV of CDT Anode High Voltage.

2

PRODUCT SAFETY NOTICE

R793

R792

Many electrical mechanical parts in the color monitor

units have special safety related characteristics.

These are often not evident from visual inspection nor

can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

DC VOLT METER

(10 V range)

VARIABLE

V

Clockwise

RESISTER

300 k -B (1/2 W)

have these special safety characteristics are identified in

this Service Manual.

Electrical components having such features are

identified by marking with on the schematics and on

the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

RESISTER

To

CHASSIS

GROUND

manufacturer recommended replacement one, sh own in

the parts list in this Service Manual, may create shock,

fire, X -radiation, or other hazards.

FIG. 2 CHECKING CIRCUIT USING JIG

DEF BOARD ASSEMBLY

Productions are issued from time to time. For the latest

information, always consult this Service Manual.

SPECIFICATIONS

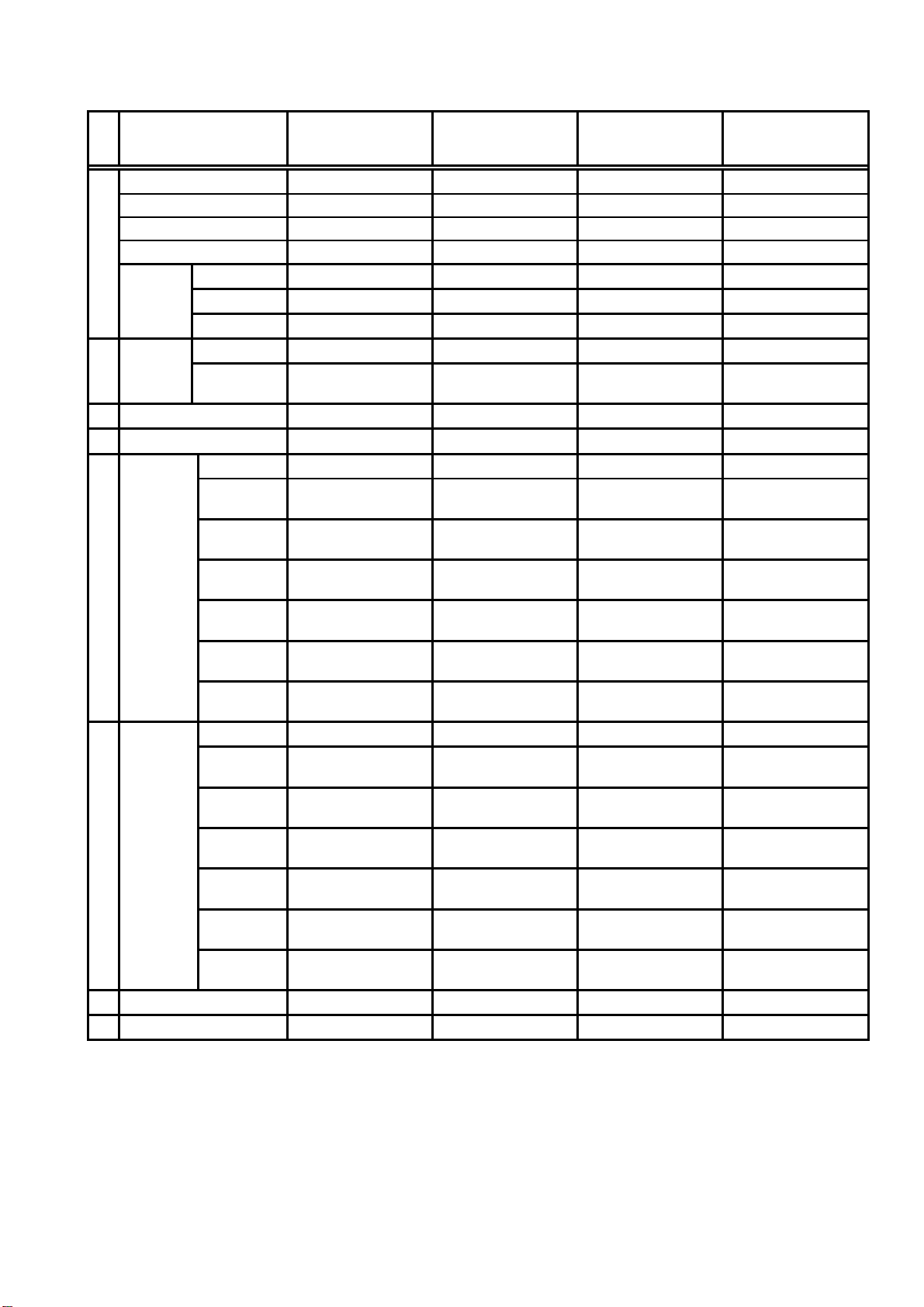

Model Name CM821FET CM823FET CM827ET CM828ET

Destination Europe Europe Europe Europe

68 k (1/2W)

Rated Voltage AC 100-120 / 200-240 V, Automatically select.

Provided with Power Circuit.

Power Consumption 145 W max (120W typ.)

Color Display Tube

(CDT)

Rated

Frequency

Resolution

Vertical Up to 1392 lines Up to 1536 lines Up to 1392 lines Up to 1536 lines

Horizontal 31 - 107 kHz 31 - 121 kHz 31 - 107 kHz 31 - 115 kHz

Vertical 50 - 160 Hz

Horizontal Up to 1856 dots Up to 2048 dots Up to 1856 dots Up to 2048 dots

21 inches diagonal, 0.21 mm horizontal dot pitch,

Invar shadow mask, Black matrix, Anti-Reflection coat, Short persistence phosphors.

Signal Inputs Red, Green and Blue analog video

H/V separate, H/V composite or Sync. on Green sync (option).

User Controls Power Switch

Degauss

Language Select

Contrast

Brightness

H. Position

H. Size

V. Position

V. Size

Rotation

Pincushion

Trapezoid

Pin.Balance

Parallelogram

H. Moiré

V. Moiré

Color Select

Red, Green, Blue

DMS Mode

OSD H-Position

OSD V -Position

Dynamic Focus

V.Linearity

V.L. Balance

Hemisphere

Total Reset

Single Recall

Top Corner Pin.

Bottom Corner Pin.

H. Convergence adj.

V. Convergence adj.

Environmental

Condition

Operation Storage

Temperature : 5 to 35 -20 to 60

Humidity : 10 % to 80 % 10 % to 90 %

Dimensions 488(W) × 483 (H) × 475 (D) mm * 488(W) × 483 (H) × 470 (D) mm *

Weight 30.5 kg(Net) 27.0 kg(Net)

* Including Tilt & Swivel base

3

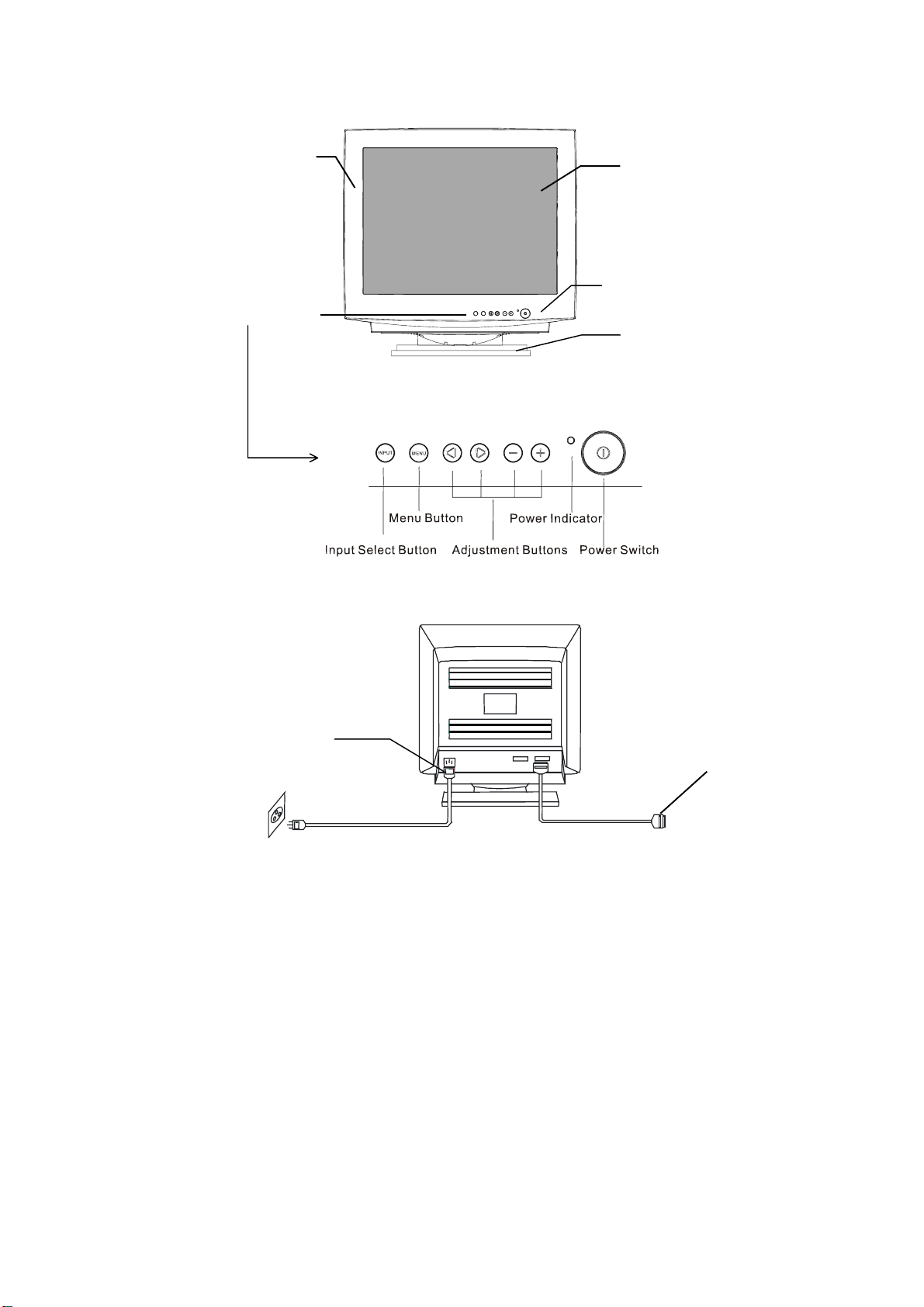

CONTROLS

Front Cover

Control Panel

FIG.3 FRONT VIEW

FIG. 4 CONTROL PANEL

CRT Surface

Tilt & Swivel Base

FIG. 3 FRONT VIEW

Signal Cable

AC Inlet

D-Sub Mini 15-pin

FIG. 5 REAR VIEW

(D-Sub Mini 15-pin)

4

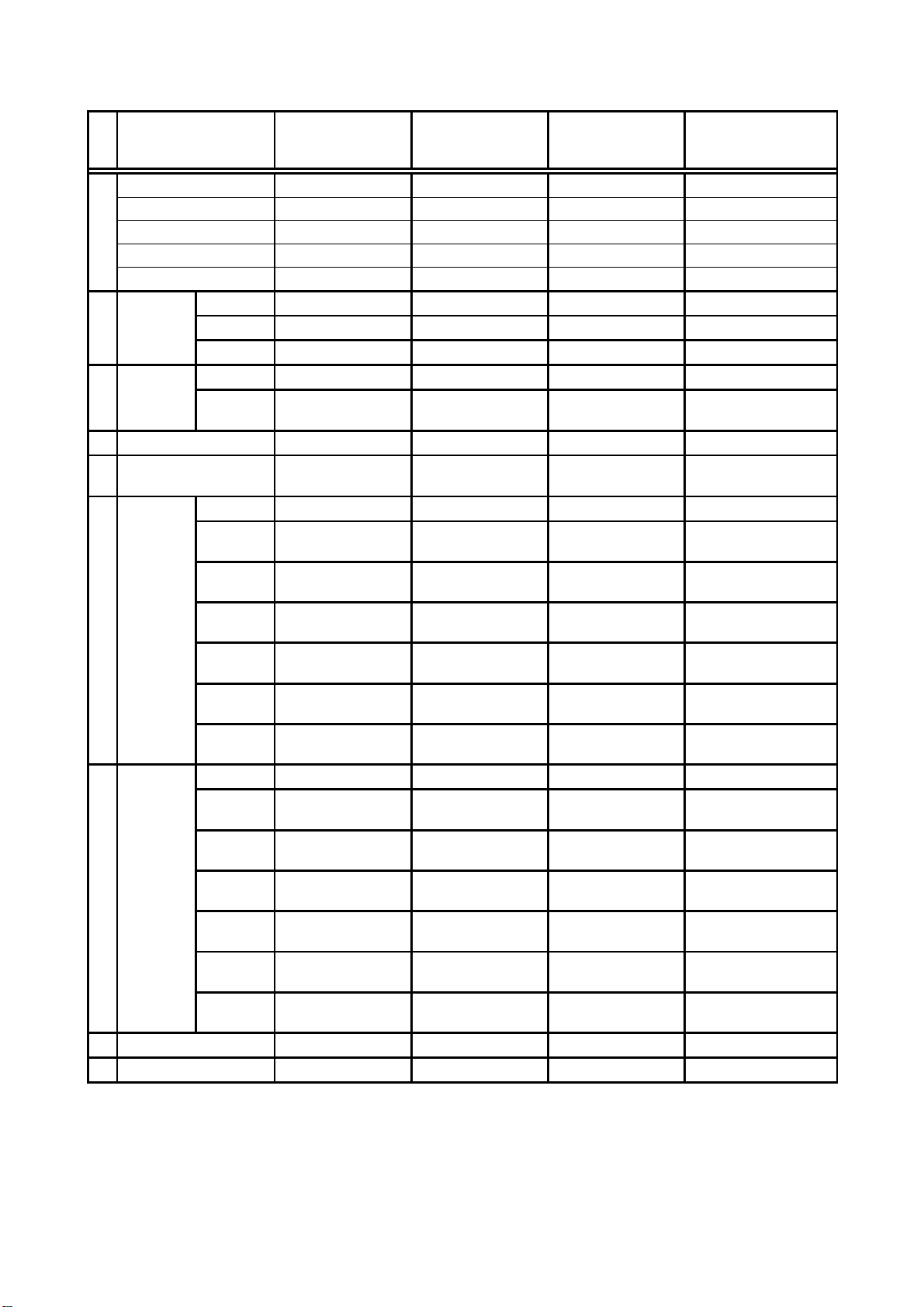

SIGNAL TIMING CHART

CM821F

CM821FET

1 Video Type R/G/B Analog R/G/B Analog R/G/B Analog R/G/B Analog

Voltage 0.7 Vp-p 0.7 Vp-p 0.7 Vp-p 0.7 Vp-p

Set Up None None None None

2 Sync Type H/V Separate H/V Separate H/V Separate H/V Separate

Amp. TTL Level

3 Video frequency 25.175 MHz 56.250 MHz 94.500 MHz 157.500 MHz

4 Character (Letter)

5 Horizontal Frequency 31.469 kHz 53.674 kHz 68.677 kHz 91.146 kHz

Front

Sync.

Back

Blanking

Display

H. period

6 Vertical Frequency 70.086 Hz 85.061 Hz 84.997Hz 85.024 Hz

Front

Sync.

Back

Blanking

Display

H. period

7 Scan System (Non-interlaced) (Non-interlaced) (Non-interlaced) (Non-interlaced)

8 Signal name 30B 54A 68A 91A

* VGA is a registered trademark of International Business Machined Corporation.

* VESA is a trademark of a nonprofit organization, Video Electronics Standard Association.

Signal

0.636 µs (16cl) 0.569 µs (32cl) 0.508 µs (48cl) 0.406 µs (64cl)

porch

3.813 µs (96cl) 1.138 µs (64cl) 1.016 µs (96cl) 1.016 µs (160cl)

width

1.907 µs (48cl) 2.702 µs (152cl) 2.201 µs (208cl) 1.422 µs (224cl)

porch

6.356 µs (160cl) 4.409 µs (248cl) 3.725 µs (352cl) 2.844 µs (448cl)

width

25.422 µs (640cl) 14.222 µs (800cl) 10.836 µs (1024cl) 8.127 µs (1280cl)

time

31.778 µs (800cl) 18.631 µs (1048cl) 14.561 µs (1376cl) 10.971 µs (1728cl)

(1H)

0.381 ms (12H) 0.019 ms (1H) 0.015 ms (1H) 0.011 ms (1H)

porch

0.064 ms (2H) 0.056 ms (3H) 0.044 ms (3H) 0.033 ms (3H)

width

1.112 ms (35H) 0.503 ms (27H) 0.524 ms (36H) 0.483 ms (44H)

porch

1.557 ms (49H) 0.578 ms (31H) 0.582 ms (40H) 0.527 ms (48H)

width

12.711 ms (400H) 11.179 ms (600H) 11.183 ms (768H) 11.235 ms (1024H)

time

14.268 ms (449H) 11.756 ms (631H) 11.765 ms (808H) 11.761 ms (1072H)

(1H)

VGA

640×400

(70Hz)

9999 9999 9999 9999

9999 9999 9999 9999

9999 9999 9999 9999

9999 9999 9999 9999

(Neg./Pos.)

640 dots×400 lines 800 dots×600 lines 1024 dots×768 lines 1280 dots×1024 lines

VESA

800×600

(85Hz)

TTL Level

(Pos./Pos.)

VESA

1024×768

(85Hz)

TTL Level

(Pos./Pos.)

VESA

1280×1024

(85Hz)

TTL Level

(Pos./Pos.)

5

Signal

CM821F

CM821FET

-

-

1 Video Type R/G/B Analog R/G/B Analog R/G/B Analog R/G/B Analog

Voltage 0.7 Vp-p 0.7 Vp-p 0.7 Vp-p 0.7 Vp-p

Set Up None None None None

2 Type H/V Separate H/V Separate H/V Separate H/V Composite

Amp. TTL Level

3 Video frequency 243.500 MHz 288.500 MHz 25.175 MHz 24.800MHz

4 Character (Letter)

5 Horizontal Frequency 112.5 kHz 112.5 kHz 31.469 kHz 31.000 kHz

Front

porch

Sync.

width

Back

porch

Blanking

width

Display

time

H. period

(1H)

6 Vertical Frequency 90.000 Hz 75.000 HZ 59.940 Hz 50.000 Hz

Front

porch

Sync.

width

Back

porch

Blanking

width

Display

time

H. period

(1H)

7 Scan System (Non-interlaced) (Non-interlaced) (Non-interlaced) (Non-interlaced)

8 Signal name 112C 112F 30C 31W

0.263 µs (64cl) 0.444 µs (128cl) 0.636 µs (16cl) 0.403 µs (10cl)

0.790 µs (192cl) 0.778 µs (224cl) 3.813 µs (96cl) 3.790 µs (94cl)

1.251 µs (304cl) 1.222 µs (352cl) 1.907 µs (48cl) 2.258 µs (56cl)

2.305 µs (560cl) 2.444 µs (704cl) 6.356 µs (160cl) 6.452 µs (160cl)

6.584 µs (1600cl) 6.444 µs (1856cl) 25.422 µs (640cl) 25.806 µs (640cl)

8.889 µs (2160cl) 8.889 µs (2560cl) 31.778 µs (800cl) 32.258 µs (800cl)

0.009 ms (1H) 0.009 ms (1H) 0.381 ms (10H) 3.548 ms (110H)

0.027 ms (3H) 0.027 ms (3H) 0.064 ms (2H) 0.129 ms (4H)

0.409 ms (46H) 0.924 ms (104H) 1.049 ms (33H) 3.097 ms (96H)

0.444 ms (50H) 0.960 ms (108H) 1.430 ms (45H) 6.774 ms (210H)

10.667 ms (1200H) 12.373 ms (1392H) 15.253 ms (480H) 13.226 ms (410H)

11.111 ms (1250H) 13.333 ms (1500H) 16.683 ms (525H) 20.000 ms (620H)

VESA

1600×1200

(90Hz)

9 9

9 9

(Pos./Pos.)

1600 dots×1200

lines

VESA

1600×1200

(75Hz)

TTL Level

(Pos./Pos.)

1600 dots×1200

lines

VGA

640×480

(60Hz)

TTL Level

(Neg./Neg.)

640 dots×480 lines 640 dots×410 lines

TTL Level (Neg./Neg.)

Adjustment

signal

6

DESCRIPTION OF CIRCUIT

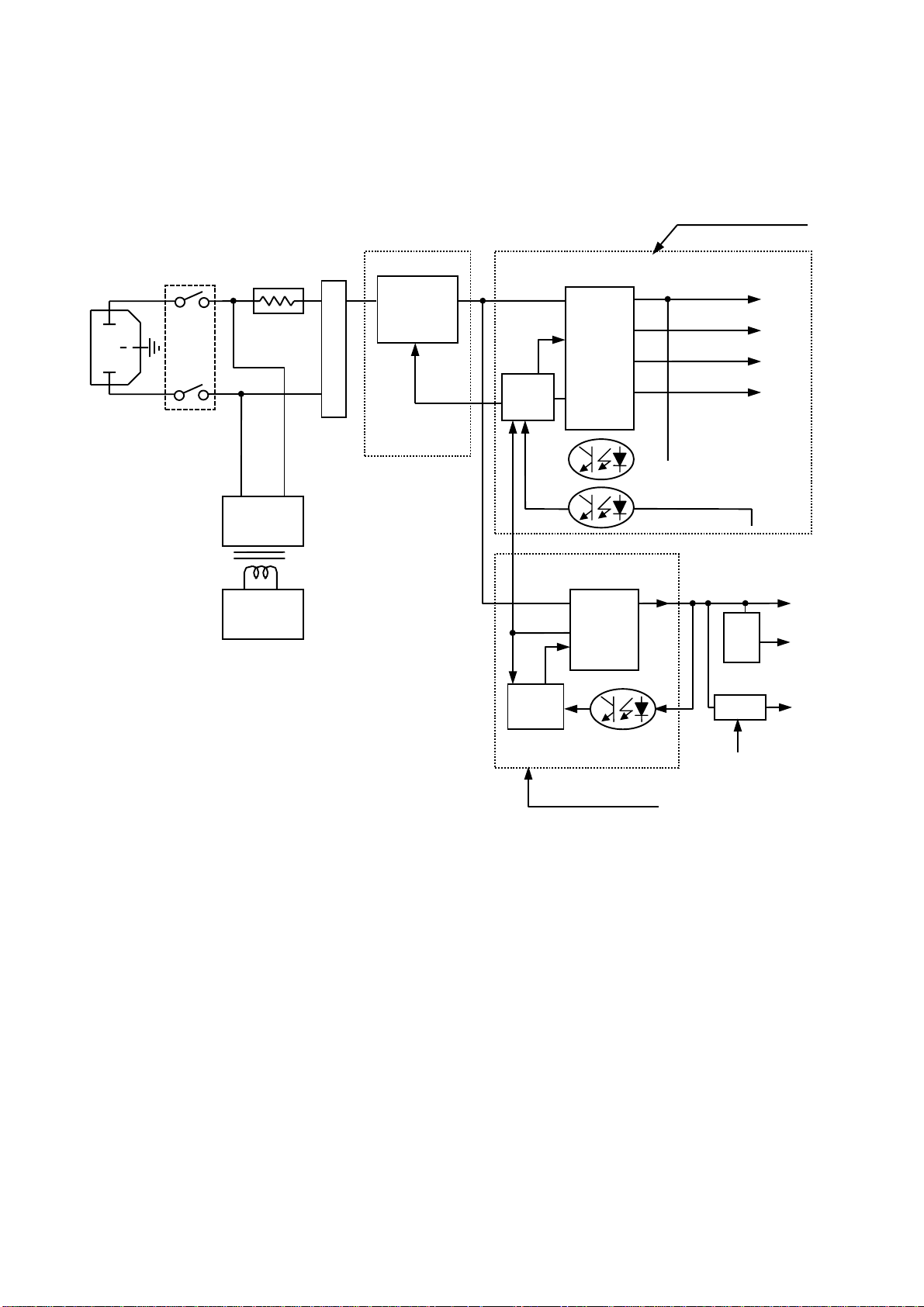

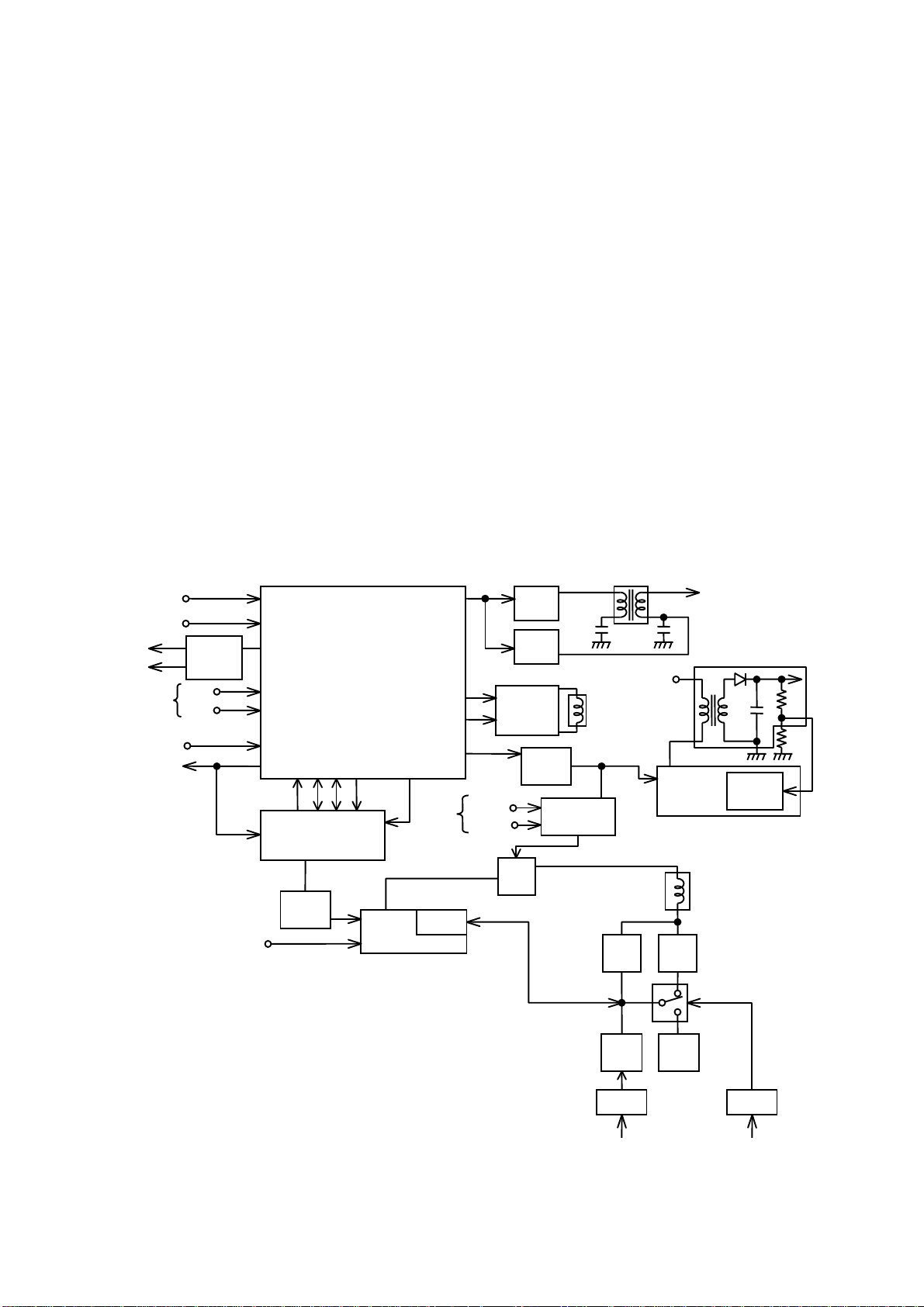

1. Power Supply Circuit

This model incorporates a wide range universal power supply utilizing a switching regulator (see block diagram in Fig.6).

1.1 AC input

AC input consists of AC inlet, EMI filter (C901~C905,C907) and rectifier (D901~D904). Rectifier circuits adapt to

full-wave method. Inrush current limiting circuit (R90A) protects from excessive inrush current at initial stage of power

on.

1.2 Switching Regulator circuit

Switching Regulator ci rcuit is designed to handle variations of two conditions t o ensure constant +B voltage to secondary circuit :

(Circuit #2) varying load conditions of video, (Circuit #3) varying horizontal frequencies and load conditions.

1.2.1 Circuit #1 :

Circuit #1 consists of chopper inductor (L910), chopper component (Q910), rectifier component (D910, C920) and

control IC (I920). R918 and R919, R91A detect output voltage and provide signal to I920 pin 20 which adjusts the pulse

width based on the pin 20 voltage level to provide constant voltage output.

1.2.2 Circuit #2 :

Circuit #2 consists of chopper transform er (T921), chopper component (Q920) and control IC (I920). T921 detects out put voltage and

provides signal to I920 pin 4 which adjus ts the pulse width based on the pin 4 voltage l evel to provide c onstant voltage output. If the

secondary circuit becomes overloaded, prim ary current through T921 is det ected at R923, R924 and stops the switching operation.

Once the circuit has overloaded, the power switch must be turned off for a short period and then turned on to re-establish power.

Switching frequency is determined by time constant of R92E and R92F, R92G.

1.2.3 Circuit #3 :

Circuit #3 has two outputs. +5V is used mainly to drive the microprocessor circuit and input the signal selection circuit.

+6.3V is used for the CRT heater.

When the DC voltage from circ uit #1 is applied to I 940, I940 s tarts osc illations . Once os cillati ons start, the switching trans is tor is dri ven

by the voltage taken from the terti ary winding of T940. The output vol tage of the T940’s tertiary winding is recti f i ed by D942 and C942.

The main power supply (Circuit #2) turns on (off) when a signal Hi gh (Low) is applied to the base of Q984 from the m icroprocessor

circuit.

1.3 Degaussing circuit

When the power is switched on, the CRT is degaussed automatically by current flowing through the degauss circuit

while the relay (S99R) is closed. Degaussing current flows for approximately 20 seconds and stops by causing relay

(S99R) to be opened after secondary circuit operation is stabilised.

The circuit also allows for manual degauss by using “DEGAUSS” control on OSD menu which closes S99R through

Q991 to allow current to flow through the degauss coil.

7

A

FIG. 6 BLOCK DIAGRAM FOR POWER SUPPLY CIRCUIT

Main power supply

Circuit #2

C inlet

Degauss

Circuit

Manual

Degauss

On/Off

control

5V

Reg.

+B

+85V

+54V

+14V

+ 6.2V

MPU

Heater

Chopper

Chopper

Control

Circuit #1

Circuit #3

+ 12V

Control

Chopper

On/Off

On/Off

control

Standby power supply

8

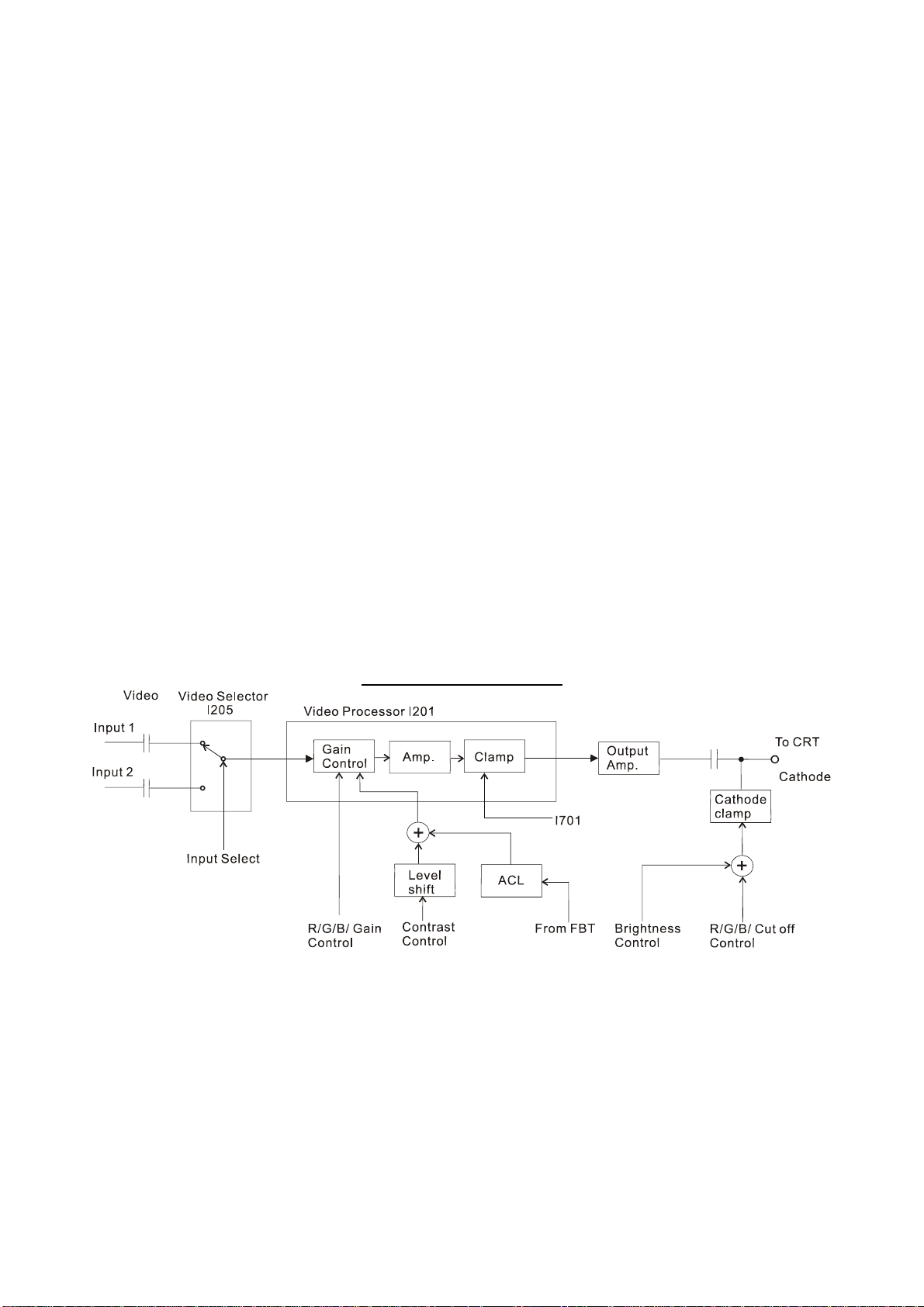

2. Video Processing Circuit

2.1 Video select circuit (Optional)

Two of Video input signals shall be switched at Video selector (I205) controlled by switching signal coming from

microprocessor.

2.2 Video Processor

The video input signal of 0.7 Vp-p is amplified to approximately 50 Vp-p by the video processing circuit and is fed to the

cathode to drive the beam current.

This chassis incorporates a single chip video processor I201, with three channels, one for each of R/G/B, which

functions as the pre-amp of the inputs, OSD mixer and also gain control. A control signal from the microprocessor

changes the amplifier gain of the video channels (R/G/B) together with white balance control.

Video Output circuit I202 amplifies R/G/B signals controlled by I201 to the enough level to drive Cathode of CRT. DC

voltage of Cathode is determined by DC Cut off voltage from Cathode Clamp Circuit. DC Cut off voltage is generated at

Level Shift Circuit which consists of I203, Q22R, Q22G and Q22B, whose R/G/B channels are also controlled by

microprocessor.

2.3 ACL Circuit

The current at the secondary winding of the flyback transformer is used to represent the CRT beam current. The current

is measured and fed to the contrast control Q281,Q282 to limit the maximum beam current with negative feedback.

2.4 Blanking Circuit

Video blanking during the beam retrace period is achieved by applying both horizontal and vertical blanking pulses to

I201.

2.5 Precedence of Clamp Pulse Circuit

Video Processor I201 receives Clamp pulse signal from I701, Precedence of Clamp Pulse Circuit.

2.6 OSD Circuit

I301 receives H/V pulses from Deflection Circuit and control signal from microprocessor, whose output feeds Clock

signals synchronized with H pulse and control signals from microprocessor, OSD display signals in R/G/B, OSD

blanking signal to OSD Mixer Circuit in I201.

FIG. 7 VIDEO PROCESS CIRCUIT

9

(

)

A

A

)

3. Horizontal Deflection and High Voltage Regulation Circuit

3.1 Horizontal Deflection Circuit

The purpose of the horizontal deflection circuit is to cause the CRT electron beam to be scanned horizontally by driving

a current through the deflection yoke, synchronized by the H sync pulse. The circuit consists of an AFC circuit, made up

of an H phase locked loop and VCO (voltage controlled oscillator), and the deflection output.

The H.sync. signal is input to I701 where it is delayed and then input to a phase detector. The phase locked loop (I701)

also accepts input from a saw tooth waveform which is provided by the deflection feedback (flyback pulse) through the

R707. The output of the phase detector creates an error voltage between the feedback pulse and the input pulse and is

then fed to the VCO after processing by an AFC Filter.

If the oscillator frequency deviates more than 4% of H.SYNC, PLL1 (I701) goes into search mode and HUNLOCK (I701)

changes to “H”. The minimum horizontal frequency is determined by the capacitor at C706 and R704. Horizontal

frequency range is determined by R705. H.SIZE, S.PIN and Trapezium are controlled by PWM circuit (Q801). The

output pulse from the VCO is fed to the pre-drive and then output from I701 to the drive buffer Q701 / Q702. The

pre-drive circuit within I701 is controlled by duty cycle by the internal circuit.

In case of no sync signals supplied or excessive frequency change, such as a s ignal timing change, HUNLOCK once

changes to “H”, and PWM circuit (Q801) output is stopped.

The deflection circuit of the DJ72 chassis has been separated from the high voltage regulation circuit to provide

improved H linearity performance by utilizing the consonant conditions of the horizontal beam current characteristics.

The S-consonant capacitors, C770~C777, are changed by Q767~Q771 and S77R, which provide 8~12 stages of

consonant conditions. The horizontal linearity coils L771~L772 are changed by S77R to provide two stages of H

Linearity conditions.

The H.DEF +B voltage chopper power supply parabolically modulates the H.DEF +B voltage of the deflection circuit,

based on the horizontal frequency, to provide a frequency - dependent voltage of between 42.5V and 160V to the

deflection circuit.

FIG. 8 HORIZONTAL DEFLECTION CIRCUIT

HFLB

V.SYNC

H.CP

V.BLK

From MPU

H.SYNC/Composite SYNC

SEPA

RATER

SDA

SCL

MPU

+B (+200V

I701

14

16

19

18

15

17

5 3 4 6

OSCILLATOR

Drive

Buffer

E / W

H.SIZE

PWM

From

MPU

32

12

13

I601

Vertical

Output

f

H-V

Def

Out

H.DF

mp

mp

H.DRIVER

+B E

V.DY

Lin.

Coil

85V

EHV PWM

Module

Lin.

Coil

T751

T751

L771

S77R

C771~

C777

Q767~

Q771

10

S.fig.

Cap.

From MPU

S.fig.

Cap.

C770

Select Select

From MPU

A

r

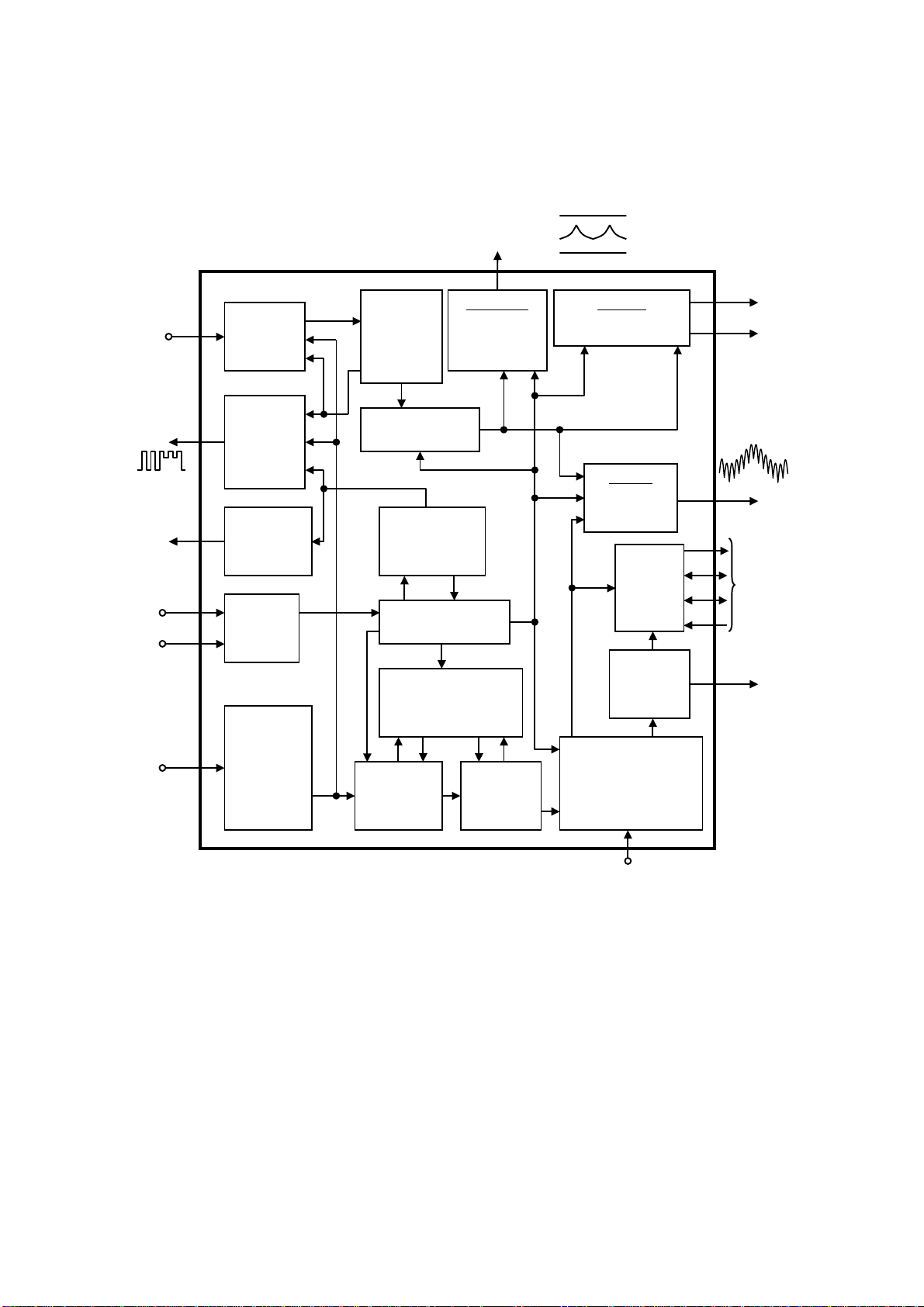

FIG. 9 DEFLECTION CONTROL IC BLOCK DIAGRAM

7V

V-sync

clamping

blanking

HUNLOCK

SDA

SCL

I701

14

16

17

19

18

V-Sync

Integrator

Video

Clamping

nd

V-BLANK

HUNLOCK

Output

I2C-BUS

Receiver

H/C-Sync

Vertical

Oscillator

and AGC

V-Position

V-Size,VOVSCN

Protection

and Soft Start

I2C-BUS Registers

Coincidence

Detector

EWDRV

11

EW-Output

H-Pincushion

H-Corner

H-Trapezium

-

1.2V

V-Output

V-Linearity

V-Linearity Balance

FOCUS

Horizontal

and Vertical

H-Size

Control

H-Output

Stage

12

13

32

6

4

3

5

V

OUT2

V

OUT1

Focus

H-Size

Control

Oscillato

HDRV

8

H/C-sync

15

Input and

Polarity

Correction

PLL1 and

H-Position

Horizontal

Oscillator

PLL2,Parallelogram,

Pin Unbalance and

Soft Start

1

HFLB

11

FBT

3.2 High Voltage Regulation Circuit

The output pulse from Q701 is also fed to the high voltage regulation circuit with the same design of consonant circuit as

the horizontal deflection circuit. High voltage of 27.5 kV is obtained by the step-up windings of the flyback transformer to

drive the CRT anode. The high voltage is monitored by the E

error detection circuit. The error detection circuit

HV

functions by stepping the high voltage down and comparing it with the reference voltage of inside I740 whose output

controls I740, the Integrated Circuit included with E

switching transistor.

HV

3.3 Dynamic focus drive circuit

This monitor’s CRT includes a dynamic focusing electron gun to achieve sharp and uniform focus throughout the display

area. The CRT’s Focus anode receives a DC component of approximately 27% of the CRT anode voltage, combined

with the AC voltage parabolic wave form of magnitude of 600 Vp-p horizontal, and 180 Vp-p vertical. DC focus voltage is

obtained from a tap of the flyback transformer’s bleeder resister, and fed to G3 focus electrode. Horizontal and vertical

parabolic output pulses are amplified at Q501~Q508, T506 and fed to the flyback transformer where they are combined

with the DC component (27% of anode voltage). The potentiometers (focus 1, focus 2) at the flyback adjust the DC

focus voltage. The focus 2 potentiometer mainly adjusts horizontal beam shape (vertical line width), and the focus 2

potentiometer mainly adjusts the vertical beam shape (horizontal line width) by optimizing the DC component of the

parabolic waveform.

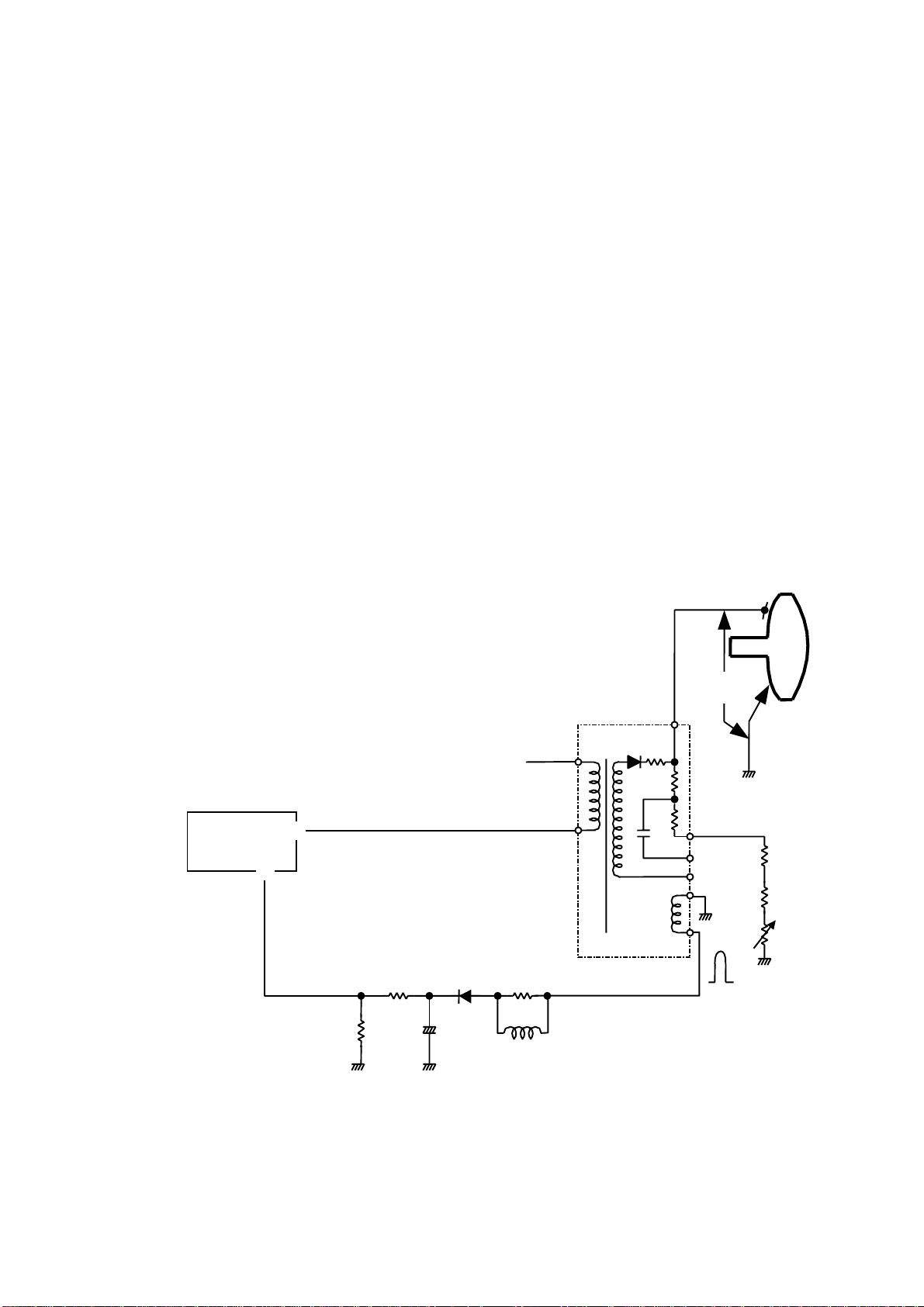

3.4 High Voltage Hold-Down Circuit

DJ82- Chassis uses a system that stops H/V DRIVE SIGNAL output when abnormal high voltage is detected. So that

the high voltage output will be declined to zero. The circuit operation in detail is as follows.

When an input voltage to I740 (pin15, it is determined by R792 and R793) exceeds the specified level, the high voltage

is declined to zero.

FIG.10 HIGH VOLTAGE HOLD-DOWN CIRCUIT DIAGRAM

For the models CM823FU, CM823FET

8

10

E

HV

I740

module

EHV +B

HIGH

VOLTAGE

CRT

R746

R756

R747

R792 R791

R793

+

C791

D790

L791

-

12

4. Vertical Deflection Circuit

The purpose of the vertical deflection circuit is to cause the CRT electron beam to be scanned vertically by driving a

current through the deflection yoke, synchronised by the V sync pulse. V sync is input to the V oscillator circuit, I701,

generating the vertical saw tooth wave. The vertical saw tooth wave is fed to I601 to be amplified of I601 to drive the

vertical deflection yoke.

The feedback circuit inside I601 works such that the differential voltage between pin9 and pin4 equals zero. The

differential input current is compared with the feedback current, and the differential drives the output amplifiers. By

varying resistor R612 or R619 one can set the desired deflection current.

The picture can be shifted in vertical direction by making a DC-offset current through the coil. DC-offset current through

the coil is controlled by the differential input current from I701.

I601 uses an external flyback supply voltage, which is connected to pin7. The signal from the I601 8pin output is used

for protection. The guard output is also activated during thermal shutdown i.e. when Tj>=160

of range.

FIG. 11 VERTICAL DEFLECTION CIRCUIT

V.BLK

I601

83 5 7

P

C609

+

GND

+

C613

V

V

FB

o

C, and feedback loop out

V.SYNC

From MPU

SDA

SCL

I701

V.OUT

14

V.Lin

V.Lin balance

V.Position

19

18

13

12

IN A

IN B

1

2

INPUT

STAGE

GUARD

CIRCUIT

PROTEC

TION

FLYBACK

GENERATOR

AMPLIFIER

A

AMPLIFIER

B

6

OUT A

9

FEEDB

4

OUT B

C610

R620

R619

R611

V.DY

R612

13

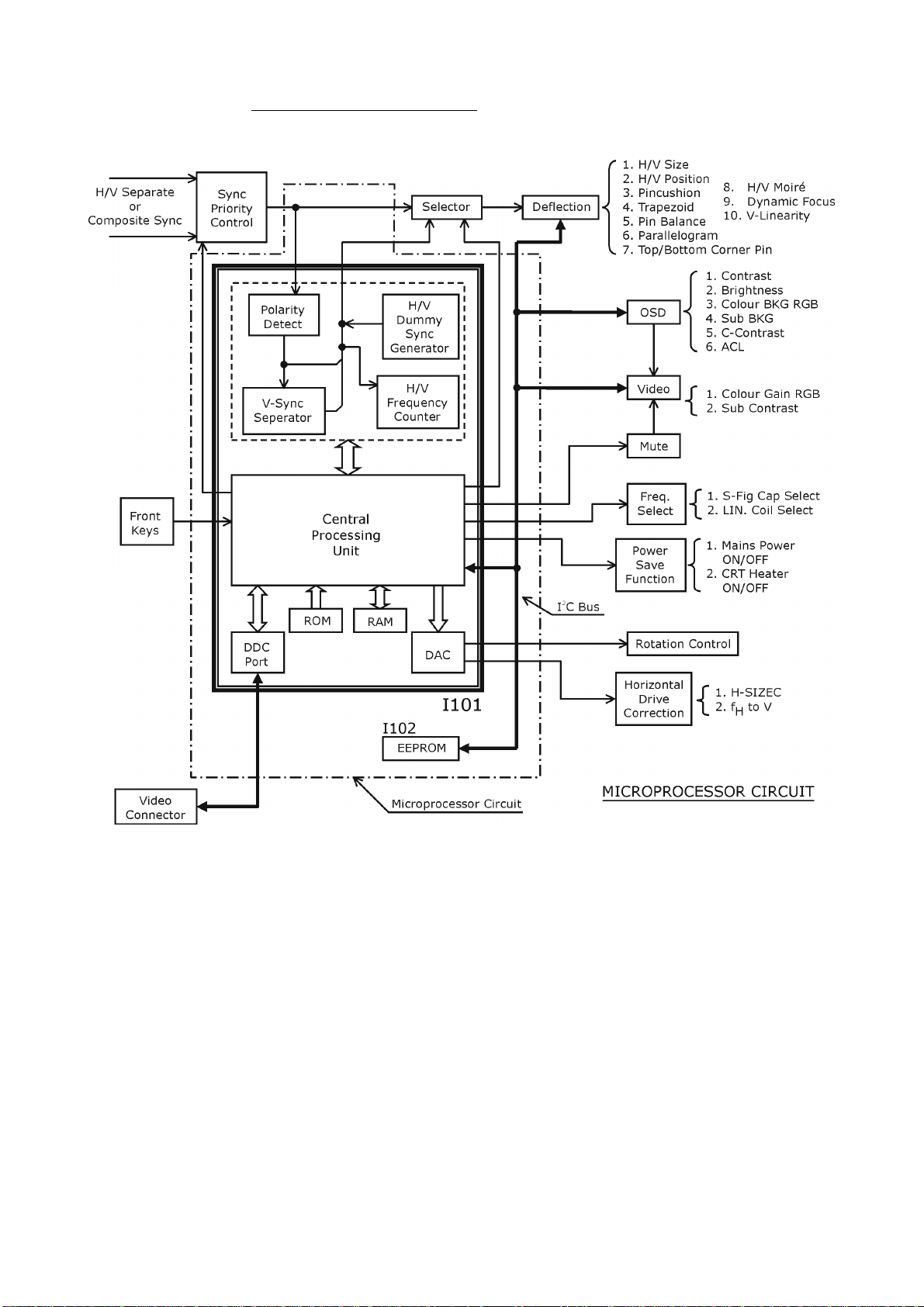

5. Microprocessor Circuit

The microprocessor circuit consists of the following four detailed circuits as shown in Fig.12.

1. Sync detect circuit

2. Front panel key data Input / Output (I/O)

3. Processing and memory

4. Control output

5.1 Sync detect circuit

The sync priority selector (I302) outputs H/V separate or composite sync signal to the sync processor inside the

microprocessor (I101). The sync processor has H/V polarity detector and sync separator for composite sync, H/V

frequency counter, dummy frequency generator, and outputs the processed H/V sync signal to the deflection processing

IC (I701) through the sync selector (I104).

5.2 Front panel key data Input / Output (I/O)

Microprocessor (I101) received user input from the front panel keys, which consists of: one menu key, four adjustment

keys (two pairs)

Contrast and Brightness are adjusted by four adjustment keys when OSD is disappeared.

Other feature requires controlling four adjustment keys when OSD is appeared by a menu key.

Current settings (including picture size, geometry, and color setting) are automatically stored to non-volatile memory.

The maximum memory capacity is for 48 presets including factory standard settings.

5.3 Processing and memory

I101 is an 8-bit microprocessor that equips with ROM and RAM for system program and sync processing circuit. Data

memory consists of one EEPROM chip (I102) for preset data.

5.4 Control output

Output of the microprocessor (I101) controls the deflection processing IC (I701) and the video pre-amplifier IC (I201),

the OSD control IC (I301), the rotation circuit, Horizontal drive correction circuit, the mute circuit, the sync priority

selector (I302), sync selector (I104), power save function. The deflection processing IC receives the signal through I

2

C

Bus to control the geometric function (H/V size and position, Pincushion, Trapezoid, Pin.Balance, Parallelogram, H/V

Moiré, H/V Convergence, Dynamic focus, Top/Bottom corner pincushion, V.Linearity, V.L.Balance). The video

pre-amplifier IC receives the signal through I

receives the signal through I

2

C Bus to control R/G/B Cut off and Contrast, Brightness, Sub BKG, ACL, C-Contrast, and

2

C Bus to control R/G/B Gain and Sub Contrast. The OSD control IC

shows guidance for monitor control function on screen display by generating video signal for OSD and feeding it to video

pre-amplifier IC. Power save function has Standby mode (main power supply has no output if either H sync or V sync is

not supplied) and Off mode (all power supply except +5V have no output if both H sync and V sync are not supplied).

The mute circuit brings video output to black level when timing signal changes or the monitor goes into the power saving

mode.

This chassis is capable of communication with external PC for factory adj ustment through video connector (D-sub).

14

FIG. 12 MICROPROCESSOR CIRCUIT

15

6. Power Save Function

The DJ82 chassis is capable of power savings by sensing of the sync input conditions by the microprocessor. The

microprocessor can identify two sync conditions, (1) No detection of H.sync, (2) No detection of V sync.

The following table shows the details of the Power save mode.

TABLE: POWER SAVE FUNCTION

Sync

V Sync Yes Yes No No

VESA

Standard

Effect None Minimum Minimum Maximum

Circuit

Operation

Video

Power LED CM823F

Power consumption

(Typical) : AC (120V)

H Sync Yes No Yes No

Name Normal Standby Suspend Off

Recovery Time N/A Short Short

H. Deflection

V. Deflection

CM823FET

Normal

operation

Normal

operation

Normal

operation

Lighting

Green

All White : 120 W

All Black : 100 W

System

Dependent

Stop Stop Stop

Stop Stop Stop

Mute Mute Mute

Lighting

Orenge

less than 10W less than 10W less than 3W

Lighting

Orenge

Lighting

Orenge

16

Loading...

Loading...