Page 1

CG 22EAS (SLP)

CG 22EAS (SL)

CG 22EAS (S)

CG 22EAD (SLP)

CG 22EAD (SL)

Grass Tri m me r/ Br u sh Cutter

Coupe-Herbes/Débroussailleuse

Motoguadañas/Desbrozadoras

CG 22EAB (SLP)

CG22EAS (SLP)

CG 22EAB (L)

SAFETY INSTRUCTIONS AND INSTRUCTION MANUAL

WARNING

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily injury!

This manual contains important information about product safety. Please read and understand this manual

BEFORE operating the power tool. Please keep this manual available for other users and owners before they

use the power tool. This manual should be stored in safe place.

WARRANTY: CG22EAB(SLP),

CG22EAB(L) are NOT intended for commercial use, and therefore, NO warranty is provided to their

commercial applications and rental applications.

INSTRUCTIONS DE SECURITE ET MODE D’EMPLOI

AVERTISSEMENT

Une utilisation INCORRECTE OU DANGEREUSE de cet outil motorisé peut entraîner la mort ou de

sérieuses blessures corporelles !

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de ce produit. Prière de

lire et de comprendre ce mode d’emploi AVANT d’utiliser l’outil motorisé. Garder ce mode d’emploi à la

disponibilité des autres utilisateurs et propriétaires avant qu’ils utilisent l’outil motorisé. Ce mode d’emploi

doit être conservé dans un endroit sûr.

GARANTIE : Les modèles CG22EAB(SLP) et

CG22EAB(L) NE sont PAS destinés à un usage commercial, par conséquent, AUCUNE garantie n’est

fournie concernant toute utilisation commerciale ou locative.

INSTRUCCIONES DE SEGURIDAD Y MANUAL DE INSTRUCCIONES

ADVERTENCIA

¡La utilización INAPROPIADA O PELIGROSA de esta herramienta eléctrica puede provocar lesiones

graves o la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea y comprenda este manual

ANTES de utilizar la herramienta eléctrica. Guarde este manual para que puedan leerlo otras personas

antes de utilizar la herramienta eléctrica. Este manual debe ser guardado en un lugar seguro.

GARANTÍA: CG22EAB(SLP),

LOS CG22EAB(L) no están destinados a uso comercial y, por lo tanto, NO se garantizan sus aplicaciones

comerciales y aplicaciones de alquiler.

Page 2

English

MEANINGS OF SYMBOLS

NOTE: Some units do not carry them.

Symbols

WARNING

The following show symbols used for the machine. Be sure that you understand

their meaning before use.

It is important that you read, fully

understand and observe the

following safety precautions and

warnings. Careless or improper

use of the unit may cause

serious or fatal injury.

Shows maximum shaft

speed. Do not use the cutting

attachment whose max rpm

is below the shaft rpm.

Read, understand and follow all

warnings and instructions in this

manual and on the unit.

Always wear eye, head and ear

protectors when using this unit.

Do not use metal/rigid blades

when this sign is shown on the

unit.

Keep all children, bystanders

and helpers 50 ft (15 m)

away from the unit. If anyone

approaches you, stop the

engine and cutting attachment

immediately.

Be careful of thrown objects.

Before using your machine

• Read the manual carefully.

• Check that the cutting equipment is correctly assembled and adjusted.

• Start the unit and check the carburetor adjustment. See “MAINTENANCE”.

Contents

WHAT IS WHAT ....................................................3

WARNINGS AND SAFETY INSTRUCTIONS ........ 4

WARRANTY .......................................................... 5

2

SPECIFICATIONS ................................................. 6

ASSEMBLY PROCEDURES .................................7

OPERATING PROCEDURES .............................. 11

MAINTENANCE .................................................. 14

Gloves should be worn

when necessary, e.g.,

when assembling cutting

equipment.

Use anti-slip and sturdy

footwear.

Blade thrust may occur when

the spinning blade contacts

a solid object in the critical

area. A dangerous reaction

may occur causing the entire

unit and operator to be thrust

violently. This reaction is

called blade thrust. As a result,

the operator may lose control

of the unit which may cause

serious or fatal injury. Blade

thrust is more likely to occur in

areas where it is diffi cult to see

the material to be cut.

Indicate handle location. Do

not attach handle above this

point.

Indicates blade guard

location for a trimmer head or

semi-auto cutting head.

Page 3

English

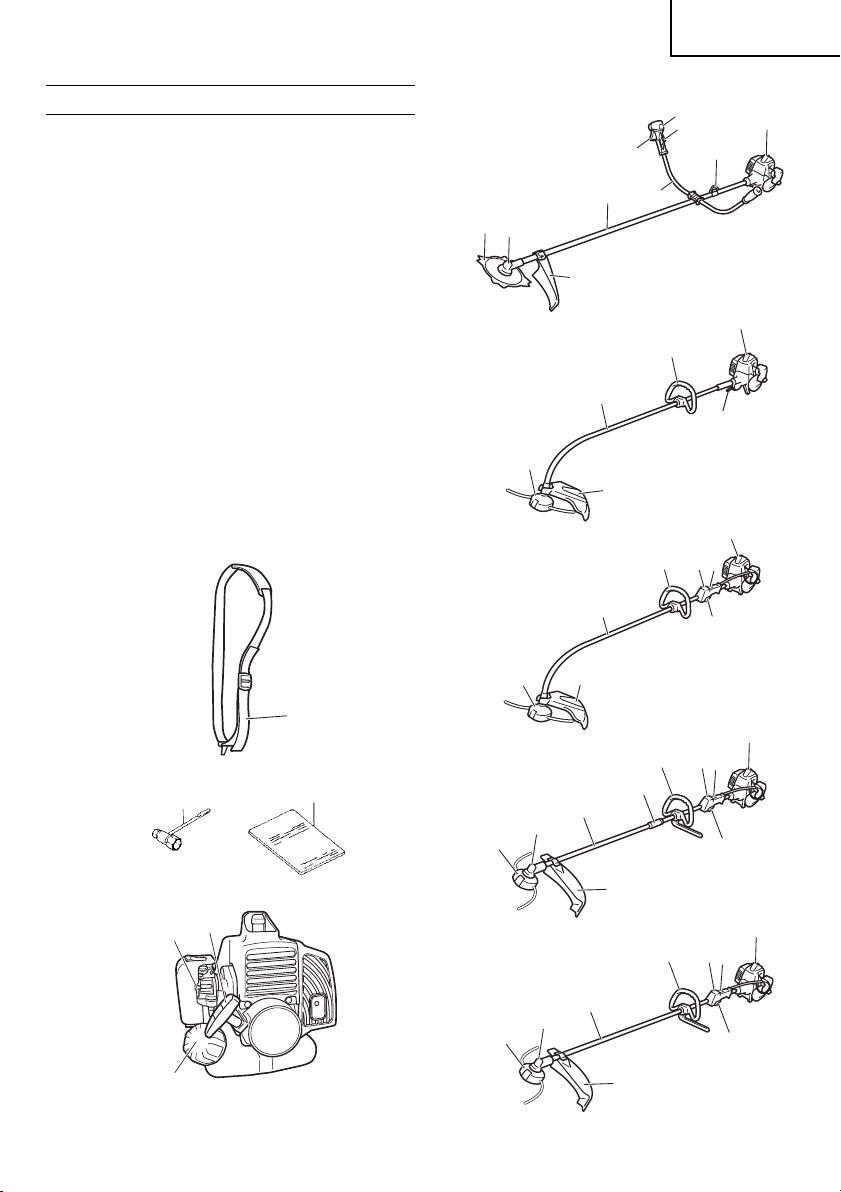

WHAT IS WHAT

Since this manual covers several models, there may

be some diff erence between pictures and your unit.

Use the instructions that apply to your unit.

1. Fuel cap

2. Throttle trigger

3. Starter handle

4. Blade guard

5. Cutting attachment

6. Drive shaft tube

7. Handle

8. Suspension eyelet

9. Ignition switch

10. Harness

11. Throttle trigger lockout

12. Choke lever

13. Engine

14. Angle transmission

15. Joint case

16. Combi box spanner

17. Handling instructions

9

11

2

7

6

5

14

4

7

6

5

4

9

7

6

5

4

13

8

13

2

13

11

2

12

10

13

9

7

11

16

3

1

17

14

5

14

5

15

6

2

4

13

7

9

11

6

2

4

3

Page 4

English

WARNINGS AND SAFETY

INSTRUCTIONS

Operator safety

○ Always wear a safety face shield or goggles.

○ Always wear heavy, long pants, boots and

gloves. Do not wear loose clothing, jewelry, short

pants, sandals or go barefoot. Secure hair so it is

above shoulder length.

○ Do not operate this tool when you are tired,

ill or under the infl uence of alcohol, drugs or

medication.

○ Never let a child or inexperienced person operate

the machine.

○ Wear hearing protection. Pay attention to your

surroundings. Be aware of any bystanders who

may be signaling a problem. Remove safety

equipment immediately upon shutting off engine.

○ Wear head protection.

○ Never start or run the engine inside a closed

room or building. Breathing exhaust fumes can

kill.

○ Keep handles free of oil and fuel.

○ Keep hands away from cutting equipment.

○ Do not grab or hold the unit by the cutting

equipment.

○ When the unit is turned off , make sure the cutting

attachment has stopped before the unit is set

down.

○ When operation is prolonged, take a break from

time to time so that you may avoid possible

Hand-Arm Vibration Syndrome (HAVS) which is

caused by vibration.

WARNING

● Antivibration systems do not guarantee that

you will not sustain Hand-Arm Vibration

Syndrome or carpal tunnel syndrome.

Therefore, continual and regular users

should monitor closely the condition of

their hands and fi ngers. If any symptoms

of the above appear, seek medical advice

immediately.

● If you are using any medical electric/

electronic devices such as a pacemaker,

consult your physician as well as the device

manufacturer prior to operating any power

equipment.

Unit/machine safety

○ Inspect the entire unit/machine before each use.

Replace damaged parts. Check for fuel leaks and

make sure all fasteners are in place and securely

tightened.

○ Replace parts that are cracked, chipped or

damaged in any way before using the unit/

machine.

○ Make sure the safety guard is properly attached.

○ Keep others away when making carburetor

adjustments.

○ Use only accessories as recommended for this

unit/machine by the manufacturer.

WARNING

Never modify the unit/machine in any way.

Do not use your unit/machine for any job

except that for which it is intended.

Fuel safety

○ Mix and pour fuel outdoors and where there are

no sparks or fl ames.

○ Use a container approved for fuel.

○ Do not smoke or allow smoking near fuel or the

unit/machine or while using the unit/machine.

○ Wipe up all fuel spills before starting engine.

○ Move at least 10 ft (3 m) away from fueling site

before starting engine.

○ Stop engine before removing fuel cap.

○ Empty the fuel tank before storing the unit/

machine. It is recommended that the fuel be

emptied after each use. If fuel is left in the tank,

store so fuel will not leak.

○ Store unit/machine and fuel in area where fuel

vapors cannot reach sparks or open fl ames

from water heaters, electric motors or switches,

furnaces. etc.

WARNING

Fuel is easy to ignite or get explosion or

inhale fumes, so that pay special attention

when handling or fi lling fuel.

Cutting safety

○ Do not cut any material other than grass and

brush.

○ Inspect the area to be cut before each use.

Remove objects which can be thrown or become

entangled.

○ For respiratory protection, wear an aerosol

protection mask when cutting the grass after

insecticide is scattered.

○ Keep others including children, animals,

bystanders and helpers outside the 50 ft (15 m)

hazard zone. Stop the engine immediately if you

are approached.

○ Always keep the engine on the right side of your

body.

○ Hold the unit/machine fi rmly with both hands.

○ Keep fi rm footing and balance. Do not over-

reach.

4

Page 5

English

○ Keep all parts of your body away from the muffl er

and cutting attachment when the engine is

running.

○ Keep cutting attachment below waist level.

○ When relocating to a new work area, be sure to

shut off the machine and ensure that all cutting

attachments are stopped.

○ Never place the machine on the ground when

running.

○ Always ensure that the engine is shut off and any

cutting attachments have completely stopped

before clearing debris or removing grass from the

cutting attachment.

○ Always carry a fi rst-aid kit when operating any

power equipment.

○ Never start or run the engine inside a closed

room or building and/or near infl ammable liquids.

Breathing exhaust fumes can kill.

Maintenance safety

○ Maintain the unit/machine according to

recommended procedures.

○ Disconnect the spark plug before performing

maintenance except for carburetor adjustments.

○ Keep others away when making carburetor

adjustments.

○ Use only genuine Hitachi replacement parts as

recommended by the manufacturer.

Transport and storage

○ Carry the unit/machine by hand with the engine

stopped and the muffl er away from your body.

○ Allow the engine to cool, empty the fuel tank,

and secure the unit/machine before storing or

transporting in a vehicle.

○ Empty the fuel tank before storing the unit/

machine. It is recommended that the fuel be

emptied after each use. If fuel is left in the tank,

store so fuel will not leak.

○ Store unit/machine out of the reach of children.

○ Clean and maintain the unit carefully and store it

in a dry place.

○ Make sure engine switch is off when transporting

or storing.

○ When transporting in a vehicle, cover blade with

blade cover.

WARNING

Indicates a strong possibility of severe

personal injury or loss of life, if instructions

are not followed.

CAUTION

Indicates a possibility of personal injury or

equipment damage, if instructions are not

followed.

NOTE

Helpful information for correct function and use.

CAUTION

Do not disassemble the recoil starter. You

may get a possibility of personal injury with

recoil spring.

WARRANTY

The warranties provided by Hitachi Koki U.S.A., Ltd.

are explained in the warranty card enclosed with this

product titled “Hitachi Outdoor Power Equipment

Limited Warranty”.

Models CG22EAB(SLP) and CG22EAB(L) are NOT

intended for commercial use, and therefore, NO

warranty is provided to their commercial applications

and rental applications. Therefore, the two year

warranty for “the fi rst commercial end user” and one

year warranty for “rental applications” mentioned in

the warranty card are provided on CG22EAS(SLP),

CG22EAS(SL), CG22EAS(S), CG22EAD(SLP) and

CG22EAD(SL), but NOT on CG22EAB(SLP) and

CG22EAB(L).

If situations occur which are not covered in this

manual, take care and use common sense. Contact

your Hitachi dealer if you need assistance. Pay

special attention to statements preceded by the

following words:

5

Page 6

English

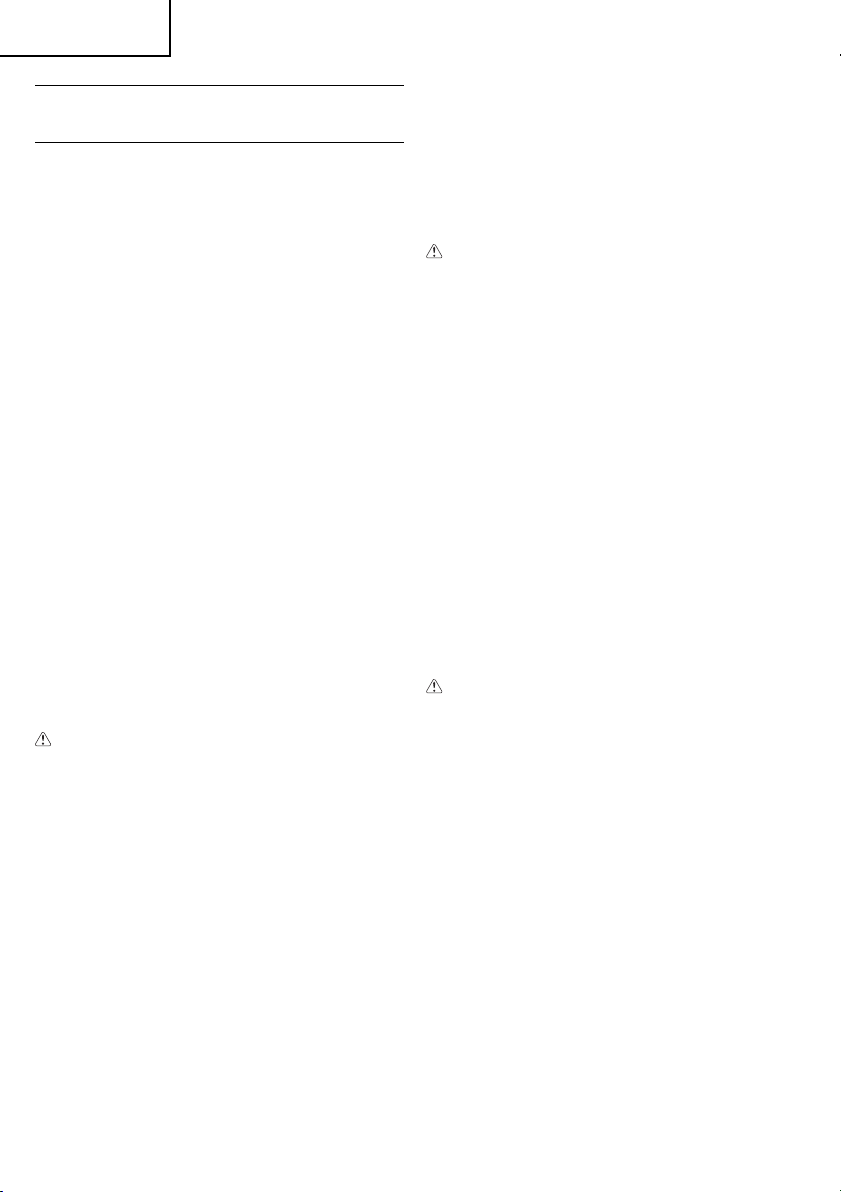

SPECIFICATIONS

CG22EAS (SLP)

Model

Engine Size (cu. in.) 1.27 (21.1 ml)

Spark Plug Champion CJ6 or equivalent

Fuel Tank Capacity (fl . oz) 14.9 (0.44 l)

Dry Weight (Ibs) 9.7 (4.4 kg) 10.4 (4.7 kg) 10.4 (4.7 kg)

Sound pressure

level LpA (dB (A))

(EN27917)

Measured sound

power level LwA

(dB (A))

Measured sound

power level LwA

(dB (A))

Guaranteed

sound power

level LwA (dB (A))

Equivalent

(ISO10884)

Equivalent

(2000/14/EC)

Racing

(2000/14/EC)

Racing

CG22EAS (SL)

90 89 91 90 90

104 104 103 104 104

107 107 106 107 107

108 109 108 108 109

CG22EAS (S)

CG22EAD (SLP)

CG22EAD (SL)

CG22EAB (SLP)

CG22EAB (L)

8.8 (4.0 kg)

8.6 (3.9 kg)

Vibration level (m/s2)

(ISO7916)

Equivalent (Front / Left handle)

Equivalent (Rear / Right handle)

Idling (Front / Left handle)

Idling (Rear / Right handle)

Racing (Front / Left handle)

Racing (Rear / Right handle)

NOTE

Equivalent noise level/vibration level are calculated as the time-weighted energy total for noise/vibration

levels under various working conditions with the following time distribution: 1/2 Idle, 1/2 racing.

* All data subject to change without notice.

6

6.7

4.1

4.9

3.3

8.0

4.7

4.5

4.8

2.7

3.4

5.8

5.9

4.7

4.3

2.7

3.4

6.1

5.1

7.7

4.7

4.1

3.7

10.1

5.5

6.5

6.9

5.3

3.8

7.6

8.9

Page 7

English

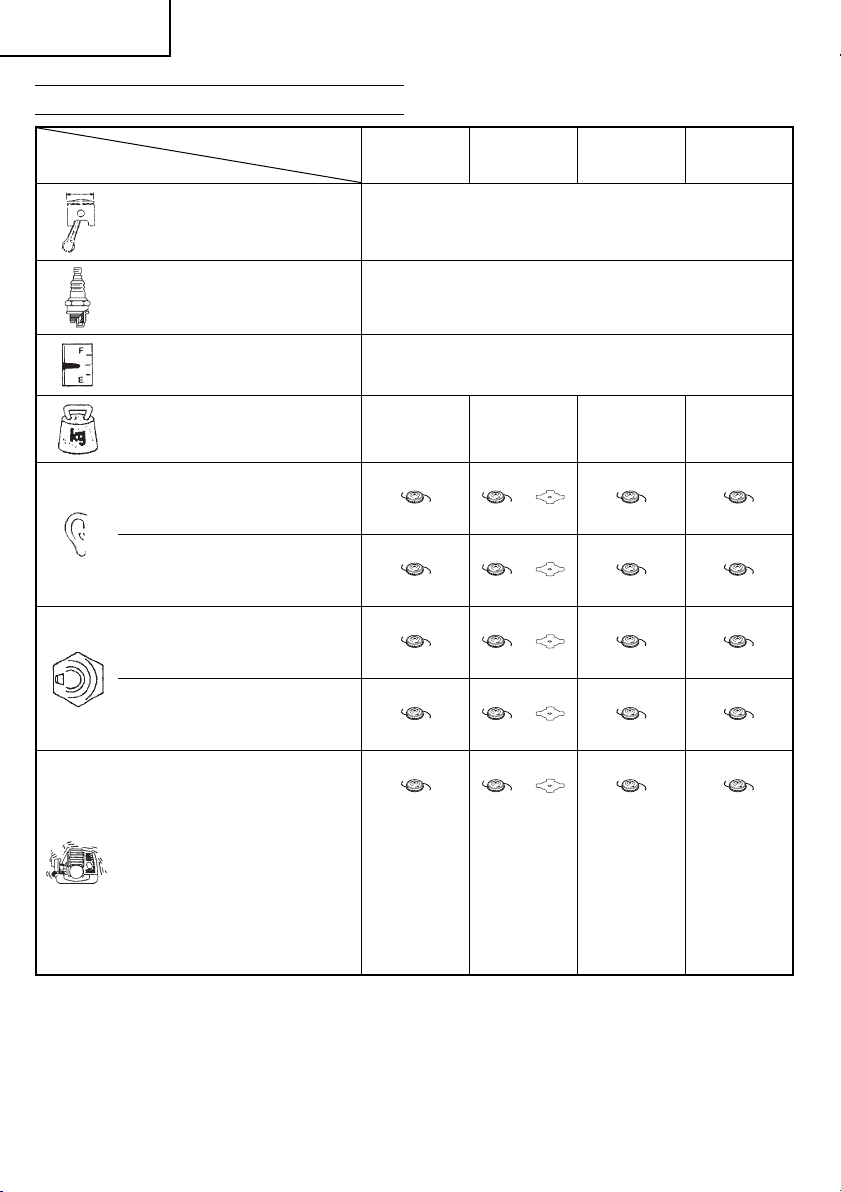

ASSEMBLY PROCEDURES

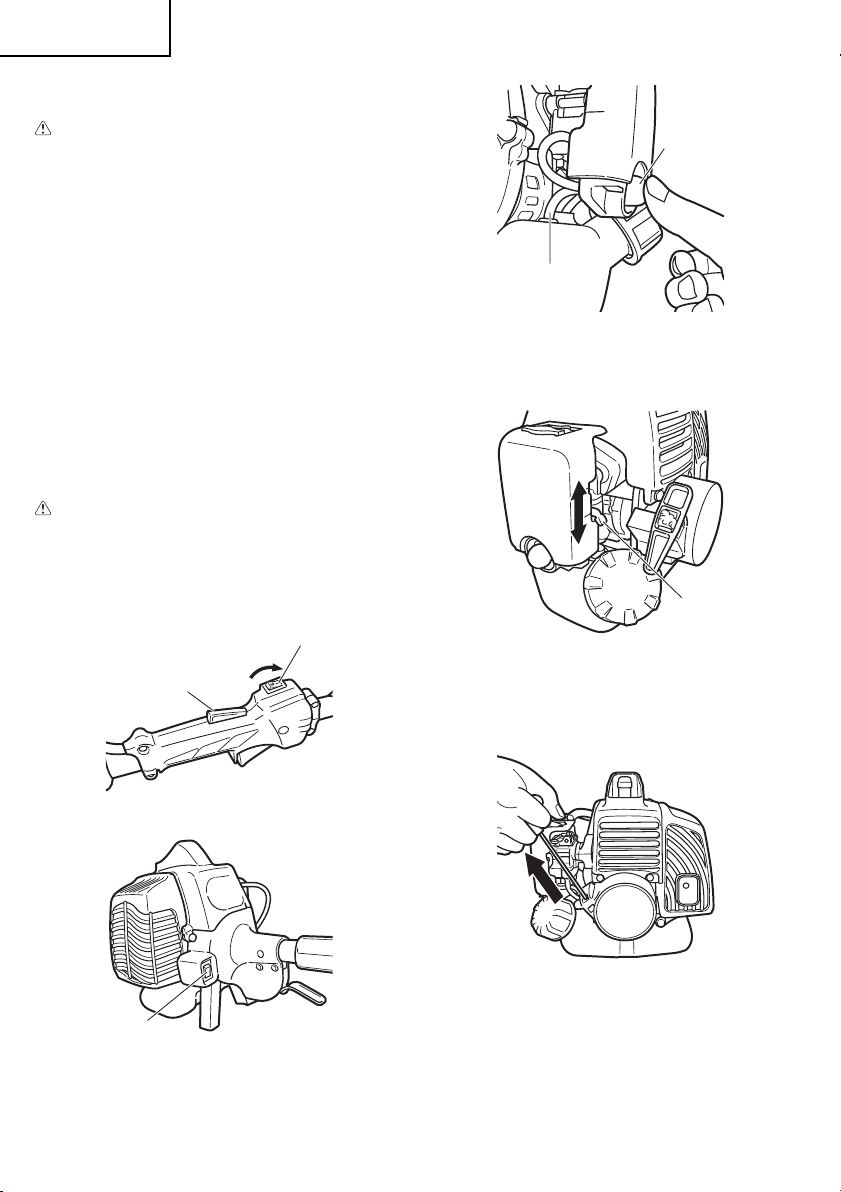

Drive shaft to engine (Fig. 1)

Loosen tube locking bolt (1) about ten turns so that

the bolt point will not obstruct drive shaft tube to be

inserted. When inserting drive shaft tube, hold the

tube locking bolt outward preventing inside fi tting

from obstructing as well.

Insert the drive shaft into the clutch case of the

engine properly until the marked position (2) on the

drive shaft tube meets the clutch case.

Some models may come with the drive shaft already

installed.

1

2

Fig. 1

NOTE

When it is hard to insert drive shaft up to the

marked position on the drive shaft tube, turn

drive shaft by the cutter mounting end clockwise

or counter-clockwise. Tighten tube locking bolt

lining up the hole in the shaft tube. Then tighten

clamp bolt securely.

Installation of attachment

1. Join the attachment in place of it.

2. Make sure the lock pin (3) fi ts in the location hole

(4) of tube and that the tube will not come off .

(Fig. 2)

3. Tighten the knob nut (5) securely. (Fig. 2)

1

2

Installation of handle

WARNING

When you use steel/rigid blades on straight

shaft trimmers or brush cutters, always use

a barrier bar (6) and shoulder harness with

the loop handle. (Fig. 3)

6

Fig. 3

Attach the handle to the drive shaft tube with the

angle towards the engine.

Adjust the location to the most comfortable position

before operation.

NOTE

If your unit has handle location label on drive

shaft tube, follow the illustration.

Remove the handle bracket (7) from the assembly.

(Fig. 4)

Place the handles and attach the handle bracket with

four bolts lightly. Adjust to appropriate position. Then

attach it fi rmly with the bolts.

7

3

5

4

Fig. 4

Fig. 2

7

Page 8

English

Attach the protection tube to the drive shaft or handle

using cord clamps (8). (Fig. 5)

8

Fig. 5

NOTE

If the protection tube is set apart from the handle

or pipe, it will be caught by something during

operation and it may cause serious injury. Do not

set the protection tube apart from the handle or

pipe.

Throttle wire / stop cord

Press the upper tab (9) and open the air cleaner

cover. (Fig. 6)

9

If the throttle outer end (10) is threaded on your unit,

screw it and the earth terminal (11) (if so equipped)

into the cable adjuster stay (12) all the way, and then

tighten this cable end using the adjuster nut (13)

against the cable adjuster stay (12).

Connect throttle wire end (14) to carburetor (15)

and install swivel cap (16) (if so equipped) where is

included in tool bag, onto swivel (15) (Fig. 8).

Some models may come with the parts installed.

12

11

10

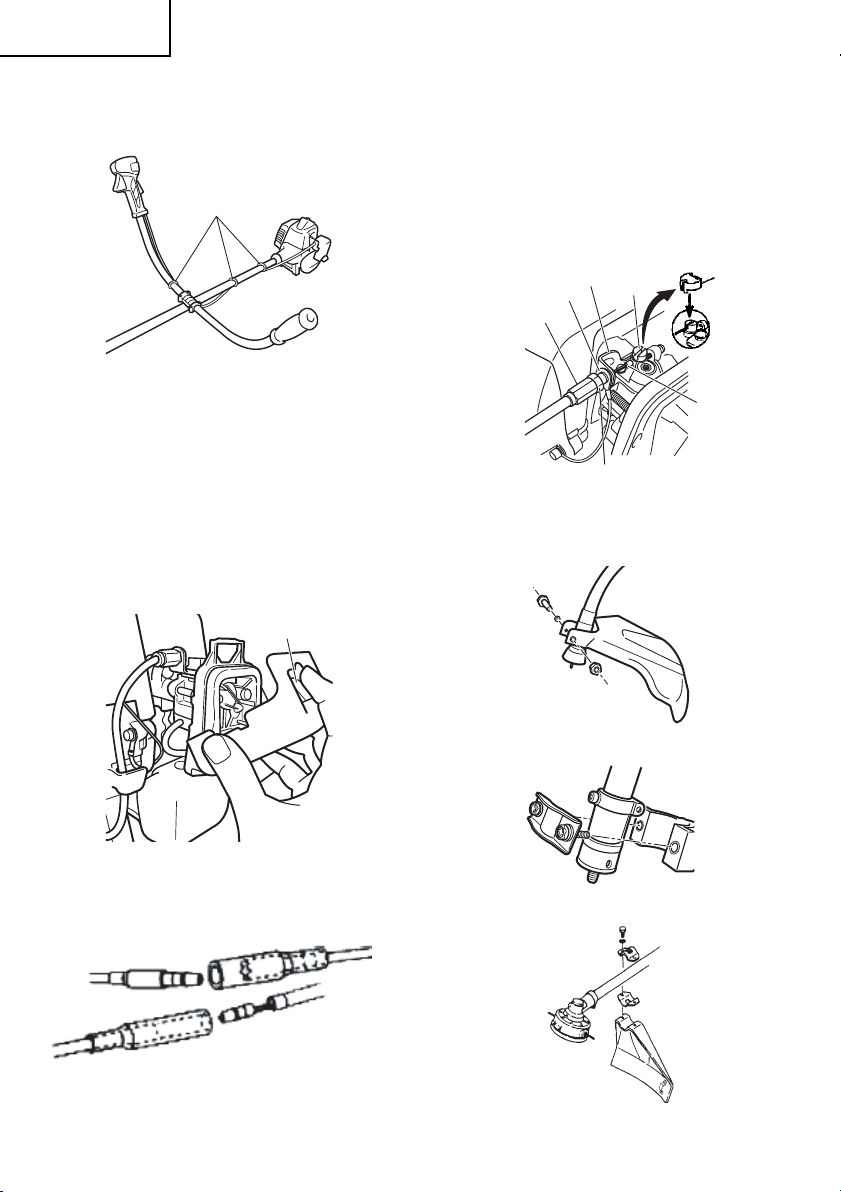

Installation of blade guard (Fig. 9, 10, 10-1, 11)

15

13

Fig. 8

16

14

Fig. 6

Connect stop cords. (Fig. 7)

Fig. 7

8

Fig. 9

Fig. 10

Fig. 10-1

Page 9

Fig. 11

NOTE

The guard bracket may come already mounted to

the gear case on some models.

Install the blade guard on drive shaft tube against

angle transmission. Tighten the guard bracket fi rmly

so that the blade guard does not swing or move

down during operation.

English

NOTE

○ When attaching the guard extension to the blade

guard, the sharp line limiter must be removed

from the blade guard, (if so installed).

○ If your unit has guard location label on drive shaft

tube, follow the indication.

○ To remove the guard extension, refer to the

drawings. Wear gloves as the extension has a

sharp line limiter, then push the four square tabs

on the guard one by one in order. (Fig. 13)

Install the blade guard to the guard bracket, which

also secures the guard to the gear case using the

two guard mounting screws.

CAUTION

Some blade guards are equipped with sharp

line limiters. Be careful with handling it.

When using a trimmer head with two piece type

blade guard, attach the guard extension to the blade

guard. (Fig. 12)

Fig. 12

Fig. 13

Installation of semi-auto cutting head

1. Function

Automatically feeds more nylon cutting line

when it is tapped at low rpm (not greater than

4,500 rpm).

9

Page 10

English

Specifi cations

Code No.

6696454

6696597

Applicable nylon cord

2. Precautions

○ The case must be securely attached to the cover.

○ Check the cover, case and other components for

○ Check the case and button for wear.

If the wear limit mark (17) on the case is no longer

Type of

attaching

screw

Female

screw

Female

screw

Cord diameter: 1/8˝ (Φ3.0 mm) Length: 6.5 ft (2 m)

Cord diameter: 3/22˝ (Φ2.4 mm) Length: 13 ft (4 m)

cracks or other damage.

visible or there is a hole in the bottom (18) of the

button, change the new parts immediately. (Fig.

14)

17

Direction of

rotation

Counterclockwise

Clockwise

18

Size of

attaching

screw

M10×P1.25LH

M8×P1.25RH

19

Fig. 15

For curved shaft models, the mounting nut is righthand-threaded. Turn counterclockwise to loosen/

clockwise to tighten.

NOTE

○ Since the cutter holder cap is not used here, keep

it for when a metal blade is used, if so equipped.

○ Insert Allen wrench (19) into the hole of the gear

case in order to lock the cutter holder.

4. Adjusting line length

○ Set the engine speed as low as possible and tap

the head on the ground. The nylon line will be

drawn out about 1-3/16˝ (3 cm) with each tap.

(Fig. 16)

Fig. 14

○ The cutting head must be securely mounted to

the unit’s gear case.

○ For outstanding performance and reliability,

always use Hitachi nylon cutting line. Never

use wire or other materials that could become a

dangerous projectile.

○ If the cutting head does not feed cutting line

properly, check that the nylon line and all

components are properly installed. Contact your

Hitachi dealer if you need assistance.

3. Installation (Fig. 15)

○ Install cutting head on gear case of grass

trimmers/brush cutters. The mounting nut is

left-hand-threaded. Turn clockwise to loosen/

counterclockwise to tighten.

10

Fig. 16

Also, you can extend the nylon line by hand but

the engine must be completely stopped. (Fig. 17)

Fig. 17

○ Adjust the nylon line to the proper length

of 4-11/32˝–5-1/2˝ (11–14) cm before each

operation.

Page 11

English

Installation of cutting blade (Fig. 18)

(If so equipped)

When installing a cutting blade, make sure that there

are no cracks or any damage in it and that the cutting

edges are facing the correct direction.

19

21

20

22

23

Fig. 18

NOTE

○ When installing cutter holder cap (20), be sure to

set concave side upward.

○ Insert the alien wrench (19) into the hole of the

angle transmission in order to lock the cutter

holder (21). Please note that the cutter fi xing bolt

or nut (22) has left-handed threads, (clockwise to

loosen/ counter-clockwise to tighten). Tighten the

fi xing bolt or nut with the box wrench.

○ If your unit is of a nut securing type and equipped

with a cotter pin, the blade must be retained with

a new pin (23) each time installed. (Fig. 19)

23

Fig. 19

CAUTION

● Before operation, make sure the blade has

been properly installed.

● If your unit is equipped with protection cover

under a cutting blade, check it for wear or

cracks before operation. If any damage or

wear is found, replace it, as it is an article of

consumption.

WARNING

For Hitachi heads, use only fl exible,

non-metallic line recommended by the

manufacturer. Never use wire or wire ropes.

They can break off and become a dangerous

projectile.

OPERATING PROCEDURES

Fuel (Fig. 20)

Fig. 20

WARNING

● The trimmer is equipped with a two-stroke

engine. Always run the engine on fuel, which

is mixed with oil.

Provide good ventilation, when fueling or

handling fuel.

● Fuel contains highly fl ammable and it is

possible to get the serious personal injury

when inhaling or spilling on your body.

Always pay attention when handling fuel.

Always have good ventilation when handling

fuel inside building.

Fuel

○ Always use branded 89 octane unleaded

gasoline.

○ Use genuine two-cycle oil or use a mix between

25:1 to 50:1, please consult the oil bottle for the

ratio or Hitachi dealer.

○ If genuine oil is not available, use an anti-oxidant

added quality oil expressly labeled for air-cooled

2-cycle engine use (JASO FC GRADE OIL or ISO

EGC GRADE). Do not use BIA or TCW (2-stroke

water-cooling type) mixed oil.

○ Never use multi-grade oil (10 W/30) or waste oil.

○ Always mix fuel and oil in a separate clean

container.

Always start by fi ling half the amount of fuel, which

is to be used. Then add the whole amount of oil. Mix

(shake) the fuel mixture. Add the remaining amount

of fuel.

Mix (shake) the fuel-mix thoroughly before fi lling the

fuel tank.

11

Page 12

English

Fueling

WARNING

● Always shut off the engine before refueling.

● Slowly open the fuel tank, when fi lling up

with fuel, so that possible over-pressure

disappears.

● Tighten the fuel cap carefully, after fueling.

● Always move the trimmer at least 10 ft (3 m)

from the fueling area before starting.

● Always wash any spilled fuel from clothing

immediately with soap.

● Be sure to check for any fuel leakage after

refueling.

Before fueling, clean the tank cap area carefully,

to ensure that no dirt falls into the tank. Make sure

that the fuel is well mixed by shaking the container,

before fueling.

Starting

CAUTION

Before starting, make sure the cutting

attachment does not touch anything.

1. Set ignition switch (24) to ON position. (Fig. 21,

22)

24

26

25

39

Fig. 23

2. Set choke lever (27) to CLOSED position (A).

(Fig. 24)

B

A

27

Fig. 24

3. Pull recoil starter briskly, taking care to keep the

handle in your grasp and not allowing it to snap

back. (Fig. 25)

Fig. 21

24

Fig. 22

* Push priming bulb (25) several times so that fuel

fl ows through return pipe (39). (Fig. 23)

12

Fig. 25

Page 13

4. When you hear the engine want to start, return

choke lever to RUN position (open) (B). Then pull

recoil starter briskly again.

NOTE

If engine does not start, repeat procedures from

2 to 5.

5. Then allow the engine about 2–3 minutes to warm

up before subjecting it to any load.

English

Cutting (Fig. 26, 27, 28)

○ When cutting, operate engine at over 6,500 rpm.

Extended time of use at low rpm may wear out

the clutch prematurely.

○ Cut grass from right to left.

○ Cut grass from left to right (only curve shaft

model).

○ Blade thrust may occur when the spinning blade

contacts a solid object in the critical area.

A dangerous reaction may occur causing the

entire unit and operator to be thrust violently. This

reaction is called blade thrust. As a result, the

operator may lose control of the unit which may

cause serious or fatal injury. Blade thrust is more

likely to occur in areas where it is diffi cult to see

the material to be cut.

○ Wear the harness as shown in the fi gure (if so

equipped). The blade turns counter-clockwise,

therefore, be advised to operate the unit from

right to left for effi cient cutting. Keep onlookers

out of working area at least 50 ft (15 m).

Fig. 27

50 ft

(15 m)

Fig. 28

WARNING

If cutting attachment should strike against

stones or other debris, stop the engine and

make sure that the attachment and related

parts are undamaged. When grass or vines

wrap around attachment, stop engine and

attachment and remove them.

Stopping (Fig. 29, 30)

Decrease engine speed and run at an idle for a few

minutes, then turn off ignition switch (24).

24

26

Fig. 26

Fig. 29

13

Page 14

English

Carburetor adjustment (Fig. 31)

24

Fig. 30

For models with an engine ignition switch, keep the

ignition switch pressed until the engine comes to a

complete stop.

WARNING

A cutting attachment can injure while it

continues to spin after the engine is stopped

or power control is released. When the unit is

turned off , make sure the cutting attachment

has stopped before the unit is set down.

Semi-auto cutting head

○ When cutting, operate engine at over 6,500 rpm.

Extended time of use at low rpm may wear out

the clutch prematurely.

○ Cut grass from right to left.

○ Cut grass from left to right (only curve shaft

model).

WARNING

A cutting attachment can injure while it

continues to spin after the engine is stopped

or power control is released. When the unit is

turned off , make sure the cutting attachment

has stopped before the unit is set down.

Automatically feeds more nylon cutting line when it is

tapped at low rpm (not greater than 4,500 rpm).

MAINTENANCE

MAINTENANCE, REPLACEMENT OR REPAIR

OF THE EMISSION CONTROL DEVICES AND

SYSTEMS MAY BE PERFORMED BY ANY NONROAD ENGINE REPAIR ESTABLISHMENT OR

INDIVIDUAL.

Fig. 31

WARNING

● The cutting attachment may be spinning

during carburetor adjustments.

● Never start the engine without the complete

clutch cover and tube assembled! Otherwise

the clutch can come loose and cause

personal injuries.

In the carburetor, fuel is mixed with air. When the

engine is test run at the factory, the carburetor is

basically adjusted. A further adjustment may be

required, according to climate and altitude. The

carburetor has one adjustment possibility:

T = Idle speed adjustment screw.

Idle speed adjustment (T)

Check that the air fi lter is clean. When the idle

speed is correct, the cutting attachment will not

rotate. If adjustment is required, close (clockwise)

the T-screw, with the engine running, until the

cutting attachment starts to rotate. Open (counterclockwise) the screw until the cutting attachment

stops. You have reached the correct idle speed

when the engine runs smoothly in all positions well

below the rpm when the cutting attachment starts to

rotate.

If the cutting attachment still rotates after idle speed

adjustment, contact your Hitachi dealer.

NOTE

Standard Idle rpm is 2,800 – 3,200 rpm.

WARNING

When the engine is idling the cutting

attachment must under no circumstances

rotate.

14

Page 15

English

Air fi lter (Fig. 32)

The air fi lter must be cleaned from dust and dirt in

order to avoid:

○ Carburetor malfunctions

○ Starting problems

○ Engine power reduction

○ Unnecessary wear on the engine parts

○ Abnormal fuel consumption

Clean the air fi lter daily or more often if working in

exceptionally dusty areas.

28

Fig. 32

Cleaning the air fi lter

Open the air fi lter cover and the fi lter (28). Rinse it in

warm soap suds. Check that the fi lter is dry before

reassembly. An air fi lter that has been used for some

time cannot be cleaned completely. Therefore,

it must regularly be replaced with a new one. A

damaged fi lter must always be replaced.

Fuel fi lter (Fig. 33)

Drain all fuel from fuel tank and pull fuel fi lter line

from tank. Pull fi lter element out of holder assembly

and rinse element in warm water with detergent.

Rinse thoroughly until all traces of detergent are

eliminated. Squeeze, do not wring, away excess

water and allow element to air dry.

NOTE

If element is hard due to excessive dirt buildup,

replace it.

Spark plug (Fig. 34)

The spark plug condition is infl uenced by:

○ An incorrect carburetor setting

○ Wrong fuel mixture (too much oil in the gasoline)

○ A dirty air fi lter

○ Hard running conditions (such as cold weather)

These factors cause deposits on the spark plug

electrodes, which may result in malfunction and

starting diffi culties. If the engine is low on power,

diffi cult to start or runs poorly at idling speed, always

check the spark plug fi rst. If the spark plug is dirty,

clean it and check the electrode gap. Re-adjust

if necessary. The correct gap is 0.024˝ (0.6 mm).

The spark plug should be replaced after about 100

operation hours or earlier if the electrodes are badly

eroded.

0.024˝

(0.6 mm)

Fig. 34

NOTE

In some areas, local law requires using a resistor

spark plug to suppress ignition signals. If this

machine was originally equipped with resistor

spark plug, use same type of spark plug for

replacement.

Flexible drive shaft (Fig. 35)

Flexible drive shaft should be removed and

lubricated with good quality lithium grease every

20 hours. To remove the fl exible shaft, fi rst remove

screw (29), loosen bolt (30) and remove the gear

case then pull the shaft out of the drive shaft pipe.

Clean the shaft off and apply a generous coat of

lithium grease to it and insert if back into the drive

shaft pipe, turn it unit it drops into place then install

the gear case, install & tighten screw (29) and screw

(30).

Fig. 33

15

Page 16

English

Wind both halves of the line on the reel in the

same direction, keeping each half of the line on

its own side of the partition. (Fig. 38)

30

29

Fig. 35

Angle transmission (Fig. 36)

Check angle transmission or angle gear for

grease level about every 50 hours of operation by

removing the grease fi ller plug on the side of angle

transmission.

If no grease can be seen on the fl anks of the gears,

fi ll the transmission with quality lithium based

multipurpose grease up to 3/4. Do not completely fi ll

the transmission.

Fig. 36

Semi-auto cutting head

4˝ (10 cm)

32

Fig. 38

(4) Push each line into the stopper holes (33),

leaving the loose ends approx. 4˝ (10 cm) in

length. (Fig. 39)

4˝ (10 cm)

33

4˝ (10 cm)

Fig. 39

(5) Insert both loose ends of the line through the cord

guide (34) when placing the reel in the case. (Fig.

40)

33

Nylon line replacement

(1) Remove the case (31) by fi rmly pushing inward

the locking tabs with your thumbs as shown in

Fig. 37.

31

Fig. 37

(2) After removing the case, take out the reel and

discard the remaining line.

(3) Fold the new nylon line unevenly in half as shown

in picture.

Hook the U-shaped end of the nylon line into the

groove (32) on the center partition of the reel.

16

34

Fig. 40

NOTE

When placing a reel in the case, try to line up the

stopper holes (33) with the cord guide (34) for

easier line release later.

Page 17

English

(6) Place the cover over the case so that the cap

locking tabs (35) on the case meet the long holes

(36) on the cover. Then push the case securely

until it clicks into place. (Fig. 41)

36

35

Fig. 41

(7) The initial cutting line length should be approx.

4-11/32˝–5-1/2˝ (11–14 cm) and should be equal

on both sides. (Fig. 42)

4-11/32˝–5-1/2˝

(11-14 cm)

Fig. 42

4-11/32˝–5-1/2˝

(11-14 cm)

○ When replacing blade, purchase one

recommended by Hitachi, with a 25.4 mm (one

inch) fi tting hole.

○ When installing a saw blade (38), always face

the stamped side up. In the case of a 3 or 4 tooth

blade (37), it can be used on either side.

○ Use the correct blade for the type of work.

○ When replacing blades, use appropriate tools.

○ When cutting edges become dull, re-sharpen

or fi le as shown in the illustration. Incorrect

sharpening may cause excessive vibration.

○ Discard blades that are bent, warped, cracked,

broken or damaged in any way.

NOTE

When sharpening blade it is important to maintain

an original shape of radius at the base of the

tooth to avoid cracking.

Maintenance schedule

Below you will fi nd some general maintenance

instructions. For further information please contact

your Hitachi dealer.

Daily maintenance

○ Clean the exterior of the unit.

○ Check that the harness is undamaged.

○ Check the blade guard for damage or cracks.

Change the guard in case of impacts or cracks.

○ Check that the cutting attachment is properly

centred, sharp, and without cracks. An off -centre

cutting attachment induces heavy vibrations that

may damage the unit.

○ Check that the cutting attachment nut is

suffi ciently tightened.

○ Make sure that the blade transport guard is

undamaged and that it can be securely fi tted.

○ Check that nuts and screws are suffi ciently

tightened.

Blade (Fig. 43)

WARNING

Wear protective gloves when handling or

performing maintenance on the blade.

37

○ Use a sharp blade. A dull blade is more likely to

snag and thrust. Replace the fastening nut if it is

damaged and hard to tighten.

38

Fig. 43

Weekly maintenance

○ Check the starter, especially the cord and return

spring.

○ Clean the exterior of the spark plug.

○ Remove it and check the electrode gap. Adjust it

to 0.024˝ (0.6 mm), or change the spark plug.

○ Check that the angle gear is fi lled with grease up

to 3/4.

○ Clean the air fi lter.

Monthly maintenance

○ Rinse the fuel tank with gasoline.

○ Clean the exterior of the carburetor and the space

around it.

○ Clean the fan and the space around it.

17

Page 18

Français

SIGNIFICATION DES SYMBOLES

REMARQUE:

Certains appareils n’en sont pas pourvus.

Symboles

ATTENTION

Les symboles suivants sont utilisés pour l’outil. Bien se familiariser avec leur

signifi cation avant d’utiliser l’outil.

Il est essentiel de lire et de comprendre

parfaitement les consignes de sécurité

et autres avertissements suivants.

Vous devez les observer strictement.

L’utilisation inattentive ou inadéquate

de cette machine risque de provoquer

des blessures graves ou fatales.

Indique la vitesse maximale de l’arbre.

N’utilisez pas d’outil de coupe dont la

vitesse de rotation (nombre de tours/

minute) est inférieure à la vitesse

de rotation de l’arbre.

Lisez attentivement et respectez toutes les

instructions et tous les avertissements donnés

dans ce manuel et sur le produit.

Utilisez toujours des lunettes de protection

ainsi qu’un casque et des protections

d’oreilles lorsque vous utilisez ce

produit.

N’utilisez pas de lames métalliques/

rigides lorsque ce signe apparaît sur

la machine.

Maintenez les enfants, spectateurs

et aides à plus de 50 pieds (15 m) de

l’appareil. Si quelqu’un s’approche de

vous, coupez immédiatemment le moteur

et arrêtez l’outil de coupe.

Faites attention aux projections

d’objets.

Avant l’utilisation de votre nouvelle machine

• Lisez attentivement le manuel d’utilisation.

• Vérifi ez que l’équipement de coupe est monté et réglé correctement.

• Démarrez la machine et vérifi ez le réglage du carburateur. Voir la section “ENTRETIEN”.

Sommaire

DESCRIPTION ..................................................... 19

PRÉCAUTIONS ET CONSIGNES DE SÉCURITÉ

GARANTIE ........................................................... 21

18

CARACTÉRISTIQUES ......................................... 22

... 20

MONTAGE ........................................................... 23

UTILISATION ........................................................ 27

ENTRETIEN ......................................................... 30

Au besoin, utilisez des gants,

notamment lors du montage de

l’équipement de coupe.

Utilisez des chaussures antidérapantes

et solides.

Une réaction de poussée de la lame peut

survenir lorsque la lame en rotation entre

en contact avec un objet solide dans la

zone critique. Une réaction dangereuse

peut alors survenir, provoquant un

mouvement incontrôlé et violent de

toute la machine et de l’utilisateur.

Cette réaction est appelée rebond.

Elle peut faire perdre le contrôle de la

machine et être à l’origine de blessures

sérieuses, voire fatales. Cette réaction

incontrôlée de la lame risque davantage

de survenir lorsque l’opérateur ne peut

voir le matériau à couper.

Indique l’emplacement de la poignée.

Ne positionnez pas la poignée audessus de ce point.

Indique l’emplacement du protègelame pour un coupe-herbe ou une tête

de coupe semi-automatique.

Page 19

Français

DESCRIPTION

Ce manuel étant commun à plusieurs modèles, vous

constaterez peut-être certaines diff érences entre

les images et votre appareil. Suivez les instructions

relatives à votre modèle.

1. Bouchon du réservoir de carburant

2. Commande des gaz

3. Poignée du lanceur

4. Protège-lame

5. Outil de coupe

6. Tube de transmission

7. Poignée

8. Œillet d’accrochage

9. Interrupteur marche-arrêt

10. Harnais

11. Levier accélérateur bloqué

12. Levier d’étranglement

13. Moteur

14. Boîtier de renvoi d’angle

15. Boîtier de raccordement

16. Clé à douille multiple

17. Mode d’emploi

9

11

2

7

6

5

14

4

7

6

5

4

9

7

6

5

4

13

8

13

2

13

11

2

12

10

13

9

7

11

16

3

1

17

14

5

14

5

15

6

2

4

13

7

9

11

6

2

4

19

Page 20

Français

PRÉCAUTIONS ET CONSIGNES

DE SÉCURITÉ

Sécurité de l’utilisateur

○ Portez toujours une visière et des lunettes de

protection.

○ Portez toujours un pantalon, des chaussures

et des gants de sécurité. Évitez les vêtements

amples, les shorts, les sandales et les pieds nus.

Veillez à ce que vos cheveux ne descendent pas

au-dessous des épaules.

○ Utilisez cette machine uniquement si vous êtes

en pleine possession de vos moyens physiques.

Évitez strictement la consommation d’alcool, de

drogue ou de médicaments.

○ Ne laissez jamais un enfant ou une personne

inexpérimentée se servir de ces machines.

○ Portez un dispositif de protection auditive

contre le bruit. Restez vigilant à tout ce qui vous

entoure. Restez attentif dans l’éventualité où une

personne située à proximité vous signalerait un

problème. Retirez les équipements de sécurité

immédiatement après avoir coupé le moteur de

l’appareil.

○ Protégez-vous la tête.

○ Ne mettez jamais le moteur en marche dans un

local clos, les gaz d’échappement étant toxiques.

○ Nettoyez les poignées de toute trace d’huile ou de

carburant.

○ N’approchez jamais les mains du guide-chaîne et

de la chaîne.

○ N’attrapez jamais et ne tenez jamais la machine

par l’extrémité du guide-chaîne.

○ Après l’arrêt de la machine, attendez l’arrêt

complet de l’outil de coupe avant de poser la

machine.

○ Lors d’une utilisation prolongée, veillez à pratiquer

des pauses régulières afi n d’éviter des troubles

éventuels provoqués par les vibrations.

ATTENTION

● Les systèmes anti-vibrations ne préviennent

pas de la maladie des doigts blancs, ni du

syndrome du canal carpien. Par conséquent,

en cas d’utilisation régulière et continue de

votre machine, surveillez soigneusement

l’état de vos mains et de vos doigts. Si l’un

des symptômes ci-dessus venait à apparaître,

il serait indispensable de vous faire examiner

immédiatement par votre médecin.

● Si vous êtes équipé d’un appareillage médical

électrique/électronique tel qu’un stimulateur

cardiaque, consultez votre médecin et le

fabricant de cet appareillage avant d’utiliser

tout appareil électrique.

Règles de sécurité concernant l’utilisation de la

machine.

○ Contrôlez entièrement votre machine avant

chaque utilisation. Remplacez les pièces

endommagées. Vérifi ez l’absence de fuites de

carburant et assurez-vous que tous les dispositifs

de fi xation sont en place et solidement fi xés.

○ Remplacez les éléments Hitachi de la machine

qui présentent des fi ssures, des ébréchures ou

toute autre avarie.

○ Vérifi ez que les systèmes de sécurité sont

fonctionnels.

○ Ne laissez personne s’approcher lorsque vous

réglez le carburateur.

○ Utilisez uniquement les accessoires recommandés

par le constructeur pour cette machine.

ATTENTION

Ne modifi ez en aucun cas la machine.

N’utilisez jamais la débroussailleuse pour

un autre usage que celui pour lequel elle est

prévue.

Sécurité au niveau du carburant

○ Faites le mélange et le plein à l’air libre, à distance

de toute étincelle ou fl amme.

○ Utilisez un récipient agréé pour l’essence.

○ Ne fumez pas et ne laissez personne fumer

à proximité du carburant ou de la machine, ni

lorsque vous utilisez la machine.

○ Essuyez soigneusement toutes les traces de

carburant avant de mettre le moteur en marche.

○ Pour démarrer la débroussailleuse, écartez-vous

d’au moins 10 pieds (3 mètres) de l’endroit où

vous avez fait le plein.

○ Arrêtez le moteur avant de dévisser les bouchons

des réservoirs de carburant ou d’huile.

○ Vidangez le réservoir de carburant avant de ranger

la machine. Cette opération est recommandée

après chaque utilisation. Si le réservoir n’est pas

vide, rangez alors la machine dans une position

empêchant toute fuite de carburant.

○ Rangez la machine et le carburant dans un endroit

où les vapeurs d’essence ne risquent pas d’entrer

en contact avec des étincelles ou une fl amme

en provenance d’un chauff e-eau, d’un moteur

électrique, d’un commutateur, d’une chaudière,

etc.

ATTENTION

Le carburant peut s’enfl ammer facilement ou

exploser et l’inhalation de ses vapeurs est

dangereuse. Faites particulièrement attention

lorsque vous manipulez le carburant ou faites

l’appoint du réservoir.

20

Page 21

Français

Sécurité au niveau de la coupe

○ Ne coupez rien d’autre que de l’herbe et des

broussailles.

○ Examinez la zone de coupe avant chaque

utilisation. Enlevez tout objet pouvant être projeté

ou s’emmêler dans la machine.

○ Pour la protection des voies respiratoires, portez

un masque de protection contre les aérosols lors

de la coupe d’une végétation traitée avec des

insecticides.

○ Veillez à ce que personne (enfants, animaux,

spectateurs ou aides) ne se tienne à l’intérieur d’un

périmètre de sécurité de 50 pieds (15 mètres).

Arrêtez immédiatement le moteur si quelqu’un

s’approche de vous.

○ Tenez toujours le moteur à votre droite.

○ Maintenez fermement la machine des deux

mains.

○ Tenez-vous bien en équilibre sur les deux jambes.

Ne travaillez jamais en porte-à-faux.

○ Restez toujours éloigné du silencieux

d’échappement et de l’ensemble de coupe

lorsque le moteur est en marche.

○ Maintenez l’outil de coupe en-dessous de la

taille.

○ Quand vous déplacez l’appareil d’un lieu à un

autre, vérifi ez qu’il est complètement arrêté et que

tous les accessoires de coupe sont à l’arrêt.

○ Ne posez jamais l’appareil sur le sol lorsque le

moteur tourne.

○ Assurez-vous toujours que le moteur est

arrêté et que tous les accessoires de coupe

sont complètement à l’arrêt avant de nettoyer

l’accessoire principal de coupe de tout débris ou

amas d’herbe.

○ Lors de l’utilisation de n’importe quel appareil

électrique/thermique, emportez toujours avec

vous une trousse de premiers soins.

○ Ne démarrez jamais le moteur de l’appareil, et ne

l’utilisez jamais dans un local clos et/ou à proximité

de produits infl ammables, les gaz d’échappement

étant toxiques.

Sécurité au niveau de l’entretien

○ Entretenez votre machine selon les

recommandations du constructeur.

○ Débranchez la bougie avant toute intervention

d’entretien, à l’exception des opérations de

réglages du carburateur.

○ Ne laissez personne s’approcher lorsque vous

réglez le carburateur.

○ Utilisez uniquement les pièces de rechange

d’origine Hitachi.

Transport et rangement

○ Portez la machine avec moteur arrêté et silencieux

orienté vers l’extérieur.

○

Laissez le moteur refroidir, videz le réservoir de

carburant et veillez à la stabilité de la machine lors du

rangement ou du chargement à bord d’un véhicule.

○ Vidangez le réservoir de carburant avant de ranger

la machine. Cette opération est recommandée

après chaque utilisation. Si le réservoir n’est pas

vide, rangez alors la machine dans une position

empêchant toute fuite de carburant.

○ Rangez la machine hors de portée des enfants.

○ Nettoyez soigneusement la machine avant de

l’entreposer dans un endroit sec.

○ Assurez-vous que le commutateur d’arrêt du

moteur est bien sur la position « stop » lors du

transport ou du rangement de la machine.

○ Lors du transport en véhicule, recouvrez la lame

avec le couvre-lame.

Dans l’éventualité de situations qui ne seraient pas

prises en compte par le présent manuel, redoublez

d’attention et usez de bon sens. Contactez un

concessionnaire Hitachi pour toute assistance. Faites

particulièrement attention aux stipulations introduites

par les mots ci-dessous.

ATTENTION

Information de première importance pour éviter

des dommages corporels graves ou mortels.

IMPORTANT

Information importante afi n d’éviter des

dommages corporels ou matériels.

REMARQUE

Information utile pour une utilisation et un

fonctionnement corrects de la machine.

IMPORTANT

Ne démontez pas le lanceur à retour

automatique. Vous pourriez vous blesser à

cause du ressort de recul.

GARANTIE

Les garanties fournies par Hitachi Koki U.S.A., Ltd.

sont indiquées sur le bon de garantie accompagnant

ce produit intitulé “Garantie limitée applicable aux

appareils électriques extérieurs Hitachi”.

Les modèles CG22EAB(SLP) et CG22EAB(L)

NE sont PAS destinés à un usage commercial,

par conséquent, AUCUNE garantie n’est fournie

concernant toute utilisation commerciale ou locative.

Ainsi, la garantie de deux ans accordée au “premier

utilisateur fi nal du produit à des fi ns commerciales”

et la garantie d’un an concernant la “location”,

mentionnées sur le bon de garantie, s’appliquent

aux modèles CG22EAS(SLP), CG22EAS(SL),

CG22EAS(S), CG22EAD(SLP) et CG22EAD(SL),

mais PAS aux modèles CG22EAB(SLP) et

CG22EAB(L).

21

Page 22

Français

CARACTÉRISTIQUES

Modèle

Taille du moteur

(cu. in.)

Bougie d’allumage Champion CJ6 ou équivalent

Contenance du réservoir de

carburant (fl . oz)

Poids à sec (livre) 9.7 (4.4 kg) 10.4 (4.7 kg) 10.4 (4.7 kg)

Niveau de pression

acoustique

LpA (dB (A)) (EN27917)

Niveau de puissance

acoustique mesuré

LwA (dB (A))

Niveau de puissance

acoustique mesuré

LwA (dB (A))

Niveau de puissance

acoustique garanti

LwA (dB (A))

Équivalent

(ISO10884)

Équivalent

(2000/14/CE)

Vitesse de

course

(2000/14/CE)

Vitesse de

course

CG22EAS (SLP)

CG22EAS (SL)

90 89 91 90 90

104 104 103 104 104

107 107 106 107 107

108 109 108 108 109

CG22EAS (S)

CG22EAD (SLP)

CG22EAD (SL)

1.27 (21.1 ml)

14.9 (0.44 l)

CG22EAB (SLP)

CG22EAB (L)

8.8 (4.0 kg)

8.6 (3.9 kg)

Niveau de vibrations (m/s2)

(ISO7916)

Équivalent (Poignée avant / gauche)

Équivalent (Poignée avant / droite)

Ralenti (Poignée avant / gauche)

Ralenti (Poignée avant / droite)

Vitesse de course

(Poignée avant / gauche)

Vitesse de course

(Poignée avant / droite)

REMARQUE

Les niveaux de bruit/vibrations équivalents sont calculés comme total d’énergie pondérée en fonction du

temps pour les niveaux de bruit/vibrations dans diverses conditions de travail avec la répartition temporelle

suivante : 1/2 ralenti, 1/2 vitesse de course.

* Toutes les données sont susceptibles d’être modifi ées sans préavis.

22

6.7

4.1

4.9

3.3

8.0

4.7

4.5

4.8

2.7

3.4

5.8

5.9

4.7

4.3

2.7

3.4

6.1

5.1

7.7

4.7

4.1

3.7

10.1

5.5

6.5

6.9

5.3

3.8

7.6

8.9

Page 23

Français

MONTAGE

Arbre d’entraînement du moteur (Fig. 1)

Desserrez la vis de blocage du tube (1) de dix tours

environ pour que la pointe de la vis n’entrave pas

le tube de protection de l’arbre de transmission à

insérer. Lors de l’insertion du tube, maintenez la

vis de blocage de ce dernier vers l’extérieur pour

empêcher que la garniture intérieure ne devienne un

obstacle.

Insérez correctement l’arbre de transmission dans

le carter d’embrayage du moteur jusqu’à ce que

la position marquée (2) sur le tube de l’arbre de

transmission touche le carter d’embrayage.

Sur certains modèles, l’arbre de transmission peut

être déjà installé.

1

2

Fig. 1

REMARQUE

Lorsque l’insertion de l’arbre de transmission

jusqu’à la position marquée sur le tube est

diffi cile, faites tourner l’arbre de transmission

autour de l’embout d’entraînement de l’outil de

coupe dans le sens des aiguilles d’une montre ou

inversement. Resserez la vis de blocage du tube

tout en alignant l’orifi ce sur le tube de l’arbre de

transmission. Ensuite, resserez fermement la vis

de blocage.

1

2

Montage de la poignée

ATTENTION

Utilisez toujours une barre de protection (6)

et un harnais de sécurité avec la poignée

lors de l’utilisation de lames en acier/rigides

montées sur un coupe-herbes ou une

débroussailleuse à arbre droit. (Fig. 3)

6

Fig. 3

Fixez la poignée au tube de transmission orientée

vers le moteur.

Choisissez la position la plus pratique avant la mise

en marche.

REMARQUE

Si le tube de l’arbre moteur comporte une étiquette

indiquant la position de la poignée, suivez les

indications fournies.

Démontez le support de poignée (7). (Fig. 4)

Ajustez les poignées puis serrez légèrement le

support de poignée à l’aide des quatre vis. Réglez

selon la position appropriée. Fixez ensuite fermement

au moyen des vis.

Montage de l’accessoire de coupe

1. Mettez le nouvel accessoire à la place du

précédent.

2. Assurez-vous que la cheville de blocage (3)

pénètre bien dans l’orifi ce de blocage (4) du tube

et que le tube ne se détache pas. (Fig. 2)

3. Serrez fermement l’écrou de blocage (5). (Fig. 2)

3

5

4

Fig. 2

7

Fig. 4

Fixez le tube de protection au tube de transmission

ou à la poignée à l’aide des colliers de cordon (8).

(Fig. 5)

23

Page 24

Français

8

Fig. 5

REMARQUE

Le tube de protection, s’il est détaché de la

poignée ou du tuyau, risque de rester accroché

pendant l’utilisation et entraîner des blessures

graves. Ne séparez pas le tube de protection de

la poignée ou du tuyau.

Câble de commande des gaz / câble de marchearrêt

Appuyez sur l’onglet supérieur (9) et ouvrez le

couvercle du fi ltre à air. (Fig. 6)

9

Si, sur votre appareil, l’extrémité externe du papillon

des gaz (10) est fi letée et que la prise de terre (11) (si

l’appareil en est équipé) est introduite à fond dans le

support d’ajustage de câble (12), serrez l’extrémité

de ce câble à l’aide de l’écrou d’ajustage (13) au

support d’ajustage de câble (12).

Connectez l’extrémité du câble de commande des

gaz (14) au carburateur (15) et installez le chapeau

tournant (16) (le cas échéant) qui se trouve dans la

trousse à outils sur le pivot (15) (Fig. 8)

Sur certains modèles, certaines parties peuvent être

déjà installées.

12

11

10

Montage du protège-lame (Fig. 9, 10, 10-1, 11)

15

13

Fig. 8

16

14

Fig. 6

Reliez les câbles de marche-arrêt. (Fig. 7)

Fig. 7

24

Fig. 9

Fig. 10

Fig. 10-1

Page 25

Fig. 11

REMARQUE

Sur certains modèles, le crochet de garde peut

déjà être installé sur le boîtier d’engrenages.

Installez le protège-lame sur le tube de l’arbre

de transmission contre le renvoi d’angle. Serrez

fermement le crochet de garde afi n que le protège-

lame ne puisse pas osciller ou bouger pendant

l’utilisation de la machine.

Français

REMARQUE

○ Lorsque vous attachez l’extension de protection

au protège-lame, le limiteur aiguisé doit être

enlevé du protège-lame (le cas échéant).

○ Si le tube de l’arbre moteur comporte une étiquette

indiquant la position de la protection, suivez les

indications fournies.

○ Pour enlever l’extension de protection, référez-

vous aux illustrations. Portez des gants, l’extension

possédant un limiteur aiguisé, puis poussez les

quatre attaches carrées sur le protège-lame l’une

après l’autre dans l’ordre. (Fig. 13)

Montez le protège-lame sur le crochet de garde, qui

stabilise également la protection au niveau du boîtier

d’engrenage à l’aide des deux vis de garde.

IMPORTANT

Certains protège-lames sont équipés d’un

limiteur aiguisé. Prenez garde lorsque vous

le maniez.

Lors de l’utilisation d’un coupe-herbes avec un

protège-lame en deux parties, attachez l’extension

de protection au protège-lame. (Fig. 12)

Fig. 12

Fig. 13

25

Page 26

Français

Montage de la tête de coupe semi-automatique

1. Fonction

Fait avancer automatiquement le fi l de coupe en

nylon lorsqu’elle est tapotée à bas régime (au plus

4,500 tr/min).

Caractéristiques

N° de

code

6696454 Vis creuse

6696597 Vis creuse

Cordon de nylon applicable

Diamètre du cordon :

Diamètre du cordon :

2. Précautions

○ Le boîtier doit être attaché solidement au

○ Vérifi ez s’il y a des fi ssures ou d’autres

○ Vérifi ez si le boîtier et le bouton sont usés.

Si la marque de limite d’usure (17) sur le boîtier

Type de

vis de

fi xation

couvercle.

dommages sur le couvercle, le boîtier et les autres

composants.

n’est plus visible ou qu’il y a un trou au bas (18)

du bouton, changez immédiatement les nouvelles

pièces. (Fig. 14)

17

Sens de la

rotation

Sens

antihoraire

Dans le sens

des aiguilles

d’une montre

1/8˝ (Φ3.0 mm)

Longueur

3/22˝ (Φ2.4 mm)

Longueur :

: 6.5 pieds (2 m)

13 pieds (4 m)

18

Taille de vis

de fi xation

M10×P1.25LH

M8×P1.25RH

d’autres matériaux qui pourraient constituer de

dangereux projectiles.

○ Si le fi l de coupe n’avance pas bien dans la tête de

coupe, vérifi ez si le fi l nylon et tous les composants

sont bien installés. Contactez un concessionnaire

Hitachi pour toute assistance.

3. Installation (Fig. 15)

○ Installez la tête de coupe sur le boîtier

d’engrenages du coupe-herbes ou de la

débroussailleuse. L’écrou de montage est muni

d’un fi let à gauche. Tournez dans le sens des

aiguilles d’une montre pour desserrer et dans le

sens inverse pour serrer.

19

Fig. 15

Pour les modèles à arbre courbe, l’écrou de montage

est muni d’un fi letage à droite. Tournez dans le sens

inverse des aiguilles d’une montre pour desserrer et

dans le sens des aiguilles d’une montre pour serrer.

REMARQUE

○ Puisque le capuchon de porte-lame n’est pas

utilisé ici, conservez-le en vue d’une utilisation

ultérieure d’une lame métallique, le cas échéant.

○ Insérez la clé Allen (19) dans le trou du boîtier

d’engrenages afi n de bloquer le porte-lame.

Fig. 14

○ La tête de coupe doit être montée solidement sur

le boîtier d’engrenages de l’appareil.

○ Pour bénéfi cier d’un rendement et d’une fi abilité

remarquables, utilisez toujours du fi l de coupe en

nylon Hitachi. N’utilisez jamais de fi l métallique ou

26

4. Ajustement de la longueur du fi l

○ Réglez le moteur sur la vitesse la plus faible

possible et tapotez la tête de coupe contre le sol.

Le fi l nylon avancera d’environ 1-3/16˝ (3 cm) pour

chaque coup donné. (Fig. 16)

Fig. 16

Page 27

Français

Vous pouvez également étendre le fi l nylon à la

main, mais uniquement après l’arrêt complet du

moteur. (Fig. 17)

Fig. 17

○ Ajustez le fi l nylon à une longueur comprise entre

4-11/32˝–5-1/2˝ (11 et 14 cm) avant chaque

utilisation.

Montage de la lame de coupe (Fig. 18)

(le cas échéant)

Lors de l’installation d’une lame de coupe,

assurez-vous que celle-ci ne possède ni fi ssure ni

dommage et que ses bords tranchants sont tournés

correctement.

19

21

20

22

23

23

Fig. 19

IMPORTANT

● Avant utilisation, assurez-vous que la lame a

été bien installée.

● Si votre machine est équipée d’une couverture

de protection sous la lame de coupe, assurezvous qu’elle ne présente aucune usure

excessive ou fi ssure avant utilisation. En cas

de dommage ou d’usure, remplacez-la.

ATTENTION

Utilisez uniquement des fi ls non métalliques

recommandés par le fabricant pour les têtes

Hitachi. N’utilisez jamais de fi l de fer ou de

câble métallique. Ils peuvent se rompre et

devenir de dangereux projectiles.

UTILISATION

Carburant (Fig. 20)

Fig. 18

REMARQUE

○ Lors de l’installation du capuchon du porte-lame

(20), veillez à ce que le côté concave soit tourné

vers le haut.

○ Insérez la clé de serrage (19) dans le trou du

boîtier de renvoi d’angle afi n de bloquer le porte-

lame (21). Remarquez que la vis ou l’écrou de

fi xation (22) possède un fi letage pour gauchers,

(desserrez dans le sens des aiguilles d’une

montre / serrez dans le sens inverse). Serrez la

vis ou l’écrou de fi xation avec la clé à douille.

○ Si votre appareil est pourvu d’une fi xation par

écrou et équipé d’une clavette, la lame doit être

fi xée à l’aide d’une nouvelle clavette (23) lors de

chaque installation. (Fig. 19)

Fig. 20

ATTENTION

● La débroussailleuse est équipée d’un moteur

deux temps. Veillez à toujours l’alimenter en

mélange essence/huile.

Veillez à une bonne aération pendant

l’opération de remplissage du réservoir.

● Le carburant contient des substances

hautement infl ammables. Vous risquez des

blessures sévères en cas d’inhalation de

vapeurs ou d’éclaboussure accidentelle

du produit sur votre corps. Faites toujours

très attention lorsque vous manipulez le

carburant. Si vous prévoyez de manipuler le

carburant en intérieur, faites-le dans un local

bien ventilé.

27

Page 28

Français

Essence

○ Utilisez toujours de l’essence sans plomb avec un

indice d’octane de 89.

○ Utilisez une huile pour moteur à deux temps ou un

mélange variant de 25:1 à 50:1. Veuillez consulter

le réservoir d’huile pour la proportion du mélange

ou contacter un concessionnaire Hitachi.

○ Si vous n’utilisez pas une huile d’origine, utilisez

une huile de qualité contenant un antioxydant

recommandé pour être utilisé avec un moteur à

deux temps refroidi à l’air (JASO FC GRADE OIL

ou ISO EGC GRADE). N’utilisez jamais d’huiles

mélangées BIA ou TCW (pour les moteurs à

essence 2 temps à refroidissement par eau).

○ N’utilisez jamais d’huile Multigrade (10 W/30), ni

d’huile usagée.

○ Eff ectuez toujours le mélange dans un récipient

propre.

Commencez toujours par verser la moitié de

l’essence à mélanger. Versez ensuite la totalité de

l’huile. Mélangez en agitant le récipient. Ajoutez le

reste de l’essence.

Puis agitez le récipient afi n de mélanger

soigneusement le carburant avant de faire le plein.

Faire le plein

ATTENTION

● Éteignez toujours le moteur avant de faire le

plein.

● Desserrez lentement le bouchon du réservoir

de carburant pour eff ectuer le remplissage

afi n d’évacuer une éventuelle surpression.

● Serrez le bouchon soigneusement après

avoir rempli le réservoir de carburant.

● Avant de redémarrer le moteur, éloignezvous toujours d’au moins 10 pieds (3 mètres)

de l’endroit où vous avez fait le plein de

carburant.

● En cas de projection accidentelle de carburant

sur vos vêtements, lavez immédiatement ces

derniers avec du savon.

● Après chaque appoint de carburant, vérifi ez

toujours l’absence de fuite.

Démarrage

IMPORTANT

Avant le démarrage, vérifi ez que la lame n’est

en contact avec aucun objet.

1. Placez l’interrupteur de marche/arrêt (24) en

position “marche” (ON). (Fig. 21, 22)

24

26

Fig. 21

24

Fig. 22

* Pressez la poire de la pompe d’amorçage (25) à

plusieurs reprises pour que le carburant puisse

s’écouler par le tuyau de retour (39). (Fig. 23)

25

Avant le remplissage, essuyez autour du bouchon

du réservoir afi n d’éviter que des corps étrangers ne

pénètrent dans le réservoir. Veillez à l’homogénéité

du mélange en agitant à intervalle régulier le récipient

avant et pendant le remplissage.

28

39

Fig. 23

Page 29

Français

2. Réglez le starter (27) sur la position FERMÉE (A).

(Fig. 24)

B

A

27

Fig. 24

3. Tirez vivement sur la corde du lanceur en

accompagnant son retour, sans relâcher

brusquement la poignée. (Fig. 25)

○ Coupez l’herbe de la droite vers la gauche.

○ Coupez l’herbe de gauche à droite (uniquement

sur le modèle à arbre courbe).

○ Une réaction de poussée de la lame peut survenir

lorsque la lame en rotation entre en contact avec

un objet solide dans la zone critique.

Une réaction dangereuse peut alors survenir

provoquant un mouvement incontrôlé et violent de

toute la machine et de l’utilisateur. Cette réaction

est appelée rebond de la lame. Elle peut faire

perdre le contrôle de la machine et être à l’origine

de blessures sérieuses, voire fatales. Cette

réaction incontrôlée de la lame risque davantage

de survenir lorsque l’opérateur ne peut voir le

matériau à couper.

○ Portez le harnais comme indiqué sur l’illustration

(si la machine en est munie). La lame tourne dans

le sens inverse des aiguilles d’une montre. Par

conséquent, il est préférable d’utiliser la machine

de la droite vers la gauche pour assurer un

débroussaillage effi cace. Éloignez les personnes

se trouvant à proximité de la zone de travail d’une

distance d’au moins 50 pieds (15 m).

Fig. 25

4. Dès les premiers soubresauts du moteur,

ramenez le starter en position ouverte (B). Puis

tirez à nouveau vivement sur le lanceur.

REMARQUE

Si le moteur ne démarre pas, répétez la procédure

décrite entre les points 2 et 5.

5. Laissez ensuite le moteur chauff er pendant

2 à 3 minutes avant de le soumettre à un eff ort

quelconque.

Débroussaillage (Fig. 26, 27, 28)

○ Faites fonctionner le moteur à un régime supérieur

à 6,500 tours par minute lors du débroussaillage.

L’utilisation prolongée de la machine au ralenti peut

aboutir à une usure prématurée de l’embrayage.

Fig. 26

Fig. 27

29

Page 30

Français

50 pieds

(15 m)

Fig. 28

ATTENTION

Si l’outil de coupe bute contre des pierres ou

autres débris, arrêtez le moteur et assurezvous que l’outil et ses pièces connexes ne

sont pas endommagés. Lorsque des herbes

ou des plantes grimpantes s’enroulent autour

de l’outil de coupe, arrêtez le moteur, attendez

que la lame s’arrête de tourner et retirez les

herbes et plantes grimpantes.

Arrêt de la débroussailleuse (Fig. 29, 30)

Ralentissez le moteur et faites-le fonctionner au

ralenti quelques minutes puis mettez l’interrupteur de

marche-arrêt (24) sur la position “stop”.

24

ATTENTION

L’outil de coupe peut blesser lorsqu’il

continue de tourner après l’arrêt du moteur

ou lorsque l’on déclenche la commande

d’alimentation du moteur. Après l’arrêt de la

machine, attendez l’arrêt complet de l’outil de

coupe avant de poser la machine.

Tête de coupe semi-automatique

○ Faites fonctionner le moteur à un régime supérieur

à 6,500 tr/min lors du débroussaillage. L’utilisation

prolongée de la machine au ralenti peut aboutir à

une usure prématurée de l’embrayage.

○ Coupez l’herbe de la droite vers la gauche.

○ Coupez l’herbe de gauche à droite (uniquement

sur le modèle à arbre courbe).

ATTENTION

L’outil de coupe peut blesser lorsqu’il

continue de tourner après l’arrêt du moteur

ou lorsque l’on déclenche la commande

d’alimentation du moteur. Après l’arrêt de la

machine, attendez l’arrêt complet de l’outil de

coupe avant de poser la machine.

Fait avancer automatiquement le fi l de coupe en

nylon lorsqu’elle est tapotée à bas régime (au plus

4,500 tr/min).

26

Fig. 29

24

Fig. 30

Sur les modèles équipés d’un interrupteur de marche/

arrêt, maintenez ce dernier enfoncé jusqu’à ce que le

moteur s’arrête complètement.

30

ENTRETIEN

L’ENTRETIEN, LE REMPLACEMENT OU LA

RÉPARATION DES DISPOSITIFS ET SYSTÈMES

DE CONTRÔLE DE L’ÉCHAPPEMENT PEUVENT

ÊTRE EFFECTUÉS PAR N’IMPORTE QUEL

ATELIER DE RÉPARATION OU MÉCANICIEN DE

MOTEUR NON AUTOMOBILE.

Réglage du carburateur (Fig. 31)

Fig. 31

Page 31

ATTENTION

● La lame peut entrer en mouvement pendant

le réglage du carburateur.

● N’essayez jamais de démarrer le moteur tant

que le carter de protection de l’embrayage

et le tube ne sont pas parfaitement en place.

Dans le cas contraire, l’embrayage risquerait

de se détacher, entraînant des blessures

corporelles.

Dans la carburateur, l’air est mélangé au carburant.

Le carburateur est réglé pendant les essais en usine.

Ce réglage peut nécessiter des modifi cations selon

les conditions climatiques et l’altitude. Le carburateur

présente une possibilité de réglage:

T = Vis de réglage du ralenti.

Réglage du ralenti (T)

Commencez par vérifi er la propreté du fi ltre à air.

Lorsque le ralenti est correct, la chaîne ne doit pas

tourner. Si un réglage s’avère nécessaire, vissez,

dans le sens des aiguilles d’une montre, avec le

moteur en marche, jusqu’à ce que la lame commence

à tourner. Dévissez alors en sens contraire (sens

inverse des aiguilles d’une montre) jusqu’à ce que

la chaîne s’immobilise à nouveau. Un ralenti correct

permet au moteur de tourner sans variation de régime

dans toutes les positions, ce qui assure une marge

de sécurité avant la mise en rotation de la chaîne.

Si le dispositif de coupe tourne encore après le réglage

du régime de ralenti, contactez un concessionnaire

Hitachi.

REMARQUE

Le nombre normal de tours par minute au ralenti est de

2,800 – 3,200 tr/mn.

ATTENTION

L’outil de coupe doit être absolument

immobile lorsque le moteur tourne au ralenti.

Français

28

Fig. 32

Nettoyage du fi ltre à air

Ouvrez le couvercle du fi ltre à air et le fi ltre (28).

Lavez-les à l’eau savonneuse chaude. Veillez ensuite

à ce que le fi ltre soit bien sec avant de le remonter.

Un fi ltre à air ayant servi longtemps ne peut être

complètement nettoyé. Par conséquent, il doit être

remplacé régulièrement par un fi ltre neuf. Remplacez

toujours le fi ltre s’il est endommagé.

Filtre à carburant (Fig. 33)

Purgez tout le carburant se trouvant dans le réservoir

et retirez la durite du fi ltre à carburant du réservoir.

Démontez la cartouche du fi ltre et rincez-la dans de

l’eau chaude contenant un produit détergent.

Rincez soigneusement jusqu’à élimination de toute

trace de détergent. Pressez la cartouche sans la

tordre afi n d’éliminer l’excès d’eau et laissez-la

sécher à l’air libre.

REMARQUE

Si le fi ltre a durci à cause des impuretés contenues

dans le carburant, il convient de le remplacer.

Filtre à air (Fig. 32)

Nettoyez le fi ltre à air régulièrement pour éviter :

○ les troubles de fonctionnement du carburateur

○ les problèmes de démarrage

○ les pertes de puissance

○ l’usure prématurée des organes du moteur

○ une consommation anormalement élevée

Nettoyez le fi ltre à air quotidiennement ou plus

fréquemment en milieu poussiéreux.

Fig. 33

Bougie (Fig. 34)

L’état de la bougie est infl uencé par :

○ Un mauvais réglage du carburateur

○ Un mélange incorrect (trop riche en huile)

○ Un fi ltre à air sale

○ Des conditions d’utilisation diffi ciles (par temps

froid par exemple)

31

Page 32

Français

Ces facteurs contribuent à la formation de dépôts

sur les électrodes de la bougie et peuvent entraîner

des troubles de fonctionnement et des diffi cultés

de démarrage. Si la débroussailleuse manque de

puissance, si elle démarre mal ou si son ralenti est

irrégulier, commencez toujours par vérifi er l’état de

la bougie. Si la bougie est encrassée, nettoyez-la

et vérifi ez l’écartement des électrodes. Ajustez-

le si nécessaire. Il doit être de 0.024˝ (0.6 mm). La

bougie devra être remplacée après une centaine

d’heures d’utilisation, ou plus tôt si les électrodes

sont endommagées.

0.024˝

(0.6 mm)

Fig. 34

REMARQUE

Dans certaines régions, la réglementation locale

exige l’utilisation d’une bougie équipée d’une

résistance d’antiparasitage afi n d’éliminer les

signaux d’allumage. Si cette machine était

équipée à l’origine d’une bougie avec résistance

d’antiparasitage, utilisez le même type de bougie

lorsque vous la remplacez.

Arbre d’entraînement fl exible (Fig. 35)

L’arbre d’entraînement fl exible doit être démonté

et lubrifi é avec de la graisse au lithium de bonne

qualité toutes les 20 heures de service. Pour

démonter l’arbre fl exible, commencez par retirer la

vis (29), desserrer le boulon (30) puis démonter le

boîtier d’engrenages pour sortir l’arbre de son tube.

Nettoyez l’arbre et appliquez une couche généreuse

de graisse au lithium. Insérez-le dans son tube puis