Page 1

A

HITACHI AC SERVO DRIVES

With Programmable Functions(Enhancement)

ADAX4 Series

Instruction Manual

Thank you very much for purchasing the HITACHI AC servo drives.

This instruction manual describes the handling, maintenance, and others of the HITACHI

D series servo drives with AC servo programmable functions. Please read this manual

thoroughly before operating it so that installation, maintenance, inspection may be

performed correctly. For the program function, read the instruction manual pertaining to the

Programmable Function.

When using option products related to this servo drives, read the instruction manuals for the

related products thoroughly.

Keep this manual handy for your quick reference.

NB284X

Page 2

SAFETY

SAFETY

For the Best Results with AD Series servo drives, read this manual and all of the warning sign

attached to the servo drive carefully before installing and operating it, and follow the instructions exactly .

Keep this manual handy for your quick reference.

Definitions and Symbols

A safety instruction (message) is given with a hazard alert symbol and a signal word;

WARNING or CAUTION. Each signal word has the following meaning throughout this manual.

WARNING

This symbol means hazardous high voltage. It used to call your attention to

items or operations that could be dangerous to you or other persons operating

this equipment.

Read these message and follow these instructions carefully.

This is the "Safety Alert Symbol" This symbol is used to call your attention

to items or operations that could be dangerous to you or other persons

operating this equipment.

Read these messages and follow these instructions carefully.

WARNING

Indicates a potentially hazardous situation which, if not avoided, can result in

serious injury or death.

CAUTION

CAUTION

Indicates a potentially hazardous situation which, if not avoided, can result in

minor to moderate injury, or serious damage of product.

The matters described under may, if not avoided, lead to

serious results depending on the situation. Important matters are described in

CAUTION (as well as WARNING), so be sure to observe them.

CAUTION

NOTE

NOTE

When servicing drives and electronic controllers, there might be exposed components with cases or

protrusions at or above line potential. Extreme care should be taken to product against shock.

Always work with another person in case an emergency occurs. Disconnect power before checking

controllers or performing maintenance. Be sure equipment is properly grounded. Wear safety glasses

HAZARDOUS HIGH VOLTAGE

Motor control equipment and electronic controllers are connected to hazardous line voltages.

Stand on an insulating pad and make it a habit to use only one hand when checking components.

Notes indicate an area or subject of special merit, emphasizing either the

product's capabilities or common errors in operation or maintenance.

whenever working on an electronic controller or rotating electrical equipment.

ii

Page 3

PRECAUTION

SAFETY

WARNING

maintenance personal familiar with the construction and operation of the equipment and the hazards

involved. Failure to observe this precaution could results in bodily injury.

WARNING

mechanism not supplied by Hitachi, and process line material are capable of safe operation at an

applied maximum speed to the AC servo motor. Failure to do so can result in destruction of

equipment and injury to personnel should a single point failure occur.

WARNING

capable of large currents to avoid an unnecessary operation. The ground fault protection circuit is not

designed to protect personal injury.

WARNING

BEFORE WORKING ON THIS CONTROL.

WARNING

PROTECTION IS REQUIRED TO BE PROVIDED IN ACCORDANCE WITH THE SAFETY CODES

REQUIRED BY JURISDICTIONAL AUTHORITIES.

CAUTION

series equipment.

: This is equipment should be installed, adjusted and serviced by qualified electrical

: The user is responsible for ensuring that all driven machinery, drive train

: For protection, install an earth leakage breaker with a high frequency circuit

: HAZARD OF ELECTRICAL SHOCK. DISCONNECT INCOMING POWER

: SEPARATE MOTOR OVERCURRENT, OVERLOAD AND OVERHEATING

: These instructions should be read and clearly understood before working on AD

CAUTION

are the responsibility of the user and are not provided by Hitachi.

CAUTION

CAUTION

Therefore, it is strongly recommended that all electrical work conform to the National Electrical Codes

and local regulations. Only qualified personnel should perform installation, alignment and

maintenance. Factory recommended test procedures, included in the instruction manual, should be

followed. Always disconnect electrical power before working on the unit.

: Proper grounds, disconnecting devices and other safety devices and their location

: DANGEROUS VOLTAGE EXISTS UNTIL CHARGE LAMP IS OFF.

: Rotating shafts and above ground electrical potentials can be hazardous.

NOTE : POLLUTION DEGREE 2

The servo drives must be used environment of the degree 2.

Typical constructions that reduce the possibility of conductive pollution are;

1) The use of an unventilated enclosure

2) The use of a filtered ventilated enclosure when the ventilation is fan forced that is, ventilation is

accomplished by one or more blowers within the enclosure that provide a positive intake and

exhaust.

iii

Page 4

SAFETY

Cautions for EMC (Electromagnetic Compatibility)

It is required to satisfy the EMC directive (89/336/EEC) when using AD series servo drives in EU

country. To satisfy the EMC directive and to comply with standard (EN61800-3), the followi ng should

be kept.

WARNING

familiar with construction and operation of the equipment and the hazards involved. Failure to

observe this precaution could result in bodily injury.

1. The power supply to the drives must meet these specifications:

a. Voltage fluctuation +10%/-15% or less.

b. Voltage unbalance +/-3% or less.

c. Frequency variation +/-4% or less.

d. Voltage distortion THD = 10% or less.

2. Installation measure:

a. Use a filter designed for AD series servo drives.

3. Wiring

a. Shielded wire (screened cable) is required for motor wiring, and the length must be less

than 30 meters.

b. Separate the main circuit from the signal/process circuit wiring.

: This equipment should be installed, adjusted, and serviced by qualified personal

4. Environmental conditions – when using a filter, follow these guidelines:

a. Ambient air temperature: 0 - +55 ºC.

b. Humidity: 20 to 90% RH (non-condensing)

2

c. Vibration: 5.9 m/sec

d. Location: 1000meters or less altitude, indoors (no corrosive gas or dust)

(0.6 G) 10 – 55Hz.

iv

Page 5

SAFETY

X

Conformity to the Low Voltage Directive (LVD)

The protective enclosure is required to satisfy the Low Voltage Directive (73/23/EEC).

The drives can conform to the LVD and comply with standard (EN50178) by mounting into the

following enclosure.

1.Enclosure

The drives must be installed into a enclosure which has the protection degree of Type IP2X (See

EN60529). In addition the top surface or front surface of enclosure are easily accessible shall meet at

least the requirements of the Protective Type IP4X.

2.Protection device

A double pole disconnection device must be fitted to the incoming mains supply close to the drive.

Additionaly, a protection device meeting IEC947-1/IEC947-3 must be fitted at this point. (protection

device data shown in page vii)

IP4

IP2X with louver

v

Page 6

SAFETY

UL Warnings and Cautions Manual for AD series

This auxiliary instruction manual should be delivered to the end user.

1. Wiring Warnings for Electrical Practices and Wire Specifications

(1) ! WARNING : "Use 60/75 ºC CU wire only" or equivalent.

(2) ! WARNING: "Open Type Equipment."

(3) ! WARNING: " Suitable for use on a circuit capable or delivering not more than 10,000 rms

symmetrical amperes, 240 V maximum.

2.Tightening Torque and Wire Range

(1) ! WARNING : Tightening torque and wire range for field wiring terminals are marked

adjacent to the terminal or on the wiring diagram.

Model Name

ADAX4-R5MS 1.2 18 18

ADAX4-01MS 1.2 18 18

ADAX4-02MS 1.2 18 18

ADAX4-04MS 1.2 16 18

ADAX4-R5LS 1.2 18 18

ADAX4-01LS 1.2 18 18

ADAX4-02LS 1.2 18 18

ADAX4-04LS 1.2 18 18

ADAX4-08LS 1.2 18 18

ADAX4-10LS 1.2 16 16

ADAX4-20LS 1.2 14 14

ADAX4-30LS 1.2 12 10

ADAX4-50LS 2.0 10 10

Tightening Torque [N•m] Wire Range (AWG)

Input Output

ADAX4-01NSE 1.2 18 18

ADAX4-02NSE 1.2 18 18

ADAX4-04NSE 1.2 18 18

ADAX4-08NSE 1.2 16 18

ADAX4-15HPE 0.5~0.6 18 18

ADAX4-35HPE 0.5~0.6 14 14

ADAX4-70HPE 2.0 10 10

vi

Page 7

SAFETY

3. Fuse Size

(1) ! WARNING : Distribution fuse size marking is included in the manual to indicate that the

unit shall be connected with an UL Listed Class J fuse rated 600 V with the

current ratings as shown in the table below.

Model Name Input Phase

ADAX4-R5MS 3 3

ADAX4-01MS 3 6

ADAX4-02MS 3 10

ADAX4-04MS 3 15

ADAX4-R5LS 3 3

ADAX4-01LS 3 3

ADAX4-02LS 3 3

ADAX4-04LS 3 6

ADAX4-08LS 3 10

ADAX4-10LS 3 10

ADAX4-20LS 3 20

ADAX4-30LS 3 30

ADAX4-50LS 3 50

ADAX4-01NSE 1/3 3/3

ADAX4-02NSE 1/3 6/3

ADAX4-04NSE 1/3 10/6

ADAX4-08NSE 1/3 15/10

ADAX4-15HPE 3 10

ADAX4-35HPE 3 20

ADAX4-70HPE 3 50

Fuse [A]

4.Others

(1) ! WARNING : "Field wiring connection must be made by an UL Listed and CSA Certified

closed-loop terminal connector sized for the wire gauge involved. Connector must be fixed using the

crimp tool specified by the connector manufacturer. ", or equivalent wording included in the manual.

(2) ! WARNING : Use the transient voltage surge suppressors recognized in

UL1449.

(3) ! W ARNING : “Solid st ate motor over load protection is provided in each model.”, or equivalent.

(4) ! WARNING : “Maximum Surrounding Air Temperature 55°C.”

(5) ! WARNING : “Not incorporating Over-speed Protection.” or an equivalent statement.

vii

accordance with

Page 8

CONTENTS

Contents

CHAPTER 1 SAFETY PRECAUTIONS

1.1 Installation...................................1 − 2

1.2 Wiring..........................................1 − 3

1.3 Control and operation...................1 −4

1.4 Maintenance, inspection and ......1 − 5

part replacement

1.5 Others......................................... 1 − 5

CHAPTER 2 INTRODUCTION

2.1 Inspection upon unpacking.........2 − 2

2.1.1 Checking the product.............2 − 2

2.1.2 Instruction manual..................2 − 5

2.2 Inquiry about the Product

and Warranty ..............................2 − 5

2.2.1 Notes for making an

inquiry ....................................2 − 5

2.2.2 Product warranty....................2 − 5

2.2.3 Charged repair.......................2 − 5

2.3 Appearance and Names

of Parts .......................................2 − 6

2.4 Combination of servo amplifiers

and servo motors........................2 − 8

CHAPTER 3 INSTALLATION AND WIRING

3.1 Installation...................................3 − 2

3.1.1 Precautions on

installation..............................3 − 3

3.2 Wiring..........................................3 − 5

3.2.1 Terminals and connectors......3 − 6

3.2.2 Main circuit wiring...................3 − 8

3.2.3 Wiring for the control power

connector (TM2)

(200V class).........................3 − 21

3.2.4 Connecting the backup

battery for absolute

encoder................................3 − 22

3.2.5 Input/output signal

wiring....................................3 − 23

3.2.6 Wiring for encoder

signals..................................3 − 39

CHAPTER 4 OPERATION

4.1 Operating Method.......................4 − 2

4.1.1 Speed-control operation

by analog input.......................4 − 4

4.1.2 Speed control operation

by multistage speed...............4 − 5

4.1.3 Position control operation

by pulse train input.................4 − 6

4.2 Test Run.....................................4 − 7

4.2.1 Test run by analog input ........4 − 7

4.2.2 Test run by multistage

speed.....................................4 − 8

4.2.3 Jogging operation and teaching

operation from the digital

operator .................................4 − 9

4.2.4 Test run by using the

setup software AHF..............4 − 11

CHAPTER 5 FUNCTIONS

5.1 Terminal Functions List...............5 − 2

5.2 Input Terminal Functions.............5 − 4

5.3 Output Terminal Functions........5 − 15

5.4 Analog Input/output

Function....................................5 − 21

5.4.1 Analog Input Function...........5 − 21

5.4.2 Analog Output Function.........5 − 27

5.5 Analog Input Acceleration/

Deceleration Function...............5 − 28

5.6 Multistage Speed Function........5 − 29

5.7 Position Pulse Train Input

Function....................................5 − 31

5.8 Smoothing Function..................5 − 34

5.9 Encoder Monitor Function.........5 − 36

5.10 Adjusting the Control Gain......5 − 38

5.10.1 Basic Rules of Gain

Adjustment ........................5 − 38

5.10.2 Rigidity and Response

Setting of The Mechanical

System ..............................5 − 39

5.10.3 Adjusting The Speed

Feedback Loop..................5 − 40

5.10.4 Adjusting The Position

Feedback Loop..................5 − 41

5.1 1 Offline Auto-tuning Function...5 − 42

5.1 1.1 Offline Auto-tuning

Method...............................5 − 42

5.1 1.2 Offline Auto-tuning Using

the AD series Setup

Software AHF.....................5 − 45

5.12 Online Auto-tuning Function...5 − 47

5.12.1 Online Auto-tuning

Method...............................5 − 47

Page 9

Contents

CONTENTS

5.12.2 Online Auto-tuning Using

the Setup Software AHF ....5 − 50

5.13 Gain Change Function............5 − 51

5.13.1 Changing the Control

Gain................................... 5 − 51

5.14 Functions for Absolute

Position Encoder ....................5 − 54

5.15 Clearing the Trip Log and

Factory Settings......................5 − 58

5.16 Directions of Run of the Servo

Motor and Servo Drive............5 − 60

5.17 Speed Limit Function..............5 − 60

5.18 Fast positioning Function........5 − 61

5.19 Notch filter Function................5 − 62

CHAPTER 6 DETAILS OF PARAMETERS

6.1 Names of Digital Operator

Parts and Operating the

Digital Operator...........................6 − 2

6.1.1 Names of Digital Operator

Parts.......................................6 − 2

6.1.2 Operating the Digital

Operator.................................6 − 3

6.2 List of Functions..........................6 − 6

6.2.1 List of Monitor Functions........6 − 7

6.2.2 List of Setting Parameters......6 − 8

6.3 Details of Functions ..................6 − 14

6.3.1 Details of Monitor

Indication..............................6 − 14

6.3.2 Details of Setting

Parameters ..........................6 − 18

6.4 Control Block Diagram and

Monitors....................................6 − 48

CHAPTER 7 MAINTENANCE AND

INSPECTION

7.1 Precautions on Maintenance

and Inspection.............................7 − 2

7.1.1 Request at Maintenance

and Inspection........................7 − 2

7.1.2 Daily Inspection......................7 − 2

7.1.3 Cleaning.................................7 − 2

7.1.4 Periodic Inspection.................7 − 2

7.2 Daily Inspection and Periodic

Inspection ...................................7 − 3

7.3 Megger Test and Withstand

Volt age Test ................................7 − 4

7.4 Checking the Inverter and

Converter....................................7 − 4

7.5 Capacitor Life Curve ..................7 − 6

7.6 Battery Life for

Absolute Encoder ......................7 − 6

CHAPTER 8 SPECIFICATIONS AND

DIMENSIONS

8.1 Specification Table Standard.......8 − 2

8.2 External Dimension and

Mounting Hole

Drawing of Servo Drive...............8 − 4

CHAPTER 9 TROUBLESHOOTING

9.1 Trip Indication (Trip Log).............9 − 2

9.2 List of Protective Functions.........9 − 3

9.3 Troubleshooting..........................9 − 5

9.3.1 When a trip is not caused ......9 − 5

9.3.2 When a trip is caused ............9 − 8

CHAPTER 10 OPTIONAL FUNCTIONS

10.1 Outline of Modbus communication

option module...........................10 − 2

10.2 Wiring of Modbus-Network........10 − 3

10.3 Modbus communication

specifications ............................10 − 5

10.4 Modbus commuication

setting.......................................10 − 5

10.5 Modbus transmission

procedure................................10 − 6

10.6 List of Modbus Coil number

and Register number..............10 − 15

10.7 Teaching Function..................10 − 26

10.7.1 Name and operation of

each parts of

Teaching UNIT....................10− 26

10.7.2 Mode change operation and

operation with each mode ..10− 28

10.7.3 Other explanations .............10− 31

CHAPTER 11 APPENDIXES

11.1 Options...................................11 − 2

1 1.2 Electronic Thermal Operation

Time.....................................11 − 19

11.3 Internal Block Diagram of

Servo Drive...........................11 − 23

Page 10

CONTENTS

11.4 Example Connection with

Programmable Controller .....11 − 27

11.4.1 Main circuit connection.....11 − 27

11.4.2 Connection with Hitachi 4 axes

positioning module

EH-POS4(I/O)..................11 − 29

11.4.3 Connection with Hitachi one

axis positioning

module EH-POS(I/O)........11 − 30

11.4.4 Connection with Hitachi 4

axis positioning module

EH-POS4(I/O)...................11

11.4.5 Connection with Hitachi one

axis positioning module

EH-POS(I/O).....................11

11.4.6 Modbus connection

example.............................11

11.5 Example Connection with

peripheral equipment ...........11 − 34

11.5.1 Connection of Speed/

Torque control operation...11

− 31

− 32

− 33

− 34

Contents

Page 11

CHAPTER 1 SAFETY PRECAUTIONS

Read this manual and all of the warning sign attached to the drives carefully

before installing and operating it, and follow the instructions exactly . Keep this

manual handy for your quick reference.

1.1 Installation.................................................... 1 − 2

1.2 Wiring........................................................... 1 − 3

1.3 Control and operation ………………………... 1 − 4

1.4 Maintenance, inspection and part ............... 1 − 5

replacement

1.5 Others.......................................................... 1 − 6

1 - 1

Page 12

CHAPTER 1 SAFETY PRECAUTIONS

1.1 Installation

CAUTION

• Be sure to install the unit on flame resistant material such as metal.

Otherwise, there is a danger of fire.

• Be sure not to place anything inflammable in the vicinity.

Otherwise, there is a danger of fire.

• Do not carry unit by top cover, always carry by supporting base of unit.

There is a risk of falling and injury.

• Be sure not to let the foreign matter enter such as cut wire refuse, spatter

from welding, iron refuse, wire, dust, etc.

Otherwise, there is a danger of fire.

• Be sure to install it in a place where can bear the weight according to the

specifications in the text.

Otherwise, it may fall and there is a danger of injury.

• Be sure to install the unit on a perpendicular wall where is not subject to

vibration.

Otherwise, it may fall and there is a danger of injury.

• Be sure not to install and operate AC servo drive which is damaged or parts

of which are missing.

Otherwise, there is a danger of injury.

• Be sure to install it in a room where is not exposed to direct sunlight and is

well ventilated. Avoid environments which tend to be high in temperature,

high in humidity or to have dew condensation, as well as places with dust,

corrosive gas, explosive gas, inflammable gas, grinding-fluid mist, salt

damage, etc.

Otherwise, there is a danger of fire.

1 - 2

Page 13

1.2 Wiring

• Be sure to ground the unit.

Otherwise, there is a danger of electric shock and/or fire.

• Wiring work shall be carried out by electrical experts.

Otherwise, there is a danger of electric shock and/or fire.

• Implement wiring after checking that the power supply is off.

It might incur electric shock and/or fire.

• After installing the main body, carry out wiring.

Otherwise, there is a danger of electric shock and/or injury.

WARNING

CHAPTER 1 SAFETY PRECAUTIONS

• Make sure that the input voltage is:

Three phase 200 to 230V 50/60Hz (for models with suffix L)

Single phase 100 to 115V 50/60Hz (for models with suffix M)

Single phase 220 to 230V / Three phase 200 to 230V 50/60Hz

(for models with suffix N)

Three phase 380 to 480V 50/60Hz (for models with suffix H)

Control power supply 200 to 240V 50/60Hz (for models with suffix H)

Otherwise, there is a danger of fire.

• Be sure not to input a single phase for models with suffix H and suffix L.

Otherwise, there is a danger of fire.

• Be sure not to connect AC power supply to the output terminals(U, V, W).

Otherwise, there is a danger of injury and/or fire.

• Be sure not to connect the resistor to DC terminals (+1,+ and –) directly.

Otherwise, there is a danger of fire.

• As for motor leads, fuses and electromagnetic contactors, be sure to use the

equivalent ones with the specified capacity (rated).

Otherwise, there is a danger of fire.

• Fasten the screws with the specified fastening torque. Check so that there is

no loosening of screws.

Otherwise, there is a danger of fire.

CAUTION

• Connection to field wiring terminals must be reliably fixed having two

independent means of support. Using terminal with cable support, cable

gland or cable clamp etc.

Otherwise, there is a danger of fire.

• Be sure to connect between servo drive logic ground (L) and controller ground

when pulse train input is used by servo drive with source type logic.

Otherwise, A equipment failure will be caused.

1 - 3

Page 14

CHAPTER 1 SAFETY PRECAUTIONS

1.3 Control and operation

WARNING

• While the servo drive is energized, be sure not to touch the main terminal or

to check the signal or put on/off wire and/or connector.

Otherwise, there is a danger of electric shock.

• Be sure to turn on the input power supply after closing the terminal cover.

While being energized, be sure not to open the terminal cover.

Otherwise, there is a danger of electric shock.

• Be sure not to operate the switches with wet hands.

Otherwise, there is a danger of electric shock.

• While the servo drive is energized, be sure not to touch the servo drive

terminals even during stoppage.

Otherwise, there is a danger of electric shock.

• It may suddenly restart after the incoming power failure. Be sure not to

approach the machine. (Be sure to design the machine so that personnel

safety will be secured even if it restarts.)

Otherwise, there is a danger of injury.

• Even if the power supply is cut for a short period of time, it may restart

operation after the power supply is recovered if the operation command is

given. If it may incur danger to personnel, be sure to make a circuit so that it

will not restart after power recovery.

Otherwise, there is a danger of injury.

• After the operation command is given, if the alarm reset is conducted, it will

restart suddenly. Be sure to set the alarm reset after checking the operation

command is off.

Otherwise, there is a danger of injury.

• Be sure not to touch the inside of the energized servo drive or to put a bar

into it.

Otherwise, there is a danger of electric shock and/or fire.

1 - 4

Page 15

CHAPTER 1 SAFETY PRECAUTIONS

• Cooling fin will have high temperature. Be sure not to touch them.

Otherwise, there is a danger of getting burned.

• Install external break system if needed.

Otherwise, there is a danger of injury.

CAUTION

1.4 Maintenance, inspection and part replacement

• After a lapse of more than 10 minutes after turning off the input power supply,

perform the maintenance and inspection.

Otherwise, there is a danger of electric shock.

• Make sure that only qualified persons will perform maintenance, inspection

and part replacement. (Before starting the work, remove metallic objects

from your body (wristwatch, bracelet, etc.)

(Be sure to use tools protected with insulation.)

Otherwise, there is a danger of electric shock and/or injury.

WARNING

1.5 Others

• Never modify the unit.

Otherwise, there is a danger of electric shock and/or injury.

WARNING

1 - 5

Page 16

CHAPTER 1 SAFETY PRECAUTIONS

MEMO

1 - 6

Page 17

CHAPTER 2 INTRODUCTION

This chapter explains the checking, warranty, and names of parts of the

product that you purchased.

2.1 Inspection upon unpacking.......................... 2 − 2

2.1.1 Checking the product ............................ 2 − 2

2.1.2 Instruction m anual................................. 2 − 5

2.2 Inquiry about the Product and Warranty...... 2 − 5

2.2.1 Notes for making an inquiry................... 2 − 5

2.2.2 Product warranty................................... 2 − 5

2.2.3 Charged repair ...................................... 2 − 5

2.3 Appearance and Names of Parts................. 2 − 6

2.4 Combination of servo amplifiers

and servo motors.................................... 2 − 8

2 - 1

Page 18

CHAPTER 2 INTRODUCTION

2.1 Inspection upon unpacking

2.1.1 Checking the product

After unpacking, take out the servo drive and check the following items.

If you have any doubt or fault on the product, please contact your dealer.

(1) Make sure that there was no damage (injury, falling or dents in the body) of the product.

(2) After unpacking, make sure that the package contains the following articles.

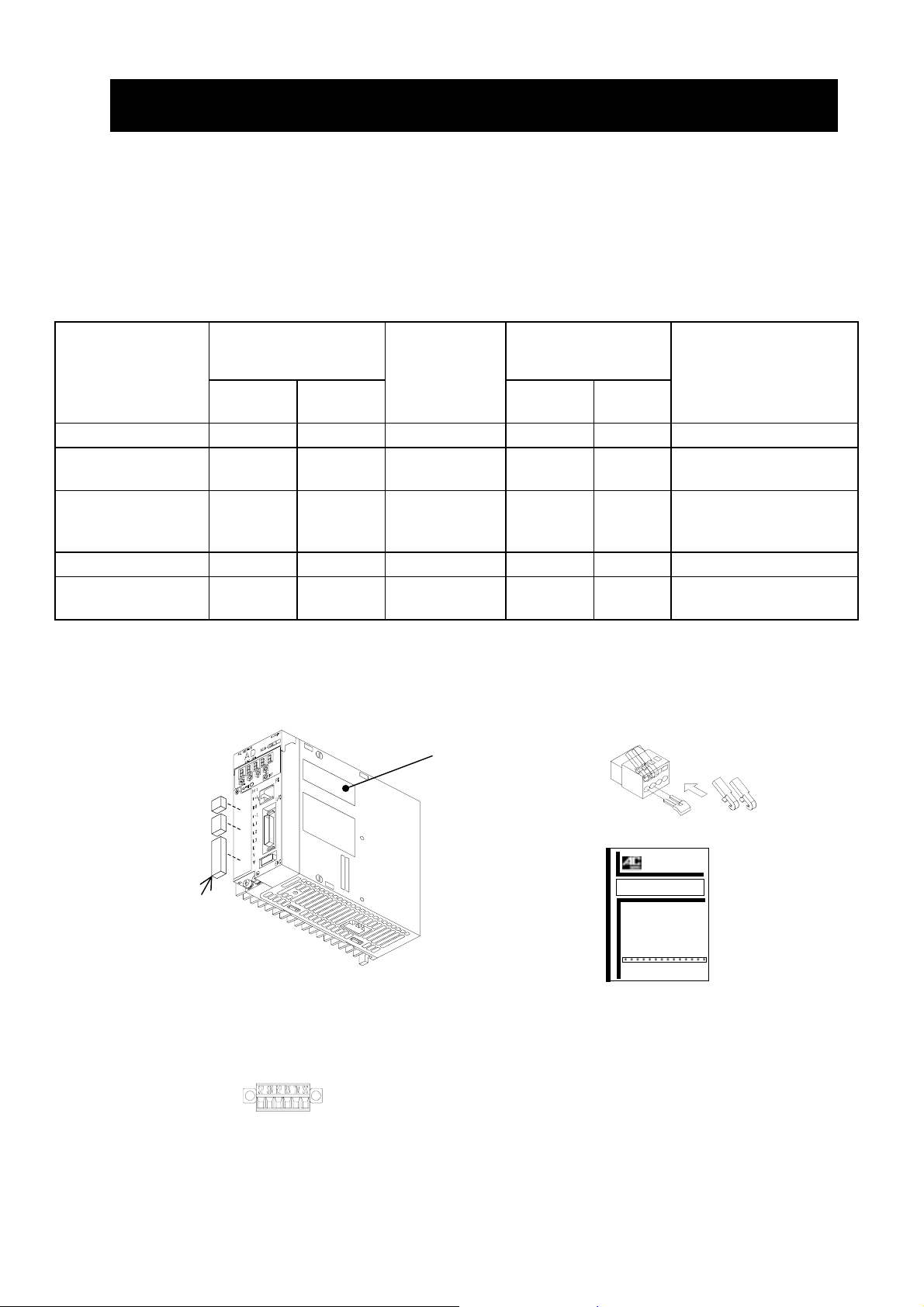

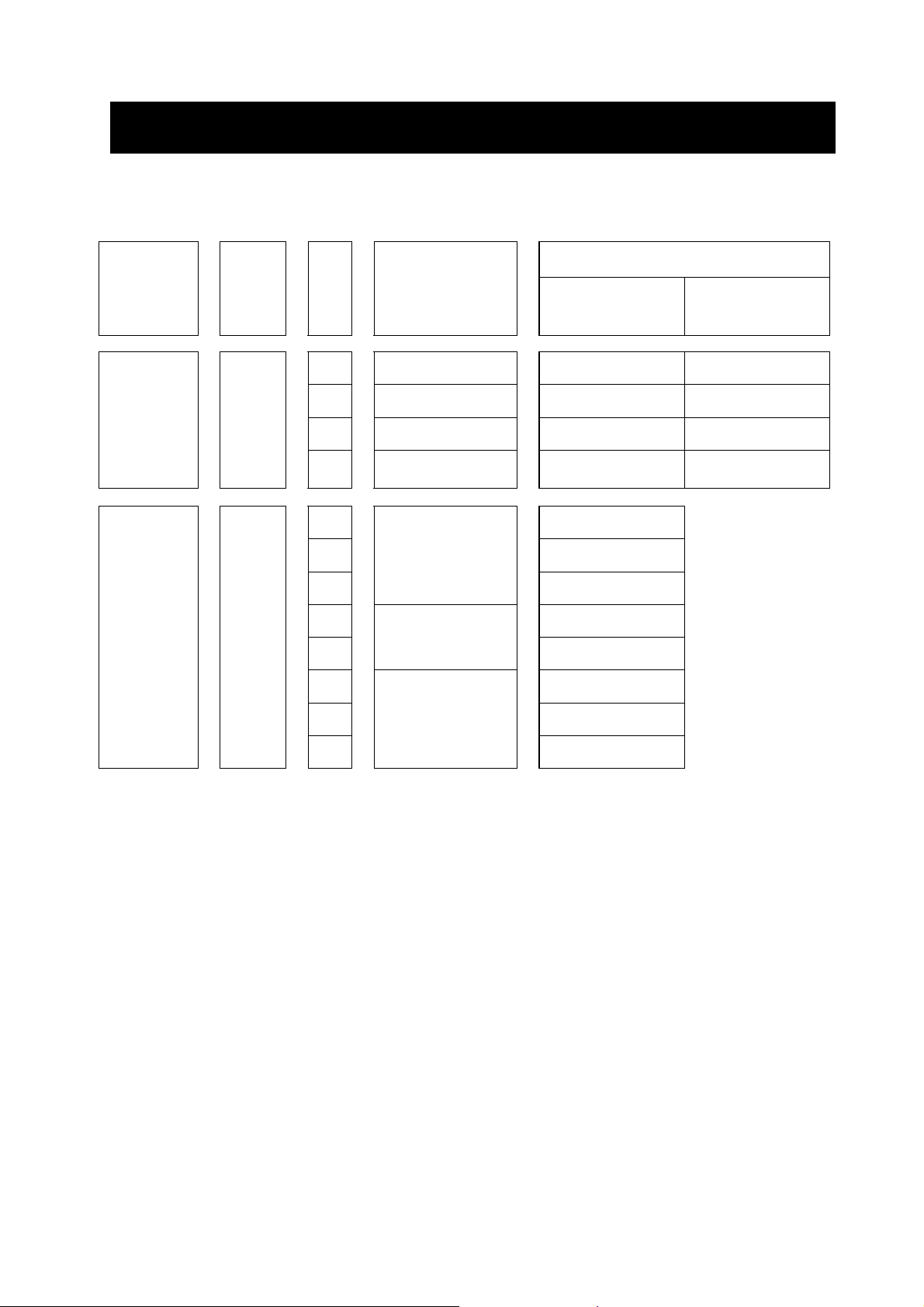

ADAX4-LS/MS

Packed article

(a) Servo drive 1 unit 1 unit 1 unit 1 unit 1 unit (b) Control power

supply connector

(c) Main power circuit

/ control power

circuit connector

(d)Instruction manual 1 copy 1 copy 1 copy 1 copy 1 copy Installation manual

(e)communication

connector

ADAX4-LSMB/MSMB

50~1.5kw more than

2kW

1 piece Not

provided

Not

provided

1 piece 1 piece 1 piece 1 piece 1 piece Only ADAX4-

Not

provided Not provided 3 pieces

ADAX4-NS

ADAX4-NSMB

(200V class)

1 piece

ADAX4-HP

ADAX4-HPMB

(400V class)

1.5, 3.5kW 7kW

Not

provided

Not

provided

Not

provided

Remarks

With wire inserting jig

With B1-B2 short bar

Main power circuit : 2

Control power circuit : 1

MB

The attached manual with the servo drive is the simple one for installation, maintenance and

inspection. This detailed manual is not attached.

(3) Check on the specification nameplate whether the product is as ordered or not.

(a)

Specification

(b)

nameplate

(Located on the

front cover for

3-phase 400V

3.5kW and

7kW)

(c)

d)

(

HITACHI AC Servo Drives

ADAX4 Series

Instruction Manual

3-phase 400V

1.5, 3.5kW

(Without cover)

HITACHI

Specification nameplate position

(200V class and 400V 1.5kW)

(e)

(e) Only ADAX4-MB

2 - 2

Page 19

CHAPTER 2 INTRODUCTION

p

r

A

r

r

p

r

A

r

r

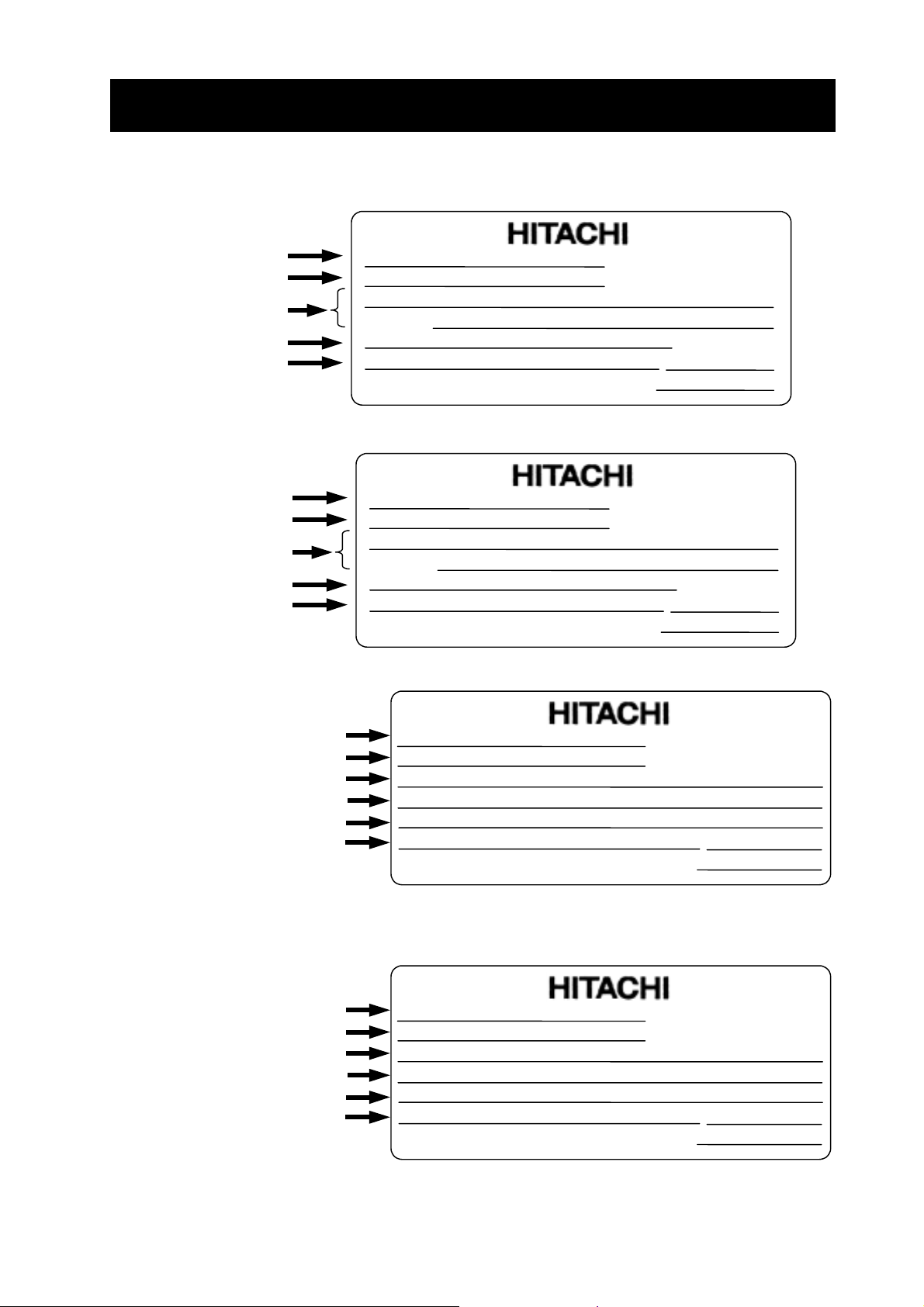

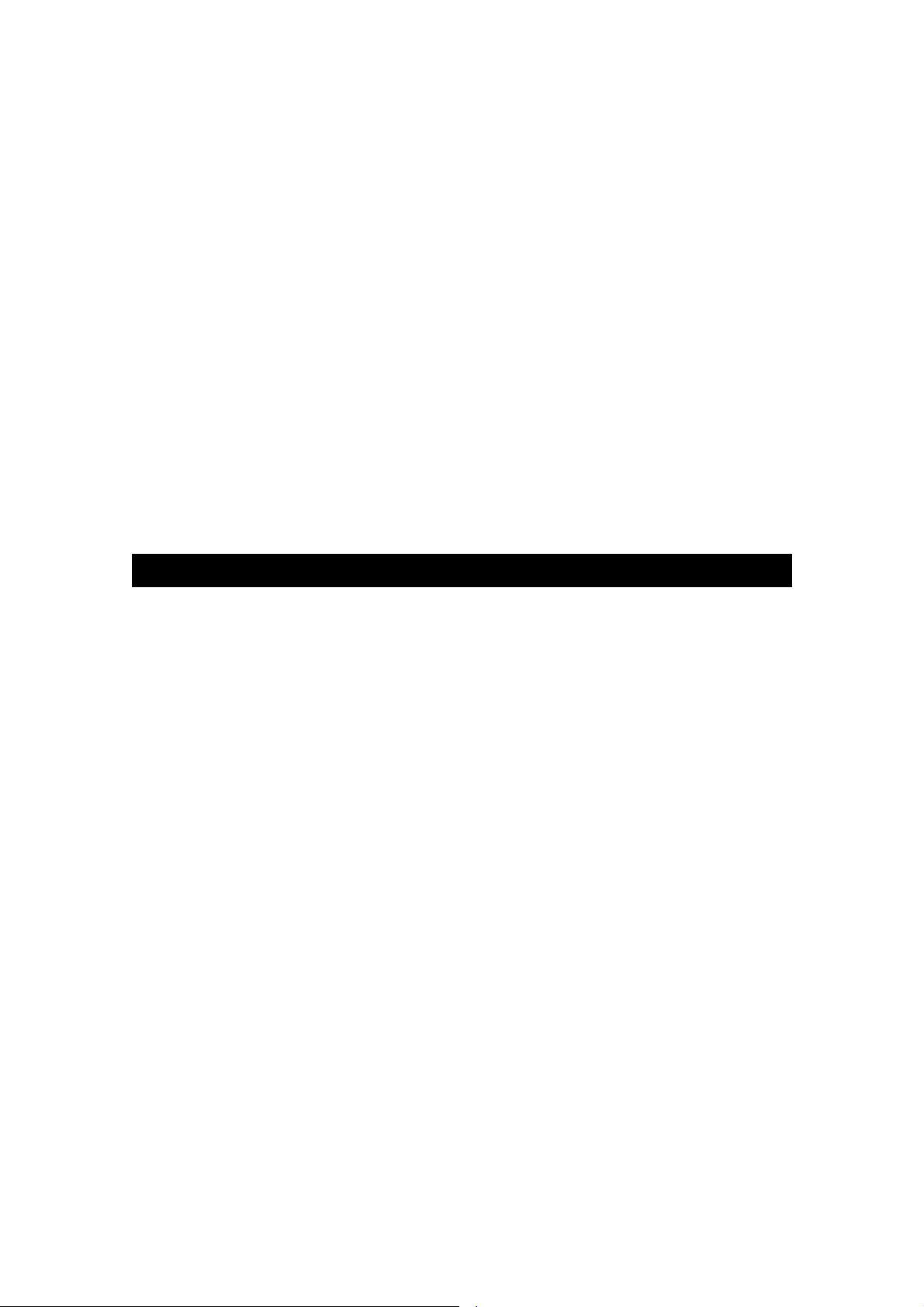

[200V class servo amplifiers]

Drive model

Applicable motor

maximum rated out

Input rating

Output rating

Production numbe

ut

Model :

kW

Input :

Input :

Output : 3Ph

MFG No.

Hitachi Industrial Equipment

ADAX3-02NSE

1Ph

3Ph

212U N12345 20001 0209

Systems

Co.,Ltd

0.2

220-230 2.5

200-230

230

Vmax

MADE IN JAPAN

[200V class servo amplifiers with Modbus optional board]

Drive model

Applicable motor

maximum rated out

Input rating

Output rating

Production numbe

ut

Model :

kW

Input :

Input :

Output : 3Ph

MFG No.

Hitachi Industrial Equipment

ADAX3-02NSEMB

0.2

1Ph

3Ph

220-230 2.5

200-230

230

212U N12345 20001 0209

Systems

Co.,Ltd

Vmax

[400V class servo amplifiers]

V

1.5

V

1.7

V

1.5

V

1.7

MADE IN JAPAN

50Hz

A

50Hz

A

A

Date:

NE17121

50Hz

A

50Hz

A

A

Date:

NE17121

,60Hz

,60Hz

-39

,60Hz

,60Hz

-39

Drive model

pplicable moto

maximum rated output

Control power circuit input

Main power circuit Input

Output rating

Production numbe

Model :

kW

Input(Control): 1Ph

Input(Main) : 3Ph

Output :

MFG No.

Hitachi Industrial Equipment

ADAX3-35HPE

24A N12345 20001 0209

Systems

Co.

3.5

3Ph

,Ltd

200-240 0.3

380-4801213

480

[400V class servo amplifiers with Modbus optional board]

Drive model

pplicable moto

maximum rated output

Control power circuit input

Main power circuit Input

Output rating

Production numbe

Model :

kW

Input(Control): 1Ph

Input(Main) : 3Ph

Output :

MFG No.

Hitachi Industrial Equipment

ADAX3-35HPEMB

3.5

3Ph

24A N12345 20001 0209

Systems

Co.

,Ltd

200-240 0.3

380-4801213

480

V

V

Vmax

MADE IN JAPAN

V

V

Vmax

MADE IN JAPAN

A

50Hz

50Hz

A

0 -420Hz

A

Date:

NE17609

A

50Hz

50Hz

A

0 -420Hz

A

Date:

NE17609

,60Hz

,60Hz

-2

,60Hz

,60Hz

-2

Contents of Specification Nameplate

2 - 3

Page 20

CHAPTER 2 INTRODUCTION

(4) When the 200V class servo motor with the serial incremental encoder (17bit / revolution) is

different from the specification of the standard product, connect the encoder and then perform

initialize processing. For the procedure, refer to Chapter 5, “Clearing the Trip Log and

Performing Factory-setting”.

(5) In case that you use the motor with the serial absolute encoder (17bit / revolution), Absolute

Battery Error (E90) occurs after connecting the backup battery and turning on the power

supply. Clear the trip and then clear the encoder data. For the procedure, refer to Chapter

5, “Functions for Absolute Position Encoder”, (2) Clearing the absolute position.

Explanation of Drive model

AD

AX4

Series name

AD : AD series

Drive name

AX4 : Programmable

function build-in

–

08 N

S

E

MB

Option

None : Standard

MB :

Modbus

I/O polarity

None:

Input…Sink/Source Output…Sink

Pulse input… insulation

Input…Sink/Source Output…Source

E:

Pulse input… no insulation

Encoder type

S:

17bit / revolution

Serial encoder

(Incremental, Absolute)

P: Wire-saving incremental encoder

Input power supply

M: Single phase 100V class

L: Three phase 200V class

N: Single / Three phase 200V class

H: Three phase 400V class

Output rating

Symbol

Rating(kW)

Voltage

(Note) Drive is becomes an article of order by combination of input power supply, Encoder type and

I/O polarity. Refer to chapter 8 for Standard models.

R5 01 02 04 08 10 15 20 35 50 70

0.05 0.1 0.2 0.4 0.8 1.0 1.5 2.0 3.5 5.0 7

M

L

-

-

M

L

N

-

M

L

N

M

L

N

L

N

-

2 - 4

-

-

-

-

-

-

L

L

L

L

L

-

-

-

-

-

-

-

-

H

-

H

-

H

Page 21

CHAPTER 2 INSTRUCTION

2.1.2 Instruction manual

This instruction manual explains the detail of the Hitachi AD series servo.

Please read this manual thoroughly to operate the product correctly before operating it. Keep the

manual in custody with care.

When using option products related to this servo drive, read the instruction manuals for the related

products thoroughly.

2.2 Inquiry about the Product and Warranty

2.2.1 Notes for making an inquiry

If you have to make an inquiry about product damage, doubt, failure, etc., inform the dealer of the

following items.

(1) Servo drive type a nd form (model No.)

(2) Production number (MFG. No.)

(3) Date of purchase

(4) Contents of your inquiry

- Damage position, status, etc.

- Doubtful item, contents, etc.

2.2.2 Product warranty

The product warranty period shall be one year after purchase.

In the following cases, however , the product is out of the warranty range and shall be repa ired with

charge even within the warranty period.

(1) The failure is due to an operation error or improper repair or modification.

(2) The failure is due to any other reason that is not related to your purchased product.

(3) The product was operated over the specification value rang e.

(4) The failure is due to a natural calamity, disaster, or secondary disaster.

The warranty herein referred to means the warranty of the delivered product proper. Any damage

induced by a failure of the delivered product shall be excluded.

2.2.3 Charged repair

After the lapse of the warranty period (one year), any investigation and repair shall be performed

with charge. In the warranty period, repair or investigation that is out of the above warranty range

shall be undertaken with charge.

For asking for a charged repair, contact with the dealer.

2 - 5

Page 22

CHAPTER 2 INSTRUCTION

r

r

A

r

r

A

a PC

r

A

r

r

A

r

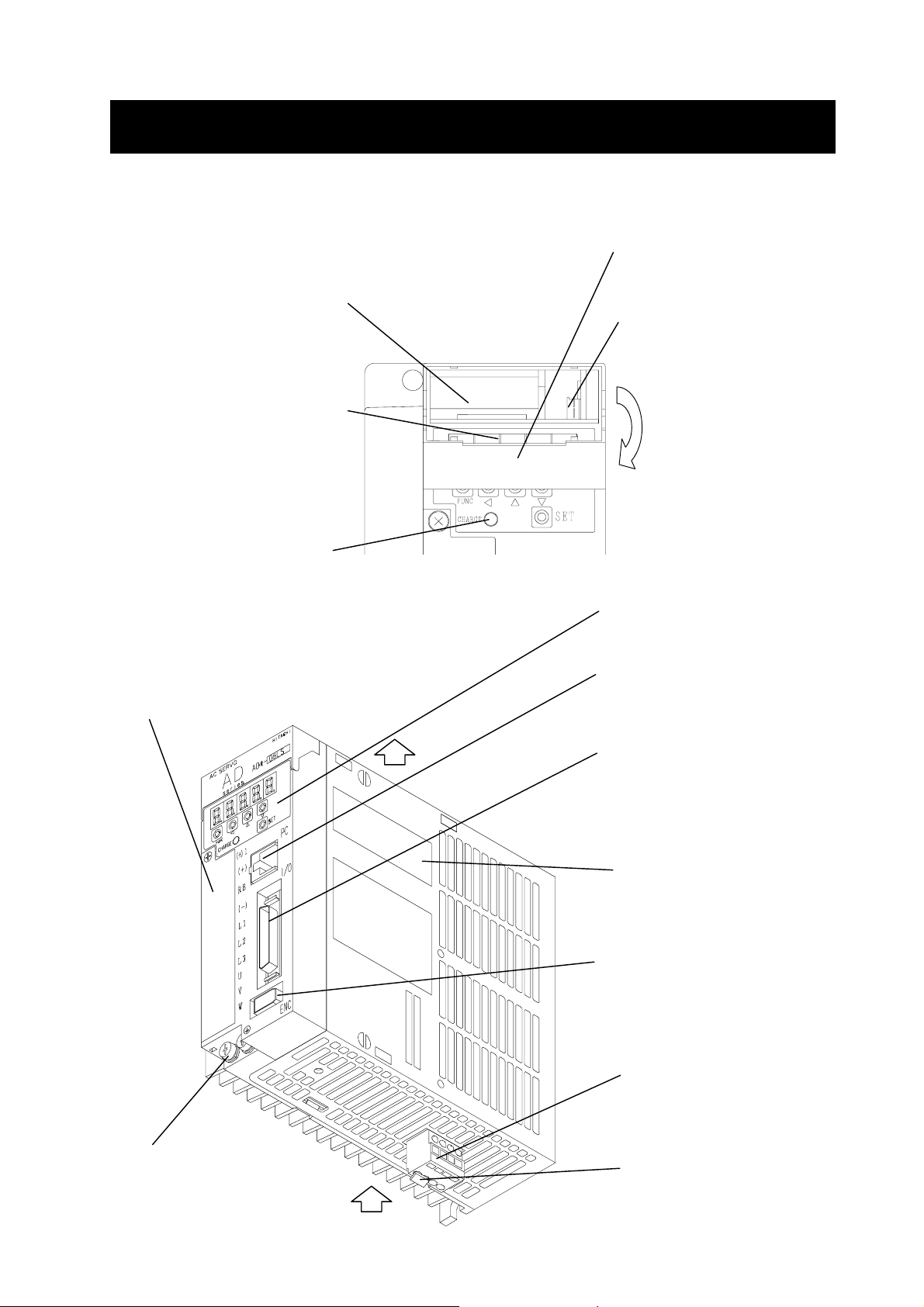

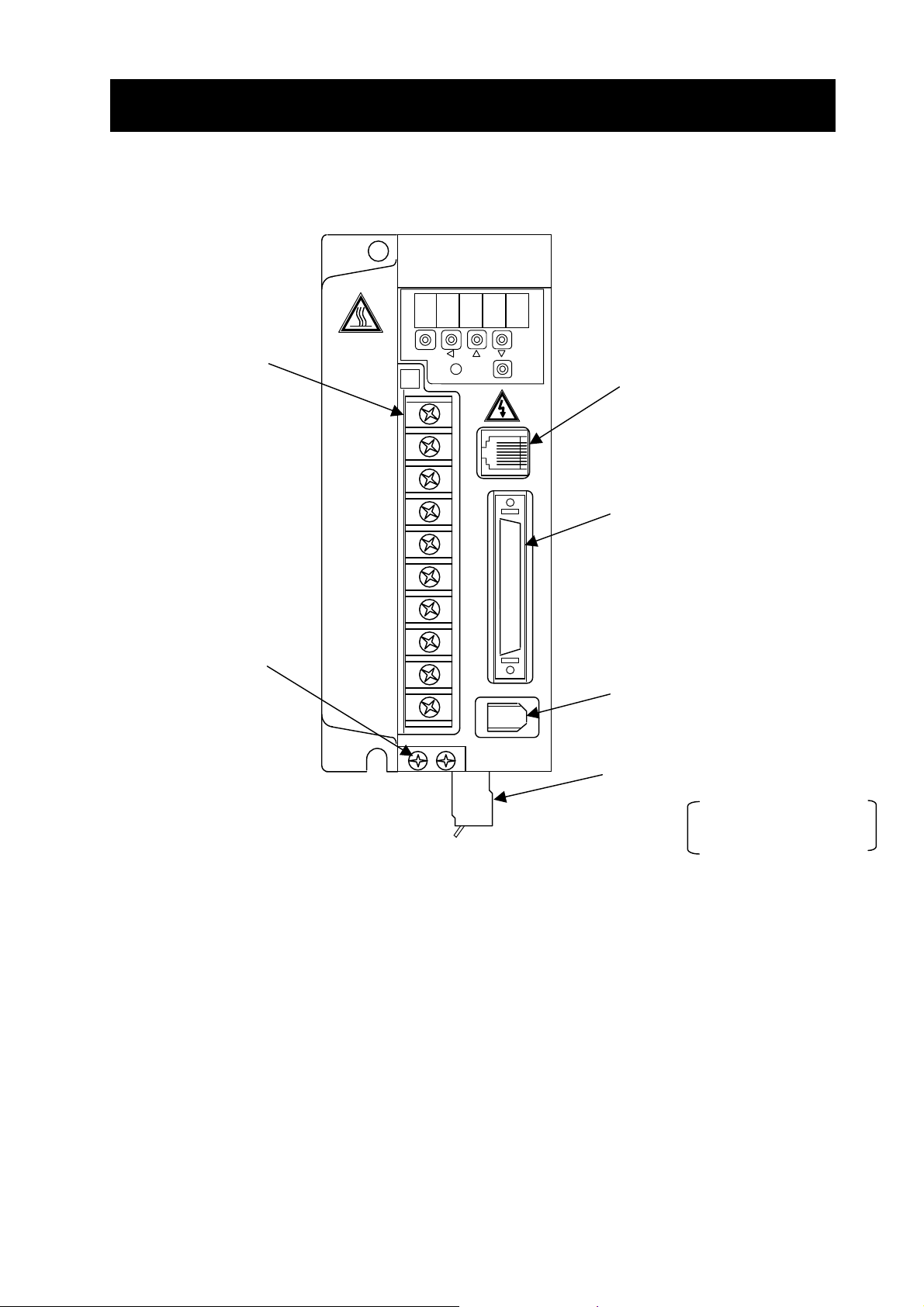

2.3 Appearance and Names of Parts

(The following drawings describe 200V class servo without optional board.)

Battery holde

Houses the backup battery when

the absolute encoder is used.

Panel display unit

Used to indicate the servo drive

condition or parameter setting by

using a 5-digit 7-segment LED.

Charge lamp

Lights up when the main circuit

power supply is turned on. While

the electric charge remains on the

main circuit capacitor after the

power supply is turned off, this

lamp continues to light. Do not

touch the servo drive during

lighting.

Main circuit terminal block (TM1)

Connection terminals with the main circuit

power supply, external regenerative

resistor, and motor power cable.

This terminal block is covered with a cover.

Connector for connecting a PC

(PC)

Battery housing cove

cover for the battery holder.

Battery connecto

Used to connect the backup

battery for the absolute

encoder.

Digital operato

Used to set parameters.

connector for communication with

.

Ground terminal

Used for protection against an

electric shock.

Exhaust

air

Input/output signal connecto

(I/O)

connector for command input

signals and sequencer input signals.

Specification nameplate

Used to indicate the servo

drive type and form and

ratings.

Encoder connecto

Used to connect the encoder of

the servo motor.

Control power supply connecto

(TM2)

connector for connecting the

control power supply.

B1-B2 short ba

Be sure to connect this

short bar when using the

internal braking resistor.

(ENC)

Intake air

2 - 6

Page 23

CHAPTER 2 INSTRUCTION

t

2.4 Combination of servo amplifiers and servo motors

The applicable combination of servo amplifiers and servo motors is shown in the following table.

Phase /

Volt age

for main

power

circuit

Single-phase

220~230V

/3-phase

200~230V

3-phase

380~480V

Rated

speed

3000

-1

(min

2000

-1

(min

Outpu

(kW)

0.1

0.2

)

0.4

0.7

5

Servo amplifier

Model code

ADAX4-01NSE(MB)

ADAX4-02NSE(MB)

ADAX4-04NSE(MB)

ADAX4-08NSE(MB)

— ADMA-01SA

— ADMA-02SA

— ADMA-04SA

— ADMA-08SA

0.5 — ADMG-05HP

1.0 — ADMG-10HP

ADAX4-15HPE(MB)

1.5

2.0 — ADMG-20HP

)

3.5

ADAX4-35HPE(MB)

Note 2)

— ADMG-15HP

Note 2)

— ADMG-35HP

4.5 — ADMG-45HP

5.5 — ADMG-55HP

ADAX4-70HPE(MB)

7.0

Note 2)

— ADMG-70HP

Applicable servo motor

With

Incremental

encoder

With

Absolute

encoder

ADMA-01SF

ADMA-02SF

ADMA-04SF

ADMA-08SF

Note 1) ADAX4 describes the standard high performance type, and ADAX3 describe

the programmable function built-in type.

Note 2) Single-phase 200 ~ 240V is needed for the control power circuit. Do not supply 3-phase

2 - 7

Page 24

MEMO

2 - 8

Page 25

CHAPTER 3 INSTALLATION AND WIRING

This chapter explains the procedure for installing this product, main circuit

wiring, and input/output signal wiring. Typical connection examples are

shown.

3.1 Installation ................................................... 3 − 2

3.1.1 Precautions on installation..................... 3 − 3

3.2 Wiring .......................................................... 3 − 5

3.2.1 Terminals and connectors...................... 3 − 6

3.2.2 Main circuit wiring.................................. 3 − 9

3.2.3 Wiring for the control power

connector (TM2) (200V class).............. 3 − 21

3.2.4 Connecting the backup

battery for absolute encoder.................. 3 − 22

3.2.5 Input/output signal wiring....................... 3 − 23

3.2.6 Wiring for encoder signals..................... 3 − 39

3 − 1

Page 26

CHAPTER 3 INSTALLATION AND WIRING

3.1 Installation

CAUTION

• Be sure to install the unit on flame resistant material such as metal.

Otherwise, there is a danger of fire.

• Be sure not to place anything inflammable in the vicinity.

Otherwise, there is a danger of fire.

• Do not carry unit by top cover, always carry by supporting base of unit.

There is a risk of falling and injury.

• Be sure not to let the foreign matter enter such as cut wire refuse, spatter from welding, iron

refuse, wire, dust, etc.

Otherwise, there is a danger of fire.

• Be sure to install it in a place which can bear the weight according to the specifications in the

text.

Otherwise, it may fall and there is a danger of injury.

• Be sure to install the unit on a perpendicular wall which is not subject to vibration.

Otherwise, it may fall and there is a danger of injury.

• Be sure not to install and operate AC servo drive which is damaged or parts of which are

missing.

Otherwise, there is a danger of injury.

• Be sure to install it in a room which is not exposed to direct sunlight and is well ventilated.

Avoid environments which tend to be high in temperature, high in humidity or to have dew

condensation, as well as places with dust, corrosive gas, explosive gas, inflammable gas,

grinding-fluid mist, salt damage, etc.

Otherwise, there is a danger of fire.

A failure will be caused.

• Be sure to connect between servo drive logic ground (L) and controller ground when pulse

train input is used by servo drive with source type logic.

Otherwise, A equipment failure will be caused.

3 − 2

Page 27

CHAPTER 3 INSTALLATION AND WIRING

3.1.1 Precautions on installation

1) Precaution at transportation

The servo drive employs plastic parts. Handle it so that these plastic p arts may not be damaged.

In particular, do not carry the servo drive in such a way that force is applied to only the front

surface cover and the terminal block cover. Falling may be caused.

If any part is damaged or missing, do not install and operate the servo drive.

2) Install the servo drive on an incombustible (metal) surface.

The servo drive goes to a high temperature. Install the servo drive on an incombustible vertical

metal wall surface so as to avoid a fire.

Ensure an enough space around the installation place. In particular, if there is any heat

generating device (braking resistor, reactor, etc.), keep the servo drive away from such a

material.

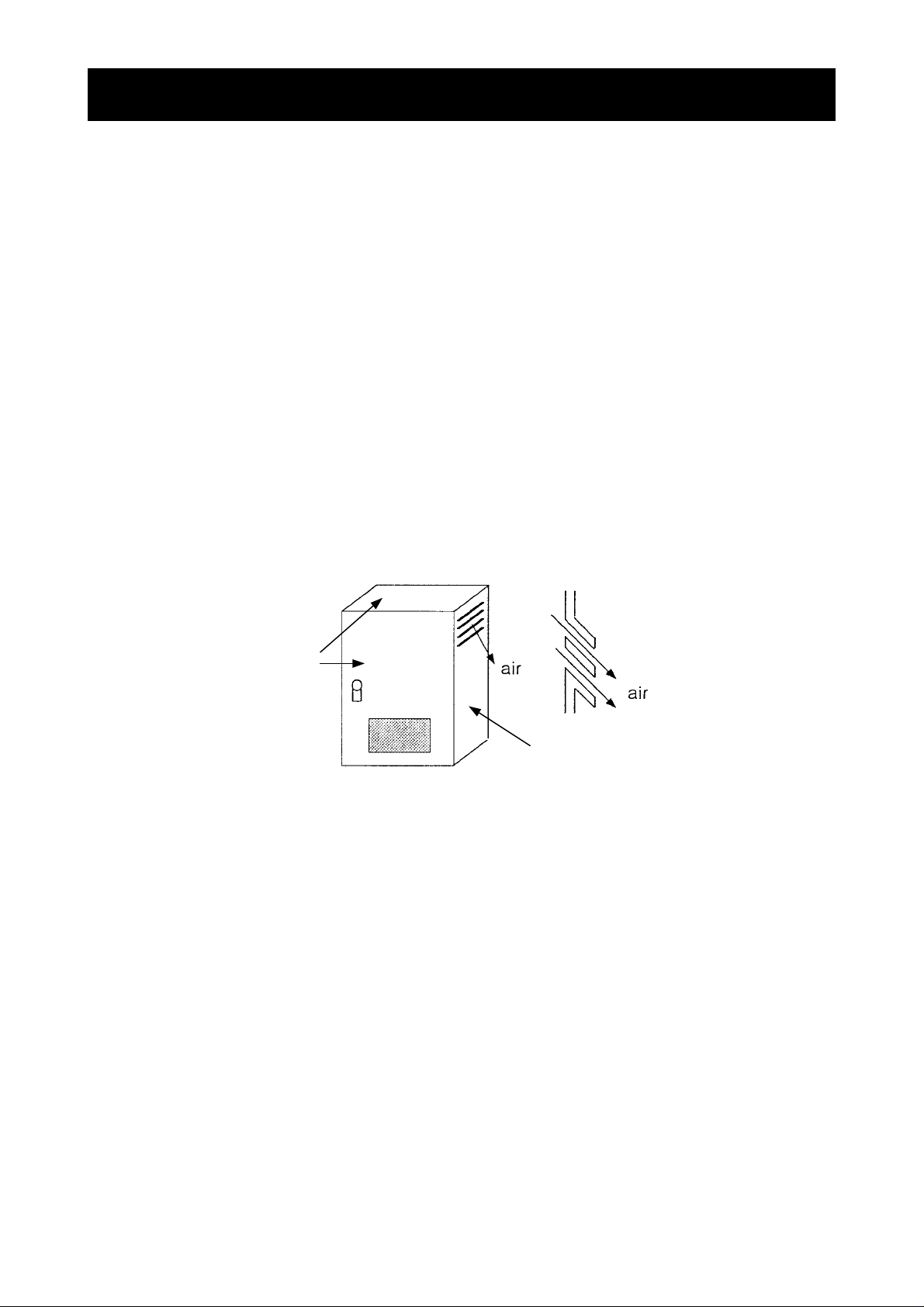

Ensure an enough space so

Air flow

Servo

drive

that the upper/lower wiring

ducts may not prevent the

cooling air from flowing.

Wall

3) Precaution about the ambient temperature

The ambient temperature in the installation place should not exceed the allowable operating

temperature range (0 to 55°C) described in the standard specification.

Measure the ambient temperature at an about 50 mm position away from the lower center of the

servo drive body, and make sure that it is within the allowable operating temperature range.

Operating the servo drive over the allowable operating temperature range may lead to its shorter

life (especially, the life of the capacitor) or damage.

4) Do not install the servo drive in a high-temperature and high-humidity place that may easily

cause condensation.

Operate the servo drive within the allowable operating humidity range (20 to 90%RH) described

in the standard specification. In particular, operate it in a place free from condensation.

If water-drops are attached inside the servo drive by condensation, the section between

electronic parts is shorted, resulting in a failure.

Avoid installing the servo drive in a place that is exposed to direct sunlight.

5) Precaution about the installing environment

Do not install the servo drive in a place where there is dust, corrosive gas, explosive gas,

combustible gas, grinding lubricant mist, or injury from salt. Admitting foreign substances or dust

inside the servo drive will result in a failure.

Therefore, if the servo drive must be operated in very dusty place, for example, house it in a

sealed type box.

3 − 3

Page 28

CHAPTER 3 INSTALLATION AND WIRING

6) Precaution about the installing method and direction

Install the servo drive on a mounting surface that can withstand its weight, firmly and vertically

without any screw or bolt looseness.

If the servo drive is not installed vertically on the wall surface, it may lower the cooling capacity

with a result of trip or damage.

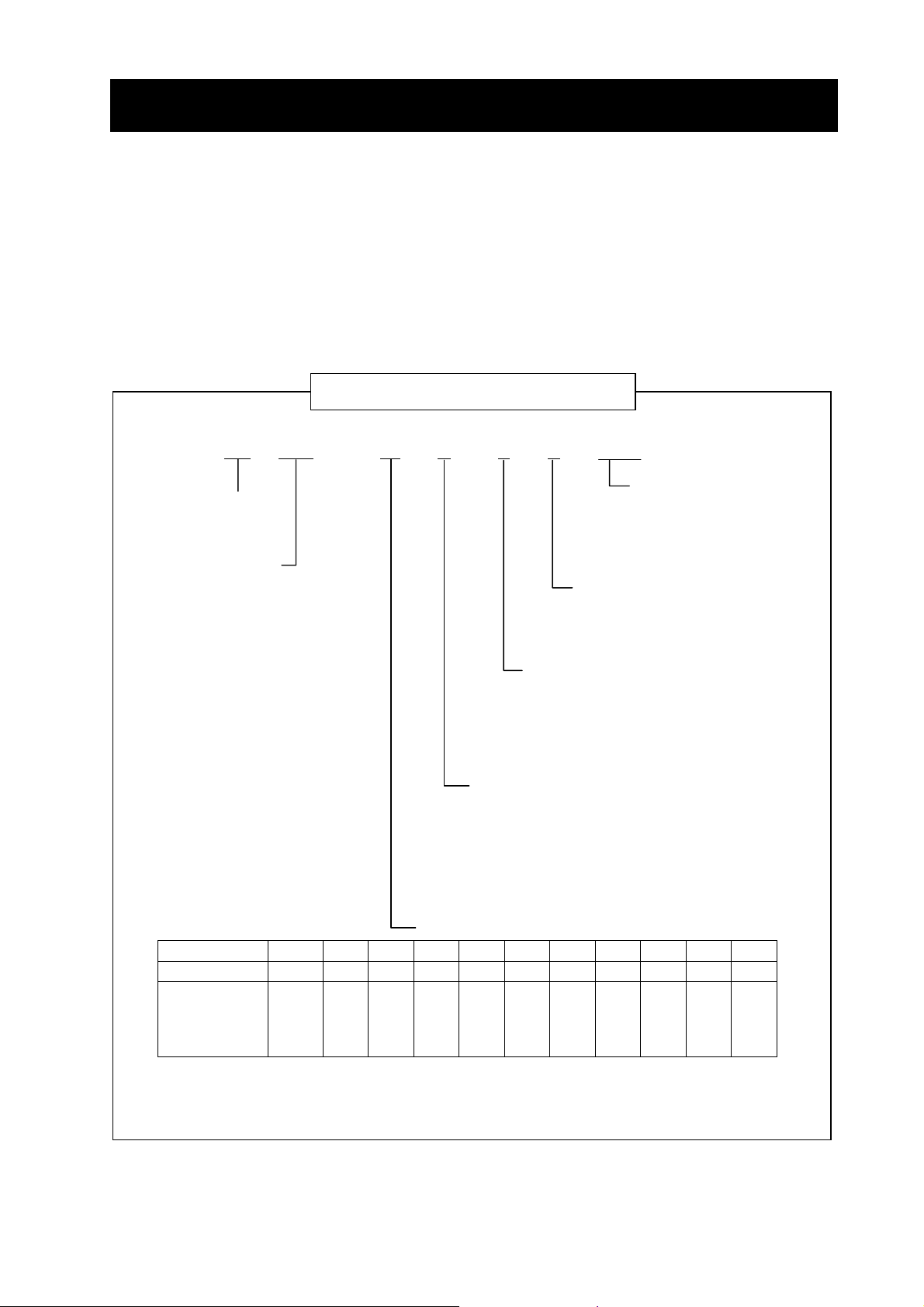

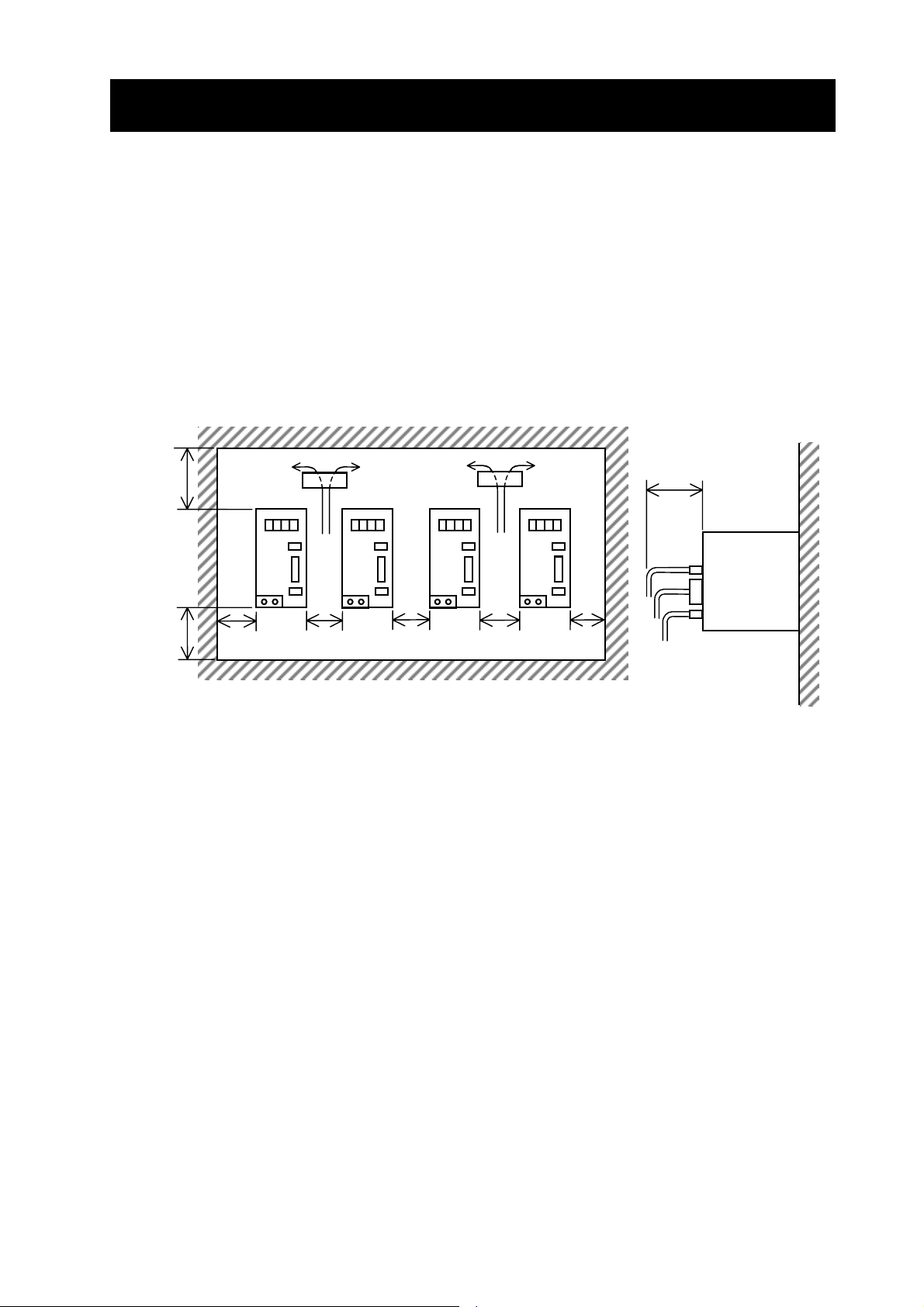

7) Precaution for housing servo drives in a box

When multiple servo drives are housed in a box and ventilation fans are equipped in the box,

provide the fans in the following way so as to make the ambient temperature of each servo drive

uniform.

100 mm

or more

Fan Fan

75 mm or more

Servo drive

100 mm

Wiring space of

or more

40 mm

or more

10 mm

or more

10 mm

or more

10 mm

or more

40 mm

or more

In the case of boxes arranged in a row , inst all them at 40 mm or more from the wall surfaces with a

space of 10 mm or more between servo drives and a clearance of 100 mm or more from the top or

bottom.

3 − 4

Page 29

CHAPTER 3 INSTALLATION AND WIRING

3.2 Wiring

WARNING

• Be sure to ground the unit.

Otherwise, there is a danger of electric shock and/or fire.

• Wiring work shall be carried out by electrical experts.

Otherwise, there is a danger of electric shock and/or fire.

• Implement wiring after checking that the power supply is off.

It might incur electric shock and/or fire.

• After installing the main body, carry out wiring.

Otherwise, there is a danger of electric shock and/or injury.

CAUTION

• Make sure that the input voltage is:

Three phase 200 to 230V 50/60Hz (for models with suffix L)

Single phase 100 to 115V 50/60Hz (for models with suffix M)

Single phase 220 to 230V / Three phase 200 to 230V 50/60Hz (for models with suffix N)

Three phase 380 to 480V 50/60Hz (for models with suffix H)

Control power supply 200 to 240V 50/60Hz (for models with suffix H)

Otherwise, there is a danger of fire.

• Be sure not to input a single phase for models with suffix H.

Otherwise, there is a danger of fire.

• Be sure not to connect AC power supply to the output terminals(U, V, W).

Otherwise, there is a danger of injury and/or fire.

• Be sure not to connect the resistor to DC terminals (+1,+ and –) directly.

Otherwise, there is a danger of fire.

• As for motor leads, fuses and electromagnetic contactors, be sure to use the equivalent ones

with the specified capacity (rated).

Otherwise, there is a danger of fire.

• Fasten the screws with the specified fastening torque. Check so that there is no loosening of

screws.

Otherwise, there is a danger of fire.

• Connection to field wiring terminals must be reliably fixed having two independent means of

support. Using terminal with cable support, cable gland or cable clamp etc.

Otherwise, there is a danger of fire.

• Be sure to connect between the servo drive logic common and master controller logic

common when using pulse count input on source type logic.

Otherwise, there is a danger of equipment failure.

3 − 5

Page 30

A

CHAPTER 3 INSTALLATION AND WIRING

3.2.1 Terminals and connectors

(1) 200V class [less or equal 1.5kW(ADAX4-LS(MB) )]

[less or equal 750W(ADAX4-NS(MB)

)]

Main circuit

terminals (TM1)

Grounding

terminal

C SERVO

AD

series

FUNC

CHARGE

HITACHI

AD*-04NSE

SET

PC connecting

connector (PC)

Input/output signal

connector (I/O)

Encoder (sensor)

connector (ENC)

Control power

connector (TM2)

This figure is without

optional board

3 − 6

Page 31

A

CHAPTER 3 INSTALLATION AND WIRING

(2)200V class [greater or equal 2kW]

C SERVO

AD

series

HITACHI

AD*-20LS

Main circuit

terminals (TM1)

Grounding

terminal

2 screws

for 2kW to 3kW

FUNC

CHARGE

SET

PC connecting

connector (PC)

Input/output signal

connector (I/O)

Encoder (sensor)

connector (ENC)

3screws

for 5kW

Note 1) 5kW drive is a different appearance.

3 − 7

This figure is without

optional board

Page 32

A

CHAPTER 3 INSTALLATION AND WIRING

(3) 400V class

Note1)

Note2)

Control power

Note1)

Main circuit

connector 1

Note1)

Main circuit

connector 2

200~240V

C SERVO

AD

series

FUNC

CHARGE

HITACHI

AD*-15HPE

SET

PC connecting

connector (PC)

Input/output signal

connector (I/O)

Encoder (sensor)

connector (ENC)

Grounding

terminal

2 screws

for 1.5 to

3.5kW

This figure is without

optional board

3screws

for 7kW

Note 1) 3.5 and 7kW drive is a different appearance.

For 7kW, the control power and main circuit connectors are a terminal block.

Note 2) The input voltage to the control power connector is AC 200 to 240V.

Do not input the main power supply voltage to the control power connector.

3 − 8

Page 33

* 1

CHAPTER 3 INSTALLATION AND WIRING

3.2.2 Main circuit wiring

(1) Terminal connection diagram

a) 200V class

Short bar

(DC reactor connecting terminal)

Regenerative braking resistor

(option)

Note 1)

Power supply

Three-phase

AC 200 to 230 V

/ single-phase

AC 220 to 230 V

/ single-phase

AC 100 to 115 V

Note 3)

For using an external regenerative

braking resistor, disconnect the B1-B2

short bar.

FUSE

MC

TM1

(+)1

(+)

RB

(-)

L1

L2

L3

TM2

L1C

L2C

B1

B2

AD

servo drive

I/O

3 series

CNBT

TM1

ENC

Note 2)

Battery

PC

W

U

V

PC for setting and

Servo

motor

*

Encoder

7 bits serial

encoder

monitoring

Master

controller

Note 1: For single-phase 100 to 115 V AC and single-phase 220 to 230 V AC,

connect only L1 and L2. (For three phase connect L1, L2 and L3.)

Note 2: The battery is used only for the absolute encoder.

Note 3: The regenerative braking resistor is built in the model of…

L series class 200 V, 400W to 5kW.

M series class 100 V, 200W and 400 W

N series class 200 V, 400W and 750 W

3 − 9

Page 34

*

r

CHAPTER 3 INSTALLATION AND WIRING

b) 400V class

Short bar

(DC reactor connecting terminal)

Regenerative braking resistor

(option)

For using an external regenerative

braking resistor, disconnect the B1-RB

short bar.

Note 1)

Power supply

Three-phase

AC 380

to 480 V

FUSE

Note 1)

Transforme

T

MC

single-phase

200 to 240 V

Note 1)

(+)1

(+)

RB

B1

(-)

L1

L2

L3

L1C

L2C

AD

3 series

servo drive

ENC

PC

W

U

V

Servo

motor

*

Encoder

Incremental

encoder

I/O

Master

controller

PC for setting and

monitoring

Note 1: Connect three phase 380 to 480 V to L1, L2 and L3, and single phase 200 to 240 V to

L1C and L2C. Do not input 380 to 480 V to L1C and L2C. Be sure to be the secondary

voltage 200 to 240 V when the transformer is used.

3 − 10

Page 35

(+)

(+)

(–)

(+)

(+)

(–)

r

)

r

CHAPTER 3 INSTALLATION AND WIRING

(2) Terminal assignment

Type

200V class less or equal 1.5kW

Terminal

name

Main circuit

terminals

(TM1)

Grounding

terminal

Control

power

connector

(TM2)

Terminal assignment

Short

bar

1

RB

DC reactor connecting terminal

(Shorted in the unused status)

External braking resisto

DC power supply input

L1

L2

Main power supply input

L3

U

V

Motor connection

W

Grounding

Short

bar

B1

B2

L1C

Short terminal for internal braking

resistor (Open when the external

resistor is used)

Control power supply inputControl power supply input

L2C

Note: The figure shows a view of the servo drive seen

from the lower side. Refer to 3.2.3 “Wiring for

the control terminal”.

Termina

l screw

size

M4 8.1

M4

Applicable cable

size: 0.5 mm

2.0 mm

2

Termina

l width

(mm)

–

2

to

2 to 3 kW

200V class

5 kW

200V class

Main circuit

and control

power

connectors

Grounding

terminal

Main circuit

and control

power

terminals

Grounding

terminal

Short

bar

or

wire

L1C

L2C

1

B1

RB

L1

L2

L3

U

V

W

Control power supply input

connecting terminal

DC reactor connecting terminal

(Shorted in the unused status)

Short terminal for internal braking

resistor (Open when the external

resistor is used)

External braking resisto

DC power supply input

Main power supply input

Motor connection

Grounding(2 to 3kW: 2screws,

5kW: 3screws

M3

M4

M5 13

M5

–

–

–

3 − 11

Page 36

(+)

(+)RB(–)

)

r

CHAPTER 3 INSTALLATION AND WIRING

Type

400V class

1.5 to 3.5 kW

7 kW

400V class

Terminal

name

Main circuit

and control

power

connectors

Grounding

terminal

Main circuit

and control

power

terminals

Grounding

terminal

Short

bar

or

wire

Terminal assignment

L1C

L2C

1

B1

L1

L2

L3

U

V

W

Control power supply input

connecting terminal

DC reactor connecting terminal

(Shorted in the unused status)

Short terminal for internal braking

resistor (Open when the external

resistor is used)

External braking resisto

DC power supply input

Main power supply input

Motor connection

Grounding(1.5, 3.5kW: 2screws,

7kW: 3screws

Termina

l screw

size

M3

M4

M5 13

M5

Terminal

width

(mm)

–

–

–

CAUTION

1. For the connectors, perform wiring after removing them from the servo drive.

Otherwise, the servo drive way be broken.

2. When inserting the cable, take care not to bring the core whisker into contact with the

other terminal.

The servo drive may be broken.

3. If the cable core has not enough contact for any reason, strip it again and them connect

the cable.

The servo drive may be broken.

(2-1) 400V class main circuit and control power connectors

The front terminal of the servo drive separates as follows.

Model

200V class

1.5kW 3.5kW 7kW

Terminal Terminal Connector Connector Terminal

The connectors of the front main circuit and control power are attached to the servo drive.

The specification of the connectors of 400V class is shown in the following table.

400V class

ADAX4-HP(MB)

3 − 12

Page 37

CHAPTER 3 INSTALLATION AND WIRING

Specification of connectors

Model ADAX4-15HPE(1.5kW) ADAX54-35HPE(3.5kW)

Spec.

Connector

name

Control power

connector

(L1C, L2C)

Main circuit

connector 1

Connector model Assignment Connector model Assignment

Model:MSTB2.5/2

-ST-5.08

Pin No. :2P

Pin pitch:5.08mm

Wire size:1.25 -

2.5mm2/AWG16 - 12

Manufacture:

PHOENIX CONTACT

GMBH & CO.

L1C L2C +1 + B1 RB

Model:PC4/2

-STF-7.62

Pin No. :2P

Pin pitch:7.62mm

Wire size:1.25 -

4mm2/AWG16 - 10

Manufacture:

PHOENIX CONTACT

GMBH & CO.

L1C L2C

Note1)

Note1)

Model:MSTB2.5/4

-ST-5.08

Pin No. :4P

Pin pitch:5.08mm

Wire size:1.25 -

2

2.5mm

/AWG16 - 12

Manufacture:

PHOENIX CONTACT

GMBH & CO.

Model:PC4/5

-STF-7.62

Pin No. :5P

Pin pitch:7.62mm

Wire size:1.25 -

4mm2/AWG16 - 10

Manufacture:

PHOENIX CONTACT

GMBH & CO.

+1 + B1 RB -

-

L1

L2

L3

U

V

W

Note2)

Model:PC4/6

-STF-7.62

Pin No. :6P

Pin pitch:7.62mm

Wire size:1.25 -

2

/AWG16 - 10

4mm

Manufacture:

PHOENIX CONTACT

GMBH & CO.

Main circuit

connector 2

Model:GMSTB2.5/7

-ST-7.62

Pin No. :7P

Pin pitch:7.62mm

Wire size:1.25 -

2

2.5mm

/AWG16 - 12

Manufacture:

PHOENIX CONTACT

GMBH & CO.

Cover

Note1) Short bars or wires are connected between +1 and +, B1 and RB.

Do not remove them except for the optional use.

Note2) This cove prevents a faulty wiring.

When (-) terminal is used, remove it.

L1

L2

L3

U V W

3 − 13

Page 38

CHAPTER 3 INSTALLATION AND WIRING

(2-2) 400V class cable terminal treatment for connectors

Strip the cable cover as follows. Then the cable can be used as it is.

7mm

(2-3) Connecting method

Insert the core the cable in the opening of the connector. Tighten the terminal screws with

the specified torque. Insufficient tightening way result in a short cicuit or fire. Make sure not

to remove the cable by pulling. For 3.5kW, tighten the screws of both sides of the connector

after connecting it.

M3 screw

Fixing screw

Fixing screw

Fixing screw

M3 screw

Fixing screw

Connection procedure

3 − 14

Page 39

CHAPTER 3 INSTALLATION AND WIRING

(3) Precautions on wiring

Before starting wiring, make sure that the charge lamp is completely extinguished. Take care

about the capacitor that is charged at a high voltage. In 10 minutes or more after shutting off

the power supply, check with a tester that no residual voltage exists between (+) and (–) on

the main circuit terminal block, and then start the wiring work.

(3-1)Main power supply input connecting terminal (L1, L2, L3)

- Use fuses for circuit (wiring) protection between the power supply and the main power

supply terminal (L1, L2, or L3).

- Connect an electromagnetic contactor that shuts off the power supply of the servo drive

to prevent a failure or accident from spreading when the protective function of the servo

drive is actuated.

- Do not start or stop the servo drive by turning on or off each electromagnetic contactor

provided on the primary side and secondary side of the servo drive.

- Do not input a single phase to the main power supply input of 400V class servo drive

(AD*3-HPE).

- In the following cases, the converter module may be damaged.

The unbalance of power supply voltage is 3% or more.

The power supply capacity is 10 times as large as the servo drive capacity, or 500 kVA or

more.

A sudden power supply change occurs.

(Example) Multiple servo drives are interconnection with a short bus.

- Turn on and off the power supply, at least, at intervals of 5 minutes per operation.

Otherwise, the servo drive may be damaged.

(3-2)Motor cable connecting terminal (U, V, W)

- Perform wiring by using a thicker cable than applicable cable in order to suppress a

voltage drop.

(3-3)DC reactor connecting terminal ((+) 1, (+))

- This terminal is used to connect the DC reactor (option) for improvem ent of power factor.

A short bar or wire is connected between terminals (+) 1 and (+) at delivery from the

factory. When connecting the DC reactor, disconnect it bar beforehand. When the DC

reactor is not used, do not remove it.

(3-4)External braking resistor connecting terminal ((+), RB))

- The regenerative braking circuit and the braking resistor are built-in the servo drive (But

200V class 100W, 200W not provided it). To enhance the braking capacity, connect the

optional external braking resistor to this terminal. For using the external braking resistor ,

disconnect the short bar or wire between the terminals (B1 and B2 or RB) for internal

braking resistor. The wiring length should be 5 m or less and perform wiring by twisting

two wires without making inductance.

- Install a resistor exceeding the resistance value R

shown in the following table.

BRmin

Installing a resistor not exceeding the resistance value shown in the table will cause

damage to the regenerative braking circuit.

3 − 15

Page 40

CHAPTER 3 INSTALLATION AND WIRING

Servo drive capacity Built-in R

50W Not provided 35Ω

Single-phase

100V

(M)

100W Not provided 35Ω

200W 30 W 75Ω (9 W, 1.0%) 25Ω

400W 50 W 20Ω (17 W, 1.0%) 17Ω

50W,100W Not provided 100Ω

200W Not provided 100Ω

400W 30 W 75Ω (15 W, 0.5%) 50Ω

Three-phase

200V

750W 50 W 50Ω (15 W, 0.5%) 40Ω

1kW,1.5kW 70 W 25Ω (27 W, 0.5%) 25Ω

(L)

2kW 120 W 10Ω (70 W, 0.5%) 10Ω

3kW 120 W 10Ω (70 W, 0.5%) 10Ω

5kW 180 W 6Ω (120 W, 0.5%) 6Ω

Single-phase/

Three-phase

200 V

(N)

Three-phase

400 V

(H)

100 W Not provided 100Ω

200 W Not provided 100Ω

400 W 50 W 50Ω (15 W, 0.5%) 50Ω

750 W 50 W 50Ω (15 W, 0.5%) 40Ω

1.5 kW 50 W 100Ω (27 W, 0.5%) 100Ω

3.5 kW 120 W 50Ω (70 W, 0.5%) 50Ω

7 kW 180 W 25Ω (120 W, 0.5%) 25Ω

BR

Minimum resistance

value R

BRmin

Note: The power of the built-in braking resistor RBR is the nominal power value. The values

in parentheses are the available average power (W) and the allowable operating ratio

(%).

(3-5)DC power supply input connecting terminal ((+), (–))

- To supply the DC power from an external converter, this terminal is used to connect the

DC power supply. The DC power supply voltage should be 270 V DC to 310 V DC for

200V class, 510V DC to 650V DC for 400V class (+10%, –15%). Use a power supply of

enough capacity.

- When supplying the DC power supply, do not connect anything to the main power supply

input connecting terminals (L1, L2, L3).

- When supplying the DC power supply, set the PN power supply (FA-07) to Pn. If this is

not set, a momentary power failure will be detected by mistake for 200 V class servo

drive.

(3-6)Control power supply input connecting terminal (L1C, L2C)

- This servo drive has to supply the control power supply apart from the main circuit power

supply. Be sure to connect the single-phase AC power supply to the control power

supply input terminal (L1C, L2C). For this power supply, use a fuse for circuit (wiring)

protection.

- The control power supply of 400V class servo drive (AD*3-HPE) is AC 200 – 240 V.

- Turn on and off the power supply, at least, at intervals of 5 minutes per operation.

Otherwise, the servo drive may be damaged.

3 − 16

Page 41

CHAPTER 3 INSTALLATION AND WIRING

(3-7)Grounding connecting terminal ( ) )

- For prevention ag ainst an electric shock, be sure to be grounded the servo drive and the

servo motor as specified.

- Use a larger size than the applicable wire as the grounding conductor. It should be as

short as possible.

Note 1: For wiring to the terminals, use a solderless terminal conforming to the terminal screw

size and terminal width. If a too wide solderless terminal width is used, this connection

may not be made. In particular, take care about the terminal width in the following

cases.

-2 mm

-8 mm

Note 2: Separate the servo drive signal input cable or encoder cable from the main circuit power

cable or control power cable 30 cm or more from each other. If they must intersect each

other, cause them to intersect at a right angle as shown in the following figure. If they

are not separated enough, a malfunction may be caused.

2

or more cable is connected to the main circuit terminals of 200 V class.

2

or more cable is connected to the main circuit terminals of 400 V class 7kW.

30 cm or more

Main circuit power cable

(L1, L2, L3, U, V, W, (+), (+)1, RB)

Control power supply cable

(L1C, L2C)

Intersect at a right angle.

Signal input or encoder cable

3 − 17

Page 42

r

A

A

C

r

r

CHAPTER 3 INSTALLATION AND WIRING

(4) Wiring equipment, options

Name Model Function

1 Setup software AHF AHF-P01,P02 Setting,monitoring and graphic display by PC

2 Enco der cable ADCE-C---S,HP -C:standard type, -CH:high flexure life type

Power cable

3

(with or without brake)

4 Command cable ADCC-03 Cable with I/O connector

5 PC connecting cable ADCH-AT2 Cable with DOS/V PC connector(D-SUB 9P)

6 Connector set for I/O ADCC-CON Connector and its cover

Lithium battery

7

(for absolute encorder)

ADABS-BT

8 Terminal block ADCC-TM

9 Above adapter cable ADCC-T01,T02

10 Input –side rea cto r ALI- Power factor improvement, power cooperation

1 1 DC reactor DCL- Power factor improvement

12 Noise filter NF- EMC noise filter

Radio noise filter

13

(zero-phase reactor)

ZCL-B40,B75

ZCL-A

14 Input-side noise filter CFI-L,-H Reduction for radiating noise

External braking

15

resistor

RB,JRB---,SRB--- Braking power capacity improvement

16 Noise filter SUP-E1H-EP EMC noise filter for 400 V class control power

17

Teaching unit ADOPE-SR Teaching unit for optional board

Teaching unit

18

connecting cable

ADICS-1/ADICS-3

Motor cable (Prepared by customer)

Encoder data are kept by battery at control power

off for the absolute encoder use.

Terminal connection adapter for I/O connector

with 1m or 2m cable

Reduction for radiating noise

Cable with Teaching unit connector.

This is necessity using teaching unit.

10.Input

side

reactor

Power supply

Power supply

for brake

11.DC reactor

Earth

leakage

breaker

15.External

braking

resistor

Electromagnetic

contactor

12.Noise

filter

Prepared by

customer

13.Radio

noise filter

14.Input-

side noise

filter

16.Noise

filter

7.Lithum

battery

Servo drive

AC SERVO

series

FUN

CHARGE

3.Powe

cable

3.Brake cable

3 − 18

D

(+1)

+

(

RB

-

)

(

L1

L2

L3

U

V

W

D*-08LS

)

SET

PC

I/O

ENC

18.Teaching

unit

connecting

cable

5.PC

connecting

cable

6.Connector

set for I/O

9.Adapter cable

13.Radio

noise filter

17.Teaching unit

2.Encode

cable

1.Setup software

AHF

4.Command

cable

8.Terminal block

Servo moto

Master

DOS/V PC

Page 43

CHAPTER 3 INSTALLATION AND WIRING

5) Recommended wire size and wiring equipment

- For the wire size and wiring equipment to be used for wiring to the servo drive, refer to the

following table.

- For safety, use fuses.

- As the cable, use a 75°C copper electric cable.

- When the wiring length exceeds 20 m, the power cable m ust be larger.

- Tighten the terminal screw with the specified tightening torque. Insufficient tightening may result

in a short circuit or fire.

(Tightening torque)

For 1.5kW, 3.5kW (M3 screw): 0.6 N.m(max.0.66N.m)

For 7kW (M5 screw): 2.0 N.m(max.2.2N.m)

For up to 750W (M4 screw): 1.2 N.m(max.1.35N.m)

Voltage

class

Single

phase

100V

class

Three

phase

200V

class

Single

/ Three

phase

200V

class

Three

phase

400V

class

Main circuit power

MotorkWServo drive

model

0.05 ADAX4-R5MS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2) 5A H10C

0.1 ADAX4-01MS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2) 5A H10C

0.2 ADAX4-02MS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2) 10A H10C

0.4 ADAX4-04MS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2) 15A H10C

0.05 ADAX4-R5LS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2) 5A H10C

0.1 ADAX4-01LS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2) 5A H10C

0.2 ADAX4-02LS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2) 5A H10C

0.4 ADAX4-04LS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2) 5A H10C

0.75 ADAX4-08LS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2) 10A H10C

1 ADAX4-10LS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2) 10A H10C

1.5 ADAX4-15LS* AWG 14 (2mm2) AWG 14 (2mm2) AWG 18 (1.25mm2) 15A H20

2 ADAX4-20LS* AWG 14 (2mm2) AWG 12 (3.5mm2) AWG 18 (1.25mm2) 20A H20

3 ADAX4-30LS* AWG 12 (3.5mm2) AWG 10 (5.5mm2) AWG 18 (1.25mm2) 30A H20

5 ADAX4-50LS* AWG 10 (5.5mm2)AWG 8 (8mm

0.1 ADAX4-01NS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2) 3A H10C

0.2 ADAX4-02NS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2)

0.4 ADAX4-04NS* AWG 18 (1.25mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2)

0.75 ADAX4-08NS* AWG 16 (2mm2) AWG 18 (1.25mm2) AWG 20 (0.5mm2)

~ 1.5 ADAX-15HP* AWG 18 (1.25mm

~ 3.5 ADAX-35HP* AWG 14 (2mm

~ 7 AD*3-70HP* AWG 10 (5.5mm

cable

(L1, L2, L3)

(+)1, (+), RB, (−)

2

) AWG 18 (1.25mm2) AWG 18 (1.25mm2) 10A H10C

2

) AWG 14 (2mm2) AWG 18 (1.25mm2) 20A H20

2

) AWG 10 (5.5mm2) AWG 18 (1.25mm2) 50A H20

Motor cable

(U, V, W)

Grounding cable

Control power cable

(L1C, L2C)

2

) AWG 18 (1.25mm2) 50A H25

Fuse (class J)

rated 600 V

6A (1 ph.)

3A (3 ph.)

10A (1 ph.)

6A (3 ph.)

15A (1 ph.)

10A (3 ph.)

Electromagnetic

contactor

(MC)

(Note 1)

H10C

H10C

H10C

Note 1 : The electromagnetic contactor are the model manufactured by Hitachi Industrial

Equipment Systems Co., Ltd.

Note 2 : Field wiring connection must be made by a UL Listed and CSA Certified closed – loop

terminal connect or sized wire gauge involved. Connector must be fixed using the crimp

tool specified by the connector manufacturer.

3 − 19

Page 44

CHAPTER 3 INSTALLATION AND WIRING

(6) Opening the main circuit terminal block (TM1) cover (200 V class)

1- Loosen a fixing screw of the main circuit terminal cover.

2- Take the main circuit terminal cover on the body away from the front slowly.

3- Remove the cover from the hook.

2

3

1 Fixing

screw

Main circuit terminal cover

Hook

3 − 20

Page 45

CHAPTER 3 INSTALLATION AND WIRING

3.2.3 Wiring for the control power connector (TM2) (200V class)

CAUTION

1. For the control power connector (TM2), perform wiring after removing it from the servo drive.

Otherwise, the servo drive may be broken.

2. Insert one cable in one wiring hole of the control power connector (TM2). Otherwise, the

servo drive may malfunction.

3. When inserting the cable, take care not to bring the core whisker into contact with the other

terminal. The servo drive may be broken.

4. If the cable core has not enough contact for any reason, strip it again and then connect the

cable. The servo drive may be broken.

(1) Cable terminal treatment

Strip the cable cover as shown in Fig. 1. Then, the cable can be used as it is. The

applicable wire size is as follows.

Solid wire...............Wire size 0.5 to 2.0 mm

Stranded wire .........Wire size 0.5 to 2.0 mm

(2) Connecting method

Insert the core of the cable in the opening of the control power connector (TM2) (Fig. 2) by

using one of the methods shown in Fig. 3 and Fig. 4. Make sure that the cable cannot be

pulled out.

2

2

8 to 9 mm

Fig. 1

1- Insert the cable by using an attached lever as shown in Fig. 3.

2- Insert the cable by using a bladed screwdriver as shown in Fig. 4.

Fig. 2

B1

B2

L2C

L1C

Fig. 3 Fig. 4

3 − 21

Page 46

y

r

r

CHAPTER 3 INSTALLATION AND WIRING

3.2.4 Connecting the backup battery for absolute encoder

3

Lay the cable

on the battery

surface.

2

Batter

Battery holde

Battery connecto

Cable housing

1

Black (-)

3

Red (+)

Battery housing

cover

Fig. 1 Fig. 2

1- Set the click in the groove on the top surface of the battery housing cover and then open the cover.

2- Set the battery in the battery housing with its positive side on the receptacle side a s sh own in Fig. 1.

3- Insert the connector in the receptacle firmly.

4- Lay the battery cable surely on the battery surface as shown in Fig. 1 and house the excessive cable

in the cable housing.

5- Mount the battery housing cover on the front cover by pushing the upper part of the battery housing

cover (Fig. 2) with a finger until a click is produced.

Note 1: After mounting the battery and co nnecting the encoder, turn o n the po wer supply. At that

time, an absolute battery error (E90) may occur. In this case, clear the encoder to zero. For

the procedure, refer to Chapter 5, Function for absolute position encoder, (2) Clearing the

absolute position.

If the following trip related to the absolute battery occurs, take one of the measures shown below

.

Trip name Measure

Absolute battery error E90 - Replace the battery after turning off the control and main power

supply.

- Clear the encoder to zero. Perform the system adjustment

from the beginning.

Absolute battery alarm E91 - Replace the battery with the control power supply (L1C, L2C)

incoming after a lapse of more than 10 minutes af ter turning off

the main power supply (L1, L2, L3).

- Turn ON and OFF the alarm reset signal RS.

Note2: The absolute battery alarm (E91) occurs if the battery is removed with the control power

supply incoming. In this case, take the above measure

.

3 − 22

Page 47

A

3.2.5 Input/output signal wiring

(1) Input/output signal connector

In the input/output signal connector , the upper left pin is pin no.1 when the servo drive is viewed

from the front as shown in the figure. The signal assignment on the input/output signal

connector (servo drive side) is shown in the following table.

Pin

No.

1 P24 Interface power 26 SON/

2 PLC Intelligent input common 27 RS Alarm reset

Input/output

3MOD/

signal

connector(I/O)

4TL//

C SERVO

AD

series

Front view of the

0.4 kW servo drive

HITACHI