Page 1

Operator's Manual

BM/Hitachi 917

S

V 2.1 – Operator's Manual

Page 2

BM/Hitachi 917

The contents of this manual, including all drawings and tables, are the property of

BOEHRINGER MANNHEIM GmbH. They may not be copied or duplicated without prior

written consent, or used in whole or in parts for the manufacture or sale of items.

BOEHRINGER MANNHEIM GmbH reserves the right to make changes to their manual

without being obliged to give notice of this.

No responsibility is accepted by BOEHRINGER MANNHEIM GmbH for any errors this manual

may contain.

This manual describes the BM/Hitachi 917 Software Version 2.

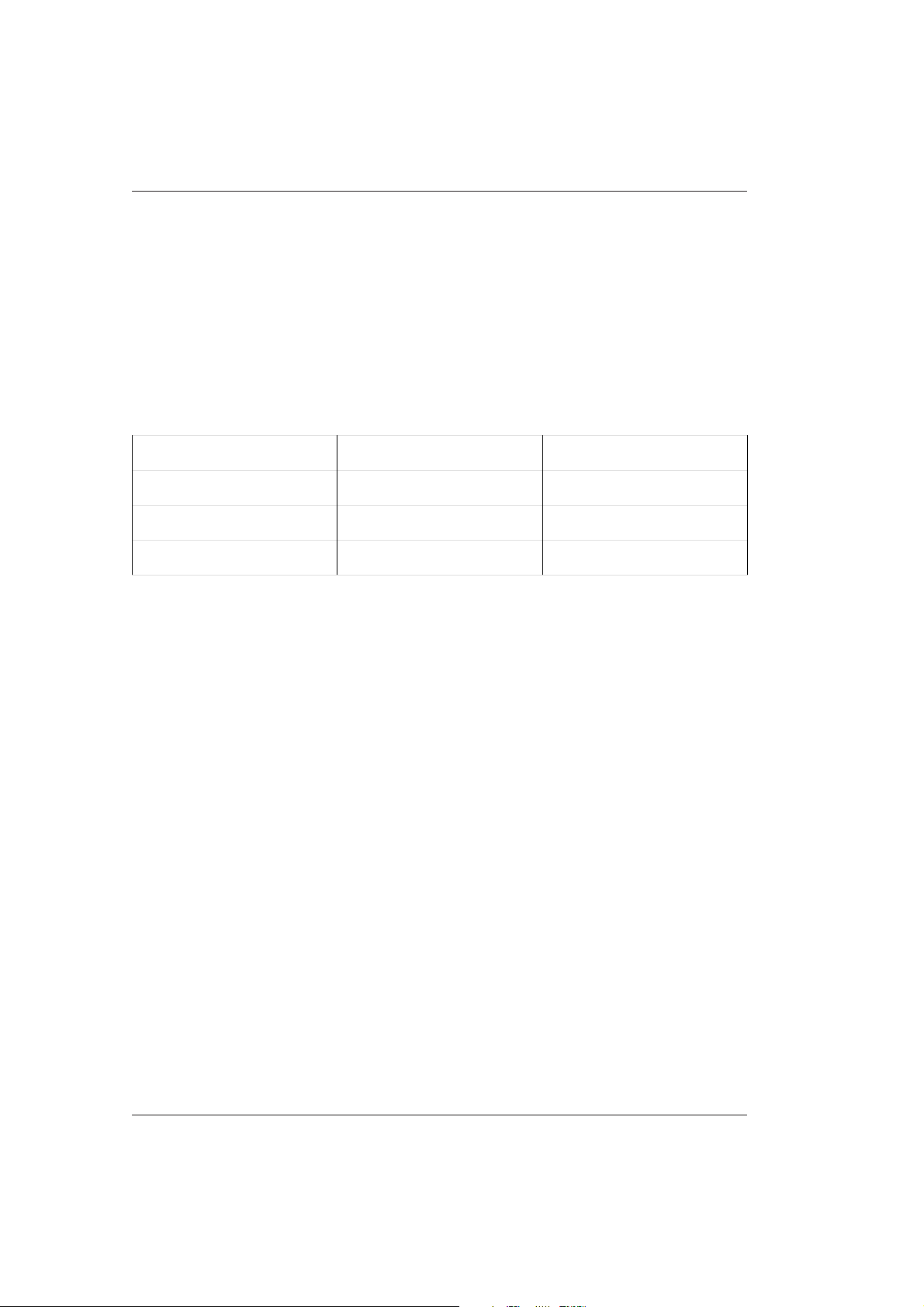

Version Published Software affected

V 1.0 January 1995 V 1.03

V 2.0 June 1996 V 2

V 2.1 March 1997 V 2

First Edition – March, 1997

Boehringer Mannheim GmbH, Mannheim

Production: P. Hirn, D.H. Jung, B. Koroknay, J. Lutzke, I. Reinhardt, J. Westera

Layout: Scriptor Dokumentations Service GmbH, Bielefeld

V 2.1 – Operator's Manual

Page 3

Contents

Contents

V 2.1 – Operator's Manual 1

Page 4

BM/Hitachi 917

0. Potential Hazards and Safety Precautions 0-1

1. Introduction 1-1

1.1 Manual Outline 1-2

2. Daily Routine 2-1

2.1 Introduction 2-2

2.2 Daily Maintenance - Outline 2-3

2.3 System Start 2-6

2.3.1 Introduction 2-6

2.3.2 Power On 2-6

2.3.3 Automatic Start Procedure 2-7

2.3.4. Log On/Log Off 2-8

2.4 Daily Start Up 2-10

2.4.1 Checking the Reagents REQUIREMENTS Screen 2-11

2.4.2 Reconstituting Calibrators and Controls 2-13

2.4.3 Air Purge (Photometric System) 2-15

2.4.4 ISE Prime, Conditioning, Calibration 2-16

2.5 Calibration Test Selection 2-18

2.5.1 Automatic Calibration 2-18

2.5.2 Manual Control Test Selection (from Sample Disk 2) 2-24

2.6 Initiate Run with Routine Patient Test Selections 2-25

2.6.1 Routine Patient Test Selection 2-25

2.6.2 Initiate Run Procedure 2-29

2.6.3 Entering Non-Barcoded or Unreadable Barcoded Samples

(in the Barcode Mode) 2-34

2.7 Sample Tracking 2-36

2.8 Measurement of Additional Routine Samples 2-37

2.9 STAT Test Selections 2-38

2 V 2.1 – Operator's Manual

Page 5

Contents

2.10 Processing of Rerun Samples 2-41

2.10.1 Automatic Rerun 2-42

2.10.2 Manual Rerun 2-43

2.11 Adding Reagent During a Run 2-45

2.12 Patient Reports 2-47

2.12.1 Selecting the Patient Report Format for Real Time Printing 2-47

2.12.2 Printing Patient Reports in Batch 2-48

2.13 Data Management 2-49

2.13.1 Reviewing Data 2-49

2.13.2 Editing Data 2-50

2.13.3 Deleting Functions 2-55

2.14 Quality Control Procedures 2-58

2.14.1 Selecting Controls for Real Time QC 2-59

2.14.2 Individual QC List 2-60

2.14.3 Setting of Controls in the Individual QC Chart 2-61

2.14.4 Validation of Individual QC with Real Time QC

(Rejection of Single Test Couplings) 2-63

2.15 QC File Maintenance 2-65

2.15.1 Accumulate QC Data 2-65

2.15.1 Deleting QC Data 2-66

2.15.3 Cumulative QC List 2-67

2.15.4 Validation of Cumulative QC 2-68

2.15.5 Printing the Cumulative QC List and Chart 2-69

2.15.6 Deleting the Cumulative QC 2-70

2.16 System Shutdown 2-71

2.16.1 Instrument Shutdown 2-71

2.16.2 Activating the SLEEP Mode 2-72

V 2.1 – Operator's Manual 3

Page 6

BM/Hitachi 917

3. Maintenance and Daily Care 3-1

3.1 Introduction 3-2

3.1.1 Necessary Material and Safety Precautions 3-2

3.1.2 Automatic System Cleaning (Daily) 3-5

3.1.3 ERGO Console Cleaning 3-6

3.1.4 Maintenance and Care Schedule 3-7

3.2 Daily System Maintenance 3-9

3.2.1 Emptying the Waste Container 3-9

3.2.2 Checking/Replacing the Detergent 3-10

3.2.3 Checking the Detergent/Replenishing the Bottles 3-12

3.2.4 Cleaning the Reagent Probes and Sample Probe 3-13

3.2.5 Cleaning the Stirring Unit 3-14

3.2.6 Checking the Paper Supply 3-15

3.2.7 Cleaning the Instrument Surfaces 3-15

3.2.8 Cleaning the Nozzles of the Cell Rinse Unit 3-15

3.2.9 Priming, Conditioning and Calibrating the ISE Unit 3-16

3.2.10 Cleaning the ISE Unit with ISE Wash Solution 3-17

3.2.11 Checking the Temperature of the Incubation Bath 3-17

3.2.12 Performing a Photometer Check 3-18

3.3 Weekly System Maintenance 3-19

3.3.1 Cleaning the Reaction Cells 3-19

3.3.2 Performing the Cell Blank Measurement 3-20

3.3.3 Cleaning the Rinse Bath for the Sample Probe, Reagent Probes,

and the Stirring Paddle 3-21

3.4 Monthly System Maintenance 3-22

3.4.1 Replacing the Reaction Cell Segments 3-22

3.4.2 Cleaning the Incubation Bath and the Incubation Bath Drain Filter 3-24

3.4.3 Cleaning the Inside of the Sample and Reagent Disks 3-28

3.4.4 Cleaning the Air Filter 3-30

3.4.5 Replacing the ISE Pinch Valve Tubing 3-32

4 V 2.1 – Operator's Manual

Page 7

Contents

3.5 Quarterly System Maintenance 3-33

3.5.1 Cleaning the Inlet Water Filter 3-33

3.5.2 Replacing the Syringe Seals 3-34

3.6 Six Monthly System Maintenance 3-42

3.6.1 Replacing the ISE Reference Electrode 3-42

3.6.2 Replacing the Teflon Block (Nozzle Tip) 3-44

3.7 Analyzer Maintenance As Required 3-45

3.7.1 Emptying the Vacuum Tank 3-45

3.7.2 Replacing the Photometer Lamp 3-47

3.7.3 Cleaning/Replacing Clogged Probes 3-52

3.7.4 Checking the Alignments 3-54

3.7.5 Cleaning Clogged Rinse Nozzles 3-63

3.7.6 Replacing the Stirring Paddles 3-65

3.7.7 Replacing the ISE Measurement Electrodes (Na+, K+, Cl-) 3-67

3.8 Printer Maintenance 3-70

3.8.1 Start-Up 3-70

3.8.2 Replacing the Ink Ribbon Cartridge 3-71

3.8.3 Loading Continuous-Feed Paper 3-74

3.8.4 Inserting Single Sheets 3-78

3.8.5 Setting the Paper Thickness 3-80

V 2.1 – Operator's Manual 5

Page 8

BM/Hitachi 917

4. Operation Support 4-1

4.1 Adding a New Application 4-2

4.1.1 Loading New Applications from Disk 4-3

4.1.2 Loading New Applications from a Barsheet 4-5

4.1.3 Adding of User-Definable Applications (901 to 905) 4-9

4.1.4 Key Setting 4-11

4.1.5 Assigning the Print Order 4-12

4.1.6 Reagent Registration 4-13

4.1.7. Programming Preset K Factors for Assays 4-13

4.2 Loading of a Serum Index Application 4-14

4.3 Special Wash Programming 4-16

4.3.1 Reagent Probe Wash 4-16

4.3.2 Sample Probe Wash 4-19

4.3.3 Cell Wash 4-22

4.4 Calculated and Compensated Tests 4-25

4.4.1 Calculated Tests 4-25

4.4.2 Compensated Tests 4-30

4.5 Loading Calibrator Information 4-33

4.5.1 Manual Setting of Calibrator 4-33

4.5.2 Loading Calibrator Setpoints from a Barsheet 4-34

4.5.3 Assigning a Calibrator Position 4-35

4.5.4 Deleting a Calibrator 4-36

4.5.5 Deleting a Calibrator Position 4-37

4.6 Loading Control Information 4-38

4.6.1 Manual Setting of Controls 4-38

4.6.2 Loading Control Setpoints from a Barsheet 4-40

4.6.3 Assigning a Control Position 4-42

4.6.4 Deleting a Control 4-43

4.6.5 Deleting a Control Position 4-44

4.6.6 Activating Controls 4-45

4.6.7 Assigning Key Settings for Controls 4-46

4.6.8 Manual Control Test Selections (Sample Disk 2) 4-47

4.6.9 Setting Controls for the QC 4-48

6 V 2.1 – Operator's Manual

Page 9

Contents

4.7 Defining Profiles 4-50

4.7.1 Adding a Profile 4-50

4.7.2 Deleting a Profile / Deleting a Test from a Profile 4-52

4.7.3 Default Profiles 4-54

4.8 Operator-ID / Password Management 4-55

4.8.1 Assigning an Operator ID 4-56

4.8.2 Delete Operator ID 4-57

4.8.3 Password Registration 4-58

4.9 Disk Management 4-59

4.9.1 Writing System Parameters (Application Settings) on a Floppy

Disk 4-59

4.9.2 Reading System Parameters from a Floppy Disk 4-60

4.9.3 Formatting a Floppy Disk 4-61

4.9.4 Archive Data 4-62

4.9.5 Saving QC Data 4-63

4.10 Define Maintenance Frequency and Maintenance Item 4-64

4.10.1 Defining the Maintenance Frequency 4-64

4.10.2 Defining the Maintenance Item 4-66

V 2.1 – Operator's Manual 7

Page 10

BM/Hitachi 917

5. Printouts 5-1

5.1 MEASUREMENT DATA Printout 5-2

5.1.1 REPORT Format 5-2

5.1.2 MONITOR Format 5-5

5.2 REACTION MONITOR Printout 5-6

5.3 REQUISITION LIST Printout 5-8

5.3.1 Requisition List Without Sample Barcode 5-8

5.3.2 Requisition List With Sample Barcode 5-9

5.4 RERUN LIST Printout 5-10

5.5 PRECISION CHECK Printout 5-12

5.6 PROFILING LIST Printout 5-13

5.7 SYSTEM REQUIREMENTS Printout 5-14

5.8 REAGENT STATUS Printout 5-15

5.9 CALIBRATION MONITOR Printout 5-17

5.9.1 CALIBRATION MONITOR Photometry 5-18

5.9.2 CALIBRATION MONITOR ISE 5-22

5.10 REACTION MONITOR Printout 5-23

5.10.1 The Primary and Secondary Wavelengths Option 5-24

5.10.2 The Primary Minus Secondary Wavelengths Option 5-25

5.11 CALIBRATOR LOAD LIST Printout 5-26

5.12 CALIBRATION TRACE Printout 5-27

5.12.1 CALIBRATION TRACE Photometry, Rate 5-28

5.12.2 CALIBRATION TRACE Photometry, Endpoint 5-30

5.12.3 CALIBRATION TRACE ISE 5-31

5.13 INDIVIDUAL QC CHART Printout 5-32

5.14 INDIVIDUAL QC LIST Printout 5-34

5.15 CUMULATIVE QC CHART Printout 5-35

5.16 CUMULATIVE QC LIST Printout 5-37

5.17 ALARM TRACE Printout 5-38

5.17.1 DAILY ALARM TRACE 5-38

5.17.2 CUMULATIVE ALARM TRACE 5-39

8 V 2.1 – Operator's Manual

Page 11

Contents

5.18 SYSTEM COMMUNICATION TRACE Printout 5-40

5.19 OPERATOR ID TRACE Printout 5-42

5.20 CUMULATIVE OPERATION LIST Printout 5-43

5.21 MAINTENANCE REPORT Printout 5-45

5.22 REPORT EXAMPLE Printout 5-46

5.22.1 Setting ONE REPORT/PAGE 5-47

5.22.2 Setting TWO REPORTS/PAGE 5-49

5.23 CELL BLANK MEASUREMENT Printout 5-51

5.24 PHOTOMETER CHECK Printout 5-52

5.25 CELL BLANK MEASUREMENT Printout 5-53

5.26 PRINTER CHECK Printout 5-55

5.27 BARCODE READER CHECK Printout 5-56

5.28 ISE CHECK Printout 5-57

5.29 HD CHECK Printout 5-59

5.30 FD CHECK Printout 5-61

V 2.1 – Operator's Manual 9

Page 12

BM/Hitachi 917

6. Troubleshooting 6-1

6.1 Overview 6-2

6.2 General Troubleshooting Strategy 6-6

6.2.1 Troubleshooting Conditions at power up 6-8

6.2.2 Test troubleshooting 6-9

6.2.3 Preparation of reagents, calibrators, controls 6-10

6.2.4 High test results 6-11

6.2.5 Low test results 6-12

6.2.6 Erratic test results 6-13

6.2.7 Problems with a single sample or control 6-15

6.2.8 Problems with a single test 6-16

6.2.9 Problems with tests with one calibration set point 6-17

6.2.10 Problems with all tests with more than one calibration set point 6-18

6.2.11 Problems with multiple tests (photometrics only) 6-19

6.2.12 Problems with all tests, including ISEs 6-20

6.2.13 Problems with ISE, all results are erratic,

excessive air in sipper syringe 6-21

6.2.14 Erratic ISE results 6-22

6.2.15 Problems with ISE, high internal standard values 6-24

6.2.16 Problems with low sodium, potassium and chloride values 6-25

6.2.17 Problems with a biased enzymes 6-26

6.3 Data Alarms 6-27

6.3.1 Calculation disabled 6-27

6.3.2 Absorbance over 6-28

6.3.3 Absorbance maximum over (non-linear calibration) 6-29

6.3.4 ADC abnormal 6-29

6.3.5 Calculation test error 6-30

6.3.6 Calibration result abnormal 6-30

6.3.7 Calibration error 6-31

6.3.8 Cell blank abnormal 6-32

6.3.9 Test-to-test compensation error 6-33

6.3.10 Test-to-test compensation disabled 6-34

6.3.11 Duplicate error 6-34

6.3.12 Edited test 6-36

6.3.13 Outside of reference value 6-36

10 V 2.1 – Operator's Manual

Page 13

Contents

6.3.14 Internal standard concentration abnormal 6-37

6.3.15 Level error 6-38

6.3.16 Technical value limit over 6-40

6.3.17 Reaction limit over at all points (Limt0) 6-41

6.3.18 Reaction limit over at 1 point (Limt1) 6-42

6.3.19 Reaction limit over (Limt2) 6-43

6.3.20 Linearity abnormal (Lin.) 6-44

6.3.21 Linearity abnormal (Lin.8) 6-46

6.3.22 ISE Preparation abnormal 6-48

6.3.23 Noise error 6-49

6.3.24 Overflow 6-50

6.3.25 Prozone error 6-50

6.3.26 QC error 1 6-51

6.3.27 QC error 2 6-52

6.3.28 Random error 6-53

6.3.29 Reagent short 6-54

6.3.30 Value outside repeat limit 6-55

6.3.31 Sample value abnormal 6-55

6.3.32 Sample short 6-56

6.3.33 SD error 6-57

6.3.34 Sensitivity error 6-58

6.3.35 Slope abnormal 6-59

6.3.36 Standard error 6-60

6.3.37 Systematic error 1 6-61

6.3.38 Systematic error 2 6-62

6.3.39 Systematic error 3 6-63

6.3.40 Systematic error 4 6-64

6.3.41 Systematic error 5 6-65

6.3.42 Systematic error 6 6-66

6.3.43 Standard 1 absorbance abnormal 6-67

7. Appendix

A.1 Glossary A-2

A.2 Index A-13

V 2.1 – Operator's Manual 11

Page 14

BM/Hitachi 917

12 V 2.1 – Operator's Manual

Page 15

Potential Hazards and Safety Precautions

0. Potential Hazards and Safety Precautions

V 2.1 – Operator's Manual 0 - 1

Page 16

BM/Hitachi 917

❚ Safety Warnings

Before putting the analyzer into operation, you should become acquainted with all

precautions and regulations concerning the handling of the analyzers electrical and

mechanical components in order to rule out any potentially hazardous situations to

yourself and your colleagues.

All safety warnings that the operator must consider in this manual are classified as

below. Acquaint yourself with the following labels and pictures.

WARNING

If these instructions are not strictly adhered to, there is a risk of fatal injury e.g. from

power supplies or infection.

CAUTION

If these instructions are not strictly adhered to, there is an increased risk of injury and/or

serious functional disruptions to the analyzer.

ATTENTION

Identifies all other situations where increased attention is necessary (e.g. to avoid

damage to the analyzer).

Note

Indicates information to be considered e.g. remarks, etc.

is the international symbol for caution

0 - 2 V 2.1 – Operator's Manual

Page 17

❚ Safety Precautions

WARNING

Electrical Safety

Never open the back or side panels when the analyzer is connected to the

mains supply (wall socket)! Pull the plug out beforehand!

You can receive an electric shock by touching supply-carrying components.

CAUTION

Flammable and Explosive Materials

Avoid using flammable materials around the analyzer.

Electrical sparks can cause fires and explosions.

Potential Hazards and Safety Precautions

CAUTION

Analyzer in Operation

Never touch the sample pipetter, reagent pipetters, stirrer, rinse units and

all other moving components when the analyzer is operating.

There is a risk of injury from the moving components and the analyzer can

also be damaged.

WARNING

Photometer Lamp

Never look for long periods into the light of the photometer lamp without

eye protection.

If this warning is not heeded, damage to the eyes can occur. Wear

darkened protective goggles to protect yourself from ultra violet light,

when you must look at the light transmitted from the photometer lamp for

long periods.

V 2.1 – Operator's Manual 0 - 3

Page 18

BM/Hitachi 917

WARNiNG

CAUTION

Samples

1. Avoid direct contact with samples that contain bacteria or are poten-

tially infectious.

If sample material comes in contact with the analyzer surface, clean it

up immediately with a towel.

2. Ensure that the sample contains no fibrin clots, dust or other insoluble

contaminations.

If the sample contains insoluble material, false results can be produced. This applies especially when fibrin clots block the sample

pipetter.

Liquid Waste

1. Potentially infectious waste must be disposed of according to the legal

regulations.

There is a risk of contamination from potentially infectious waste.

2. Contact the manufacturer of the reagent, if you require more informa-

tion about its environmental compatibility.

CAUTION

Correctness/Precision of the Measurements

To ensure that the analyzer operates correctly, controls must be measured

and the functions must be monitored.

Erroneous measurements can lead to a false diagnosis resulting in an

incorrect therapy that puts the patient at risk.

0 - 4 V 2.1 – Operator's Manual

Page 19

Potential Hazards and Safety Precautions

❚ Safety Precautions During Operation

CAUTION

Correct Usage

1. The analyzer was designed for clinical-chemical analyses, electrolyte analyses,

immunological tests and medical analyses using water-soluble samples and reagents.

Comply with the manufacturer regulations of the reagent when using the tests on the

analyzer.

2. If reagents are used other than those developed by Boehringer Mannheim, then

Boehringer Mannheim guarantees the technical specifications of the analyzer but

takes no responsibility for the measured results.

CAUTION

Operator Qualifications

1. The operation of the analyzer should only be performed under the control of a

qualified person, who has taken part in a recognized training from Boehringer

Mannheim.

2. For clinical tests, the analyzer should only be controlled by a practitioner or a

laboratory doctor.

CAUTION

Operation and Maintenance

1. The operation and maintenance of the analyzer may only be performed according to

the described procedures. No other components other than those specified may be

touched.

2. Never open the screwed down analyzer covers when the analyzer is connected to a

power supply. Contact with the circuit boards can damage the electronic components.

V 2.1 – Operator's Manual 0 - 5

Page 20

BM/Hitachi 917

3. Never touch the sample pipetter, reagent pipetter, stirrer, rinse units and all other

moving components of the analyzer when it is in operation.

If this precaution is not adhered to, damage or interruption to the analyzer can occur.

4. Never touch the reaction disk, sample disk and reagent disk when they are rotating.

If this precaution is not adhered to, damage or interruption to the analyzer can occur.

CAUTION

Environment Conditions (Installation Conditions)

Consider the specified installation conditions. If the analyzer is to be located somewhere else, contact Boerhinger Mannheim customer support.

CAUTION

Limitations for Samples and Reagents

1. The reaction cells, sample cups and the tubing for liquid waste are not impervious to

organic solutions. Never use organic solutions.

2. Never use samples or reagents that can stick to the sample probe, reagent probes

or the reaction cells. This also applies to samples and reagents that may block the

sample probe or reagent probes. False measurements may be produced.

CAUTION

Loading Samples and Reagents

Only load samples and reagents into the intended positions on the analyzer. Spilt

samples and reagents can cause disruptions to the analyzer. Only load reagents when

the analyzer is in the "stand-by" mode, or when the reagent stop function permits

loading.

If this precaution is not adhered to, damage or interruption to the analyzer can occur.

0 - 6 V 2.1 – Operator's Manual

Page 21

Potential Hazards and Safety Precautions

CAUTION

Analyzer Cover

The analyzer cover should always be closed during operation. Only open the cover to

load samples, etc.

CAUTION

Sample Disk

Never load new samples or change the sample disk when the LEDs, indicating that the

disk is rotating, are lit or blinking.

LED 1 indicates that sample disk 1 is rotating.

LED 2 indicates that sample disk 2 is rotating.

If this precaution is not adhered to, the analyzer can be damaged.

CAUTION

Reaction Disk

1. Never touch the reaction disk when the analyzer is operating.

2. Always follow the corresponding instructions when removing, loading or replacing

the reaction disk or the reaction cell segments.

If this precaution is not adhered to, damage or interruption to the analyzer can occur.

CAUTION

Reagent Disk

Only open the reagent disk cover in order to replace reagents.

If this precaution is not adhered to, the cooling can be affected thus causing the

reagents to expire. Opening the cover during an analysis causes an analyzer alarm.

V 2.1 – Operator's Manual 0 - 7

Page 22

BM/Hitachi 917

CAUTION

Reaction Cells

If a reaction cell dries out after use, cracks can occur and contaminations may not be

able to be removed. Therefore, the reaction cells must be stored after use in deionized

water. If the analyzer is not going to be used for more than three days, the reaction cells

must be removed from the reaction disk and must be stored in a 2% solution of

Hitergent.

CAUTION

Switching the Analyzer On

Never switch the analyzer off and then immediately back on. Wait at least 30 seconds

before switching back on.

If this is not adhered to, the analyzer may be damaged.

CAUTION

Handling Detergents

Never touch detergents with bare fingers, this can cause skin damage. Wear rubber

gloves when handling detergents.

CAUTION

Photometer Lamp

Do not touch the hot lamp or lamp housing, there is a risk of burns.

CAUTION

Stirrer

Do not bend the stirring paddle. Bent stirring paddles can cause false measurements.

0 - 8 V 2.1 – Operator's Manual

Page 23

1. Introduction

Manual Outline

V 2.1 – Operator's Manual 1 - 1

Page 24

BM/Hitachi 917

1.1 Manual Outline

The Operator’s Manual is a part of the documentation for the analyzer BM/Hitachi 917,

which additionally includes the volume System Description and the Short Guide.

The volume Operator’s Manual offers a detailed overview of all processes concerned with

the daily operation and those processes required fro the daily routine of the analyzer.

– In chapter 0 potentially hazardous sources are brought to light as well as safety notes

and precautionary measures.

– Chapter 2 provides detailed information about the daily routine on the analyzer.

– Procedures for analyzer care and maintenance are described in detail in chapter 3.

– Chapter 4 deals with operation support that could be useful when tuning the analyzer

to the laboratory requirements.

– In chapter 5 all printouts are described that can be requested from the analyzer.

– The 6th and last chapter describes errors and what measures must be taken to cure

them.

– The Appendix consists of a Glossary and an Index, allowing you quick access to any

required information.

1 - 2 V 2.1 – Operator's Manual

Page 25

2. Daily Routine

Introduction

V 2.1 – Operator's Manual 2 - 1

Page 26

BM/Hitachi 917

2.1 Introduction

In this chapter you find a description how the daily routine is prepared, performed and

shut down. Step by step you will get to know how to switch on the analyzer, how to

access the menus, how to determine the type and number of samples, how to allocate

tests, how to start the analysis, and how to obtain results at the end of the analysis.

Your service person at Boehringer Mannheim

Name:

Address:

Tel.:

Fax.:

2 - 2 V 2.1 – Operator's Manual

Page 27

Daily Maintenance - Outline

2.2 Daily Maintenance - Outline

Perform all daily operational checks prior to beginning the first run of the day. Each daily

operational check should be logged on the MAINTENANCE LOG sub menu. Default daily

maintenance items include:

1. Empty waste container

2. Check / replace cell detergent supply

3. Check / replace detergent supplies (1D1 - 2D3)

4. Check W1/W2 positions on sample disk 2

5. Clean sample and reagent probes

6. Clean stirrer paddles

7. Check paper supplies

8. Clean instrument surfaces

9. Clean cell rinse unit nozzles

10. Wash ISE unit with ISE Wash Solution (in position W2)

11. ISE prime/condition/calibrate

12. Check incubation bath temperature

13. Perform photometer check

14. Update Maintenance Log

V 2.1 – Operator's Manual 2 - 3

Page 28

BM/Hitachi 917

The following table displays an overview of the above maintenance procedures. More

detailed information can be found in chapter 3 Maintenance and Daily Care of the

Operator's Manual.

No. Maintenance Item Material required Note Details Page

1 Empty waste

container

2 Check / replace cell

detergent supply

3 Check / replace

detergent supplies

(1D1 - 2D3)

4 Check W1, W2

position on sample

disk 2

5 Clean sample and

reagent probes

disinfecting solution, water for

rinsing, paper

towels

Detergent 1

(NaOH-D)

fresh detergent Hitergent is used for position

NaOH-D

ISE wash solution

alcohol, lint-free

cloth

Content of the waste container is

potentially hazardous. Wear

disposable gloves.

Place both tube filters in the first

NaOH-D bottle. Execute a Cell

detergent prime, before running

analysis.

1D1 and 2D1.

NaOH-D (70 mL bottle) is used

for position 1D2 and 2D2.

Detergent for additional rinsing is

used for position 1D3 and 2D3.

NaOH-D is used for position W1.

ISE wash solution is used for

position W2.

Switch off the instrument to

move the pipettors.

3-9

3-10

3-12

3-5

3-13

6 Clean stirrer

paddles

7 Check paper supply printer paper Load new printer paper, if

8 Clean instrument

surfaces

9 Clean nozzles of the

cell rinse unit

alcohol, lint-free

cloth

disinfecting

solution, water,

lint-free cloth

alcohol, lint-free

cloth

Switch off the instrument to

move the stirrer paddles.

necessary.

Clean all surfaces with a lint-free

cloth and water or disinfecting

solution, if needed.

Instrument must be in Standby

or OFF.

3-14

3-15

3-15

3-15

2 - 4 V 2.1 – Operator's Manual

Page 29

Daily Maintenance - Outline

No. Maintenance Item Material required Note Details Page

10 Wash ISE Unit with

ISE wash solution (in

position W2)

11 ISE prime/condition/

calibration

12 Check incubation

bath temperature

13 Perform photometer

check

14 Update

Maintenance log

ISE wash solution ISE maintenance has to be

performed once a day. Ensure

that ISE conditioning and

calibration are performed prior to

the start of the next routine.

ISE reagents,

human sample,

calibrators

Perform an ISE prime and

calibration once a day.

Check the incubation bath

temperature displayed on the

SAMPLE TRACKING global

menu screen (Tolerance: 37°C ±

0.2 °C)

Check that the results do not

exceed 16000

in the MAINTE LOG sub menu

(MAINT/UTILITY main menu)

3-17

3-16

3-17

3-18

V 2.1 – Operator's Manual 2 - 5

Page 30

BM/Hitachi 917

2.3 System Start

2.3.1 Introduction

There are two ways to start the routine operation - by pressing the main switch of the

analyzer (POWER ON) on the right side of the front panel, or by waking up the instrument

from the SLEEP mode.

2.3.2 Power On

1. If necessary, turn on the external water supply and open the tap, before starting the

daily routine operation.

2. Switch on the analyzer using the main switch (on the right side of the front panel). The

computer, screen, and the printer are also switched on, if the main switches of these

components are permanently left in the ON position.

2 - 6 V 2.1 – Operator's Manual

Page 31

System Start

2.3.3 Automatic Start Procedure

If the automatic start procedure is selected, the instrument initializes at a set time and

performs the startup maintenance functions. Then it is ready for operation. The SLEEP

mode can be canceled at any time by pressing the displayed EXECUTE button. If the

SLEEP mode is automatically or manually canceled, the LOG ON screen is displayed again.

After the initialization phase, the LOG ON screen is displayed.

Note

If the analyzer is automatically initialized (“waking up” from the SLEEP mode), a photometer check is automatically performed. If the instrument is manually started, a photometer

check has to be requested manually in the MAINTE LOG sub menu (MAINT/UTILITY main

menu).

V 2.1 – Operator's Manual 2 - 7

Page 32

BM/Hitachi 917

2.3.4 Log On/Log Off

Your service person activates the LOG ON function during installation.

❚ Log On

1. Switch on the instrument. If the screen saver is on, just touch the screen to open the

LOG ON screen.

2. When the analyzer is in STANDBY mode, enter your operator ID and password in the

corresponding fields. If the entries are correct, you can now open the individual

software menus.

Note

A supervisor must assign operator IDs and the operator level from the MAINT/UTILITY

main menu, SYSTEMS sub menu, LOG ON window.

If the Log On mode is not activated, the LOG ON screen is not displayed.

2 - 8 V 2.1 – Operator's Manual

Page 33

System Start

❚ Log Off

1. When you have finished your routine work on the analyzer so that you are ready to

log off, touch the START button to display the START CONDITIONS global menu.

2. Touch the LOG OFF button to display the LOG OFF window.

3. Touch YES to log off the analyzer.

4. The system returns to the LOG ON screen so that next operator can log on the

system.

V 2.1 – Operator's Manual 2 - 9

Page 34

BM/Hitachi 917

2.4 Daily Start Up

The automated start up procedures require minimal operator involvement. Do not omit

any of the described procedures from your daily routine. Only touchscreen instructions

for the following procedures are given. Most of the procedures may also be performed

using the keyboard. Keyboard equivalents of the touchscreen navigation methods are

described in the guidance field in the upper right-hand corner of the screen.

Safety Precautions:

While the analyzer is in operation, follow these precautions:

❚ Keep the top cover of the analyzer closed.

❚ Do not place, replace or remove samples while the sample disk is rotating.

❚ Avoid touching the sample probe, reagent probes, stirring paddles, and other moving

parts.

❚ Do not remove or replace the reagent disk covers.

❚ Do not place reagent or sample containers on the cover of the analyzer.

2 - 10 V 2.1 – Operator's Manual

Page 35

Daily Start Up

2.4.1 Checking the Reagents REQUIREMENTS Screen

1. Touch WORKPLACE followed by REQUIREMENTS to display the REQUIREMENTS sub

menu.

2. The screen is divided into two list boxes. The list box on the left displays the

corresponding test.

Different highlight colors in the columns REAG, CALIB and QC are used to indicate the

current status, e.g. which method requires reagent or if a calibration or control failure

occurred.

The list box on the right displays detailed information about the specific highlighted

test in the left list box:

For photometric reagents:

Red highlight indicates that there is no reagent volume or that the reagent bottle is

missing. The bottle is canceled and the barcode cannot be reused.

Yellow highlight indicates that the remaining reagent volume is less than the reagent

level defined for the analyzer. This number is defined on the MAINT/UTILITY, SYSTEM

screen.

Purple highlight indicates that the remaining reagent volume is less than the reagent

level check volume defined for that test. This number is defined in the REAGENT CHECK

window of the REAGENTS main menu and can be different for each reagent. This

number should be entered to reflect your workload needs.

V 2.1 – Operator's Manual 2 - 11

Page 36

BM/Hitachi 917

For ISE reagents:

Red highlight indicates < 10 mL of any ISE reagent remains.

Yellow highlight indicates that < 50 mL of Internal Standard solution or < 30 mL of

either KCl or diluent remain.

For calibrations:

Red highlight indicates that a calibration is required or that a calibration has failed.

For controls:

Red highlight indicates that a QC violation occurred and a random or system alarm

was issued or that the control is not on the analyzer.

3. To print a copy of the list, if desired, touch the PRINT button to open the corresponding

global menu. Touch SYSTEM REQUIREMENTS in the displayed list, then touch the PRINT

button.

4. Put the required reagents into the corresponding reagent disks (see package insert for

preparation details).

2 - 12 V 2.1 – Operator's Manual

Page 37

Daily Start Up

2.4.2 Reconstituting Calibrators and Controls

Quality control products are used to verify calibration as well as the precision and

accuracy of the instrument. Controls should be performed after every calibration, or

should be measured according to the corresponding legal guidelines. Additional control

runs should be established by your laboratory, based upon its needs.

1. Reconstitute all calibrators and control materials according to the instructions provided with each kit of material or according to legal regulations.

2. Print out a calibrator load list.

V 2.1 – Operator's Manual 2 - 13

Page 38

BM/Hitachi 917

3. Touch QC, followed by CONTROLS to display the position list of the controls and

calibrators in sample disk 2.

4. Put calibrators and controls in the indicated positions.

2 - 14 V 2.1 – Operator's Manual

Page 39

Daily Start Up

2.4.3 Air Purge (Photometric System)

The air purge procedure occurs automatically when the instrument is powered ON or after

Wake-Up. If you have not assayed any samples within an eight-hour period and (instrument in Stand-by), perform an air purge to ensure that there is no air in the hydraulic

tubing between the probes (photometric reagent and sample) and their respective pipettors. Air in the syringes or tubings can result in imprecise pipetting. This procedure

replaces the hydraulic line water with freshly degassed, DI water and takes approximately

one minute to complete. This procedure does not purge the ISE system pipettors.

1. Touch MAINT/UTILITY.

2. Touch MAINTENANCE.

3. Touch AIR PURGE.

4. Touch SELECT.

5. Touch EXECUTE.

6. DI water will be flushed through the pipettor. Check the water jet ejecting from the

pipettors. Check for leaks and excess air. Check the syringes for air bubbles.

7. Repeat steps 1-5, if necessary, to remove all air.

V 2.1 – Operator's Manual 2 - 15

Page 40

BM/Hitachi 917

2.4.4 ISE Prime, Conditioning, Calibration

Perform an ISE prime if you have not assayed any samples within an eight-hour period

(instrument in Stand-by) to ensure that there is no air in the hydraulic tubings. Replace

used up reagent bottles by new one. If you are replacing ISE reagents, reset the reagent

volumes by pressing the green ISE reset buttons (to the right of the ISE compartment) or

enter the volume in the REAGENTS main menu. Never fill old reagent into the new bottles,

which may result in bacterial growth.

1 Touch MAINT/UTILITY, followed by MAINTENANCE to open the corresponding sub

menu. Touch ISE PRIME and SELECT to display the corresponding window. Select the

ALL option and touch EXECUTE.

2. Condition the electrodes by performing an ISE measurement of 10 human serum

samples.

2 - 16 V 2.1 – Operator's Manual

Page 41

Daily Start Up

3. Calibrate the ISE unit. Open the STATUS sub menu (CALIBRATION main menu) and

touch the REPEAT CALIB button. Select the ISE item from the displayed list and touch

FULL.

4. Touch the EXECUTE button in the STATUS sub menu to initiate the full ISE calibration. If

the instrument is in Stand-by, touch the EXECUTE button in the START CONDITIONS

global menu.

V 2.1 – Operator's Manual 2 - 17

Page 42

BM/Hitachi 917

2.5 Calibration Test Selection

Your 917 analyzer offers the opportunity to select between the automatic calibration

feature and a manually requested calibration. To ensure proper operation of your 917

analyzer, calibrate each Boehringer Mannheim assay at the recommended interval specified on the APPLICATION sub menu (MAINT/UTILITY main menu).

2.5.1 Automatic Calibration

Calibrations are recommended to be performed when the calibration expires (time out

calibration) or a new bottle or lot is used up. Each Boehringer Mannheim test can be

automatically calibrated. Controls are automatically run for each requested test following

calibration, if requested.

❚ Time Out Calibration

1. Touch CALIBRATION, followed by STATUS to display the STATUS sub menu. Then

touch REPEAT CALIB.

2. The second number is the defined time interval. The remaining time is displayed as

the first number, e.g. the 1 in 1/48. This means that during the next hour an automatic calibration is executed, and the time interval is 48 hours. After the calibration

the time display is updated to 48/48.

2 - 18 V 2.1 – Operator's Manual

Page 43

Calibration Test Selection

3. All tests requiring calibration within a defined time period (e.g. 5 hours) are highlighted. The tests have to be marked before. Then, press the TIME OUT button.

Define the time period of all tests within this time period (yellow highlight). Tests

with the remaining time interval zero are not displayed in yellow. They are automatically calibrated if the START button is pressed. Press EXECUTE to start the calibration. If you want to delete already entered control requests, touch the corresponding calibration type button (BLANK, 2 POINT, FULL or SPAN). The yellow highlight

disappears again.

V 2.1 – Operator's Manual 2 - 19

Page 44

BM/Hitachi 917

❚ Start Up Calibration

Use the START UP CALIB button to display a list from which you can select tests for

start up calibration. A start up calibration performs the calibration for the requested

tests at the beginning of a run and can be initiated in Stand-by only.

1. Touch CALIBRATION, followed by STATUS to display the STATUS sub menu.

2. Touch START UP CALIB.

3. Touch the tests in the list box which are to be calibrated.

4. Touch BLANK, 2 POINT, FULL or SPAN to choose a calibration option.

IF a calibrator load list is desired,

THEN proceed to step 5.

IF no calibrator load list is desired,

THEN proceed to step 8.

5. Touch PRINT to display the PRINT global menu.

2 - 20 V 2.1 – Operator's Manual

Page 45

Calibration Test Selection

6. Touch CALIB LOAD LIST, then touch SELECT.

7. Touch START UP, then touch PRINT to print the calibrator load list.

8. Load calibrators and controls on sample disk 2 according to the printed load list.

9. Touch START, to display the START CONDITIONS global menu. Touch CALIBRATION

START UP

and EXECUTE to request a start up calibration. Press the START button in

the START CONDITIONS global menu to activate the analyzer.

10. Verify that no alarms exist on the calibration and that the QC results are in range.

V 2.1 – Operator's Manual 2 - 21

Page 46

BM/Hitachi 917

❚ Repeat Calibration

Use the REPEAT CALIB button to request tests for a repeat calibration. Any failed

calibrations are automatically put on the repeat list. A repeat calibration can either be

performed in Stand-by or Operate mode.

1. Touch CALIBRATION, followed by STATUS to display the STATUS sub menu.

2. Touch REPEAT CALIB.

3. Touch the tests in the list box for which you want a repeat calibration.

4. Touch BLANK, 2 POINT, FULL or SPAN to choose a calibration option.

IF a calibrator load list is desired,

THEN proceed to step 5.

IF a calibrator load list is not desired,

THEN proceed to step 8.

5. Touch PRINT to display the PRINT global menu.

2 - 22 V 2.1 – Operator's Manual

Page 47

Calibration Test Selection

6. Touch CALIBRATION, followed by CALIB LOAD LIST, then touch SELECT.

7. Touch RE CALIB, then touch PRINT to print out the calibrator load list.

8. Load calibrators and controls on sample disk 2 according to the printed list of the

required Standards.

9. If the analyzer is in operation, touch EXECUTE, followed by YES to start the repeat

calibration.

If the analyzer is in Stand-by mode, touch EXECUTE, followed by YES and the START

button in the START CONDITIONS global menu to start the analyzer.

10. Verify that no alarms exist on the calibration and that the QC results are in range.

V 2.1 – Operator's Manual 2 - 23

Page 48

BM/Hitachi 917

2.5.2 Manual Control Test Selection (from Sample Disk 2)

Independent from calibrator or control intervals, controls can be requested and measured

manually on sample disk 2 during operation.

1. Touch WORKPLACE, followed by TEST SELECTION. Touch the CONTROL button.

2. Touch the S. DISK 2 button only if the barcode reader is activated. Then open the

CONTROL/LOT assist box.

3. Select the desired control from the list and press ENTER. The available tests for this

control appear in the TEST KEY matrix field.

4. Select the desired test and press ENTER.

5. Touch the EXECUTE button to integrate the control test request in the processing run. If

the analyzer is in Stand-by mode, the analyzer has to be started first.

6. The results are transferred to the INDIVIDUAL QC list. An automatic data evaluation in

the REAL TIME QC is only possible, if the specifically defined controls are requested

together.

Note

If the EXECUTE button is pressed several times, the control is nevertheless measured only

once.

2 - 24 V 2.1 – Operator's Manual

Page 49

Initiate Run with Routine Patient Test Selections

2.6 Initiate Run with Routine Patient Test Selections

Routine patient test selections can be made when the instrument is in Stand-by, Stop,

Operate or Sample Stop mode. It is also possible to enter patient test selections manually

with or without barcode reader in use.

Patient test selections can either be entered manually or downloaded from a host

computer with or without barcode reader in use.

Use this procedure to enter test selections manually for barcoded samples that are not

downloaded from the host and for non-barcoded samples. The procedure varies slightly

depending on whether:

❚ sample barcode reader is on or off

❚ host communication is on or off

2.6.1 Routine Patient Test Selection

1. Touch WORKPLACE, followed by TEST SELECTION to display the TEST SELECTION sub

menu.

2. Touch ROUTINE to enter routine patient test selections.

V 2.1 – Operator's Manual 2 - 25

Page 50

BM/Hitachi 917

3. For non-barcode mode:

The SAMPLE NO. field is highlighted. Enter the first sample number, then press ENTER.

Enter the sample disk number in the second field, followed by ENTER. Then proceed

with entering the sample disk position number and confirm with ENTER. The cursor

advances to the PATIENT ID text box. Type the PATIENT ID number, if required, then

press ENTER.

For barcode mode:

The PATIENT ID field is highlighted. Enter the barcode number of the sample, then

press ENTER.

4. To change the default setting for the sample type, move the cursor to the SAMPLE

assist box. Open the box and touch the desired sample type. The assist box

TYPE

closes and the selected sample type is displayed.

5. To change the default setting for the sample cup, move the cursor to the SAMPLE CUP

assist box. Open the box and touch the desired sample cup. The assist box closes

and the selected sample cup is displayed.

6. To change the default setting for the sample volume, touch STANDARD, DEC or INC to

choose standard sample volume, decreased sample volume or increased sample

volume respectively.

7. Touch the DEMOGRAPHIC button to display the DEMOGRAPHICS window. Enter all

desired demographic information about the sample. Then, touch the ENTER button.

2 - 26 V 2.1 – Operator's Manual

Page 51

Initiate Run with Routine Patient Test Selections

8. Touch the desired test keys or profile keys on the test key matrix at the lower portion

of the screen. Selecting a test individually or by profile key, results in the test key(s) on

the screen turning white in color. When all desired tests for the sample have been

selected, touch the ENTER button. The test selections are stored and the white color

disappears.

❚ If a yellow dot appears on the test key matrix for a specific test, this indicates that

the test was masked by the operator in the START CONDITIONS global menu.

Masked tests are not be run.

❚ If a red line appears on the test key matrix for a specific test, this indicates that the

test is masked by the analyzer. Masked tests are not be run. Check the REAGENTS

main menu to resolve the situation that caused the test to be automatically

masked.

9. The repeat function can be used only if the sample barcode reader is OFF. The repeat

function is used for batch programming. It is available only after test selections are

made for the first sample in the batch. Touch the REPEAT button to display the REPEAT

window. Type the number of the last sample you want to be processed with the

repeated test selections. Touch the ENTER button. (The sample number increments

automatically.)

V 2.1 – Operator's Manual 2 - 27

Page 52

BM/Hitachi 917

10. If you want to print out a load list of the test selections, touch the PRINT button to open

the corresponding global menu. Touch WORKPLACE, followed by REQUISITION LIST.

Then touch the SELECT button to display the REQUISITION LIST window. Enter the first

and last sample number and then touch the PRINT button.

2 - 28 V 2.1 – Operator's Manual

Page 53

Initiate Run with Routine Patient Test Selections

2.6.2 Initiate Run Procedure

After the patient test selections have been made, touch the START button to display the

START CONDITIONS global menu and to define the settings for the subsequent run.

1. Touch the START button to open the START CONDITIONS global menu. Depending on

barcode mode and host mode, entries vary as follows:

Sample

barcode reader

no no À

yes yes Á

yes no

no yes Â

Host

communication

START SAMPLE

see

➀ If the analyzer is being operated without sample barcode reader and there is no

host connection, then only 1 field is displayed. The sequence number that is used

for the run start must be entered here.

➁ If the sample barcode reader is switched on, 3 fields appear, independent of

whether there is a host connection present or not. The sequence number, disk

number and disk position number that are used for the run start must be entered

here.

V 2.1 – Operator's Manual 2 - 29

Page 54

BM/Hitachi 917

➂ If the analyzer is being operated without sample barcode reader but with host, then

5 fields appear. Sequence number, disk number, disk position number of the start

sample, the last disk and last disk position number must be entered here.

2. You may request a start up calibration. Touch the START UP EXECUTE button to

perform a start up calibration. A control measurement of all installed and active tests

is automatically performed after the start up calibration.

3. ISE maintenance should not be performed during daily routine. Touch the NO button. If

YES is pressed, the analyzer performs after each run an automatic ISE maintenance

with ISE wash solution on disk 2. Conditioning and ISE calibration is necessary after

each ISE maintenance.

4. Check the following mode settings to ensure parameters are set correctly for the run

you are starting. Open the RERUN MODE window by touching the corresponding

button in the START CONDITIONS global menu.

To change the routine rerun setting there are two options available in the opened

window. If the AUTOMATIC option is selected, all tests with faulty results (outside the

limits) are automatically rerun. Two modes are available:

REAL TIME: If this button is activated, this sample will be measured again during the

current run.

AFTER 1ST: If this button is activated, the rerun will be carried out at the end of the run.

2 - 30 V 2.1 – Operator's Manual

Page 55

Initiate Run with Routine Patient Test Selections

If the RERUN ONLY option is activated, samples that were scheduled for the rerun can

be measured again. The system marks results in the DATA REVIEW sub menu (WORK-

PLACE

main menu) that are outside the limits defined for the applications. These

samples are scheduled for a rerun.

If the STAT RERUN option is activated, a rerun of STAT samples will be performed

automatically under certain conditions.

If the results of a STAT sample are outside the limits, the system will automatically

measure that sample again. If the NO button is activated, the STAT sample will not be

rerun.

5. To change the REAL TIME DATA PRINT and REAL TIME CALIB PRINT setting, touch the

PRINT/HOST button in the START CONDITIONS global menu. Touch the print options

you prefer. If the button MONITOR is activated, the results will be printed out in the

monitor format. if REPORT is selected, the results will be printed out in the more

extensive report format. If NO PRINT is activated, the results will not be printed out, but

can be checked in the DATA REVIEW sub menu (WORKPLACE main menu) and printed

out via the PRINT global menu.

To activate the HOST COMMUNICATION setting, touch the PRINT/HOST button. Touch

ON-LINE or OFF-LINE to set the desired host communication mode. Then, touch the

CLOSE button.

V 2.1 – Operator's Manual 2 - 31

Page 56

BM/Hitachi 917

6. To change any test masking, touch the MASKING button to open the corresponding

window. A list of all tests appears in the list box. A masked test has an asterisk (*)

following the test name. To mask a test, touch the test name in the list box and then

the MASKED button. An asterisk (*) appears following the test name.

To unmask a test, touch first the test name in the list box and then the MASKED button.

The asterisk following the test name disappears.

Touch the ENTER button to save any changes to test masking.

7. Touch the CLOSE button to close the window. Touching CLOSE does not change any

modifications you previously made to the START CONDITIONS global menu.

2 - 32 V 2.1 – Operator's Manual

Page 57

Initiate Run with Routine Patient Test Selections

Before you start the analysis:

8. Results of up to 10,000 samples are stored on the hard disk for later retrieval. You

must ensure that each sequence number is used only once before archiving data and

then clearing the data from the hard disk. The data with the same sequence number

will be overwritten. If the sequence number reaches 10,000, the following sequence

number (i.e. 1) will be overwritten.

9. Before you start the analysis, check the ALARM global menu for the presence of any

alarms (as indicated by the ALARM button turning red). Review the alarm(s) and correct

the condition(s) before continuing.

10. Place all patient samples, controls, and calibrators in their appropriate positions on

the sample disks 1 and 2. Place a sample cup with a recommended wash solution in

the ”W” positions on sample disk 2.

11. Touch the START button when you are ready to initiate the run.

V 2.1 – Operator's Manual 2 - 33

Page 58

BM/Hitachi 917

2.6.3 Entering Non-Barcoded or Unreadable Barcoded Samples (in the Barcode Mode)

1. Touch WORKPLACE, followed by TEST SELECTION. Touch ROUTINE to enter routine

patient test selections. The cursor will highlight the PATIENT ID text box.

2. To change the default setting for the sample type (e.g. serum/plasma, urine), touch the

SAMPLE TYPE assist key. Touch the desired sample type in the displayed list. The

assist box closes and the selected sample type is displayed.

3. To change the default setting for the sample cup, touch the SAMPLE CUP assist key.

Touch the desired sample cup in the displayed list. The assist box closes and the

selected sample cup is displayed.

4. To change the default setting for the sample volume, touch the desired SAMPLE VOL

button, STANDARD, DEC or INC, to choose standard sample volume, decreased

sample volume or increased sample volume respectively.

5. Enter the patient ID in the PATIENT ID text box and press ENTER. Touch the DEMO-

GRAPHIC

button to display the DEMOGRAPHICS window. Enter all desired demograph-

ic information about the sample. Touch the ENTER button. If there are no requests

from the host, touch the desired test key or profile key on the keyboard matrix.

Selecting a test individually or by profile key results in the test key or keys on the

screen turning white in color. When all desired tests for the sample have been

selected, press ENTER.

2 - 34 V 2.1 – Operator's Manual

Page 59

Initiate Run with Routine Patient Test Selections

6. Touch the NON-ID ASSIGNMENT button to display the NON-ID ASSIGNMENT window.

The NON-ID ASSIGNMENT function can be used if a barcode is damaged and cannot

be read by the barcode reader. Enter a vacant, not registered, disk position number in

the POSITION text box and press ENTER. Enter the patient ID number. Touch the

REGIST button, and then the CLOSE button. The POS and patient ID number is

displayed in the list box on the left side.

V 2.1 – Operator's Manual 2 - 35

Page 60

BM/Hitachi 917

2.7 Sample Tracking

Use the SAMPLE TRACKING global menu to monitor the progress of samples through

sample processing. Information about any sample currently being processed is displayed

inside the sample disk ring on the screen. Samples can be searched by ID or by name.

The sample ring has individual circles that represent each sample disk position.

These positions are highlighted as follows:

indicates a completed sample

indicates a sample that is in process

indicates an open position

indicates that the sample needs further attention from the operator and that the

sample has to be measured again (rerun).

1. Touch SAMPLE TRACK, to display the SAMPLE TRACKING global menu.

2. The sample position and test currently being processed is automatically displayed in

the text fields inside the graphic display of the sample disk.

3. To find a sample of the current run on the disk, you can use the SEARCH function, as

indicated in the upper left corner of the screen. Touch ROUTINE or STAT and enter the

PATIENT ID number or the SAMPLE number that you want to find. If the sample is

found, it is marked with a "▼". A comment is also displayed for this particular sample.

4. In the RERUN list all reruns of the current run are displayed. Touch DISPLAY to display:

the position, sample type, sample number and ID of the rerun. The rerun list selection

lists contains all samples highlighted in red.

2 - 36 V 2.1 – Operator's Manual

Page 61

Measurement of Additional Routine Samples

2.8 Measurement of Additional Routine Samples

Additional routine samples may be requested at any time. Follow the procedure for

programming routine samples. If the analyzer is not in operation, for example in Sampling

Stop or Stand-by mode, you must touch START in the START CONDITIONS global menu to

begin the run.

V 2.1 – Operator's Manual 2 - 37

Page 62

BM/Hitachi 917

2.9 STAT Test Selections

STAT patient test selections can be made at any time, independent of the instrument

mode. In the barcode mode STAT samples can be put in every position on the sample

disk. In the non-barcode mode STAT samples can only be placed in the reserved

positions. STAT samples are pipetted with the highest priority and are processed during

the pipetting of routine samples.

1. Touch WORKPLACE, followed by TEST SELECTION. Touch STAT to enter STAT patient

test selections.

2. The cursor highlights the POSITION text box, if the barcode reader is off.

The cursor highlights the POSITION test box, if the barcode reader is on. Enter the

position number and/or the patient ID number.

2 - 38 V 2.1 – Operator's Manual

Page 63

STAT Test Selection

3. To change the default setting for the sample type (e.g. to urine or CSF), touch the

SAMPLE TYPE assist box. Touch the desired sample type in the displayed list. The

assist box closes and the selected sample type is displayed.

4. To change the default setting for the sample cup, touch the SAMPLE CUP assist box.

Touch the desired sample cup in the displayed list. The assist box closes and the

selected sample cup is displayed.

5. To change the default setting for the sample volume, touch STANDARD, DEC or INC to

choose standard sample volume, decreased sample volume or increased sample

volume respectively.

6. Touch the DEMOGRAPHIC button to display the DEMOGRAPHIC window. Enter all

desired demographic information about the sample. Touch the ENTER button. Request the desired tests or profiles by pressing the corresponding test keys and

confirming with ENTER.

7. If there are no requests from the host, touch the desired test key or profile key on the

keyboard matrix. Selecting a test individually or by profile key results in the test key or

keys on the screen turning white in color. When all desired tests for the sample are

selected, press ENTER.

If a yellow dot appears on the test key matrix for a specific test, this indicates that the

test is masked by the operator from the START CONDITIONS global menu.

If a red bar appears on the test key matrix for a specific test, this indicates that the test

is masked by the analyzer. Masked tests may be requested, but are however not

processed.

V 2.1 – Operator's Manual 2 - 39

Page 64

BM/Hitachi 917

❚ Change Routine Sample to STAT Sample (in barcode mode only)

You may change a sample that has been programmed as a routine sample to a STAT

sample. This enables the sample to be processed as a STAT, i.e. before any remaining

routine samples.

1. Touch WORKPLACE, followed by TEST SELECTION and ROUTINE.

2. Type the PATIENT ID number and press ENTER.

3. Touch the CHANGE TO STAT button to display the CHANGE TO STAT window.

4. Enter the sample position number, corresponding to the sample’s position on the

sample disk, then press ENTER.

5. The sample located in this position will be processed as a STAT sample.

2 - 40 V 2.1 – Operator's Manual

Page 65

Processing of Rerun Samples

2.10 Processing of Rerun Samples

You may process rerun samples in two different ways, as automatic reruns or as manual

reruns, requested by the operator.

All tests for a sample with results that do not meet the defined criteria are placed on a

rerun list independent of the run mode.

In the START CONDITIONS global menu, two different modes are selectable - REAL TIME

and AFTER 1ST.

❚ REAL TIME: The sample is rerun without delay during the current run.

❚ AFTER 1ST: The rerun is performed at the end of the current analytical run.

The RERUN ONLY option can be used to request manually rerun samples. The instrument

highlights in the DATA REVIEW sub menu (WORKPLACE main menu) all result that are

outside the limits that are specified in the applications. These samples can be defined for

a rerun.

V 2.1 – Operator's Manual 2 - 41

Page 66

BM/Hitachi 917

2.10.1 Automatic Rerun

1. Touch the START button to display the START CONDITIONS global menu.

2. Touch the RERUN button to display the RERUN MODE window.

3. Touch AUTOMATIC to request that reruns be processed without operator intervention.

4. Touch REAL TIME if you want rerun samples to be processed during the current routine

run. Touch AFTER 1ST if you want reruns processed at the end of the current run.

5. Touch the ENTER button to save the rerun settings.

2 - 42 V 2.1 – Operator's Manual

Page 67

Processing of Rerun Samples

2.10.2 Manual Rerun

1. Touch the START button to display the START CONDITIONS global menu.

2. Touch the RERUN button to display the RERUN MODE window.

3. Touch NO in the ROUTINE RUN area to request that reruns are not processed during or

after routine runs.

4. Touch the ENTER button to save the rerun settings.

5. After the analytical run is finished: Touch WORKPLACE and DATA REVIEW to display the

DATA REVIEW sub menu.

Sample barcode reader on Sample barcode reader off

Samples that have incomplete results are marked with an I (left column on the lefthand side). Touch a sample you wish to review and the individual test results are

displayed in the list on the right. Rerun tests are marked with a symbol The symbol

indicates the sample volume for rerun (■: normal, ▲: increased, ▼: decreased). If you

want an other than the recommended volume, touch the respective buttons: Touch

the NORMAL button to select tests for rerun with normal sample volumes. Touch the

INCREASE button to select tests for rerun with in-creased sample volumes. Touch the

DECREASE button to select test for rerun with decreased sample volumes. For each

sample, additional test requests can be made in Stand-by mode. Touch the bars “- -

-” at the end of the test result list and select the desired VOLUME. A window is

displayed in which you can select a test for an additional rerun. Then, touch SELECT.

V 2.1 – Operator's Manual 2 - 43

Page 68

BM/Hitachi 917

6. Repeat step 5 for any other samples that have to be rerun.

7. Touch the START button to display the START CONDITIONS global menu.

8. Touch the RERUN button to display the RERUN MODE window.

9. Touch RERUN ONLY to request rerun processing, then touch ENTER.

10. Enter the start sample number for the rerun in the START CONDITIONS global menu.

11. Press the START button.

2 - 44 V 2.1 – Operator's Manual

Page 69

Adding Reagent During a Run

2.11 Adding Reagent During a Run

Use the REQUIREMENTS sub menu (WORKPLACE main menu) to check the levels of

reagents.

If reagent levels are highlighted in yellow (REAG column) for any reagent, you may need to

add reagent during the run. A reagent is highlighted in yellow when the defined number of

remaining tests in the bottle reaches or falls below the limit that is set in the MAINT/UTILITY,

SYSTEM, ALARM SETTING, REAGENT CHECK LEVEL screen.

If reagents must be added during a running analysis, perform the following steps:

V 2.1 – Operator's Manual 2 - 45

Page 70

BM/Hitachi 917

1. Touch REAGENTS, followed by INTERRUPT to display the REAGENT INTERRUPT window in which the time remaining for the reload interrupt is specified. Then touch

EXECUTE.

Press EXECUTE after adding reagent. The time remaining before you can add reagent

counts down on the screen. After reaching zero, a message (“Place reagent replace

reagent tray lid. Then press EXECUTE for reagent registration”) is displayed in the

window.

Place the reagent bottles into their assigned positions and touch the EXECUTE button.

2. The system automatically performs a reagent registration and resumes the current

run.

2 - 46 V 2.1 – Operator's Manual

Page 71

Patient Report

2.12 Patient Reports

There are two patient result printout formats: MONITOR and REPORT.

❚ The MONITOR format is a shorter report format giving each test result. In the MONITOR

format date and time, sample type, sequence number, ID number and comment 1 is

printed out for each sample. The results are printed out next to each other with data

flags.

❚ The REPORT format additionally gives the header, patient demographic information,

results, units and expected values. Choose your format on the START CONDITIONS

global menu, PRINT/HOST window.

You can request patient report print-outs automatically or manually. The report format

can be customized to fit your laboratory needs (MAINT/UTILITY main menu, REPORT

FORMAT

2.12.1 Selecting the Patient Report Format for Real Time Printing

1. Touch START followed by PRINT/HOST to display the PRINT/HOST window.

2. From the REAL TIME DATA PRINT selections, touch MONITOR to select the monitor

3. Touch CLOSE to save the print settings.

4. The patient reports will print in real time, when all results for the patient sample are

sub menu).

format. Touch REPORT to select the report format. Touch NO PRINT to get no real time

print.

available.

V 2.1 – Operator's Manual 2 - 47

Page 72

BM/Hitachi 917

2.12.2 Printing Patient Reports in Batch

1. Touch START followed by PRINT/HOST to display the PRINT/HOST window.

2. From the REAL TIME DATA PRINT selections, touch NO PRINT to select no real time

report printing.

3. Touch CLOSE to save the print settings.

4. To print results at a later time, touch WORKPLACE, DATA REVIEW to display the DATA

REVIEW

sub menu.

5. Mark the data with the marking key M or R on the scrollbar. The scroll bars on the right

side of each box have an R at the top and an M at the bottom. When R is highlighted,

a consecutive range of samples may be selected by touching the first and last sample

in the desired range. When M is highlighted, multiple, non-consecutive samples may

be selected. If neither is highlighted, only one sample at a time may be selected.

6. Touch the PRINT button to display the PRINT global menu.

7. Select MEASUREMENT DATA from the list box and touch SELECT. Touch MONITOR or

REPORT to choose the report format.

8. Touch ALL or EDITED to print all results or only results that have been edited.

9. Touch PRINT to print out the patient reports.

2 - 48 V 2.1 – Operator's Manual

Page 73

Data Management

2.13 Data Management

The way results are documented, depends on the mode settings selected from the START

CONDITIONS

Data is saved on the hard drive but can also be saved on a floppy disk.

You may edit and delete data as necessary. Edited data can be printed out as a patient

report or be transmitted to the host.

2.13.1 Reviewing Data

Use the DATA REVIEW sub menu and the steps below to review patient data:

global menu, PRINT/HOST window.

1. Touch WORKPLACE, followed by DATA REVIEW to display the DATA REVIEW sub menu.

2. Touch SEARCH to display the SEARCH CRITERIA window. Select the desired search

criteria and touch the ENTER button.

3. All samples meeting the selected search criteria are displayed in the left box. If control

is selected as the search criterion, all other search criteria have to be deactivated.

V 2.1 – Operator's Manual 2 - 49

Page 74

BM/Hitachi 917

2.13.2 Editing Data

❚ Overwrite First Result with Rerun Result

1. Touch the sample that needs to be edited in the left box. Details of the test

information appear in the right box, including first run results and rerun results.

2. Touch the page key -1- to access the second window level and then the EDIT

button to display the EDIT DATA window.

3. Touch the REPLACE button if you only need to replace first run results with rerun

results. The replace function automatically overwrites all tests of this sample with

the rerun result.

4. Touch the CLOSE button to close the window and save the edits.

5. Repeat steps 1-4 for all samples where the first result has to be overwritten by the

rerun result.

2 - 50 V 2.1 – Operator's Manual

Page 75

Data Management

❚ Overwrite Results

1. Touch the sample that needs to be edited in the left box. Details of the test

information appear in the right box, including first run results and rerun results.

2. Touch the page key -1- to access the second window level and then the EDIT

button to display the EDIT DATA window.

3. Touch the test name in the list box if you need to edit manually the result. The first

run result and rerun result appear in the EDIT DATA text boxes. Enter the new

results.

4. Touch the CLOSE button to close the window and save the edits.

5. Repeat steps 1-4 for all samples where the first result has to be overwritten by the

rerun result.

V 2.1 – Operator's Manual 2 - 51

Page 76

BM/Hitachi 917

❚ Sending Edited Data to the Host

1. Mark the data on the DATA REVIEW sub menu with the marking keys R or M. The

scroll bars on the right side of the sample list box have an R at the top and an M at

the bottom. When R is highlighted, a consecutive range of samples may be

transmitted by touching the first and last sample in the desired range. When M is

highlighted, multiple, non-consecutive samples may be transmitted. If neither is

highlighted, only one sample at a time may be transmitted.

2. Touch the SEND TO HOST button to display the SEND TO HOST window.

3 Touch ALL or EDITED to select which data is sent to the host. Touch EDITED to send

only edited data to the host.

4. Touch RESULT to send the results to the host. Touching ABS. sends the absorbance readings.

5. Touch ENTER to begin the data transmission to the host.

6. Touch QUIT to stop host transmission.

2 - 52 V 2.1 – Operator's Manual

Page 77

Data Management

❚ Printing Edited Data

1. Touch WORKPLACE, followed by DATA REVIEW to display the DATA REVIEW sub

menu.

2. Mark the data in the DATA REVIEW sub menu with the marking keys M or R. The

scroll bars on the right side of the sample list box have an R at the top and an M at

the bottom. When R is highlighted, a consecutive range of samples may be printed

by touching the first and last sample in the desired range. When M is highlighted,

multiple, non-consecutive samples may be printed. If neither is highlighted, only

one sample at a time may be printed.

3. Touch the PRINT button to display the PRINT global menu.

4. Touch WORKPLACE and select the MEASUREMENT DATA report from the list box.

Touch SELECT to display the MEASUREMENT DATA window.

V 2.1 – Operator's Manual 2 - 53

Page 78

BM/Hitachi 917

5. Touch MONITOR or REPORT to choose the report format.

6. Touch ALL or EDITED to print all results or only results that have been edited.

7. Touch PRINT to print out the patient reports.

2 - 54 V 2.1 – Operator's Manual

Page 79

Data Management

2.13.3 Deleting Functions

❚ Deleting Samples

1. Touch WORKPLACE, then DATA REVIEW to display the DATA REVIEW sub menu.

With the left list box selected:

2. Select the sample(s) to be deleted. You can delete a single sample, a range or all

samples. The scroll bars on the right side of the sample list box have an R at the

top and an M at the bottom. When R is highlighted, a consecutive range of samples

may be deleted by touching the first and last sample in the desired range. When M

is highlighted, multiple, non-consecutive samples may be deleted. If neither is

highlighted, only one sample at a time may be deleted.

If you want to delete samples with all corresponding data:

3. Touch the page key -1 - to access the second window level and then DELETE to

open the corresponding window.

4. Touch YES to delete the highlighted samples. Note that the test selection is deleted

together with the results.

V 2.1 – Operator's Manual 2 - 55

Page 80

BM/Hitachi 917

❚ Deleting Single Tests

1. Touch WORKPLACE and DATA REVIEW to display the DATA REVIEW sub menu.

2. Select the test(s) to be deleted in the left list box. You can delete a single test, a

range of tests or all tests.

3. The scroll bars on the right side of the test list box have an R at the top and an M at

the bottom. When R is highlighted, a consecutive range of tests for the selected

sample may be deleted by touching the first and last test in the desired range.

When M is highlighted, multiple, non-consecutive tests for the selected sample

may be deleted. If neither is highlighted, the whole sample is deleted.

4. Touch DELETE to open the DELETE RECORD window.

5. Touch YES to delete the selected test. Note that only the single test result but not

the test selection is deleted.

2 - 56 V 2.1 – Operator's Manual

Page 81

Data Management

❚ Deleting Sample Types (Batch Delete)

To delete all samples of a sample type:

1. Touch WORKPLACE, DATA REVIEW to display the DATA REVIEW sub menu. Touch

the BATCH DELETE button to display the BATCH DELETE window.

2. Touch STAT to delete all STAT sample data.

Touch ROUTINE to delete all routine sample data.

Touch CONTROL to delete all control sample data.

Touch ALL to delete all data.

3. Touch ENTER, followed by YES to delete the selected data.

4 Touch CANCEL to cancel the deletion of the selected data.

Note

This procedure deletes also the test selections.

V 2.1 – Operator's Manual 2 - 57

Page 82

BM/Hitachi 917

2.14 Quality Control Procedures

During routine operation, the instrument compares paired (X) and (Y) control values

against the mean and standard deviation entered for each control in the REAL TIME QC

window (INDIVIDUAL QC sub menu). The REAL TIME QC screen evaluates quality control

results by a multi-rule Shewhart method. The rules are selected by the operator.

Each set of control results is either acceptable or causes a random, system, or QC error.

If a random, systematic, or QC alarm occurs, an alarm message appears on the ALARM

global menu.

In addition, an audible alarm occurs when an error of this type is detected. Consult the

above screens during a test run to ensure that patient results are properly controlled.

2 - 58 V 2.1 – Operator's Manual

Page 83

Quality Control Procedures

2.14.1 Selecting Controls for Real Time QC

1. Touch QC, followed by INDIVIDUAL and REAL TIME QC to display the REAL TIME QC

window. Daily QC results can be reviewed and checked in this window.

2. Touch the TEST assist box to display the list of tests. Touch the name of the test you

want to review and press ENTER.

3. Touch the SELECT button to display the SELECT CONTROL window to choose the

controls you wish to review.

4. Touch the control in the list, followed by AXIS X to assign a control to the X-axis.

5. Touch the control in the list, followed by AXIS Y to assign a control to the Y-axis. Touch

ENTER to display the graph.

6. Touch RULES if you wish to change the rules by which the QC data are evaluated. The

SELECT RULES window is displayed. Touch the rules you want used in the evaluation,