Page 1

SERVICE MANUAL

FOR

MODEL 902 AUTOMATIC

ANALYZER

Copyright Hitachi, Ltd. 1997. All rights reserved. Printed in Japan. Part No. 713-9039 KN-K (H-LT)

Page 2

MODEL 902 AUTOMATIC ANALYZER

CONTENTS

1. PRODUCT SPECIFICATIONS................................................................................. 1-1

2. TROUBLESHOOTING ............................................................................................. 2-1

3. FLOW PATH DIAGRAMS ........................................................................................ 3-1

4. BLOCK DIAGRAMS................................................................................................. 4-1

5. ISE ........................................................................................................................... 5-1

6. SWITCH SETTING................................................................................................... 6-1

7. EXPLANATION OF FUNCTION............................................................................... 7-1

8. MOTORS, DETECTORS AND FUSES .................................................................... 8-1

9. ANALYTICAL METHODS......................................................................................... 9-1

10. CIRCUIT DIAGRAMS............................................................................................... 10-1

11. CROSS WIRING REFERENCE ............................................................................... 11-1

12. INSTALLATION........................................................................................................ 12-1

13. MAINTENANCE AND INSPECTION ........................................................................ 13-1

14. ADJUSTMENT SPECIFICATIONS........................................................................... 14-1

15. OEM......................................................................................................................... 15-1

16. SYSTEM INTERFACE.............................................................................................. 16-1

- i -

Page 3

1.PRODUCT SPECIFICATIONS

1.1 Overall System.........................................................................................................1-1

1.2 Sampling System.....................................................................................................1-2

1.3 Reagent System.......................................................................................................1-3

1.4 Reaction System......................................................................................................1-4

1.5 Photometic System..................................................................................................1-5

1.6 ISE (option)..............................................................................................................1-5

1.7 Installation Conditions..............................................................................................1-6

1.8 User Interface...........................................................................................................1-6

1.9 Dionized Water........................................................................................................1-6

1.10 Analytical Methods...................................................................................................1-7

1.11 Accuracy Methods....................................................................................................1-7

1.12 Data Storage............................................................................................................1-7

1.13 System Interface......................................................................................................1-8

1.14Options for Analyzer.................................................................................................1-8

1 - 0

Page 4

1.PRODUCT SPECIFICATIONS

1.1 Overall System

Configuration : Console type automatic analyzer, with analytical and operation units

integrated

Principle : Discrete type, random access, single-line multi-analysis system;

entire reaction monitoring system

Analytical methods : Colorimetry (absorbance measurement), ion selective electrode

method (ISE; option)

Throughput : Colorimetry ; 200 tests/hr (Photometry only max. 300 tests/hr

inclusive of ISE)

No. of analysis items: Colorimetry ; 36

ISE ; 3 (Na, K, Cl)

Serum indexes ; 3

Calculation items; 8

Reaction time : 10 minutes max.; 3, 4, 5, 10 minutes for concentration calculation

(same as Model 7070/7170)

Measurable samples : Serum (or blood plasma) and urine; one sample kind per channel

Application : Emergency (stat) and routine analyses

Test item selection : Via entry from operation panel, entry from system interface, entry

from no. of items settable (11 kinds)

1 - 1

Page 5

1.2 Sampling System

Sample container : Hitachi standard sample cup

Sample tube ;diameter 13 to 17 mm

length 75 to 100 mm

Sample disk : 60 positions

Outer row;35 positions (routine and stat samples)

(with free adapter, barcode reader attachable)

Inner row;25 positions (standard + control samples (22),

rinse solutions (3))

Detergents : 3 kinds

(W1;for sample probe rinsing) HITERGENT

(W2;for sample carryover evasion) ISE RINSE SOLUTION

(W3;for sample carryover evasion) HICARRYNON

Sampling mechanism : Pipetter driven by stepping motor

2 to 50 µL of sample/test (in 0.1 µL steps)

Pipetting mode : Normal ; prescribed volume discharged at cell

bottom

Aqueous sample; system water solution for sample probe

internal rinsing usable as STD-1

Sample pre-dilution not performed

Insufficient sample detection: Resistance detection method

Sample ID : Barcode reader (option)

Following code shemes are usable in combination; CODE 39,

CODE 128, INTERLEAVED 2 OF 5, NW7 (Modulas 10,

Modulas 16)

Automatic rerun : Auto rerun function not provided

Stat sample analysis : Routine sample analysis interruptible for stat sample analysis

Sample carryover : Sample carryover evasion function available; 2 kinds of

detergents settable on sample disk inner row

Sample conveyance : Can be sampled directly from belt-line

1 - 2

Page 6

1.3 Reagent System

Reagent disk : One disk, 40 positions

(20 positions each on inner and outer rows)

Reagent cooling : Cooling water circulating system (3 to 15°C) (option for China-

destined instrument)

Reagent bottle : 50 mL, 20 mL (adapter necessary)

(without barcode, concentrated reagent unusable)

Detergents : HITERGENT (50 mL); position 40 (fixed)

(for addition to reaction bath)

Detergent 1; for reagent probe, stirring rod rinsing, reagent

probe carryover evasion, reaction cell carryover

evasion

Detergent 2; for reagent probe carryover evasion, reaction cell

carryover evasion

(settable on reagent disk inner row)

ISE reagent : Internal standard solution(position 37 (fixed))

Diluent (position 38 (fixed))

Pipetting mechanism : Pipetter driven by stepping motor; 20 to 350 µL/test (in 1 µL

steps)

Reagent addition timing: 3 steps (0, 1.5 and 5 minutes); throughput is maintained even

when adding 3 reagents.

Carryover evasion : Rinsing for carryover evasion possible; throughput may decrease

by specifying carryover evasion.

1 - 3

Page 7

1.4 Reaction System

Reaction disk : Turntable type disk (10-minute reaction per rotation)

Reaction cell : Optical path length 6 mm (area 6 × 5 mm)

No. of reaction cells : 48

Reaction cell control : One rotation + one pitch feed (18 seconds)

Sample pipetting position: One position (fixed)

Reagent pipetting position: One position (fixed)

Reaction temperature : 37 ± 0.1°C (warm water circulating system)

Stirring : By means of stirring rod rotation

Timing for stirring; after each addition of R1,R2,R3

Stirring possible for a minimum volume of 100 µL

Stirring position : One position (fixed)

Reacting solution volume: Minimum; 250 µL (minimum required volume for photometry)

Maximum; 500 µL (temperature control, rinsing upper limit)

Photometric position : One position (fixed)

Cell rinsing : After completion of photometry (rinsing 3 times; rinsing with

detergent not performed)

Carryover evasion : Rinsing for carryover evasion possible; throughput may decrease

by specifying cell carryover evasion

1 -4

Page 8

1.5 Photometric System

Photometer : Multiwavelength photometer (absorptiometry)

Wavelengths : 12 wavelengths

(340, 376, 415, 450, 480, 505, 546, 570, 600, 660, 700, 800 nm)

Monochromator : Grating

Detector : Photodiode

Linearity : Up to 2.5 Abs (10 mm cell conversion)

Photometric method: Direct photometry of reaction cell (at one or two wavelengths)

Correction : Cell blank correction prior to analysis

(passed cell blank measurement alone)

1.6 ISE (option)

Electrodes : Flow cell type, liquid-membrane ISE cartridge

Reference electrode flow path: 1 MKCL, liquid flow path

Measuring temperature : 36°C ± 2°C (warm water circulating system)

System : Indirect (dilution) potentiometry, 50-times dilution

Measuring cycle : 36 sec/sample (18 sec for sample, 18 sec for internal

standard solution)

Measured items : Na, K, Cl

Measurable samples : Serum and urine

Linearity : Na;10 to 250 mmol/L

K ;1 to 100 mmol/L

Cl;10 to 250 mmol/L

Reagent bottle : Internal standard solution ; 50 mL max.

Diluent ; 50 mL max.

Reference electrode solution; 500 mL max.

1 - 5

Page 9

1.7 Installation Conditions

Power requirement : 230 V, 50/60 Hz, less than 1.5 kVA

Deionized water consumption: Less than 15 L/hr

Waste liquid drain : 2 systems (for concentrated and diluted liquids)

Ambient temperature/humidity: Temperature; 18 to 30°C

Humidity ; 20 to 80% (non-condensing)

Analyzer dimensions : 720 W × 720 D × 1085 H mm

Analyzer weight : Within 200 kg

BTU : 1300 kcal/hr max.

Noise (mean) in operation : < 55 dB

1.8 User Interface

Application : Routine analysis for Asia version

Display : Backlighted LCD; 256 × 128 dots, graphic

Keyboard : Touch screen keys (72 keys)

Printer : Thermal roll-paper printer (20 digits)

Multi-language

compatibility : Display; Japanese/English/Chinese/German/Spanish applicable

Printer; English alone

1.9 Deionised Water

Pressure : 0.5 to 3.5 kgf/cm

2

Conductivity: 1 µs/cm or less, germ-free

1 - 6

Page 10

1.10Analytical Methods

Assay modes : One-point

One-point end (+ prozone check)

Two-point rate

Two-point end (+ prozone check)

Three-point two-item

One-point rate two-item

Rate A (+ sample blank correction)

Rate A (+ serum indexes)

Rate B two-item (same wavelength)

Rate B two-item (different wavelengths)

ISE

Data alarms : Based on Model 7070/7170

Standard solution : 22 kinds max. (positions to be shared with control sera)

Calibration types : Linear (2-point linear)

K factor

4 parameter LOGIT-LOG

5 parameter LOGIT-LOG

Spline

Segmented line

Calibration method : At startup only; all points (FULL) and reagent-blank-corrected

calibration

Calculation channels : For 8 channels

Test-to-test compensation : For 8 channels

1.11Accuracy Control

Control serum : 5 kinds max. (positions shared with standard solutions)

1.12Data Storage

Routine sample data : 400 samples (in data disk)

Stat sample data : 50 samples (in data disk)

Control sample data : 5 kinds × 30 (in SRAM)

1 - 7

Page 11

1.13System Interface

Interface : RS-232C and current loop

Communication protocol: Based on Model 7070/7170

Communication details : Communication with host; communication details based on Model

7070/7170

1.14Options for Analyzer

ISE

Sample ID accessory : Model ; BL180

Maker ; Keyence

Barcode spec.; CODE 39, ITF, NW7 (Modulas 10, Modulas 16),

CODE 128

1 - 8

Page 12

2. TROUBLESHOOTING

2.1 Alarm Code Table ....................................................................................................2-1

2.1.1 LCD Display Alarm .....................................................................................2-24

2.2 Motor Control Alarms................................................................................................2-26

2.2.1 Operation Check Procedure at Occurrence of Alarm .................................2-27

2.3 Parameter Check .....................................................................................................2-29

2.3.1 Processing Flow .........................................................................................2-29

2.3.2 Details of Parameter Check........................................................................2-30

2.3.3 Details of Twin Test Simultaneous Analysis ...............................................2-34

2.4 Data Alarm...............................................................................................................2-35

2.4.1 Data Alarm Registratin Flow.......................................................................2-35

2.4.2 Data Alarm Code List..................................................................................2-36

2.4.3 Data Alarm Codes ......................................................................................2-37

2.4.4 ISE Data Alarms.........................................................................................2-49

2.4.5 Alarm Check Method..................................................................................2-52

2.4.6 Check and Set Alarm of Each Data............................................................2-60

2.4.7 Details of Data and Alarm Outputs Resulting from Calibration...................2-61

2.4.8 Output Check List for Each Photometry Assay CALIB. METHOD .............2-62

2.5 Retry Code Table.....................................................................................................2-64

2.5.1 Logging Program List......................................................................................2-65

2.6 Daily Alarm Trace.....................................................................................................2-67

2.6.1 Cumulative Alarm Trace.............................................................................2-69

2.6.2 Parameter Code List...................................................................................2-72

2.6.3 Communication Trace.................................................................................2-74

2.6.4 Cumulative Instrument Operation List.........................................................2-78

2.6.5 FD File Management..................................................................................2-79

2 - 0

Page 13

2. TROUBLESHOOTING

2.1 Alarm Code Table

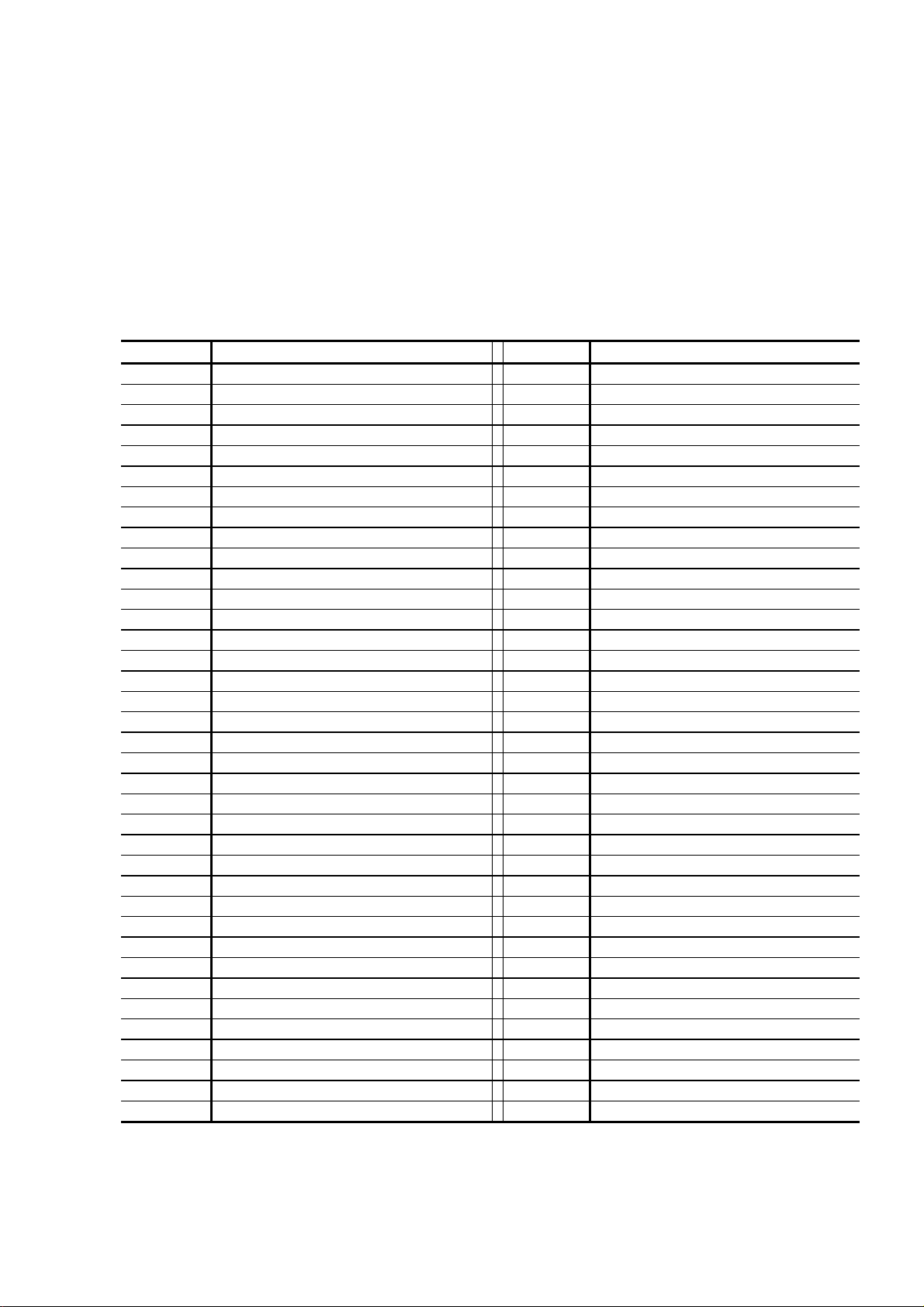

Category Alarm Name Category Alarm Name

1 STIRRER 38 VAC. TANK

2 39

3 RINSE 40

4 41 LAMP

5 R.DISK 42

6 S.PROBE 43

7 44

8 S.DISK 45 CELL BNK1

9 46 CELL BNK2

10 47 ADC1 ?

11 S. SHORT 48 ADC2 ?

12 49 ADC3 ?

13 50 BARCODE 1

14 51

15 S. SYRINGE 52

16 REAG. PROBE 53

17 54 BARCODE 2

18 REAG. DISK 55

19 56

20 57 REAG. SHORT

21 58

22 R. SYRINGE 59 REAG. LEVEL

23 60

24 ISE SIPPER 61

25 62

26 ISE SYRING. 63

27 ISE STOP ? 64

28 TEMP CONT. 65

29 INC. WATER 66

30 REF. WATER 67 TS OVER

31 DIST. WATER 68 PATNT OVER

32 DIST. SENS. 69 SAMP. END

33 70

34 RESERVOIR 71 DC POWER

35 72 FUSE

36 73 POWER FAIL

37 SIPPER 74

2 - 1

(cont’d)

Page 14

Category Alarm Name Category Alarm Name

75 MOTOR CONT. 114 ACI ERROR

76 MOTOR TOUT 115

77 116

78 117

79 118

80 119 FD WRITE ?

81 120 FD READ ?

82 121 NO FD

83 STANDARD ? 122

84 CALIB. 123 FD PROTECT

85 CALIB. SD ? 124

86 SENS. ? 125 PRINTER

87 126 SYSTEM I/F

88 127

89 128

90 ISE LEVEL 129

91 ISE NOISE 130 WATER EXG.

92 ISE PREP. 131

93 ISE SLOPE 132

94 ISE I. STD 133

95 REF. SHORT 134

96 TWIN TEST ? 135

97 136

98 CHEM. PARAM ? 137

99 CLB. PARAM ? 138

100 VOLUME ? 139

101 140 PANEL I/F

102 141 REAGNT ?

103 CMP. TEST ? 142

104 S. INDEXES ? 143

105 144

106 ON BOARD ? 145 CELL C. O.

107 REAG. POS ? 146 ISE C. O.

108 CLB (IS) POS 147

109 148

110 149

111 150

112 151

113 152

2 - 2

Page 15

Alarm

Control

No.

1 to 8 STIRRER 1 1 STOP In ascending action of the

21,22 RINSE 3 1 STOP The rinsing mechanism does

Alarm Category

1 2 STOP In ascending action of the

1 3 STOP In descending action of the

1 4 STOP When the stirrer moves

1 5 STOP The stirrer does not come to

1 6 STOP At resetting, the stirrer does

1 7 STOP At resetting, the stirrer does

1 8 STOP In rotation of the stirrer, it is

3 2 STOP The rinsing mechanism does

Subcode

Level Description Remedy

stirrer, it does not reach the

upper dead point (on the

rinsing bath side).

(Alarm at the first upper

dead point after resetting will

be issued from other than

the cell side.)

stirrer, it does not reach the

upper dead point (on the cell

side).

stirrer, it does not leave the

upper dead point.

toward the rinsing bath, it

does not reach the rinsing

bath position.

the cell position.

not reach the rinsing bath

position (home position) in

its return movement to the

home position.

not leave the rinsing bath

position (home position) in

its departing movement

from the home position.

not set at the upper dead

point.

not reach the upper dead

point in ascending motion.

not leave the upper dead

point in descending motion.

Check the upper dead

point detector.

Same as above

Same as above

Check the home

detector.

Check the detector on

the cell side.

Check the home

detector.

Same as above

Check the upper dead

point detector.

Check the upper dead

point detector.

Same as above

2 - 3

Page 16

Alarm

Control

No.

Alarm Category

Subcode

Level Description Remedy

61 to 65 R. DISK 5 1 STOP The reaction disk cannot

recognize its stop position.

5 2 STOP The reaction disk does not

stop at the specified

position.

5 3 STOP At resetting, the reaction

disk cannot recognize its

home position.

5 4 STOP At resetting, the first cell

on reaction disk does not

stop at the specified

position.

5 5 STOP When the reaction disk

turns, the serum probe,

reagent probe, stirrer or

rinsing mechanism is not

set at the upper dead point

(on the cell side).

(When this alarm is

issued, another alarm (on

rinsing or stirring

mechanism) may concur.)

71 SAMPLE

PROBE

6 1 S.STOP/

STOP

(Note 1)

The serum probe does not

reach the upper dead point

in ascending motion (on

other than the cell side).

(Alarm at the first upper

dead point after resetting

will be issued from other

than the cell side.)

72 to 85 SAMPLE

PROBE

6 2 STOP The serum probe does not

reach the upper dead point

in ascending motion (on

the cell side).

6 3 S.STOP/

STOP

(Note 1)

The serum probe moves

down abnormally in

descending action (on

other than the cell side).

(±3 mm from cup bottom,

0 to 4 mm from cell

bottom)

6 4 STOP The serum probe moves

down abnormally in

descending action (on the

cell side).

6 5 S.STOP/

STOP

(Note 1)

The serum probe does not

go down from the upper

dead point in descending

motion.

NOTE: 1. S.STOP may be issued only during operation.

(cont’d)

Check the detectors for

stop positions on the

inner and outer tracks.

Same as above

Check the home

detector.

Check the home

detector or inner/outer

track detector.

(1) Perform resetting.

(2) Check the upper

dead point detector

of the mechanism

which caused

alarm.

Check the upper dead

point detector.

Same as above

(1) Check the liquid

level detector.

(2) Replace the liquid

level detector PC

board.

Same as above

Check the upper dead

point detector.

2 - 4

Page 17

Alarm

Control

Alarm Category

No.

72 to 85 SAMPLE

6 6 STOP The serum probe does not

Sub-

code

Level Description Remedy

PROBE

6 7 S.STOP/

STOP

(Note 1)

6 8 S.STOP/

STOP

(Note 1)

6 9 S.STOP/

STOP

(Note 2)

6 11 S.STOP/

STOP

(Note 1)

6 12 WARNINGThe serum probe moves

6 13 S.STOP/

STOP

(Note 2)

6 14 STOP In rotation of the serum

6 15 STOP In rotation of the serum

101 to

106

SAMPLE

DISK

8 1 S.STOP/

STOP

(Note 2)

8 2 S.STOP/

STOP

(Note 2)

8 3 S.STOP/

STOP

(Note 2)

8 4 S.STOP/

STOP

(Note 2)

NOTE: 2. S.STOP may be issued only during operation.

go down from the upper

dead point in descending

motion (on the cell side).

Detection of abnormal

descending motion of the

serum probe remains on.

When serum probe turns to

the cell side, the cell position

cannot be detected.

When the serum probe turns

from the cell side to other

position, it does not come off

the cell position.

Before the probe goes down,

the liquid level detector is

already turned on.

down abnormally in

descending action (only at

turning of the serum probe in

adjustment).

In rotation of the serum

probe, it is not set at the

upper dead point.

probe from the reset

position, it does not come off

the reset position.

probe to the reset position, it

cannot detect the reset

position.

The sample disk cannot

detect the stop position on

outer track.

The sample disk does not

stop at the specified position

on outer track.

The sample disk cannot

detect the stop position on

inner track.

The sample disk does not

stop at the specified position

on inner track.

(cont’d)

Check the upper dead

point detector.

Refer to alarm code

6-3.

Check the home

detector.

Same as above

Refer to alarm code

6-3.

Same as above

Check the upper dead

point detector.

Check the home

detector.

Same as above

Check the outer track

detector.

Same as above

Check the inner track

detector.

Same as above

2 - 5

Page 18

(cont’d)

Alarm

Control

Alarm Category

No.

101 to

106

SAMPLE

DISK

107 SAMPLE

DISK

251 to

310

551 to

552

561 to

568

SAMPLE

SHORT

SAMPLE

SYRINGE

REAGENT

PROBE

Subcode

Level Description Remedy

8 5 STOP At resetting, the sample disk

cannot detect the home

position.

8 6 STOP At resetting, the sample disk

does not stop at the specified

point of home position.

8 7 STOP At resetting, the sample disk

does not leave the home

position.

11 1 to 60WARNING In sipping from the sample

cup, sample on the sample

disk is inadequate.

Sub-code groups

Routine/

stat samples:1 to 35

Control STD:36 to 57

W1 to W3 :58 to 60

15 1 S.STOP/

STOP

15 2 S.STOP/

STOP

The serum syringe does not

reach the upper dead point.

The serum syringe does not

go down from the upper dead

point.

16 1 STOP The reagent probe does not

reach the upper dead point in

ascending motion.

16 2 STOP The reagent probe moves

down abnormally in

descending motion.

16 3 STOP The reagent probe does not

go down from the upper dead

point in descending motion.

16 4 WARNINGDetection of abnormal

descending motion of the

reagent probe remains on.

Check the home

detector.

Same as above

Check the home

detector.

Add sample.

Check the upper

dead point detector.

Same as above

Check the upper

dead point detector.

Check liquid level

detection.

Check the upper

dead point detector.

Check the

descending error

detector.

2 - 6

Page 19

Alarm

Control

No.

561 to

568

Alarm Category

REAGENT

PROBE

16 5 STOP When the reagent probe

Subcode

Level Description Remedy

turns toward the cell, it

cannot detect the cell

position.

16 6 STOP When the reagent probe

turns from the cell side to

other position, it does not

leave the cell position.

16 7 STOP Before the probe goes down,

the liquid level detector is

already turned on.

16 8 STOP In rotation of the reagent

probe, it is not set at the

upper dead point.

581 to

593

REAGENT

DISK

18 1 STOP The stop position of reagent

disk cannot be detected.

18 2 STOP The reagent disk does not

stop at the specified position.

18 3 STOP The home position of reagent

disk cannot be detected.

621 to

622

REAGENT

SYRINGE

22 1 STOP The reagent syringe does not

reach the upper dead point.

22 2 STOP The reagent syringe does not

move down from the upper

dead point.

641 ISE

SIPPER

24 1 STOP The sipper nozzle does not

reach the upper dead point

(during resetting/

operation).

642 ISE

SIPPER

661 to

662

ISE

SYRNG

671 ISE STOP

OK ?

24 2 WARNING/

STOP

(Note 4)

26 1 WARNING/

STOP

(Note 4)

26 2 WARNING/

STOP

(Note 4)

27 1 WARNING/

STOP

(Note 4)

The sipper nozzle does not

leave the upper dead point.

The sipper syringe does not

reach the upper dead point.

The sipper syringe does not

leave the upper dead point.

The ISE function is stopped

due to alarm.

(This warning is indicated

when restart in the sampling

stop status was attempted.)

NOTES: 3. S.STOP may be issued only during operation.

4. Though the photometry assay function works, the ISE function does not work.

(cont’d)

Check the home

detector.

Same as above

Check liquid level

detection.

Check the upper

dead point detector.

Check home

detection or count

detector.

Same as above

Check home

detection.

Check the upper

dead point detector.

Same as above

Check the upper

dead point detector of

ISE sipper.

Same as above

Check the upper

dead point detector of

ISE Syringe.

Check alarm log and

deal with the alarm.

2 - 7

Page 20

(cont’d)

Alarm

Control

Alarm Category

No.

681 TEMP

CONTROL

28 1 WARNING The water temperature of

Subcode

Level Description Remedy

incubation bath is higher

than 45.0°C.

28 2 WARNING The water temperature of

incubation bath is outside a

range of 37 ± 0.5°C.

(This is checked only at

operation.)

691 INCUBA-

TOR

29 1 WARNING The water level of

incubation bath is too low.

WATER

701 REF

WATER

30 1 WARNING A period of 24 hours has

passed since exchange of

incubation bath water.

711 DISTILLED

WATER

31 1 STOP The water level of distilled

water tank is too low.

(This alarm will not be

issued during initialization

and water exchange.)

712 DIST

WATER

721 DIST

WATER

SENSOR

724 RESER-

VOIR

31 2 WARNING The water level of distilled

water tank is too low.

32 1 WARNING The water level sensor in

distilled water tank is

abnormal.

34 1 WARNING The waste solution reservoir

is full.

771 SIPPER 37 1 STOP The negative pressure of

vacuum pump is too low.

781 VACUUM

TANK

811 to

813

PHOTOMETER LAMP

38 1 WARNING Water is accumulated in the

vacuum tank.

41 1 WARNING In passed cell blank

measurement, a value of

more than 3.3 Abs is

indicated in any one of 4

measurements.

(3 times or less)

41 2 S.STOP

(Restart

unallowable

41 3 S.STOP

(Restart

un-

In passed cell blank

measurement, a value of

more than 3.3 Abs is

indicated for all of ADC1,

)

ADC2 and λ

to λ12.

1

The above alarm code 41-1

is issued 10 times

consecutively.

allowable)

Check the thermistor

or thermostat of

heater.

Same as above

Replenish water or

check the drain

solenoid valve.

Exchange incubation

bath water.

Check the water level

sensor.

Same as above

Check float switch.

Check waste solution

tank detection.

Check vacuum level

at vacuum suction.

Check SV12 or SV14.

(1)Replace light

source lamp.

(2)Check 12 V

power supply.

2 - 8

Page 21

(cont’d)

Alarm

Control

Alarm Category

No.

1231 CELL

BLANK

1241 to

1400

1441 to

PASS CELL

BLANK

ADC1? 47 1 WARNING Any one of I/O error,

1444

Subcode

45 1 S.STOP

Level Description Remedy

In passed cell blank

(Restart

unallowable)

measurement, any one of

ADC1, ADC2, λx and λy

differs from the reference

value (Note 5) by more than

0.1 Abs through 10

consecutive cycles.

(Counting is not made in

use for stopped cell blank

test.)

46 1 to 48WARNING In 4 passed cell blank

measurements, any one of

ADC1, ADC2, λx and λy

differs from the reference

value (Note 5) by more than

0.1 Abs twice or more.

(In case any one of those

values differs only once, the

average value of normal

data is treated as a value of

passed cell blank.)

boundary error of parameter

block pointer, I/O device

busy, channel error and I/O

device error (PC board not

mounted, device

inoperable, time-out) has

occurred.

47 2 WARNING •A/D count value remains

at 0.

•After A/D conversion,

interruption is impossible.

•The command or

parameter given to A/D

PC board is abnormal.

•A/D conversion cannot be

completed.

(Time-out occurs.)

(Reference voltage is

checked.)

47 3 WARNING The number of A/D starts

cannot be reset to 0.

(This is checked at reaction

measurement.)

(1)Carry out cell

washing.

(2)Replace the cell.

Same as above

Replace ECPU230 or

EMIO100 PC board.

(1)Replace Log Amp

PC board.

(2)Check 2 V and

6 V reference

voltages.

Same as above

2 - 9

Page 22

(cont’d)

Alarm

Control

No.

1441 to

1444

1451 to

1453

1461 to

1462

1471 to

4506

Alarm Category

ADC1? 47 4 WARNING •A/D count for 2 V is

Subcode

Level Description Remedy

Same as above

abnormal.

•A/D count for 6 V is

abnormal.

Normal count for 2 V

(7547 < count value <

8341)

Normal count for 6 V

(22460 < count value <

25023)

(This is checked at

measurement of

reference voltage.)

ADC2? 48 1 WARNING Refer to alarm code 47-1. Replace ISE AMP PC

board.

48 2 WARNING Refer to alarm code 47-2. Same as above

48 3 WARNING Refer to alarm code 47-4.

Reference voltage for

ISE: 2 V and 8 V

Normal count for 2 V

(7547 < count value <

8341)

Normal count for 8 V

(30184 < count value <

33364)

Normal offset value

(22811 < count value <

40547)

ADC3? 49 1 WARNING Refer to alarm code 47-2. Replace EMIO100

49 2 WARNING •A/D count for 2 V is

abnormal.

Same as above

PC board.

Same as above

•A/D count for 6 V is

abnormal.

Normal count for 2 V

(12452 < count value <

13763)

Normal count for 6 V

(37356 < count value <

41288)

BARCODE1 50 1 to 35WARNING Data reception from the

barcode reader has not

been completed before ID

reception time-out.

(Sub-code indicates the

position No. on disk.)

Replace the label or

barcode reader.

2 - 10

Page 23

(cont’d)

Alarm

Control

Alarm Category

No.

1801 to

BARCODE2 54 1 to 5WARNING An error has occurred in

1805

1931 to

1971

2231 to

2271

2781 to

2830

2851,

REAGENT

SHORT

REAGENT

LEVEL

UNASSIGNED

TS OVER 67 1 WARNING Because 400 samples are

2852

2861 PATIENT

SAMPLE

OVER

Subcode

Level Description Remedy

communication with the

barcode reader. (Parity

error, framing error or

overrun error)

Sub-code indication

1:Unassigned

2:Unassigned

3:Sample disk barcode

reader

4:Unassigned

5:Unassigned

57 1 to 40WARNING •The volume of reagent to

be sipped from a reagent

bottle is inadequate.

•The reagent volume is a

total amount of one kind

of reagent for each test

item.

(1)Sub-code indicates

position No.

(2)Positions 37 and 38

are used for ISE.

(3)Position 40 is used for

HITERGENT.

(4)Position 39 is used for

HIALKALI.

59 1 to 40WARNING Reagent volume is smaller

than the remaining reagent

check value specified with

system parameter.

registered in routine sample

test selecting information,

new test selecting

information cannot be

registered from the host.

68 1 WARNING Because 400 samples are

registered in routine sample

test selecting information, a

new routine sample cannot

be analyzed.

Check the

communication cable

of barcode reader.

Set new reagent.

Set reagent newly.

After completion of

analysis, register TS

again.

Same as above

2 - 11

Page 24

(cont’d)

Alarm

Control

No.

2891 to

2894

Alarm Category

DC POWER 71 1 STOP 15 V DC power supply is

Subcode

Level Description Remedy

Replace the ±15 V

abnormal.

power supply

module.

71 2 STOP -15 V DC power supply is

Same as above

abnormal.

71 3 WARNING 12 V lamp power supply is

abnormal.

71 4 STOP 5 V power supply is abnormal.

71 11 E.STOP 24 V DC

Replace the 12 V

power supply.

5 V for other than

CPU board

2911 FUSE 72 1 E.STOP AC fuse has blown. Replace the F3

fuse.

2921 POWER

FAIL

2941 to

2973

MOTOR

CONTROL-

73 1 WARNING Power supply to the

instrument is interrupted

75 1 to 18 STOP Data cannot be written into

the motor controller.

Check power

supply.

Replace ECPU230.

LER

2991 to

3023

MOTOR

TIMEOUT

76 1 to 18 E.STOP Motor operation was

abnormal. Error has been

detected in the time-out check

of motor controller.

(1) Replace

ECPU230.

(2) Check the

mechanism

which caused

Sub-code Motor

alarm.

1 Reaction disk

2 Sample disk

3 Reagent disk

4 Rinsing mechanism

up/down

5 Sample arm

up/down

6 Sample arm

rotation

7 Reagent arm

up/down

8 Reagent arm

rotation

9 Stirrer up/down

10 Stirrer rotation

11 ISE sipper up/down

12 (Unassigned)

13 Serum syringe

14 Reagent syringe

15 ISE syringe

16 (Unassigned)

17 GMCNT

18 (Unassigned)

2 - 12

Page 25

(cont’d)

Alarm

Control

No.

3101 to

3189

3251 to

3291

3401 to

3438

Alarm Category

Subcode

STANDARD? 83 1 to 40

(ch.)

CALIBRATION

84 1 to 40

(ch.)

CALIB.SD? 85 1 to 36

(ch.)

Level Description Remedy

WARNING <<Photometry assay>>

(1) In calibration, the

STD absorbance data

is indicated with

alarm.

(2) In calibration, data

calculation is

disabled.

(Photometry assay)

•Replace STD

sample.

•Check the

concentration

parameter.

(ISE assay)

Same as above

<<ISE assay>>

(1) In calibration, the

potential data of

standard or internal

standard solution is

indicated with ADC

error, insufficient

sample alarm, noise

alarm or level alarm.

(2) In calibration, data

calculation is

disabled.

(The result of calibration

is not updated nor saved

onto FD.)

WARNING <<Photometry assay>>

The factor value 'K'

determined in calibration

(Photometry assay)

(ISE assay)

Same as above

differs from the previous

value by more than ±20%.

<<ISE assay>>

The calibrator

concentration value and

slope value determined in

calibration differ from the

previous values by more

than the compensation

limit (%).

WARNING The mean error determined

in multi-point calibration is

Replace STD and

check again.

larger than the SD limit

(input value).

2 - 13

Page 26

(cont’d)

Alarm

Control

No.

3551 to

3588

Alarm Category

SENSITIVITY?

Subcode

86 1 to 36

(ch.)

Level Description Remedy

WARNING In linear (with 2 to 6 points) or

nonlinear calibration, a

difference between the mean

STD (1) absorbance and the

mean STD (N)

(Note 7 )

The result of

calibration is not

updated nor saved

onto FD.

absorbance is smaller than

the sensitivity limit (input

value).

NOTES :

7.N:=2 for linear

(2points)

=2 to 6 for nonlinear

and linear (3 to 6

points)

(Span point input value)

8.If either STD (1) or STD

(N) alone has been

measured, the

absorbance value of the

other STD is checked

using the previous data.

4151 to

4153

4161 to

4163

ISE LEVEL 90 1 WARNING The mean potential value

(EAV) at three out of five

measurement points of

internal standard solution is

outside the following range.

(Internal standard)

Na:-90.0mV ≤ EAV ≤-10mV

⇒OK

90 2 WARNING K:-90.0mV ≤ EAV ≤ -10mV

⇒OK

90 3 WARNING Cl:100.0mV ≤ EAV ≤

180.0mV

⇒OK

ISE NOISE 91 1 WARNING A difference (FIV) between

maximum and minimum

potential values at three of

five measurement points of

internal standard solution is

outside the following range.

(Internal standard, sample)

Na:0.7mV < FIV(2) - FIV(4)

91 2 WARNING K :1.0mV < FIV(2) - FIV(4) Same as above

(1)Replace STD

and carry out

calibration.

(2)Replace the Na

electrode.

(1)Same as above

(2)Replace the K

electrode.

(1)Same as above

(2)Replace the Cl

electrode.

Carry out reagent

priming and check

for bubble

formation.

91 3 WARNING Cl:0.8mV < FIV(2) - FIV(4) Same as above

2 - 14

Page 27

Alarm

Control

No.

4171 to

4173

Alarm Category

Subcode

Level Description Remedy

ISE PREP. 92 1 WARNING Upon calibration, the slope

value is within the following

range.

Na : 45.0mV ≤ Slope value

≤ 49.9mV or

68.1mV ≤ Slope value

92 2 WARNING K : 45.0mV ≤ Slope value

≤ 49.9mV or

68.1mV ≤ Slope value

92 3 WARNING Cl : -39.9mV ≤ Slope value

≤ -35.0mV or

-68.1mV ≥ Slope value

(cont’d)

•Make sure that the

standard solution

and reagent are set

properly.

•Make sure that the

standard solution is

free from

concentration or

deterioration.

•Make sure that the

electrodes (Na, K,

Cl) are within their

guaranteed life.

4181 to

4183

4191 to

4193

ISE SLOPE 93 1 WARNING (1) In the result of

calibration, the slope

value is within the

following range.

(2) The response

characteristic of

electrode is poor (in case

carry-over rate (A) is as

indicated below).

Na : (1)SLOPE < 45.0mV

(2)0.232 < A

93 2 WARNING K : (1)SLOPE < 45.0mV

(2)0.160 < A

93 3 WARNING Cl : (1)SLOPE < -35.0mV

(2)0.490 < A

ISE I.STD 94 1 WARNING The concentration of internal

standard solution (C(IS)) is

within the following range.

Na : C(IS) < 120.0mEq/L or

160.0mEq/L < C(IS)

94 2 WARNING K : C(IS) < 3.0mEq/L or

7.0mEq/L < C(IS)

94 3 WARNING Cl : C(IS) < 80.0mEq/L or

120.0mEq/L < C(IS)

Refer to alarm

codes 92-1 to 3.

Same as above

Same as above

(1) Replace STD

and carry out

calibration

again.

(2) Replace t he

internal

standard

solution.

Same as above

Same as above

2 - 15

Page 28

Alarm

Control

Alarm Category

No.

4201 to

4203

ISE

REAGENT

SHORT

4211 TWLN

TEST?

Subcode

Level Description Remedy

95 1 Unassigned

(Liquid level detection for

IS/DIL solution)

95 2 Unassigned (Same as

above)

95 3 WARNING The volume of reference

electrode solution is 30 mL

or less.

96 1 to 36

(ch.)

WARNING (1) when analyzing two

tests at a time, the

assigned method for

the corresponding test

is inadequate.

(2) Assignment of the

corresponding test is

being done or not

being done when

analysis for two tests is

not being made at the

same time.

(3) When analyzing two

tests at the same time,

the analytical

parameters are not

identical.

Sub-codes (1 to 36)

signify the channel

numbers.

(cont’d)

Replace the

reference electrode

solution with new

one.

Check the ISE

reagent volume.

•Start setting in

order from the

tests that are

designated by the

Measured Point of

the first half of the

1 channel 2 Test

Analysis Method (3

Point, 1 Point and

Rate, Rate B)

•When not

analyzing two tests

at the same time,

do not designate

'Two Test Analysis'

for the Analysis

Parameter.

•With the Analysis

Parameter screen

for the applicable

test, unify all the

parameters below

for the

Simultaneous 2

Test Analysis Test.

• Analytical Method

• Reaction Time

• Sample Volume

• Reagent

Pipetting volume

(R1-R3)

• Calibration

Method

• Calibration Point

• Standard solution

volume

• Standard solution

position

2 - 16

Page 29

Alarm

Control

No.

4511 to

4548

4661 to

4698

Alarm Category

CHEMISTRY

PARAMETER?

CALIBRATION

PARAMETER CALIB.

Sub-

code

98 1 to 36

(ch.)

99 1 to 36

(ch.)

Level Description Remedy

WARNING(1)The relationship

between assay code and

Correct the

parameter.

photometric point is

improper.

(2)The assigned

photometric point lags

behind the specified

reaction time.

(Operation is

impossible.)

WARNING (1)The relationship

between assay code and

Check parameter

and input it again.

calibration type is

improper.

(2)Necessary calibration

points for calibration

type are not input.

(3)Necessary standard

positions for calibration

are not input.

(4)The relationship

between calibration type

and calibration method

is improper.

(5)The standard

concentration values are

not set in ascending

order. (Except for STD

(3) and (4) for isozyme)

(6)Concentration value is

not zero when '99' is

entered for POS. of STD

(1).

1.The photometry assay

data in other than

manual mode is

checked.

2.Operation is

unallowable.

3.Check in (4) is made

with regard to

specifications of timeout calibration, lot-to-lot

calibration, bottle-tobottle calibration and

test selecting

information.

(cont’d)

2 - 17

Page 30

(cont’d)

Alarm

Control

No.

4811 to

4848

Alarm Category

VOLUME

CHECK?

Sub-

code

100 1 to 36

(ch.)

Level Description Remedy

WARNING (1)The total reagent

volume up to the last

photometric point is

more than 250 to

500 µL.

(2)The volumes of

reagents 1 to 3 are all

Check parameter.

If the improper

condition indicated

by alarm can be

detected, correction

and reentry are

required.

zero.

(3)The reagent volume

having a timing behind

the reaction time is not

zero.

(4)The total liquid volume

of sample and reagent is

less than 250 µL.

1.When '999' (stirring

only) is specified for

reagent volume, 0 µL is

taken for the volume.

However, when '999' is

specified for the reagent

volume having a timing

behind the reaction time,

an error occurs.

2.Operation is

unallowable.

3.The final liquid volume

is a total volume of

sample and reagent

within 250 to 500 µL.

5261 CMP. TEST 103 1 to 8 WARNING The setting of formula

number corresponding to

the relevant code is

improper.

(1)An unmeasurable test is

specified for

compensation.

(2)A compensated test is

not included in the

formula.

(3)In photometry assay for

compensated test, the

electrolyte parameter is

specified.

2 - 18

Call up calculation

item screen and

check the

compensation

formula on it.

Page 31

Alarm

Control

No.

5271 to

5356

Alarm Category

SERUM

INDEXES?

104 1 to 36

Subcode

(ch.)

Level Description Remedy

WARNING (1)Although the sub-code

corresponds to the

serum index

measurement test, the

rate-A assay is not

assigned.

(2)Although the sub-code

corresponds to the

serum index

measurement test and

sample blank is to be

corrected, reagent 2

discharge is specified.

(Analysis does not start.)

5431 ON BOARD? 106 1 WARNING There is no measurable

channel.

There is no channel for

which necessary reagent

has been prepared.

(Analysis does not start.)

5441 REAG.POS? 107 1 to 38WARNING (1)The reagent position

specified for a

photometry assay is

also specified for other

photometry assay.

(2)The same reagent

position is specified for

both carry-over cleaning

agent and photometry

assay or ISE test.

(Analysis does not

start.)

5481 CLB(IS)

POS.

108 1 WARNING When ISE is provided,

calibrator or control

positions are set at 55 to 57.

(Analysis does not start.)

5511 to

5516

ACI ERROR 114 1 to 6WARNING Barcode IC malfunctions.

1:Unassigned

2:Unassigned

3:Sample

4:Unassigned

5:Unassigned

6:Transfer

(cont’d)

Check parameter

for serum indexes.

Check each

parameter.

Check each

reagent.

Check the position

for control

calibration.

Replace RSDIST

PC board.

2 - 19

Page 32

Alarm

Control

No.

5561 to

5568

5571 to

5578

Alarm Category

FD-WRITE? 119 1 WARNING A hardware error has

119 2 WARNING A hardware error has

119 3 WARNING A hardware error has

119 4 WARNING A hardware error has

119 5 WARNING A hardware error has

119 6 WARNING A hardware error has

119 7 WARNING A hardware error has

119 8 WARNING A hardware error has

FD READ? 120 1 WARNING A hardware error has

120 2 WARNING A hardware error has

120 3 WARNING A hardware error has

120 4 WARNING A hardware error has

Subcode

Level Description Remedy

occurred in writing the

routine sample

measurement data.

occurred in writing the stat

sample measurement data.

occurred in writing the

control sample

measurement data.

occurred in writing the

individual or cumulative

alarm information.

occurred in writing the

parameter data.

occurred in execution of FD

formatting, copying into FD

or FDD cleaning.

occurred in writing the cell

blank data.

occurred in writing the

routine sample test

selecting information.

occurred in reading the

routine sample

measurement data.

occurred in reading the stat

sample measurement data.

occurred in reading the

control sample

measurement data.

occurred in reading the

individual or cumulative

alarm information.

(cont’d)

(1)Clean the FD.

(2)Replace the FD

with a new one.

(3)Replace the FD

drive.

Refer to alarm

category No. 119.

2 - 20

Page 33

Alarm

Control

No.

5571 to

5578

5581 FD NOT

5601 FD

5621 to

5625

Alarm Category

FD READ? 120 5 WARNING A hardware error has

INSERTED

PROTECT

PRINTER 125 1 WARNING Power supply is turned off

Subcode

120 6 WARNING A hardware error has

120 7 WARNING A hardware error has

120 8 WARNING A hardware error has

121 1,2 WARNING System disk is not set in

123 1,2 WARNING A write-protected disk is

125 2 WARNING Paper has run out or the

125 4 WARNING A hardware error has

125 5 WARNING A time-out error of the

Level Description Remedy

occurred in reading the

parameter data.

occurred in reading the

channel assignment.

occurred in reading the cell

blank data.

occurred in reading the

control parameter.

drive 1 or data disk is not

set in drive 2.

inserted.

or the connector is

disconnected.

printer head has risen.

occurred on the printer.

printer has occurred.

(cont’d)

Refer to alarm

category No. 119.

Insert the relevant

disk.

Unprotect the disk.

Check the power

supply or connector.

Set paper or lower

the printer head.

Check the printer

cable.

(1)Check the

printer cable.

(2)Replace the

printer.

2 - 21

Page 34

Alarm

Control

No.

5631 to

5643

Alarm Category

Subcode

Level Description Remedy

SYSTEM I/F 126 1 WARNING A reception time-out error

has occurred.

126 2 WARNING A transmission time-out

error has occurred.

126 3 WARNING A BCC error or checksum

error has occurred.

126 4 WARNING A parity error has occurred.

126 5 WARNING A framing error has

occurred.

126 6 WARNING An overrun error has

occurred.

126 7 WARNING Frame error

126 8 WARNING Text length error

126 9 WARNING Function character error

(cont’d)

(1)Check the cable

of system I/F.

(2)Check the

contents of

communication

trace.

(3)Check the

contents of

communication

by line analyzer.

(4)Check if a

change has

occurred in

system

parameters.

126 10 WARNING Sample information error

126 11 WARNING Test selecting information

error

126 12 WARNING Comment information error

126 13 WARNING Reception cannot continue

up to the end code because

an illegal character is

received from the host.

Example)A null code is

received from

the host.

5681 BATH

EXCHANGE

FAILURE

130 1 WARNING The start key has been

pressed despite failure in

incubation bath water

exchange.

5696 PANEL I/F 140 1 WARNING An error has occurred in

LCD display module

communication.

('Communication error'

appears on the LCD

display.)

5701 REAGENT? 141 1 to 36WARNING Either reagent positions R1

to R3 or reagent volume

alone is "0" (no

specification).

Do incubation bath

water exchange

again.

(1)Check the

communication

cable of LCD.

(2)Replace the

LCD.

Check and correct

the contents of

parameters R1 to

R3.

2 - 22

Page 35

Alarm

Control

No.

5771 CELL C. O. 145 1 to 10WARNING (1)More than 2 types of

5821 ISE C. O. 146 1 to 40WARNING R1 type is not specified for

Alarm Category

Subcode

Level Description Remedy

carry over evasion (cell)

are specified for 1 test.

(2)Sub-codes (1 to 10)

signify the evasion

types.

ISE test of Reagent Probe

Carry Over Evasion.

(cont’d)

Check and correct

the carry over

evasion (cell).

Check and correct

the Reagent Probe

carry over evasion.

2 - 23

Page 36

2.1.1 LCD Display Alarm

Output of Boot Error

Boot error is output to the console and the buzzer for small-size automatic analyzer (beeper is

used). Output is issued unconditionally to the console whenever connected. For the small-size

automatic analyzer, on the other hand, either of the destinations shown below is selected

depending on system. For selection method, refer to (3).

(1) Output to Console

Output to the console always uses a log message. This is because output cannot be

issued in the EAT format within a period from system start to EAT task start. Upon output,

a message is sent out line by line by scroll-up method as in the logging message of

VxWorks. Note that a line is fed before and after a message.

Output format is shown below. For contents of output, refer to (4).

(2) Buzzer Output for Small-Size Automatic Analyzer

The kinds of output are the same as the three kinds in the small-size immunological

system. Each output has a distinctive tone at the frequency indicated below.

1) Self Test Error : 50 Hz

2) Loading Error : 250 Hz

3) OS Initial Error : 1 Hz

Sounding : Continuous

(3) Distinction in Error Message Output

For distinction in error output of small-size automatic analyzer, the configuration register of

a flash memory is used.

According to the readout value of this register, output destination is distinguished as shown

below. The value is set by hardware. (No setting is required in software.)

Table 2-1 Flash-Memory Configuration Register

(0xf2000b)

Value Meaning

0x01 Output to small-size automatic analyzer

Bus error Other

2 - 24

Page 37

(4) Contents of Output

Output for the small-size automatic analyzer comes in 3 kinds described above. So, the

kinds of console output are listed below.

Table 2-2 Kinds of Console Message Output

Error Output Message

Self-test error 1. Self Test Error (0xXX)

XX: Self-test error code

Boot error 1. Rom Uncompress Error

2. F/D Boot Error (0xXXXXXXXX)

3. FROM Boot Error (0xXXXXXXXX)

XXXXXXXX: Boot error code (Refer to Section 5.)

OS initial error 1. OS Initial Error (Vect = 0xXX,PC=0xXXXXXXXX)

Vect = 0xXX: Vector No.

PC = 0xXXXXXXXX: Program counter

Note that EAT output is issued when possible.

2 - 25

Page 38

2.2 Motor Control Alarms

Alarm

Code

1 - 1 (3) - 4) 6 - 9 (4) - 5) 17 Unused

2 Unassigned 10 (5) - 6)

3 (4) - 5) 11 (7) - 8) 18 - 1 (2) - 3)

4 (2) - 2)ž3) 12 (6) - 7) (3) - 4)

5 (2) - 2)ž3) 14 Unassigned (2) - 2)

6 Unassigned 7 - 1 (2) - 3) (3) - 4)

7 (4) - 5) (3) - 4) 19 Unused

8 (8) - 9) (9) - A

9 Unassigned (10) - A 20 Unused

10 Unassigned 2 (2) - 3)

2 - 1 Unused 3 (3) - 4) 21 Unused

2 4 (2) - 3)

3 (10) - C 22 - 1 (1) - 1)

4 7 - 5 (1) - 1) 2 (4) - 5)

5 (2) - 2) 23 Unused

6 (9) - B

7 (10) - B 24 - 1 (1) - 1)

8 8 Unused 2 (4) - 5)

9 25 Unused

10 9 Unused

3 - 1 (3) - 4) 26 - 1 (1) - 1)

2 (4) - 5) 10 Unused 2 (4) - 5)

3 3

4 11 Unused 4

5

6 (OP) 12 Unused

7

8 13 Unused

9

10 14 Unused

4 Unused

5 - 1 (2) - 3) 15 - 1 (1) - 1)

2 (2) - 2) 3 Unassigned

3 (3) - 4) 4 Unassigned

4 (2) - 2) 16 - 1 (3) - 4)

5 (1) - 1) 2 (6) - 7)

6 Unassigned 3 (4) - 5)

6 - 1 (3) - 4) 4 (70 - 8)

2 (3) - 4) 5 (3) - 4)

3 (5) - 6) 6 (4) - 5)

4 (6) - 7) 7 (7) - 8)

5 (4) - 5) 8 (8) - 9)

6 (4) - 5) 9 Unassigned

7 (7) - 8) 10 Unassigned

8 (3) - 4)

Check

Procedure

(3) - 4) 13 (8) - 9) 2 (1) - 1)

(3) - 4) 15 Unassigned 3 (2) - 3)

(3) - 4) 2 (4) - 5) (*) : OPTION

Alarm

Code

Check

Procedure

Alarm

Code

Check

Procedure

2 - 26

Page 39

2.2.1

1. For items other than 7 and 8 ,

check whether the motor remains

running even after timeout.

NOTE:

If so, it should be identified as a

motor time out error.

2. Operation check method for 2-pitch

returning of sample disk.

3. Item 10 ; Operation check method

for 2-pitch feed of sample disk.

4. Item 9 ; Check at resetting.

2 - 27

Page 40

Notes:

1. In check procedure other than 7 and 8 ,

motor running status is checked after time-out.

When running, a motor time-out error occurs.

2. Operation check procedure at 2-pitch return of

the sample disk.

3. 10 is the operation check procedure at 2-pitch

feed of the sample disk.

4.

9 is the check at resetting.

.

2 - 28

Page 41

2.3 Parameter Check

Parameter check is carried out on the channel for which test is selected on the CHANNEL

ASSIGNMENT screen at start of analysis.

2.3.1 Processing Flow

(1) At input of START key in STANDBY status.

Twin test

simultaneous analysis

parameter check

Check result?

NG

STOP

Analytical method

OK

check

Calibration parameter Serum index analytical

check method check

Volume check Reagent relationship check

1)

at carry-over cleaning

Upper/lower limit value CH, ACTIVATE check

check

Test-to-test Check result?

compensation check

Analytical mode check

1)

OK

NG

START

STOP

2 - 29

Page 42

2.3.2 Details of Parameter Check

Designation

No.

of Check

1 Check of

parameters

for twin test

simultaneous

analysis

Details of Check

The following are checked

for measurable (level 1,

Note 1) photometry tests.

(1) In case of twin test

simultaneous analysis,

the opposite test must

be specified properly.

• Two tests must form

a unique pair, and

one of them alone

must designate the

other.

(2) In case of other than

twin test simultaneous

analysis, tests must not

be paired.

(3) In case of twin test

simultaneous analysis,

two tests must be

identical in all of the

following parameters.

• Data mode

• STD POS.

• STD S. VOL

• Assay code

• Reaction time

• Sample volume

• Reagent volume

• Calibration type

• Calibration point

• Span point

Alarm

Display Subdivision

TWIN TEST? 1 to 37

(CH No.)

Remarks

Details of this check

are given in "Details

of twin test

simultaneous

analysis" in 2.3.3.

In case of twin test

simultaneous

analysis, an alarm

is issued if one of

two tests is not

registered or the

manual mode is

selected.

NOTE:

1. The term

'measurable'

indicates either

of the following

two levels.

Level 1:

Test registered

and manual

mode not

selected

Level 2:

Same as above

and reagent

provided

2 Assay code

check

The following are checked

for measurable (level 1)

photometry tests.

(1) Relationship between

assay code and

photometric point

(check of photometric

point input and input

range)

Refer to the analytical

method table in 1.1.1.

CHEM

PARAM?

2 - 30

1 to 37

(CH No.)

Page 43

Designation

No.

of Check

2 Assay code

check

3 Calibration

parameter

check

Details of Check

(2) Photometric points after

the specified reaction

time must not be set.

Refer to Note 6 in

"analytical method

table" of 1.1.1.

The following are checked

for measurable (level 1)

photometry tests.

(1) Relationship between

assay code and

calibration type

Refer to "relationship

between calibration type

and analytical method"

in 2.1.

(2) Entry must be made for

CALIB. POINTS

necessary for calibration

type.

Refer to "output by each

calibration method and

check table" in 2.7.

(3) Entry must be made for

STD POS. necessary

for calibration.

For STD specified by

measured STD No. in

"output by each

calibration method and

check table" of 2.7, it is

checked whether STD

POS. is input or not.

Alarm

Display Subdivision

CHEM

PARAM?

1 to 37

(CH No.)

CLB. PARAM? 1 to 37

(CH No.)

(cont’d)

Remarks

NOTES:

1. Checked

against the

specification of

calibration test

selecting

information.

2 - 31

Page 44

Designation

No.

of Check

3 Calibration

parameter

check

4 Volume

check

Details of Check

(4) The input value for

SPAN POINT must be

normal.

• When calibration

type is LINEAR (2 to

6-point) or LOGITLOG (3P or 4P)

1) The above input

value must not

equal 0.

2) The above input

value must not

exceed that for

CALIB. POINTS.

(5) Relationship between

calibration type and

calibration method

Refer to "output by each

calibration method and

check table" in 2.7.

(Note 2)

(6) STD CONC. must be

set in ascending order.

Check is made only for

necessary STD POS.

Note that isozyme STD

(3) and (4) are

excluded.

"=" is not regarded as in

ascending order.

(7) When '99' is entered for

POS. of STD (1),

CONC. must be 0.

The following are checked

for measurable photometry

tests.

(1) The total liquid volume

up to the final

photometric point must

be 500 µL or less.

(2) At least one of R1 to R3

volumes must not be 0.

(3) The reagent volume

having a timing behind

the reaction time is not 0.

(4) The minimum liquid

volume must be at least

250 µL.

Alarm

Display Subdivision

CLB. PARAM? 1 to 37

(CH No.)

VOLUME ? 1 to 37

(CH No.)

(cont’d)

Remarks

NOTES:

2. Checked

against the

specification of

calibration test

selecting

information.

When reagent

volume = 0, the

relevant reagent is

not used.

2 - 32

Page 45

Designation

No.

of Check

5 Test-to-test

compensation check

6 Serum index

analytical

method

check

7 Cell carry

over

8 ISE carry

over

Details of Check

For formula No. where

compensated test is

measurable:

(1) The compensation test

must be measurable.

In addition, when the

compensation test is

already registered as a

compensated test in any

preceding formula No.,

the check result for the

formula No. must be

OK.

(2) The compensated test

must be on the right

side of the formula.

(3) When the compensated

test is a photometry

test, no ISE test must

be registered for the

compensation test.

(1) The assay code for tests

for serum index

measurement must be

RATE-A. This check is

made only when the

tests are measurable.

(2) In the RATE-A test with

serum indexes, no R2

must be specified when

sample blank correction

is carried out.

(1) More than 2 types of

carry over evasion (cell)

are specified for 1 test.

(2) Sub-codes (1 to 10)

signify the evasion

types.

R1 type is not specified for

ISE test of Reagent Probe

Carry Over Evasion.

(cont’d)

Alarm

Remarks

Display Subdivision

CMP. TEST? 44 to 51

(FORMULA

No.)

This check is not

performed in case

of ORIGINAL ABS.

S. INDEXES? 1 to 37

(CH No.)

CELL. C. O. 1 to 10 Check and correct

the carry over

evasion (cell).

ISE C. O. 1 to 40 Check and correct

the Reagent Probe

carry over evasion.

2 - 33

Page 46

2.3.3 Details of Twin Test Simultaneous Analysis

∇ NG Note 2

CH = 1 to 37 Assay code P: Designates OK

for twin test opposite test.

Note 1 simultaneous Q: Designated by NG Note 2

P.Q

P.Q

P.Q

analysis opposite test. OK

P.Q

Designated

by one test

alone

Check result OK

Identical in

all parameters

with opposite

test Note 3

OK

Not paired

NGNote 2

NG Note 2

OK

NG Note 2

∆

NOTES: 1. Unmeasurable channels are excluded.

However, in twin test simultaneous analysis, alarm occurs when either

one of the two tests is unmeasurable.

2. Alarm is registered with a channel No. assigned for subdivision.

3. Refer to "Details of Parameter Check" in 2.3.2.

2 - 34

Page 47

2 - 35

Page 48

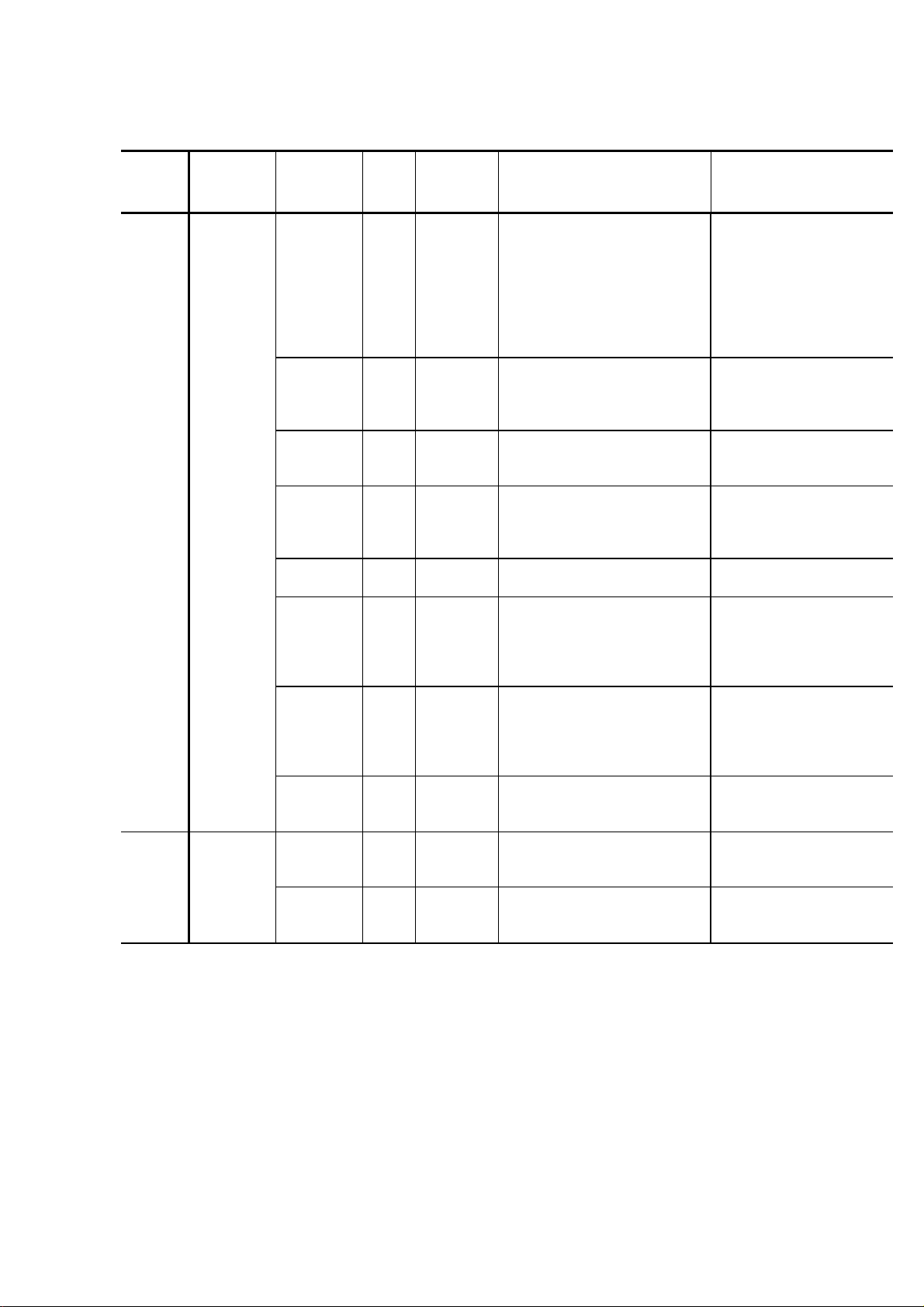

2.4.2 Data Alarm Code List

No. Data Alarm Remarks

Output String ISE

PRINTER C

R

T

1

ADC abnornal

2

Cell blank abnormal

3

Sample short

4

Reagent short

5

Absorbance over

6

Prozone error

7

Reaction limit over at all

points

8

Reaction limit over except 1

point

9

Reaction limit over except 2

or 3 points

10

Linearity abnormal at 9

points or more

11

Linearity abnormal at 8

points or less

12

Standard 1 absorbance

abnormal

13

Duplicate error

14

STD error

15

Sensitivity error

16

Calibration error

17

SD error

18

Noise error

19

Level error

20

Slope abnormal

21

Internal standard

concentration abnormal

22

Sample value abnormal

23

Test-to-test compensation

error

24

Test-to-test compensation

disabled

25

Calculation test error

26

Overflow

27

Calculation disabled

28

Expected value high limit

over

29

Expected value low limit over

30 Electrode preparation PREP. R

31 SD absorbance over >AMAX > >

ADC?

CELL?

SAMPLE

REAGN

ABS?

∗∗∗∗∗P

LIMT0

LIMT1

LIMT2

LIM.

LIM.8

S1ABS?

DUP

STD?

SENS

CALIB

SD?

NOISE

LEVEL

SLOPE?

I.STD

R.OVER

CMP.T

CMP.T!

CALC?

OVER

???

H

L

A

Q

V

T

Z

P

I

J

K

W

F

N

L

&

C

M

%

0

X

Photometry

Assay

S.

I/FRo

u

t

i

n

e

O

A

O

Q

O

V

O

T

O

Z

O

P

O

I

O

J

O

K

O

W

O

F

H

U

S

Y

B

G

N

L

E

O

D

O

&

C

O

O

O

M

O

%

O

0

X

O O O

S

C

S

R

S

C

S

t

o

T

o

t

o

T

a

n

D

u

a

n

D

t

t

t

t

t

r

i

r

o

n

o

l

e

l

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

•Data may become blank

space.

•Data may become blank

space.

•Prozone value is output to the

printer only when the monitor

is in the real time mode.

∗∗∗∗∗ indicates a prozone

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

value (5-digit).

O

O

O

O

O

O

•Data becomes blank space.

O

•Data becomes blank space

•Data becomes blank space.

•May concur with other alarm.

•May concur with other alarm.

O

•Data becomes blank space.

BM only

NOTES: 1. If any data caused multiple data alarms, the alarm registered first will be output.

2. When [Specify] is entered for measured value space parameter in the start condition screen.

2 - 36

Page 49

2.4.3 Data Alarm Codes

No. Data Alarm Printer S. I/F Description Remedy

ADC abnormal ADC? A The ADC value of main or

sub wavelength (only main

wavelength in single

wavelength photometry) is

zero.

Cell blank

abnormal

Sample short SAMPL V Before sample aspiration,

Reagent short REAGN T Before reagent aspiration,

CELL? Q (Photometry assay only)

Two or more of the four

passed cell blank values to

be used for CELL BLANK

are abnormal.

Note: Abnormal when the

difference from the

reference value

(value measured

with cell blank

function on the

maintenance

screen) is ± 0.1 Abs

or more.

the presence/absence of

sample is checked and it is

found that the sample is

absent.

the presence/absence of

reagent is checked and it is

found that the reagent is

absent.

• Perform measurement

again.

• Turn off the power switch,

and then turn it on.

• Perform cell blank

measurement once a

week or after

replacement of the light

source lamp or reaction

cuvette.

• Confirm the adequate

volume of HITERGENT.

After taking a proper

measure, exchange

incubation bath water

once.

• Rinse or replace the

reaction cuvette and

perform cell blank

measurement.

• After washing the light

transmitting window in the

incubation bath, perform

cell blank measurement.

• Inject the sample in a

volume of expected

consumption + 50 µL or

more into a standard cup.

• Insert the lead wire.

• Prepare and set reagent

newly.

• Insert the lead wire.

2 - 37

Page 50

No. Data Alarm Printer S. I/F Description Remedy

Absorbance over ABS? Z (Photometry assay)

The absorbance value to be

used for calculation after cell

blank correction exceeds 3.3

Abs. The absorbance is

checked for every

wavelength.

Prozone error

*****P

('*****'

indicates

a

prozone

value.)

P (Photometry assay only)

In 1-point or 2-point assay

with prozone check, the

prozone error is indicated if

'prozone' is detected.

Prozone check is performed

by comparing the prozone

value (hereafter referred to

as PC value) obtained from

calculation mentioned below

with the prozone limit value

preset on the chemistry

parameter screen. For the

lower prozone limit, the

prozone error is indicated if

the PC value is smaller. For

the upper prozone limit, the

error is indicated if the PC

value is larger.

In the event of prozone error,

the relevant PC value is also

printed out (only in real-time

monitor printing mode).

• In 1-point & rate, rate-A

or rate-B assay, check is

not carried out for the

interval to determine the

absorbance change rate

if an ascending reaction

setting is made for that

interval.

• Dilute the sample or

reduce its volume, and

then perform

measurement again.

• Set the sample correctly.

• Prepare the reagent

again.

• Prozone check values

are printed out only in

the real-time monitor

printing mode.

• Delution or retest with

decreased volume is

performed.

• For no-check, enter