HITACHI 50PD9800TA Service Manual

YK

No.040E

SERVICE MANUAL

The PDP panel made from FHP is used for this product.

50PD9800TA(FW1)

Caution

Be sure to read this manual before servicing. To assure safety from fi re, electric shock, injury, harmful

radiation and materials, various measures are provided in this HITACHI display.

Be sure to read cautionary items described in the manual to maintain safety before servicing.

Service Warning

1. Since Panel Module and front Filter are made of glass, handling the broken Module and Filter shall be

taken care suffi ciently in order not to be injured.

2. Replacing work shall be started after the Panel Module and the AC/DC Power supply become suffi -

ciently cool.

3. Special care shall be taken to the display area in order not to damage its surface.

4. The Panel Module shall not be touched with bare hand to protect its surface from stains.

5. It is recommended to use clean soft gloves during the replacing work in order to protect not only the

display area of the Panel Module but also a serviceman himself.

6. The Chip Tube of Panel Module (located upper left of the back and surrounded by frame) and fl exible

cables connecting Panel glasses to drive circuit PWBs are very weak, so shall be taken care suffi -

ciently not to break. If you break Chip Tube, the Panel doesn’t display anything forever.

Contents

1. Features ----------------------------------------------- 3

2. Specifi cations ----------------------------------------- 4

3. Service point ------------------------------------------ 5

4. Component names ---------------------------------- 6

5. New adoption technology -------------------------- 8

6. Adjustment ------------------------------------------ 12

7. Troubleshooting ------------------------------------ 28

8. Self-diagnosis function --------------------------- 32

9. Basic circuit diagram ------------------------------ 35

10.Printed wiring board diagram ------------------- 57

11.Block diagram -------------------------------------- 62

12.Connection diagram ------------------------------ 63

13.Wiring diagram ------------------------------------- 64

14.Disassembly diagram ---------------------------- 66

Replacement Parts list

15.

----------------------------- 71

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

Plasma Display

December 2006

50PD9800TA (FW1)

CAUTION FOR SAFETY

Please read this page before repair the monitor.

This page explains to following items for keep the safety of set and prevent to accident during

repair work.

We explain by symbol at happen the damage or injury when took wrong repair.

Warning

Caution

This symbol means "possible to die or heavy damage"

This symbol means "possible to damage or something will break"

We made the symbol as below, which are kind of following items.

This symbol means "CAUTION"

This symbol means "POSSIBLE to

ELECTRIC SHOCK"

This symbol means "MUST"

This symbol means "DO NOT"

WARNING

Should be follows to instructions.

We indicates to cabinet, chassis and parts

by label, which are special attention part.

Please follow to note and [Safety Instructions]

of User’s Manual.

Prevent the electric shock.

Please take care during working because

monitor has high voltage part and power

supply part.

Possible to die if you tough to these place

by miss take.

Please disconnect power plug during

overhaul, reassemble or change parts.

You will die or take damage by electric

shock if you touch to live part.

Use recommended components.

Please use to same characteristic compo-

nent, which is same as previous for your

safety and keep reliability especially marked

in parts list and circuit diagram.

by

It is reason of electric shock or fire if you

use non-recommended component.

Should be kept same style of wiring or component.

Monitor uses tubes or tapes, which made

by insulator, and some components are

keep distance from surface of PWB for

safety.

Internal leads kept from hot part or high voltage

part by clamper or styling, so please return to

original condition for prevent to electric shock

or fire.

Should be done safety check after finished.

Every part (removed screws, component

and wiring) should be returned to previous

condition.

Check around repair position for make

damage by miss take and measure the

insulated impedance by meg-ohm meter.

Confirm the value of impedance, that val-

ue is more than 4M ohm.

It is reason for electric shock or fire if that

value is less than 4M ohm.

2

50PD9800TA (FW1)

PRECAUTIONS

How to clean the plasma screen panel of the monitor

Before cleaning the monitor, turn off the monitor and disconnect the power plug from the power outlet.

To prevent scratching or damaging the plasma screen face, do not knock or rub the surface with sharp or

hard objects. Clean the screen with a soft cloth moistened with warm water and dry with a soft cloth. If it is

not enough, then use a cloth with diluted neutral detergent. Do not use harsh or abrasive cleaners.

How to clean the cabinet of the monitor

Use a soft cloth to clean the cabinet and control panel of the monitor. When excessively soiled a diluted neutral

detergent in water, wet and wring out the soft cloth and afterward wipe with a dry soft cloth.

Never use acid/alkaline detergent, alcoholic detergent, abrasive cleaner, powder soap, OA cleaner, car wax,

glass cleaner, etc. especially because they would cause discoloration, scratches or cracks.

1. Features

Large-screen, high-definition plasma display panel

The 50-inch color plasma display panel, with a resolution of 1280 (H) x 1080 (V) pixels, creates a high-definition,

large-screen(aspect ratio : 16:9) and low-profile flat display. Free from electromagnetic interferences from geomagnetic sources and ambient power lines, the panel produces high-quality display images free from color misconvergence and display distortion.

High Performance Digital Processor

A wide range of input signals can be handed,including composite, component,and HDMI.High Definition Digital

Processor creates the fine-textured image with dynamic contrast. In addition, it corresponds to a broad array of

personal computer signals, from 640 x 400 and 640 x 480 VGA to 1280 x 1024 SXGA.(RGB Input)

Easy-to-use remote control and on screen display system

The remote control included eases the work of setting display controls. Further, the on-screen display system, displays the status of signal reception and display control settings in an easy-to-view fashion.

Power saving system

The power saver feature saves power consumption automatically when input signals are not available.

When connected to a VESA DPMS-compliant PC, the monitor cuts its power consumption while it is idle.

Connecting to an Audio Visual Device

1

• Two composite/S terminal*

have been added. A composite video output terminal is also provided as a

monitoring output.

*1

One composite/S terminal are on the front input. Composite terminal and S terminal should not be

connected at the same time

*2

Two composite terminal and two component terminal cannot be used at the same time.

• A wide range of devices other than personal computers can also be connected.

,two composite terminal*2, two component terminal*2 and two HDMI terminal

3

2. Specifications

50PD9800TA (FW1)

Panel

Net dimensions

Net weight

Ambient

conditions

Power supply AC110 - 240V, 50/60Hz

Power consumption / at standby 470W / <1W

Audio output speaker total 20W

(VIDEO input)

Input terminals

Input signals

Output Signal

(RF input)

Input terminal / Receiving range ANT : 75Ω Unbalanced / 44~870MHz

RF Video System

(RGB input)

Input terminals

Input signals 0.7Vp-p, analog RGB (Recommended Signal)

Sync signals H/V separate, TTL level [2KΩ]

Display dimensions Approx. 50 inches (1106(H) x 626(V)mm, diagonal 1270mm)

Resolution 1280(H) x 1080(V) pixels

including Optional Stand : 1240(W) x 900(H) x 423(D)mm

excluding Optional Stand : 1240(W) x 836(H) x 125(D)mm

including Opional Stand : 46.5kg

excluding Opional Stand : 40.7kg

Temperature Operating : 5°C to 35°C, Storage :0°C to 40°C

Relative humidity Operating : 20% to 80%, Storage : 20% to 90% (non-condensing)

AV1•2 : composite video input terminal (RCA)

component video input terminal (RCA)

L/R audio input terminal (RCA)

AV3•4 : composite video input terminal (RCA)

S video input terminal.

L/R audio input terminal (RCA)

HDMI1•2 : HDMI input terminal

Audio input terminal (L/R audio input terminal (RCA))*

Composite video : PAL, SECAM, NTSC3.58, NTSC4.43, PAL60

Component video : 480i, 576i, 480p, 576p, 720p/50, 720p/60, 1080i/50, 1080i/60

HDMI : VGA/60, 480i, 576i, 480p, 576p, 720p/50, 720p/60, 1080i/50, 1080i/60,

1080p/50, 1080p/60

OUTPUT (MONITOR) : composite video monitor-output terminal (RCA)

OUTPUT (MONITOR) : L/R audio monitor-output terminal (RCA)

OUTPUT (HEADPHONE) : L/R audio monitor-output terminal (Mini-pin)

OUTPUT (SUB-WOOFER) : Woofer output terminal (RCA)

PAL B, G, H / I / D, K

SECAM B, G / D, K / K1

NTSC-M

Analog RGB input terminal (D-sub 15-pin)

Audio input terminal (L/R audio input terminal (RCA))*

•The unit takes at least 30 minutes to attain the status of optimal picture quality.

*This analog audio input terminal can be used for PC (RGB) or HDMI1/2 only.

4

50PD9800TA (FW1)

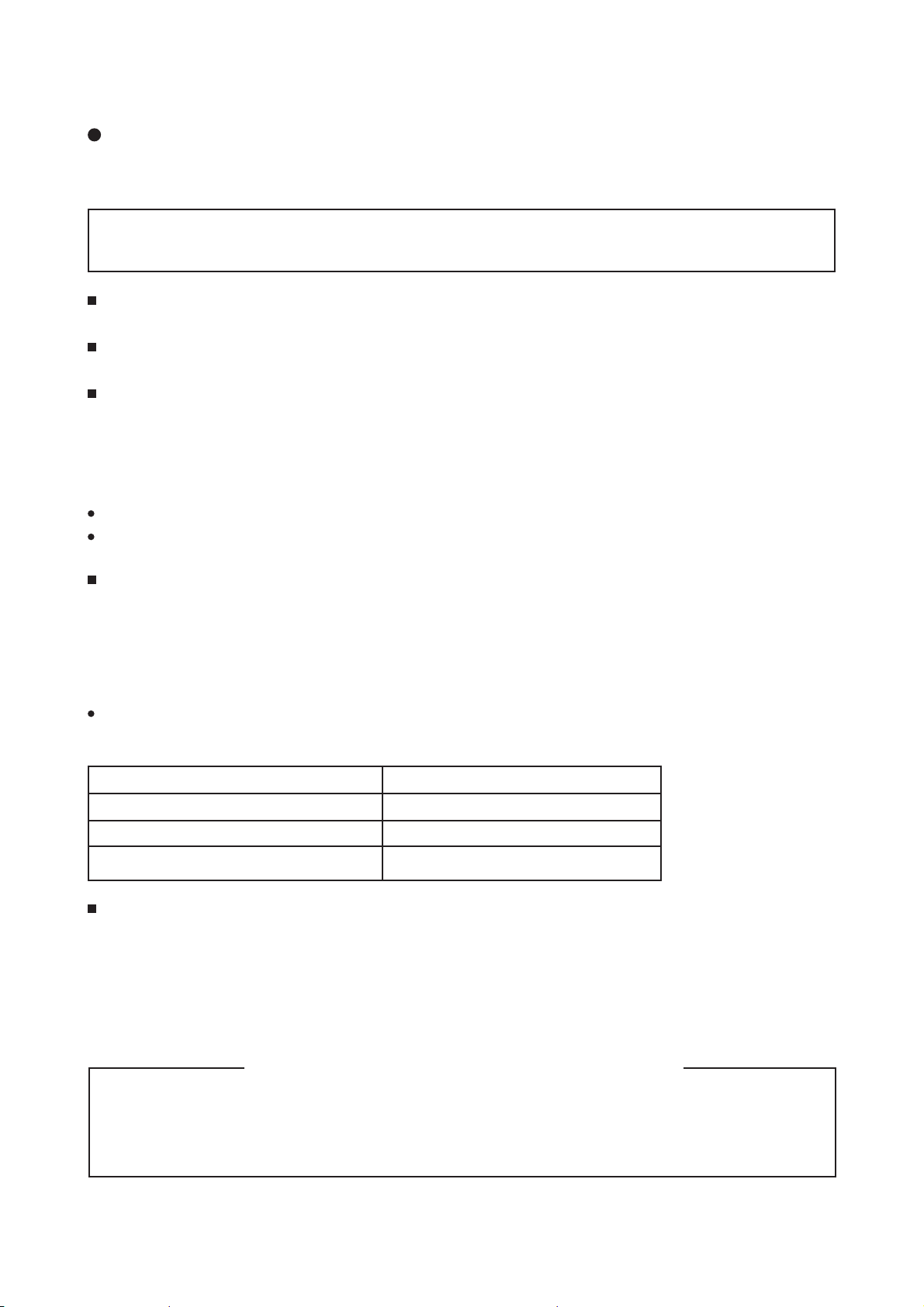

3. Service points

Lead free solder

This product uses lead free solder (unleaded) to help preserve the environment. Please read these

instructions before attempting any soldering work.

Caution: Always wear safety glasses to prevent fumes or molten solder from getting into the eyes. Lead

free solder can splatter at high temperatures (600˚C).

Lead free solder indicator

Printed circuit boards using lead free solder are engraved with an "F."

Properties of lead free solder

The melting point of lead free solder is 40-50˚C higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended.

Although servicing with leaded solder is possible, there are a few precautions that have to be taken. (Not

taking these precautions may cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the

lead free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450˚C)

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320˚C±30˚C

Mounting (chips) on empty PCB 380˚C±30˚C

Chassis, metallic shield, etc. 420˚C±30˚C

Readjustment Power supply voltage

When a PANEL or a Power Unit is exchanged, power supply voltage needs to be adjusted. Please adjust to

make the values of Vs and Va, as should on the label currently stuck on the panel back upper parts.Adjustment

is performed by VR in the power supply unit. Please refer to the procedures of “Vs” and “Va” adjustments on

21page.

The PWB assembly which has used lead free solder

Filter PWB (Filter PWB)

Sub PWB (Sub PWB)

MAIN PWB (Main PWB)

Control PWB (Control PWB, LED PWB)

5

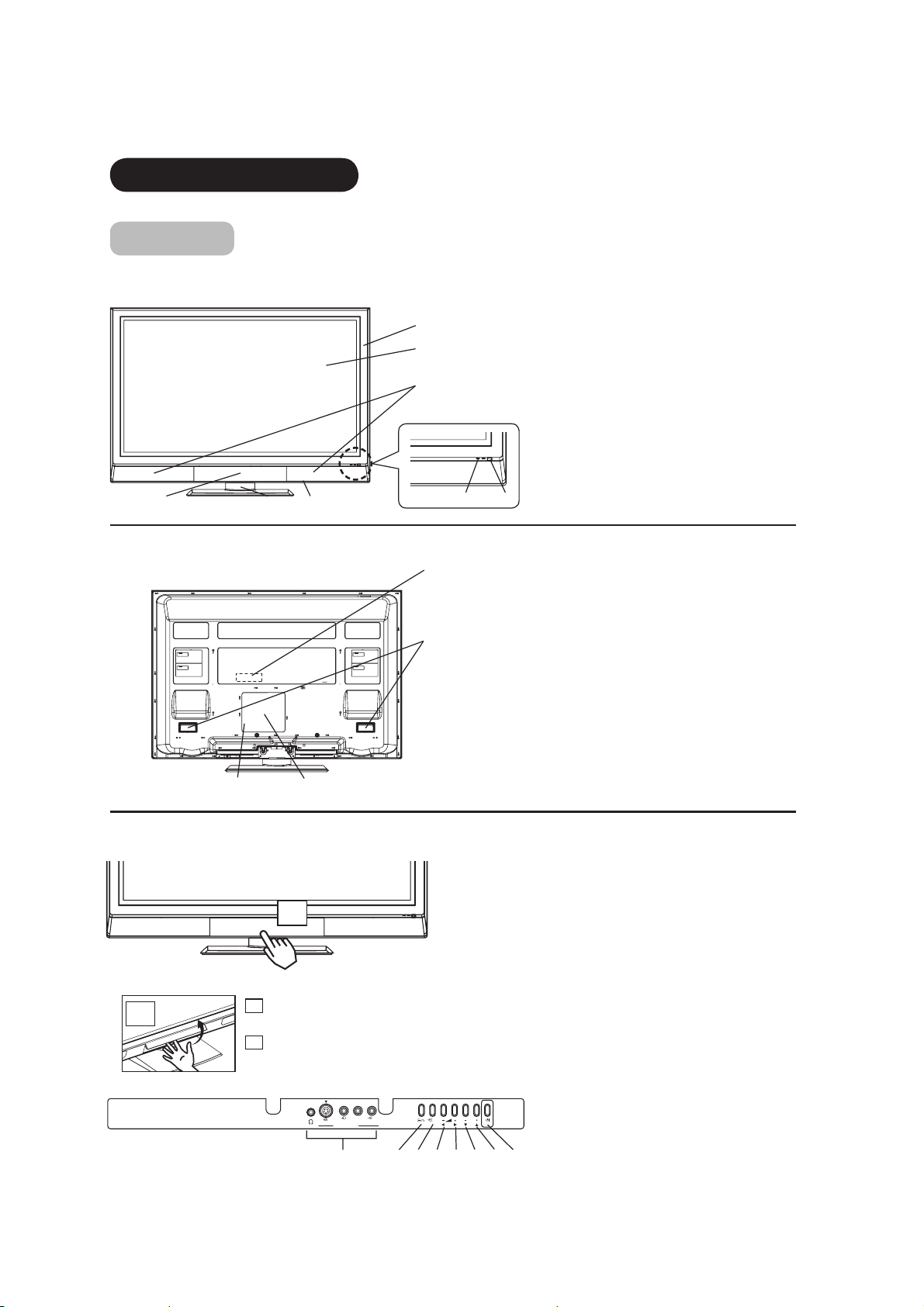

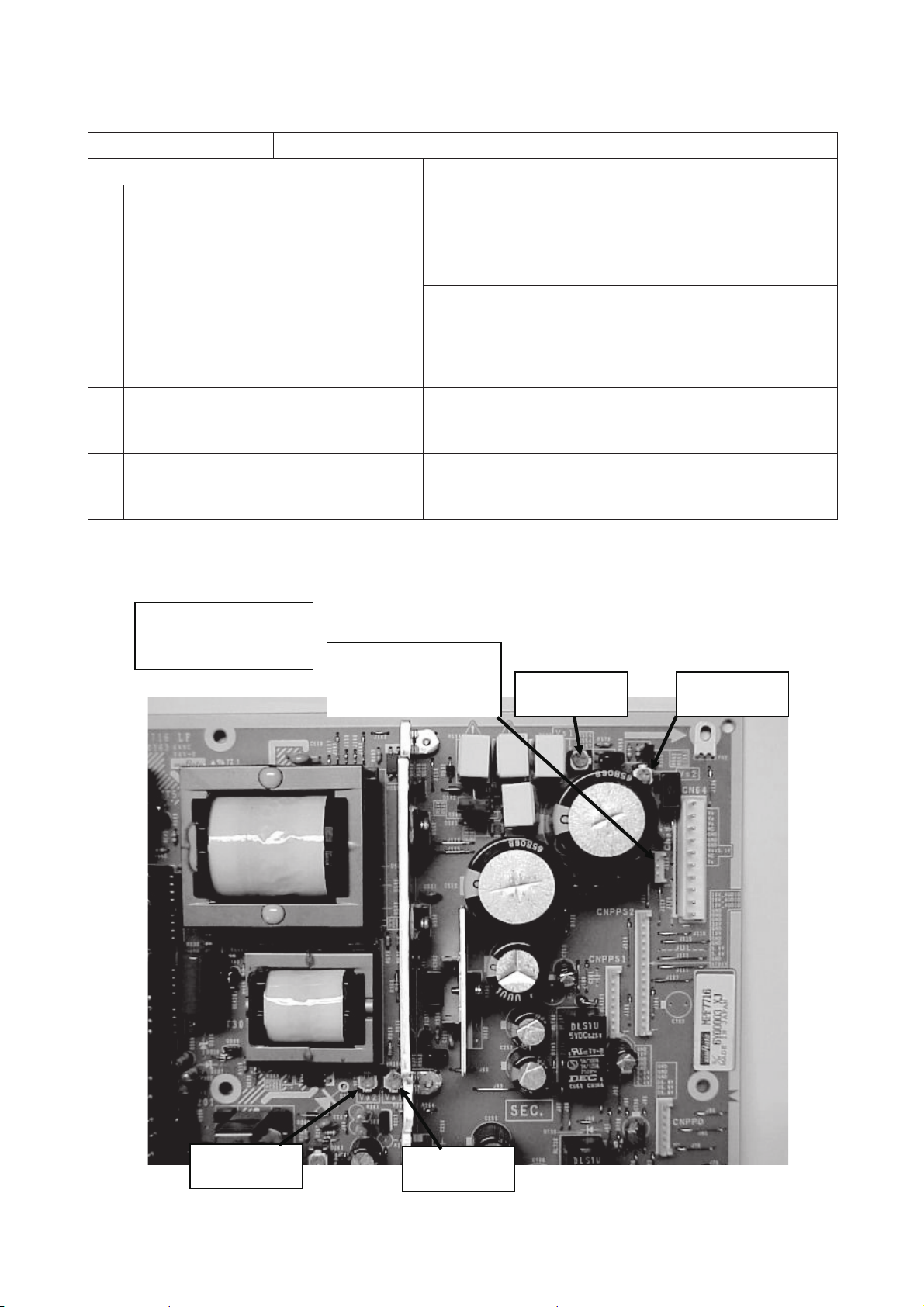

4. Component names

[Main unit]

COMPONENT NAMES

Main Unit

Front Panel

50PD9800TA (FW1)

Cabinet

q

Panel

w

Remote Control Receiver

q

w

i

e

Indicating Lamp

r

Main Power Switch (on the bottom surface)

t

Control Panel and Front Input (see below for details)

y

Desktop Stand (option)

u

Speaker

i

tuy

Rear Panel

w

q

Control Panel (including front input)

A

r

e

r

e

Terminal Board (External Device Connection)

q

Power Cord Socket

w

Handgrips

e

Motor Fan

r

>PS<

PH40173

B

Push here to open the door.

A Push the bottom center of

the front door to unlock.

B Lift it up from the underside

of the door.

RL/MONO

AUDIO

VIDEO

S-VIDEO

INPUT(AV4)

q

wertyui

Front Input (AV4)

q

Menu/Return button

w

Input Select/OK button

e

Volume Down/◄button

r

Volume Up/►button

t

OK

P

Channel Down/▼button

y

Channel Up/▲button

u

Sub Power button

i

6

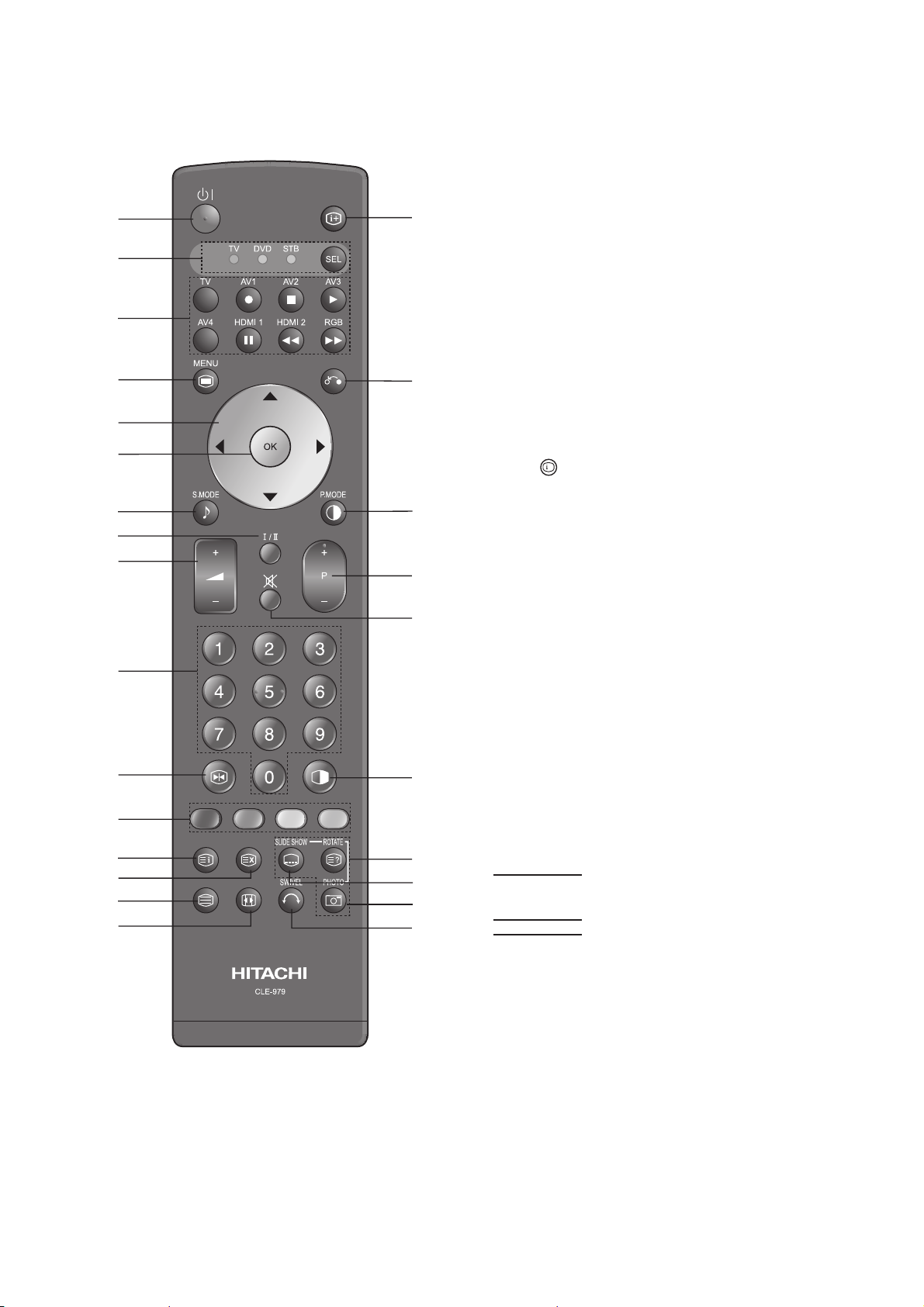

[Remote control]

q

w

e

r

t

y

u

i

o

a

s

d

f

g

h

j

50PD9800TA (FW1)

Sub Power

q

Function Select (TV/DVD/STB)

w

indicating LED lamp.

Normally, select “

Input Select/DVD Control

k

l

1(

2)

2!

2@

2#

2$

2%

2^

e

Press this button to change input mode.

operating the selected brand of DVD player.

Menu

r

Cursor

t

OK

y

Sound Mode

u

in the following sequence. Movie→Music→

Speech→Favorite

CHI/II

i

This is exclusively for TV audio A2/NICAM mode.

Volume Up/Down

o

Program Select [Page Select]

a

directly. For 2 or 3 digits channel selection,

press

Freeze [Hold]

s

mode. Press it again to return to normal picture.

(Also, it holds the page in teletext mode.)

[Color (Red, Green, Yellow, Blue)]

d

[Index]

f

Time [Cancel]

g

receiving a TV program.

The time is not displayed if the signal received

does not have any time information.

TV/Text [TVÙText]

h

Teletext mode.

Zoom [TextÙTV+Text]

j

Press this button to change picture size.

Recall

k

Return

l

You can use this to return to the previous menu.

Picture Mode

1(

Picture mode can be changed each time pressed

in the following sequence. Dynamic→Natural→

Cinema

Channel Up/Down [Page Select]

2)

Mute

2!

Not Available

2@

[Reveal]

2#

[Subtitle]

2$

Not Available

2%

Not Available

2^

TV”.

+

button in advance.

edomnoitcnuftcelesotnottubsihtsserP

elihwsnottubesehtesunacuoy,noitiddanI

desserpemithcaedegnahcebnacedomdnuoS

margorpVTatcelesotsnottubesehtsserP

ezeerfoterutcipehtegnahcotnottubsihtsserP

nehwemitehtyalpsidotnottubsihtsserP

VTehtneewtebsehctiwssihT

ehtdnaedom

.sutatslangistupniehtwohsotnottubsihtsserP

7

50PD9800TA (FW1)

5. New adoption technology

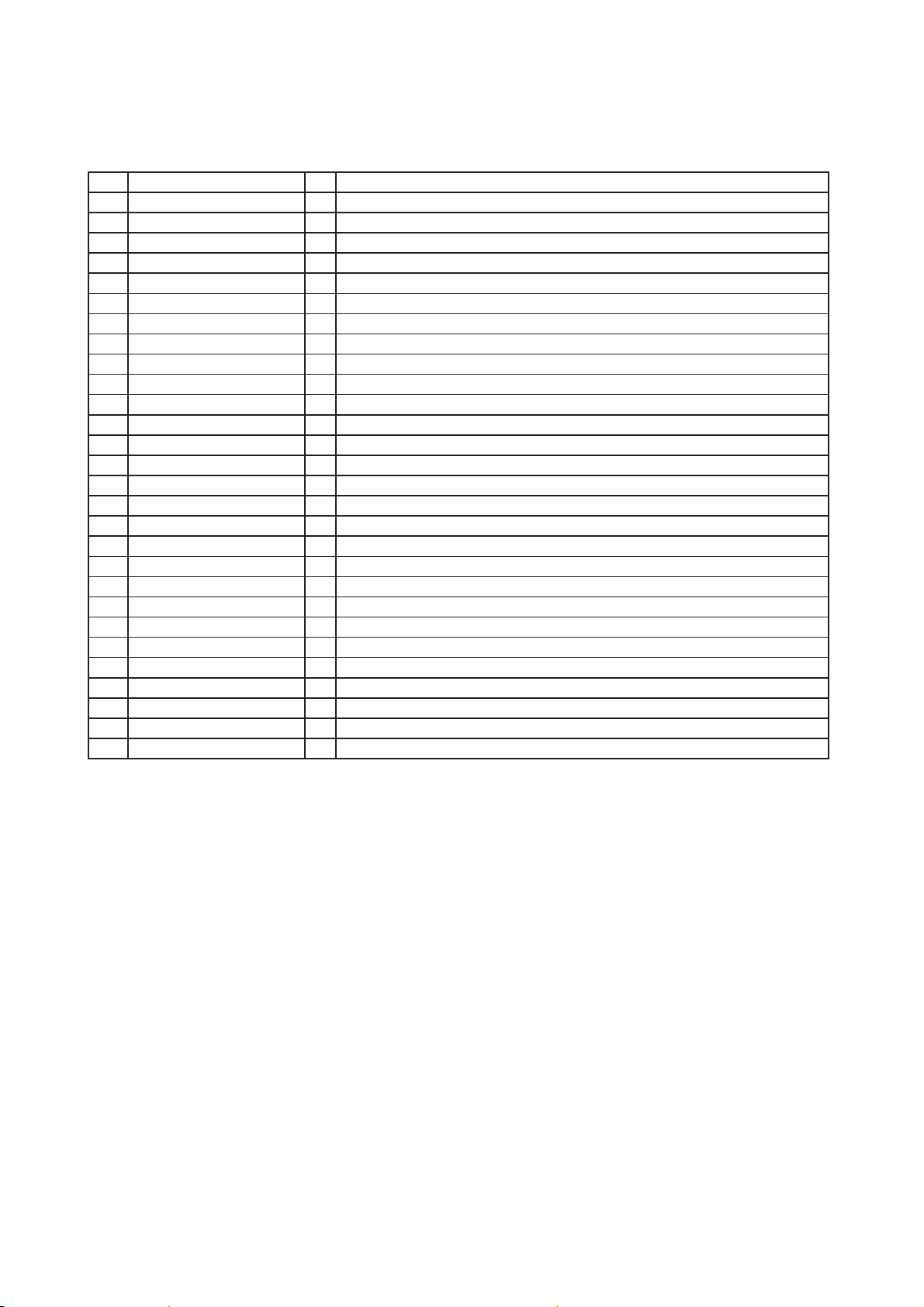

[System control micom I001(M30627)]

Pin function table

No. Pin Name I/O FUNCTION

1 VREF (+5.0V) I 5V

2 +5.0V I 5V

3 M_SW1 I/O Main SW1

4 M_SW2 I/O Main SW2

5 S_SW1 I/O Sub SW1

6 BL_CONT I/O LCD Backlight control (DA-out)

7 G_HB I/O GENESIS HEART BEAT

8 G_XRST I/O GENESIS XRST

9 G_BUSY I/O GENESIS BUSY

10 EXT_CONT_1 I/O NC

11 BL_INST I/O Black Insert On/Off for 32V LCD (37V=Low)

12 BL_BLINK I/O Backlight Blink On/Off for 32V LCD (37V=Low)

13 GND I GND

14 CNVSS(FLASH) I CNVSS(FLASH)

15 FC6_DATA_DIR I/O FC6 DATA I/O control

16 S_SW2 I/O Sub FE SW2

17 RESET I Reset

18 16MHz oscillate O OSC-OUT

19 GND I GND

20 16MHz oscillate I OSC-IN

21 +5.0V I 5V

22 NMI(+5.0V) I 5V PULL UP

23 RMCON I/O RX remote controller signal

24 FC6_VSYNC I/O FC6 V.SYNC Input

25 V.FREQ_3 I/O V.Frequency

26 SCV.SYNC I/O SUB_Y.SYNC (composite)

27 IRQ(PM-IRQ) I/O PDP control

28 MCV.SYNC I/O MAIN_Y.SYNC (composite)

29 POWER_LED I/O L : Lighting ( Power save )

30 EXT_CONT_2 I/O NC

31 CEC_OUT I/O CEC OUT(CEC2)

32 H.FREQ_3 I/O H.Frequency

33 PDWN I/O Panel LVDS

34 RXD2 I/O GENESIS communication

35 TXD2 I/O GENESIS communication

36 TXD1(RS232C/FLASH) I/O RS-232C communication / FLASH write

37 I 5V

38 RXD1(RS232C/FLASH) I/O RS-232C communication / FLASH write

39 I GND

40 SCLK(FLASH) I/O FLASH write

41 BUSY(FLASH) I/O FLASH write

42 TXD0(DTT) I/O DTT

43 RXD0(DTT) I/O DTT

44 SDA4(panel) I/O PDP communication (I2C bus)

45 SCL4(panel) I/O PDP communication (I2C bus)

46 M_ENABLE I/O Media Enable

47 M_SCLK I/O Media Clock

48 M_SDA I/O Media Data

49 M_WAKEUP I/O Media Wakeup

50 PDPGO(PM_ON) I/O PDP control / LCD Panel 12V

8

50PD9800TA (FW1)

No. Pin Name I/O FUNCTION

51 CPUGO(PM_CPU) I/O PDP control / Inverter (V)

52 EPM (FLASH) I/O FLASH write

53 DISPEN I/O DISPEN / Backlight on

54 SCL1 I/O I2C(to Sub PWB) FE/MSP4450G or MSPxxxxG

55 SDA1 I/O I2C(to Sub PWB) FE/MSP4450G or MSPxxxxG

56 HDMI-RESET I/O HDMI-Reset

57 HDMI-HPD_RESET I/O Hot Plug Detect Reset

58 SCL6 I/O I2C(to Sensor PWB) (AD7414)

59 SDA6 I/O I2C(to Sensor PWB) (AD7414)

60 TUNER.DET_1 I/O TUNER setting ( Tuner / 2 Tuner )

61 CE (FLASH) I/O FLASH write

62 STAND.CIR_DET I/O Stand Detect

63 SW_L_OUT I/O Swivel L out

64 SW_R_OUT I/O Swivel R out

65 M_SW I/O B.M. distinction

66 IRQ_DTT/DTT_RESET I/O DTT IRQ/DTT_RESET(for AUS-DTT)

67 DTT_GPIO1 I/O DTT_GPIO1 (for AUS-DTT)

68 DTT_POWER I/O DTT POWER

69 SCDT I/O HDMI Power Save ( return )

70 RS232_SEL1 I/O RS-232C select1 ( Main MPU / GNSS )

71 NC I/O NC

72 CUR_PRTCT I/O Detect Power Swivel overload

73 SP_MUTE I/O SP relay

74 AUDIO_MUTE I/O Audio MUTE

75 REC_MUTE I/O Audio REC_MUTE

76 HP_MUTE I/O Head Phone MUTE

77 SCL5 I/O I2C(Sil9021)

78 SDA5 I/O I2C(Sil9021)

79 SYNC_SW2 I/O sync SW

80 SYNC_SW1 I/O PC/BM sync SW

81 RGB_BLK_2 I/O NC

82 RGB_BLK_3 I/O NC

83 AUDIO_RESET I/O Audio RESET

84 IR_SW I/O IR Through SW

85 +5.0V I 86 EDID_PROTECT_1 I/O Memory Protect

87 GND I GND

88 WSS_1 I/O NC

89 WSS_2 I/O NC

90 TV.AFC(S) / WSS_3 I/O Sub tuner control (AFC)

91 TV.AFC(M) I/O Main tuner control (AFC)

92 DEALY_SW1 I/O Audio Delay SW1(Lipsync)

93 DEALY_SW2 I/O Audio Dealy SW2(Lipsync)

94 EDID_PROTECT_2 I/O Memory Protect

95 HP_DETECT I/O HEAD PHONE DETECT

96 VCD_CE I/O for SAA7117A CE

97 INT_HDMI I/O INT(HDMI)

98 CEC_IN I/O CEC IN(CEC1)

99 RS232_SEL2 I/O RS-232C SEL2 (DTT / RS-232C SEL1)

100 DEMP_OUT I/O HDMI demphasis control out

9

50PD9800TA (FW1)

No. Pin Name I/O FUNCTION

101 FC6_XRST I/O FC6 XRST

102 SCL0 I/O

103 SDA0 I/O

104 SCL3(EEPROM) I/O I2C(EEPROM)

105 SDA3(EEPROM) I/O I2C(EEPROM)

106 EPGGO I/O EPGGO

107 FC6_EXTLD I/O FC6 EXTLD

108 FC6_CLK I/O FC6 CLK

109 FC6_ENABLE I/O FC6 ENABLE

110 V_P_DET_1 I/O V_DET_1(Power Save return)

111 V_P_DET_2/POW_DL I/O V_DET_2(Power Save return)

112 FC6_DATA7 I/O FC6 DATA7

113 FC6_DATA6 I/O FC6 DATA6

114 FC6_DATA5 I/O FC6 DATA5

115 FC6_DATA4 I/O FC6 DATA4

116 FC6_DATA3 I/O FC6 DATA3

117 FC6_DATA2 I/O FC6 DATA2

118 FC6_DATA1 I/O FC6 DATA1

119 FC6_DATA0 I/O FC6 DATA0

120 FC6_PBLK I/O FC6 PBLK

121 PDP_LCD_SW I/O PDP(A4/A4SF/50),LCD(32/37) detect

122 AD_KEY2 I/O AD KEY2*

123 AD_KEY1 I/O AD KEY1(Power)

124 TV.POWER I/O H:Power ON, L:(Standby, Power Save)

125 DIP.DET I/O DIP DET

126 POWER_SAVE I/O L:Lighting (standby, power save), H:Lighting off

127 GND I GND

128 FAN_ALARM *1 I/O FAN ALARM

I2C (for Main PWB & Sub PWB)(SAA7117A/AN15867A/MM1631/MAX9723DETE)

I2C (for Main PWB & Sub PWB)(SAA7117A/AN15867A/MM1631/MAX9723DETE)

10

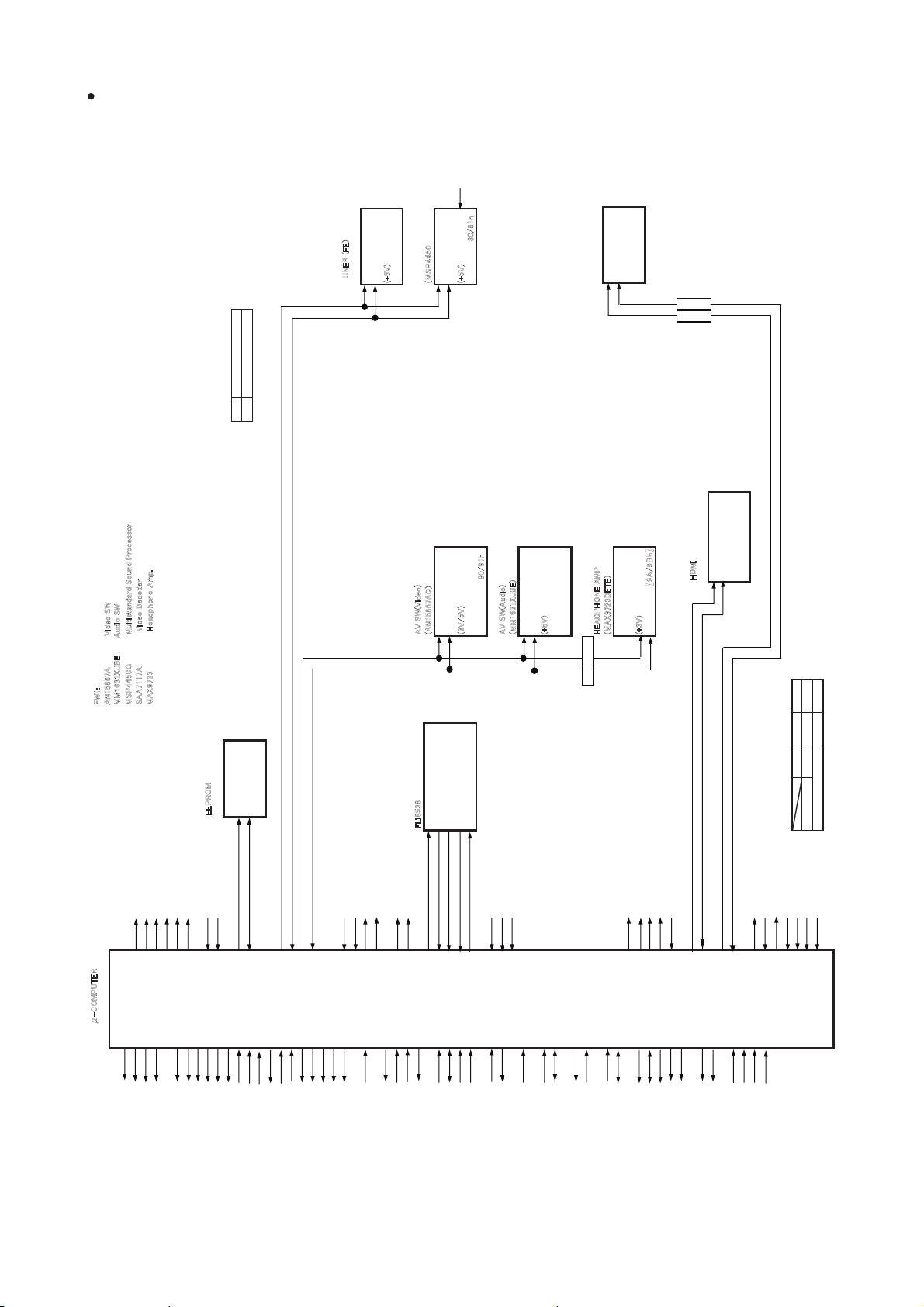

Block diagram

50PD9800TA (FW1)

㩷

㪇㪚䇼

㪈㪘㪛㪪㪫

㪈㪣㪚㪪㪫

㪥㪜㪩㩷㩿㪝㪜㪀

㪬

㪂㪌㪭㪀 䇼㪚㪍㪿䇽

㪫

㪭㪧㪘㪄㪈㪌㪩㪆㪭㪧㪄㪈㪌㪩

㪈

㪘

㪛㪪

㪪㫆㫌㫅㪻㩷㪤㫌㫃㫋㫀㫇㫃㪼㫏

䇽 㩿㪏㪋㪆㪏㪌㪿㪃㪏㪏㪆㪏㪐㪿㪀

㪿

㪇㪆㪏㪈

㪏

㪋㪣㪚㪪

㪧㪛㪧㩷㪧㪘㪥㪜㪣

㪛

㪪

㪙㫌㪽㪽㪼㫉

㪙㫌㪽㪽㪼㫉

㪧㪛㪧㩿㪘㪜㪈㪀

㪘㪥㪍 㪧㪘㪥㪜㪣㩷㪫㪰㪧㪜

㫉

㫆

㫊

㪼㫊

㪺

㩷㪧㫉㫆

㫅㪻

㫌

㫇㪅

㫆

㫉

㪼

㪻

㪺㫆

㫅㪼㩷㪘㫄

㪼

㫋㪸㫅㪻㪸㫉㪻㩷㪪

㫊

㪼㫆㩷㪪㪮

㫌㫃㫋㫀

㪻

㫌㪻㫀㫆㩷㪪㪮

䊶䊶䊶䇭㪟㪼㪸㪻㫇㪿 㫆

䊶䊶䊶䇭㪭㫀㪻㪼㫆㩷㪛

䊶䊶䊶㩷㩷㪭㫀

㩷

㪜 䊶䊶䊶 㪘

㩷

䇭䊶䊶䊶㩷㪤

㩷

㪙

㩷

㪡

㪘

㪘

㪇㪞

㪯

㪊

㪎

㪌

㪈

㪈㪎

㪍

㪋

㪎㪉

㪈

㪍㪊

㪐

㪎

㪑

㪌㪏

㪈

㪈

㪮

㪝

㪯

㪈

㪪㪧㪋

㪤

㪘

㪥

㪘㪘

㪤

㪪

㪤

㪤

㪘

䇽㪿㪈㪘

㪆㪇㪘䇼

㪀㪋

㪍㪚㪮㪋㪉㪫㪘㪚㩿

㪤

㪊㪘㪛㪪

㪊

㪩㪦

㪣

㪚㪪

㪜㪧

㪜

㪉㪶

㪊㪶㪢㪣

㪈㪮㪪㪶㪤㪎㪐㪧㪋㪌㪧㪥㪜㪧㪪㪠㪛

㪉㪮㪪㪶㪤㪍㪐㪧㪇㪋㪈㪧㪢㪥㪠㪣㪙㪶㪣㪙

㪈㪮㪪㪶㪪㪌㪐㪧㪈㪋㪈㪧㪫㪪㪥㪠㪶㪣㪙

㪚㪥

㪢㪣㪙㪶㪙

㪙㪶

㪙㪞㪩㪉㪉㪈㪧㪎㪌

㪞㪩㪊㪉

㪫㪚㪫㪩㪧㪶㪩㪬㪚㪇㪋㪧㪈㪉㪈㪧㪫㪪㪩㩷㪛㪬㪘

㪫㪜㪪㪜㪩㪶

㪬

㪬

㪦㪶

㪦㪶

㪠㪤㪛㪟㪈㪊

㪣㪶㪮㪪㪌㪉㪈

㪣㪶㪮

㪪㪍

㪫

㪜

㪪

㪜㪩㪶

㪛

㪧㪟㪶

㪠㪤㪛㪟㪇㪊

㪀 㩿㪤㪪㪧㪋 㪋㪌㪇㪞㪀㩷㩷㩷

㪨

㪍㪎㪘

㪌㪏

㪘㪥㪈

㪏 㪘㪭㩷㪪㪮㩿㪭㫀㪻㪼㫆㪀㩷

㪫㪪㪩

㪊

㪯㩷

㪣㪠㪏㪌

㪞㪉

㪣㫆㫎㪑㩷㫀㫅㫇㫌㫋㩷㪹㪼㫃㫆㫎㩷㪇㪅㪊㪭

㪟㫀㪾㪿㪑㩷㫀㫅㫇㫌㫋㩷㪸㪹㫆㫍㪼㩷㪇㪅㪍㪭

䇽

㪈㪿

㪆㪐

㪇

䇼㪐

㪀 㩿㪂㪌㪭㪀 㪩㪜㪪㪜㪫

㪭

㪇㪘㪛㪪㪙

㪇㪣㪚㪪㪰㪪㪬㪙㩷㪞

㪊㪭㪆㪌

㪟㪶

㪞㪄㪫㪯㪛㪉

㪞㪄㪩㪯㪛㪉

㪞㪥㪠㪊㪙㪫㪇㪇㪧㪣

䇽

㪙㪿

㪐

㪛㪤㪠

㪪㪚㪣㪌

㪀

㩷

㫌㪻㫀㫆㪀

㪘

㪊㪈㪯㪡㪙㪜

㪭㩷㪪㪮㩿

㪤㪤㪈㪍

㪘

㩿

㪪㪚㪣㪇

䇼㪐㪋㪆㪐㪌㪿䇽 㩿㪐㪍㪆㪐㪎㪿㪀

㪇

㪭㪀

㪘

㪌

㪛㪪

㪂

㪜㪘㪛㪧㪟㪦㪥㪜㩷㪘㪤㪧

㪟

㪣㪜㪭㪜㪣㩷㫊㪿㫀㪽㫋

㪐㪘㪆

㪫㪜㪀

㪉㪊㪛㪜

㪇

㪘㪛

㪂㪊㪭㪀 䇼㪊㪇㪆㪊㪈㪿䇽

㪤㪘㪯㪐㪎

㩿

㩿

㪪㪜

㪧㪬㪜㪢

㪣㪙

㪢

㪘㪥

㪘㪮㪶

㪚㪪㪶㪤

㪜㪶㪤㪎㪊㪈

㪤

㩿㪪㫀㫃㪐㪇㪉㪈㪀

㫊㫊

㪭㪥

㪇㪭㪌㪭

㪚㪤㪧

㪇㪭

㪜㪜

㪌㪭 㪌㪭

㪚

㪧㫉㫆㪾㫉㪸㫄㩷㫋㫆㩷㪝㪣㪘㪪㪟

㪥㫆㫉㫄㪸㫃 㪇㪭

㪘㪛㪪㪶㪤㪌㪊㪈

㪜㪧㪤

㪚㪜

㪩

㱘㪄㪚㪦㪤㪧㪬㪫㪜

㩿㪤㪊㪇㪍㪉㪎㪀

㪎㪇㪧㪇㪏㪧㪀㪨

㪈

㪋㪧㪈㪘㪛㪫㪥㪦㪚㪶㪣㪙

㪧㪏㪍 㪪㪶㪪㪮㪉

㪧㪦㪮㪜㪩㪶㪪㪘㪭㪜 㪧㪈㪇㪈 㪧㪉㪊 㪛㪜㪣㪘㪰㪶㪪㪮㪈

㪫㪭㪅㪧㪦㪮㪜㪩 㪧㪈㪇㪊

㪧㪦㪮㪜㪩㪶㪣㪜㪛 㪧㪎㪍 㪧㪉㪉 㪛㪜㪣㪘㪰㪶㪪㪮㪉

㪍

㪇

㪈㪧

㪧㪊㪋㪧㪫㪛㪚㪪

㪌

㪇㪧㪦

㪧

㪀㪥㪦㪶㪤㪧㩿㪦㪞㪧㪛㪧

㪩㪠㪄㪤㪧㩿㪨㪩㪠

㪞

㪞㪧

㪚㪧㪬㪞㪦㩿㪧㪤㪶㪚㪧㪬㪀 㪧㪌㪍

㪜

㪈

㪊㪊

㪈

㪈㪧

㪧㪎㪊㪧㪜㪫㪬㪤㪶

㪉㪇㪈

㪉㪎

㪧

㪧

㪫

㪜

㪥㪮㪛㪧

㪛㪶

㪧

㪠㪛

㪧

㪭㪶㪧㪶㪛㪜㪫㪶㪈 㪧㪇㪈

㪟㪧㪶㪛㪜㪫㪜㪚㪫 㪘㪥㪉㪇 㪧㪈㪊㪉

㪘㪬㪛㪠㪦㪶㪤㪬㪫㪜 㪧㪊㪍 㪧㪈㪇

㪪

㪩㪜㪚㩷㪤㪬㪫㪜 㪧㪊㪌

㪋

㪊㪧㪜㪫㪬㪤㩷㪧㪟

㪉㪈㪧

㪧

㪧㪈㪉㪎 㪪㪫㪘㪥㪛㪅㪚㪠㪩㪶㪛㪜㪫

㪫

㪬㪦

㪉

㪋

㪏㪧

㪘㪫

㪫㪬

㪥

㪦㪶

㪦

㪚㪤㪩

㪚

㪜㪚 㩿

㪈

㪐

㪐㪧

㪛

㪈㪧

㪈㪧

㪌

㪍㪈

㪈㪧㪥

㪧

㪀㪠㪤

㪛

㪠㪶

㪟㩿㩷㪫㪥

㪚㪜

㪠 䇽㪿

㪚

㪛㪜㪤㪧㪶㪦㪬㪫 㪧㪈㪊 㪝

㪛㪯㪫㪥

㪧 㩿

㪇㪫

㪥㪠㪊㪶㪨㪜㪩㪝㪅㪭 㪪㪚㪣㪈

㪯㪩㪥㪠㪋㪘㪫㪚㪥㪰㪪㪅㪭㪚㪪 㩿

㪛

㪶㪮㪦㪧㪆㪉㪶

㪫

㪜㪛㪶㪧㪶㪭

㪘㪥㪉㪌 㪫㪭㪅㪘㪝㪚㩿㪪㪀

㪫

㪥

㪜

㪫㪭㪅㪘㪝㪚㩿㪤㪀 㪘㪥㪉㪋

㪠

㪇㪇

㪈㪘㪫㪊㪶㪨㪜㪩㪝㪅㪟

㪪

㪇

㪌㪎

㪜㪩

㪐㪧㪥㪚

㪈

㪧

㪧

㪤㪩

㪘

㪣㪘㪶㪥

㪫㪜㪪㪜㪩 㩿

㪘

㪥㪚

㪝

㪠

㪊㪘㪫

㪚

㪥㪰

㪪

㪅㪭

㪚㪤 䇼

㪜㪛㪠㪛㪶㪧㪩㪦㪫㪜㪚㪫㪶㪈 㪧㪊㪇 㪘㪥㪉㪍 㪥㪚

㪜㪛㪠㪛㪶㪧㪩㪦㪫㪜㪚㪫㪶㪉 㪧㪉㪈 㪘㪥㪉㪎 㪥㪚

㪍

㪋

㪊㪈㪧㪇㪛

㪊㪈㪧㪇㪛㪯㪫㪫㪫

㪧

㪧

㪊㪌㪧

㪉㪌㪧㪍㪘㪛㪪 㪪㪚㪣㪇 㪋㪘

㪍㪋㪧㪛㪫㪫㩷㪩㪼㫊㪼㫋

㪯㪩

㪍㪣㪚

㪫㪫

㪛 䇼

㪛

㪛㪫㪫㪶㪧㪦㪮㪜㪩 㪧㪋㪋

㪪

㩿㪛㪫㪫㪶㪞㪧㪠㪦㪀 㪧㪋㪌 㪧㪋㪎 㪤㪶㪪㪮

㪈㪍

㪧㪍㪇 㪪㪛㪘㪌

㪧

㪧㪈㪈㪊 㪟

㪌㪥㪘㪉㪰

㪋㪥㪘㪈㪰

㪜

㪜

㪢㪶㪛㪘 䇼㪍㪏㪆㪍㪐㪿䇽

㪢㪶㪛㪘

㪩㪪㪉㪊㪉㪶㪪㪜㪣㪉 㪧㪈㪋

㪩㪪㪉㪊㪉㪶㪪㪜㪣㪈 㪧㪋㪉 㪧㪈㪈㪉

㫊㫊

㪌

㪍㪧

㪭㪥

㪧㪍㪋 㪙㪬㪪㪰㩿㪝㪣㪘㪪㪟㪀

㪧㪌㪌

㪧㪌㪇

㪚 㪧㪌㪍㩷㪚㪧㪬㪞㪦

㪫㪬㪥㪜㪩㪅㪛㪜㪫 㪧㪌㪈 㪩㪯㪛㪈 㪩㪪㪉㪊㪉㪚㪆㪝㪣㪘㪪㪟㪶㪩㪯㪛

㩿㪈㪫㫌㫅㪼㫉㪆㪉㩷㪫㫌㫅㪼㫉㩷㪪㪼㫃㪼㪺㫋㪀 㪪㪚㪣㪢㩿㪝㪣㪘㪪㪟㪀

㪧㪛㪧㪶㪣㪚㪛㪶㪪㪮 㪘㪥㪍 㪫㪯㪛㪈 㪩㪪㪉㪊㪉㪚㪆㪝㪣㪘㪪㪟㪶㪫㪯㪛

11

50PD9800TA (FW1)

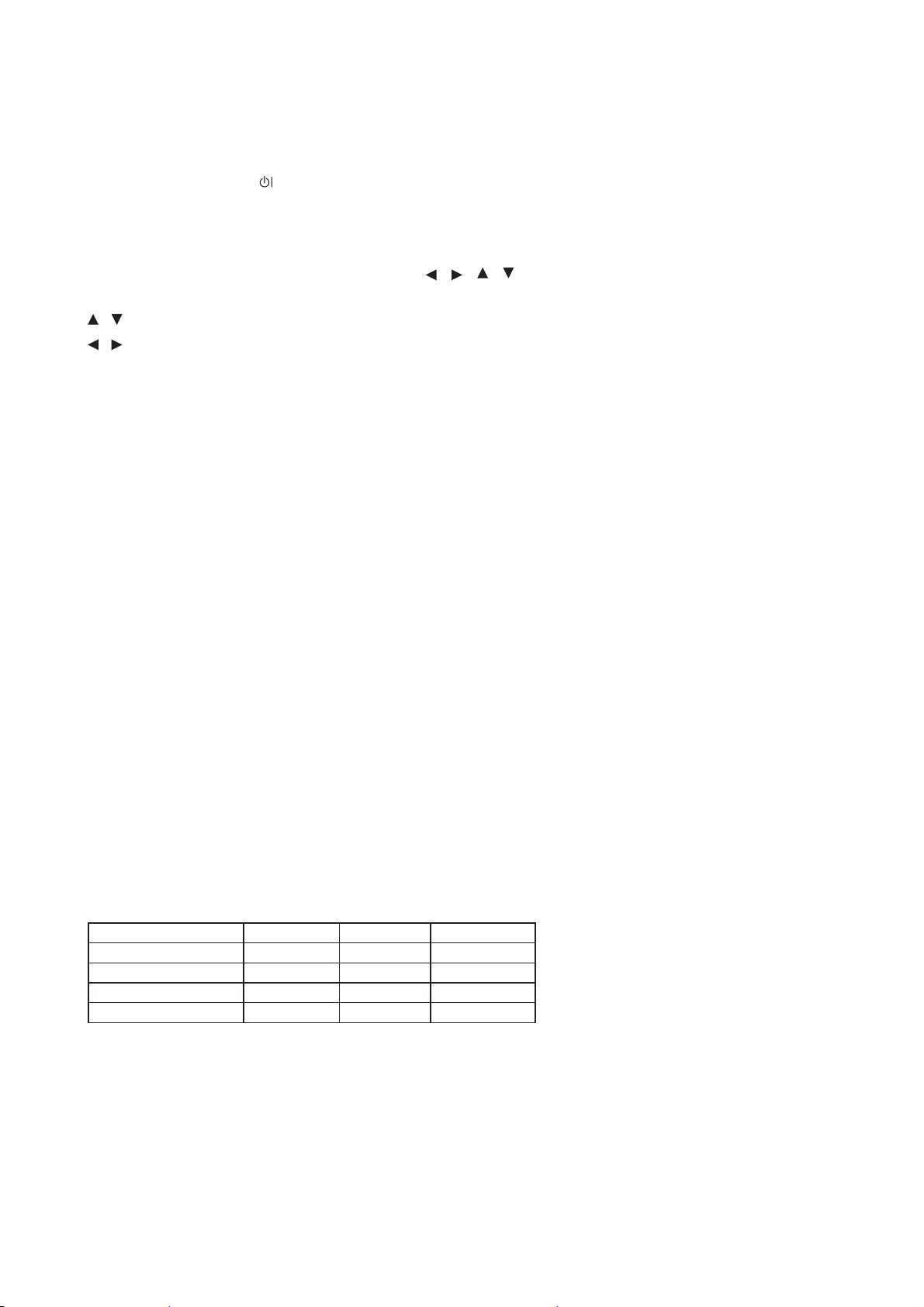

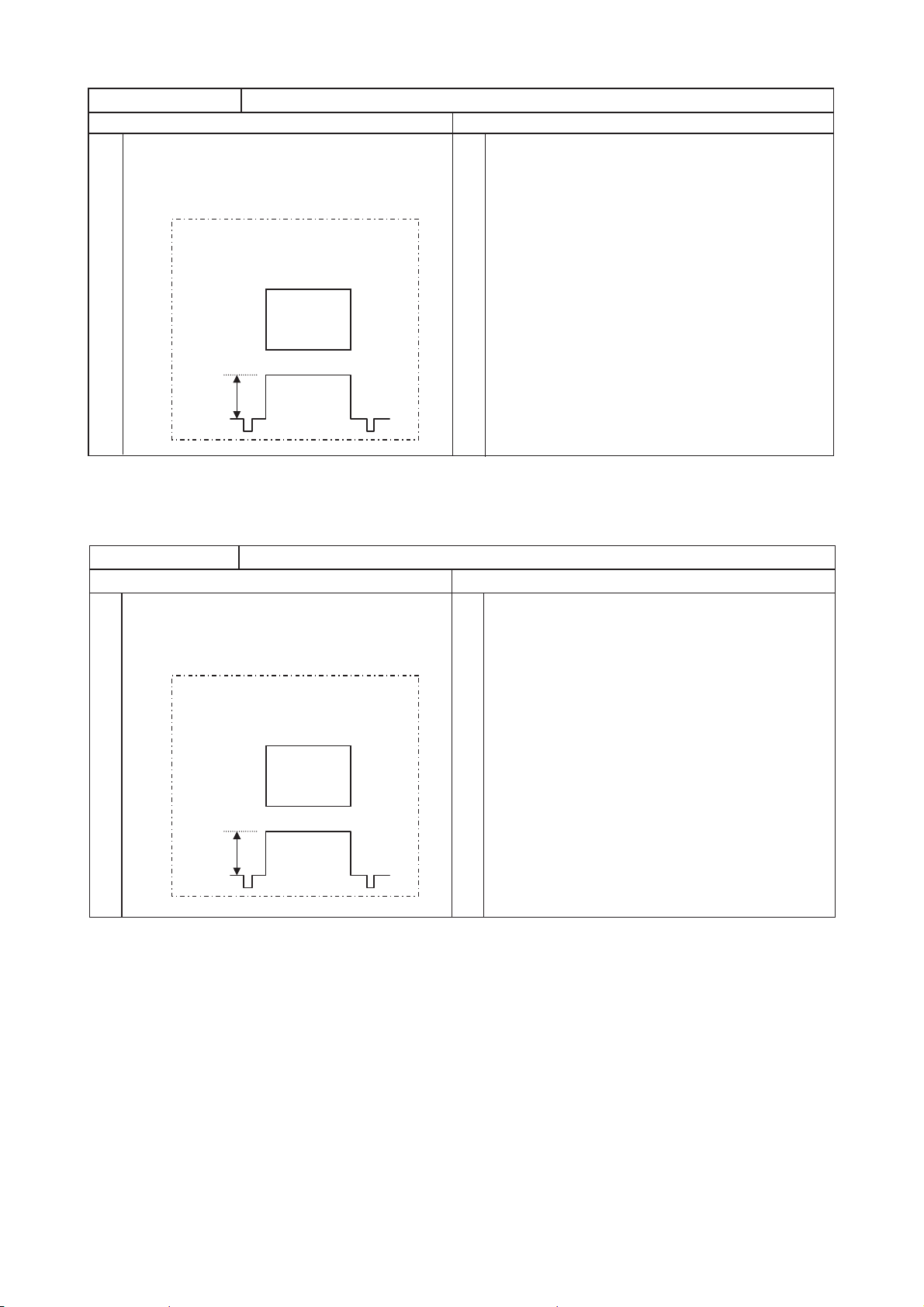

6. Adjustment

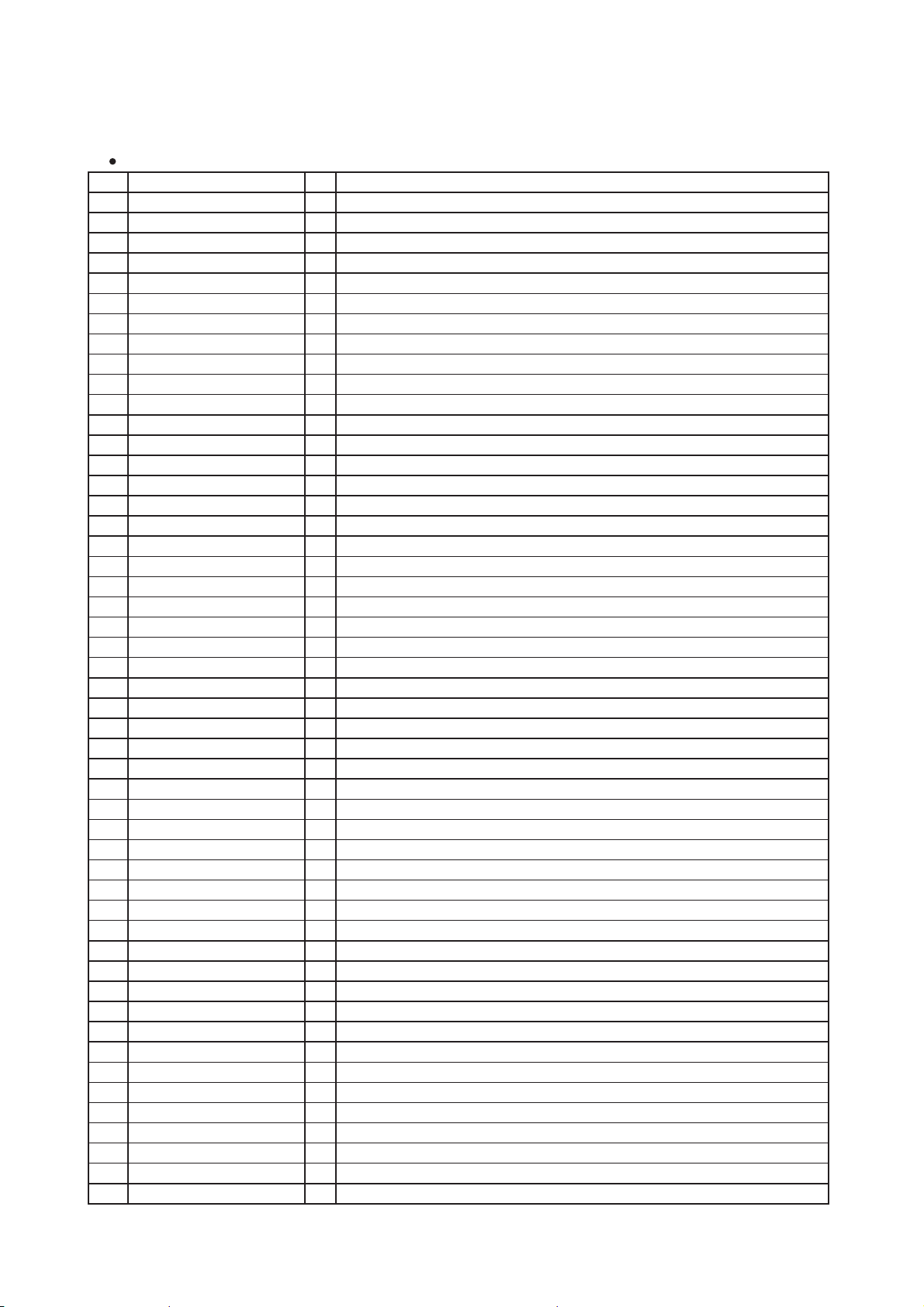

● How to get to Adjustment mode

Using the front buttons with the set turned off (standby) can activate it.

Press the SUB-POWER(

The set turns on in adjustment mode with OSD.

● Changing data and Selecting Adjustment code

When the set is in adjustment mode, the cursor , , , and OK buttons of the remote control or front

buttons may be used as the adjustment keys.

, buttons are used for selecting adjustment code.

, buttons are used for changing data values.

OK button is used for to fix data.

After finishing the necessary adjustment press MENU button. Adjustment mode is released and the set

returns to normal condition.

● Memory Initialize operation

The execution of this function returns the adjustment codes to the preset values, therefore, adjustment data

will be lost.

Procedure

(1) Enter Adjustment Mode.

(2) Select MEMORY INIT adjustment code (No.598) and change the data value from 0 to 1.

(3) Activate MEMORY INIT by pressing OK button.

(4) Select No.407 and change data value from 1 to 0.

(5) Check that the receiving channel goes to P1. Unit is set to preset values.

) button, and MENU button at the same time, and hold for more than 5 seconds.

● How to check method of the use accumulation time for panel.

Select No. 594 of Service Adjustment Menu.

● Do for the following when flicker is anxious.

This phenomenon depends on a contrast inprovement function of a panel.

In the following condition, there is the case that this phenomenon occurs.

But outbreak frequency is very low.

• A still image of a single raster

• A signal of the video specification gradation input

ADJ Items ADJ No. Init. Value Max. value

PC mode 132 0 1

Dynamic mode 129 0 1

Normal mode 130 0 1

Cinema mode 131 0 1

• When changed a main PWB for a service board, refer to P22 (Instructions in software renewal) at work.

12

50PD9800TA (FW1)

A

_

]

e

_

]

e

_

]

e

A

_

]

e

A

_

]

A

_

]

A

_

]

A

_

]

A

_

]

A

_

]

A

_

]

A

(

]

A

(

]

A

(

]

A

(

]

A

(

]

A

(

A

(

]

A

)

A

)

A

)

A

)

A

p

A

p

A

p

A

p

A

p

A

p

A

p

A

p

]

A

p

A

p

A

p

A

p

A

p

A

_Q(

L

)(

A

_Q(

L

)(

]

A

p

A

_Q(

A

_Q(

A

p

A

p

A

p(

W

A

p(

]

A

_DL(

A

_DL(

A

_DL(

A

_DL(

A

_DL(

A

_DL(

A

_DL(

A

_DL(L)

A

_DL(L')

A

_DL(

A

_DL(

A

_DL(

A

[

]

A

[

]

A

AFC_

]

A

AFC_

]

A

AFC_

]

A

AFC_

]

A

AFC_

]

A

AFC_

]

A

[

]

A

_

]

A

A

A

]

A

A

A

A

A

[

]

A

[

A

A

p

A

_

A

_

A

p

E

A

p

y

A

p

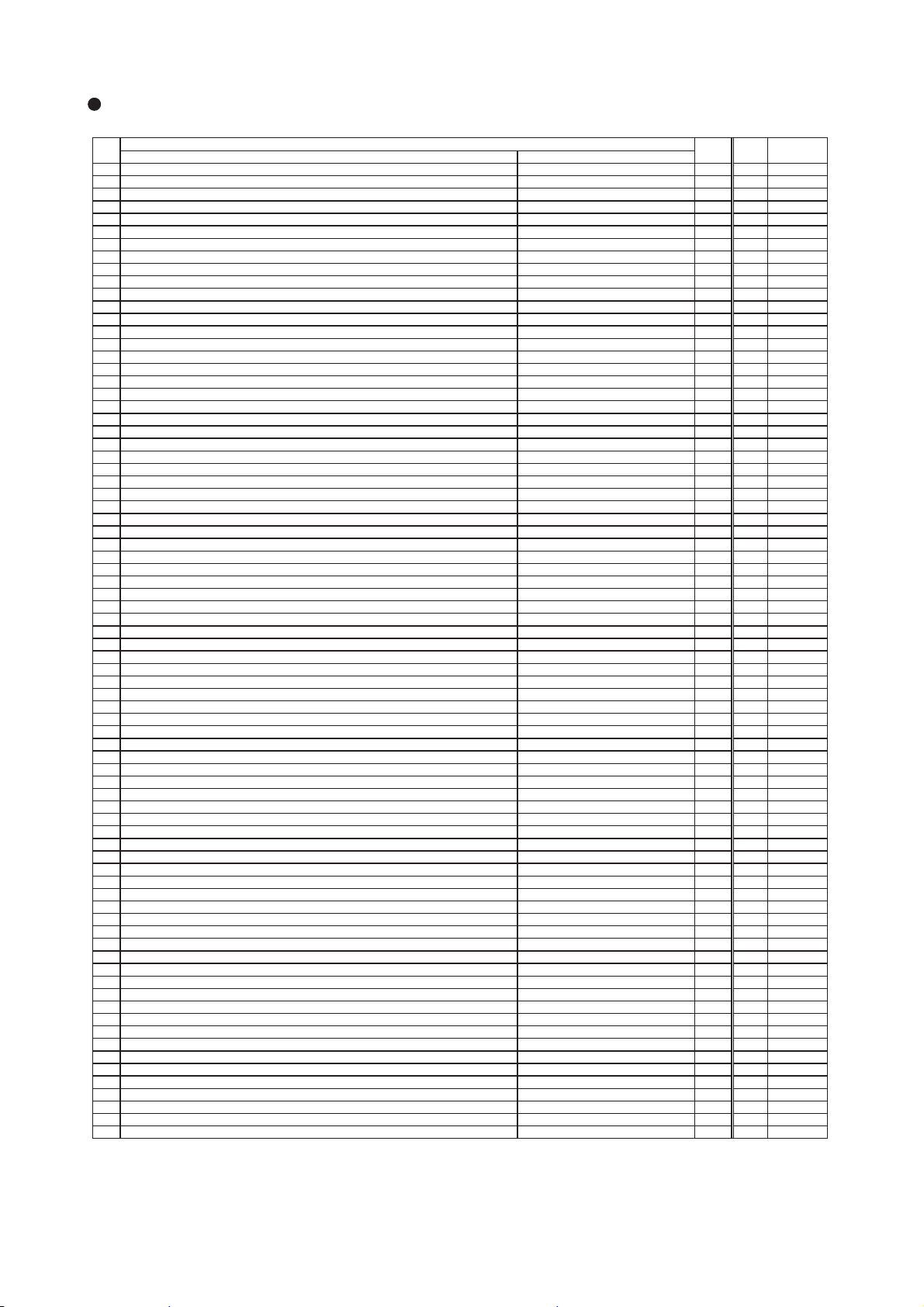

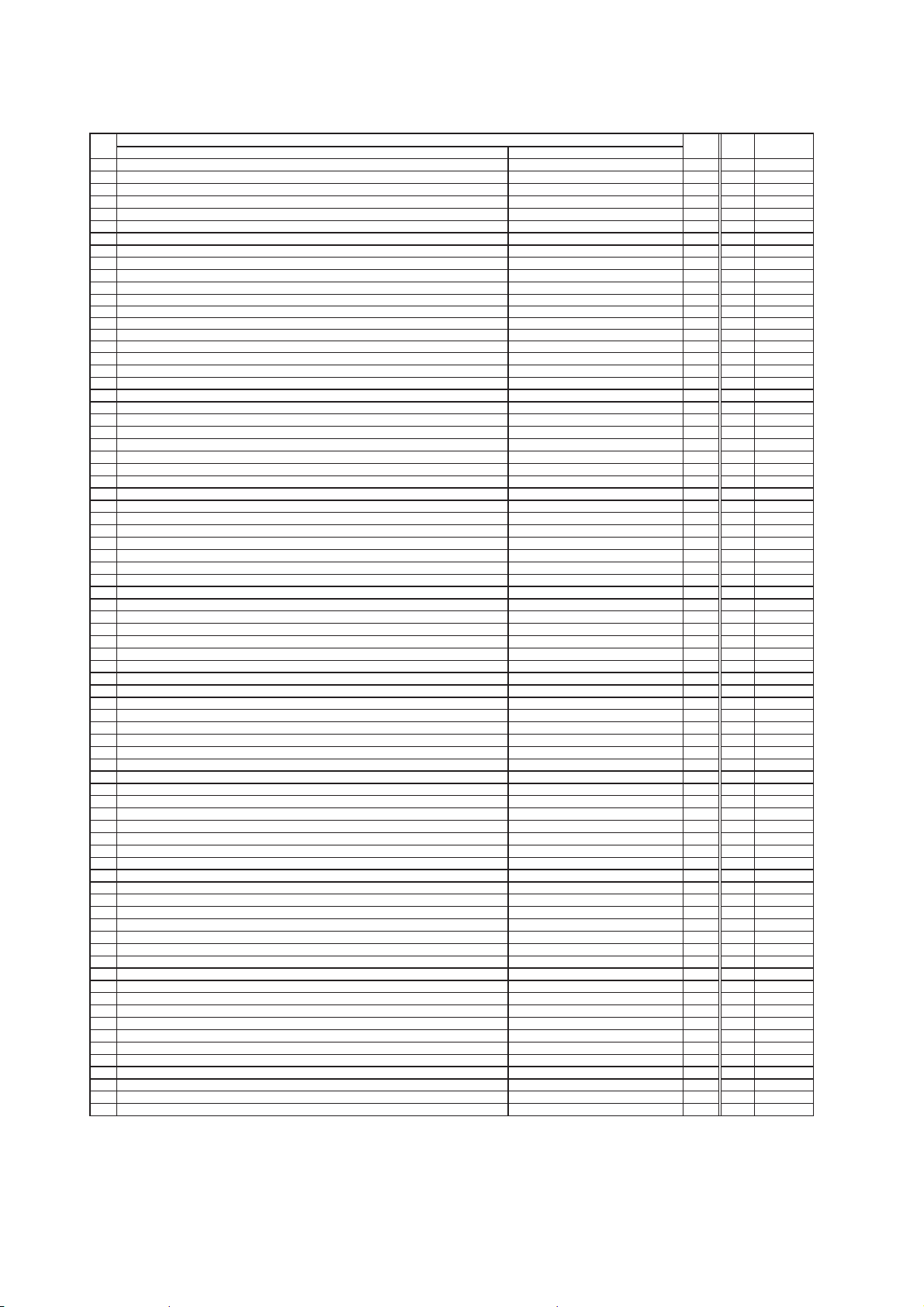

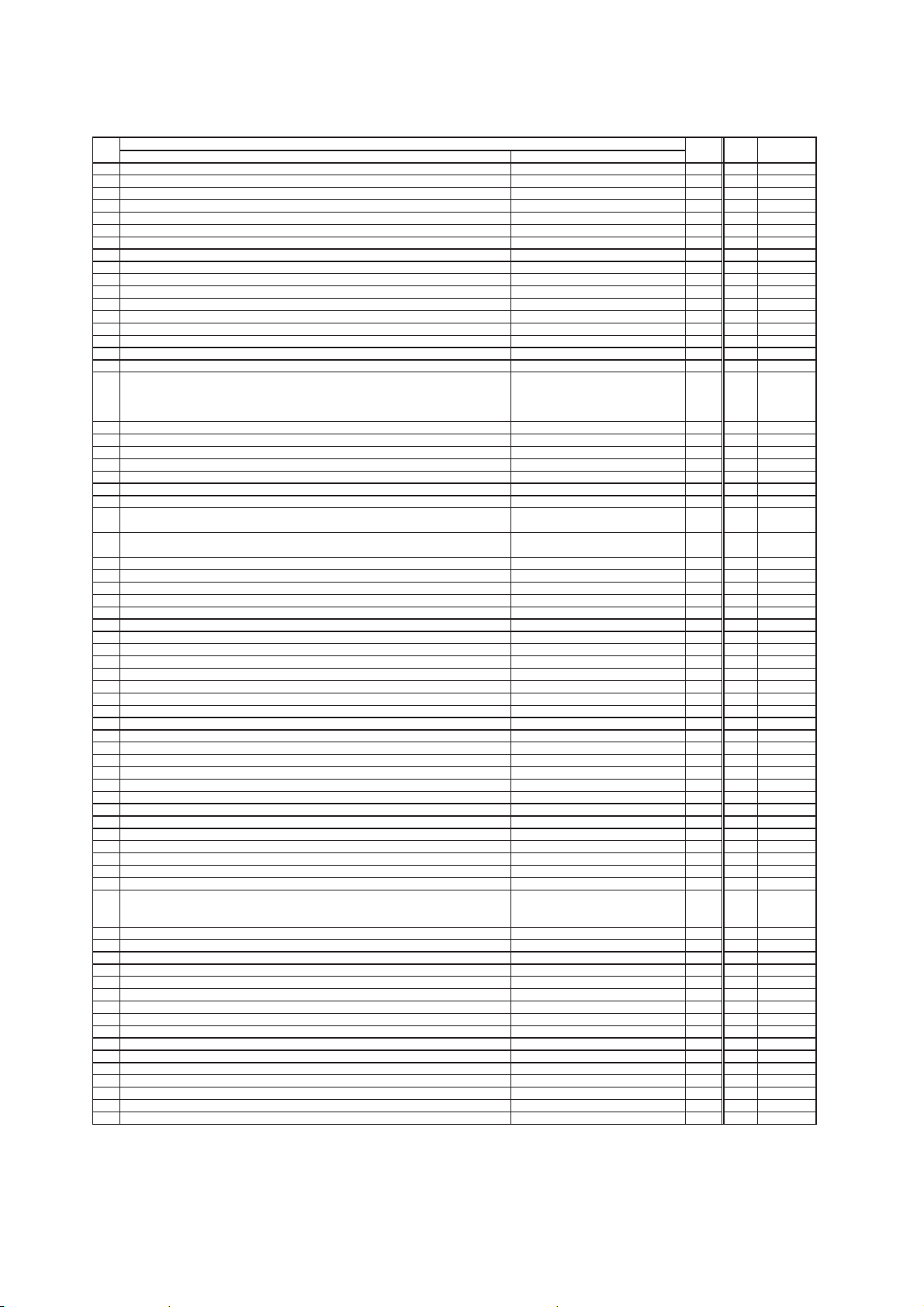

Service

No.

0

SUB

1

SUB

2

SUB

3

SUB

4

SUB

5

SUB

6

SUB

7

SUB

8

SUB

9

SUB

10

SUB

11

Sub Color M

12

Sub Color B/G

13

Sub Color D/K

14

Sub Color I

15

Sub Color L

16

Sub Color L'

17

Sub Color

18

TINT㧔RF

19

TINT㧔RF

20

TINT㧔VIDEO

21

TINT㧔VIDEO

22

Shar

23

Shar

24

Shar

25

Shar

26

Shar

27

Shar

28

Shar

29

Shar

30

Shar

31

Shar

32

Shar

33

Shar

34

IGP0 Out

35

BPF

36

BPF

37

IGP1 Out ut Control

38

BPF

39

BPF

40

I-

41

I-

42

SECAM D-Tra

43

SECAM D-Tra

44

Y

45

Y

46

Y

47

Y

48

Y

49

Y

50

Y

51

Y

52

Y

53

Y

54

Y

55

Y

56

Cb offset OFFU

57

Cr offset OFFV

58

59

60

61

62

63

64

P/N ID QTHR

65

S

66

HS Phase IRHP

67

UTO mode AUTO[1:0

68

NALOG GAIN 1 AGA1[2]&AGA1[1:0

69

NALOG GAIN 2 AGA2[2]&AGA2[1:0] *serves both AGA3 and AGA

70

DIGITAL GAIN 1 DGA1

71

DIGITAL GAIN 2 DGA2

72

VSޓPhaseޓIRVP

73

LLC Out

74

LLC2

75

LLC2

76

XTOUT Out

77

RTS

adjustment items by I

CONTRAST(AV1) DCON[7:0

CONTRAST(AV2) DCON[7:0

CONTRAST(AV3) DCON[7:0

CONTRAST(AV4) DCON[7:0

CONTRAST(AV5) DCON[7:0

CONTRAST M(4.5) DCON[7:0

CONTRAST B/G (5.5) DCON[7:0

CONTRAST D/K (6.5) DCON[7:0

CONTRAST I(6.0) DCON[7:0

CONTRAST L(6.5) DCON[7:0

CONTRAST L'(6.5) DCON[7:0

4.5) DSAT[7:0

5.5) DSAT[7:0

6.5) DSAT[7:0

6.0) DSAT[7:0

6.5) DSAT[7:0

6.5) DSAT[7:0

VIDEO) DSAT[7:0

PAL/N-PAL/M-PAL/SECAM HUEC[7:0

NTSC3.58/NTSC4.43 HUEC[7:0

PAL/N-PAL/M-PAL/SECAM HUEC[7:0

NTSC3.58/NTSC4.43 HUEC[7:0

ness Gain/f0(RF/NR) LUFI[3:0

ness Gain/f0(RF) M LUFI[3:0

ness Gain/f0(RF) BG/DK/I LUFI[3:0

ness Gain/f0(RF) L LUFI[3:0

ness Gain/f0(RF) L' LUFI[3:0

ness Gain/f0(VIDEO) PAL LUFI[3:0

ness Gain/f0(VIDEO) NTSC3.58 LUFI[3:0

ness Gain/f0(VIDEO) SECAM,B/W LUFI[3:0

ness Gain/f0(VIDEO) NTSC4.43 LUFI[3:0

ness Gain/f0(VIDEO) N-PAL LUFI[3:0

ness Gain/f0(VIDEO) M-PAL LUFI[3:0

ness Gain/f0(S.VIDEO) LUFI[3:0

ut Control polarity IG0

4.43MHz:NTSC4.43/PA

4.43MHz:NTSC4.43/PA

3.58MHz:NTSC3.58/M-PAL/N-PAL)(for AUTO[1:0]=11) LUB

3.58MHz:NTSC3.58/M-PAL/N-PAL)(for AUTO[1:0]=11) LCBW[2:0

ort signal definitions IGP0 IDG0[2-0

ort signal definitions IGP1 IDG1[2-0

GAIN(AV00) HTC[1:0

GAIN(AV00) ATVT[1:0

GAIN(AV1-5) HTC[1:0

GAIN(AV1-5) ATVT[1:0

GAIN(RF) HTC[1:0

GAIN(RF) ATVT[1:0

ID STHR[3:0

LLC54 Output Enable LLC2 Sub

LLC54 Select Line Locked Clock SLLC Sub

1 Out

for AUTO[1:0]=11) LUB

for AUTO[1:0]=11) LCBW[2:0

4.5MHz) YDEL[2:0

5.5MHz PAL/NTSC) YDEL[2:0

5.5MHz SECAM) YDEL[2:0

6.0PAL/NTSC) YDEL[2:0

6.0SECAM) YDEL[2:0

6.5PAL/NTSC) YDEL[2:0

6.5SECAM) YDEL[2:0

YDEL[2:0

YDEL[2:0

VIDEOޓPAL/NTSC4.43) YDEL[2:0

VIDEOޓSECAM) YDEL[2:0

VIDEOޓNTSC3.58) YDEL[2:0

1:0

1:0

3:0

ut Enable LLC Sub

ut Control XTOUT

ut Control polarit

]

]

]

]

]

]

]

]

]

]

]

]

P

olarity IG1

P

]

]

]

5:0

5:0] *serves both DGA3 and DGA

E

1

]

for AUTO[1:0]=11) LUBW

for AUTO[1:0]=11) LCBW[2:0

]

]

]

]

]

]

]

]

]

]

]

]

E

2

]

2

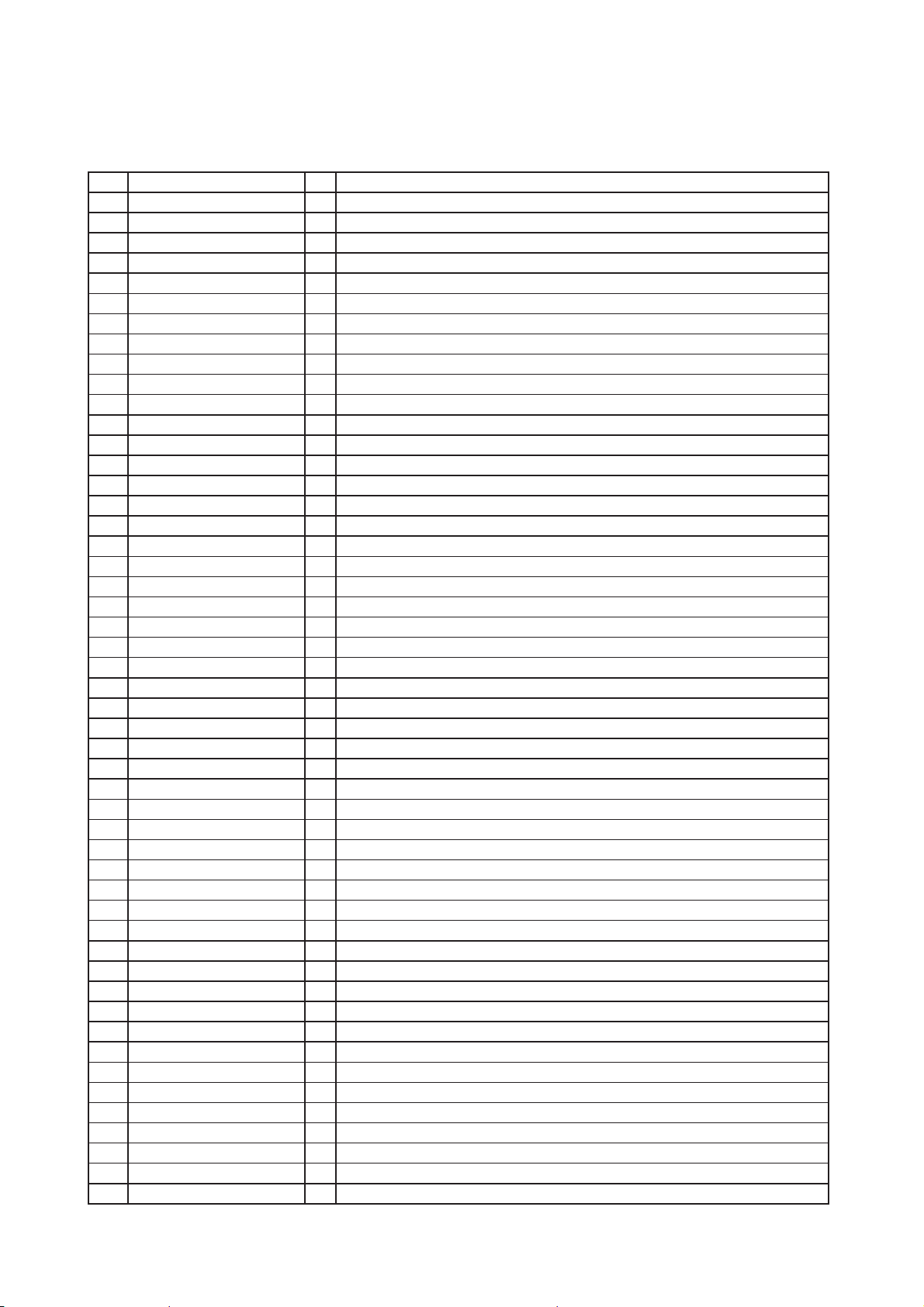

C-bus control (MAIN Part)

noitcnuF.jdA

Sub Composite mod

Sub Composite mod

Sub Composite mod

Sub Composite mod

Sub Composite mode for EUR

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

]

]

W

4

4

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

]

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

Sub

buSPTR

Init.

Max.

edoMsmetI.JD

Value

254 68 SAA7117

254 68 SAA7117

254 68 SAA7117

254 68 SAA7117

254 68 SAA7117

O

254 68 SAA7117

254 68 SAA7117

254 68 SAA7117

254 68 SAA7117

254 68 SAA7117

254 68 SAA7117

254 60 SAA7117

254 62 SAA7117

254 62 SAA7117

254 62 SAA7117

254 62 SAA7117

254 62 SAA7117

254 60 SAA7117

254 0 SAA7117

254 253 SAA7117

254 0 SAA7117

254 253 SAA7117

15 0 SAA7117

15 5 SAA7117

15 5 SAA7117

15 5 SAA7117

15 5 SAA7117

15 4 SAA7117

15 4 SAA7117

15 11 SAA7117

15 4 SAA7117

15 4 SAA7117

15 4 SAA7117

15 0 SAA7117

1 0 SAA7117

1 0 SAA7117

7 6 SAA7117

1 0 SAA7117

1 0 SAA7117

7 6 SAA7117

7 0 SAA7117

7 0 SAA7117

1 0 SAA7117

7 6 SAA7117

7 7 SAA7117

7 7 SAA7117

7 6 SAA7117

7 7 SAA7117

7 6 SAA7117

7 7 SAA7117

7 6 SAA7117

7 7 SAA7117

7 7 SAA7117

7 7 SAA7117

7 7 SAA7117

7 7 SAA7117

3 0 SAA7117

3 0 SAA7117

3 2 SAA7117

3 2 SAA7117

3 2 SAA7117

3 2 SAA7117

3 2 SAA7117

3 2 SAA7117

15 0 SAA7117

15 7 SAA7117

1 0 SAA7117

3 2 SAA7117

7 2 SAA7117

7 2 SAA7117

63 45 SAA7117

63 45 SAA7117

1 1 SAA7117

1 1 SAA7117

1 1 SAA7117

1 0 SAA7117

1 0 SAA7117

1 0 SAA7117

Value

Device

A

A

13

50PD9800TA (FW1)

A

p

0

A

p

]

A

p

]

A

g

]

A

y

y)

e

y

y)

y

y)

A

N

e

(

)

A

A

C

A

g

]

A

g

]

A

p

]

A

p

]

A

p

A

p

]

A

p

]

A

e

p

s

e

p

s

p

s

p

s

(

)

(

)

)

(

)

γ

)

γ

)

p

(

)

(

)

k

(

)

(

)

k

(

)

_

)

_

_B

_

_

_B

_

_G

_

_R

d

F

e

F

F

F

(

)

(

)

(

)

(CT_

)

(CT_

)

(

)

pp

)

(

)

pp

)

(

)

pp

)

(

)

(

)

(

)

pp

)

t

(

)

(

)

A

)

A

)

A

)

A

)

A

)

A

)

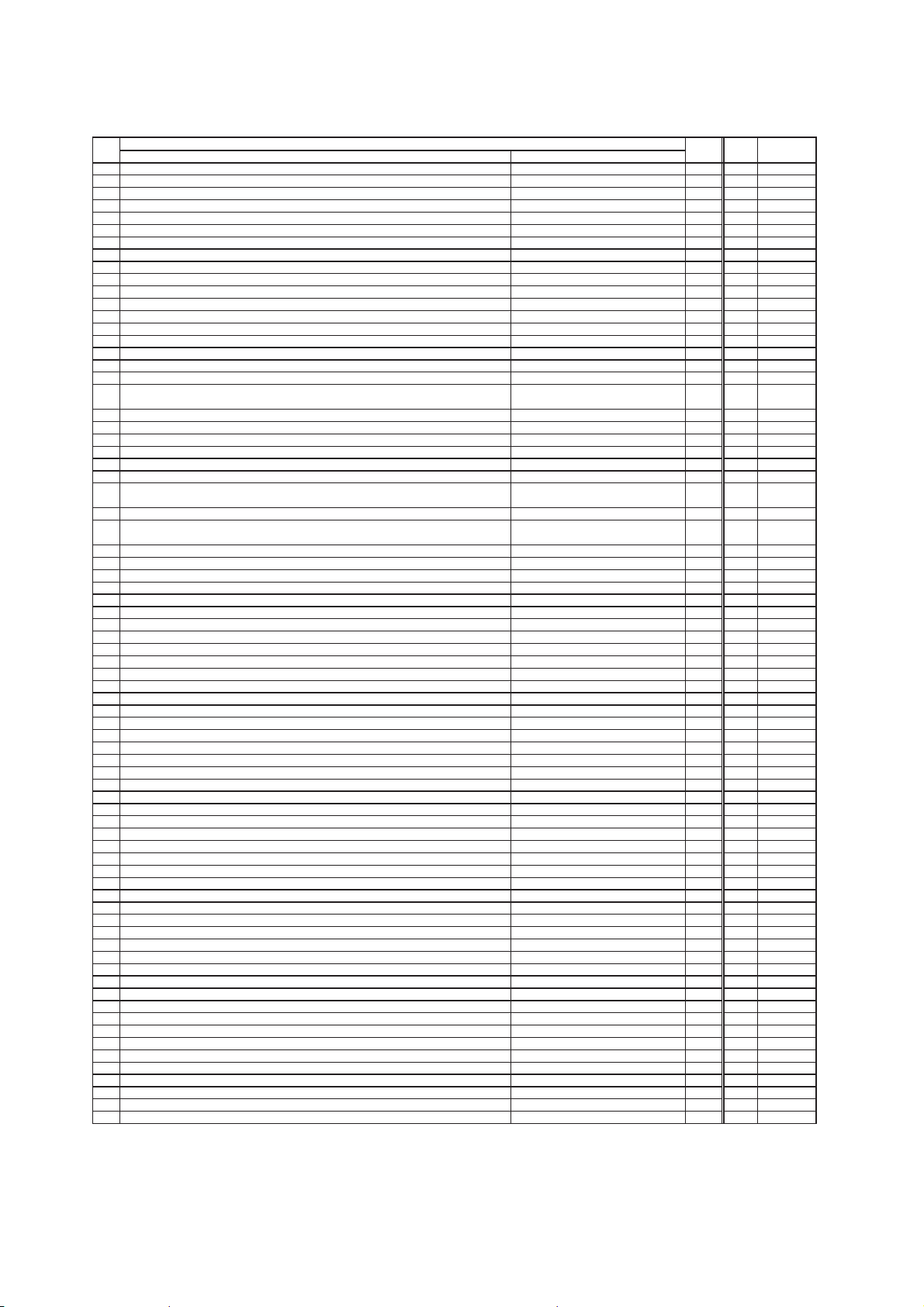

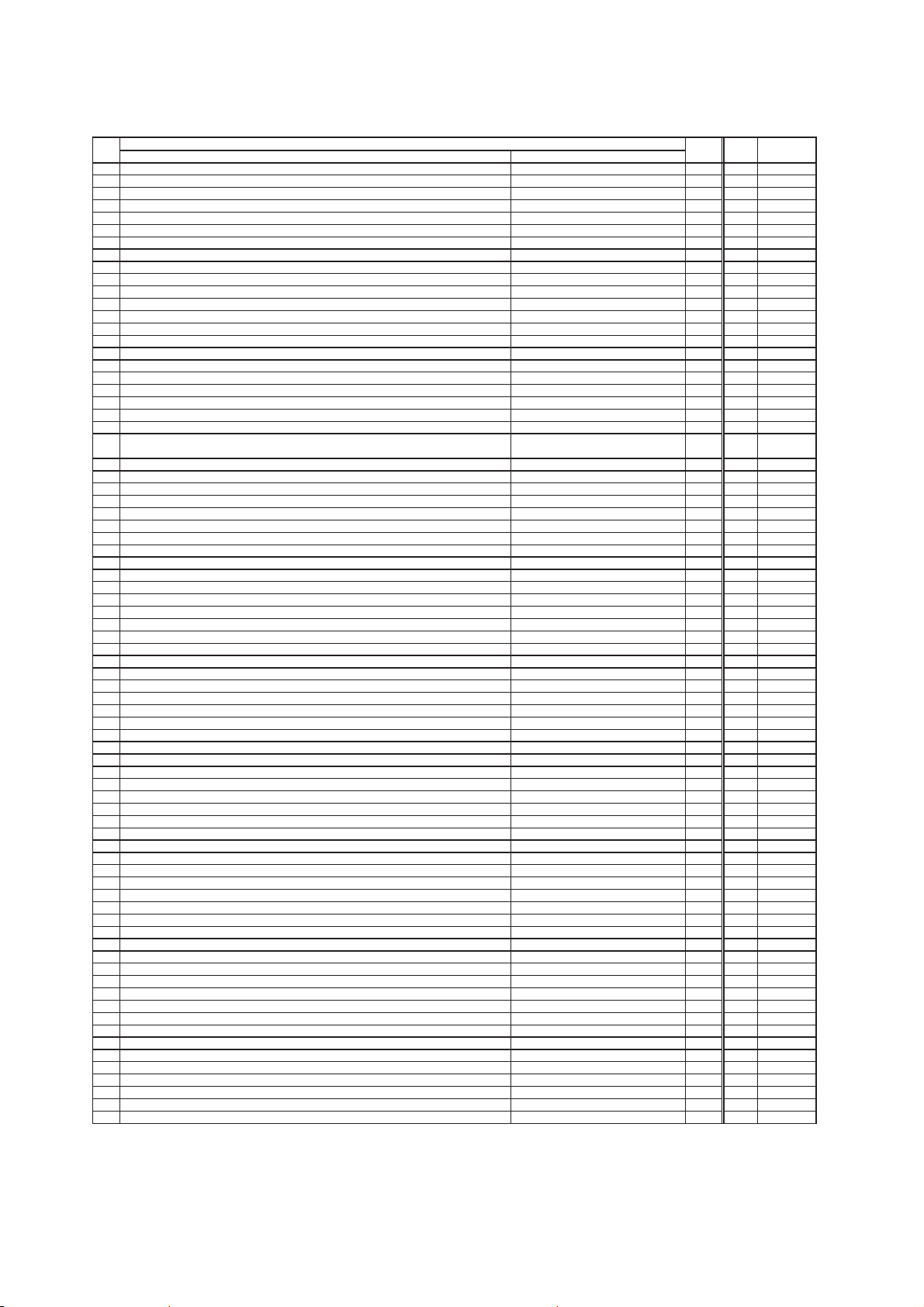

Adj. Function

No.

78

0 Out

RTS

79

RTS

80

RTS

81

Limit Level Ima

82

D

83

D

84

D

85

86

HDMI PC Function 0:OFF, 1:ON

87

Video2-RGB MODE ON For ASI

88

89

Chrominance

90

Chrominance

91

X92

X-

*move to later 216

93

94

Standard detection search loo

95

CCFMD function RF/VIDEO

96

CCFMD function DSUB-RGB

97

Shar

98

Shar

99

CHINA HD-STANDARD 0:Not Available, 1:Availabl

100

Dis

101

Dis

102

Dis

103

Dis

104

NTSC/EBU

105

NTSC/EBU

106

NTSC/EBU

107

108

109

Color Tem

110

Select for APC function

111

C3OTON

112

C3OTLV

113

C3OTON

114

C3OTLV

115

SRV16

116

GAM

117

N-APSON 0:OFF 1:ON

118

B-APSON 0:OFF 1:ON

119

C3TBL

120

C3TBL

121

C3OTLEV

122

C3OTLEV

123

C3OTLEV

124

WTI-VW 1:ON, 0:OFF

125

WTI-WAVE 0:AUTO1, 1:AUTO2, 2:fixe

126

Reserved

127

Reserved

128

Reserved

129

SFDOFF 0:ON, 1:OF

130

SFDOFF 0:ON, 1:OF

131

SFDOFF 0:ON, 1:OF

132

SFDOFF 0:ON, 1:OF

133

Vak OFfSet

134

Vak to Vra Parameter

135

Vsk to Vrs Parameter

136

VFB WAIT CounTer

137

VFB CORRection Counter

138

Vsk OFFSet

139

Vsk DETect u

140

Vsk DETect lower 8 bit

141

Vsk detect INIT. u

142

Vsk detect INIT. lower 8 bit

143

Vak DETect u

144

Vak DETect lower 8 bit

145

DeLTa Vrs value

146

DeLTa Vra value

147

Vak detect INIT. U

148

Vak detect INIT. Lower 8 bi

149

TCASE

150

151

152

153

154

155

ut Control polarity RTP

1 Out

ut Control RTSE1[3:0

0 Out

ut Control RTSE0[3:0

namic Back Light 0:OFF, 1:ON(LCD onl

namic Back Light 0:OFF, 1:ON(LCD onl

namic Back Light 0:OFF, 1:ON(LCD onl

PL Enhancer 0:OFF, 1:O

utomatic Chrominance Gain ON/OFF ACG

ort XRH output selection XRHS[1:0

ort XRV output selection XRVS[1:0

ness Gain/f0(RF/NR) SECAM,B/W LUFI[3:0

ness Gain/f0(RF) SECAM,B/W LUFI[3:0

ersion Time of Sustain current (55 only) 0:2 Times, 1:4 time

ersion Time of Sustain current (55 only) 0:2 Times, 1:4 time

ersion Time of Sustain current (55 only) 0:2 Times, 1:4 time

ersion Time of Sustain current (55 only) 0:2 Times, 1:4 time

-select(0:1.0, 1:2.2, 2:2.8

-select(0:1.0, 1:2.2, 2:2.8

RS 0:old map 1:new map(range

DM1(Temperature detection value

DM2(Temperature detection value

DM3(Temperature detection value

DM4(Temperature detection value

DM5(Temperature detection value

DM6(Temperature detection value

e Port ILLV[1:0

ain value (NTSC) CGAIN[6:0

ain value (PAL) CGAIN[6:0

CCFORM

CCFORM

CCFORM

. Correction

COOL

COOL

NORMAL/WARM

NORMAL/WARM

INTFPC

SEL

SEL_G

SEL

SEL

SEL

Vak_OFS

VaktoVra

VsktoVrs

VWAIT

Vsk_OFS

er 2 bit(Vsk_DET

Vsk_DET

er 2 bit (Vsk_INIT

er 2 bit (Vak_DET

Vak_DET

DLT_Vrs

DLT_Vra

er 2 bit (Vak_INIT

ACCC Operation Level

Vsk_INIT

Vak_INIT

DJ. Items Mode

corresponds to items

latency LATY[2:0

VCORR

Sub

Sub

Sub

Sub

For Dynamic mod

For Natural mode

For Cinema mode

For Dynamic mod

Sub

Sub

Sub

For A4SF Panel

For Dynamic mod

For Natural mode

For Cinema mode

For PC mode

SD(YCbCr)/Scart-RGB

HD(YPbPr

DSUB-RGB

RF/VIDEO

DSUB-RGB

1:ON, 0:OFF

1:Standard, 0:Wea

1:ON, 0:OFF

1:Standard, 0:Wea

1:ON, 0:OFF

Dynamic mod

Normal mode

Cinema mode

PC mode

0014H

0015H

0016H

0017H

0018H

0019H

001AH

Init.

Max.

Value

1 0 SAA7117

15 1 SAA7117

15 15 SAA7117

3 0 SAA7117

11 -

11 -

11 -

11 -

10 -

10 -

1 0 SAA7117

127 46 SAA7117

127 51 SAA7117

3 0 SAA7117

3 0 SAA7117

7 5 SAA7117

1 0 PDP

1 0 PDP

15 12 SAA7117

15 11 SAA7117

11 -

1 0 PDP

1 1 PDP

1 1 PDP

1 1 PDP

1 0 PDP

1 0 PDP

1 0 PDP

2 1 PDP

2 1 PDP

3 2 PDP

1 0 PDP

1 1 PDP

1 0 PDP

1 1 PDP

1 0 PDP

1 0 PDP

1 1 PDP

1 1 PDP

1 0 PDP

1 0 PDP

1 0 PDP

3 0 PDP

3 0 PDP

3 0 PDP

10 PDP

2 0 PDP

-- -

-- -

-- 1 0 PDP

1 0 PDP

1 0 PDP

1 0 PDP

255 0 PDP

255 1 PDP

255 1 PDP

255 60 PDP

255 15 PDP

255 0 PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

Value

Device

14

50PD9800TA (FW1)

A

A

)

A

A

(

)

(

)

(

)

(

)

(

)

e

e

7

y

s

7

(

g

g

A

)

A

)

A2_

)

A2_

)

)

_

)

_

)

_

_

)

_

)

_

)

)

_

)

)

_

)

_

_

)

K

_

)

K

7

jug

x

7

judg

x

7

jug

x

7

judg

7

jug

7

g

7

jug

7

e

7

_

y

p

g

_

)

_

)

_

A

A

_

A

A

_

p

A

_

p

A

_

A

A

_

A

A

_

p

A

_

p

A

A

7

A

7

g

A

g

A

g

A

g

A

g

A

g

A

g

A

g

A

R

(

A

(

A

(

A

[

A

[

]

A

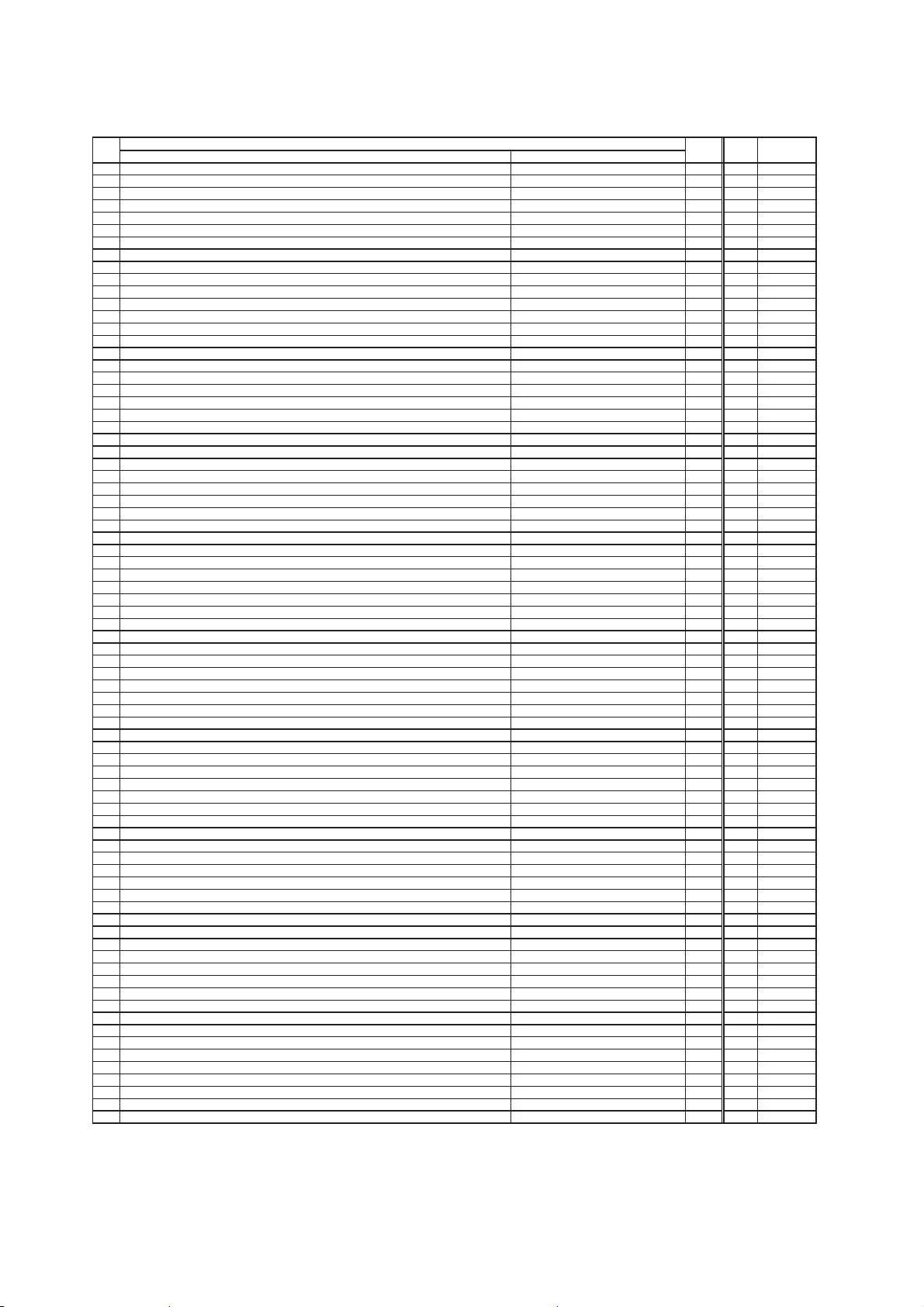

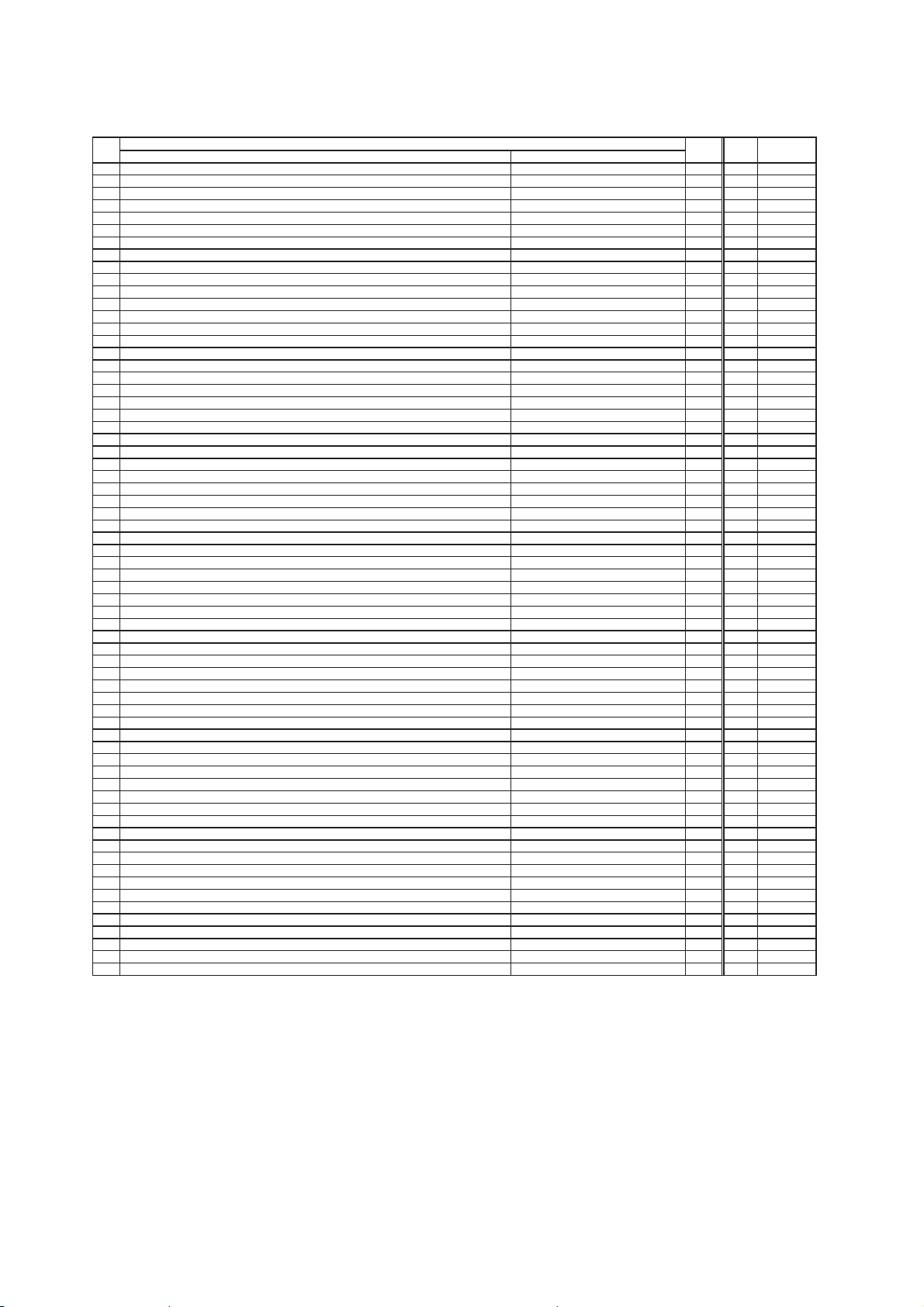

No.

156

ADM7(Temperature detection value)

157

DM8(Temperature detection value

158

DM9(Temperature detection value) only for A4SF Pane

159

DM10(Temperature detection value) only for A4SF Pane

160

MAXAVE

161

Iak

162

USER Vrs

163

USER Vra

164

Uvrs/Uvra RECALL

165

SWIVEL DEMO MODE ON

166

Black insert function 0:Not available, 1:Availabl

167

D

168

DVI

169

170

171

172

173

174 PRE_AM

175

VOL

176

VOL

177

PRE

178

PRE

179

PRE

180

PRE

181 PRE_FM

182

PRE

183 PRE_FM

184

PRE

185

PRE

186

CM

187

CM

Sound Multiplex special operation (0:Normal 1:Korea)

188

Set Stereo

189

Set Dual

190

Set Stereo

191

Set Dual

192

Set

193

Set Countin

194

Set

195

Select over modulated mod

196

197

Set over modulated mode For Korea special version 255

198

199

L

HDMI Ccolorimetr

200

201

BPMA : Back Porch Mode,Field2

202

Reserved

203

Select HDMI 1/2 at no usin

204

CM

205

CM

206

M

207

M

208

M

209

M

210

M

211

M

212

M

213

M

214

215

216

Luminance bri

217

Luminance bri

218

Luminance bri

219

Luminance bri

220

Luminance bri

221

Luminance bri

222

Luminance bri

223

Luminance bri

224

ISXAV

225

TUNER UNIT SELECT 0:FW1-UNIT, 1:PW3-UNIT

226

COMPONENT

227

COMPONENT

228

COMPONENT

229

XCLK OUTPUT CLOCK PHASE CONTROL XPCK

230

EVENT HANDLER CONTROL STRC

Maximum mean value of ADM

Maximum current of Address

Uvrs

Uvra

RCLVr

namic Backlight function 0:No, 1:Ye

HDMI) Range Scalin

UTO_FM/AM(D11-D8

UTO_FM/AM(D 7-D0

THRESHOLD(D11-D8

THRESHOLD(D 7-D0

SCART1(D15-D8

SCART1(D 7-D5

SCART 㧙

FM 4.5MHz(JAPAN

FM 4.5MHz(Except BTSC-SAP mode

FM 4.5MHz(BTSC-SAP

FM 4.5MHz(KOREA㧙Dual/Stereo

FM Except 4.5MHz(Dual/Stereo mode

NICAM 㧙

THRESHOLD(D15-D8

THRESHOLD(D7 -D0

dment level at turn on mode of Sound Multiple

ment level at turn on mode of Sound Multiple

dment level at normal mode of Sound Multiple

ment level at normal mode of Sound Multiple For Korea special version 128

dment time for jugd to Multiplex at turn on mod For Korea special version 255

time for jugdmenet of normal mod For Korea special version 255

dment time for jugd to Multiplex at normal mod For Korea special version 255

PLL.GAIN

THRESHOLD(D15-D8

THRESHOLD(D7 -D0

LPF1 OUT1 PbPr LPF Selec

LPF2 OUT1 PbPr LPF Selec

LPF3 OUT1 PbPr LPF Selec

LPF4 OUT1 PbPr LPF Selec

LPF5 OUT1 CY LPF Selec

LPF6 OUT1 CY LPF Selec

LPF7 OUT1 CY LPF Selec

LPF8 OUT1 CY LPF Selec

udio Delay Time(0:149ms, 1:131ms, 2:93ms, 3:75ms

udio Delay Time(0:149ms, 1:131ms, 2:93ms, 3:75ms

htness control NTSC3.58 DBRI[7:0

htness control NTSC4.43 DBRI[7:0

htness control PAL DBRI[7:0

htness control N-PAL DBRI[7:0

htness control M-PAL DBRI[7:0

htness control PAL-60 DBRI[7:0

htness control SECAM/BW(50) DBRI[7:0

htness control BW(60) DBRI[7:0

AV2&3-RGB) brightness control CBRI[7:0

AV2&3-RGB) contrast control CCON[7:0

AV2&3-RGB) saturation control CSAT[7:0

0:Limited Range(Normal), 1:Full Range For DVI-Video Timin

e

e

e

2

adjustment 0:priority signal Format / 1:priority AVI InfoFram 1IMDH

osition adjustmen

0: Both no select,1:Select HDMI 1, 2:Select HDMI

t

t

t

t

t

t

t

t

1:0

t

]

]

]

]

]

]

]

1:0

noitcnuF.jdA

001BH

001CH

005EH

005FH

001EH

000DH

For LCD Dynamic mode or Day mod

For LCD

TTDroFELBANEGOLTTD

㧙

㧙

㧙

㧙

Except 4.5MHz (Except Dual/Stereo

mode

㧙

㧙

4.5MHz(Except KOREA㧙

Dual/Stereo mode

Except 4.5MHz(Except Dual/Stereo

mode

Sync=O

Sync=O

For Korea special version 127

For Korea special version 128

x

)

)

]

]

]

]

]

For Korea special version 127

For Korea special version 2

e

2

Sync=NG

Sync=NG

RF/Video

480i/576i

480p/576

1080i/720

RF/Video

480i/576i

480p/576

1080i/720

RF

except RF

000BH

edoMsmetI.JD

Init.

Max.

Value

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

- - PDP

1 0 PDP

50 0 -

1 0 M3062

1 1 M3062

1 0 HDMI

10 -

15 2 MSP4450G

254 189 MSP4450G

15 0 MSP4450G

254 112 MSP4450G

254 17 MSP4450G

254 115 MSP4450G

7 0 MSP4450G

254 25 MSP4450G

254 34 MSP4450G

254 32 MSP4450G

254 60 MSP4450G

254 36 MSP4450G

254 34 MSP4450G

254 17 MSP4450G

254 27 MSP4450G

254 57 MSP4450G

254 0 MSP4450G

254 200 MSP4450G

1

552noisrevlaicepsaeroKroF1edomdetaludomrevoteS

1 0 TDA9885

1 1 HDMI

-- -

2 0 HDMI

254 0 MSP4450G

254 0 MSP4450G

31

32

32AN15867

33AN15867

31

32

32AN15867

33AN15867

3 0 M3062

3 0 M3062

255 128 SAA7117

255 145 SAA7117

255 128 SAA7117

255 128 SAA7117

255 145 SAA7117

255 145 SAA7117

255 128 SAA7117

255 145 SAA7117

- - PDP

10 255 128 SAA7117

255 64 SAA7117

255 64 SAA7117

3 1 SAA7117

3 0 SAA7117

Device

Value

0 M3062

18 M3062

18 M3062

18 M3062

18 M3062

117 M3062

10 M3062

64 M3062

0 M3062

18 MSP4450G

32 MSP4450G

HDMI

0

N15867

N15867

N15867

N15867

15

No.

A

V

A

V

A

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

A

8

A

A

8

A

[

]

8

A

[

]

8

A

A

3

A

A

3

A

[

]

3

A

[

]

3

A

A

A

A

A

[

]

A

[

]

A

A

A

[

]

A

A

A

[

]

A

A

A

[

]

A

p

A

p

A

p

]

A

p

]

A

p

A

p

]

A

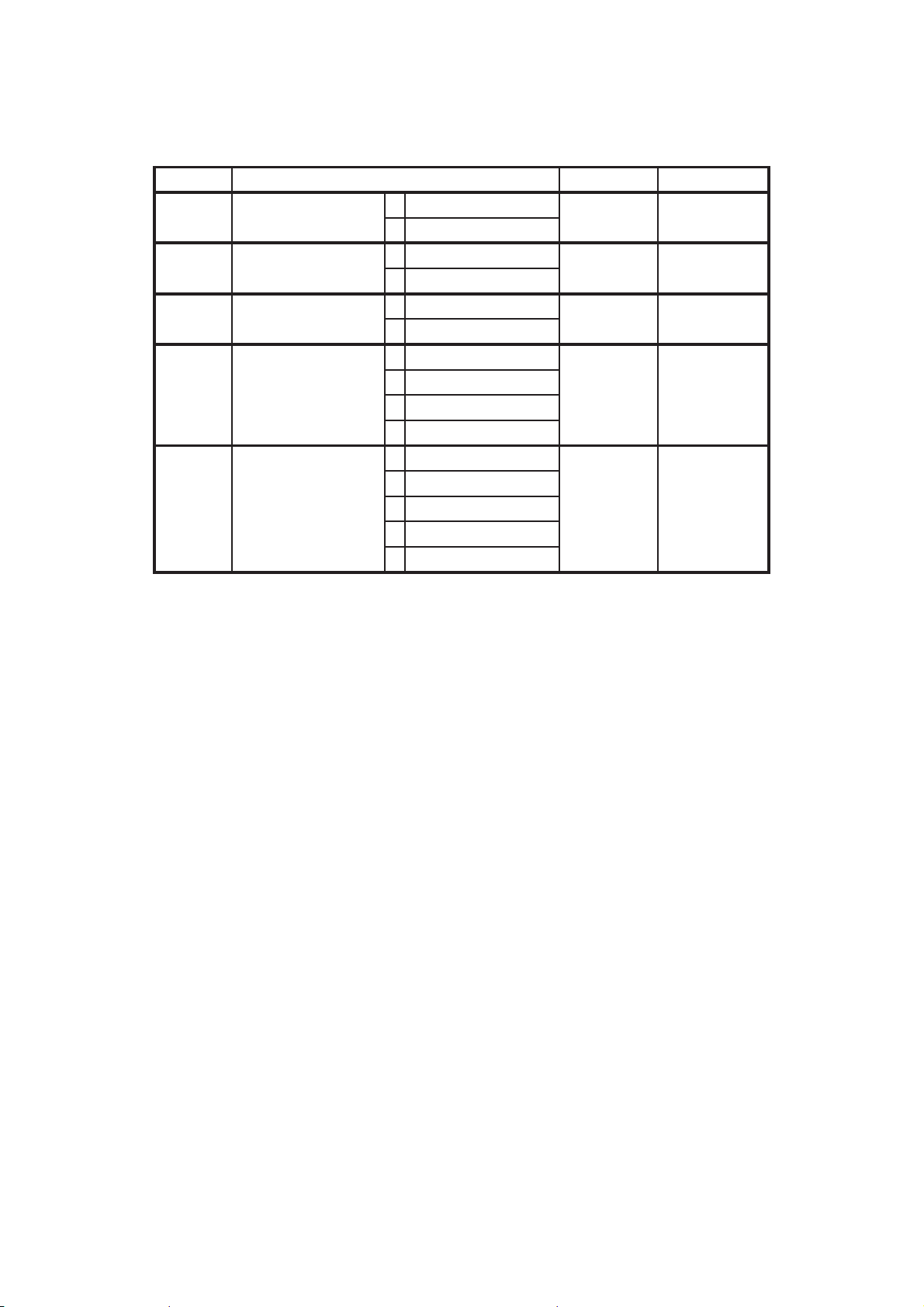

231

CONFIGURATION SOURCE SELECTION CONL

232

CONFIGURATION SOURCE SELECTION HLDF

233

LOUD MAIN

234

LOUD MAIN

235

BASS OFST

236

BASS OFST

237

LOUD MAIN

238

LOUD MAIN

239

SUBW FREQ

240

MB HP

241

MB LP

242

MB STR

243

SUBW FREQ

244

MB HP

245

MB LP

246

MB STR

247

SRS FOCUS

248

SRS FOCUS

249

SUR SUR

250

SUR SUR

251

SUR FRONT

252

SUR FRONT

253

NALOG GAIN 1 AGA1[2]&AGA1[1:0

254

NALOG GAIN 2 AGA2[2]&AGA2[1:0

255

DIGITAL GAIN 1 DGA1

256

DIGITAL GAIN 2 DGA2

257

NALOG GAIN 1 AGA1[2]&AGA1[1:0

258

NALOG GAIN 2 AGA2[2]&AGA2[1:0

259

DIGITAL GAIN 1 DGA1

260

DIGITAL GAIN 2 DGA2

261

NALOG GAIN 1 AGA1[2]&AGA1[1:0

262

NALOG GAIN 2 AGA2[2]&AGA2[1:0

263

DIGITAL GAIN 1 DGA1

264

DIGITAL GAIN 2 DGA2

265

NALOG GAIN 1 AGA1[2]&AGA1[1:0

266

DIGITAL GAIN 1 DGA1

267

NALOG GAIN 1 AGA1[2]&AGA1[1:0

268

DIGITAL GAIN 1 DGA1

269

NALOG GAIN 1 AGA1[2]&AGA1[1:0

270

DIGITAL GAIN 1 DGA1

271

Luminance Im

272

Luminance Im

273

Luminance Im

274

Chrominance Im

275

Chrominance Im

276

Chrominance Im

277

Reserved

278

Reserved

279

Reserved

280

Reserved

281

Reserved

282

Reserved

283

Reserved

284

Reserved

285

Reserved

286

Reserved

287

Reserved

288

Reserved

289

Reserved

290

Reserved

291

Reserved

292

Reserved

293

Reserved

294

Reserved

295

Reserved

296

Reserved

297

Reserved

298

Reserved

299

Reserved

300

Reserved

301

Reserved

302

Reserved

303

Reserved

304

Reserved

305

Reserved

306

Reserved

307

Reserved

308

Reserved

for BBE=LOW , Truebase=OFF

for BBE=HIGH, Truebase=OFF

for BBE=LOW , Truebase=OFF

for BBE=HIGH, Truebase=OFF

for BBE=LOW , Truebase=LOW/HIGH

for BBE=HIGH, Truebase=LOW/HIGH

for Truebase=LOW

for Truebase=LOW

for Truebase=LOW

for Truebase=LOW

for Truebase=HIGH

for Truebase=HIGH

for Truebase=HIGH

for Truebase=HIGH

for SRS=NRML

for SRS=WIDE

for SRS=NRML

for SRS=WIDE

for SRS=NRML

for SRS=WIDE

5:0

5:0

5:0

5:0

5:0

5:0

5:0

5:0

5:0

rovement Control [LIMOD

rovement Control [LIFIL

rovement Control [LIWGT

rovement Control [CIMOD

rovement Control [CIFIL

rovement Control [CIWGT

50PD9800TA (FW1)

Init.

noitcnuF.jdA

]

]

]

]

]

]

]

]

]

]

]

]

Y/C : NTSC3.5

Y/C : NTSC3.5

Y/C : NTSC3.5

Y/C : NTSC3.5

Y/C : NTSC4.4

Y/C : NTSC4.4

Y/C : NTSC4.4

Y/C : NTSC4.4

Y/C : OTHERS

Y/C : OTHERS

Y/C : OTHERS

Y/C : OTHERS

CVBS: NTSC3.58

CVBS: NTSC3.58

CVBS: NTSC4.43

CVBS: NTSC4.43

CVBS: OTHERS

CVBS: OTHERS

edoMsmetI.JD

Max.

Value

1 0 SAA7117

1 0 SAA7117

254 20 MSP4450G

254 28 MSP4450G

10 1 MSP4450G

10 3 MSP4450G

254 16 MSP4450G

254 22 MSP4450G

40 15 MSP4450G

48 10 MSP4450G

48 15 MSP4450G

75 52 MSP4450G

40 15 MSP4450G

48 10 MSP4450G

48 15 MSP4450G

75 57 MSP4450G

127 0 MSP4450G

127 0 MSP4450G

3 1 MSP4450G

3 0 MSP4450G

2 0 MSP4450G

2 0 MSP4450G

7 2 SAA7117

7 2 SAA7117

63 42 SAA7117

63 42 SAA7117

7 2 SAA7117

7 2 SAA7117

63 42 SAA7117

63 42 SAA7117

7 2 SAA7117

7 2 SAA7117

63 45 SAA7117

63 45 SAA7117

7 2 SAA7117

63 42 SAA7117

7 2 SAA7117

63 42 SAA7117

7 2 SAA7117

63 45 SAA7117

3 0 SAA7117

7 0 SAA7117

7 6 SAA7117

3 0 SAA7117

7 0 SAA7117

3 0 SAA7117

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

Value

Device

16

50PD9800TA (FW1)

A

Adj. Function

No.

309

Reserved

310

Reserved

311

Reserved

312

Reserved

313

Reserved

314

Reserved

315

Reserved

316

Reserved

317

Reserved

318

Reserved

319

Reserved

320

Reserved

321

Reserved

322

Reserved

323

Reserved

324

Reserved

325

Reserved

326

Reserved

327

Reserved

328

Reserved

329

Reserved

330

Reserved

331

Reserved

332

Reserved

333

Reserved

334

Reserved

335

Reserved

336

Reserved

337

Reserved

338

Reserved

339

Reserved

340

Reserved

341

Reserved

342

Reserved

343

Reserved

344

Reserved

345

Reserved

346

Reserved

347

Reserved

348

Reserved

349

Reserved

350

Reserved

351

Reserved

352

Reserved

353

Reserved

354

Reserved

355

Reserved

356

Reserved

357

Reserved

358

Reserved

359

Reserved

360

Reserved

361

Reserved

362

Reserved

363

Reserved

364

Reserved

365

Reserved

366

Reserved

367

Reserved

368

Reserved

369

Reserved

370

Reserved

371

Reserved

372

Reserved

373

Reserved

374

Reserved

375

Reserved

376

Reserved

377

Reserved

378

Reserved

379

Reserved

380

Reserved

381

Reserved

382

Reserved

383

Reserved

384

Reserved

385

Reserved

386

Reserved

DJ. Items Mode

Init.

Max.

Value

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

Value

Device

17

50PD9800TA (FW1)

A

play

7

play

)

7

7

e

7

y

7

y

7

n

n

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

y

x

play

n

[

]

y

y

(

g

7

q

7

7

7

e

7

y

g

7

y

7

y

g

7

y

7

7

g

7

7

g

7

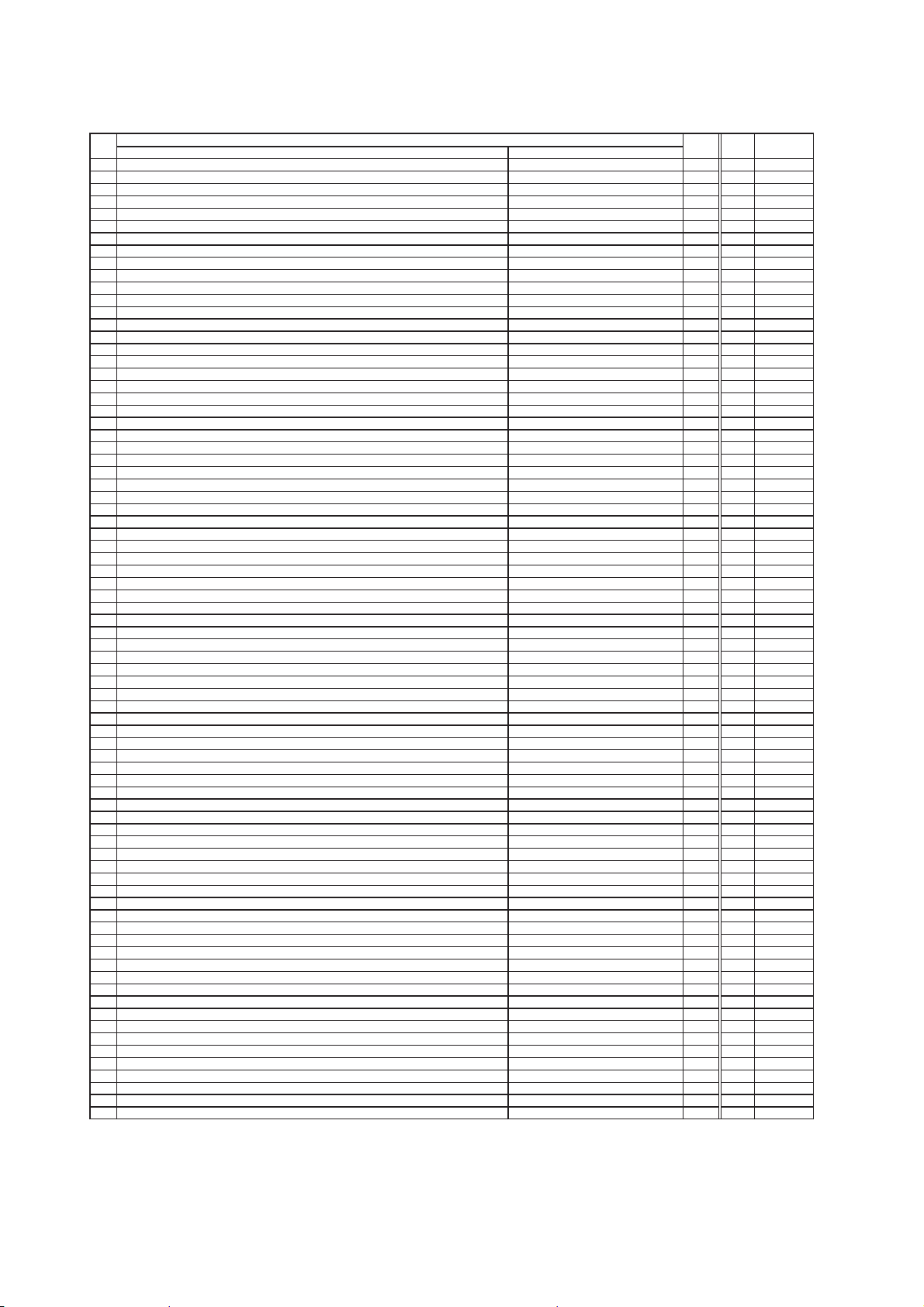

No.

387

Reserved

388

Reserved

389

Reserved

390

Reserved

391

Reserved

392

Reserved

393

Reserved

394

Reserved

395

Reserved

396

Reserved

397

Reserved

398

Reserved

399

Custom tuning 0:SINGAPORE, 1:HONG_KONG, 2:AUSTRALIA, 3:CHINA, 4:Reserved

400

Mode dis

401

Temperature for Fun start (Temp_High)

402

Temperature for Fun stop (Temp_Low)

403

Dis

404 Power Save/Screen Saver On/Off Setting at Initialize, Reset and Shipping

405

PC Power Save function

406

Waite Time for POWER SAVE function

407

BURN-IN enable/ disenable 0:Disenable, 1:Enabl

408

BURN-IN mode

409

Recover

410

EURO DK-SECAM MASK(V=60) 0:Normal 1:Mask(V=60)

411

Set Sound S

Power condition at power save mode of PC mode

412

after done RESET functio

Select Wide mode for Europe model

413

(Normal= 5mode/ For Service= 10 mode)

414

Thermo sensor function available or not 0:None, 1:Ye

415

EURO SOUND SYSTEM DK Disable 0:Enable, 1Disable

416

Remote Function available 0:NO, 1:YES

417

Ke

y Function available 0:NO, 1:YES

418

Terminal Mode Function available 0:Not Available, 1:Available RS232C

419

Set Taiwan/Korea/South America 0:Others 1: Taiwan/Korea/South America

420

Language (Refer to below)

421

Hotel Mode(0:No, 1:Yes)

Initial Audio Level available (0:No 1: Yes) 1

422

Initial Audio Level 63

423

Size button available

424

Multi Picture button available (0:No 1:Yes) 1

425

Photo button available (0:No 1:Yes) 1

426

427

Analog Data (0:Keep EEPROM, 1:Not Keep to EEPROM)

428

Maximum Volume Limit

429

Power Mode(0:Last mode, 1:Pos1, 2-7:V1-6, 8-9:RGB1-2)

430

Channel Select (0:CCIR, 1:CHINA)

431

Auto_sound 4.5 (0:Korea, 1:BTSC, 2:Japan)

432

T/TEXT

433

Channel Preset

Australia Preset 0: None, 1: yes 10

434

435

V FREQ 60Hz Force (0:None, 1:Yes)

436

Power control for Pay TV

437

Set timer to power off (for Pay TV)

438

Gra

439

Dis

440

PANORAMIC1/2 for AUTO

441 Set upper limit value(%) of stable picture of DTT

442

T/Text Station Name Timeou

443

DTT-TEXT Analog/Digital SW (for Continental Model)

444

For Event Timer Function check 0:Normal

445

DTT Function Available 0: Not Available, 1: Available

446

fH fre

447

fV frequency of decision agreement (M30627) 㧙

448

fV frequency of decision agreement (SAA7117A) 㧙

449

Lower Limits value for S

450

Lower Limits value for S

451

Lower Limits value for S

452

Lower Limits value for S

453

Lower Limits value for S

454

Upper Limits Value for Sync Detect of 2ms interval For AFC at TV mod

455

Upper Limits Value for Sync Detect of 2ms interval For Free Runnin

456

Upper Limits Value for Sync Detect of 2ms interval For AUTO OFF at TV mod

457

U

pper Limits Value for Sync Detect of 2ms interval For Free Runnin

0:Normal, 1:RF mode only, 2:Al

of internal temperature (Temperature

(0:Impossible, 1:Possible

to an error of OSC frequency of Ceramic resonator for time

stem at Auto mode of Sound Sys.(0:auto, 1:4.5MHz Main

(0:No 1:Yes) 1

(0:None, 1:Yes)

(0:VESTEL, 1:GIFU, 2:HAMA, 3:HFDM, 4:AUSTRALIA)

of BM versio

uency of decision agreement (M30627) 㧙

PANORAMIC PANORAMIC1[0]㧛2[1

t×80ms

y domVTtaCFAroFavretnism2fotceteDcn

(s) VIDEO/PC

s

]

(Off), 1:High, 2:Middle

noitcnuF.jdA

P.S/S.S

0:Off/20m

1:On/Off

2:Off/Off

r

0:Keep last condition,

1:Return to normal conditio

0:Normal, 1:For service 1 0 M30627

ednIMBfolevel

0:alwa

s invalidit

1:100%,2:80%,3:60%,

4:40%,5:20%,6:0%

, 1:Digital

0:Analo

edoMsmetI.JD

always validit

ninnuReerFroFavretnism2fotceteDcn

at TV mod

ninnuReerFroFavretnism2fotceteDcn

at AV mod

e

at TV mod

at AV mod

e

domVTtaFFOOTUAroFavretnism2fotceteDcn

e

e

domVAtaevaSrewoProFavretnism2fotceteDcn

e

e

e

e

Max.

Value

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- 43

2 0 M3062

254 58 TEMP

254 55 TEMP

125 - TEMP

2 0 M30627

1 1 M3062

254 15 M3062

1 1 M3062

2 2 PDP

62 34 M3062

10 -

1 0 M3062

1 0 M30627

1 0 M3062

1 0 M3062

1 1 M3062

1 1 M3062

1 1 M3062

1 0 M3062

10 0 M3062

2 0 M3062

1 0 M3062

63 63 M3062

9 0 M3062

1 0 M3062

2 0 M3062

1 1 M3062

4 1 M3062

1 0 M3062

255 0 M3062

255 0 M3062

31 4 BM

127 - BM

10 -

6 0 M30627

y)

255 80 -

10 -

20 -

1 0 M3062

31 2 M3062

31 2 M3062

31 2 M3062

254 25 M3062

254 30 M3062

254 25 M3062

254 25 M3062

254 25 M3062

254 40 M3062

254 45 M3062

254 35 M3062

254 35 M3062

Init.

Device

Value

0 M3062

20 M3062

1 M3062

1 M3062

1 M3062

M3062

-

18

50PD9800TA (FW1)

A

pp

7

(

)

7

(

)

7

y

7

y

7

(

(

(

(

(

(

(

(

y

p

(

)"

y

y1

g

_

yp

(req

yp

(req

y

1

(H)

(L)

(H)

(L)

g

7

(

7

(

A

(

A

(

A

put(

A

(

A

[

)

A

(

_

L

_

_

L

_

_

L

_VFP

_

T

_HFP

_

_

1

end Source sid

1

)

uest

tes

)

)

noitcnuF.jdA

)

)

uest

Main

Sub

e

)

r

No.

458

U

er Limits Value for Sync Detect of 2ms interva For Power Save at AV mod

459

COLOR SYSTEM CONTROL-MODE

460

COLOR SYSTEM CONTROL-MODE

461

2ms s

462

463

464

465

466

467

468

469

470

471

472

473

474

475

476

477

478

479

480

481

482

483

484

485

486

487

488

489

490

491

492

493

494

495

496

497

498

499

500

501

502

503

504

505

506

507

508

509

510

511

512

513

514

515

516

517

518

519

520

521

522

523

524

525

526

527

528

529

530

531

532

533

534

nchronus count valu Main

nchronus count valu Sub

2ms s

TB1274 Read Data

TB1274 Read Data

MSP Read Data

MSP Read Data

MSP Read Data

MSP Read Data

MSP Read Data

MSP Read Data

HDMI Read Data SYNC1 : VSYNC/Clock detect/S

HDMI Read Data NHRDL1 : N hardware value 1 lower 7 bit

HDMI Read Data NHRDM1 : N hardware value 1 1 lower 7 bit

HDMI Read Data NHRDH1 : N hardware value 1 1 lower 4 bit

HDMI Read Data CHRDL1 : CTS hardware value 1 1 lower 7 bit

HDMI Read Data CHRDM1 : CTS hardware value 1 1 lower 7 bit

HDMI Read Data CHRDH1 : CTS hardware value 1 1 lower 4 bit

HDMI Read Data ACR1 : ACR PLL hardware value

HDMI Read Data ACRS1 : ACR PLL hardware value 1 de

HDMI Read Data SFREQ1 : "Extracted Sampling Frequency 1

channel status b24-27

HDMI Read Data CLKFRQ1: Clock Accurac

HDMI Read Data ALNG1 : Audio len

HDMI Read Data MT

HDMI Read Data VTYP1 : AVI infoframe t

HDMI Read Data VVER1 : AVI infoframe version code 1

HDMI Read Data VINFO11: AVI infoframe data 1

HDMI Read Data VINFO21:

HDMI Read Data VINFO31:

HDMI Read Data VINFO41:

HDMI Read Data VINFO51:

HDMI Read Data ATYP1 : AUDIO InfoFrame T

HDMI Read Data AVER1 : AUDIO InfoFrame Version Code 1

HDMI Read Data AINFO11: AUDIO InfoFrame Data B

HDMI Read Data AINFO21:

HDMI Read Data AINFO31:

HDMI Read Data AINFO41:

HDMI Read Data AINFO51:

HDMI Read Data H-RES

HDMI Read Data H-RES

HDMI Read Data V-RES

HDMI Read Data V-RES

HDMI Read Data INTR1:

HDMI Read Data INTR2:

HDMI Read Data INTR3:

HDMI Read Data INTR4:

HDMI Read Data INTR5:

HDMI Read Data INTR6:

h available 0:NO, 1:YE

IR throu

Sub Video

Sub Video decoder Read Data 430Eh

Sub Video decoder Read Data 431Eh

Sub Video decoder Read Data 431Fh

Sub Video decoder Out

Gain Control GAFIXA/GAFIXD 0:Auto

CSTD

Reserved

Screen saver available

Reserved

Reserved

HDMI Read Data DE

HDMI Read Data DE

HDMI Read Data DE

HDMI Read Data DE

HDMI Read Data VID

HDMI Read Data VID

HDMI Read Data VID

HDMI Read Data VID

HDMI Read Data VID

HDMI Read Data VID

Reserved

Reserved

Reserved

Reserved

Reserved

SAA7117A)/RGB available Sub/RGB(0:N/N, 1:Y/Y, 2:N/Y, 3:Y/N)

2:0] for AUTO(4:PAL/NTSC-J, 5:SECAM/NTSC-M, other:PAL/NTSC-M

e

e

00h Sub

)

01h Sub

)

CNTROL)(D15-D8

CNTROL)(D 7-D0

STANDARD_RES)(D15-D8

STANDARD_RES)(D 7-D0

STATUS)(D15-D8

STATUS)(D 7-D0

same value at 0x30

MD1 : AV mute/HDMI mode 1

for Teletext=ON) 0:No, 1:Ye

PIX

PIXH

LIN

LINH

VTAV

STA

HSWIDL

HSWIDH

0:BW, 2:3.58NTSC, 3:4.43NTSC, 㨯㨯㨯

0:BW, 2:3.58NTSC, 3:4.43NTSC, 㨯㨯㨯

)

th/Audio length max

decimal x 100

decimal x 1

decimal x 10

decimal x 1

S

Chrominance control 1

Status byte 1

0:I-Port, 1:X-Port) *X-Port = quality NG -> use I-Po

Status byte 2

l

)

)

)

)

)

nc detect

1

/Sampling Frequenc

e code 1(request

e Code 1(request

0

)

)

AGC), 1:Manual(static

s

Init.

Max.

edoMsmetI.JD

e

Value

254 45 M3062

- - M3062

- - M3062

- - M3062

- - M3062

- - TB1274

- - TB1274

- - MSP4450G

- - MSP4450G

- - MSP4450G

- - MSP4450G

- - MSP4450G

- - MSP4450G

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

1 1 M3062

3 1 M3062

- - SAA7117

- - SAA7117

- - SAA7117

1 0 SAA7117

1 1 SAA7117

5 4 SAA7117

-- 10 -

-- -

-- -

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

- - HDMI

-- -

-- -

-- -

-- -

-- -

Value

Device

19

50PD9800TA (FW1)

A

p

ys

(

y

y

ys

p

(

(

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

p

y

g

g

p

p

pen(

7

7

(

T

7

l

t

7

A

play

7

j

)

(

7

j

7

y

No.

535

Reserved

536

Reserved

537

Reserved

538

Reserved

539

Reserved

540

Reserved

541

Reserved

542

Reserved

543

Reserved

544

Reserved

545

Reserved

546

Reserved

547

Reserved

548

Reserved

549

Reserved

550

Reserved

551

Reserved

552

Reserved

553

Reserved

554

RF-PAL IF com

555

DTT Force Reset 5:Yes

556

Sub s

557

Sub s

558

HDMI Out

559

HDMI OUTPUT FORMAT

560

Sub s

561

Sub s

562

Sub s

563

Sub s

564

Sub s

565

Sub s

566

Sub s

567

Sub s

568

Sub s

569

Sub s

570

Sub s

571

Sub s

572

Sub s

573

Sub s

574

Sub s

575

Sub s

576

Sub s

577

Sub s

578

Sub s

579

Sub s

580

Sub s

581

Sub s

582

In

.Mode(0-2:AUTO, 3-10:576i/480i/576p/480p/720p60/1080i50/60/720p50)

583

Sub s

584

Force Sub Video Decoder ON mod

585

586

587

588

589

590

591

592

593

594

595

596

597

598

599

600

nal Power-ON DEBUG mod

No si

Panel Blankin

In

ut H.Freq.(Subsys-02&03h / 10) * cutoff below decimal point(31.5kHz -> "31")

ut V.Freq.(Subsys-04&05h / 10) * cutoff below decimal point(59.9Hz -> "59")

In

IIC BUS Data/Clock O

HDMI EDID WRITE ENABLE

RS232C Terminal control mode 0:Terminal, 1:Genesis, 2:DTT

Reset function of accumulation time for LCD Pane

ccumulation time for Panel (hours

Dis

W/B Initialize

Gain ad

EEPROM Initialize

Enter to ad

Enter to service menu of Sub-s

ensation Enable 0:Disable, 1:Enabl

stem Busy Check 0:Disable, 1:Enabl

stem Blanking(for DEBUG 0:Normal, 1:Main, 2:Sub, 3:Both

ut clock invert 0:Normal(Rising edge), 1:Invert(Falling edge

stem status [00h]: Signal, Panel frame rate, Color syste

stem status [01h]: Input signal mod

stem status [02h]: H.Freq.(H

stem status [03h]: H.Freq.(L

stem status [04h]: V.Freq.(H

stem status [05h]: V.Freq.(L

stem status [06h]: V.Total(H

stem status [07h]: V.Total(L

stem status [08h]:(OSD mode

stem status [09h]:(Factory menu

stem status [0Ah]: Teletext status(H

stem status [0Bh]: Teletext status(L

stem status [0Ch]: WSS info.

stem status [0Dh]: CNI code(H

stem status [0Eh]: CNI code(L

stem status [0Fh]: NI code(H

stem status [10h]: NI code(L

stem status [11h]: Version(H

stem status [12h]: Version(L

stem "Status-read" request available (0:No 1:Yes

stem "OSD-packet" refresh available (0:No 1:Yes

stem "Control-packet" refresh available (0:No 1:Yes

stem H.B. stop coun

Enable (when the input signal is changed

of Panel map versio

ustment(Calibration

ust menu(2