Page 1

PA

DW

2-U

C

09.27.06

CH 1

Part Numbers Changed

02.06.07

CH 2

Change 1 updated part description information

Revised Service Menu sequence on pages 44 and 45

(FACT RESET >< MEMORY INIT)

02.22.07

CH 3

Updated part number information link

CH 4

04.19.07

No. 0217

42HDX99/DW2-U

42HDT79/DW2-U

SERVICE MANUAL

NTSC

ATSC

42HDS69/DW2-U

hassis

SERVICE MANUAL REVISION HISTORY INFORMATION

DATE REVISON # REASON

Apr , 28 SM00001 FIRST ISSUE OF MANUAL

05.03.07

CH 5

Changed text, Increase > Decrease

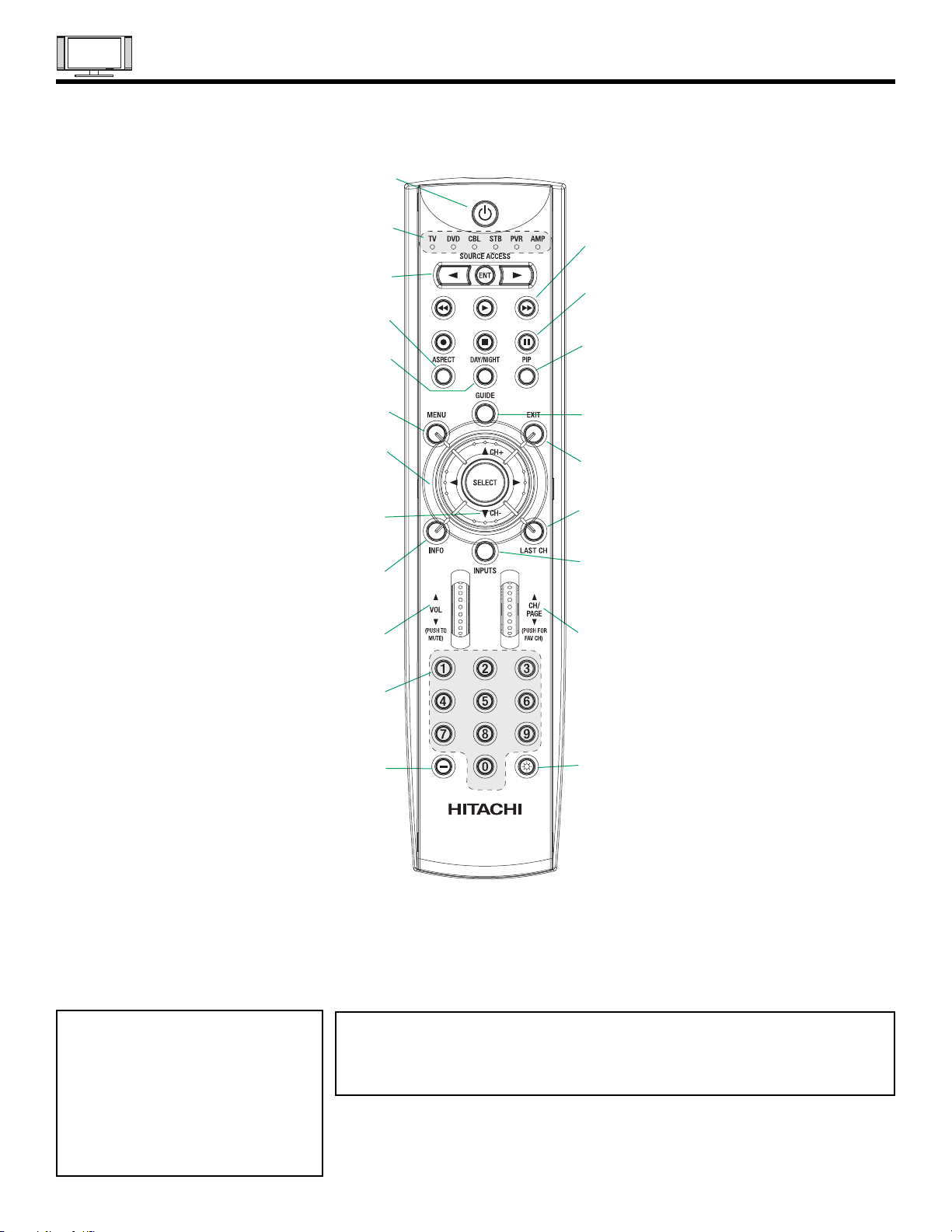

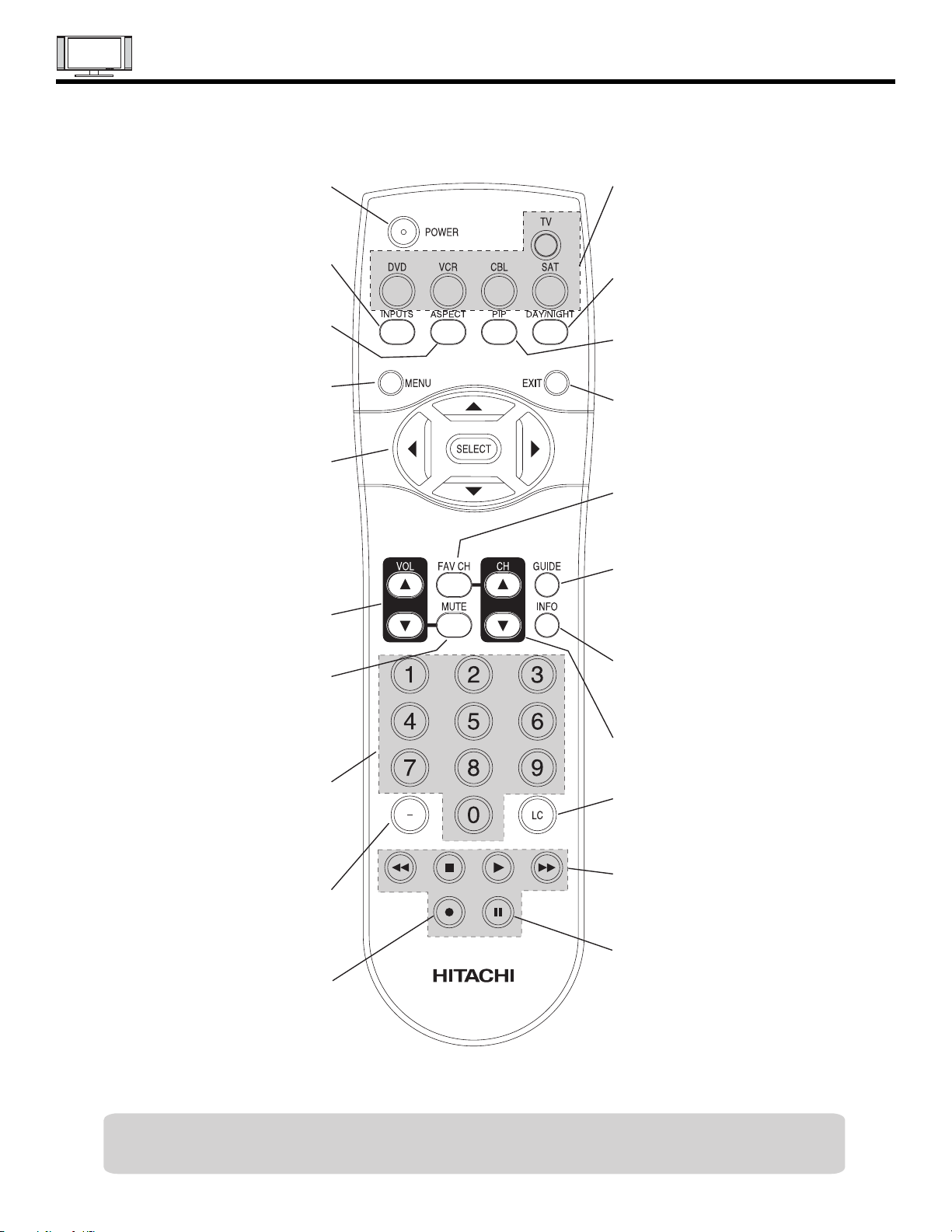

R/C: CLU-4352UG2 42HDS69

R/C: CLU-3861WL 42HDT79/42HDX99

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

PLASMA DISPLAY PANEL

APRIL 2006 HHEA-MANUFACTURING DIVISION

Page 2

PA

DW12-U

No. 0217

42HDX99/DW2-U

42HDT79/DW2-U

SERVICE MANUAL

NTSC

ATSC

42HDS69/DW2-U

PDD

A CChassis

TO GO TO A CHAPTER, CLICK ON ITS HEADING BELOW

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PRODUCT SAFETY NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SERVICING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

AGENCY REGULATORY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

ACKNOWLEDGMENTS AND TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

BASIC SETUP & OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

TROUBLESHOOTING FLOWCHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

BLOCK DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

CONNECTION DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

FINAL WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

QUICK DISASSEMBLY GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

FINAL ASSEMBLY GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

DC VOLTAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

CIRCUIT SCHEMATIC DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

PRINTED CIRCUIT BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

QUICK REFERENCE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

R/C: CLU-4352UG2 42HDS69

R/C: CLU-3861WL 42HDT79/42HDX99

CAUTION: These servicing instructions are for use by qualified service personnel only. To reduce the risk of

electric shock do not perform any servicing other than that contained in the operating instructions

unless you are qualified to do so. Before servicing this chassis, it is important that the service

technician read the “IMPORTANT SAFETY INSTRUCTIONS” in this service manual.

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

Components having special safety characteristics are identified by a on the schematics and on the parts list in this

Service Data and its supplements and bulletins. Before servicing the chassis, it is important that the service technician

read and follow the “Important Safety Instructions” in this Service Manual.

!

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

PLASMA DISPLAY PANEL

APRIL 2006 HHEA-MANUFACTURING DIVISION

Page 3

SAFETY PRECAUTIONS

NOTICE: Comply with all cautions and safety-related notes

located on or inside the cover case and on the chassis or plasma

module.

WARNING: Since the chassis of this receiver is connected to

one side of the AC power supply during operation, whenever the

receiver is plugged in service should not be attempted by any-

one unfamiliar with the precautions necessary when working on

this type of receiver.

1. When service is required, an isolation transformer should be

inserted between power line and the receiver before any

service is performed on a “HOT” chassis receiver.

2. When replacing a chassis in the receiver, all the protective

devices must be put back in place, such as barriers, nonmetallic knobs, insulating cover-shields, and isolation

resistors, capacitors, etc.

DW2U

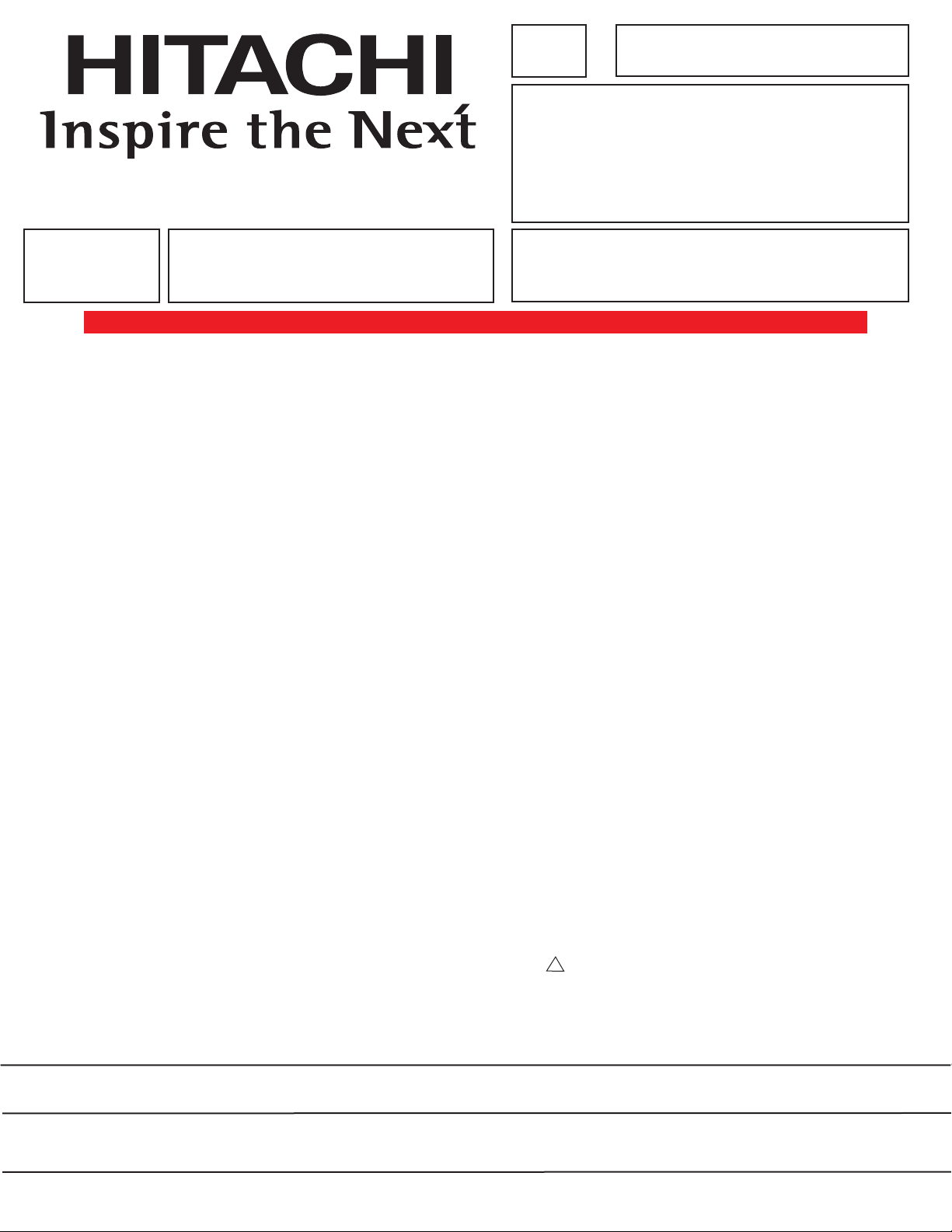

Leakage Current Hot Check

Plug the AC line cord directly into a 120V AC outlet. (Do not use an

isolation transformer during this test.) Use a leakage current

tester or a metering system that complies with the American

National Standards Institute (ANSI) C101.0 Leakage Current

for Appliances. In the case of the PDP monitor set the AC

switch first in the ON position and then in the OFF position,

measure from across Line 1 and Line 2 of the three plug

prongs, do not connect with the third prong, which is physical

ground, to all exposed metal parts of the instrument

(antennas, handle bracket, metal cabinet, screw heads,

metallic overlays, control shafts, etc.), especially any exposed

metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5 MIU. Reverse the

instrument power cord plug in the outlet and repeat test.

3. When service is required, observe the original lead dress.

4. Always use manufacturer’s replacement components. Critical

components as indicated on the circuit diagram should not be

replaced by another manufacturer’s. Furthermore, where a

short circuit has occurred, replace those components that

indicate evidence of over heating.

5. Before returning a serviced receiver to the customer, the

service technician must thoroughly test the unit to be certain

that it is completely safe to operate without danger of electrical

shock, and be sure that no protective device built into the

receiver by the manufacturer has become defective, or

inadvertently defeated during servicing.

Therefore, the following checks should be performed for the

continued protection of the customer and service technician.

Leakage Current Cold Check

With the AC plug removed from the 120V AC 60Hz source,

place a jumper across Line 1 and Line 2 of the three plug

prongs, do not connect with the third prong, which is physical

ground.

Using an insulation tester (DC500V), connect one of its leads

to the AC plug jumper and touch with the other lead each

exposed metal part (antennas, screwheads, metal overlays,

control shafts, etc.), particularly any exposed metal part

having a return path to the chassis should have a resistor

reading over 4MΩ. Any resistance value below this range

indicates an abnormality which requires corrective action. An

exposed metal part not having a return path to the chassis will

indicate an open circuit.

AC LEAKAGE TEST

(READING

SHOULD NOT

BE ABOVE 0.5MIU)

EARTH

GROUND

DEVICE

UNDER

TEST

TEST ALL

EXPOSED

METAL SURFACES

3-WIRE CORD

ALSO TEST WITH PLUG

REVERSED

(USING AC ADAPTER

PLUS AS REQUIRED)

LEAKAGE

CURRENT

TESTER

ANY MEASUREMENTS NOT WITHIN THE LIMITS OUTLINED

ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD

AND MUST BE CORRECTED BEFORE RETURNING THE

RECEIVER TO THE CUSTOMER.

TABLE OF CONTENTS

2

Page 4

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in HITACHI television

receivers have special safety-related characteristics. These are

often not evident from visual inspection nor can the protection

afforded by them necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement

parts which have these special safety characteristics are

identified in this Service Manual.

Electrical components having such features are identified with a

mark in the schematics and parts list in this Service Manual.

!

The use of a substitute replacement component which does not

have the same safety characteristics as the HITACHIrecommended replacement component, shown in the parts list in

this Service Manual, may create shock, fire, X-radiation, or other

hazards.

Product safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current HITACHI Service Manual. A subscription to,

or additional copies of HITACHI Service Manuals may be

obtained at a nominal charge from HITACHI Sales Corporation.

DW2U

PDP Module Handling

When there is need to replace a broken PDP module which is the

displaying device from the Plasma monitor unit, consider the

following:

1. When carrying the PDP module, two persons should stand at

both shorter-edge sides of the glass-panel and transport it with

their palms. Avoid touching the Flexible Printed Circuits or the

chip tube on the corner of the glass-panel. Handle only by the

surface of the glass panel. In case of some PDP modules,

electrode repair is done by connecting between regular

terminal with Cu tape and Cu wire. Please do not hook and/or

damage this repair line. If it is damaged, the module will not

function unless the glass-panel is exchanged with a new

glass-panel.

2. When carrying PDP module, watch surrounding objects, such

as tables, and also do not carry it alone since it may be

dangerous and it will be damaged due to excessive stress to

the module (glass-panel).

3. Please do not stand the module with the edge of the glasspanel on the table since this might result in damage to the

glass-panel and/or flexible printed circuits due to excessive

stress to the module (glass-panel).

1. Follow the general caution recommendations from “Safety

precautions” section.

42HDS69/HDT79/HDX99 - Plasma Monitor Unit

55HDS69/HDT79/HDX99 - Plasma Monitor Unit

1. Follow the general caution recommendations from “Safety

precautions” section.

2. Since the Panel module and front filter are made of glass,

sufficient care shall be taken when handling the broken

module and filter in order to avoid injury.

3. If necessary to replace Panel module, this work must be

started after the panel module and the AC/DC Power supply

becomes sufficiently cool.

4. Special care must be taken with the display area to avoid

damaging its surface.

5. The Panel Module shall not be touched with bare hands to

protect its surface from stains.

6. It is recommended to use clean soft gloves during the

replacing work of the Panel module in order to protect, not

only the display area of the panel module but also the

serviceman.

7. The Chip Tube of the panel module (located upper left of the

back of the panel module) and flexible cables connecting

Panel glasses to the drive circuitry Printed Wiring Boards

(P.W.B.) are very weak, so sufficient care must be taken to

prevent breaking or cutting any of these. If the Chip Tube

breaks the panel module will never work, replacement for a

new plasma panel module will be needed.

8. AV Digital Block, power supply and PDP driving circuit

P.W.B.’s are assembled on the rear side of the PDP module,

take special care with this fragile circuitry; particularly, Flexible

Printed Circuits bonded to surrounding edges of the glass

panel. They are not strong enough to withstand harsh outer

mechanical forces. Avoid touching the flexible printed circuits

by not only your hands, but also tools, chassis, or any other

object. Extreme bending of the connectors must be avoided

too. In case the flexible printed circuits are damaged, the

corresponding addressed portions of the screen will not be lit

and exchange of a glass panel will be required.

WARNING

Lead in solder used in this product is listed by the California

Health and Welfare agency as a known reproductive toxicant

which may cause birth defects or other reproductive harm

(California Health and Safety Code, Section 25249.5).

When servicing or handling circuit boards and other components

which contain lead in solder, avoid unprotected skin contact with

solder. Also, when soldering make sure you are in a well

ventilated area in order to avoid inhalation of any smoke or

fumes released.

SAFETY NOTICE

USE ISOLATION TRANSFORMER

WHEN SERVICING

POWER SOURCE

This plasma television is designed to operate on 120 Volts

60Hz, AC house current. Insert the power cord into a 120 Volts

60Hz outlet.

NEVER CONNECT THE PLASMA TELEVISION TO OTHER

THAN THE SPECIFIED VOLTAGE OR TO DIRECT CURRENT

AND TO 50HZ. TO PREVENT ELECTRIC SHOCK, DO NOT

USE THE PLASMA TELEVISION’S (POLARIZED) PLUG WITH

AN EXTENSION CORD, RECEPTACLE, OR THE OUTLETS

UNLESS THE BLADES AND GROUND TERMINAL CAN BE

FULLY UNSERTED TO PREVENT BLADE EXPOSURE.

TABLE OF CONTENTS

3

Page 5

SERVICING PRECAUTIONS

CAUTION: Before servicing instruments covered by this

service data and its supplements and addenda, read and

follow the “Important Safety Instructions” on page 3 of this

publication.

NOTE: If unforeseen circumstances create conflict between

the following servicing precautions and any of the safety

precautions on page 3 of this publication, always follow the

safety precautions. Remember: Safety First.

DW2U

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some fieldeffect transistors and semiconductor “chip” components. The

following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

General Servicing Guidelines

1. Always unplug the instrument AC power cord from the AC

power source before:

a. Removing or reinstalling any component, circuit

board, module, or any other instrument assembly.

b. Disconnecting or reconnecting any instrument

electrical plug or other electrical connection.

c. Connecting a test substitute in parallel with an

electrolytic capacitor in the instrument.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic

capacitors may result in an explosion

hazard.

2. Do not spray chemicals on or near this instrument or any

of its assemblies.

3. Unless specified otherwise in these service data, clean

electrical contacts by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator: 10% (by volume)

Acetone and 90% (by volume) isopropyl alcohol (90%99% strength).

CAUTION: This is a flammable mixture. Unless

specified otherwise in these service data,

lubrication of contacts is not required.

4. Do not defeat any plug/socket of voltage interlocks with

which instruments covered by this service data might be

equipped.

5. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heatsinks are correctly installed.

6. Always connect the test instrument ground lead to the

appropriate instrument chassis ground before connecting

the test instrument positive lead. Always remove the test

instrument ground lead last.

7. Use with this instrument only the test fixtures specified in

this service data.

CAUTION: Do not connect the test fixture ground strap

to any heatsink in this instrument.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge

buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

desolder ES devices.

4. Use only an anti-static type solder removal device. Some

solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ES

device.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive

material.)

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or

circuit, and observe all other safety

precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the

lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ES device.)

TABLE OF CONTENTS

4

Page 6

DW2U

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range 500°F to 600°F.

2. Use an appropriate lead free solder (see page 8). Lead

solder can be used, but there is a possibility of failure due

to insufficient strength of the solder.

3. Keep the soldering iron tip clean and well-tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

small wire-bristle (0.5 inch or 1.25 cm) brush with a metal

handle. Do not use freon-propelled spray-on cleaners.

5. Use the following desoldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. Heat the component lead until the solder melts.

Quickly draw away the melted solder with an antistatic, suction-type solder removal device or with

solder braid.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. First, hold the soldering iron tip and solder strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and

hold it there only until the solder flows onto and

around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil or components.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as

the solder melts.

2. Draw away the melted solder with an anti-static suctiontype solder removal device (or with solder braid) before

removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to areas.)

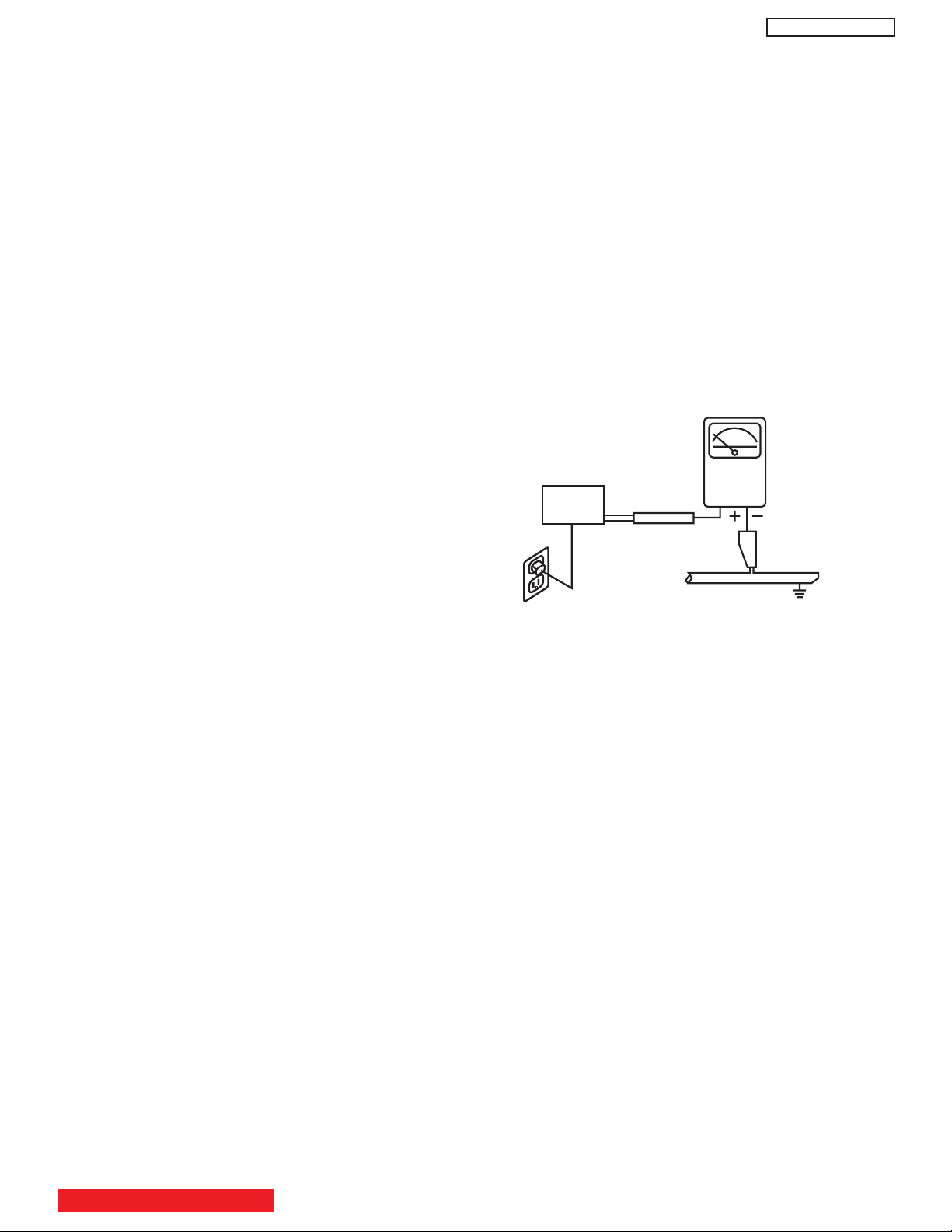

“Small-signal” Discrete Transistor Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a “U” shape the end of each of the three leads

remaining on the circuit board.

3. Bend into a “U” shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the “U” with long nose pliers to insure metal to

metal contact, then solder each connection.

Power Output Transistor Devices Removal/Replacements

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the circuit board.

d. Closely inspect the solder area and remove any

excess or splashed solder with a small wire-bristle

brush.

Use Soldering Iron to Pry Leads

IC Removal/Replacement

Some Hitachi unitized chassis circuit boards have slotted

holes (oblong) through which the IC leads are inserted and

then bent flat against the circuit foil. When holes are the

slotted type, the following technique should be used to

remove and replace the IC. When working with boards using

the familiar round hole, use the standard technique as

outlined in paragraphs 5 and 6 above.

4. Insert new transistor in circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicularly to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints

of the two “original leads”. If they are not shiny, reheat

them and, if necessary, apply additional solder.

5

Page 7

DW2U

Fuses and Conventional Resistor Removal/Replacement

1. Clip each fuse or resistor lead at top of circuit board

hollow stake.

2. Securely crimp leads of replacement component around

stake 1/8 inch from top.

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent

components and the circuit board, to

prevent excessive component

temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the foil to

the circuit board, causing the foil to separate from, or “liftoff,” the board. The following guidelines and procedures

should be followed whenever this condition is encountered.

In Critical Copper Pattern Areas

High component/copper pattern density and/or special

voltage/current characteristics make the spacing and

integrity of copper pattern in some circuit board areas more

critical than in others. The circuit foil in these areas is

designated as Critical Copper Pattern. Because Critical

Copper Pattern requires special soldering techniques to

ensure the maintenance of reliability and safety standards,

contact your Hitachi personnel.

At Other Connections

Use the following technique to repair defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the component

side of the circuit board.

DEFECTIVE

COPPER

REMOVED

Insulated Jumper Wire

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both wire sides of

the pattern break and locate the nearest component

directly connected to the affected copper pattern.

At IC Connections

To repair defective copper pattern at IC connections, use the

following procedure to install a jumper wire on the copper

pattern side of the circuit board. (Use this technique only on

IC connections.)

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as absolutely

necessary.)

2. Carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

BARE JUMPER

WIRE

CRIMP AND

SOLDER

Install Jumper Wire and Solder

3. Bend a small “U” in one end of a small-gauge jumper wire

and carefully crimp it around the IC pin. Solder the IC

connection.

3. Connect insulated 20-gauge jumper wire from the

nearest component on one side of the pattern break to

the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is

dressed so that it does not touch

components or sharp edges.

4. Route the jumper wire along the path of the cut-away

copper pattern and let it overlap the previously scraped

end of the good copper pattern. Solder the overlapped

area, and clip off any excess jumper wire.

6

Page 8

DW2U

NOTE: These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when removing. Usually applying heat to the component for a short

time while twisting with tweezers will break the component loose.

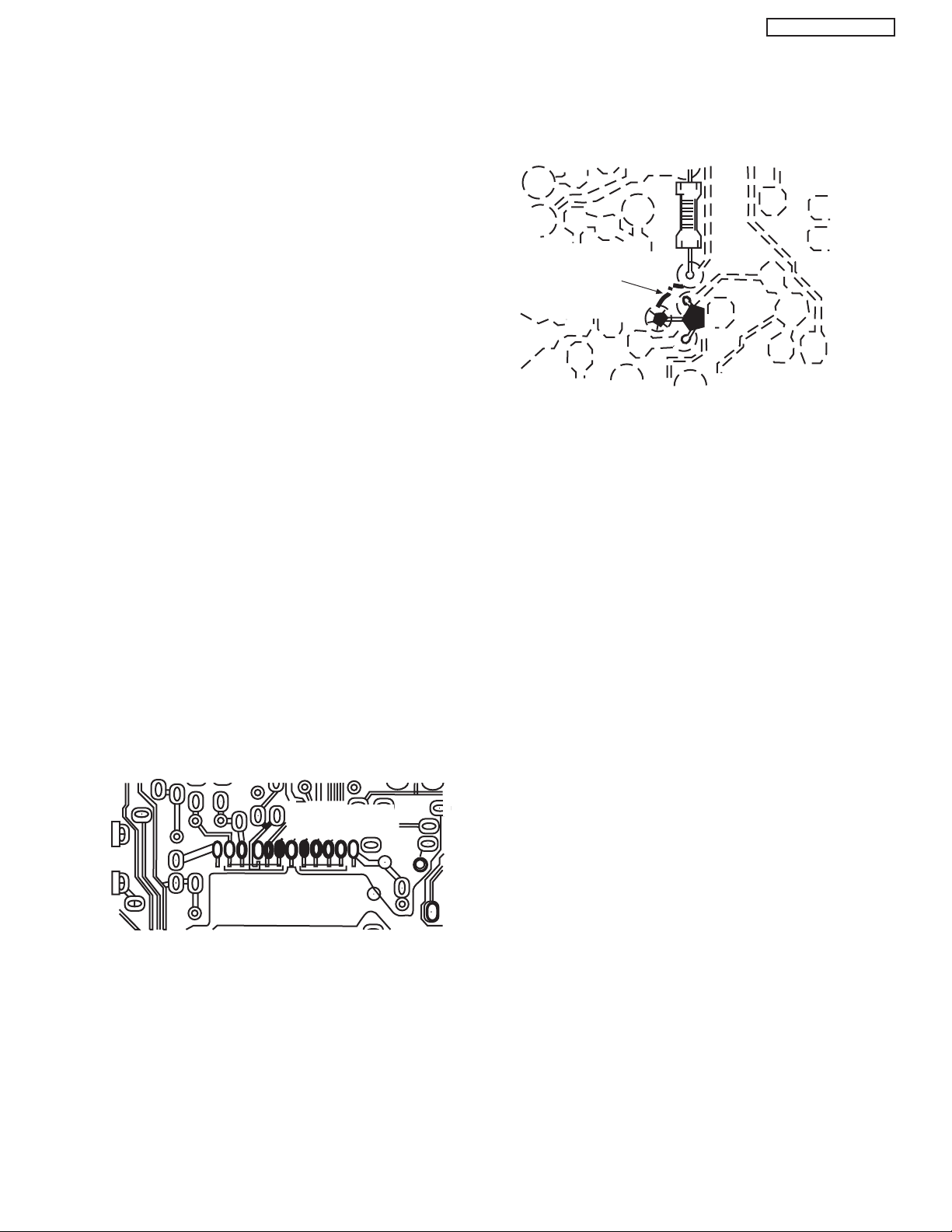

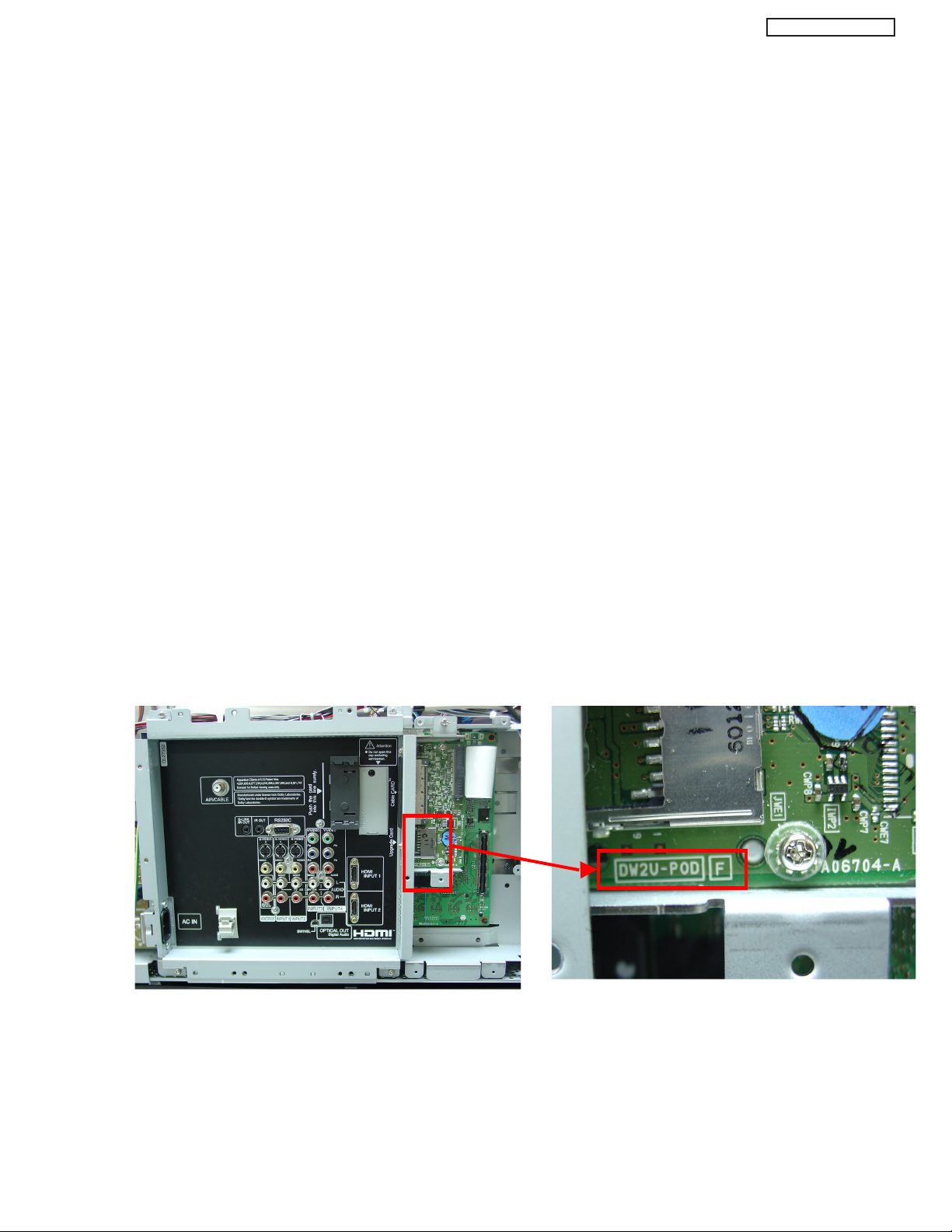

Leadless Chip Components

(surface mount)

Chip components must be replaced with identical

chips due to critical foil track spacing. There are no

holes in the board to mount standard transistors or

diodes. Some chip capacitor or resistor board solder

pads may have holes through the board, however the

hole diameter limits standard resistor replacement to

1/8 watt. Standard capacitors may also be limited for

the same reason. It is recommended that identical

chip components be used. .

Chip resistors have a three digit numerical resistance

code -1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6KΩ resistor, 0 = 0Ω

(jumper).

Chip capacitors generally do not have the value

indicated on the capacitor. The color of the component

indicates the general range of the capacitance.

Chip transistors are identified by a two letter code. The

first letter indicates the type and the second letter, the

grade of transistor.

Chip diodes have a two letter identification code as

per the code chart and are a dual diode pack with

either

common anode or common cathode. Check the parts

list for correct diode number.

Component Removal

1. Use solder wick to remove solder from component

end caps or terminals.

2. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal .

Chip Component Installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator

clip and apply heat to the pad area with a 30 watt

iron until solder flows. Do not apply heat for more

than 3 seconds

TYPE

Chip Components

C

GRADE

SOLDER

CAPS

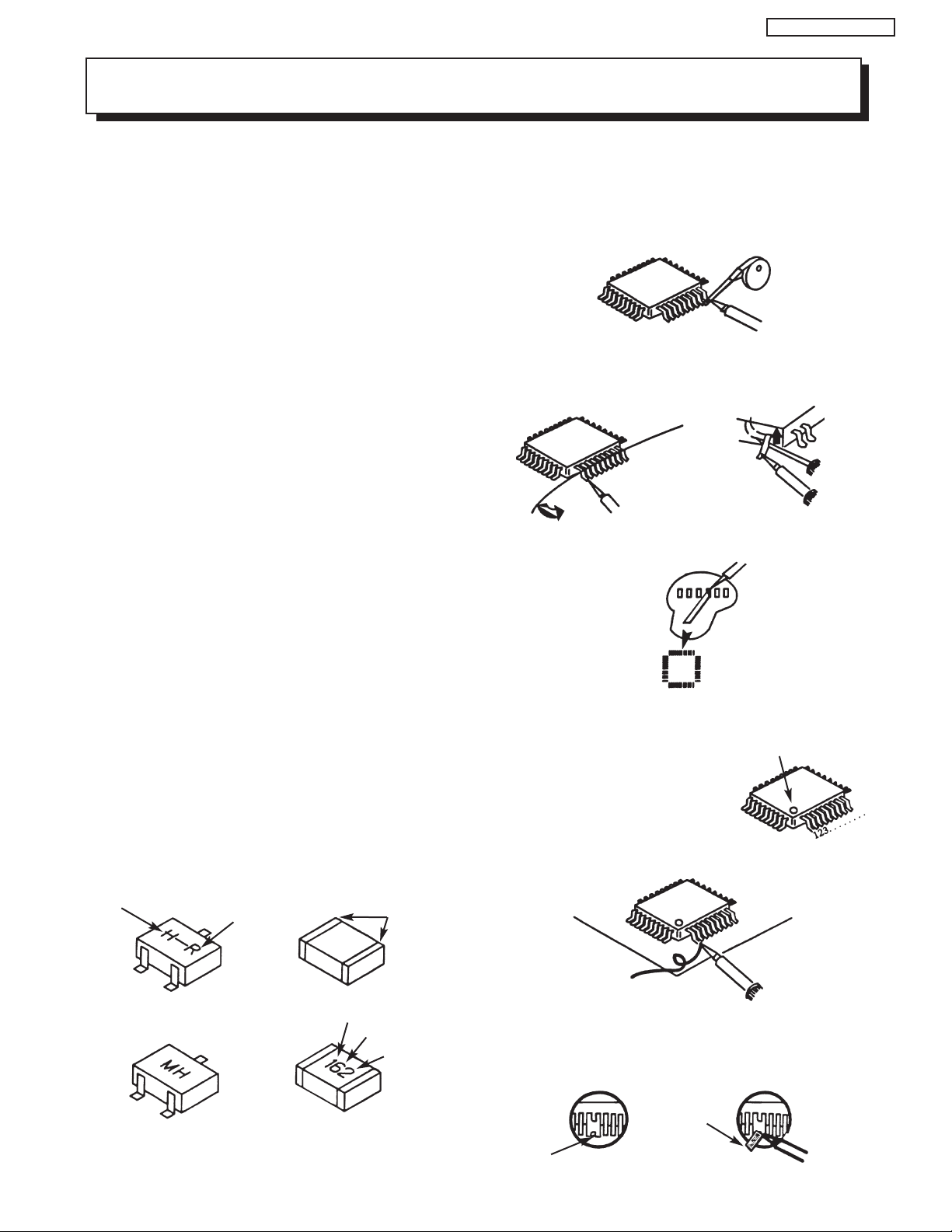

How to Replace Flat-lC

—Required Tools—

• Soldering iron • iron wire or small awl

• De-solder braids • Magnifier

1. Remove the solder from all of the pins of a Flat-lC

by using a de-solder braid.

De-Solder

Braid

Soldering

Iron

2. Put the iron wire under the pins of the Flat-lC and

pull it in the direction indicated while heating the

pins using a soldering iron. A small awl can be

used instead of the iron wire.

Pull

Soldering

Iron

3. Remove the solder from all of the pads of the

Fiat-lC by using

a de-solder braid.

4. Position the new Flat-lC in place (apply the pins of

the Flat-lC to the soldering pads where the pins

need to be soldered). Properly

determine the positions of the

soldering pads and pins by

correctly aligning the polarity

symbol.

5. Solder all pins to the soldering pads using a fine

tipped soldering iron.

Iron

Wire

Awl

Soldering

Iron

Soldering

Iron

De-Solder

Braid

Flat-IC

Polarity Symbol

B

ANODES

E

COMMON CATHODE

MH DIODE

TRANSISTOR

SOLDER CAPS

1ST DIGIT

RESISTOR

CAPACITOR

2ND DIGIT

MULTIPLIER

= 1600 = 1.6K

Solder

Soldering

Iron

6. Check with a magnifier for solder bridge between

the pins or for dry joint between pins and soldering

pads. To remove a solder bridge, use a de-solder

braid as shown in the figure below.

De-Solder

Braid

Bridge

Solder

7

Soldering

Iron

Page 9

Information for service about lead-free solder introduction

Hitachi introduced lead-free solder to conserve the "Earth Environment".

Please refer to the following before servicing.

(1) Characteristic of lead-free solder

Melting point of lead free solder is 40-50

(2) Solder for service

Following composition is recommended.

" Sn - 3.0Ag - 0.5Cu " , or " Sn - 0.7 Cu "

Lead solder can be used, but there is a possibility of failure due to insufficient strength of the solder.

Caution when using solder containing lead.

Please remove previous solder as much as possible from the soldering point.

When soldering, please perfectly melt the lead-free solder to mix well with the previous solder.

(3) Soldering iron for lead-free solder.

Melting point of lead-free solder is higher than solder containing lead.

Use of a soldering tool "with temperature control" and "with much thermal capacitance" is recommended.

(Recommended temperature control : 320

o

C higher than solder containing lead.

o

C - 450oC)

DW2U

Recommended temperature

PWB with chip parts

PWB without chip parts

Chassis, metal, shield etc.

320oC +/- 30oC

380oC +/- 30oC

420oC +/- 30oC

(4) Identification of lead-free PWB

2004 models >> lead-free solder is introduced

2006 models >> lead-free solder apply

On lead-free PWB, "F" is added at the beginning of stamp on PWB. (e.g. DW2-POD F)

8

Page 10

AGENCY REGULATORY

INFORMATION

Federal Communications Commission Notice

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate radio frequency energy and if not

installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/television technician for help.

FCC Information

This device complies with part15 of the FCC Rules.Operation is subject to the following two conditions :

(1) This decide may not cause harmful interference and (2) This decide must accept any interference

received, including interference that may cause undesired operation.

DW2U

Modifications

The FCC requires the user to be notified that any changes or modifications made to this device that are not

expressly approved by Hitachi America ,Ltd. Home Electronics Division may void the user’s authority to

operate the equipment.

Cables

Connections to this device must be made with shielded cables with metallic RFI/EMI connector hoods to

maintain compliance with FCC Rules and Regulations.

Any cables that are supplied with the system must be replaced with identical cables in order to assure

compliance with FCC rules. Order Hitachi spares as replacement cables.

Note

This Plasma Television receiver will display television closed captioning, ( or ), in accordance with

paragraph 15.119 of the FCC rules.

INDUSTRY CANADA AGENCY REGULATORY INFORMATION

Cable Compatible Television Apparatus- Tèlèvision câblocompatible, Canada.

In the United States, TV GUIDE and other related marks are registered marks of Gemstar-TV Guide International,

Inc. and/or one of its affiliates. In Canada, TV GUIDE is a registered mark of Transcontinental Inc., and is used

under license by Gemstar-TV Guide International, Inc.

The TV Guide On Screen system is manufactured under license from Gemstar-TV Guide International, Inc.

and/or one of its affiliates.

The TV Guide On Screen system is protected by one or more of the following issued United States patents

6,498,895; 6,418,556; 6,331,877; 6,239,794; 6,154,203; 5,940,073; 4,908,713; 4,751,578; 4,706,121.

Gemstar-TV Guide International Inc. and/or its related affiliates are not in any way liable for the accuracy or

availability of the program schedule information or other data in the TV Guide On Screen system and cannot

guarantee service availability in your area. In no event shall Gemstar-TV Guide International, Inc. and/or its

related affiliates be liable for any damages in connection with the accuracy or availability of the program

schedule information or other data in the TV Guide On Screen system.

9

TABLE OF CONTENTS

Page 11

ACKNOWLEDGMENTS

AND TRADEMARKS

This Plasma Television complies with VESA DDC2B specifications, Plug & Play

is a system with computer, peripherals (including monitors) and operating

system. It works when the monitor is connected to a DDC ready computer that

is running an operating system software that is capable for the plug & play.

When a Plug and Play PC is powered on, it sends a command to the Monitor

requesting identification. The Monitor sends back a string of data including its

characteristics.

TRADEMARK ACKNOWLEDGMENT

TM

DDC is a trademark of Video Electronics Standard Association.

IBM PC/AT and VGA are registered trademarkds of International Business Machines Corporation of the U.S.A.

Apple and Macintosh are registered trademarks of Apple Computer, Inc.

VESA is a trademark of a nonprofit organization, Video Electronics Standard Association.

DW2U

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Cable Compatible Television Apparatus- Tèlèvision câblocompatible, Canada.

Notes on Closed Caption:

This Plasma Television receiver will display television closed captioning, ( or ), in accordance with

paragraph 15.119 of the FCC rules.

*Manufactured under license from Dolby Laboratories. “Dolby” and the double-D symbol are

trademarks of Dolby Laboratories.

In the U.S. , TV GUIDE and other related marks are registered marks of Gemstar-TV Guide International, Inc. and/or

one of its affiliates. In Canada , TV GUIDE is a registered of transcontinental Inc. , and is used under license by Gemstar-TV

Guide International, Inc.

TABLE OF CONTENTS

10

Page 12

DW2U

INTRODUCTION

The Digital AV Block is inside of the Panel assembly controls most of the user functions of the complete TV set and conditions the signal

to the plasma panel.

The 42” and 55” monitors contain the displaying device, which is the plasma display panel module, and the driving circuitry, which

receives the signal from the Digital AV Block and after processing, delivers the image to the display module.

This HITACHI Service Manual is intended for the qualified service personnel and it contains the necessary information for

troubleshooting the Plasma television set in case of malfunction.

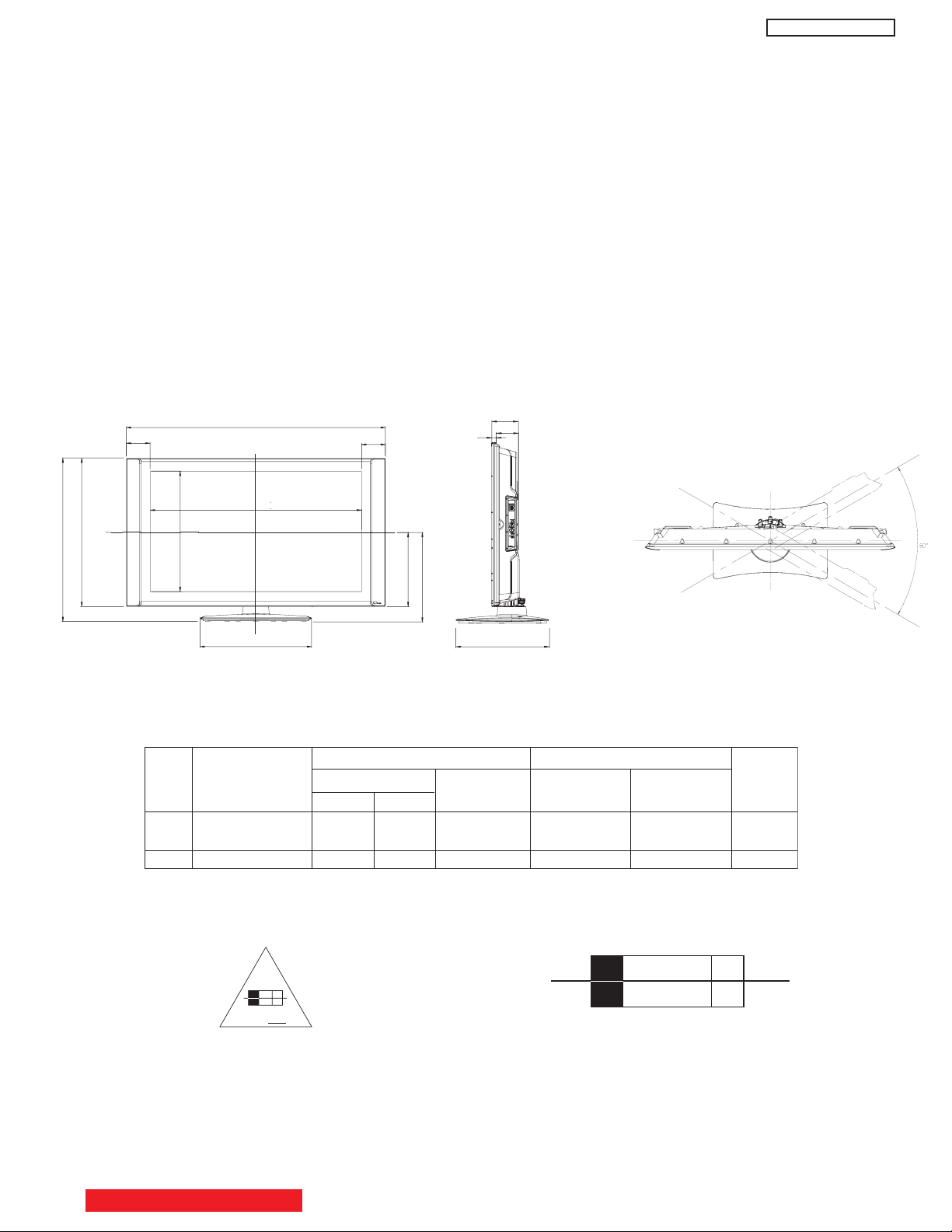

DIMENSIONS:

42HDS69/HDT79/HDX99

104 mm

713.2 mm

648 mm

POWER RATINGS:

No.

1 42HDS69/HDT79 370W 3.4A 236W 0.6W 14W DW-2U

526.6 mm

Model Name

42HDX99

1134 mm

485.3 mm

926 mm

104 mm

Indicated Value

Max Rating

(W) (A)

328 mm

393.2 mm

108.5 mm

90.5 mm

17 mm

365 mm

Average

Rating (W)

P

Without POD.

less than 1W

ST(W)

With POD.

less than 14W

Chassis

CIRCUIT PROTECTION

CAUTION: Below is an EXAMPLE only. See Replacement Parts List for details. The following symbol near the fuse

Example:

“RISK OF FIRE - REPLACE FUSE AS MARKED”

TABLE OF CONTENTS

indicates fast operation fuse (to be replaced). Fuse ratings appear within the symbol.

F

6.3 A 125V

The rating of fuse F9A2 is 6.3 A - 125V.

6.3 A

125V

Replace with the same type fuse for continued protection

against fire.

11

Page 13

SC/ATSC(8VSB),64QAM,256QAM)

,

)

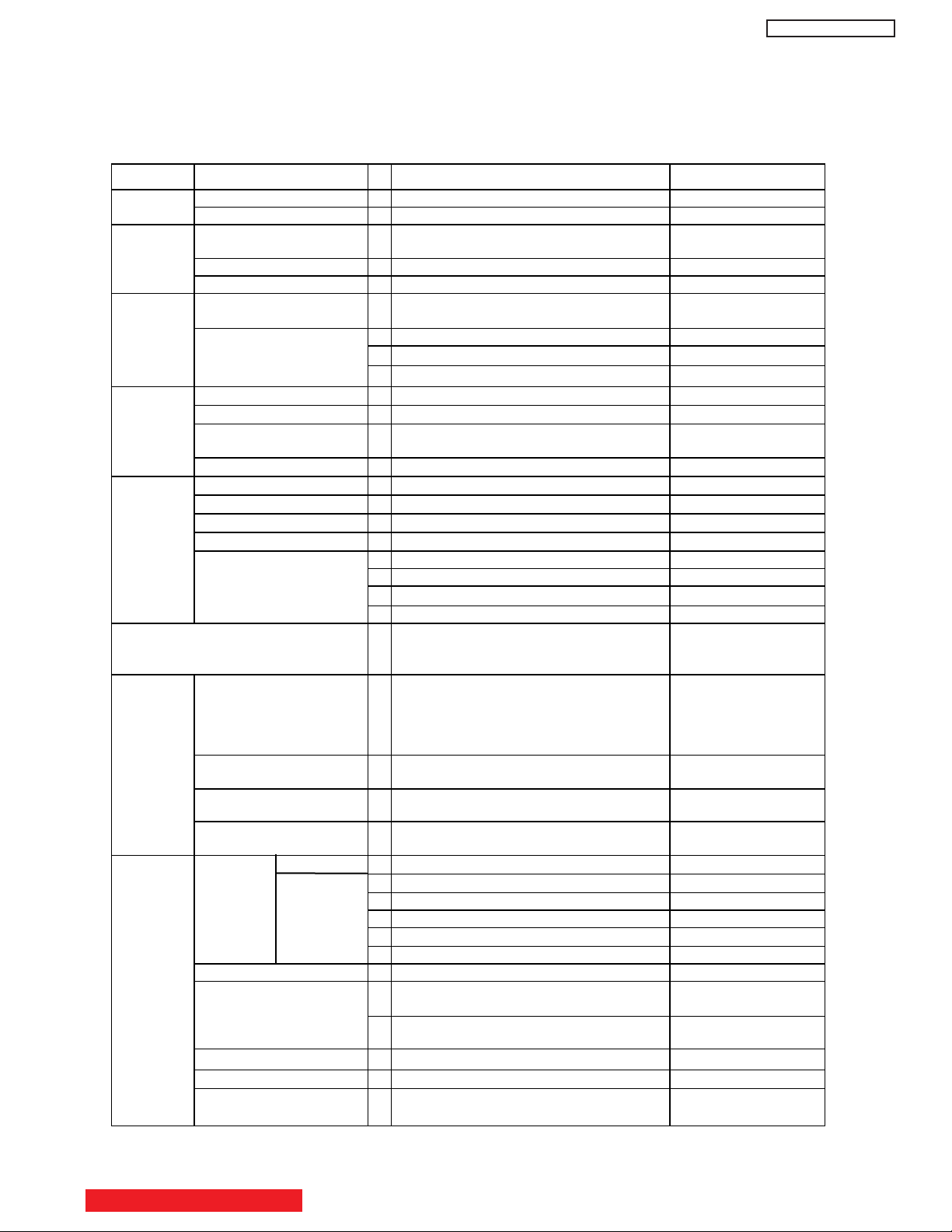

SPECIFICATIONS

FEATURES

A- Plasma

Model 42HDS69/42HDT79/42HDX99

Dimension Size

Weight

A/C Input

Voltage

Front End

Input Signal

Picture

Sound Enhancement

Input AC Voltage

Input AC Frequency

Power Consumption

Front End(NTSC & ATSC)

Available Channel

Video Signal

Component Signal

PC Signal

HDMI Signal

Y/C Separation

Line Correction

I-P Conversion

Picture Mode

Display Mode

1

1134mm x 713.2mm x 365mm

2

39.8k g

3

AC108V~132V (with 3 Plug AC Power Cord inlet

type ,1.8m length)

4

60Hz

5

370W, SBY/POD -SBY less than 1W/14W

6

ENGD6305

NT

7

2~13

8 14 ~ 69

9

A-5~A-1,A~W,W+1~W+94

NTSC

10

480 i /p. 1080 i , 720p

11

12

V G A - U X G A fH:24KHz-1 09KHz,fV:50Hz85Hz)

13

480i,480p,720p,1080i(EIA-861B)

14

3D Y/C (ON fix)

15 No

16

Motion Adaptive & Multi Angle Interpolation

17

Day.Night

18

42:1024i,55:768p Video Signal

19

42:1024i,55:768p ComponentSignal

20

42:1024i,55:768p PinP Mode

21

22

BassBoost & Surround (Normal, Wide, Off)

DW2U

VHP

UHF

CATV

3

FC6

-

Adjustment

General

Function

POP 30

PIP 31

Freeze

23

24

25

26

27

28

29

32

33

34

36

37

38

Settings for Video Signal

Settings for Sound

PinP Split

Mode Strobe

Wide Mode

Aspect Video Selection

PC 35

Film Theater

Color Temperature

Input Signal Selection

Picture,Contrast,Brightness,Color,Tint , Sharpness,

W/B Temp.Black Enhancement .Contrast Mode.Color

Management/Decoding ,Auto Color.Noise

Reductfon.Auto Movie Mode, .Black Side Panel

Vol, Balance, Bass.Treble, Source, Internal Speakers

,Auto Noise Cancel.Perfect Volume.Mute.Soft Mute

With(ANT/CABLE DIGITAL CHANNEL & Video.480i ,720p,1080i)

With(3Pix:only ANT/CABLE DIGITAL CHANNEL,Video,480i)

With Main: ANT/CABLE DIGITAL CHANNEL,Video.480i ,720p,1080i)

With(Main:ANT/CABLE DIGITAL CHANNEL,Video.480i ,720p,1080i)

With(3Pix:only ANT/CABLE DIGITAL CHANNEL,Video,480i)

7Mode

4:3 Standard/16:9 Standard1 /16:9 Standard 2

4:3 Expanded/Zoom1/Zoom 2/16:9 Zoom

Full/Normal/Real (Real

55:VGA/SVGA/XGA/WXGA

42:VGA

With(Auto Movie Mode:On/Off)

4Mode (High/Medium/Standard/Black & White)

VIDEO1/2/3/4/5, Cable/ Air,IEEE1394,Photo

Input

Except Photo Input only HDT/HDX

Except Photo Input only HDT/HDX

Except Photo Input only HDT/HDX

Except Photo Input only HDT/HDX

Except Photo Input only HDT/HDX

Black & White only HDT/HDX

IEEE1394 only HDT/HDX

Photo Input only HDT/HDX

TABLE OF CONTENTS

12

Page 14

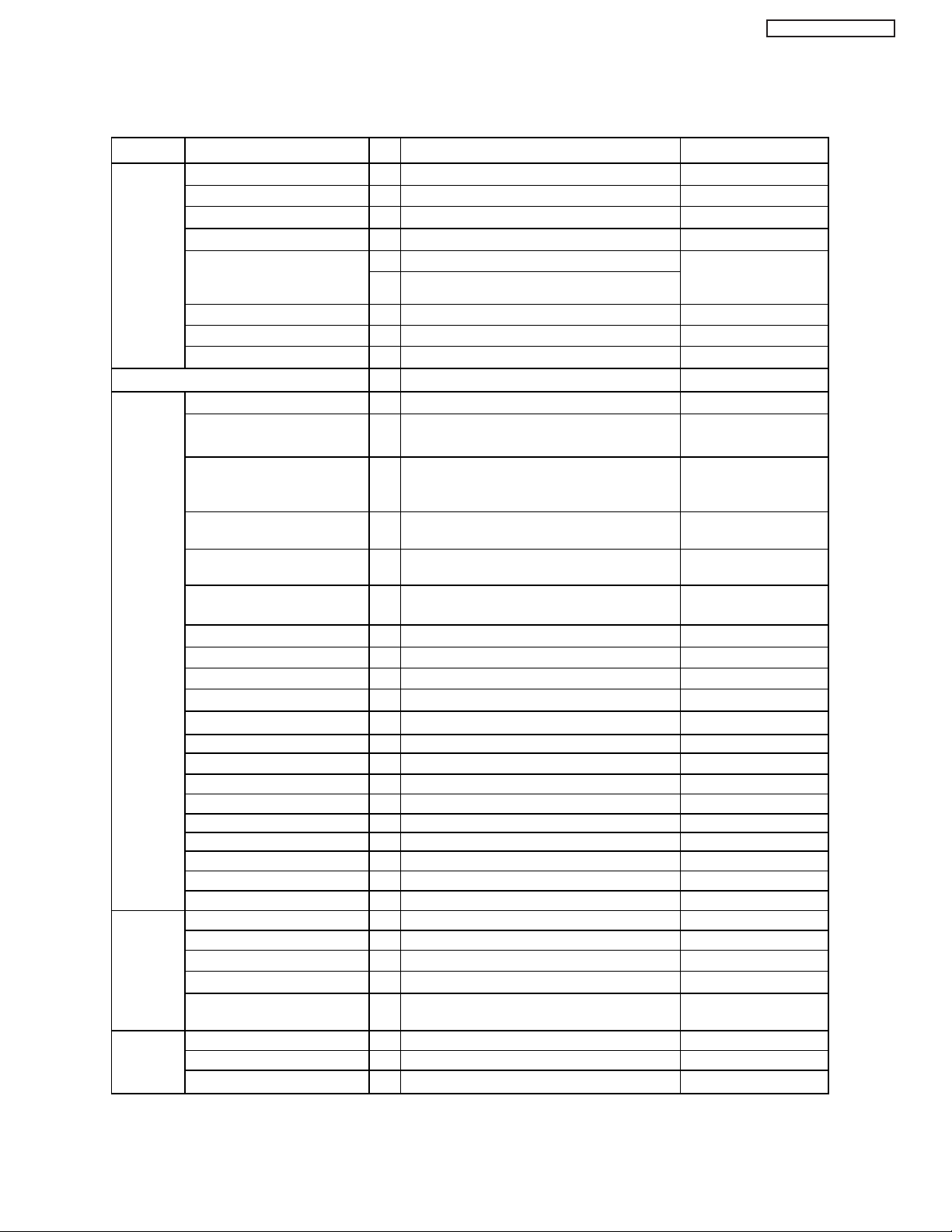

SPECIFICATIONS

FEATURES

DW2U

Model

General Gamma Correction

Function Picture Enhancer

Input Signal Identification

Audio Special Mode

Power Save Mode

Burning Protection

OSD Language (VIDEO)

Power Swivel

R/C Handset

In/Out

Terminal

Composite Video Input

(VIDEO1~5)

S-ln(S2 Terminal) (Video/S are

common selector, priority is S-ln) .

Component Signal Input

(VIDEO3.VIDEO4.VIDEO5)

Digital Input(HDMH-HDCP)

Audio In (L/R) (Lch:mono)

42HDS69/42HDT79/42HDX99

39

Only for Service Menu

40

-

41

yes

42

No

43

With (On/Off) (Video In) LED Normal: Blue

44

45

With (Raster Shift:3 option.AII White Pattern)

46

ENGLISH.FRANCAIS.ESPANOL

47

With

42HDT79 and 42HDX99 only

48

CLU-3861WL/CLU-123S

49

50

5 Input: RCA pin* 5 (1 Input Side Panel)

51

2 InputMini Din-4P x 2

52

3 lnput:RCA pin x 9(Y of VIDEO1/2/5 is common

/CLU-4352UG2

input for Composite-In)

53

3 lnput:HDMI(18P)X3 (Selected by component

Video1/2/5.Digital input priority)

54

5 lnput:RCApinx10

Power Save: Orange

PANASONIC/UEI/HOSHIDEN

Auto Link

Video Control Terminal (BS)

U/V Ant Input

BS-I/F Input

Video Monitor Out Terminal

Audio Output Terminal

Audio Monitor Out Terminal

IR-OUTPUT 62

Headphone Terminal

IEEE 1394 Input

RS-232C Terminal 66

Photo Input

Audio Optical Output

Front Main Power Switch

Key

Power On/off Switch

IR Receiving Unit

Power Indicator LED

Menu Control Key

Option

POP TV Stand

Wall Mount Unit

55

1 Input (VIDEO2 LINK)

56

No

57

CABLE / AIR

58

No

59

1 Output: RCA pin x 1

1 Output UR:RCA pin x 2( Common input for No.59 )

60

61

1 Output L/R:RCA pin x 2

2 Terminal

63

No

64

65

2 (4pin connector)

1 (Female type)

67

1 (On Side panel)

68

1 (Square type)

69

Yes , below panel

70

Yes, on side panel

Yes, on front panel

71

72

Yes, on front panel

73

Yes, on side panel (Channel U/D, Vol U/D, A/V Input

Select , Menu Select)

74

With

75

With

76

-

Auto Link Function

42HDT79/42HDX99 Only

42HDX99 Only

42HDT79/42HDX99 Only

13

Page 15

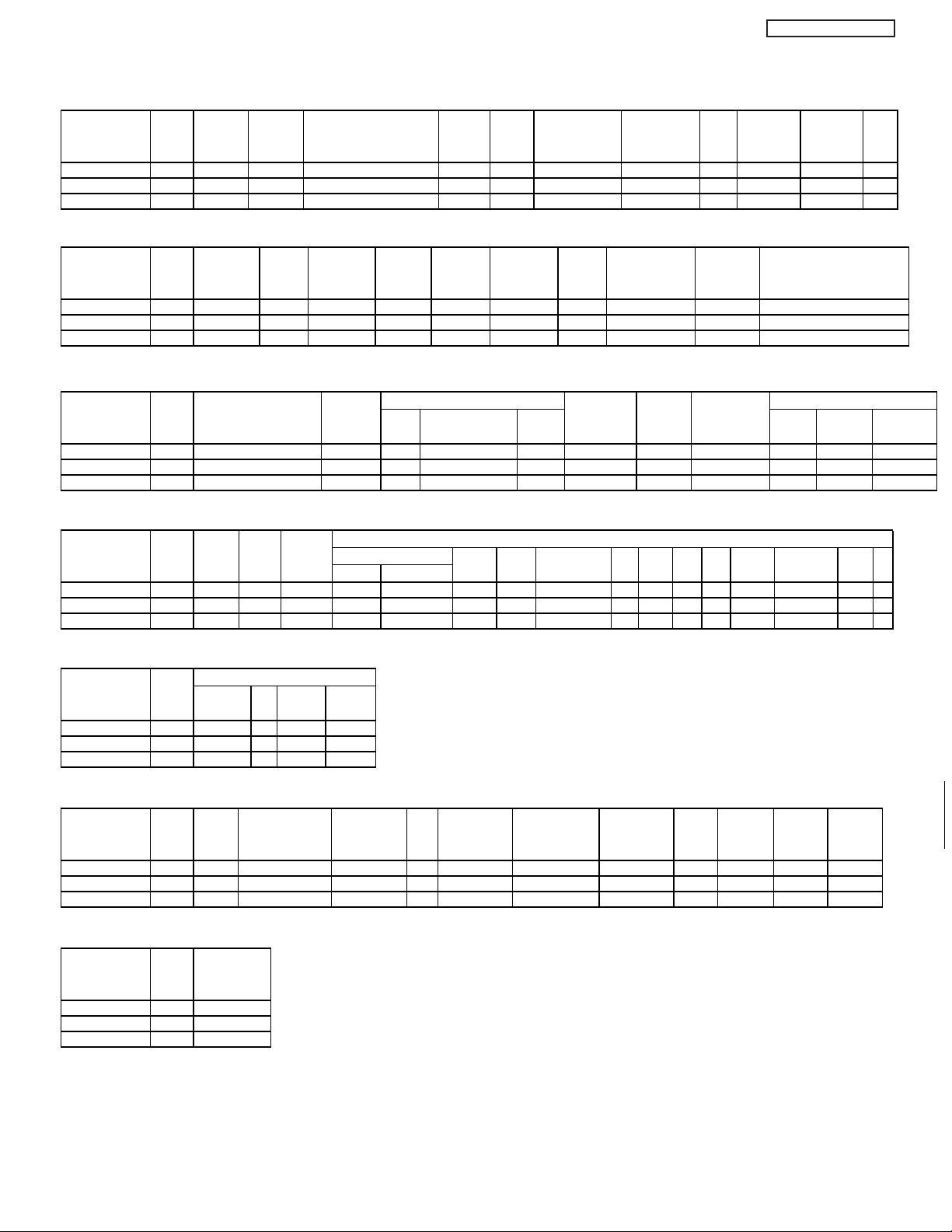

DW2U

FEATURES & DIFFERENCES

QAM Basic

Model Name Class Chassis Series Cabinet Aspect ATSC ATSC/NTSC Digital POD MPEG EPG M/C

Name Design 1Tuner Cable Decoder Gemstar

42HDX99

42HDT79

42HDS69

Model Name Class

42HDX99

42HDT79

42HDS69

Model Name Class

42HDX99

42HDT79

42HDS69

HDX

HDT

HDS

DW2C

DW2B

DW2A

Directors Leggero(ALL BLK) 16x9 X X X X X X USB

UltraVision Leggero(SP:BLK, DECO:SIL) 16x9 X X X X X X USB

UltraVision Leggero(ALL SIL) 16x9 X X X X X --

DTV Memory

NTSC Seine 3/2 Fill by Shield Comb Resolution OSD Color Temp

FORMAT Pulldown Mode inputs Filter

HDX

HDT

HDS

1080i Seine2 Auto/off 7modes

1080i Seine2 Auto/off 7modes X 36% sputter 3DYC A4웛1024x1080 06 OSD A 3Mode(High, Med,Std)

1080i Seine2 Auto/off 7modes X 36% sputter 3DYC A4웛1024x1080 06 OSD B 3Mode(High, Med,Std)

X 31% sputter 3DYC A4웛1024x1080 06 OSD Dir 4Mode(High, Med,Std, B&W

Remote Sound function

PIP AV NET Type Source Simple IR Descrete Dolby Perfect Surround BassBoost

Color UEI Pass Thru Code Volume

Digital Tuner/Ext SPLIT X

HDX

Digital Tuner/Ext SPLIT

HDT

Digital Tuner/Ext SPLIT

HDS

Rotate PANA/Black X X X AC3 Downmix × × ×

- Rotate PANA/Black - X X AC3 Downmix × × ×

- TVU Hoshiden/BLACK - - X AC3 Downmix × × ×

Model Name Class

42HDX99

42HDT79

42HDS69

HDX

HDT

HDS

Model Name Class

42HDX99

42HDT79

42HDS69

HDX

HDT

HDS

Model Name Class

42HDX99

42HDT79

42HDS69

HDX

HDT

HDS

Model Name Class

Rear Jacks

TV Output Speaker RS232C IR-Out YPbPr S IN AV IN S V AUDIO Y As 6CH RF

Center Watt

L/mono 36 2FR2W

L/mono 36 2FR2W - 2 122(1H,2H,2.14H) 2 4 1 1 1 X OPT 1

L/mono 36 2FR2W - 2 1-2(1H,2H,2.14H) 2 4 1 1 1 X OPT 1

Front/Side Jack

HDMI

Composite L/R (Ver1.1) Y,Pb,Pr

Digital I/F

IEEE1394 HDMI(Ver1.1) OUT OUT OUPUT Composite OUT

1 2 122(1H,2H,2.14H) 2 4 1 1 1 X OPT 1

111 1

111 1

111 1

Downloadable Option Swivel Table Top Hotel Adjust Color Contrast

Power V Chip Energy Star PLC Wall mount

Pow/Manual Stand Mode Color Manage Mode

LED Decoder

Blue X X X WM51 Pow × BLK(9000) × X X X

Blue X X X WM51 Pow × SIL(9000) × X X X

Blue X X X WM51 Manual × SIL(9000) × - - X

White Level

Black Level

42HDX99

42HDT79

42HDS69

HDX

HDT

HDS

X

-

-

14

Page 16

General Specification

A

(

)

e

)

)

)

)

g

yp)

h

)

)

(

757m)

DW2U

Model Spec

Model Name Item

Destination U.S.A. / CANAD

Exterior

Cabinet Dimensions

(Main Body) (Speaker &

stand inclusive)

Frame Color Screen

Stand

Weight (Main Body)

(Speaker & stand

inclusive)

Main Body: Packed

Screen Siz

Display Panel

Resolution

Dot Pitch (H

Dot Pitch (V

Viewing Angle (H

Viewing Angle (V

Front Filter Surface Finishin

Brightness

Peak Brightness (1%

window)

42HDS69/42HDT79/42HDX99

1134mm x 713.2mm x 365mm

Dark Charcoal Metallic (HDT/HDX)

Brightness Silver (HDS)

Inclusive (With Power Swivel)

39.20 kg typ. 44.0 kg

922x524mm(42lnch 16:9)

1024x1080 pixels

0.90mm

0.485mm

±85°

±85°

1.2ohm Sputter

320 cd/m2 or more

(When VIDEO, Day mode, Color temperature 'HIGH' Input Signal A mplitude 100 % is set)

Environment Specifications

NO

1

2

3

4

5

6

7

8

9

Item Specification

Operating Temp.

Stock Temp.

Operating Humidity

Stock Humidity

Operating Atmosphere

Pressure

+5°C~+35°C

-15°C

20%~80%RH

20%~90%RH

800~1114h Pa

(1888m~-757m)

Stock Atmosphere Pressure

300~1114h P a

4727m~-

Warranty Gravity Vertical

Warranty Drop High

Tilt Angle 12° Over

~+60°C

0.85 G

30cm

All White Pattern

5Ocd/m2 or more

Contrast Contrast ratio 1000 : 1 (t

Color

Color Reproduction 16.7 million colors

or more

Reproduction

Audio Output Audio Output

Panel Operation

Main Power Switc

Power Switch

18W+ 18W(6ohm>,10%Distortion)

PUSH (LOCK) 1 switch

PUSH (NON-LOCK) 1 switch

Input Terminal Video/Audio Input RCA , HDMI DV connector

Output Terminal

Audio Line Output

Speaker Output

Sub Woofer Output 1 system

-

Connector 3 Polarity ReceptaclePower Supply

Source

Guaranteed

Environment

Condition

Input Voltage

Temp. (Operating)

Temperature (Stored

Humidity (Operating)

Single Phase AC108 -132V, 6OHz

5~35°C (41F~95F)

-15~60°C (5F~140F)

20~80%RH

(Non-condensing)

Humidity (Stored) 20~90%RH (Non-condensing)

Atmospheric Pressure

(Operating)

800 to 1114hPa

(altitude: 1888m to -757m,

6194feet to -2483feet

Atmospheric Pressure

(Storage)

300 to 1114hPa (Altitude:

9727m to -757m, 31912feet to 2483feet)

15

Page 17

DW2U

Display Specification

Picture Format for Each Input Source

Aspect, Virtual HD, Black Side Panel, Vertical Position, PIP Mode

9.1.1 Aspect

Input Auto Aspect Aspect

Signal Aspect Video ID 16:9

ANT

Video NTSC 웎 4x3 Yes 웎 Yes Yes Yes Yes Yes

Analog

ANT YCBCR480p 웎 16x9 Yes 웎 Yes 웎 Yes 웎 웎

Digital 480i 웎 4x3 웎 웎 웎 Yes Yes Yes Yes

YPBPR1080i/720p 웎 16x9 Yes Yes Yes 웎 Yes 웎 웎

IEEE1394 YCBCR480p 웎 16x9 Yes 웎 Yes 웎 Yes 웎 웎

Digital 480i 웎 4x3 웎 웎 웎 Yes Yes Yes Yes

YPBPR1080i/720p 웎 16x9 Yes Yes Yes 웎 Yes 웎 웎

웎웎 웎 1394DV 웎 웎 웎 Yes Yes Yes Yes

Input 1 HDMI 1080i/720p 웎 16x9 Yes Yes Yes 웎 Ye s 웎 웎

Input 2 HDMI 1080i/720p 웎 16x9 Yes Yes Yes 웎 Ye s 웎 웎

Input 3 YPBPR1080i/720p 웎 16x9 Yes Yes Yes 웎 Yes 웎 웎

480p Auto ON 16x9 Yes Initial 웎 Yes 웎 웎 웎 웎

480i Letter 웎 웎 웎 Yes Yes Yes Initial Yes

Video NTSC Auto ON 16x9 Yes Initial 웎 Yes 웎 웎 웎 웎

S-Video Letter 웎 웎 웎 Yes Yes Yes Initial Yes

Video NTSC Auto ON 16x9 Yes Initial 웎 Yes 웎 웎 웎 웎

S-Video Letter 웎 웎 웎 Yes Yes Yes Initial Yes

Video NTSC Auto ON 16x9 Yes Initial 웎 Yes 웎 웎 웎 웎

Auto OFF 웎 Yes 웎 Yes Yes Yes Yes Yes

Auto OFF 웎 Yes 웎 Yes Yes Yes Yes Yes

480p Auto ON 16x9 Yes Initial 웎 Yes 웎 웎 웎 웎

480i Letter 웎 웎 웎 Yes Yes Yes Initial Yes

Auto OFF 웎 Yes 웎 Yes Yes Yes Yes Yes

Auto OFF 웎 Yes 웎 Yes Yes Yes Yes Yes

480p Auto ON 16x9 Yes Initial 웎 Yes 웎 웎 웎 웎

480i Letter 웎 웎 웎 Yes Yes Yes Initial Yes

Auto OFF 웎

No Signal 웎 웎

Auto OFF 웎

Standard 1

4x3 웎 웎 웎 Yes Yes Initial Yes Yes

No Info Yes 웎 Yes Yes Yes Ye s Yes

4x3 웎 웎 웎 Yes Yes Initial Yes Yes

No ID Yes 웎 Yes Yes Yes Yes Yes

4x3 웎 웎 웎 Yes Yes Initial Yes Yes

No Info Yes 웎 Yes Yes Yes Ye s Yes

4x3 웎 웎 웎 Yes Yes Initial Yes Yes

No ID Yes 웎 Yes Yes Yes Yes Yes

4x3 웎 웎 웎 Yes Yes Initial Yes Yes

No ID Yes 웎 Yes Yes Yes Yes Yes

Letter 웎 웎 웎 Yes Yes Yes Initial Yes

4x3 웎 웎 웎 Yes Yes Initial Yes Yes

No ID Yes 웎 Yes Yes Yes Yes Yes

Yes : Selectable 웎 : Un-selectable

16:9

16:9

4:3

Standard 2

Zoom

Standard

4:3

Expanded

4:3

Zoom 1

4:3

Zoom 2

웉Continuation웊

Input Auto Aspect Aspect

Signal Aspect Video ID 16:9

Input 4 YPBPR1080i/720p 웎 16x9 Yes Yes Yes 웎 Yes 웎웎

Input 5 HDMI 1080i/720p 웎 16x9 Yes Yes Yes 웎 Yes 웎 웎

480p Auto ON 16x9 Yes Initial 웎 Yes 웎웎웎웎

480i Letter 웎웎웎Yes Yes Yes Initial Yes

Auto OFF 웎

No Signal 웎웎

Video NTSC Auto ON 16x9 Yes Initial 웎 Yes 웎웎웎웎

Auto OFF 웎

480p

Auto ON 16x9 Yes Initial 웎 Yes 웎 웎 웎 웎

480i

YPBPR1080i/720p 웎 16x9 Yes Yes Yes 웎 Yes 웎 웎

Video NTSC Auto ON 16x9 Yes Initial 웎 Yes 웎 웎 웎 웎

Horizontal Expansion 16x9 105% 100% 133% 웎 133% 웎 웎

Auto OFF 웎 Yes 웎 Yes Yes Yes Yes Yes

480p

Auto ON 16x9 Yes Initial 웎 Yes 웎 웎 웎 웎

480i

Auto OFF 웎

No Signal 웎 웎

Auto OFF 웎

Vertical Expansion 105% 100% 133% 110% 110% 133% 176%

Standard 1

4x3 웎웎웎Yes Yes Initial Yes Yes

No ID Yes 웎 Yes Yes Yes Yes Yes

Letter 웎웎웎Yes Yes Yes Initial Yes

4x3 웎웎웎Yes Yes Initial Yes Yes

No ID Yes 웎 Yes Yes Yes Yes Yes

Letter 웎 웎 웎 Yes Yes Yes Initial Yes

4x3 웎 웎 웎 Yes Yes Initial Yes Yes

No Info Yes 웎 Yes Yes Yes Yes Yes

Letter 웎 웎 웎 Yes Yes Yes Initial Yes

4x3 웎 웎 웎 Yes Yes Initial Yes Yes

No ID Yes 웎 Yes Yes Yes Yes Yes

Letter 웎 웎 웎 Yes Yes Yes Initial Yes

4x3 웎 웎 웎 Yes Yes Initial Yes Yes

No ID Yes 웎 Yes Yes Yes Yes Yes

4x3 105% 100% 133% 75% 100% 100% 133%

16:9

Standard 2

16:9

Zoom

4:3

Standard

4:3

Expanded

4:3

Zoom 1

Zoom 2

4:3

16

Page 18

[Expansion]

90%

75%

4x3

90%

4x3

75%

<4x3 Format> <16x9 Format>

16:9

Standard1

16:9

Zoom

90%

75%

16x9

90%

16x9

16x9

75%

16:9

Standard1

16:9

Standard2

16:9

Zoom

Horizontal

Expansion

Ratio

(%)

4:3 Expanded Mode

Horizontal Position

DW2U

162%

113%

90%

90%

75%

56%

4x3

4x3

4x3

4x3

75%

4:3

Standard

4:3

Expanded

4:3

Zoom1

4:3

Zoom2

90%

16x9

4:3

Expanded

4x3

Format

100%

162%

4:3

Expanded

113%

16x9

Format

100%

162%

17

Page 19

DW2U

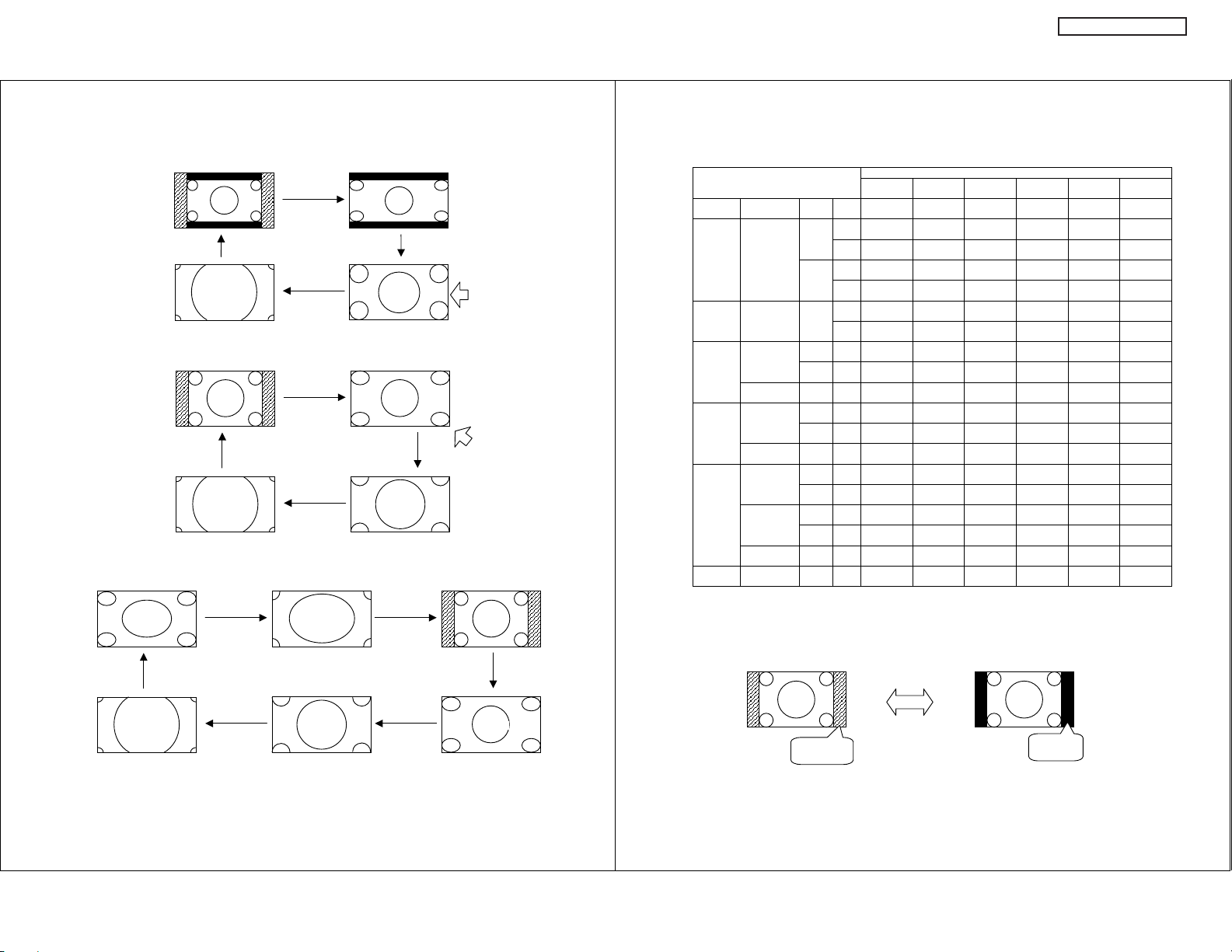

Aspect Key Operation

(1) ANT Analog Channel

16:9

Standard1

Aspect

Key

4:3

Zoom2

(2) ANT Digital Channel

(a) Aspect: 16x9

(b) Aspect: 4x3

16:9

Standard1

Aspect

4:3

Expanded

4:3

Standard

4:3

Zoom2

Aspect

Key

Aspect

Key

Key

Aspect

Key

Aspect

Key

Aspect

Key

Aspect

Key

Aspect

Key

16:9

Zoom

4:3

Zoom1

Standard2

Aspect

Key

Expanded

16:9

16:9

Zoom

4:3

4:3

Zoom1

Aspect

Key

Aspect

Key

Aspect

Key

4:3

Standard

Aspect

Key

4:3

Expanded

(This mode is for

1080i/720p only.)

(3) HDMI/YPBPR: 1080i/720p

16:9

Standard1

Aspect

Key

4:3

Expanded

(4) HDMI/YPBPR: 480p/480i, Video/S-Video

(4-1) Auto Aspect OFF

Aspect

16:9

Standard1

Aspect

Key

4:3

Zoom2

(4-2) Auto Aspect ON

(a) Video ID/HDMI Info: 16x9

Video ID: 16x9

Power ON Initial

Key

Aspect

Key

Standard1

16:9

Aspect

Key

Aspect

Key

16:9

Zoom

4:3

Zoom1

Aspect

Key

Aspect

Key

Standard2

Aspect

Key

16:9

16:9

Zoom

Aspect

Key

Aspect

Key

16:9

Zoom

Aspect

Key

4:3

Standard

4:3

Expanded

18

Page 20

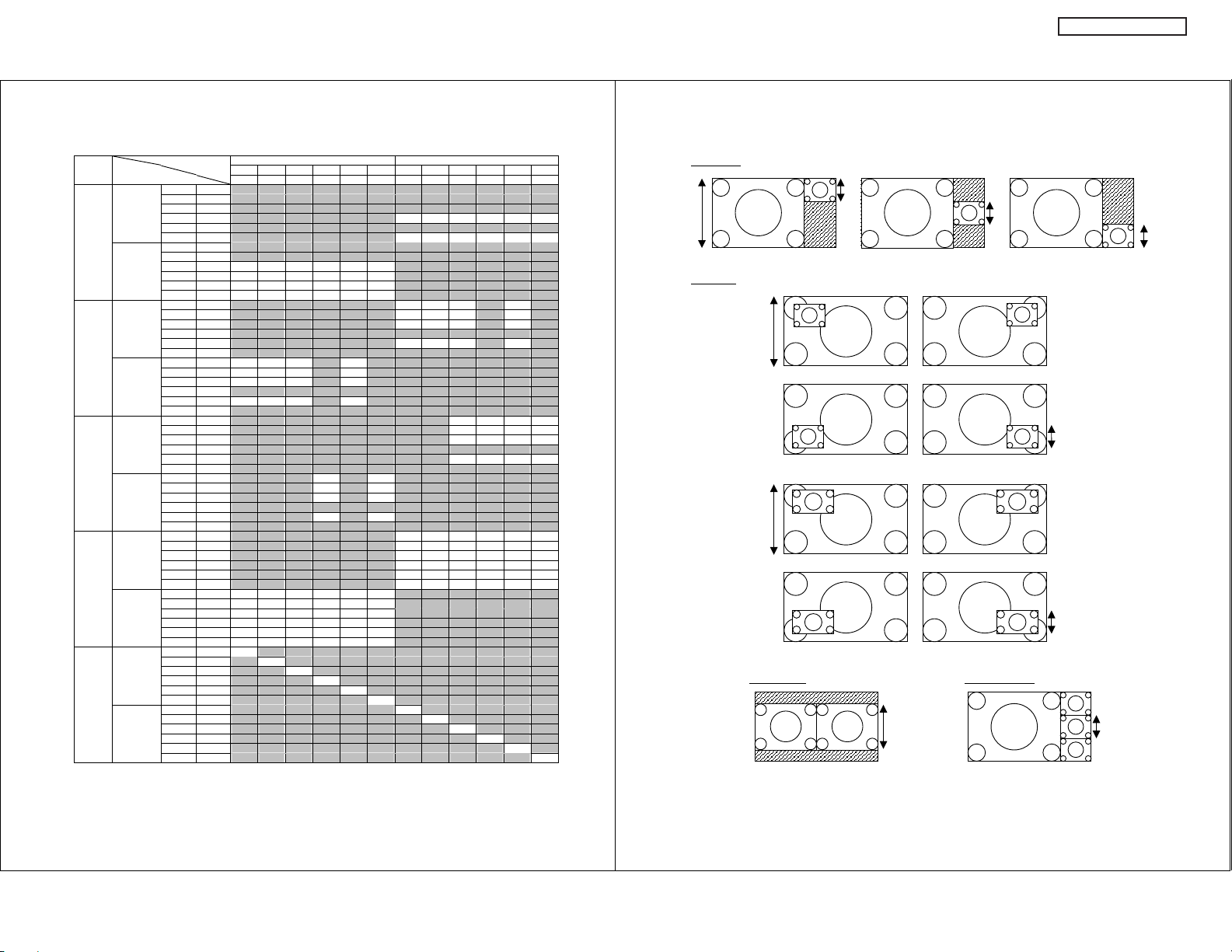

DW2U

(b) Video ID/HDMI Info: Letter

4:3

Standard

Aspect

4:3

Zoom2

(c) Video ID/HDMI Info: 4x3

4:3

Standard

Aspect

4:3

Zoom2

(d) No Video ID, No HDMI Info

Aspect

16:9

Standard

Aspect

4:3

Zoom2

Key

Key

Aspect

Key

Key

Key

Aspect

Key

Aspect

Key

Aspect

Key

Aspect

Key

16:9

Zoom

4:3

Zoom1

Aspect

Key

4:3

Expanded

4:3

Zoom1

4:3

Expanded

Aspect

Key

4:3

Zoom1

Aspect

Key

Aspect

Key

Video ID: Letter

Power ON Initial

Video ID: 4x3

Power ON Initial

4:3

Standard

Aspect

Key

4:3

Expanded

Vertical Position Operation

Input Vertical Position

ANT

Video NTSC 4x3 ¢0 step

Analog

ANT

YPBPR 1080i

Digital

IEEE1394 YPBPR 1080i

Input 1 - 2 HDMI 1080i

S-Video

Video

Input 3 - 4 YPBPR 1080i

Video NTSC 웎¢0 step

Input5 HDMI 1080i

YPBPR 1080i

Video NTSC 웎¢0 step

PIP Mode SPLIT/POP/

PIP/STROBE

16x9 ¢0 step

720p

480p 4x3 웎웎¢0 step

480i 16x9 ¢0 step

4x3 웎웎¢0 step

16x9 ¢0 step

720p

480p

4x3 웎웎¢0 step

480i

16x9 ¢0 step

720p

480p

16x9

480i

4x3

NTSC 웎¢0 step

16x9 ¢0 step

720p

480p

16x9

480i

4x3

16x9 ¢0 step

720p

480p

16x9

480i

4x3

16x9 ¢0 step

720p

480p

16x9

480i

4x3

9.1.4 Black Side Panel Operation

Black Side Panel OFF

(Power ON Initial)

4:3

Standard

Gray Side

Panel

16:9

Standard1/2

Gray

Gray

Gray

Gray

Gray

¢0 step

Gray

Gray

Gray

¢0 step

Gray

Gray

Gray

¢0 step

Gray

Gray

¢0 step

Gray

Gray

¢0 step

Gray

16:9

Zoom

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

¢10 step

(¢30 lines)

out

out

Black Side Panel

Menu

4:3

Standard

¢0 step

Gray

웎¢10 step

Gray

웎¢10 step

Gray

웎¢10 step

Gray

웎¢10 step

¢0 step

Gray

¢0 step

Gray

웎¢10 step

¢0 step

Gray

¢0 step

Gray

웎¢10 step

¢0 step

Gray

웎¢10 step

¢0 step

Gray

¢0 step

Gray

out

out

out

out

out

out

out

out

out

out

out

4:3

Expanded

¢10 step

(¢10 lines)

(¢10 lines)

¢10 step

(¢10 lines)

(¢10 lines)

¢10 step

(¢10 lines)

(¢10 lines)

¢10 step

(¢10 lines)

(¢10 lines)

¢10 step

(¢10 lines)

¢10 step

(¢10 lines)

(¢10 lines)

¢10 step

(¢10 lines)

¢10 step

(¢10 lines)

(¢10 lines)

¢10 step

(¢10 lines)

(¢10 lines)

¢10 step

(¢10 lines)

¢10 step

(¢10 lines)

Black Side Panel ON

4:3

Standard

Black

Side

4:3

Zoom 1

¢10 step

(¢30 lines)

웎웎

¢10 step

(¢30 lines)

웎웎

¢10 step

(¢30 lines)

웎웎

¢10 step

(¢30 lines)

웎웎

¢10 step

(¢30 lines)

¢10 step

(¢30 lines)

웎웎

¢10 step

(¢30 lines)

¢10 step

(¢30 lines)

웎웎

¢10 step

(¢30 lines)

웎웎

¢10 step

(¢30 lines)

¢10 step

(¢30 lines)

4:3

Zoom 2

¢10 step

(¢50 lines)

¢10 step

(¢50 lines)

¢10 step

(¢50 lines)

¢10 step

(¢50 lines)

¢10 step

(¢50 lines)

¢10 step

(¢50 lines)

¢10 step

(¢50 lines)

¢10 step

(¢50 lines)

¢10 step

(¢50 lines)

¢10 step

(¢50 lines)

¢10 step

(¢50 lines)

19

Page 21

PIP Mode

PIP Sub Digital Component/Composite/S-IN/HDMI

Mode 1080i 720p 480p 480p 480i 480i 1080i 720p 480p 480p 480i 480i

Main 16x9 16x9 16x9 4x3 16x9 4x3 16x9 16x9 16x9 4x3 16x9 4x3

Digital

POP

(Air or

Cable)

Component

Composite

S-IN

HDMI

Digital

PIP

(Air or

16x9

Cable)

Component

Composite

S-IN

HDMI

Digital

PIP

(Air or

4x3

Cable)

Component

Composite

S-IN

HDMI

Digital

SPLIT

(Air or

Cable)

Component

Composite

S-IN

HDMI

Digital

STROBE

(Air or

(4pix)

Cable)

Component

Composite

S-IN

HDMI

Yes*1: Auto Aspect OFF

Yes*2: Auto Aspect ON

1080i 16x9 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

720p 16x9 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

480p 16x9 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

480p 4x3 웎 웎 웎 웎 웎 웎 Yes Yes Yes Yes Yes Yes

480i 16x9 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

480i 4x3

1080i 16x9 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

720p 16x9 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

480p 16x9 Yes*1 Yes*1 Yes*1 Yes*1 Yes*1 Yes*1 웎 웎 웎 웎 웎 웎

480p 4x3 Yes Yes Yes Yes Yes Yes 웎 웎 웎 웎 웎 웎

480i 16x9 Yes*1 Yes*1 Yes*1 Yes*1 Yes*1 Yes*1 웎 웎 웎 웎 웎 웎

480i 4x3 Yes Yes Yes Yes Yes Yes

1080i 16x9 웎 웎 웎 웎 웎 웎 Yes Yes Yes* 2 웎 Yes* 2 웎

720p 16x9 웎 웎 웎 웎 웎 웎 Ye s Yes Yes* 2 웎 Yes* 2 웎

480p 16x9 웎 웎 웎 웎 웎 웎 Ye s Yes Yes* 2 웎 Yes* 2 웎

480p 4x3 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

480i 16x9 웎 웎 웎 웎 웎 웎 Yes Yes Yes*2 웎 Yes*2 웎

480i 4x3

1080i 16x9 Yes Yes Yes 웎 Ye s 웎 웎 웎 웎 웎 웎 웎

720p 16x9 Yes Yes Yes 웎 Yes 웎 웎 웎 웎 웎 웎 웎

480p 16x9 Yes*2 Yes*2 Yes*2 웎 Yes*2 웎 웎 웎 웎 웎 웎 웎

480p 4x3 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

480i 16x9 Yes*2 Yes*2 Yes*2 웎 Ye s*2 웎 웎 웎 웎 웎 웎 웎

480i 4x3

1080i 16x9 웎 웎 웎 웎 웎 웎 웎 웎 Yes*1 Yes Yes*1 Yes

720p 16x9 웎 웎 웎 웎 웎 웎 웎 웎 Yes *1 Yes Yes*1 Yes

480p 16x9 웎 웎 웎 웎 웎 웎 웎 웎 Yes *1 Yes Yes*1 Yes

480p 4x3 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

480i 16x9 웎 웎 웎 웎 웎 웎 웎 웎 Yes* 1 Yes Yes*1 Yes

480i 4x3

1080i 16x9 웎 웎 웎 Ye s 웎 Yes 웎 웎 웎 웎 웎 웎

720p 16x9 웎 웎 웎 Yes 웎 Yes 웎 웎 웎 웎 웎 웎

480p 16x9 웎 웎 웎 Yes*2 웎 Yes*2 웎 웎 웎 웎 웎 웎

480p 4x3 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

480i 16x9 웎 웎 웎 Yes*2 웎 Yes*2 웎 웎 웎 웎 웎 웎

480i 4x3

1080i 16x9 웎 웎 웎 웎 웎 웎 Yes Yes Yes Yes Yes Yes

720p 16x9 웎 웎 웎 웎 웎 웎 Ye s Yes Yes Yes Yes Yes

480p 16x9 웎 웎 웎 웎 웎 웎 Ye s Yes Yes Yes Yes Yes

480p 4x3 웎 웎 웎 웎 웎 웎 Yes Yes Yes Yes Yes Yes

480i 16x9 웎 웎 웎 웎 웎 웎 Yes Yes Yes Yes Yes Ye s

480i 4x3

1080i 16x9 Yes Yes Yes Yes Yes 웎 웎 웎 웎 웎 웎

720p 16x9 Yes Yes Yes Yes Yes Yes 웎 웎 웎 웎 웎 웎

480p 16x9 Yes Yes Yes Yes Yes Yes 웎 웎 웎 웎 웎 웎

480p 4x3 Yes Yes Yes Yes Yes Yes 웎 웎 웎 웎 웎 웎

480i 16x9 Yes Yes Yes Yes Yes Yes 웎 웎 웎 웎 웎 웎

480i 4x3 Yes Yes Yes Yes Yes Yes

1080i 16x9 Yes 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

720p 16x9 웎 Yes 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

480p 16x9 웎 웎 Yes 웎 웎 웎 웎 웎 웎 웎 웎 웎

480p 4x3 웎 웎 웎 Yes 웎 웎 웎 웎 웎 웎 웎 웎

480i 16x9 웎 웎 웎 웎 Yes 웎 웎 웎 웎 웎 웎 웎

480i 4x3

1080i 16x9 웎 웎 웎 웎 웎 웎 Yes 웎 웎 웎 웎 웎

720p 16x9 웎 웎 웎 웎 웎 웎 웎 Yes 웎 웎 웎 웎

480p 16x9 웎 웎 웎 웎 웎 웎 웎 웎 Yes 웎 웎 웎

480p 4x3 웎 웎 웎 웎 웎 웎 웎 웎 웎 Yes 웎 웎

480i 16x9 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 Yes 웎

480i 4x3

웎 웎 웎 웎 웎 웎 Yes Ye s Yes Yes Yes Yes

웎 웎 웎 웎 웎 웎

웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎

웎 웎 웎 웎 웎 웎 Yes Ye s Yes Yes Yes Yes

웎 웎 웎 웎 웎 Yes 웎 웎 웎 웎 웎 웎

웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 웎 Yes

Yes

웎 웎 웎 웎 웎 웎

POP Mode:

1024/768 Lines

PIP Mode

4x3

4x3

341/256 Lines

4x3

4x3

:

4x3

16x9

1024/768 Lines

16x9

4x3

16x9

16x9

1024/768 Lines

16x9

16x9

16x9

16x9

16x9

16x9

SPLIT Mode: STROBE Mode

4x34x3

768/576 Lines (93%)

341/256 Lines

4x3

4x3

16x9

16x9

:

4x3

4x3

341/256 Lines

341/256 Lines

4x3

4x3

4x3

DW2U

4x3

341/256 Lines

341/256 Lines

20

Page 22

g

DW2U

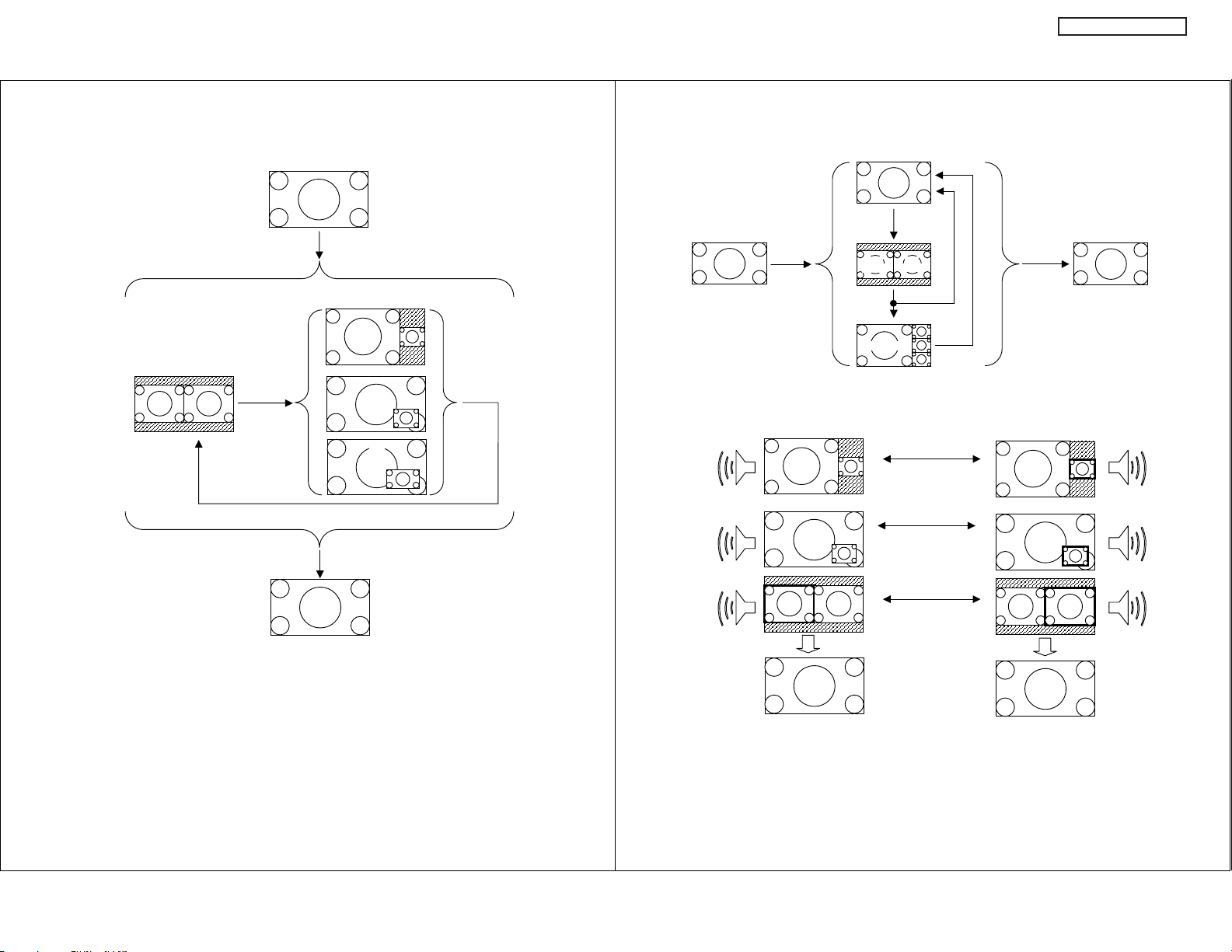

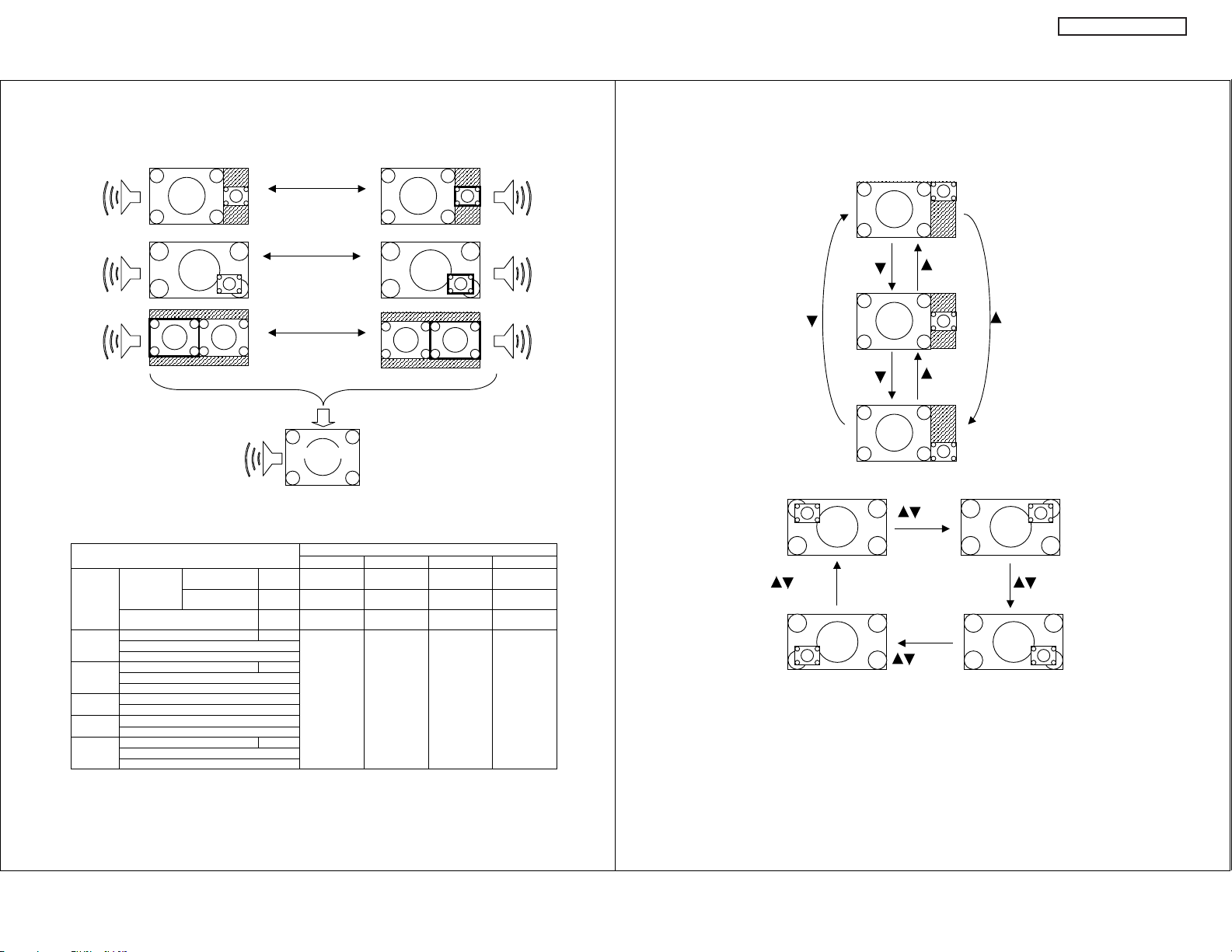

(1) PIP Key Operation

SPLIT

PIP

Key

Normal Viewing

PIP

Key

Exit

Key

POP

PIP

4x3

PIP

16x9

PIP

Key

(2) Freeze Operation

(3) SWAP Operation

Main

Audio

Main

Audio

Main

Audio

Main

Frozen

Freeze

Key

Freeze

Key

Freeze

Main

Movin

Key

STROBE

Sub

Frozen

Freeze

Key

Key

A

Key

AA

B

Key

AB

Exit

Key

Sub

Audio

AB

B

Sub

Audio

B

Sub

Audio

BA

(Note)

If PIP Key is pushed from a Normal screen, PIP of Last Mode will be displayed.

A shipment setup of PIP Mode is SPLIT Mode.

POP/PIP Mode cannot display 720p/480p signals. Therefore, it displays by SPLIT Mode.

ሩWhen Last mode is POP/PIP Mode and a Main signal is 1080i, PIP Mode is set to PIP.

ሩWhen Last mode is POP/PIP Mode and a Main signal is 480i/NTSC, PIP Mode is set to PIP.

ሩSURF Mode is not displayed at a V-Chip setup. SPLIT Mode is displayed at this time.

When EXIT Key is pushed, PIP turns off.

When PIP is turns off, PIP Mode of a display turns into Last Mode.

PIP OFF

A

(Note)

When right and left Key are pushed, the sound of Main and Sub interchanges.

A Channel/Input change can do the screen out of which the sound has come.

When PIP OFF [EXIT Key], the screen where sound is sounding turns into a normal screen.

PIP OFF

B

21

Page 23

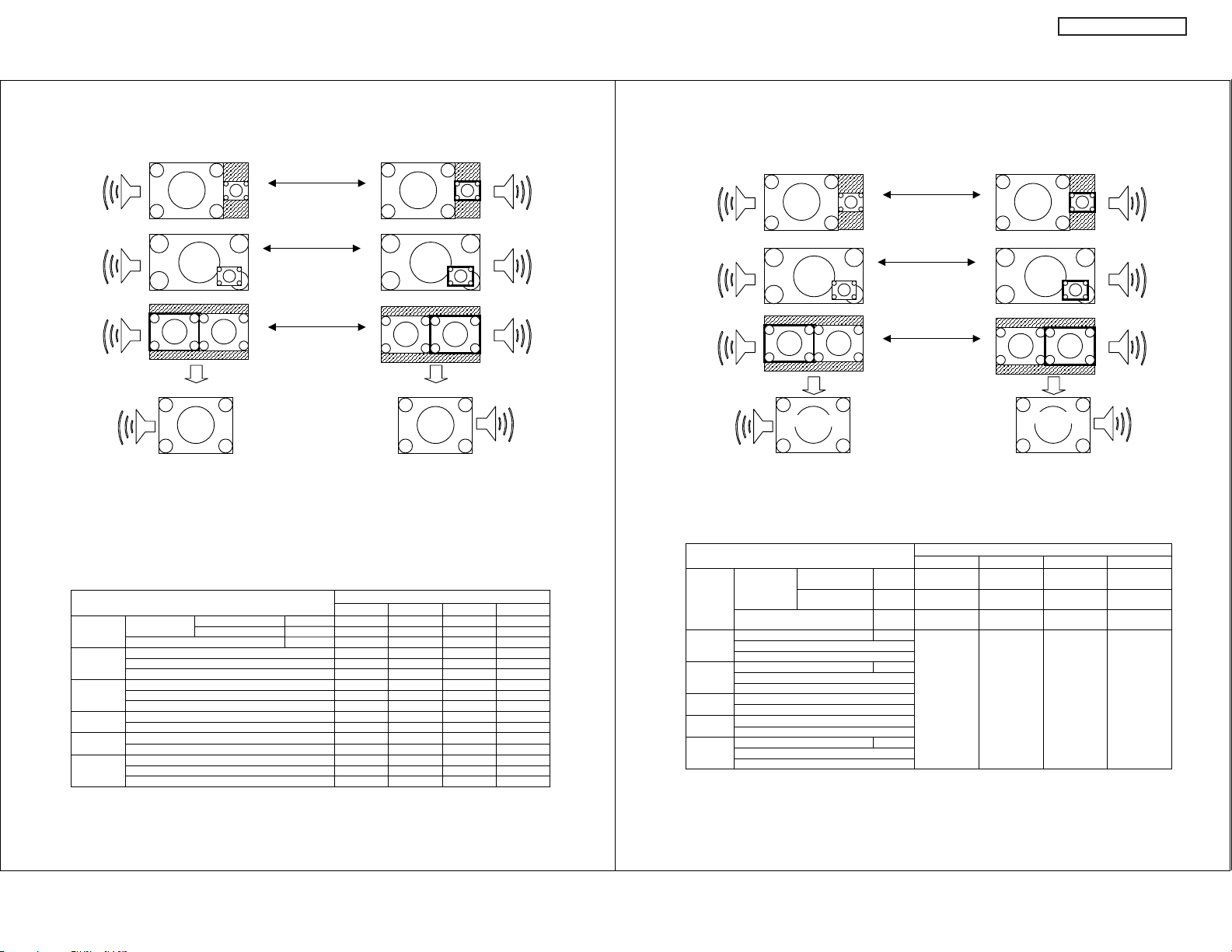

(4) Monitor Out

(4-1) Set the Monitor out: Monitor out

Main

Audio

A

DW2U

Sub

Key

B

A

Audio

B

(4-2) Set the Monitor out: TV out

Main

Audio

A

Sub

Key

B

A

Audio

B

Main

Audio

A

B

Main

Audio

Main

Audio

A

Monitor Out

BA

A

(Note)

When right and left Key are pushed, the sound of Main and Sub interchanges.

The picture and sound of the selected picture are outputted from Monitor out.

When the selected picture is Component or HDMI signal and audio out is monitor,

monitor out is no picture and no audio.

When the selected picture is Component or HDMI signal and audio out is HiFi out,

monitor out is no picture but audio is output.

When the selected picture is Composite Video signal, S-Video of monitor out is no picture.

When Macrovision signal is included in the ANT Digital channel, monitor out is no picture and no audio.

Main/Sub Audio Select

ANT No Macrovision S-Video YES YES YES YES

(AIR or

CABLE) Analog Channel Video 웎 YES YES YES

Input1 HDMI_1 웎웎웎YES

Input2 HDMI_2 웎웎웎YES

Input3 YPBPR_3 웎웎웎YES

Input4 YPBPR_4 웎웎웎YES

Input5 HDMI_5 웎웎웎YES

Side YPBPR_5 웎웎웎YES

Input Mode Monitor Out

Digital

Channel

Macrovision S-Video 웎웎 웎YES

S-Video_1 YES YES YES YES

Video_1 웎 YES YES YES

S-Video_2 YES YES YES YES

Video_2 웎 YES YES YES

Video_3 웎 YES YES YES

Video_4 웎 YES YES YES

Video_5 웎 YES YES YES

Key

A

B

Key

B

Monitor Out

Sub

Audio

B

S-Video Video L/R HiFi

Sub

Audio

Sub

Audio

Main

Audio

A

B

Main

Audio

A

Monitor Out

(Note)

When right and left Key are pushed, the sound of Main and Sub interchanges.

The picture and sound of ANT is outputted from Monitor out.

When ANT is analog channel, S-Video of monitor out is no picture.

When Macrovision signal is included in the ANT Digital channel, monitor out is no picture and no audio.

Main/Sub Audio Select

ANT

(AIR or

Input_1 HDMI_1 YPBP

Input_2 HDMI_2 YPBP

Input_3 YPBPR_3

Input_4 YPBPR_4

Input_5 HDMI_5 YPBP

Digital

Channel

CABLE)

Analog Channel Video 웎 YES

S-Video_1

Video_1

S-Video_2

Video_2

Video_3

Video_4

Side YPBPR_5

Video_5

BA

C

No Macrovision S-Video YES

Macrovision S-Video 웎웎웎YES

Key

A

B

Key

Monitor Out: TV out Input Mode

S-Video Video L/R HiFi

ANT

YES

R

ANT

Digital only

R

R

YES

ANT

ANT

YES

ANT

B

Monitor Out

D

YES

ANT

YES

ANT

YES

ANT

YES

ANT

ANT

YES

ANT

YES

ANT

Sub

Audio

Sub

Audio

22

Page 24

(4-3) At the time of reservation videotape recording

Main

Audio

A

B

DW2U

Sub

Key

A

Audio

B

(4) PIP Position Operation

Main

Audio

A

B

Main

Audio

A

(Note)

At the time of reservation videotape recording, the picture and sound of ANT is outputted from Monitor out.

When Macrovision signal is included in the ANT Digital channel, monitor out is no picture and no audio.

Main Audio Select

ANT

(AIR or

Input_1 HDMI_1 YPBP

Input_2 HDMI_2 YPBP

Input_3 YPBPR_3

Input_4 YPBPR_4

Input_5 HDMI_5 YPBP

Side YPBPR_5

Digital

Channel

CABLE)

Analog Channel Video 웎 YES

S-Video_1

Video_1

S-Video_2

Video_2

Video_3

Video_4

Video_5

When Macrovision signal is included in the ANT Digital channel, monitor out is no picture and no audio.

No Macrovision S-Video YES

Macrovision S-Video 웎웎웎YES

Key

A

Key

Monitor Out

C

Monitor Out: TV out Input Mode

S-Video Video L/R HiFi

ANT

YES

R

ANT

Digital only

R

R

YES

ANT

ANT

YES

ANT

AB

YES

ANT

YES

ANT

YES

ANT

Sub

Audio

B

Sub

Audio

B

YES

ANT

ANT

YES

ANT

YES

ANT

Key

Key

Key

Key

Key

Key

Key

Key Key

Key

(Note)

The Sub screen position of POP Mode moves up and down by the upper and lower sides Key.

A Sub screen position of PIP Mode moves clockwise by the upper and lower sides Key.

23

Page 25

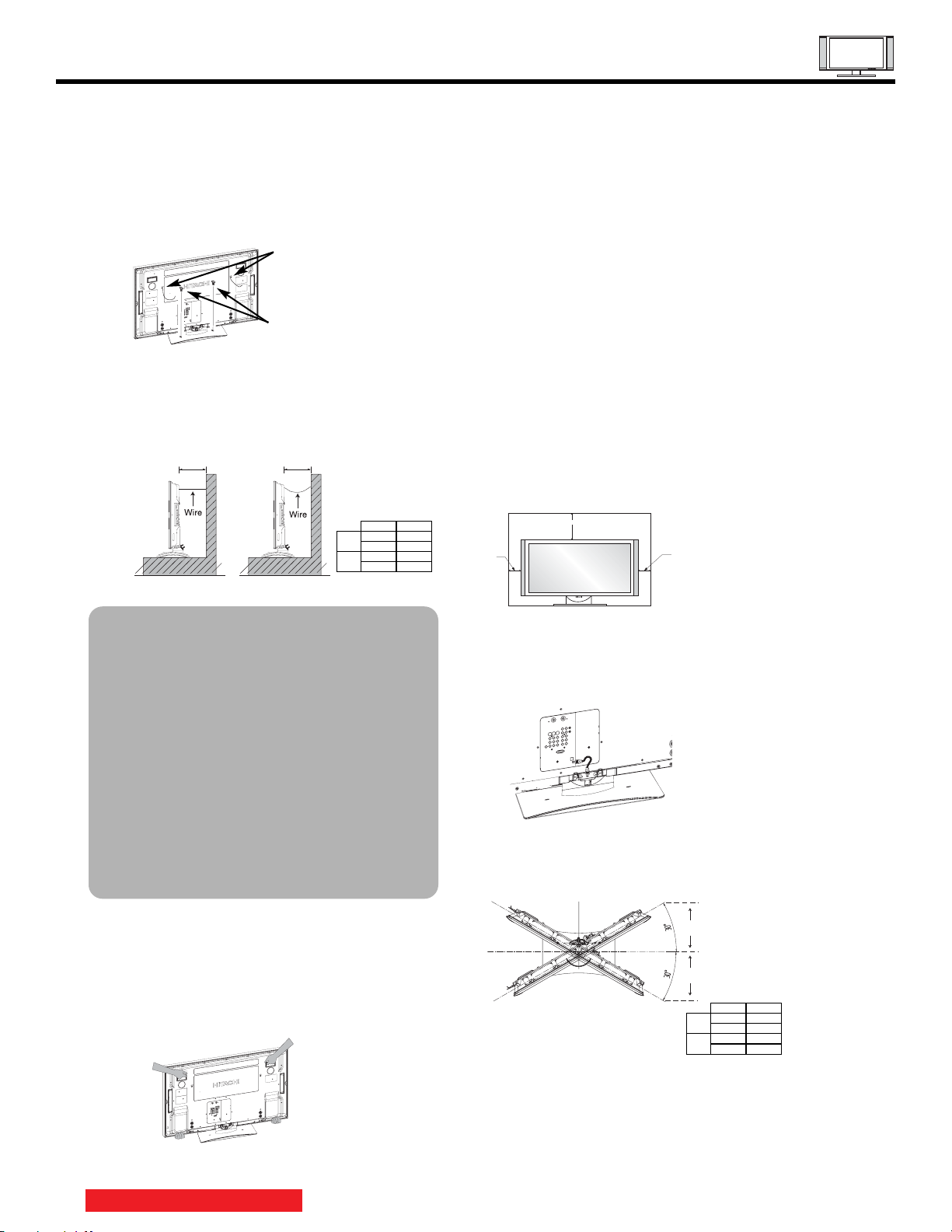

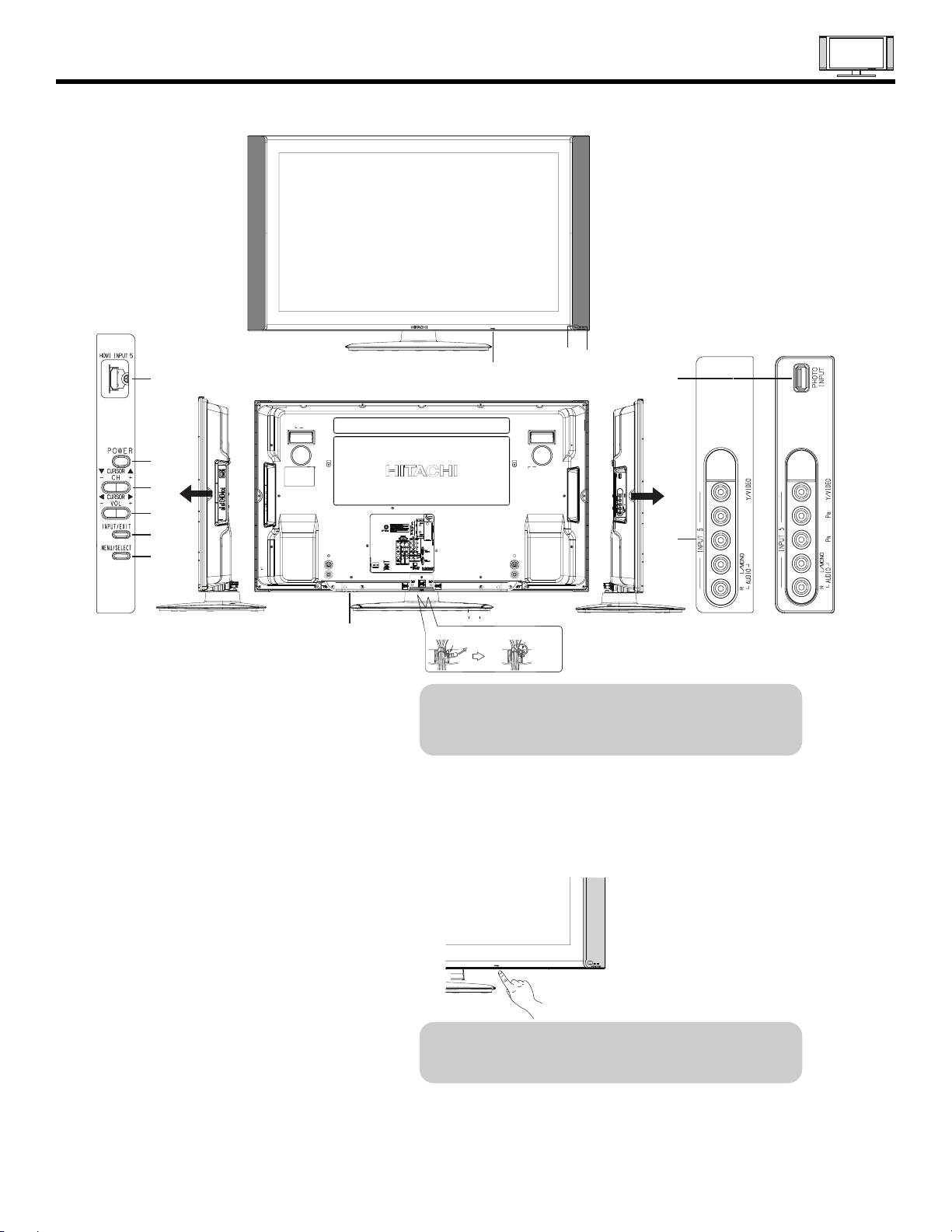

How To Set Up Your New Hitachi Plasma Television

To take measures to prevent the Plasma Display from tipping over and prevent possible injury it

is important to mount the unit in a stable and flat surface.

Securing to a table-top

1. Using wood screws (two) fasten the set to the

clamping screw holes on the rear of the Plasma

Display stand as shown below.

2. Using commercially available wood screws, secure

the set firmly in position.

Wire

Wood screw

two places

Securing to a Wall

1. Keep the Plasma television 4 inches away from the

wall except when mounted using the wall mount

bracket.

2. Secure the television to the wall as shown in fig. (a)

or (b).

10cm (4 inches)

or more

(a) Power Swivel

NOT USED

30cm (11.8 inches)

or more

(b) Power Swivel

USED

42"

55"

AB

4 in. 12 in.

10 cm 30 cm

4 in. 16 in.

10 cm 39 cm

ANTENNA

Unless your Plasma Television is connected to a cable

TV system or to a centralized antenna system, a good

outdoor color TV antenna is recommended for best

performance. However, if you are located in an

exceptionally good signal area that is free from

interference and multiple image ghosts,

an indoor antenna may be sufficient.

LOCATION

Select an area where sunlight or bright indoor

illumination will not fall directly on the picture screen.

Also, be sure that the location selected allows a free

flow of air to and from the perforated back cover of the

set. In order to prevent an internal temperature

increase, maintain a space of 10 cm (4 inches) from the

sides/back of the monitor, and 30 cm (12 inches) from

the top of the television to the wall. To avoid cabinet

warping, cabinet color changes, and increased chance

of set failure, do not place the TV where temperatures

can become excessively hot, for example, in direct

sunlight or near a heating appliance, etc.

30 cm (12 inches)

10 cm (4 inches)

10 cm (4 inches)

NOTES: 1. Do not block the ventilation holes of

the Plasma Display monitor. Blocking

the ventilation holes might cause fire

or defect.

2. In case of an abnormal symptom,

unplug the AC cord.

3. If you purchased the wall mount

bracket option, please ask for

professional installer. Do not install

by yourself.

4. If the Power Swivel feature will not be

used, the Plasma television should be

secured to the wall as shown in

fig. (a).

5. If the Power Swivel feature will be

used, the Plasma television should be

secured to the wall as shown in

fig. (b). The wires need to be long

enough to allow the television to turn

30˚ to the left and right.

Caution when moving the main unit

As this product is heavy, whenever it is moved, two

people are required to transport it safely. Whenever the

unit is moved it should be lifted forward using the top

and base on both sides of the Display Monitor for

stability. When moving the Display Monitor, lift the

handles and the bottom frame as shown below. Do not

grab the speakers or the back cover when lifting.

CONNECT POWER SWIVEL CABLE

Connect one end of cable (Arrow mark facing left) to

the swivel slot of the Plasma Rear Panel. Connect the

other end (Arrow mark facing front)to the swivel slot of

the Table Top Stand.

TURNING RADIUS

The maximum turning radius is 30˚ (left and right). Do

not place any objects on the path of the monitor when

using the power swivel feature.

11.8in

C

(30cm)

11.8in

D

(30cm)

CD

42"

12 in. 12 in.

30 cm 30 cm

55"

15.26 in. 16.46 in.

38.77 cm 41.8 cm

TABLE OF CONTENTS

24

Page 26

HOW TO SET UP YOUR NEW HITACHI PLASMA TELEVISION

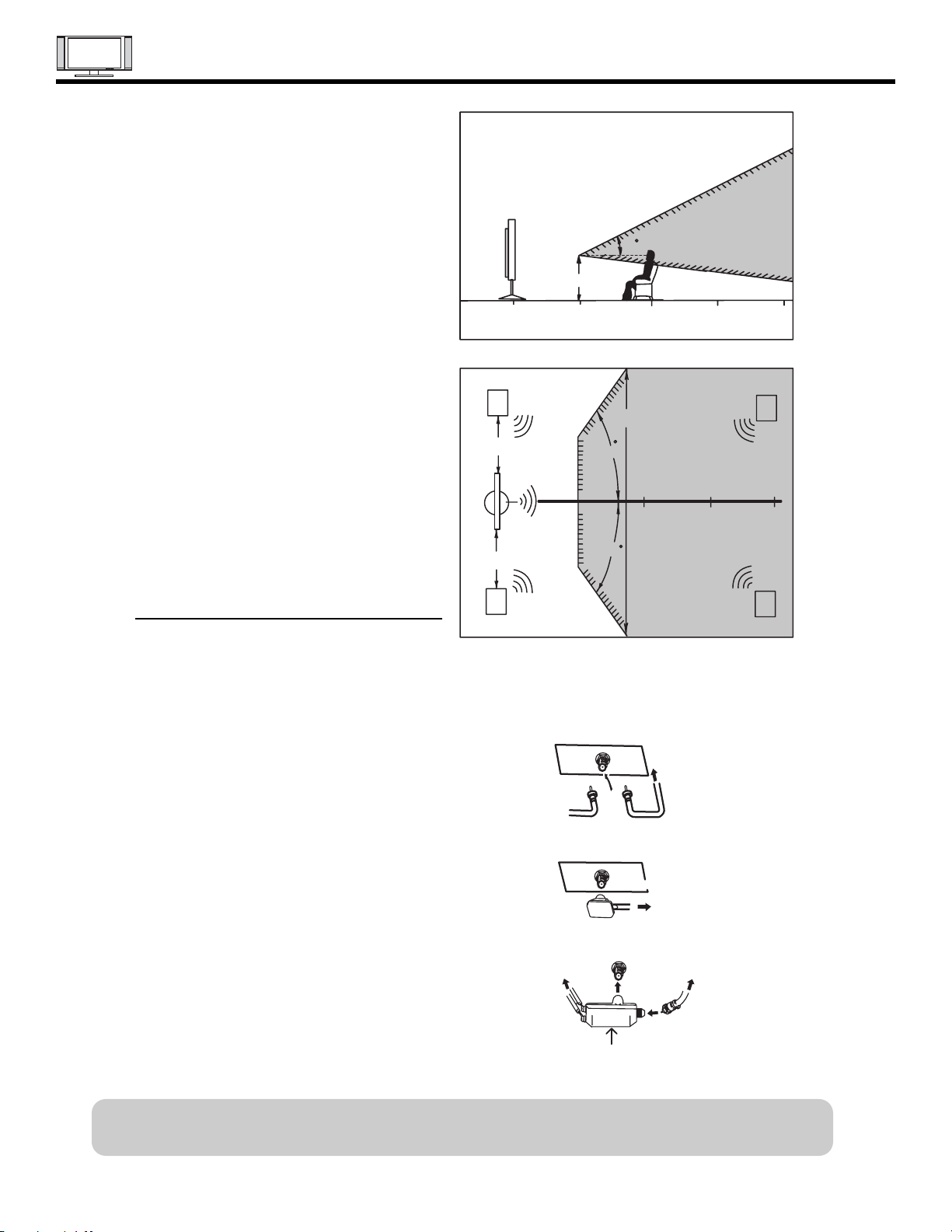

VIEWING

The best picture is seen by sitting directly in front of