Page 1

SERVICE MANUAL

Be sure to read this manual before servicing. To assure safety from fire, electric shock, injury, harmful radiation

and materials, various measures have been provided for in this HITACHI Plasma displayservice manual.

Be sure to read all cautionary items described in the manual to maintain safety before servicing.

Contents

1. Sincethe Panel Module and front Filter are made of glass, handlea broken Module and/or Filter with

sufficient care, in order not to be injured.

2. Repair work should not be started until after the Panel Module and the AC/DC Power supply have cooled

sufficiently.

3. Special care should be exercised in the proximity of the display area in order not to damage its surface.

4. The Panel Module should not be touched with bare hands, as this will protect its surface from stains.

5. It is recommended to use clean soft gloves during the repair work in order to protect not only the display

area of the Panel Module but also the technician.

6. The Chip Tube of the Panel Module (located in the upper left corner of the back of the glass panel)

is very fragile; as well, the flat cables connecting the Panel to the drive circuit PWBs are very weak. Take

care not to damage these, otherwise, the panel will never light again.

Service Warning

Caution

1. Safety Precaution------------------------------------2

2. Precaution --------------------------------------------21

3. Features ----------------------------------------------21

4. Specifications----------------------------------------22

5. Service Points---------------------------------------27

6. Service Mod e A c c e s s --------------------------------28

7. Troubleshooting Flow Chart----------------------55

8. Block Diagram---------------------------------------58

9. Connector Connection Diagram-----------------61

10. Circuit Board Layers-----------------------------63

11. Basic Circuit Diagram----------------------------64

12. Printed Wiring Board Diagram-----------------68

13. Disassembly Diagram----------------------------71

14. Replacement Parts List ---------------------------- 72

15. DC Voltages -----------------------------------------74

16. Speaker Installation ------------------------------- 82

CH 1, CH 2

Version 0198.3

NN TT SS CC

PA

42EDT41A

CMP420V1A / CMP420V2A

PPWW11AA

R/C: CLU-W900 / SMK

CChhaassssiiss

TO GO TO A CHAPTER, CLICK ON ITS HEADING BELOW

No. 0198

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

NOVEMBER 2004 HHEA-MANUFACTURING DIVISION

PLASMA DISPLAY PANEL

CH 3

Page 2

SAFETY PRECAUTIONS

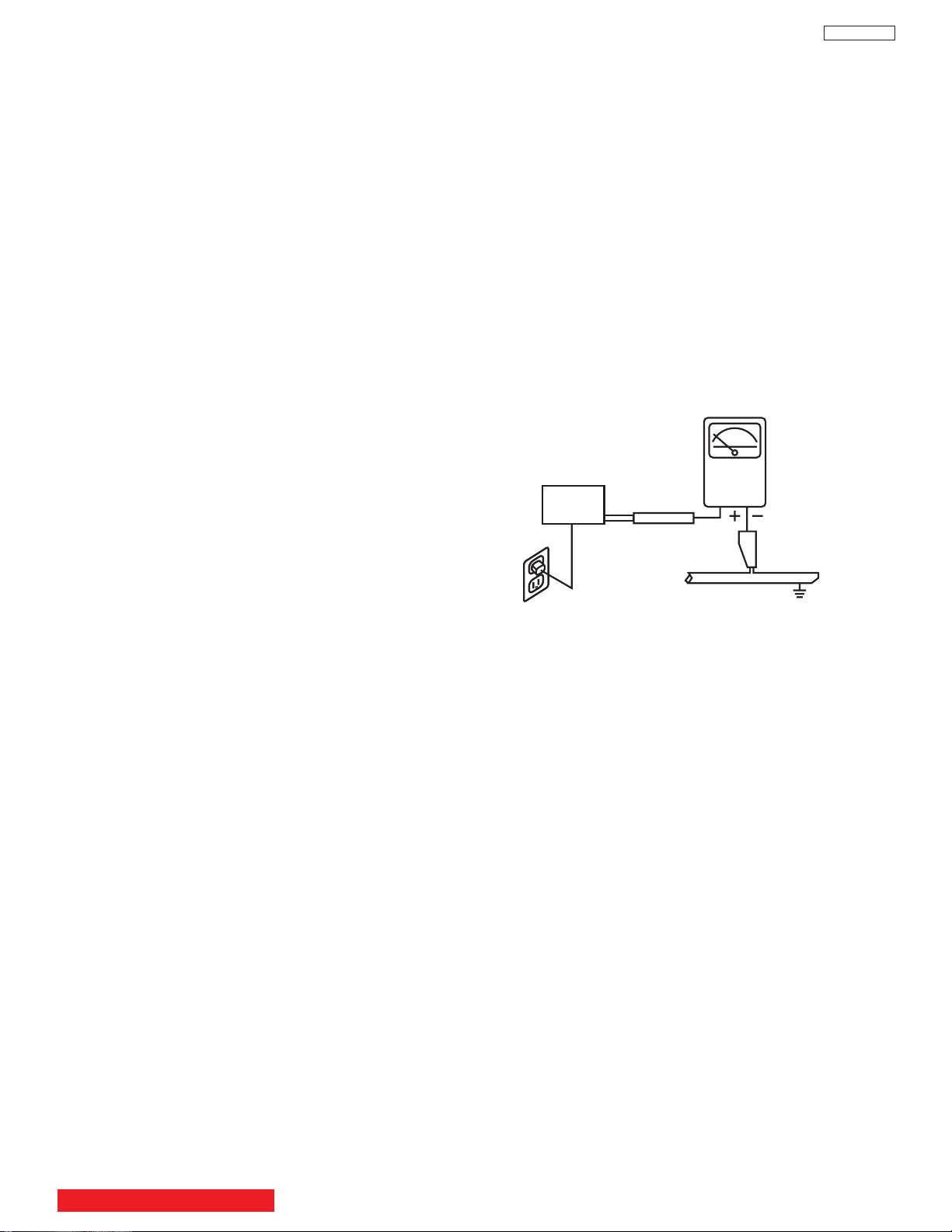

LEAKAGE

CURRENT

TESTER

(READING

SHOULD NOT

BE ABOVE 0.5MIU)

EARTH

GROUND

TEST ALL

EXPOSED

METAL SURFACES

DEVICE

UNDER

TEST

3-WIRE CORD

ALSO TEST WITH PLUG

REVERSED

(USING AC ADAPTER

PLUS AS REQUIRED)

NOTICE: Comply with all cautions and safety-related notes

located on or inside the cover case and on the chassis or plasma

module.

WARNING: Since the chassis of the AVC unit and Plasma Panel

unit is connected to both sides of the AC power supply during

operation, whenever the receiver is plugged in, service should

not be attempted by anyone unfamiliar with the precautions

necessary when working on this type of receiver.

1. When service is required, an isolation transformer should be

inserted between power line and the receiver before any

service is performed on a “HOT” chassis receiver.

2. When replacing a chassis in the receiver, all the protective

devices must be put back in place, such as barriers, nonmetallic knobs, insulating cover-shields, and isolation

resistors, capacitors, etc.

3. When service is required, observe the original lead dress.

4. Always use manufacturer’s replacement components. Critical

components as indicated on the circuit diagram should not be

replaced by another manufacturer’s. Furthermore, where a

short circuit has occurred, replace those components that

indicate evidence of over heating.

PW1A

Leakage Current Hot Check

This check must be done considering the AVC or the PDP

monitor as one instrument each.

With any of the instruments completely reassembled (being

the instrument either the AVC center or the PDP monitor), plug

the AC line cord directly into a 120V AC outlet. (Do not use an

isolation transformer during this test.) Use a leakage current

tester or a metering system that complies with the American

National Standards Institute (ANSI) C101.0 Leakage Current

for Appliances. In the case of the PDP monitor set the AC

switch first in the ON position and then in the OFF position,

measure from across Line 1 and Line 2 of the three plug

prongs, do not connect with the third prong, which is physical

ground, to all exposed metal parts of the instrument

(antennas, handle bracket, metal cabinet, screw heads,

metallic overlays, control shafts, etc.), especially any exposed

metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5 MIU. Reverse the

instrument power cord plug in the outlet and repeat test.

AC LEAKAGE TEST

5. Before returning a serviced receiver to the customer, the

service technician must thoroughly test the unit to be certain

that it is completely safe to operate without danger of electrical

shock, and be sure that no protective device built into the

receiver by the manufacturer has become defective, or

inadvertently defeated during servicing.

Therefore, the following checks should be performed for the

continued protection of the customer and service technician.

Leakage Current Cold Check

With the AC plug removed from the 120V AC 60Hz source,

place a jumper across Line 1 and Line 2 of the three plug

prongs, do not connect with the third prong, which is physical

ground.

Using an insulation tester (DC500V), connect one of its leads

to the AC plug jumper and touch with the other lead each

exposed metal part (antennas, screwheads, metal overlays,

control shafts, etc.), particularly any exposed metal part

having a return path to the chassis should have a resistor

reading over 4MΩ. Any resistance value below this range

indicates an abnormality which requires corrective action. An

exposed metal part not having a return path to the chassis will

indicate an open circuit.

ANY MEASUREMENTS NOT WITHIN THE LIMITS OUTLINED

ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD

AND MUST BE CORRECTED BEFORE RETURNING THE

RECEIVER TO THE CUSTOMER.

TABLE OF CONTENTS

2

Page 3

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in HITACHI television

receivers have special safety-related characteristics. These are

often not evident from visual inspection nor can the protection

afforded by them necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement

parts which have these special safety characteristics are

identified in this Service Manual.

Electrical components having such features are identified with a

!

1 mark in the schematics and parts list in this Service Manual.

The use of a substitute replacement component which does not

have the same safety characteristics as the HITACHIrecommended replacement component, shown in the parts list in

this Service Manual, may create shock, fire, X-radiation, or other

hazards.

Product safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current HITACHI Service Manual. A subscription to,

or additional copies of HITACHI Service Manuals may be

obtained at a nominal charge from HITACHI Sales Corporation.

1. Follow the general caution recommendations from “Safety

precautions” section.

42EDT41A - Plasma Monitor Panel

CMP420V1A - Plasma Monitor Panel

CMP420V2A - Plasma Monitor Panel

1. Follow the general caution recommendations from “Safety

precautions” section.

2. Since the Panel module and front filter are made of glass,

sufficient care shall be taken when handling the broken

module and filter in order to avoid injury.

3. If necessary to replace Panel module, this work must be

started after the panel module and the AC/DC Power supply

becomes sufficiently cool.

4. Special care must be taken with the display area to avoid

damaging its surface.

5. The Panel Module shall not be touched with bare hands to

protect its surface from stains.

6. It is recommended to use clean soft gloves during the

replacing work of the Panel module in order to protect, not

only the display area of the panel module but also the

serviceman.

7. The Chip Tube of the panel module (located upper left of the

back of the panel module) and flexible cables connecting

Panel glasses to the drive circuitry Printed Wiring Boards

(P.W.B.) are very weak, so sufficient care must be taken to

prevent breaking or cutting any of these. If the Chip Tube

breaks the panel module will never work, replacement for a

new plasma panel module will be needed.

8. Signal, power supply P.W.B.’s and PDP driving circuits

P.W.B.’s are assembled on the rear side of the PDP module,

take special care with this fragile circuitry; particularly, Flexible

Printed Circuits bonded to surrounding edges of the glass

panel. They are not strong enough to withstand harsh outer

mechanical forces. Avoid touching the flexible printed circuits

by not only your hands, but also tools, chassis, or any other

object. Extreme bending of the connectors must be avoided

too. In case the flexible printed circuits are damaged, the

corresponding addressed portions of the screen will not be lit

and exchange of a glass panel will be required.

PW1A

PDP Module Handling

When there is need to replace a broken PDP module which is the

displaying device from the Plasma monitor unit, consider the

following:

1. When carrying the PDP module, two persons should stand at

both shorter-edge sides of the glass-panel and transport it with

their palms. Avoid touching the Flexible Printed Circuits or the

chip tube on the corner of the glass-panel. Handle only by the

surface of the glass panel. In case of some PDP modules,

electrode repair is done by connecting between regular

terminal with Cu tape and Cu wire. Please do not hook and/or

damage this repair line. If it is damaged, the module will not

function unless the glass-panel is exchanged with a new

glass-panel.

2. When carrying PDP module, watch surrounding objects, such

as tables, and also do not carry it alone since it may be

dangerous and it will be damaged due to excessive stress to

the module (glass-panel).

3. Please do not stand the module with the edge of the glasspanel on the table since this might result in damage to the

glass-panel and/or flexible printed circuits due to excessive

stress to the module (glass-panel).

WARNING

Lead in solder used in this product is listed by the California

Health and Welfare agency as a known reproductive toxicant

which may cause birth defects or other reproductive harm

(California Health and Safety Code, Section 25249.5).

When servicing or handling circuit boards and other components

which contain lead in solder, avoid unprotected skin contact with

solder. Also, when soldering make sure you are in a well

ventilated area in order to avoid inhalation of any smoke or

fumes released.

SAFETY NOTICE

USE ISOLATION TRANSFORMER

WHEN SERVICING

POWER SOURCE

This plasma television and the AVC Center is designed to

operate on 120 Volts/60Hz, AC house current. Insert the power

cord into a 120 Volts/60Hz outlet.

NEVER CONNECT THE PLASMA AND THE AVC CENTER TO

OTHER THAN THE SPECIFIED VOLTAGE OR TO DIRECT

CURRENT AND TO 50HZ. TO PREVENT ELECTRIC SHOCK,

DO NOT USE THE PLASMA TELEVISION’S (POLARIZED)

PLUG WITH AN EXTENSION CORD, RECEPTACLE, OR THE

OUTLETS UNLESS THE BLADES AND GROUND TERMINAL

CAN BE FULLY UNSERTED TO PREVENT BLADE

EXPOSURE.

TABLE OF CONTENTS

3

Page 4

SERVICING PRECAUTIONS

CAUTION: Before servicing instruments covered by this service

data and its supplements and addenda, read and follow the

“Important Safety Instructions” on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions

on page 3 of this publication, always follow the safety

precautions. Remember: Safety First.

General Servicing Guidelines

1. Always unplug the instrument AC power cord from the AC

power source before:

a. Removing or reinstalling any component, circuit board,

module, or any other instrument assembly.

b. Disconnecting or reconnecting any instrument electrical

plug or other electrical connection.

PW1A

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors

and semiconductor “chip” components. The following techniques

should be used to help reduce the incidence of component

damage caused by static electricity.

1. Immediately before handling any semiconductor component

or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying power to

the unit under test.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the instrument.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may

result in an explosion hazard.

2. Do not spray chemicals on or near this instrument or any of its

assemblies.

3. Unless specified otherwise in these service data, clean

electrical contacts by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator: 10% (by volume)

Acetone and 90% (by volume) isopropyl alcohol (90%-99%

strength).

CAUTION: This is a flammable mixture. Unless specified

otherwise in these service data, lubrication of

contacts is not required.

4. Do not defeat any plug/socket of voltage interlocks with which

instruments covered by this service data might be equipped.

5. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat-sinks

are correctly installed.

6. Always connect the test instrument ground lead to the

appropriate instrument chassis ground before connecting the

test instrument positive lead. Always remove the test

instrument ground lead last.

7. Use with this instrument only the test fixtures specified in this

service data.

CAUTION: Do not connect the test fixture ground strap to

any heatsink in this instrument.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or desolder

ES devices.

4. Use only an anti-static type solder removal device. Some

solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ES device.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material.)

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

CAUTION: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

TABLE OF CONTENTS

4

Page 5

PW1A

Use Soldering Iron to Pry Leads

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range 500°F to 600°F.

2. Use an appropriate gauge of resin-core solder composed of

60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well-tinned.

4. Thoroughly clean the surfaces to be soldered. Use a small

wire-bristle (0.5 inch or 1.25 cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following desoldering technique.

a. Allow the soldering iron tip to reach normal temperature

(500°F to 600°F).

b. Heat the component lead until the solder melts. Quickly

draw away the melted solder with an anti-static, suctiontype solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach normal temperature

(500°F to 600°F).

b. First, hold the soldering iron tip and solder strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it

there only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil or components.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as the

solder melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing

the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush. (It is

not necessary to reapply acrylic coating to areas.)

“Small-signal” Discrete Transistor Removal/Replacement

1. Remove the defective transistor by clipping its leads as close

as possible to the component body.

2. Bend into a “U” shape the end of each of the three leads

remaining on the circuit board.

3. Bend into a “U” shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the “U” with long nose pliers to insure metal to metal

contact, then solder each connection.

Power Output Transistor Devices Removal/Replacements

1. Heat and remove all solder from around the transistor leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the circuit board.

4. Insert new transistor in circuit board.

IC Removal/Replacement

Some Hitachi unitized chassis circuit boards have slotted holes

(oblong) through which the IC leads are inserted and then bent

flat against the circuit foil. When holes are the slotted type, the

following technique should be used to remove and replace the

IC. When working with boards using the familiar round hole, use

the standard technique as outlined in paragraphs 5 and 6 above.

TABLE OF CONTENTS

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicularly to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two “original leads”. If they are not shiny, reheat them and,

if necessary, apply additional solder.

5

Page 6

PW1A

CRIMP AND

SOLDER

BARE JUMPER

WIRE

Install Jumper Wire and Solder

DEFECTIVE

COPPER

REMOVED

Insulated Jumper Wire

Fuses and Conventional Resistor Removal/Replacement

1. Clip each fuse or resistor lead at top of circuit board

hollow stake.

2. Securely crimp leads of replacement component around stake

1/8 inch from top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the

circuit board, to prevent excessive component

temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board, causing the foil to separate from, or “lift-off,” the board.

The following guidelines and procedures should be followed

whenever this condition is encountered.

In Critical Copper Pattern Areas

High component/copper pattern density and/or special

voltage/current characteristics make the spacing and integrity of

copper pattern in some circuit board areas more critical than in

others. The circuit foil in these areas is designated as Critical

Copper Pattern. Because Critical Copper Pattern requires

special soldering techniques to ensure the maintenance of

reliability and safety standards, contact your Hitachi personnel.

At IC Connections

To repair defective copper pattern at IC connections, use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections.)

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely

necessary.)

2. Carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

At Other Connections

Use the following technique to repair defective copper pattern at

connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both wire sides of the

pattern break and locate the nearest component directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the nearest

component on one side of the pattern break to the lead of the

nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so

that it does not touch components or sharp

edges.

3. Bend a small “U” in one end of a small-gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the cut-away copper

pattern and let it overlap the previously scraped end of the

good copper pattern. Solder the overlapped area, and clip off

any excess jumper wire.

TABLE OF CONTENTS

6

Page 7

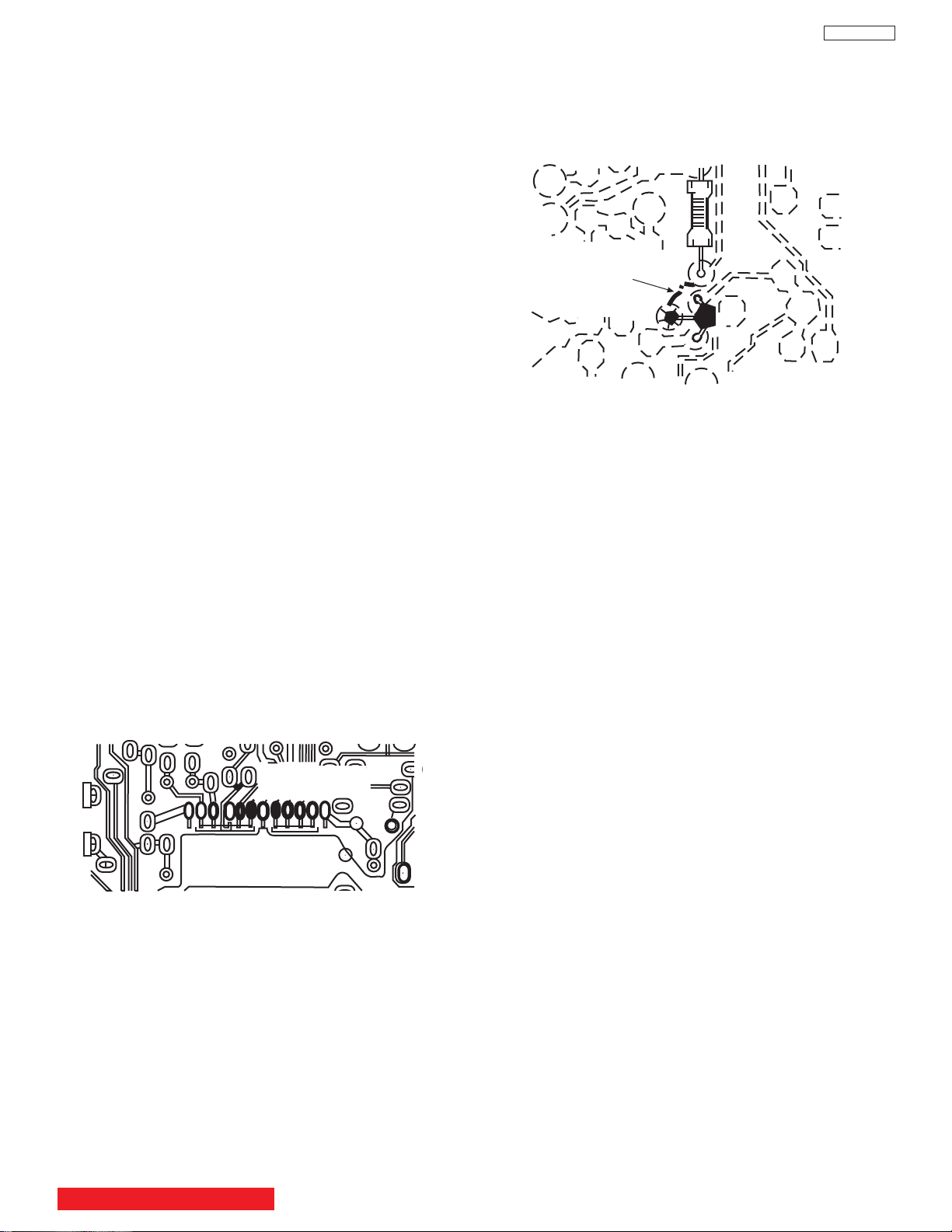

PW1A

NOTE: These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when removing. Usually applying heat to the component for a short time

while twisting with tweezers will break the component loose.

Leadless Chip Components

(surface mount)

Chip components must be replaced with identical chips

due to critical foil track spacing. There are no holes in the

board to mount standard transistors or diodes. Some chip

capacitor or resistor board solder pads may have holes

through the board, however the hole diameter limits

standard resistor replacement to 1/8 watt. Standard

capacitors may also be limited for the same reason. It is

recommended that identical chip components be used. .

Chip resistors have a three digit numerical resistance code

-1st and 2nd significant digits and a multiplier. Example:

162 = 1600 or 1.6KΩ resistor, 0 = 0Ω (jumper).

Chip capacitors generally do not have the value indicated

on the capacitor. The color of the component indicates the

general range of the capacitance.

Chip transistors are identified by a two letter code. The first

letter indicates the type and the second letter, the grade of

transistor.

Chip diodes have a two letter identification code as per the

code chart and are a dual diode pack with either

common anode or common cathode. Check the parts list

for correct diode number.

Component Removal

1. Use solder wick to remove solder from component end

caps or terminals.

2. Without pulling up, carefully twist the component with

tweezers to break the adhesive.

3. Do not reuse removed leadless or chip components

since they are subject to stress fracture during

removal .

Chip Component Installation

1. Put a small amount of solder on the board soldering

pads.

2. Hold the chip component against the soldering pads

with tweezers or with a miniature alligator clip and

apply heat to the pad area with a 30 watt iron until

solder flows. Do not apply heat for more than 3

seconds

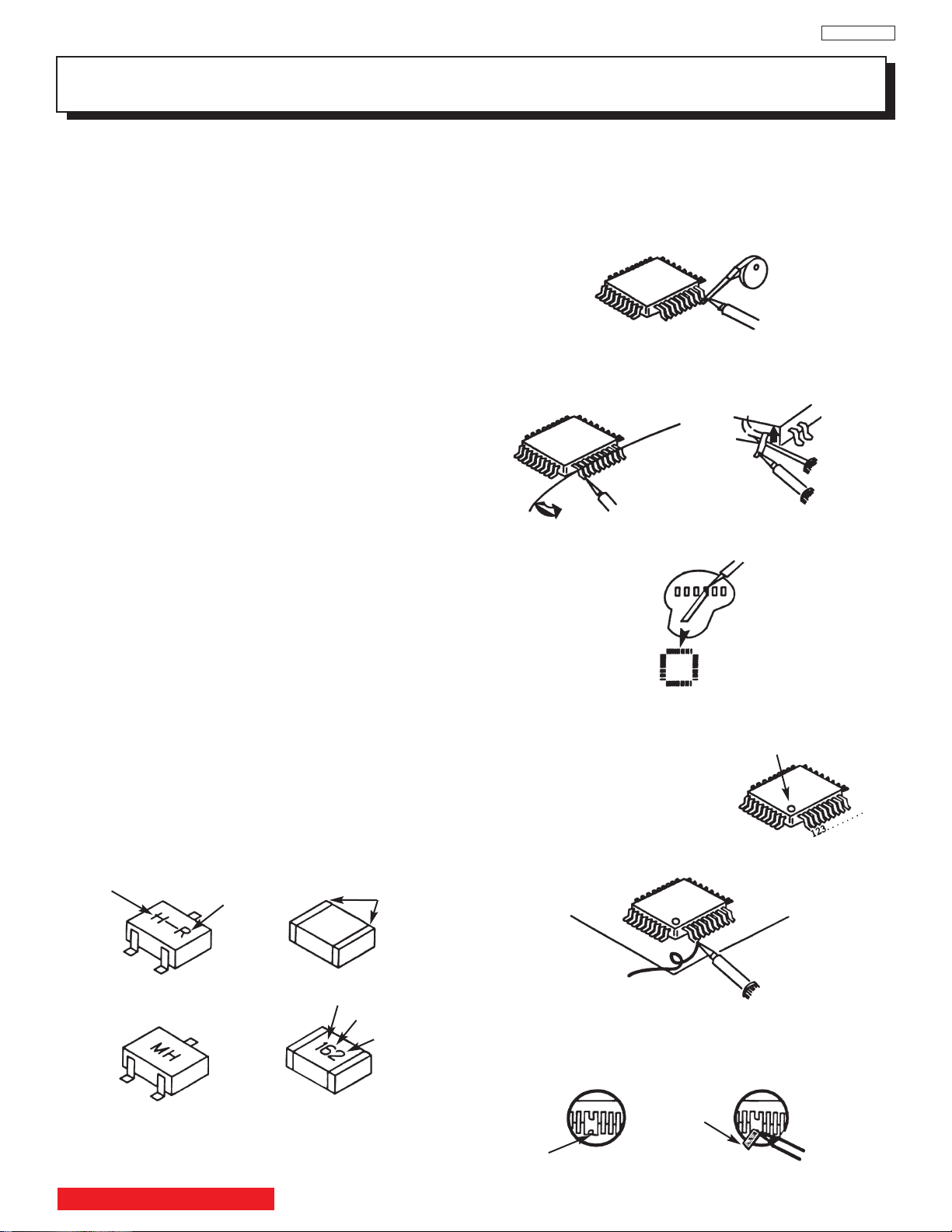

How to Replace Flat-lC

—Required Tools—

• Soldering iron • iron wire or small awl

• De-solder braids • Magnifier

1. Remove the solder from all of the pins of a Flat-lC by

using a de-solder braid.

Flat-IC

2. Put the iron wire under the pins of the Flat-lC and pull

it in the direction indicated while heating the pins using

a soldering iron. A small awl can be used instead of

the iron wire.

Iron

Wire

Pull

Soldering

Iron

Soldering

3. Remove the solder from all of the pads of the FiatlC by using

a de-solder braid.

De-Solder

Braid

Flat-IC

4. Position the new Flat-lC in place (apply the pins of the

Flat-lC to the soldering pads where the pins need to be

soldered). Properly determine

the positions of the soldering

pads and pins by correctly

aligning the polarity symbol.

De-Solder

Braid

Soldering

Iron

Awl

Iron

Soldering

Iron

Polarity Symbol

TYPE

B

E

ANODES

MH DIODE

C

GRADE

TRANSISTOR

COMMON CATHODE

TABLE OF CONTENTS

Chip Components

SOLDER CAPS

1ST DIGIT

RESISTOR

SOLDER

CAPS

CAPACITOR

2ND DIGIT

MULTIPLIER

= 1600 = 1.6K

5. Solder all pins to the soldering pads using a fine tipped

soldering iron.

Solder

Soldering

Iron

6. Check with a magnifier for solder bridge between the

pins or for dry joint between pins and soldering pads. To

remove a solder bridge, use a de-solder braid as shown in

the figure below.

De-Solder

Braid

Bridge

Solder

7

Soldering

Iron

Page 8

AGENCY REGULATORY

INFORMATION

Federal Communications Commission Notice

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy and if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference

to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/television technician for help.

Modifications

The FCC requires the user to be notified that any changes or modifications made to this device that are not expressly

approved by Hitachi Home Electronics (America), Inc. may void the user’s warranty.

PW1A

Cables

Connections to this device must be made with shielded cables with metallic RFI/EMI connector hoods to maintain

compliance with FCC Rules and Regulations.

Any cables that are supplied with the system must be replaced with identical cables in order to assure compliance with

FCC rules. Order Hitachi spares as replacement cables.

Declaration of Conformity

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device

may not cause harmful interference and (2) this device must accept any interference received, including interference

that may cause undesired operation.

For questions regarding this declaration, contact:

Hitachi America, LTD.

Home Electronics Division

900 Hitachi Way

Chula Vista, CA 91914

Tel. 1-800-448-2244 (1-800-HITACHI)

ATTN: CUSTOMER RELATIONS

TABLE OF CONTENTS

8

Page 9

ACKNOWLEDGMENTS

AND TRADEMARKS

This Plasma Television complies with VESADDC2B specifications, Plug & Play

is a system with computer, peripherals (including monitors) and operating

system. It works when the monitor is connected to a DDC ready computer that

is running an operating system software that is capable for the plug & play.

When a Plug and Play PC is powered on, it sends a command to the Monitor

requesting identification. The Monitor sends back a string of data including its

characteristics.

TRADEMARK ACKNOWLEDGMENT

TM

DDC is a trademark of Video Electronics Standard Association.

IBM PC/AT and VGA are registered trademarkds of International Business Machines Corporation of the U.S.A.

Apple and Macintosh are registered trademarks of Apple Computer, Inc.

VESA is a trademark of a nonprofit organization, Video Electronics Standard Association.

PW1A

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Cable Compatible Television Apparatus- Tèlèvision câblocompatible, Canada.

Notes on Closed Caption:

This Plasma Television receiver will display television closed captioning, ( or ), in accordance with

paragraph 15.119 of the FCC rules.

TruBass and the SRS ®symbol are trademarks of SRS Labs, Inc. TruBass technology is incorporated under license

from SRS Labs, Inc.

TABLE OF CONTENTS

9

Page 10

Plasma TV

Hitachi RS232C Communication Specification

This document defines the detailed RS232C control protocol for the following Hitachi Plasma

Televisions:

Model: 42EDT41A

CMP420V1A

CMP420V2A

The Information enclosed is subject to change without notice. Please refer to revision number

shown above when inquiring about product support.

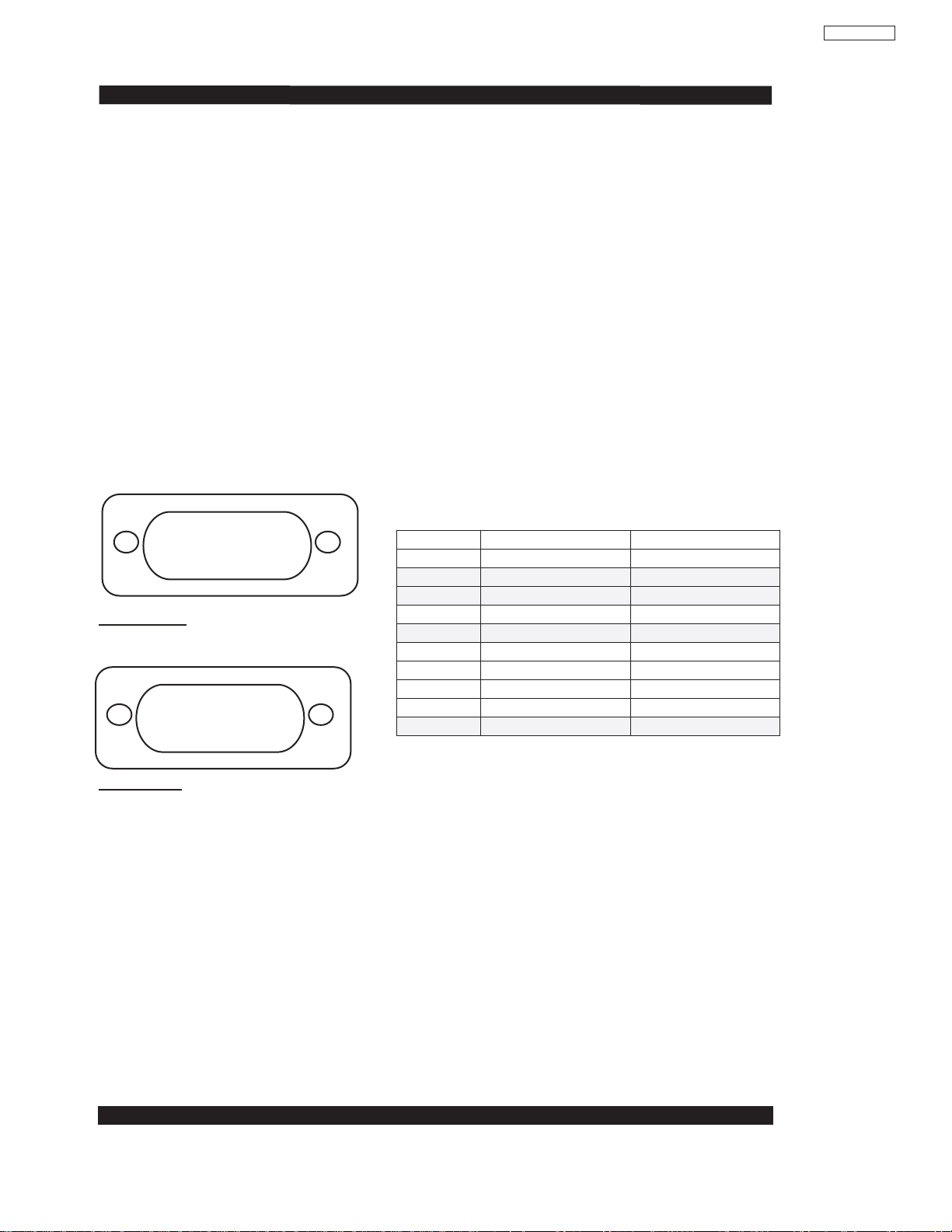

1. Hardware Interface

1.1- The cable interface to the monitor is a 9 pin D-Sub type.

1.2- The gender of the 9 pin D-sub on the monitor is male. Therefore, the cable interface to

the monitor should be female.

1.3- The cable is configured in a null modem wiring scheme

1.4- A pin reference illustrations is provided below:

Figure. 1 (a) Male 9 pin D-sub

(Outside View)

Figure. 1 (b) Female 9 pin D-Sub

(Outside View)

1.5- Electric: Electrical specification is based on the current RS232C standard.

2. Communication Format

2.1- Port Configuration

(1) Communications System: Asynchronous

(2) Bit Rate: 9600 bps

(3)Data Length: 7 bit

(4) Parity: None

(5) Start Bit: None

(6) Stop Bit: 1 bit

¬ ® ¯ °

±²³´

°¯®¬

´³²±

Pin #

Signal

Remark

1

NC

2

RXD0

PDP ← Control PC

3

TXD0

PDP → Control PC

4

NC

5

GND

PDP ↔ PC GND

6

NC

7

NC

8

NC

9

NC

Frame

GND

PW1A

10

Page 11

Plasma TV

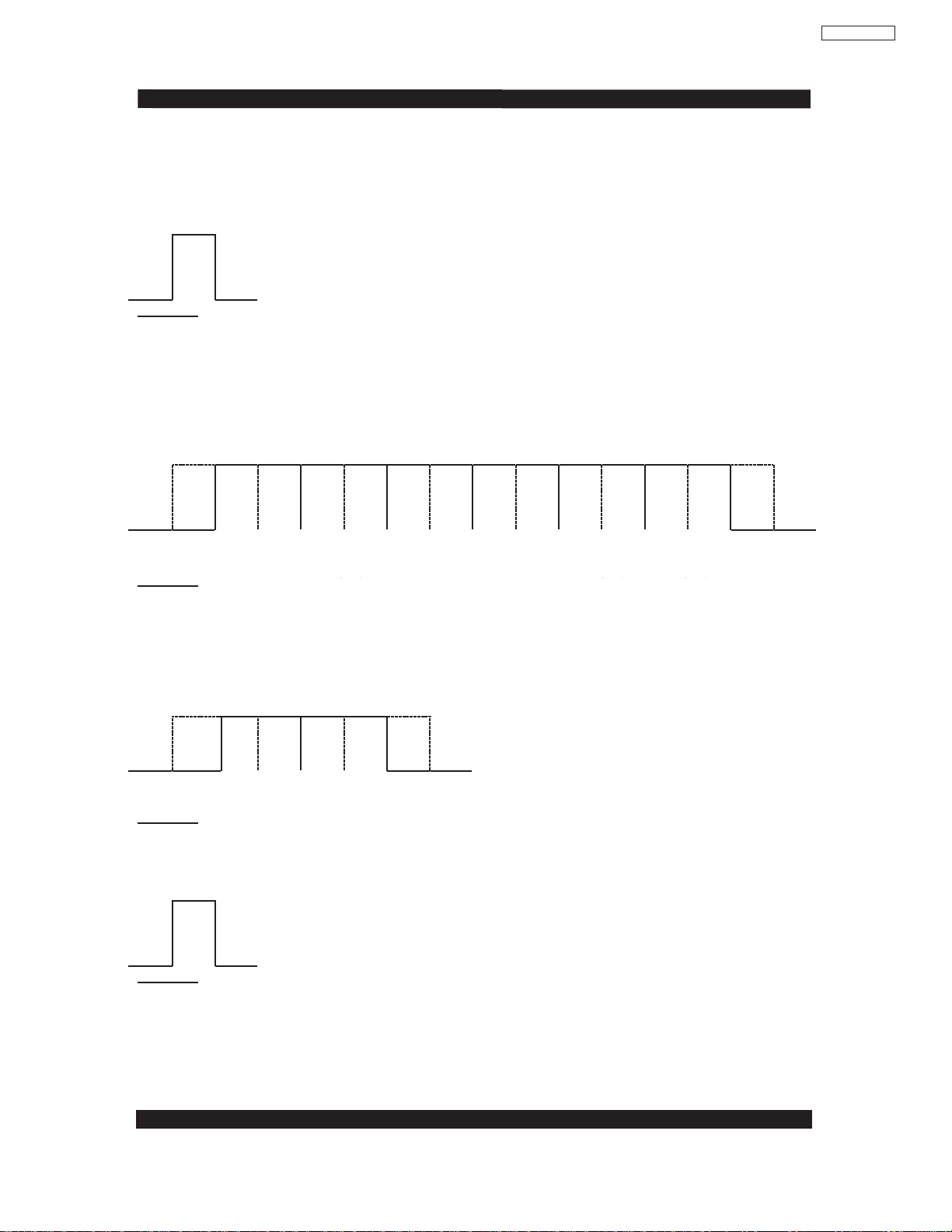

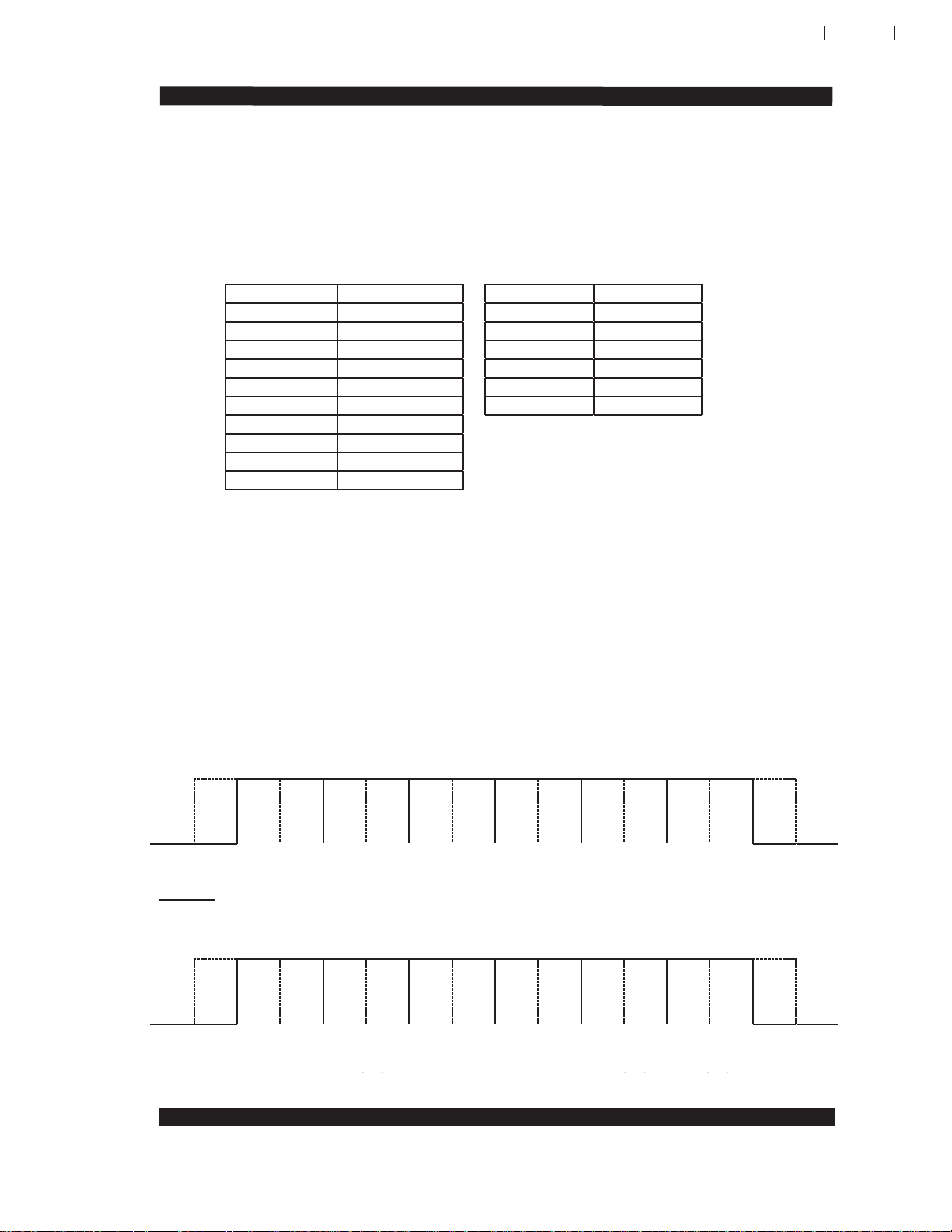

2.2- Data Format

(1) Terminal Mode control format (Turning on and Off Terminal Mode)

- Terminal On is achieved by sending a 1 byte command of 05 (Hex).

- Terminal Off is achieved by sending a 1 byte command of 04 (Hex)

ON

/

Off

Figure. 2

(2) Terminal Communication Format (Sending Commands to TV)

- Commands are sent to the TV in 14 byte strings

- The strings consist of the following:

Start: 1 byte (02) Hex (STX)

Command: 12 byte

Stop: 1 Byte (03) Hex (ETX)

12345678910111213

14

Start

Stop

Figure. 3

(3) Television Answer Format (Showing current Status)

- The television responds with a 6 byte answer strings as follows:

Start: 1 byte (02) Hex (STX)

Response: 4 byte (Upper Data/Lower Data)

Stop: 1 Byte (03) Hex (ETX)

12345

6

Start

Stop

Figure. 4

(4) Television Answer Format (Status of Command Execution)

- Acknowledgement: (06) Hex (ACK)

- No Acknowledgement: (15) Hex (NAK)

ACK

/

NAK

Figure. 5

Function

(2 Byte)

Function

(2 Byte)

Function

(2 Byte)

Read/Write

(2 Byte)

Upper Data

(2 Byte)

Lower Data

(2 Byte)

STX

(1 Byte)

ETX

(1 Byte)

Upper Data

(2 Byte)

STX

(1 Byte)

ETX

(1 Byte)

Lower Data

(2 Byte)

PW1A

11

Page 12

Plasma TV

3. Communication Protocol

3.1- Terminal Mode (Communication between television and external PC)

- When the RS232C mode is set from Off to On by the television OSD menu and

the TXD2 and RXD2 serial communication lines are switched to AV control, the

television can communicate with and external PC.

Table 3.2.1 Terminal Mode Control

(1) External PC can turn terminal mode On and Off.

(2)Communication is prohibited when terminal mode is Off.

(3) When terminal mode is on, Front Keys and Remote do not operate. The only button that will

operate is main power.

(4) When TV set is turned Off and On, terminal mode remains in its current state

(5) Factory Setting: Terminal Mode is Off and AV Control Mode is Off.

(6)The television will always respond when an attempt to turn terminal mode on or off is made

with either an ACK or a NAK.

(7) In the following cases, even if the check box of menu is checked, Terminal mode cannot be

turned on.

- Adjust mode

- While Event Timer and Timer Recording

- While Auto CH scan operates

- While upgrade operates

(8) Write function in terminal mode will write data to the EEPROM in the same manner as when

unit is operated in Normal Mode through the OSD.

(9) For OSD functionality in terminal mode, see table 5.

(10) When the Life extension mode is active, the unit will not accept changes in the contrast

control.

Set Up t

Set AV Control t

If you want to use AV control

Function, please set the RS232C.

4 Connected RS232C

s

Move

t

Select

Plasma Television

Terminal Mode Switching

Command sent to PDP

Response from PDP

Action

Request On

Accept / Reject

Character

ENQ

ACK/NAK

ON

Code (Hex)

05

06/15

Action

Request OFF

Accept / Reject

Character

EOT

ACK/NAK

OFF

Code (Hex)

04

06/15

PW1A

12

Page 13

Plasma TV Revision 1.0

3.2- Command Summary (Sending and Receiving Data)

3.2.1- Data received by Television

• TV will accept data from the PC when it is properly formatted as shown in table 3.2.1.1 only

when the Terminal Mode is ON.

• The command length is 12 bytes with a start and stop byte. Therefore total command strings

are 14 bytes

• The command consists of 6 Hex codes from 1

st

to 6th as shown below. (Total 12 bytes)

• All command strings should be described in character code and then converted to Hex Code.

• Table 3.2.1.2 shows the 3 types of command formats

• All commands are classified into these 3 types of command by the 1

st

and 2nd command byte.

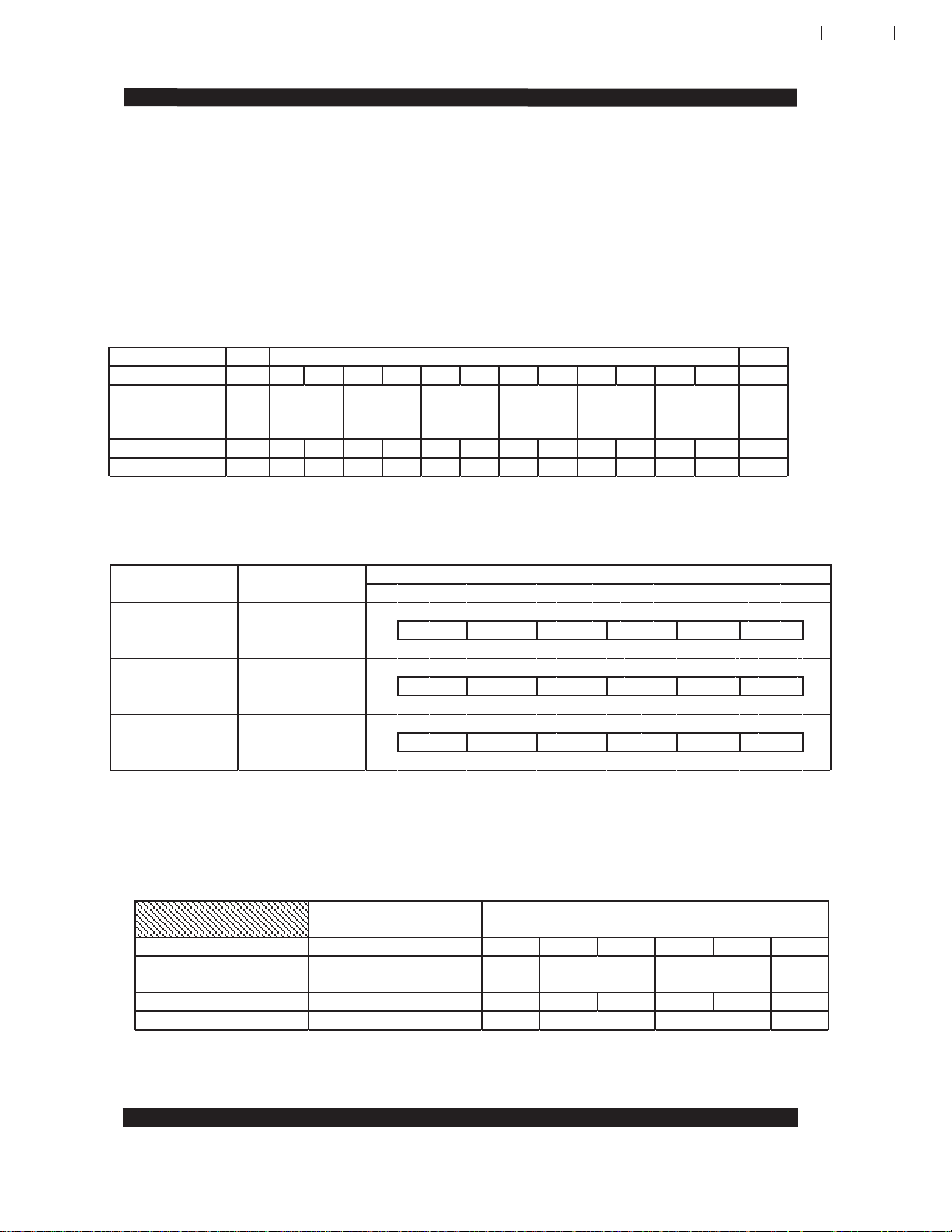

Table 3.2.1.1 Communication format received by Television

*1 Character Code: “0”-“9” → 30-39, “A” –“F” →41-46

Note- See code conversion examples in section 4 for conversion details.

Table 3.2.1.2 Format of Commands Received by Television (12 bytes)

3.2.2 Format of commands sent from television to PC

• Upon completion of a command sent to the television as shown in table 3.2.1.2, The

television will respond with an answer as shown in table 3.2.2.

• In the event that a command is rejected by the television, an Hex 15 will be sent to the PC.

Table 3.2.2 Answer format from television to PC

*1 Character Code: Example “0”-“9” → “30”-“39” , “A-F → 41- 46

Start

Stop

Received byte #

1

234567891011121314

Contents

Start

1st2nd3rd4th5th6th

Stop

Of

Function

R/W

Upper byte

Lower byte

Upper byte

Lower byte

Commands

(Function)

(Function)

(Data)

(Data)

Character -Hex

STX

0~F

0~F

0~F

0~F

0~F

0~F

0~F

0~F

0~F

0~F

0~F

0~F

ETX

Code- Hex

02

*1*1*1*1*1*1*1*1*1*1*1*103

Command (12 byte)

Form No.

Action

1st 2nd 3rd 4

th

5

th

6

th

Command

Dummy

Dummy

Dummy

Dummy

Dummy

(a)

Reset

Write/Read

(**)

(00)

(00)

(00)

(00)

(00)

Command

Operation

Command

Command

Dummy

Dummy

(b)

Read Data

(**)

(**)

(**)

(**)

(00)

(00)

Command

Operation

Command

Command

Data

Data

(c)

Write Data

(**)

(**)

(**)

(**)

(**)

(**)

Communication

Normal/Error

When requesting read data only from the TV

To the PC, the following format applies

Sent byte No.

1

12345

6

Contents of the

command

Accepted or

Rejected

Start

Data

Upper byte

Data

Lower byte

Stop

Character (Hex)

ACK/NAK

STX

0~F

0~F

0~F

0~F

ETX

Code (Hex)

06/15

02*1*1

03

PW1A

13

Page 14

Plasma TV

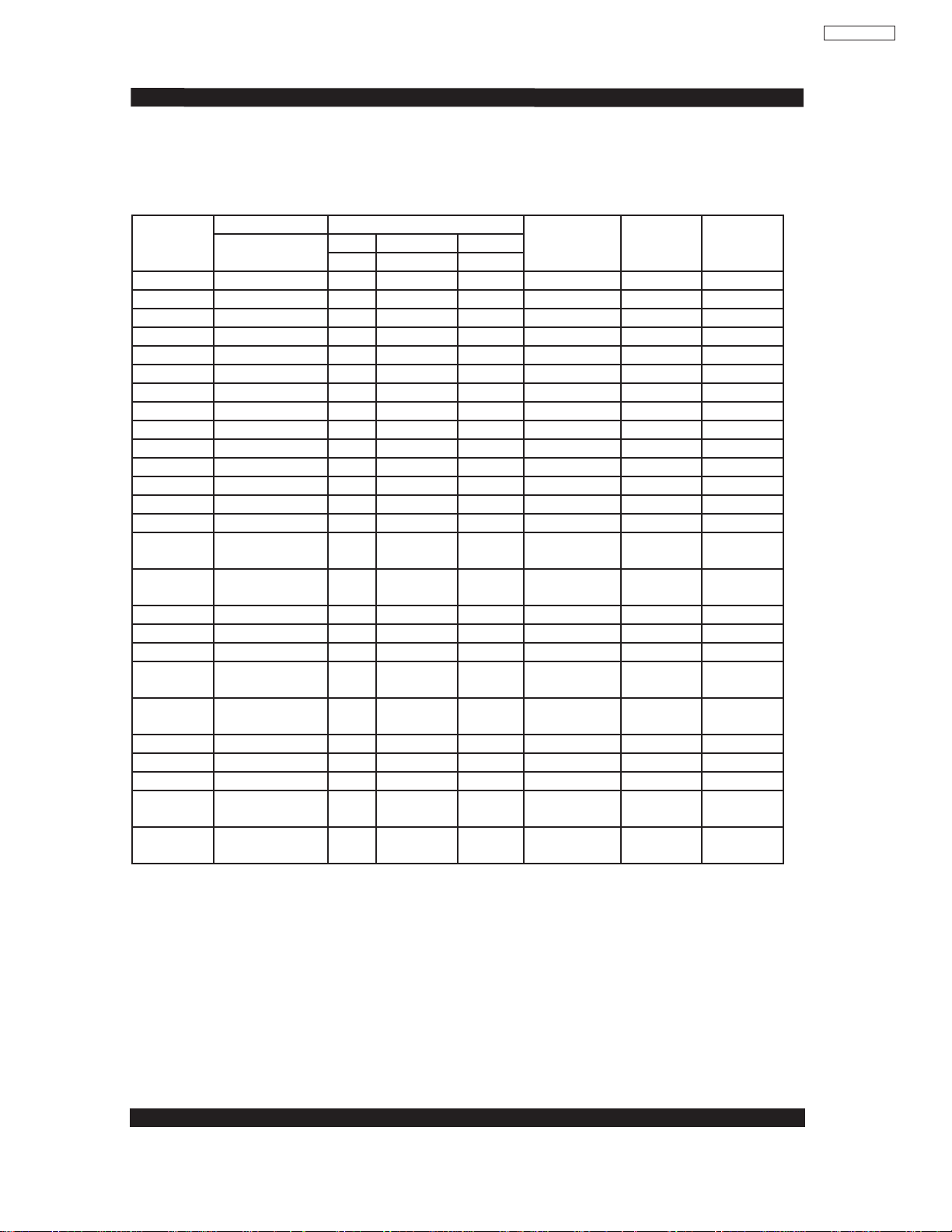

3.3 Command Table

3.3.1- 1

st

sub command (for function) table

Table 3.3.1 1

st

Sub Command and Adjustment Table

3.3.2 2

nd

sub command (Read / Write) table

R: Read Only. 01 Hex can be accepted. Data (absolute value) will be read from the TV.

W : Write Only. 00(Hex) can be accepted. Data (absolute value) will be written to TV

R/W : Read and Write. Both 00 and 01 (Hex) can be accepted

When 01 (Hex) is sent to TV, the data (Absolute Value) will be read from TV

When 00 (Hex) is sent to T V, the data (absolute value will be written to TV

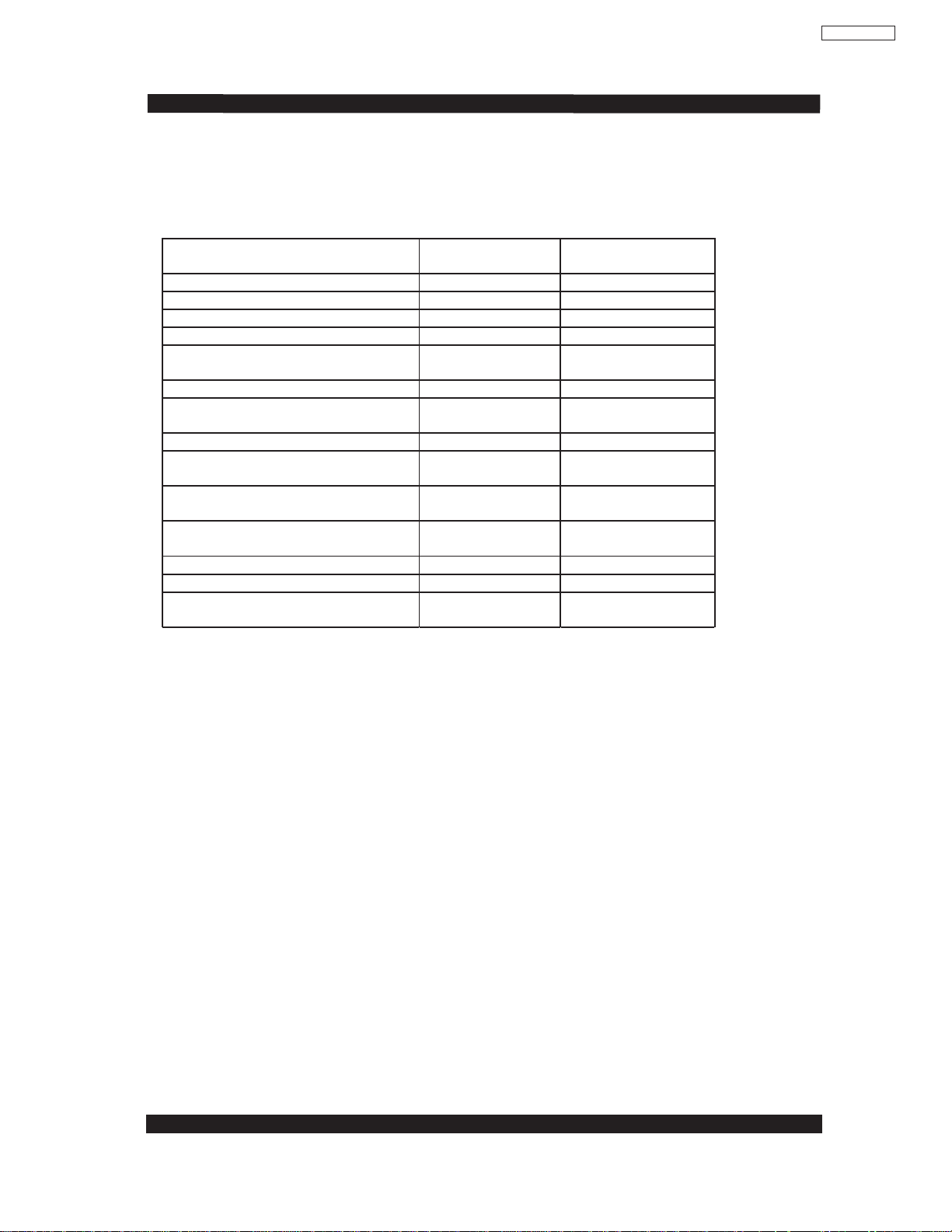

Setting

Command

1stR/W

3rd/4

th

No.

Function

Hex

Control

Hex

OSD

E2PROM

Command

Format

(*1)

1

POWER

6E

R/W

0000

Info

Write

( c )

2

INPUT6FR/W

0000

Info

Write

( c )

3

Volume27R/W

0000

Volume Bar

( c )

4

Balance28R/W

0000

No OSD

( c )

5

Treble2BR/W

0000

No OSD

( c )

6

Bass2AR/W

0000

No OSD

( c )

(TV Mode)

7

Audio Mute

29

R/W

0000

No OSD

( c )

8

Picture Mode

A4

R/W

0003

Day/Night

( c )

9

Contrast

59

R/W

0000

No OSD

( c )

10

Brightness

1F

R/W

0000

No OSD

( c )

11

Color10R/W

0000

No OSD

( c )

12

Tint13R/W

0000

No OSD

( c )

13

Sharpness

14

R/W

0000

No OSD

( c )

14

Color

Temperature

60

R/W

0000

No OSD

( c )

15

Aspect40R/W

0000

Aspect

(Info OSD)

( c )

16

INFOB2W

0000

Info

( c )

17

Direct CH 0~9

D0W0000

CH No.

Write

( c )

18

Direct CH -

D0W0001

CH No.

Write

( c )

19

Direct CH

Select

D0W0002

CH No.

Write

( c )

20

Auto Movie

Mode

D4

R/W

0000

No OSD

( c )

(RGB Mode)

21

Contrast

59

R/W

0000

No OSD

( c )

22

Brightness

1F

R/W

0000

No OSD

( c )

23

Color

Temperature

60

R/W

0000

No OSD

( c )

24

Aspect40R/W

0000

Aspect

(Info OSD)

( c )

PW1A

14

Page 15

Plasma TV

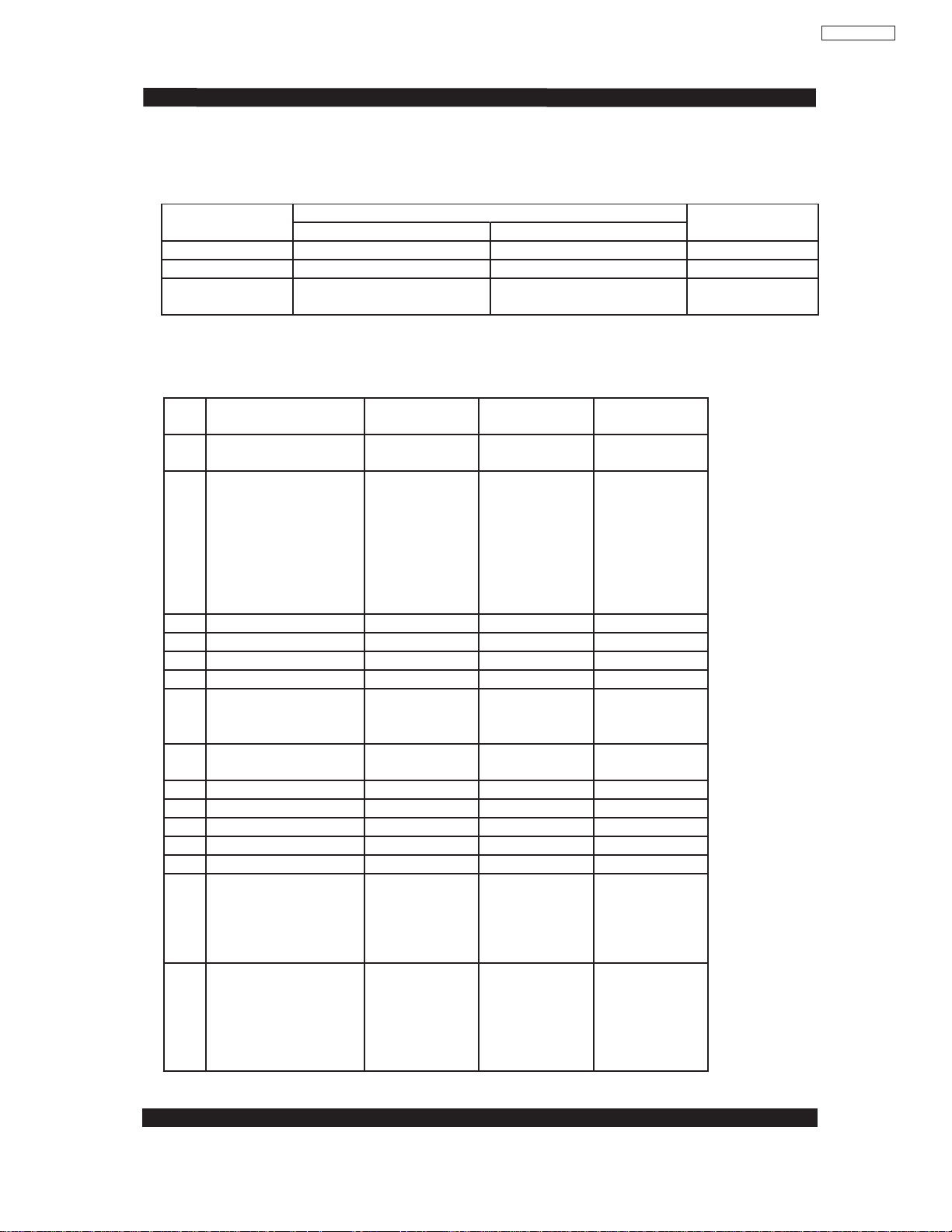

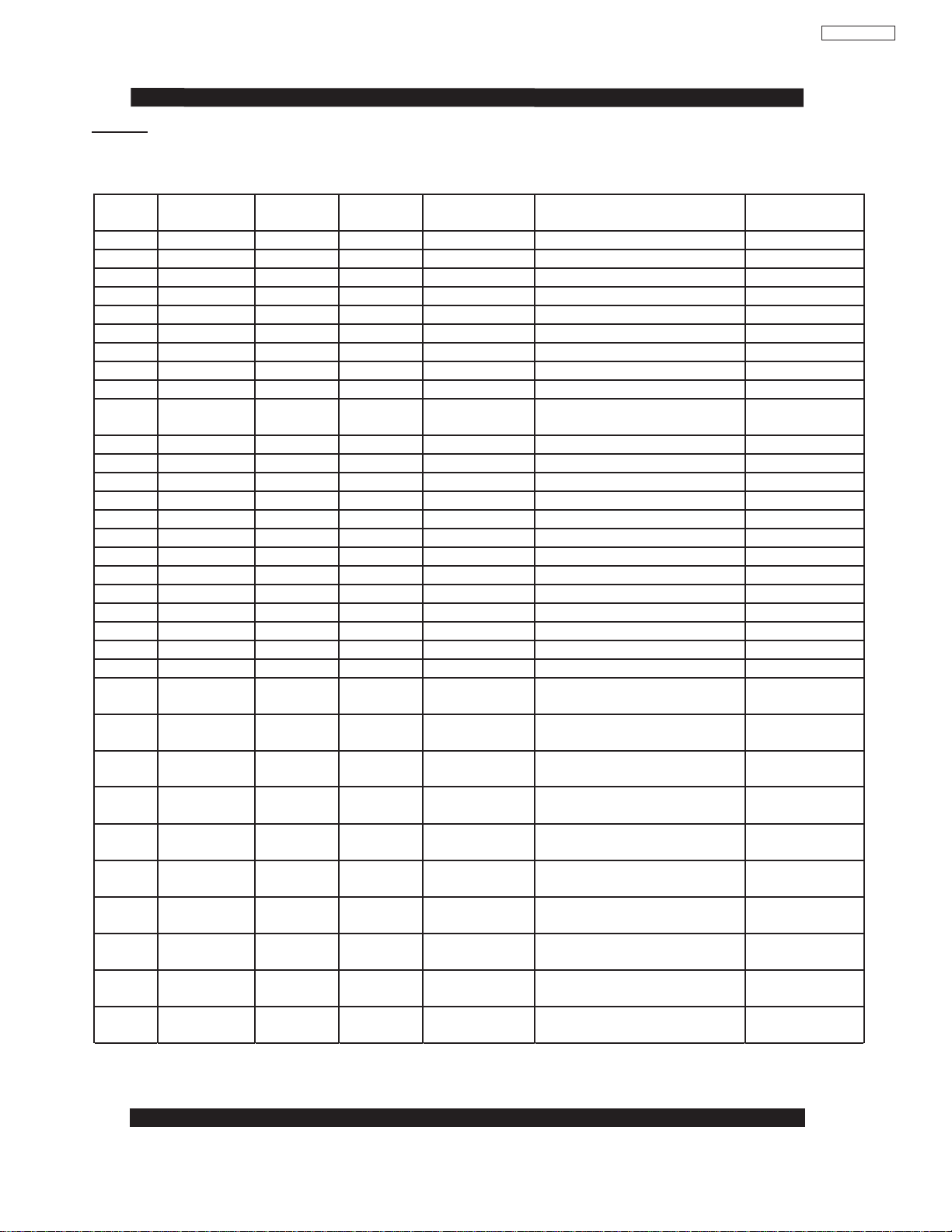

3.3.3 5th and 6th Data Command Table

The table below shows the specification for the 5

th

and 6th data bytes.

Table 3.3.3 Specification for 5

th

and 6th data bytes in normal command

Note- Any data that is transferred as Dummy data will be ignored by both the PC and the TV

3.3.4 Setting Items (Data Range of Commands)

Table 3.3.4 (Setting Item List)

No.

Setting Item

5th / 6

th

Data Range

Initial

Setting

Comments

1

Power

0: Off

1: On

0

2

Input

0: Input 1

1: Input 2

2: Input 3

3: Input 4

4: Input 5

6: Ant. A

7: Ant. B

9: Photo Input

-

3

Volume

0~63 Step

20

4

Balance

0~20 Step

10

5

Treble

0~20 Step

10

6

Bass

0~20 Step

10

7

Audio Mute

0: Off

1: On

2: Soft Mute

0

8

Picture Mode

0: Day

1: Night

0

9

Contrast

0~68 Step

-

10

Brightness

0~60 Step

-

11

Color

0~60 Step

-

12

Tint

0~60 Step

-

13

Sharpness

0~60 Step

-

14

Color Temperature

0: High

1: Medium

2: Standard

3: Black &

White

-

15

Aspect

0: 16:9 Std.

1: 16:9 Zoom

2: 4:3 Std

3: 4:3 Expand

4: 4:3 Zoom

5: 4:3 Zoom 2

-

Transfer Data (Hex)

No.

5th

6th

Note

1

Dummy Data

Dummy Data

2

Dummy Data

Transfer Data (1 byte)

3

Transfer Data

(upper 1 byte)

Transfer Data

(lower 1 byte)

PW1A

15

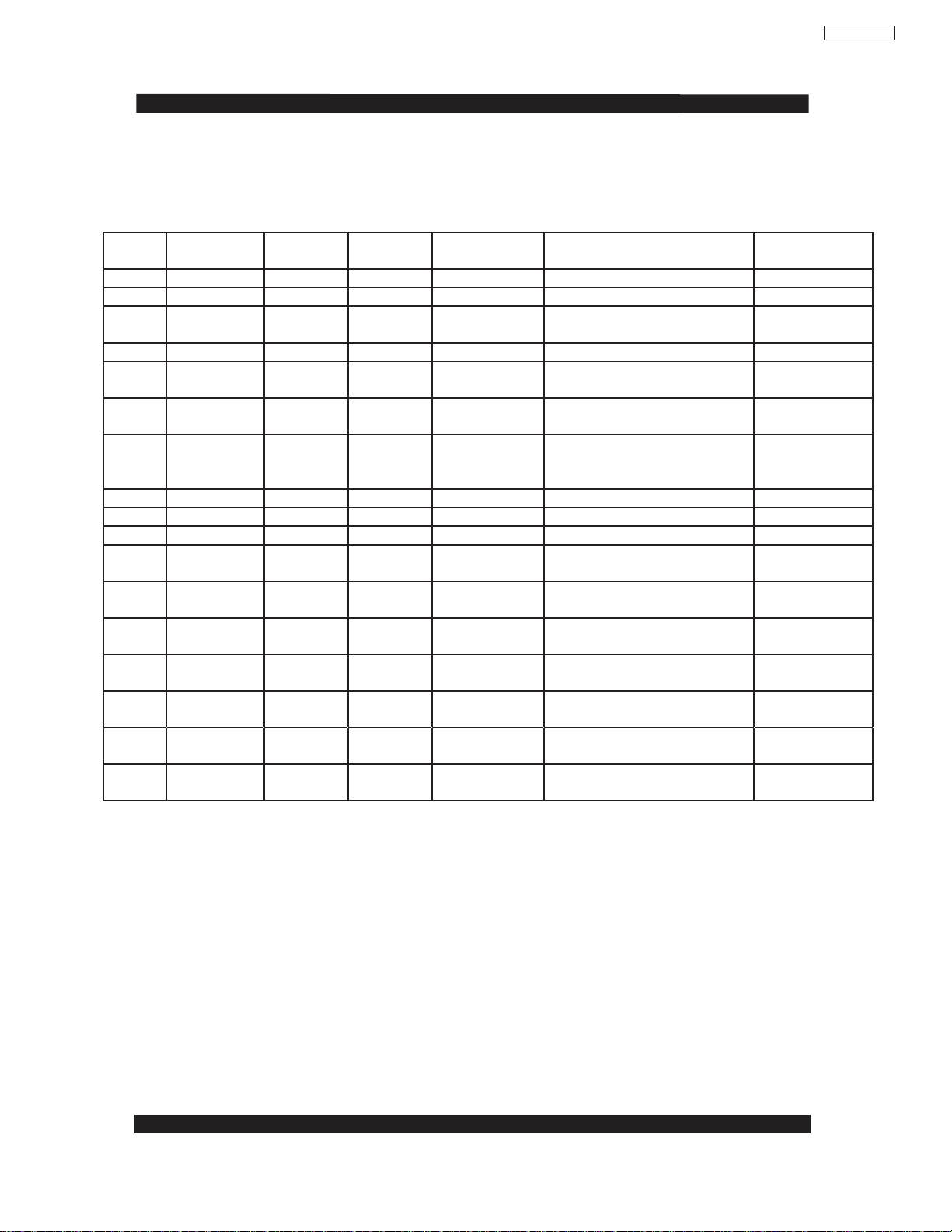

Page 16

Plasma TV

No.

Setting Item

5th / 6

th

Data Range

Initial

Setting

Comments

16

Info

0: Off

1: On

0

17

Direct CH 0~9

Key Code

0~9-0~9

-

18

Direct Channel (-)

0

-

19

Direct Channel Select

0

-

20

Auto Movie Mode

0: Off

1: On (Auto)

0

(RGB Mode)

21

Contrast

0~68 Step

-

22

Brightness

0~60 Step

-

23

Color Temperature

0: High

1: Medium

2: Standard

3: Black &

White

-

24

Aspect

0: 16:9 Std.

1: 2: 4:3 Std.

3: 4: 5: 6: Real

-

PW1A

16

Page 17

Plasma TV

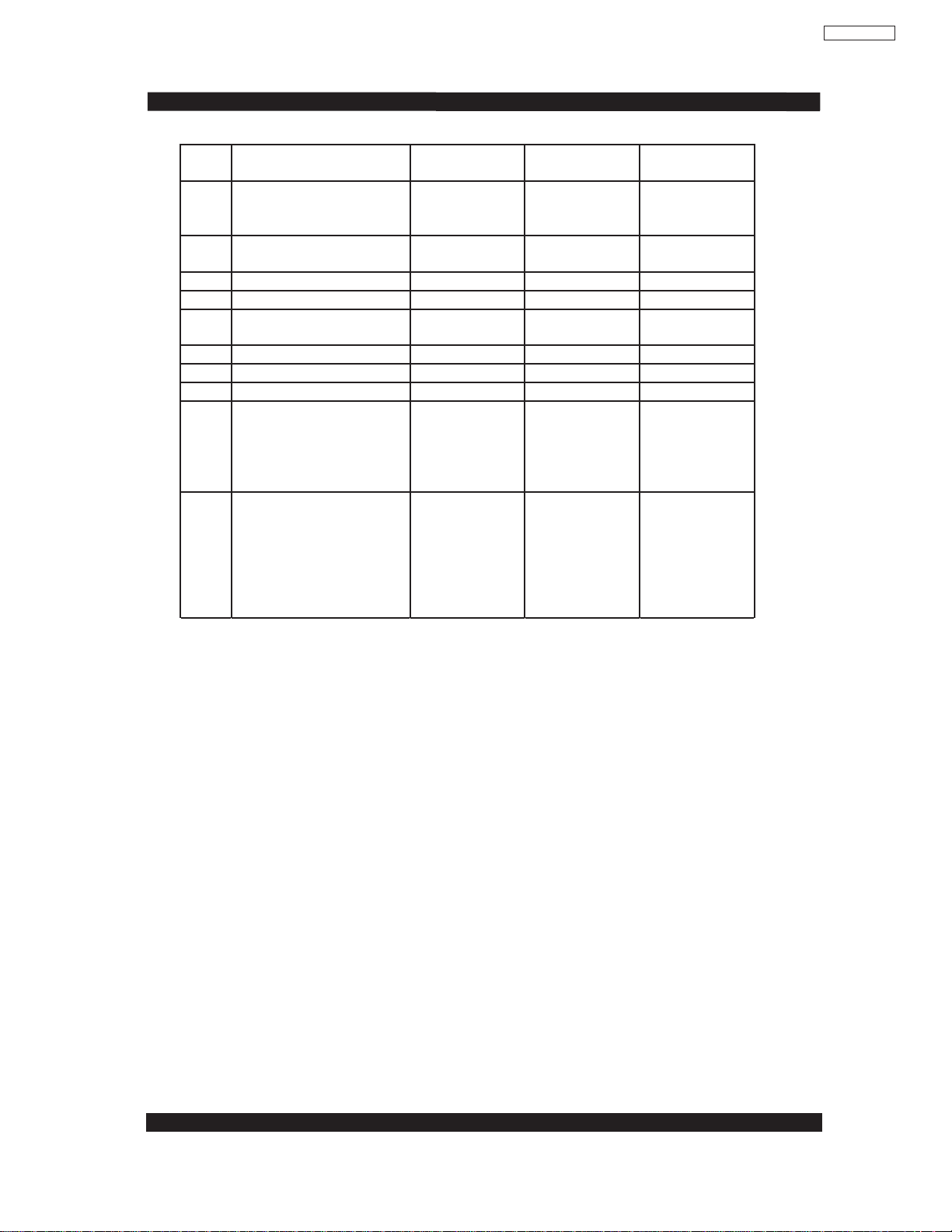

3.3.5 Combination Control Specification

(1) Active Terminal On/Off States

• If you send a Terminal On command when the OSD is active, the OSD will disappear

• The remote control keys will also be invalid except for the Power button on the front of the

unit.

• Closed Caption Display (CCD) function will be usable when in Terminal Mode

Table 3.3.5 (Variables of Activating Terminal On / Terminal Off

Terminal On

Command

Terminal Off

Command

Power On

Executable

Executable

Stand-By

Executable

Executable

Adjust Mode

Prohibited

Prohibited

When Auto-CH is operating

Prohibited

Prohibited

While Magic Focus is operating

(On Magic Menu Mode)

Prohibited

Prohibited

While upgrade is operating

Prohibited

Prohibited

When Lock is Set

When Lock is turned on (BLK/Mute)

Executable

Executable

When Sleep Timer is Active

Executable

Executable

When CableCARD is inserted

When CableCARD is in Stand-By

Executable

Executable

When the Event Timer / Timer

Record are set

Executable

Executable

When the Event Timer / Timer

Record are operating

Prohibited

Prohibited

When Auto Link is in Stand-By

Executable

Executable

When Day/Night Timer is set

Executable

Executable

When Quick Start Up Stand-By is

active

Executable

Executable

• If the Terminal Mode is turned on while the Sleep Timer is active and unit is powered off by

the controller, the time values in the Sleep Timer will be cleared.

• The Event Timer/ Timer Rec. will not operate when the unit is Terminal Mode On.

• If the Terminal Mode is activated when the Auto Link Setting is in Stand-By, The Auto Link

operation will be cancelled.

• The Urgent Broadcast Signal will take precedence when Terminal Mode is on with the

CableCARD installed.

• The Magic Timer function is disabled when Terminal Mode is On.

(2)Other Terminal Control Considerations

• Terminal Mode will remain On when you turn the power supply Off or On.

• If the TV is unplugged at the wall outlet, the Terminal Mode will turn Off.

• If the TV is turned off in normal mode and the Terminal On command is sent, the unit can be

turned on via RS232C.

• The commands executed in Terminal mode should be executed and displayed after exiting

Terminal Mode.

(3) Command Execution

1- The time delay between 1 byte characters in a command string is 99mS. Any delay

longer than 100mS will be cancelled and the unit will respond with a “NACK” (16H).

2- When transmitting command strings, an ACK or NAK should be sent by the TV. However,

this will not be the case when commands are re-executed or the command does not

execute.

3- The framing delay between continuos commands is 32mS.

4-When communicating with the unit in Terminal Mode, the unit must respond with either

an ACK or an NAK before sending it another command. Failure to do so will result in

commands that are not executed.

5- Please note that when the Power on command is sent to the unit, it will be necessary to

wait 12 seconds before sending any other command.

PW1A

17

Page 18

Plasma TV

4. Command String Development Information

4.1- To assist with developing command strings, the table below shows a Hex character

conversion chart

Table 4.1.1 Hex Character Conversion Chart

4.2 - An example of the proper coding technique is demonstrated below for the “Power On”

Command.

Hex Character Set: 6E: Power Function

00: Write Function (Note- A “01” would indicate a read function)

00: 3

rd

(Upper byte-Function)

00: 4

th

(Lower byte-Function)

00: 5

th

(Upper byte-Data)

01: 6

th

(Lower byte- Data

Hex Coded Data: 364530303030303030303031

Note- an STX (02-Hex) would be added at the start of the string and ETX (03-Hex) would be

added at the end of the string to create a complete command.

4.3- Figure 6 shows the 14 byte string formatted in Hex Characters for the “Power On Function”.

12345678910111213

14

Start

Stop

026E0000000001

Figure 6

4.4- Figure 7 shows the “Power On” function converted to Hex Code set

12345678910111213

14

Start

Stop

02364530303030303030303031

Hex Character

Hex Code

0

30

1

31

2

32

3

33

4

34

5

35

6

36

7

37

8

38

9

39

Hex Character

Hex Code

A

41

B

42

C

43

D

44

E

45

F

46

Function

(2 Byte)

Function

Read/Write

(2 Byte)

Upper Data

(2 Byte)

Lower Data

(2 Byte)

STX

(1 Byte)

ETX

Function

(2 Byte)

Function

(2 Byte)

Read/Write

(2 Byte)

Upper Data

(2 Byte)

Lower Data

(2 Byte)

STX

ETX

Function

(2 Byte)

Function

(2 Byte)

PW1A

18

Page 19

Plasma TV

4.5- The following table provides the conversion strings for the “Write” commands

Table 4.5.1 Write Data Command Summary

No.

Item

Command

Initial

Condition

Hex Character

Hex Code Set

Result

1

PowerOn0

6E0000000001

364530303030303030303031

Turns Power On

2

Power

Off

0

6E0000000000

364530303030303030303030

Turns Power Off

3

Input

Input 1

-

6F0000000000

364630303030303030303030

Input 1

4

Input

Input 2

-

6F0000000001

364630303030303030303031

Input 2

5

Input

Input 3

-

6F0000000002

364630303030303030303032

Input 3

6

Input

Input 4

-

6F0000000003

364630303030303030303033

Input 4

7

Input

Input 5

-

6F0000000004

364630303030303030303034

Input 5

8

Input

Antenna A

6F0000000006

364630303030303030303036

Antenna A

9

Input

Antenna B

-

6F0000000007

364630303030303030303037

Antenna B

10

Input

Photo

Input

-

6F0000000009

364630303030303030303039

Photo Input

11

Volume

Set to 0

20

270000000000

323730303030303030303030

Set to 0

12

Balance

Set to 31

30

280000000031

323830303030303030303331

Set to 31

13

Treble

Set to 16

15

2B0000000016

324230303030303030303136

Set to 16

14

Bass

Set to16

15

2A0000000016

324130303030303030303136

Set to 16

15

Audio Mute

Set to off

0

290000000000

323930303030303030303030

Set to Off

16

Audio Mute

Set to On

0

290000000001

323930303030303030303031

Set to On

17

Picture Mode

Set to Day

0

A40000000000

413430303030303030303030

Set to Day

18

Picture Mode

Set to Night

0

A40000000001

413430303030303030303031

Set to Night

19

Contrast

Set to 59

60

590000000059

353930303030303030303539

Set to 59

20

Brightness

Set to 29

30

1F0000000029

314630303030303030303239

Set to 29

21

Color

Set to 29

30

100000000029

313030303030303030303239

Set to 29

22

Tint

Set to 29

30

130000000029

313330303030303030303239

Set to 29

23

Sharpness

Set to 29

30

140000000029

313430303030303030303239

Set to 29

24

Color

Temperature

Set to

High

-

600000000000

363030303030303030303030

Set to

High

25

Color

Temperature

Set to

Medium

-

600000000001

363030303030303030303031

Set to

Medium

26

Color

Temperature

Set to

Standard

-

600000000002

363030303030303030303032

Set to

Standard

27

Color

Temperature

Set to

B&W

-

600000000003

363030303030303030303033

Set to

B&W

28

Aspect Ratio

Set to

16:9 Std.

-

400000000000

343030303030303030303030

Set to Standard

29

Aspect Ratio

Set 16:9

Zoom

-

400000000001

343030303030303030303031

Set 16:9 Zoom

30

Aspect Ratio

Set to 4:3

Standard

-

400000000002

343030303030303030303032

Set to 4:3

Standard

31

Aspect Ratio

Set to 4:3

Expanded

-

400000000003

343030303030303030303033

Set to 4:3

Expanded

32

Aspect Ratio

Set to 4:3

Zoom

-

400000000004

343030303030303030303034

Set to 4:3

Zoom

33

Aspect Ratio

Set to 4:3

Zoom 2

-

400000000005

343030303030303030303035

Set to 4:3

Zoom 2

Figure 7

PW1A

19

Page 20

Plasma TV

Table 4.5.1 Write Data Command Summary (Continued)

No.

Item

Command

Initial

Condition

Hex Character

Hex Code Set

Result

34

InfoOn0

B20000000001

423230303030303030303031

Turns Info On

35

Info

Off

0

B20000000000

423230303030303030303031

Turns Info Off

36

Direct CH

0~9

Key Code

to 0

-

D00000000000

443030303030303030303030

Key code to 0

37

Direct CH -

CH-

-

D00000010000

443030303030303130303030

CH-

38

Direct CH

Select

Select CH

-

D00000020000

443030303030303230303030

CH Select

39

Auto Movie

Mode

Auto

Movie Off

-

D40000000000

443430303030303030303030

Auto Movie Off

40

Auto Movie

Mode

Auto

Movie On

(Auto)

-

D40000000000

443430303030303030303031

Auto Movie On

(Auto)

(RGB Mode)

41

Contrast

Set to 59

60

590000000059

353930303030303030303539

Set to 59

42

Brightness

Set to 29

30

1F0000000029

314630303030303030303239

Set to 29

43

Color

Temperature

Set to

High

-

600000000000

363030303030303030303030

Set to

High

44

Color

Temperature

Set to

Medium

-

600000000001

363030303030303030303031

Set to

Medium

45

Color

Temperature

Set to

Standard

-

600000000002

363030303030303030303032

Set to

Standard

46

Color

Temperature

Set to

B&W

-

600000000003

363030303030303030303033

Set to

B&W

47

Aspect Ratio

Set to

16:9 Std.

-

400000000000

343030303030303030303030

Set to Standard

48

Aspect Ratio

Set to 4:3

Standard

-

400000000002

343030303030303030303032

Set to 4:3

Standard

49

Aspect Ratio

Set to

Real

-

400000000006

343030303030303030303036

Set to Real

PW1A

20

Page 21

PRECAUTIONS

● How to clean the plasma screen panel of the monitor

Before cleaning the monitor, turn off the monitor and disconnect the power plug from the power outlet.

To prevent scratching or damaging the plasma screen face, do not knock or rub the surface with sharp or

hard objects. Clean the screen with a soft cloth moistened with warm water and dry with a soft cloth. If it is

not enough, then use a cloth with mild detergent. Do not use harsh or abrasive cleaners.

● How to clean the cabinet of the monitor

Use a soft cloth to clean the cabinet and control panel of the monitor. When excessively soiled dilute a neutral detergent in water, wet and wring out the soft cloth and afterward wipe with a dry soft cloth.

Never use acid/alkaline detergent, alcoholic detergent, abrasive cleaner, powder soap, OA cleaner, car wax,

glass cleaner, etc. especially because they would cause discoloration, scratches or cracks.

1. Features

● Large-screen, high-definition plasma display panel

The 42-inch color plasma display panel, with a resolution of 852 (H) x 480(V) pixels, creates a high-definition,

large-screen (aspect ratio : 16:9) and low-profile flat display. Free from electromagnetic interferences from

geomagnetic sources and ambient power lines, the panel produces medium-quality display images free from

color misconvergence and corner focus distortion.

● High Performance Digital Processor

A wide range of personal computer signals can be handled, from 640 x 400, 640 x 480 VGA to 1600 x 1200 UXGA.

(RGB Analog input)

● Easy-to-use remote control and on screen display system (OSD)

The remote control included eases the work of setting display controls. Further, the on-screen display (OSD)

displays the input status control settings in an easy-to-view fashion.

● Power saving system

The International ENERGY STAR power saver feature saves power consumption automatically when

input signals are not available.

When connected to a VESA DPMS-compliant PC, the monitor cuts its power consumption while it is idle.

● TruBass

TruBass, SRS and () symbol are trademarks of SRS Labs,Inc.

TruBass technology is incorporated under license from SRS Labs, Inc.

[AV MONITOR model] CMP420V1A, CMP420V2A

● One mini D-sub terminal and one DVI-D terminal for RGB input.

(The D-sub terminal can also receive component RGB - selectable via customer OSD.)

(One of the component inputs has the capability to select RGB via customer OSD.)

● One composite/S-video input terminal and two component video input terminals, added with VIDEO board.

(It operates as composite/S-video input and RGB input and RGB input terminal, or composite video output terminal.)

● One SCART terminal for EUROPEAN, added with VIDEO board.

● One composite video output terminal as a monitoring output, added with VIDEO board.

● Simple type remote (CP-RD4).

[TELEVISION model] 42EDT41A

● Various input/output terminals added with VIDEO board. (same features as above mentioned AV MONITOR)

● Tuner input added with VIDEO board

● Complex type remote (CLU-W900)

PW1A

21

Page 22

2. Specifications

Panel

Display

dimensions

Approx. 42 inches (920 (H) x 518 (V) mm, diagonal 1059mm)

Resolution

852 (H) x 480 (V) pixels

Net dimensions

(excluding Speakers/Stand)

1030 (W) x 636 (H) x 91 (D) mm

Net weight

(excluding Speakers/Stand)

CMP420V1A/V2A:33.2kg 42EDT41A:34.2kg

Ambient

conditions

Temperature

Relative humidity

Operating : 20% to 80%, Storage : 20% to 90% (non-condensing)

Power supply

AC100 - 240V, 50/60Hz

Power consumption/at standby

310W / <3W

Audio output

(RGB input)

Input signals

Input terminals

RGB1 DVI input terminal (DVI-D)

RGB1 audio input terminal (3.5mm Stereo Mini Jack)

RGB2 analog RGB input terminal (D-sub 15-pin)

RGB2 audio input terminal (3.5mm Stereo Mini Jack)

Video signals

0.7 V/1.0 Vp-p, analog RGB (Recommended Signal)

480i, 576i, 480p, 576p, 1080i/50, 1080i/60, 720p/60

Sync signals

H/V separate, TTL level [2K ]

H/V composite, TTL level [2K ]

Sync on green, 0.3 Vp-p [75 ]

(Video input)

(RF input)

Input signals

Input signals

Input terminals

Input terminals

RF Video System

AV1: composite video input terminal (RCA)

AV1: Y PB PR video input terminal (RCA)

AV1: L/R audio input terminal (RCA)

AV2: composite video input terminal (RCA)

AV2: Y/G PB/B PR/R video input terminal (RCA)

AV2: L/R audio input terminal (RCA)

AV3: composite video input terminal (RCA)

AV3: S video input terminal (RCA)

AV3: L/R audio input terminal (RCA)

AV4: composite video / S video / RGB / L/R audio input terminal (Scart)

Video signals

AV1: NTSC-M, PAL-M, PAL-N

AV1: 480i, 576i, 480p, 576p, 1080i/50, 1080i/60, 720p/60

AV2: NTSC-M, PAL-M, PAL-N

AV2: 480i, 576i, 480p, 576p, 1080i/50, 1080i/60, 720p/60, RGB

AV3: NTSC-M, PAL-M, PAL-N

AV4: NTSC-M, PAL-M, PAL-N

NTSC-M

AV4: RGB

Video output Signal

OUTPUT (MONITOR): composite video monitor-output terminal (RCA)

OUTPUT (MONITOR): L/R audio monitor- output terminal (RCA)

AV4: composite video / L/R audio monitor-output terminal (SCART)

Operating : 5 to 35, Storage : -15 to 60

12W + 12W (6 )

ANT : 75 unbalanced

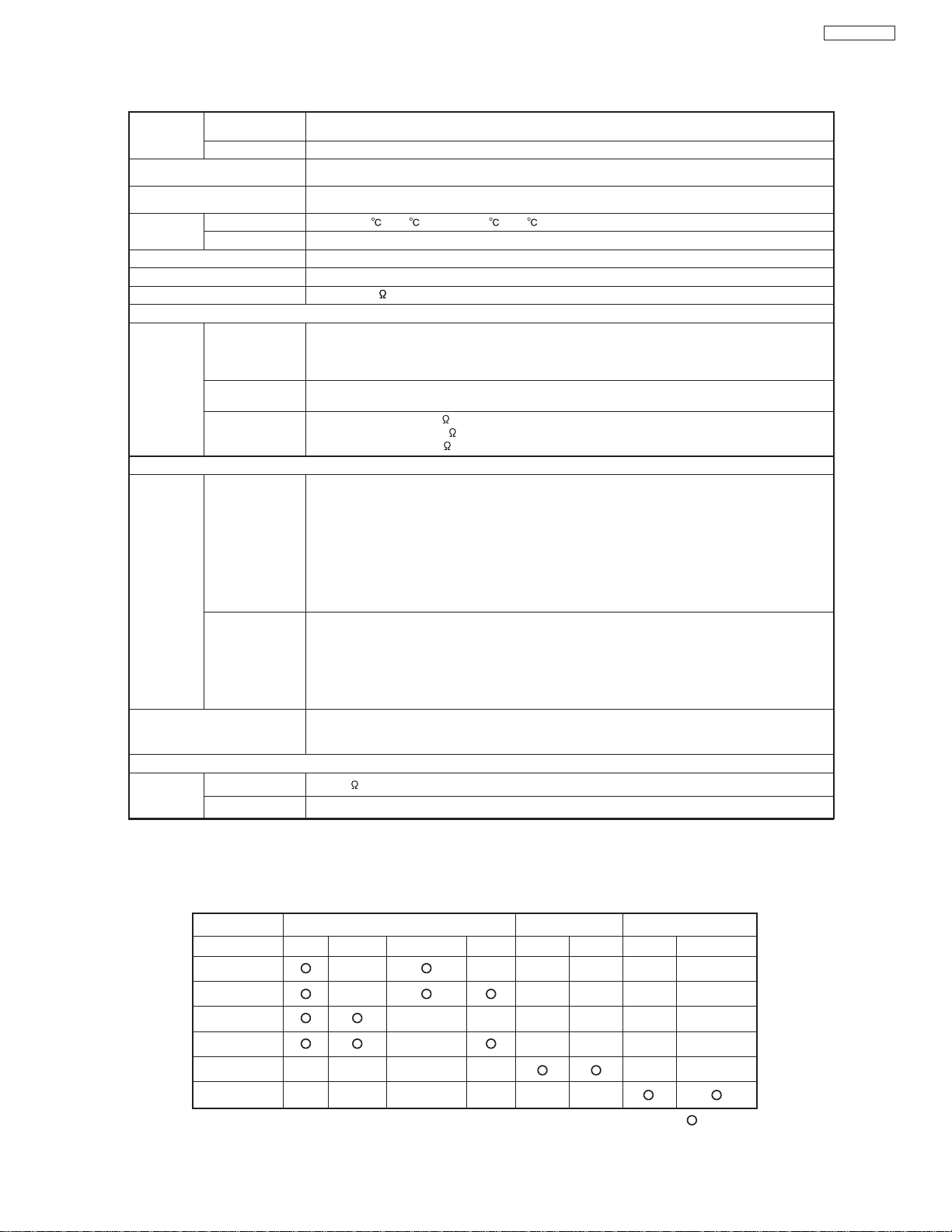

Applicable video signals for each input terminal

Terminal RCA/SCART DVI D-sub

Signal CVBS S-video Component RGB PC STB RGB Component

AV1

AV2

AV3

AV4

RGB1

RGB2

( :Available)

PW1A

22

Page 23

S-input connector pin specifications

Pin Input signal

1 Y

2 Y-GND

3 C

4 C-GND

Frame GND

20 18 16 14 12 10 8 6 4 2

21

19 17

15 13 11 975

31

Scart connector pin specifications

Pin Signal Pin Signal

1

AUDIO OUT (RIGHT)

12

Not Used

2

AUDIO IN (RIGHT)

13

RGB-R GND

3

AUDIO OUT (LEFT/MONO)

14

GND

4

AUDIO GND

15

RGB-R / S.VHS CHROMINANCE IN

5

RGB-B GND

16

BLANKING SIGNAL

6

AUDIO IN (LEFT/MONO)

17

COMPOSITE VIDEO GND

7

RGB-B IN

18

BLANKING SIGNAL GND

8

AUDIO/RGB SWITCH / 16:9

19

COMPOSITE VIDEO OUT

9

RGB-G GND

20

COMPOSITE VIDEO / S.VHS LUMINANCE IN

10

Not Used

21

GND / SHIELD (CHASSIS)

11

RGB-G IN

RGB terminal (D-sub 15-pin connector)

• When different kinds of input signals are simultaneously input to

the monitor via a graphics board or the like, the monitor will

automatically select the signals in the following priority order:

*Even in the case of the recommended signals shown on the

following page, there may be instances when correct display is

not possible. In this case, use H/V separate sync, H/V composite

sync.

Sync signal type Priority

H/V separate sync. 1

H/V composite sync. 2

sync.on Green * 3

Pin

Input signal

1 R (PR/CR)

2 G or sync on green (Y)

3 B (PB/CB)

4 No connection

5 No connection

6 R.GND (PR/CR, GND)

7 G.GND (Y, GND)

8 B.GND (PB/CB, GND)

9 No connection

10 GND

11 No connection

12 [SDA]

13 H. sync or H/V composite sync

14 V.sync. [V.CLK]

15 [SCL]

( ) : With component input

12345678

9 10 11 12 13 14 15 16

17 18 19 20 21 22 23 24

DVI terminal (DVI-D)

Signal Input

Pin Input signal Pin Input signal

1

T.M.D.S. Data2-

14

+5V Power

2

T.M.D.S. Data2+

15

Ground (for+5V)

3

T.M.D.S. Data2/4 Shield

16

Hot Plug Detect

4

T.M.D.S. Data4-

17

T.M.D.S. Data0-

5

T.M.D.S. Data4+

18

T.M.D.S. Data0+

6

DDC Clock

19

T.M.D.S. Data0/5 Shield

7

DDC Data

20

T.M.D.S. Data5-

8

No Connect

21

T.M.D.S. Data5+

9

T.M.D.S. Data1-

22

T.M.D.S. Clock Shield

10

T.M.D.S. Data1+

23

T.M.D.S. Clock+

11

T.M.D.S. Data1/3 Shield

24

T.M.D.S. Clock-

12

T.M.D.S. Data3-

Frame GND

13

T.M.D.S. Data3+

PW1A

23

Page 24

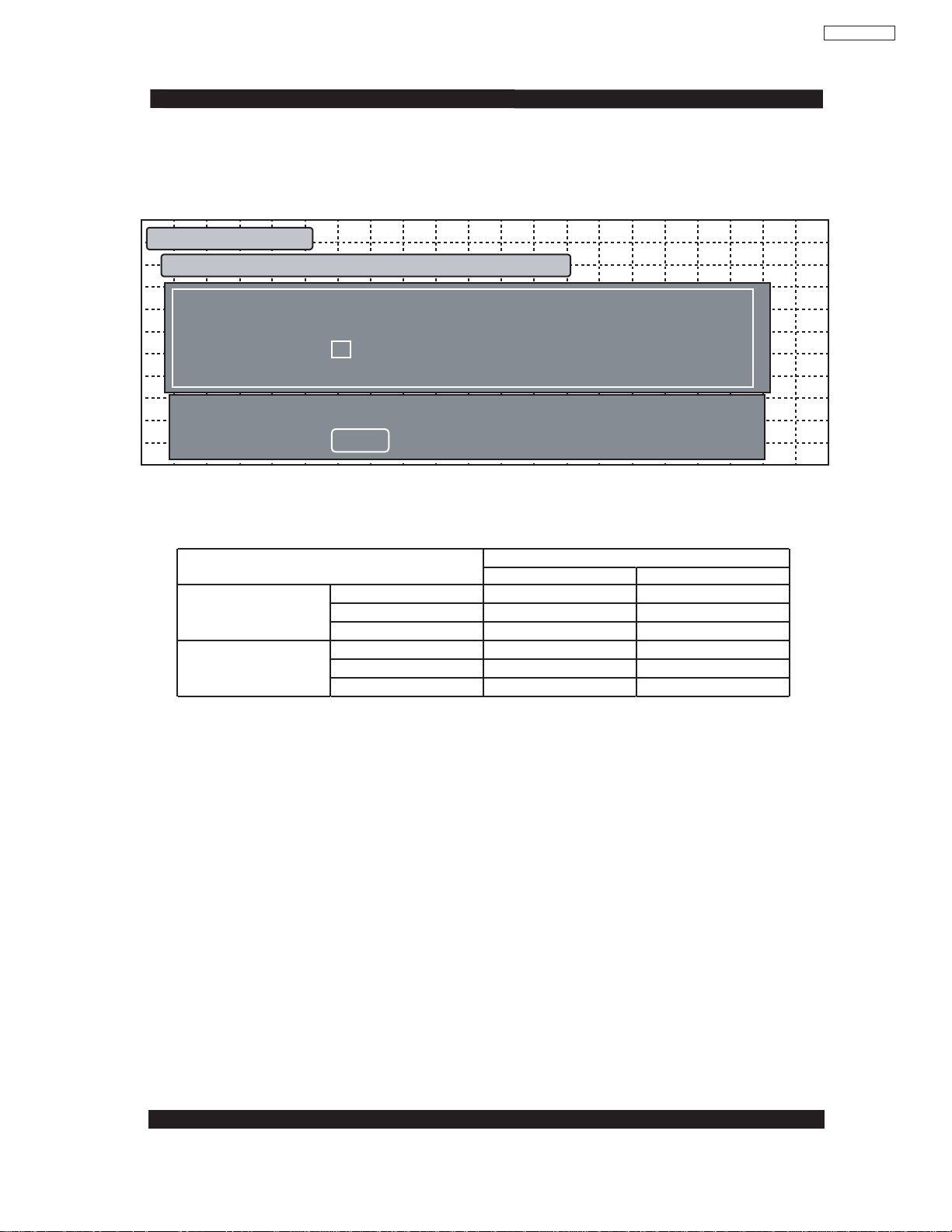

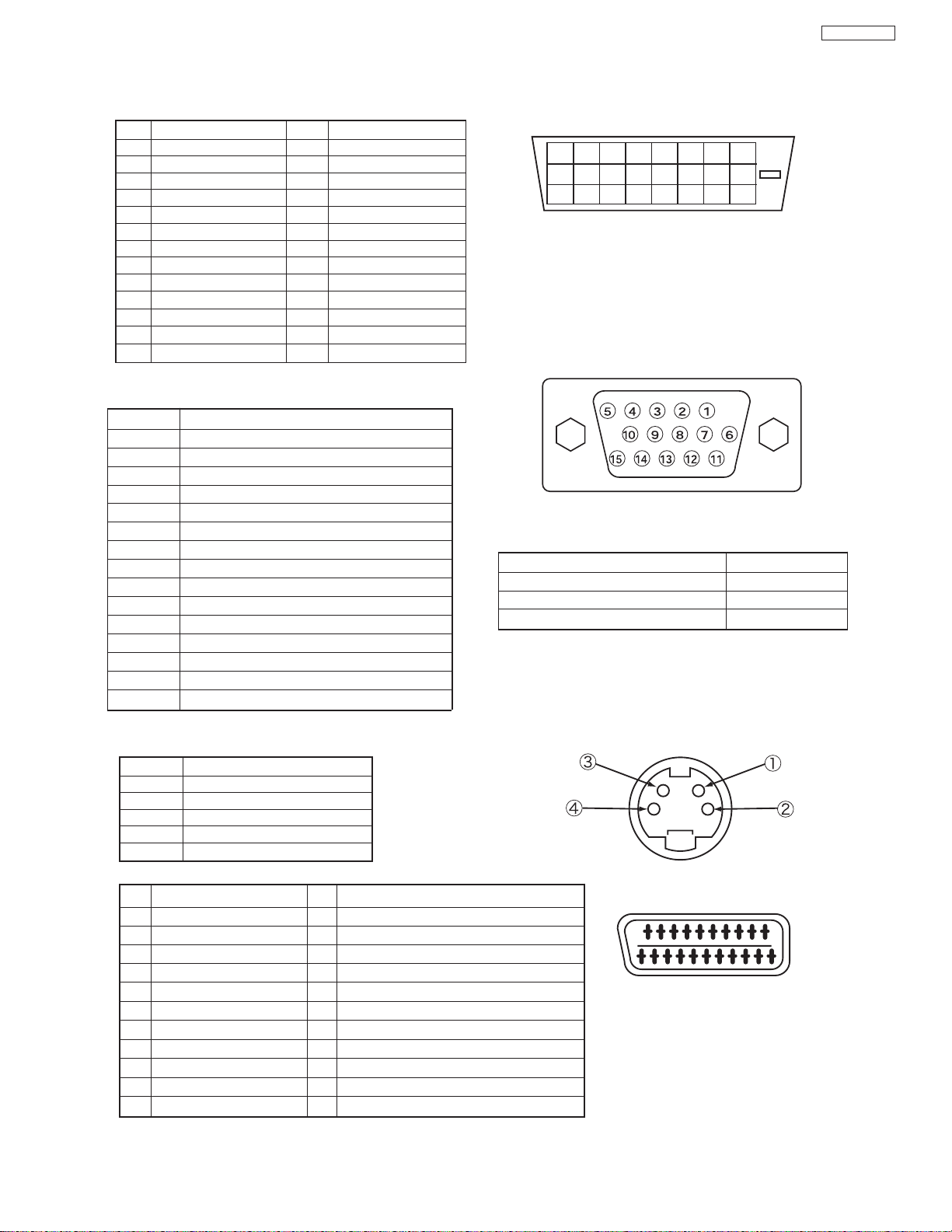

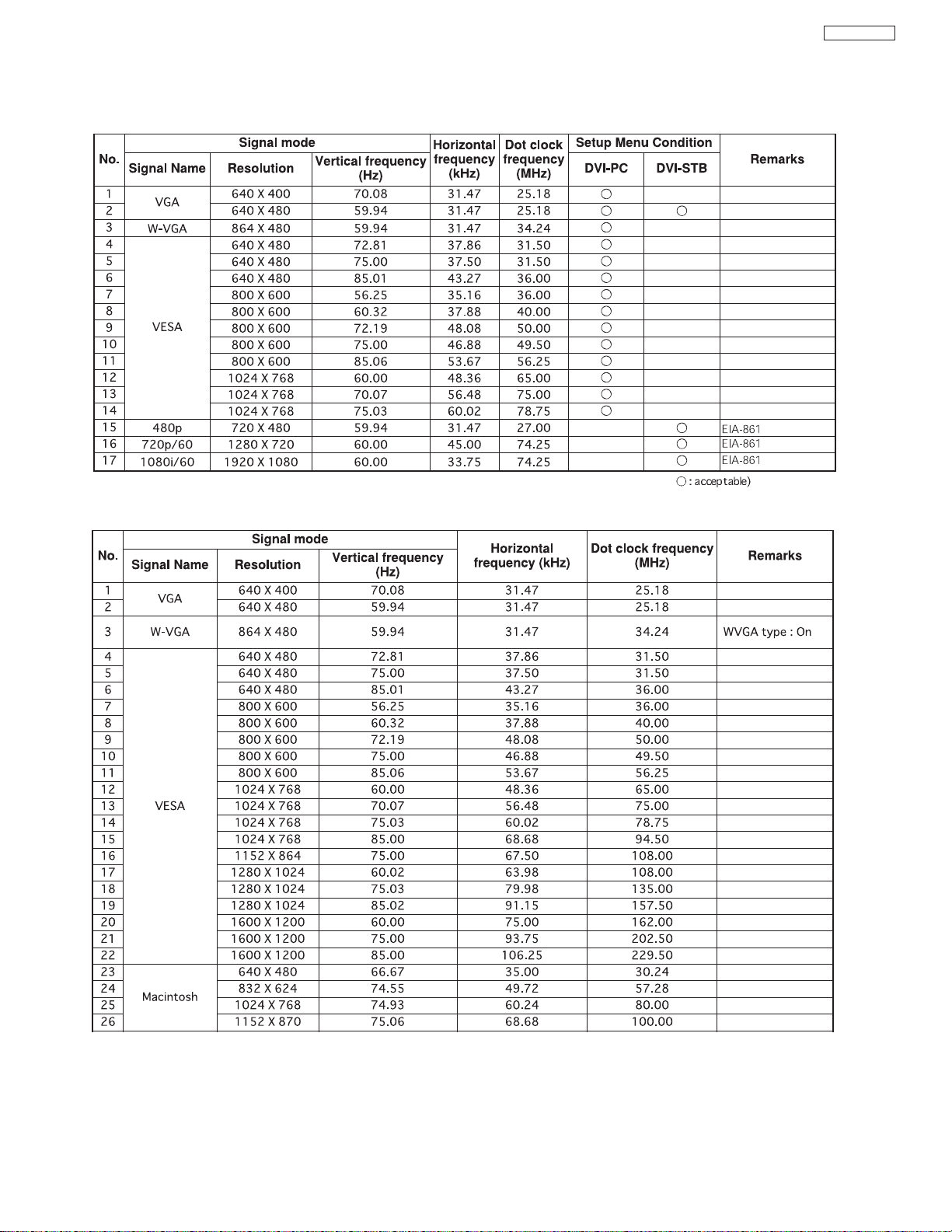

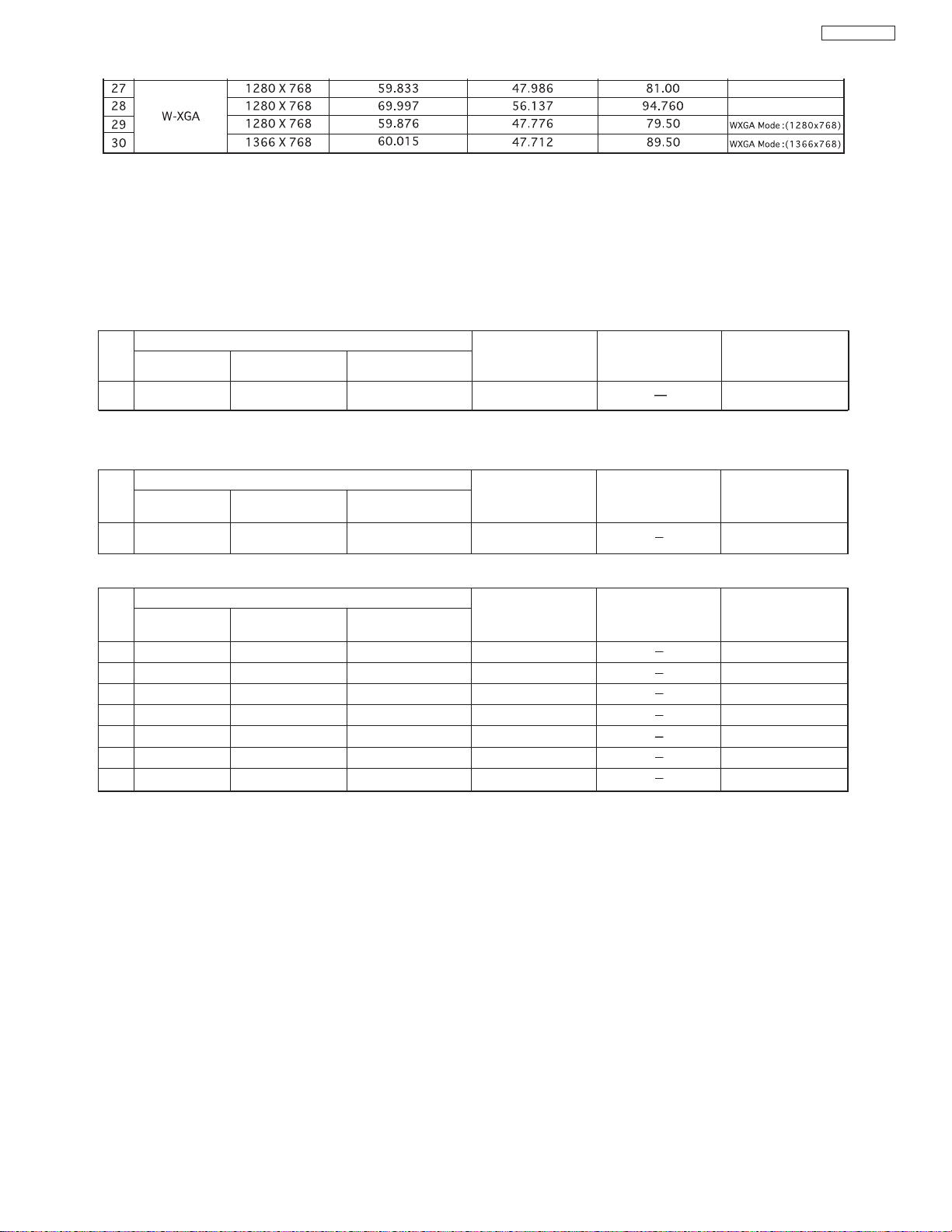

Recommended Signal List

With Digital RGB signal input (RGB1 input)

(

With Analog RGB signal input (RGB2 input)

• Make sure that the signal of the equipment to be connected is compatible with the pecifications of this list.

PW1A

24

Page 25

PW1A

• The type of video board or connecting cable used may not allow for correct displays adjustment of Horizontal Position, Vertical Position, Horizontal

Clock and Clock Phase.

• The monitor may fail to display an animation image correctly when a signal having a vertical frequency of 85Hz or higher is input to it.

• The monitor differentiates the signal modes according to the horizontal and vertical frequencies and the horizontal and vertical sync signal

polarities. Note that different signals having all these elements alike may be handled as the same signal.

• Displaying images with more than 480 lines of vertical resolution at Full diplay (compressed display) can result in the interpolation of stripes.

No.

Signal mode

Horizontal

frequency (kHz)

Dot clock

frequency (MHz)

Remarks

Signal Name Resolution

Vertical frequency

(Hz)

1

NTSC-M

525 59.94 15.73

With Composite Input(AV1~AV4 input) and S-video Input (AV3 and AV4 input).

No.

Signal mode

Horizontal

frequency (kHz)

Dot clock

frequency (MHz)

Remarks

Signal Name Resolution

Vertical frequency

(Hz)

1

(NTSC-M)

525 59.94 15.73

With R, G, B Video input (AV2 and AV4 input).

No.

Signal mode

Horizontal

frequency (kHz)

Dot clock

frequency (MHz)

Remarks

Signal Name Resolution

Vertical frequency

(Hz)

1 576i 576 50.00 15.63

2 480i 480 59.94 15.73

3 576p 576 50.00 31.26

4 480p 480 59.94 31.47

5 1080i/50 1080 50.00 28.13

6 1080i/60 1080 60.00 33.75

7 720p/60 720 59.94 44.96

With component input (AV1, AV2 and RGB2-component input).

• The monitor differentiates the signal modes according to the horizontal and vertical frequencies and the horizontal and vertical sync signal

polarities. Note that different signals having all these elements alike may be handled as the same signal.

• Displaying images with more than 480 lines of vertical resolution at Full diplay (compressed display) can result in the interpolation of stripes.

25

Page 26

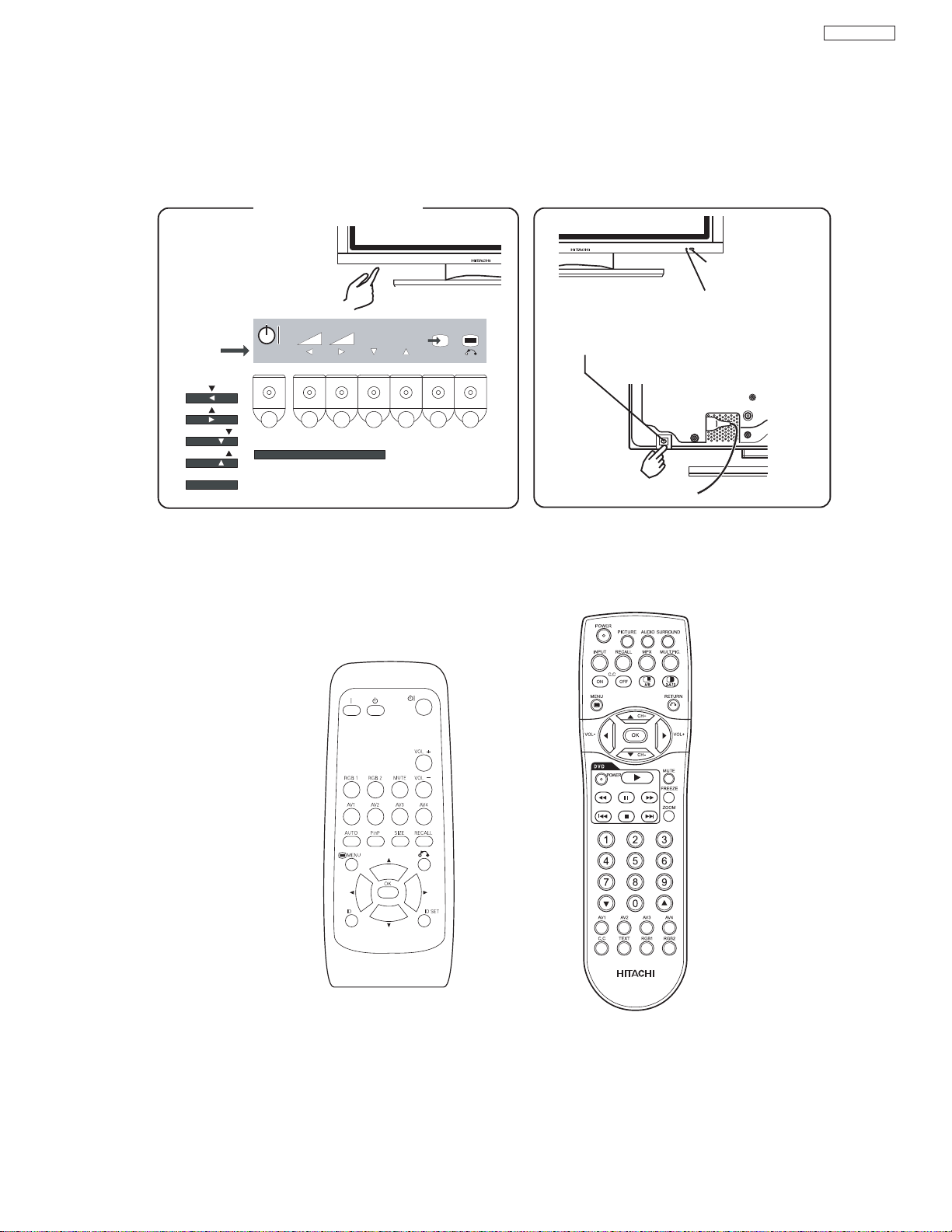

3. Component names

Remote-control

receiver

• Adjustment buttons are located

on the bottom.

• The back cover is provided with

indications to distinguish the

adjustment buttons.

Control panel

Main power switch

• The main power switch is located at the back, on the

lower surface.

Indicating lamp

for

42EDT41A

[Remote control]

[Main unit]

for

CMP420V1A

CMP420V2A

NOTE:

1st number indicates normal button operation

2nd number indicates function during MENU

Rear Label

7654321

- +

OK

2. VOL

2. ADJ

1. SUB POWER

3. VOL

3. ADJ

4. PROGRAM

4. SELECT

5. PROGRAM

5. SELECT

6. INPUT SELECT

6. OK

7. MENU

PW1A

26

Page 27

4. Service points

Lead free solder

This product uses lead free solder (unleaded) to help preserve the environment. Please read these

instructions before attempting any soldering work.

Caution: Always wear safety glasses to prevent fumes or molten solder from getting into the eyes. Lead

free solder can splatter at high temperatures (600˚C).

Lead free solder indicator

Printed circuit boards using lead free solder are engraved with an "F."

Properties of lead free solder

The melting point of lead free solder is 40-50˚C higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended.

Although servicing with leaded solder is possible, there are a few precautions that have to be taken. (Not

taking these precautions may cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the

lead free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450˚C)

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320˚C±30˚C

Mounting (chips) on empty PCB 380˚C±30˚C

Chassis, metallic shield, etc. 420˚C±30˚C

(1) FILTER PWB, SW PWB, LED/RECEIVER PWB, TACT SW PWB, SP TERMINAL(L/R) PWB

(2) AUDIO PWB, JOINT PWB

(3) VIDEO PWB

(4) FORMATTER PWB

(5) POWER BOARD

The PWB assembly which has used lead free solder

PW1A

27

Page 28

CMP420V1 / CMP420V2 / 42EDT41 (PW1A)

5. SERVICE MODE ACCESS

BURN-IN MODE

BURN-IN MODE

When the Burn-in feature is turned ON, the plasma panel operates normally on all inputs that

have a signal. On inputs that do not have a signal, the plasma panel displays a cycling single

color test pattern (see below) which is generated internally. This can be helpful to determine

if the panel is capable of displaying anything.

NOTE:

1st number indicates normal button operation

2nd number indicates function during MENU

Rear Label

7654321

- +

OK

2. VOL

2. ADJ

1. SUB POWER

3. VOL

3. ADJ

4. PROGRAM

4. SELECT

5. PROGRAM

5. SELECT

6. INPUT SELECT

6. OK

7. MENU

1 2 6

BURN-IN MODE (ON)

With unit in standby mode

(turned off), press and hold: >

After the unit comes on, continue to hold the

buttons down until the initial OSD goes

away. OSD will then appear indicating that

BURN-IN MODE is engaged.

(OSD > Burn In On)

1 2

BURN-IN MODE (OFF)

With unit in standby mode

(turned off), press and hold: >

After the unit comes on, continue to hold the

buttons down until the initial OSD goes

away. OSD will then appear indicating that

BURN-IN MODE is disengaged.

(OSD > Burn In Off)

White Yellow Cyan Green Magenta Red Blue Black

7

PW1A

28

Page 29

CMP420V1 / CMP420V2 / 42EDT41 (PW1A)

DEMO MODE

When the DEMO feature is turned ON, both the remote and the plasma panel front panel

buttons (with the exception of the SUB POWER button) are non-operational. This can be

useful for the Sales / Dealers to prevent anyone from playing with any of the settings.

NOTE: This is the front panel shortcut to parameter #175 in the I2C ADJUSTMENT MODE.

NOTE:

1st number indicates normal button operation

2nd number indicates function during MENU

Rear Label

7654321

- +

OK

2. VOL

2. ADJ

1. SUB POWER

3. VOL

3. ADJ

4. PROGRAM

4. SELECT

5. PROGRAM

5. SELECT

6. INPUT SELECT

6. OK

7. MENU

DEMO MODE (OFF)

With unit in standby mode

(turned off), press and hold: >

After the unit comes on, continue to hold

the buttons down until the initial OSD goes

away. DEMO MODE is now disengaged,

although you will not see any OSD confirmation.

1 3

DEMO MODE (ON)

With unit in standby mode

(turned off), press and hold: >

After the unit comes on, continue to hold the

buttons down until the initial OSD goes

away. DEMO MODE is now engaged, although you will not see any OSD confirmation.

1 3 6

SERVICE MODE ACCESS

DEMO MODE

PW1A

29

Page 30

CMP420V1 / CMP420V2 / 42EDT41 (PW1A)

I2C ADJUSTMENT MODE

When the set is in the I2C Adjustment mode, use the cursor buttons

for selecting the

adjustment parameter, and for changing the parameterʼs value. Use the OK button to

confirm. After adjustments are complete, press the MENU button to return the set to normal

operating condition.

NOTE:

1st number indicates normal button operation

2nd number indicates function during MENU

Rear Label

7654321

- +

OK

2. VOL

2. ADJ

1. SUB POWER

3. VOL

3. ADJ

4. PROGRAM

4. SELECT

5. PROGRAM

5. SELECT

6. INPUT SELECT

6. OK

7. MENU

I2C Adjustment Mode

With unit in standby mode

(turned off), press and hold: >

After the unit comes on, continue to hold the

buttons down until the initial OSD goes

away. OSD will then appear indicating that

I2C ADJUSTMENT MODE is engaged.

1 4 6

MEMORY INITIALIZATION