Hitachi 32LD7800TA Schematic

YK

No.015E

32LD7800TA

SERVICE MANUAL

Caution

Be sure to read this manual before servicing. To assure safety from fi re, electric shock, injury, harmful radiation and materials, various measures are provided in this HITACHI LCD display.

Be sure to read cautionary items described in the manual to maintain safety before servicing.

Service Warning

1. Since Panel Module is made of glass, handling the broken Module shall be taken care suffi ciently in order

not to be injured.

2. Replacing work shall be started after the Panel Module and the AC/DC Power supply become suffi ciently

cool.

3. Special care shall be taken to the display area in order not to damage its surface.

4. The Panel Module shall not be touched with bare hand to protect its surface from stains.

5. It is recommended to use clean soft gloves during the replacing work in order to protect not only the display area of the Panel Module but also a serviceman himself.

6. The Chip Tube of Panel Module (located upper left of the back and surrounded by frame) and fl exible

cables connecting Panel glasses to drive circuit PWBs are very weak, so shall be taken care suffi ciently

not to break. If you break Chip Tube, the Panel doesn’t display anything forever.

(PW2L)

Contents

1. Features --------------------------------------------------3

2. Specifi cations --------------------------------------------4

3. Service points ------------------------------------------- 5

4. Component names -------------------------------------6

5. New adoption technology -----------------------------7

6. Adjustment --------------------------------------------- 11

7. Troubleshooting --------------------------------------- 38

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

8. Seif-Diagnosis Function ----------------------------- 47

9. Block diagram ----------------------------------------- 48

10. Disassembly diagram -------------------------------- 50

11. Replacement parts list ------------------------------- 54

12. Connection diagram --------------------------------- 55

13. Wiring diagram ---------------------------------------- 56

LCD Display

November 2004 Digital Media Division

32LD7800TA (PW2L)

CAUTION FOR SAFETY

Please read this page before repair the monitor.

This page explains to following items for keep the safety of set and prevent to accident during

repair work.

We explain by symbol at happen the damage or injury when took wrong repair.

Warning

Caution

We made the symbol as below, which are kind of following items.

This symbol means "CAUTION"

This symbol means "POSSIBLE to

ELECTRIC SHOCK"

This symbol means "possible to die or heavy damage"

This symbol means "possible to damage or something will break"

This symbol means "MUST"

This symbol means "DO NOT"

WARNING

Should be follows to instructions.

We indicates to cabinet, chassis and parts

by label, which are special attention part.

Please follow to note and [Safety Instructions]

of User’s Manual.

Prevent the electric shock.

Please take care during working because

monitor has high voltage part and power

supply part.

Possible to die if you tough to these place

by miss take.

Please disconnect power plug during

overhaul, reassemble or change parts.

You will die or take damage by electric

shock if you touch to live part.

Use recommended components.

Please use to same characteristic compo-

nent, which is same as previous for your

safety and keep reliability especially marked

by in parts list and circuit diagram.

It is reason of electric shock or fire if you

use non-recommended component.

Should be kept same style of wiring or component.

Monitor uses tubes or tapes, which made

by insulator, and some components are

keep distance from surface of PWB for

safety.

Internal leads kept from hot part or high voltage

part by clamper or styling, so please return to

original condition for prevent to electric shock

or fire.

Should be done safety check after finished.

Every part (removed screws, component

and wiring) should be returned to previous

condition.

Check around repair position for make

damage by miss take and measure the

insulated impedance by meg-ohm meter.

Confirm the value of impedance, that

value is more than 4M ohm.

It is reason for electric shock or fire if that

value is less than 4M ohm.

Nobody can check and repair to the code

and combination circuit of HDCP.

Never remove the shield case, which is

assembled to the code and combination

circuit of HDCP.

2

32LD7800TA (PW2L)

PRECAUTIONS

How to clean the LCD screen panel of the monitor

Before cleaning the monitor, turn off the monitor and disconnect the power plug from the power outlet.

To prevent scratching or damaging the LCD screen face, do not knock or rub the surface with sharp or hard

objects. Clean the screen with a soft cloth moistened with warm water and dry with a soft cloth. If it is not

enough, then use a cloth with mild detergent. Do not use harsh or abrasive cleaners.

How to clean the cabinet of the monitor

Use a soft cloth to clean the cabinet and control panel of the monitor. When excessively soiled dilute a neutral

detergent in water, wet and wring out the soft cloth and afterward wipe with a dry soft cloth.

Never use acid/alkaline detergent, alcoholic detergent, abrasive cleaner, powder soap, OA cleaner, car wax,

glass cleaner, etc. especially because they would cause discoloration, scratches or cracks.

1. Features

Large-screen, high-definition LCD display panel

The 32-inch LCD display panel, with a resolution of 1366 (H) x 768 (V) pixels, creates a high-definition, largescreen(aspect ratio : 16:9) and low-profile flat display. Free from electromagnetic interferences from geomagnetic

sources and ambient power lines, the panel produces high-quality display images free from color misconvergence

and display distortion.

High Performance Digital Processor

A wide range of input signals can be handed,including composite, component,and HDMI.High Definition Digital Processor creates the fine-textured image with dynamic contrast. In addition, it corresponds to a broad array of personal computer signals, from 640 x 400 and 640 x 480 VGA to 1600 x 1200 UXGA.(Analog Input)

Easy-to-use remote control and on screen display system

The remote control included eases the work of setting display controls. Further, the on-screen display system,

displays the status of signal reception and display control settings in an easy-to-view fashion.

Power saving system

The International ENERGY STAR power saver feature saves power consumption automatically when input signals are not available.

When connected to a VESA DPMS-compliant PC, the monitor cuts its power consumption while it is idle.

Connecting to an Audio Visual Device

1

• Two composite/S terminal*

been added. A composite video output terminal is also provided as a monitoring output.

*1

A composite/S terminal = A side input

*2

Two composite terminal and two component terminal are used at the same time, the component terminal

would govern.

• A wide range of devices other than personal computers can also be connected.

• A RGB input is possible to switch to component signal from the Menu screen.

Power Swivel Feature

It allows to turn the LCD display left or right within ± 30 degree using the remote control.

,three composite terminal*2, two component terminal*2, a HDMI terminal have

3

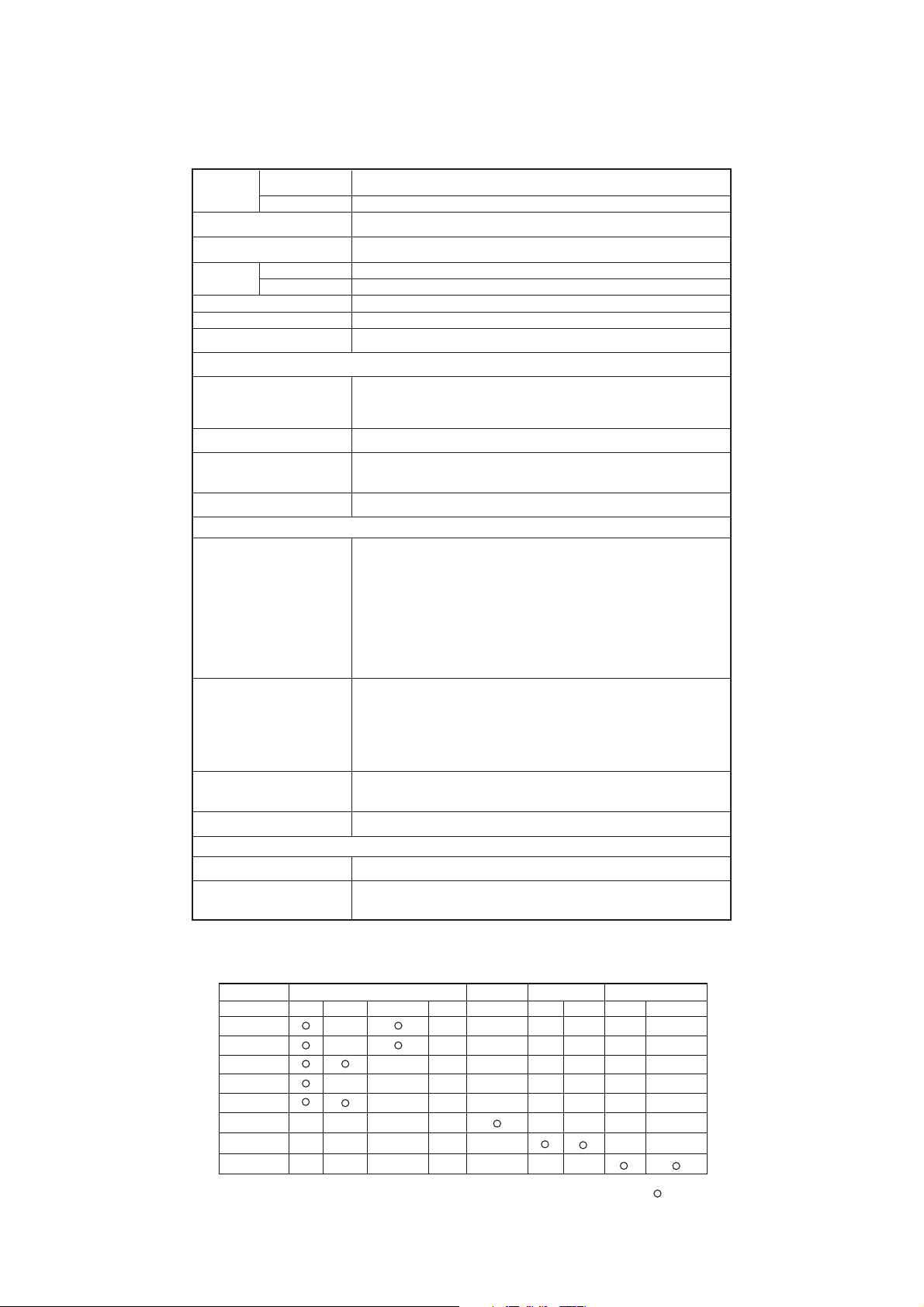

2. Specifications

Panel

Net dimensions

Net weight

Ambient

conditions

Power supply

Power consumption/at standby

Audio output

(RGB input)

Input terminals

Input signals

Sync signals

Recommended signal

(Video input)

Input terminals

Input signals

Output Signal

Recommended signal

(RF input)

Input terminals

RF Video System

Display

dimensions

Resolution

Temperature

Relative humidity

32LD7800TA (PW2L)

Approx. 32 inches (698 (H) x 392 (V) mm,

1366 (H) x 768 (V) pixels

1015 (W) x 618 (H) x 340 (D) mm

25kg

Operating : 5˚C to 35˚C, Storage : 0˚C to 40˚C

Operating : 20% to 80%, Storage : 20% to 90% (non-condensing)

AC100 - 240V, 50/60Hz

158W / <1W ; <2W(When DVI)

speaker 12W + 12W (6Ω)

RGB1 DVI input terminal (DVI-D)

RGB1 audio input terminal (3.5mm Stereo Mini Jack)

RGB2 analog RGB input terminal (D-sub 15-pin)

RGB2 audio input terminal (3.5mm Stereo Mini Jack)

0.7 V/1.0 Vp-p, analog RGB (Recommended Signal)

480i, 576i, 480p, 576p, 1080i/50, 1080i/60, 720p/60

H/V separate, TTL level [2KΩ]

H/V composite, TTL level [2KΩ]

Sync on green, 0.3 Vp-p [75 Ω]

44 modes

AV1: composite video input terminal (RCA)

B/ PR video input terminal (RCA)

AV1: Y/ P

AV1: L/R audio input terminal (RCA)

AV2: composite video input terminal (RCA)

B

/ PR video input terminal (RCA)

AV2: Y/ P

AV2: L/R audio input terminal (RCA)

AV3: composite video input terminal (RCA)

AV3: S video input terminal

AV3: L/R audio input terminal (RCA)

AV4: composite video / L/R audio input terminal (RCA)

AV5 = AV3

AV6: HDMI input terminal

AV1: PAL, SECAM, NTSC3.58, NTSC4.43

AV1: 480i, 576i, 480p, 576p, 1080i/50, 1080i/60, 720p/60

AV2: PAL, SECAM, NTSC4.43, NTSC3.58

AV2: 480i, 576i, 480p, 576p, 1080i/50, 1080i/60, 720p/60

AV3: PAL, SECAM, NTSC4.43, NTSC3.58,

AV4: PAL, SECAM, NTSC4.43, NTSC3.58,

AV5 = AV3

AV6: HDMI input signal

OUTPUT (MONITOR): composite video monitor-output terminal (RCA)

OUTPUT (MONITOR): L/R audio monitor- output terminal (RCA)

OUTPUT (HEADPHONE): L/R audio monitor- output terminal (

23 modes

ANT : 75Ω Unbalanced

PAL B, G, H / I / D, K

SECAM B, G / D, K / K1

NTSC-M

diagonal 800mm)

3.5mm Stereo Mini Jack)

Applicable video signals for each input terminal

Terminal RCA DVI D-sub

Signal CVBS S-video Component RGB PC STB RGB Component

AV1

AV2

AV3

AV4

AV5

AV6

RGB1

RGB2

HDMI

4

( :Available)

32LD7800TA (PW2L)

3. Service points

Lead free solder

This product uses lead free solder (unleaded) to help preserve the environment. Please read these instructions

before attempting any soldering work.

Caution: Always wear safety glasses to prevent fumes or molten solder from getting into the eyes. Lead free

solder can splatter at high temperatures (600˚C).

Lead free solder indicator

Printed circuit boards using lead free solder are engraved with an "F."

Properties of lead free solder

The melting point of lead free solder is 40-50˚C higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended.

Although servicing with leaded solder is possible, there are a few precautions that have to be taken. (Not taking

these precautions may cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the lead

free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450˚C)

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320˚C±30˚C

Mounting (chips) on empty PCB 380˚C±30˚C

Chassis, metallic shield, etc. 420˚C±30˚C

The PWB assembly which has used lead free solder

SW PWB, LED/RECEIVER PWB, SP TERMINAL(L/R) PWB, SUB POWER PWB,

MAIN POWER PWB

AUDIO PWB, JOINT PWB, Swievel PWB, HDMI PWB, control PWB

VIDEO PWB

TUNER PWB

5

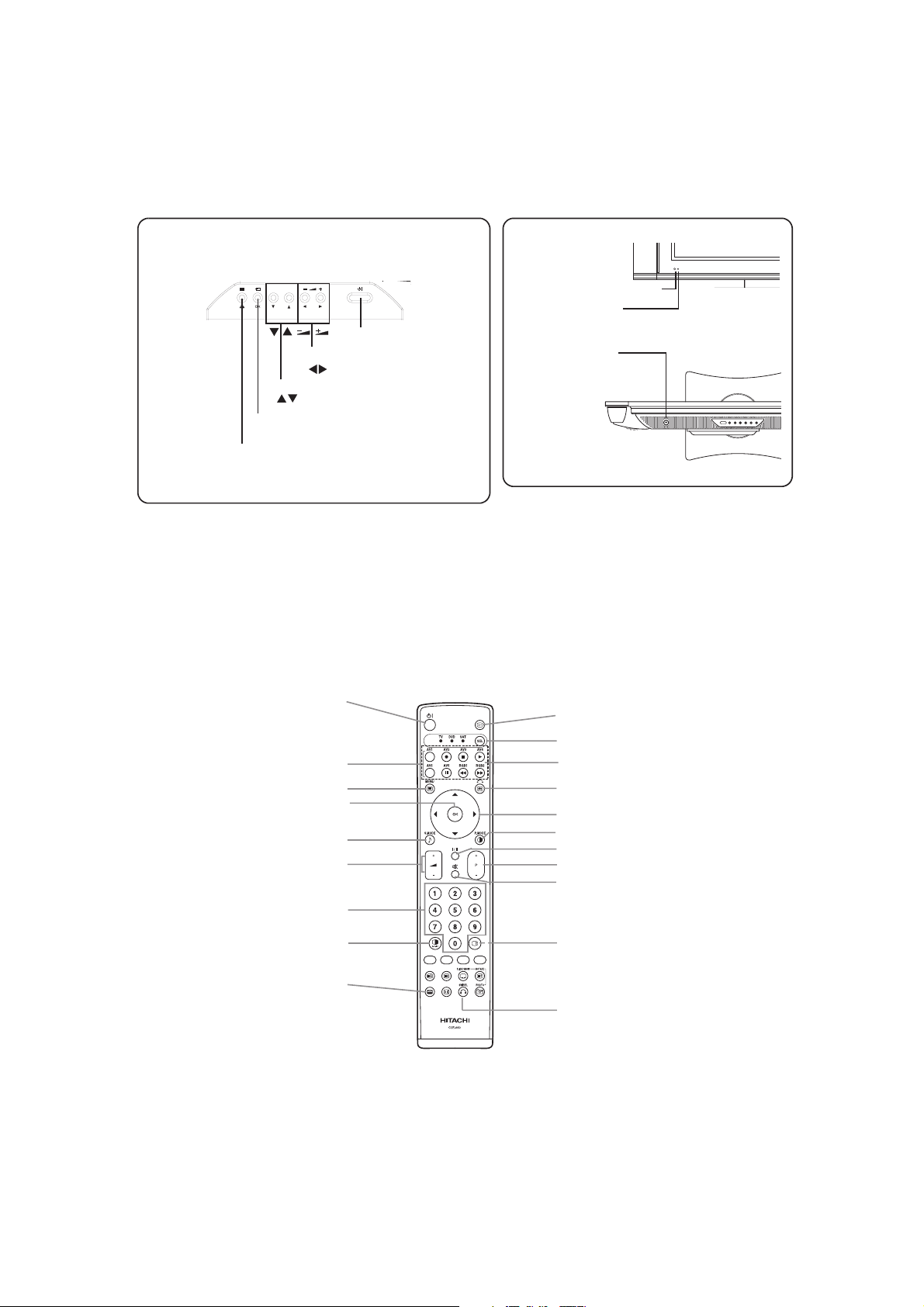

4. Component names

[Main unit]

Control panel

• Adjustment buttons are located

on the top.

32LD7800TA (PW2L)

Remote-control receiver

Indicating lamp

MENU button

• ( ) indicates the function while the MENU is displayed on the screen.

[Remote control]

VOLUME UP/DOWN button

VOLUME UP/DOWN buttons

(

ADJUST buttons)

CHANNEL UP/DOWN buttons

( SELECT buttons)

INPUT SELECT button

(OK button)

POWER button

INPUT SELECT buttons

MENU button

OK button

SOUND MODE button

SUB-POWER button

• The main power switch is located on the top.

Main power switch

RECALL button

FUNCTION SELECT button

DVD CONTROL buttons

FREEZE/RETURN button

SELECT/ADJUST button

PICTURE MODE button

CH I/CH II button (TV)

CHANNEL UP/DOWN button (TV)

MUTE button

Front

Rear

PROGRAM SELECT buttons

(TV)

MULTI MODE button

T/TEXT button

(TV)

MULTI PICTURE button

SWIVEL button

CLE-960

6

32LD7800TA (PW2L)

5. New adoption technology

[System control micom I001(M3062)]

Pin function table

No. PIN name I/O

1

2

3

4

5

6

7

8 DATA_OUT(FC)

9 DATA_IN(FC)

10 CLK(FC)

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

VREF (+5.0V) I

+5.0V I

NC I/O

OSD_DATA I/O

OSD_CLK I/O

HP_VOL

FE.AGC_O(M) I/O

EDID_PROTECT I/O

TRAP_MAIN I/O

GND I

CNVSS(FLASH) I

DSUB COMP I/O

RGBSW I/O

RESET I

16MHz oscillation O

GND I

16MHz oscillation I

+5.0V I

NMI(+5.0V) I

RMCON(AVC) I/O

V.FREQ_2(VIDEO) I/O

V.FREQ_1/

SCV.SYN

IRQ䋨PM-IRQ) I/O

MCV.SYNC I/O

POWER_LED I/O

H.FREQ_2(VIDEO) I/O

PDP_WVGA_LCD_SW_2 I/O

H.FREQ_1/_3 I/O

TXD1(RS232C/FLASH) I/O

RXD1(RS232C/FLASH) I/O

SCLK(FLASH) I/O

BUSY(FLASH) I/O

TXD0(PDP) I/O

RXD0(PDP) I/O

SDA4(panel) I/O

SCL4(panel) I/O

M_ENABLE I/O

M_WAKEUP I/O

PDPGO(PM_ON) I/O

3 I/O

C I/O

PDWN

RXD2 I/O

TXD2 I/O

M_SCLK I/O

M_SDA I/O

I/O

I/O

I/O

I/O

I/O

5V

FUNCTION

5V

NC

OSD DATA

OSD CLK

Head Phone Volume

AGC Voltage(F/E)

FC DATA

FC DATA

FC CLOCK

Memory Protect

TRAP-MAIN

GND

CNVSS(FLASH)

SYNC-SW

SYNC-SW

RESET

OSC-OUT

GND

OSC-IN

5V

5V PULL UP

IR Signal

TA1370(LA7213), COMPONENT2

TA1370(LA7213), COMPONENT(Main)/ DSUB COMPONENT

CVBS for SYNC Detection(Sub Picture)

PANEL MODULE Condition(L:Normal,H:Error)

CVBS for SYNC Detection(Main Picture)

L䋺LED ON(Power Save)

TA1370(LA7213), COMPONENT2

PDP/42WVGA/LCD detection

TA1370(LA7213), COMPONENT1(Main), D-SUB

RESERVE(LVDS Power Down mode(PANEL))

DTT

DTT

DATA(RS-232C)

5V

I

DATA(RS-232C)

GND

I

CLOCK(FRASH MEMORY Writing)

BUSY(FRASH MEMORY Writing)

Ether Net

Ether Net

2

I

C-BUS Contorol DATA

2

C-BUS Contorol CLOCK

I

Media Enable

Media Clock

Media Data

Media Wakeup

PDP PALEL Contorol

7

32LD7800TA (PW2L)

No. PIN name I/O FUNCTION

CPUGO(PM_CPU) I/O

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

EPM (FLASH) I/O

VIDEO.DET_1 I/O

1 I/O

SCL

SDA1 I/O

HDMI-RESET I/O

HDMI-HPD_RESET I/O

VIDEO.DET_2 I/O

VIDEO.DET_3 I/O

TUNER.DET_1 I/O

CE (FLASH) I/O

STAND.CIR_DET I/O

SW_L_OUT I/O

SW_R_OUT I/O

M_SW I/O

INITIALIZE I/O

D.RESET(DARST) I/O

DVI-PD I/O

SCDT I/O

HS-DJTR I/O

DVI-SW I/O

CUR_PRTCT I/O

SPRLY I/O

MUTE I/O

ASEL1 I/O AUDIO Signal SW

ASEL2 I/O AUDIO Signal SW

SDA2 I/O

SCL2 I/O

D-SUB COMP_SYNC.S

BM_SW I/O

RGB_BLK_2 I/O NC

RGB_BLK_3 I/O NC

AUD RST I/O

PDP_WVGA_LCD_SW_1 I/O

+5.0V I

RGB1_DET I/O NC

GND I

1I/ONC

WSS_

WSS_2 I/O NC

WSS_3 I/O NC

TV.AFC(S) I/O AFC Voltage(Sub TUNER)

TV.AFC(M) I/O

FE_AGC_I(M) I/O AGC Voltage(Main TUNER)

FE_AGC_I(S) I/O

HP_DETECT I/O

HDMI_DET I/O

INT_HDMI I/O

NC I/O NC

COMP_SW I/O

DEMP_OUT I/O

W I/O

PDP PALEL Contorol

FRASH MEMORY Writing

Detecting VIDEO PWB

I2C䋨to PWB TUNER side䋩 FE/MSP3455or MSP3415G/SAA5361/TB1274(Sub)/M306V7/M62320P

I2C䋨to PWB TUNER side䋩 FE/MSP3455or MSP3415G/SAA5361/TB1274(Sub)/M306V7/M62320P

HDMI-Reset

Hot Plug Detect Reset

Detecting VIDEO PWB

Detecting VIDEO PWB

Detecting TUNER PWB

FRASH MEMORY Writing

Detecting SWIVEL PWB

SWIVEL(L-output)

SWIVEL(R-output)

Discriminate terminal of bridge media circuit connecting.

Initializing EEPROM

RESET(DVI)

DVI Contorol

DVI Contorol

DVI Contorol

DVI Contorol

Detecting Power-SWIVEL

SP ON/OFF Relay Control

MUTE

I2C(NJW1163,AD7414,TA1370)

I2C(NJW1163,AD7414,TA1370)

SYNC-SW

BM switch

RESET for LIPSYNC IC

PDP/42WVGA/LCD detection

GND

AFC Voltage(Main TUNER)

AFC Voltage(Sub TUNER)

HEAD PHONE DETECT

HDMI 5V DET

INT(HDMI)

Component SW Main

de-emphasis control output for HDMI

㹤 DSUB

8

32LD7800TA (PW2L)

No. PIN name I/O FUNCTION

101

102

103

104

105

106

107

108

109

110

111

CONTROL I/O

SCL0 I/O

SDA0 I/O

SCL3(EEPROM) I/O

SDA3(EEPROM) I/O

HDMI_CIR_DE

T I/O

EXT_RESET I/O

OSD_CS I/O

FC_ENABLE I/O

NC I/O

NC I/O

112 IRQ_DTT

113 DTT_POWER

114 DISPEN

115

116

117

HDMI_A_SW I/O

SCL5 I/O

SDA5 I/O

118 FUNC_1

119 FUNC_2

12

0NC

121

122

123

124

125

126

127

128

AD_KEY3 I/O

AD_KEY2 I/O

AD_KEY1 I/O

TV.POWER I/O

DIP.DET I/O

POWER_SAVE I/O

GND I

FAN_ALARM

LCD PANEL

2

I

C-BUS Contorol CLOCK

2

I

C-BUS Contorol DATA

I2C-BUS Contorol CLOCK

I2C-BUS Contorol DATA

Detecting HDMI circuit connection

EXTERNAL RESET

OSD CS

FC ENABLE

NC

NC

I/O

DTT IRQ

I/O

DTT POWER

DISPEN

I/O

HDMI AUDIO SW

2

C-BUS Contorol CLOCK

I

2

I

C-BUS Contorol DATA

Function 1

I/O

Function 2

I/O

I/O NC

AD KEY3

AD KEY2

AD KEY1(INPUT)

POWRE ON/OFF(H:ON䇮L:STANDBY)

DIP DET

POWER ON/OFF(L䋺ON(STANDBY䍃POWER SAVE), H䋺OFF)

GND

I/O

FAN ALARM

9

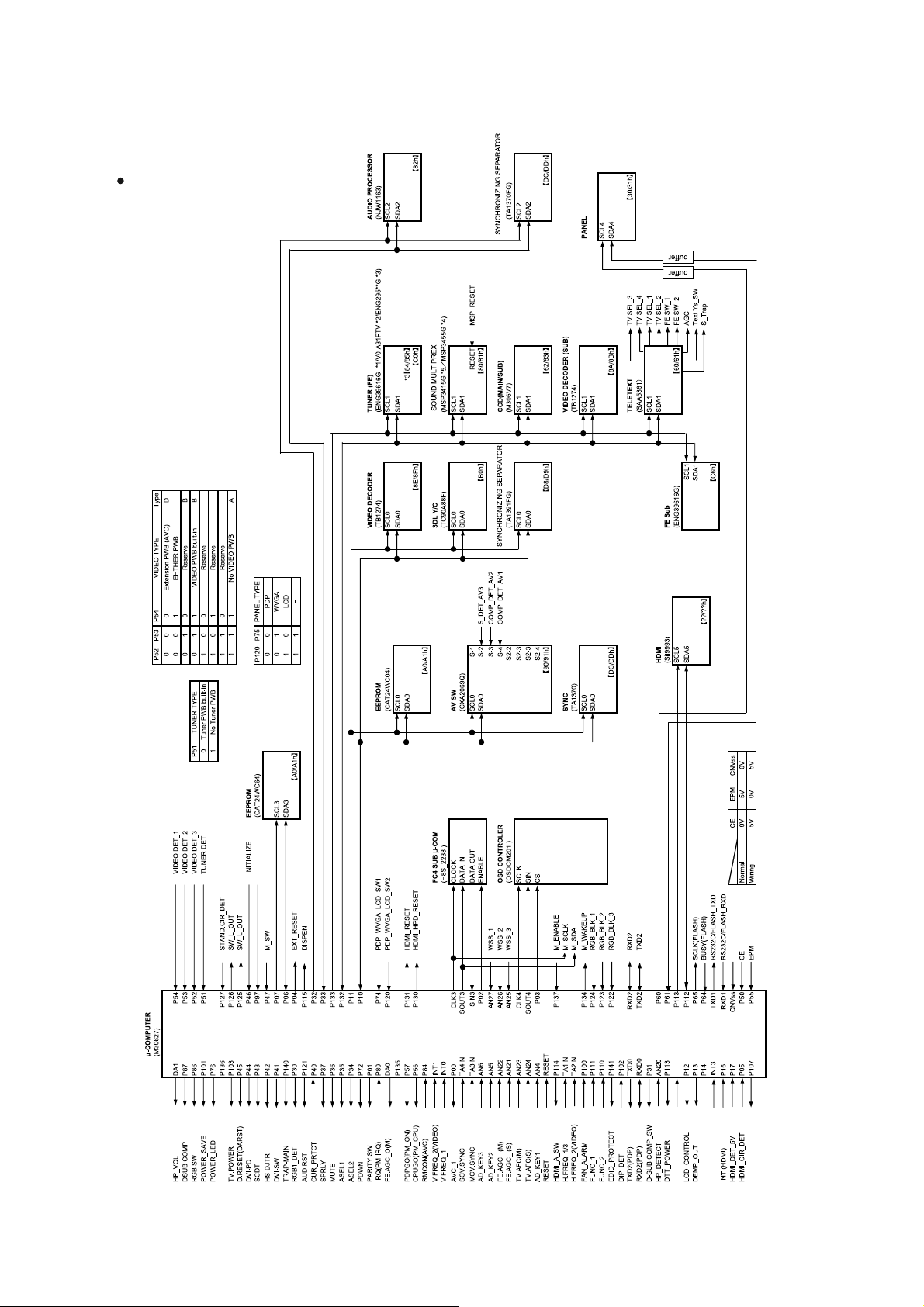

Block diagram

32LD7800TA (PW2L)

10

32LD7800TA (PW2L)

6. Adjustment

● How to get to Adjustment mode

Using the center of the upper control buttons with the set turned off (standby) can activate it.

Press the SUB-POWER(

more than 5 seconds.

The set turns on in adjustment mode with OSD.

● Changing data and Selecting Adjustment code

When the set is in adjustment mode, the cursor , , , and OK buttons of the remote control or the control

buttons may be used as the adjustment keys.

, buttons are used for selecting adjustment code.

, buttons are used for changing data values.

OK button is used for confirming the data.

After finishing the necessary adjustment press MENU button. Adjustment mode is released and the set returns to

normal condition.

● Memory Initialize operation

NOTE: The execution of this function returns the adjustment codes to the preset values, therefore, adjustment

data will be lost.

Procedure

(1) Enter Adjustment Mode.

(2) Select MEMORY INIT adjustment code (No.658) and change the data value from 0 to 1.

(3) Activate MEMORY INIT by pressing OK button for more than 3 seconds.

(4) Select No.525 and change data value from 1 to 0.

(5) Check that the receiving channel goes to P1. Unit is set to preset values.

) button, INPUT SELECT( ) button and button at the same time, and hold for

11

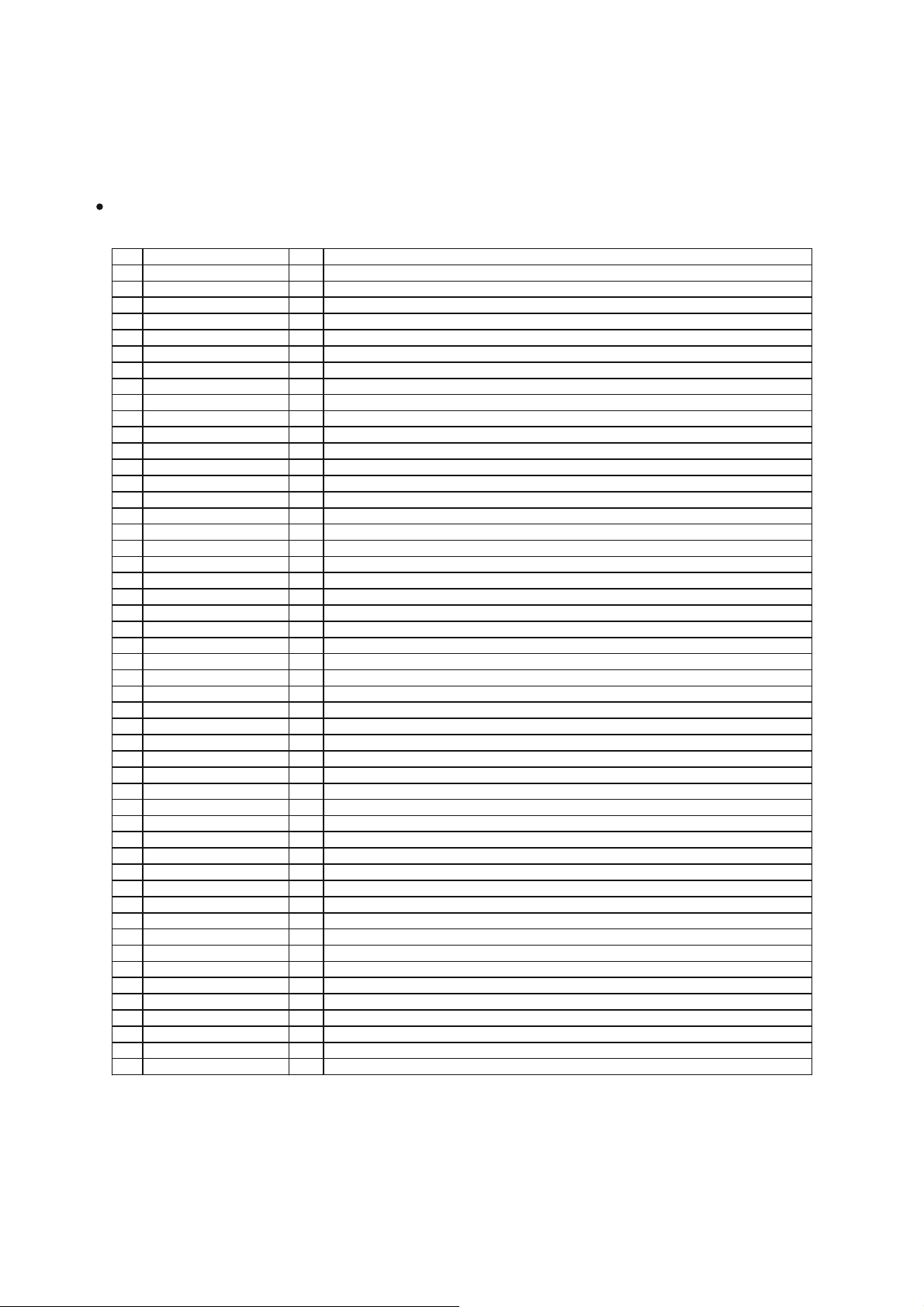

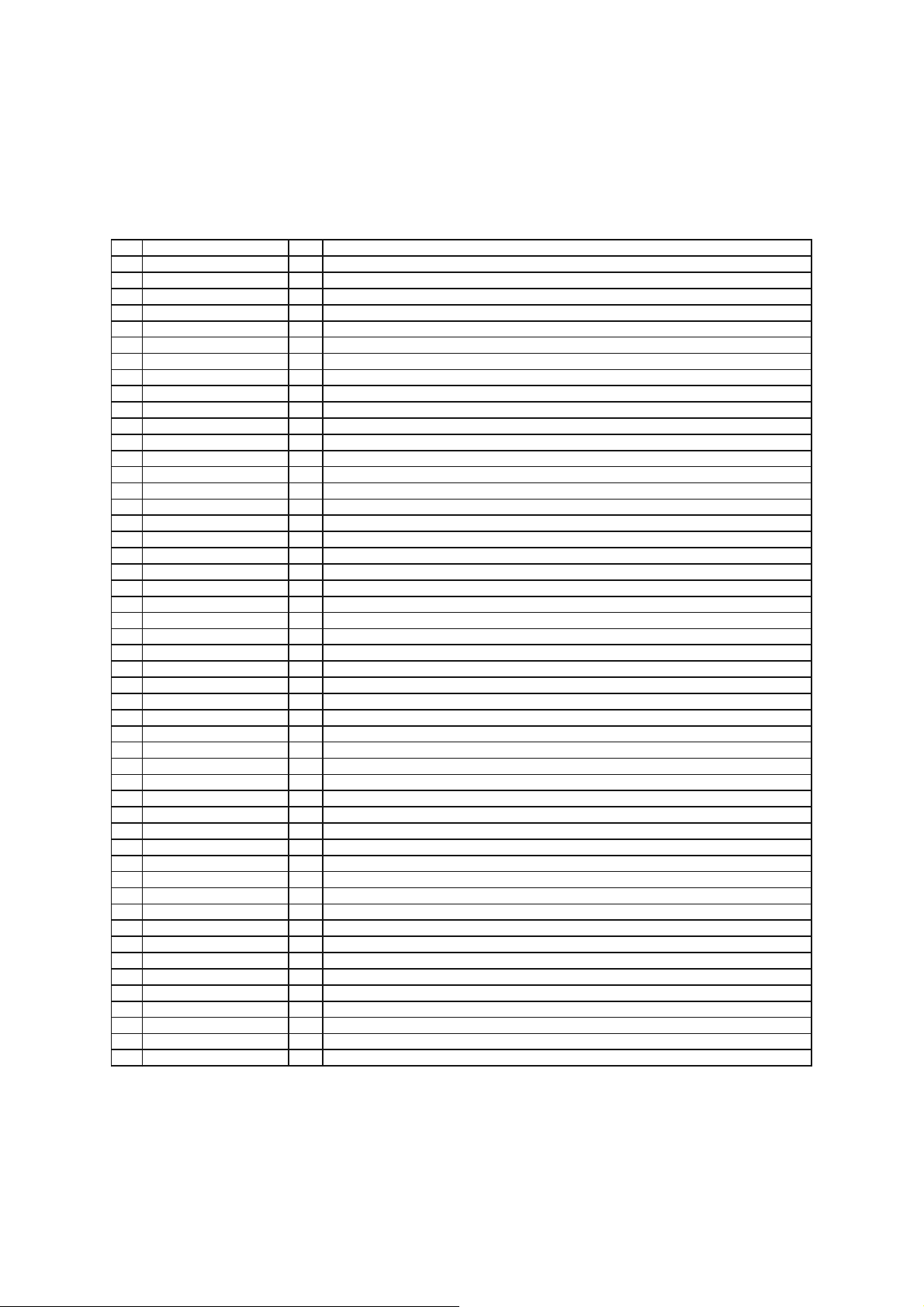

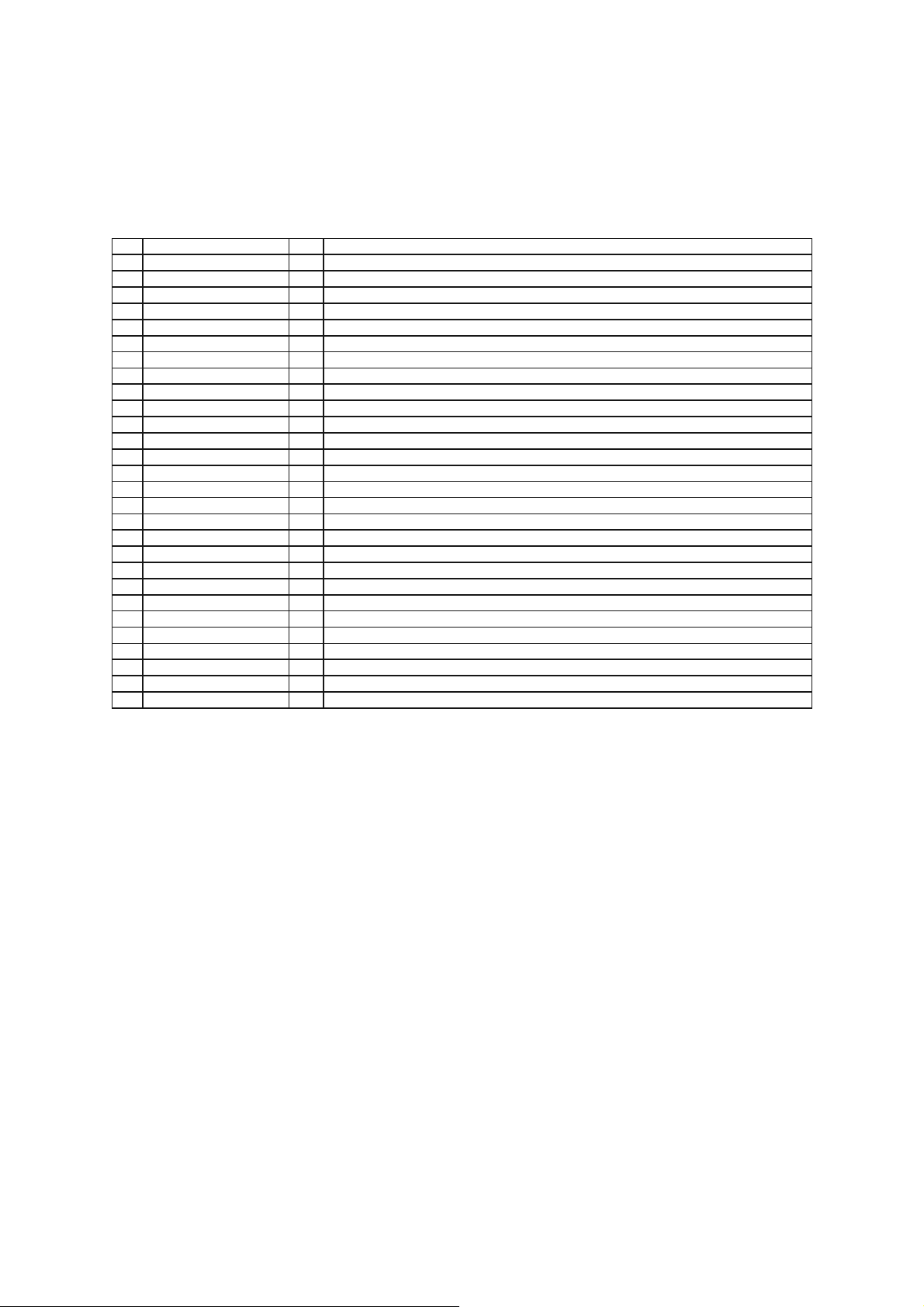

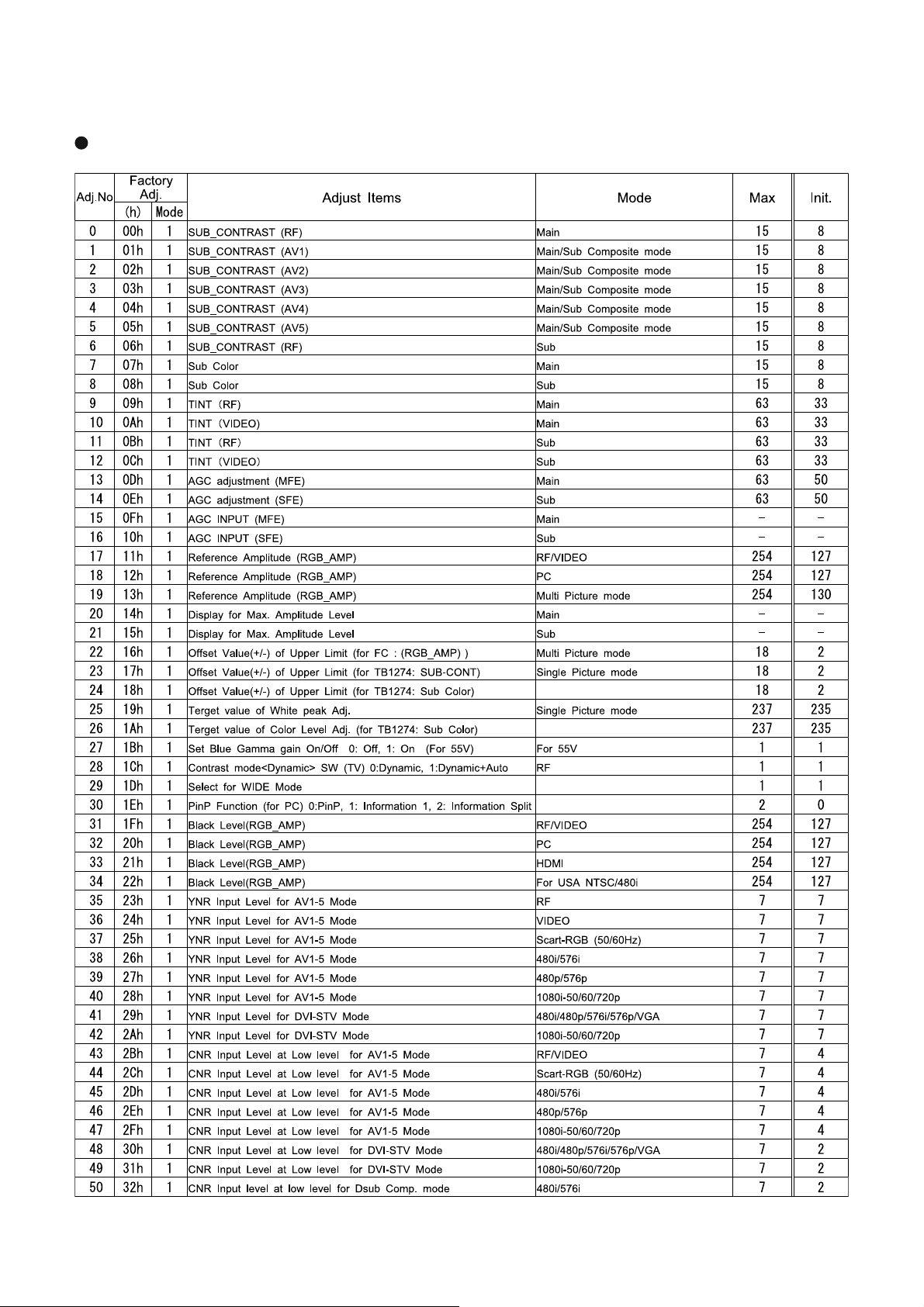

32LD7800TA (PW2L)

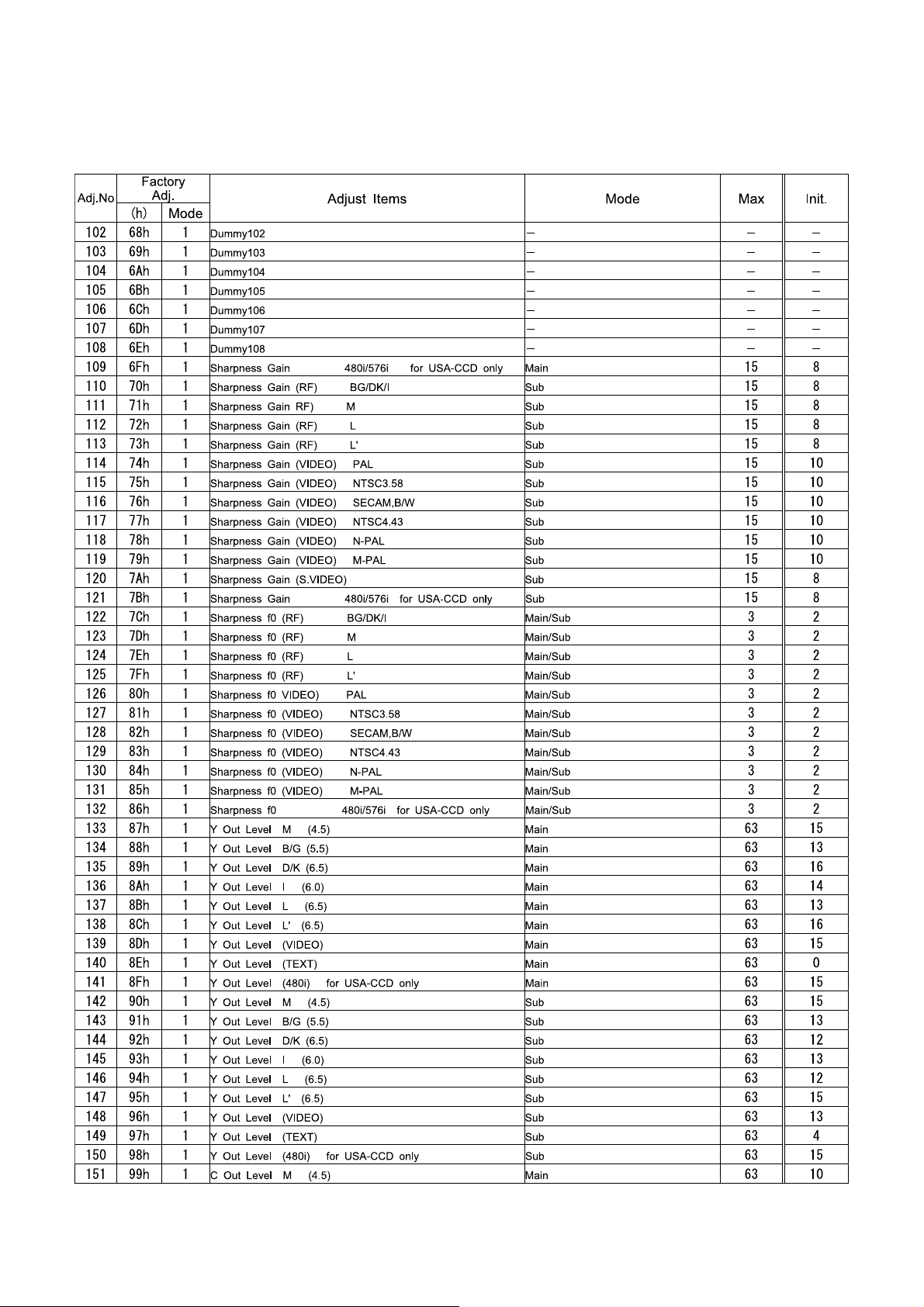

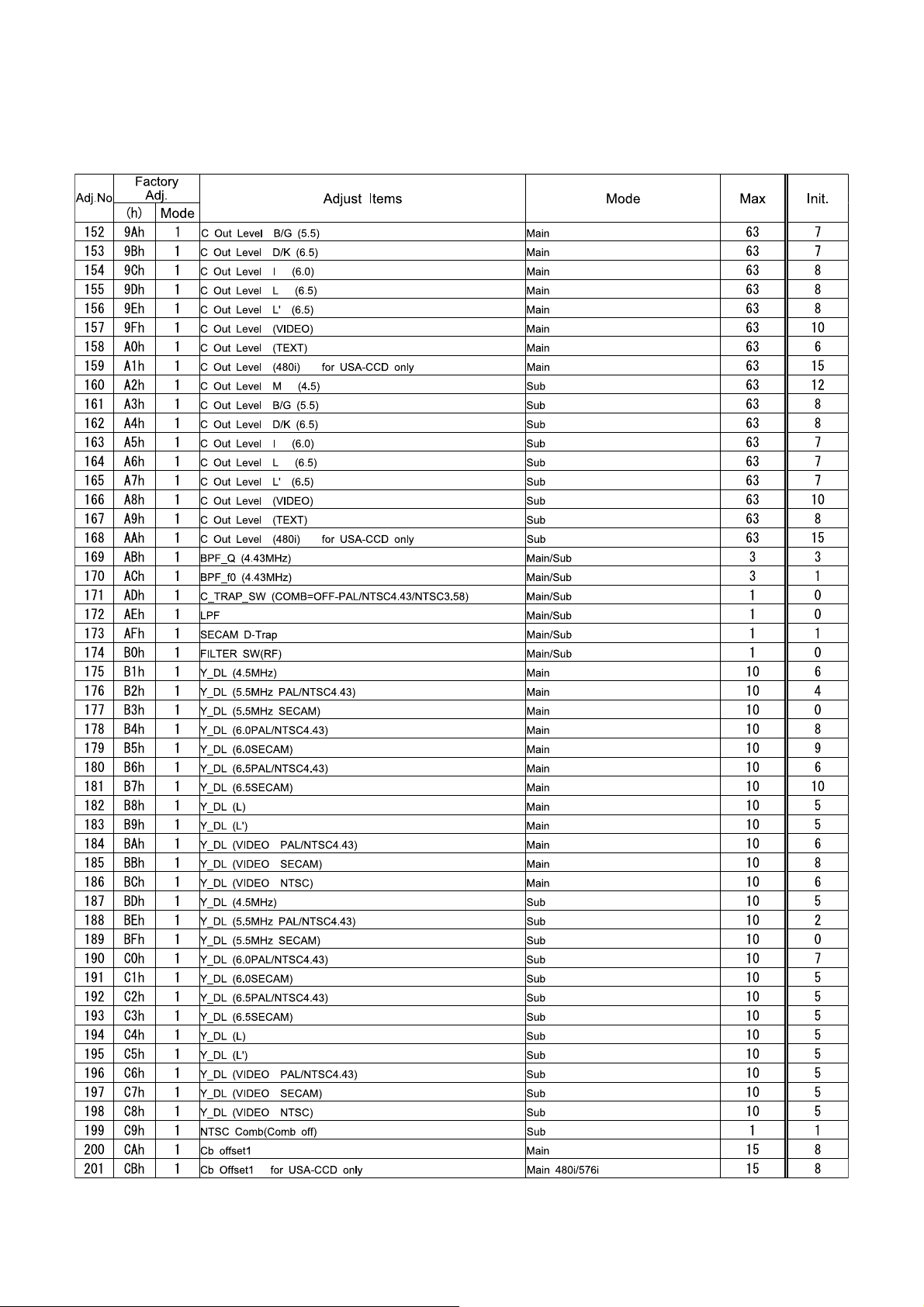

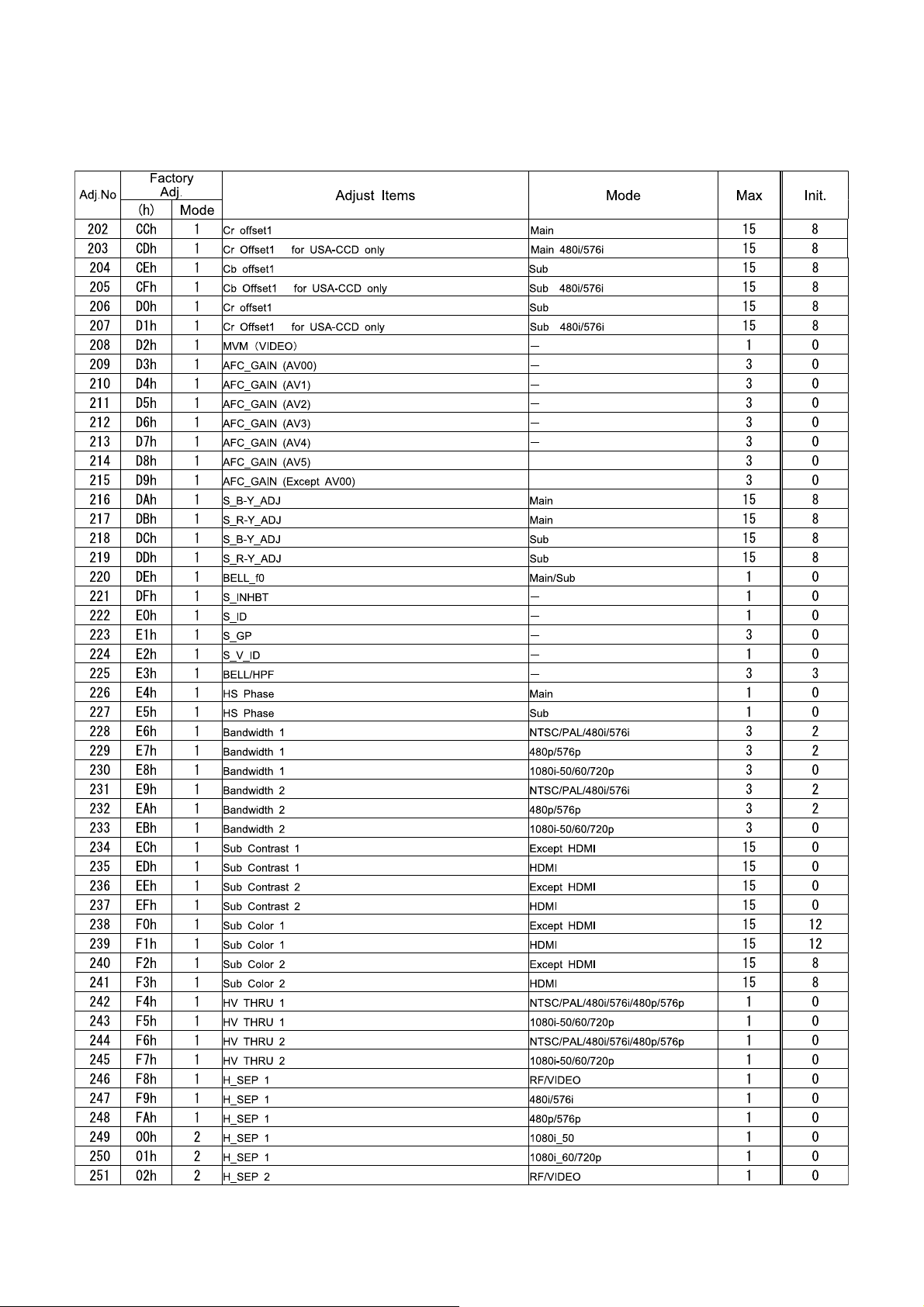

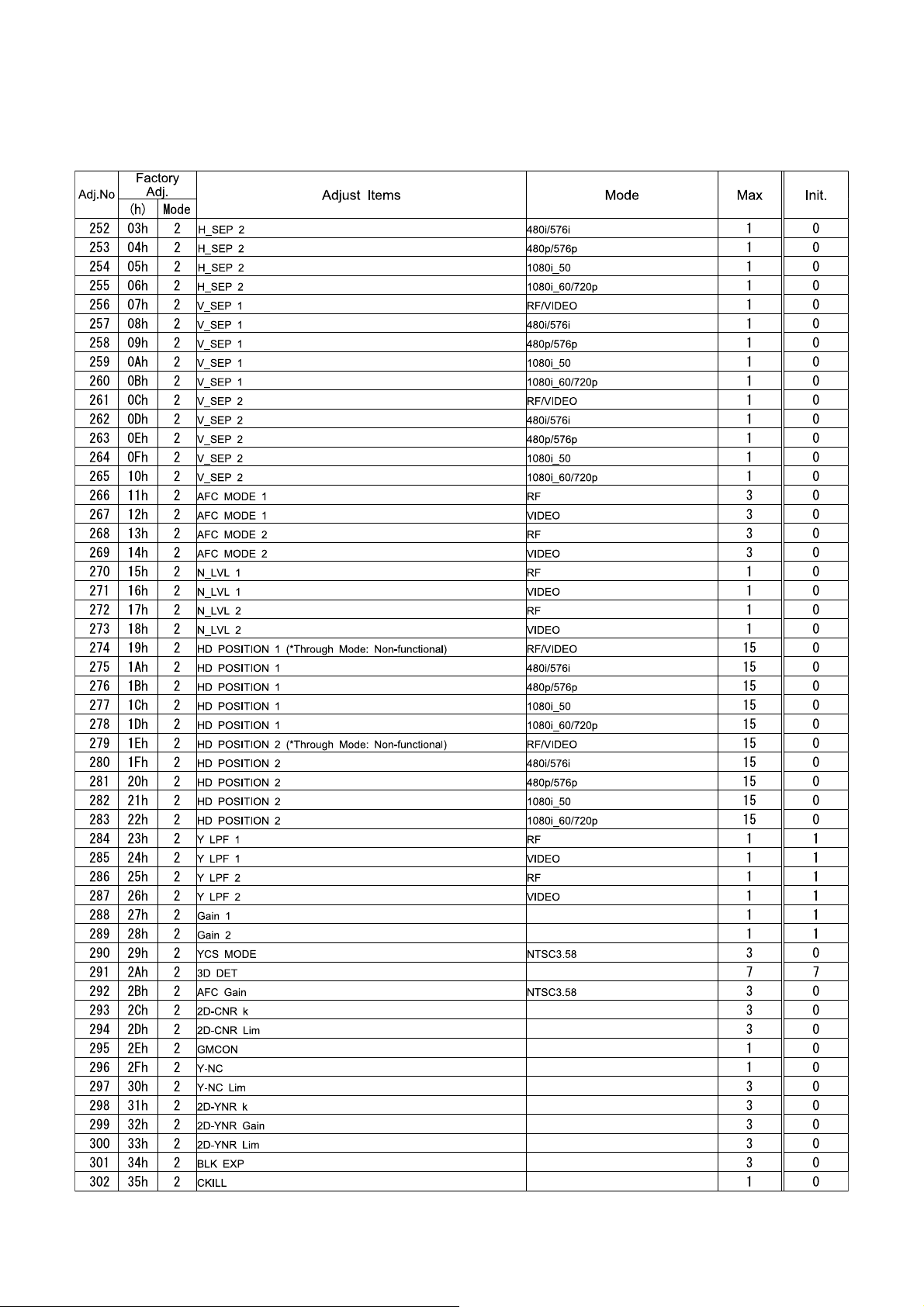

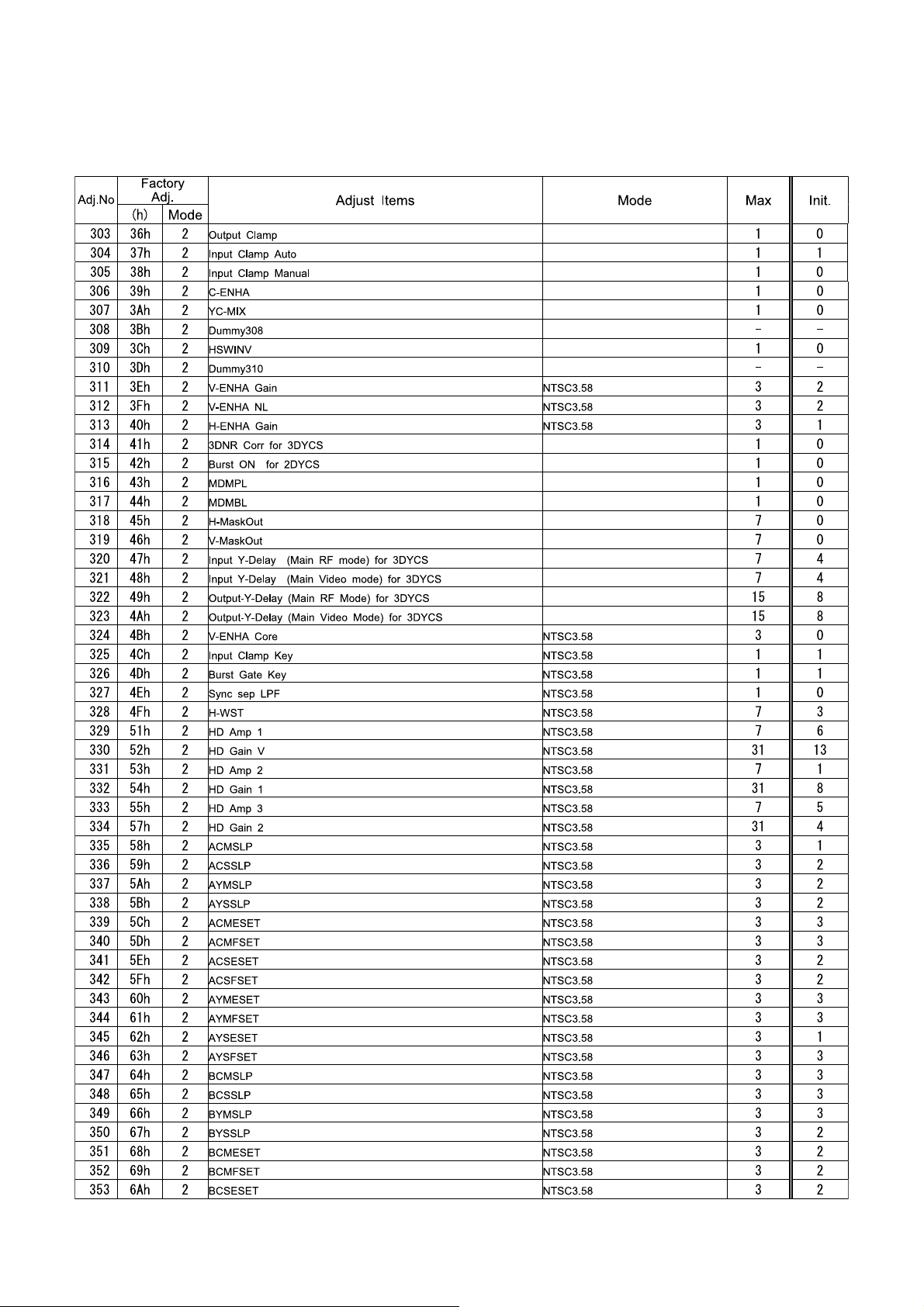

Service

adjustment items by I

2

C-bus control (MAIN Part)

12

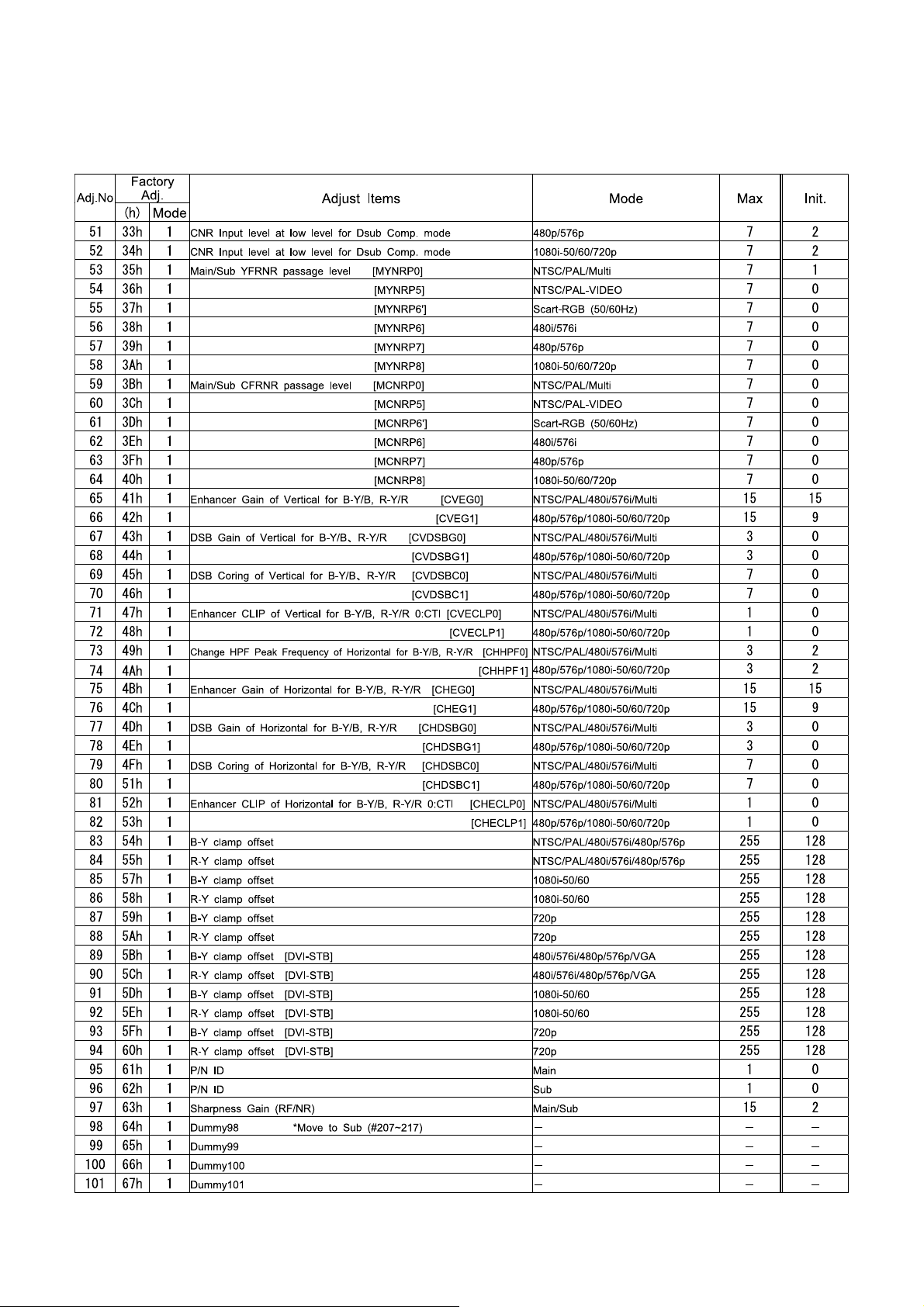

32LD7800TA (PW2L)

13

32LD7800TA (PW2L)

14

32LD7800TA (PW2L)

15

32LD7800TA (PW2L)

16

32LD7800TA (PW2L)

17

32LD7800TA (PW2L)

18

Loading...

Loading...