Page 1

27CX31 B 511

SERVICE MANUAL

27CX31

B 521

1 NTSC ] 1 GXCHASSIS 1

WC: CLU-418U2

CLU-411 ou

CAUTION: Before servicing this chassis, it is important that the service technician read

the “Safety Precautions” and “Product Safety Notices” in this Service Manual.

This television receiver will display television

Closed Captioning (pi ) or ( I)) in accordance

with paragraph 15.119 of the FCC rules)

TABLE OF CONTENTS

Introduction .................

Service Menu ................ 2

Factory Settings .............. 4

Servicing ..................

IF and Audio Alignment .......... 7

Purity & Convergence Procedure

Remote Control

Component Parts List ...........

.............. 10

...... 8

1

5

13-l 8 Remote Schematic .............

Interconnect Diagram ............ 19

Main Module Schematics

Main Module S.M.D. Layout ........

Main Module Component Layout ......

PIP Module Schematic ........... 27

Jack Pack Schematic ............ 28

Keyboard Schematic ............ 29

Tuner Schematic ..............

.......... 20

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

25

26

30

31

SOLID STATE COLOR TELEVISION

JULY 1997 HHEA - MANUFACTURING DIVISION

Page 2

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

CAUTION: Do not attempt to modify this product in any way. Never

perform customized installations without manufacturer’s approval.

Unauthorized modifications will not only void the warranty, but may Iead to

your being liable for any resulting property damage or user injury.

Service work should be performed only after you are thoroughly familiar with

all of the following safety checks and servicing guidelines. To do otherwise

increases the risk of potential hazards and injury to the user.

While servicing, use an isolation transformer for protection from AC line

shock.

After the original service problem has been corrected, make a check of the

following:

FIRE AND SHOCK HAZARD

1.

Be sure that all components are positioned to avoid a possibility of

adjacent component shorts. This is especially important on modules

transported to and from the repair shop.

2.

Never release a repair unless all protective devices such as insulators,

harriers, covers, shields, strain reliefs, power supply cords, and other

hardware have been reinstalled per the original design. Be sure that the

safety purpose of the polarized line plug has not been defeated.

3.

Soldering must be inspected to discover possible cold solder joints,

solder splashes, or sharp solder points. Be certain to remove all loose

foreign particles.

4.

Check for physical evidence of damage or deterioration to parts and

components, for frayed leads or damaged insulation (including the AC

cord), and replace if necessary. Follow the original layout, lead length,

and dress.

5.

No lead or component should touch a receiving tube or a resistor rated at

1 watt or more. Lead tension around protruding metal surfaces must be

avoided.

6.

All critical components such as fuses, flameproof resistors, capacitors,

etc. must be replaced with exact factory types. Do not use replacement

components other than those specified or make unauthorized circuit

modifications.

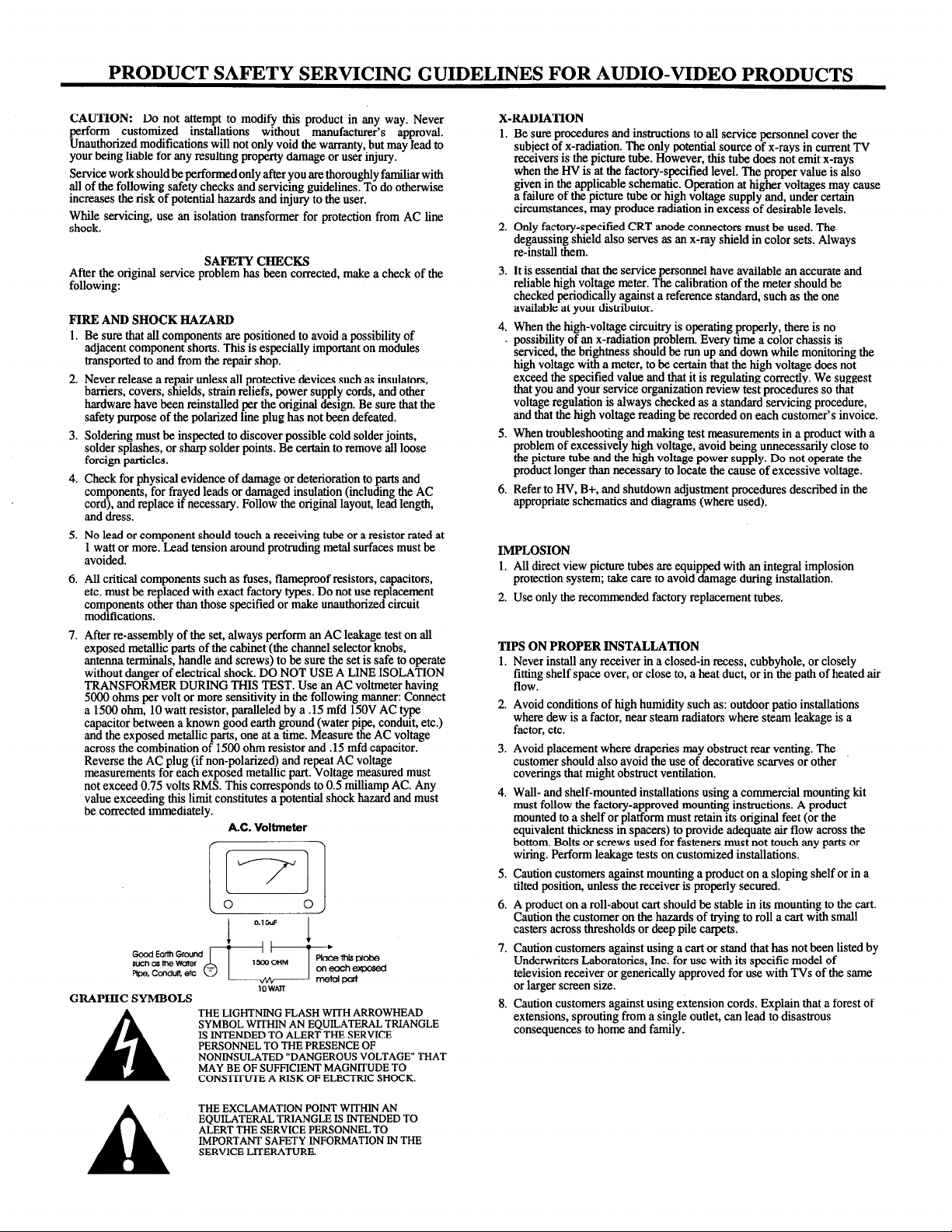

I.

After reassembly of the set, always perform an AC leakage test on all

exposed metallic parts of the cabinet (the channel selector knobs,

antenna terminals, handle and screws) to be sure the set is safe to operate

without danger of electrical shock. DO NOT USE A LINE ISOLATION

TRANSFORMER DURING THIS TEST. Use an AC voltmeter having

5000 ohms per volt or more sensitivity in the following manner: Connect

a 1500 ohm, 10 watt resistor, paralleled by a .15 mfd 15OV AC type

capacitor between a known good earth ground (water pipe, conduit, etc.)

and the exposed metallic parts, one at a time. Measure the AC voltage

across the combination of 1500 ohm resistor and .15 mfd capacitor.

Reverse the AC plug (if non-polarized) and repeat AC voltage

measurements for each exposed metallic part. Voltage measured must

not exceed 0.75 volts RMS. This corresponds to 0.5 milliamp AC. Any

value exceeding this limit constitutes a potential shock hazard and must

he corrected immediately.

GRAPHIC SYMBOLS

Q

SAFETY CHECKS

A.C. Voltmeter

f, I

LO

THE LIGHTNING FLASH WITH ARROWHEAD

SYMBOL WlTHIN AN EQUILATERAL TRIANGLE

IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF

NONINSULATED “DANGEROUS VOLTAGE” THAT

MAY BE OF SUFFICIENT MAGNITUDE TO

CONSTTTUTE A RISK OF ELECTRIC SHOCK.

OJ

X-RADIATION

1.

Be sum procedures and instructions to all service personnel cover the

subject of x-radiation. The only potential source of x-rays in current TV

receivers is the picture tube. However, this tube does not emit x-rays

when the HV is at the factory-specified level. The proper value is also

given in the applicable schematic. Operation at higher voltages may cause

a failure of the picture tube or high voltage supply and, under certain

circumstances, may produce radiation in excess of desirable levels.

2.

Only factory-specified CRT anode connectors must be used. The

degaussing shield also serves as an x-ray shield in color sets. Always

m-install them.

3.

It is essential that the service personnel have available an accurate and

reliable high voltage meter. The calibration of the meter should he

checked periodically against a reference standard, such as the one

available at your distributor.

4.

When the high-voltage circuitry is operating properly, there is no

possibility of an x-radiation problem. Every time a color chassis is

serviced, the brightness should be run up and down while monitoring the

high voltage with a meter, to be certain that the high voltage does not

exceed the specified value and that it is regulating correctly. We suggest

that you and your service organization review test procedures so that

voltage regulation is always checked as a standard servicing procedure,

and that the high voltage reading be recorded on each customer’s invoice.

5.

When troubleshooting and making test measurements in a product with a

problem of excessively high voltage, avoid being unnecessarily close to

the picture tube and the high voltage power supply. Do not operate the

product longer than necessary to locate the cause of excessive voltage.

Refer to HV, B+, and shutdown adjustment procedures described in the

6.

appropriate schematics and diagrams (where used).

IMPLOSION

1. All direct view picture tubes are equipped with an integral implosion

protection system; take care to avoid damage during installation.

2. Use only the recommended factory replacement tubes.

TIPS ON PROPER INSTALLATION

1.

Never install any receiver in a closed-in recess, cubbyhole, or closely

fitting shelf space over, or close to, a heat duct, or in the path of heated air

flow.

2.

Avoid conditions of high humidity such as: outdoor patio installations

where dew is a factor, near steam radiators where steam leakage is a

factor, etc.

3.

Avoid placement where draperies may obstruct rear venting. The

customer should also avoid the use of decorative scarves or other

coverings that might obstruct ventilation.

4.

Wall- and shelf-mounted installations using a commercial mounting kit

must follow the factory-approved mounting instructions. A product

mounted to a shelf or platform must retain its original feet (or the

equivalent thickness in spacers) to provide adequate air flow across the

bottom. Bolts or screws used for fasteners must not touch any parts or

wiring. Perform leakage tests on customized installations.

5.

Caution customers against mounting a product on a sloping shelf or in a

tilted position, unless the receiver is properly secured.

6.

A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small

casters across thresholds or deep pile carpets.

I.

Caution customers against using a cart or stand that has not been listed by

Underwriters Laboratories, Inc. for use with its specific model of

television receiver or generically approved for use with TVs of the same

or larger screen size.

Caution customers against using extension cords. Explain that a forest of

8.

extensions, sprouting from a single outlet, can lead to disastrous

consequences to home and family.

A

THE EXCLAMATION POINT WITHIN AN

EQUILATERAL TRIANGLE IS INTENDED TO

ALERT THE SERVICE PERSONNEL TO

IMPORTANT SAFETY INFORMATION IN THE

SERVICE LITERATURE.

Page 3

GX CHASSIS

INTRODUCTION

The new GX series chassis has been developed for 27” screen size stereo models. Additional plug-in boards wil1 be adder

the chassis to accommodate the different features: Stereo, Mono, PIP, etc.

The new GX series chassis features four 12C compatible ICs for all signal, sync and sweep processing. ICX2200 handles

the audio/video, sync, and sweep drive processing. IC6000 is the microprocessor and IC6001 is the memory. The keybo;

and IR detector are tied directly to IC6000. IC2100 handles the vertical sweep.

ICX3431 is in the power supply. This is a switching type supply powered by the bridge rectifier circuit. At turn on, volta

for the vertical and video output circuit are derived from the sweep circuit.

rl to

all (

xd

.ges

Page 4

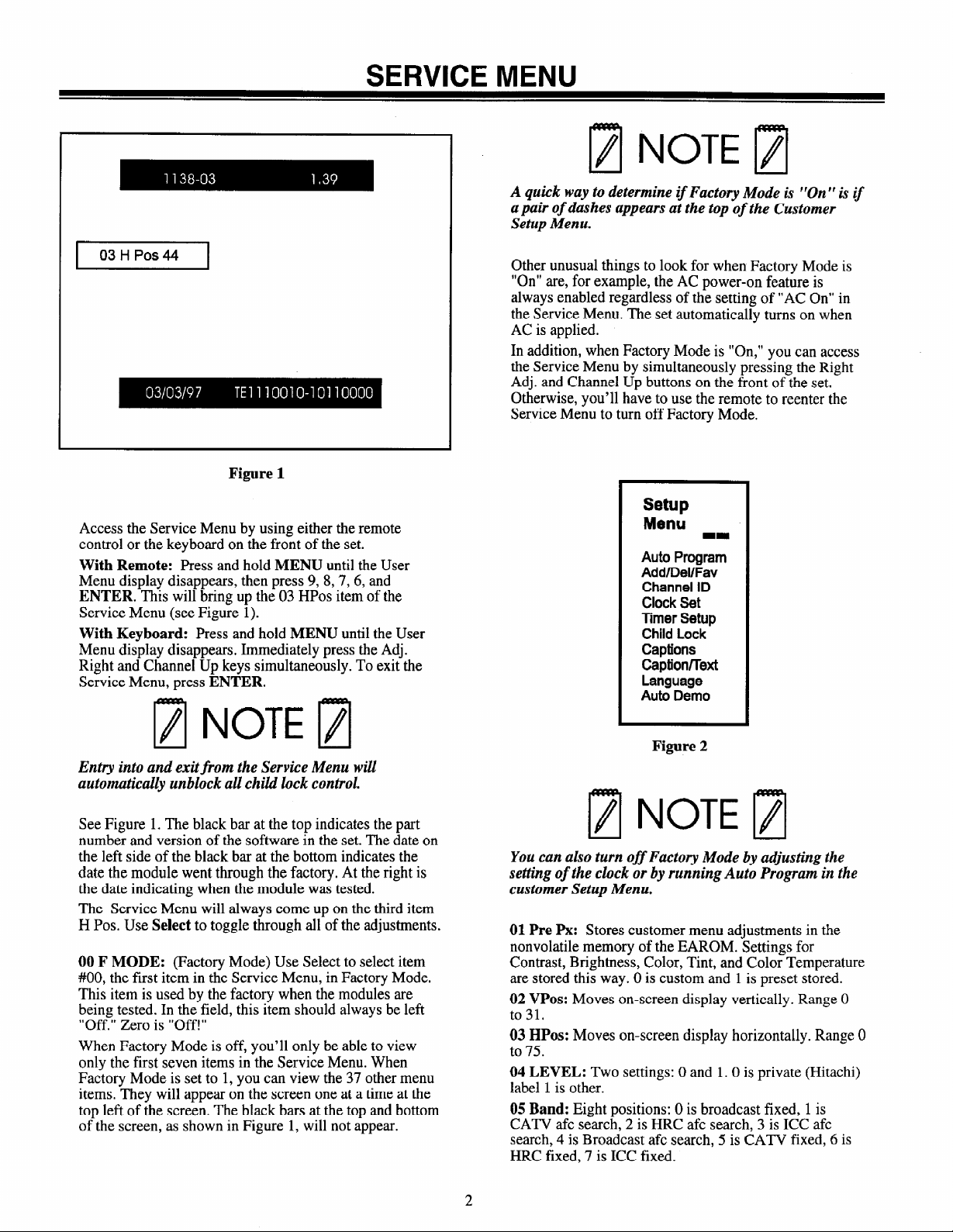

SERVICE MENU

A quick way to determine $-Factory Mode is “On” is if

a pair of dashes appears at the top of the Customer

Setup Menu.

03 H Pos 44

I 1

Access the Service Menu by using either the remote

control or the keyboard on the front of the set.

With Remote: Press and hold MENU until the User

Menu display disappears, then press 9, 8,7,4, and

ENTER, This will bring up the 03 HPos item of the

Service Menu (see Figure 1).

With Keyboard: Press and hold MENU until the User

Menu display disappears. Immediately press the Adj.

Right and Channel Up keys simultaneously. To exit the

Service Menu, press ENTER.

I I

Figure 1

Other unusual things to look for when Factory Mode is

“On” are, for example, the AC power-on feature is

always enabled regardless of the setting of “AC On” in

the Service Menu. The set automatically turns on when

AC is applied.

In addition, when Factory Mode is “On,” you can access

the Service Menu by simultaneously pressing the Right

Adj. and Channel Up buttons on the front of the set.

Otherwise, you’ll have to use the remote to reenter the

Service Menu to turn off Factory Mode.

Setup

Menu

Auto Program

Add/Del/Fav

Channel ID

Clock Set

Timer Setup

Child Lock

Captions

Caption/Text

Language

Auto Demo

II

Entry into and exit from the Service Menu will

automatically unblock all child lock control.

See Figure 1. The black bar at the top indicates the part

number and version of the software in the set. The date on

the left side of the black bar at the bottom indicates the

date the module went through the factory. At the right is

the date indicating when the module was tested.

The Service Menu will always come up on the third item

H Pos. Use Select to toggle through all of the adjustments.

00 F MODE: (Factory Mode) Use Select to select item

#OO, the first item in the Service Menu, in Factory Mode.

This item is used by the factory when the modules are

being tested. In the field, this item should always be left

“Off.” Zero is “Off!”

When Factory Mode is off, you’ll only be able to view

only the first seven items in the Service Menu. When

Factory Mode is set to 1, you can view the 37 other menu

items. They will appear on the screen one at a time at the

top left of the screen. The black bars at the top and bottom

of the screen, as shown in Figure 1, will not appear.

Figure 2

You can also turn off Factory Mode by adjusting the

setting of the clock or by running Auto Program in the

customer Setup Menu.

01 Pre Px: Stores customer menu adjustments in the

nonvolatile memory of the EAROM. Settings for

Contrast, Brightness, Color, Tint, and Color Temperature

are stored this way. 0 is custom and 1 is preset stored.

02 VPos: Moves on-screen display vertically. Range 0

to 31.

03 HPos: Moves on-screen display horizontally. Range 0

to 75.

04 LEVEL: Two settings: 0 and 1. 0 is private (Hitachi)

label 1 is other.

05 Band: Eight positions: 0 is broadcast fixed, 1 is

CATV aft search, 2 is HRC aft search, 3 is ICC aft

search, 4 is Broadcast aft search, 5 is CATV fixed, 6 is

HRC fixed, 7 is ICC fixed.

2

Page 5

SERVICE MENU

06 AC On: Two positions: 0 is off and 1 is AC on. In the

On position, the set will turn on when AC power is

applied.

07 C Phas: (Caption Phase) Determines captioning

phase. Range 0 to 254.

08 C Srch: (Caption Search) Range 0 to 1.

09 C Line: (Caption Line) Range 0 to 32.

10 RF Bpf: (RF bandpass Filter) Range 0 to 1.

113.58: 3.58 Mhz trap. Range 0 to 1.

12 RF Brt: (RF Brightness) Sets adjustment range of the

customer control for brightness in the RF mode. Range 0

to 63,

13 Ax Brt: (Aux Brightness) Sets adjustment range of the

customer control for brightness in the AUX mode. Range

0to63.

14 MaxCon: (Max Contrast) Sets adjustment range of the

customer control for contrast. Range 0 to 63.

15 V Phase: (Vertical Phase) Shifts picture vertically.

Range 0 to 7.

16 HPhase: (Horizontal Phase) Shifts picture

horizontally. Range 0 to 3 1.

17 AudLvl: (Audio Level) Sets gain for the MTS Stereo.

Range 0 to 63.

18 AudAdj: (Sound Balance) Range 0 to 63.

19 RF AGC: Range from 0 to 63.

20 H AFC: Horizontal AFC 0= AFC 2 Normal,

l= AFC 2x3.

21 Wh Comp: (White Compression) Two settings: 0

and 1.

22 60 HzSw: (60 Hz Switched) O=Normal, l=H/V

Locked, 2=Ideal, 3=V Locked, Range 0 to 3.

23 PifVco: (PIF Voltage Controlled Oscillator) Range 0

to 127.

24 R Cut (Red Cutoff) Range 0 to 254.

25 G Cut: (Green Cutoff) Range 0 to 254.

26 B Cut: (Blue Cutoff) Range 0 to 254.

27 G DVR: (Green gain) Range 0 to 254.

28 B DVR: (Blue gain) Range 0 to 254.

PIP Parameters

29 PIP Ras: (PIP Raster Register) Range 0 to 255.

30 PIP SW: (Pip switch delay) Centers PIP Border and

PIP picture in the Horizontal Direction. Range is 0 to 15.

31 PIP Lud: (PIP Luminance Delay) Matches Lum and

Chroma of the inset picture. Range 0 to 7.

32 PIPl: Range 0 to 127.

33 PIPX2: Range 0 to 127.

34 PIPYl: Range 0 to 127.

35 PIPY2: Range 0 to 127.

36 PIPTnt: Range 0 to 63.

Audio Parameters

The following items are factory aligned. See Bar

Code label for correct settings.

37 Spectr: Range 0 to 15.

38 WideBa: (Stereo Voltage Controlled Oscillator)

Range 0 to 63.

39 SapVco: (Second Audio Program Voltage

Controlled) Range 0 to 63.

40 SapLpf: (Second Audio Program Low Pass Filter)

Set to 0 (not adjustable).

41 StLpf: (Stereo Low Pass Filter) Set to 0 (not

adjustable).

42 Spectr: (High Frequency Separation) Set to 0 (not

adjustable).

43 WideBa: (Wide Band Low Frequency Separation)

Set to 0 (not adjustable).

Items 24 -28 are

depending on the Color Temp setting in the Video Menu.

for B&W

tracking and change

Page 6

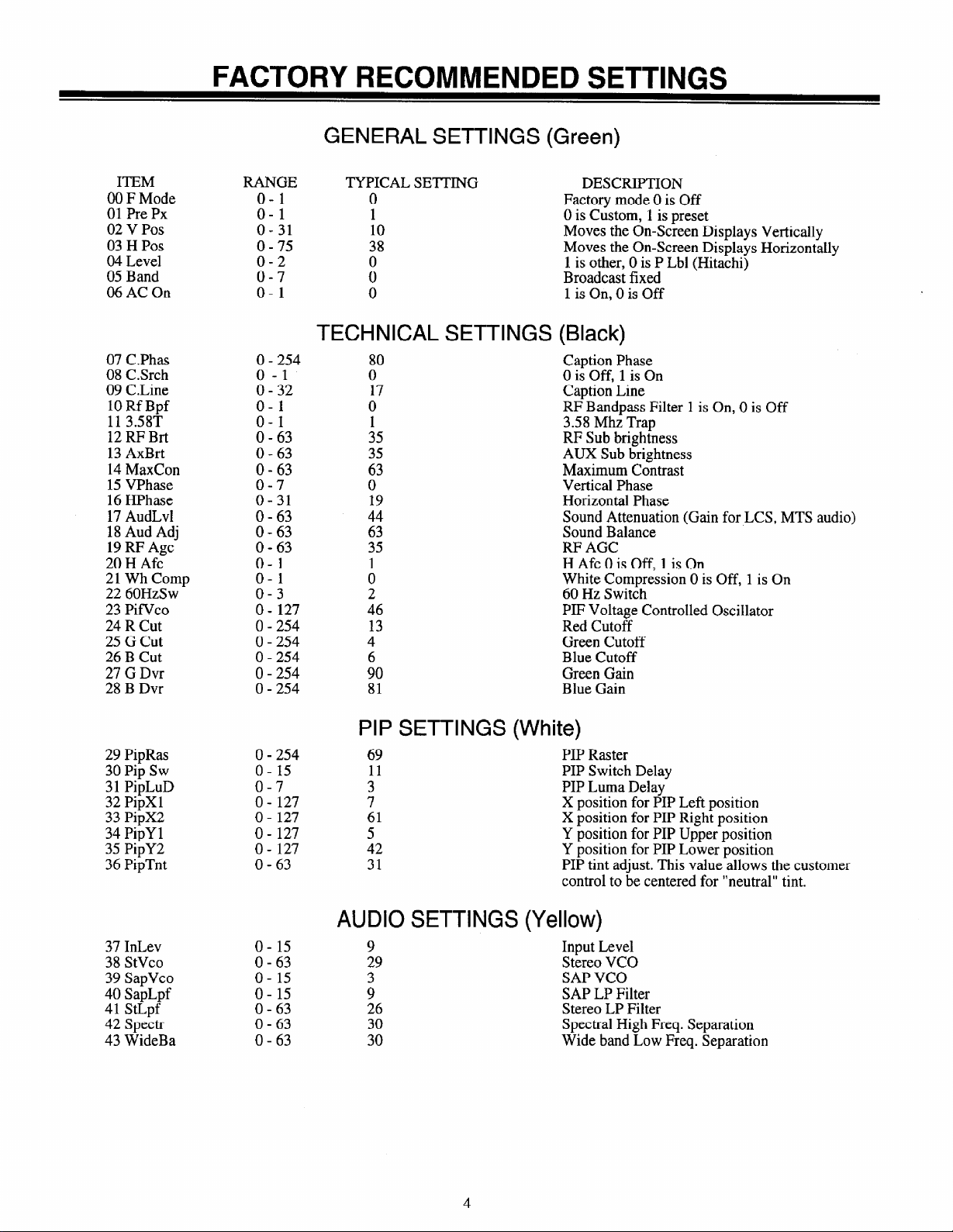

FACTORY RECOMMENDED SETTINGS

GENERAL SETTINGS (Green)

ITEM

00 F Mode

01 Pre Px

02 v Pos

03 H Pos

04 Level

05 Band

06 AC On

07 C.Phas

08 C.Srch

09 C.Line

10RfBpf

11 3.58T

12 RF Brt

13 AxBrt

14 MaxCon

15 VPhase

16 HPhase

17 AudLvl

18 Aud Adj

19 RF Age

20 H Aft

21 Wh Comp

22 60HzSw

23 PifVco

24 R Cut

25 G Cut

26 B Cut

27 G Dvr

28 B Dvr

RANGE

;::

o- 31

0 - 75

;:;

o- 1

0 - 254

: --32

O-l

O-l

0 - 63

0 - 63

O-63

o-7

o- 31

0 - 63

0 - 63

0 - 63

;::

o-3

0- 127

0 - 254

0 - 254

0 - 254

0 - 254

0 - 254

TYPICAL SETTING

0

1

10

38

:

0

DESCRIPTION

Factory mode 0 is Off

0 is Custom, 1 is preset

Moves the On-Screen Displays Vertically

Moves the On-Screen Displays Horizontally

1 is other, 0 is P Lb1 (Hitachi)

Broadcast fixed

1 is On, 0 is Off

TECHNICAL SETTINGS (Black)

80

0

17

0

35

z:

0

19

ii;

35

;

46

13

4

;0

81

Caption Phase

0 is Off, 1 is On

Caption Line

RF Bandpass Filter 1 is On, 0 is Off

3.58 Mhz Trap

RF Sub brightness

AUX Sub brightness

Maximum Contrast

Vertical Phase

Horizontal Phase

Sound Attenuation (Gain for LCS, MTS audio)

Sound Balance

RF AGC

H Aft 0 is Off, 1 is On

White Compression 0 is Off, 1 is On

60 Hz Switch

PIF Voltage Controlled Oscillator

Red Cutoff

Green Cutoff

Blue Cutoff

Green Gain

Blue Gain

29 PipRas O-254

30 Pip SW o- 15

31 PipLuD o-7

32 PipXl

33 PipX2 0- 127

34 PipY 1 0- 127

35 PipY2 0- 127

36 PipTnt 0 - 63

37 InLev

38 StVco

39 SapVco

40 SapLpf

41 StLpf

42 Spectr

43 WideBa

0- 127

o- 15

0 - 63

o- 15

o- 15

0 - 63

0 - 63

0 - 63

PIP SETTINGS (White)

69

11

;

61

5

42

31

PIP Raster

PIP Switch Delay

PIP Luma Delay

X position for PIP Left position

X position for PIP Right position

Y position for PIP Upper position

Y position for PIP Lower position

PIP tint adjust. This value allows the customer

control to be centered for “neutral” tint.

AUDIO SETTINGS (Yellow)

Input Level

Stereo VCO

SAP VCO

SAP LP Filter

Stereo LP Filter

Spectral High Freq. Separation

Wide band Low Freq. Separation

Page 7

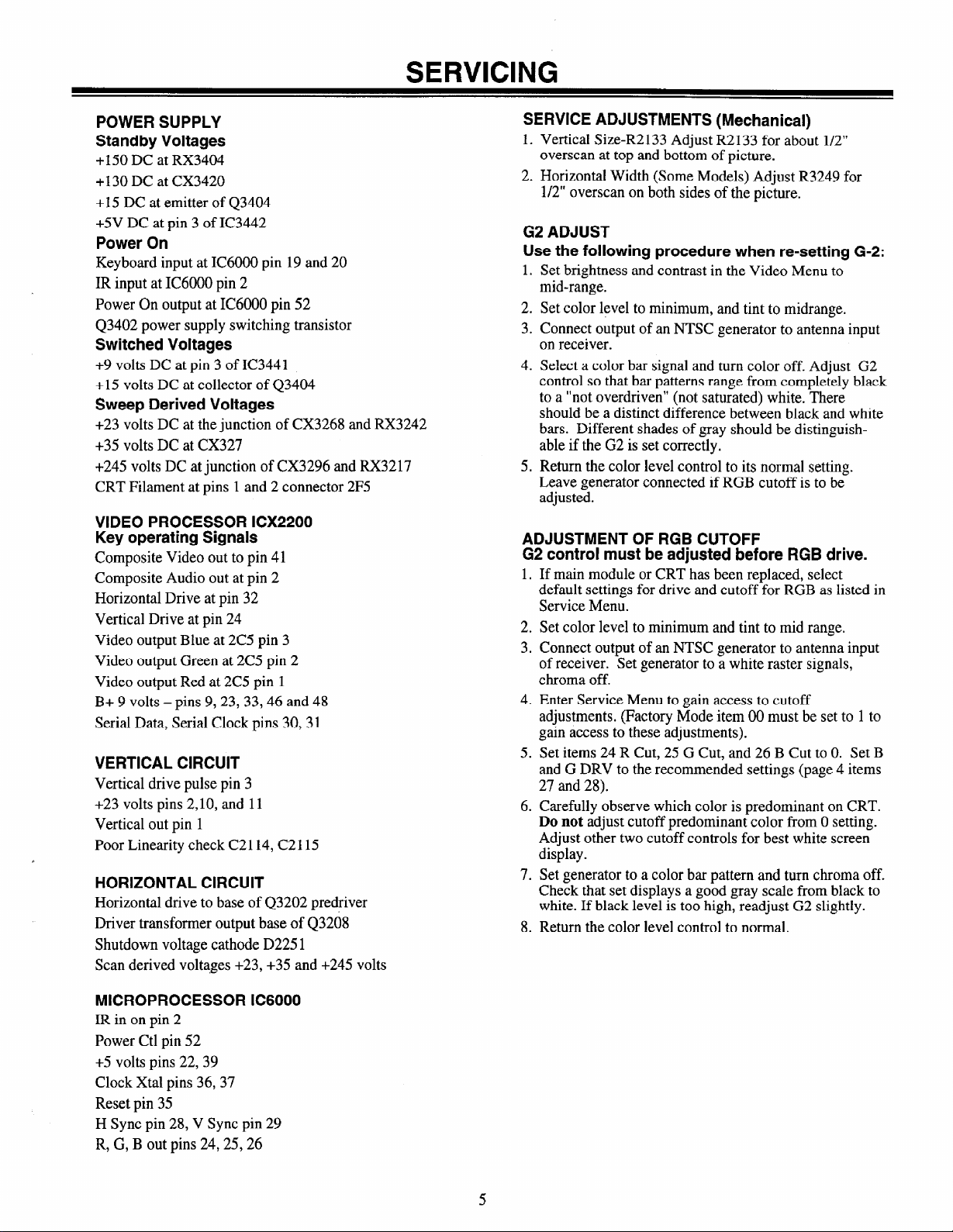

SERVICING

POWER SUPPLY

Stand by Voltages

+150 DC at RX3404

+ 130 DC at CX3420

+ 15 DC at emitter of Q3404

+5V DC at pin 3 of IC3442

Power On

Keyboard input at IC6000 pin 19 and 20

IR input at IC6000 pin 2

Power On output at IC6000 pin 52

Q3402 power supply switching transistor

Switched Voltages

+9 volts DC at pin 3 of IC3441

+15 volts DC at collector of Q3404

Sweep Derived Voltages

+23 volts DC at the junction of CX3268 and RX3242

+35 volts DC at CX327

+-245 volts DC at junction of CX3296 and RX3217

CRT Filament at pins 1 and 2 connector 2F5

VIDEO PROCESSOR ICX2200

Key operating Signals

Composite Video out to pin 41

Composite Audio out at pin 2

Horizontal Drive at pin 32

Vertical Drive at pin 24

Video output Blue at 2C5 pin 3

Video output Green at 2C5 pin 2

Video output Red at 2C5 pin 1

B+ 9 volts -pins 9,23,33,46 and 48

Serial Data, Serial Clock pins 30, 3 1

VERTICAL CIRCUIT

Vertical drive pulse pin 3

+23 volts pins 2,10, and 11

Vertical out pin 1

Poor Linearity check C2114, C2115

r

HORIZONTAL CIRCUIT

Horizontal drive to base of Q3202 predriver

Driver transformer output base of Q3208

Shutdown voltage cathode D225 1

Scan derived voltages +23, +35 and +245 volts

SERVICE ADJUSTMENTS (Mechanical)

1. Vertical Size-R2133 Adjust R2133 for about l/2”

overscan at top and bottom of picture.

2. Horizontal Width (Some Models) Adjust R3249 for

l/2” overscan on both sides of the picture.

G2 ADJUST

Use the following procedure when re-setting G-2:

1.

Set brightness and contrast in the Video Menu to

mid-range.

2.

Set color level to minimum, and tint to midrange.

3.

Connect output of an NTSC generator to antenna input

on receiver.

4.

Select a color bar signal and turn color off. Adjust G2

control so that bar patterns range from completely black

to a “not overdriven” (not saturated) white. There

should be a distinct difference between black and white

bars. Different shades of gray should be distinguishable if the G2 is set correctly.

5.

Return the color level control to its normal setting.

Leave generator connected if RGB cutoff is to be

adjusted.

ADJUSTMENT OF RGB CUTOFF

G2 control must be adjusted before RGB drive.

1. If main module or CRT has been replaced, select

default settings for drive and cutoff for RGB as listed in

Service Menu.

2.

Set color level to minimum and tint to mid range.

3.

Connect output of an NTSC generator to antenna input

of receiver. Set generator to a white raster signals,

chroma off.

4.

Enter Service Menu to gain access to cutoff

adjustments. (Factory Mode item 00 must be set to 1 to

gain access to these adjustments).

5.

Set items 24 R Cut, 25 G Cut, and 26 B Cut to 0. Set B

and G DRV to the recommended settings (page 4 items

27 and 28).

6.

Carefully observe which color is predominant on CRT.

Do not adjust cutoff predominant color from 0 setting.

Adjust other two cutoff controls for best white screen

display.

7.

Set generator to a color bar pattern and turn chroma off.

Check that set displays a good gray scale from black to

white. If black level is too high, readjust G2 slightly.

8.

Return the color level control to normal.

MICROPROCESSOR IC6000

IR in on pin 2

Power Ctl pin 52

+5 volts pins 22, 39

Clock Xtal pins 36, 37

Reset pin 35

H Sync pin 28, V Sync pin 29

R, G, B out pins 24,25,26

Page 8

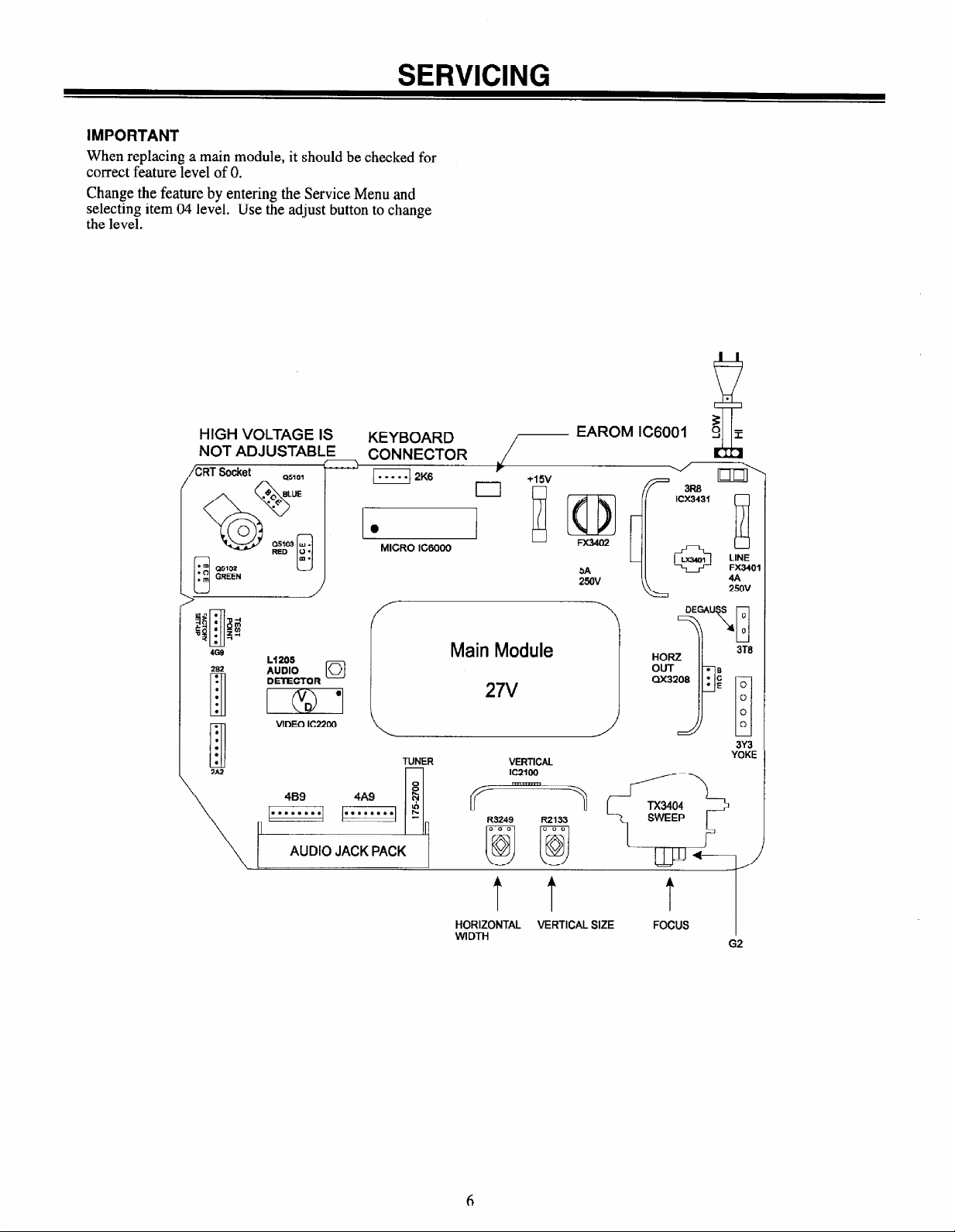

SERVICING

IMPORTANT

When replacing a main module, it should be checked for

correct feature level of 0.

Change the feature by entering the Service Menu and

selecting item 04 level. Use the adjust button to change

the level.

HIGH VOLTAGE IS

NOT ADJUSTABLE

CRT Socket

ml

45101

LIZ05

AUDIO

DETECTOR

VIDEO IC2200

KEYBOARD

CONNECTOR

II 2K6

[oi

MICRO IC6000

TUNER

/

r

I

Main Module

27V

VERTICAL

EAROM IC6001

FX3402

5A

2!5ov

LINE

FX3401

4A

25ov

YOKE

t t

HORIZONTAL VERTICAL SIZE

WIDTH

6

t

FOCUS

G2

I

Page 9

SERVICING

IF AND AUDIO ALIGNMENT PROCEDURE

VIDEO DETECTOR

If there is no viewable picture, enter Service Menu and

check default settings for the following items:

Item 05 Band should be set to 0.

Item 19 RFAgc should be set to 44.

Item 23 PIFVco should be set to 48.

With a high impedance DC meter, measure VDC at pin

44 on ICX2200 or on R 12 19 with good standard signals

such as off-air. Adjust item 23 PIFVco for VDC = 2SV+

This is also the AFC Crossoverpoint.

AGC DELAY

With a strong noise-free antenna signal, adjust Service

Menu item 19 RFAgc setting lower until signal looks

noisier, increase setting for a noise free picture.

If

you &just above setting 40, the tuner input will

overload under certain conditions, causing other beats

in the picture.

A more accurate method is to apply a channel 6 signal at

750~ V 75 ohms to the antenna. Then adjust Service

Menu item 19 RF Age until tuner Age drops 1 VDC

from typical, Voltage can be measured at (+) terminal of

capacitor C6028.

AUDIO DETECTOR

If no audio is present, enter the Service menu and check

default setting for the following items:

Item 17 AudLvl should be set to 44.

Item 18 AudAdj should be set to 63. This item is not to

be field adjusted.

With a high impedance DC meter, measure VDC on

ICX2200 Pin 54 or (+) terminal of C 12 11 with a good

standard signal such as off-air. Adjust L1205 for 4.0

VDC.

JACK PACK REMOVED

1.

Attach a high impedance AC meter with a 47k load to

pin 3 and ground lead to pin 4 of 4A9.

2.

Ground pin 7 of 4A9.

3.

Ground pin 2 of 4B9 through a 10k resistor.

4.

Interrupt main AC power to reset microprocessor.

Apply an RF signal with good video and audio at 400

5.

Hz and 100% modulation.

6.

Go to Service Menu item 17 AudLvl and adjust setting

for 490 to 500 MVAC.

JACK PACK ATTACHED

1. Attach a high impedance AC meter to W1611 and

ground lead to W 1603 on top of jackpack.

Ground

jumper W53 on main chassis to reduce high frequency

noise.

2. Interrupt main AC power to reset microprocessor.

3. Apply an RF signal with good video and audio at 400Hz

and 100% modulation.

4. Go to Service Menu item 17 AudLvl and adjust setting

for 490 to 500 MVAC.

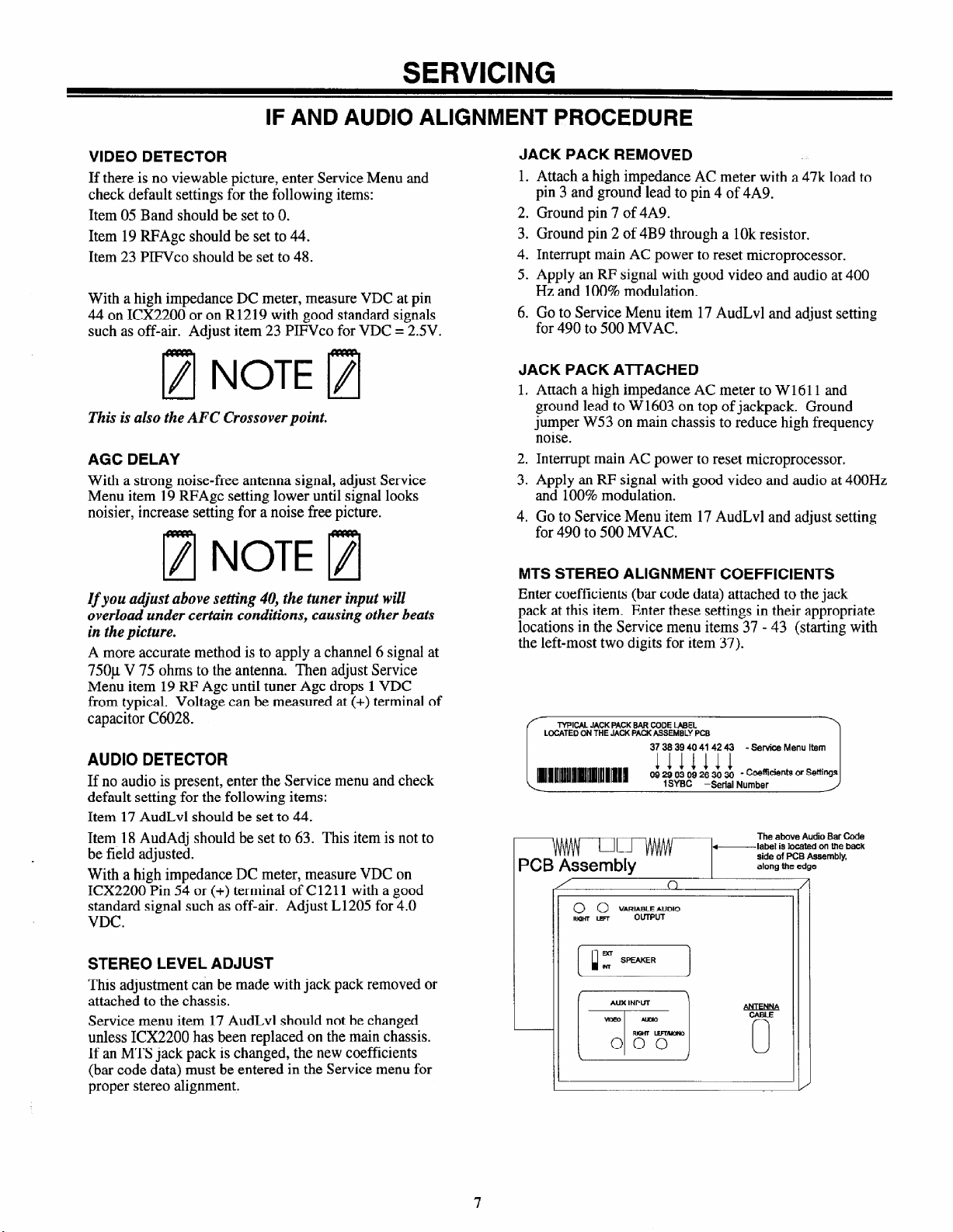

MTS STEREO ALIGNMENT COEFFICIENTS

Enter coefficients (bar code data) attached to the jack

pack at this item. Enter these settings in their appropriate

locations in the Service menu items 37 - 43 (starting with

the left-most two digits for item 37).

-iWlCAl JACK PACK SAR CODE LABEL

LOCATED ON THE JACK PACK ASSEMBLY PCS

lllllnlllllllllilllmllnIllll

i

PCB Assembly

0 0 VARIABLE AUDIO

RDM LEFT

37383940414243 -ServiceMenultam

09

1111111

29 03 09 26 30 30

ISYBC

-Serial Number

II J w

OUTPUT

-label is located on the back

0

The above Audio Bar Code

side of PCB Assembly,

along the edge

/’

STEREO LEVEL ADJUST

This adjustment c& be made with jack pack removed or

attached to the chassis.

Service menu item 17 AudLvl should not be changed

unless ICX2200 has been replaced on the main chassis.

If an MTS jack pack is changed, the new coefficients

(bar code data) must be entered in the Service menu for

proper stereo alignment.

YEP

0

/

7

Page 10

SERVICING

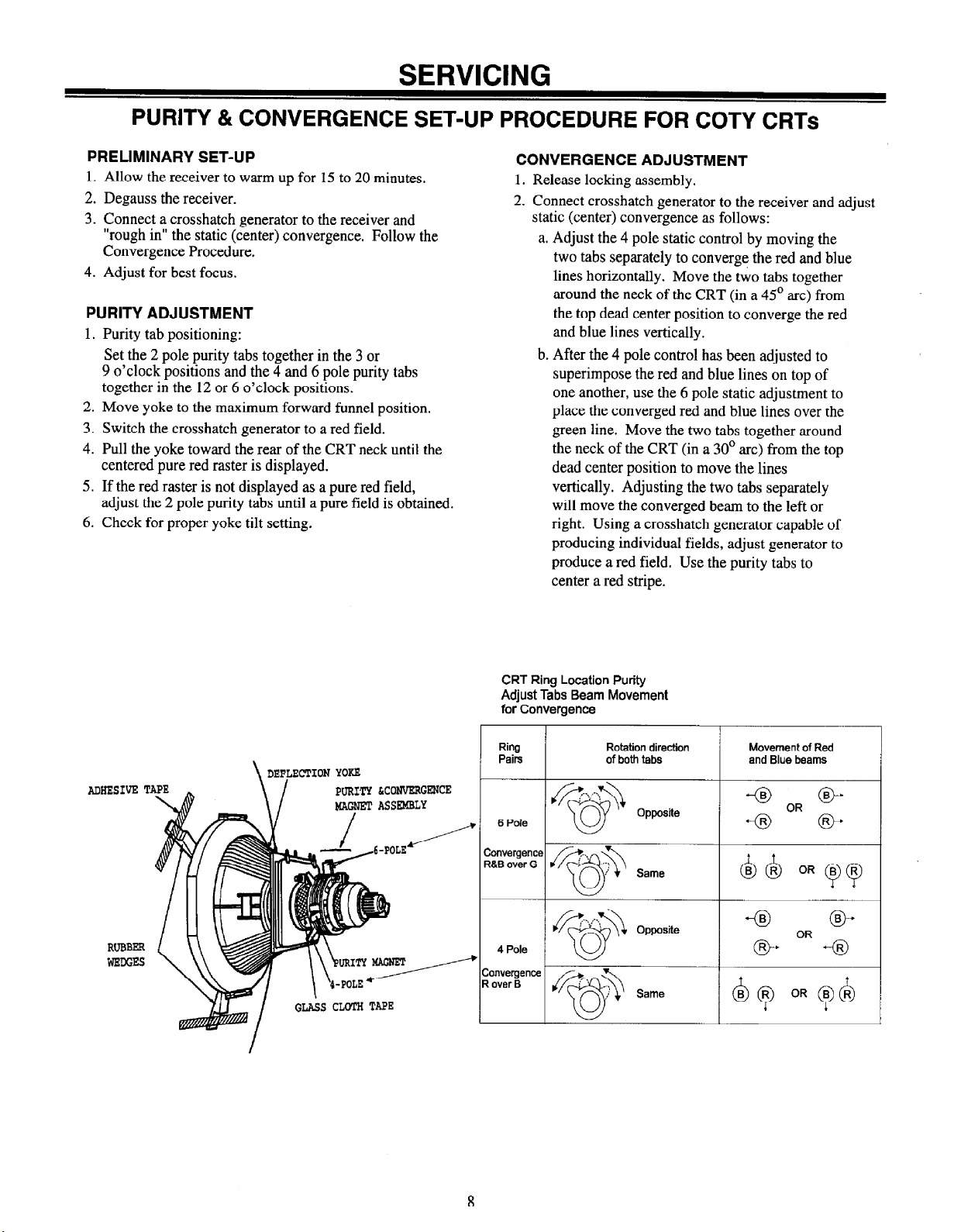

PURITY & CONVERGENCE SET-UP PROCEDURE FOR COTY CRTs

PRELIMINARY SET-UP

1. Allow the receiver to warm up for 15 to 20 minutes.

2. Degauss the receiver.

3. Connect a crosshatch generator to the receiver and

“rough in” the static (center) convergence. Follow the

Convergence Procedure.

4. Adjust for best focus.

PURITY ADJUSTMENT

1. Purity tab positioning:

Set the 2 pole purity tabs together in the 3 or

9 o’clock positions and the 4 and 6 pole purity tabs

together in the 12 or 6 o’clock positions.

2. Move yoke to the maximum forward funnel position.

3. Switch the crosshatch generator to a red field.

4. Pull the yoke toward the rear of the CRT neck until the

centered pure red raster is displayed,

5. If the red raster is not displayed as a pure red field,

adjust the 2 pole purity tabs until a pure field is obtained.

6, Check for proper yoke tilt setting.

CONVERGENCE ADJUSTMENT

1. Release locking assembly,

2. Connect crosshatch generator to the receiver and adjust

static (center) convergence as follows:

a. Adjust the 4 pole static control by moving the

two tabs separately to converge the red and blue

lines horizontally. Move the two tabs together

around the neck of the CRT (in a 45’ arc) from

the top dead center position to converge the red

and blue lines vertically.

b. After the 4 pole control has been adjusted to

superimpose the red and blue lines on top of

one another, use the 6 pole static adjustment to

place the converged red and blue lines over the

green line. Move the two tabs together around

the neck of the CRT (in a 30’ arc) from the top

dead center position to move the lines

vertically. Adjusting the two tabs separately

will move the converged beam to the left or

right. Using a crosshatch generator capable of

producing individual fields, adjust generator to

produce a red field. Use the purity tabs to

center a red stripe.

PURITY &CONVERGENCE

CRT Ring Location Purity

Adjust Tabs Beam Movement

for Convergence

Ring

Pairs

6 Pole

Rotation direction Movement of Red

of both tabs and Blue beams

Opposite

43 (9

8

Page 11

SERVICING

VERTICAL-TILT - WEDGE ADJUSTMENT

Converge the vertical lines at 6 and 12 o’clock by

vertically tilting the yoke and inserting a wedge at the top

of the yoke until it is firmly seated between the CRT glass

and the horizontal coils.

HORIZONTAL - TILT WEDGE ADJUSTMENT

Converge the vertical line at 3 o’clock and 9 o’clock by

horizontally tilting the yoke and inserting a wedge.

First, at 4 or 8 o’clock, whichever has a larger space,

insert a second wedge until it is firmly seated between the

CRT glass and yoke coils. Then insert the third wedge in

the remaining horizontal tilt position until firmly seated

between the CRT glass and yoke coils. Convergence at 3

and 9 o’clock should be maintained during this operation.

When the three wedges are firmly installed for acceptable

convergence, lock the wedges in place by applying a strip

of tape (2.5” long) across the tabs of each wedge, firmly

against the CRT glass. The CRT glass surface should be

clean and free of dust and other foreign material,

UNUSUAL TILT CASE

There may be some cases of picture tube and yoke that

require vertical tilt in the opposite (or up) direction to

obtain convergence. In such cases, insert the vertical tilt

wedge at the bottom (or 6 o’clock) position. Follow

through the horizontal tilt adjustment by using the 2 and

10 o’clock position and secure each wedge with a piece of

tape as described above.

IMPROVING CRT CORNER PURITY

CRTs that display corner purity problems even after

following service procedures can be modified with a

picture correction kit (P/N 949-50). The purity can be

improved by placing a picture correction magnet

(included in the kit) on the CRT funnel. Refer to the

following modification steps and illustration to place the

magnet properly.

MODIFICATION

1. Place the magnet on the CRT funnel (as shown) in the

quadrant exhibiting impurity.

2. Rotate the magnet in place to the position shown for

best purity.

3. Place a piece of l/2” x 2” Fiberglass tape over the

magnet to hold it in place.

4. Degauss the CRT once the magnet is in place to insure

that the magnet is not over the internal magnet shield.

If the magnet is placed over the internal magnet shield,

any apparent purity correction will disappear after

degaussing. Reposition the correction magnet off the

internal shield and degauss again.

TT

LClamp and Screw

I6 Pole Magnets

L-

2 Pole Magnets

-4 Pole Magnets

To 3”

9

Page 12

REMOTE CONTROL

/’

A B C FAV

‘\

-i

I),

/ . . . . . . . . .-

\

/

PAUSE

f --\

i 1

i,-..:

HITACHI

CLu-4lIuu

HITACHI

CLU-418U2

10

Page 13

REMOTE CONTROL

PROGRAMMING YOUR REMOTE

If you’re using Hitachi products, the remote is already

programmed for the most common codes:

TV = 121 and VCR = 215. For other brands, or if your

remote fails to control your Hitachi products, you’ll have

to

program the remote.

1.

Make sure the batteries are installed.

2.

Press and hold

release the

3.

Press the mode key to be programmed:

VCR OR AUX.

4.

Enter 3-digit product code from chart on next page.

5.

Press and release

6.

Point remote at product and press

product operation. If it does not turn on, reprogram

remote using a different code.

7.

Repeat above steps to program remote for another

*

proauct.

PRG

PRG

key for about 5 seconds, then

key.

ENTER

to save the code.

POWER

TV, CABLE,

to test

4.

Enter “O-O-O,” then press

ENTER

within two

seconds.

5.

Point the remote at the product.

4.

Press and release

POWER

repeatedly, about once a

second, until your product turns Off.

7.

Press

ENTER

8.

Press

POWER

9.

Test your product. If the remote fails to operate the

immediately to save the code.

to turn On your product.

functions you use most often, use Auto Find again to

search for a better code. (Auto Find resumes its

search after the last code that was entered and saved

in step 7).If the product you want to control has not

turned off, your remote will not work with that

product.

T/,

cancel Auto Find, press PRG at any time.

sv

AUTO FIND OPTION

(ALTERNATE PROGRAMMING METHOD)

If you’ve tried all codes for your product and none

operates it, you can use Auto Find to search for the code

you need. Follow the steps below for each product you

want to program. Please be patient while using this

method; the remote may have to search all of the codes

shown in the chart on the next page.

To Auto Find a Code

1. Turn On the product you want to operate.

2. Press and hold

release the

3. Press the mode key to be programmed:

VCR OR AUX.

PRG

PRG

key for about 5 seconds, then

key.

TV, CABLE,

Refer to product operating guide for detailed

programming information.

Page 14

OPERATING CODES BY BRAND NAME

Sanyo 1 tO8.109.118 NEC t 202.218

Bell & Howell I 12t

Broksonic I 131, 136

Candle

Centurion 119

Citizen 1 121,139

Contec 141

Coronado 103

Crown 103

Curtis Mathes

Daewoo 149,159

Daewoo TV/VCR 148

Daytron 119

Elektra 121

Emerson

Emerson TVNCR 158

Fisher loY.118

Funai TV/VCR 154

General

Electric

Goldstar

Goldstar TV/VCR I 153

Hitachi 102. 103, 121,

J.C. Penney

JVC

KMC

KTV

Kurazai 121

Lodgenet I21

Lo&k

LX1 133,137

Magnavox 103, 112, 113,

Magnavox TV/VCR 173

Majestic

Marantz 104, 120, 155

Megatron 146

Memorex

MGA/ 104. 119, 120,

Mitsubishi 130,140, 155

Montgomery 103, 104, 105,

Ward 113. 114, 119.

NEC

Panasonic I 106, 107, 160, 166 1

Panasonic IV/VCR I 174

Philco

Philips 112.113

QWX

I

139 I

116.119, 121

103, 104, 123,

124, 131,136,

145

106. 107, 114,

116, 117.161

129, 163 I

104. 110, 114.

117.119

t 125, 132, 164

I

103

1 103,104, I38 1

121

117. 119, 127,

128, 139, 165

121

I

121

121,130, 133

I

104. 119

1 106, 107

I

I

Sharp

Signature 2OtKl 103,104.105,

Sony 115,143,151,170

Soundesign 139

Sylvania 112,113,117,119,

Sym~TvNcR 154

Tatung 106

Teknika 103, 112, 121.

Telerent 103,121

Toshiba 110,111,134,~71

XRlLHlO 121

Yorx 119

Zenith 101.149.175

Zenith TV/VCR I 153,154.172

113.114.119,

121,130.133

127,128,139

124, 139

I

Admiral 1208,261

Adventura 231

Aiwa I231

1

I

Bell & Howell

Craig

Curtis Mathes I 214,259

Daewoo I X4,246,248,254 I

Daytron

DBX 1202,218

Emerson

1

Fisher

Funai

I

General

Electric

J.C. Penney 214,215,218.227

JVC

Kenwood

Logik

Lx1

Magnavox t207,214,231 I Panasonic 1 3 13,320

MatalIt 207,218

I

Marta 1209

212

1 236,246

211,212,2I3.247

231

214,216,220

202,224,225,258

t 202

1239

t209.231

REMOTE CONTROL

Ward I219,231,249

Multi Tech

Orion

Panasonic

Pentax

Philco I 207.214

Philips t 207,214,227 1 I Texscan t 339.356.371 t

Pioneer

,i,,“/::“““”

Sanyo

Scott

Sears

Sharp

Shintom I 239

Tatung

Teat t 202,231

I

I

Allegro 358,362

Allegro A/B Switch 361

Gemini 305,331,338

General Electric 367

General 304,305,306,

Instrument

Harnlin 302,303,345,

Jerrold 304,307.308,309,

I

Oak

I

Paragon

I

t 239 Samsung 103,119.134,141

250

t 214.251,259

I215

I 210,215

240,242,249,260

206,212,247

204,205,233,243

206,209,211,

212.215

208,261

I

202

] 229,237

307,308,309,

310,318

365,366

1311.332.342 1

I Stargate

Tocom

I

Unika

United Satellite

Universal

Vid Tech

Video Way

Viewstar

Zenith

Zenith Satellite

I

Akai

I

I

Goldstar

Harman/Kardon

1 Magnavox ]421,422,433,434 1

1 Mitsubishi 1423,424

Nakamichi

NEC

onkyo

Panasonic

Pioneer

Radio Shack

RCA

I saw0

Sharp

Sony

I Soundesign I46J,498,.501,502 1

I

317,318.346

348.362

344

358,362

340

349

354,355,372

301,353,374

312,328, 330,

351.378

409,424

410

411

412,438

460

413

415

412,416,417.441

430

431,432

421,433,434

431,435

432

431, 436,439,440,

441

437

I 438,439

Kenwood I450

Onkyo 1458

Pioneer 1477.478479

Radio Shack 487,488

Realistic I480

Sanyo 1481

Scott

Sharp

Sherwood

Sony

Soundesign

Teat

Technics

Yamaha

I

Zenith

482

483

487.488

489.490.49 1,492

461.4Y8.501,502

494,495

497

496

460,461,498.501.

502

I

I

I

12

Page 15

MODEL PARTS LIST

A 27CX31 B511 (ZHT2772DT)

B 27CX318521 (MZHT2772DT

C 27CX22B501 (CZHT2771 DT)

NOTE:

This combined parts list will enable you to more easily determine the part number for parts used on each model chassis or assembly.

Each has been assigned a reference coda (RC), which is in the first column.

RC

ABCDEF

ABCDEF

CDE

ABF

ABCDEF

ABCDEF

ABCDEF

ABCDEF

ABCDEF

ABCDEF

ABCDEF

ABD

CEF

ABCDEF

PART #

0 14-12038

014-12165

014-12186-21

014-12186-23

020-04330-30

049-01368-03

050-01699-03

050-01989-0 1

050-01989-02

095-03797-05

A68AGDOlXl

124-00220

124-00220-01

152-00335

CABINET TRAY 25V, MOLDED PLASTIC

CABINET REAR TV, MOLDED PLASTIC

CABINET FRONT TV, MOLDED PLASTIC

CABINET FRONT TV, MOLDED PLASTIC

COIL DEGAUSSER

SPEAKER OVAL (2)

CONNECTOR&CABLE ASSY, 2.5 MM, 5 CONTACT

CONNECTORkABLE ASSY, 25MM,

CONNECTOR&CABLE ASSY, 2.5MM, 2 CONTACT

TRANSFORMER DEFLECTION YOKE

VACUUM TUBE CRT, COLOR, 27 INCH DIAG

SPACE COMMAND TRANSMllTER

SPACE COMMAND TRANSMIITER

WEDGE YOKE SPACER/POSITIONER

g-1814 PIP MODULE

REF PART # DESCRIPTION

I

L2001, L2004

L2cO3

C2CO7

C2041

c202.2

C2017, C2018

C2040

C2W8, c2019

C2032

C.2006. C2033

c2060

C2026, C2047

C2026, C2047

c2002, czoi 1

C2015, C2024

C2046

C2003m. C2045m.

C205Om

CZOlOm,

C2014m

C2048m. C2049m

C.2001 m, CZ028m

C2021 m

CZW9m, C2031 m

C2035m

C2205m, C2012m,

C2013m, C2016m

C2023m. C2025m

C2029m, C2030m

C2036m, C2037m

020-04129-20

02044277.73

022-08048-24

022-0.9049

022-08227-09

022-08227-i 1

022-08227-11

022-08227-i 5

022-08227-15

022-08241-12

02208241-34

02208309-l 1

022-08309-I 1

022.08312~7

022-06312-06

022-06312-08

022~08352-12

022-08352-i 2

022-08352-28

022-06353-20

022-08353-36

022-08366-13

022-06367-08

022-06367-12

022-08369-20

022-08369-20

022-08369-20

022-08369-20

022-08369-20

COIL 10 MICROHENRY

COIL 3.3 MICROHENRY

CAPACITOR

0.10

CAPACITOR 0.0010 MFD 10% 50~

CAPACITOR 0.068 MFD 5% 50V

CAPACITOR 0.1 MFD 5% 50V

CAPACITOR 0.1 MFD 5% 5OV

CAPACITOR 0.22 MFD 5% 5OV

CAPACITOR 0.22 MFD 5% 50V

CAPACITOR 12 PFD 5% 50J

CAPACITOR 1 CO PFD 5% 5OV

CAPACITOR 47 MFD 20% 16V

CAPACITOR 47 MFD 20% 16V

CAPACITOR 4.7 MFD 20% 50V

CAPACITOR IO MFD 20% 50V

CAPACITOR 10 MFD 20% 50V

CAPACITOR 10 PFD +0.5 B. -0.5 PFD 5

CAPACiTOR IO PFD +OS C -C).5 PFD 5

CAPACITOR 47 PFD 5% 50V

CAPACITOR 22 PFD 10% 5OV

CAPACITOR

CAPACITOR 2,700 PFD 10% 50V

CAPACITOR 1 $00 PFD 20% 5OV

CAPACITOR 2.200 PFD 20% 5OV

CAPAClTOR 10,OOU PFD 20% 25.V

CAPACITOR iO.ooO PFD 20% 25V

CAPACITOR 10,ooO PFD 20% 25V

CAPACITOR IO,WO PFD 20% 25V

CAPACITOR 10,COO PFD 20% 25V

DESCRIPTION

MFD 5% 5OV

2 CONTACT

D 27CX22B511 (MT2771 DT)

E 27CX22B521 (MZHT2771 DT)

f 27CX318501 (CZHT2772DT)

C 206-03326 INSTR BOOK OPERATION GUIDE

A 206-03326

E 206-03325

INSTR BOOK OPERATION GUIDE

INSTR BOOK OPERATION GUIDE

B 206-03327 lNSTR BOOK OPERATION GUIDE

F 206-03333 INSTR BOOK OPERATION GUIDE

D 206-03324 INSTR BOOK OPERATION GUIDE

ABCDEF A-18035-02

ABCDEF F-52621

ABF

~~~~~~~,.‘:.‘-~~~~~~MoDULE pIp

LINE CORD ASSY WITH JST CONNECTOR

KEYBOARD ASSY IO POSITION

CDABCDEF

ABCDEF

REF PART #

C2042m, C2043m

C2052m, C2053m

C2054m

2A2,282

R2035, R2038

R2010

R2005

R2037

R2036

R2013

R2014

JWlm

R2203m. R2004m

R2011 m. R2012m.

R2015m. R20i 6m

R2017m

RZOOBm

R2202m, R2021m

R2028m

R2019m

R2020m

R2001 m

R22009m

R2006m

02000, D2001

D2032

cl2OcQ

IC2000

X2002, X2003

x2001

022-os%9-20

022-08369-20 CAPACITOR 10,000 PFD 20% 25V

022-08369-20 CAPACITOR 10,ooO PFD 20% 25V

05800636-06

063-10235-72 RESISTOR FILM 1K OHM 5% 1/4W

063-10235-80 RESISTOR FILM 2.2~ OHM 5% 114~

063-10235-98 RESISTOR FILM 12K OHM 5% 1/4W

063-10236 RESISTOR FILM 15K OHM 5% 1/4W

063-10236-08

063-10236-16

063-10236-20 RESISTOR FILM iOOK OHM 5% 114W

063-l 1059 RESISTOR THICK FILM CHIP 0 OHM 5% l/l OW

063-l 1059-25 RESISTOR THICK FILM CHIP 100 OHM 5% IHOW

063-i 1059-25 RESISTOR THICK FILM CHIP 100 OHM 5% wow

063-l 1059-25 RESISTOR THICKFILM CHIP tOO OHM 5% 1HOW

063-l 1059-25 RESISTOR THICKFILM CHIP 100 OHM 5% l/lOW

063-l 1059-37

063-l 1059-49

063-l 1059-54

063-l 1059-59 RESISTOR THICK FILM CHIP 2.7K OHM 5% l/low

063-l 1059-75 RESISTOR THICK FILM CHIP 12K

063-l 1059-90

063-l 1059-92

063-11060-13 RESISTOR THICK FILM CHIP 470K OHM 5% l/low

103-00461 DIODE ULTRA FAST SWITCHING

10300461 DIODE ULTRA FAST SWITCHING

121-01310 TRANSISTOR NPN, SILICON

221 -CO987 INTEGRATED CKT PIP CONTROLLER

224-COO6104 CRYSTAL QUARTZ, 14.31818 MHZ

224-00201 RESONATOR CERAMIC, 503N KHZ

CAPACITOR 10,003 PFD 20% 25V

CONNECTOR MULTIPRONG

RESISTOR FILM 33K 5% 114W

RESISTOR FILM 68~ OHM 5% i/4w

RESISTOR THICK FILM CHIP 330 OHM 5% l/low

RESiSTOR THICK FILM CHIP 1K OHM 5% l/low

RESISTOR THICK FILM CHIP 1.6K OHM 5% l/low

RESISTOR THICK FILM CHIP 51 K OHM 5% 1 I1 OW

RESISTOR THICK FILM CHIP 62K OHM 5% l/low

DESCRIPTION

okhi

5% l/low

** Critical Safety Components Shaded

13

Page 16

9-1824 MTS AUDIO JACKPACK MODULE

NOTE: This combined parts list will enable you to more easily determine the part number for parts used on each model chassis or assembly,

Each has been assigned a reference code (RC), which is in the first column.

Cl419

Cl414

Cl420

coe.42. CO853

CO863

Cl416 Cl417

C1426. Cl427

Cl422

Cl424

Cl421

CO843 CO852

co662, Cl430

CXO854. CXc664

cxO841

Cl415 Cl418

C1408, CI410, C1425,

C1428, Cl432

CO851, CO861, Cl413

C1450M, C1452M

Co855M, C0856M

Cl402M, C1404M

C1431M

C1401M. C1403M

C1406M

9L4. 9R4

9&i

9A4

012-10681-10

019-00957-07

022-07669-14

022-07669-15

022.08049-13

022-08049-24

022-08049-24

022-08188-05

022-08188-05

022-08227-07

022-08257-17

022-08257-21

022-68309-12

022-08309-12

022-08309-l 6

022-08310-16

022-08312-04

022-0831 Z-07

022-08312-07

022-08312-08

022-08352-36

022-08366-08

022-08368-18

022-08368-20

022-08370-22

022-08370-24

058-60542-02

058-66636-06

058-66636-09

MOLDED PLASTIC PANEL, JACK PACK

CLIP TRANSISTOR MOUNTING

CAPACITOR 3.3 MFD 10% 5OV

CAPACITOR 10 MFD 10% 50V

CAPACITOR

CAPACITOR 0.10 MFD 10% 50V

CAPACITOR 0.10 MFD 10% 50V

CAPACITOR lo MFD 20% 25V

CAPACITOR 10 MFD 20% 25.V

CAPACITOR 0.647 MFD 5% 50V

CAPACITOR 2700 PFD 10% 5QV

CAPACITOR 5600 PFD 10% 50V

CAPACITOR 100 MFD 20% 16V

CAPACITOR 100 MFD 20% 16V

CAPACITOR IOM) MFD 20% 16V

CAPACITOR loo0 MFD 20% 25V

CAPACITOR 1 MFD 20% 50V

CAPAClTOR 4.7 MFD 20% 56V

CAPAClTOR 4.7 MFD 26% 56V

CAPACITOR 10 MFD 20% 50V

CAPACITOR 100 PFD 5% 50V

CAPACITOR 1 ,QOQ PFD IO% 50V

CAPACITOR 6.800 PFD 10% 50V

CAPACITOR 10.000 PFD 10% 25V

CAPACITOR 15,000 PFD 10% 16V

CAPACIT0R22.600 PFD 10% 16V

PLUG 2.5 MM. 2 POSITION

CONNECTOR MULTIPRONG

CONNECTOR MULTIPRONG

COMPONENT PARTS LIST

REF PART #

I

JO802, Jo804

JO801, Jo803 078-03402-01 CONNECTOR PHONO, WHITE

JO806

SW0801 085-01778-03 SWITCH SLIDE, REGULAR

R0859. ROB69 063-10235-24

ROOOl

R1401, R1402 Q63-f0235-46 RESISTOR FILM 100 OHM 5% v4w

ROQ.43 063-10236-60

RX0842

RO854, R0864, RI423 063-10235-80 RESISTOR FILM 2.2K OHM 5% 1/4W

R1424, R1427, RI428 063-10235-60 RESISTOR FILM 2.2K OHM 5% 1/4W

RO844, RO858, RO868 063-10235-88 RESISTOR FILM 4.7K OHM 5% 1/4w

RX0653. RX6863

RX0646 063-10565-08 RESISTOR FILM 2.2 OHM 5% 1/2W

ROBSaM, R0862M

R1407M. Ri406M 063-i 1059.61 RESISTOR THICK FILM CHIP 3.3K OHMS% 1HOW

R1405M

R142lM 063-i 1059-71 RESISTOR THICK FILM CHIP 8.2K OHM 5% IHOW

RO85IM, R0881M 083-l 1059-73

RI422M 063-l 1059-73 RESISTOR THICK FILM CHIP IOK OHM 5% l/IOW

R1477M 063-l 105985

R6809M 063-11059-89 RESISTOR THICK FILM CHIP 47K OHM 5% l/low

R1405M 063-l 1059.97

RI424M. R1426M 083-11060-2t RESISTOR THICK FILM CHIP 1 MEG OHM 5% i/low

R1464M 083-l 1244-76 RESISTOR THICK FILM CHIP 61.9K OHM 1% 1HOW

00800 121*01310 TRANSISTOR NPN, SILICON

CO804 221-06596-01 INTEGRATED CKT AUDIO POWER AMPLIFIER

ICI406 221-01127 INTEGRATED CKT MTS STEREO DECODEWVOLL

078-03402

078-3402-62

063-10235-45

063-10235-72

063-10559-12

683-l 1059-57

663-11059-63

DESCRIPTION

CONNECTOR PHONO, RED

CONNECTOR PHONO. YELLOW

RESISTOR FILM 10 OHM 5% 1/4W

RESISTOR FILM 75 OHM 5% Il4W

RESISTOR FILM 336 OHM 5% 1/4W

RESISTOR FILM IK OHM 5% 1/4W

RESISTOR FILM 3.3 OHM 5% 1/4W

RESISTOR THICK FILM CHIP 2.2K OHM 5% l/iOW

RESISTOR THICK FILM CHIP 3.9K OHM 5% IllOW

RESISTOR THICK FILM CHIP IOK OHM 5% I/IOW

RESISTOR THICK FILM CHIP 33K OHM 5% l/IOW

RESISTOR THICK FILM CHIP IOOK OHM 5% l/lOW

Page 17

COMPONENT PARTS LIST

9-1908 MAIN, 27V WITH COMB FILTER MODULE

I

REF DESCRfPTlON

012-l 0696 MOLDED PLASTIC BRACKET

020-03907-12 COIL 10 MICROHENRY

Li2oa 020-03907-25 COIL 120 MICROHENRY

I

L6001, L6002, L6003 020-94129-o6 COIL 1 MICROHENRY

I

L6003. L6004, L6005 020-o4129-08 COIL 1 MICROHENRY

L6006. L6007, LWO8 02004129-06

L2401 OZO-O4129-20 COIL 10 MICROHENRY

L1206 020134277u9 COIL 0.62 MICROHENRY

L.2202 02004277-20

L2203

Li 203 020-04277-23 COIL 12 MICROHENRY

L5100 020-04277-29 COIL39 MICROHENRY

( ., ( (

:“i::“. .:.., ‘. ‘:‘,.:‘,:,:::~::,i:.r’:,:~‘:‘:‘:’,:’,~~,::::::~,:,‘:,~~,~~,~~ :ii:r::,i:,I’i::~:“i:::“)iii :

ili~~~~~,:c~iiltIZt,,:,:.::.~::1”MZ~~~~~DS:ii:i::.:‘;t:i:~~~~~~~~‘~~~~~~~~~~~~~~.~~~~.~,~~~

. . . . . . . . . . . . . . .../.! . . . . . . . . . . . . . . . . . . . . . . ;..,. ..,.. / . . . . . ..,.,./.. . . ,. . . .,,.,.,.,..,,/, .,.~,.,.,.,..,..,..,..,. .’ ,.,/ ..,.,.....,. .;. j:,:,:: ..:. . . . . . . . . . . ., i :..:..:.

I

02003907-24 COIL 100 MICROHENRY

COIL 1 MICROHENRY

COIL 6.8 MICROHENRY

0201)4277-Z?

020-04277-B COIL 10 MICROHENRY

020-04278 COIL RCF, TUNABLE

020-04462-l 6 COIL 33 MICROHENRY

02o-o45o6 COIL RCF, FIXED

022.0752341 CAPACITOR 0.01 MFD +60 % A -20 %

COIL 10 MICROHENRY

.,. .,

FIEF PART # DESCRIPTION

., / ,. ,., .,. .,

~‘:::::::‘~~;.j~~~~~~~~:r:i’li;j:j:~:,.~.~~-;:;i:,

( ., .1 ../.

C2203, C22O4

c2205

C1229, Cl232

Cl.235

C1207, Cl208

c2215, c2217

C2218, c2219

C2226. C2227

C6020, CM)64

c2211, Lx026

C1211,C3246

cm12

,..‘..... / . . . . . . . .././........

022-08312

022-o6312

022-08312U3

022-oa31203

022-08312-04

022-06312x!4

022-09312-O4

022-06312-O4

022-o631 Z-04

022-o&312-05

022-08312-07

022-08312-07

. . . . . . . . . . .,: : Q.. ., ., ., ., .,,

. . . . . . . . .

CAPACITOR 0.1 MFD 20% 5OV

CAPACITOR 0.1 MFD 20% 5OV

CAPACITOR 0.47 MFD 20% 50V

CAPACtTOR 0.47 MFD 20% 5OV

CAPACITOR 1 MFD 20% 5OV

CAPACITOR 1 MFD 20% 5OV

CAPACITOR 1 MFD 20% sov

CAPACITOR 1 MFD 20% 5OV

CAPACITOR 1 MFD 20% XIV

CAPACITOR 2.2 MFD 20% 5OV

CAPACITOR 4.7 MFD 20% 5OV

CAPACITOR 4 7 MFO

..,. :..>.: : : :i ,......., .,., ..:.: ..,. .,. . . . . ,.: ,.:..:s: .,/ /

1 CZlO6. C2232

C6OQl 022-08049-20

C1222. C2114 022-06049-24 CAPACITOR 0.10 MFD 10% 50V

I

1 C2115, C3426 CAPACITOR 0.10 MFD 10% 50V

C2401 CAPACtTOR 47 MFD 20% 6.3V

I

I

13233. C2208 022-08308-15

022-07774-24

022-07796-17

022-07667-10 CAPACITOR 0.1 MFD 20% 250VAC

022-omo6-12 CAPACITOR .Ol MFD 5% 1250V

022-08241-36 CAPACITOR 120 PFD 5% 5OV

022-oa257-oa

022-08309-15 CAPACITOR 470 MFD 20% 16V

CAPACITOR 0.1 MFD 10% 1DDV

CAPACITOR 2200 PFD 10% 5OOV

CAPACtTOR 0.047 MFD 10% WV

CAPACITOR 470 PFD 10% 5W

CAPACITOR 470 MFD 20% 1OV

** Critical Safety Components Shaded

c5105

C2202M

C6OlBM

C6O19M

C1206M

C2234M

C1213M

C2240M

C2241M

C2225M, C2236M

C2250M

C2221 M

C1212M. C3214M

CBOOBM, C6009M

CWOM. C6011M

CM)SOM, CM)51 M

CWOOM, C6021 M

C6022M, C6023M

C6024M

C5101M, C5102M

C5103M

C2257M

C6OO2M, C6005M

C1221M, C1224M

C1231M, C2237M

C1202M, C6031 M

C1227M C1228M

C1234M, C5107M

C6052M, C6053M

C6054M, C6055M

C6056M, C6057M

022-O831864 CAPACITOR 1 MFD 20% 35OV

022-08352-14 CAPACITOR 12 PFD 5% 5OV

022-08352-20 CAPACITOR 22 PFD 5% W.’

022-08352-22 CAPACITOR 27 PFD 5% 5OV

02206352-24 CAPACITOR 33 PFD 6% 5OV

022-08352-38 CAPACITOR 120 PFD 5% 50V

022-08352-3s

022-08352-38 CAPACITOR 120 PFD 5% 50V

022-Ol3352-36 CAPACITOR 120 PFD 5% 50V

022-08352-42 CAPACITOR 160 PFD 5% 5OV

02208352-49 CAPACITOR 330 PFD 5% 5oV

022-08353-20 CAPACITOR 22 PFD 10% WV

022-06353-28

022-08353-28

02208353-26 CAPACITOR 47 PFD 10% 50V

022-08353-28 CAPACITOR 47 PFD 10% 50V

022-08353-36 CAPACITOR 100 PFD 10% 50V

022-08353-36 CAPACKOR 100 PFD 10% 5OV

02209353.36 CAPACITOR

022Xx3364-52

022-08364-52 CAPACITOR 470 PFD 5% 5OV

02208366-04 CAPACITOR 470 PFD 10% 5OV

022-OB366-05 CAPACITOR 560 PFD 10% 5OV

02268366-08 CAPACITOR 1 $00 PFD 10% 5oV

022-08366-08

022-08366-16 CAPACITOR 4.700 PFD 10% 50V

022-08367-08 CAPACITOR I ,000 PFD 20% 5ov

022-O8367-08 CAPACITOR 1 ,COO PFD 20% 50V

02248367-08 CAPACITOR 1 ,ooO PFD 20% 50V

02208367-08 CAPACtTOR 1 ,ooO PFD 20% 5OV

022-08367-08

CAPACITOR 120 PFD 5% 5OV

CAPACITOR 47 PFD 10% 5OV

CAPACITOR 47 PFD 10% 5OV

100 PFD 10% 50V

CAPACITOR 470 PFD 5% 50V

CAPACFTOR 1 .ooO PFD 10% 5OV

CAPACtTOR 1 $03 PFD 20% 50V

15

Page 18

COMPONENT PARTS LIST

9-1908 MAIN, 27V WITH COMB FILTER MODULE

REF PART # DESCRIPTION REF PART #

CW58M, C6059M

C6060M, C6007M

C6036M, C6081M

C6062M

C1215M, Cl216M

C1218M. C1219M

C1223M. C1225M

C1226M. C2207M

C2209M, C1220M

C1235M. C2402M

C2403M, C6003M

C6016M. C6026M

C6029M. C6033M

C1236M. C6006M

C6025M

2F5/5FZ 050-01664-05 CONN. & CABLE ASSY, P.SMM. 3 CONTACT, 2 UP

2C5l5C2 050-01667-05 CONN. &CABLE ASSY. ZSMM. 6 CONTACT. 2 UP

2K64GS 058-00526-05 PLUG 0.098P 5 CONTACT

3TB 058-00546-02

3Y3 058-00546-04 PLUG MULTIPRONG

3RBALT

L22w 063-l 0235-24 RESISTOR FiLM 10 OHM 5% 1/4W

R1223. R2212 063-l 0235.48 RESISTOR FILM 100 OHM 5% 114W

R2219, R2220 063-l 0235.48

R2278 063-l 0235.48 RESISTOR FILM 100 OHM 5% 1/4W

RI209 R2282 963-l 0235-56

R3243 063-l 0235-56 RESISTOR FILM 220 OHM 5% l/4W

R2231

022-08367-08 CAPACITOR 1 ,CGY PFD 20% 5OV

022-08367-08 CAPACITOR t ,$QO PfD 20% 50V

022-08367-06 CAPACITOR 1,00a PFD 20% 50~

022-08367-08 CAPACITOR 1.000 PFD 2B% 5OV

022-06369-20 CAPACITOR 10,000 PFD 20% 25V

022-08369-20 CAPACITOR 10.000 PFD 20% 25V

022-08369-20 CAPACITOR 10,OW PFD 2wb 25V

022+08369-20 CAPACITOR 10,000 PFD 2B% 25V

022-08369-20 CAPACITOR 10,000 PFD 20% 25V

022-08369-20 CAPACITOR 10.000 PFU 20% 25V

022-08369-20 CAPACITOR 1 D,OW PFD 20% 25V

022-08369-20 CAPACITOR iO.OCU PFD 20%25V

022-08369-20 CAPACITOR 10,OW PFO 20% 25V

022-08371-24 CAPACITOR 22,000 PFO 20% 16V

022-08371-24 CAPACITOR 22.OW PFO 20% i6V

PLUG JOOO4M. JOOO6M 063-11059

058-00570-02 PLUG MULTIPRONG

RESISTOR FILM 100 OHM 5% 114W

RESISTOR FILM 220 OHM 5% 114W

063-l 0235-64 RESISTOR FILM 4700HM 5% 1/4W

063-l 0235-66 RESISTOR FILM 5600HM 5% 1/4W

063+10235-67

RESISTOR FILM 6200HM 5% 1/4W

R6036

R2146 063-10236-24 RESlSTOR FILM 1SOK OHM 5% 1/4W

R2132

R5116, R5117 063-iO243-72 RESISTOR FILM 1K OHM 5% 1/2w

R.5118, R5119

R5120 063-30243-72 RESISTOR FILM 1K OHM 5% 1/2W

R5123 063-10246-46 RESISTOR FILM 1.2M OHM 10% 1/2W

R2111, R2113 083-10565-81 RESISTOR FlLM 3&B OHM 5% 1/2W

R2133, R3249 063-l 1967-56 CONTROL ROTARY, TRIMMER

JCKtOPM, JOOOO3M 063-l 1059 RESISTOR THICK FILM CHIP 0 OHM 5% l/iOW

&007M, FOOOBM

R2246h4, R6072M

R1226M

R1230M

R2252M, R2266M

R2263M, R5102M

R5f13M, R5114M

063-10236-20

063-10236-26

063~t0243-72 RESISTOR FILM IK OHM 5% 1!2w

063-I 1059

063-l 1059

063.11059-cl9

063-11059-13

RESISTOR FILM 1BBK 5% 114W

RESISTOR FILM 1BOK OHM 5% 1/4W

RESISTOR FILM 220K OHM 5% 1/2W R5122 063-10244-28

RESISTOR THICK FlLM CHIP 0 OHM 5% 1HOW

RESISTOR THICK FILM CHIP 0 OHM 5% i/i ow

RESISTOR THICK FILM CHIP 0 OHM 5% l/lOW

22 OHM 5% l/lOW

RESISTOR THICK FILM CHIP 33 OHM 5% l/low

RESISTOR THICK FILM CHIP 47 OHM 6% l/lOW

RESISTOR THICK FlLM CHIP 47 OHM 5% l/low

RESISTOR THICK FlLM CHIP 47 OHM 5% l/lOW

DESCRIPTION

Rl228

R2122, R2248 063-10235-60 RESISTOR FILM 2.2K OHM 5% 1/4W

R5132

R3201 063-t0235-82 RESISTOR FILM 2.7K OHM 5% 1/4W

R2109 963-10235-84

R3248 063-10235-86 RESISTOR FILM 3.BK OHM 5% i/4W

R2279, RZ610 063-10235-96 RESISTOR FILM IOKOHM 5% 1/4W

R3247. R6029

I36039 063-10235-96 RESISTOR FILM 10K OHM 5% ll4W

R2277 063-10236-02 RESlSTOR FILM ISK OHM 5% 114W

R6023 063-10236-04

R5121 063-10236-05

R6051 063-10236-17

l

* Critical Safety Components Shaded

063-l 0235-78 RESISTOR FILM 1.5K OHM 5% 114W

063-10235-80 RESISTOR FILM 2.2K OHM 5% 114W

RESISTOR FILM 3.3LK OHM 5% 114W

063-10235-96 RESISTOR FILM IOKOHM 5% 114W

RESISTOR FILM 22K OHM 5% I/4W

RESISTOR FILM 24K OHM 5% 1/4W

RESISTOR FlLM 75K OHM 5% 1/4W

R5104M, R5t05M RESISTOR THICK FILM CHIP 150 OHM 5% l/low

R5108M 063-l 1059-29

R2214M, R2215M

R2214M, R2215M

R2229M, R2244M 063-l 1059-39 390 OHM 5% l/low

Ri227M. RZm7M

R2209M. R221 I M

R2260M, R2261 M 063-l 1059-41 RESISTOR THICK FILM CHIP 470 OHM 5% l/low

R2222M 063-l 1059-41

R5108M. R5109M

R1232M. R2216M

R2284M. R2285M

RtPllM. R7213M

R2217M. R2228M

063-l 105933

063-l 1059-33 RESISTOR THICK FILM CHIP 220 OHM 5% l/low

063-l 1059-33 RESISTOR THICK FILM CHIP 220 OHM 5% IIIOW

063-l 1059-41

063.11059-41

063-l 1059-44

063-l 1059-46

063-l 1059-46

063-t 1059-48

063-l 1059-49

063-l 1059-49

RESISTOR THICK FlLM CHIP 150 OHM 5% 1llOW

RESISTOR

THlCK FILM CHIP 220 OHM 5% 1llOW

RESISTOR THICK FILM CHlP 330 OHM 5% l/low R2245M 063-l 1059-37

RESISTOR THICK FILM CHIP 470 OHM 5% l/lOW

RESISTOR THICK FILM CHIP 470 OHM 5% 1IlOW

RESISTOR THICK FILM CHlP 470 OHM 5% IHOW

RESISTOR THICK FILM CHIP 620 OHM 5% view

RESISTOR THICK FILM CHIP 750 OHM 5% l/lOW

RESISTOR THICK FILM CHIP 750 OHM 5% l/low

RESISTOR THICK FILM CHIP 750 OHM 5% lllow

tK OHM 5%

lKOHM5%

16

ll1OW

l/low

Page 19

COMPONENT PARTS LIST

g-1908 MAIN, 27V WITH COMB FILTER MODULE

REF PART # DESCRIPTION

R2259M. R2265M.

RGWOM, R6WZM

RM)OBM, R6007M

R6031 M. R6037M

RiZliM, Rl213M

R2217M. R2226M

R2259M, R2265M

FBOOOM, R6002M

R6003M. R6007M

R6031 h4 R6037M

R2108M, R2230M

R2270M, R2272M

R2274M

R2200M, R2240M

R2257M. R227lM

R2273M, R2275M

R5124M

R1212M. R2239M

R2242M. R6015M

R6016M

Rl212M. R2239M

R2242M, R6015M

RM)lGM. R6017M

R6018M, R6046M

R2205M

R2206M, R2208M

R22lOM

Rl22lM, Rl222M

R1233M, R2234M

R2237M. R229OM

R3414M. R3442M

R6006M. R6006M

R6030M. R6040M

R6041M

R2143M, R2145M

R2235M. R224lM

R6038M

R213lM, R2218M

R3223M

R1234f.A R2142M

R2243M

R2144M, R2147M

R6014M, R6019M

Rl220M

Rl235M. R2221 M

R6020M, R6042M

R6045M, R2258M

R3212M

R2224M, R6047M

R6048M

R214lM

R3252 063-i 1067-64 RESISTOR FILM 470 OHM 55 i12W

R3225, R3226

R3418. R3421

063-11059-49

063-tl059-49

063-l 1059-49

063-I 1059-49

063-I 1059-49

063-l 1059-49

063-l 1059-49

063-l 1059-49

063-l 1059-49

063-l 1059-49

063-I 1059-57

063-l 1059.59

063-11059-59

063-11059-61

063-I 1059.63

063-l 1059.63

063-l 1059-63

063-11059-65

063-11059-65

063-l 1059-65

063-l 105945

063-l 1059-65

063-i 1059-65

063-i 1059-65

063-i 1059-69

063-l 1059-70

063-I 1059-70

063-I 1059-73

063-l 1059-73

063-11059-73

063-l 1059-73

063-11059-73

063-I 1059-73

063-l 1059-73

063-I 1059-77

063-l 1059-77

063-l 1059-77

063-l 1059-61

063-I 1059-61

063-i 1059-67

063-l 1059-87

063-l 1059-89

063-I 1059-69

063-l 1059-95

063-I 1059-97

063-I 1059-97

063-I 1059-97

063-I 1060-05

063-I 1060-I 3

063-l 1060-13

063-l 1060-l 8

063-i 1087-66 RESISTOR FILM 560 OHM 5% 1/2W

063-l 1087-72 RESISTOR FILM 1 .OK OHM 5% i/2W

RESISTOR THlCK FILM CHIP 1K OHM 5% l/loW

RESISTOR THICK FILM CHIP 1K OHM 5% l/low

RESISTOR THICK FILM CHIP iK OHM 5% IHOW

RESISTOR THICK FILM CHIP 1K OHM 5% 111 OW

RESISTOR THICK FILM CHIP IK OHM 5% i/low

RESISTOR THICK FILM CHIP IK OHM 5% i/low

RESISTOR THICK FILM CHIP IK OHM 5% i/lOW

RESISTOR THICK FILM CHIP 1K OHM 5% l/low

RESISTOR THICK FILM CHIP 1K OHM 5% l/low

RESISTOR THICK FILM CHIP IK OHM 5% l/low

RESISTOR THICK FILM CHIP 2.2KOHM 5% l/low

RESlSTOR THICK FILM CHIP 2.7K OHM 5% l/iOW

RESISTOR THICK FILM CHIP 2.7K OHM 5% l/low

RESlS+OR THiCK FILM CHIP 3.3K OH,., 5% l,,OW

RESISTOR THICK FILM CHIP 3.9K OHM 5% l/low

RESISTOR THICK FILM CHIP 3.9K OHM 5% l/low

RESISTOR THICK FILM CHIP 3.9K OHM 5% l/low

RESISTOR THICK FILM CHIP 4.7K OHM 5% l/low

RESISTOR THICK FILM CHIP 4.7K OHM 5% VIOW

RESISTOR THICK FILM CHIP 4.7K OHM 5% l/low

RESISTOR THICK FILM CHIP 4.7K OHM 5% 1IlOW

RESISTOR THICK FILM CHIP 4.7K OHM 5% l/lOW

RESISTOR THICK FILM CHIP 4.7K OHM 5% l/low

RESISTOR THICK FILM CHIP 4.7K OHM 5% l/lOW

RESISTOR THICK FILM CHIP 6.EKOHM 5% l/low

RESISTOR THICK FILM CHIP 7SKOHM 5% l/lOW

RESISTOR THfCK FILM CHIP 7.5K OHM 5% l/low

RESISTOR THICK FILM CHIP IOK OHM 5% i!iow

RESISTOR THICK FILM CHIP IOK OHM 5% l/lOW

RESISTOR THICK FILM CHIP 1OKOHM 5% l/lOW

RESISTOR THICK FILM CHIP IOKOHM 5% IHOW

RESISTOR THICK FILM CHIP 1OKOHM 5% lllOW

RESISTOR THICK FILM CHIP 1OKOHM 5% l/lOW

RESISTOR THICK F1Lb.i CHIP IOK OHM 5% 1HOW

RESISTORTHICK FILM CHIP 15KOHM 5% l/low

RESISTOR THICK FILM CHIP 15K OHM 5% l/low

RESISTOR THICK FILM CHIP 15KOHM 5% l/low

RESISTOR THICK FILM CHIP 22KOHM 5% l/low

RESISTORTHICK FILM CHIP 2ZK OHM 5% l/lOW

RESISTOR THICK FILM CHlP39K OHM 5% l/low

RESISTOR THICK FILM CHdP39KOHM 5% l/low

RESISTOR THICK FILM CHIP 47K OHM 5% l/iOW

RESISTOR THICK FILM CHIP 47K OHM 5% l/low

RESISTOR THICK FILM CHIP 82K OHM 5% l/low

RESISTORTHICK FILM CHIP IWK OHM 5% i/iOW

RESISTOR THICK FILM CHIP 10OK OHM 5% l/rOW

RESISTOR THICK FILM CHIP 1OOK OHM 5% l/low

RESISTOR THICK FILM CHIP 220K OHM 590 l/low

RESISTOR THICK FILM CHIP 470K OHM 5% WOW

RESISTOR THICK FILM CHIP 470K OHM 5% l/low

RESISTOR THICK FILM CHIP 750K OHM 5% l/lOW

063-l 1235-03 RESISTORFILM 0.18 OHM 10%3W

T3205 095.04477 TRANSFORMER HORIZONTALURIVER

202252 103-00279-18 DIODE ZENER

tD6001 t03-00279.36 DIODE ZENER

I(33442 221-00166 INTEGRATED CKT 5 VOLT, 500MA

IC6001 221-00745-04 INTEGRATED CKT 4K BIT SERIAL EEPROM

. ..,..

:. :.:p:.‘:::_ .::y .:: .:i. . . . i.;.::

:k~~~~.;:::::::::::i:i-:: ! ;:. : : ~~~~~~~j:,j:,;:,;i,:,~~~l~~~osM~!~~~~~~~~~~ ej ;,i:+= :’ ,’ ;,:j,:j;<

,.. ,. I .,. I /

IC6000

DL2400 223-00045 DELAY LINE

U1202

CR2200 224-00027 CRYSTAL QUARTZ

u1200 224-W139-01 FILTER 4.5 MHZ CERAMIC BANDPASS

CRY6OOO 224-00157 CRYSTALQUARTZ, 12.083916 MHZ

,, :,:::::: :

:

: ,.

.:....... . . . . . . . . . . . ..i..............~~~:~.:.:..

.:L.:.::.::..:.y ..::i . . . . . . . . . . . ..>.I’>.. .“I::?): . . . . . . . . . ..l........ I:i:,:,/. ,,, ., ., ., ., ,, ,,, .,

221-01136-02 INTEGRATED CKT MICROCONTROLLER

224-00023 CERAMIC FILTER 4.5 MHZTPAP

.), . . .

.~.l.l::.::........... ..,. :y.: :.,:: p>>:*> /-.+:,/:i// ,:y.,:,,: :, 1 ,. :&

. . . . . . .../..... . . . . . . :,,: ,:.:,..,,.,,.:..,.:,,,,,,,,,,,,,,,,,,,,,, .,,,,,,,,

** Critical Safety Components Shaded

17

Page 20

9-1908 MAIN, 27V WITH COMB FILTER MODULE

18

REF PART # DESCRIPTION

u1201 224-00160

224-00178 RESONATOR CERAMIC. 503 KHZ

FILTER SURFACE ACOUSTIC WAVE

F-4731 8

F-49646 LIST BELOW)

F-49700 WIRE&TERM ASSY SINGLE CONDUCTOR, SIMPLE

F-51055 BELOW)

F-51 056 BELOW)

F-51115 LISTED BELOW)

F-51116 LISTED BELOW)

F-51213 BELOW)

Q3201 121-01237 TRANSISTOR PNP. SILICON

019-00824-02 CLIP TRANSISTOR MOUNTING

019-01197-02 CLIP HEATSINK MOUNTING

‘i’.~~:~:i’~:i:i’,i::i:‘:: :::~:~:~~.~.‘~#~&~~ : j .:::rlii::i::i:i’id:~~~~~~~l~~~~~~~s~~.~~~~~~~’~~liil~j81I::lijlil:~:i,:i:i:i:

.:..:..:, . . . . ..,.../....,..,..,....,. .,..,..,.,..,..,..,.......... . . . . . . . . .,. .::l.l:.:‘:,::.:.:.:.::I’::::: i.,.::.:::::: ,i, :.:::.::.::.::.::.:: .,..,..,.........,j,,,,/...,..,..,..,..,......... . .,.

:il~:WQ%.ti’i’i::i:l‘i:.i ;!:!:::::i::22$0002-fl .~:i:i::i.:::jji:,i:Ifnm:%KTi:g~iG~M~~l~:~~T~ $xQufig~:c : !

./j ;: j_: . . . . :.‘ri:,.:.:;~.i : .,. 1.::....~.:.:...:;:;:~.:: :: I : .I I.. . . . . . . .: .A..... iii,,i ,,:‘I i,:~i;j.l’i ..: ,;:,..:r.: . . . . Y ,....,.. :I.?.: .,..,.., :,: ,..,...,... :.. .... ,. .... 1..

::j:j:_::: : : .“:‘)‘:,.y::: ,.:,.

,,i,i,,~ ,:,:., ., ., .,,:.,..,,,:~:_.,. .,~,~:,i,:~~ibss:,,:iI; .;:,I: ~:.~.:1::1,.-:s’~~~;~~~;~:~~~~~~~~~;~,,i;t~,’;1i~:ilii’i!jj:~..l.:~ ;. :

,...,... ., ., . ../....: .,... :.:.: .,... ,... :.,:.,:.,: ,: ,: ,.:,: ,.>,: /..... : .,...,. .,... ,. .,. ,..,.., . ../ :.,.:,,.: ,.:,,,::../.: /... .,. .,.:>>.. . . . . .>, . . . . . . . . . . . . . . . :., >,:,,:, >. .., ,.. ,...,.......,.,.,..,.,.,. .,..

IC2100 221.00992 INTEGRATED CKT VERTICAL DEFLECTION

. . . L. L.:.::.:...:.. .i i

.,. ./. /........., .., ..,... .,. ., /.., .., ,..., ,..,..,.., ., / ::::::i$;;: xl:::‘. :::,ni: > : .: :,, : ,,‘,.:,,:::::,:::::~(:, ., !’ :;i : :>:,:!!: :! / ::::;:::;:::i ‘y:;::’ ::‘::‘: ‘:’

,‘~‘-“.~i;ii:i~ii~~:~,~::,:‘::::iir.:’:’i::~~~~~,~~~~~:~:~~:~~~~~~~~~~~~$~~~~~~,~:: :‘:‘::‘;4’1:E(;‘1!:‘1:::

.~ ,.,. :,. :,. :,. :, ,.: ., ,.

.: . . ..i :i . . ‘..~.~:i:P:‘:i~i.i.:t .: ‘;(,:’ :‘,17..1:.,:i.:‘,,......,..:.::.::.::.,:~ .,:.:.,.:,:,:,,

019-01197-02 CLIP HEATSINK MOUNTING

pi&~..:.:.:.: : :::.:+ .,.. :I / .,.

019-00824-02 CLIP TRANSISTOR MOUNTING

019-01197-02 CLIP HEATS INK MOUNTING

: .: :c:::i::,‘:: I: !::.:i : j : i::-:‘$ Fyi’.

012-09632 METAL STAMPING BRACKET

103-00339-04 DIODE ~cwf VOLTAGE GENERAL

FERRITE BEAD AND WIRE ASSEMBLY

TRANSISTOR AN0 HEATSINK ASSEMBLY (SEE PART

IC AND HEATSINK ASSEMBLY (SEE PART LIST

IC AND HEATSINKASSEMBLY (SEE PART6 LIST

DIODE AND HEATSINK ASSEMBLY (SEE PART6

DIODE AND HEATSINK ASSEMBLY (SEE PARTS

IC AND HEATSINK ASSEMBLY (SEE PARTS LISTED

,.:,.:::“::‘:‘:‘:‘i’..,: ;.,; ,: ::‘,:‘::.;‘, .,,., ,, ,,., ., ‘.( ‘::‘::i:‘::‘::‘..‘: :,‘:“‘:.:.’

1 .1 .1 .1 .1

.:..:. I ,..

., ., ., ., ., ., ., .,

.,. _. ., ,. ., ., .,. .,.

.., : : : ,.,

,. .

. .

012-09632 METAL STAMPING BRACKET

I(33441 221-00213-09 INTEGRATED CKT 9 VOLT, 1 AMP

l

* Critical Safety Components Shaded

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Loading...

Loading...