Page 1

SERVICE MANUAL

TECHNICAL INFORMATION

RAS-14CH3

RAS-14CH1

RAC-14CH3

RAC-14CH1

PM

NO. 0159E

RAS-14CH3/

RAS-14CH1

RAC-14CH3/

RAC-14CH1

REFER TO THE FOUNDATION MANUAL

CONTENTS

SPECIFICATIONS ------------------------------------------------------------------- 4

SAFETY PRECAUTION ----------------------------------------------------------- 5

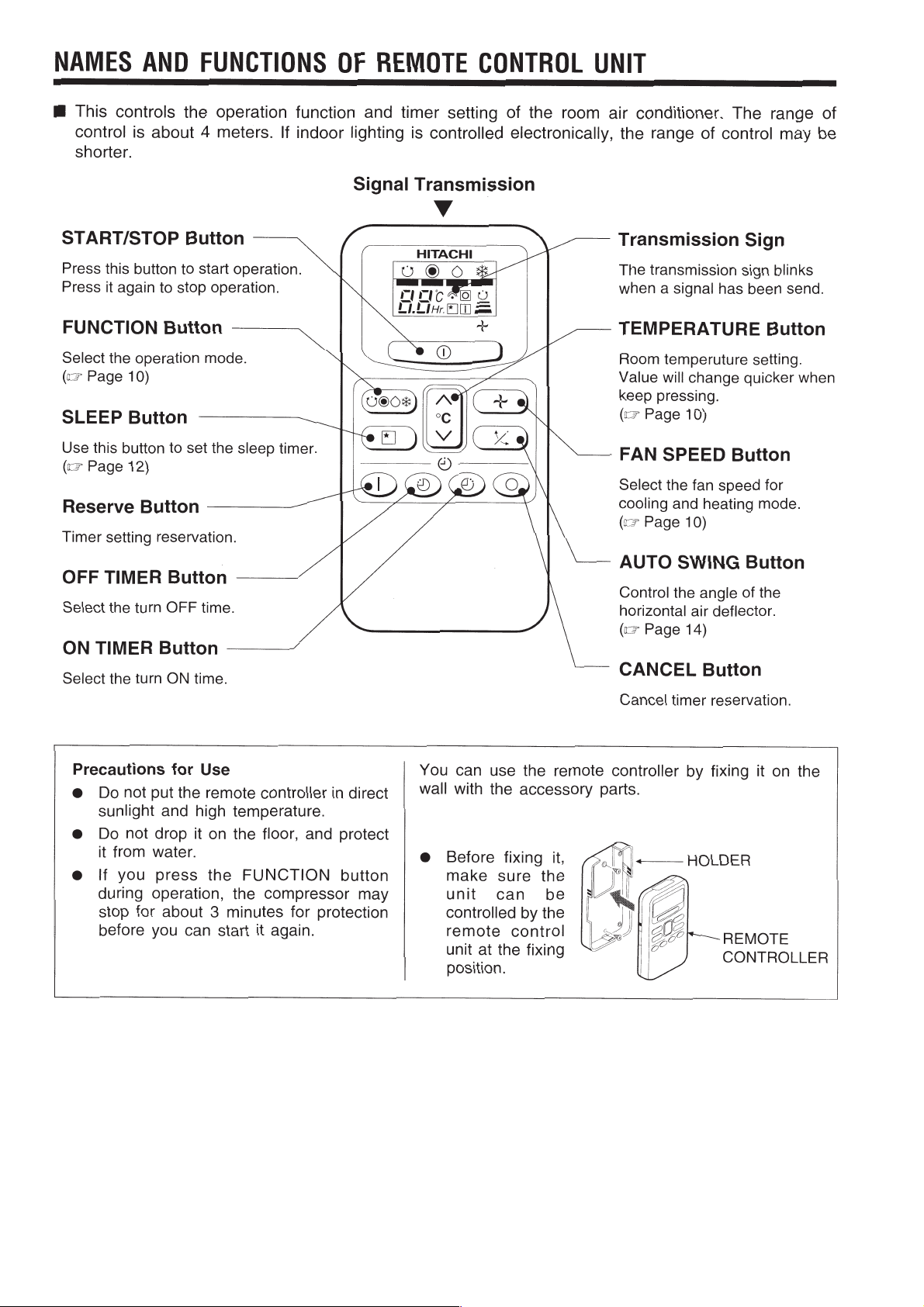

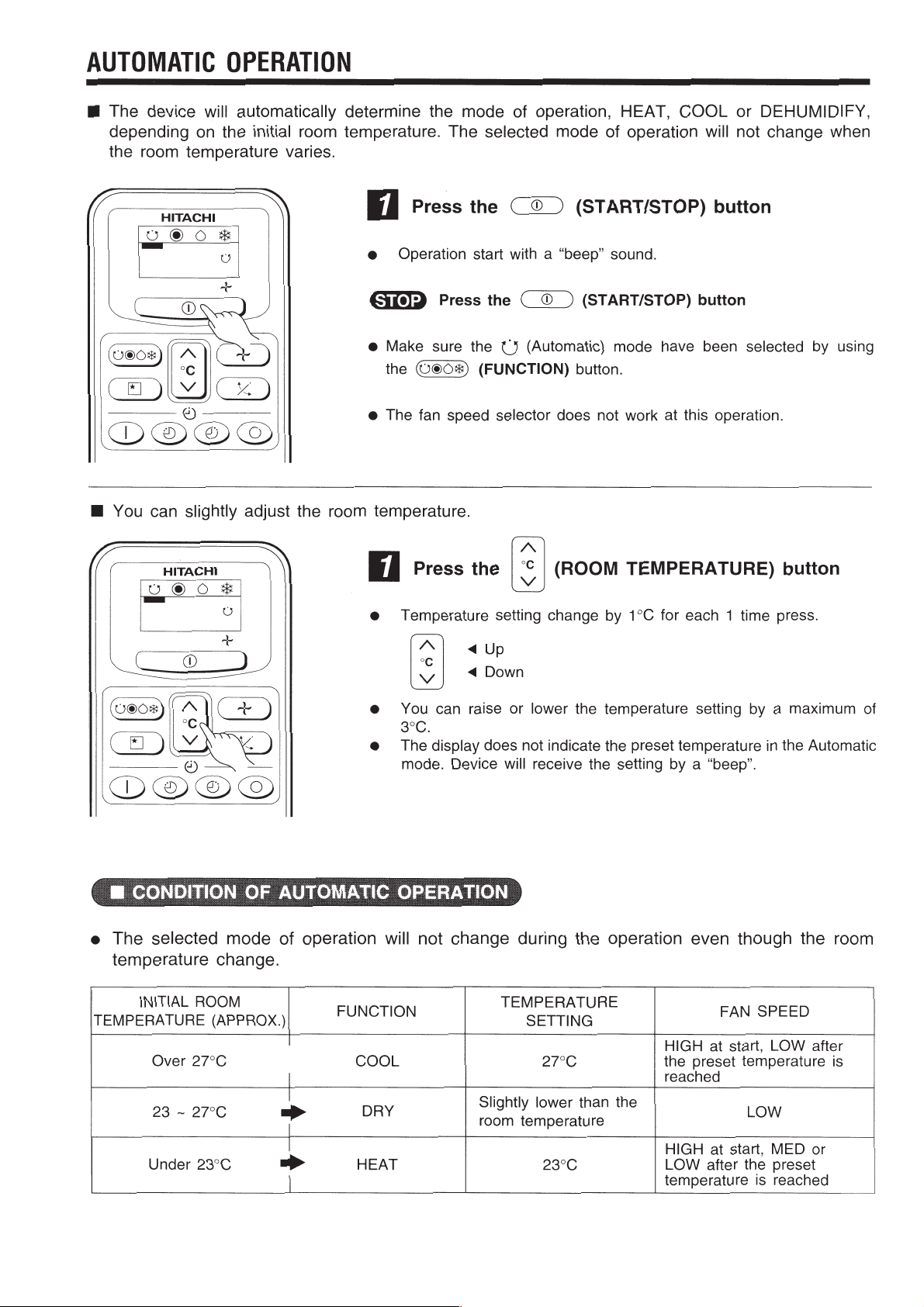

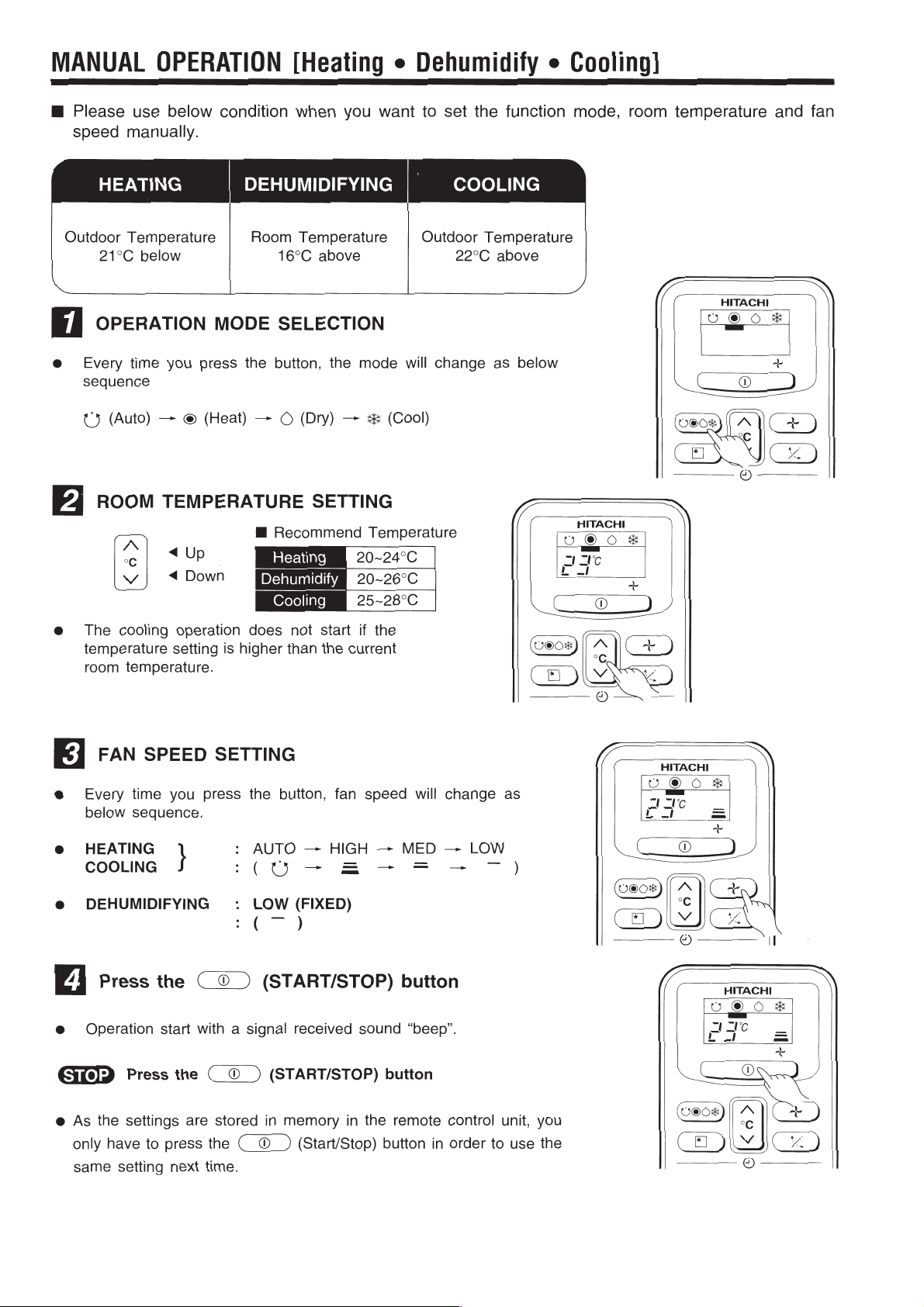

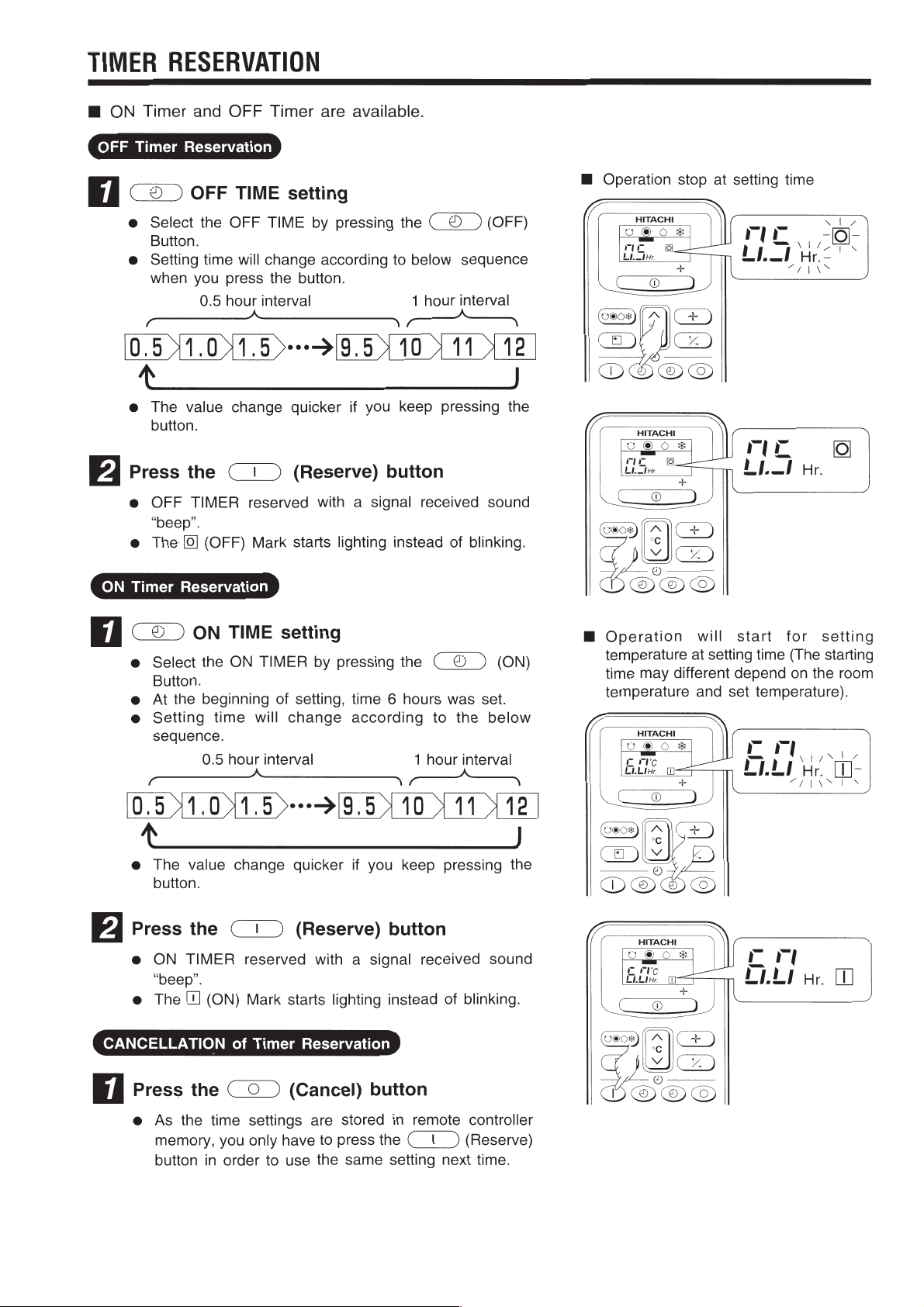

HOW TO USE ------------------------------------------------------------------------ 7

CONSTRUCTION AND DIMENSIONAL DIAGRAM ---------------------- 25

MAIN PARTS COMPONENT --------------------------------------------------- 26

WIRING DIAGRAM ----------------------------------------------------------------- 28

BASIC MODE ------------------------------------------------------------------------ 35

AUTO SWING FUNCTION ------------------------------------------------------- 39

REFRIGERATING CYCLE DIAGRAM ---------------------------------------- 28

SERVICE CALL Q & A ----------------------------------------------------------- 28

TROUBLE-SHOOTING ------------------------------------------------------------40

PARTS LIST AND DIAGRAM --------------------------------------------------- 42

SPECIFICATIONS

TYPE

MODEL

POWER SOURCE

TOTAL INPUT

COOLING

HEATING

DIMENSIONS (mm)

NET WEIGHT (kg)

TOTAL AMPERES

CAPACITY

TOTAL INPUT

TOTAL AMPERES

CAPACITY

(W)

(A)

(kW)

(B.T.U./h)

(W)

(A)

(kW)

(B.T.U./h)

W

H

D

WALL TYPE

INDOOR UNIT OUTDOOR UNIT

RAS-14CH3, RAS-14CH1 RAC-14CH3, RAC-14CH1

1Ø, 220 – 230 V, 50 Hz

1290 – 1330

6.0 – 5.9

3.55 – 3.60

12110 – 12284

1370 – 1410

6.3 – 6.2

4.10 – 4.15

13990 – 14160

815 820

298 520

179❈(185) 280

839

❈ After installation

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

ROOM AIR CONDITIONER

INDOOR UNIT + OUTDOOR UNIT

JANUARY 2003

H.A.P.M.

Page 2

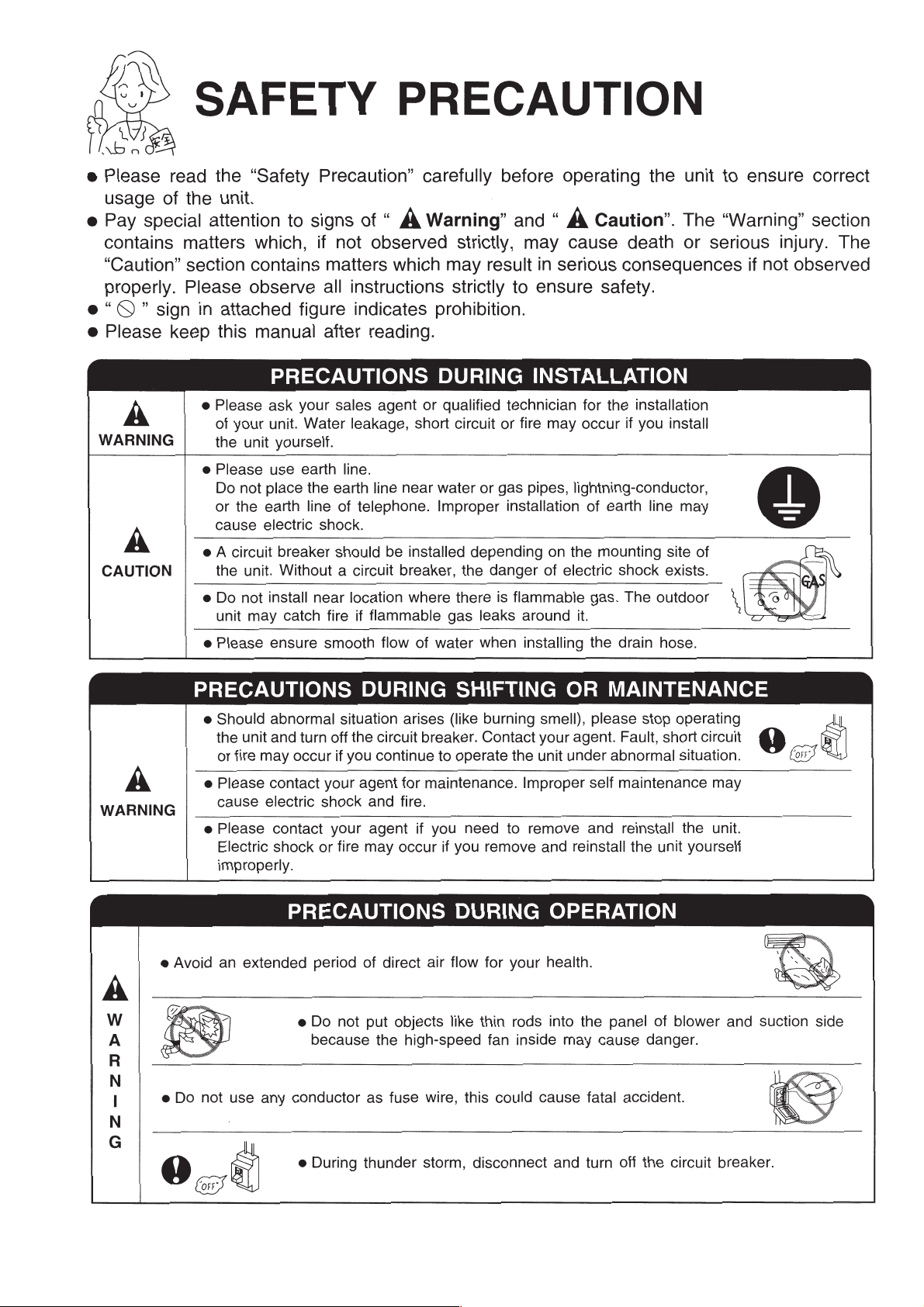

SAFETY DURING REPAIR WORK

First, I must disconnect

the power cord plug

from the power outlet.

DANGER

1. In order to disassemble and repair the unit

in question, be sure to disconnect the power

cord plug from the power outlet before

starting the work.

2. If it is necessary to replace any parts, they should be replaced with respective genuine parts for the unit,

and the replacement must be effected in correct manner according to the instructions in the Service Manual

of the unit.

If the contacts of electrical

parts are defective, replace

the electrical parts without

trying to repair them.

3. After completion of repairs, the initial state should

be restored.

4. Lead wires should be connected and laid as in

the initial state.

5. Modification of the unit by the user himself should

absolutely be prohibited.

6. Tools and measuring instruments for use in repairs or inspection should be accurately calibrater in advance.

7. In installing the unit having been repaired, be careful to prevent the occurrence of any accident such as

electrical shock, leak of current, or bodily injury due to the drop of any part.

8. To check the insulation of the unit, measure the insulation resistance between the power cord plug and

grounding terminal of the unit.

The insulation resistance should be 1 MΩ or more as measured by a 500V DC megger.

9. The initial location of installation such as window, floor or the other should be checked for being safe enough

to support the repaired unit again.

If it is found not so strong and safe, the unit should be installed at the initial location after reinforced or at

a new location.

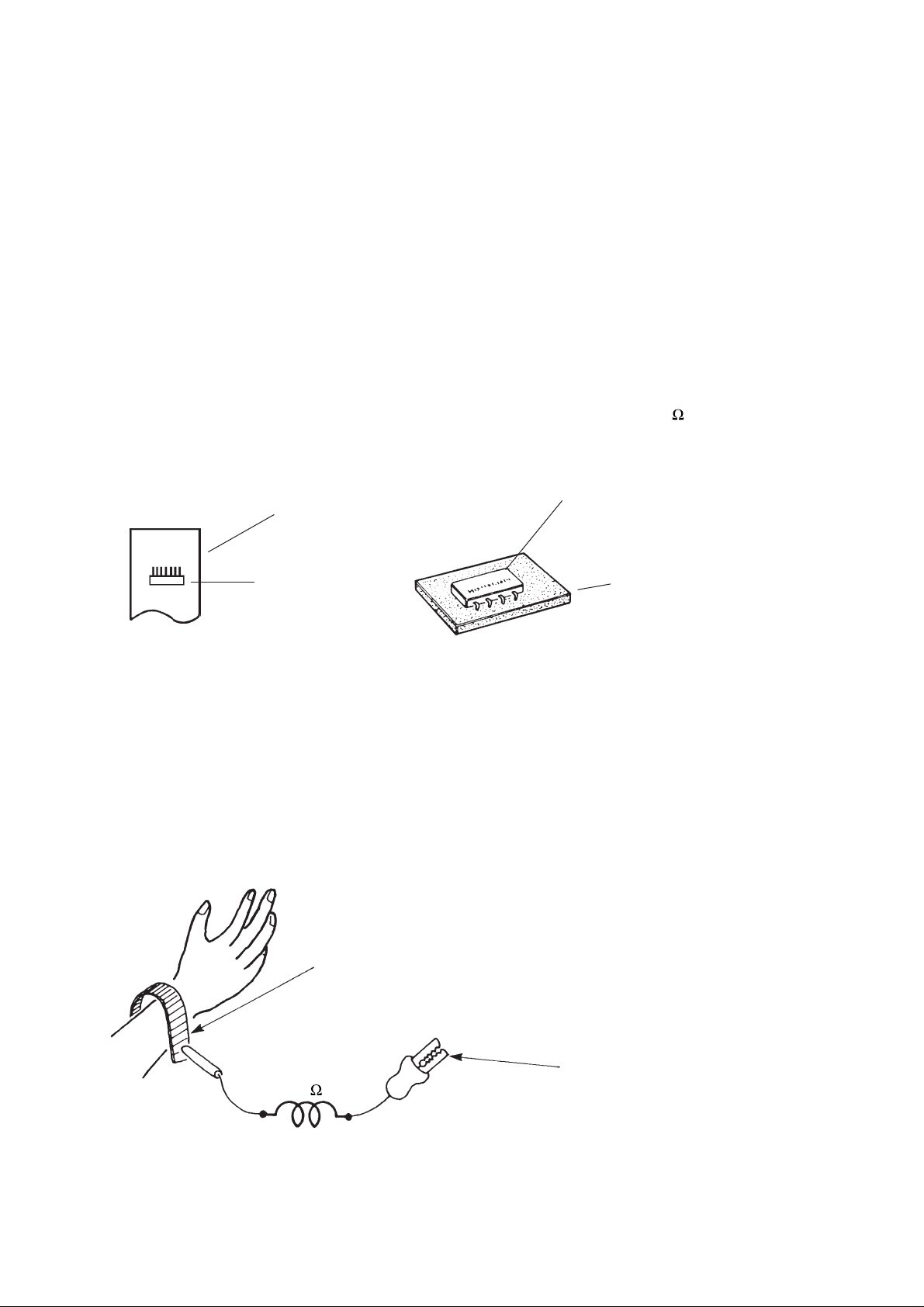

10. Any inflammable thing should never be

placed about the location of installation.

11. Check the grounding to see whether it

is proper or not, and if it is found

improper, connect the grounding

terminal to the earth.

– 1 –

Page 3

PREVENTION OF DAMAGE TO SEMICONDUCTORS

1. When carrying and handling semiconductors adopted in your Model during maintenanace and inspection

thereof, much care should be taken to prevent the semiconductors from being damaged. Also, such care

should be taken when handling any faulty Model which is to be returned to factory.

2. The semiconductors used in your Model are the following :

(1) Micro computer

(2) Integrated circuits (IC)

(3) Field-effect transistors (FET)

(4) Printed circuit boards (PC boards) or the like on which the parts in (1) and (2) above are provided

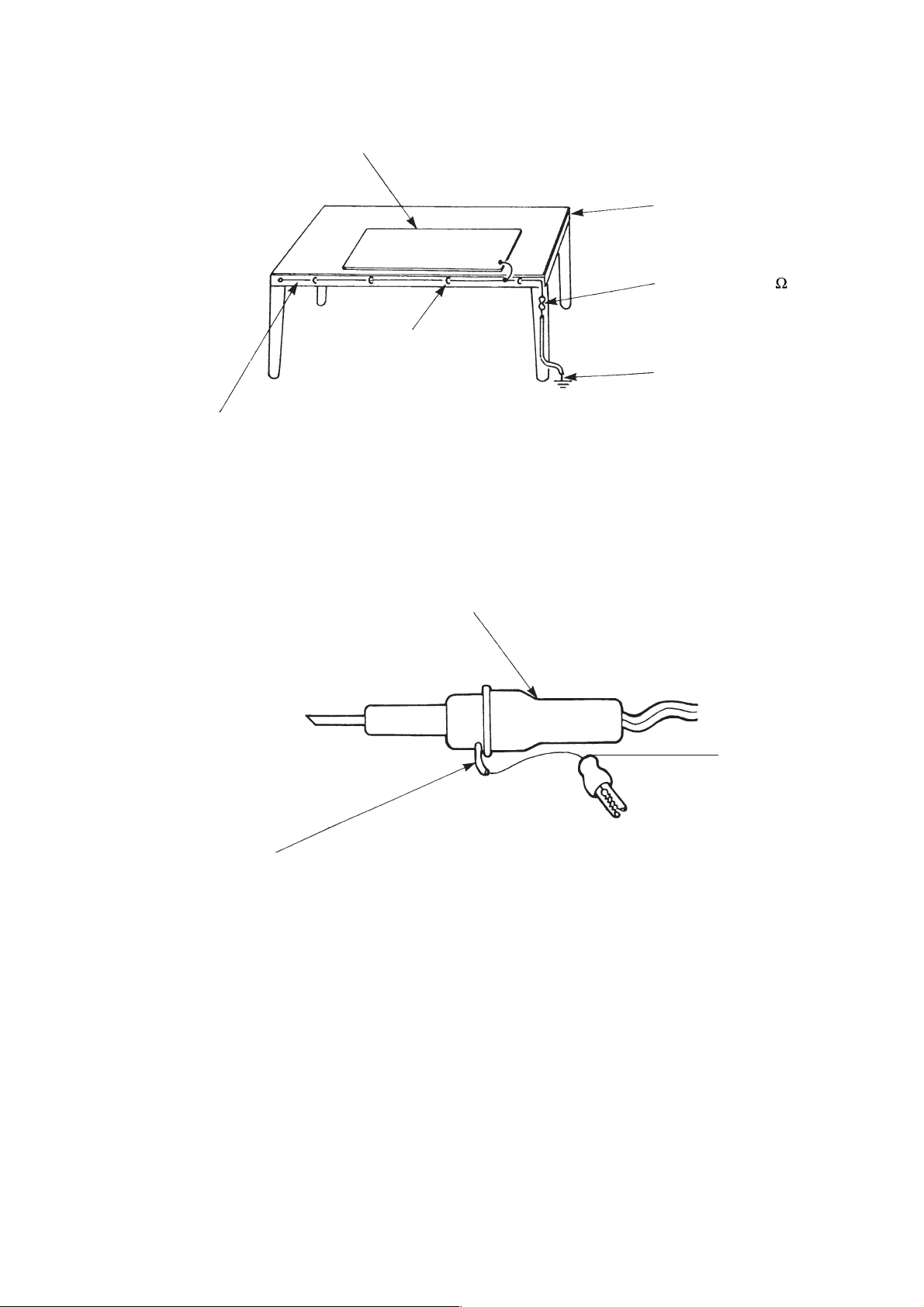

3. Cautions in handling

(1) Use a conductive container to carry or store the semiconductive parts. Even if they are faulty ones, also

handle them using such container.

(2) When parts as uncovered are handled (for counting, packing or for the like purpose), the hadler must use

his own body as conductor for earthing. For this purpose, put on an electrically conductive ring or bracelet

at the wrist. Connect to the bracelet a conductor provided with a resistor of 1 M

and at the other end

with a clip for connection to the earth wire.

Conductive polyvinyl bag

▲

▲

IC

▲

IC

Conductive sponge

▲

Fig. 1 Conductive Container

(3) Be careful not to have your clothes be in contact with any part while you are holding it, even if the body

earthing is established.

(4) Be sure to place the parts on a grounded metallic plate.

(5) Never fail to disconnect the power supply before starting repair of any PC board. Then, proceed to the repair

of the PC board on the grounded metallic plate.

Bracelet for body earthing

(Elimik conductive band)

1M

Fig. 2 Body Earthing

Clip for connection to each wire

– 2 –

Page 4

(6) Soldering iron to be used should be a one with three wires (including an earth wire).

Metallic plate (of aluminium, stainless steel or other)

or conductive rubber sheet

Work table

Bare copper wire (for body earthing)

Staple the wire

Fig. 3. Earthing of Work Table

Soldering iron

Resistor of 1 M

Earth wire

(1/2W)

2

Screw here using a rag plate

Fig. 4. Earthing of Soldering Iron

An ordinary soldering iron may also be used, but in such case, be sure to provide a perfect insulation (10MΩ

or more to 100volts).

(7) While checking the circuits during maintenance, inspection or the other, strictly avoid any shortcircuiting of the

load circuit or other by the test probe of the measuring instrument.

Earth wire

– 3 –

Page 5

SPECIFICATIONS

MODEL

FAN MOTOR

FAN MOTOR CAPACITOR

FAN MOTOR PROTECTOR

COMPRESSOR

COMPRESSOR MOTOR CAPACITOR

OVERLOAD PROTECTOR

PROTECTOR

FUSE (for MICRO COMPUTER)

POWER RELAY

POWER SWITCH

RAS-14CH3

10 W

1 µF, 450V

YES (INTERNAL)

NO

NO

NO

NO

3.0A

G4A-RY-200

YES

RAS-14CH1

10 W

1 µF, 450V

YES (INTERNAL)

NO

NO

NO

NO

3.0A

G4A-RY-200

YES

RAC-14CH3

20 W

2.5 µF, 450V

YES (INTERNAL)

SH933RC2-U

35 µF, 440V

NO

YES

NO

NO

NO

RAS-14CH1

20 W

2.5 µF, 450V

YES (INTERNAL)

SH933RC2-U

35 µF, 440V

NO

YES

NO

NO

NO

TEMPORARY SWITCH

SERVICE SWITCH

TRANSFORMER

VARISTOR

NOISE SUPPRESSOR

SOLID STATE RELAY FOR FAN (FAN SSR)

EXTERNAL FAN AND REVERSING VALVE RELAY

REMOTE CONTROL SWITCH (LIQUID CRYSTAL)

THERMOSTAT

FUSE CAPACITY

UNIT

450NR

S26MD02

YES (IC)

––––– ❈ 1,080g

YES

YES

YES

NO

G4U

YES

YES

YES

YES

450NR

NO

S26MD02

G4U

YES

YES (IC)

15 A TIME DELAY FUSE

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

❈ 1,080g–––––

REFRIGERANT

CHARGING VOLUME

(Refrigerant 22)

❈ 1080g for piping set of 5 ~ 8m, additional 25g/m R22 is required for additional 8m onward, but cannot exceed

10m.

PIPES

WITHOUT REFRIGERANT BECAUSE

COUPLING IS FLARE TYPE.

P-103VK1 (3m), P-105VK1 (5m),

P-108VK1 (8m), (P-103VK), (P-105VK)

– 4 –

Page 6

– 5 –

Page 7

– 6 –

Page 8

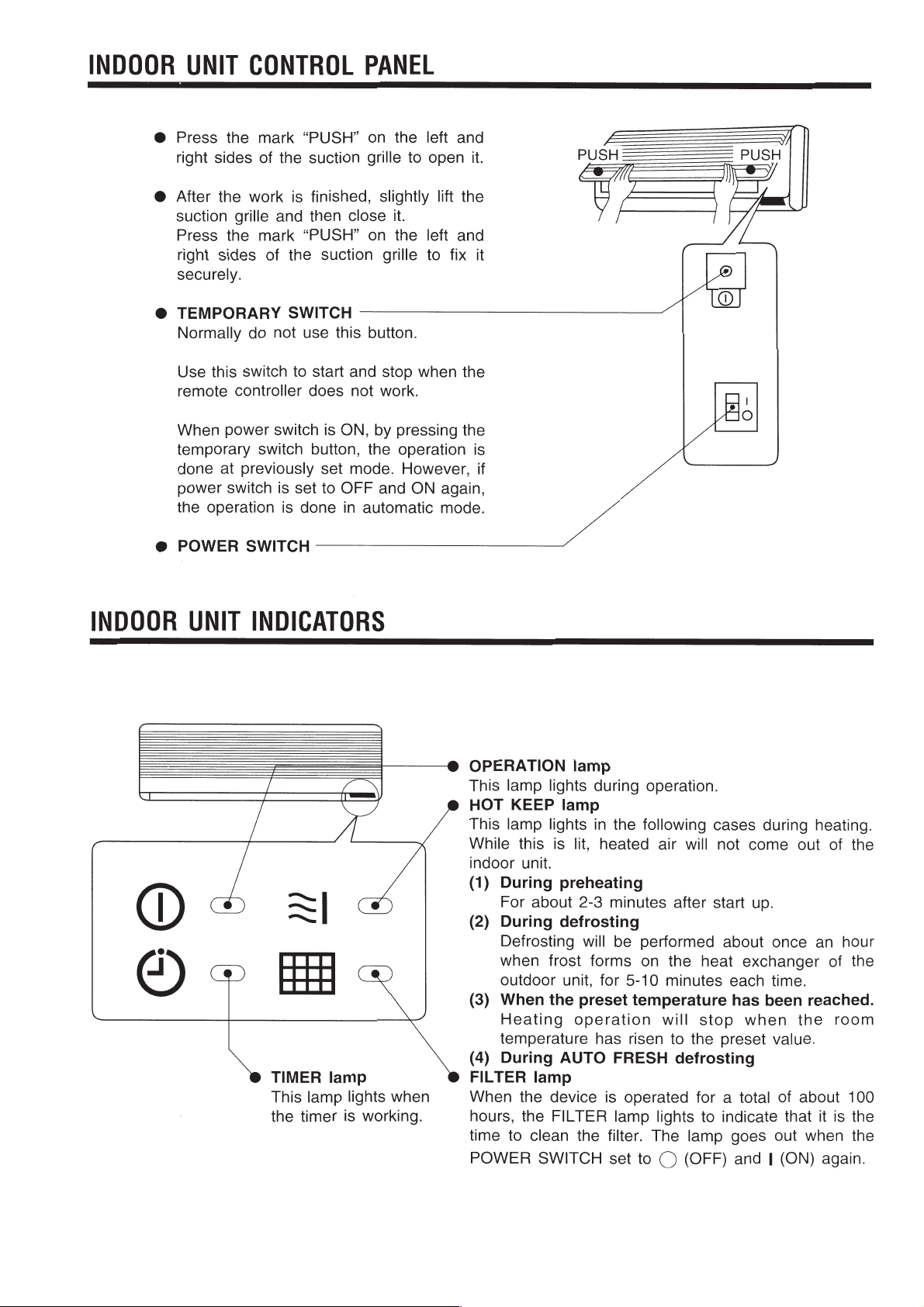

– 7 –

Page 9

– 8 –

Page 10

– 9 –

Page 11

– 10 –

Page 12

– 11 –

Page 13

– 12 –

Page 14

– 13 –

Page 15

– 14 –

Page 16

– 15 –

Page 17

THE IDEAL W AYS OF OPERA TION

Suitable Room Temperature Install curtain or blinds

Warning

Freezing temperature

is bad for health and a

waste of electric power.

Ventilation Effective Usage Of Timer

Caution

Do not close the room for a long period of

time. Occasionally open the door and windows

to allow the

entrance of

fresh air.

It is possible to

reduce heat

entering the

room through

windows.

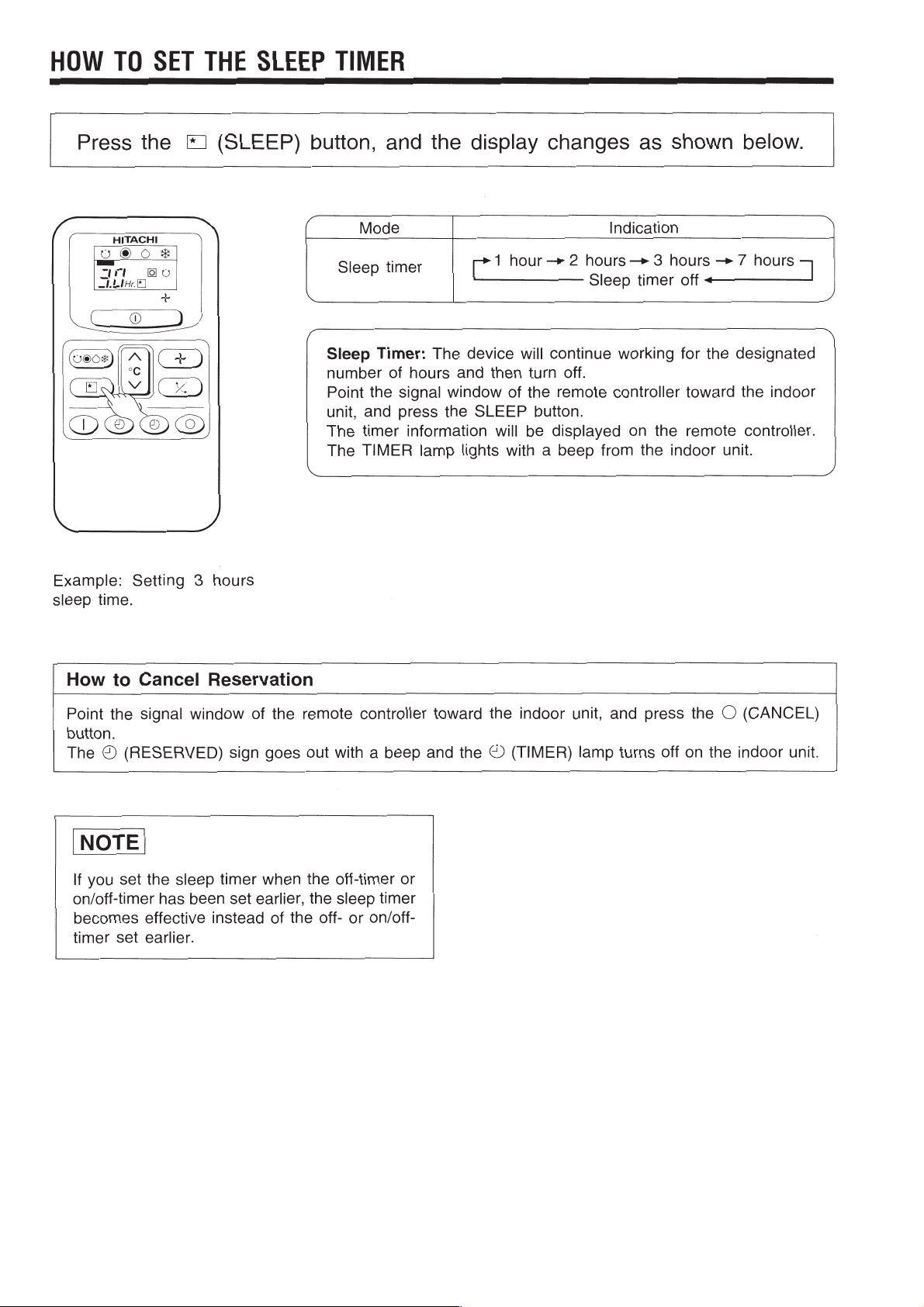

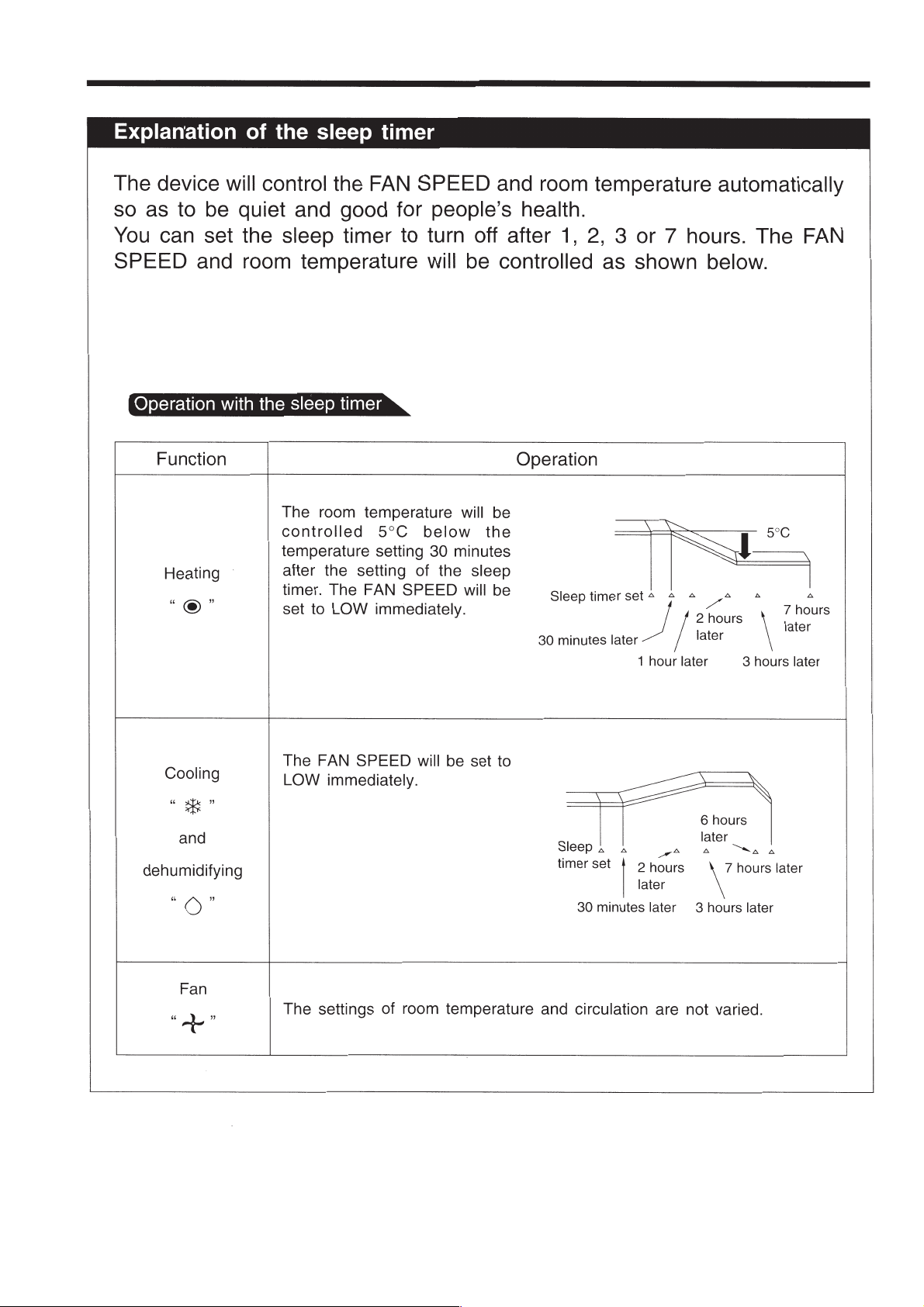

At night, please use the “sleep timer operation

mode”, together with your wake up time in the

morning. This will enable you to enjoy a

comfortable room temperature. Please use the

timer effectively.

Do Not Forget To Clean The Air Filter

Dusty air filter will reduce the air volume and

the cooling efficiency. To prevent from wasting

electric energy, please clean the filter every 2

weeks.

Please Adjust Suitable Temperature

For Baby And Children

Please pay attention to the room temperature

and air flow direction when operating the unit

for baby, children and old folks who have

difficulty in movement.

(The ideal temperature

difference between

outdoor and indoor

is about ±5˚C).

– 16 –

Page 18

FOR USER’S INFORMA TION

OFF

The Air Conditioner And The Heat Source In The Room

Caution

If the amount of heat in the room is above the cooling

capability of the air conditioner (for example: more

people entering the room, using heating equipments

and etc.), the preset room temperature cannot be

achieved.

After Power Failure

When the power is resumed after a power failure,

the indoor unit will still remain “OFF”. To operate the

unit, please press the “ON/OFF” button again.

After power

failure

Not Operating For A Long Time

When the indoor unit is not to be used for a long

period of time, please switch off the power from the

mains. If the power from mains remains “ON”, the

indoor unit still consumes about 15W in the operation

control circuit even if it is in “OFF” mode.

When Lightning Occurs

Warning

To protect the whole unit during lightning, please

stop operating the unit and remove the plug from the

socket.

Operate

– 17 –

Page 19

– 18 –

Page 20

– 19 –

Page 21

– 20 –

Page 22

280(11-1/32")

260(10-1/4")

145(5-11/16")

12(1/2")

50(2")

500(19-11/16")

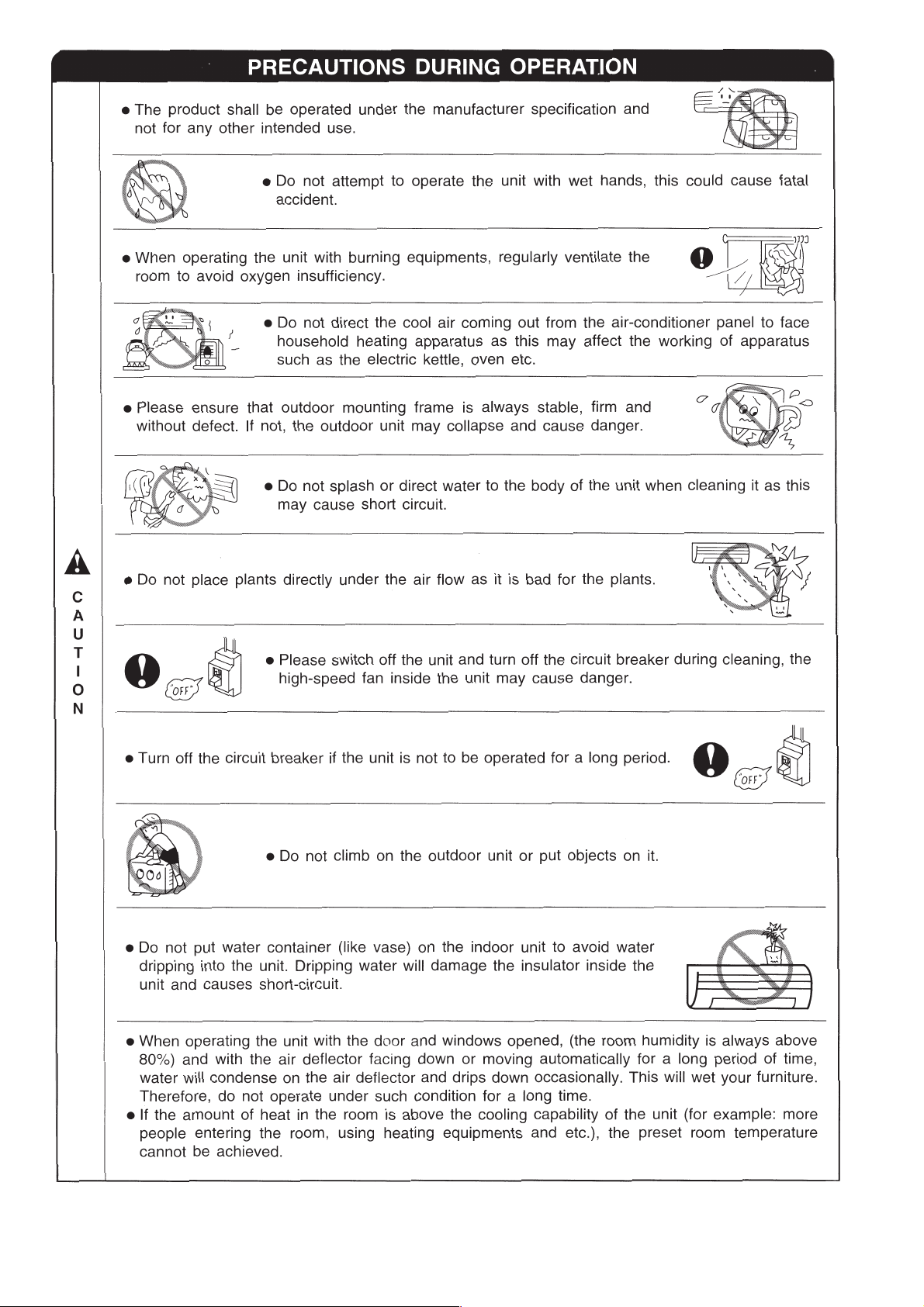

CONSTRUCTION AND DIMENSIONAL DIAGRAM

15

MODEL RAS-14CH3

RAS-14CH1

Air suction grill

6(1/4")

Mounting plate

56

(2-3/16")

Viewed from P

(bottom direction pipe lead-out)

About 290

(11-3/8")

About 360

179(7-1/16")

Discharge grill

About 400

(15-3/4")

VIEWED FROM BACK

(PIPE LEAD-OUT)

(14-3/16")

40(1-9/16")

64(2-1/2")

103(4-1/16")

110

(4-5/16")

42.5(1-11/16")

785(30-7/8")

Vertical air deflector

182.5

(7-3/16")

Hole on the wall for

ø65mm(2-9/16") pipe

450(17-11/16")

58(2-5/16") 58(2-5/16")

Drain outlet

Drain hose

Connecting cable

Line cord

815(32-1/16")

Wide pipe (ø12.70(1/2"))

62

Wireless remote controller

Top Air suction grill

Front cover

179(7-1/16")

298(11-3/4")

Horizontal air

deflector

Drain pan

182.5

(7-3/16")

P

Drain cap

connection port

7(1/4")

❈When piping is drawn horizontally,

exchange the drain hose for the drain cap.

Narrow pipe (ø6.35(1/4"))

120

Cabinet

47(1-7/8")

mm(inch)

MODEL RAC-14CH3

RAC-14CH1

820(32-5/16")

500(19-11/16")

12(1/2")

50(2")

520(20-1/2")

500(19-11/16")

270(10-21/32")

145(5-11/16")

280(11-1/32")

260(10-1/4")

– 21 –

Page 23

MAIN PARTS COMPONENT

THERMOSTAT

Thermostat Specifications

MODEL

RAS-14CH3, RAS-14CH1

THERMOSTAT MODEL

OPERATION MODE

INDICATION

16

ON

OFF

COOL

17.6 (63.7)

17.3 (63.1)

TEMPERATURE

°C (°F)

INDICATION

24

INDICATION

32

ON

OFF

ON

OFF

25.6 (78.1)

25.3 (77.5)

33.6 (92.5)

33.3 (91.9)

FAN MOTOR

Fan Motor Specifications

MODEL

RAS-14CH3, RAS-14CH1 RAC-14CH3, RAC-14CH1

PHASE SINGLE

IC

HEAT

19.6 (67.3)

19.3 (66.7)

27.6 (81.7)

27.3 (81.1)

35.6 (96.1)

35.3 (95.5)

RATED VOLTAGE 220 – 240 V

RATED FREQUENCY 50 Hz

OUTPUT 10 W 20 W

POLE NUMBER 4 6

INTERNAL

THERMAL FUSE

BLACK

CAPACITOR

RA = 162.37

RM = 328.36

RA = 197.46

RM = 399.32

RM

CONNECTION

RESISTANCE VALUE

(

1

A1

3

A2

2

A3

654

20°C

(68°F)

)

75°C

(167°F)

RM = 444.00 RA2 = 53.10

RA1 = 113.90 RA3 =125.30

RM = 539.95 RA2 = 64.58

RA1 = 138.50 RA3 =152.38

M

T. F

Cr

RED

RA

GRAY

– 22 –

Page 24

COMPRESSOR

POWER

SOURCE

RUNNING

CAPACITOR

RM

RA

INTERNAL

PROTECTOR

Compressor Motor Specifications

MODEL RAC-14CH3, RAC-14CH1

COMPRESSOR MODEL SH933RC2-U

PHASE SINGLE

RATED VOLTAGE 220 – 240 V

RATED FREQUENCY 50 Hz

LOCKED ROTOR CURRENT 27 A

POLE NUMBER 2

RUNNING

CONNECTION

CAPACITOR

POWER

SOURCE

S

RA

R

RM

C

INTERNAL

PROTECTOR

RESISTANCE VALUE

(

20°C

(68°F)

)

75°C

(167°F)

RM = 2.87

RA = 2.15

RM = 3.49

RA = 2.61

M/R (ORANGE)

S (RED)

C (WHITE)

CAUTION

When the Air Conditioner has been operated for a long time with the capiliary tubes clogged or crushed

or with too little coolant, check the color of the refrigerant oil inside the compressor. If the color has been

changed conspicuously, replace the compressor.

– 23 –

Page 25

WIRING DIAGRAM

MODEL RAS-14CH3, RAS-14CH1

RAC-14CH3, RAC-14CH1

A : COMPRESSOR

B : FAN MOTOR

C : POWER SWITCH

D : 1,000 pF CAPACITOR

E : INDOOR FAN MOTOR

PROTECTOR (INTERNAL)

F:1 µF CAPACITOR

G : 35 µF CAPACITOR

H : 2.5 µF CAPACITOR

I : FAN MOTOR PROTECTOR

J : TERMINAL BOARD

K : LINE CORD

L : EXTERNAL FAN RELAY

M : STICK RELAY

N : REVERSING VALVE

P : POWER RELAY

Q : THERMAL FUSE

R : SURGE ABSORBER

S : THERMISTOR

T : TRANSFORMER

U : INTERNAL PROTECTOR

V : VARISTOR

W : SOLID STATE RELAY FOR FAN (FAN SSR)

X : FUSE

Y : REVERSING VALVE RELAY

Z : AUTO SWEEP MOTOR

BLU : BLUE YEL : YELLOW BRN : BROWN WHT : WHITE

GRY : GRAY ORN : ORANGE GRN : GREEN RED : RED

BLK : BLACK PNK : PINK VIO : VIOLET

INDOOR UNIT OUTDOOR UNIT

C

(3.0A)

X

(96°C)

V

2

PRINTED WIRING

BOARD ASSEMBLY

V

Q

1

(109°C)

X

R

I

T

D

P

H M L

B

W

Y

F

J

B B

L

I

(165°C)

B

N

U

H

A

G

M

A A

C C

D D

E

– 24 –

Page 26

BRNBRN

BLUBLU

BLUBLU

(RED) S(RED) S

ORNORN

M/RM/R

(ORN)(ORN)

(WHT) C(WHT) C

REDRED

GRYGRY

GRYGRY

BLK

BLKBLK

BLKBLK

BLK

WHTWHT

REDRED

BLK

A

B

A

B

N

H

G

B

A

J

BLK

WHTWHT

BLU

PNKPNK

YELYEL

ORNORN

REDRED

CN13CN13

REDRED

REDRED

S

8

CN11CN11

CN12CN12

BLK

BLKBLK

S

B

E

BLKBLK

F

CN3CN3

W

L

M

H

R

K

2

CN1CN1

(96°C)C)

Q

T

ORNORN

ORNORN

GRYGRY

GRYGRY

CN2CN2

BRNBRN

V

V

BLK

X

P

M

34

34

(3.0A)(3.0A)

C

2 BRN2 BRN

4 BLU

1

3

BRNBRN

BLU

YELYEL

+GRN +GRN

YEL

GRYGRY

BLU

WHTWHT

REDRED

BLK

YELYEL

GRYGRY

BLU

WHTWHT

RED

1

BRNBRN

YEL+GRNYEL+GRN

INDOOR UNIT OUTDOOR UNITINDOOR UNIT OUTDOOR UNIT

Z

Y

L

C

D

BRWBRW

REDRED

CN4CN4

C

D

M

– 25 –

Page 27

– 27 –

Page 28

– 29 –

Page 29

– 31 –

Page 30

– 33 –

Page 31

– 34 –

Page 32

– 35 –

Page 33

– 36 –

Page 34

– 37 –

Page 35

– 38 –

Page 36

– 39 –

Page 37

– 40 –

Page 38

– 41 –

Page 39

– 42 –

Page 40

PARTS LIST AND DIAGRAM

MODEL RAS-14CH3, RAS-14CH1

27

100

26

44

23

104

42

109

101

12

13

102

49

61

60

24

48

89

11

10

7

1

62

190

63

86

– 43 –

Page 41

MODEL RAS-14CH3, RAS-14CH1

NO. Q’TY/UNIT PARTS NAME

1 PMRAS-12CH1 002 1 EVAPORATOR

7 PMRAS-12CH1 001 1 FAN MOTOR 10W

10 PMRAS-09C1 003 1 TANGENTIAL FLOW FAN

11 PMRAS-05C 013 1 P-BEARING ASSEMBLY

12 PMRAS-14CH1 001 1 CAPACITOR 1µF, 450V

13 PMRAS-07C1 006 2 TERMINAL BOARD (2P)

23 PMRAS-12CH1 003 1 CABINET

24 PMRAS-12CH1 004 1 DRAIN PAN ASSEMBLY

26 PMRAS-12CH1 005 1 FRONT COVER ASSEMBLY

27 PMRAS-252B 012 2 FILTER

42 PMRA-13CDF 905 1 THERMAL FUSE

44 PMRAS-14CH1 004 1 MOUNTING PLATE

48 RAS-288CX 004 1 FAN COVER

RAS-14CH3, RAS-14CH1

PART N0.

49 PMRAS-07C1 013 1 DRAIN HOSE

62 PMRAS-14CH1 003 1 FAN MOTOR SUPPORT (L)

63 PMRAS-14CH1 005 1 FAN MOTOR SUPPORT (R)

86 PMRAS-25CNH2 017 1 REMOTE CONTROL HOLDER

89 PMRAS-12CH1 006 1 AUTO SWEEP MOTOR

100 PMRAS-25CNH2 013 1 REMOTE CONTROL

101 PMRAS-12CH1 007 1 P.W.B. (MAIN)

102 PMRAS-5142CHA 002 1 P.W.B. INDICATE

104 PMRAS-5142CH 004 1 TRANSFORMER

109 PMRAS-18CP2R 002 1 SWITCH

112 PMRAS-14CH1 006 1 THERMISTOR (ROOM TEMP.)

115 PMRAS-14CH1 002 1 FUSE (3.0A)

190 PMRAS-5101C 915 1 THERMISTOR (HEAT EXCHANGER)

– 44 –

Page 42

MODEL RAC-14CH3, RAC-14CH1

2

54

4

17

40

1

38

39

55

46

47

21

26

25

41

44

24

– 45 –

Page 43

MODEL RAC-14CH3, RAC-14CH1

NO. Q’TY/UNIT PARTS NAME

1 PMRAC-5142CHV 902 1 COMPRESSOR

2 PMRAC-12CH1 901 1 CONDENSER

4 PMRAC-12CH1 902 1 REVERSING VALVE

17 PMRAC-12CH1 903 1 MG-COIL (REVERSING VALVE)

21 PMRAC-5142CV 905 1 FAN MOTOR 20W/3KG

24 PMRAC-13CV6 904 1 PROPELLER FAN

25 PMRAC-14CH1 902 1 CAPACITOR 35µF, 440V

26 PMRAC-14CH1 901 1 CAPACITOR 2.5µF, 450V

38 PMRAC-12CH1 904 1 CABINET

39 PMRAC-5142CV 907 1 SIDE PLATE (L)

40 PMRAC-5142CV 908 1 SIDE PLATE (R)

41 PMRAC-5142CV 909 1 BACK PLATE

44 PMRAS-07C1 006 2 TERMINAL BOARD (2P)

RAC-14CH3, RAC-14CH1

PART N0.

46 PMRAC-5142CV 910 1 VALVE (2S)

47 PMRAC-5142CV 911 1 VALVE (4S)

54 PMRAC-5142CV 913 1 STRAINER

55 PMRAC-5142CHV1 902 3 COMPRESSOR RUBBER

– 46 –

Page 44

RAS-14CH3, RAS-14CH1 PM NO. 0159E

RAC-14CH3, RAC-14CH1

– 47 –

Printed in Malaysia

Loading...

Loading...