Hisense WFU7012, WFU7012S, WFUA7012, WFUA7012S Service Manual

WASHING MACHINE

SERVICE MANUAL

WFU7012&WFU7012S

WFUA7012&WFUA7012S

CAUTION

READ THIS MANUAL CAREFULLY TO DIAGNOSE

PROBLEMS CORRECTLY BEFORE SERVICING THE UNIT.

CONTENTS

1

CONTENTS

1. SAFETY NOTICES………………………………………………….…….…1

2. SPECIFICATIONS…………………………………………………………...3

3. FEATURES & TECHNICAL EXPLANATION…………………..………….4

3.1 FEATURES .......................................................................................... 3

3.2 INTELLIGENT FUZZY CONTROL ...................................................... 4

3.3 POWER SUPPLY CONTROL .............................................................. 4

3.4 WATER LEVEL CONTROL ................................................................. 5

3.5 DOOR LOCK CONTROL .................................................................... 5

3.6 LAUNDERING CONTROL .................................................................. 6

3.7 HEATING CONTROL .......................................................................... 7

3.8 SPINNING CONTROL ......................................................................... 7

4. PARTS IDENTIFICATION.....................................................................10

5. INSTALLATION AND TEST...................................................................11

5.1 STANDARD INSTALLATION ............................................................. 10

5.2 CONNECT THE INLET HOSE .......................................................... 11

5.3 CONNECT THE DRAIN HOSE ......................................................... 11

5.4 CONNECT POWER PLUG ............................................................... 11

5.5 TEST OPERATION ............................................................................ 11

6. OPERATION.........................................................................................14

6.1 CONTROL PANEL ............................................................................. 13

6.2 CYCLE GUIDE .................................................................................. 14

6.3 COMMON FUNCTIONS .................................................................... 16

6.4 ADDITIONAL FUNCTIONS ............................................................... 18

7. WIRING DIAGRAM/PROGRAM CHART...............................................22

7.1 WIRING DIAGRAM ........................................................................... 21

CONTENTS

2

7.2 PROGRAM CHART ........................................................................... 23

8. TEST MODE.........................................................................................25

8.1 SELF-INSPECTION MODE ............................................................... 24

8.2 SPECIAL FUNCTION MODE ............................................................ 26

9. TROUBLESHOOTING..........................................................................29

9.1 SAFETY CAUTION ........................................................................... 28

9.2 ERROR MODE SUMMERY .............................................................. 28

9.3 TROUBLESHOOTING WITH ERROR .............................................. 30

9.4 TROUBLE SHOOTING ELSE ........................................................... 36

10. COMPONENT TESTING INFORMATION..........................................40

10.1 FILTER ............................................................................................ 39

10.2 DOOR LOCK ................................................................................... 40

10.3 MOTOR ........................................................................................... 41

10.4 PUMP .............................................................................................. 42

10.5 INLET VALVE .................................................................................. 43

10.6 HEATER .......................................................................................... 44

11. DISASSEMBLY INSTRUCTIONS.......................................................46

11.1 CONTROL PANEL ASM .................................................................. 45

11.2 DISPENSER ASM ........................................................................... 46

11.3 FILTER ............................................................................................. 47

11.4 DOOR ASM ..................................................................................... 48

11.5 FRONT PANEL ................................................................................ 49

11.6 PUMP .............................................................................................. 50

11.7 HEATER .......................................................................................... 50

11.8 MOTOR ........................................................................................... 51

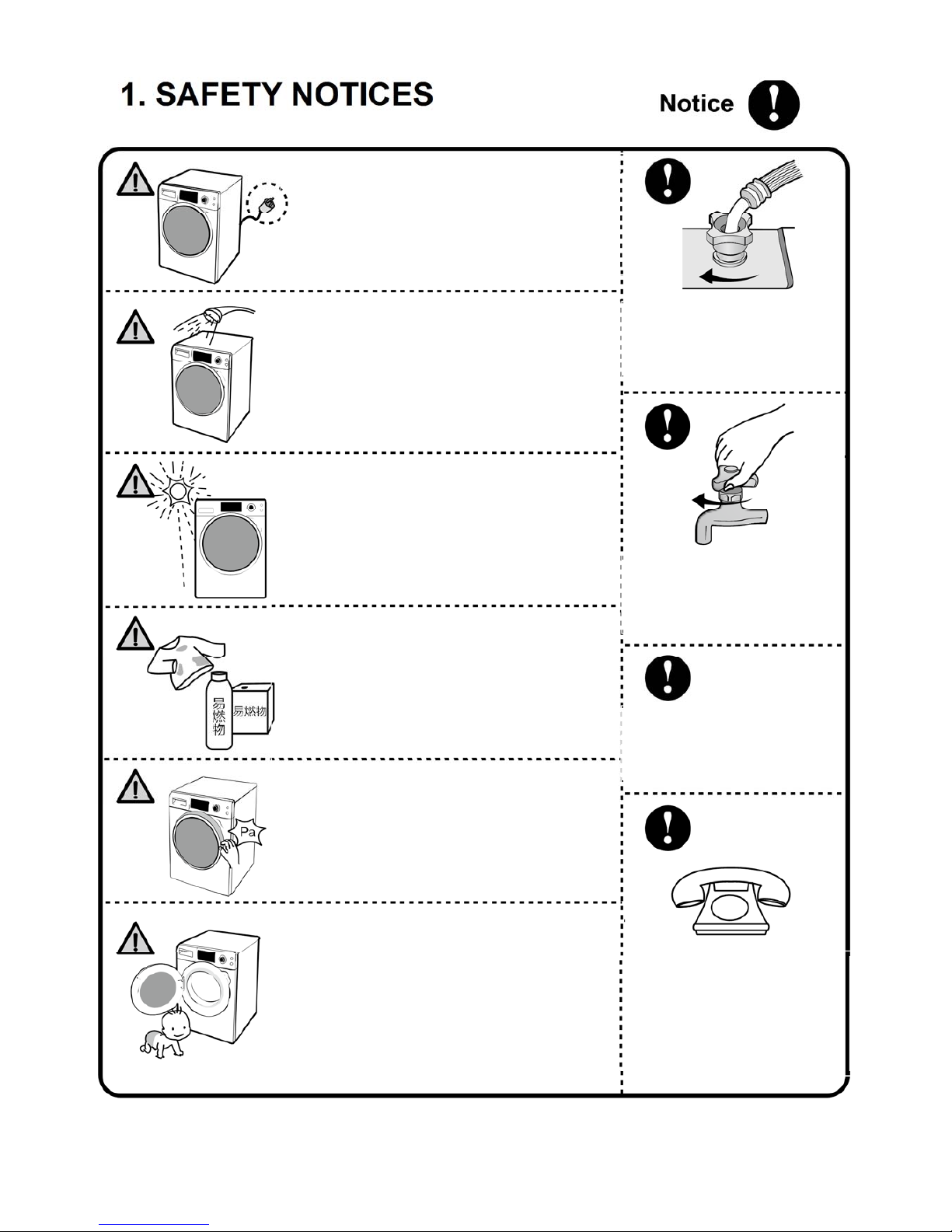

1. SAFETY NOTICES

1

• Cut off the power first before maintaining and

repairing the washing machine.

• It is for preventing from harms duet to electric

leakage.

• Please do not sprinkle or spray water directly

to any part of the washing machine during

maintenance and repair.

• Otherwise, accidents like short circuit or

electric shock may happen.

• Please do not place the washing machine in

places where are damp or are exposed to wind,

rain and the sun.

• It is for preventing from fire accidents due to

electric shock or electric leakage.

Explosion Or Fire

• It is strictly prohibited to place the clothes

smeared with inflammables into the drum of

washing machine.

• It is for preventing from possible explosion or

fire accident.

Mechanical Injury

• Do not open the door in a forced way.

• It is for preventing from possible damage.

Safety Tips For Children

• Please do not let the children to use the

washing machine, and do not place rack,

stools, etc. around the washing machine.

• The children may suffer personal injury due

to they climbing the washing machine or

crawling into the drum.

The nut connecting water

inlet tube to the machine

must be screwed u

p

.

When the washing machine

is unused, please be sure to

turn off the faucet.

Please dismantle the door of

machine before discarding

and handlin

g

.

If the washing machine is

damaged during transportation,

please do not use it. Please

call the “After-sales Service

Personnel”.

2. SPECIFICATION

2

ITEM WFU7012& WFUA7012/ WFU7012S& WFUA7012S

COLOR WHITE/SILVER

POWER SUPPLY

AC 220-240 V,50 Hz

PRODUCT WEIGHT 72 Kg

ELECTRIC POWER

CONSUMTION

WASHING 300 W

HEATER 1900 W

REVOLUTION

SPEED

WASH 55 rpm

SPIN 1200 rpm

CYCLES 15

WASH/RINSE TEMPERATURES

20-❉/30/40/60/95℃

SPIN SPEEDS 0/600/800/1000/1200 rpm

OPTIONS

Delay、Eco wash、Prewash、Rinse hold、Extra rinse

、

Intensive wash、Mute Function、Child lock

WATER CIRCULATION 0.1-1 MPa

CONTROL TYPE Electronic

Washing Capacity 7 Kg

Dimension 595 X600 X 850 mm

DELAY WASH up to 24 hours

DOOR LOCK TYPE PTC

WATER LEVEL FWL Sensor control

LAUNDRY LOAD SENSING

Incorporated(Cotton、Synthetics)

ERROR DIAGNOSIS Incorporated

AUTO POWER OFF Incorporated

3. FEATURES & TECHNICAL EXPLANATION

3

3.1 FEATURES

■ Ultra Capacity

The larger drum enables not just higher head drop and

stronger centrifugal force, but also less tangling and wrinkling

of the laundry. Heavier loads, such as king size comforters,

blankets, and curtains, can be washed.

■ Automatic Wash Load Detection

Automatically detects the load and optimizes the washing

time.

■ Built-in Heater

Internal heater helps to maintain water temperature at its

optimum level for selected cycles.

■ Child Lock

The Child lock prevents children from pressing any button to

change the settings during operation.

3. FEATURES & TECHNICAL EXPLANATION

4

3.2 INTELLIGENT FUZZY CONTROL

In order to achieve the best washing effects, it is necessary to determine the

optimum time and washing water level based on the water supply conditions.

3.3 POWER SUPPLY CONTROL

♦ After the washing machine is energized, the PCB is under “Off mode”, and all

buttons and knobs except for the “ON/OFF” button are disabled; all loads are in

the state of ready-for-activating.

♦ After pressing the “ON/OFF” button, the PCB will switch to “Ready mode” from

“Off mode”, and conduct status inquiry for minutes, with values of parameters

like water level, water temperature, air temperature, motor speed, door lock

state, etc. obtained.

♦ When the PCB runs a complete routine to end, the “Ready mode” will display

the previous completed program, with the settings corresponding to those set

by default. If the previous flow that is not run to end, then it will restore to the

“Cotton” program by default.

• washing program

• Water supply

Sensing

• Intelligence

fuzzy

Handling

• washing time

• water level

Adjust

3. FEATURES & TECHNICAL EXPLANATION

5

♦ When the program finishes and displays “End”, the door will be unlocked, and

the PCB will enter in “End mode”.

♦ If no button-press operation is done for 3 minutes when the washing machine

is under “Ready mode”, the PCB will automatically be power off and switch to

“Off mode”. If no button-press operation is done for 30 seconds when the

washing machine is under “End mode” where the washing is completed, the

PCB will automatically be power off and switch to “Off mode”.

♦ In order to avoid the user to falsely triggering the “ON/OFF” button, two

successive seconds are required for switching from “On mode” to “Off mode”,

and only one click is required for switching from “Off mode” to “On mode”.

3.4 WATER LEVEL CONTROL

♦ This module contains a FWL sensorfor detecting the water level of tub.

♦ During water inflowing, the PCB controls the inlet valve to function and execute

the water inflow operation. When the water level reaches the “Washing water

level”, the water inflow stops and the washing process begins. If the water level

declines during washing, it will automatically activate the water inflow and

replenishing program so as to reach the “Washing water level” again.

♦ During water draining, the PCB controls the draining pump to continuously

work and begin the water draining process. When the water of tub is discharged

down to the “Spinning water level”, the Spinning process will begin.

3.5 DOOR LOCK CONTROL

♦ When the PCB enters in “Ready mode”, it will detect the state of door lock and

execute operation accordingly. When the door is unlocked, no operation is done

if the unlocking conditions are satisfied, otherwise, the door should be locked;

when the door is locked, execute unlocking operation if the unlocking conditions

3. FEATURES & TECHNICAL EXPLANATION

6

are satisfied, otherwise, the door should be maintained locked.

♦ After selecting the program and function, press the “Start/Pause” button, the

PCB controls the door lock to execute locking operation, and the “Door lock”

icon on display window is on.

♦ After the program ends, the “Door lock” icon on display window is flickering

when the unlocking conditions are satisfied, and the PCB controls the door lock

to execute unlocking operation. When the “Door lock” icon on display window is

off, the door is unlocked.

♦ The program enters in “Pause mode” from “Run mode”, and the unlocking

operation can be executed if conditions permit.

♦ In case of power outage during washing, the door will be unlocked 3 min later

(the specific time depends on the different ambient temperature).

♦ The door lock clicks when it executes the program of “lock/unlock”.

♦ Door unlocking conditions: the motor stops, the water temperature is below

50°C, and the water level is below the “Door-opening water level”.

3.6 LAUNDERING CONTROL

♦ After the PCB enters in the “Ready mode”, select proper program and function,

press down “Start/Pause” button, and the PCB controls the door lock to lock,

controls the inlet valve for water inflowing up to the “washing water level”, and

then begins the laundering process.

♦ The PCB controls the motor to execute intermittent operations in clockwise

and counterclockwise directions at a constant frequency, driving the drum to

rotate via belt sheave for purpose of laundering.

♦ Motor speed and rotation/stop ratio under “Cotton” program:

3. FEATURES & TECHNICAL EXPLANATION

7

Course Water inflow Pre-wash Wash Rinse

Motor speed 45rpm 55rpm 55rpm 55rpm

Rotation/Stop ratio 10:5 20:10 20:10 12:8

3.7 HEATING CONTROL

♦ When the temperature set by the user is higher than the water temperature,

the PCB will control the heater to function and run the heating process until the

water temperature reaches the set temperature.

♦ When the temperature set by the user is higher than the water temperature,

no heating operation is required.

♦ The heater is enabled and proceeds to function until 3 seconds pass by after

the set temperature is reached.

♦ When the water level is below the “Heating water level”, the heater should be

forced to shut down, and then replenish water.

3.8 SPINNING CONTROL

♦ During draining, the Spinning process will begin after the water of tub is

discharged down to the “Spinning water level”.

♦ The PCB controls the motor to drive the drum to rotate in clockwise direction.

Carry out distribution measurement at low speed (about 110rpm) first, and then

measure the equilibrium value. After the equilibrium value is up to standard, the

distribution measurement succeeds, and enter the stage of high-speed

Spinning.If the distribution measurement fails as the equilibrium value is too big

and does not meet the requirements, then it is necessary to continuously carry

out distribution measurement operation.

♦ Spin speed limit: The spin speed shall neither exceed the maximum speed set

by the program nor exceed the speed manually set via the “Spin” button.

3. FEATURES & TECHNICAL EXPLANATION

8

♦ During the distribution measurement, time is not reckoned in the first 10 times,

and if the distribution measurement still fails, then the time will decrease

progressively and occupy the Spinning time until the latter is run out.

♦ During Spinning, if the clothes are not spinning at last as the distribution

measurement fails all the time, then “End/Unb” will alternately display after the

program ends at an interval of 1s, the display window is on all the time, and the

alarm will give out buzzing sound.

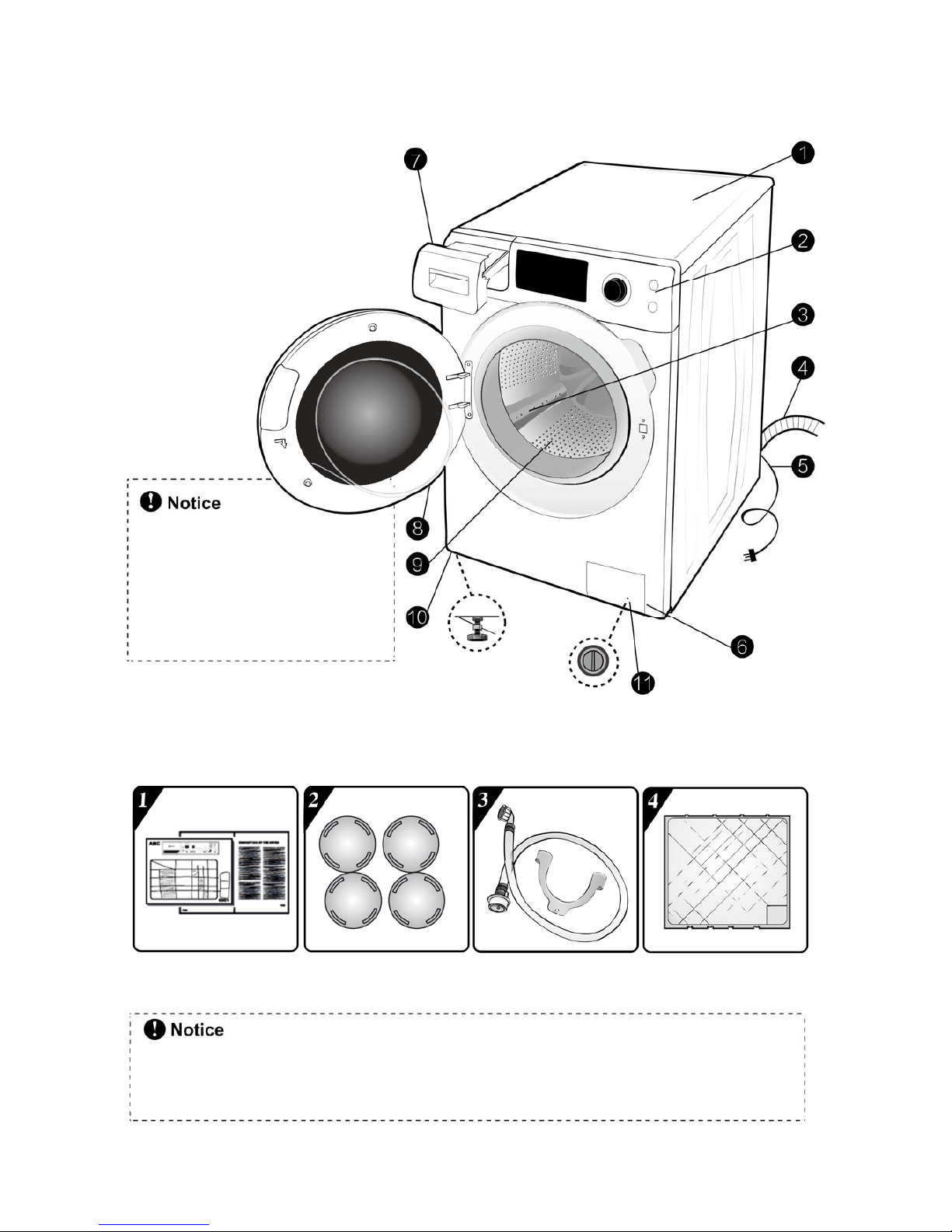

4. PARTS IDENTIFICATION

9

MARKS OF PARTS

1. Top Cover

2. Control Panel

3. Lifter

4. Drain Hose

5. Power Plug

6. Filter Cover Cap

7. Dispenser

8. Door

9. Drum

10. 4 Adjustable

Feet

11. Drain Pump

Filter

As for the product improvement

and expansion in series, products

purchased by you may differ from

the graphical representations in this

manual, the actual product shall

p

revail.

The appearance depends on different machine models

Some models are not equipped with “U” elbow bracket or noise reduce board but not affect

th

e usage,

IFU ASM 4 Plastic Caps Of

Inlet Tube +“U”

Noise Reduce

Board

ACCESSORIES

5. INSTALLATION AND TEST

10

1. Before servicing, ask the customer what the trouble is.

2. Check the setup (power supply is 220-240V AC, remove the transit bolts,

level the washer....).

3. Check with the troubleshooting guide.

4. Plan your service method by referring to the disassembly instructions.

5. Service the unit.

6. After servicing, operate the appliance to see whether it functions correctly.

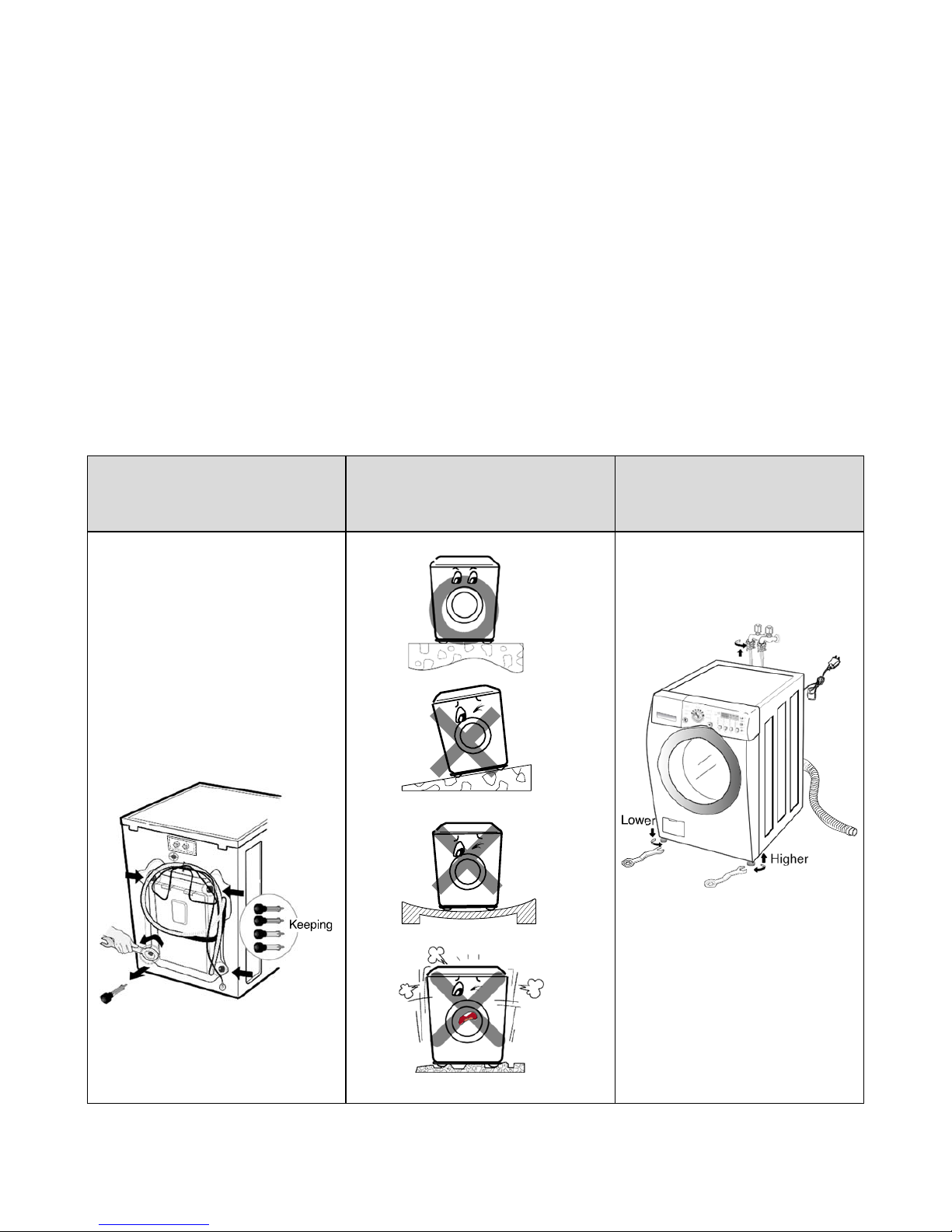

5.1 STANDARD INSTALLATION

REMOVE THE

SHIPPING BOLTS

INSTALL THE APPLIANCE

ON A FLAT AND FIRM

ADJUST THE LEVELING

♦ Remove the 4 shipping bolts with

the supplied wrench.

※Do first lower side to remove

easily.

♦ Keep the shipping bolts and

spanner for future use.

♦ Insert the 4 caps (provided) into the

hole.

♦ Turn the leveling feet to adjust the

appliance.

♦ Turn clockwise to raise;

♦ Turn counterclockwise to lower.

5. INSTALLATION AND TEST

11

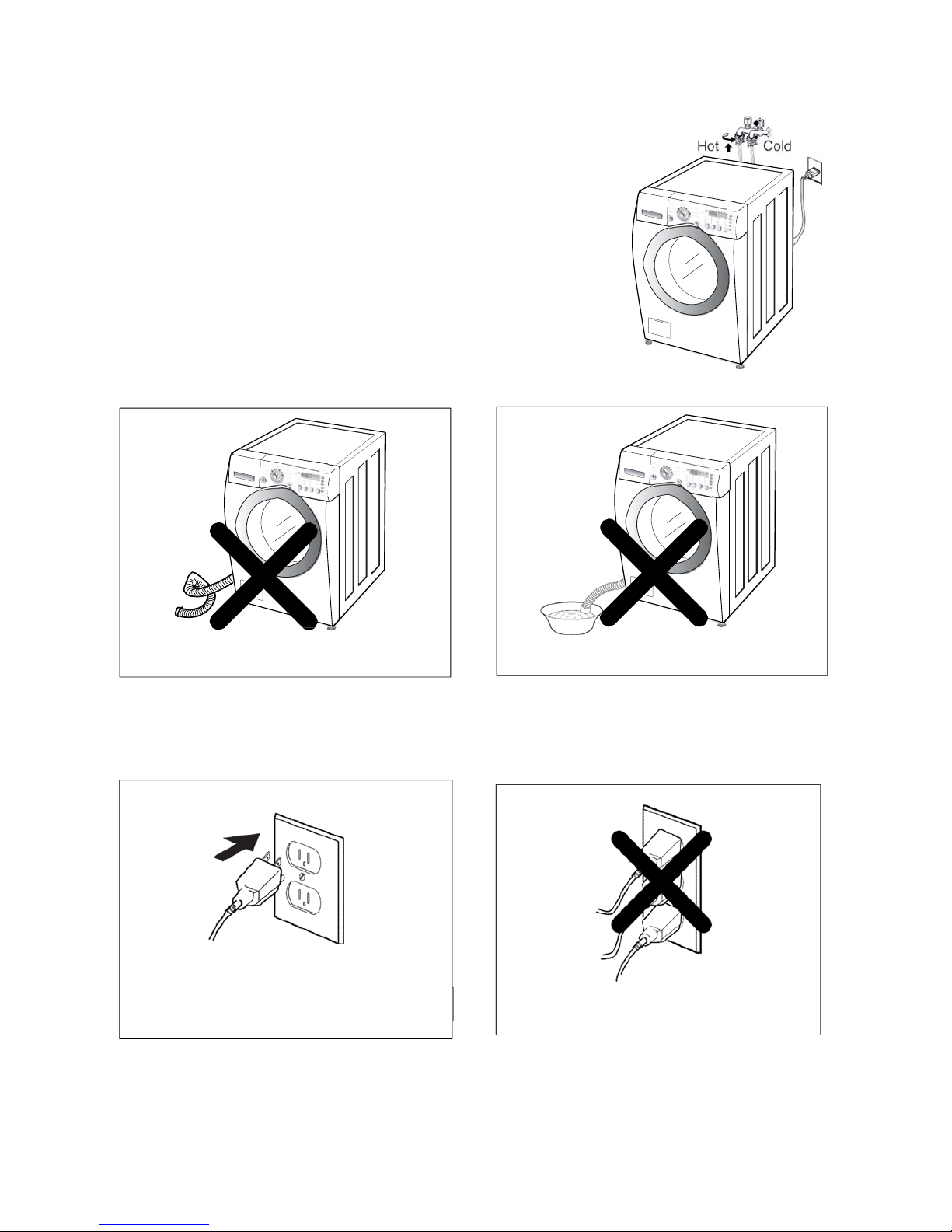

5.2 CONNECT THE INLET HOSE

♦ Verify that the rubber washer is inside of the valve

connector.

♦ Tighten the inlet hose securely to prevent leaks.

5.3 CONNECT THE DRAIN HOSE

※ The end of the drain hose should be placed less than 96” from the floor

5.4 CONNECT POWER PLUG

5.5 TEST OPERATION

Make sure that the hose is not twisted

A

void submerging the end of the hose

Connect the power plug to the wall outlet

·Avoid connecting several electric devices,

as doing so may cause a fire

5. INSTALLATION AND TEST

12

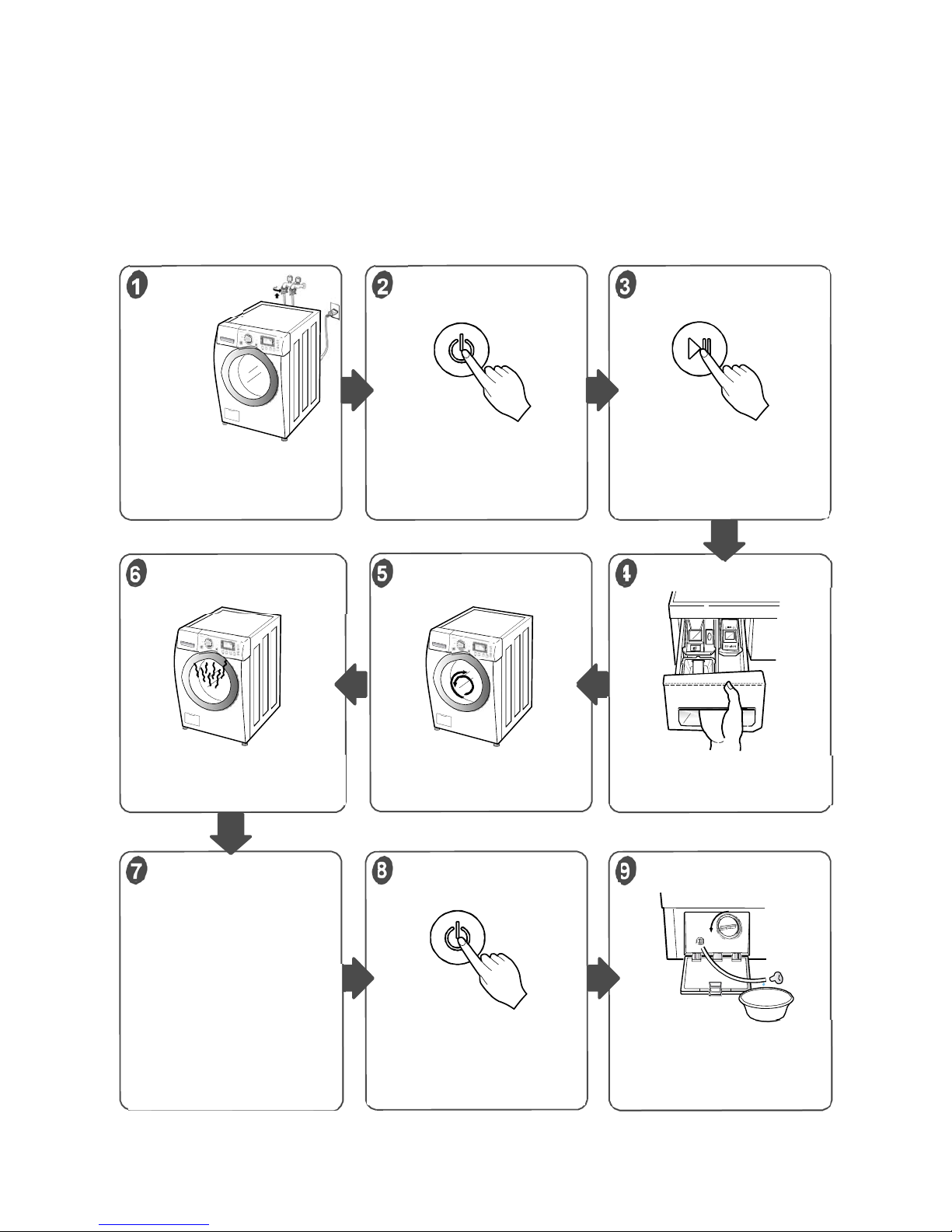

Carry out self-inspection on washing machine as per Figure 8-1 or carry out trial

run as shown in figure below

[CAUTION] Before carrying out inspection in this way, please turn on the special function mode as per

Figure 8-2; after the inspection is finished, please turn off the special function mode, otherwise, it may

lead to mal-operation of users and further affect the normal usage of washing machine.

Select a short program and set

the laundering temperature

above the room tem

p

erature.

6

Connect the power plug to the

outlet.

Connect the inlet hose.

The “door lock icon”on display

screen is on if the door has

locked.

Display the present temperature

as per Figure 8-2

Check if the drum rotates

clockwise and anticlockwise

Check if water is supplied

through the detergent dispenser

During water draining, check

the drain and spin functions.

A

fter the spinning ends, The

“door lock icon”on display

screen is flickering if the door

execute unlocking operation.

The display screen displays

“End”. Press down the

“ON/OFF” button for 3s, and

then turn off the power supply

If service is needed during

check, remove the remaining

water by pulling out hose cap

8

1

2

3

6

5 4

7 9

Check the water supply

Check the automatic

reverse rotation

Check the water heating

function

Check the drain and

Spin functions.

Water removal

Press the “ON/OFF”

button

Press the “ON/OFF”

button

Press the “Start/Pause”

button

Preparation

for washing

6. OPERATION

13

6.1 CONTROL PANEL

A: “ON/OFF” button

Turn on/off the power with this button

B: “Start/Pause” button

Start/ Stop the washer with this button

C: Cycle Selector Knob

Rotate the Cycle selector knob to select the cycle designed for different types

of fabric and soil levels.

D: Display window

Display the information such as the washing program, function, state and

residual time of washer

E: “Select” button

Confirm the selection of additional function of laundering by pressing this

button.

F: “Option” button

Choose the additional function of laundering by repeatedly pressing this

button to switch over from one option to another.

G: “Spin” button

6. OPERATION

14

Change the final spinning speed by repeatedly pressing this button to switch

over from one option to another.

H: “Temp.” button

Change the heating temperature of laundering by repeatedly pressing this

button to switch over from one option to another.

I: “Load” button

Manually select the range of clothes quantity by repeatedly pressing this

button to switch over from one option to another.

J: “Delay” button

This function allows the user to wash clothes at his/her convenience, such as

the time period where the electricity is cheap.

6.2 CYCLE GUIDE

The cycle guide below shows the options and recommended fabric types for

each cycle.

Loading...

Loading...