Page 1

CONTENTS

1. X - RAY RADIATION PRECAUTION

2. SAFETY PRECAUTION

3. PRODUCT SAFETY NOTICE

4. THE ALIGNMENT FLOW CHART

5. INSTALLATION AND SERVICE ADJUSTMENTS

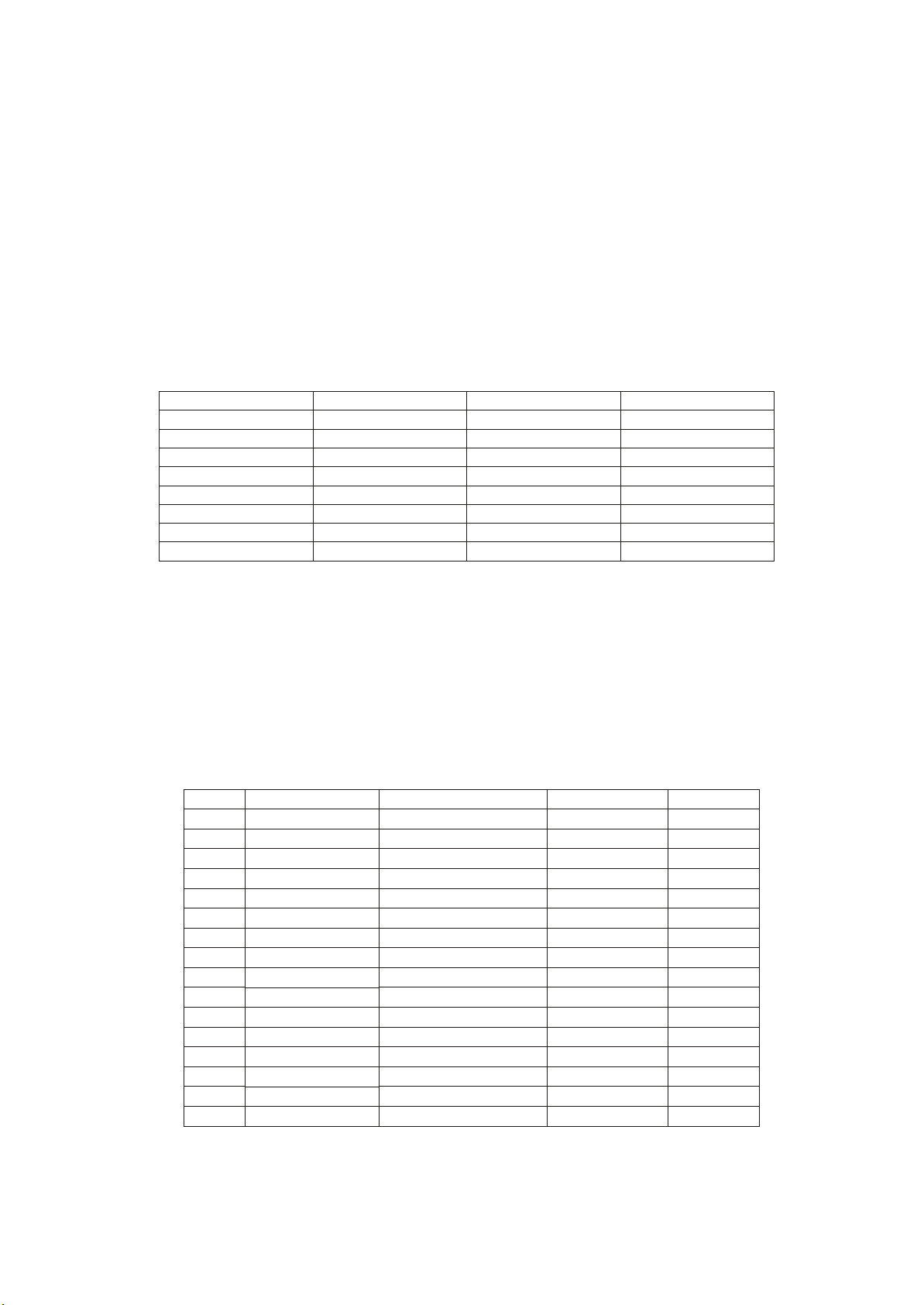

6. USA CHANNEL FREQUENCY TABLE (181 CH)

7. WIRING DIAGRAM

8. BLOCK DIAGRAM

9. IC BLOCK DIAGRAM

10. TDA9850 BLOCK DIAGRAM

11. COMPONENT AND BOTTOM VIEW

12. SCHEMATIC DIAGRAM

13. ELECTRICAL PARTS LIST

………………………………………………………. ……………

…………………………………………………………..……

………………………………………………………. ……..…………

………………………………………………………. ……...…….……

………………………………………………………. ……...………

………………………………………………. ……..….……

………………………………………………. …………..….……

………………………………………………. ………..….……

………………………………………………………

……………………………………………………..……

………………………………………………....……

…………………………………………

…………………………………...……

1

1

2

3

3

9

12

13

14

15

16

23

24

Page 2

CAUTION: BEFORE SERVICING THE CHASSIS, READ THE “X-RAY RADIATION

PRECAUTION” “SAFETY PRECAUTION” ON PAGE 1 AND “PRODUCT

SAFETY NOTICE” ON PAGE 2 OF THIS MANUAL.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous X - RAY RADIATION. To avoid such

hazards, the high voltage must not be above the specified limit. The normal value of the high

voltage of this receiver is 28.5kV at zero beam current (minimum brightness) under a 120V AC

power source. The high voltage must not, under any circumstances, exceed 30kV.

2. Each time a receiver requires servicing, the high voltage should be checked following the HIGH

VOLTAGE CHECK procedure in this manual. It is recommended the reading of the high voltage

be recorded as a part of service record. It is important to use an accurate and reliable high voltage

meter.

3. This receiver is equipped with a Fail Safe (FS) circuit which prevents the receiver from

producing an excessively high voltage even if the B+ voltage increases abnormally. Each time the

receiver is serviced, the FS circuit must be checked to determine that the circuit is properly

functioning, following the FS CIRCUIT CHECK procedure in this manual.

4. The primary source of X - RAY RADIATION in this TV receiver is the picture tube. For

continuous X - RAY RADIATION protection, the replacement tube must be exactly the same type

tube as specified in the parts list.

5. Some parts in this receiver have special safety-related characteristics for X - RAY RADIATION

protection. For continuous safety, parts replacement should be undertaken only after referring to

the PRODUCT SAFETY NOTICE below.

SAFETY PRECAUTION

WARNING:

Service should not be attempted by anyone unfamiliar with the necessary precaution on this

receiver. The following are the necessary precautions to be observed before servicing this chassis.

1. Since the power supply circuit of this receiver is directly connected to the AC power line, an

isolation transformer should be used during any dynamic service to avoid possible shock hazard.

2. Always discharge the picture tube anode to the CRT conductive coating before handling the

picture tube. The picture tube is highly evacuated and if broken, glass fragments will be violently

expelled. Use shatter proof goggles and keep picture tube away from the unprotected body while

handling.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are put

back in place, such as: non-metallic control knobs, insulating covers, shields, isolation

resistor-capacitor network etc.

4. When replacing parts or circuit boards, disconnect the power cord.

5. When replacing a high wattage resistor (oxiode metal film resistor) on the circuit board, keep the

resistor 10mm (1/2in) away from circuit board.

6. Connection wires must be kept away from components with high voltage or high temperature.

7. If any fuse in this TV receiver is blown, replace it with the FUSE specified in the chassis parts

list.

- 1 -

Page 3

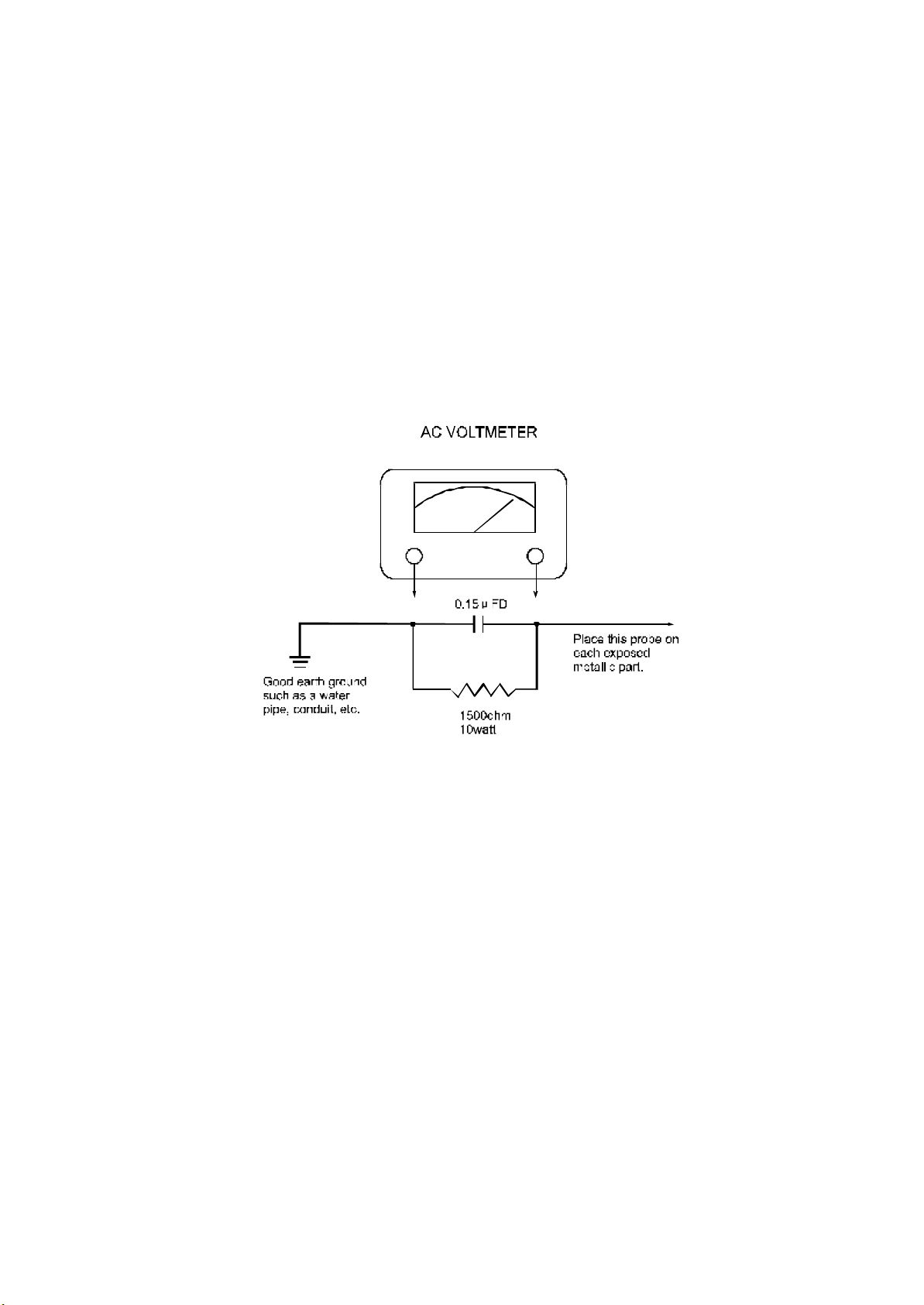

8. Before returning the set to your customer, always perform an AC leakage current check on the

exposed metallic parts of the cabinet, such as antennas, terminals, screwheads, metal overlays,

control shafts etc. to be sure the set is safe to operate without danger of electrical shock. Plug the

AC line cord directly into a 120V AC outlet (do not use a line isolation transformer during this

check). Use an AC voltmeter having 5000 ohms per volt or more sensitivity in the following

manner:

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15μF, AC type capacitor, between a known

good earth ground (water pipe, conduit, etc.) and the exposed metallic parts, one at a time. Measure

the AC voltage across the combination of 1500 ohm resistor and 0.15 μF capacitor. Reverse the

AC plug at the AC outlet and repeat AC voltage measurements for each exposed metallic part.

Voltage measured must not exceed 0.3 volts RMS. This corresponds to 0.2 milliamp. AC. Any

value exceeding this limit constitutes a potential shock hazard and must be corrected immediately.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the chassis have special safety-related characteristics.

These characteristics are often passed unnoticed by a visual inspection and the X-RAY

RADIATION protection afforded by them cannot necessarily be obtained by using replacement

components rated for higher wattage, etc. Replacement parts which have these special safety

characteristics are identified in this manual and its supplement electrical components having such

features are shaded on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of

substitute replacement parts which do not have the same char acteristic as specified in the parts list

may create shock, fire, X-RAY RADIATION or other hazards.

- 2 -

Page 4

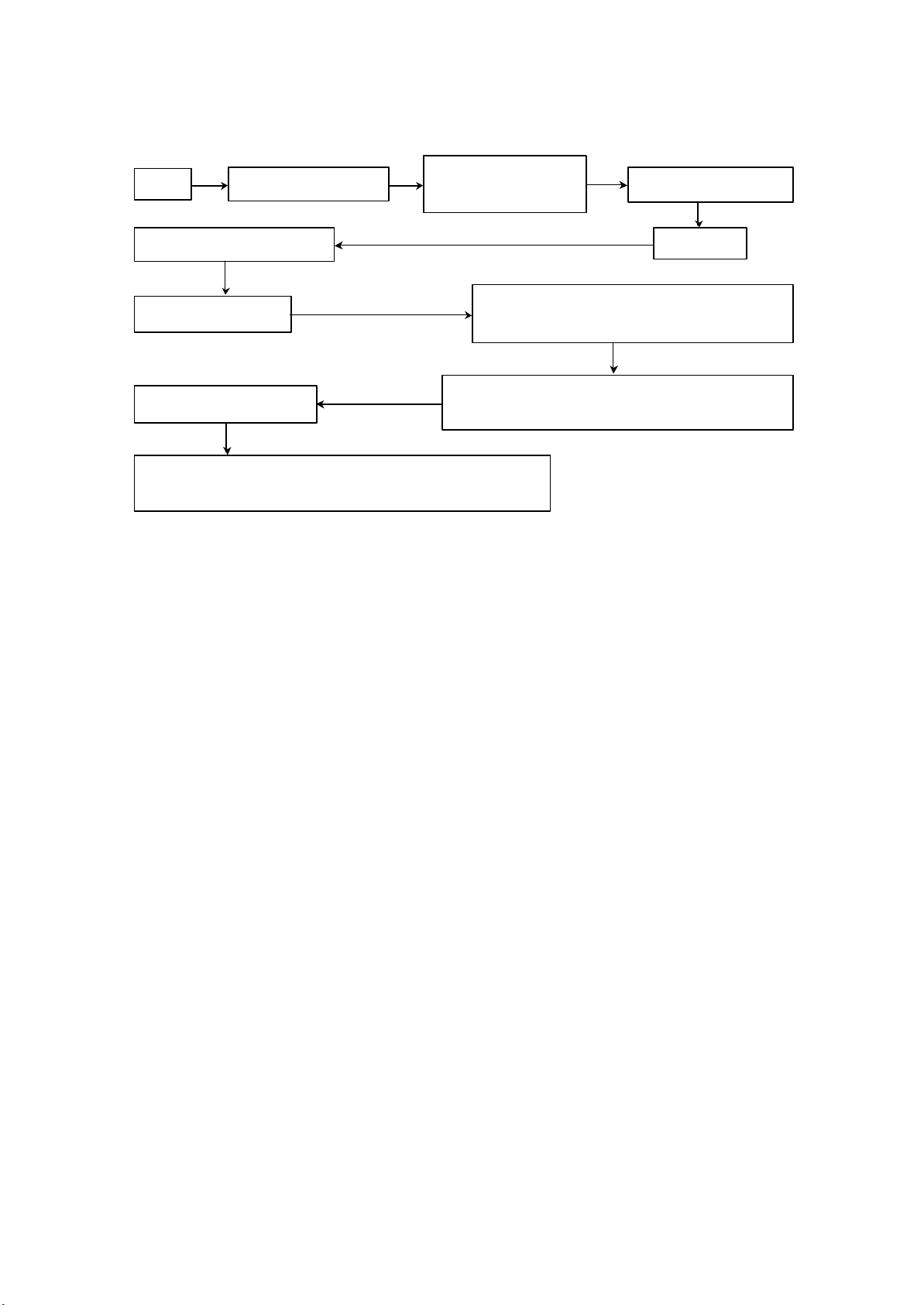

THE ALIGNMENT FLOW CHART

PIF

To fit the front cabinet,

Focus

alignment, focus, high

BTSC, secret code setting, AV function check.

Control buttons, channels, white balance, sound, hit the set

Factory items’ adjustment

Heatrun for 2 hours

To fit the back cabinet

B+, AGC,H-frequency

external degaussing

Preheat for 30 minutes

White balance revoltage,

X-ray protection test, sound power test, CCD, V-chip,

INSTALLATION AND SERVICE ADJUSTMENTS

GENERAL

In the majority of cases, a color television receiver will need only slight touch-up adjustment upon

installation. Check the basic characteristics such as FS、EHV and focus. Observe the picture for

good black and white details without objectionable color shading. If color shading is evident,

demagnetize the receiver.

If color shading still persists, perform purity and c onvergence adjustments. This should be all that is

necessary to achieve optimum receiver performance.

FOCUS ADJUSTMENT

Adjust the FOCUS control (on T471) for well defined scanning lines on the picture screen.

HIGH VOLTAGE CHECK

CAUTION: These is no HIGH VOLTAGE ADJUSTMENT on this chassis. Checking should be

done following the steps below.

1. Connect an accurate high voltage meter to the second anode of the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS and CONTRAST controls to minimum (zero beam

current).

3. High voltage will be measured about 28.5kV.

4. Vary the BRIGHTNESS control to both extremes to be sure the high voltage does not exceed the

limit under any conditions.

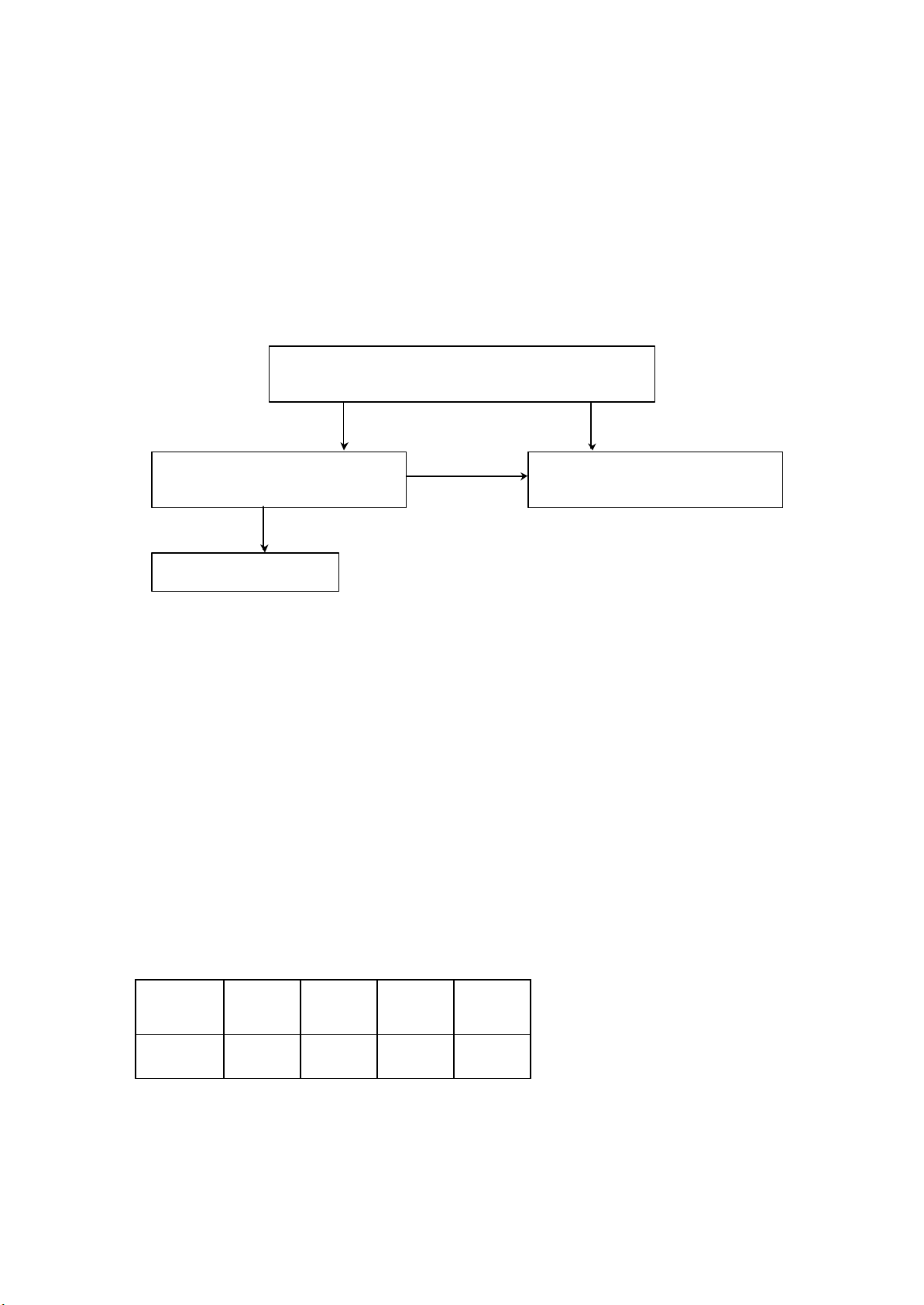

FS CIRCUIT CHECK

The Fail Safe (FS) circuit check is indispensable for the final check in the servicing. Checking

should be done following the steps below.

- 3 -

Page 5

1. Turn the power switch on and adjust customer controls for normal operation.

Check that the set returns to normal operation when pin

34 of N101 on the Main Board is grounded with jumper

Power Circuit or Horizontal Circuit

Check if the voltage across capacitor

C411 is approximately 21V.

2. Temporarily short R412 on the Main Board with a jumper wire. Raster and sound will

disappear.

3. The receiver must remain in this state even after removing the jumper wire. This is the evidence

that the FS circuit is functioning properly.

4. To obtain a picture again, temporarily turn the receiver off and allow the FS circuit more than 30

seconds to reset. Then turn the power switch on to produce a normal picture.

Troubleshooting Guide for Fail Safe Circuit

YES NO

NO

YES

Faulty

Defective Fail Safe Circuit

PIF alignment

1) Apply DC 12V to output pin of N551(pin3 of N551 ) , connect pin7 of LA76814(N101)

to GND.

2) Apply 95dBμ, 45.75MHz RF signal to the tuner's IF pin through a 1000P ceramic

capacitor. Connect the DC voltameter's⊕pole to LA76814 pin 47 , ⊙ pole to GND.

Note: For LA76814 ES01 version, the voltameter's⊕pole should connect to pin50 .

3) Adjust T202 with a non-inductive screwdriver until the reading on the DC voltameter is DC

3.6V±0.01V.

B+ CHECK

1) Prepare the test equipment.

2) Use the DC voltameter at DC 200V position to test VD551⊕, i.e. B+.

3) Connect the power plug to AC 120V/60Hz, turn on the power switch, wait for normal raster,

then adjust RP551 to make B+ = 110V±0.5V.

Test point

VD551⊕ VD556⊕ VD554⊕ VD555⊕

DC(V) 110 25 15 18

- 4 -

Page 6

TEST EQUIPMENT

1) DC regulated power supply PAB18-1.8

2) Audio voltameter

3) Oscilloscope

4) High-voltage meter

5) Digital multimeter

6) AC voltameter

TEST MODE SET(CHECK)

TEST MODE ADJUSTMENT INSTRUCTION

TEST MODE adjustment is a special adjustment which is controlled by I2C BUS. The TV set has

been set at optimum mode at the factory. Except for special need, such as replacing CRT、

MEMORY 、IC etc., it is hoped not to adjust it. To conduct TEST MODE's adjustment, please do it

according to the following steps :

There are two special romote controller for the set. One is "Under Adjustment" and the other is

"Under Adjustment for W/B Balance".

1) Press "PROD" button to enter the FACTORY, B/W BALANCE, ADJUST or SETUP mode.

2) In B/W BALANCE mode, select the item you want to adjust directly by pressing the button on

the"Under Adjustment for W/B Balance" remote controller and use the "ADJ+" or "ADJ-" button

to adjust. You can press "ADJUP" or "ADJDOWN" to select needed adjustment item and use

the "ADJ+" or "ADJ-" button to adjust too.

3) In ADJUST mode, select the item you want to adjust directly by pressing the button on the "Under

Adjustment" remote controller and use the "ADJ+" or "ADJ-" button to adjust. You can press

"ADJUP" or "ADJDOWN" to select needed adjustment item and use the "ADJ+" or "ADJ-"

button to adjust too.

4) In SETUP mode, select the item you want to adjust by pressing the button "ADJUP" or

"ADJDOWN" on the "Under Adjustment". Then use the "ADJ+" or "ADJ-" button to adjust.

adjust.

5) Press "PROD" to exit the TEST MODE.

H-blanking, H-center adjustment

1) Receive test signal, enter into the ADJUST mode.

2) Select the H.BLK.LEFT and H.BLK.RIGHT item, adjust the level to make the H -blanking

amount on the left and right screen at an appropriate position.

3) Select the H.PHASE item, adjust the level to make the left and right picture sysmmetrical.

V-amplitude, linearity, S-correction, center adjustment

1) Receive test signal, enter into the ADJUST mode. adjust the value to make V-center and the CRT's

2) Select the V.POS item , adjust the value to make V-center and the CRT's geometric center is in

accordance. Then select the V.SIZE item, adjust the value to make the overscan is less than or

- 5 -

Page 7

Equate 10% .

2) Select the V.LINE item, adjust the value to make the upper and lower grid's(on the screen) vertical

distance equal. Select the V.SC item, adjustthe value to make the vertical distance from upper

grid to middle screen is equal to the vertical distance from lower grid to middle screen.

3) Repeat the above steps 2) &3) to make the V-center, V-amplitude, V-linearity at the optimum

mode.

White balance, sub-brightness adjustment

1) Receive test signal, enter into B/W BALANCE mode with the special remote controller of

"Under Adjustment for B/W BALANCE".

2) Set the value of item as the following table:

Name

Name

S-BRI

R-BIA

G-BIA

B-BIA

R-DRV

G-DRV

B-DRV

C.B/W

3) Set the value of S-BRI=85, then press "LINE" button. Adjust the SCREEN potentiameter

clockwise until a slight bright horizontal line appears on the screen. Adjust the value of

R-BIA, G-BIA and B-BIA, until the line change white. Press "LINE" button again. Then

decrease S-BRI to a proper value.

4) Press "LINE" button to exit B/W BALANCE mode.

Value

0~127

0~255

0~255

0~255

0~127

0~15

0~127

0~3

Default

-

-

-

-

65

7

65

0

Description

Sub Brightness

Red Bias

Green Bias

Blue Bias

Red Drive

Green Drive

Blue Drive

Cross B/W

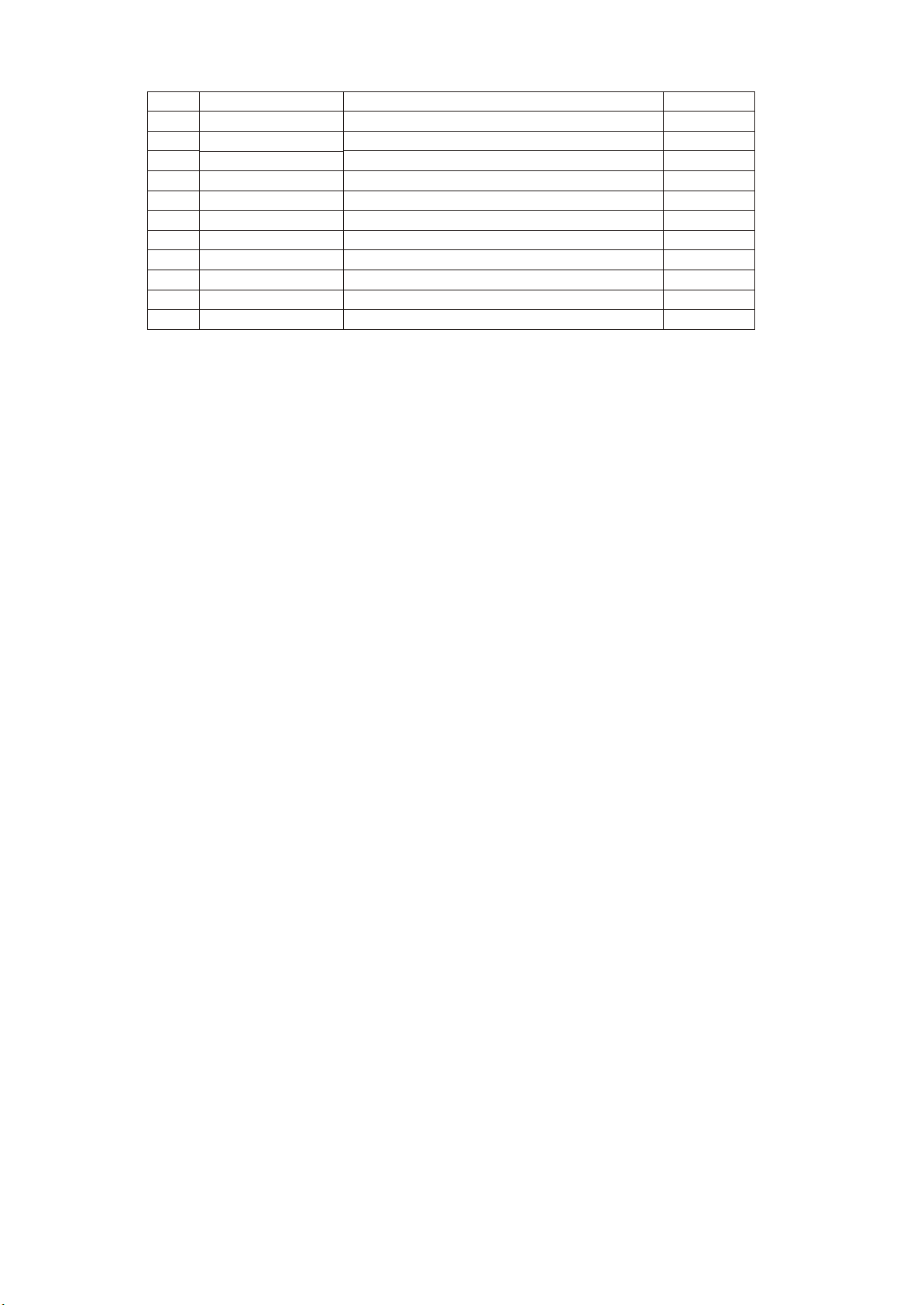

ADJUST MENU LIST

Receive test signal, enter into ADJUST mode with the special remote controller of

"Under Adjustment".

Item

00*

01**

02**

03**

04*

05*

06*

07*

08**

09**

10**

11**

12

13

14

15

Name

H.PHASE

NT.H.PHASE

H.BLK.LEFT

H.BLK.RIGHT

V.SIZE

V.LINE

V.POSI

V.SC

NT.V.SIZE

NT.V.LINE

NT.V.POSI

NT.V.SC

RF.AGC

VOL.OUT

OSD.H.POSI

OSD.V.POSI

Description

H.PHASE

Vertical Size

Vertical Linearity

Vertical DC

Vertical S-Correction

RF AGC Delay

Volume Control

Value

0~31

0~31

0~7

0~7

0~127

0~31

0~63

0~31

-32~+31

-16~+15

-32~+31

-16~+15

0~63

0~127

0~127

0~31

Default

13

00

7

0

82

3

33

6

00

00

00

00

30

127

11

16

- 6 -

Page 8

16

17

18

19

21

22

INPUT LEVEL

SPECTRAL

WIDE BAND

STEREO

FILTER SET

SAP VCO

0~15

0~63

0~63

0~63

0~31

0~63

7

0

0

63

63

63

Note: 1.All the items sign with "*" can adjust to different value for different

TV set.

2.All the items sign with "**" do not affect the IC of La76814.

ADJUST MENU LIST

Receive test signal, enter into ADJUST mode with the special remote controller of

"Under Adjustment".

Item

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Name

LA76814/LA76812

SAP IC SELECT

SUB.CONT

SUB.COLOR

SUB.SHARP

SUB.TINT

BLK.STR.DEF

AFC GAIN

V.SETUP

CD.MODE

DIGITALOSD

OSD CONT

GRAY MOD

B.GAMSEL

RG.GAM.DEF

FBPBLK.SW

BRIGHT ABL.TH

EMG.ABL.DEF

BRT.ABL.DEF

MID.STP.DEF

R-Y/B-Y G.BL

R-Y/B-Y ANG

C.KILL.OFF

SND.TRAP

VOL.FIL

VIF.SYS.SW

VIDEO.LEVEL

FM.LEVEL

POWER OPT

POWER FLAG

SEARCH CHECK

SEARCH SPEED

AV OPTION

POSITION L/R

BLUE BACK

BLACK BACK

Description

0:LA76814; 1:LA76812

0:TDA9850; 1:CXA2104; 2:TDA9855; 3:UPC1851B

Subcontrast(0~31)

Subcolor(0~63)

Subsharpness(0~31)

Subtint(0~63)

Black Stretch Definition(0:on; 1:off)

AFC Gain(0:low; 1:high)

Vertical Synchronization Separate Sense(0:low; 1:high)

Count Down Mode(LA76814:0/1;LA76812:0~7)

Digital OSD(0:Analog; 1:Digital)

OSD Contrast(0~127)/LA76814(0~3)

Gray Mode(0/1)

Blue Selection(0~3)

Red&Green Definition(0/1)

FBPBLK.SW(0/1)

Bright.Abl.Threshold(0~7)

Emg.Abl.Def(0/1)

Brt.Abl.Def(0/1)

Mid.Stp.Def(0/1)

R-Y/B-Y Gain Balance(0~15)(None for)(LA76814)

R-Y/B-Y Angle(0~15)

C_Kill OFF(0/1)

Sound Trap(0~7)

Volume Filter Defeat(0/1)

Video IF(0:45.75M;1:58.75M)

Video Level(0~7)

FM Level(31)

0:Twice On; 1:Memory; 2or3:Once On

0:No Power On Screen;1:Power On Screen

0:No Power On Search;1:Power On Search

0:Slow;1:Quick

AV Input (0:No; 1:1; 2:2; 3:3)

Position of CH Number(0:Upper Left;1:Upper Right)

Blue Back When No Signal(0:Off; 1:On)

Black Back When Switch Channel(0:Off;1:On)

Default

0

0

0

31

10

31

1

1

1

0

1

2

0

2

0

0

0

0

0

0

8

8

0

3

1

0

7

16

1

0

1

0

2

1

1

0

- 7 -

Page 9

STEREO OPTION

36

37

WOOFER/H.PHONE

38

WOOFER VOL.OPT

39

40

41

42

43

44

45

46

47

SENSITIVITY

V.MUTE P.OFF

CCD OPTION

V-CHIP OPTION

PASSWORD OPT

COMB.OPTION

TUNER OPTION

GAME OPTION

SCREEN OPTION

Stereo Option(0:off;1:on)

0:Woofer;1:Headphone

Volume of H.Phone(0:No Woofer;1:Woofer)

Sensitivity Function(0:off;1:on)

Cut Video Out Before Power Off(0:on; 1:off)

CCD Function(0:off; 1:on)

V-CHIP Function(0:off; 1:on)

Password of V-CHIP(0:off;1:on)

Y/C Separate Function(0:off;1:on)

0:TDF-3M3;1:PHOLIPUV1336B

Game Option(0:on; 1:off)

0:No Screen;1:Screen When Power On;2:ScreenWhen Power Off;3:Screen When Power On/Off

1

0

0

0

0

1

1

1

0

1

1

0

- 8 -

Page 10

USA CHANNEL FREQUENCY TABLE

U.S.A. Channel

PIF 45.75MHZ, CIF 42.17MHZ, SIF 41.25MHZ.

UNIT:MHZ

Channel fp(picture) fs(sound) Channel fp(picture) fs(sound)

2 55.25 59.75 36 603.25 607.75

3 61.25 65.75 37 609.25 613.75

4 67.25 74.75 38 615.25 619.75

5 77.25 81.75 39 621.25 625.75

6 83.25 87.75 40 627.25 631.75

7 175.25 179.75 41 633.25 637.75

8 181.25 185.75 42 639.25 643.75

9 187.25 191.75 43 645.25 649.75

10 193.25 197.75 44 651.25 655.75

11 199.25 203.75 45 657.25 661.75

12 205.25 209.75 46 663.25 667.75

13 211.25 215.75 47 669.25 673.75

14 471.25 475.75 48 675.25 679.75

15 477.25 481.75 49 681.25 685.75

16 483.25 487.75 50 687.25 691.75

17 489.25 493.75 51 693.25 697.75

18 495.25 499.75 52 699.25 703.75

19 501.25 505.75 53 705.25 709.75

20 507.25 511.75 54 711.25 715.75

21 513.25 517.75 55 717.25 721.75

22 519.25 523.75 56 723.25 727.75

23 525.25 529.75 57 729.25 733.75

24 531.25 535.75 58 735.25 739.75

25 537.25 541.75 59 741.25 745.75

26 543.25 547.75 60 747.25 751.75

27 549.25 553.75 61 753.25 757.75

28 555.25 559.75 62 759.25 763.75

29 561.25 565.75 63 765.25 769.75

30 567.25 571.75 64 771.25 775.75

31 573.25 577.75 65 777.25 781.75

32 579.25 583.75 66 783.25 787.75

33 585.25 589.75 67 789.25 793.75

34 591.25 595.75 68 795.25 799.75

35 597.25 601.75

69 801.25 805.75

-9-

Page 11

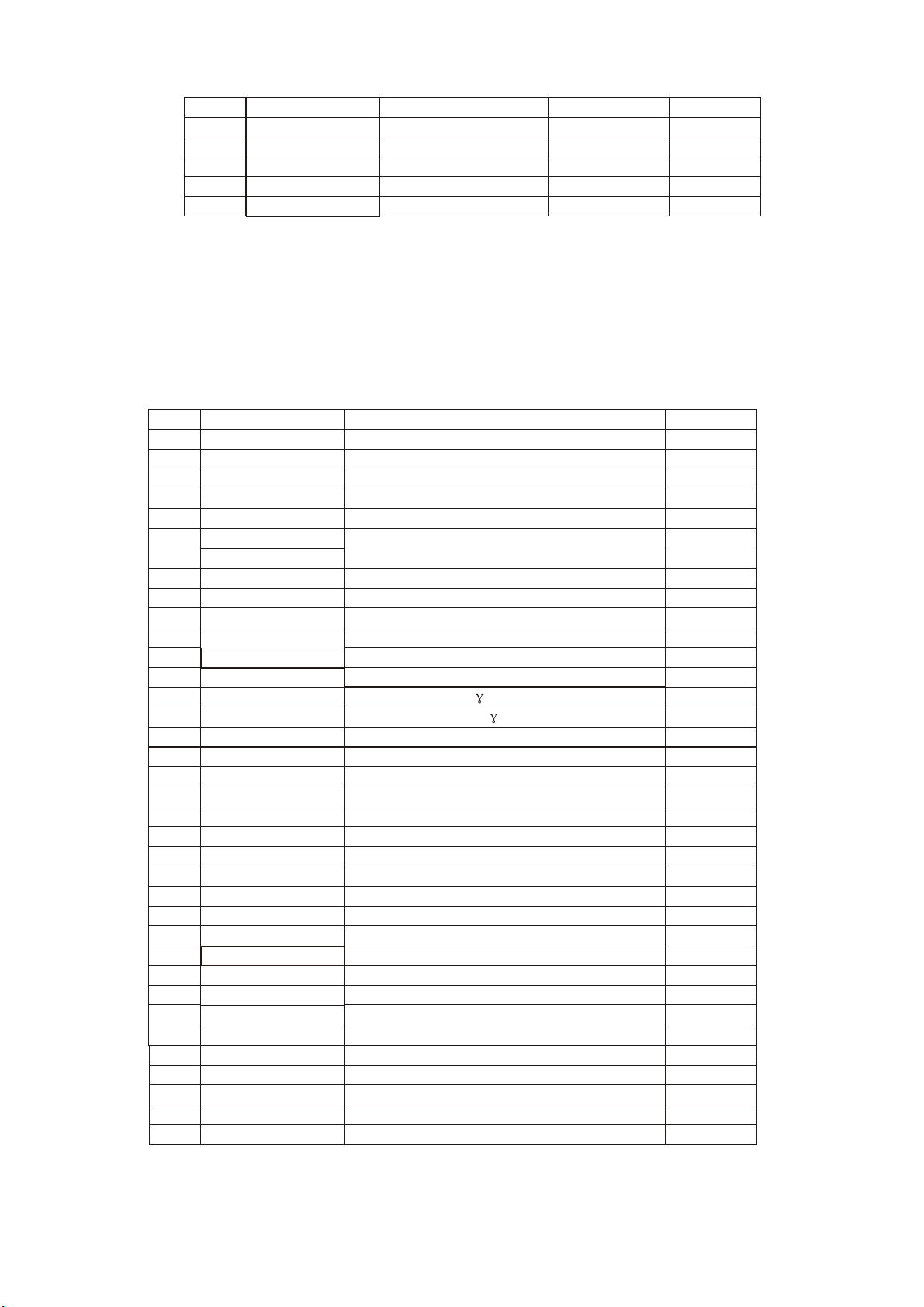

USA CHANNEL FREQUENCY TABLE

U.S.A. CATV Channel

PIF 45.75MHZ, CIF 42.17MHZ, SIF 41.25MHZ.

UNIT:MHZ

Channel fp(picture) fs(sound) Channel fp(picture) fs(sound)

1 73.25 77.75 36 295.25 299.75

2 55.25 59.75 37 301.25 305.75

3 61.25 65.75 38 307.25 311.75

4 67.25 74.75 39 313.25 317.75

5 77.25 81.75 40 319.25 323.75

6 83.25 87.75 41 325.25 329.75

7 175.25 179.75 42 331.25 335.75

8 181.25 185.75 43 337.25 341.75

9 187.25 191.75 44 343.25 347.75

10 193.25 197.75 45 349.25 353.75

11 199.25 203.75 46 355.25 359.75

12 205.25 209.75 47 361.25 365.75

13 211.25 215.75 48 367.25 371.75

14 121.25 125.75 49 373.25 377.75

15 127.25 131.75 50 379.25 383.75

16 133.25 137.75 51 385.25 389.75

17 139.25 143.75 52 391.25 395.75

18 145.25 149.75 53 397.25 401.75

19 151.25 155.75 54 403.25 407.75

20 157.25 161.75 55 409.25 413.75

21 163.25 167.75 56 415.25 419.75

22 169.25 173.75 57 421.25 425.75

23 217.25 221.75 58 427.25 431.75

24 223.25 227.75 59 433.25 437.75

25 229.25 233.75 60 439.25 443.75

26 235.25 239.75 61 445.25 449.75

27 241.25 245.75 62 451.25 455.75

28 247.25 251.75 63 457.25 461.75

29 253.25 257.75 64 463.25 467.75

30 259.25 263.75 65 469.25 473.75

31 265.25 269.75 66 475.25 479.75

32 271.25 275.75 67 481.25 485.75

33 277.25 281.75 68 487.25 491.75

34 283.25 287.75 69 493.25 497.75

35 289.25 293.75

70 499.25 503.75

-10-

Page 12

USA CHANNEL FREQUENCY TABLE

U.S.A. CATV Channel

PIF 45.75MHZ, CIF 42.17MHZ, SIF 41.25MHZ.

UNIT:MHZ

Channel fp(picture) fs(sound) Channel fp(picture) fs(sound)

71 505.25 509.75 99 115.25 119.75

72 511.25 515.75 100 649.25 653.75

73 517.25 521.75 101 655.25 659.75

74 523.25 527.75 102 661.25 665.75

75 529.25 533.75 103 667.25 671.75

76 535.25 539.75 104 673.25 677.75

77 541.25 545.75 105 679.25 683.75

78 547.25 551.75 106 685.25 689.75

79 553.25 557.75 107 691.25 695.75

80 559.25 563.75 108 697.25 701.75

81 565.25 569.75 109 703.25 707.75

82 571.25 575.75 110 709.25 713.75

83 577.25 581.75 111 715.25 719.75

84 583.25 587.75 112 721.25 725.75

85 589.25 593.75 113 727.25 731.75

86 595.25 599.75 114 733.25 737.75

87 601.25 605.75 115 739.25 743.75

88 607.25 611.75 116 745.25 749.75

89 613.25 617.75 117 751.25 755.75

90 619.25 623.75 118 757.25 761.75

91 625.25 629.75 119 763.25 767.75

92 631.25 635.75 120 769.25 773.75

93 637.25 641.75 121 775.25 779.75

94 643.25 647.75 122 781.25 785.75

95 91.25 95.75 123 787.25 791.75

96 97.25 101.75 124 793.25 797.75

97 103.25 107.75 125 799.25 803.75

98 109.25 113.75

-11-

Page 13

- 12 -

Page 14

V

OUT

IDE

O

V

I

D

IN

E

O

AU

IN

D

IO

AU

O

U

DI

T

O

I

N

1

IN2

LA

4

28

7

TC4

SW

0

53

I

TC

B

P/

H

BF

A

MP

A

U

D

IO

T

DA

985

0

A

NTS

C

1

2

C

0V

MU2

IR

8

P038

TX

1

BT

S

C

25

V

2SC

V5

4

13

2

3

7

IN

OU

T

OU

T

B

8

P

1

6

V

OWER

1

8V

13

0V

V

ID

E

O

FM

B

3

B

2

B1

I

R RX

G

B

D

RI

V

E

C

RT

C

R

T

CH

R

O

MA

R

BLOCK DIAGRAM

LC

LC

C

C

P

AT

2

4C

0

4

SIF

P

8

8

U

U

6

6

323

323

N70

N70

2A

2A

1

1

N

7

0

2

3D

D

25

5

3

M

EM

ORY

V

43

2

VI

D

EO

H

O

U

T

F

B

T

PI

F

T

4

7

1

T

U

N

E

R

S

S

A

A

W

W

F

F

A1

0

1

L

A7

8

4

1

Z

2

0

1

D

EFL

EC

T

IO

N

N

V O

4

51

U

T

N1

0

1

L

A

76

8

1

4

- 13 -

Page 15

LA76814IC BLOCK DIAGRAM

AudioOutput

FMOutput

PIFAGCFilter

RFAGCOutput

PIFInput1

PIFInput2

IFGround

IFVcc

FMFilter

AFTOutput

BusData

BusClock

ABL

2.5

2.5

2.53

2.56

2.8

2.8

5V

2.12

2.34

4.8

4.8

3.52

3

SIFInput

2.4

SIFAPCFilter

1.93

SIFOutput

2.11

Ext.AudioInput.

2.3

FLLFilter

4

VCOCoil1

4

VCOCoil2

3.7

APCfilter

2.18

VideoOutput

2.53

BlackLevelDetector

2.7

InternalVideoInput(S_CIN)

Video/VerticalGround

5V

2.4

ExternalVideoInput(YIN)

RedInput

GreenInput

BlueInput

FastBlankingInput

RGBVcc

RedOutput

GreenOutput

BlueOutput

B.AKBInput

Vertical

Output

RAMPALC

Filter

Holizontal/Bus

HolizontalAFC

Holizontal

Vcc

Filter

Output

1.1

1.15

1.13

0

8

3.16

3.16

3.05

0

2.51

2.63

5V

2.63

0.48

Video/Vertical/BUSGround

0

2.32

SelectedVideoOutput

3.06

ACCFilter

2.64

3.58MHzCrystal

0.53

fsc(3.58MHz)Output

3.3

ChromaAPC1Filter

0.35

KillerFilter

0

X-RAY

HolizontalGround

0

2.9

OSDContrast

NC

NC

1.7

VCOIREF

1.11

FBPInput

- 14 -

Page 16

C13

C12 C11

C16

C15

C17 C14

composite

baseband

input

C1

+

11

+

5

4

DEMODULATOR

SAP

ADJUST

INPUT

LEVEL

DETECTOR

STEREODECODER

C3

R1

+

+

C2

C4

C5

NOISE

Q1

+

+ + + + +

R3

326

R2

21

DBX

STEREO/SAP

SWITCH

TDA9850

1713 14 15 16

ceramic

resonator

onlyduring

adjustment

VrefV CAPVCC

C10 C9 CL CR

C19 C18

SDA

SCL

L-R/SAP

SELECT

MODE

+

21

OUTR

SAP

to

audio

processing

L+R

DEMATRIX

18 19

27

OUTL

stereo

mono

C6 C7

+

+

303132

29

STEREO

ADJUST

+

102025

SUPPLY

12

DE-EMPHASIS

23

22

C8

SAPwithoutDBX

MHA010

6

24

8

9

TRANSCEIVER

LOGIC,IC-

2

28

7

MAD

++

- 15 -

Page 17

COMPONENT VIEW OF MAIN BORAD

- 16 -

Page 18

Page 19

Page 20

COMPONENT VIEW OF CRT BORAD

- 18 -

Page 21

COMPONENT VIEW OF STEREO BORAD

- 20 -

Page 22

NISPT-2

U902

AC110V

60HZ

233-3.15A/125V

1/2DJ220K

F501

R501

LIVE AREA

DJ22K

R515

C515

FJ0.01

400KM2200S

OMIT-SS-112LM

C533

RL551

1/2W5.6M

R531

VD553

10V470

1N4148

12V

B6

AN7805

N552

1

2

C572

3

+

B7

5V

10V470

25V2200

2SJ1.5K

+

C570

B5

5V

CIRCUIT DIAGRAM OF MODEL TC14FS68

C407

50V1

R402

3.3K

R408

2.2K

R499

4.7K

680

R413

10K

1N4148

VD401

VD402

1N4148

+

C408

50V0.47

R403

330K

+

35V1000

C302

R305

1K5

R306

56K

R307

2.2K

2.7K

R311

1N4148

VD301

3DD3852

components replacement pointed out by the

mark.

6.This circuit diagram covers a basic or

representative chassis only.There may be

some comonents or partial circuit

differences between the acutal chassis

and the circuit diagram.

+

35V47

C301

8.2K

R301

100K

R302

C303

FK0.082

270K

R303

10K

R304

2SC1815Y

V301

FK0.082

C304

RP301

B-50K

PCC H-W

RP302

B-10K

R308

68K

R309

56K

R310

2.7k

2SA1015Y

V302

C315

1000

V303

have special signficance to product safety. It

is particularly recommended that only the

parts specified in service manual be used for

1/2SJ560

+

35V470

C306

DJ5.6K

R312

2W4.7

R313

5.Product safety should be considered when a

component replacement is made in any area

of receiver.The values of components

indicated by a mark in this circuit diagram

QHXC-73Q

L909

1

2

2

00

0

VD514

D

15K

R522

R524

B8

4.7K

R553

UZ6.2BSB

VD561

20

G OUT

KILLER FLT

35

22K

R411A

JDT1904

T431

Z2073

L433

0

00

PTDCA1BF3R0Q100

RT501

HF2836

L502

250V220

C507

5W6.8

7

8

1KV470

C556

2KV470

RP551

B-2K

2SC1815Y

V553

R554

150K

R556

22K

+

16V47

C244

C245

0.01

19

R OUT

APC1 FIL36FSC OUT

C207

FK0.01

50V0.47

C208

2M

+

R205

R206

47K

25V

+

50V10

C434

2SD1879

V432

1

TJC2-2A

+

1W100K

R520

1KV2700p

C516

R525

9

C551

+

1/2DJ100K

1/2DJ47K

R555

270

18

VCC (RGB)

37

R268

1K

R207

B8

2W220

R434

XS501

1000KM1000p

C504

1000KM1000p

C506

500K1000p

C518

BCK-42-25

3

10

RU4AM

160V220

C561

2SJ47K

R551

R552

1N4148

VD552

R243

17

XTAL

38

C209

J

S3.58

G201

16V0.47

R232

10K

C231

50NP1

T511

VD551

ACC FIL

+

C210

C532

HF2836

250HM0.1

C501

R517

100

2SC3807

V512

+

C565

2FJ1

R562

R568

18V

B2

N553

AN7805

1

2

3

1/2DJ270

+

FK0.068

C406

26

27

H AFC FIL

H OUT

VCO IREF

FBP IN

29

28

3K

R273

4.7K

R409

0.01

UZ5.6BSB

VD499

R404

820

24V

R314

160V47

4.The rated voltage of all capacitance is 50 V

unless otherwise rated.

F.

represents

F,n represents nF.

400KM470p

L501

250HM0.1

C502

7WK1

2SA1015

5.6K

V511

VD516

1N4148

2.2K

R526

2

13

14

VD555

EU2

R567

1.2K

2SC1815Y

V552

R561

10K

R400

FK0.47

C403

FK0.22

+

16V220

C404

C405

2.2K

0.01

4700P

TEM2011

C499

L401

24

25

RAMP ALC.FIL

VCC (H)

CLOCK OUT

VCC (CCD)

30

31

16V10

R272

4.7K

C279

3K

C431

X

C433

500KK3900

400NJ0.033

C437

B4

C305

VD436

RU4C

L301

600uH

2.The rated power of all resistance is 1/6W

unless otherwise noted.

3.All capacitance values without unit are in

R502

R511

VD517

EU1

15

FK0.1

R519

C514

1KV4700P

C520

5W47

2SC4237

V513

1

11

12

1KV470

C554

ES1

VD556

RU4AM

VD554

+

50V220

C566

+

25V1000

C564

1FJ2.2

R569

25V

R566

10K

2SB764

V554

1

2

3

3W39

R563

AN7812

N551

12V

B6

50V0.47

C401

+

C402

R244

2.7K

R401

21

22

23

B OUT

AKB IN

V OUT

OSD CONTRAST

GND (CCD/H)

X-RAY

32

34

33

R414

10K

C276

+

R274

R275

C274

0.01

C412

50V1

+

UZ7.5BSB

VD412

R415

3.9K

8.2K

R412

+

35V47

C411

1/2W3.3

VD411

EU1

R432

J

2SC2383-O

V431

R433

1/2SJ1K

C432

500KK1000

ZZ008

L431

ZZ008

L432

2000MJ1500

C435

2000MJ9200

C438

RU4DS

VD435

NOTICE:

1.All resistance values are in ohms.K represents

K

, M represents M

.K=10E3,M=10E6

TA30-10

VD504

VD506

TA30-10

43

N501

PC817B

OMIT-SS-112M

RL552

SEL VIDEO OUT

39

H-PULSE

ABL

TEST

TEST

R233

1/2W1.5K

TA30-10

VD503

TA30-10

VD505

1

2

130V

40

TP-G

JF0501-91802

TP-H

1000KM1000p

1000KM1000p

B1

GND (V/C/B)

41

50V1

C212

X

T471

C503

C505

R242

100

12

ABL13R IN14G IN15B IN16BLANK IN

EXT VIDEO IN

VCC (V/C/D)

43

42

0.01

C205

+

16V47

C206

+

24V

35V100

C472

+

130V

B1

R472

2

1

8

X

R241

100

C204

50V1

B4

EU2

1FJ1

2SC1815Y

R733

47K

100K

R114

C118

0.01

AFT OUT

DATA11CLOCK

BLK STRETCH FIL

INT VIDEO IN

44

+

+

C203

16V4.7

VD472

R472

SCREEN

FOCUS

10K

10

45

76543

R732

3.3K

50V1

560K

1.2K

V705

R730

R120

C117

R204

R202

9

2SC1815Y

V703

2SC1815Y

V704

R729

150K

R113

100K

+

9

FM FIL

VIDEO OUT

46

R201

1K

+

50V0.47

C137

10

1FJ1

EU1

HV

250V22

TRL-R

W700

J

R721

10K

R736

4.7K

L102

22UH

+

16V100

C115

C116

0.01

8

VCC (VIF)

APC FIL

47

220K

R474

VD474

+

C474

SCN-4Y

VD701

W704

X

470

10K

10K

21

V SYNC

H SYNC

R OUT22G OUT

R738

4.7K

B7

5V

38M

7

VIF IN2

GND(IF)

VCO COIL48VCO COIL

T101

200FK0.33

C441

+

R446

160V4.7

C444

1/2SJ1K

1FJ3.3

R491

2

2

TUNER

R774

C772

R758

5V

+

C733

R630

INPUT

A101

+

C103

50V2.2

R102

100K

12K

6

VOL-R

MUTE

37

22K

B5

V632

2SC1815Y

PUMP OUT

NON INPUT

OUTPUT

AGC

R776

10K

KK470

R759

8.2K

560

LA7841

XS701

1K

R772

R770

100

C771

5

VOL-L

AV238AV1

10K

R777

R778

N451

NC

R103

12K

W-VOL

R760

JPP2197BCS32

SDA

100

12V

R773

R735

10K

3

4

AV/TV

39

40

R761

22K

16V100

1N4148

VD610

16V100

K6D

SCL

R105

B6

22K

2.2K

+

C612

1N4148

+

C622

SCN-4Y

1

1

2

2

3

3

4

4

R748

R762

VD611

16V100

V-MUTE

XP901

C101

0.01

100

22K

41

22K

16V/2.2

0.01

1N4148

FO

+

C102

5V

R104

16V100

1N4148

C627

VD621

16V10

16V470

50V0.47

D

5V

5V

R101

33KB7

5V

R746

LNA150/602ALARM

COMB-FILTER

42

R763

22K

22K

+

C613

VD612

+

C628

16V100

1N4148

+

C931

C933

+

C934

+

VD933

2KV1000

CW574CS

50V4.7

C708

B5

R764

R765

16V/2.2

C618

0.01

1N4148

+

C623

VD622

12V

B6

R935

39

C939

N705

+

VD620

7

7

1

1

33V

+

C617

R727

470

UZ3.6BSB

VD703

R723

8.2K

2SA1015Y

V702

R728

R734

C729

0.01

R731

270K

R726

16V2.2

C714

+

R725

C713

50V1

330

+

17

19

20

RESET

FILT18CVBS-IN

BLANK

B OUT

23

24

R740

4.7K

0.01

R109

1K

R111

82

5

6

VIF IN1

VCO FIL

49

50

R128

X

C140

470

+

R442

R441

XS401

3.3K

3.3K

C110

0.01

0.01

D45U

50V1

50V0.47

220

2140

R742

R743

C112

C119

C136

L442

NC

25

220

2SC2216

V102

Z101

1K

FK0.022

C120

4

PIF AGC

RF AGC

EXT AUDIO IN

SIF OUT

51

+

C139

R127

L441

+

16V100

C450

12V

B3

26

R745

0.68UH

R119

3

52

1000

3K

12K

1SJ1

5.6K

220

L101

R454

R453

SDA0

SDA

R108

R110

C121XC122

FM OUT

SIF APC FIL

C123

R459

R722

1.5K

R724

4.7K

R720

10K

27

R747

22K

4

AT24C04

SCL

5

0.01

100

12V

B3

X

2

53

+

C124

50V1

R121

1K

1K

1/2DJ120

R461A

10K

0.01

LC863232A

SCL0

28

22K

2 3

N702

GND

6

R744

220

C111

R107

1

AUDIO OUT

SIF IN

54

15UH

1000

R455

12K

R458

50V1

25V2200

TJC2-5Y

N701

R749

7

5.6K

R708

C703

AFT IN

SDA1

VCC

LA76814

L121

R451

C453

+

C456

+

C457

XP402

150K

27K

8.2K

3.9K

2.7K

14NC15NC16

29

R751

22K

1

8

N101

330

153

153

4.7K

1.5K

680

39

18

12K

39K

R700

R701

R702

R703

R704

R705

R706

R707

16V47

13

SCL1

30

16V47

0.01

C126

C125

R122

35V1000

50V1

R456

R457

100FK0.1

2

2

0.01

22K

1W1R

C454

1Z75

+

C701

C702

R753

+

C719

C720

R451A

C452

+

+

2W270

C458

VDD12KEY IN

SAFTY

24V

VD452

R460

B5

5V

SW701

CH+

SW702

CH-

SW703

VOL+

SW704

VOL-

SW705

MENU

SW706

AV/TV

L701

39UH

C704

15P

C705

18P

G701

32K

390K

R709

10

11

XTAL2

S-VHS

NC

33

31

32

R754

10K

R755

R756

22K

22K

R602

1K

2SC1815Y

V601

R116

100

16V/100

C631

+

VD631

D

B4

35V100

EM01Z

VD451

C451

+

500FK10

C455

R452

1

100FK0.1

C459

4

4

XS402

TJC2-5A

GND9XTAL1

IR

34

100

B10K

RP601

10K

SRS ON/OFF

35

R766

22K

HS-0038

A701

5V

2SC1815Y

V633

R632

V631

2SA1015Y

7

6

5

4

3

2

1

R775

10K

100

KK470

7NC8

POWER

WOOFER ON/OFF

36

R757

22K

B7

R779

8.2K

+

C734

16V/10

R780

560

16V/10

R631

10K

10K

VCC2

VCC1

GND

130V

B1

3W10K

R718

IF

16V10

C611

+

R611

680

C621

16V10

680

25V/470

C615

+

12V

B3

XS403

SCN-5

XP902

SCN-5Y

54321

L901

10UH

DJ10K

R900

V932

2SC

R940

33

10

10

9

6118

6118

9

A59QDF891X002

U901

+

R621

25V470

C625

1.5K

C821

50V1

R821

1K

C819

220

+

2.2

R933

16V10

W902 JG0034

+

2SC

R822

4.7K

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

R615

63V0.1

C616

R931

1K

R932

15K

C932

+

V931

2SA

XP903

TJC2-2A

GZS10-2-AC2DG

XS901

B7

5V

V821

100K

R804

16V470

C805

+

12V

R610

R622

R924

CJ56R

0.01

16V220

C923

2SC

27K

C802

+

C801

16V10

1K

18V

63V0.1

C626

TJC3-2A

TJC3-2Y

5W8OHM

V801

R801

+

C814

SDA

SCL

AUDIO

Rout

Lout

R620

B2

XS602

XP602

B902

100

V922

2SC2688

R928

1/2SJ2.7K

B3

B7

5V

16

15

14

1X

13

OX

12

A

11

B

10

C

9

0.01

R922

CJ390

680

2SJ10K

R927

R803

220

50V1

C803

R802

68K

+

R823

68K

R612

3K

1K

3K

INT

GND

EXT

N601

SW

VOL

LA4285(R)

FLI

NFB

GND

OUT

VCC

INT

GND

EXT

SW

N602

VOL

FLI

LA4285(L)

NFB

GND

OUT

VCC

+

C606

25V1000

C607

0.01

R625

2.2

TJC3-3A

XS601

TJC3-3Y

XP601

5W8OHM

B901

330

CJ390

C921

R926

680

VD921

D

50V1

VDD

Y COM

X COM

C804

C911

R916

C822

+

TC4053BP/BF

50V1

50V1

50V10

50V10

50V10

100nF

50V2.2

16V100

15nF

50V10

50V2.2

50V4.7

50V4.7

B503F58

Q01

R914

330

CJ56R

VD911

D

16V10

C823

R833

220

R832

68K

N801

2SC1815Y

C12

+

C11

+

C10

+

C09

+

C20

+

C17

CL

+

C18

+

C08

C21

+

CR

+

C07

+

C06

+

C913

R918

1/2SJ2.7K

+

27K

V803

2SC2688

R834

100

12V

B3

V802

2SC

R831

27K

50V1

1Y

1

0Y

2

1Z

3

Z COM

4

OZ

5

INH

6

VEE

7

VSS

8

82

+

16V10

C813

VD801

D

R824

R820

3.3K

R819

1K

Rout

Lin

Rin

Lout

Cs

32

Cw

31

Cts

30

Ctw

29

MAD

28

OUTL

27

Cnd

26

Cl

25

Vref

24

SAP

23

Csde

22

OUTR

21

Cr

20

Css

19

Cmo

18

CER

17

R904

330

R912

100

V912

CJ390

2SJ10K

CJ56R

C901

560

R906

VD901

D

1/2SJ2.7K

R908

R917

R838

100

16V10

C825

+

R837

220

V803

2SC

16V10

4.7K

B7

12V

2SC2688

68K

16V10

+

C807

+

C808

16V10

C809

+

+

+

R815

B6

VEO

VEI

Cnr

Cm

Cdec

AGND

DGND

SDA

SCL

Vcc

COMP

Vcap

Cp1

Cp2

Cph

Cadj

TDA9850

100

V902

2SJ10K

16V10

R902

16V10

1

2

3

4

5

6

7

8

9

R835

27K

R836

R808

82

R810

47K

R809

4.7K

47K

R811

4.7K

4.7K

R814

47K

R813

R805

4.7K

R806

47K

C810

C811

X

VHS

R817

82

C812

0.01

R816

8.2K

12V

B6

RJ8.2K

R02

47nF

C13

RJ160

R03

+

50V10

C14

100nF

C15

+

50V4.7

C16

R21

100

R20

100

10

+

11

50V10

C01

+

12

16V100

C19

13

470nF

C02

50V4.7

2.2K

R01

C03

14

+

C04

15

220nF

+

16

50V10

C05

N641

R907

C824

+

R818

5V

C903

12V

B3

R807

82

16V10

C806

+

R812

W801

82

+

16V100

39

CRT BOARD

XS801-2

Vout

AVout

Lout

Rout

XS803

V1in

AV1

L1in

R1in

XS801-1

AV2

V2in

L2in

R2in

XS802

Y

C

R825

C00

R00

12V

B6

Page 23

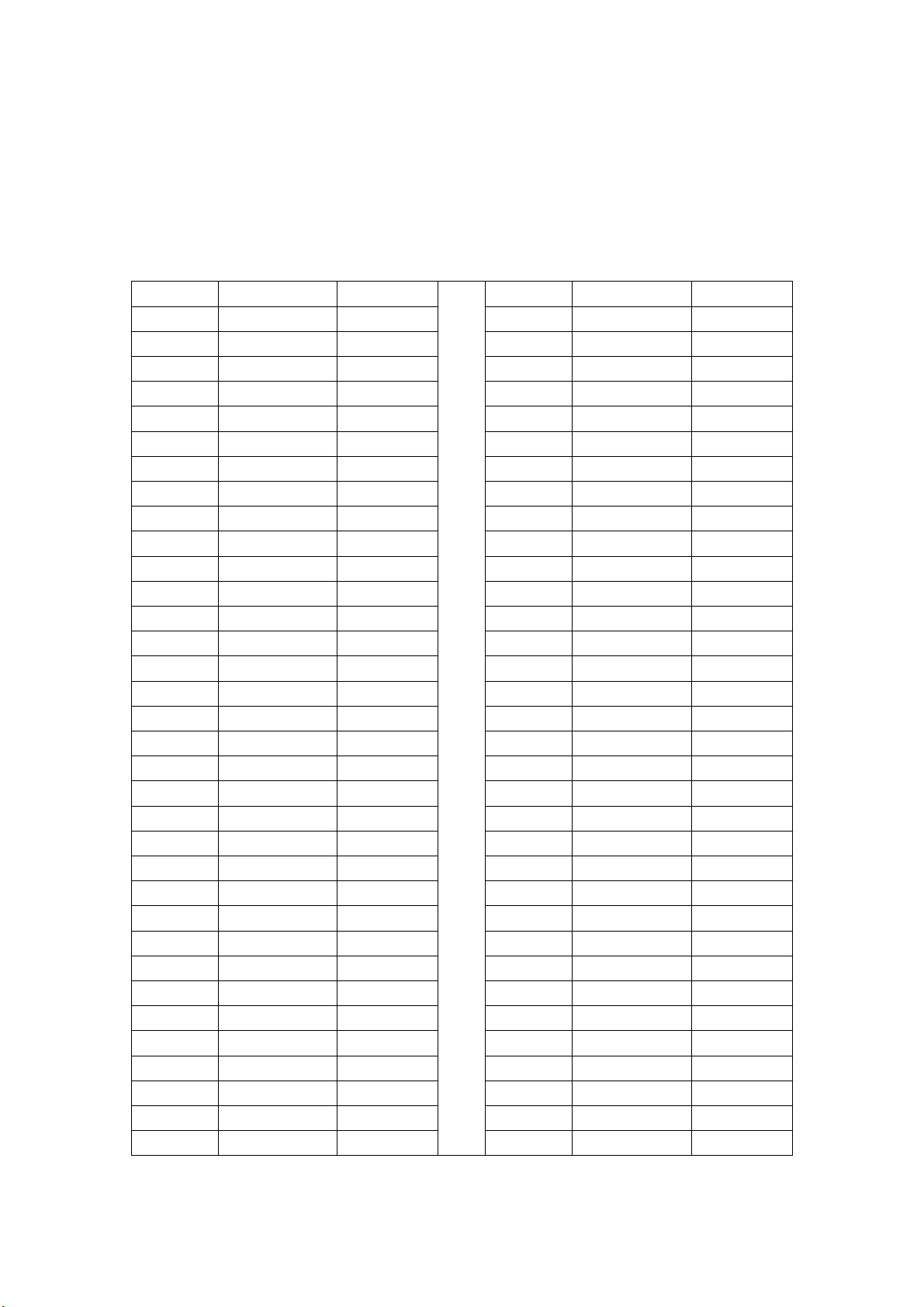

PARTS LIST FOR TC14FS68

NO DESCRIPTION UNIT QTYLOCATION

PCB

1 E/RSAG7.820.041 PCS 1 A1 (THE MAIN PCB)

2 E/RSAG7.820.304A PCS 1 A2 (THE CONTROL PCB)

3 E/RSAG7.820.291A PCS 1 A4 (THE FRONT AV PCB)

4 E/RSAG7.820.042 PCS 1 A5 (THE STEREO PCB)

5 E/RSAG7.820.036 PCS 1 A6 (THE CRT PCB)

1/6W CARBON RESISTOR

6 RT13-1/6W-2R2-J PCS 2 R615 R625

7 RT13-1/6W-75R-J PCS 2 W805 R803

8 RT13-1/6W-82R-J PCS 5 R817 R818 R825 R1801 R1802

9 RT13-1/6W-100R-J PCS 12 R116 R241 R242 R766 R770 R774 R834 R838 R804 R902

R912 R922

10 RT13-1/6W-220R-J PCS 7 R127 R744 R745 R833 R837 R03 R02

11 RT13-1/6W-270R-J PCS 1 R243

12 RT13-1/6W-330R-J PCS 5 R122 R725 R904 R914 R924

13 RT13-1/6W-470R-J PCS

14 RT13-1/6W-560R-J PCS 3 R778 R780 R906

15 RT13-1/6W-680R-J PCS 6 R409 R707 R611 R621 R916 R926

16 RT13-1/6W-820R-J PCS 1 R404

17 RT13-1/6W-1K0-J PCS 15 R103 R119 R121 R201 R268 R458 R602 R821 R610 R620 R931 R104 R105 R612 R622

18 RT13-1/6W-1K2-J PCS 2 R202 R567

19 RT13-1/6W-1K5-J PCS 3 R722 R1707 R933

20 RT13-1/6W-2K2-J PCS

21 RT13-1/6W-2K7-J PCS 3 R244 R1706

22 RT13-1/6W-3K0-J PCS 3 R272 R275 R454

23 RT13-1/6W-3K3-J PCS 4 R402 R742 R743 R820

24 RT13-1/6W-3K9-J PCS 2 R1705 R415

25 RT13-1/6W-4K7-J PCS 20 R274 R724 R736 R738 R740 R809 R811 R813 R814 R815 R816 R822 R827

2 R727 R728

3 R401 R408 R760

R1704 R1805 R1806 R747 R749 R751 R753

27 RT13-1/6W-8K2-J PCS 6 R412 R723 R777 R779 R826 R1703

28 RT13-1/6W-10K-J PCS 24 R414 R561 R566 R630 R631 R632 R708 R720 R721 R730 R731

R733 R734 R735 R754 R772 R775 R819 R232 R413 R499 R755 R761 R762

29 RT13-1/6W-12K-J PCS 4 R453 R455 R773 R776

30 RT13-1/6W-15K-J PCS 1 R932

31 RT13-1/6W-22K-J PCS 10 R205 R746 R748 R756 R757 R758 R759 R763 R764 R765

32 RT13-1/6W-27K-J PCS 5 R801 R824 R831 R835 R1702

33 RT13-1/6W-33K-J PCS 2 R101 R120

35 RT13-1/6W-47K-J PCS 2 R206 R732

37 RT13-1/6W-68K-J PCS 4 R802 R805 R832 R836

Page 1 of 22

Page 24

NO DESCRIPTION UNIT QTYLOCATION

38 RT13-1/6W-100K-J PCS 3 R102 R113 R114

39 RT13-1/6W-150K-J PCS 2 R729 R1701

40 RT13-1/6W-270K-J PCS 1 R726

41 RT13-1/6W-330K-J PCS 1 R403

42 RT13-1/6W-390K-J PCS 1 R709

43 RT13-1/6W-560K-J PCS 1 R204

44 RT13-1/6W-2M0-J PCS 1 R207

1/4W CARBON RESISTOR

45 RT14-1/4W-15R-J PCS 1 R519

46 RT14-1/4W-33R-J PCS 2 R935 R940

47 RT14-1/4W-56R-J PCS 1 R01

48 RT14-1/4W-100R-J PCS 1 R517

49 RT14-1/4W-270R-J PCS 1 R400

50 RT14-1/4W-2K2-J PCS 1 R526

51 RT14-1/4W-3K3-J PCS 1 R451

52 RT14-1/4W-4K7-J PCS 1 R553

53 RT14-1/4W-5K6-J PCS 1 R511

54 RT14-1/4W-12K-J PCS 1 R456

55 RT14-1/4W-15K-J PCS 1 R522

56 RT14-1/4W-22K-J PCS 2 R515 R556

57 RT14-1/4W-39K-J PCS 1 R457

58 RT14-1/4W-220K-J PCS 1 R446

1/2W METAL OXIDE FILM RESISTOR

59 RY25-1/2W-1R-J PCS 1 R452

RY25-1/2W-270R-J PCS 1 R713

61 RY25-1/2W-1K-J PCS 1 R433

62 RY26-1/2W-2K7-J PCS 3 R908 R918 R928

63 RY25-1/2W-3K3-J PCS 1 R557

64 RY25-1/2W-47K-J PCS 1 R555

65 RY25-1/2W-100K-J PCS 1 R552

66 RY25-1/2W-150K-J PCS 1 R554

67 RY25-1/2W-220K-J PCS 1 R501

1W METAL OXIDE FILM RESISTOR

68 RY26-1W-1R0-J PCS 1 R451A

69 RY25-1/2W-120R-J PCS 1 R461A

70 RY26-1W-100K-J PCS 1 R520

2W METAL OXIDE FILM RESISTOR

72 RY27-2W-220R-J PCS 1 R434

73 RY27-2W-330R-J PCS

75 RY27-2W-1K-J PCS 1 R441

76 RY27-2W-15K-J PCS 3 R907 R917 R927

77 RY27-2W-47K-J PCS 1 R551

3W METAL OXIDE FILM RESISTOR

1 R460

Page 2 of 22

Page 25

NO DESCRIPTION UNIT QTYLOCATION

78 RY18-3W-12K-J PCS 1 R718

79 RY28-3W-39R-J PCS 1 R563

1W INSURANCE RESISTOR

80 RF10-1W-1R0-J PCS 2 R472 R474

RF10-1/2W-3R3-J PCS 1 W425

82 RF10-1W-3R9-J PCS 1 R491

2W INSURANCE RESISTOR

83 RF10-2W-1R0-J PCS 1 R562 R569

1/4W METAL FILM RESISTOR

84 RJ14-1/4W-4K7-F 1 R273

1W METAL FILM RESISTOR

85 RJ16-1W-1R-J 1 R459

1/2W GLASS-GLAZED RESISTOR

86 RI40-1/2W-1K5-K 1 R233

87 RI40-1/2W-5M6-K 2 R531 R532

5W WIREWOUND RESISTOR

88 RX27-6-5W-47R-J(18×14) PCS 1 R524

89 RX27-6-5W-6R8-J(18×14) PCS 1 R525

RELAY

OMIT-SS-112LM PCS 2 RL551 RL552

7W WIREWOUND RESISTOR

90 RX27-3Y-7W-1R-J PCS 1 R502

VARIABLE RESISTOR

91 WI06-2-2-2K PCS 1 RP551

DEGAUSSING RESISTOR

PTDCA1BF3R0Q100

94

CERAMIC CAPACITOR

95 CC1-08A-CH-50V-15P-J PCS 1 C704

96 CC1-08A-CH-50V-18P-K PCS 2 C125 C705

97 CC1-06A-RH-50V-22P-J PCS 1 C209

98 CC1-06A-RH-50V-39P-J PCS 1 C126

100 CC1-10A-RH-50V-470P-J PCS 3 C140 C771 C772

PCS 1 RT501

101 CT1-06A-2B4-50V-1000P-K PCS 3 C123 C453

102 CT1-08A-2F4-50V-0.01µ-Z PCS 23 C102 C112 C116 C118 C119 C205 C245 C274 C279 C405

C607 C617 C627 C702 C703 C720 C729 C802 C804 C812 C999

103 CT1-08C-2B4-500V-10P-K PCS 1 C455

104 CT1-08C-2B4-500V-1000P-K PCS 1 C432

105 CT1-08C-2B4-500V-3900P-K PCS 1 C433

106 CT81-08C-2R-1KV-470P-K PCS 2 C554 C552

107 CT81-06C-2R-1KV-1000P-K PCS 4 C503 C504 C505 C506

108 CT81-10C-B-1KV-2700P-K PCS 1 C516

109 CT81-10C-2R-2KV-470P-K PCS 1 C551

110 CT81-AC400V-B-470P-M PCS 1 C532

Page 3 of 22

Page 26

NO DESCRIPTION UNIT QTYLOCATION

111 CT81-AC400V-E-2200P-M PCS 1 C533

112 CC1-RH-50V-390P-J PCS 3 C901 C911 C921

113 CC1-RH-50V-56P-J PCS 3 C903 C913 C923

POLYESTER CAPACITOR

114 CL11-63V-0.01µ-K PCS 2 C207 C515

115 CL11-63V-0.022µ-K PCS 1 C120

116 CL11-63V-0.033µ-K PCS 1 C406

117 CL11-63V-0.22µ-K PCS 1 C402

118 CL11-63V-0.47µ-K PCS 1 C403

119 CL11-63V-0.1µ-K PCS 4 C514 C408 C616 C626

120 CL11-100V-0.1µ-K PCS 2 C458 C459

121 CBB62-AC250V-0.1µ-M PCS 2 (EMC)C501 (EMC)C502

POLYPROPYLENE CAPACITOR

127 CBB21A-400V-0.3µ-J PCS 1 C441

128 CBB81A-2KV-7n8-J PCS 1 C435

129 CBB81A-2KV-1n5-J PCS 1 C438

ELECTROLYTIC CAPACITOR

131 CD110-16V-2.2µ-M PCS 4 C103 C618 C628 C714

132 CD110-16V-4.7µ-M PCS 1 C203

133 CD110-16V-10µ-M PCS 15 C276 C601 C602 C611 C621 C733 C734 C806 C807 C808 C809 C810

C811 C823 C825

134 CD110-16V-47µ-M PCS 6 C206 C244 C404 C701 C719

135 CD110X-16V-100µ-M PCS 9 C101 C115 C450 C612 C613 C622 C623 C631 C805

136 CD110X-16V-220µ-M PCS 1 C801

137 CD110-16V-330µ-M PCS 1 C933

138 CD110X-16V-470µ-M PCS 3 C570 C572

139 CD110-25V-10µ-M PCS 2 C931 C932

CD110-25V-330µ-M PCS 1 C799

140 CD110X-25V-470µ-M PCS 2 C615 C625

141 CD110X-25V-1000µ-M PCS 4 C452 C564 C565 C606

142 CD110X-25V-2200µ-M PCS 1 C457

143

CD110X-35V-47µ-M PCS 1 C411

144 CD110X-35V-100µ-M PCS 2 C451 C472

146 CD110X-35V-1000µ-M PCS

147 CD110-50V-0.47µ-M PCS 6 C137 C139 C208 C401 C207A C934

148 CD110-50V-1µ-M PCS 14 C117 C124 C136 C204 C212 C407 C412 C454 C456 C713 C803

CD110-50V-4.7µ-M

149

CD110-50V-10µ-M

150

145 CD110X-50V-470µ-M PCS

CD110-50V-1000µ-M

CD110-160V-1µ-M

151

4 C564 C452 C606 C302

C821 C822 C824

PCS 1 C708

PCS 5 C434

1 C567

PCS 1 C565

PCS 1 C444

Page 4 of 22

Page 27

NO DESCRIPTION UNIT QTYLOCATION

CD110-160V-220µ-M

153

CD110-250V-22µ-M

154

CD110-250V-470µ-M

155

NO ELECTRODE ELECTROLYTIC CAPACITOR

CD71-BP-50V-1µ-M

156

INDUCTOR COIL

LGA0305-15µH-K PCS 2 L102 L121

157

158 LGA0305-39µH-K PCS 1 L701

159 TEM2011 PCS 1 L401

160 ZZ0008 PCS 2 (EMC)L431 (EMC)L432

162 AC0042 PCS 2 L441

164

165 TRANSFORMER

166 ST6017 PCS 1 T101

167

PCS 1 C561

PCS 1 C474

PCS 1 C507

PCS 1 C231

168

169 JDT1904 PCS 1 T431

170 BCK-42-25 PCS 1 T511

171 JF0501-91802A PCS 1 T471

FILTER 滤波器

172 LCL-01B PCS 1 (EMC)L501

173 HF562Y2R5 PCS 1 (EMC)L502

DIODE

174 1N4148 PCS 18 VD401 VD402 VD514 VD516 VD552 VD553 VD610 VD611 VD612 VD620

VD621 VD622 VD631 VD801 VD901 VD911 VD921 VD933

1N4002 PCS 1 VD711

175 UZ3.6BSB PCS 1 VD703

176 UZ6.2BSB PCS 1 VD561

177 UZ7.5BSB PCS 1 VD412

178 UZ5.6BSB PCS 1 VD499

179 1Z75 PCS 1 VD452

180 EM01Z PCS 1 VD451

181 RU4AM PCS 2 VD551 VD554

182 EU2 PCS 2 VD472 VD555

183 RM4A PCS 4 VD503 VD504 VD505 VD506

EU1

184

187 ES1 PCS 1 VD556

188 BT-204L-31 PCS 1 VD701

TRANSISTOR

189 2SC1815Y PCS 16 V552 V553 V601 V632 V633 V703 V704 V705 V801 V802 V803 V804 V711

190 2SA1015Y PCS 4 V511 V631 V702 V931

2SC3807

191

PCS 3 VD411 VD474 VD517

V821 V301 V932

PCS 1 V512

Page 5 of 22

Page 28

NO DESCRIPTION UNIT QTYLOCATION

2SB892S

192

2SC2383

195

2SC2688

196

197 2SC4237 PCS 1 V513

198 2SD1879 PCS 1 V432

IC

199 LA76814 PCS 1 N101

200 LC863232A-5V57 PCS 1 N701

201 LA7841 PCS 1 N451

202 LA4285 PCS 2 N601 N602

203 L7805CV PCS 2 N552 N553

204 L7812CV PCS 1 N551

205 CW574CS PCS 1 N705

206 AT24C04 PCS 1 N702

207 TC4053BP PCS 1 N801

PCS 1 V554

PCS 1 V431

PCS 3 V902 V912 V922

208 TDA9850 PCS 1 N01

OPTICAL-ELECTRONIC COUPLER

209 PC817B/HS817 PCS 1 N501

CERAMIC OSC

210 JA25D-3.58MHZ PCS 1 (EMC)G201

211 32.768KHz PCS 1 (EMC)G701

212 CSB503F58 PCS 1 X01

SAW FILTER

213 D45U PCS 1 (EMC)Z101

PUSH SWITCH

214 KAN-C202-5 PCS 6 S1701 S1702 S1703 S1704 S1705 S1706

FUSE

215 125V/250V-3.15A PCS 1 F501

TUNER

216 TEDH9-243A PCS 1 (EMC)A101

POWER SWITCH

KDC-A06(0) PCS 1

CRT SOCKET

218 GZS10-2-AC2DG PCS 1 XS901

RCA JACK

219 AV302-1 PCS 1 XS801 XS801A

220 S-JACK PCS 1 XS802

JUMPER

222 5mm mm 6 W213 W701 W801 C110 L511 V102

223 7.5mm mm 65 W102 W110 W118 W201 W203 W204 W205 W210 W215 W218 W221

W402 W403 W405 W409 W410 W411 W416 W417

W419 W423 W424 W426 W451 W555 W562 W601

W605 W606 W607 W608 W609 W610 W616 W617 W620 W632

Page 6 of 22

Page 29

NO DESCRIPTION UNIT QTYLOCATION

W700 W703 W704 W713 W716 W722 W734 W735

W736 W740 W755 W756 W762 W804 W806 W807 W808 W809 W811

W812 W815 W845 R270 R432 R781 W552 W01 W02

224 10mm mm 54 W109 W111 W113 W114 W117 W121 W124 W125 W212 W214

W216 W222 W404 W407 W408 W412 W413 W414 W420 W421

W422 W431 W433 W475 W551 W557 W570 W612 W613 W626 W631

W702 W705 W706 W707 W708 W709 W710 W714 W718 W720 W723

W724 W725 W726 W727 W739 W750 W802 W600 W721 W901 L901 W05

225 12.5mm mm 13 W432 W442 W443 W474 W515 W571W602 W604 W624 W625 W761 W737 W799 W03 W04

15mm mm 10 W472 W507 W553 W571 W623 W728 W729 W738 W442 R471

226 17.5mm mm 2 W611 W501

227 20mm mm 1 W554

HOLLOW RIVET

228 XRY1.6×2.8BD PCS 13 L501-1 L501-2 L502-1 L502-2 T511-1 T511-7 T511-8 T511-14 T471-1 T471-2

T471-4 T471-8 T471-10

229 XRY2.5×3.5BD PCS 18 C507+ C507- V513-1 V513-2 V513-3

POWER RADIATOR4、6 V432-1 V432-2 V432-3

H/V RADIATOR4、5、6、7 RL551-1 RL551-2

RL552-1 RL552-2 THE LEFT POWER MAGNIFY RADIATOR1、2

THE LEFT POWER MAGNIFY RADIATOR1、2

CONNECTOR

231 TJC3-5A PCS 1 XS403

233 TJC2-5A PCS 1 XS402

234 TJC3-6A PCS 1 XS603 XS604

235 TJC2-3Y PCS 1 XS502A

TJC3-4A PCS 3 XS806 XS1803 XP901

TJC3-2A PCS 1 XS501A

AV3-W-F PCS 1 XS1805

TJC3B-10P PCS 1 XS03

CK3-3.5-3AK PCS 1 XS1804

CONNECTOR PLUG

237 TJC3B-5Y-450 PCS 1 XP902

238 TJC3B-2Y-SCNW-650 PCS 1 XS1701

TJC3B-4Y-600 PCS 1 XP1801

TJC3H-4Y-400 PCS 1 XP1802

TJC3B-6Y-150 PCS 2 XS01 XS02

230 TJC3B-4Y-450 PCS 2 XP901 XS401

240

241

GND COIL PLUG

RSR8.381.0105 PCS 1

242 TJC2-1Y-B-450 PCS 1

POWER PLUG

Page 7 of 22

Page 30

NO DESCRIPTION UNIT QTYLOCATION

243 TJC2-3Y PCS 1 FOR AC CORD

DEGAUSSING COIL PLUG

244 TJC2-2A PCS 1 XS501

GROUND LINE SUBASSEMBLY

245 TJC2-1A PCS 1 XP903

POWER CORD

246 NISPT-2 PCS 1

SPEAKER

247 YDT411E-5W-8R C PCS 2 BL301 BL302

DEGAUSSING COIL

248 AHA-HXC35A4 PCS 1 L909

249 A36CPAA00X02 PCS 1

HEAT SINK

250 RSR7.308.0181 PCS 2

251 RSR5.861.0201 PCS 1

252 RSR5.861.0135 PCS 1

253 RSAG7.308.043 PCS 1

254 PCS

255 PCS

FUSE SUPPORTER

256 RSR7.736.0102 PCS 2 FOR FUSE

SPACER

257 RSR7.854.0108 PCS 1 (FOR THE WIRE OF H-DRIVER TRANSFORMER)

BRACKET

258 RSR8.078.0207 PCS 1

SPRING(CRT-GND ASSY)

259 RSR8.381.0105 PCS 1

DEGAUSSING COIL CLIP

260 RSAG8.667.003 PCS 4 for degaussing coil

CLIP

261 RSAG8.667.004 PCS 7

262 SPRING

263 RSR8.382.0102 PCS 1

LENS LED

264 RSAG8.640.018 PCS 1

RUBBER CUSHION

265 RSR8.683.0145 PCS 4 (FOR CRT)

FRONT CABINET

266 RSAG8.074.044 PCS 1

REAR CABINET

267 RSAG8.074.046 PCS 1

Page 8 of 22

Page 31

NO DESCRIPTION UNIT QTYLOCATION

268

POWER KNOB

269 RSAG8.337.018 PCS 1

KNOB(FOR THE FRONT TUNCTION)

270 RSAG8.335.005 PCS 1

271

272

273

274

275

BAR CODE TAGBOAD

276 PCS 9

NAMEPLATE

277 E/RSR8.807.991 PCS 1

WASHER

278 RSR8.942.0104 PCS 4 FOR CRT

279 RSR8.610.0137 PCS 2

280 RSR8.683.0128 PCS 3

281 RSR8.942.0106 PCS 1

282 RSR7.844.0113 PCS 1

3 3-140HV GB97.1-85 PCS 1

283 Ф

GASKET

284 RSAG8.870.188 PCS 1 TOP

285 RSAG8.870.189 PCS 1 BOTTOM

SUPPORTOR(FOR CRT)

286 RSR6.150.0118 PCS 4 FOR CRT

SPONGE

287 40X15X5(mm) PCS 1

288

AC CORD CLIP

289 QH009 PCS 1

290

LABEL

291 E/RSR8.808.142 PCS 1 CRT

292 RSAG8.817.008 PCS 1

293

SCREW

294

295

SJ2824-87 PCS 6 ST4X16C

Page 9 of 22

Page 32

NO DESCRIPTION UNIT QTYLOCATION

296

SJ2824-87 PCS 12 ST4X20C

297

SJ2825-87 PCS 7 ST3X12C (BLACK 2)

298

SJ2825-87 PCS 11 ST3X10C

299

SJ2843-87 PCS 4 M5

300

SJ2835-87 PCS 2 M3X8

301

SJ2832-87 PCS 3 ST3×8

302

SJ2835-87 PCS 1 M3X10

303

SJ2835-87 PCS 2 M3X12

304

NUT M3 PCS 5

305

306

307

WRAPPING BOX

308

E/RSR8.865.1077 PCS 1

PLASTIC BAG

309

RSAG8.840.005 PCS 1 FOR THE USER'S MANUAL

310

RSAG8.840.009 PCS 1 FOR THE TV SET

BOPP ADHESIVE TAPE

311

24X400mm PCS 2

312

24X100mm PCS 2

313

72X900mm PCS 1

TV USE DIRECTORY

314

IES031110 PCS 1

RC TRANSMITTER

315 HYDFSR-0073 PCS 1 (WITH PACKING BAG)

Page 10 of 22

Page 33

NO DESCRIPTION UNIT QTYLOCATION

Page 11 of 22

Loading...

Loading...