Page 1

Global LCD Panel Exchange Center

˖

TFT LCD Preliminary Specification

www.panelook.com

MODEL NO.

Customer:

Approved by:

Note:

HC315BH-D04

Approved By Date:

Reviewed By Date:

Prepared By Date:

1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

NO. ITEM PAGE

CONTENT 2

DESCRIPTION 3

1 ABSOLUTE MAXIMUM RATINGS 4

2 INITIAL OPTICAL CHARACTERISTICS 6

3 ELECTRICAL CHARACTERISTICS 9

4 BLOCK DIAGRAM 12

5 INTERFACE PIN ASSIGNMENT 13

6 MECHANICAL CHARACTERISTICS 19

7 PACKAGING 21

8 PRECAUTIONS 23

www.panelook.com

CONTENT

2

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

www.panelook.com

DESCRIPTION

The following specifications are applied to the following Hisense module.

Product Name: HC315BH-D04

General Specifications

Effective Display Area :(H)697.6845×(V)392.256 (mm)

Number of Pixels :(H)1366×R.G..B×(V)768 (Pixels)

Pixel Pitch :(H)0.17025×(V)0.51075 (mm)

Color Pixel Arrangement : R+G+B Vertical Stripe

Display Mode : Transmissive Mode

Normally Black Mode

Top polarizer Type : Anti-Glare

Number of Colors : 16.7M (colors)

Viewing Angle Range : +88/-88(H), +88/-88(V) Typ.

Back Light : 6 CCFL

Color Chromaticity : R=0.642, 0.332

G=0.277, 0.598

B=0.145, 0.066

W=0.285, 0.293

External Dimensions : (H)760.0×(V)450.0×(D)32.5 (mm)

Weight : 6.3 (Kg)

3

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

www.panelook.com

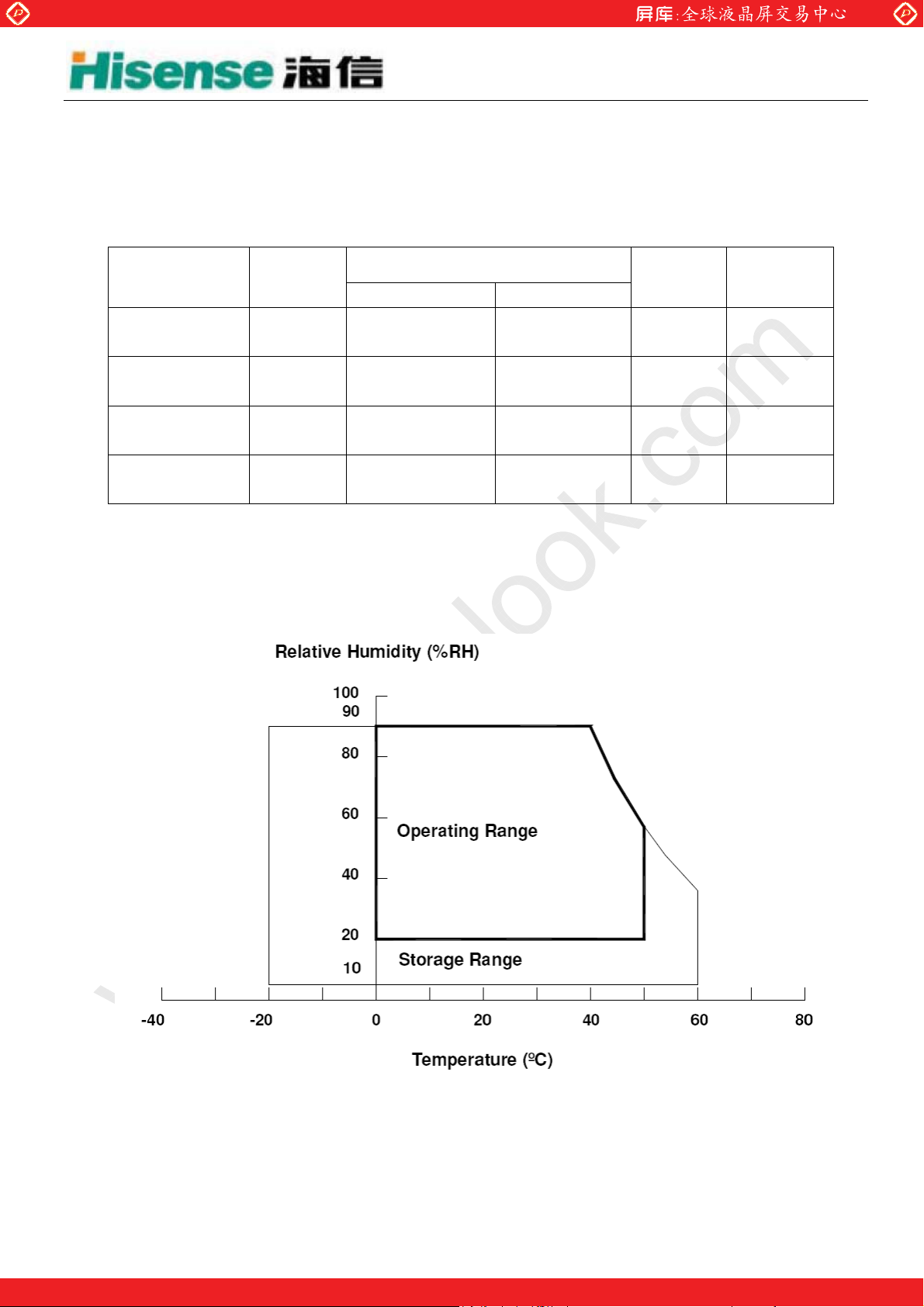

1. ABSOLUTE MAXIMUM RATINGS

1.1 Environment Absolute Maximum Ratings

The following items are maximum values which, if exceeded, may cause faulty operation or

damage to the LCD module.

TFT Module

Parameter Symbol

Va l ue

Min. Max.

Operating

Temperature

Storage

Temperature

Altitude

Operating

Vibration

(Non-Operating)

TOP 0 50 ć (1),(2),(3)

TST -20 60 ć (1),(3)

AOP 0 5000 M (3)

AST 0 12000 M (3)

Notes : 1) Temperature and relative humidity range is shown in the figure below.

(a) 90 %RH Max. (Taİ40 ºC).

(b) Wet-bulb temperature should be 39 ºC Max. (Ta > 40 ºC).

(c) No condensation.

Unit Note

2) The maximum operating temperature is based on the test condition that the surface

temperature of display area is less than or equal to 65 ºC with LCD module alone in a

temperature controlled chamber. Thermal management should be considered in final

product design to prevent the surface temperature of display area from being over 65 ºC.

4

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

www.panelook.com

The range of operating temperature may degrade in case of improper thermal management

in final product design.

3) The rating of environment is base on LCD module. Leave LCD cell alone, this environment

condition can’t be guaranteed. Except LCD cell, the customer has to consider the ability

of other parts of LCD module and LCD module process.

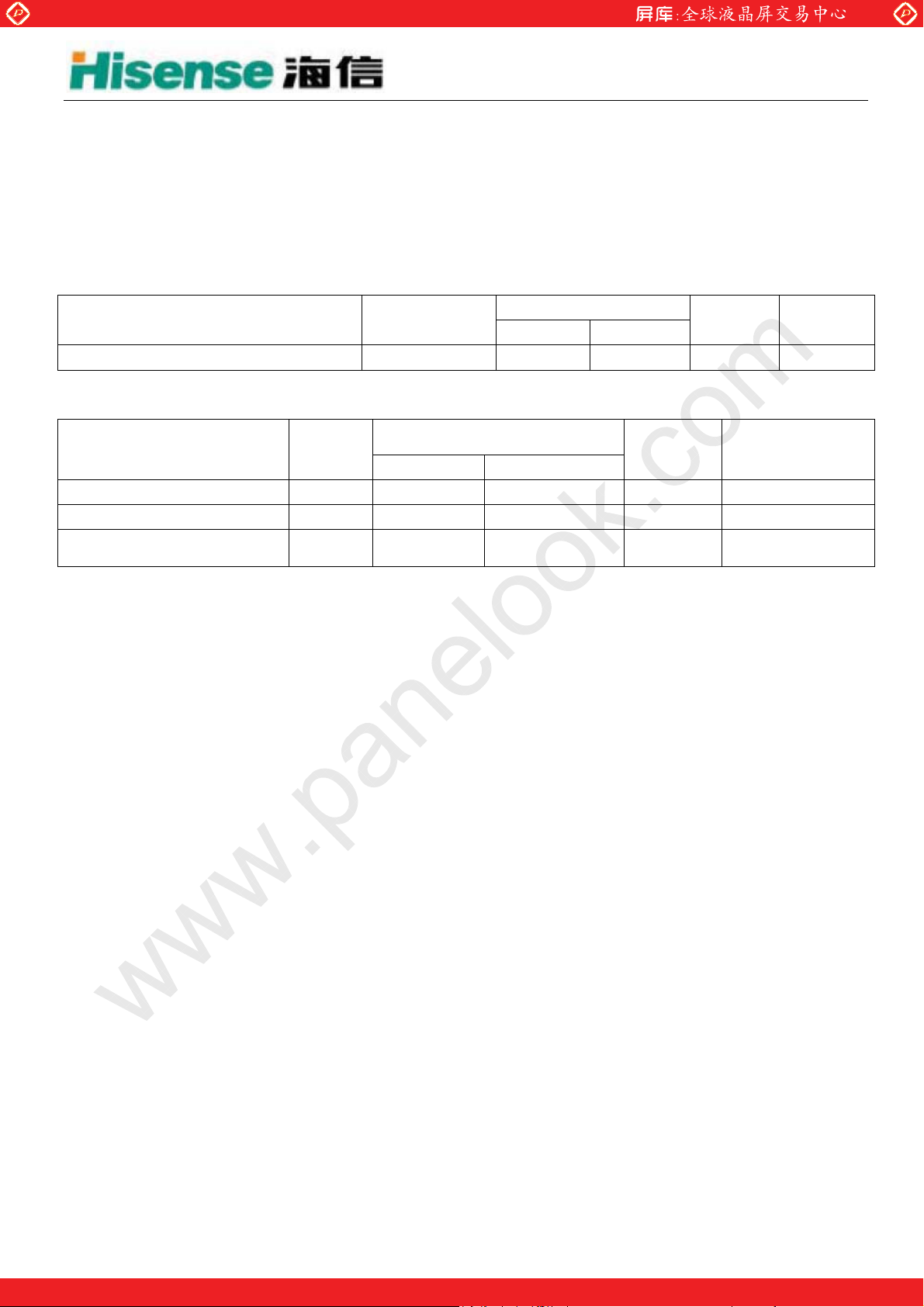

1.2 BACKLIGHT UNIT

1.2.1 TFT LCD MODULE

ITEM Symbol

Va l ue

Unit Note

Min. Max.

Power Supply Voltage

VCC -0.3 13.0 V (1)

1.2.2 BACKLIGHT UNIT

ITEM Symbol

Va l ue

Unit Note

Min. Max.

Lamp Voltage Vw - 3000 VRMS

Power Supply Voltage VBL 0 30 V (1)

Control Signal Level -0.3 7 V (1),(3)

Note (1) Permanent damage to the device may occur if maximum values are exceeded. Functional

operation should be restricted to the conditions described under normal operating conditions.

Note (2) No moisture condensation or freezing.

Note (3) The control signals includes Backlight On/Off Control, I_PWM Control, E_PWM Control and

ERR signal for inverter status output.

5

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

www.panelook.com

2. INITIAL OPTICAL CHARACTERISTICS

The following optical characteristics are measured under stable conditions. It takes about 30 minutes to

reach stable conditions. The measuring point is the center of display area unless otherwise noted. The

optical characteristics should be measured in a dark room or equivalent state.

Measuring equipment˖SR-3 and LIPS

Ambient Temperature=25±2°C, V

=12.0V, fV=60Hz, Dclk=74.25MHz V

LCD

Item Symbol Condition Min. Typ. Max. Unit Note

Red

Green

Color

Chromaticity

Blue

white

Center Transmittance T% - 5.8 ˁ (1),(7)

Contrast Ratio CR

Response Time

White Variation W x=0°, y=0° 1.5 - (1),(6)

Horizontal

Viewing

Angle

Vertical

x 0.652

y 0.332

x 0.277

y 0.598

x 0.145

y 0.066

x=0°, y=0° viewing

angle at normal

direction

Typ.- 0.03

x 0.285

y

0.293

x=0°, y=0°

2000 3000 - (1),(3)

Gray to

gray

average

+

80 88 -

X

-

X

+

80 88 -

Y

-

Y

x=0°, y=0° with

Module@60Hz

CRı20

- 6.5 12 ms (4)

80 88 -

80 88 -

Note (1) Driving voltages are based on suitable gamma voltages.

The calculated method is as following:

1. Measure module’s and backlight’s spectrum. White and R, G, B are with signal input.

2. Calculate cell’s spectrum.

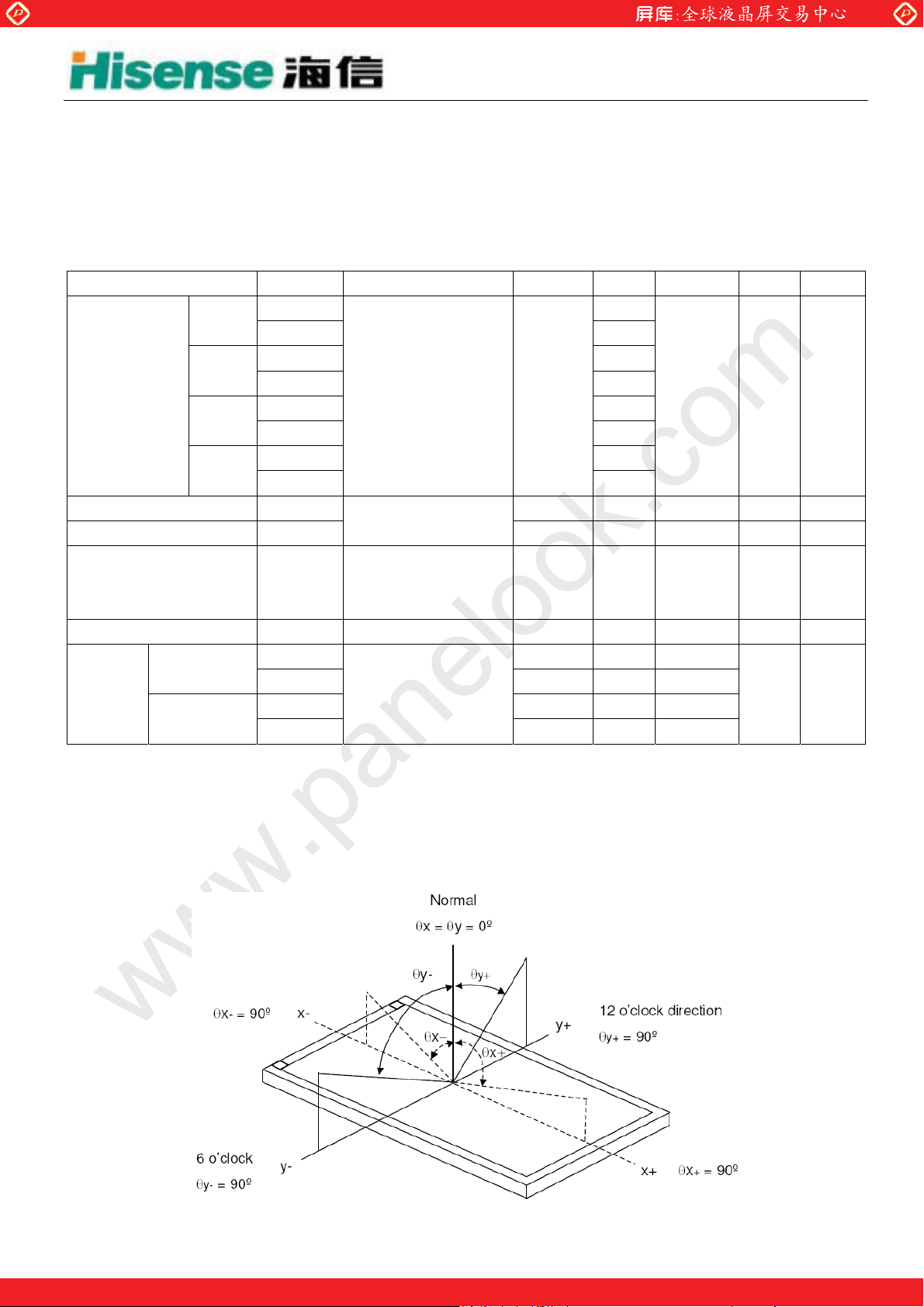

Note (2) Definition of Viewing Angle (x, y):

Viewing angles are measured by EZ-Contrast 160R (Eldim)

=1.65V, EXTV

BR_A

Typ.+0.03 - (1),(5)

Deg. (1),(2)

BR_B

=100%

6

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

www.panelook.com

Note (3) Definition of Contrast Ratio (CR):

The contrast ratio can be calculated by the following expression.

Contrast Ratio (CR) = L255 / L0

L255: Luminance of gray level 255

L 0: Luminance of gray level 0

CR = CR (5), where CR (X) is corresponding to the Contrast Ratio of the point X at the figure

in Note (6).

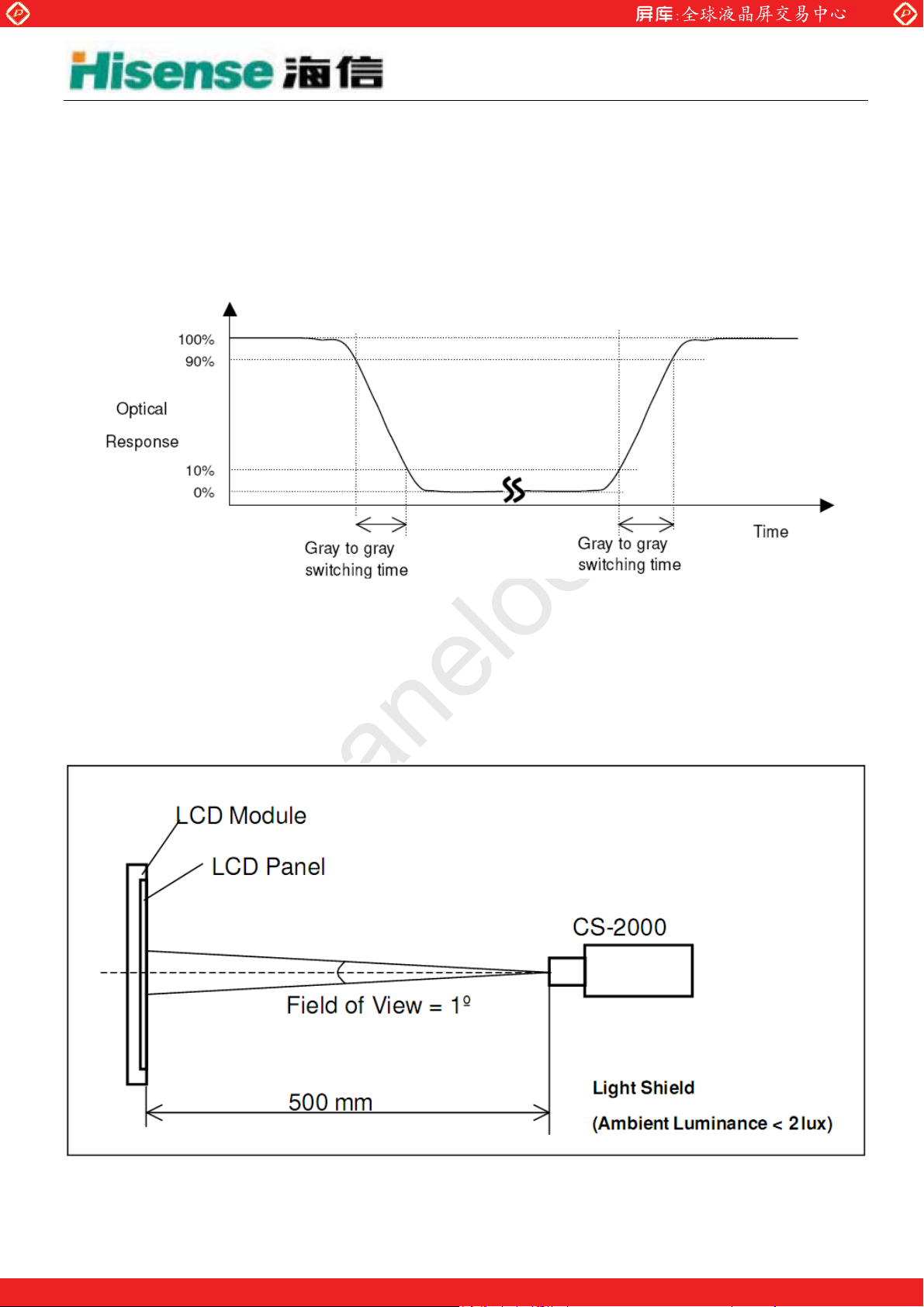

Note (4) Definition of Gray to Gray Switching Time:

The driving signal means the signal of gray level 0, 123, 168, 202, 230, 255. Gray to gray average

time means the average switching time of gray level 0, 123, 168, 202, 230, 255 to each other.

Note (5) Measurement Setup:

The LCD module should be stabilized at given temperature for 60 minutes to

avoid abrupt temperature change during measuring. In order to stabilize the luminance,

the measurement should be executed after lighting Backlight for 60 minutes in a windless room.

7

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

Note (6) Definition of White Variation (W):

Measure the luminance of gray level 255 at 5 points

W = Maximum [L (1), L (2), L (3), L (4), L (5)] / Minimum [L (1), L (2), L (3), L (4), L (5)]

where L (X) is corresponding to the luminance of the point X at the figure below.

www.panelook.com

Note (7) Definition of Transmittance (T%):

Module is without signal input.

8

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

3. ELECTRICAL CHARACTERISTICS

3.1 TFT-LCD Module

www.panelook.com

Parameter Symbol

Va l ue

Min. Typ. Max.

Power Supply Voltage VCC 11.4 12.0 12.6 V (1)

Rush Current I

- - 3.4 A (2)

RUSH

White - 0.45 0.52 A

Power Supply

Current

Black - 0.33 - A

Vertical

Stripe

I

CC

- 0.45 - A

Differential input

High Threshold

V

- - +100 mV

LV TH

Voltage

Differential input

LVDS

Low Threshold

Voltage

V

-100 - - mV

LV TL

Interface

Common input

Voltage

VCM 1.0 1.2 1.4 V

Terminating Resistor RT - 100 - ohm

CMOS

Interface

Differential input

voltage

Input High

Threshold Voltage

Input Low

Threshold Voltage

| 200 - 600 mV

|V

ID

VIH 2.7 - 3.3 V

0 - 0.7 V

V

IL

Note (1) The module should be always operated within above ranges.

Unit Note

(3)

9

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

Note (2) Measurement Conditions:

www.panelook.com

10

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

www.panelook.com

Note (3) The specified power supply current is under the conditions at Vcc =12V, Ta = 25 ± 2 ºC, fv = 60

Hz, where as a power dissipation check pattern below is displayed.

Note (4) The LVDS input characteristics are as follows:

11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

4. BLOCK DIAGRAM

4.1 TFT Module

www.panelook.com

12

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

5. INTERFACE PIN ASSIGNMENT

5.1 TFT-LCD MODULE

CNF1 Connector Pin Assignment

Pin No. Symbol Description Note

1 VCC Power supply: +12V

2 VCC Power supply: +12V

3 VCC Power supply: +12V

4 VCC Power supply: +12V

5 GND Ground

6 GND Ground

7 GND Ground

8 GND Ground

9 SELLVDS Select LVDS data format (2)

10 ODSEL Overdrive Lookup Table Selection (3)

11 GND Ground

12 RX0- Negative transmission data of pixel 0

13 RX0+ Positive transmission data of pixel 0

14 GND Ground

15 RX1- Negative transmission data of pixel 1

16 RX1+ Positive transmission data of pixel 1

17 GND Ground

18 RX2- Negative transmission data of pixel 2

19 RX2+ Positive transmission data of pixel 2

20 GND Ground

21 RXCLK- Negative of clock

22 RXCLK+ Positive of clock

23 GND Ground

24 RX3- Negative transmission data of pixel 3

25 RX3+ Positive transmission data of pixel 3

26 GND Ground

27 TST_AGE Aging Mode (4)

28 NC No connection (5)

29 GND Ground

30 GND Ground

Note (1) Connector type: STARCONN 093G30-B0001A or P-TWO 187053-30091or compatible

LVDS connector pin orderdefined as follows

www.panelook.com

Note (2) Low = Open or connect to GND: VESA Format, High = Connect to +3.3V: JEIDA Format.

Please refer to 5.5 LVDS INTERFACE

13

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

Note (3) Overdrive lookup table selection. The Overdrive lookup table should be selected in

accordance to the frame rate to optimize image quality.

Low = Open or connect to GND, High = Connect to +3.3V

ODSEL Note

L or Open Lookup table was optimized for 60 Hz frame rate

H Lookup table was optimized for 50 Hz frame rate

Note (4) Ground or OPEN: Disable, High: Enable.

Note (5) Reserved for internal use. Left it open.

Note (6) LVDS signal pin connected to the LCM side has the following diagram.

R1 in the system side should be less than 1K Ohm. (R1 < 1K Ohm)

www.panelook.com

14

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

www.panelook.com

5.2 RELATIONSHIP BETWEEN DISPLAY COLORS AND INPUT SIGNALS

The brightness of each primary color(red,green,blue) is based on the 8-bit gray scale data input for

the color. The higher binary input, the brighter the color. The table below provides the assignment of

color versus data input.

15

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

www.panelook.com

5.4. Signal Timing Specifications

The following table shows the signal timing required at the input of the LVDS transmitter. All of the

interface signal timing should be satisfied with the following specification for normal operation.

Signal Item Symbol Min. Typ. Max. Unit Note

Frequency 1/Tc 60 76 82 MHz

LVDS Receiver Clock

Input cycle to cycle

jitter

Spread spectrum

modulation range

Trcl - - 200 ps (3)

F

clkin_modFclkin

-ˁ - F

+ˁ MHz

clkin

Spread spectrum

modulation

200 KHz

F

SSM

frequency

LVDS Receiver Data

Setup Time Tlvsu 600 - - ps

Hold Time Tlvhd 600 - - ps

Frame Rate

Fr5 47 50 53 Hz

Fr6 57 60 63 Hz

Vertical Active Display

Term

Total Tv 778 806 888 Th Tv=Tvd+Tvb

Display Tvd 768 768 768 Th -

Blank Tvb 10 38 120 Th -

Total Th 1442 1560 1936 Tc Th=Thd+Thb

Horizontal Active Display

Term

Display Thd 1366 1366 1366 Tc -

Blank Thb 76 194 570 Tc -

Note (1) Please make sure the range of pixel clock has follow the below equation:

Fclkin(maxı)Uh7Yh7K

)Uh7Yh7Kı)FONLQPLQ

Note(2) This mode is operated in DE only mode and please follow the input signal timing diagram below:

(4)

(5)

(2)

16

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

www.panelook.com

Note (3) The input clock cycle-to-cycle jitter is defined as below figures. Trcl = |T1 – T|

Note (4) The SSCG (Spread spectrum clock generator) is defined as below figures.

Note (5) The LVDS timing diagram and setup/hold time is defined and showing as the following figures.

17

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

5.5. Power On/Off Sequence

www.panelook.com

18

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

6. MECHANICAL CHARACTERISTICS

www.panelook.com

19

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

www.panelook.com

20

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

7. PACKAGING

7.1 PACKAGING SPECIFICATION

(1) 5 LCD TV modules / 1 Box

(2) Box dimensions : 826(L)x376(W)x540(H)mm

(3) Weight : approximately 50Kg (5 modules per box)

7.2 PACKAGING METHOD

Figures 7-1 and 7-2 are the packing method

www.panelook.com

Figure.7-1 packing method

21

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

www.panelook.com

Figure.7-2 packing method

22

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

8. PRECAUTIONS

8.1 ASSEMBLY AND HANDLING PRECAUTIONS

1) Do not apply rough force such as bending or twisting to the module during assembly.

2) It is recommended to assemble or to install a module into the user’s system in clean working areas.

The dust and oil may cause electrical short or worsen the polarizer.

3) Do not apply pressure or impulse to the module to prevent the damage of LCD panel and

backlight.

4) Always follow the correct power-on sequence when the LCD module is turned on. This can

prevent the damage and latch-up of the CMOS LSI chips.

5) Do not plug in or pull out the I/F connector while the module is in operation.

6) Do not disassemble the module.

7) Use a soft dry cloth without chemicals for cleaning, because the surface of polarizer is very soft

and easily scratched.

8) Moisture can easily penetrate into LCD module and may cause the damage during operation.

9) High temperature or humidity may deteriorate the performance of LCD module. Please store LCD

modules in the specified storage conditions.

10) When ambient temperature is lower than 10ºC, the display quality might be reduced. For

example, the response time will become slow, and the starting voltage of CCFL will be higher than

that of room temperature.

8.2 SAFETY PRECAUTIONS

1) The startup voltage of a backlight is over 1000 Volts. It may cause an electrical shock while

assembling with the inverter. Do not disassemble the module or insert anything into the backlight unit.

2) If the liquid crystal material leaks from the panel, it should be kept away from the eyes or mouth.

In case of contact with hands, skin or clothes, it has to be washed away thoroughly with soap.

3) After the module’s end of life, it is not harmful in case of normal operation and storage.

8.3 STORAGE PRECAUTIONS

When storing modules as spares for a long time, the following precaution is necessary. 1) Do not

leave the module in high temperature, and high humidity for a long time. It is highly

recommended to store the module with temperature from 0 to 35ćat normal humidity without

condensation.

2) The module shall be stored in dark place. Do not store the TFT-LCD module in direct sunlight or

fluorescent light.

23

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...