TM6101

HIOKI TM6101A981-06

Instruction Manual

LED OPTICAL METER

May 2021 Revised edition 6

TM6101A981-06 21-05H

Video

Scan this code to watch the

instructional video(s).

Carrier charges may apply.

EN

*600341246*

HIOKI TM6101A981-06

Contents

Introduction.................................................................................1

HIOKI TM6101A981-06

i

Contents

1

Confirming Package Contents....................................................2

Safety Information ......................................................................3

Operating Precautions................................................................4

Chapter 1

Overview __________________________________ 11

1.1 Product Overview and Features .......................................11

1.2 Names and Functions of Parts ..........................................13

1.3 External Dimensions .........................................................15

1.4 Measurement Flowchart ...................................................17

Chapter 2

Measurement Preparations___________________ 19

2.1 Installation & Connection Procedures ...............................19

2.2 Installing the Software ....................................................... 20

System Requirements ......................................................................20

Recommended System ....................................................................20

Installing Hardware Drivers ...............................................................21

Installing PC application software .....................................................22

2.3 Install the Ferrite Cores .....................................................23

2

3

4

5

6

7

8

TM6101A981-06

2.4 Connecting the Sensor Unit ..............................................24

2.5 Connecting the USB Cable ...............................................25

2.6 Connecting the AC Adapter ..............................................26

2.7 Configuring the Instrument for Measurement ...................27

Setting the Measurement Mode ........................................................27

Setting the Sensitivity Range ............................................................28

Setting the Integration Time ..............................................................28

Configuring Auto-range Operation ....................................................29

Setting the Detection Level Upper and Lower Limits ........................29

Setting the Average Times ...............................................................29

Setting a Trigger ...............................................................................30

Setting Calculation Data ...................................................................30

Performing Dark Correction ..............................................................30

2.8 Using Correction Functions ...............................................31

Dark Correction .................................................................................32

Chromaticity Correction ....................................................................33

Illuminance Correction ......................................................................34

Luminous Intensity Correction ..........................................................34

9

10

11

12

付

録

索

引

ii

HIOKI TM6101A981-06

Contents

Luminous Flux Correction ................................................................ 34

Chapter 3

Measurement ______________________________35

3.1 Pre-Operation Inspection .................................................. 35

3.2 Measurement .................................................................... 38

Conducting Measurements Using the PC application software ....... 38

Building Software and Making Measurements Using Library

Functions .......................................................................................... 38

3.3 Measurement Example ..................................................... 39

Measuring CIE Averaged LED Intensity, Chromaticity,

and Other Properties ........................................................................ 39

Measuring Total Luminous Flux, Chromaticity,

and Other Properties Using an Integration Sphere .......................... 40

Measuring the Brightness, Chromaticity, and Color Rendering Index

of a Light .......................................................................................... 41

More Rigorous Chromaticity and Luminous Intensity Measurement

(Comparison with a Calibrated Sample) .......................................... 42

Chapter 4

External Control ____________________________43

4.1 External Input/Output Connector and Signals ..................43

Connector Type and Signal Pinouts ................................................. 44

4.2 Timing Chart ..................................................................... 46

4.3 Internal Circuitry ................................................................ 48

Electrical Specifications ................................................................... 49

Connection Examples ...................................................................... 50

4.4 External I/O Settings ......................................................... 51

Setting Signal Output after the Completion of Measurement

(INDEX

Setting) ................................................................................ 51

Setting the Trigger (TRIG) Signal Logic ........................................... 51

4.5 External Control Q&A .......................................................51

Chapter 5

Specifications ______________________________ 53

5.1 Basic Specifications .......................................................... 53

5.2 Functions .......................................................................... 54

5.3 General Specifications ...................................................... 55

5.4 PC Software Specifications .............................................. 56

Chapter 6

HIOKI TM6101A981-06

Maintenance and Service ____________________ 57

6.1 Troubleshooting ................................................................57

Inspection and Repair .......................................................................57

6.2 Cleaning ............................................................................58

iii

Contents

1

2

3

4

5

6

7

8

9

10

11

12

付

録

索

引

iv

HIOKI TM6101A981-06

Contents

Introduction

HIOKI TM6101A981-06

1

Introduction

Thank you for purchasing the HIOKI Model TM6101 LED Optical Meter. To

obtain maximum performance from the instrument, please read this manual first,

and keep it handy for future reference.

This manual uses the following conventions:

• The TM6101 LED Optical Meter (consisting of the sensor unit and TM6101

main unit) is referred to as the “instrument.”

• The TM6101 itself is referred to as the “main unit.”

• The TM6101 sensor is referred to as the “sensor unit.”

The "TM6101 Utility" and "TM6101 Measuring Library" software packages are

included with the instrument. Use of both is subject to the terms of a license

agreement. Please use the software only after reading and accepting the license

agreement at the back of the book.

Trademarks

• Adobe and Reader are either registered trademarks or trademarks of Adobe

Systems Incorporated in the United States and/or other countries.

• Microsoft, Windows, Visual Studio, Visual C++, Visual Basic, VIsual C#, and

.NET Framework are either registered trademarks or trademarks of Microsoft

Corporation in the United States and other countries.

Other Conventions

• Unless otherwise specified, “Windows” represents Windows 7, Windows 8, or

Windows 10.

• Dialog box represents a Windows dialog box.

• Menus, commands, dialogs, buttons in a dialog, and other names on the

screen and the keys are indicated in brackets.

Mouse Operation

• Click: Press and quickly release the left button of the mouse.

• Right-click: Press and quickly release the right button of the mouse.

• Double click: Quickly click the left button of the mouse twice.

• Drag: While holding down the left button of the mouse, move the mouse and

then release the left button to deposit the chosen item in the desired position.

• Activate: Click on a window on the screen to activate that window.

2

Confirm that these contents are provided.

□ Model TM6101 LED Optical Meter (main unit + sensor unit) (1)

□ Model 9418-15 AC Adapter (1)

□ TM6101

Instruction Manual (1)

□ USB Cable (1)

□ CD (1)

•

PC application software*

(TM6101 Utility)

• Library software

(TM6101 Measuring Library)

• TM6101 Utility Instruction Manual

• TM6101 Measuring Library Instruction Manual

• TM6101 Instruction Manual

□ Main unit/sensor unit connection

cable (1)

□ Cap (1)

□ Port connection screws (4)

(Instrument ships with cap attached to sensor unit.)

□ Ferrite cores (3)

(Instrument ships with one ferrite core attached to the Main unit/sensor unit connection cable.)

□ Rubber feet (4)

* The latest version can be down-

loaded from our website.

HIOKI TM6101A981-06

Confirming Package Contents

Confirming Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches,

and connectors. If damage is evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

Safety Information

HIOKI TM6101A981-06

This instrument is designed to comply with IEC 61010 Safety Standards,

and has been thoroughly tested for safety prior to shipment. However, mishandling during use could result in injury or death, as well as damage to

the instrument. Using the instrument in a way not described in this manual

may negate the provided safety features.

Be certain that you understand the instructions and precautions in the

manual before use. We disclaim any responsibility for accidents or injuries

not resulting directly from instrument defects.

This manual contains information and warnings essential for safe operation of

the instrument and for maintaining it in safe operating condition. Before using it,

be sure to carefully read the following safety precautions.

3

Safety Information

Safety Symbols

In the manual, the symbol indicates particularly important information that

the user should read before using the instrument.

The symbol printed on the instrument indicates that the user should refer

to a corresponding topic in the manual (marked with the symbol) before

using the relevant function.

Indicates DC (Direct Current).

The following symbols in this manual indicate the relative importance of cautions

and warnings.

Indicates that incorrect operation presents an extreme hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to the

user or damage to the instrument.

Indicates advisory items related to performance or correct operation

of the instrument.

Other symbols

(p. #)

*

[ ]

Indicates a prohibited action.

Indicates the location of reference information.

Indicates that descriptive information is provided below.

Menus, commands, dialogs, buttons in a dialog, and other names on the

screen and the keys are indicated in brackets.

4

HIOKI TM6101A981-06

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits

of the various functions.

Preliminary Checks

Before using the instrument for the first time, verify that it operates normally to

ensure that no damage occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Instrument Installation

Operating temperature and humidity:

5 to 35°C at 80%RH or less (non-condensing)

Temperature and humidity range for guaranteed accuracy:

23±5°C, 80%RH or less (non-condensing)

At least 60 minutes after power-on

Within ±5°C after performing dark correction

Avoid the following locations that could cause an accident or damage

to the instrument.

Exposed to direct

sunlight

Exposed to high temperature

Exposed to water, oil,

other chemicals, or

solvents

Exposed to high

humidity or condensation

Exposed to high levels of particulate dust

Subject to vibration

The instrument’s sensor unit consists of precision optical components. Dropping

the sensor unit or subjecting it to mechanical shock may damage it. Optical components inside the sensor unit may fall out of alignment if the unit is dropped or

subjected to mechanical shock, affecting measured values.

In the presence of corrosive or explosive

gases

Exposed to strong

electromagnetic fields

Near electromagnetic

radiators

Near electromagnetic

radiators (e.g., highfrequency induction

heating systems and IH

cooking utensils)

5

Jig for securing sensor unit

(provided by customer)

Attach

rubber

feet here

Attach

rubber

feet here

Base of main unit

HIOKI TM6101A981-06

Operating Precautions

Installation

• Do not slant the instrument or place it on top of an uneven surface. Dropping or

knocking down the instrument can cause injury or damage to the instrument.

• The instrument’s sensor unit consists of precision optical components. The

sensor unit should be secure mounted on a jig using the screw hole in its base.

Dropping the sensor unit or subjecting it to mechanical shock may damage it.

• When orienting the instrument’s main unit so that a part other than its base is

facing down, fix it in place so that it cannot fall. Failure to do so may cause a

fire or other malfunction in the main unit.

• The instrument is housed in a metal case and emits heat. Be sure to leave

adequate space around the instrument. Failure to do so may cause the ambient temperature to rise, affecting measured values and potentially damaging

the instrument.

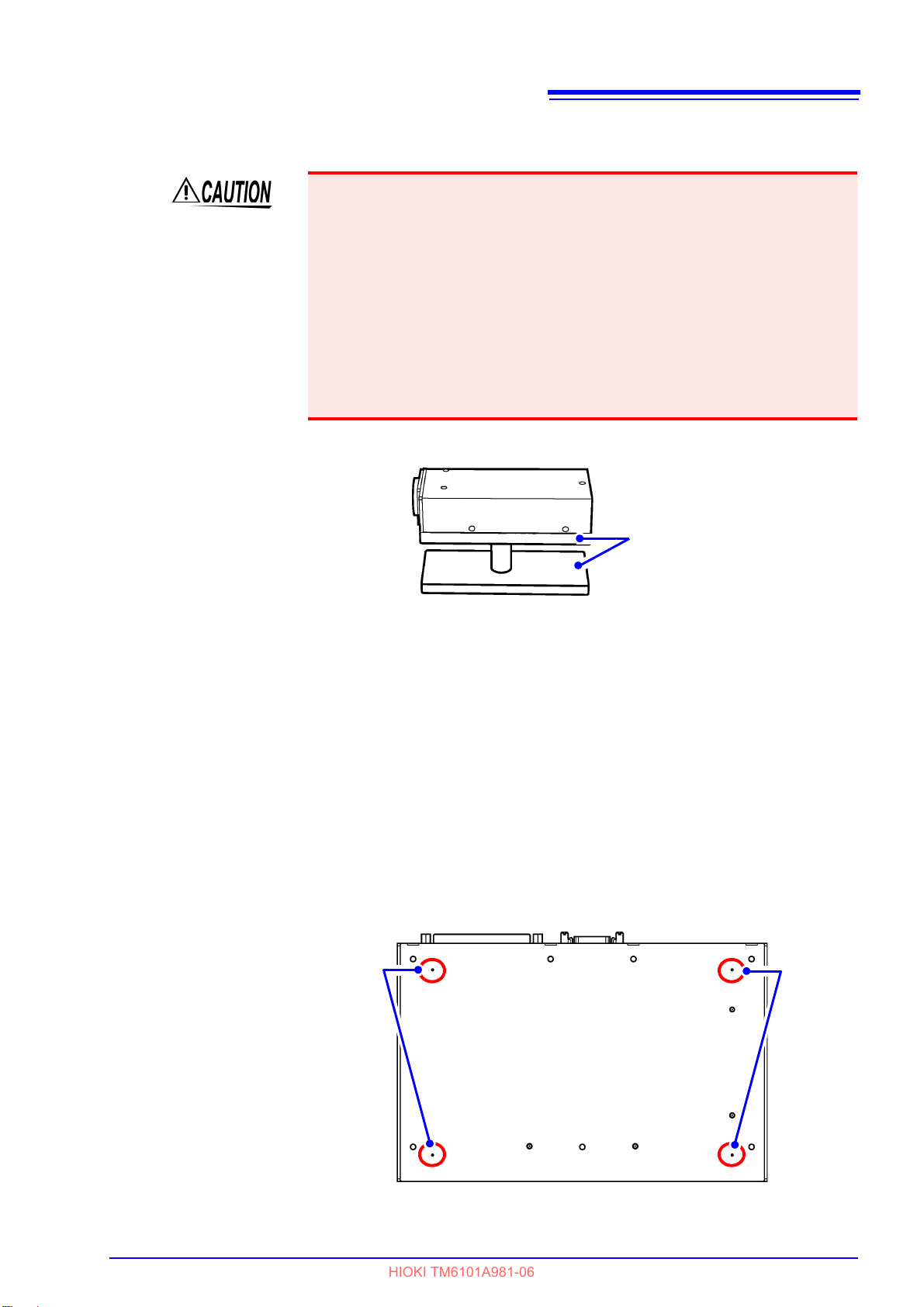

Attaching rubber feet to the main unit

• The instrument ships with four rubber feet for use with the main unit. Attach

the rubber feet to the bottom of the instrument as necessary.

• When attaching the rubber feet to the base of the main unit, refer to the following diagram for a rough indication of how the feet should be positioned.

6

Connecting

screws for connecting port

Jig for securing sensor unit

(provided by customer)

HIOKI TM6101A981-06

Operating Precautions

Connecting the sensor unit to an integration sphere

• When connecting the sensor unit to an integration sphere, use the included

screws to affix it to the integration sphere’s port. If the instrument is not compatible with the size of the integration sphere’s port, please contact HIOKI.

• Small pieces of paint may fall out of the screw holes when attaching the

screws. Remove any pieces of paint before affixing the instrument to the integration sphere.

• When connecting the sensor unit to the integration sphere, you are responsible

for providing a jig to support the sensor unit. Use the screw hole in the base of

the sensor unit to attach it securely to the jig.

Handling the Instrument

HIOKI TM6101A981-06

To avoid electric shock, do not remove the instrument's cover and panel.

The internal components of the instrument carry high voltages and may

become very hot during operation.

• Do not allow the instrument to get wet, and do not take measurements

with wet hands. This may cause an electric shock.

• Do not use the instrument where it may be exposed to corrosive or com-

bustible gases. The instrument/ device/ product may be damaged or

cause an explosion.

• To avoid damage to the instrument, protect it from physical shock when transporting and handling. Be especially careful to avoid physical shock from dropping.

• The instrument’s sensor unit consists of precision optical components. Dropping the sensor unit or subjecting it to mechanical shock may cause operation

to diverge from its accuracy specifications. An inspection is necessary in the

event the instrument is subject to mechanical shock.

• The upper limit of the instrument’s measurement range is 100,000 lx.

Do not expose the instrument to light in excess of 100,000 lx. Doing so may

cause degradation of the sensor unit’s internal optical components.

• This instrument is designed for use indoors. It can be operated at temperatures between 5 and 35°C without degrading safety.

• Do not store or use the instrument where it could be exposed to direct sunlight,

high temperature or humidity, or condensation. Under such conditions, the

instrument may be damaged and insulation may deteriorate so that it no longer

meets specifications.

• This instrument is not designed to be entirely water- or dust-proof. Do not use

it in an especially dusty environment, nor where it might be splashed with liquid. This may cause damage.

• This instrument is not drip-proof. Water droplets on the connector may result in

malfunctions.

• Do not allow the instrument to get wet, and do not take measurements with wet

hands. This may cause an electric shock.

• Do not use the instrument near a source of strong electromagnetic radiation, or

near a highly electrically charged object. These may cause a malfunction.

• Do not use the instrument in the vicinity of induction heating equipment (highfrequency induction heating equipment, induction heating cook tops, etc.).

Doing so may damage the instrument or cause fire.

7

Operating Precautions

Correct measurement may be impossible in the presence of strong magnetic

fields, such as near transformers and high-current conductors, or in the presence of strong electromagnetic fields such as near radio transmitters.

8

HIOKI TM6101A981-06

Operating Precautions

Handling the sensor unit’s detector window

• Do not touch the detector window.

The instrument may fail to operate to its full level of performance if the detector

window is dirty.

• Avoid contacting the detector window with sharp objects (the tip of a pair of

tweezers, etc.) or hard surfaces. The instrument may fail to operate to its full

level of performance if the detector window is damaged.

• The detector window is made of glass and should never be subject to mechanical shock. Doing so may damage the detector window.

• Do not use organic solvents other than ethyl alcohol to clean the detector window. Doing so may cause the detector window’s performance to deteriorate.

"Cleaning the sensor unit’s detector window" (p.58)

Handling the Cords

HIOKI TM6101A981-06

Before using the instrument, make sure that the insulation on the cords is

undamaged and that no bare conductors are improperly exposed. Using

the instrument in such conditions could cause an electric shock, so contact your dealer or Hioki representative for replacements.

Use only the specified connection cables. Using a non-specified cable may

result in incorrect measurements due to poor connection or other reasons.

Handling the AC Adapter

Use only the supplied Model 9418-15 AC Adapter. AC adapter input voltage

range is 100 to 240 VAC (with ±10% stability) at 50/60 Hz. To avoid electrical

hazards and damage to the instrument, do not apply voltage outside of this

range.

9

Operating Precautions

CD

• Always hold the disc by the edges, so as not to make fingerprints on the disc or

scratch the printing.

• Never touch the recorded side of the disc. Do not place the disc directly on

anything hard.

• Do not wet the disc with volatile alcohol or water, as there is a possibility of the

label printing disappearing.

• To write on the disc label surface, use a spirit-based felt pen. Do not use a ballpoint pen or hard-tipped pen, because there is a danger of scratching the surface and corrupting the data. Do not use adhesive labels.

• Do not expose the disc directly to the sun's rays, or keep it in conditions of high

temperature or humidity, as there is a danger of warping, with consequent loss

of data.

• To remove dirt, dust, or fingerprints from the disc, wipe with a dry cloth, or use

a CD cleaner. Always wipe from the inside to the outside, and do no wipe with

circular movements. Never use abrasives or solvent cleaners.

• Hioki shall not be held liable for any problems with a computer system that

arises from the use of this disc, or for any problem related to the purchase of a

Hioki product.

Before Connecting

Before turning the instrument on, make sure the supply voltage matches

that indicated on the AC adapter. Connection to an improper supply voltage may damage the instrument or AC adapter and present an electrical

hazard.

10

HIOKI TM6101A981-06

Operating Precautions

1.1 Product Overview and Features

This section describes the principles by which the Model TM6101 measures light and color.

The instrument’s light detector consists of diffusion optics that diffuse incident light and a series of optical sensors that detect the diffused light. The optical sensors detect light by separating the diffused incident light into 16 wavelength regions in the visible spectrum. The characteristics of the 16 optical

sensors have been precisely measured with a spectroscope, and correction coefficients that

approximate the color matching function have been calculated.

Chromaticity and illuminance are calculated from the strength of the light detected with the 16 optical

sensors and the correction coefficients. The sensors use measurement photodiode arrays and microcurrent measurement technology to deliver a high signal-to-noise ratio and high dynamic range.

Illuminance measured with the instrument is calibrated with a luminous intensity standard lamp and

HIOKI standard illuminometer

*1

, while chromaticity is calibrated with a spectral irradiance standard

lamp

*2

.

*1: The standard illuminometer is calibrated by a calibration facility.

*2: The spectral illuminance of the spectral irradiance standard lamp is calibrated by a calibration facility.

High-speed, high-precision measurement of LED light

•

The integration time can be set as low as 0.1 ms

• Instrumental error can be corrected using the reference value correction function

• Low incident angle dependence enables illuminance measurement, CIE averaged LED intensity measurement,

and light and color measurement while the instrument is attached to an integration sphere.

Measurement items

(1) Illuminance, luminous flux, and luminous intensity

(2) Chromaticity

(3) Color rendering index

(4) Correlated Color Temperature and Δuv

(5) Dominant Wavelength and Excitation Purity

HIOKI TM6101A981-06

Overview Chapter 1

1.1 Product Overview and Features

11

12

Functionality facilitating automatic testing

Standard USB 2.0 interface

•

PC connectivity and automatic control

• High-speed reception of measured values

Digital I/O equipped (p.43)

•

Automatic measurement using an external trigger

• Signal output at completion of measurement

Reference value correction function (p.31)

•

Correction of instrument sensitivity based on standard light source spectral data provided by the customer and

measured values

Auto range function (p.29)

•

Auto-ranging at start of measurement, eliminating troublesome adjustments

PC-based instrument control

Instrument ships standard with Windows

®

software.

•

Measurement control and data transfer via PC operation

Display of measurement results and ability to save data as a CSV file

• Display items

Illuminance, luminous flux, luminous intensity, chromaticity (xy), color rendering index (R1 to R15, Ra), correlated

color temperature, Δuv, dominant wavelength, excitation purity

Software development library

•

Windows® API

Enables customer development of Windows software.

• Supported development environments

Visual Studio

®

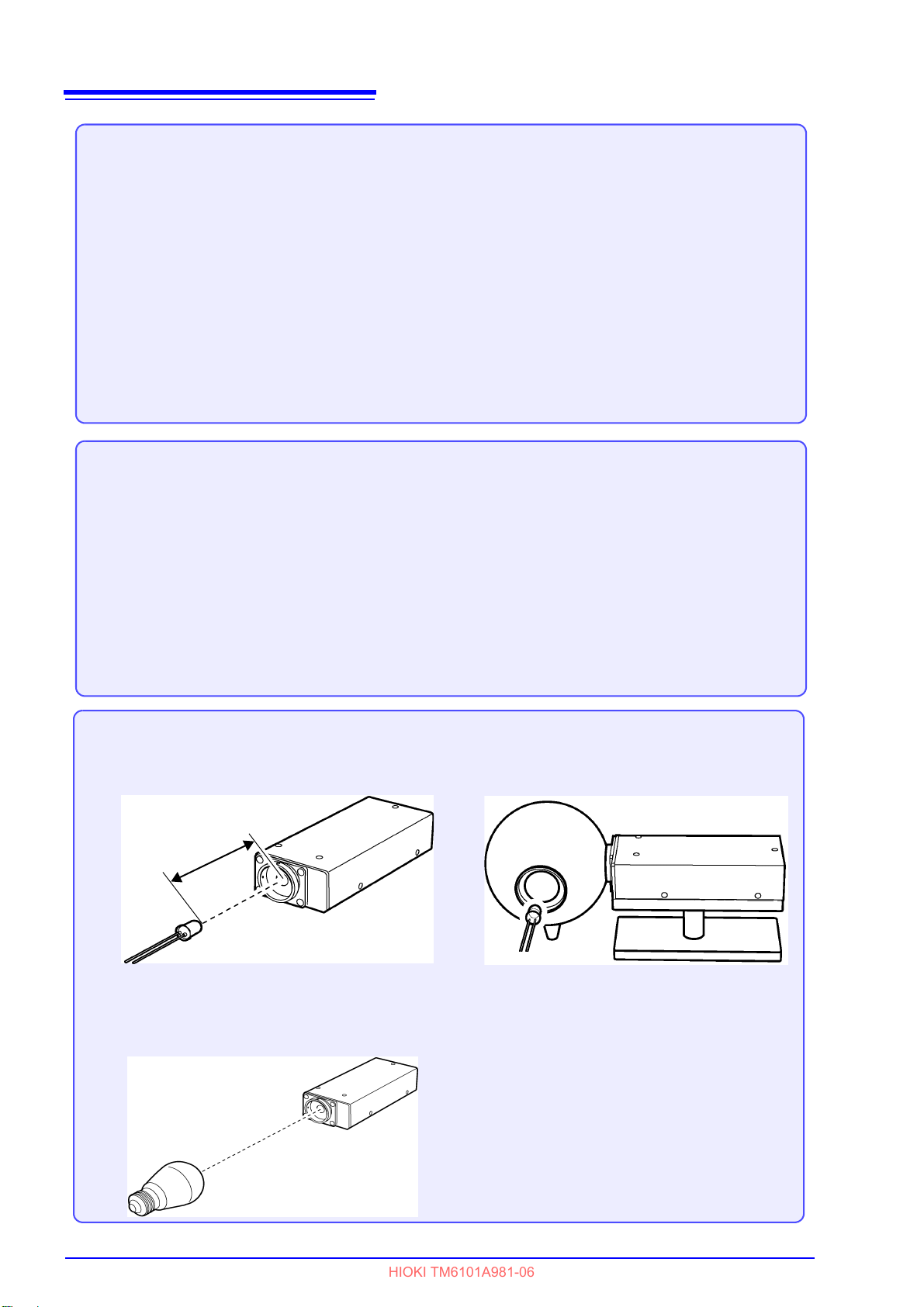

2017, 2019 (Visual C++®, Visual Basic®, Visual C#®)

Support for a variety of testing applications (p.39)

Testing of white LEDs

•

Measurement of CIE averaged LED intensity, chromaticity, and color rendering index

Testing of white LED light

•

Measurement of illuminance and testing of chromaticity

and color rendering index

• Measurement of total luminous flux, chromatic-

ity, and color rendering index

Integration sphere

Sensor unit

Total Luminous Intensity Measurement Setup

100 mm

LED element

Sensor unit

CIE Averaged LED Intensity

Measurement Setup (0.01 sr)

Sensor unit

LED light

LED element

HIOKI TM6101A981-06

1.1 Product Overview and Features

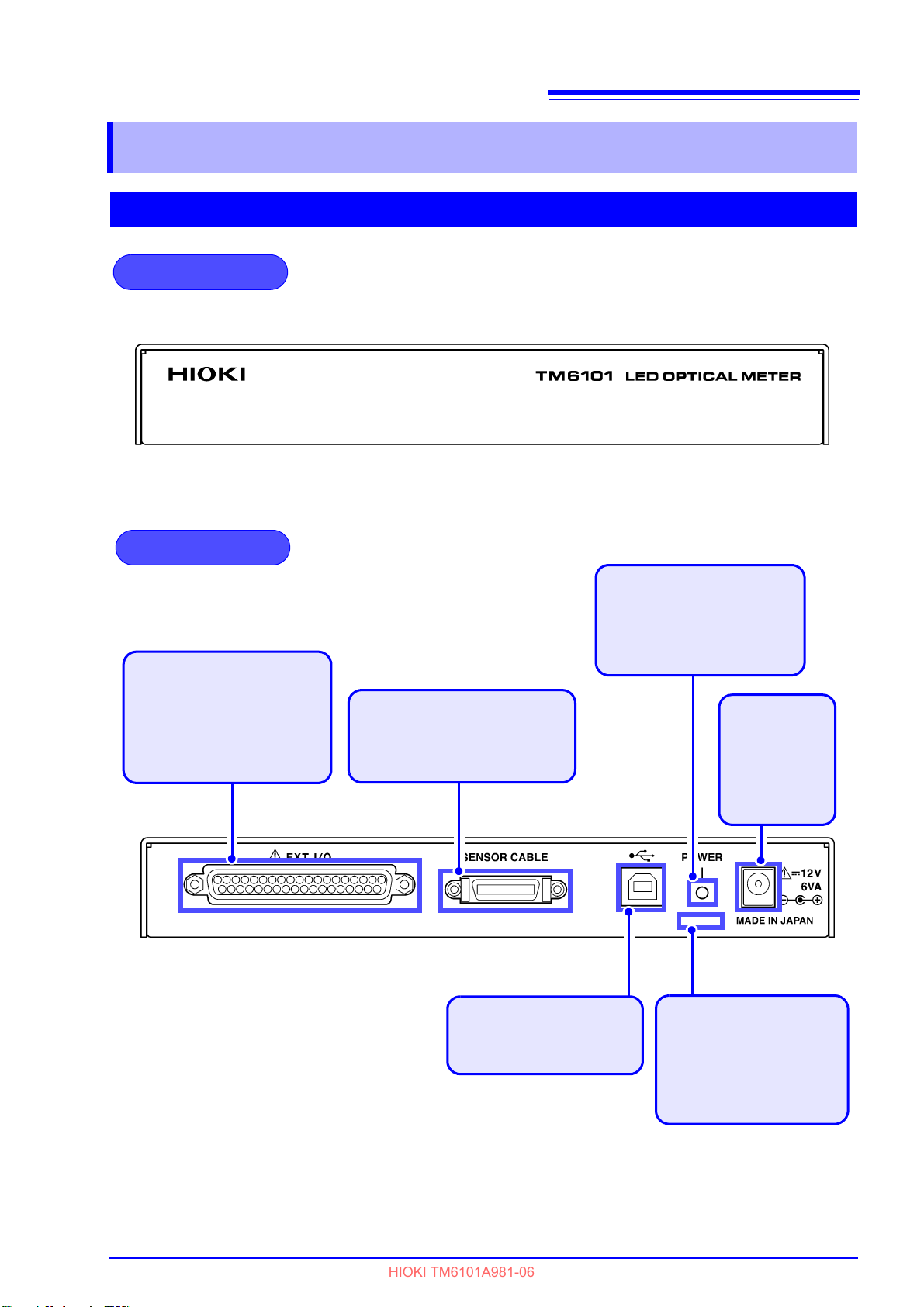

1.2 Names and Functions of Parts

Front panel

Rear panel

EXT I/O Connector

Accepts external trigger input

and outputs the measurement

complete, judgment output, and

other signals.

See: (p.43)

Sensor unit connection port

Connect the Main unit/sensor unit

connection cable.

See: (p.24)

USB port

Connect the USB cable.

See: (p.25)

AC adapter

terminal

Connect the

9418-15 AC

Adapter.

See: (p.26)

Serial No.*

Differentiates between instruments by serial number when

controlling the instrument with

the TM6101 Utility or TM6101

Measuring Library.

Power indicator

Lights up when the instrument is

on.

Green : Operating

Red : Standby

*: Serial number

The first four digits of the 9-digit

number indicate the year (the first

two digits omitted) and the month of

manufacture.

HIOKI TM6101A981-06

1.2 Names and Functions of Parts

Main Unit

13

14

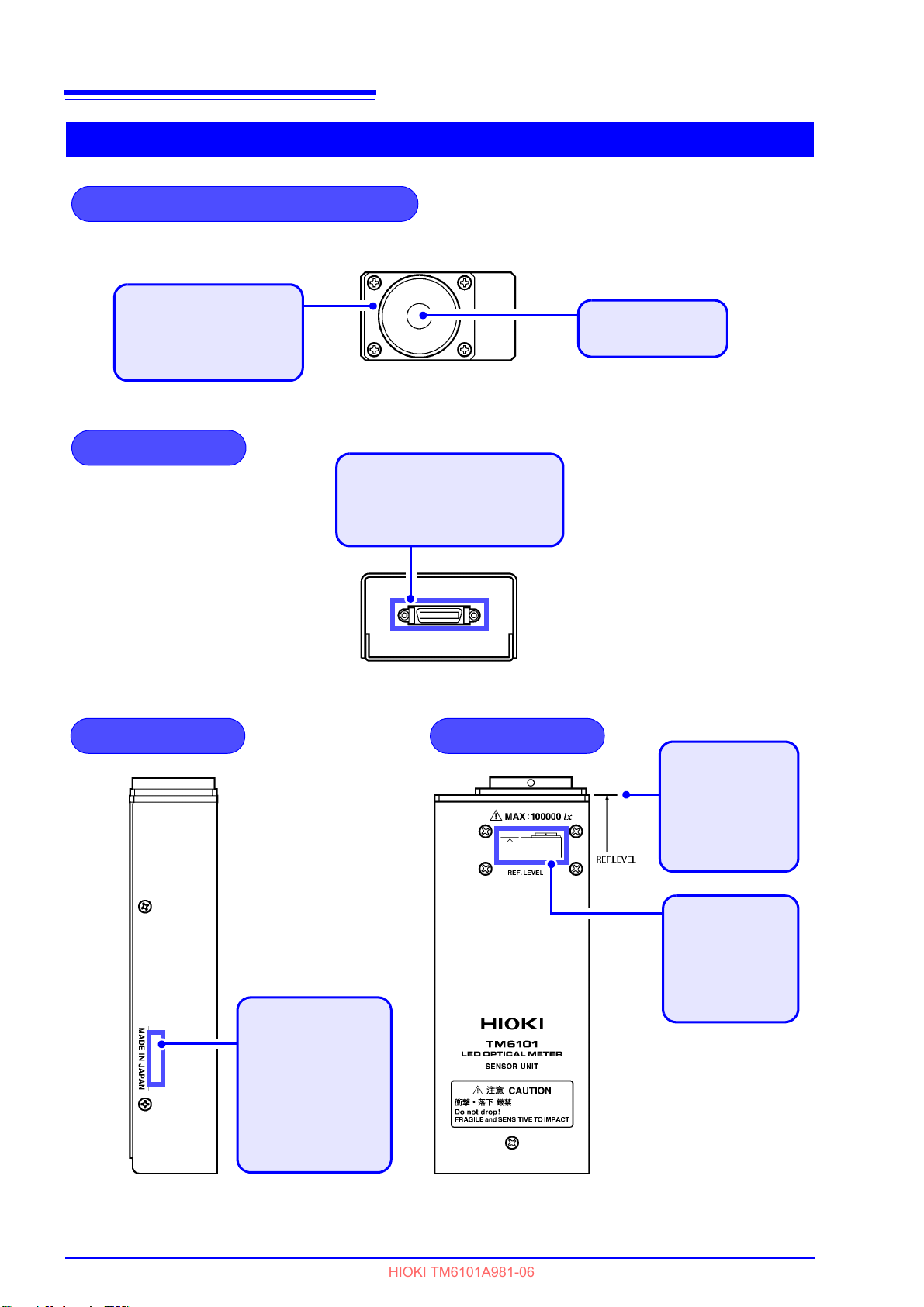

Rear panel

Incident light detector window

Top

Integration sphere port

Allows an integration sphere

to be attached.

See: (p.6)

Detector window

Receives light.

Measurement

reference

surface

Serves as the measurement reference surface.

Measurement

reference

surface mark

Indicates the measurement reference

surface.

Right side

Sensor unit connection port

Connect the Main unit/sensor unit

connection cable.

See: (p.24)

Serial No.

Differentiates between

instruments by serial

number when controlling the instrument with

the TM6101 Utility or

TM6101 Measuring Library.

HIOKI TM6101A981-06

1.2 Names and Functions of Parts

Sensor Unit

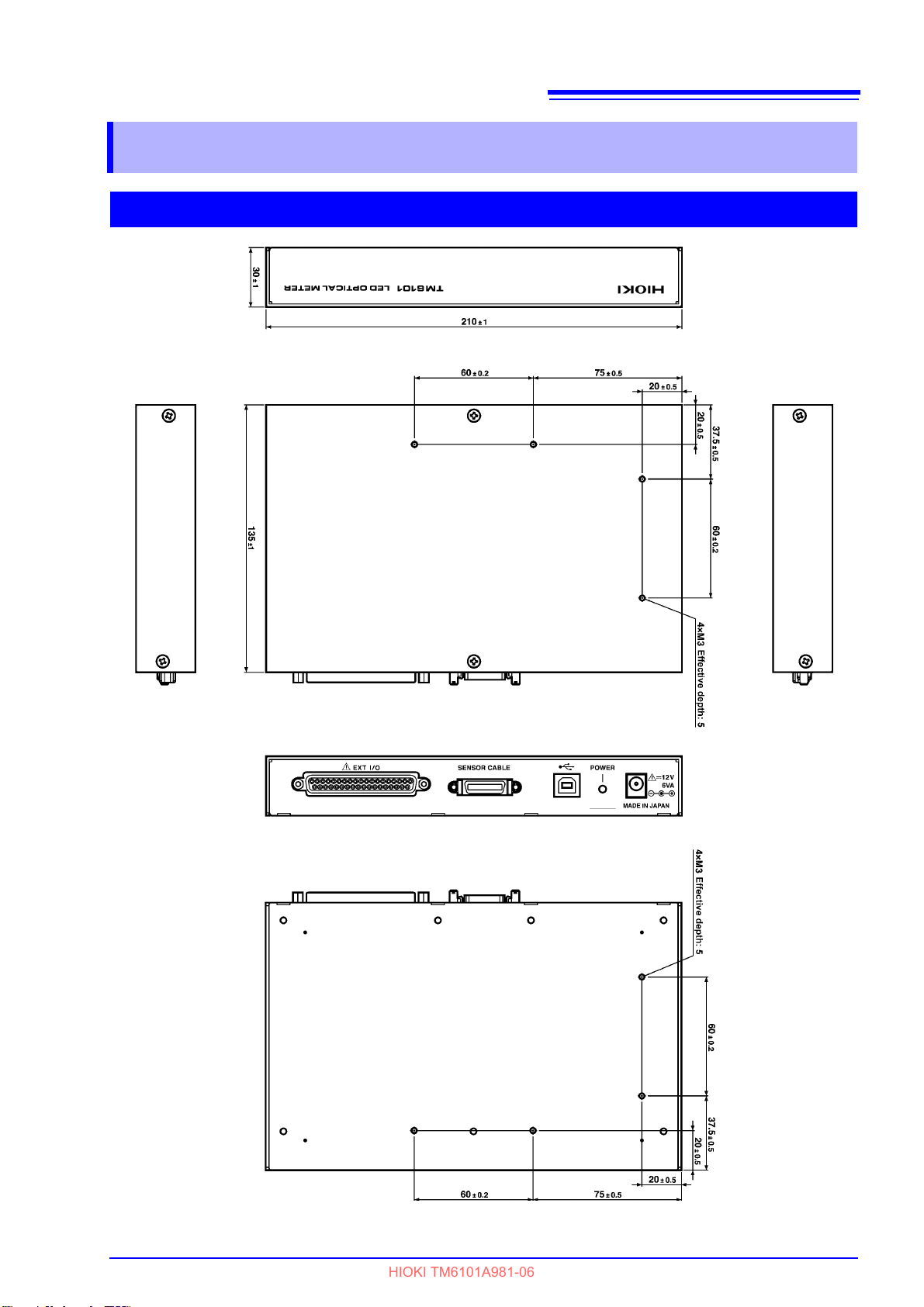

1.3 External Dimensions

HIOKI TM6101A981-06

Main Unit

15

1.3 External Dimensions

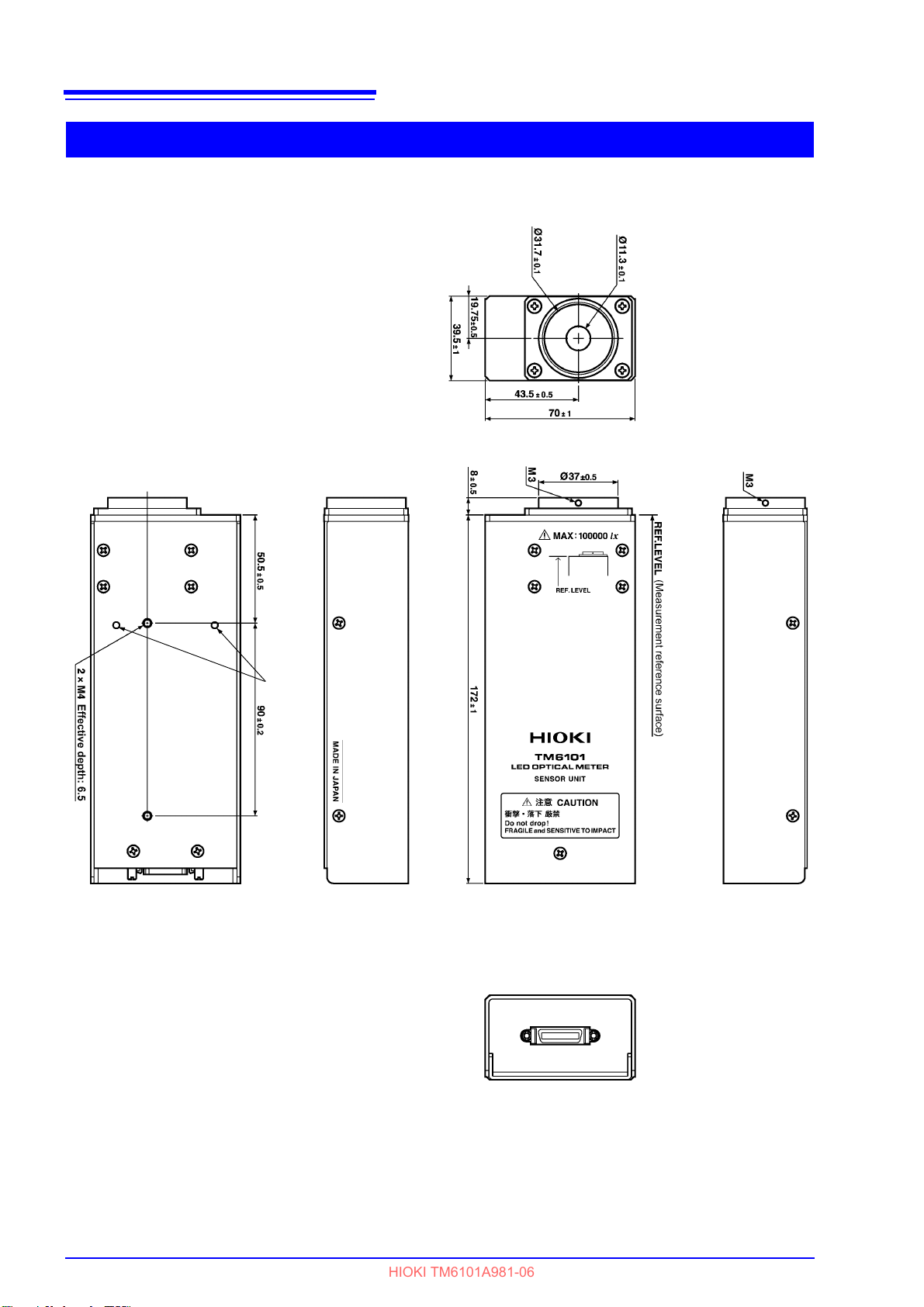

16

Do not use

HIOKI TM6101A981-06

1.3 External Dimensions

Sensor Unit

“REF.LEVEL” indicates the measurement reference surface.

Loading...

Loading...