Instruction Manual

SM7860-01 to -07

SM7860-21 to -27

POWER SOURCE UNIT

February 2012 Revised edition 1 SM7860A981-01 12-02H

Contents

Introduction.................................................................................1

i

Contents

1

Confirming Packa g e Co n te n ts.............. .. ... .. ... ..................... ... .. ..1

Safety Informa tion ............. .. ... .. .. ...................... .. ... .. ...................2

Operating Precautions................................................................3

Chapter 1

Overview___________________________________ 7

1.1 Product Overview and Features .........................................7

1.2 Names and Functions of Parts ............................................8

1.3 Screen Layout ...................................................................10

Chapter 2

Preparing to Use the Device and

Supplying Power ___________________________ 11

2.1 Installation & Connection Procedures ...............................11

2.2 Connecting the Power Cord ..............................................12

2.3 Connecting the Device to the Measuring Instrument ........13

2

3

4

5

6

7

2.4 Pre-Operation Inspection ..................................................14

2.5 Turning the Power On and Off ..........................................15

2.6 Setting the Operating Conditions ......................................16

Chapter 3

Communication (GP-IB/RS-232C Interface)______ 17

3.1 Overview and Features .....................................................17

3.2 Specifications ............................................................ ........ 18

3.3 Connect a cable to the GP-IB

connector or RS-232C connector 19

3.4 Configuring the Communications Protocol ........................21

3.5 Communication Methods ..................................................22

Status Byte Register .........................................................................24

Eve n t R e g is te rs ..... ... ..................................... ...................................2 6

Error Registers ..................................................................................28

3.6 Message List .....................................................................29

3.7 Listener Specification Precautions ....................................32

Input buffer size ................................................................................32

Reading from the output buffer .........................................................32

8

9

10

11

12

付

録

索

引

ii

Contents

Chapter 4

External Control ____________________________33

4.1 External Input/Output Connector and Signals ..................33

Connector Type and Signal Pinouts .................................................34

Signal Descriptions ..........................................................................35

4.2 Timing Chart .....................................................................36

4.3 Internal Circuitry ................................................................38

Chapter 5

Specifications______________________________39

5.1 General Specifications ......................................................39

5.2 Basic Specifications ..........................................................40

5.3 Input / Output Functions ...................................................44

Chapter 6

Maintenance and Service ____________________45

6.1 Troubleshooting ................................................................ 45

Inspection and Repair ......................................................................45

6.2 Replacing the Power Fuse ................................................47

6.3 Error Displays ...................................................................48

6.4 Cleaning .................................................... ........................48

Introduction

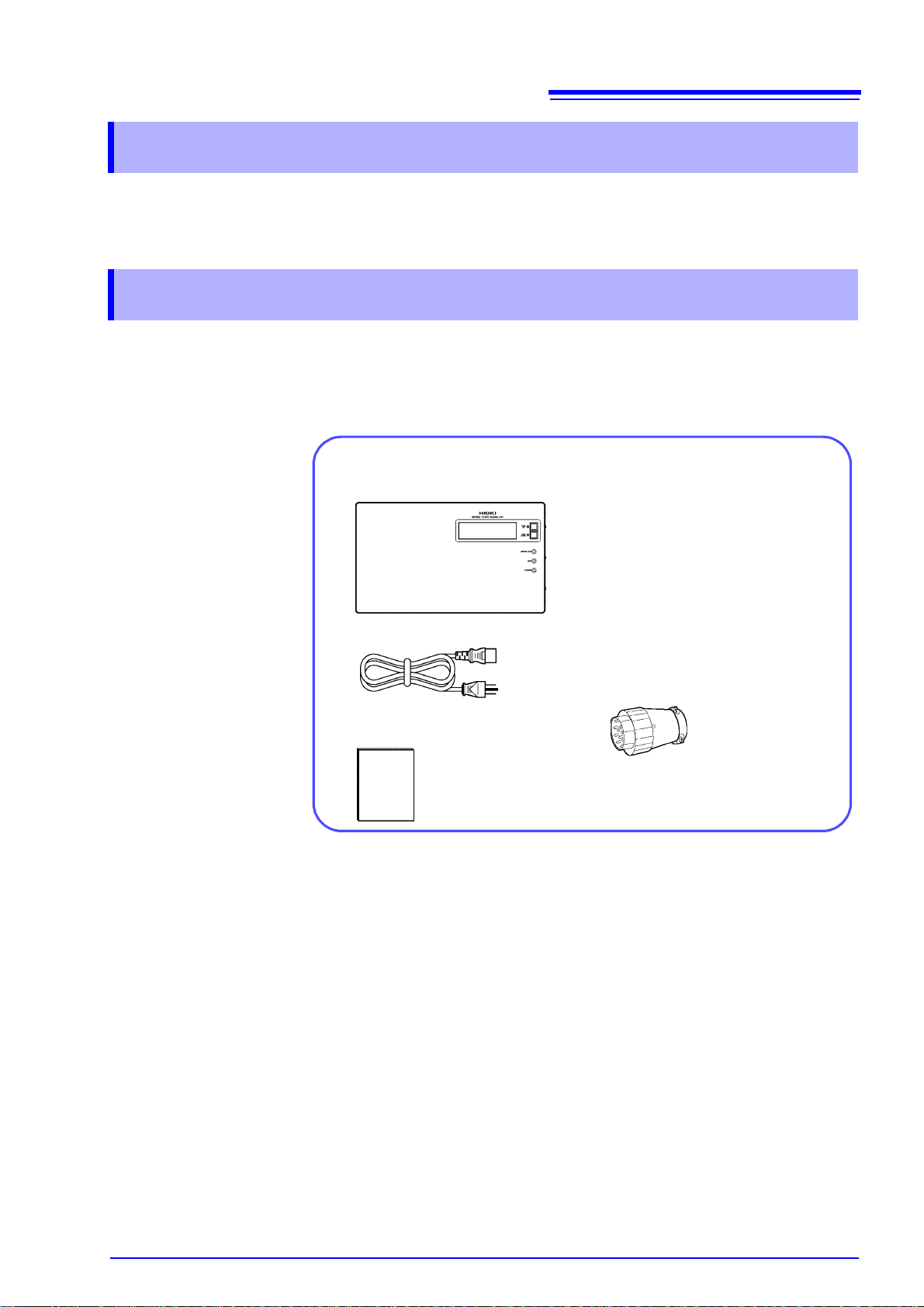

Confirm that th e se contents are provided.

□ SM7860 series Power Source Unit (1)

□ Power Cord (1)

□ Instruction Manual (1)

□ Voltage output connector

SM7860-01, -02, -21, -22.............2

SM7860-03, -04, -05, -06, -07,

-23, -24, -25, -26, -27 ......4

Thank you for purchas ing the HIOKI Model SM7860 series Power Source Unit.

To obtain maximum performance from the devic e, please read this manu al first,

and keep it handy for future reference.

Confirming Package Contents

When you receive the device, inspect it carefully to ensure that no damage

occurred during shipp ing. In particular, check the accessor ies, panel switches,

and connectors . If damage is evident, or if it fa ils to operate according to the

specifications, contact your dealer or Hioki representative.

1

Introduction

Options □ Model 9637 RS-232C Cable (9pin-9pin/Cross/1.8m)

Transportation

Notes on

□ Model 9638 RS-232C Cable (9pin-25pin/Cross/1.8m)

□ Model 9151-02 GP-IB Connector Cable (2 m)

• To ensure safe handling, when transporting the device, please use the original

box and packing materials, but do not use if the box is damaged or warped, or

if the packing materials are in poor condition or incomple te.

• When packing the device, m ake sure to disconnec t the power c ords from t he

main device.

• When transporting, avoid dropping or other excessive impact.

2

Safety Information

Safety Information

This device is des igned to comply with IEC 61010 Safety Standards, and

has been thoroughly tested for safety prior to shipment. However, mishandling during use could result in injury or death, as well as damage to the

device. Using the device in a way not described in this manual may negate

the provided safety features.

Be certain that you understand the instructions and precautions in the

manual before use. We disclaim any responsibility for accidents or injuries

not resulting directly from device defects.

This manual contain s information and warnings essential for safe operation of

the device and for maintaining it in safe operati ng condition. Be fore using it, b e

sure to carefully read the following safety precautions.

Safety Symbols

In the manual, the symbol indicates particularly important information that

the user should read before using the device.

The symbol printed on the device indicates that the user should refer to a

corresponding topic in the manual (marked with the symbol) before using

the relevant function.

Indicates a grounding termi nal.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of cautions

and warnings.

Indicates that incorrect operation presents an extreme hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

Indicates that incor rect operatio n presen ts a po ssib ility of injury to the

user or damage to the device.

Indicates advisory items related to performance or correct operation

of the device.

Other symbols

*

PA GE UP

(Bold)

( p. )

Indicates a prohibited action.

Indicates that descriptive information is provided below.

Bold characters within the text indicate operating key labels.

Indicates the location of reference information.

Operating Precautions

Follow these precaut ions to ensure s afe ope ration an d to obta in the fu ll bene fits

of the various functions.

Preliminary Checks

Before using the device for the first time, verify that it operates normally to

ensure that no damage occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

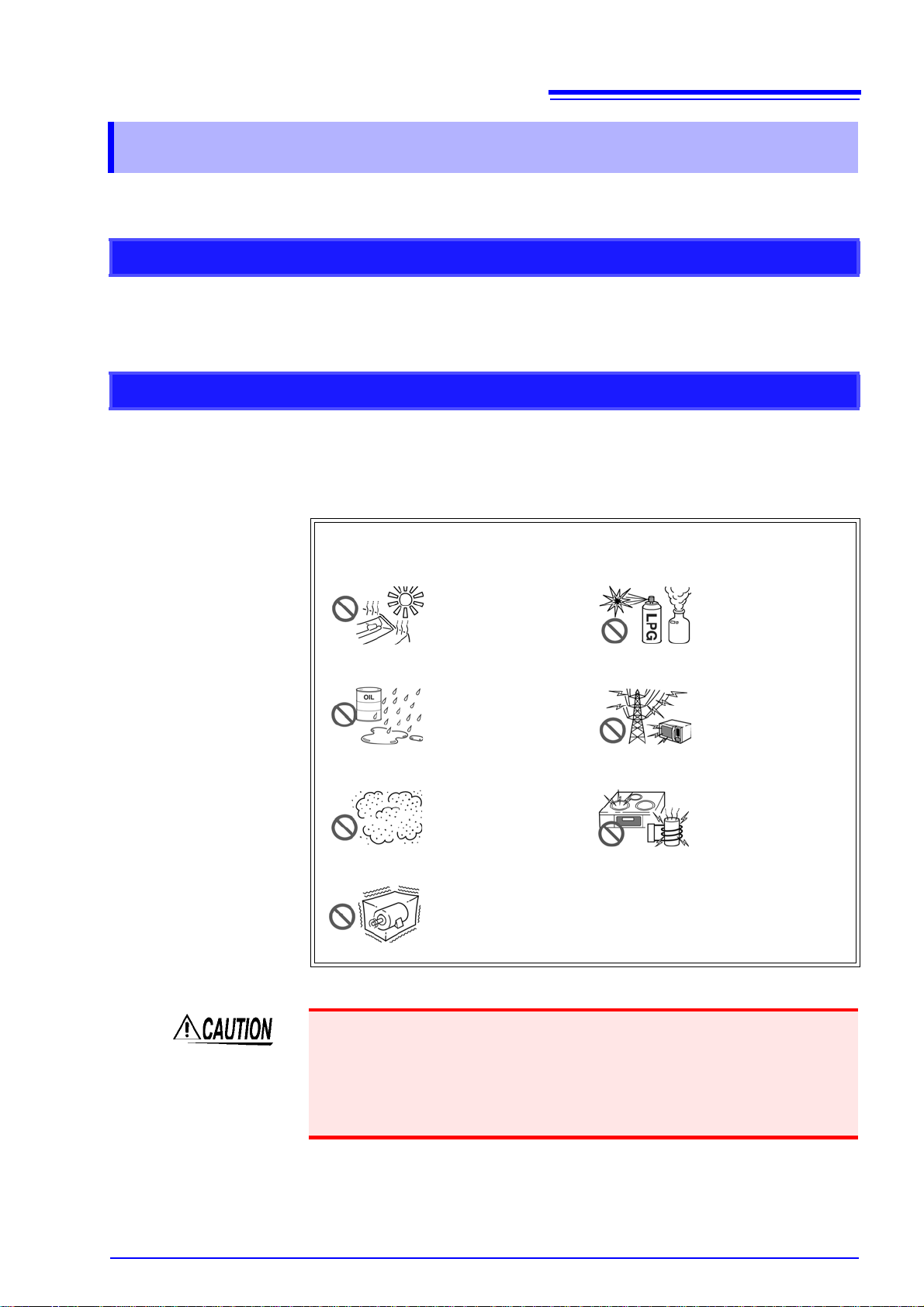

Device Installation

Operating temperature and humidity

Temperature and humidity range for guaranteed accuracy

3

Operating Precautions

: 0 to 40°C at 80%RH or less (non-condensing)

: 23±5°C, 80%RH or less (non-condensing)

Avoid the following locations that could cause an accident or damage

to the device.

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil,

other chemicals, or

solvents

Exposed to high humidity or condensation

Exposed to high levels of particulate dust

Subject to vibration

In the presence of corrosive or explos ive gas es

Exposed to strong electromagnetic fields

Near electromagnetic

radiators

Near electromagnetic

radiators (e.g., high-frequency induction heating systems and IH

cooking utensils)

• Do not slant the device or place it on top of an uneven surfa ce. Dropping or

knocking down the device can cause injury or damage to the device.

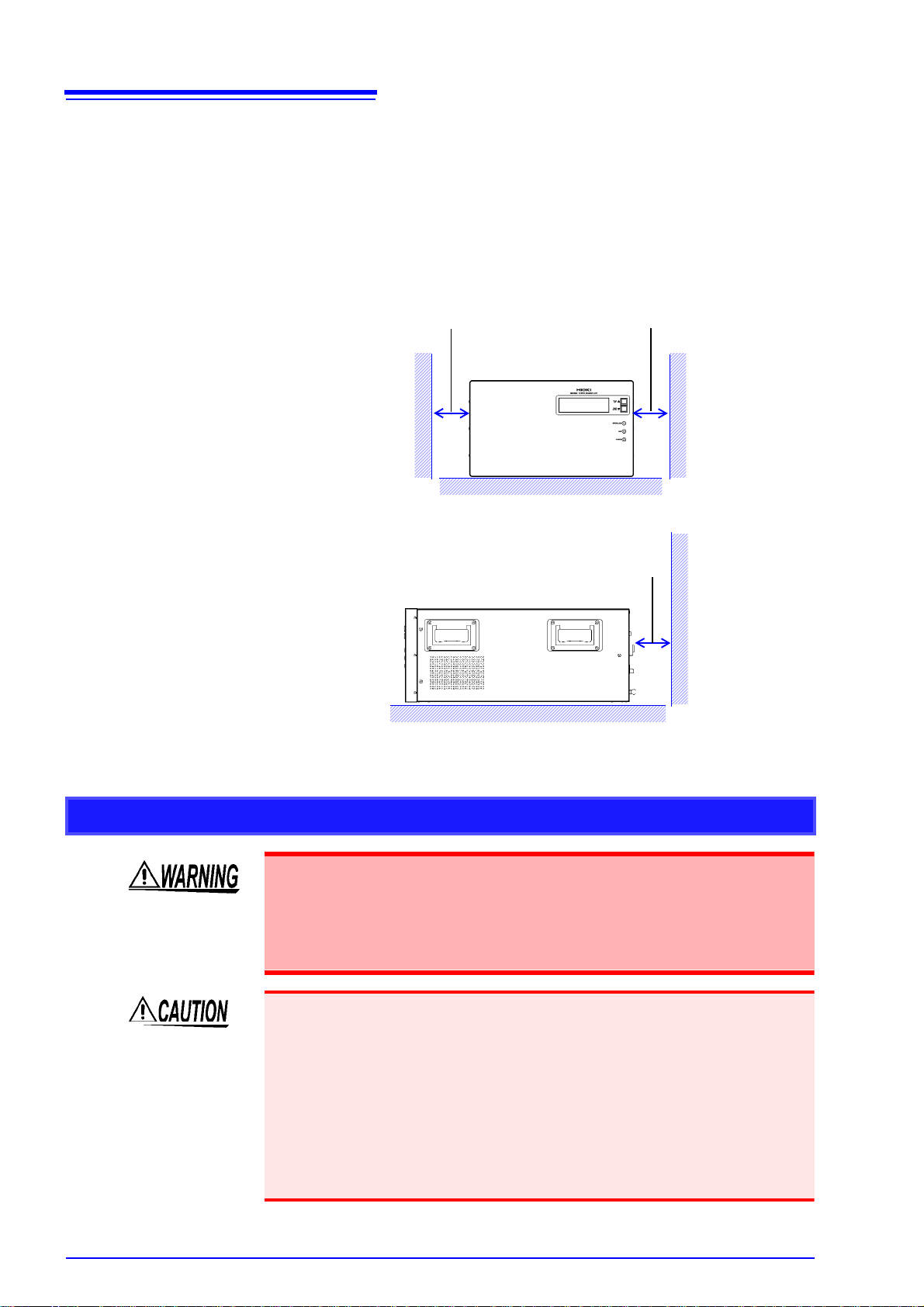

• Ventilation holes for heat radiation are provided on the si de and re ar panels of

the device. Leave sufficient space aroun d the ventilation holes and install t he

device with the holes unobstructed. Installation o f the device with the venti lation holes obstructed may cause a malfunction or fire.

4

100 mm or more

50 mm or more

50 mm or more

Operating Precautions

Installing To prevent overheating, be sure to leave the specified clearances around the

unit.

• Vents must not be obstructed.

• When rack-mounting the dev i ce, fans must be in stalle d abov e or on top of the

rack to ensure proper ventila tion. Be sure that the rack is adequately ven tilated so that the i nternal temperature remains at o r below 40°C. Continued

use of the device in a high-temperature envir onment will shorten its servic e

life. Keep the temperature as low as possible.

Handling the Device

• Do not allow the device to get wet, and do not take measurements with

wet hands. This may cause an electric shock.

• Touching any of the high-voltage points inside the device is very danger-

ous. Do not attempt to modify, disassemble or repair the device; as fire,

electric shock and injury could result.

• To avoid damage to the device, protec t it from physic al shock whe n transport-

ing and handling. Be especially careful to avoid physical shock from dropping.

Failure to observe the following precaution may result in bodily injury.

• The device weighs approxi mately 45 kg (SM7860-07, -27: approximately 32

kg). It should be move d by at least two people, who should grip it using the

handles on the left and right sides.

• The device is he avy. When transporting it, foll ow your company's workplace

safety standards to assure safety (for example, by wearing non-slip gloves and

protective footwear).

Handling the Cords

5

Operating Precautions

Before using the device, make sure that the insulation on the Connection

Cable is undamaged and that no bare conductors are improperly exposed.

Using the de v i ce i n s u c h conditions could cause an e lec t r i c shock, so con tact your dealer or Hioki representative for replacements.

• Avoid stepping on or pinching cab les, which could damage the cable insulation.

• To avoid breaking the cables, do not bend or pull them.

• To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from the power outlet.

• Keep the cables we ll away from heat sources, as bare c onductors could be

exposed if the insulation melts.

Use only the specified connection cables. Using a non-specified cable may

result in incorrect measurements due to poor connection or other reasons.

Before Connecting

• Before turning the device on, make sure the supply voltage matches that

indicated on its power connector. Connection to an improper supply voltage may damage the device and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety speci ficat ion s of

this device, connect the power cord only to a 3-contact (two-conductor +

ground) outlet.

T o ensure measurements are accurate,

• Warm up the device an hour or more before use.

• The device should be calibrated once a year.

6

Operating Precautions

1.1 Product Overview and Features

Overview Chapter 1

1.1 Product Overview and Features

The SM7860-01 to -07 and SM786 0-21 to -27 ar e power supp ly units d esigned

for use with the Model SM7810 or SM7810-20 Super MΩ HiTester. They support

bipolar, multi-channel output and are compatible with multi-channel systems.

Used in combination with the Model SM7810 or SM7810-20 Super MΩ HiTester,

they are ideal for use in automated testing and measurement of capacitors.

Bipolar, multi-channel output

The device delive rs an 8-channel, positive/negative power supply, allowing an

optimized test ing line to be built using th e smallest possible number of power

supplies.

7

Independent on/off output switching and current limitations

for all channels

Since each channel has its own output on/off switch, it is possible to control voltage application without an external circuit (allowing charging and dis charging).

Use of semiconduc tor switches elimina tes the need for mainten ance. Additionally, the ability to limit current (to 50 mA) for individual channels means the measurement of other channe ls won't be affected when a target workpiece has a

short.

Output current capacity: 50 mA/channel

High-capacity capacitors can be charged rapidly, and the number of charges can

be reduced.

Output voltage: 1,000 V/channel

Devices are available with output voltages of up to ±1,000 V.

Standard interfaces

Devices ship standard with external I/O, GP-IB, and RS-232C interfaces for

sequencing. Interfaces are used to configure and power the devices.

Inter-lock Function

8

LCD screen

The screen uses a 2-page

layout to display setting values and setting status inf ormation.

"1.3 Screen Layout" (p.10)

Front Panel

Scroll keys (PAGE UP▲/ PAGE DOWN▼)

Used to scroll through the display pages.

"1.3 Screen Layout" (p.10)

The scroll keys are also used to se t the GP-IB add ress.

(p.21)

Inter-lock indicator

Lights up when the interlock is

on.

V oltage output indicator

Lights up when a voltage is being output.

Power indicator

Lights up when the d evi ce is on.

Rear Panel

Power inlet

Connect the supplied power cord

here. (p.12)

Fuse holder

Allows the fuse to be replaced.

(p.47)

RS-232C connector

Connect to a compute r when

using the RS-232C interface.

(p.19)

EXT I/O connector

The external I/O connector

can be used to control the

device.

(p.33)

Voltage output terminal

Connect the included voltage

output connector.

(p.13)

Vent

Keep clear of obstructions.

POWER switch

Turns the device o n and off .

: Power On

: Power Off

(p.15)

GP-IB connector

Connect to a compu ter whe n using the

GP-IB interface.

(p.19)

GND terminal

Serves as the ground terminal.

The GND terminal is connected

to the device’s enclosure.

1.2 Names and Functions of Parts

1.2 Names and Function s of Parts

9

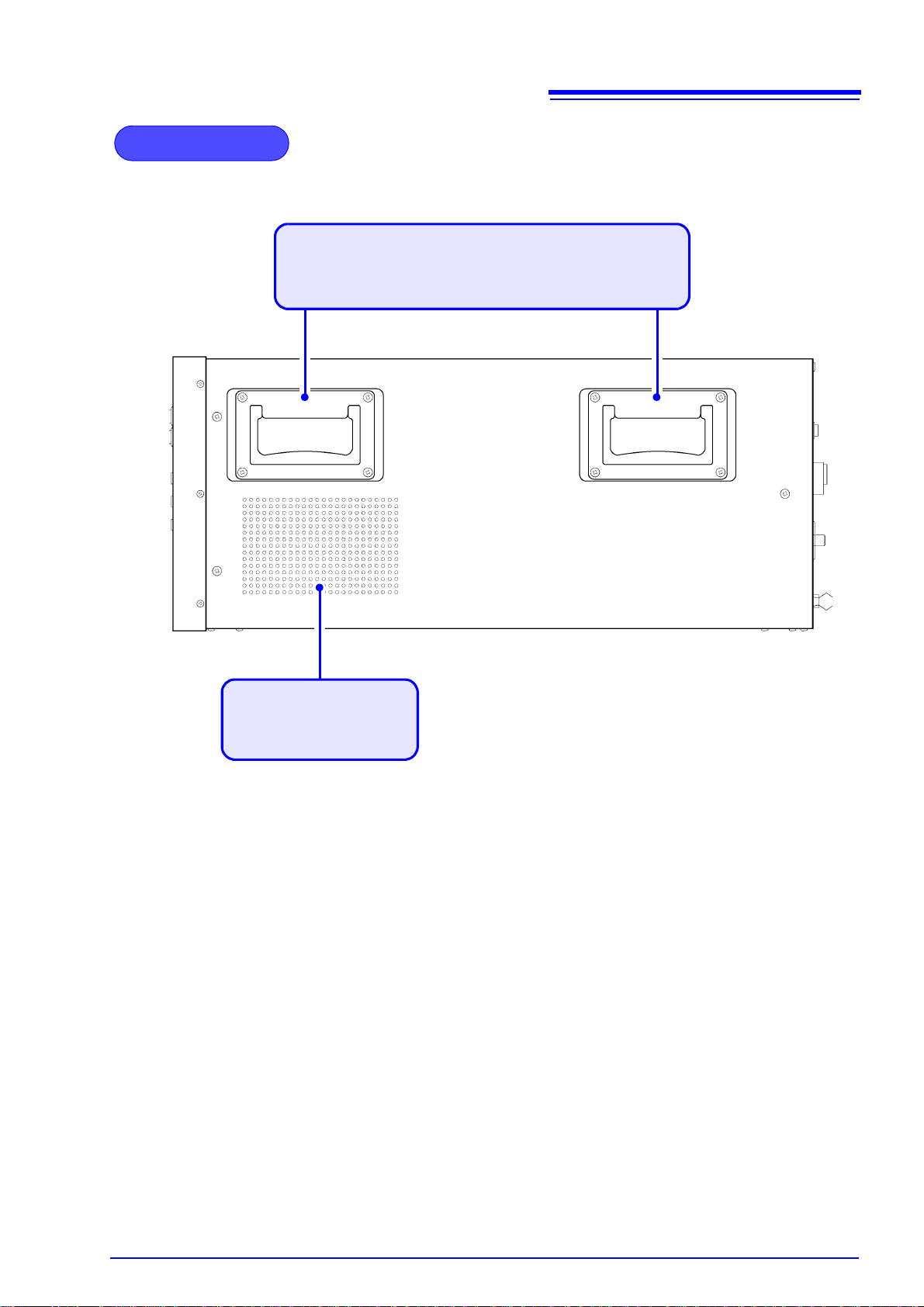

Side Panel

Handle

It should be moved by at least two p eople, who shoul d grip it using

the handles on the left and right sides.

Vent

Keep clear of obstructions.

1.2 Names and Functions of Parts

10

VA (+) IR:1000.0

VB (+) IR: 250.0

TERMINAL:

OUT1:11100000

OUT2:11100000

OUT3:11100000

OUT4:11100000 VMA:1000.0 OK

VMB: 250.0 OK

■ Screen P1 : Displays output voltage settings.

■ Screen P2: Alarm/GP-IB address setting display

Output voltage setting

VA: Displays the power supply A circuit voltage setting.

VB: Displays the power supply B circuit voltage setting.

Temperature error display

When a temperature error is d ete cte d,

"TEMP" flashes in reverse video.

Terminal output setting state

The setting is 0 or 1.

From left to right, OUTn row 1 → row 8

0: High-impedance

1: ON

Monitor voltage value

VMA: Displays the voltage

monitor value for the

power supply A circuit.

VMB: Displays the voltage

monitor value for the

power supply B circuit.

*Fixed-po int, zero-suppr essed.

Voltage error alarm results

VA ALARM: 19

VB ALARM: 19

GPIB ADDR: 1

Voltage error alarm setting

VA: Power supply A circ uit voltage error alar m setting ± (% )

VB: Power supply B circ uit voltage error alar m setting ± (% )

OK: The monitor voltage error

relative to the output voltage setting falls with in the

normal range relative to

the voltage error alarm

setting.

NG: The monitor voltage error

relative to the output voltage setting indicates an

error relative to the voltage

error alarm setting.

Temperature error display

When a temperature error is

detected, "TEMP" flashes in reverse video.

GP-IB address

L

Key lock display

When the keys are

locked, flashes

in reverse video.

L

TEMP

TEMP

L

TEMP

TEMP

1.3 Screen Layout

1.3 Screen Layout

The LCD screen cons ists of two dis play pa ges. W hen th e SM78 60 i s turne d on,

page 1 is shown.

The scroll keys on th e front of the device (PA GE UP ▲/ PAG E D OW N▼) are

used to scroll among the di splay pages, which can also be selected directly by

sending the “

See: Message List "PAG" (p.30)

PAG” command from the GP-IB or RS-232C interface.

11

8

Install this device (p.3)

1

Rear PanelFront Panel

Turn the power on (p.15)

6

Connect the external interface

4

• Using the GP-IB or RS-232C interface

(p.17)

• Using the EXT I/O (p.33)

Connect the power cord (p.12)

2

Make device settings (p.16)

(via the external interface)

7

Connect the device to the measuring instrument. (p.13)

3

Be sure to complete the pre-operation inspection (p.14) before

using the device

5

Activate the power source

2

4

6

3

2.1 Installation & Connection Procedures

Preparing to Use the Device

and Supplying

Power Chapter 2

2.1 Installation & Connection Procedures

Be sure to read the "Operating Precautions" (p.3) befo re installing and connecting

this device.

12

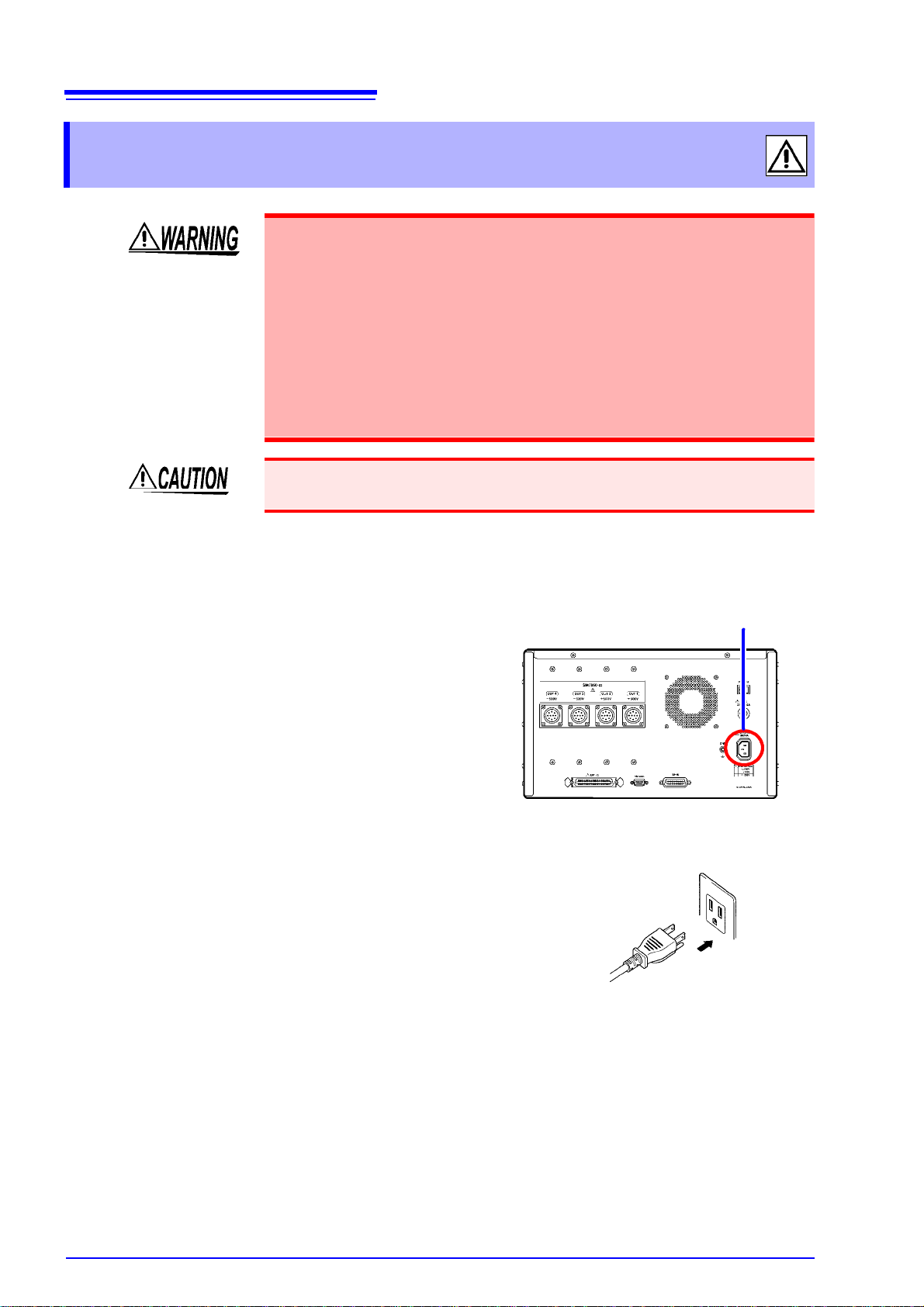

Rear Panel

1 Confirm that the device is turned off.

2 Confirm that the mains supply voltage

matches the device, and connect the

power cord to the power inlet on the

device.

3 Plug the power cord into the mains outlet.

Power inlet

2.2 Connecting the Power Cord

2.2 Connecting the Power Cord

• Before turning the device on, make sure the supply voltage matches that

indicated on its power connector . Connection to an improper supply voltage may damage the device and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety specific at ion s of

this device, connect the power cord only to a 3-contact (two-conductor +

ground) outlet.

• Before using the device, make sure that the insulation on the power cord

is undamaged and that no bare conductors are improperly exposed.

Using the device in such conditions could cause an electric shock, so

contact your dealer or Hioki representative for replacements.

To avoid damaging the po wer cord, grasp the plug, not the cord, wh en unplugging it from the power outlet.

Turn off the power before disconnecting the power cord.

Connection Methods

2.3 Connecting the Device to the Measuring Instrument

Rear Panel

1 Confirm that the device is turned off.

2 Connect the included voltage output con-

nector to the voltage output terminal on

the rear of the device.

Voltage output terminal

6 5 47

3

2

10

8

9

1

Voltage output pin assignments

(View of terminal on device)

*1 On the SM7860-05, -06, -2 5, an d - 26, ser v es as t he di s ch argin g

terminal.

*2 On the SM7860-05, -06, -07, -25, -26 and -27, serves as the dis-

charging terminal.

Pin No. OUT1

Circuit A

OUT2

*1

Circuit A

OUT3

Circuit B

OUT4

*2

Circuit B

1 CH1 CH1 CH1 CH1

2 CH2 CH2 CH2 CH2

3 CH3 CH3 CH3 CH3

4 CH4 CH4 CH4 CH4

5 CH5 CH5 CH5 CH5

6 CH6 CH6 CH6 CH6

7 CH7 CH7 CH7 CH7

8 CH8 CH8 CH8 CH8

9 NC NC NC NC

10 COM COM COM COM

2.3 Connecting the Device t o the Measuring

Instrument

To avoid electric shock or damage to the equ ipment, always observe the

following precautions when connecting to voltage output terminal.

• Always turn off the power to the device and to any dev ices to be con-

nected before connecting the voltage output connectors.

To avoid damaging the device, be sure to observe the following precautions:

• Do not connect the device to a load with a charge in exc ess of the output v oltage range.

• Do not connect the device to a load with a charge that has the opposite polarity

of the output voltage range.

• Do not connect the device to a load that has a charge when the device's power

supply is turned off.

13

Connection Methods

Specifications

14

Do not use a damaged cor d because

doing so may result in electric

shock. (Replace the cord with a new

one.)

Metal Exposed

• Is the power cord insulation torn, or is

any metal exposed?

• Is the connection cord insulation torn, or

is any metal exposed?

1

No Metal Exposed

Before using the device the fir st time, verify that it operates nor mally to ensure that the no

damage occurred during storage or shipping. If you find any damage, contact your dealer or

Hioki representative.

Peripheral Device Inspection

If damage is evident, request repairs.

Yes

Is damage to the device evident?

Device Inspecti on

2

No

Inspection complete

Please read the "Operating Precautions" (p.3) before use.

Use of a supply voltage outside the

specified range may damage the device or cause electric shock.

No

Does the supply voltage of your power

source match the supply voltage indicated

above the power source inlet on the rear of

the device?

Yes

2.4 Pre-Operation Inspection

2.4 Pre-Operation Inspection

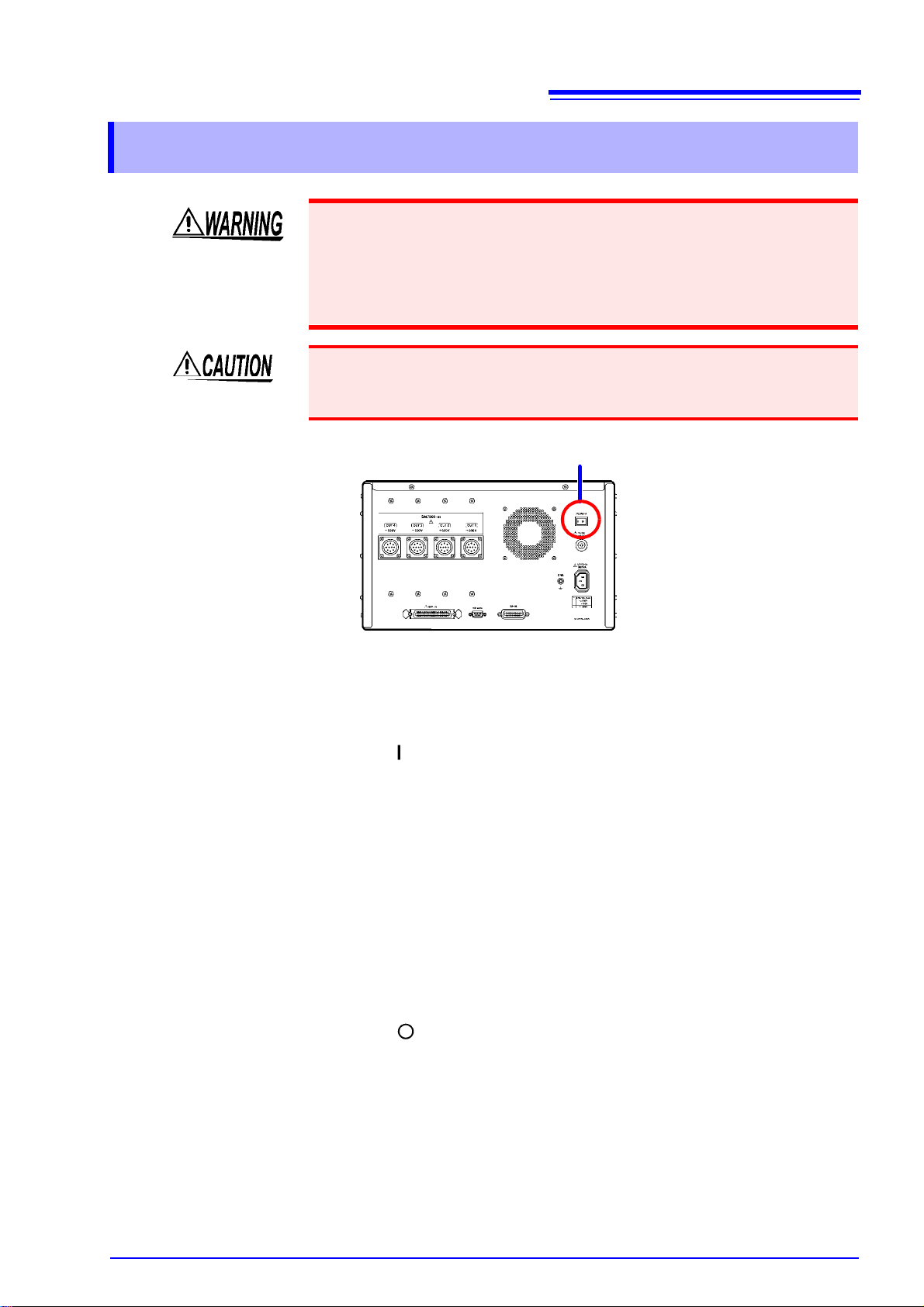

2.5 Turning the Power On and Off

Rear Panel

POWER switch

Turn the POWER switch on ( ).

The power indicator and LCD screen on the front of the device will light up.

Before Starting Measurement

To obtain precise measurements, provide about an hour warm-up after turning power on.

Turn the POWER switch off ( ).

2.5 Turning the Power On and Off

• Before turning the device on, make sure the supply voltage matches that

indicated on its power connector. Connection to an improper supply voltage may damage the device and present an electrical hazard.

• When turning the device on and off, do not touch the voltage output terminals. Doing so may cause electric shock.

When turning the device on and off, do not connect a load to the voltag e output

terminals. Tur ning the device o n or off with a l oad connected may damage the

load.

15

Turning Power On

Turning Power Off

16

2.6 Setting the Operating Conditions

2.6 Setting the Operating Conditions

This section describes how to set the operating conditions according to the manner in which the device is to be used.

Settings are configured via either of the device’s external interfaces:

See: GP-IB/RS-232C Interface (p.17)

The device cannot be configured directly in a standalone manner.

Setting function Description of operation and settings See page

Output voltage

Voltage error alarm

LCD display mode

Sets the output volta ge.

Setup ranges: 1.0 to 1000.0 V (0.1 V resolution)

Generates an alarm when the monitor voltage error relative to the output

voltage setting falls outside the set value range.

Setup ranges: ±2 to ±19% (1% resolution)

Turns the LCD dis play on and off.

[OFF/ ON]

p.29

p.29

p.30

17

Wiring Diagram ( p.19)

Connect the device and Controller with a GP-IB or RS-232C

Interface Cable

Communications Protocol Settings

Enter a GP-IB address.

Set the device to the same

communications protocol as

the controller

Set the transmission format.

3.1 Overview and Features

Communication

(GP-IB/RS-232C Interface) Chapter 3

The symbol shown below in dicates that the following ins tructions are sp ecific to

the RS-232C or the GP -IB interface. Instructio ns without these symbo ls are for

both the RS-232C and the GP-IB interface.

: GP-IB only

: RS-232C only

Before Use • Always make use of the connector screws to affix the GP-IB or RS-232C con-

nectors.

• When issuing commands tha t contain data, make certain tha t the data is pro-

vided in the specified format.

3.1 Overview and Features

The device provides standard communication fun ctionality in the form of GP-IB

and RS-232C interfaces, both of which can be used to control the device

remotely and to transfer data.

• This device is designed with reference to the following standard:

Reference standard IEEE 488.1-1987

18

3.2 Specifications

3.2 Specifications

Precautions

RS-232C and GP-IB communications cannot be used simultaneously.

GP-IB Specifica-

tions

Electrical machinery specifications: IEEE std. 488.1-1987 compliant

Address setting : Can be set to talker/listener addresses 1 to 30.

Interface Functions

SH1 All Source Handshake functions ●

AH1 All Acceptor Handshake functions ●

T6 Basic talker functions

Serial poll function

Talk-only mode

The talker cancel function with MLA (My Listen Address)

L4 Basic listener functions

Listen-only mode

The listener cancel function with MTA (My Talk Address)

SR1 All Service Request functions ●

RL1 All Remote/Local functions ●

PP0 Parallel Poll function −

DC1 All Device Clear functions ●

DT1 All Device Trigger functions ●

C0 Controller functions −

E2 Tri-state output

Operating Code: ASCII codes

●

●

−

●

●

−

●

RS-232C Specifica-

tions

Transfer method Communications: Full duplex

Synchron ization: Start-stop synchronization

Baud rate 38400 bps

Data length 8 bits

Parity none

Stop bit 1 bit

Flow control none

Electrical specification Input voltage levels 5 to 15 V : ON

-15 to -5 V : OFF

Output voltage levels +5 V or more : ON

-5 V or less : OFF

Connector RS-232C Interface Connector Pinout

(Male 9-pin D-sub, with #4-40 attachment screws)

The I/O connector is a DTE (Data Terminal Equipment)

configuration

Recommended cables:

• Model 9637 RS-232C Cable

• Model 9638 RS-232C Cable

See: "3.3 Connect a cable to the GP-IB connector or

RS-232C connector" (p.19)

Operating Code: ASCII codes

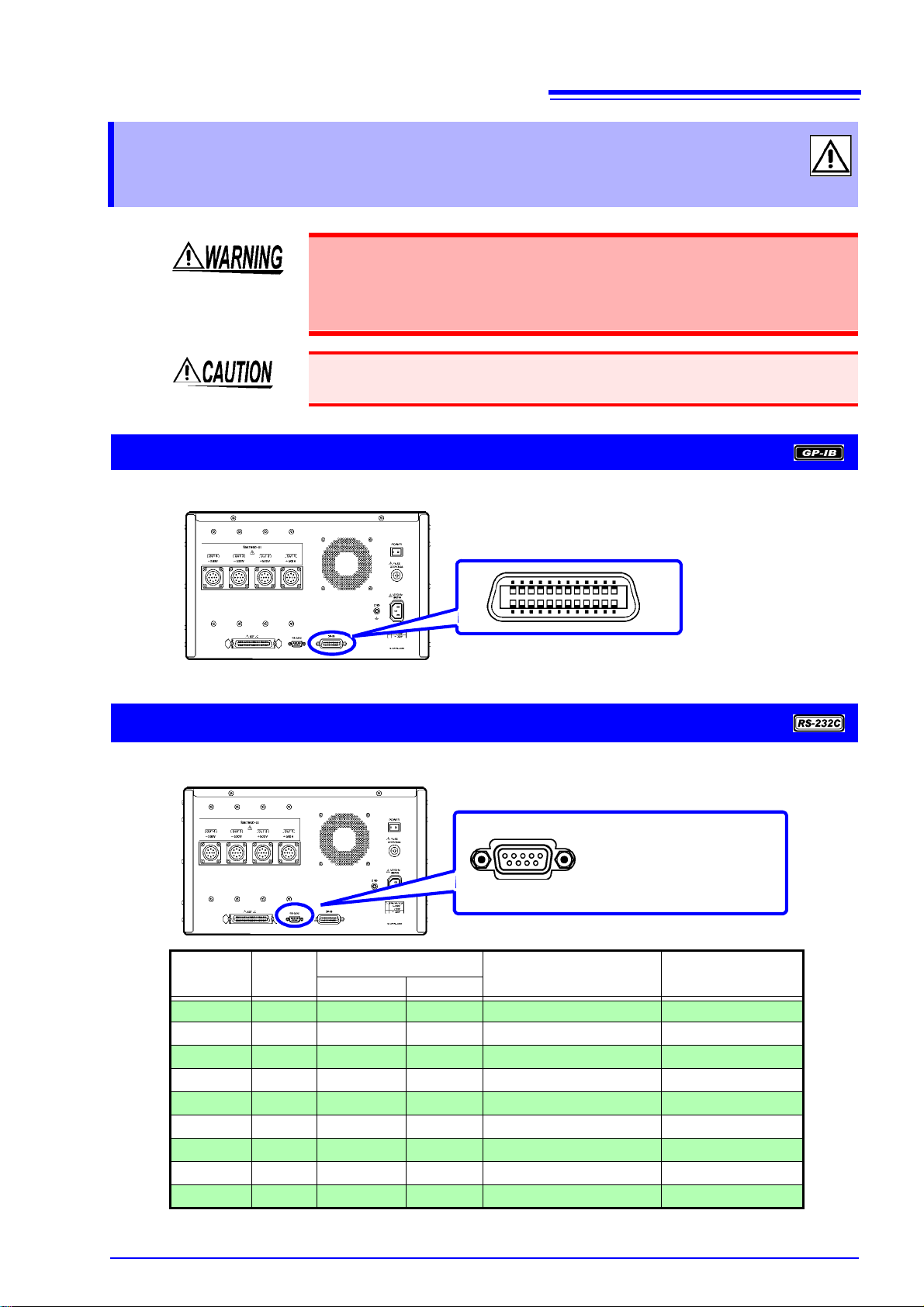

3.3 Connect a cable to the GP-IB connector or RS-232C connector

Rear Panel

Recommended cable:

HIOKI Model 9151-02 GP-IB Connector Cable (2 m)

6 7 8 9

1 2 3 4 5

Rear Panel

Male 9-pin D-sub

#4-40 attaching screws

3.3 Connect a cable to the GP-IB

connector or RS-232C connector

• Always turn both devices OFF when connecting and disconnecting an

interface connector. Otherwise, an electric shock accident may occur.

• Failure to fasten the connect ors properly may re sult is sub-spe cification

performance or damage to the equipment.

To avoid damage to the device, do not short-circuit the terminal and do not input

voltage to the terminal.

Using the GP-IB Interface

Connect the GP-IB cable to the GP-IB connector.

19

Using the RS-232C Interface

Connect the RS-232C cable to the RS-232C connector.

Pin No.

1 DCD CF CD

2 RXD BB RD

3 TXD BA SD

4DTRCD ER

5 GND AB SG

6DSRCC DR

7 RTS CA RS

8 CTS CB CS

9 RI CE CI

Signal

Name

Code Addr.

EIA JIS

Mutual connection

circuit name

Carrier Detect Not used

Receive Data

Transm it Data

Data Terminal Ready Not used

Signal Ground

Data Set Ready Not used

Request to Send Not used

Clear to Send Not used

Ring Indicator Not used

Remarks

20

Recommended cable:

HIOKI

Model 9637 RS-232C

Cable (1.8 m)

Crossover Wiring

Female 9-pin

D-sub

Model SM7860

end

Female 9-pin

D-sub

PC/AT-end

Pin No. Pin No.

DCD 1 1 DCD

RxD 2 2 RxD

TxD 3 3 TxD

DTR 4 4 DTR

GND 5 5 GND

DSR 6 6 DSR

RTS 7 7 RTS

CTS 8 8 CTS

RI 9 9 RI

3.3 Connect a cable to the GP-IB connector or RS-232C connector

When connecting the device to a computer

Use a crossover cable with female 9-pin D-sub connectors.

3.4 Configuring the Communications Protocol

1 Press and hold the scroll keys (PAG E U P▲/PA GE D O WN ▼) on the front of the device

for about 7 seconds. (The address can be set from the P1 or P2 screen.)

■ Screen P1: Status display

3 When finished making the setting, turn off the device.

4 Turn on the device.

The device will revert to the initial screen, and the GP-IB address will be set to the

selected address.

GPIB ADDR: 1

VA (+) IR:1000.0

VB (+) IR: 250.0

TERMINAL:

OUT1:11100000

OUT2:11100000

OUT3:11100000

OUT4:11100000 VMA:1000.0 OK

VMB: 250.0 OK

2 Using the scroll keys (PAGE UP▲/PAGE DOWN▼), set the desired address.

(Valid setting range: 1 to 30)

3.4 Configuring the Communications Protocol

Configuring GP-IB Interface Communications

Setting the address

21

Configuring RS-232C Interface Communications

Communication conditions

Baud rate 38400 bps

Parity none

Stop bit 1 bit

Data 8 bits

Flow control none

Remote switching requests

Send the “RMT” command from the RS-232C interface.

RS-232C interface communications will not be available until the “RMT” com-

mand is sent.

22

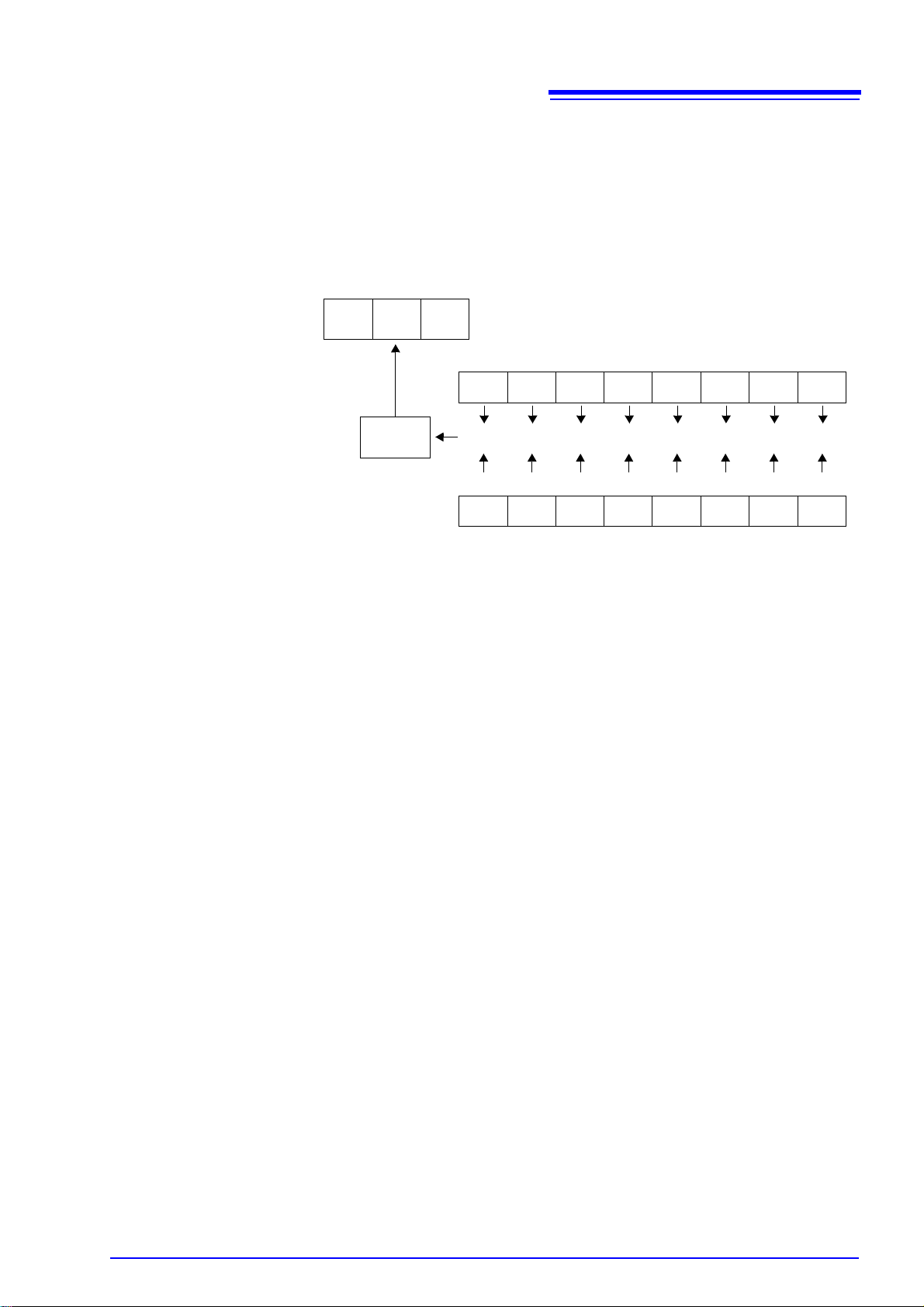

Program Messages

Response Messages

SM7860

Program Messages

Messages

Command Message

Query Message

Response Message

Controller

Message types are further categorized as follows

When issuing commands that contain data, make certain that the data is provided in the specified format.

3.5 Communication Methods

3.5 Communication Methods

Various messages are supported for controlling the device through the interfaces.

Messages can be either program messages, sent from the controller such as PC to the

device, or response messages, sent from the device to the controller.

Program Messages

1. Command Messages and Query Messages

(1) Command Messages

Commands that control the device, for example to configure settings or reset the

device.

(2) Query Messages

Requests for respon ses relating to result s of operation or me asurement, or the

state of device settings.

Query commands end with a question (

2. Message delimiter (terminator)

This device recognizes the following input message delimiters:

CR+LR with EOI

LF with EOI

CR with EOI

EOI

CR+LF

LF

?) mark.

Response Messages

1. Response Messages

When a query messag e is recei ved, its s yntax is c hecked and a r espons e message is generated.

2. Message delimiter (terminator)

The following three response message delimiters can be specified with the

“

DLM” command:

LF (initial setting)

CR+LF

EOI

Separators

1. Message Unit Separator

Multiple messag e can be writte n in on e line by se parati ng them wi th semicol ons

“

; ”

2. Header Separator

In a message consisting of both a header and data, the header is separated from

the data by a space “ ” (ASCII code 20H).

3. Data Separator

In a message containing mu ltiple data items, commas are required to separate

the data items from one another.

Data Formats

Query messages use the formats outlined in Table 1. The format is selected

according to the command.

23

3.5 Communication Methods

Table 1: Response Messages and Parameter Data Types

Data

type

NR1 Integer 0, 1, 2, 3, etc. Parameter settings, etc.

NR2

NR3

ASCII ASCII string XXXXXXXXXXXXXXXX Primarily hardware IDs

Description Example Notes

Fixed-point decimal number

Floating-point decimal number

+12.345, 400.0, etc. Primarily settings

+1.234±50, etc.

Primarily settings and measured values

24

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

ERR

RQS

ESB MAV DSB

unused unused

unused

MSS

& &&&&&&

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

ERR x ESB MAV DSB

unused unused

unused

Logical

sum

Status Byte

Register (STB)

Service Request Enable

Register (SRER)

Service Request

occurrence

Output Queue data information

Stand ard Event Register Information

Each of these bits corresponds to a specific event register

Overview of Service Request Occurrence

3.5 Communication Methods

Status Byte Register

RS-232C reads the status bytes to find out the status of the device.

The device adopts th e IE E E48 8.1 -1987 def ined status model for parts related to

the serial polling performed by the service request function. A trigger for

generating a service request is called an event.

The Status Byte Register contains information about the event registers and the

output queue. Required items are selected from this information by masking with

the Service Request Enable Register. When any bit selected by the mask is set,

bit 6 (MSS; the Master Summary Status) of the Status Byte Register is also set,

which generates an SRQ (Service Request) message and dispatches a service

request.

For RS-232C, bit 4 (MAV message available) of the status byte register is not

set.

25

3.5 Communication Methods

Status Byte Register (STB)_______________________________________

A status byte register is an 8-bit register output from the unit to the controller

during serial polling. If even one of the status byte register bits enabled by the

service request enable register changes from "0" to "1" the MSS bit becomes 1.

At the same time, the RQS bit also becomes "1" and a service request is

generated.

The RQS bit is always synchronized with the service request and only read and

simultaneously cleared upon being serial polled. The MSS bit is only read by an

"

*STB?" query and is not cleared until the event is cleared by a command such

as a "

*CLS" command.

Bit 7 ERR

Bit 6 RQS

MSS

Bit 5 ESB

Bit 4 MAV

Bit 3 DSB

Bit 2 −

Bit 1 −

Bit 0 −

Unrecoverable error

Set to 1 when a service request is dispatched.

This is the logical sum of the other bits of the Status Byte Regis-

ter.

Standard Event Status (logical sum) bit

This is logical sum of the St andard Event Status Register.

Message available

Indicates that a message is present in the output queue.

Event Status (logical sum) bit

This is the logical sum of Event Status Register.

unused

unused

unused

Service Request Enable Register (SRER)___________________________

This register masks the Status Byte Register. Setting a bit of this register to 1

enables the corresponding bit of the Status Byte Register to be used.

26

3.5 Communication Methods

Event Registers

Standard Event Status Register (SESR)____________________________

A standard event status register is an 8-bit register.

If any bit in the Standard Event Status Register is set to 1 (after masking by the

Standard Event Status Enable Register), bit 5 (ESB) of the Status Byte Register

is set to 1.

See: "Standard Event Status Enable Register (SESER)" (p.27)

The standard event status register is cleared at the following times:

• When a "

• When a "

• When the device is powered on

*CLS" command is executed

ERR?" command is executed

Bit 7 PON

Bit 6 URQ

Bit 5 CME

Bit 4 EXE

Bit 3 DDE

Bit 2 QYE

Bit 1 RQC

Bit 0 OPC

Power-On Flag

Set to 1 when the power is turned on, or upon recovery from an outage.

User Request

unused

Command error (The command to the message terminator is ignored.)

This bit is set to 1 when a recei ved command contains a sy ntactic or sema ntic

error:

• Program header error

• Incorrect number of data parameters

• Invalid parameter format

• Received a command not supported by the device

Execution Error

This bit is set to 1 when a received command cannot be executed for some

reason.

• The specified data value is outside of the set range

• The specified setting data cannot be set

• Execution is prevented by some other operation being performed

Device-Dependent Error

This bit is set to 1 when a comm and ca nnot be ex ecute d due to some reason

other than a command error, a query error or an execution error.

• When the command cannot be executed because there is an internal

anomaly

Query Error (the output queue is cleared)

This bit is set to 1 when a q uery erro r is detected by the co ntroller of th e output

queue.

• When an attempt has been made to read an empty output queue (GP-IB

only)

• When the data overflows the output queue

• When data in the output queue has been lost

Request Control

unused

Operation Complete

This bit is set to 1 in response to an "

• It indicates the com pletio n of operati ons of all mess ages up to th e "*OPC"

command

*OPC" command.

27

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

PON URQ CME EXE DDE QYE RQC OPC

&&&&&&&&

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

PON URQ CME EXE DDE QYE RQC OPC

Standard Event Status Register (SESR)

Standard Event Status Enable Register (SESER)

bit 6bit 5bit 4

SRQ

MSS

ESB MAV

Logical

sum

3.5 Communication Methods

Standar d Event Status Enable Register (SESER) ____________________

Setting any bit of the Standard Event Status Enable Register to 1 enables access

to the corresponding bit of the Standard Event Status Register.

Standard Event Status Register (SESR) and Standard Event Status Enable

Register (SESER)

28

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

− MLE

HDE DFE DRE CNE ISE BDE

Error Register

PON URQ CME EXE DDE QYE RQC OPC

Standard Event Status Register

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

MLE: Message Length Error HDE: Header Error

DFE: Data Format Error DRE: Data Range Error

CNE: Can Not Execute ISE: Internal communication Error

BDE: Environment Backup was Damaged (RAM)

Error Register structure

3.5 Communication Methods

Error Registers

The Error Register, which consists of 8 bits, manages error information. The

contents of this register are aggregated in the CME, EXE, DDE, and QYE bits of

the Standard Event Status Register (no mask processing is performed).

Error register-related message are listed below.

*CLS

Clears the following registers:

• Status Byte Register

• Standard Event Status Register

• Error Register

ERR?

Queries and clears the Error Register.

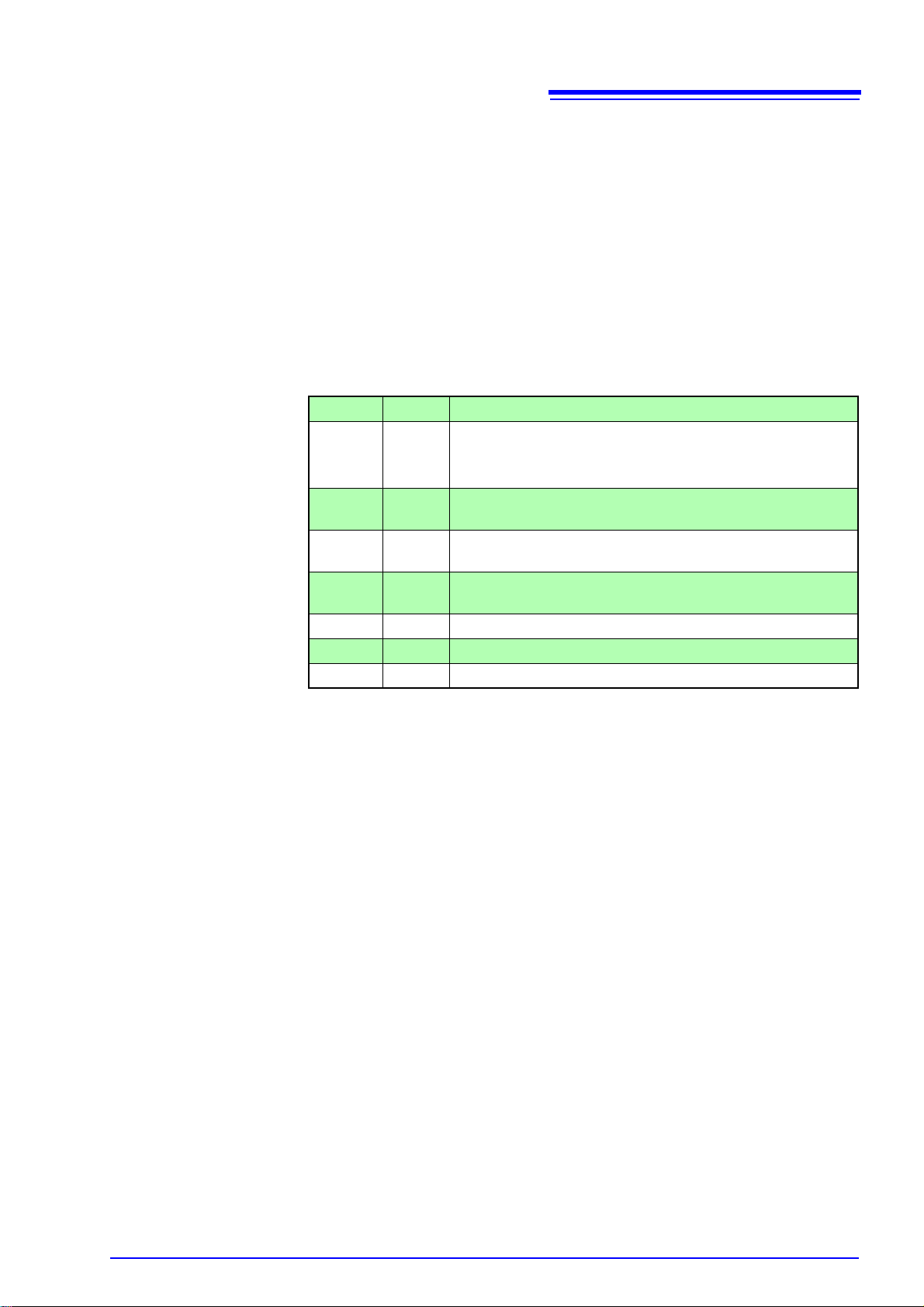

Bit No. Name Event/status indicated by set bit

Bit 7 −

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

MLE

HDE

DFE

DRE

CNE

ISE

BDE

Unused

Message Length Error

Set when the message length exceeds the allowable range.

The bit is reset after the register is read.

Message Header Error

Set when an unrecognizable message header is received.

The bit is reset after the register is read.

Data Format Error

Set when the number of parameters exceeds the stipulated number or

when there is an unrecognizable parameter.

The bit is reset after the register is read.

Data Range Error

Set when a parameter falls outside the stipulated range.

The bit is reset after the register is read.

Unexecutable command

Set when an unexecutable command is received.

The bit is reset after the register is read.

Internal communication Error

Set when an internal communication error occurs.

The bit is reset after the register is read.

Environment Backup was Damaged

Set when data stored in the instrument's backup RAM is corrupted.

The bit is reset after the register is read.

3.6 Message List

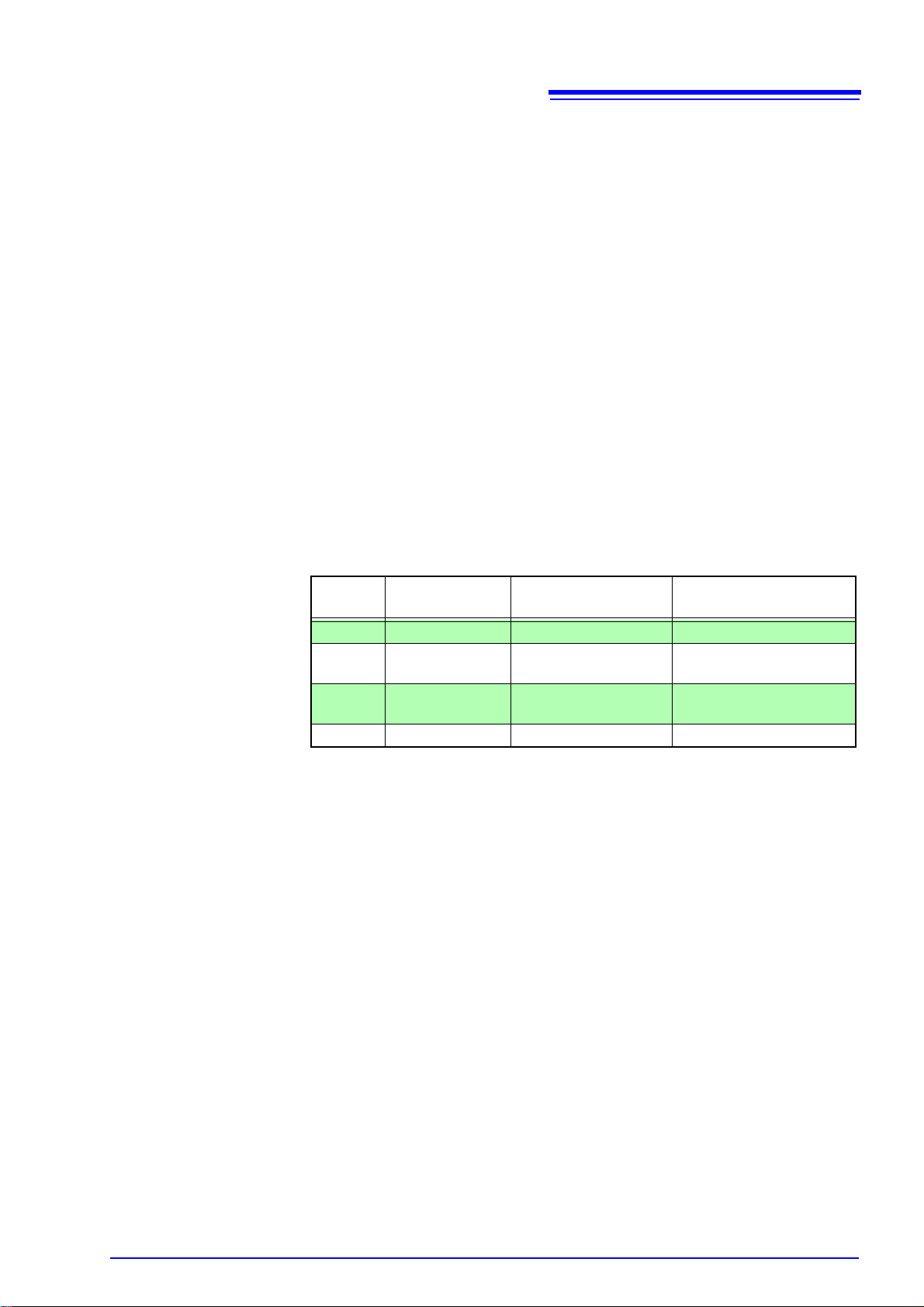

Model Lower limit (V) Uppe r limit (V)

SM7860-01, -21 1.0 500.0

SM7860-02, -22 250.0 1000.0

SM7860-03, -23 1.0 500.0

SM7860-04, -24 250.0 1000.0

SM7860-05, -25 1.0 500.0

SM7860-06, -26 250.0 1000.0

SM7860-07, -27 1.0 10.0

3.6 Message List

RS-232C-only commands are indicated by .

When using the RS -232C interface to send com mands, include a unifor m wait

time of 100 ms (excluding the following exceptions).

Command Description Formats

Communication conditions

RMT

Remote switching request

Delimiter

DLM

DLM?

Talker delimiter specification

d1 (delimiter specification: 0 to 2)

0: LF<EOI> Default

1: CRLF<EOI>

2: <EOI>

Note: This setting reverts to it s defa ul t v alu e when th e instrument

Delimiter query

The contents of responses are the same as the settings.

Output voltage setting

VAI

VAI?

VBI

VBI?

Circuit A output voltage setting

d1: 1.0 to 1000.0 V

Note: Set as an absolute value.

Circuit A output voltage setting query

The contents of responses are the same as the settings.

Circuit B output voltage setting

d1: 1.0 to 1000.0 V

Note: Set as an absolute value.

Circuit B output voltage setting query

The contents of responses are the same as the settings.

Output voltage sett ing range by mo del

is powered on. A combination CR+LF is used as the RS232C delimiter for both data transmission and reception.

The valid setting range varies with the model.

The valid setting range varies with the model.

[Format] RMT

[Format] DLM d1

[Format] DLM?

[Response] d1

[Format] VAI d1

[Format] VAI?

[Response] d1

[Format] VBI d1

[Format] VBI?

[Response] d1

29

d1: NR1 format

d1: NR2 format

d1: NR2 format

Alarm setting

ARM

ARM?

Voltage error alarm setting

d1: 2 to 19%, Circuit A voltage error alarm setting

d2: 2 to 19%, Circuit B voltage error alarm setting

Note: d1 or d2 can be omitted.

Volt age error alarm setting query

The contents of responses are the same as the settings.

[Format] ARM d1,d2

ARM d1

ARM ,d2

[Format] ARM?

[Response] d1,d2

30

3.6 Message List

Command Description Formats

Voltage monitor

VMA?

VMB?

LCD display mode

LCD

LCD?

PAG

Error information

ERR?

Others

*RST

*IDN?

*SAV

*RCL

*CLS

*SRE

*SRE?

Circuit A power supply voltage monitor value query [Format] VMA?

[Response] d1: NR2 format

Circuit B power supply voltage monitor value query [Format] VMB?

[Response] d1: NR2 format

LCD display mode setting

d1 (Display mode: 0 to 1)

0: OFF (Display off)

1: ON (Display on)

LCD display mode query

The contents of responses are the same as the settings.

LCD display page specification

d1 (Page number: 0 to 1)

0: Output voltage setting, monitor voltage value, channel-spe-

cific output setting state

1: Alarm setting, GP-IB address

Error information query

d1 (Error information: 0 to 127)

Note: Error information is cleared when the response is output.

Device initialization

Initializes all settings to their factory values.

Device operation will be stopped.

Hardware ID query

Returns the device’s hard ware ID as the respo ns e.

d1 (HIOKI, SM7860-XX, 0, 01.00)

Note: The SM7860-2X is shown as "SM7860-0X."

Save environmental data

(output voltage setting and alarm setting)

d1 (Environmental data no.: 0 to 3)

Recall environmental data

(output voltage setting and alarm setting)

d1 (Environmental data no.: 0 to 3)

Clear status register

Sets the service request enable register.

d1 (0 to 255)

Service request enable register query

d1 (0 to 63, 128 to 191)

[Format] LCD d1

[Format] LCD?

[Response] d1: NR1 format

[Format] PAG d1

[Format] ERR?

[Response] d1: NR1 format

[Format] *RST

[Format] *IDN?

[Response] d1: String

[Format] *SAV d1

[Format] *RCL d1

[Format] *CLS

[Format] *SRE d1

[Format] *SRE?

[Response] d1: NR1 format

d1: NR1 format

d1: NR1 format

d1: NR1 format

d1: NR1 format

d1: NR1 format

*STB?

*ESE

*ESE?

*ESR?

Note: Bit 6 is not set by

Status byte register query

d1 (0 to 255)

Sets the standard event status enable register.

d1 (0 to 255)

Standard event status enable register query

The contents of responses are the same as the settings.

Standard event status register query

d1 (0 to 255)

*SRE.

[Format] *STB?

[Response] d1: NR1 format

[Format] *ESE d1

d1: NR1 format

[Format] *ESE?

[Response] d1: NR1 format

[Format] *ESR?

[Response] d1: NR1 format

3.6 Message List

Command Description Formats

*OPC

*OPC?

CNF

CNF?

KLC

KLC?

Sets the standard event status register’s OPC bit after all ongoing

operations have completed.

This command is used to detect the compl etion of comman ds that

involve time-consuming processing.

Returns the value 1 when all ongoing operations have completed.

d1: 1

Operating environment se ttin g

d1 (Interlock control enable/disable: 0 to 1)

0: CONNECT (Enables interlock.)

1: CUTOFF (Disables interlock.) Default

Operating environment que ry

The contents of responses are the same as the settings.

Key lock setting

d1 (0 to 1)

0: Key lock off

1: Key lock on

Key lock query

d1 (0 to 1)

The contents of responses are the same as the settings.

[Format] *OPC

[Format] *OPC?

[Response] d1: NR1 format

[Format] CNF d1

[Format] CNF?

[Response] d1

[Format] KLC d1

[Format] KLC?

[Response] d1: NR1 format

31

d1: NR1 format

d1: NR1 format

32

3.7 Listener Specification Precautions

3.7 Listener Specification Precautions

Input buffer size

Multiple command messages can be transferred at once by joining them with

message separators. Since the instrument provides an 128-byte input buffer, the

instrument is unabl e to receive message str ings in excess of 127 cha racters in

length. In this case, the entire command will be ignored (discarded), and the

Error Register's MLE (Message Length Error) bit will be set.

Reading from the output buffer

The output buffer us es a FIFO design, with old er data being read first. Consequently, the read value may diffe r from the expe cte d va lue under ce rta in circ umstances, for example if no response is acquired after issuing a query.

Additionally, the o utpu t b uffe r is 511 b yte s i n s i ze. If d ata in excess of 511 by tes

is written to the buffer , it will be di scarded, and the Error Registe r's QY E (Que ry

Error) bit will be set.

33

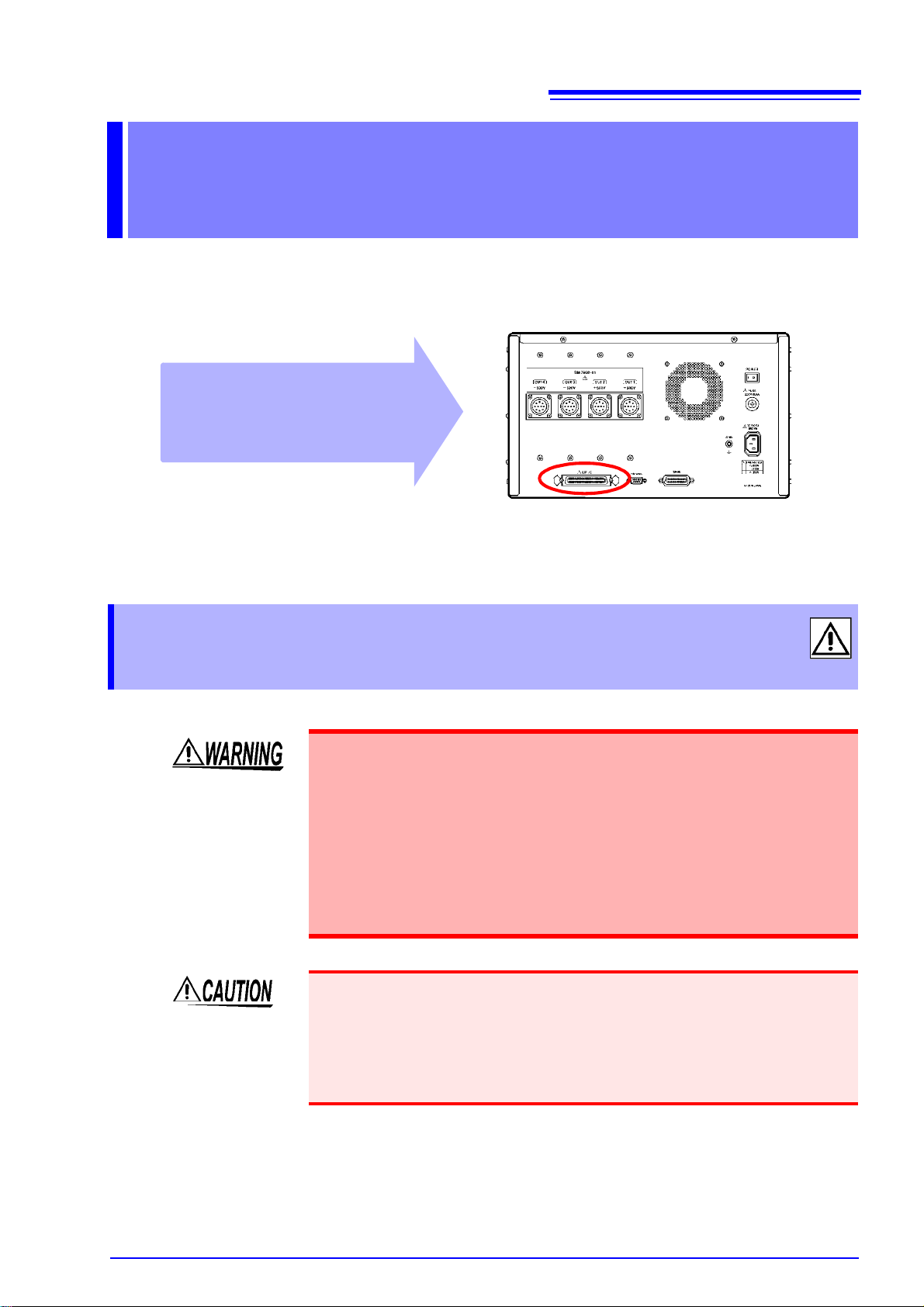

Connect the device’s EXT I/O

connector to the signal output

or input device.

Rear Panel

4.1 External Input/Output Connector and Signals

External Control Chapter 4

This chapter describes how to use the EXT I/O connector on the rear of the

device to control the device.

4.1 External Input/Output Connector and

Signals

To avoid electric shock or damage to the equ ipment, always observe the

following precautions when connecting to the EXT I/O connector.

• Always turn off the power to the device and to any dev ices to be con-

nected before making connections.

• During operation, a wire becoming dislocated and contacting another

conductive object can be serious hazard. Ensure that the cable is

securely attached to the EXT I/O connector.

• Ensure that devices and systems to be connected to the EXT I/O connec-

tor are properly isolated.

To avoid damage to the device, observe the following cautions:

• Do not apply voltage or current to the EXT I/O connector that exceeds their ratings.

• When driving relay s, be sure to ins tall diodes to abso rb counter-elec tromotive

force.

See: "Connector Type and Signal Pinouts" (p.34)

34

EXT I/O connector

Connector

• 57RE-40500-730B (50-pin: DDK)

Rear Panel

252423222120191817161514

1312111098765432

1

50494847464544434241403938373635343332313029282726

4.1 External Input/Output Connector and Signals

Connector Type and Signal Pinouts

Pin Signal name I/O Pin Signal name I/O

1 COM - 26 COM 2 EXT_DCV2(+24V)

3 OUTPUT

4 OUT1(1)_ON

5 OUT1(3)_ON

6 OUT1(5)_ON

7 OUT1(7)_ON

8 OUT2(1)_ON

9 OUT2(3)_ON

10 OUT2(5)_ON

11 OUT2(7)_ON

12 OUT3(1)_ON

13 OUT3(3)_ON

14 OUT3(5)_ON

15 OUT3(7)_ON

16 OUT4(1)_ON

17 OUT4(3)_ON

18 OUT4(5)_ON

19 OUT4(7)_ON

20

21

22

23

(Reserved)

(Reserved)

(Reserved)

(Reserved)

24 ALARM

25 TEMP

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Output

Output

27 EXT_DCV2(+24V)

28 INTERLOCK

29 OUT1(2)_ON

30 OUT1(4)_ON

31 OUT1(6)_ON

32 OUT1(8)_ON

33 OUT2(2)_ON

34 OUT2(4)_ON

35 OUT2(6)_ON

36 OUT2(8)_ON

37 OUT3(2)_ON

38 OUT3(4)_ON

39 OUT3(6)_ON

40 OUT3(8)_ON

41 OUT4(2)_ON

42 OUT4(4)_ON

43 OUT4(6)_ON

44 OUT4(8)_ON

45

46

47

48

(Reserved)

(Reserved)

(Reserved)

(Reserved)

49 BUSY

50

(Reserved)

Output

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Do not connect to reserved pins.

4.1 External Input/Output Connector and Signals

Signal Descriptions

Input Signals

EXT_DCV2(+24V) External power source input

OUTPUT Output on/off setting

OUT 1(1)_ON to OUT 1(8)_ON Channel-specific on/off settin g

OUT 2(1)_ON to OUT 2(8)_ON Channel-specific on/off settin g

OUT 3(1)_ON to OUT 3(8)_ON Channel-specific on/off settin g

OUT 4(1)_ON to OUT 4(8)_ON Channel-specific on/off settin g

INTERLOCK When on, no volt ag e can be generated.

•The INTERLOCK signal cannot be used unl ess it has been enabled with the

operating environ ment s etting (CNF =0). The devi ce s hips with this settin g disabled (CNF=1).

See: Message List "CNF" (p.31)

35

• The output voltage cannot be changed while the OUTPUT

Output Signals

ALARM Generated voltage alarm

BUSY Voltage being output

TEMP Temperature alarm

signal is enabled.

36

OUTPUT

BUSY

t1

Pre v ious ALARM r es u lt

ALARM

OUT1 (CH1) to (CH8)

OUT2 (CH1) to (CH8)

OUT3 (CH1) to (CH8)

Volt age out put * 1

New ALARM resu lt

t2

t5

t6

t4

t9

t3 t7

t8

t11t10

High-impedance

Discharge

OUT2 (CH1) to (CH8)

OUT4 (CH1) to (CH8)

Discharge*3

OUT1(1)_ON to (8)_ON

OUT2(1)_ON to (8)_ON

OUT3(1)_ON to (8)_ON

OUT4(1)_ON to (8)_ON

OUT3 (CH1) to (CH8)

OUT4 (CH1) to (CH8)

Volt age out pu t *2

High-impedance

High-impedance

High-impedance

High-impedance

High-impedance

External output terminal

Voltage output terminal

*1 to *3 vary with the model.

*1: SM7860-01, -02, -21, 22 : OUT1

SM7860-03, 04, 05, 06, -23, 24, 25, 26 : OUT1 to OUT2

SM7860-07, -27 : OUT1 to OUT3

*2: SM7860-01, 02, 05, 06, -21, 22, 25, 26 : OUT3

SM7860-03, 04, -23, 24 : OUT3 to OUT4

*3: SM7860-05, 06, -25, 26 : OUT2, OUT4

SM7860-07, -27 : OUT4

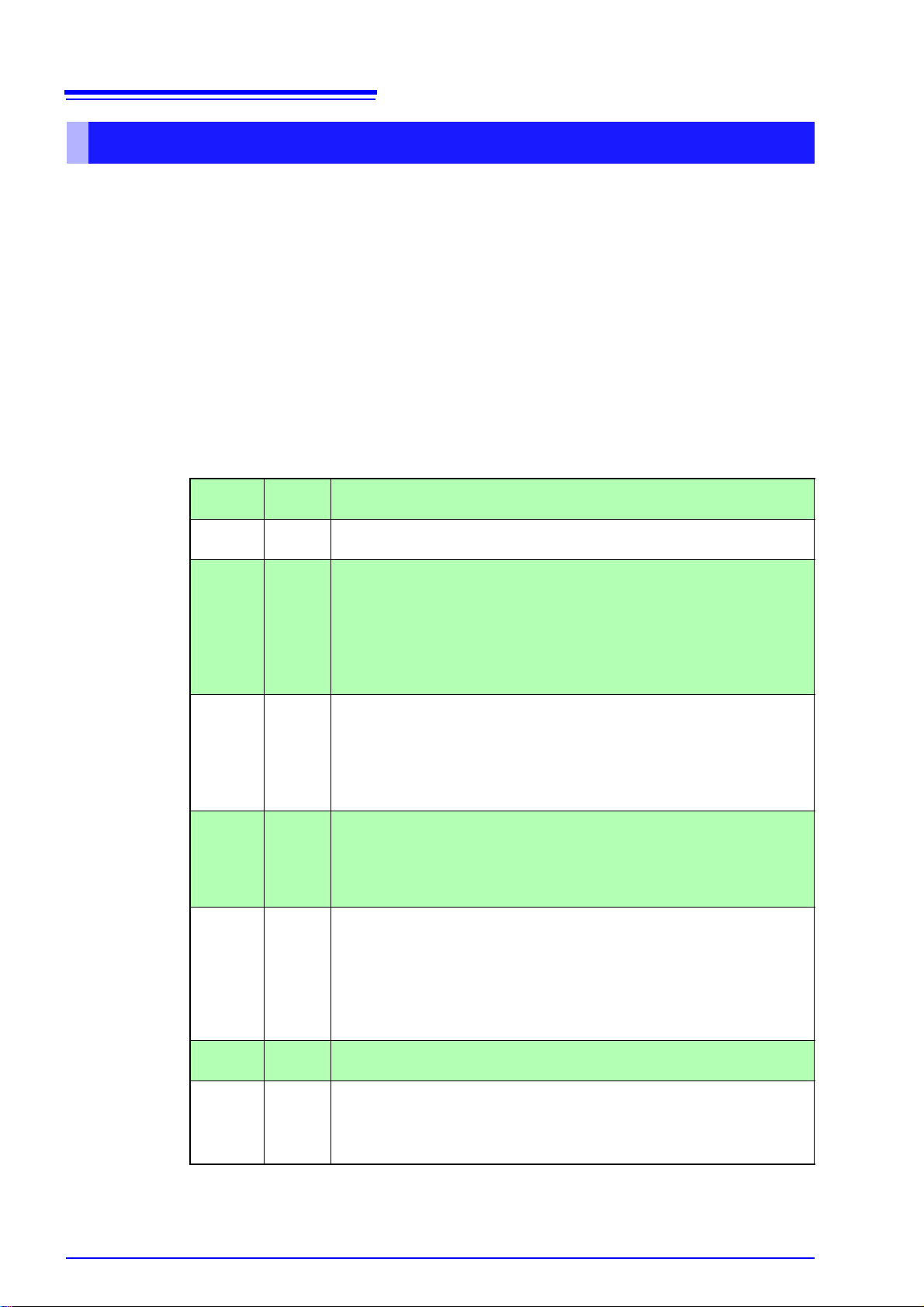

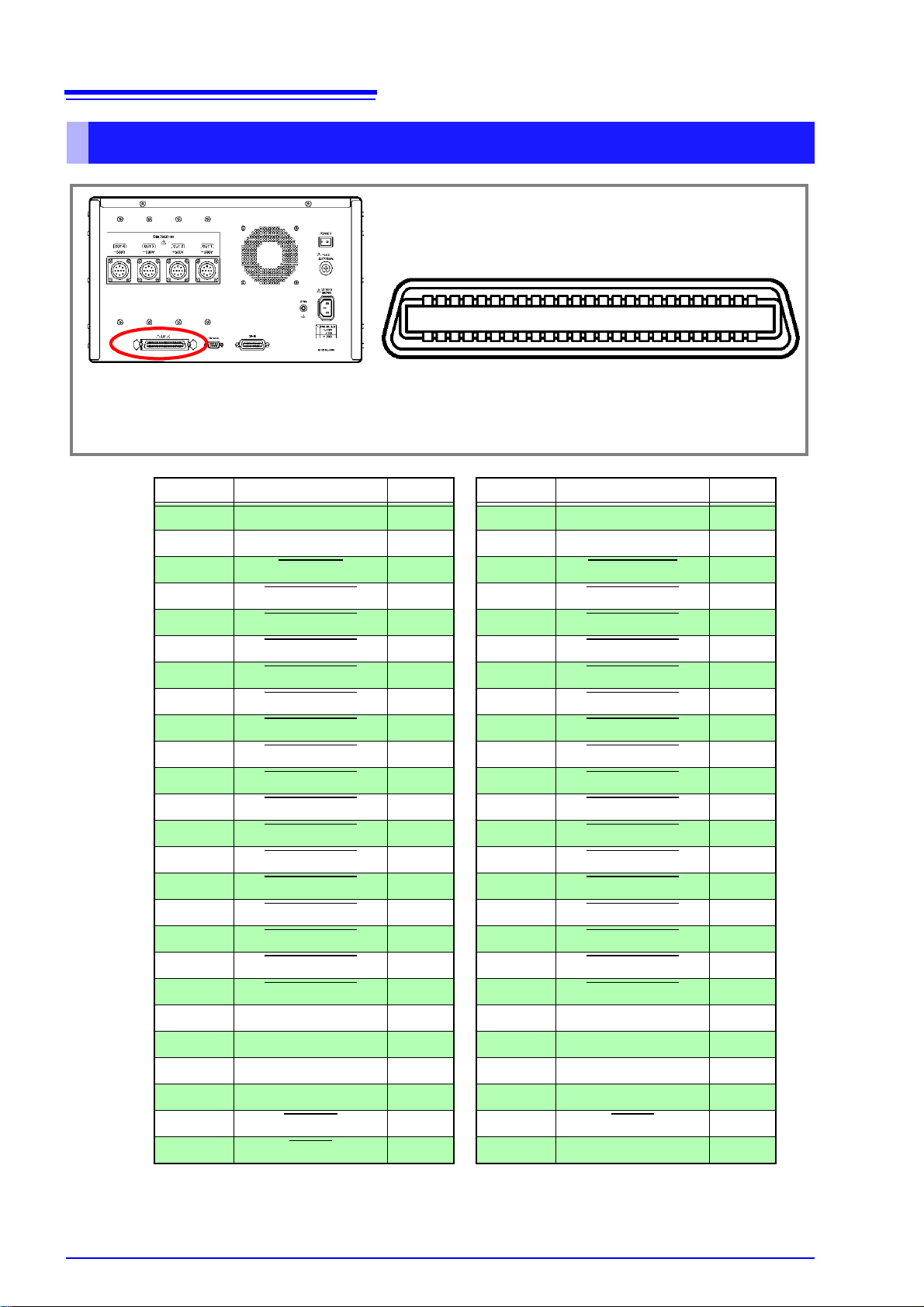

4.2 Timing Chart

4.2 Timing Chart

Each signal level indicates a corresponding voltage level.

Timing Chart Interval Descriptions

Interval Description Duration

Channel setup time 100 μs or more

t1

Channel hold time 200 μs or more

t2

t3

t4

t5

t6

t7

t8

t9

t10

t11

OUTPUT ON → Busy delay time

OUTPUT ON → Voltage output delay time

Alarm delay time 3.5 ms or less

Output pulse width 8 ms or more

OUTPUT OFF → Busy delay time

OUTPUT OFF → Voltage output delay time

Output off time 4 ms or more

OUTPUT ON → Discharging start delay time

OUTPUT OFF → Discharging complete delay time

200 μs or less

600

μs or less

800 μs or less

2.5 ms or less

1.2 ms or less

1.1 ms or less

37

4.2 Timing Chart

38

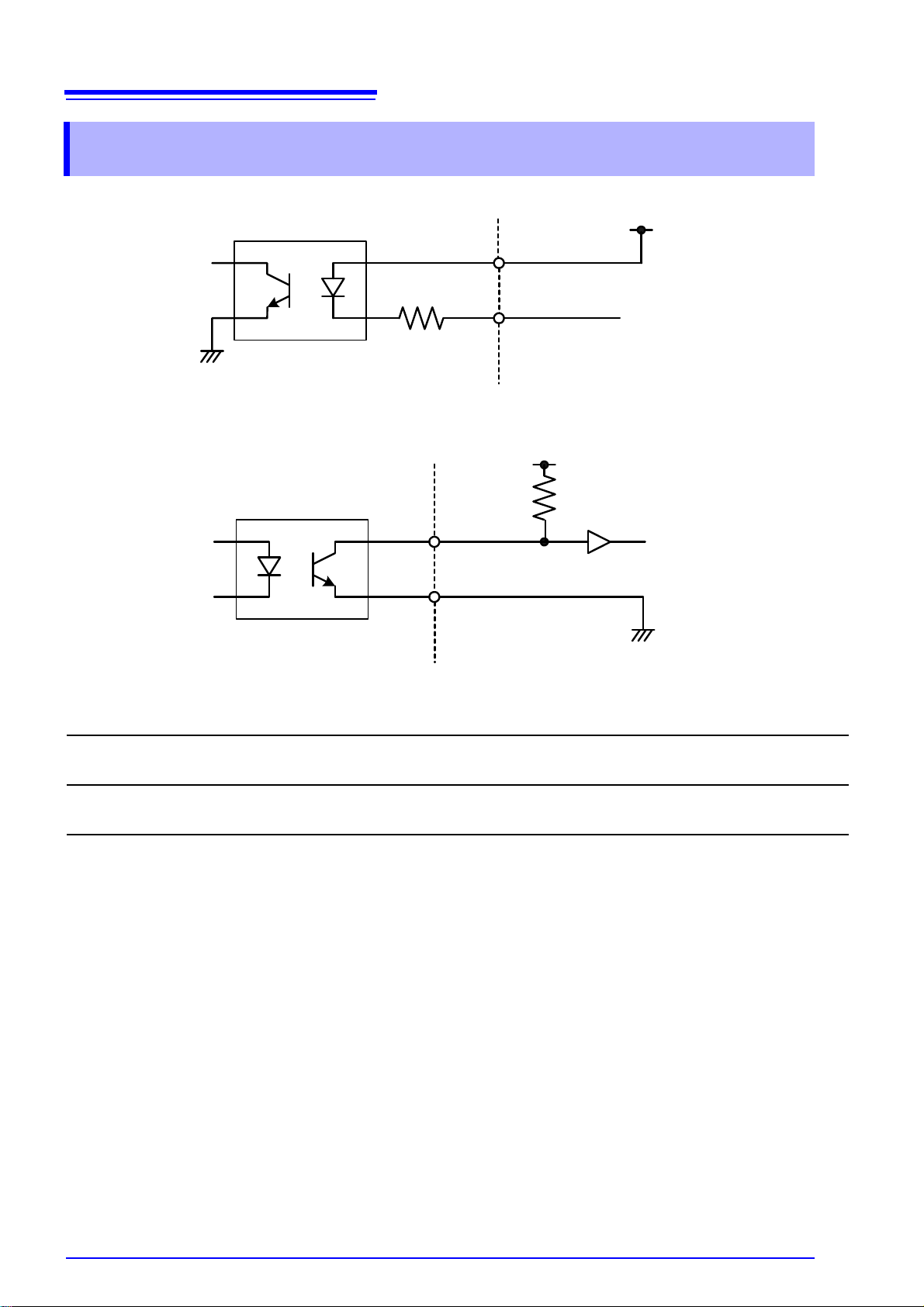

Input Circuit

Output Circuit

SM7860 side

External device side

EXT_DC2

Input signals

24 VDC

SM7860 side

External device side

COM

5 to 24 VDC

Output signals

4.3 Internal Circuitry

4.3 Internal Circuitry

Input Signals

Output Signals

Input method Photocoupler-isolated input

Input voltage LOW: 0 to 0.5 V, HIGH: 24 V±10%

Output method Photocoupler -open collector output

Output voltage/ current LOW < 0.5 V, HIGH > 5 to 24 V (depends on external voltage)/ Max. 5 mA

5.1 General Specifications

Specifications Chapter 5

5.1 General Specifications

Operating environment Indoors, Pollution degree 2, up to 2,000 m (6562-ft.) ASL

39

Operating temperature and

humidity

Storage temperature and

humidity

Dielectric strength 1.62 kV AC for 60 s, Cutoff cu rren t 10 m A, be tween all pow e r term ina ls and prot ect iv e

Applicable Standards

Safety

Power source Rated supply voltage

Maximum rated power 860 VA

Dimensions Approx. 425W × 249H × 581D mm (16.73"W × 9.80"H × 22.87"D)

Mass Approx. 45 kg (1587.3 oz.) (SM7860-01, 02, 03, 04, 05, 06, 21, 22, 23, 24, 25, 26)

Accessories Power Cord......................................... ...... ..... ...... ...... ..... ...... ..1

0 to 40°C (32 to 104°F), 80%RH or less (non-condensing)

-10 to 55°C (14 to 131°F), 80%RH or less (non-condensing)

ground, interfaces, a nd measurem ent termin als, b etween p ower supply line and power

supply neutral

EN61010

SM7860-01, 02, 03, 04, 05, 06, 07: 100 VAC, 110 VAC (Must specify when ordering)

SM7860-21, 22, 23, 24, 25, 26, 27: 220 VAC

(Voltage fluctuations of

Rated supply frequency : 50/60 Hz

Anticipated transient overvoltage : 2,500 V

Approx. 32 kg (1128.7 oz.) (SM7860-07, 27)

Instruction manual..................................................................1

Voltage output connector

SM7860-01, -02, -21, -22....................................................2

SM7860-03, -04, -05, -06, -07, -23, -24, -25, -26, -27.........4

±10% from the rated supply voltage are taken into account)

Options Model 9637 RS-232C Cable (9pin-9pin/Cross/1.8m)

Model 9638 RS-232C Cable (9pin-25pin/Cross/1.8m)

Model 9151-02 GP-IB Connector Cable (2 m)

Replacement part Fuse: MF60NRF-8A (250V M 8.0A φ6.4×30 mm)

40

5.2 Basic Specifications

5.2 Basic Specificat io n s

Design

Model Circuit A Circuit B

Maximum outp ut current 430 mA (200 VA) 430 mA (200 VA)

SM7860-01

SM7860-21

SM7860-02

SM7860-22

SM7860-03

SM7860-23

SM7860-04

SM7860-24

SM7860-05

SM7860-25

SM7860-06

SM7860-26

SM7860-07

SM7860-27

Output voltage rang e

Channels

Current limit ±50 mA/CH ±50 mA/CH

Maximum outp ut current 100 mA (100 VA) 100 mA (100 VA)

Output voltage rang e

Channels

Current limit ±10 mA/CH ±10 mA/CH

Maximum outp ut current 430 mA (200 VA) 430 mA (200 VA)

Output voltage rang e

Channels

Current limit ±50 mA/CH ±50mA/CH

Maximum outp ut current 100 mA (100 VA) 100 mA (100 VA)

Output voltage rang e

Channels

Current limit ±10 mA/CH ±10 mA/CH

Maximum outp ut current 430 mA (200 VA) 430 mA (200 VA)

Output voltage rang e

Channels

Current limit ±50 mA/CH ±50 mA/CH

Maximum outp ut current 100 mA (100 VA) 100 mA (100 VA)

Output voltage rang e

Channels

Current limit ±10 mA/CH ±10 mA/CH

Maximum outp ut current 430 mA (200 VA) 430 mA (200 VA)

Output voltage rang e

Channels

Current limit ±50 mA/CH ±50 mA/CH

1.0 V to 500.0 V

(0.1 V resolution)

OUT 1 (1) to (8): Voltage output OUT 3 (1) to (8): Voltage output

OUT 2 (1) to (8): None OUT 4 (1) to (8): None

250.0 V to 1000.0 V

(0.1 V resolution)

OUT 1 (1) to (8): Voltage output OUT 3 (1) to (8): Voltage output

OUT 2 (1) to (8): None OUT 4 (1) to (8): None

1.0 V to 500.0 V

(0.1 V resolution)

OUT 1 (1) to (8): Voltage output OUT 3 (1) to (8): Voltage output

OUT 2 (1) to (8): Voltage output OUT 4 (1) to (8): Voltage output

250.0 V to 1000.0 V

(0.1 V resolution)

OUT 1 (1) to (8): Voltage output OUT 3 (1) to (8): Voltage output

OUT 2 (1) to (8): Voltage output OUT 4 (1) to (8): Voltage output

1.0 V to 500.0 V

(0.1 V resolution)

OUT 1 (1) to (8): Voltage output OUT 3 (1) to (8): Voltage output

OUT 2 (1) to (8): Discharge OUT 4 (1) to (8): Discharge

250.0 V to 1000.0 V

(0.1 V resolution)

OUT 1 (1) to (8): Voltage output OUT 3 (1) to (8): Voltage output

OUT 2 (1) to (8): Discharge OUT 4 (1) to (8): Discharge

1.0 V to 10.0 V

(0.1 V resolution)

OUT 1 (1) to (8): Voltage output OUT 3 (1) to (8): Voltage output

OUT 2 (1) to (8): Voltage output OUT 4 (1) to (8): Discharge

-1.0 V to -500.0 V

(0.1 V resolution)

-250.0 V to -1000.0 V

(0.1 V resolution)

-1.0 V to -500.0 V

(0.1 V resolution)

-250.0 V to -1000.0 V

(0.1 V resolution)

-1.0 V to -500.0 V

(0.1 V resolution)

-250.0 V to -1000.0 V

(0.1 V resolution)

1.0 V to 10.0 V

(0.1 V resolution)

Output terminals Special round connector (support for 8 channels)

41

5.2 Basic Specifications

Setup method and operation

LED indicator POWER, Voltage output, Inter-lock

LCD screen P1: Output voltage setting, monitor voltage value, channel-specific output setting state

Supported model HIOKI Model SM7810, SM7810-20 Super MΩ HiTester

GP-IB Interface, RS-232C Interface, EXT I/O

(No setup available on the SM7860 front panel except settings for GP-IB address)

P2: Alarm setting, GP-IB address

Functions

Voltage output function

Operating method Sink/source (support for charging and discharging)

Generation control Output only when external I/O interface's OUTPUT signal is on.

Output on/off Can be set independently for each channel.

Voltage error alarm Operation : Alarm is generated when the monitor voltage falls outside the set

range.

Valid setting range: ±2 to ±19% (1% resolution)

Current limit function

Limit method Current can be limited independently for each channel.

Current limit direction Current can be limited in both directions.

Backup Function

Backup Items Output voltage setting, alarm setting, GP-IB address

Voltage monitor function

Voltage monitor Measures and displays output voltage for each circuit.

Accuracy

Conditions of guaranteed accuracy

Warm-up time 1 hour or more

Temperature and humid-

ity range for guaranteed

accuracy

Temperature coefficient From 0°C to 18°C and 28°C to 40°C, add 0.1 × accuracy specifications per °C.

Period of guaranteed ac-

curacy

Generation accuracy

Output voltage accuracy ±2% of setting ±0.5 V (no load)

Channel error ±0.01 V or less (no load, between outputs from same circuit)

Voltage monitor accuracy ±2% of output voltage ±0.5 V

23±5°C (73±9°F), 80%RH or less (non-condensing)

1 year

Limit current accuracy

SM7860-01, -03, -05, -07,

-21, -23, -25, -27

SM7860-02, -04, -06,

-22, -24, -26

50 mA ± 5 mA

10 mA ± 3 mA

42

0.1

1.0

10.0

100.0

10 100 1000

充電間隔(msec)

印加電圧

250V

500V

1000V

印加電圧

0.1

1.0

10.0

100.0

10 100 1000

充電間隔(msec)

静電容量(

4

6.3V 10V 16V 25V 50V 100V

500V

250V

100V

Figure 1: Charging Interval by Applied Voltage and Capacity

(SM7860-01, 03, 05, 07, 21, 23, 25, 27)

Figure 2: Charging Interval by Applied Voltage and Capacity

(SM7860-02, 04, 06, 22, 24, 26)

250 V

500 V

1000 V

Capacitance [μF]

Charging interval [ms]

Applied voltage

4 V 6.3 V 10 V 16 V 25 V 50 V 100 V

Applied voltage

Capacitance [μF]

Charging interval [ms]

5.2 Basic Specifications

Limitations

Voltage application target Laminated ceramic capacitor

Number of charging chan-

Up to 8 channels/circuit

nels

Operating conditions Cha rgin g in terv al must be gre ater than or equal to the time cal cu late d fro m the gra ph s

shown in Figure 1 and Figure 2 below. (Continuous charging is not supported.)

μ

V

43

37 ms

15 ms

Contact

Movement

Contact

Movement

Automated system

operation

Charging current

Almost no current during this interval

5.2 Basic Specifications

Graph description and operating precautions

Because the SM7860 is designed to be embedded in an automated system in applications in which it charges

capacitors, it cannot be used with a continuous load. Figures 1 and 2 define the minimum cycle times at which

this automated system can operate based on the output voltage and capacitor capacitance.

For example, when char ging a 25 V, 30

from the point at which a line extend ing from the 30

μF capacitor, a charge inter val of approximate ly 37 ms can be re ad

μF position on t he vert ical axis intersects the 25 V l ine.

This figure (37 ms) defines the minimum cycle for the automated system.

The time (

T) representing the interval during the 37 ms for which the SM7860 charges the capacitor at the full

power of 50 mA or 10 mA can be calculated as follows:

T = C × V / I

C : Capacitor capacitance

V : Voltage

I : Current (50 mA)

Using values of 25 V, 30

μF, and 50 mA yields:

T= 30 μF × 25 V / 50 mA

= 15 ms

The following diagram expresses this as a timing chart:

During the 37 ms interval, the charging current flows for 15 ms, and almost no current flows for the remaining

22 ms. If, for example, the automated system's cycle time were 100 ms instead of 37 ms, the charging current

would flow for 15 ms, and almost no current would flow for the remaining 85 ms. This operation describes the

normal manner in which the SM7860 is used.

Using the instrument when there are shorted components

If the capacitor being char ged were shorted, for example due to defective ins ulation, the charging current

would flow for the e ntire c ontact interva l, rathe r than just 15 ms. If the te st run is expe cted t o includ e sho rted

components, check each component before initiating testing and avoid applying current if shorted.

(1) Design the system so that each of the external input (EXT I/O) signals, from OUT1(1)_ON

OUT4(8)_ON

(2) When outputting voltage from the SM7860, check each capacitor for a short before initiating testing.

(Have the automate d system store the results of checks perfo rmed before testing, for example using

capacitance measurement.)

(3) When a shorted compo nent is encountered, turn the OUT (X)_ON

channel off before turning the external input (EXT I/O) signal's OUTPUT

Using the instrument when capacitors are not mounted by the automated system

When capacitors ar e not properly mo unted from the automat ed system's part feede r, the archite cture of the

system may cause the S M7860's output to enter the sho rted state . This i ssue can be addr essed i n the sa me

manner as described in "Using the instrument when there are shorted components" above.

, can be controlled (turned on and off) independently.

to

signal for the shorted componen t's

signal on.

44

5.3 Input / Output Functions

5.3 Input / Output Functions

GP-IB Interface

Data reception Output voltage setting, output on/off, voltage error alarm setting

Data transmission Setting read access, error description

RS-232C Interface

Data reception Output voltage setting, output on/off, voltage error alarm setting

Data transmission Setting read access, error description

Communication conditions

Baud rate

Parity

Stop bit

Data

Flow control

38.4kbps

none

1 bit

8 bit

none

External I/O

Input/Output signals

Input OUTPUT : Output on/off setting

OUT 1(1)_ON

OUT 2(1)_ON

OUT 3(1)_ON

OUT 4(1)_ON

INTERLOCK

Output BUSY : Voltage being output

ALARM

TEMP

Electrical characteristics

Input Input method : Photocoupler-isolated input

Input voltage : LOW; 0 to 0.5 V, HIGH; 24 V±10%

Output Output method : Photocoupler-open collector output

Output voltage/current : LOW <0.5 V, HIGH> 5 to 24 V (depen ds on e xternal v oltage ) /

Connector 57RE-40500-730B (50-pin: DDK)

to OUT 1(8)_ON : Channel-specific on/off setting

to OUT 2(8)_ON : Channel-specific on/off setting

to OUT 3(8)_ON : Channel-specific on/off setting

to OUT 4(8)_ON : Channel-specific on/off setting

: When on, no voltage can be generated.

: Generated voltage alarm

: Temperature alarm

Max. 5 mA

6.1 Troubleshooting

Maintenance and

Service Chapter 6

6.1 Troubleshooting

Inspection and Repair

Touching any of the high-voltage points inside the device is very dangerous. Do not attempt to modify, disassemble or repair the device; as fire,

electric shock and injury could result.

45

If the device se ems to be malfunc tioning, confirm that "If the unit malfun ctions/

before you have it repaired" (p.46) befor e contacting your dealer or Hioki representative.

Transporting

Pack the device so that it wi ll not s us tai n dam age dur ing shi pp ing , and inc lu de a

description of existi ng damage. We do not take any responsibility for damage

incurred during shipping.

Replaceable Parts and Operating Lifetimes

Useful life depends o n the oper ating envi ronment and f requency of use. Oper ation cannot be guaranteed beyond the following periods.

For replacement parts, contact your dealer or Hioki representative.

Part Life

Electrolytic Capacitors Approx. 10 years

LCD backlight Approx. 20,000 hours

Relay Approx. 1 million operations

46

6.1 Troubleshooting

If the unit malfunctions/before you have it repaired

Symptom Cause Solution See page

Neither the screen nor

LEDs light up, even when

the power switch is turned

on.

The unit isn't accepting

key input.

Settings cannot be configured from the GP-IB interface.

Settings cannot be configured from the RS-232C

interface.

No voltage is being output

from the voltage outpu t

terminal.

No voltage is being output

from the voltage outpu t

terminal. The monitor

voltage shown on the

screen is 0.0 V, and the

abnormal voltage ala rm

result is NG.

"TEMP" is flashing in reverse video on the

screen, and a voltage is

no longer being output

from the voltage outpu t

terminal.

"ERROR:011" is being

shown in reverse video

on the screen, and a volt age is no longer being

output from the voltage

output terminal.

"ERROR:012" is being

shown in reverse video

on the screen, and a volt age is no longer being

output from the voltage

output terminal.

Is the power cord properly connected? Connect th e power cord. p.12

Is the power supply fuse inst alled? Install the pow er s upply fuse. p.47

Has the power supply fuse been

tripped?

Is the uni t in the key-lo ck state (ind icated

by the key-lock display on t he screen)?

Do the GP-IB address settings on the

unit and controller differ?

Did you use the RS-232C interface? The GP-IB interface cannot be used after the

Did you send t he "

Do the controller's RS-232C settings differ from the unit's communications conditions?

Did you use the GP-IB interface? The RS- 232C inter face canno t be used aft er the

Are you usin g a straight cabl e? Use a cross cable. p.20

Is the interlock operating?

Is the interlock indicator lit up?

Is the signal that turns the output channel on being input to the external I/O

connector?

Is the signal that turns output on being

input to the external I/O connector?

Does the voltage output indi cat or light

up when output is turned on ?

The unit's protective circuit ry may have

been triggered due to a failure.

The overheat protection function has

been activ ated . Are th e limit atio ns list ed

in the basi c specifications being complied with?

The power supply A circuit's overcurrent

protection function has been activated.

Are the limitations listed in the ba si c

specifications being complied with?

The power supply B circuit's overcurrent

protection function has been activated.

Ar

e the limitations listed in the basic

specifications being complied with?

RMT" command? Send the "RMT" command. The RS-232C inter-

Replace th e power supply fu se. p.47

Cancel the key-lock st at e. p.10

Set the correct GP-IB address. p.10

RS-232C interface is used. Turn the unit off,

wait a short amount of time, and then turn the

unit back on.

face cannot be used to communicate unless the

"

RMT" command is sent first.

Change the controller's R S- 232C communications settings.

GP-IB interface is used. Turn the unit off, wait a

short amount of time, and then turn the unit back

on.

The external I/O connector's interlock input signal is on. Check the reaso n th at in te rlock has

been activated and recti fy it.

Set the channel being used to on with the input

pins that turn each channel on and off.

Set the input pin that turn s output on and off t o

on.

Please contact your dea le r or H i oki representative.

Set the operating conditions so that the limitations in the basic specifi cations are complied

with.

While "TEMP" is displayed, all channels will be

turned off, and the ability to control the unit fro m

the interfaces and external I/O connector is disabled. Once the internal temperature decreases, the "TEMP" indicator on the screen will turn

off, and you will once more be able to control the

unit. All channels will be turned off when the unit

resumes op erat ion, so yo u wi ll n eed t o rec onfi gure the output channels fo r us e.

Set the operating conditions so that the limitations in the basic specifi cations are complied

with.

All channels will turn off, a nd the inst rument will

not accept control instru ct i ons from either interface or the external I/O co nnector. There is no

way to recover from this state. Turn the unit off,

wait a short amount of time, and then turn the

unit back on.

p.31

p.21

p.18

p.21

p.21

p.18

p.8

p.34

p.34

p.34

p.10

p.10

p.42

p.10

p.42

6.2 Replacing the Power Fuse

Screwdriver

Fuse holder

Fuse:

φ6.4 mm × 30 mm

Replacing the Power Fuse

Rear panel of the device

Tools to Prepare: Phillips head screwdriver

1 Turn off the power switch and

disconnect the power cord.

2 Loosen the fuse holder screw

with the Phillips head screwdriver and remove.

3 Replace the power fuse with a

fuse of the designated rating.

4 Insert the fuse holder into its

original location and tighten the

screw.

Removing the Fuse Holder

• To avoid electric shock, turn off the power switch and disconnect the

connection cables before replacing the fuse.

• Replace the fuse only with one of t he specified characteris tics and volt-

age and current rating s. Never use unspeci fied fuses and ne ver use the

device after the fuse holder has shorted. This will damage the device and

cause injury.

Fuse type: MF60NRF-8A φ6.4 mm × 30 mm Normal-acting fuse

47

6.2 Replacing the Power Fuse

48

6.3 Error Displays

6.3 Error Displays

Error Display Description Remedy

ERROR:001 Call Service Center Backup data corrupt

ERROR:002 Call Service Center Backup data write failure

ERROR:007 Call Service Center

ERROR:011 Call Service Center Power supply circuit A overcurrent

ERROR:012 Call Service Center Power supply circuit B overcurrent

Power source controller internal

communication failure

Please contact your dealer or Hioki representative.

Please contact your dealer or Hioki representative.

Please contact your dealer or Hioki representative.

Check "If the unit malfunc tio ns /be fore y ou

have it repaired" (p.46).

Check "If the unit malfunc tio ns /be fore y ou

have it repaired" (p.46).

6.4 Cleaning

• To clean the device, wipe it gently with a soft cloth moistened with water or mild

• Wipe the LCD gently with a soft, dry cloth.