SM7860

SM7860-51

SM7860-52

SM7860-53

SM7860-54

SM7860-55

SM7860-56

SM7860-57

SM7860-58

SM7860-61

SM7860-62

SM7860-63

SM7860-64

SM7860-65

SM7860-66

SM7860-67

SM7860-68

Instruction Manual

POWER SOURCE UNIT

Be sure to read this manual

before using the device

When using the device for the rst time Troubleshooting

Part Names and Functions

Screen Conguration

Installation and Connection Procedures

July 2018 Revised edition 1

SM7860J961-01 18-07H

p.

p.

p.

10

13

15

Safety Information

Troubleshooting

Error Display

p.

p.

p.

4

53

55

EN

Contents

Introduction

Notation

Verifying Package Contents

Safety Information

Operating Precautions

........................................................1

..............................................................2

............................3

............................................4

.....................................4

1 Overview 9

1.1 Product Overview and Features

1.2 Part Names and Functions

1.3 ScreenConguration

...........................13

...........9

.................10

2 Preparation and Supply

Power

2.1 Installation and Connection

Procedures

2.2 Connecting the Power Cord

2.3 Connecting the Device to the

Measuring Instrument

2.4 Inspection Before Operation

2.5 Turn ON/OFF the power

2.6 Operating Conditions Setting

2.7 Output Setting for the Device

Interlocked

15

............................................15

................16

..........................17

...............18

......................19

..............20

.............................................21

4 External Control 37

4.1 EXT I/O Connector and Signals

Connector Type and Signal Pinouts

Signal Functions

4.2 Timing Chart

4.3 Internal Circuitry

.......................................39

..........................................40

....................................44

.........37

...........38

5 Specications 45

5.1 GeneralSpecications

5.2 BasicSpecications

Graph description and operating

precautions

...............................................50

5.3 Input / Output Functions

.........................45

.............................46

......................52

6 Maintenance and Service 53

6.1 Troubleshooting

6.2 Error Display

6.3 Repairs, Inspections, and Cleaning

6.4 Replacing the Power Fuse

Warranty Certicate

....................................53

.........................................55

...55

..................56

3 Changing the Interface 23

3.1 Overview and Features of the

Interfaces

3.2 InterfaceSpecications

3.3 Connecting the Interface

Using the GP-IB Interface

Using the RS-232C Interface

3.4 ConguringtheCommunications

Protocol

ConguringGP-IBInterface

Communications

ConguringRS-232CInterface

Communications

3.5 Communication Method

Status Byte Register

Event Register

Error Register

3.6 Message List

3.7 ListenerSpecicationPrecautions

Input buffer size

Reading from the output buffer

...............................................23

.......................24

.....................26

GP-IB

..................................................27

GP-IB

...........................27

RS-232C

.................................30

..........................................31

...........................................33

.........................................34

........................................36

..............26

RS-232C

.......................28

.......................28

..................36

.....26

.....36

SM7860J961-01

i

Contents

ii

Introduction

Introduction

Thank you for purchasing the Hioki Model SM7860 series Power Source Unit.

To obtain maximum performance from the device over the long term, be sure to read this manual carefully

and keep it handy for future reference.

Target audience

This manual has been written for use by individuals who use the product in question or who teach

others to do so. It is assumed that the reader possesses basic electrical knowledge (equivalent to that of

someone who graduated from the electrical program at a technical high school).

Finding the product’s model number

You can nd the model number on the rear of the device.

Model Overview Supply voltage

SM7860-51 500 V × 32 channels 100 V to 110 V

SM7860-52 1000 V × 32 channels 100 V to 110 V

SM7860-53 500 V × 16 channels, −500 V × 16 channels 100 V to 110 V

SM7860-54 1000 V × 16 channels, −1000 V × 16 channels 100 V to 110 V

SM7860-55 500 V × 8 channels, −500 V × 8 channels, discharge × 16 channels 100 V to 110 V

SM7860-56 1000 V × 16 channels, −1000 V × 16 channels, discharge × 16 channels 100 V to 110 V

SM7860-57 10 V × 24 channels, discharge × 8 channels 100 V to 110 V

SM7860-58 500 V × 24 channels, discharge × 8 channels 100 V to 110 V

SM7860-61 500 V × 32 channels 220 V

SM7860-62 1000 V × 32 channels 220 V

SM7860-63 500 V × 16 channels, −500 V × 16 channels 220 V

SM7860-64 1000 V × 16 channels, −1000 V × 16 channels 220 V

SM7860-65 500 V × 8 channels, −500 V × 8 channels, discharge × 16 channels 220 V

SM7860-66 1000 V × 16 channels, −1000 V × 16 channels, discharge × 16 channels 220 V

SM7860-67 10 V × 24 channels, discharge × 8 channels 220 V

SM7860-68 500 V × 24 channels, discharge × 8 channels 220 V

1

Notation

Notation

Concerning Safety

In this document, the risk seriousness and the hazard levels are classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Imminent risk of operator death or serious injury

Potential for operator death or serious injury

Potential for minor operator injury or device damage or malfunction

Indicates information related to the operation of the device or maintenance tasks

with which the operators must be fully familiar.

Prohibited actions

Actions that must be performed

Symbols Afxed to the Device

Precaution or hazard (See “Operating Precautions”.)

ON side of the power switch

OFF side of the power switch

AC (alternating current)

Grounding terminal

Others

*

p.

[ ]

ON

Additional information is presented below.

Indicates the location of reference information.

Key names are indicated in brackets.

Names and keys on the screen are shown in boldface.

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading), and dgt. (digit) values, with

the following meanings:

f.s. (maximum display value)

f.s.

rdg.

The maximum displayable value. This is usually the name of the currently

selected range.

rdg. (reading or displayed value)

The value currently being measured and indicated on the measuring device.

dgt. (resolution)

dgt.

The smallest displayable unit on a digital measuring device, i.e., the input value

that causes the digital display to show a “1” as the least-signicant digit.

2

Verifying Package Contents

Verifying Package Contents

When you receive the device, inspect it carefully to ensure that no damage occurred during shipping.

In particular, check the accessories, panel switches, and connectors. If damage is evident, or if it fails to

operate according to the specications, contact your authorized Hioki distributor or reseller.

Device and Accessories

Conrm that you have received the following items:

Model SM7860 series Power Source Unit

Power cord

Instruction Manual (This document)

Options

The following options are available for the device. Contact your authorized Hioki distributor or reseller

when ordering.

Model 9637 RS-232C Cable (9pin-9pin/1.8 m) Cross

Model 9151-02 GP-IB Connector Cable 2 m

Model L2221 Connector Voltage output

3

Safety Information

Safety Information

Before using the device, be certain to carefully read the following safety notes.

DANGER

Mishandling during use could result in injury or death, as well as damage to the

device. Be certain that you understand the instructions and precautions in the

manual before use.

WARNING

• With regard to the electricity supply, there are risks of an electric shock,

heat generation, re, and arc ash due to a short-circuit. Individuals using

an electrical measuring device for the rst time should be supervised by a

technician who has experience in electrical measurement.

• Protective gear

This device is measured on a live line. To prevent an electric shock, use

appropriate protective insulation and adhere to applicable laws and regulations.

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benets of the various functions.

Checks before use

DANGER

If the connection cord or the device is damaged, there is a risk of an electric

shock. Perform the following inspection before using the device:

• Check that the coatings of the connection cords are neither ripped nor torn and

that no metal parts are exposed. Using the device under such conditions could

result in an electric shock. Replace the connection cords with those specied

by our company.

• Verify that the device operates normally to ensure that no damage occurred

during storage or shipping. If you nd any damage, contact your authorized

Hioki distributor or reseller.

WARNING

To prevent an electric shock, conrm that the white or red portion (insulation

layer) inside the cable is not exposed. If a color inside the cable is exposed, do

not use the cable.

4

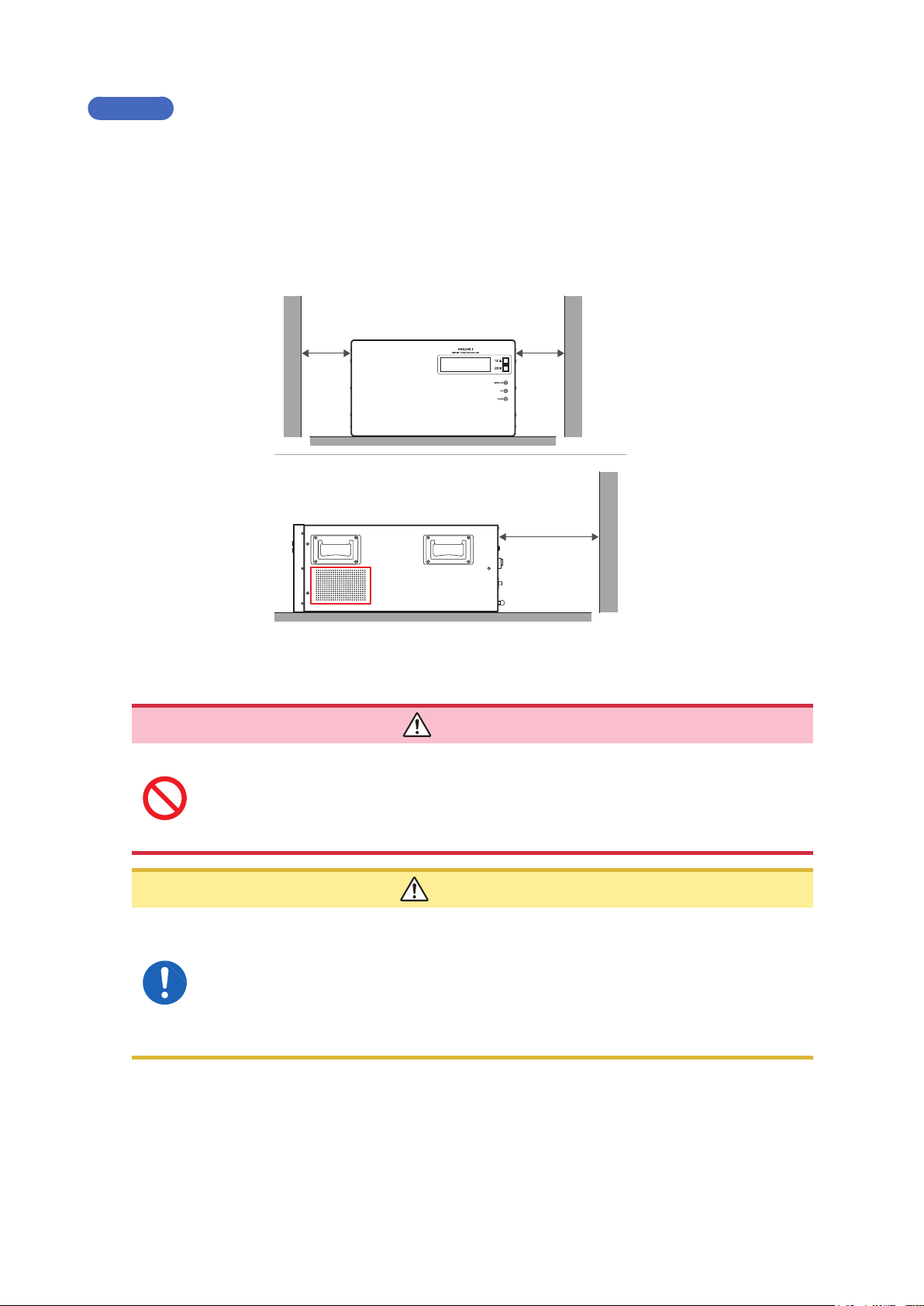

Installing the device

• Ventilation holes for heat radiation are provided on the side and rear panels of

the device. Leave sufcient space around the ventilation holes and install the

device with the holes unobstructed. Installation of the device with the ventilation

holes obstructed may cause a malfunction or a re.

• Unplugging the power cord kills power to the device. Be sure to provide enough

unobstructed space to unplug the power cord immediately in an emergency.

Installing the device in inappropriate locations may cause a malfunction of device

or may give rise to an accident. Avoid the following locations:

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to a strong electromagnetic eld or electrostatic charge

• Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

Operating Precautions

WARNING

CAUTION

Failure to observe the following precaution may result in bodily injury.

• The device weighs approx. 47 kg (Model SM7860-57 and SM7860-67: approx. 34 kg).

It should be moved by at least two people, who should grip it using the handles on the

left and right sides. The center of gravity is located on the front side of the device.

• The device is heavy. When transporting it, follow your company’s workplace safety

standards to assure safety (for example, by wearing non-slip gloves and protective

footwear).

Do not place the device on an unstable table or inclined place. Dropping or knocking

down the device can cause injury or damage to the device.

5

Operating Precautions

Installing

Prolonged operation in hot temperatures will shorten the device’s service life. Keep the ambient temperature

as low as possible.

• Avoid obstructing the ventilation holes.

• To prevent overheating, be sure to leave the specied clearances around the device.

• When rack-mounting the device, fans must be installed above or on top of the rack to ensure proper

ventilation. Be sure that the rack is adequately ventilated so that the internal temperature remains at or

below 40°C.

Handling the Device

• Do not use the device with circuits that exceed its ratings or specications.

Doing so may damage the device or cause it to become hot, resulting in a bodily

injury.

• Do not short-circuit two wires to be measured by bringing the cable into contact

with them. Arcs or such grave accidents are likely to occur.

50 mm or more

Prevent from

blocking

50 mm or more

100 mm or more

DANGER

CAUTION

Failure to observe the following precaution may result in bodily injury.

• The device weighs approx. 47 kg (Model SM7860-57 and SM7860-67: approx. 34 kg).

It should be moved by at least two people, who should grip it using the handles on the

left and right sides. The center of gravity is located on the front side of the device.

• The device is heavy. When transporting it, follow your company’s workplace safety

standards to assure safety (for example, by wearing non-slip gloves and protective

footwear).

6

Handling the Cords

If the insulation on a cord melts, the metal conductor may be exposed. Do not use

any cord whose metal conductor is exposed. Doing so could result in an electric

shock, burn, or other hazards.

To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it

from the outlet or device.

To prevent cord damage, do not step on cords or pinch them between other objects. Do

not bend or pull on cables at their base.

IMPORTANT

Use only the specied connection cords. Use of any cable not specied by our company may

result in incorrect measurements due to poor connection or other reasons.

Operating Precautions

WARNING

CAUTION

To ensure accurate measurements

• Warm up the device an hour or more before use.

• The device should be calibrated once a year.

Transporting Precautions

• To ensure safe handling, when transporting the device, please use the original box and packing

materials, but do not use if the box is damaged or warped, or if the packing materials are in poor

condition or incomplete.

• When packing the device, make sure to disconnect power supply cords from the main device.

• When transporting, avoid dropping or other excessive impacts.

7

Operating Precautions

8

1

Overview

1.1 Product Overview and Features

The SM7860 series Power Source Unit is a power source designed for use with the SM7420 Super

Megohm Meter and SM7810‑20 Super MΩ HiTester. When used in conjunction with the SM7420 or

SM7810‑20, the SM7860 serves as an ideal power source for automatic testing and measurement of

capacitors.

Positive- and negative-polarity output / Multi-channel output

• The device supports multichannel systems with up to 32 channels.

• The output voltage can be set separately for two circuits, each consisting of 8 or 16 channels.

• The device provides both positive‑ and negative‑polarity power sources.

• It can be used to create an optimal testing line with the minimum necessary number of power sources.

Independent on/off output switching and current limitations for all channels

• Since each channel has its own output on/off switch, it is possible to control voltage application

without an external circuit (allowing charging and discharging).

• Use of semiconductor switches eliminates the need for maintenance.

• Ability to limit current for individual channels means the measurement of other channels won’t be

affected when a target workpiece has a short.

Variable output current limit value

• 500 V output model: The output current limit can be set as desired from 2 mA per channel to 50 mA

per channel.

• 1000 V output model: The output current limit can be set as desired from 2 mA per channel to 10 mA

per channel.

1000 V output voltage model

• The line includes a model that can generate output of up to ±1000 V.

High-current output at 50 mA/channel*

• The device can quickly charge high‑capacity MLCC (multi‑layer ceramic capacitor). Number of

charges can be reduced.

* For the 1000 V model, limited to 10 mA/channel.

Standard interfaces

• Devices ship standard with EXT. I/O, GP‑IB, and RS‑232C interfaces for sequencing. Interfaces are

used to congure and power the device.

Interlock function

• Since the device outputs measurement and charging voltages when measurement starts, erroneous

operation poses the risk of electric shock. An interlock function is used to ensure safe measurement.

Settings can be congured by sending signals via the device’s external I/O interface.

9

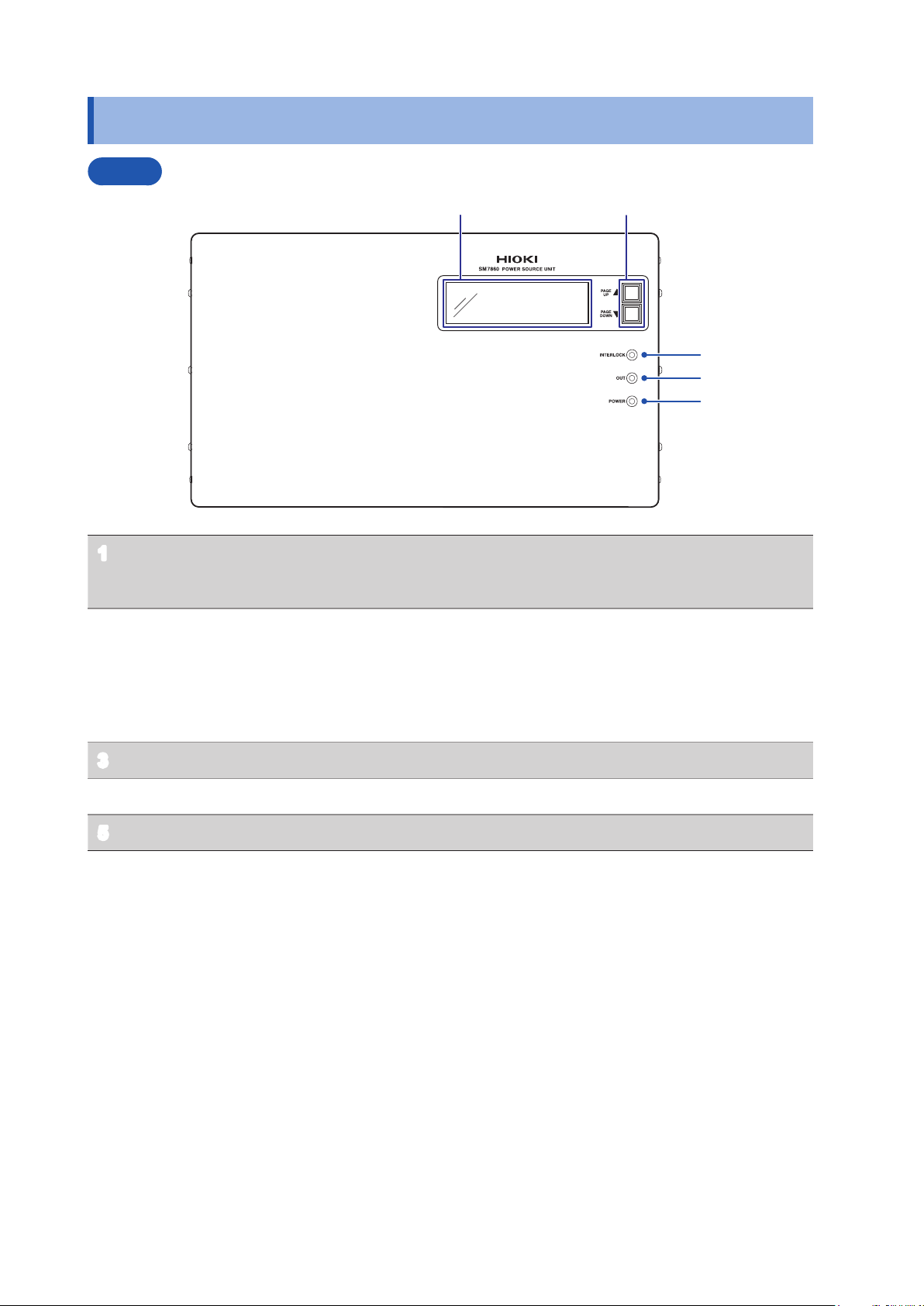

Part Names and Functions

1 2

3

4

5

1.2 Part Names and Functions

Front

Display (LCD) The screen uses a 2‑page layout to display setting values

1

and setting status information.

Refer to “1.3 Screen Conguration” (p. 13)

Scroll keys

2

[PAGE UP▲], [PAGE DOWN▼]

Interlock indicator (INTERLOCK) Lights up when the interlock is on.

3

Voltage output indicator (OUT) Lights up when a voltage is being output.

4

Power indicator (POWER) Lights up when the device is on.

5

• Use to scroll the display (LCD).

Refer to “1.3 Screen Conguration” (p. 13)

• Used to assign the GP-IP address and to congure the

output setting for the device interlocked.

Refer to “Conguring GP-IB Interface Communications

GP-IB” (p. 27)

10

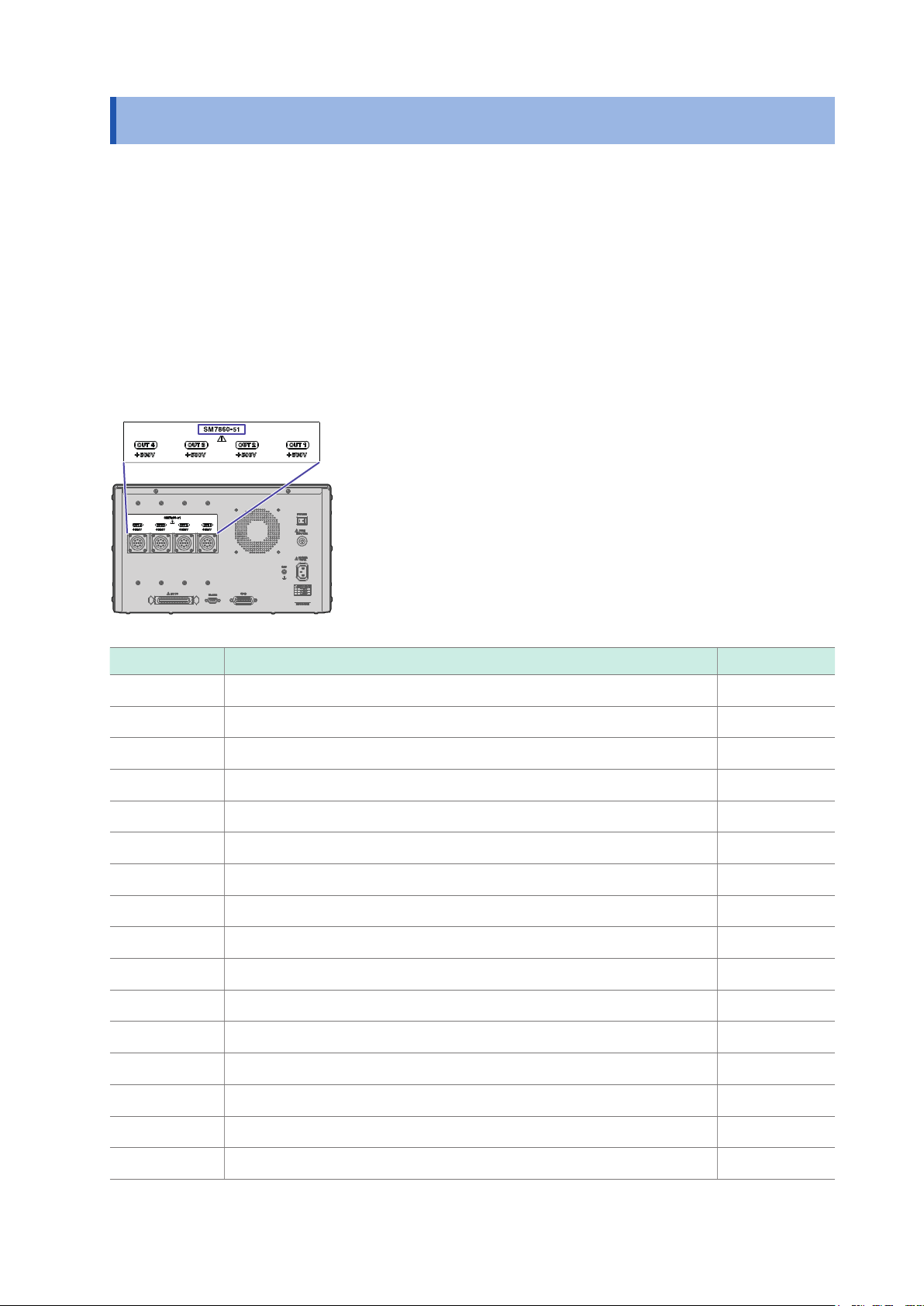

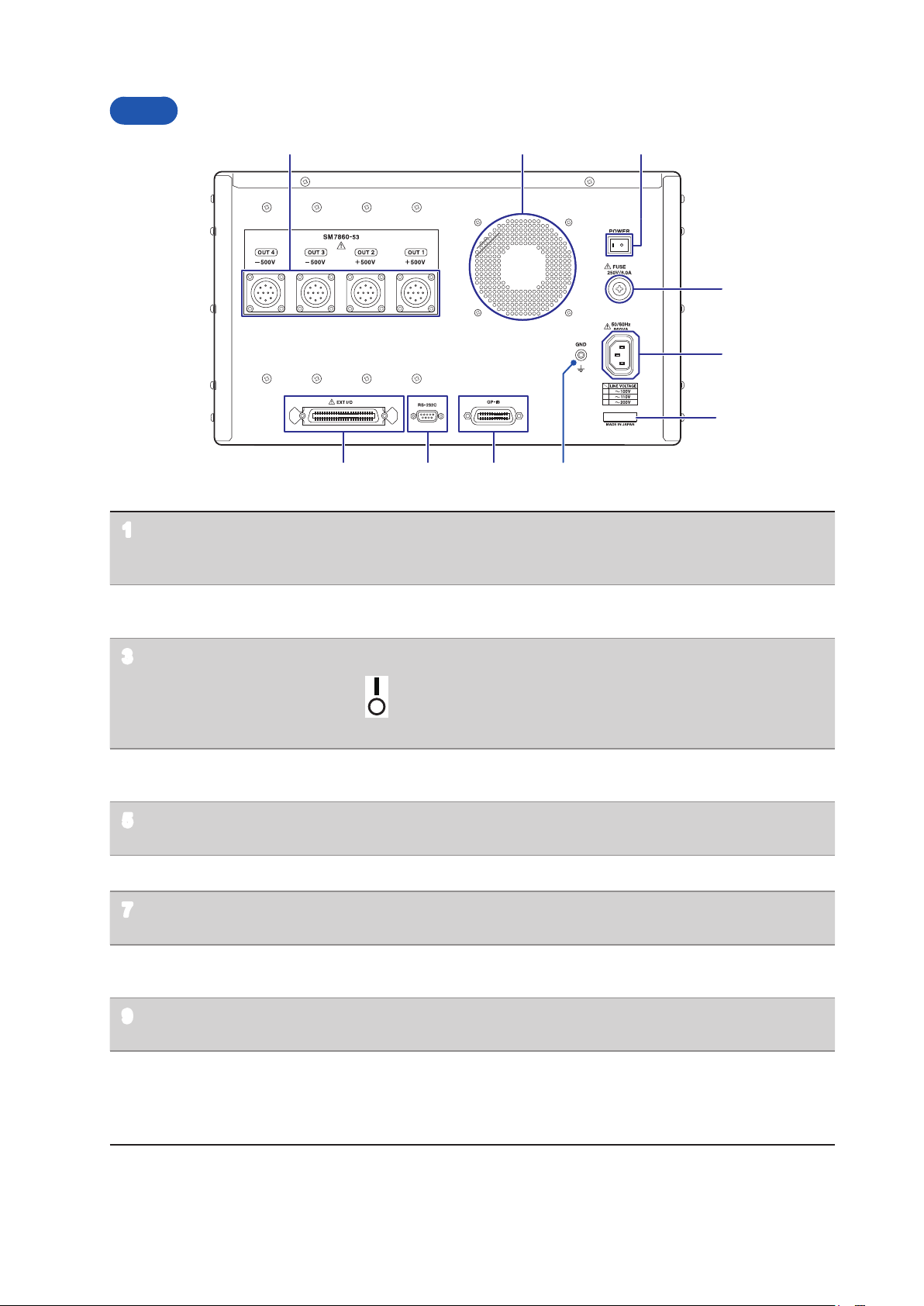

Rear

1 32

4

5

6 789

10

Part Names and Functions

Voltage output terminal Voltage is output. Connect the optional Model L2221 Connector.

1

Ventilation holes Keep clear of obstructions.

2

Power switch (POWER) Turns the device on and off.

3

Fuse holder (FUSE) Fuse can be replaced.

4

Power inlet Connect the supplied power cord.

5

GND terminal Serves as the ground terminal. Connects to the device’s enclosure.

6

GP‑IB connector Connect to a PC when using the GP‑IB interface.

7

RS‑232C connector Connect to a PC when using the RS‑232C interface.

8

Refer to “2.3 Connecting the Device to the Measuring Instrument”

(p. 17)

Refer to “Installing” (p. 6)

: Power ON

: Power OFF

Refer to “2.5 Turn ON/OFF the power” (p. 19)

Refer to “6.4 Replacing the Power Fuse” (p. 56)

Refer to “2.2 Connecting the Power Cord” (p. 16)

Refer to “Using the GP-IB Interface GP-IB” (p. 26)

Refer to “Using the RS-232C Interface RS-232C” (p. 26)

EXT I/O connector The EXT I/O connector can be used to control the device.

9

Refer to “4 External Control” (p. 37)

Serial number The serial number consists of 9 digits. The rst two (from the left)

10

indicate the year of manufacture, and the next two indicate the

month of manufacture.

Required for production control. Do not peel off the label.

11

Part Names and Functions

1

2

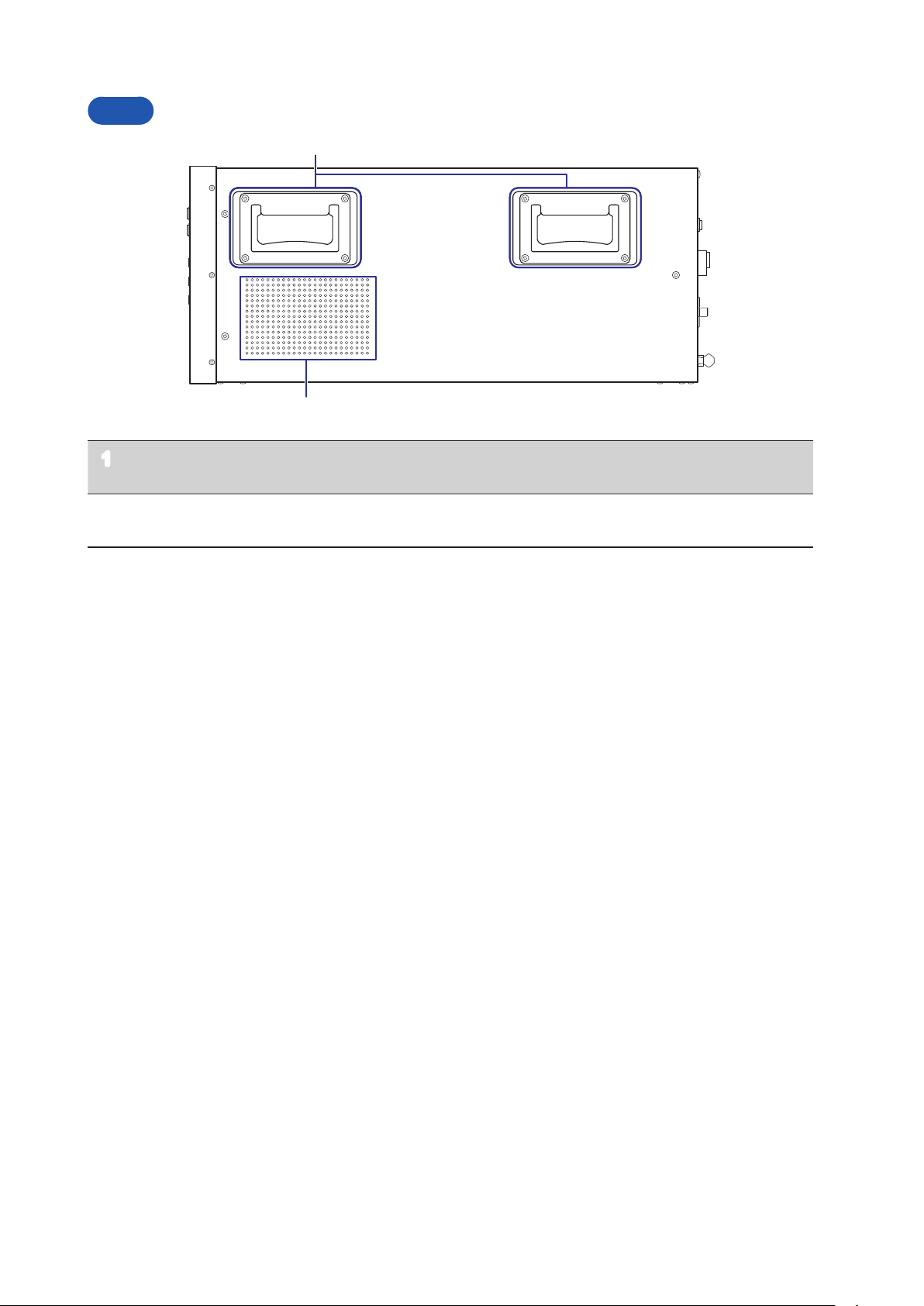

Side

Handle (total of 4, located on the

1

left and right sides of the device)

Ventilation holes Keep clear of obstructions.

2

It should be moved by at least two people, who should grip

it using the handles on the left and right sides.

Refer to “Installing” (p. 6)

12

Screen Conguration

1

3 4 5 6

27

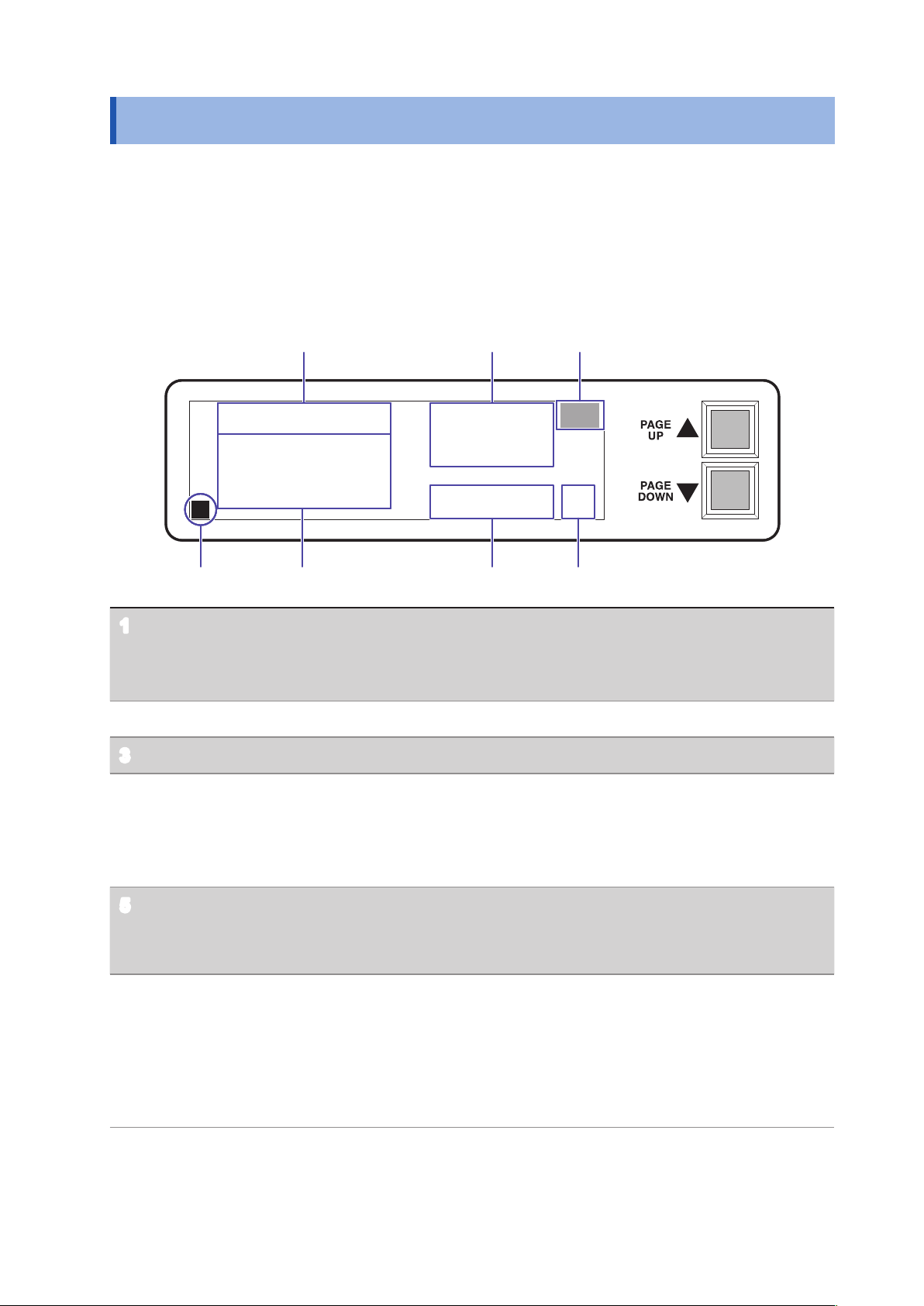

1.3 Screen Conguration

The display (LCD) consists of two display pages (Screen P1, Screen P2).

• Screen P1 is displayed when the device is turned on.

• The display pages can be scrolled using the scroll keys ([PAGE UP▲], [PAGE DOWN▼]) to the right of

the screen.

• You can select a display page directly by sending a “

interface. Refer to “3.6 Message List” (p. 34)

Screen P1: Displays output voltage settings

P1

PAG

” command from the GP-IB or RS-232C

VA (+) IR:1000.0

VB (+) IR: 250.0

TERMINAL:

OUT1:11100000

OUT2:11100000

OUT3:11100000

OUT4:11100000

L

Output voltage setting VA : Displays the power supply A circuit voltage setting.

1

VB : Displays the power supply B circuit voltage setting.

( Display example: VA (+) IR: 1000.0

Indicates that the power source’s A circuit is set to 1000.0 V.)

Temperature error display When a temperature error is detected, TEMP blinks.

2

Key lock display When the keys are locked, L is displayed.

3

Terminal output setting

4

state

Displays rows 1 through 8 of OUTn (where n indicates a value from 1

to 4), from left to right.

The setting is 0 or 1.

0 : High‑impedance

1 : ON

CLM1: 10mA

CLM2: 10mA

CLM3: 10mA

CLM4: 10mA

VMA: 1000.0

VMB: 250.0

TEMP

TEMP

OK

OK

Monitor voltage value VMA : Voltage monitor value for the power supply A circuit.

5

VMB : Voltage monitor value for the power supply B circuit.

The zero decimal point’s position is xed using zero suppression.

Voltage error alarm results

6

OK: The monitor voltage (5) error relative to the output voltage setting

(1) falls within the normal range relative to the voltage error alarm

setting (8, p. 14).

NG: The monitor voltage (5) error relative to the output voltage setting

(1) indicates an error relative to the voltage error alarm setting (8,

p. 14).

13

Screen Conguration

8

2

P2

Output current limit value CLM1 : OUT1 output current limit value setting display

7

CLM2 : OUT2 output current limit value setting display

CLM3 : OUT3 output current limit value setting display

CLM4 : OUT4 output current limit value setting display

The digit following CLM corresponds to OUT1 to 4.

( Display example: CLM1: 10mA

Indicates that the current output from OUT1 is limited to 10 mA.)

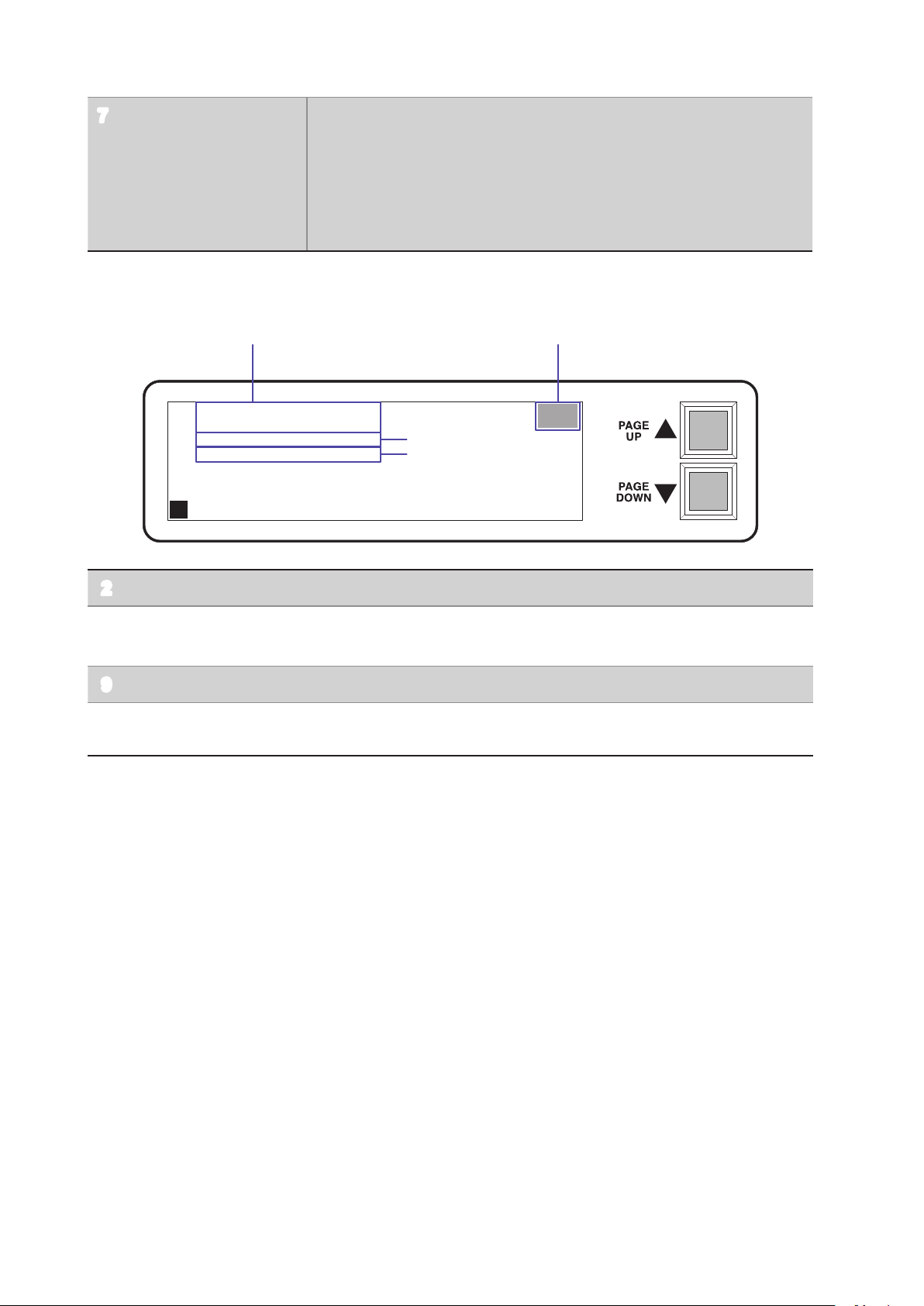

Screen P2: Displays alarms, the GP-IP address, and output setting for the device interlocked.

VA ALARM : 19

VB ALARM : 19

GPIB ADDR: 1

ILOCK DCHG: OFF

9

10

TEMP

TEMP

L

Temperature error display When a temperature error is detected, TEMP blinks.

2

Voltage error alarm setting VA ALARM : Power supply A circuit voltage error alarm setting ± (%)

8

VB ALARM : Power supply B circuit voltage error alarm setting ± (%)

GP‑IB address Refer to “Using the GP-IB Interface GP-IB” (p. 26)

9

Output setting for the

10

device interlocked

Refer to “2.7 Output Setting for the Device Interlocked” (p. 21)

14

2

Preparation and Supply Power

2.1 Installation and Connection Procedures

Be sure to read the “Operating Precautions” (p. 4) before installing and connecting the device.

3

4

6

Front Rear

Install the device. (p. 5)

1

Connect the power cord. (p. 16)

2

Connect the device to the measuring instrument. (p. 17)

3

Connect the external interface.

4

• Using the GP-IB or RS-232C interface (p. 23)

• Using the EXT I/O (p. 37)

Complete the pre-use inspection. (p. 18)

5

Be sure to inspect the device prior to use.

2

Turn the power on. (p. 19)

6

Make device settings. (p. 20)

7

(via the external interface)

Activate the power source.

8

15

Connecting the Power Cord

2.2 Connecting the Power Cord

WARNING

• Before turning the device on, make sure the supply voltage matches that indicated

on its power connector. Connection to an improper supply voltage may damage the

device and present an electrical hazard.

• To prevent an electric shock and to maintain the safety specications of this device,

connect the power cord provided only to an outlet.

• Before using the device, make sure that the insulation on the power cord is

undamaged and that no bare conductors are improperly exposed. Using the device in

such conditions could cause an electric shock, so replace the power cord with those

specied by our company.

CAUTION

To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from the

outlet or device.

Turn off the power before disconnecting the power cord.

Connection Method

1

Power inlet

2

Conrm that the device is turned off.

1

Conrm that the supply voltage

2

matches the device, and connect the

power cord to the power inlet on the

device.

Plug the power cord into the outlet.

3

This completes the process of

connecting the power cord.

16

Loading...

Loading...