Instruction Manual

SM7860-01 to -07

SM7860-21 to -27

POWER SOURCE UNIT

February 2012 Revised edition 1 SM7860A981-01 12-02H

Contents

Introduction.................................................................................1

i

Contents

1

Confirming Packa g e Co n te n ts.............. .. ... .. ... ..................... ... .. ..1

Safety Informa tion ............. .. ... .. .. ...................... .. ... .. ...................2

Operating Precautions................................................................3

Chapter 1

Overview___________________________________ 7

1.1 Product Overview and Features .........................................7

1.2 Names and Functions of Parts ............................................8

1.3 Screen Layout ...................................................................10

Chapter 2

Preparing to Use the Device and

Supplying Power ___________________________ 11

2.1 Installation & Connection Procedures ...............................11

2.2 Connecting the Power Cord ..............................................12

2.3 Connecting the Device to the Measuring Instrument ........13

2

3

4

5

6

7

2.4 Pre-Operation Inspection ..................................................14

2.5 Turning the Power On and Off ..........................................15

2.6 Setting the Operating Conditions ......................................16

Chapter 3

Communication (GP-IB/RS-232C Interface)______ 17

3.1 Overview and Features .....................................................17

3.2 Specifications ............................................................ ........ 18

3.3 Connect a cable to the GP-IB

connector or RS-232C connector 19

3.4 Configuring the Communications Protocol ........................21

3.5 Communication Methods ..................................................22

Status Byte Register .........................................................................24

Eve n t R e g is te rs ..... ... ..................................... ...................................2 6

Error Registers ..................................................................................28

3.6 Message List .....................................................................29

3.7 Listener Specification Precautions ....................................32

Input buffer size ................................................................................32

Reading from the output buffer .........................................................32

8

9

10

11

12

付

録

索

引

ii

Contents

Chapter 4

External Control ____________________________33

4.1 External Input/Output Connector and Signals ..................33

Connector Type and Signal Pinouts .................................................34

Signal Descriptions ..........................................................................35

4.2 Timing Chart .....................................................................36

4.3 Internal Circuitry ................................................................38

Chapter 5

Specifications______________________________39

5.1 General Specifications ......................................................39

5.2 Basic Specifications ..........................................................40

5.3 Input / Output Functions ...................................................44

Chapter 6

Maintenance and Service ____________________45

6.1 Troubleshooting ................................................................ 45

Inspection and Repair ......................................................................45

6.2 Replacing the Power Fuse ................................................47

6.3 Error Displays ...................................................................48

6.4 Cleaning .................................................... ........................48

Introduction

Confirm that th e se contents are provided.

□ SM7860 series Power Source Unit (1)

□ Power Cord (1)

□ Instruction Manual (1)

□ Voltage output connector

SM7860-01, -02, -21, -22.............2

SM7860-03, -04, -05, -06, -07,

-23, -24, -25, -26, -27 ......4

Thank you for purchas ing the HIOKI Model SM7860 series Power Source Unit.

To obtain maximum performance from the devic e, please read this manu al first,

and keep it handy for future reference.

Confirming Package Contents

When you receive the device, inspect it carefully to ensure that no damage

occurred during shipp ing. In particular, check the accessor ies, panel switches,

and connectors . If damage is evident, or if it fa ils to operate according to the

specifications, contact your dealer or Hioki representative.

1

Introduction

Options □ Model 9637 RS-232C Cable (9pin-9pin/Cross/1.8m)

Transportation

Notes on

□ Model 9638 RS-232C Cable (9pin-25pin/Cross/1.8m)

□ Model 9151-02 GP-IB Connector Cable (2 m)

• To ensure safe handling, when transporting the device, please use the original

box and packing materials, but do not use if the box is damaged or warped, or

if the packing materials are in poor condition or incomple te.

• When packing the device, m ake sure to disconnec t the power c ords from t he

main device.

• When transporting, avoid dropping or other excessive impact.

2

Safety Information

Safety Information

This device is des igned to comply with IEC 61010 Safety Standards, and

has been thoroughly tested for safety prior to shipment. However, mishandling during use could result in injury or death, as well as damage to the

device. Using the device in a way not described in this manual may negate

the provided safety features.

Be certain that you understand the instructions and precautions in the

manual before use. We disclaim any responsibility for accidents or injuries

not resulting directly from device defects.

This manual contain s information and warnings essential for safe operation of

the device and for maintaining it in safe operati ng condition. Be fore using it, b e

sure to carefully read the following safety precautions.

Safety Symbols

In the manual, the symbol indicates particularly important information that

the user should read before using the device.

The symbol printed on the device indicates that the user should refer to a

corresponding topic in the manual (marked with the symbol) before using

the relevant function.

Indicates a grounding termi nal.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of cautions

and warnings.

Indicates that incorrect operation presents an extreme hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

Indicates that incor rect operatio n presen ts a po ssib ility of injury to the

user or damage to the device.

Indicates advisory items related to performance or correct operation

of the device.

Other symbols

*

PA GE UP

(Bold)

( p. )

Indicates a prohibited action.

Indicates that descriptive information is provided below.

Bold characters within the text indicate operating key labels.

Indicates the location of reference information.

Operating Precautions

Follow these precaut ions to ensure s afe ope ration an d to obta in the fu ll bene fits

of the various functions.

Preliminary Checks

Before using the device for the first time, verify that it operates normally to

ensure that no damage occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Device Installation

Operating temperature and humidity

Temperature and humidity range for guaranteed accuracy

3

Operating Precautions

: 0 to 40°C at 80%RH or less (non-condensing)

: 23±5°C, 80%RH or less (non-condensing)

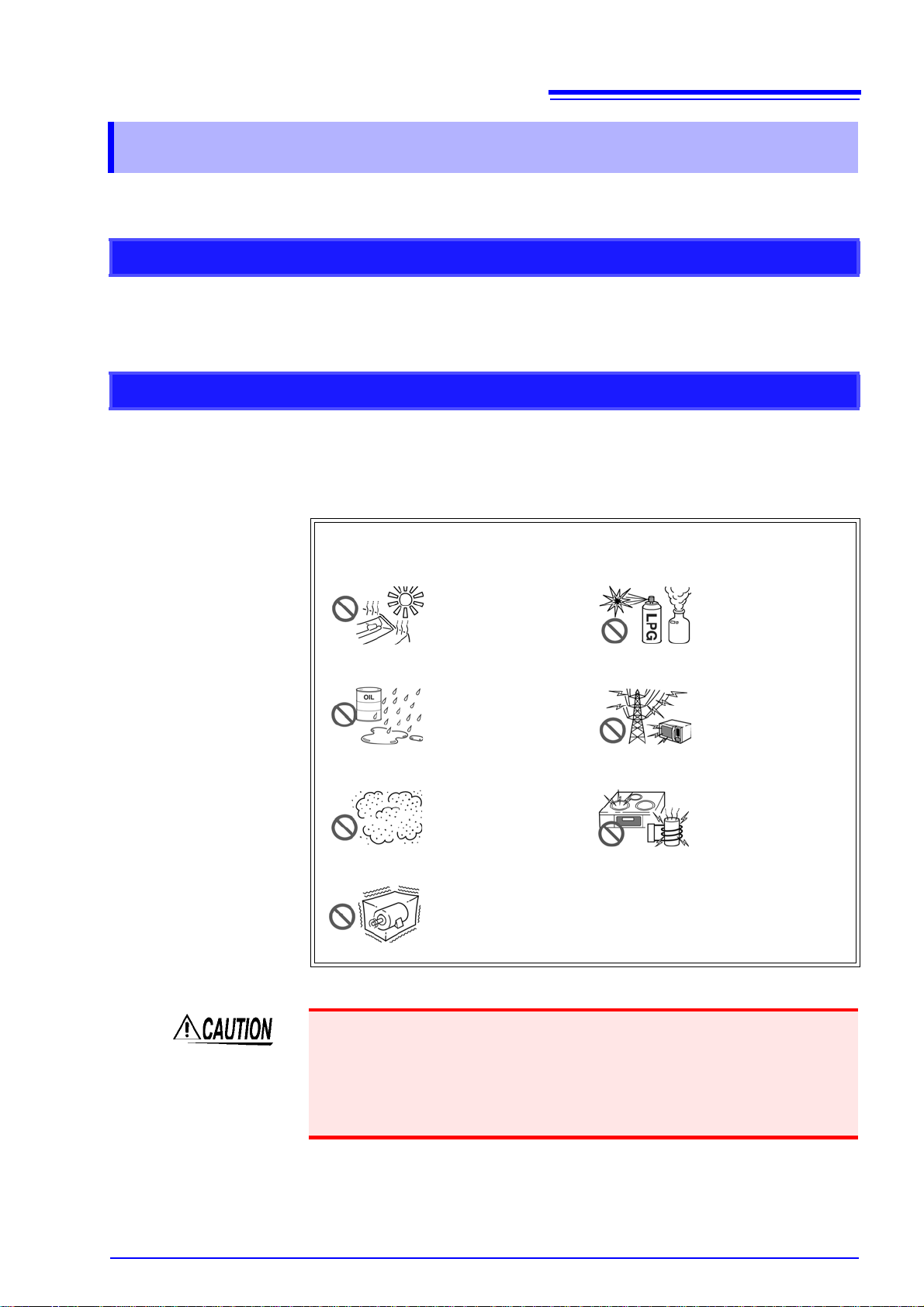

Avoid the following locations that could cause an accident or damage

to the device.

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil,

other chemicals, or

solvents

Exposed to high humidity or condensation

Exposed to high levels of particulate dust

Subject to vibration

In the presence of corrosive or explos ive gas es

Exposed to strong electromagnetic fields

Near electromagnetic

radiators

Near electromagnetic

radiators (e.g., high-frequency induction heating systems and IH

cooking utensils)

• Do not slant the device or place it on top of an uneven surfa ce. Dropping or

knocking down the device can cause injury or damage to the device.

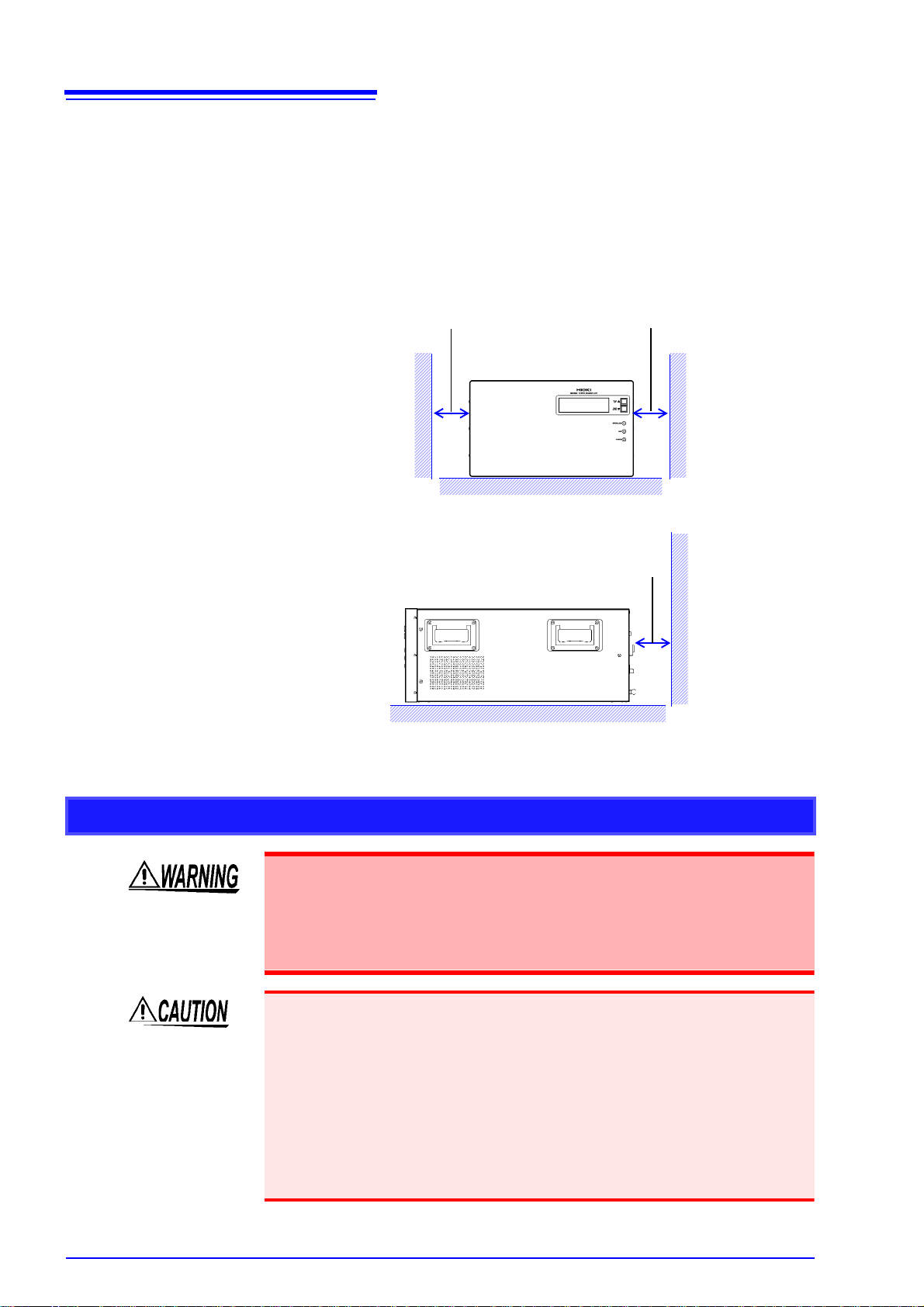

• Ventilation holes for heat radiation are provided on the si de and re ar panels of

the device. Leave sufficient space aroun d the ventilation holes and install t he

device with the holes unobstructed. Installation o f the device with the venti lation holes obstructed may cause a malfunction or fire.

4

100 mm or more

50 mm or more

50 mm or more

Operating Precautions

Installing To prevent overheating, be sure to leave the specified clearances around the

unit.

• Vents must not be obstructed.

• When rack-mounting the dev i ce, fans must be in stalle d abov e or on top of the

rack to ensure proper ventila tion. Be sure that the rack is adequately ven tilated so that the i nternal temperature remains at o r below 40°C. Continued

use of the device in a high-temperature envir onment will shorten its servic e

life. Keep the temperature as low as possible.

Handling the Device

• Do not allow the device to get wet, and do not take measurements with

wet hands. This may cause an electric shock.

• Touching any of the high-voltage points inside the device is very danger-

ous. Do not attempt to modify, disassemble or repair the device; as fire,

electric shock and injury could result.

• To avoid damage to the device, protec t it from physic al shock whe n transport-

ing and handling. Be especially careful to avoid physical shock from dropping.

Failure to observe the following precaution may result in bodily injury.

• The device weighs approxi mately 45 kg (SM7860-07, -27: approximately 32

kg). It should be move d by at least two people, who should grip it using the

handles on the left and right sides.

• The device is he avy. When transporting it, foll ow your company's workplace

safety standards to assure safety (for example, by wearing non-slip gloves and

protective footwear).

Handling the Cords

5

Operating Precautions

Before using the device, make sure that the insulation on the Connection

Cable is undamaged and that no bare conductors are improperly exposed.

Using the de v i ce i n s u c h conditions could cause an e lec t r i c shock, so con tact your dealer or Hioki representative for replacements.

• Avoid stepping on or pinching cab les, which could damage the cable insulation.

• To avoid breaking the cables, do not bend or pull them.

• To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from the power outlet.

• Keep the cables we ll away from heat sources, as bare c onductors could be

exposed if the insulation melts.

Use only the specified connection cables. Using a non-specified cable may

result in incorrect measurements due to poor connection or other reasons.

Before Connecting

• Before turning the device on, make sure the supply voltage matches that

indicated on its power connector. Connection to an improper supply voltage may damage the device and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety speci ficat ion s of

this device, connect the power cord only to a 3-contact (two-conductor +

ground) outlet.

T o ensure measurements are accurate,

• Warm up the device an hour or more before use.

• The device should be calibrated once a year.

6

Operating Precautions

1.1 Product Overview and Features

Overview Chapter 1

1.1 Product Overview and Features

The SM7860-01 to -07 and SM786 0-21 to -27 ar e power supp ly units d esigned

for use with the Model SM7810 or SM7810-20 Super MΩ HiTester. They support

bipolar, multi-channel output and are compatible with multi-channel systems.

Used in combination with the Model SM7810 or SM7810-20 Super MΩ HiTester,

they are ideal for use in automated testing and measurement of capacitors.

Bipolar, multi-channel output

The device delive rs an 8-channel, positive/negative power supply, allowing an

optimized test ing line to be built using th e smallest possible number of power

supplies.

7

Independent on/off output switching and current limitations

for all channels

Since each channel has its own output on/off switch, it is possible to control voltage application without an external circuit (allowing charging and dis charging).

Use of semiconduc tor switches elimina tes the need for mainten ance. Additionally, the ability to limit current (to 50 mA) for individual channels means the measurement of other channe ls won't be affected when a target workpiece has a

short.

Output current capacity: 50 mA/channel

High-capacity capacitors can be charged rapidly, and the number of charges can

be reduced.

Output voltage: 1,000 V/channel

Devices are available with output voltages of up to ±1,000 V.

Standard interfaces

Devices ship standard with external I/O, GP-IB, and RS-232C interfaces for

sequencing. Interfaces are used to configure and power the devices.

Inter-lock Function

8

LCD screen

The screen uses a 2-page

layout to display setting values and setting status inf ormation.

"1.3 Screen Layout" (p.10)

Front Panel

Scroll keys (PAGE UP▲/ PAGE DOWN▼)

Used to scroll through the display pages.

"1.3 Screen Layout" (p.10)

The scroll keys are also used to se t the GP-IB add ress.

(p.21)

Inter-lock indicator

Lights up when the interlock is

on.

V oltage output indicator

Lights up when a voltage is being output.

Power indicator

Lights up when the d evi ce is on.

Rear Panel

Power inlet

Connect the supplied power cord

here. (p.12)

Fuse holder

Allows the fuse to be replaced.

(p.47)

RS-232C connector

Connect to a compute r when

using the RS-232C interface.

(p.19)

EXT I/O connector

The external I/O connector

can be used to control the

device.

(p.33)

Voltage output terminal

Connect the included voltage

output connector.

(p.13)

Vent

Keep clear of obstructions.

POWER switch

Turns the device o n and off .

: Power On

: Power Off

(p.15)

GP-IB connector

Connect to a compu ter whe n using the

GP-IB interface.

(p.19)

GND terminal

Serves as the ground terminal.

The GND terminal is connected

to the device’s enclosure.

1.2 Names and Functions of Parts

1.2 Names and Function s of Parts

9

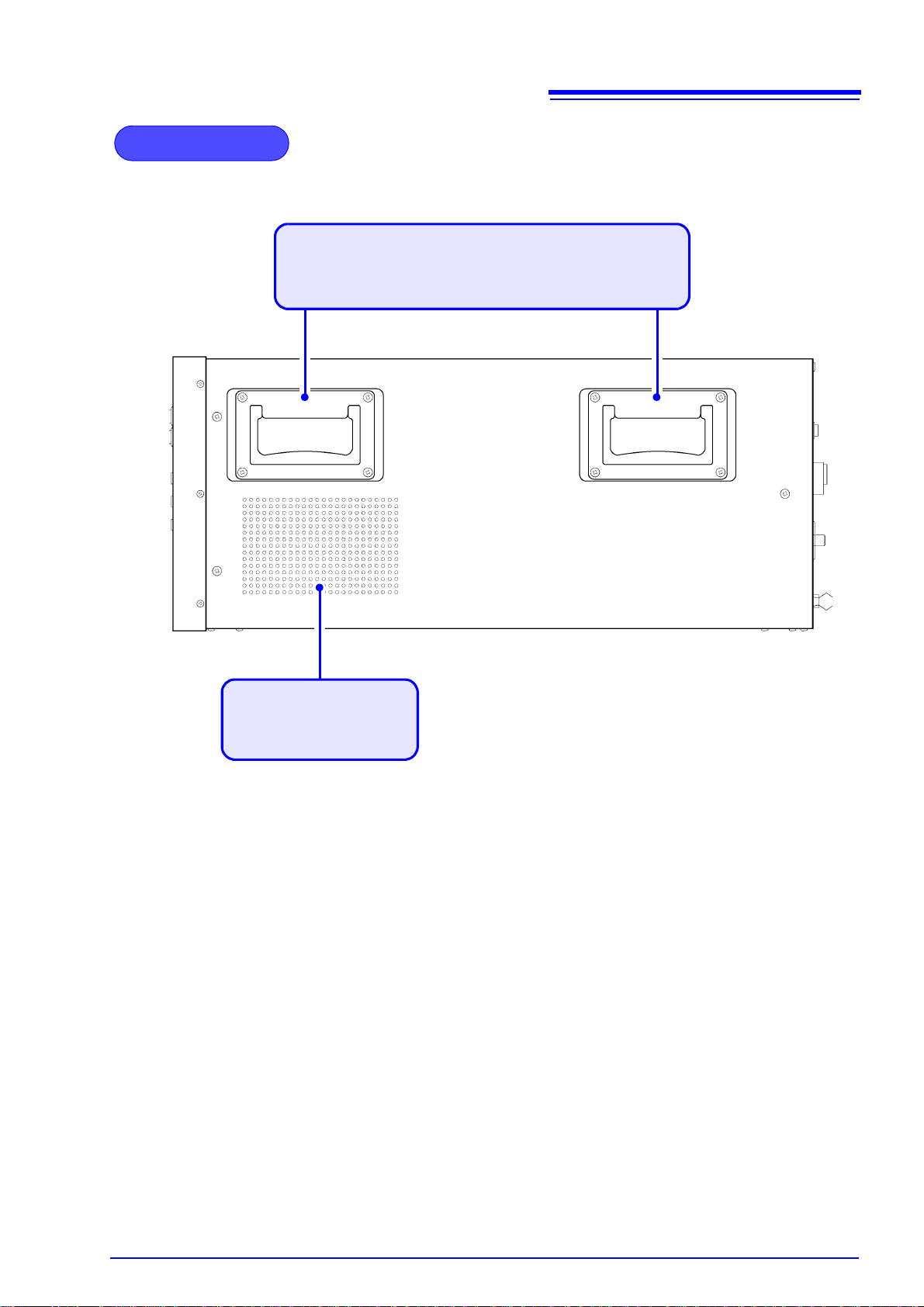

Side Panel

Handle

It should be moved by at least two p eople, who shoul d grip it using

the handles on the left and right sides.

Vent

Keep clear of obstructions.

1.2 Names and Functions of Parts

10

VA (+) IR:1000.0

VB (+) IR: 250.0

TERMINAL:

OUT1:11100000

OUT2:11100000

OUT3:11100000

OUT4:11100000 VMA:1000.0 OK

VMB: 250.0 OK

■ Screen P1 : Displays output voltage settings.

■ Screen P2: Alarm/GP-IB address setting display

Output voltage setting

VA: Displays the power supply A circuit voltage setting.

VB: Displays the power supply B circuit voltage setting.

Temperature error display

When a temperature error is d ete cte d,

"TEMP" flashes in reverse video.

Terminal output setting state

The setting is 0 or 1.

From left to right, OUTn row 1 → row 8

0: High-impedance

1: ON

Monitor voltage value

VMA: Displays the voltage

monitor value for the

power supply A circuit.

VMB: Displays the voltage

monitor value for the

power supply B circuit.

*Fixed-po int, zero-suppr essed.

Voltage error alarm results

VA ALARM: 19

VB ALARM: 19

GPIB ADDR: 1

Voltage error alarm setting

VA: Power supply A circ uit voltage error alar m setting ± (% )

VB: Power supply B circ uit voltage error alar m setting ± (% )

OK: The monitor voltage error

relative to the output voltage setting falls with in the

normal range relative to

the voltage error alarm

setting.

NG: The monitor voltage error

relative to the output voltage setting indicates an

error relative to the voltage

error alarm setting.

Temperature error display

When a temperature error is

detected, "TEMP" flashes in reverse video.

GP-IB address

L

Key lock display

When the keys are

locked, flashes

in reverse video.

L

TEMP

TEMP

L

TEMP

TEMP

1.3 Screen Layout

1.3 Screen Layout

The LCD screen cons ists of two dis play pa ges. W hen th e SM78 60 i s turne d on,

page 1 is shown.

The scroll keys on th e front of the device (PA GE UP ▲/ PAG E D OW N▼) are

used to scroll among the di splay pages, which can also be selected directly by

sending the “

See: Message List "PAG" (p.30)

PAG” command from the GP-IB or RS-232C interface.

11

8

Install this device (p.3)

1

Rear PanelFront Panel

Turn the power on (p.15)

6

Connect the external interface

4

• Using the GP-IB or RS-232C interface

(p.17)

• Using the EXT I/O (p.33)

Connect the power cord (p.12)

2

Make device settings (p.16)

(via the external interface)

7

Connect the device to the measuring instrument. (p.13)

3

Be sure to complete the pre-operation inspection (p.14) before

using the device

5

Activate the power source

2

4

6

3

2.1 Installation & Connection Procedures

Preparing to Use the Device

and Supplying

Power Chapter 2

2.1 Installation & Connection Procedures

Be sure to read the "Operating Precautions" (p.3) befo re installing and connecting

this device.

12

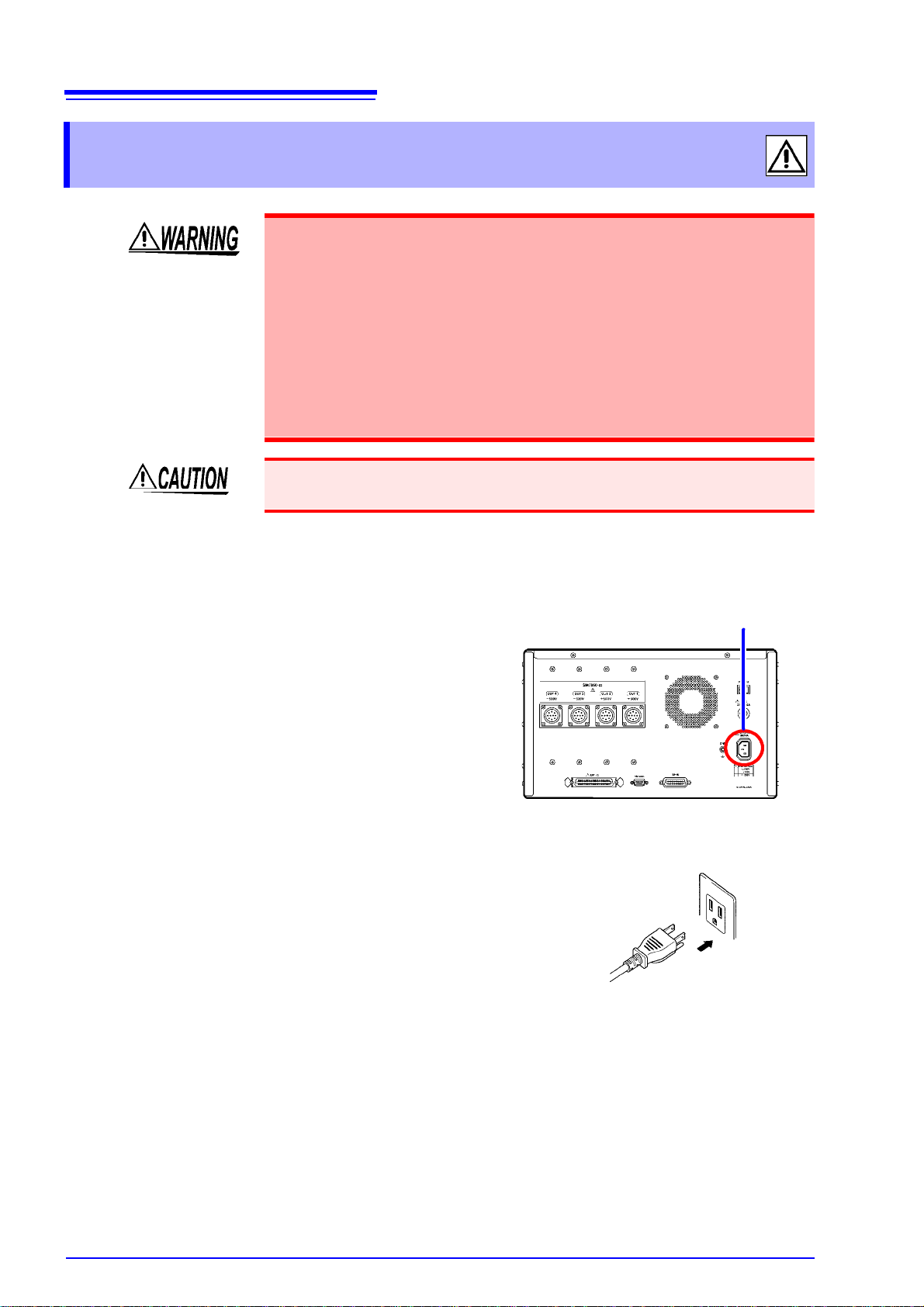

Rear Panel

1 Confirm that the device is turned off.

2 Confirm that the mains supply voltage

matches the device, and connect the

power cord to the power inlet on the

device.

3 Plug the power cord into the mains outlet.

Power inlet

2.2 Connecting the Power Cord

2.2 Connecting the Power Cord

• Before turning the device on, make sure the supply voltage matches that

indicated on its power connector . Connection to an improper supply voltage may damage the device and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety specific at ion s of

this device, connect the power cord only to a 3-contact (two-conductor +

ground) outlet.

• Before using the device, make sure that the insulation on the power cord

is undamaged and that no bare conductors are improperly exposed.

Using the device in such conditions could cause an electric shock, so

contact your dealer or Hioki representative for replacements.

To avoid damaging the po wer cord, grasp the plug, not the cord, wh en unplugging it from the power outlet.

Turn off the power before disconnecting the power cord.

Connection Methods

2.3 Connecting the Device to the Measuring Instrument

Rear Panel

1 Confirm that the device is turned off.

2 Connect the included voltage output con-

nector to the voltage output terminal on

the rear of the device.

Voltage output terminal

6 5 47

3

2

10

8

9

1

Voltage output pin assignments

(View of terminal on device)

*1 On the SM7860-05, -06, -2 5, an d - 26, ser v es as t he di s ch argin g

terminal.

*2 On the SM7860-05, -06, -07, -25, -26 and -27, serves as the dis-

charging terminal.

Pin No. OUT1

Circuit A

OUT2

*1

Circuit A

OUT3

Circuit B

OUT4

*2

Circuit B

1 CH1 CH1 CH1 CH1

2 CH2 CH2 CH2 CH2

3 CH3 CH3 CH3 CH3

4 CH4 CH4 CH4 CH4

5 CH5 CH5 CH5 CH5

6 CH6 CH6 CH6 CH6

7 CH7 CH7 CH7 CH7

8 CH8 CH8 CH8 CH8

9 NC NC NC NC

10 COM COM COM COM

2.3 Connecting the Device t o the Measuring

Instrument

To avoid electric shock or damage to the equ ipment, always observe the

following precautions when connecting to voltage output terminal.

• Always turn off the power to the device and to any dev ices to be con-

nected before connecting the voltage output connectors.

To avoid damaging the device, be sure to observe the following precautions:

• Do not connect the device to a load with a charge in exc ess of the output v oltage range.

• Do not connect the device to a load with a charge that has the opposite polarity

of the output voltage range.

• Do not connect the device to a load that has a charge when the device's power

supply is turned off.

13

Connection Methods

Specifications

Loading...

Loading...