Page 1

MR8827

Instruction Manual

MEMORY HiCORDER

Be sure to read this manual

before using the instrument.

When using the instrument

for the rst time

Part Names and Functions

Measurement Preparation

Revised edition 4Oct. 2018

18-10HMR8827A981-04

Safety Information

Troubleshooting

p.16 Maintenance and Service

p.25 Error Messages

p.3

p.383

p.389

EN

Page 2

Contents

Contents

Usage Index ............................................... 1

Introduction ................................................ 2

Package Contents ..................................... 2

Safety Information ..................................... 3

Operation Precautions .............................. 6

1 Overview 15

1.1 Product Overview ........................... 15

1.2 Part Names and Functions ............ 16

1.3 Screen Organization ...................... 19

Explanation of Screen Contents .................20

1.4 Basic Key Operations .................... 21

1.4.1 Using the HELP Key .................................... 22

1.4.2 Use a Mouse to Perform Key Operations ..... 23

2 Measurement

Preparation 25

2.1 Install or Remove Modules ............ 26

Channel Allocation ......................................27

2.2 Connection Cables ......................... 28

2.3 Prepare Storage Media .................. 40

2.3.1 Storage Media (Inserting a CF Card and

USB Memory Stick) .....................................40

2.3.2 To Format Storage Media ............................ 42

2.4 Load Instrument With Recording

Paper (When Model U8350

Printer Unit is installed) ................. 43

2.5 Power Supply ................................. 44

2.5.1 Connect the Power Cord .............................44

2.5.2 Ground the Functional Earth of This

Instrument ...................................................44

2.5.3 Turn the Power On and Off .......................... 45

2.6 Set the Clock .................................. 46

2.7 Adjust the Zero Position

(Zero-Adjust) ................................... 47

2.8 Perform Calibration (When

Model MR8990 is installed) ........... 48

3 Measurement 49

3.1 MeasurementWorkow ................. 49

3.2 Pre-measurement Inspection ........ 51

3.3 MeasurementConguration ......... 52

3.3.1 Measurement Function ................................52

3.3.2 Timebase and Sampling Rate ......................54

3.3.3 Recording Length (Number of Divisions) ...... 57

3.3.4 Screen Layout ............................................. 59

3.4 Select Input Channels .................... 60

3.4.1 ChannelSettingWorkow ............................ 61

3.4.2 Choose Analog Channel Settings ................. 63

3.4.3 Logic Channel Settings ................................66

3.4.4 Displayed Sheet...........................................67

3.5 Start and Stop Measurement ........ 68

3.6 Measurement With Automatic

Range Setting (Auto-ranging

Function) ......................................... 70

4 X-Y Recorder Function 71

4.1 MeasurementWorkow ................. 72

4.2 MeasurementConguration ......... 73

4.3 Start and Stop Measurement ........ 74

4.4 Waveform Observation .................. 75

4.4.1 To Save and Print Waveforms......................75

5 Save/Load Data and

Manage Files 77

5.1 Data That Can Be Saved and

Loaded ............................................ 79

5.2 Save Data ........................................ 81

5.2.1 SaveTypesandWorkow ........................... 81

5.2.2 Automatically Save Waveforms ...................82

5.2.3 Save Data Selectively (SAVE Key) .............. 88

5.2.4 Save Waveform Output Data to the Media ... 92

5.3 Load Data ........................................ 93

5.4 Automatically Load Settings

(Auto-setup Function) .................... 96

5.5 Manage Files ................................... 97

5.5.1 Save Data ...................................................98

5.5.2 Check the Contents of a Folder (Open a

Folder) ....................................................... 100

5.5.3 Create New Folders ................................... 100

5.5.4 Delete Files and Folders ............................ 101

5.5.5 Sort Files ................................................... 102

5.5.6 Rename Files and Folders ......................... 103

5.5.7 CopyaFileIntoaSpeciedFolder ............ 104

5.5.8 Print the File List ........................................ 105

6 Printing (When Model

U8350 Printer Unit is

installed) 107

6.1 PrintTypeandWorkow ............. 108

6.2 Auto-print Settings ....................... 109

6.3 Manual Printing With the PRINT

Key (Selective Printing) ................112

6.4 Setting the Print Density of the

Waveform .......................................114

6.5 Printer Settings .............................115

6.6 Miscellaneous Printing

Functions .......................................118

6.6.1 Screen Hard Copy ......................................118

6.6.2 Report Print (A4 Size Print) .........................118

6.6.3 List Print .....................................................119

6.6.4 Text Comment Printing ................................119

1

2

3

4

5

6

7

8

8

8

9

9

10

10

Appendix

Appx.

Index

Index

MR8827A981-04

i

Page 3

Contents

7 Waveform Screen

Monitoring and

Analysis 121

7.1 Read Measurement Values

(Using the AB Cursors) ................ 122

7.2 Specify a Waveform Range

(AB Cursor) ................................... 125

7.3 Move the Waveform Display

Position ......................................... 126

7.3.1 About the Display Position ......................... 126

7.3.2 Scroll With Jog and Shuttle Knobs (Scroll) . 126

7.3.3 Change Position (Jump Function) .............. 127

7.4 Perform Waveform X-Y

Synthesis ...................................... 128

7.5 Magnify and Compress

Waveforms .................................... 130

7.5.1 Magnify and Compress Horizontal Axis

(Time Axis)................................................. 130

7.5.2 Zoom Function

(Magnifying a Section of the Horizontal

Axis [Time Axis]) ........................................ 131

7.5.3 VerticalAxis(VoltageAxis)Magnication ... 132

7.6 Monitor Input Levels

(Level Monitor) ............................. 133

7.6.1 Level Monitor ............................................. 133

7.6.2 Numerical Value Monitor ............................ 134

7.7 Switch the Waveform Screen

Display (Display Menu) ................ 135

7.7.1 Show Upper/Lower Limit on Waveform

Screen ....................................................... 136

7.7.2 Show Comments on Waveform Screen ..... 136

7.7.3 Switch the Waveform Display Width...........136

7.7.4 Switch the Channel Range Information

Display ...................................................... 136

7.7.5 Switch the Displayed Sheet ....................... 136

7.8 View Block Waveforms ................ 137

8 Utility Functions 139

8.1 Add Comments ............................. 140

8.1.1 Add a Title Comment ................................. 140

8.1.2 Add a Channel Comment ........................... 141

8.1.3 Alphanumeric Input .................................... 143

8.2 Display Waveforms During

Recording (Roll Mode) ................. 147

8.3 Display New Waveforms Over

Past Waveforms (Overlay) ........... 148

8.4 Setting Channels to Use

(Extending the Recording Length)

8.5 Convert Input Values

(Scaling Function) ........................ 151

8.5.1 Scaling Examples ...................................... 153

150

8.6 Set the Waveform Position

(Variable Function) ....................... 158

8.7 Fine Adjustment of Input Values

(Vernier Function) ........................ 161

8.8 Invert the Waveform

(Invert Function) ........................... 162

8.9 Copy Settings to Other

Channels (Copy Function) .......... 163

8.10 Detailed Settings for Modules ..... 164

8.10.1 Settings for the Anti-Aliasing Filter (A.A.F.)

(Model 8968 High Resolution Unit) ............. 166

8.10.2 Probe Attenuation Selection ....................... 166

8.10.3 Setting Model 8967 Temp Unit ................... 167

8.10.4 Setting Model 8969 and U8969 Strain Unit . 168

8.10.5 Setting Model 8970 Freq Unit ..................... 169

8.10.6 Setting Model 8971 Current Unit ................ 172

8.10.7 Setting Model 8972 DC/RMS Unit .............. 172

8.10.8 Setting Model MR8990 Digital Voltmeter

Unit ............................................................ 173

8.10.9 Setting Model U8974 High Voltage Unit ...... 174

8.10.10 Setting Model MR8790 Waveform

Generator Unit ........................................... 175

8.10.11 Setting Model MR8791 Pulse Generator

Unit ............................................................ 177

8.10.12 Setting Model U8793 Arbitrary

Waveform Generator Unit .......................... 179

8.11 Register the Waveform in the

U8793 ArbitraryWaveform

Generator Unit .............................. 182

8.12 Save the Waveforms Registered

in the Model U8793 in the Media . 185

8.13 Setting Output Waveform

Parameters .................................... 185

9 Trigger Settings 187

9.1 SettingWorkow .......................... 188

9.2 Set the Trigger Mode .................... 189

9.3 Analog Signal Triggers ................ 190

9.4 Logic Signal Triggers

(Logic Trigger) .............................. 195

9.5 Trigger by Timer or Time

Interval (Timer Trigger) ................ 197

9.6 Apply an External Trigger

(External Trigger) ......................... 200

Trigger Manually (Manual Trigger)

9.7

9.8 Pre-trigger Settings ...................... 201

9.8.1 Set the Trigger Start Point (Pre-trigger) ...... 201

9.8.2 Set Trigger Acceptance (Trigger Priority) .... 203

9.9 Set Trigger Timing ........................ 204

Combined Trigger Logic (AND/OR)

9.10

for Multiple Trigger Sources

9.11 Use Trigger Settings to Search

Measurement Data ....................... 207

........... 206

200

12

13

14

15

16

17

18

19

9

10

ii

Page 4

Contents

10 Numerical Calculation

Functions 209

10.1 NumericalCalculationWorkow 210

10.2 Numerical Value Calculation

Settings ......................................... 212

10.2.1 Display Numerical Calculation Results ....... 215

10.3 Calculation Result Judgment ...... 216

10.3.1 Display Judgment Results and Signal

Output ....................................................... 218

10.4 Save Numerical Calculation

Results .......................................... 219

10.5 Print Numerical Calculation

Results .......................................... 221

10.6 Numerical Calculation Type and

Description ................................... 222

11 Waveform Calculation

Functions 225

11.1 WaveformCalculationWorkow 226

11.2 Waveform Calculation Settings .. 228

11.2.1 Display the Trigger Settings to Search

Measurement Data .................................... 229

11.2.2 Setting Constants ...................................... 231

11.2.3 Change the Display Method for

Calculated Waveforms ............................... 232

11.3 Waveform Calculation

Operators and Results ................. 234

12 Memory Division

Function 237

12.1 Recording Settings ...................... 239

12.2 Display Settings ........................... 240

13.3.8 Emphasize Analysis Results (Phase

Spectra Only) ............................................255

13.3.9 Analysis Mode Settings ..............................256

13.3.10

13.3.11 Set and Change Analysis Conditions on

13.4 Select Channels ........................... 262

13.5 Screen Display Settings .............. 263

13.5.1 Display Running Spectrums ....................... 265

13.6 Save Analysis Results ................. 268

13.7 Print Analysis Results ................. 269

13.8 Analysis With the Waveform

13.8.1 Analyze After Specifying an Analysis

13.9 FFT Analysis Modes ..................... 272

13.9.1 Analysis Modes and Display Examples ...... 272

13.9.2 Analysis Mode Functions ........................... 289

Set the Display Range of the Vertical Axis

(Scaling) ....................................................260

the Waveform Screen ................................ 261

Screen ........................................... 270

Starting Point ............................................. 270

14 Waveform Evaluation

Function 291

14.1 Waveform GO/NG Evaluation

(MEM, FFT Function) .................... 291

14.2 Set the Waveform Area ................ 294

14.3 Set the Waveform Evaluation

Mode .............................................. 296

14.4 Set Waveform Evaluation Stop

Mode .............................................. 297

14.5 Create the Evaluation Area .......... 299

14.6 Editor Command Details ............. 300

15 System Environment

Settings 305

11

12

13

14

15

16

17

18

13 FFT Function 243

13.1 Overview and Features ................ 243

13.2 OperationWorkow

(Reference Data) ........................... 244

13.3 FFT Analysis Condition Settings 245

13.3.1 Select the FFT Function ............................. 245

13.3.2 Select the Data Source for Analysis

(Reference Data) ....................................... 246

13.3.3 Set the Frequency Range and Number of

Analysis Points ..........................................247

13.3.4 Thin Out and Calculating Data ...................249

13.3.5 Window Function Settings .......................... 250

13.3.6 Analysis Result Peak Value Settings .......... 251

13.3.7 Average Analysis Results (Waveform

Averaging) ................................................. 252

16 Connect to a PC 309

16.1 LAN Connection and Settings

(Before Using FTP/

Internet Browser/Command

Communications) ......................... 310

16.1.1 LAN Settings on the Instrument ................. 310

16.1.2 Connect the Instrument to a PC With a

LAN Cable ................................................. 313

16.2 Perform Remote Operations on

the Instrument

(Use an Internet Browser) ........... 315

16.2.1 HTTP Settings on the Instrument ............... 315

16.2.2 Connect to the Instrument With an

Internet Browser ........................................ 316

iii

9

19

10

Appx.

Index

Page 5

Contents

16.2.3 Operate the Instrument With an Internet

Browser ..................................................... 317

16.3 Access Files on the Instrument

From a PC (Using FTP) ................ 322

16.3.1 FTP Settings at the Instrument ................... 323

16.3.2 Use FTP to Connect to the Instrument ....... 324

16.3.3 Use FTP for File Operations.......................325

16.4 Transferring Data to the PC ......... 326

16.5 Wave Viewer (Wv) ......................... 327

16.6 USB Connection and Settings

(Before Command Communication)

16.6.1 USB Settings on the Instrument ................. 328

16.6.2 Install the USB Driver ................................. 328

328

16.7 Controlling the Instrument with

Command Communications

(LAN/USB) ..................................... 333

16.7.1 Settings on the Instrument ......................... 333

16.8 Operate the Instrument

Remotely and Acquire Data

Using the Model 9333 LAN

Communicator .............................. 334

17 External Control 335

17.1 Connect to External Control

Terminals....................................... 337

17.2 External I/O ................................... 338

17.2.1 External Input (START/IN1) (STOP/IN2)

(S AVE/IN3) ................................................ 338

17.2.2 External Output (GO/OUT1) (NG/OUT2) .... 340

17.2.3 External Sampling (EXT.SMPL) ..................342

17.2.4 Trigger Output (TRIG OUT) ........................ 343

17.2.5 External Trigger Terminal (EXT.TRIG) ........344

18.6.8 Model 8973 Logic Unit ............................... 370

18.6.9 Model MR8990 Digital Voltmeter Unit ......... 371

18.6.10 Model U8974 High Voltage Unit ................ 373

18.6.11 U8793 Arbitrary Waveform Generator Unit . 375

18.6.12 MR8790 Waveform Generator Unit ..........378

18.6.13 MR8791 Pulse Generator Unit .................. 380

19 Maintenance and

Service 383

19.1 Trouble Shooting .......................... 385

19.2 Reset the Instrument ................... 388

19.2.1 Reset System Settings ..............................388

19.2.2 Reset Waveform Data ...............................388

19.3 Error Messages ............................ 389

19.4 Self-Test (Self Diagnostics) ......... 393

19.4.1 ROM/RAM Check ...................................... 393

19.4.2 Printer Check (When Model U8350

Printer Unit is Installed) .............................. 394

19.4.3 Display Check ............................................ 394

19.4.4 Key Check ................................................. 395

19.4.5SystemCongurationCheck ...................... 395

19.5 Cleaning ........................................ 396

19.6 Dispose of the Instrument

(Lithium Battery Removal) .......... 398

Appendix A1

Appx. 1 Default Values for Major

Settings .....................................A1

Appx. 2 For Reference ...........................A2

Appx. 3 About Options .......................... A9

Appx.4 FFTDenitions .......................A13

18 Specications 345

18.1 GeneralSpecicationsofthe

Unit ................................................ 345

18.2 Common Functions ..................... 348

18.3 Measurement Functions .............. 350

18.3.1 Memory Function ....................................... 350

18.3.2 Recorder Function ..................................... 351

18.3.3 X-Y Recorder Function .............................. 352

18.3.4 FFT Function ............................................. 352

18.4 Other Functions ........................... 353

18.5 File ................................................. 358

18.6 ModuleSpecications ................. 360

18.6.1 Model 8966 Analog Unit ............................. 360

18.6.2 Model 8967 Temp Unit ............................... 361

18.6.3 Model 8968 High Resolution Unit ............... 363

18.6.4 Model 8969 Strain Unit, U8969 Strain Unit . 364

18.6.5 Model 8970 Freq Unit ................................ 365

18.6.6 Model 8971 Current Unit ............................ 367

18.6.7 Model 8972 DC/RMS Unit .......................... 368

iv

Index Ind.1

Page 6

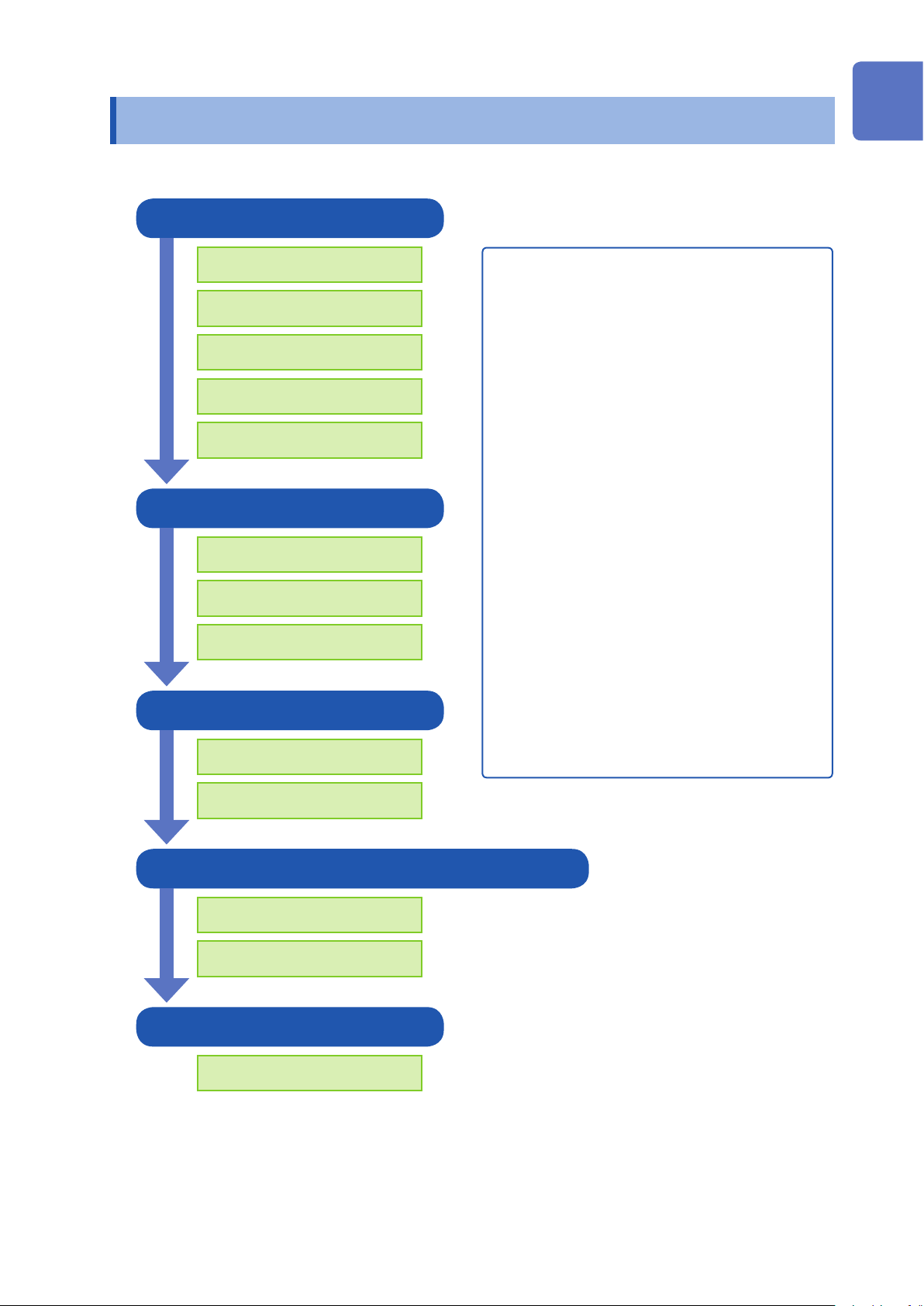

Usage Index

Basic Measurement Workow

1 Install (p. 25)

Usage Index

1

Install this instrument

To install a module

Connect cables

Insert recording paper*

Turn Power On

2 Set (p. 49)

Select a function

Select measurement settings

Select input channels

3 Measure (p. 68)

Measuring with automatic range setting

(p. 70)

Catching Changes in Input Signals (p. 187)

Applying a Manual Trigger (p. 200)

Adding Comments (p. 140)

Freely Setting the Waveform Display (p. 60)

Converting Input Values (p. 151)

Copying Settings to Other Channels (p. 163)

Suppressing Noise (Low-pass lter) (p. 65)

Composing X-Y Waveforms (p. 128)

Locking the Keys (KEY LOCK) (p. 17)

Initializing a CF card (p. 42)

2

3

4

5

6

Scaling During Measurement Using a Current

Start recording

Stop recording

4

Analyze (p. 121), Save (p. 77), Print * (p. 107)

Perform analysis

Save and/or print* (optional)

5 Finish (p. 45)

Turn power Off

* When Model U8350 Printer Unit is installed

Camp Sensor (p. 153)

7

8

9

10

Appx.

Index

1

Page 7

Introduction

Introduction

Thank you for purchasing the HIOKI MR8827 Memory HiCorder. To obtain optimal performance from this

instrument, please read this manual and keep it handy for future reference.

The optional clamps (p. A9) are called by a generic name of “clamp sensor.”

Trademarks

• Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in the

United States, Japan, and other countries

• CompactFlash is a registered trademark of Sandisk Corporation (USA).

• Sun, Sun Microsystems, Java, and any logos containing Sun or Java are trademarks or registered

trademarks of Oracle Corporation in the United States and other countries.

• Microsoft Excel and Internet Explorer are either registered trademarks or trademarks of Microsoft

Corporation in the United States and other countries.

Package Contents

When you receive your Memory HiCorder, inspect it carefully to ensure that no damage occurred during

shipping. Please pay particular attention when checking the accessories, panel keys and switches, and

connectors. If you nd damage, or your HiCorder fails to operate according to specications, contact your

authorized Hioki distributor or reseller.

Keep the packing material used for the shipping of the instrument because you need to use it when

transporting the instrument in the future.

Unit and Accessories

Conrm that you received the following items: (One each)

MR8827 Memory HiCorder

Accessories

Instruction Manual

Application disc (CD)*2

(p. 327)

• SF8000 Waveform Maker

• Wave Viewer (WV)

• Communication Command

Instruction Manual

• U8793, MR8790, MR8791

Instruction Manual

*1: If one or more Model 8967 Temp Units are installed in the instrument, two ferrite clamp-on chokes

(small) will be supplied per module.

*2:The latest version can be downloaded from our website.

Power cord

Input cable labels

USB cable

9231 Recording Paper

(When Model U8350 Printer

Unit is installed)

Paper Roll Axle

(When Model U8350 Printer

Unit is installed)

Ferrite clamp-on choke

(For LAN/USB Cable)

Other options as specied in

your order

Refer to “Appendix 3.1

Options” (p. A9).

*1

2

Page 8

Safety Information

Safety Information

This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly tested

for safety prior to shipment. However, using the instrument in a way not described in this manual may

negate the provided safety features.

Before using this instrument, read and understand the following safety notes.

DANGER

Mishandling during use could result in injury or death, as well as damage to the

instrument. Be certain that you understand the instructions and precautions in

the manual before use.

1

2

WARNING

Electricity presents risks of electric shock, heat generation, re, and arc

discharge due to short circuits. If anyone who is unfamiliar with electrical

measuring instruments will use the instrument, a person familiar with such

instruments must supervise operations.

Protective gear

WARNING

This instrument is measured on a live line. To prevent electric shock, use

appropriate protective insulation and adhere to applicable laws and regulations.

Notation

In this manual, the seriousness of risks and hazard levels are classied as follows.

Indicates an imminently hazardous situation that will result in death or serious injury to

DANGER

the operator.

3

4

5

6

7

WARNING

CAUTION

IMPORTANT

*

Indicates a potentially hazardous situation that may result in death or serious injury to

the operator.

Indicates a potentially hazardous situation that may result in minor or moderate injury

to the operator or damage to or malfunction of the instrument.

Indicates information related to the operation of the instrument or maintenance tasks

with which the operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the instrument is mishandled, this may

give rise to a hazardous situation; the operator may receive an electric shock, be

burned or even be fatally injured.

Indicates prohibited actions.

Indicates actions which must be performed.

Additional information is presented below.

8

9

10

Appx.

Index

3

Page 9

Safety Information

Symbols Afxed to the Instrument

Indicates cautions and hazards. When this symbol is printed on the instrument, refer to

the corresponding topic in this Instruction Manual.

Indicates the ON or OFF side of the power switch.

Indicates a grounding terminal.

Indicates AC (Alternating Current).

Indicates a burn hazard if touched directly.

Standards Symbols

This symbol indicates that the electrical and electronic appliance was put on the EU

market after August 13, 2005, and producers of the Member States are required to display

it on the appliance under Article 11.2 of Directive 2002/96/EC (WEEE).

This symbol indicates that the product conforms to regulations set out by the EU Directive.

Other Symbols

This manual uses the following symbols to indicate specic information for operating the instrument.

(p. ) Indicates the location of reference information.

CURSOR

(Bold text)

[ ]

Names of settings, buttons, and other screen elements are written in bold blue text.

Unless otherwise specied, “Windows” refers to Windows Vista, Windows 7, and

Windows 8.

IE is an acronym for Internet Explorer.

Menus, commands, dialogs, buttons in a dialog, and other items on the screen and keys

are enclosed in brackets.

Indicates Memory function support.

Indicates Recorder function support.

Indicates X-Y Recorder function support.

Indicates FFT Recorder function support.

Click: Press and quickly release the left button of the mouse.

Right click: Press and quickly release the right button of the mouse.

Double click: Quickly click the left button of the mouse twice.

4

Page 10

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading) and setting values,

with the following meanings:

Safety Information

f.s. (maximum display value

or scale length)

rdg. (display value) The value currently being measured and indicated on the measuring

setting Indicates the value set as the output voltage, current, or other quantity.

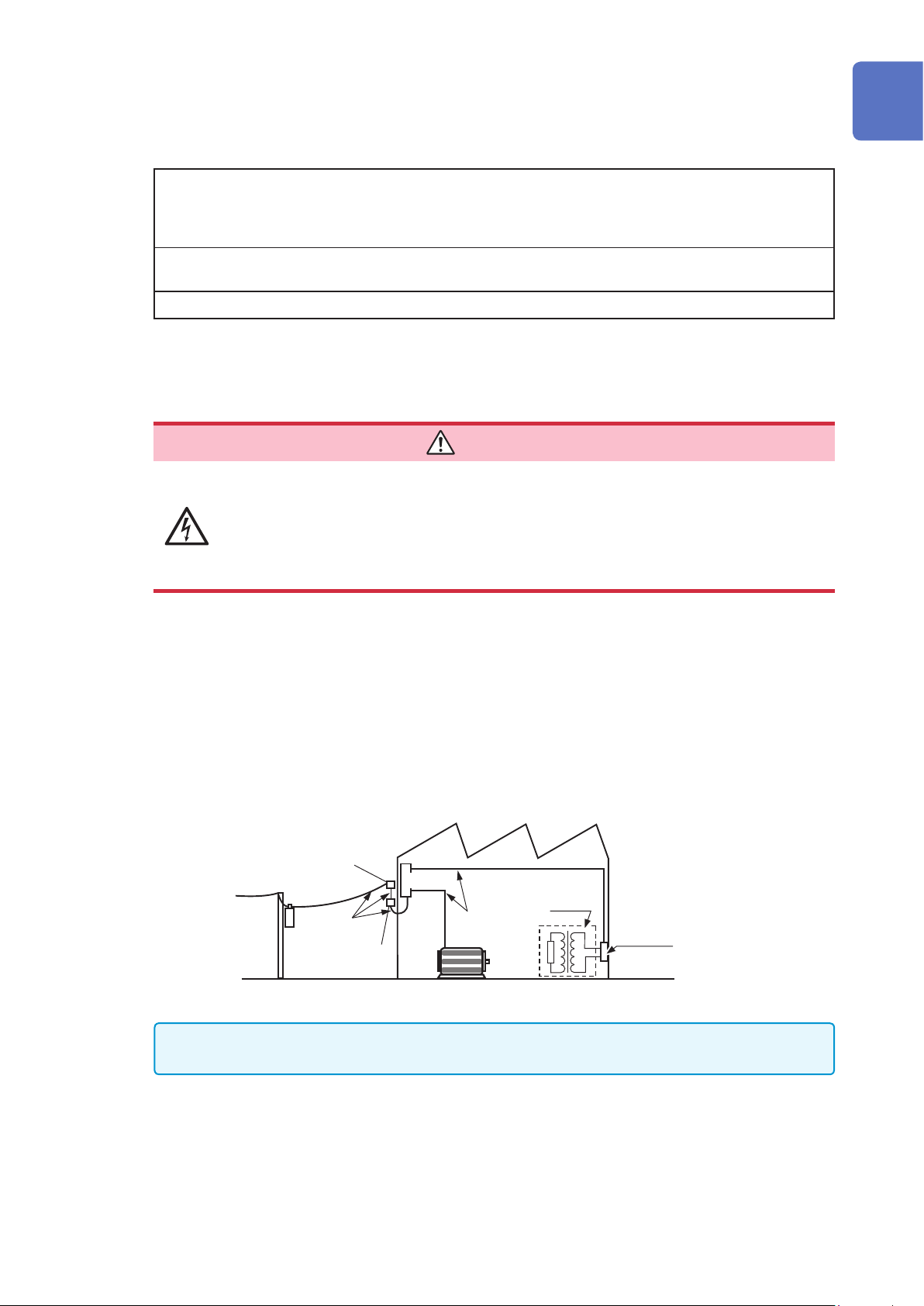

Measurement Categories

To ensure safe operation of measuring instruments, IEC 61010 establishes safety standards for

various electrical environments, categorized as CAT II to CAT IV, called measurement categories.

The maximum displayable value or scale length.

For this instrument, the maximum displayable value is the range (V/div)

times the number of divisions (20) on the vertical axis.

Example: When range is 1 V/div, f.s. = 20 V

instrument.

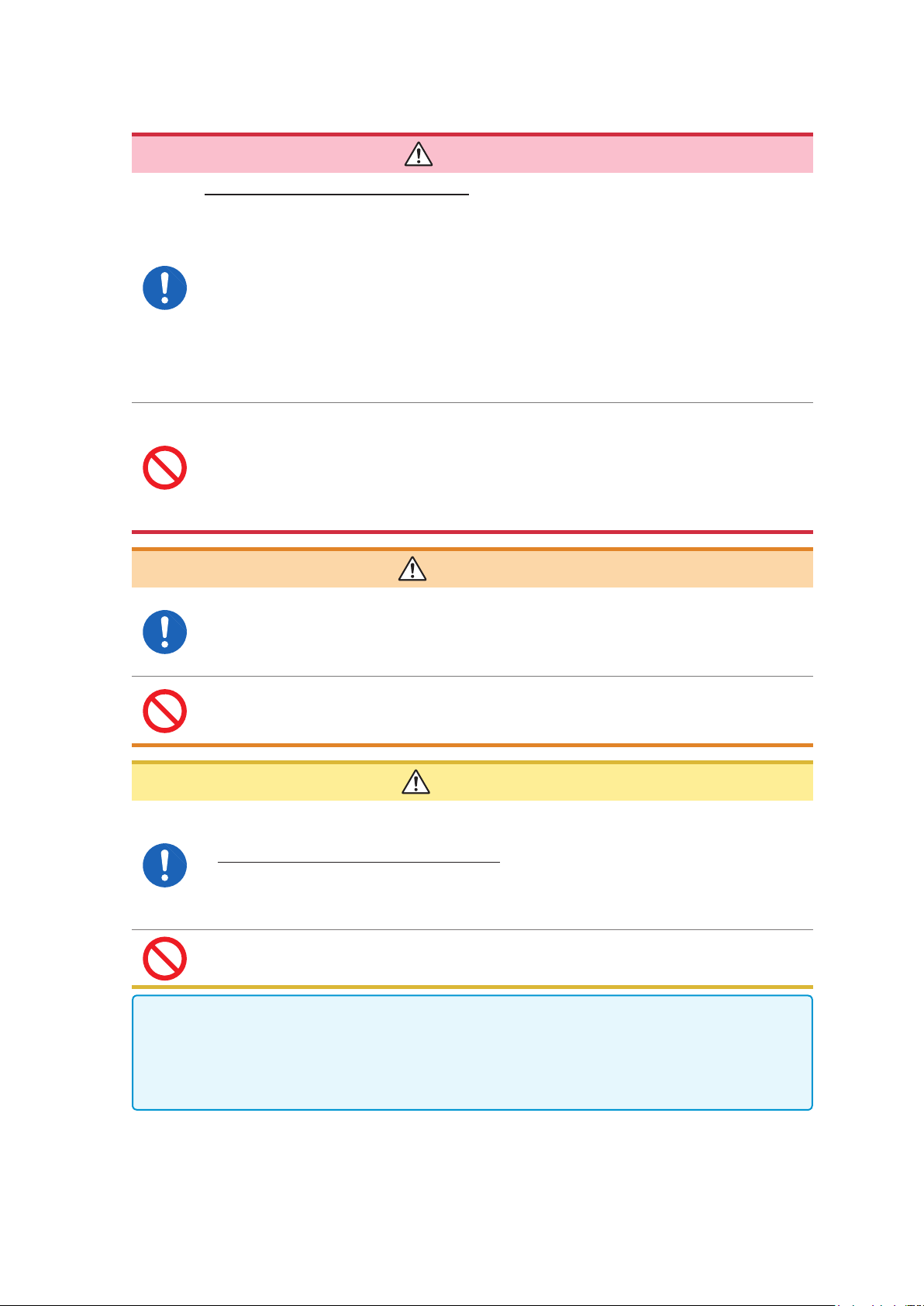

DANGER

• Using a measuring instrument in an environment designated with a higher-

numbered category than that for which the instrument is rated could result in

severe accidents, and must be carefully avoided.

• Using a measuring instrument that has no category rating in an environment

designated with the CAT II to CAT IV category could result in severe accidents,

and must be carefully avoided.

1

2

3

4

5

CAT II: When directly measuring the electrical outlet receptacles of the primary electrical circuits in

equipment connected to an AC electrical outlet by a power cord (portable tools, household

appliances, etc.)

CAT III: When measuring the primary electrical circuits of heavy equipment (xed installations)

connected directly to the distribution panel, and feeders from the distribution panel to

outlets

CAT IV: When measuring the circuit from the service drop to the service entrance, and to the power

meter and primary overcurrent protection device (distribution panel).

Service Entrance

Service Drop

CAT IV

Power Meter

The applicable measurement category is determined by the module being used.

Refer to “18.6 Module Specications” (p. 360).

Distribution panel

Fixed Installation

Internal Wiring

CAT III

CAT II

T

Outlet

6

7

8

9

10

Appx.

5

Index

Page 11

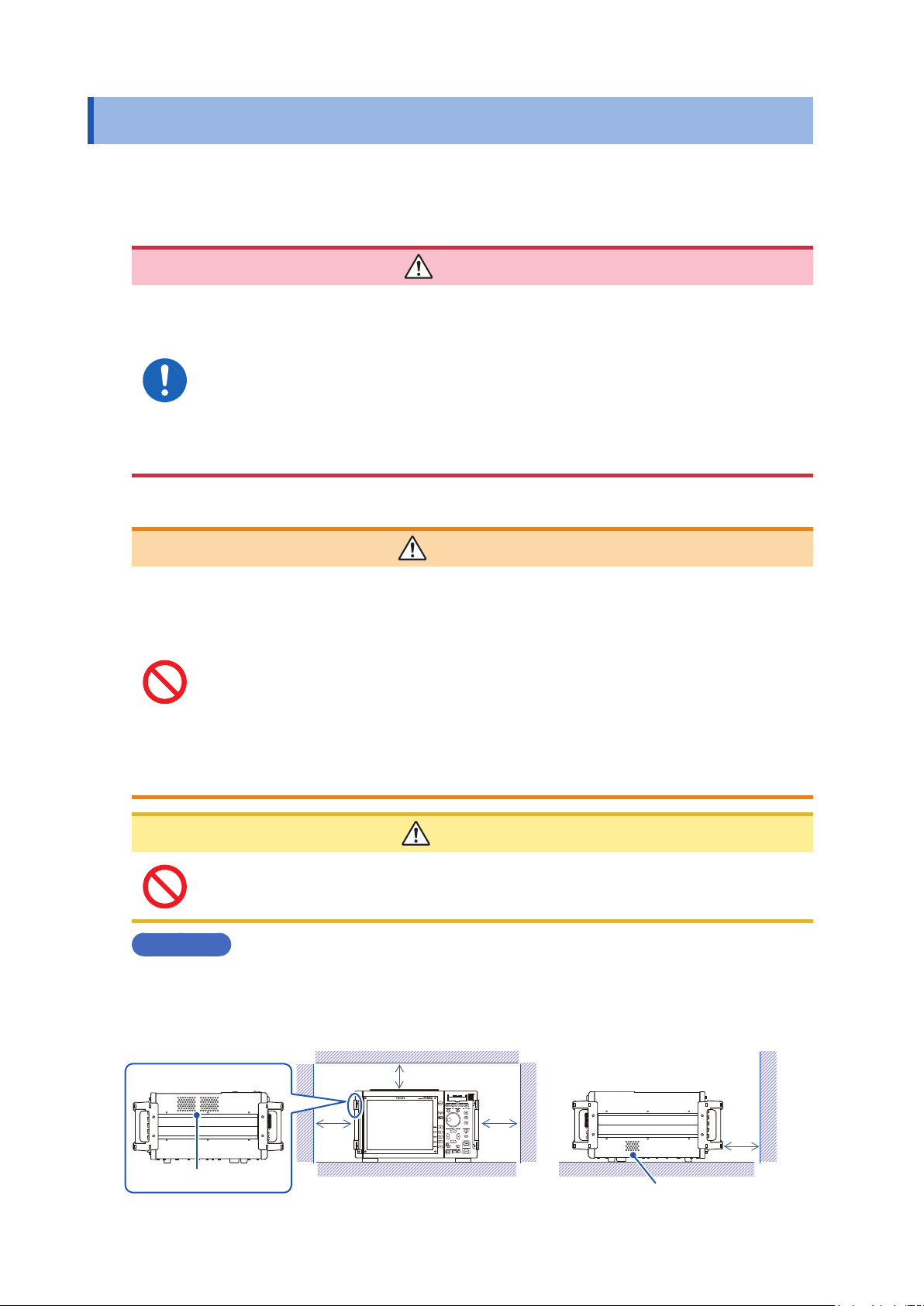

Operation Precautions

At least 5 cm

At least 5 cm on all sides

Operation Precautions

Before Use

Follow these precautions to ensure safe operation and to obtain the full benets of the various

functions.

DANGER

If connection cables or instrument are damaged, there is a risk of electric shock.

Before using the instrument, perform the following inspection.

• Before using the instrument, check that the insulation of the connection cables

is not damaged and that no metal parts are exposed. Using the instrument

under such conditions could result in electric shock. Replace the connection

cable with those specied by our company.

• Verify that the instrument operates normally to ensure that no damage occurred

during storage or shipping. If you nd any damage, contact your authorized

Hioki distributor or reseller.

Instrument Installation

To avoid accidents or damage to the instrument, do not install the instrument in

locations that are:

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to a strong electromagnetic eld or electrostatic charge

• Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

Do not place the instrument in a location that is unstable or inclined. Do not place the

unit on another unit. Knocking-over or dropping the instrument can cause injury or

damage to the instrument.

Installation

WARNING

CAUTION

Be sure to keep the specied clearances around the instrument to prevent overheating.

• Do not install the instrument with any side except the bottom facing down.

• Do not obstruct vents.

• Do not install the instrument at an angle.

Left side

Vents

At least 5 cm on all sides

Right side

6

Vents

At least 5 cm

Page 12

Handling the Instrument and Modules

• Do not exceed the range of the specications and the rated value of the cable

or the module.

Otherwise, the instrument may be damaged or may produce heat, resulting in

personal injury.

The maximum rated voltage to earth does not change when an attenuator or

similar is used at the input. Take the connection method into consideration and

make sure that the rating is not exceeded.

• To avoid electric shock, ddo not remove the instrument’s cover and the module

case.

The internal components of the instrument carry high voltages and may

become very hot during operation.

•

To avoid electric shocks, conrm that the module is turned off and the

connection cables are disconnected before removing or replacing a module.

•

To avoid electric shocks, never operate the instrument with a module removed.

To use the instrument after removing a module, install a blank panel over the

opening of the removed module.

•

To prevent instrument damage or electric shocks, use only the screws for

securing the module in place that shipped with the instrument.

If you lose any screw or nd that any screws are damaged, please contact your

Hioki distributor for a replacement.

Operation Precautions

DANGER

1

2

3

WARNING

4

5

CAUTION

• To avoid damage to the instrument, protect it from physical shock during transport and

handling. Be especially careful to avoid physical shock from dropping.

• The mounting screws must be rmly tightened or the module may not perform as

specied or may fail.

• To avoid damaging modules, do not touch the module connectors on this instrument.

• Before transporting the instrument, disconnect all cables and remove any CF cards, USB memory sticks,

and recording paper.

• When there is no input, the waveform might be unstable due to the induced voltage, but this is not an

error.

• This instrument may cause interference if used in residential areas. Such use must be avoided unless the

user takes special measures to reduce electromagnetic emissions to prevent interference to the reception

of radio and television broadcasts.

6

7

8

9

10

Appx.

7

Index

Page 13

Operation Precautions

Handling the Printer and Recording Paper

WARNING

The print head and surrounding metal parts can become hot. Be careful to avoid

touching these parts.

CAUTION

Be careful not to cut yourself with the paper cutter.

• Please use only the specied recording paper. Using non-specied paper may not only result in

faulty printing, but printing may become impossible.

• If the recording paper is skewed on the roller, paper jams may result.

• Always use the paper cutter to cut the printed paper. Excessive paper dust can accumulate on the roller

if the paper is cut by the print head, which may result in paper jams or white streaks in the printing.

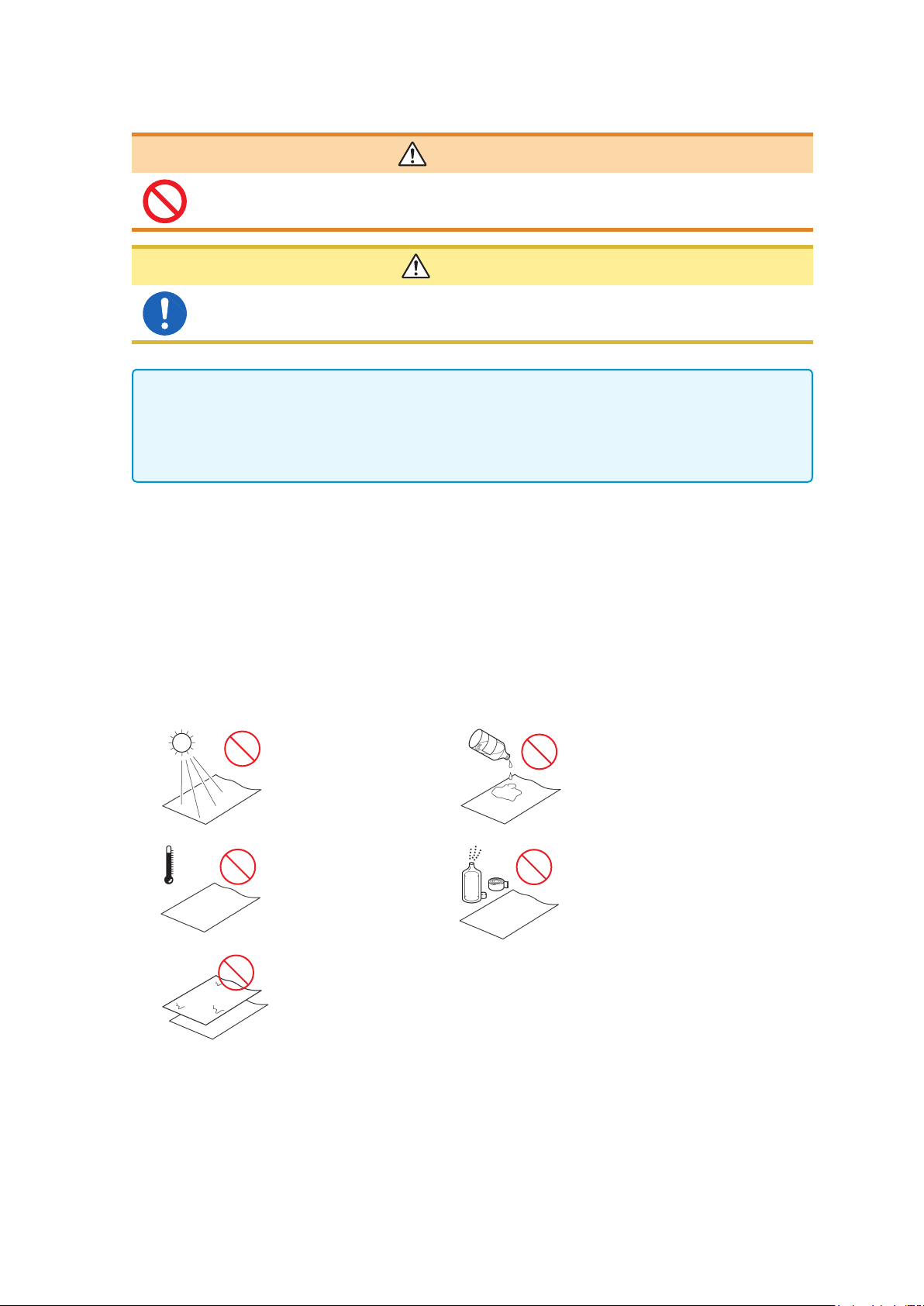

Storing Data Recordings

The recording paper is thermally and chemically sensitized. Observe the following precautions to

avoid paper discoloration and fading.

• To avoid discoloration, do not expose it to direct sunlight. Store below 40°C (104°F) and 90% RH.

• Store away from dew and damp places.

• Make photocopies of recording printouts that are to be handled or stored for legal purposes.

• If the thermal paper is exposed to an organic solvent such as alcohol or ketone, it may no longer

develop properly, and recorded data may fade. Pressure sensitive tapes such as exible PVC

lms and scotch tapes must be handled with care as they contain organic solvents.

• Also, the thermal recording paper is ruined by contact with wet Daizo copy paper.

Avoid exposure to direct

sunlight.

Do not store thermal paper

above 40°C and 90% RH.

Avoid stacking with wet

Diazo copy paper.

Avoid exposure to volatile

organic solvents like

alcohol, ethers, and

ketones.

Avoid contact with

adhesive tapes like

soft vinyl chloride and

cellophane tape.

Storing Recording Paper

• Store thermal paper where its temperature will not exceed 40°C (104°F).

• The paper will deteriorate if exposed to light for a long time, so do not remove rolls from their

wrappers until ready to use.Handling Media

8

Page 14

Handling Media

Operation Precautions

CAUTION

• Do not remove the media while it is being accessed by the instrument (while the

key is lit in blue). Data on the media could be lost.

• Do not turn off the power to the instrument while the media is being accessed by the

instrument (while the

• Do not transport the instrument while a USB ash drive is connected. Damage could

result.

• Exercise care when using such products because static electricity could damage the

external media or cause a malfunction of the instrument.

• Do not subject the SSD to extreme shock or vibration. Doing so may damage the hard

disk.

IMPORTANT

• No compensation is available for loss of data stored on the built-in drive (SSD) or removable

media, regardless of the content or cause of damage or loss. Be sure to back up any important

data stored on the built-in drive (SSD) or removable media.

• Use only CF Cards sold by Hioki. (No adapter will be required when the card is inserted into

the instrument.)

• Compatibility and performance are not guaranteed for PC cards made by other manufacturers.

You may be unable to read from or save data to such cards.

■Hioki optional CF cards (The CF card includes an adapter.)

Model 9728 PC Card 512M, Model 9729 PC Card 1G, Model 9830 PC Card 2G

key is lit in blue). Data on the media could be lost.

SAVE

SAVE

1

2

3

4

5

• With some external media, the instrument may not start up if power is turned on while the external

media is inserted. In such a case, turn power on rst, and then insert the external media. Prior

testing is recommended.

• Unusual USB ash drives, such as those that require ngerprint authentication or a password,

cannot be used.

• When saving or loading data, insert the storage media before selecting it. If the media is not

inserted, the le list display will not appear.

• All media (built-in drive, USB memory stick and CF card) have a limited service life. After

extensive use over a long period, data retention and readout may become stop working. In

such cases, you should procure new media.

• The built-in drive (SSD) is a consumable part. When the written data reaches the capacity (about

60 TB), no more data can be recorded. In such a case, the SSD should be replaced with a new

one.

• When the instrument is turned off for a long time (more than one year), the data stored on the

built-in drive (SSD) may be lost. Be sure to back up the data if the instrument is left turned off

for a long time.

• Automatic saving of data is possible only on built-in drive (SSD), USB memory stick and CF

card media.

• Data can also be saved to a USB ash drive in real time, but for data protection we recommend

using Hioki’s optional CF card instead.

6

7

8

9

10

Appx.

9

Index

Page 15

Operation Precautions

Before Connecting Cables

When measuring power line voltage

• Connecting cables should only be connected to the secondary side of a breaker

Even if there is a short circuit on the secondary side of the breaker, the breaker

cuts off the electric supply. Do not connect to the primary side of a breaker

because unrestricted current ow could damage the instrument and facilities if

a short circuit occurs.

• To prevent electrical shocks and personal injury, do not touch any input

terminals on the VT (PT), CT or the instrument when they are in operation.

• Do not permanently connect the instrument in an environment where voltage

surges exceeding the maximum input voltage may occur. Failure to observe

this precaution could result in damage to the instrument or personal injury.

• Do not short-circuit two wires to be measured by bringing the connection cables

into contact with them. Arcs or such grave accidents are likely to occur.

• To avoid short circuit or electric shock, do not touch the metal parts of the

connecting cable clips.

• To avoid electrical shocks, be careful to avoid shorting live lines with the

connection cables.

DANGER

WARNING

• To avoid electric shock and short-circuit accidents, use only the specied test

leads to connect the instrument input terminals to the circuit to be tested.

• To avoid electric shock, do not exceed the lower of the ratings shown on the

instrument and connection cords.

To prevent an electric shock accident, conrm that the white or red portion

(insulation layer) inside the cable is not exposed. If a color inside the cable is

exposed, do not use the cable.

CAUTION

• The cable is hardened under the 0°C (32°F) or colder environment. Do not bend or

pull cables in such environments to avoid tearing insulation or breaking the cable.

• Connecting to the BNC jacks on modules

Do not use a metal BNC connector. If you connect a metal BNC cable to an insulated

BNC connector, the insulated BNC connector can be damaged and the instrument

may be damaged.

• To prevent cable damage, do not step on cables or pinch them between other objects.

Do not bend or pull on cables at their base.

IMPORTANT

• Use only the specied connection cables. Using a non-specied cable may satisfy the

specication requirements due to poor connection or other reasons.

• For detailed precautions and instructions regarding connections, refer to the instruction

manuals for your modules, connection cables, etc.

10

Page 16

Before Connecting a Logic Probe to the Measurement Object

Functional Earth

DANGER

To avoid electric shock and short circuit accidents or damage to the instrument,

conrm the following:

• The ground pin in the LOGIC connector (plug) of Models 9320-01 and 9327

Logic Probes is not isolated from the instrument’s ground (common ground).

Use grounding-type polarized power cords for the measurement object and this

instrument, and obtain power from the same mains circuit.

Connecting to different mains circuits or using a non-grounding power cord

may cause damage to the measurement object or this instrument because

of current ow through the logic probes resulting from potential difference

between the grounds of the different wiring systems.

To avoid these problems, we recommend the following connection procedure:

Connect this instrument to the

same outlet as the measurement

object using the (supplied)

grounding polarized power cord.

Measurement

Object

Logic probe

Operation Precautions

1

2

3

Memory

HiCorder

4

Connect the measurement object’s

ground to the GND terminal

(functional earth terminal) of this

instrument.

(Always obtain power from the

same mains circuit.)

See “2.5.2 Ground the Functional

Earth of This Instrument” (page

44)

Before Turning the Power Supply On

• To avoid electrical accidents and to maintain the safety specications of this

instrument, only connect the provided power cord to an outlet.

• Before turning the instrument on, make sure the supply voltage matches that

indicated on its power connector. Connection to an improper supply voltage

may damage the instrument and present an electrical hazard.

Avoid using an uninterruptible power supply (UPS), DC/AC inverter with rectangular

wave or pseudo-sine-wave output to power the instrument. Doing so may damage the

instrument.

Measurement

Object

GND

WARNING

CAUTION

Logic probe

Memory

HiCorder

Terminals

5

6

7

8

9

To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it

from the power outlet.

Turn off the power before connecting or disconnecting the power cord.

10

Appx.

Index

11

Page 17

Operation Precautions

Before Connecting to an External Device

DANGER

To avoid electrical hazards and damage to the instrument, do not apply voltage

that exceeds the maximum input voltage to the external control terminals.

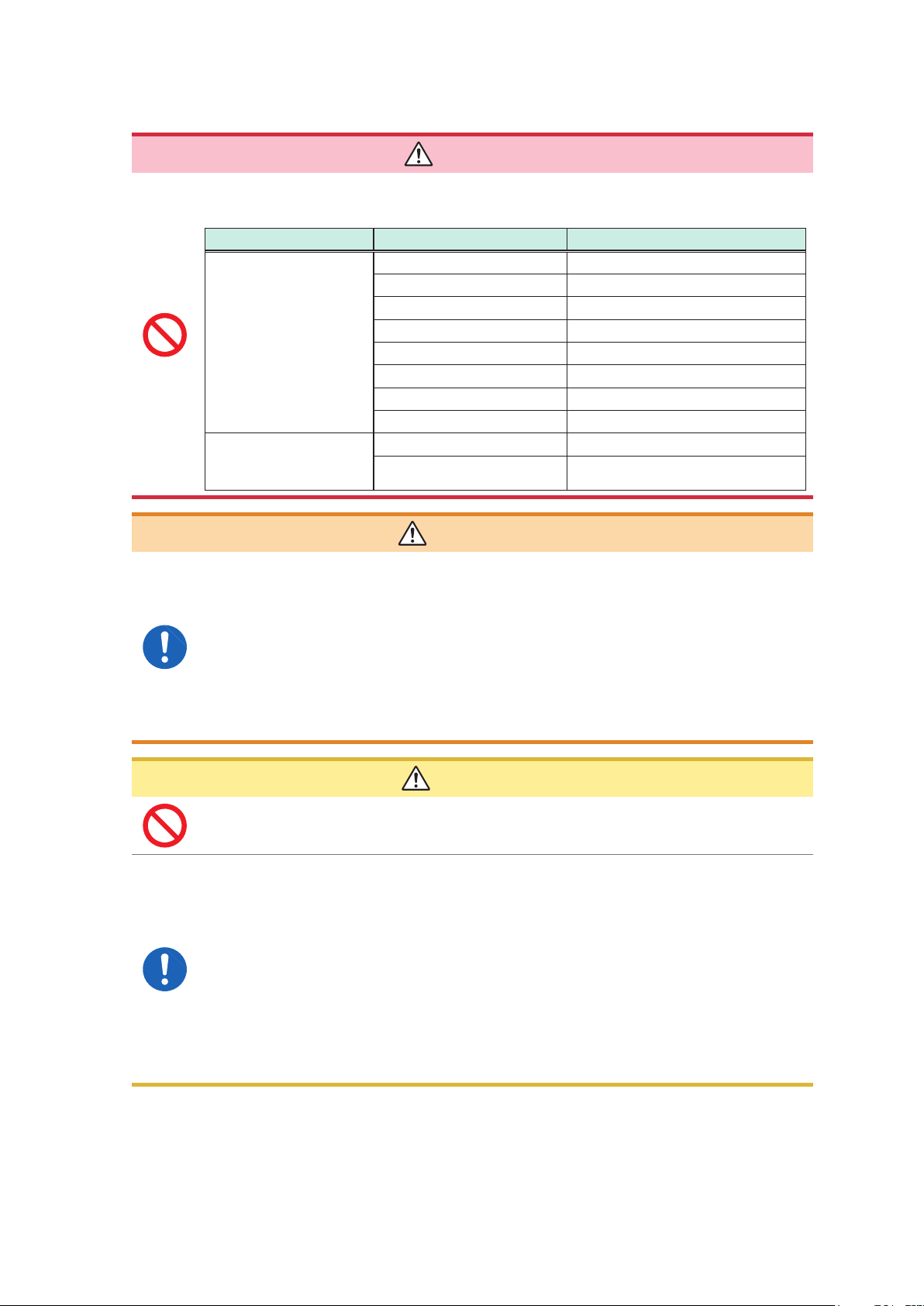

I/O terminals Maximum input voltage

Instrument START/.IN1 -0.5 V to 7 V DC

STOP/IN2 -0.5 V to 7 V DC

PRINT/.IN3 -0.5 V to 7 V DC

GO/OUT1 50 V DC, 50 mA DC, 200 mW

NG/OUT2 50 V DC, 50 mA DC, 200 mW

EXT.SMPL -0.5 V to 7 V DC

TRIG OUT 50 V DC, 50 mA DC, 200 mW

EXT.TRIG -0.5 V to 7 V DC

U8793

Arbitrary Waveform

Generator Unit

IN -0.5 V to 7 V DC

OUT 30 V DC, 50 mA DC

WARNING

To avoid electric shock or damage to the equipment, always observe the

following precautions when connecting to external control terminals or external

connectors.

• Always turn off the power to the instrument and to any devices to be connected

before making connections.

• Be careful to avoid exceeding the ratings of external control terminals and

external connectors.

• Ensure that devices and systems to be connected to the external control

terminals are properly isolated.

CAUTION

To avoid equipment failure, do not disconnect the USB cable while communication is in

progress.

• Use a common ground for both the instrument and the connection equipment.

Use of different ground circuits will result in a potential difference between the

instrument's ground and the connected equipment's ground. If the communications

cable is connected while such a potential difference exists, it may result in equipment

malfunction or failure.

• While connecting or disconnecting the communication cables, ensure that the power

supply of the instrument and the device to be connected is cut off. This may cause

damage or malfunctioning.

• After connecting the communications cable, tighten the screws on the connector

securely. Failure to secure the connector could result in equipment malfunction or

damage.

12

Page 18

CD Precautions

• Keep the recorded side of discs free of dirt and scratches. When writing text on a disc’s label, use

a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight, high temperatures, or

high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of using this

disc.

When the Instrument is Not Used for a Long Period

• To avoid straining some parts of the printer, and to prevent dirt adhering to the print head, close

the printer cover.

• Perform three or four test prints (printer check) before using a printer that has been in storage for

a long period.

Operation Precautions

1

2

Precautions During Shipment

Keep the packing material that was used for shipping this instrument because you may need to use

it when transporting the instrument in the future.

3

4

5

6

7

13

8

9

10

Appx.

Index

Page 19

Operation Precautions

14

Page 20

1

Overview

1.1 Product Overview

The MR8827 Memory HiCorder is an instrument that allows simultaneous measurement

of multiple signals. The MR8827 is easy to operate and allows quick and efficient

measurement and analysis.

Its major uses are monitoring, facility diagnosis and various tests.

1

Overview

Isolated 32 analog channels

Measurement possible using

up to 28 analog channels and

64 logic channels

Selectable module according to

the measurement details

High-speed sampling:

20 MS/s

Easy loading of recording paper

High-speed printing

The unit is electrically isolated from the channels.

All channels can be measured simultaneously.

Modules can be selected from more than eight types.

Reliable response evaluation is possible.

One-touch insertion allows quick and trouble-free

operation.

Arbitrary Waveform Generator Unit

can output the measured data

(When Model U8350 Printer Unit is installed)

You can simulate actual waveforms.

15

Page 21

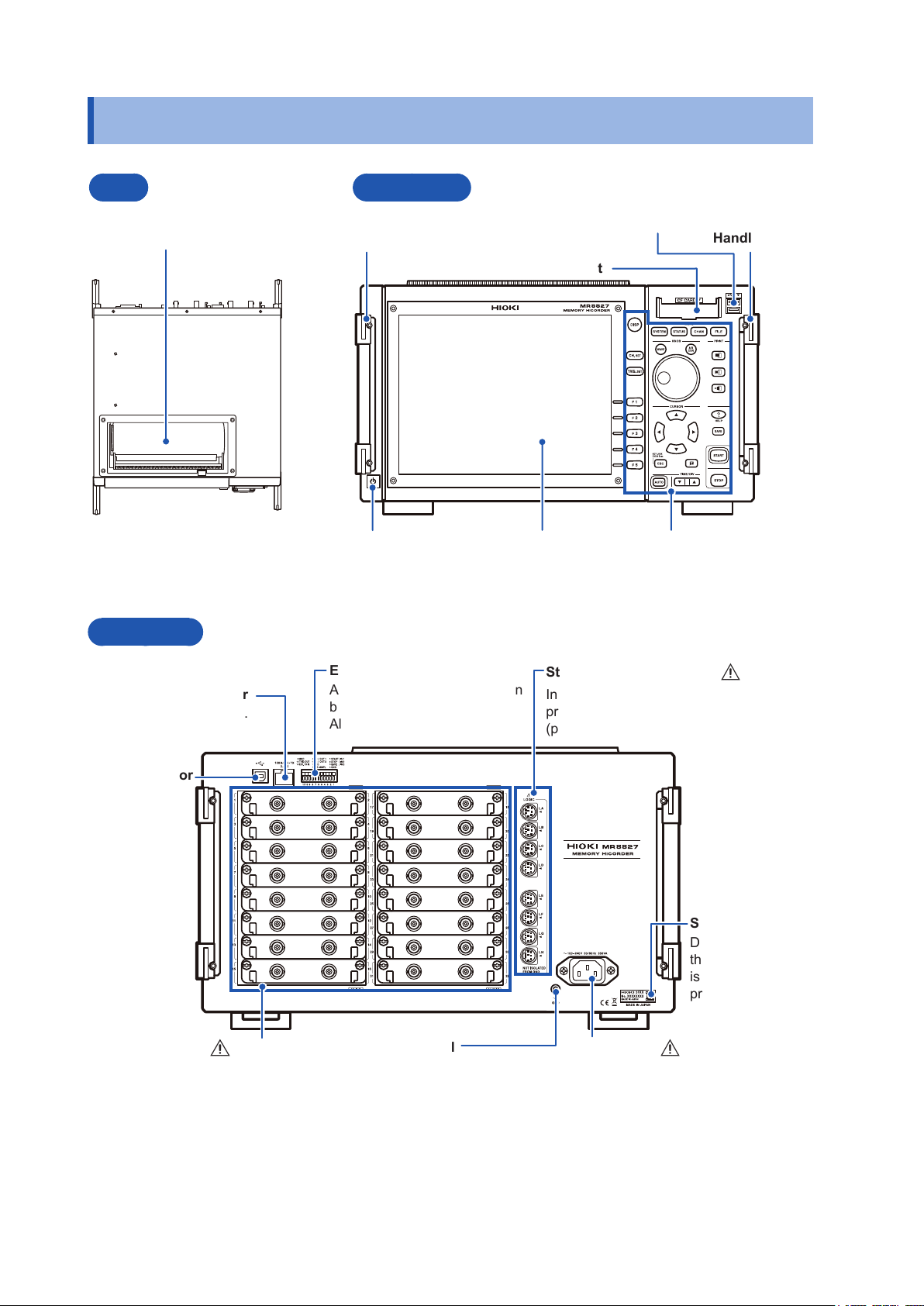

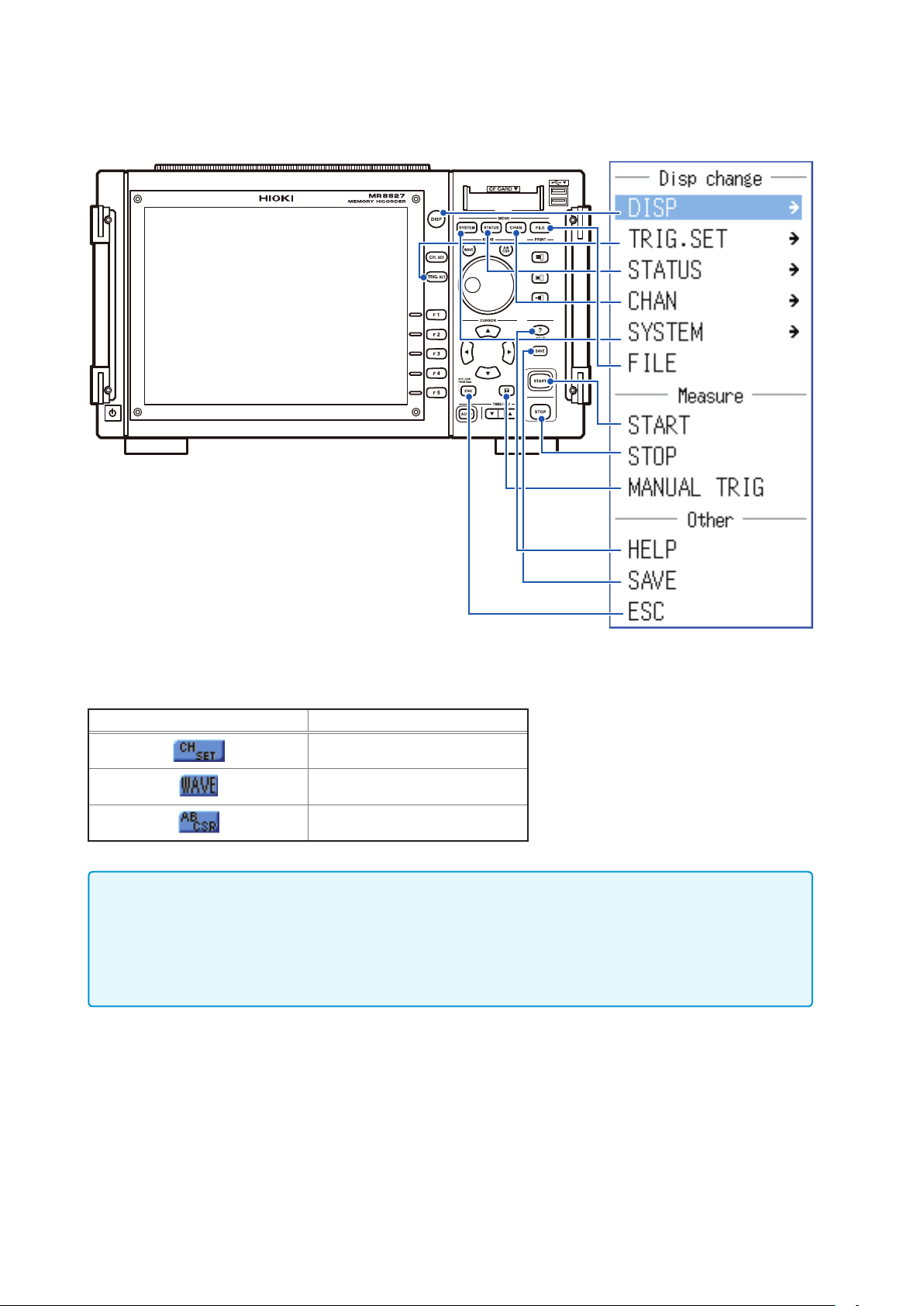

Part Names and Functions

1.2 Part Names and Functions

Top

Model U8350 Printer Unit

(Optional)

Back Side

Front Side

Handle Handle

POWER switch (p. 45)

USB connector (Type A)

Connect USB memory stick and

USB mouse here. (p. 40)

CF card slot

Display

Operation key (p. 17)

100BASE-TX connector

Connect LAN cable here.

(p. 309)

USB connector

(Type B)

Connect to the

computer (PC)

with the USB

cable.

(p. 328)

Various modules

(For details, see the instruction manual

of the respective module.)

(p. 26), (p. 28)

External control terminals

An external sampling signal can

be connected here. (p. 335)

Allows control of the unit.

GND terminal

(Functional earth terminal)

Connect to Earth ground. (p. 44)

Standard LOGIC terminals

Input connectors for optional

proprietary logic probes.

(p. 28)

Serial No.

Do not remove

this label, as it

is required for

product support.

Power inlet

Connect the supplied power

cord here. (p. 44)

16

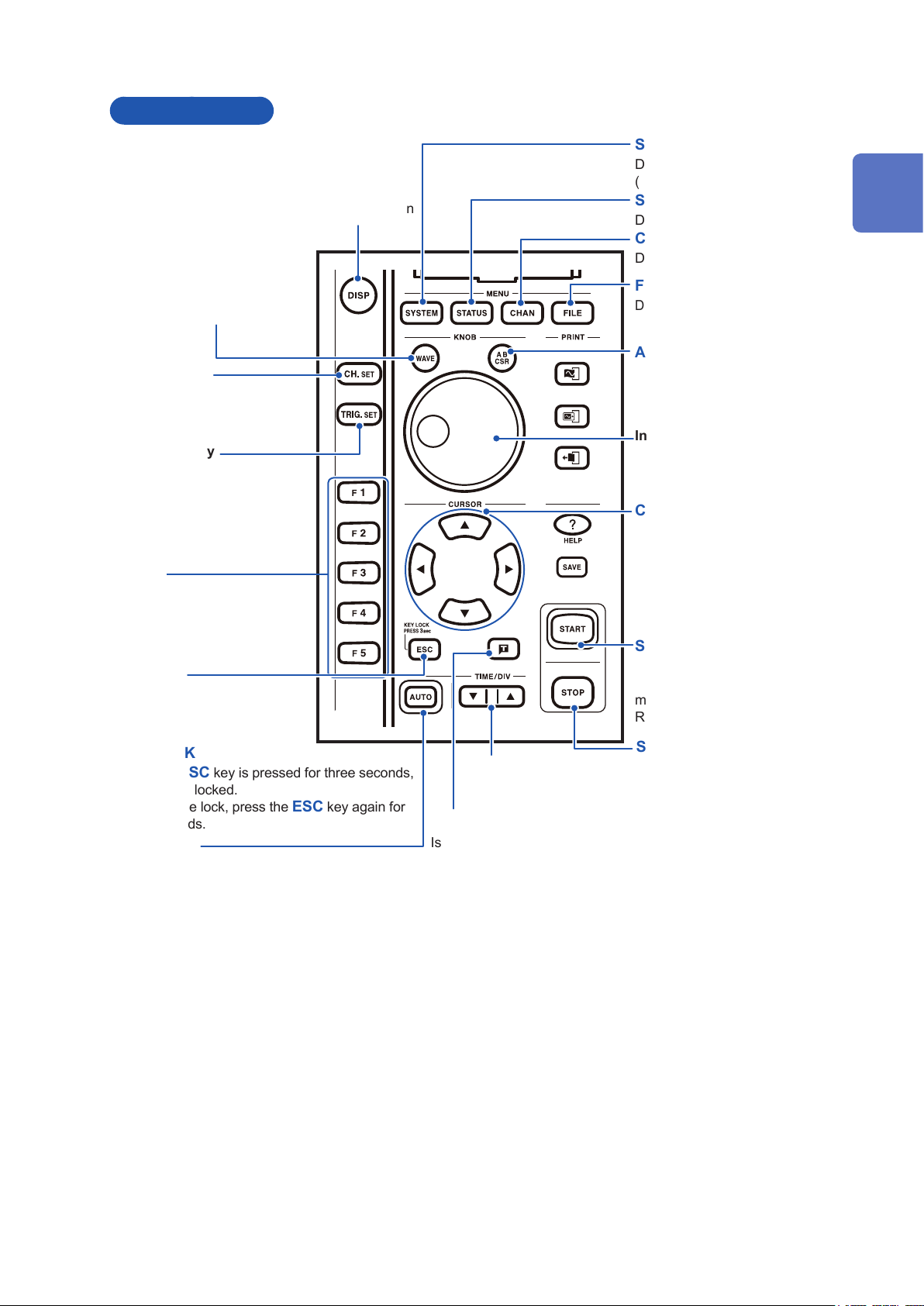

Page 22

Operation Keys

Part Names and Functions

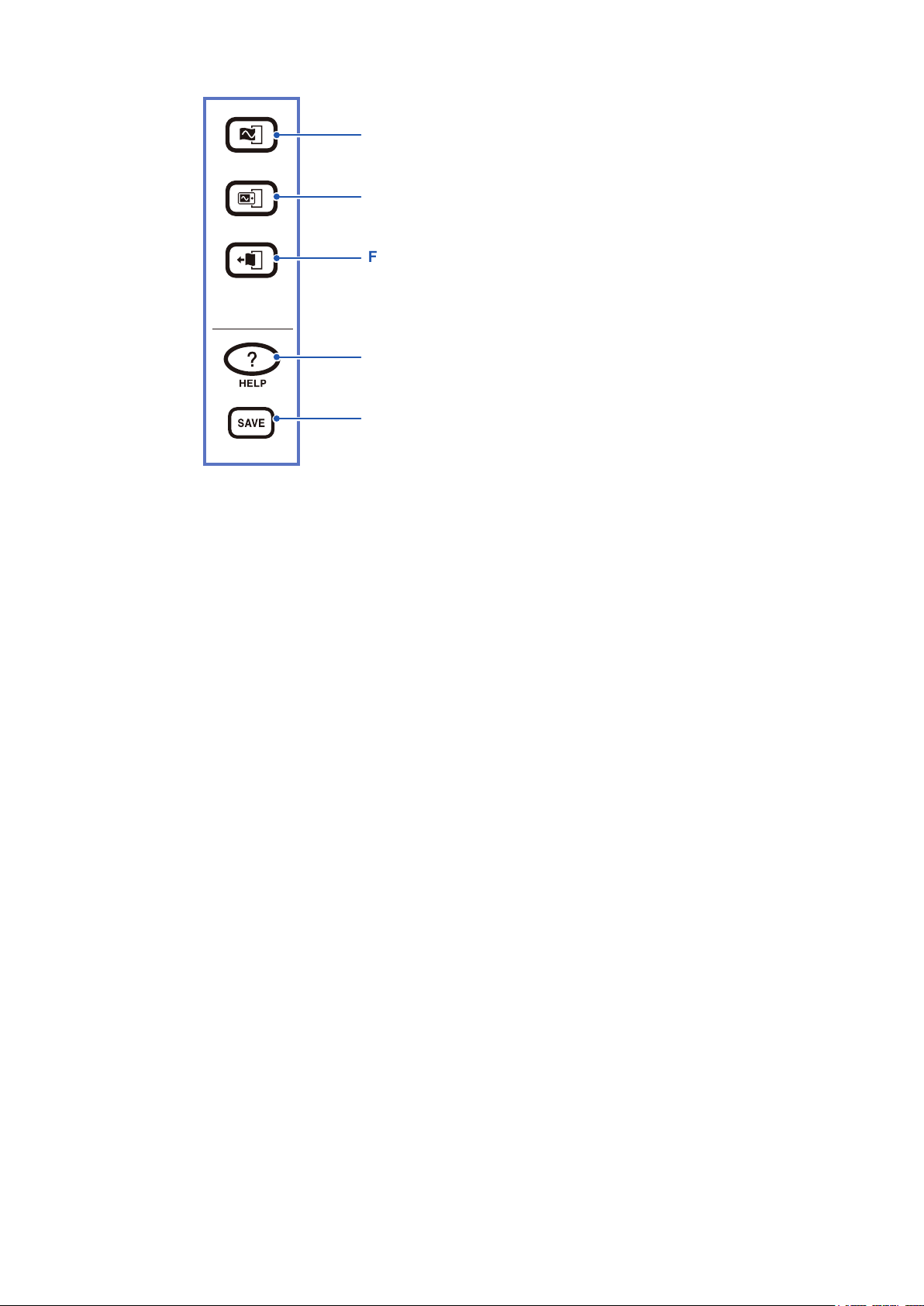

key

DISP

Displays the Waveform screen

WAVE

key

(Lights up in red when

selected)

Assigns the jog and shuttle

knobs to waveform scrolling.

(p. 126)

CH.SET

Displays the channel settings

window on the Waveform

screen. (p. 60)

TRIG.SET

Displays the trigger settings

window on the Waveform

screen. (p. 187)

F

Select setting items

key

key

key

SYSTEM

Displays the System screen

(p. 305)

STATUS

Displays the Status screen

CHAN

Displays the Channel screen

FILE

Displays the File screen (p. 97)

AB CSR

(Lights up in red when selected)

Sets AB cursors (p. 122)

Inner:

Outer:

Scrolls waveforms (p. 126)

CURSOR

Moves the cursor up, down, left

and right on the screen.

key

key

key

key

key

Jog

Shuttle

key

1

Overview

key

ESC

Cancels an operation.

Removes the displayed dialog

and window.

KEY LOCK

When the

the keys are locked.

To cancel the lock, press the

three seconds.

AUTO

Starts auto-range measurement

(p. 70)

key is pressed for three seconds,

ESC

ESC

key

key again for

TIME/DIV

Sets the time axis.

Manual Trigger

Issues a manual trigger event.

(p. 200)

key

key

START

Starts Measurement

Lights up green during

measurement.

Refer to (p. 307).

STOP

Stops Measurement

Press once:

Measurement stops after the

set recording length

Press twice:

Stop measurement

Refer to (p. 307).

key

key

17

Page 23

Part Names and Functions

PRINT

Prints waveforms and lists (p. 107)

COPY

Prints a hard copy of the display screen (p. 118)

FEED

Feeds paper

HELP

Opens help information (p. 22)

SAVE

(Lights up in blue while media is being accessed.)

Saves data to storage media. (p. 77)

Turns dialog box display during auto-save on or off.

key

key

key

key

key

18

Page 24

Screen Organization

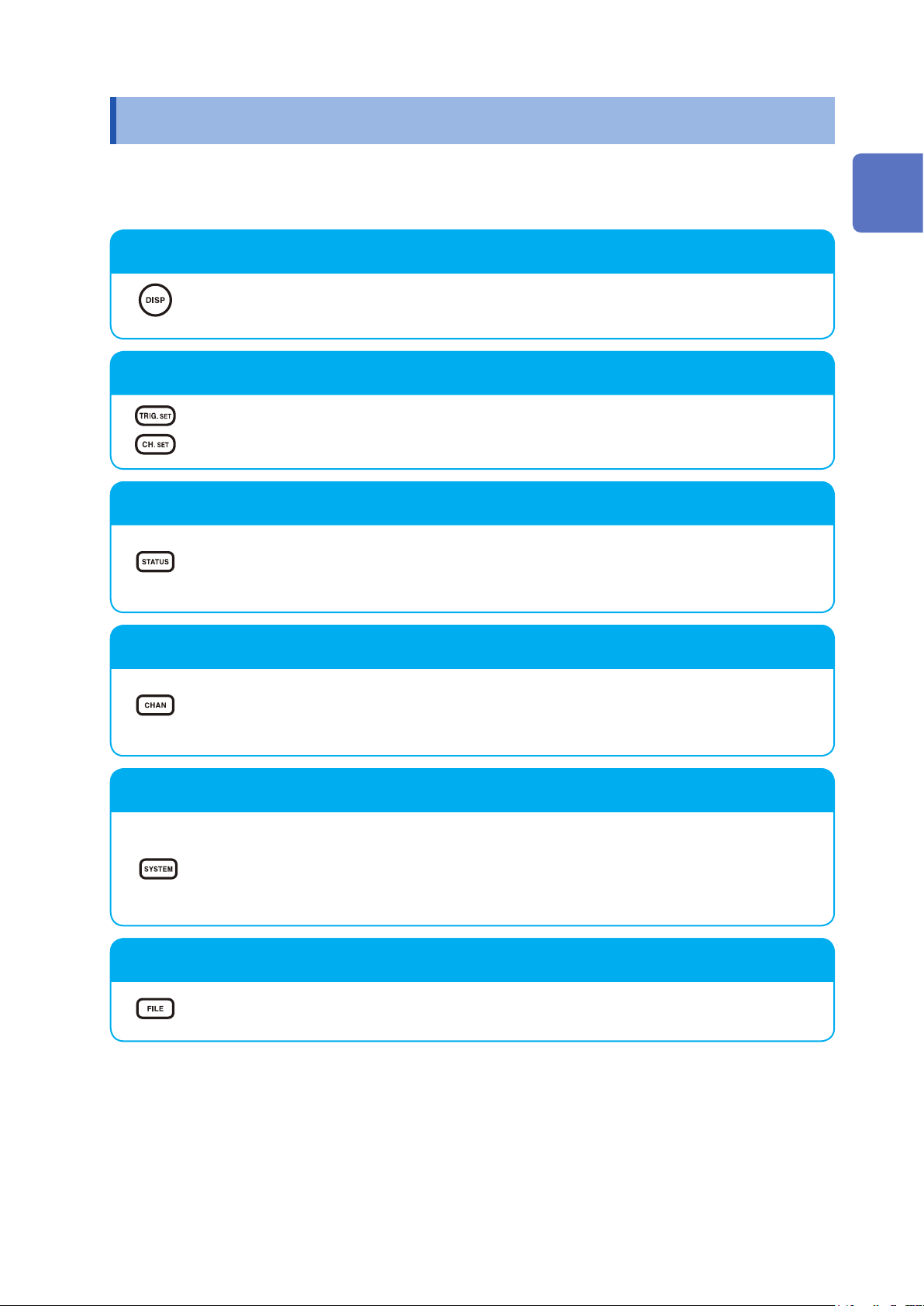

1.3 Screen Organization

The screen conguration is as listed below. Each screen or window appears when the listed key is

pressed.

The trigger settings window and channel settings window can be brought up on the Waveform screen.

Waveform Screen

Use this screen to view the waveform.

The settings window on the right displays the current measurement parameters.

Trigger Settings Window, Channel Settings Window

View the trigger settings.

View the analog channel and logic channel settings.

1

Overview

Status Screen

View and update measurement and calculation settings.

Each push of the

[Status]

Channel Screen

View and update channel, scaling, and comment settings.

Each push of the

[Unit List]

System Screen

View and update environment settings, save and print les, choose interface settings, and

perform data initialization.

Each push of the

[Environment]

sheet.

sheet,

sheet,

STATUS

key cycles through the following sheets:

[Num Calc]

CHAN

key cycles through the following sheets:

[Each Ch]

SYSTEM

sheet,

key cycles through the following sheets:

[File Save]

sheet,

sheet,

[Memory Div]

[Scaling]

sheet,

sheet,

[Printer]

sheet,

[Wave Calc]

[Comment]

sheet,

sheet.

[Interface]

sheet.

sheet,

[Init]

File Screen

View saved data les (CompactFlash cards, built-in drive, USB memory stick, internal

memory).

19

Page 25

Screen Organization

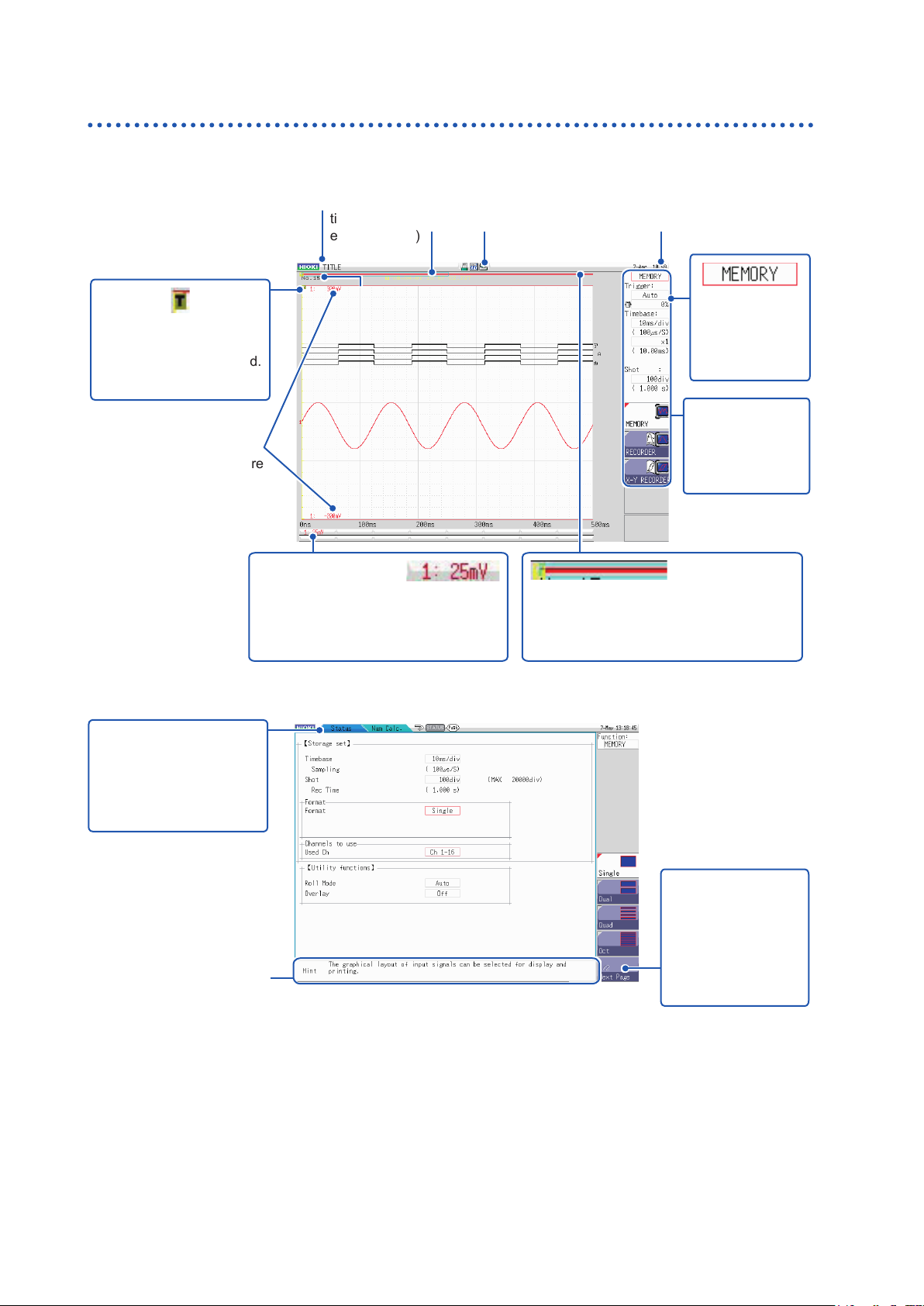

Explanation of Screen Contents

Waveform Screen

Title comment

Shows the specied

title comment.

(p. 140)

Trigger marker

Shows the point where

the trigger event occurred.

(p. 187)

Upper and lower limits

The upper and lower limit

values for each channel are

shown here. (p. 136)

Trigger time

Shows the date and

time of the last trigger

event. (p. 187)

Storage counter

Shows how many trigger

events occurred. (p. 69)

Logic waveform (p. 66)

Analog waveform (p. 63)

Media icon

Shows the media

status. (p. 40)

Vertical axis display

Shows the value per increment for each

channel. This is linked to the range

setting. (p. 63)

Current date and time

Shows the internal clock

date and time. (p. 46)

Settings cursor

The current

cursor location

ashes.

Settings window

Set measurement

conditions as

follows. (p. 52)

Scroll bar

Stored waveforms are indicated by red

bars. The displayed waveform is indicated

by a blue frame. (p. 126)

Elements Common to the Status, Channel, System, and File Screens

Sheet tab

Shows names of sheets

that can be selected.

Use the

switch between sheets.

MENU

keys to

Hint

Shows details about the item at the current settings cursor position.

Messages such as “Online,” “Key Lock active.” and error messages

are also shown here.

Next page

This is displayed if

there are more than

ve setting items.

This button brings

up the next group of

items.

20

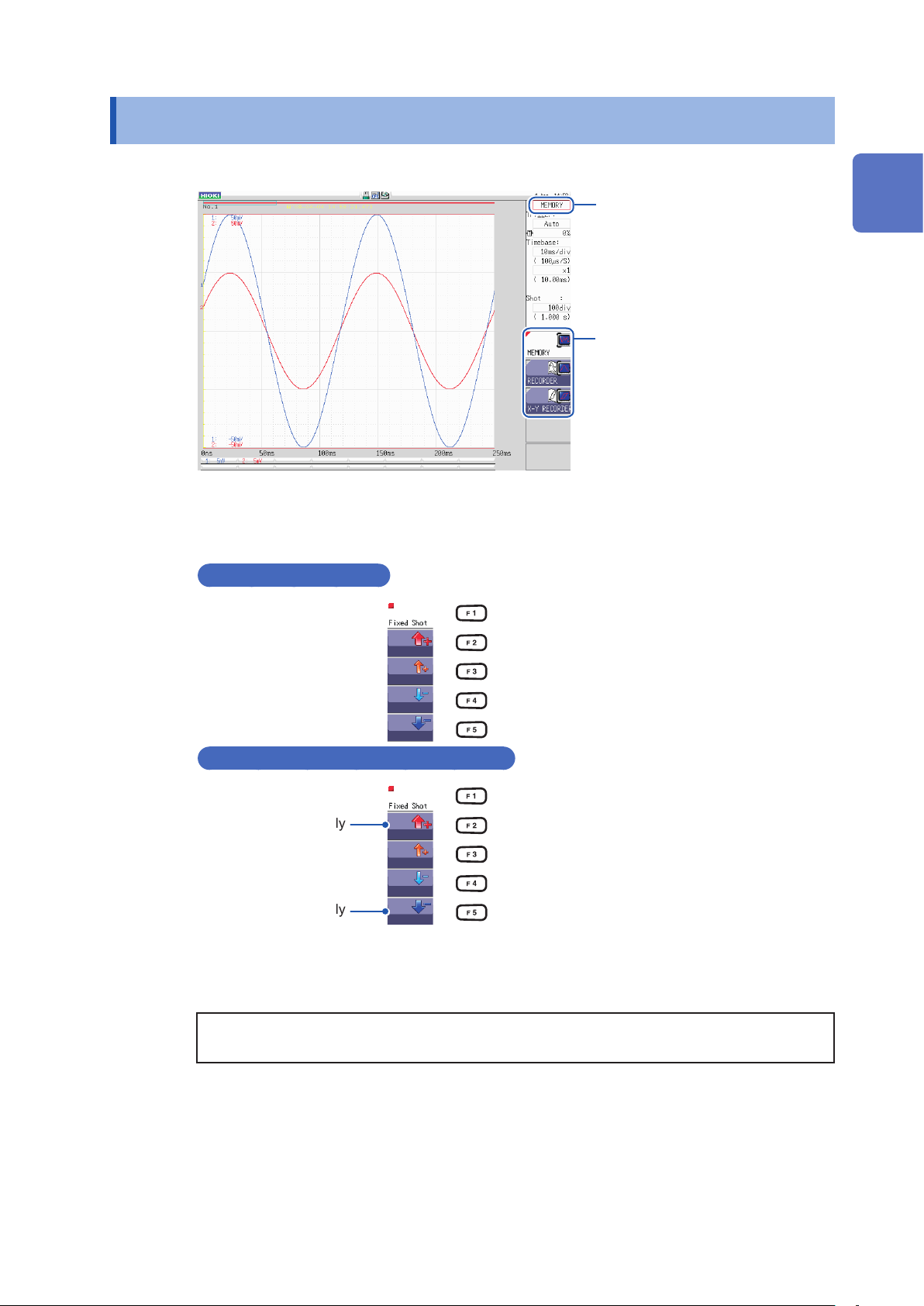

Page 26

1.4 Basic Key Operations

Basic Key Operations

1

2

Press the

Check the interface and press the function key (F key) for the setting you want to

change.

The assignment of the F keys is different for each item.

Selecting a Setting Item

CURSOR

key and move the cursor to the item you want to change.

Cursor

GUI

Press the

key to change the setting item.

F

1

Overview

3

Increasing or Decreasing a Setting Value

Increase value quickly

Decrease value quickly

For some setting items, the

selects

To enter text or numbers

[Cancel]

Refer to “8.1.3 Alphanumeric Input” (p. 143).

.

CH.SET

When there are more than ve setting items,

press

F5 [Next Page]

next page.

Press the F keys to change the setting value.

key selects

[Exec]

and the

key to switch to the

TRIG.SET

key

21

Page 27

Basic Key Operations

1.4.1 Using the HELP Key

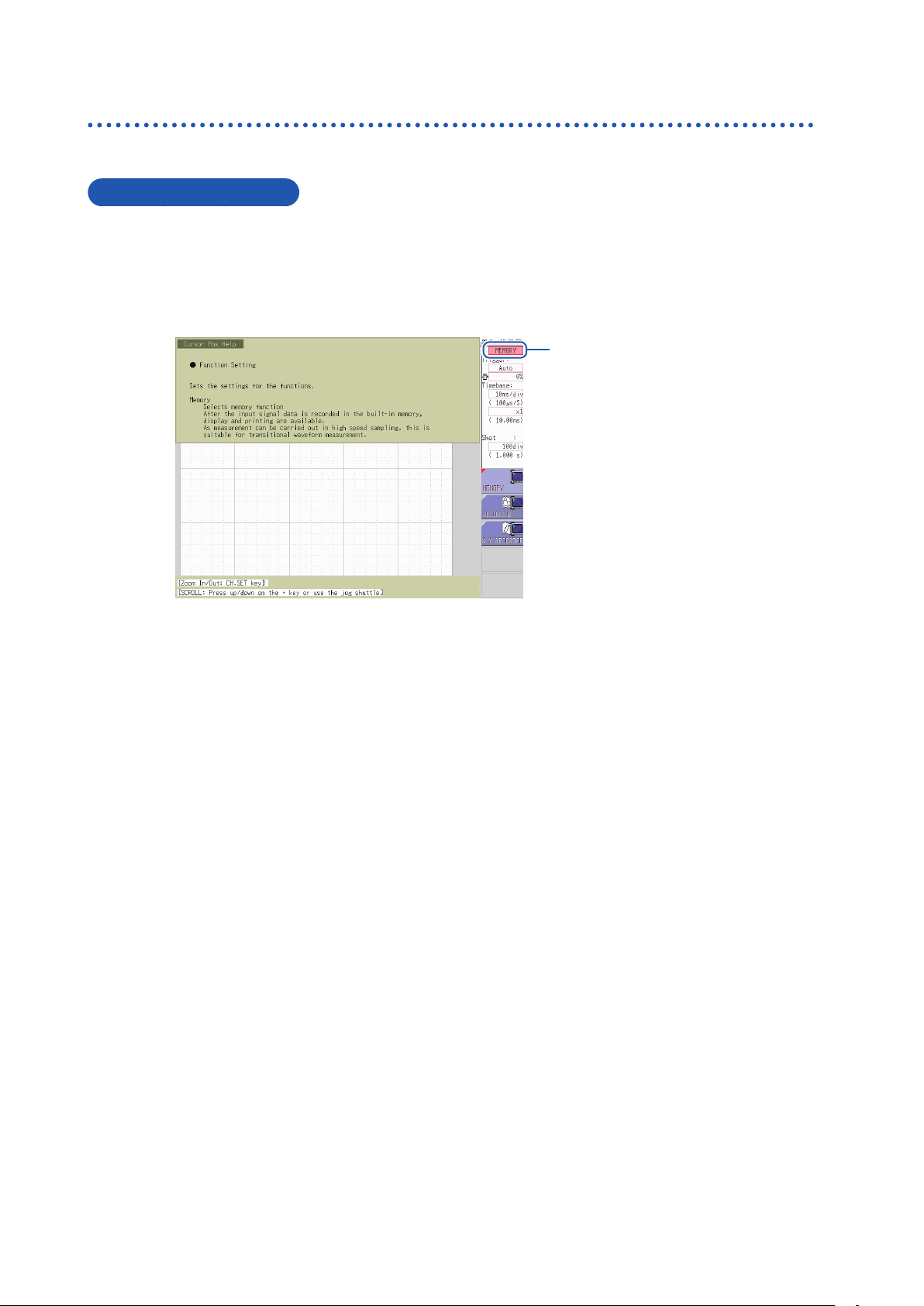

When you press the Help key a simple explanation will appear at the cursor position.

Cursor Position Help

Move the cursor to the item for which you want to display help.

1

2

Press the

You can scroll the information using the

• You can change the size of the Help sheet with the

and bottom half. The example above is for top half.

• Pressing the

HELP

key. A

HELP

[Cursor Pos Help]

key toggles Cursor Position Help, on and off.

CURSOR

sheet is displayed at the cursor position.

up/down keys or the jog knob.

Cursor

CH.SET

key. Available settings are full, top half,

22

Page 28

Basic Key Operations

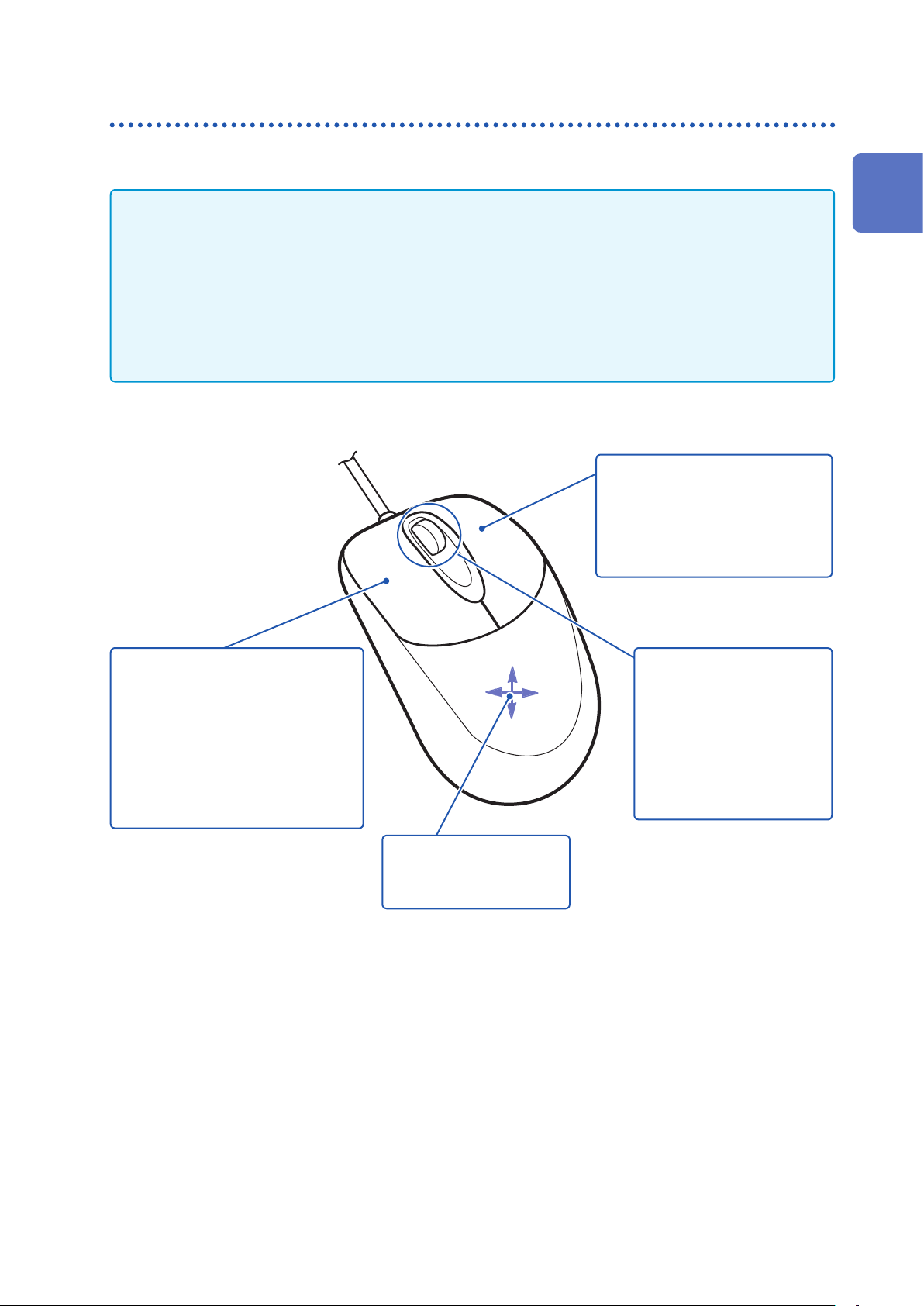

1.4.2 Use a Mouse to Perform Key Operations

You can use a commercially available USB mouse to perform the same operations as the keys on the

instrument.

• There are a variety of mice available, and not all devices will work with the instrument.

• The instrument's USB ports are designed exclusively for use with mice and USB memory sticks. Do

not connect any other type of device.

• When operating the instrument with the mouse, you may experience temporary delayed operation or

corrupted screen display.

• When using a mouse, do not change the interface on the System screen to anything other than “LAN.”

You may not be able to use the mouse while USB communications are in progress.

• External interference may cause the mouse to malfunction. Keep the mouse and mouse cable as far

away as possible from sources of interference.

To perform operations with a mouse:

Right click

Displays a menu with a list of

screens.

Screens displayed in gray cannot

be selected.

1

Overview

Left-click

Left-click to select menus and menu

items. When measuring with memory

segmentation, you can change the

displayed block by double-clicking the

left button.

Click the current path shown on the

File screen to move to one level up in

the folder hierarchy.

Center wheel

Changes the selected item.

On the File screen, you

can use the center wheel

to change the selected

le. While measuring with

memory segmentation, you

can use the center wheel to

change the displayed block.

Up/Down/Left/Right

Moves the mouse cursor

on the screen

23

Page 29

Basic Key Operations

The operation keys of the instrument and the menu displayed when you right-click the mouse are related

as follows:

To operate and carry out settings for CH.SET, WAVE, and AB CSR click the icons displayed when a

mouse is connected. The operation keys and icons are related as follows.

Icon Operation key

CH.SET

WAVE

AB CSR

Useful function

Dragging the right button of the mouse (Holding down the button, moving the mouse rightward,

leftward, or upward, and then releasing the button) works the same as the following keys:

Rightward: START

Leftward: STOP

Upward: ESC

key

key

key

24

Page 30

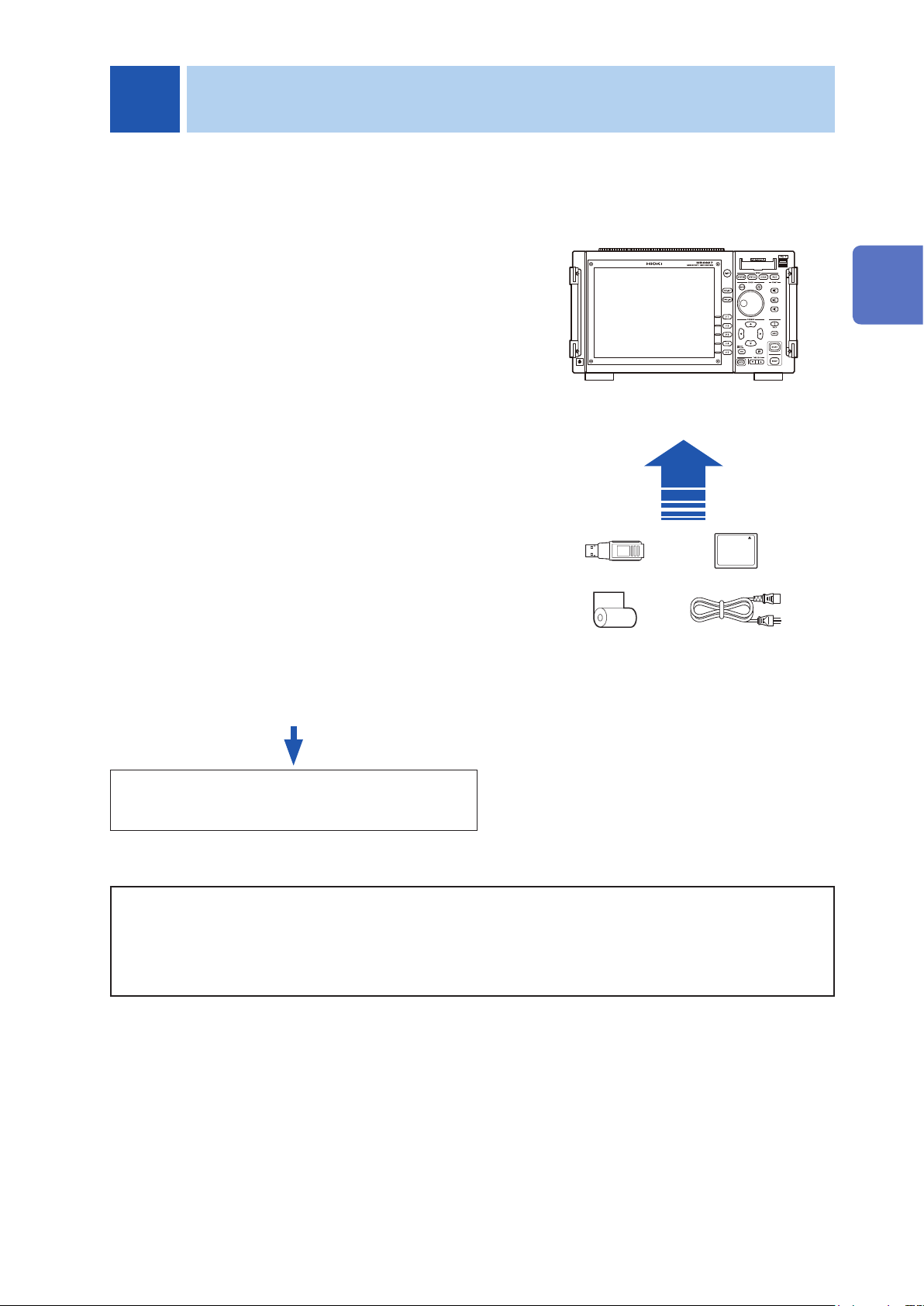

2

Procedure

Measurement Preparation

Install this instrument

1

Install or remove modules

2

(When adding or replacing modules)

Connect logic probes to the Standard

3

LOGIC terminals

(When measuring logic signals)

Connect connection cables to the module

4

(When measuring analog signals)

Probes and cables will differ depending on the type of

measurement being performed.

Insert media (CF card, USB memory stick)

5

Load recording paper

6

Connect the power cord

7

Connect the GND terminal (functional

8

earth terminal).

(When measuring in noise-prone environments)

Turn Power On

9

Set the clock

10

Perform zero-adjust

11

Perform calibration

(When using Model MR8990)

(p. 6)

(p. 26)

2

(p. 28)

Measurement Preparation

(p. 28)

(p. 40)

(p. 43)

(p. 44)

(p. 44)

(p. 45)

(p. 46)

(p. 47)

(p. 48)

When preparation is complete, start

measurement. (p. 49)

To use communication functions

Refer to “16 Connect to a PC” (p. 309).

To use external control functions

Refer to “17 External Control” (p. 335).

25

Page 31

Install or Remove Modules

2.1 Install or Remove Modules

Read “Handling the Instrument and Modules” (p. 7) carefully.

Modules specied when the instrument is ordered are supplied preinstalled. Use the following procedures

to add, replace, or remove modules from the instrument.

• Up to two logic units can be installed as units 1 to 8. Logic units installed as the other units

cannot be used. Other logic units being installed will be disabled.

• For information on the analog channel resolution when logic channels are used, refer to “8.10

Detailed Settings for Modules” (p. 164).

To Install a Module

Back side

Required items: One Phillips-head screwdriver (No. 2)

Turn off the power to the instrument.

1

Correctly orient the module and insert it rmly all the way in.

2

Make certain that the labels on the module's panel face the same

direction as the labels on the back side of the instrument.

Using a Phillips screwdriver, tighten the two module mounting

3

screws (M3 × 7.5 mm).

To Remove a Module

Back side

Handle

(Example: 8966)

Handle

Required items: One Phillips-head screwdriver (No. 2)

Turn off the power to the instrument.

1

Remove any connection cables or thermocouples connected to

2

the module.

Remove the power cord.

3

Using a Phillips screwdriver, loosen the two module mounting

4

screws (M3 × 7.5 mm).

Grasp the handles and pull the module out.

5

If not Installing Another Module After Removal

Back side

26

Blank

panel

Install a blank panel.

1

Using a Phillips screwdriver, tighten the two mounting screws

2

(M3 × 7.5 mm).

Measurements made without a blank panel installed may fail to meet

specications because of temperature instability within the module.

Page 32

Install or Remove Modules

Channel Allocation

Module number one is at the top, and channel number one is at the top left.

Information about the modules installed in the instrument can be veried in the System Conguration list.

(p. 395)

Module 1

Module 2

Module 3

Module 4

Module 5

Module 6

Module 7

Module 8

CH1

CH3

CH15 CH31

L7A

[1:4]

L7B

[1:4]

L7C

[1:4]

CH2

CH4

CH16 CH32

L7D

[1:4]

CH17

CH19

Module 9

Module 10

Module 11

Module 12

Module 13

Module 14

Module 15

Module 16

Analog channels only

Mixed analog and logic units

CH18

CH20

LA

[1:4]

LB

[1:4]

LC

[1:4]

LD

[1:4]

LE

[1:4]

LF

[1:4]

LG

[1:4]

LH

[1:4]

2

Measurement Preparation

27

Page 33

Connection Cables

2.2 Connection Cables

Measuring voltage

Read Refer to “Before Connecting Cables” (p. 10). carefully.

For detailed precautions and instructions regarding connections, refer to the instruction manuals for your

modules, connection cables, etc.

Applicable Modules

• Model 8966 Analog Unit

• Model 8968 High Resolution Unit

• Model 8972 DC/RMS Unit

Connect to the BNC jack on a module.

*1 An optional power cord or AC

adapter may be required.

*2 An optional AC adapter or a

commercially available USB cable

is required.

Connect with: connection cables

• Model L9197 Connection Cord

(Maximum input voltage: 600 V)

Large alligator clip type

• Model L9198 Connection Cord

(Maximum input voltage: 300 V)

Small alligator clip type

• Model L9217 Connection Cord

(Maximum input voltage: 300 V)

For measuring BNC output

• Model L9790 Connection Cord

(Maximum input voltage: 600 V)

Terminal type: Alligator, contact, grabber

Example: Terminal type: Alligator

To Connect to a BNC Terminal

Example: Model 8966 Analog Unit

BNC jack

Connecting the cable

BNC plug slots

Module connector

guide pins

Connect to the measurement object

28

If the voltage to be measured exceeds the maximum input rating of

the module being used

• Model 9322 Differential Probe*

• Model 9665 10:1 Probe

• Model 9666 100:1 Probe

• Model P9000-01/-02 Differential Probe*

Example: Model P9000-02 Differential Probe

1

2

Required tools: One of the above cables

Connect the BNC plug on the cable

1

to a BNC jack on the module.

Align the slots in the BNC plug with

2

the guide pins on the jack on the

module, then push in and twist the

plug clockwise until it locks.

Lock

Connect the cable clips to the

3

measurement object.

To disconnect BNC connectors

Push the BNC plug, twist it counterclockwise,

then pull it out.

Page 34

Measuring Frequency, Number of Rotations and Count

Refer to p. 28 for details about connecting to BNC terminals.

Connection Cables

Applicable Modules

• Model 8970 Freq Unit

Connect to the BNC jack on a module.

*1 An optional power cord or AC

adapter may be required.

*2 An optional AC adapter or a

commercially available USB cable

is required.

Connect with: connection cables

• Model L9197 Connection Cord

(Maximum input voltage: 600 V)

Large alligator clip type

• Model L9198 Connection Cord

(Maximum input voltage: 300 V)

Small alligator clip type

• Model L9217 Connection Cord

(Maximum input voltage: 300 V)

For measuring BNC output

• Model L9790 Connection Cable

(Maximum input voltage: 600 V)

Terminal type: Alligator, contact, grabber

Example: Terminal type: Alligator

2

Measurement Preparation

If the voltage to be measured exceeds the maximum input rating of

the module being used

• Model 9322 Differential Probe*

• Model P9000-01/-02 Differential Probe*

Example: Model P9000-02 Differential Probe

1

2

29

Page 35

Connection Cables

Measuring temperature

Applicable Modules

• Model 8967 Temp Unit

Connect to the terminal block on the

module.

To Connect to the Terminal Block

25 mm

10 mm

Outer Insulation

Inner insulation

Thermocouple

element wires

Terminal Block

Connect with: thermocouples

Thermocouple

(Compatible wire: 0.4 mm to

1.2 mm diameter)

Required device and tool:

Thermocouple, at-blade screwdriver (2.6-mm

blade)

1

Recommended wire:

Compatible wire: Thermocouple element

wires of from 0.4 mm to 1.2 mm in diameter

Stripped length: 10 mm

Strip insulation from the

1

thermocouple wires as shown at the

left.

Stripped length: approx. 10 mm

Connect to terminal block

Push the blade of a at screwdriver

Connecting a Thermocouple

Connection

Holes

3

2

4

Connect to the measurement object

5

• If surrounding equipment is affected by noise, coil the thermocouple several

times and then attach the included ferrite clamp-on choke (as seen in the

diagram to the right).

• When connecting a thermocouple using a wire run of more than 3 meters,

take into consideration the EMC environment including possible inuence of

external noise.

2

into the button on the terminal block

of the module.

Insert each thermocouple wire into

3

the appropriate terminal hole while

pressing the button. Conrm proper

polarity.

Release the button.

4

The thermocouple is connected.

Connect to the measurement object.

5

To remove a thermocouple

Hold the button while pulling the thermocouple

wire out.

30

Page 36

Connection Cables

Measuring vibration or displacement with a strain gauge transducer

Applicable Module

• Model U8969 Strain Unit

• Model 8969 Strain Unit

Connect a strain gauge transducer to a connector on Model U8969 Strain Unit via Model L9769

Conversion Cable; Model 8969 Strain Unit via Model 9769 Conversion Cable.

The following device can be connected to the module.

• Strain gauge transducer (Not available from Hioki)

Connect L9769 or 9769 Conversion Cable to the strain gauge

transducer.

Connecting the strain gauge transducer to a module’s connector

Example: Connecting the strain gauge transducer to Model U8969 Strain Unit via Model L9769

Conversion Cable

Required items:

Model L9769 Conversion Cable, strain gauge

transducer

Insert Model L9769 into a connector

1

of Model U8969 with the slot of

the plug aligned with the outward

indentation of the connector.

Insert the plug into the connector

2

until they are locked together.

Connect Model L9769 to the strain

3

gauge transducer.

Connector’s

indentation

U8969 Strain Unit

1

Connect the L9769.

Plug’s slot

2

2

Measurement Preparation

Connect Model L9769 to the strain

3

gauge transducer.

Connect the strain gauge transducer to

4

a measurement object.

Connect the strain gauge transducer

4

to a measurement object.

How to disconnect Model L9769

Pull the sleeve of the plug gently,

releasing the plug, and disconnect the

cable.

The instrument describes Model U8969 as “8969.”

31

Page 37

Connection Cables

Connector pin-out

Model U8969 Strain Unit

The metal shell is connected to

the GND of the instrument.

Pin mark Description

A BRIDGE+

B INPUT−

C BRIDGE−

D INPUT+

E

F SENSE+

G SENSE−

H, J N.C.

FLOATING COMMON

Model L9769 Conversion Cable

(Strain gauge transducer end)

A F

G

B

C D

The metal shell is connected to

the GND of the instrument.

Pin mark Description

A BRIDGE+, SENSE+

B INPUT−

C BRIDGE−, SENSE−

D INPUT+

E

F, G N.C.

Applied voltage:

E

bridge voltage of

FLOATING COMMON

2 V

Connection of Model L9769

• Pin F of the module end is connected with Pin A of the strain gauge transducer end.

• Pin G of the module end is connected with Pin C of the strain gauge transducer end.

32

Page 38

Connection Cables

Example: Connecting the strain gauge transducer to Model 8969 Strain Unit via Model 9769

Conversion Cable

1

Connect a strain gauge transducer to

2

Connect the strain gauge transducer to

3

a measurement object.

Connector pin-out

Model 8969 Strain Unit

8969 Strain Unit

Connect the 9769.

Model 9769.

Required items:

Model 9769 Conversion Cable, strain gauge

transducer

Connect Model 9769 to a connector

1

on the module.

Insert the connector of Model 9769 with

the orange part facing upward.

Connect the Model 9769 to the strain

2

gauge transducer.

Connect the strain gauge transducer

3

to a measurement object.

Model 9769 Conversion Cable

(Strain gauge transducer end)

2

Measurement Preparation

(Pin 1 is on the left when the module’s

top side is on the up)

1 2 3 4 5 6 7

Pin No. Description

1 BRIDGE+

2 SENSE+

3 INPUT+

4 INPUT−

5 BRIDGE−

6 SENSE−

7 FLOATING COMMON

IMPORTANT

• Preforming measurement with a strain gauge requires a bridge box. Use a strain gauge and bridge

box both of which are commercially available.

• The bridge box may be susceptible to the effect of noise. For more information about how to ground

the bridge box, refer to its instruction manual or contact the manufacturer of the bridge box.

A F

G

B

C D

The metal shell is connected to

the GND of Model 8969.

Pin mark Description

A BRIDGE+

B INPUT−

C BRIDGE−

D INPUT+

E FLOATING COMMON

F, G N.C.

Applied voltage:

E

bridge voltage of 2V

IMPORTANT

Do not excessively bend the cable and the base between cable and connector, pull on them, nor twist

them. Doing so may cause the conversion cable to break.

33

Page 39

Connection Cables

Measuring current

Applicable Modules

• Model 8971 Current Unit

Connect Model 9318 Conversion Cable to

the module jack.

• Model 9272-10

Clamp on Sensor

• Models 9709, CT6862,

CT6863, CT6865

AC/DC Current Sensor

• Models CT6841, CT6843,

CT6844, CT6845

AC/DC Current Probe

Connect with: Clamp sensors

To Connect to the Module's Terminals

Example: When connecting Model 9272-10 Clamp on Sensor

Sensor connector

Connect the 9318 Conversion Cable

and clamp sensor

Conversion cable plug

1

Conversion Cable

Connector

Required tools:

Model 9318 Conversion Cable, Model 9272-10

Clamp on Sensor

Align the grooves of the module’s sensor

1

connector and the conversion cable plug.

Insert the plug until it locks.

Align the grooves of the conversion cable

2

connector and the plug of the clamp

sensor to be used. Insert the plug until it

locks.

Example:

Model 9272-10 + Model 9318

Connect the clamp sensor to the item to

3

be measured.

To disconnect the conversion cable

Slide the plug to release the lock and then unplug

the cable.

Clamp sensor

plug

Model 9272-10

Connect to the measurement

3

object

2

When Measuring Current With Model 9018-50 Clamp on Probe

When using Model 9018-50 you can use a voltage measurement unit such as Model 8966 Analog Unit to

make current measurements.

For more information about how to congure the instrument for use in this type of application, refer to the

example settings in “8.5.1 Scaling Examples” (p. 153).

34

Page 40

Connection Cables

Measuring logic signals

Read “Before Connecting a Logic Probe to the Measurement Object” (p. 11) carefully.

For more information about logic probe specications, see the instruction manual that came with the logic

probe you plan to use.

Applicable Modules

• Model 8973 Logic Unit

LA to LH are supplied as standard

equipment with the unit.

To Connect to Logic Terminals

Example: Connecting the 9327 Logic Probe

Back Side

Logic terminals

Connect with: Logic Probes

• Model 9320-01 Logic Probe

• Model MR9321-01 Logic Probe

• Model 9327 Logic Probe

Required tools:

Model 9327 Logic Probe

Connect the logic probe by aligning

1

the grooves on the plug and Logic

terminal.

Connect to the measurement object.

2

1

LOGIC terminals

2