Page 1

Instruction Manual

LR5001

HUMIDITY LOGGER

July 2013 Revised edition 2 LR5001B980-02 13-07H

Page 2

Page 3

Contents

Introduction ..............................................................................1

Verifying Package Contents....................................................2

Safety Information....................................................................4

Operating Precautions.............................................................5

Measurement Preparation to Data Analysis ..........................8

i

Contents

1

2

3

Chapter 1

Overview__________________________________11

1.1 Product Overview and Features .............................11

1.2 Part Names/Functions and Display Indicators .....12

1.3 Display Organization ...............................................14

Chapter 2

Measurement Preparations___________________ 17

2.1 Installing (or Replacing) the Battery ......................17

2.2 Connecting a Temperature/Humidity Sensor .......20

2.3 Installing the PC Application Program ..................21

Chapter 3

Settings___________________________________27

3.1 Settings List .............................................................27

3.2 Making Settings on the Logger ..............................29

3.3 Making Settings from the LR5000 Utility Program 32

Chapter 4

Measurement and Analysis___________________ 39

4.1 Pre-Measurement Inspection .................................39

4.2 Installing the Logger ...............................................40

4.3 Starting and Stopping Recording ..................... ... ..42

4.4 Confirming Currently Measured Values and Data

Recording .......................... .......................... ............. 45

4.5 Automatically Importing (Saving) Recorded Data

to a Computer, and Graph Display ........................45

4

Page 4

ii

Contents

4.6 Manually Importing (Saving) Recorded Data to a

Computer, and Graph Display ............................... 55

4.7 Displaying a Graph of Saved Recording Data ..... 58

4.8 Printing Recorded Data .......................................... 60

Chapter 5

Processing Recorded Data ___________________61

5.1 Scaling ..................................................................... 63

5.2 Calculating Electric Power ..................................... 64

5.3 Calculating Energy Cost ....... .. ... .. ... ... .. .................. 65

5.4 Calculating Operating Rate ............. ... .. ... .. ... .......... 66

5.5 Integration ............................................................... 67

5.6 Calculating Dew-Point Temperature ..................... 68

5.7 Two-Data-Item Arithmetic Calculations ................ 69

5.8 Converting Over-Threshold Data Values .............. 70

Chapter 6

Organizing Data ____________________________71

6.1 Copying and Moving Data ...................................... 72

6.2 Deleting Data .................. ......................................... 73

6.3 Combining Data ...................................................... 74

6.4 Extracting Data ....................................................... 75

Chapter 7

Options Settings (LR5000 Utility Program) ______77

7.1 Changing the Saving Method for Imported Data . 78

7.2 Changing the Connection Monitoring Method,

and Logger Settings Displays ............................... 79

Chapter 8

Specifications______________________________81

8.1 Measurement Specifications ................................. 81

8.2 Functional Specifications ...................................... 82

8.3 Miscellaneous ......................................................... 83

8.4 LR5091 Communication Adapter Specifications . 84

Page 5

8.5 Temperature/Humidity Sensors Specifications ....87

Chapter 9

Maintenance and Service ____________________91

9.1 Cleaning ...................................................................91

9.2 Disposing of the Logger .........................................91

9.3 Troubleshooting ......................................................92

9.4 Error Displays . .........................................................95

iii

Contents

Appendix_________________________________ A 1

Appendix 1 About Recording Modes.............................. A 1

Appendix 2 Recording Intervals and Maximum

Recording Times.......................................... A 2

Appendix 3 Battery Life Approximation...................... ... A 2

Index _________________________________Index 1

4

5

6

7

8

9

Appendix

Index

Page 6

iv

Contents

Page 7

1

Introduction

Introduction

Thank you for purchasing the HIOKI "Model LR5001 Humidity Logger." To obtain

maximum performance from the instrument, please read this manual first, and keep

it handy for future reference.

Registered Trade Marks

Windows is

or other countries.

a registered trademark of Microsoft Corporation in the United States and/

Notation

Indicates a prohibited action.

(p. ) Indicates the location of reference information.

Indicates quick references for operation and remedies for

troubleshooting.

* Indicates that descriptive information is provided below.

Menus, commands, dialogs, buttons in a dialog, a nd other

[ ]

SET

(Bold

characters)

Windows

Dialog Dialog box represents a Windows dialog box.

names on the screen and the buttons are indicated in

brackets.

Bold characters within the text indicate operating button

labels.

Unless otherwise specified, “Windows” represents Windows XP, Windows Vista, or Windows 7.

The screen of this instrument displays characters in the following manner.

Page 8

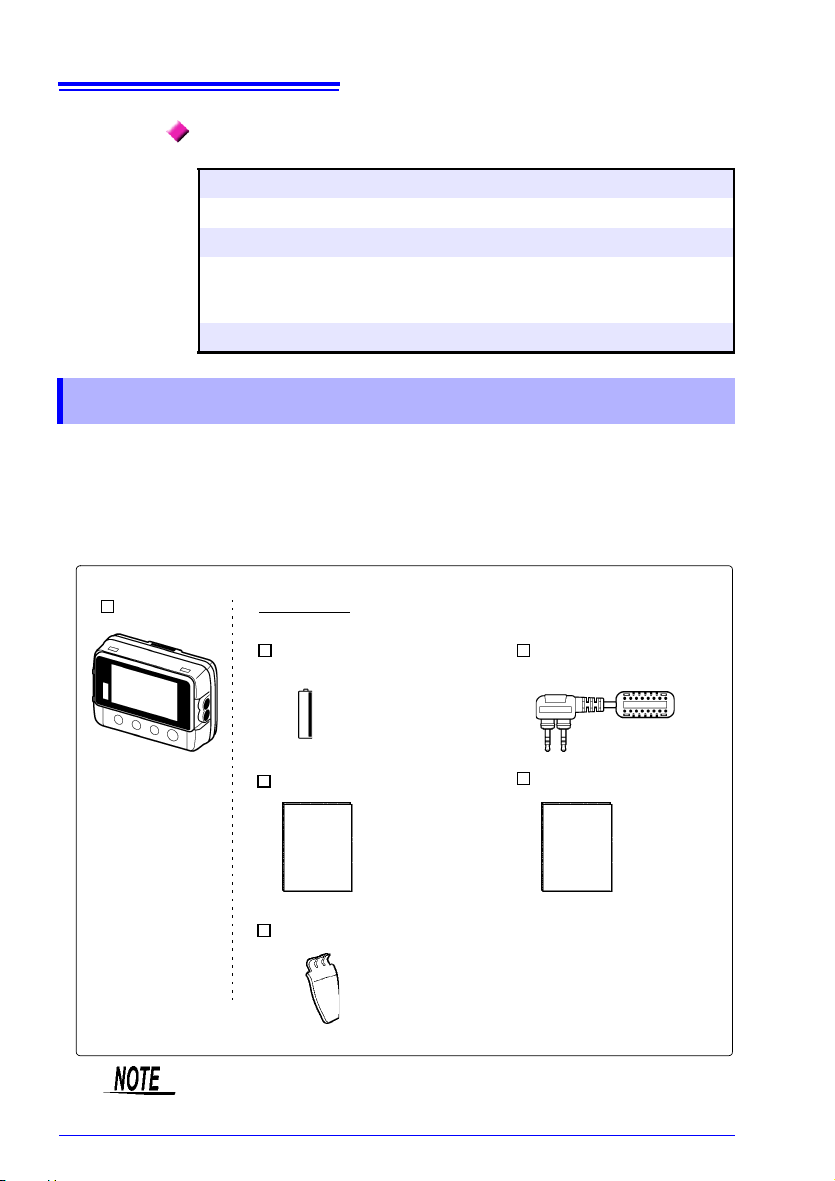

2

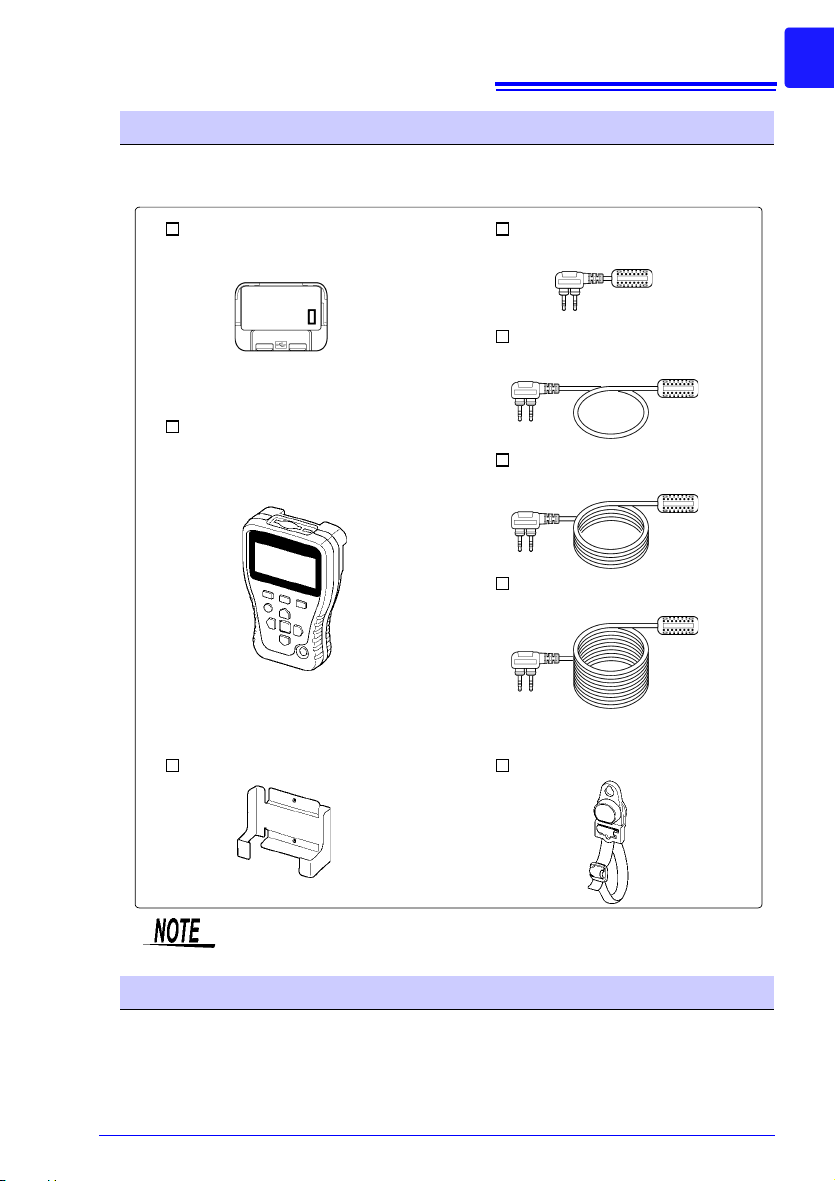

LR5001

LR6 alkaline battery (1)

(Pre-installed in the logger.)

Accessories

See: Other specified options :" Options" (p.3)

Instruction Manual (1)

Operation Manual (1)

Stand (1)

LR9504 Humidity Sensor

(Approx. length 40 m) (1)

Verifying Package Contents

Mouse Operation

Click Press and quickly release the left button of the mouse.

Right-click

Double click Quickly click the left button of the mouse twice.

Drag

Activate Click on a window on the screen to activate that window.

Press and quickly release the right button of the mouse.

While holding down the left button of the mouse, move the

mo

use and then release the left button to deposit the cho -

sen item in the desired position.

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches, and

connectors. If damage is evident, or if it fails to operate according to the specifications, contact your dealer or Hioki representative.

Quantities in parentheses ( ).

Do not throw away the plastic bag that contained the temperature/

humidity sensor because you will use it when you store the sensor.

Page 9

Verifying Package Contents

See: Temperature/Humidity Sensor

Specifications: (p.87)

LR5092-20 Data Collector

(Includes LR5000 Utility Program* CD

[PC application software], LR6 alkaline battery

x2, Instruction manual, Operation manual, and

USB Cable)

LR9504 Humidity Sensor

(Approx. length 40 m)

LR5091 Communication Adapter(1)

(Includes LR5000 Utility Program* CD [PC

application software] and USB Cable)

*:The latest version can be download-

ed from our web site.

LR9501 Humidity Sensor

(Approx. length 1 m)

LR9502 Humidity Sensor

(Approx. length 5 m)

LR9503 Humidity Sensor

(Approx. length 10 m)

See: LR5091 spec ificati on: (p.84)

LR9901 Wall-Mounted Holder

Z5004 Magnetic Strap

See: Method of mounting: (p.41)

See: Method of

mounting:

(p.41)

Options

The following logger options are available separately. Even if purchased previously,

you may want to confirm that you have them at hand.

3

Do not throw away the plastic bag that contained the temperature/

Transporting Precautions

Use the original packing materials when transporting the instrument, if possible.

humidity sensor because you will use it when you store the sensor.

Pack the instrument so that it will not sustain damage during shipping, and include a

description of existing damage. We do not take any responsibility for damage incurred

during shipping.

Page 10

4

Safety Information

Safety Information

This manual contains information and warnings essential for safe operation of the

instrument and for maintaining it in safe operating condition. Before using it, be

sure to carefully read the following safety precautions.

This instrument is designed to comply with IEC 61010 Safety Standards,

and has been thoroughly tested for safety prior to shipment. However,

mishandling during use could result i n injury or death, as well a s damage to the instrument. However, using the instrument in a way not

described

Be certain that you understand the instructions and precautions in the

manual

ries not resulting directly from instrument defects.

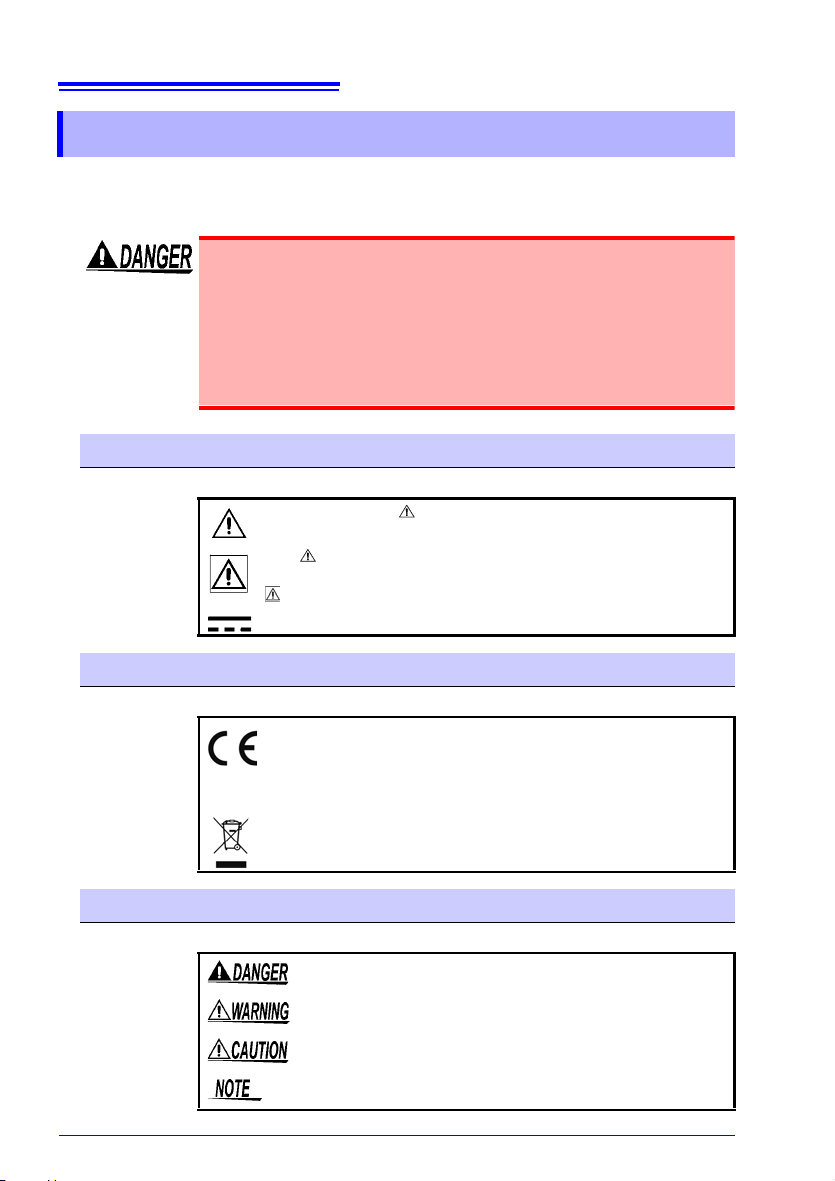

Safety Symbols

Markings on the logger have the following meanings.

in this manual may negate the provided safety features.

before use. We disclaim any responsibility for accidents or inju-

In the manual, the symbol indicates particularly important information that the user should read be

The symbol printed on the instrument indicates that the user

should refer to a corresponding topic in the manual (marked with the

symbol) before using the relevant function.

Indicates DC (Direct Current).

fore using the instrument.

Symbols for V arious Standards

Markings on the logger have the following meanings.

WEEE marking:

This symbol indicates that the electrical and electronic app liance is

ut on the EU market after August 13, 2005, and producers of the

p

Member States are required to display it on the appliance under Article 11.2 of Directive 2002/96/EC (WEEE).

This symbol indicates that the product conforms to safety re gulations set out by the EC Directive.

Danger Levels

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an extreme hazard

that could result in serious injury or death to the user.

Indicates that incorrect operation

that could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of

i

njury to the user or damage to the instrument.

Indicates advisory items related to pe

operation of the

instrument.

presents a significant hazard

rformance or correct

Page 11

5

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of

the various functio ns.

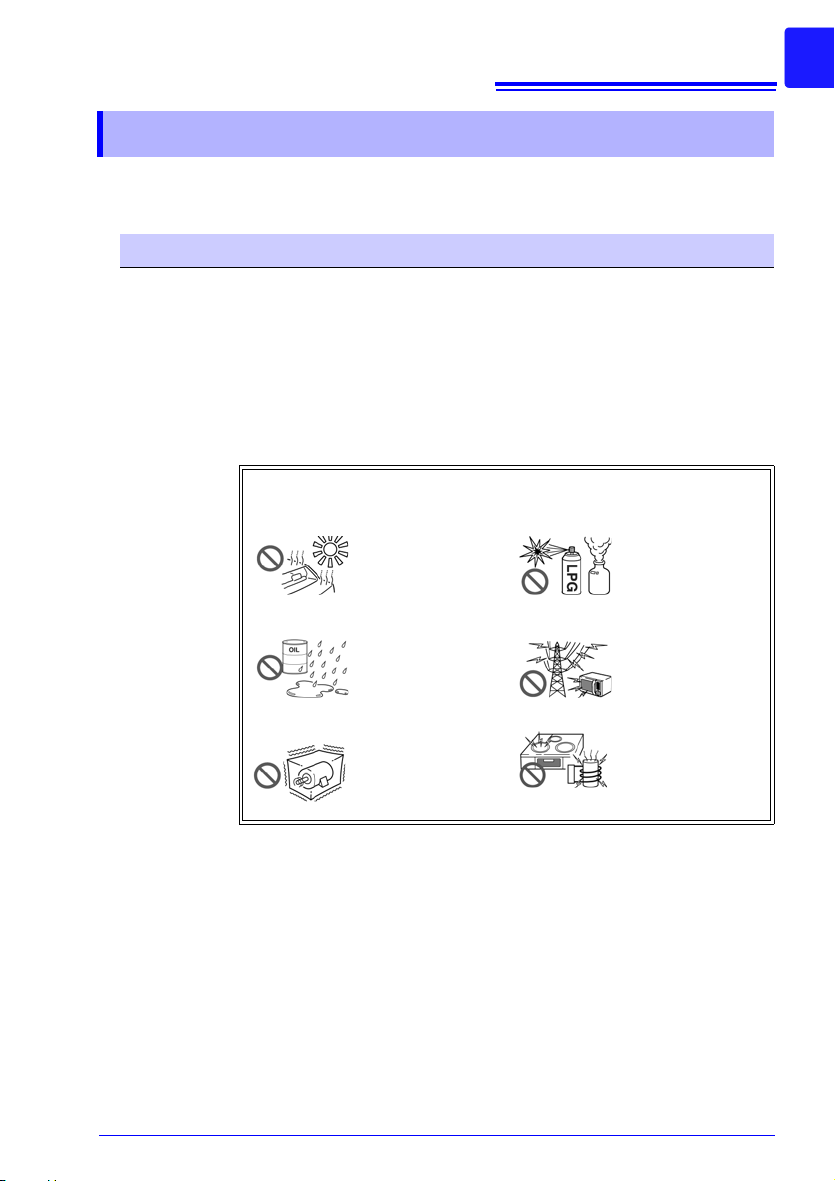

Installation Precautions

Operating temperature and humidity:

ogger:-20 to 70C (-4.0 to 158.0F), 80%RH or less (non-condensating)

L

Temperature/Humidity Sensor:-40 to 85C (-40 to 185.0F), (connector portions: -20

to 70C (-4.0 to 158.0F)), 0to 100%RH (non-condensating)

Storage temperature and humidity:

Logger: -20 to 70C (-4.0 to 158.0F), 80%RH or less (non-condensating)

Temperature/Humidity Sensor: 0 to 50C (-32.0 to 122.0F), 80%RH or less (noncondensating)

Avoid the following locations that could cause an accident or damage to the instrument.

Exposed to direct

sunlight

Exposed to high temperature

Exposed to liquids

Exposed to high

ity or condensa-

humid

tion

Subject to vibration

In the presence of

corrosive or explosive

gases

Exposed to strong

ectromagnetic

el

fields

Near electromagnetic

radiators

Near induction heating systems

(e.g., high-frequency

duction heating sys-

in

tems and IH cooking

ensils)

ut

Page 12

6

Operating Precautions

• The protection rating for the enclosure of this device (based on

EN60529) is *IP54.

• The Humidity Sensor is not designed to be entirely water- or dust-proof.

Do not use it in an especially dusty environment, nor where it might be

splashed with liquid. This may cause damage.

• The Humidity Sensor is not drip-proof. Water droplets on the grip or

conn

• Although this instrument is designed to resist the ingress of dust and

water, it is not entirely water- or dust-proof, so to avoid shock or damage, do not use it in a wet or dusty environment.

• If used outside the specified environmental ranges for operation (or

stor

and accurate measurement may not be possible.

• If used outside the specified environmental ranges for operation (or

stor

• Humidity measurement values will be affected by about 3% (hysteresis) depending on the state of humidity change (low humidity to high

hum

• Take care that the temperature/humidity sensor is not exposed to a

chemical solvent having a high concentration for a long period of time

during use or storage.

• When you will not use the temperature/humidity sensor, store it in a

cool

tic bag in which it came.

• Take care to avoid condensation. In particular, if there is a sudden

chan

warm one), condensation is likely to occur.

*IP54 :This indicates the degree of protection provided by the enclosure of the

• Testing monitor batteries installed in the unit may possibly be weak.

Replace batteries before extended measurement usage.

• Use only LR6 Alkaline batteries. Using manganese batteries may not

result in accurate measurements or proper communication with the

LR5091 Communication Adapter and LR5092-20 Data Collector.

ector may result in malfunctions.

age), the sensor accuracy may deteriorate in less than one year,

age), the operation of the unit cannot be guaranteed.

idity or high humidity to low humidity).

and dark place sealed together with desiccating agent in the p las-

ge of temperature (for example moving from a cold place to a

device against use in hazardous locations, entry of solid foreign objects,

and the ingress of water.

5 : Protected against access to hazard

mm in diameter. Dust-proof type (The penetration of dust cannot be prevented completely, but quantities of d

eration of equipment or safety

4 :The equipment inside the enclosure is protected agai

fects of spraying water.

ous parts with wire measuring 1.0

ust that may hinder the stated op-

cannot penetrate the enclosure.

nst the harmful ef-

Avoiding Instrument Damage

To avoid damage to the instrument, protect it from physical shock when

transporting and handling. Be especially careful to avoid physical shock

from dropping.

Page 13

CD Handling

7

Operating Precautions

• Always hold the disc by the edges, so as not to make fingerprints on

the disc or scratch the printing.Never touch the recorded side of the

disc. Do not place the disc directly on anything hard.

• Do not wet the disc with volatile alcohol or water, as there is a possibility of the label printing disappearing.

• To write on the disc label surface, use a spirit-based felt pen. Do not

u

se a ball-point pen or hard-tipped pen, because there is a danger of

scratching the surface and corrupting the data. Do not use adhesive

labels.

• Do not expose the disc directly to the sun's rays, or keep it in conditions of high temperature or humidity, as there is a danger of warping,

with

consequent loss of data.

• To remove dirt, dust, or fingerprints from the disc, wipe with a dry

cloth, or use a CD cleaner. Alway s wipe from the insid e to the o utside,

and do no wipe with circular movements. Never use abrasives or solvent cleaners.

• Hioki shall not be held liable for any problems with a computer system

th

at arises from the use of this CD, or for any problem related to the

purchase of a Hioki product.

Preliminary Checks

Before using the instrument the first time, verify that it operates normally to ensure

that the no damage occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Before using the instrument, make sure that the insulation on the

sensor cables is undamaged and that no bare conductors are

improperly exposed. Using the instrument in such conditions

could cause an electric shock, so contact your dealer or Hioki representative for replacements.

Page 14

8

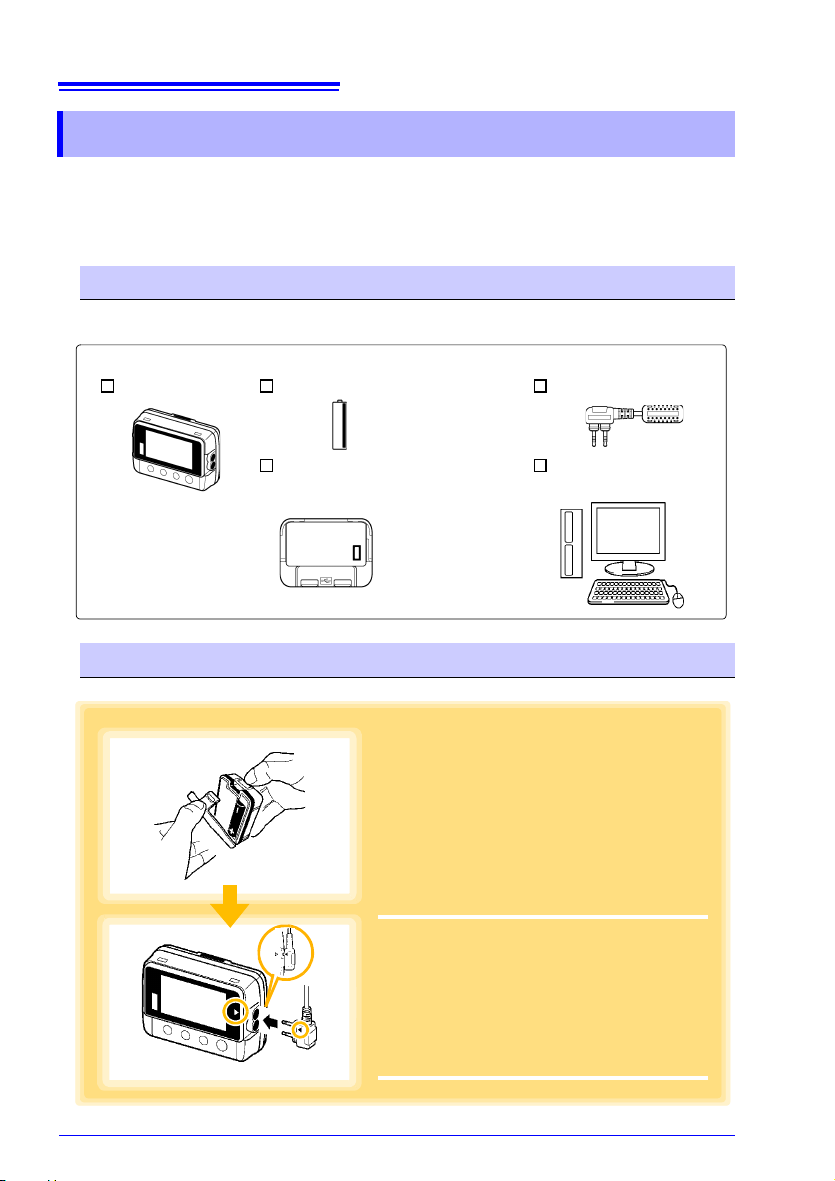

LR5001 (1) LR6 alkaline battery (1) LR9504 Humidity Sensor

(1)

LR5091 Communication Adapter(1)

(LR5000 Utility Program* CD

[PC application software] and USB Cable)

Computer (1)

1

Install the battery in the logger.

See: "2.1 " (p.17)

2

Connect the LR9504 Humidity Sensor to

the logger.

See: "2.2 " (p.20)

1

2

Measurement Preparation to Data Analysis

Measurement Preparation to Data Analysis

The steps from measurement preparation to data analysis are illustrated with a typical measurement example.

Example Case: Record warehouse temperature and humidity at 10-minute intervals

for one month, and store the data on a computer.

Required Items:

Quantities in parentheses ( ).

Procedure:

Page 15

Measurement Preparation to Data Analysis

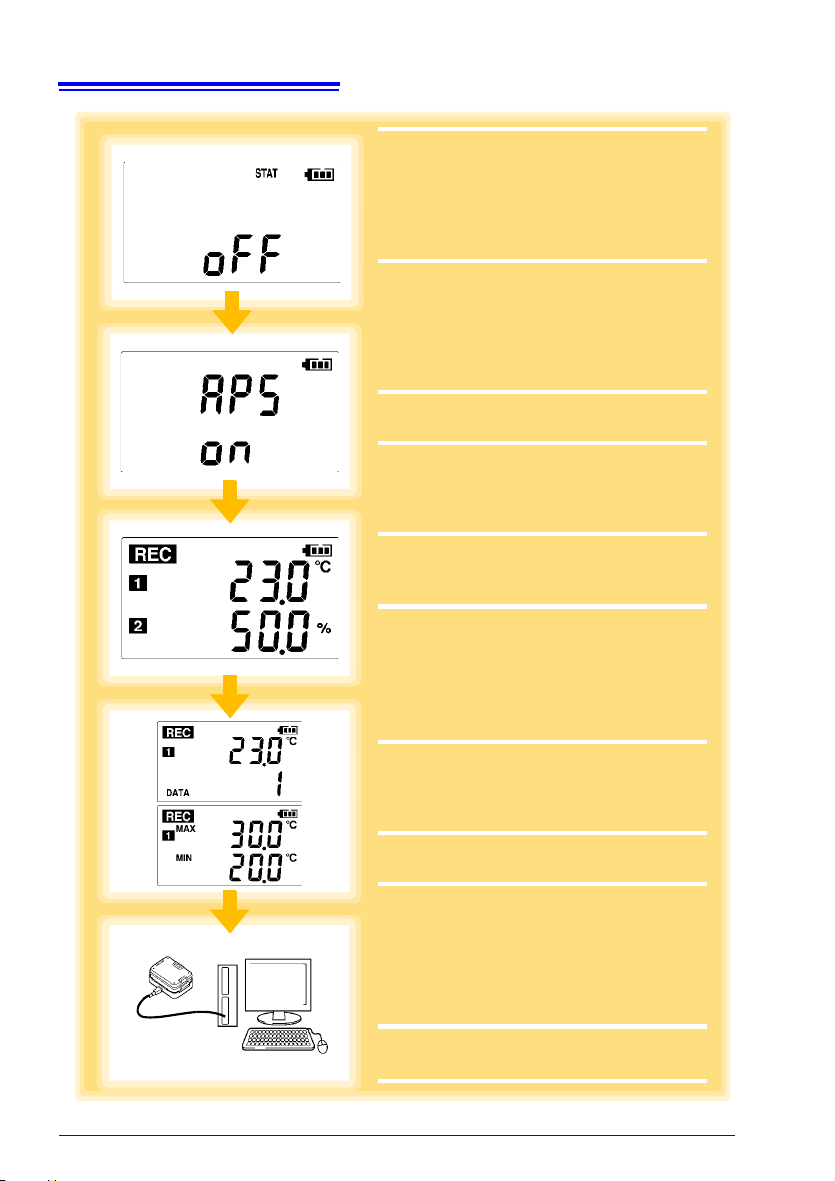

3

Install the LR5000 Utility Program on the

computer.

See: "2.3" (p.21)

4

Select the recording interval for the logger

(in this case, 10 minutes).

See: "Recording Interval Setting" (p.29)

(The setting can be made also from the

LR5000 Utility Program.) (p.35)

5

Set the logger to the correct date and time

(in this case, 15 May 2010, 13:00).

See: "Real-Time Clock Setting" (p.29)

(With the LR5000 Utility Program, the logger can be set to the computer time.)

(p.38)

6

Set the stop method to [OFF].

(This setting provides one-time measurement:

recording stops when memory becomes full.)

See:

"Stop Method Setting (for when

memory becomes full)" (p.30)

(The setting can be made also from the

LR5000 Utility Program.) (p.35)

5

4

3

6

9

Page 16

10

7

Set the recording mode to [OFF].

(This setting provides instantaneous measurement.)

See:

"Recording Mode Setting" (p.31)

(The setting can be made also from the

LR5000 Utility Program.) (p.35)

8

Set the power save setting to [ON].

(The on (enabled) setting is recommended

for long-term recording.)

See:

"Power Save Setting" (p.31)

(The setting can be made also from the

LR5000 Utility Program.) (p.34)

9

Pre-measurement inspection (p.39)

10

Install the logger at the measurement

site in the warehouse.

See: "4.2" (p.40)

(It can be wall-mounted.)

11

Hold REC/STOP on the logger for two

seconds to start recording.

See: "4.3" (p.42)

12

Press (+) and (-) on the logger to confirm

that the recording count is incrementing ,

and that recording data (maximum and

minimum values) are displayed.

(Confirm that recording is actually occurring.)

See:

"4.4" (p.45)

13

After a month, hold REC/STOP on the

logger again for two seconds to stop

recording.

See: "4.3" (p.42)

14

Retrieve the logger from the warehouse.

15

Import recorded data from the logger to

a connected computer. For analysis, display the data in a graph.

See: "4.5" (p.45)

ÅiThe data is automatically saved when

imported to the computer. By default, it is

also automatically displayed in a graph.)

16

Print recorded data as needed.

See: "4.8" (p.60)

8

11

7

15

12

Measurement Preparation to Data Analysis

Page 17

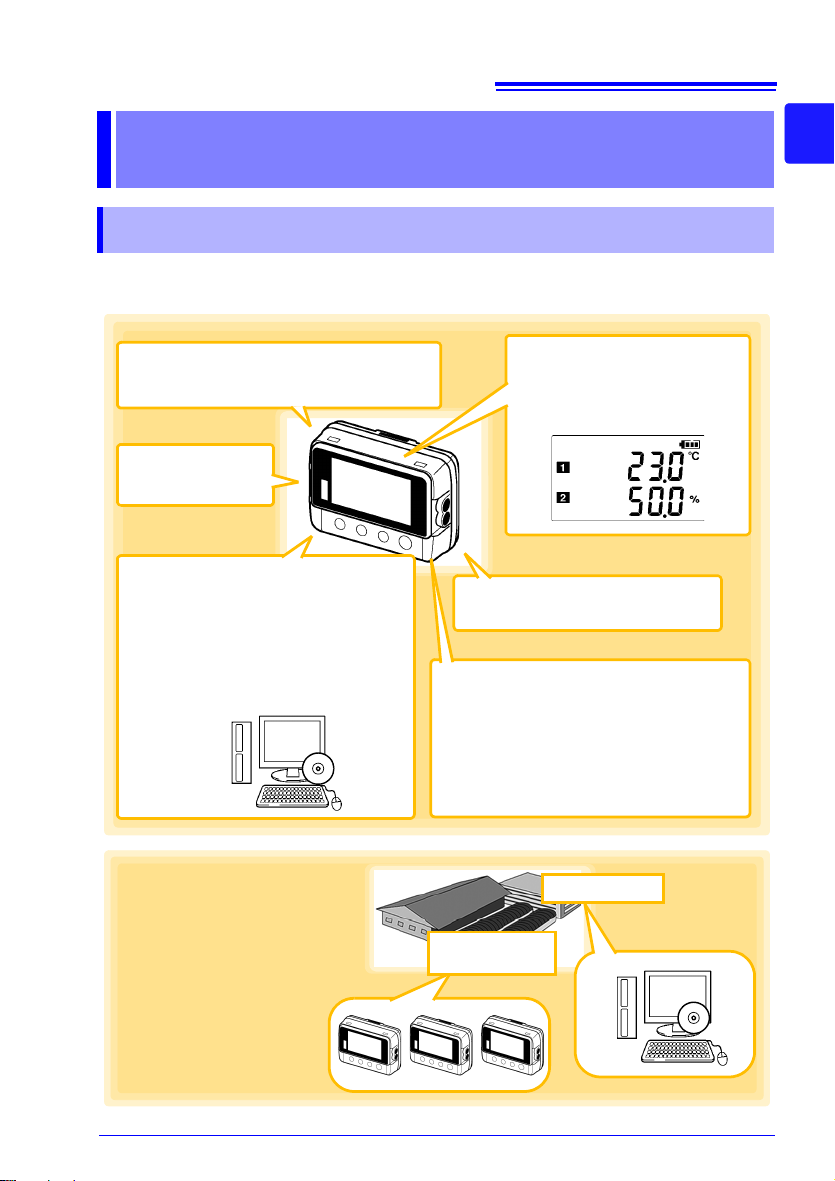

11

Browse and manage data with

LR5000 Utility Program on a PC.

The LR5000 Utility Program PC application is very easy to install.

After installation, data management and

browsing is easy with auto-start, data display and saving.

Large display shows two channels' data simultaneously

Measures temperature and humidity on separate channels.

• Data can be imported while recording.

• Records up to 60,000 measurements

Splash-proof

ingress protection

(IP54)

Advanced functions included

• Record statistical values (p.30), (p.35)

• Scaling (p.36), (p.63)

• Alarm display (p.37)

Data is preserved independently of battery state

Measurement

Sites

Analysis Site

For home, office, factory, and

warehouse environment

measurements

Suitable for ESCO, HACCP, and

ISO environmental measur ements.

1.1 Product Overview and Features

Overview Chapter 1

1.1 Product Overview and Features

This instrument is a compact portable data logger for measuring, displaying, and

recording temperature and humidity.

1

Chapter 1 Overview

3

Page 18

12

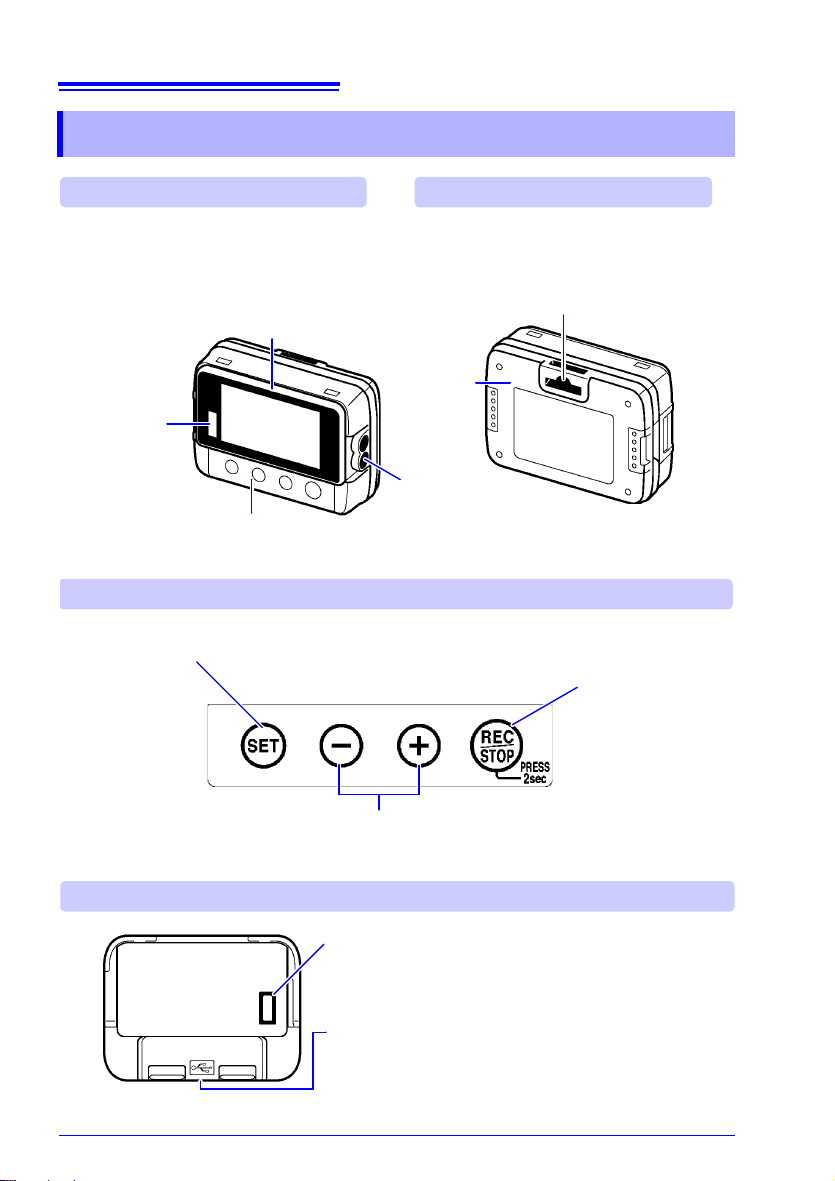

Front

LCD (p.13)

The display blanks after 30 seconds of operator inactivity (auto power save).The display

reappears by pressing a button.

When the display is visible, it refreshes about

once per second.

Battery

Cover

(p.17)

SET button

Displays settings.

Back

Operating Buttons

REC/STOP button

Hold for two seconds to start/stop recording.

From a setting display, switches to measurement

display.

Sensor Jacks

(p.20)

Connecting a Temperature/

Humidity Sensor

Operating Buttons

LR5091 Communication Adapter

USB Port (p.32)

Connect a USB cable here to communicate with a

computer. (Mini-B receptacle)

Stand/Strap Attachment Hole (p.40)

Attach the logger to a wall or other surface by

hanging it on a screw. (Supported screw head

dimensions: up to approx. 6.8 mm in diameter

and approx. 2.5 mm in thickness)

IR Port

(p.45)

Communicates

with the LR5091

Communication

Adapter or

LR5092-20 Data

Collector.

(-) button, (+) button

Changes Measurement display contents.

Changes setting values on the Settings display.

IR Port (p.45)

Communicates with the logger.

1.2 Part Names/Functions and Display Indicators

1.2 Part Names/Functions and Display Indicators

Page 19

13

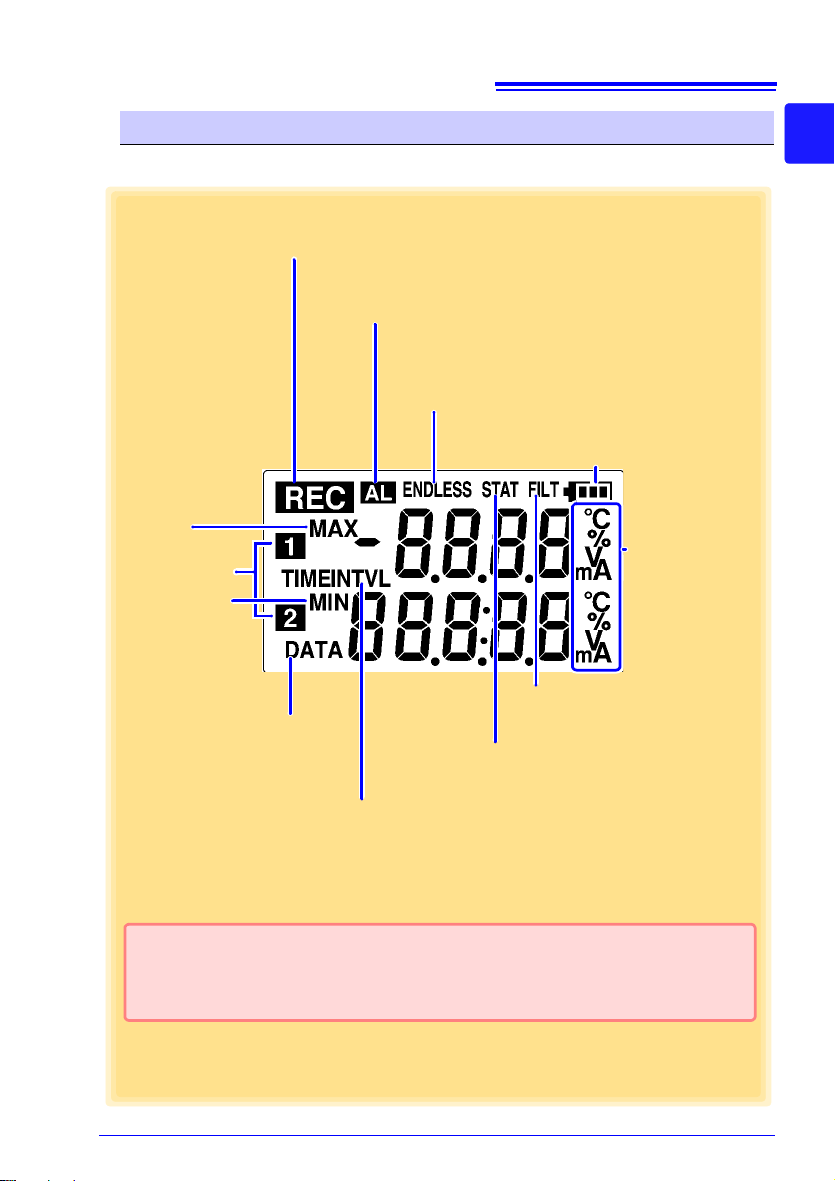

REC Indicator

Indicates recording in progress. (Blinks when waiting to record.)

ENDLESS indicator

Indicates the Stop Method Setting display.

Also appears on the Measurement display to indicate

endless recording (p.30) is enabled.

STAT indicator

Indicates the Recording Mode Setting display.

Also appears on the Measurement display to

indicate statistic recording (p.31) is enabled.

Not used by the logger.

Battery Status Indicator

Indicates the battery charge status. (p.18)

Units

Indicates the unit of

measurement on

each channel.

Measurement

Channel

MAX indicator

Indicates that the

value displayed at

the right is the maximum.

MIN indicator

Indicates that the

value displayed at

the right is the minimum.

DATA indicator

Indicates that the value displayed at the right is the data

count.

* Setting is available from the LR5000 Utility Program or via the LR5092-20 Data Col-

lector.

See: "3.3 Making Settings from the LR5000 Utility Program" (p.32), LR5092-20 Data

Collector Instruction Manual

TIME indicator

Indicates the Date-Time Setting display.

INTVL indicator

Indicates the Recording Interval Setting

display.

AL indicator

When the alarm* function is enabled, this indicates when a measured value is outside of the specified (upper/lower value*) range.

1.2 Part Names/Functions and Display Indicators

Display Indicators

The display indicators provide the following information.

1

Chapter 1 Overview

3

Page 20

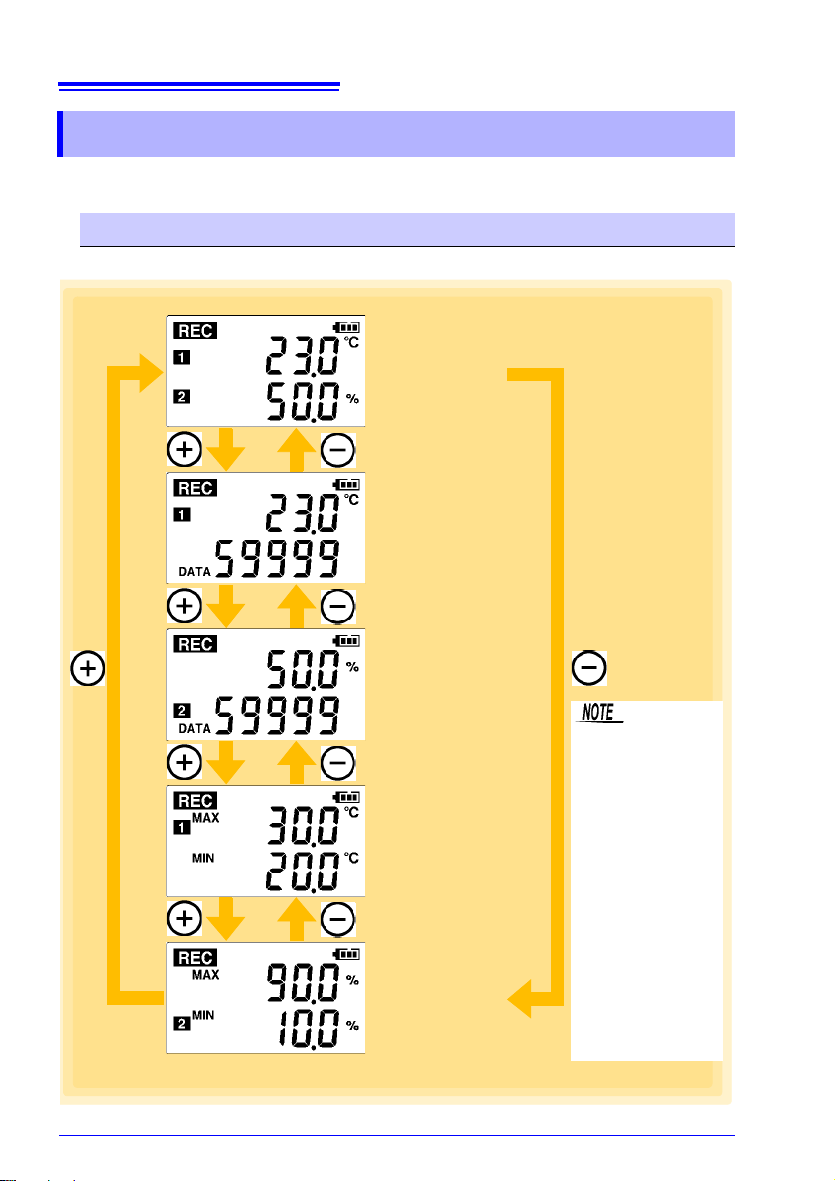

14

Channel 1

measured value

Channel 2

measured value

Channel 1

measured value

Recorded data count

Channel 2

measured value

Recorded data count

Channel 1

maximum value

Channel 1

minimum value

Channel 2

maximum value

Channel 2

minimum value

• For instantaneous

recording, the maximum and minimum

values are obtained

from all the data

measured at each

recording interval.

• For statistical

recording, the maximum and minimum

values are obtained

from all the data

measured every

second.

• The maximum and

minimum values are

not displayed when

the recorded data

count is 0.

1.3 Display Organization

1.3 Display Organization

The logger has two general display types: Measurement and Settings.

Measuring display

The (+) and (-) buttons switch the display type.

Page 21

15

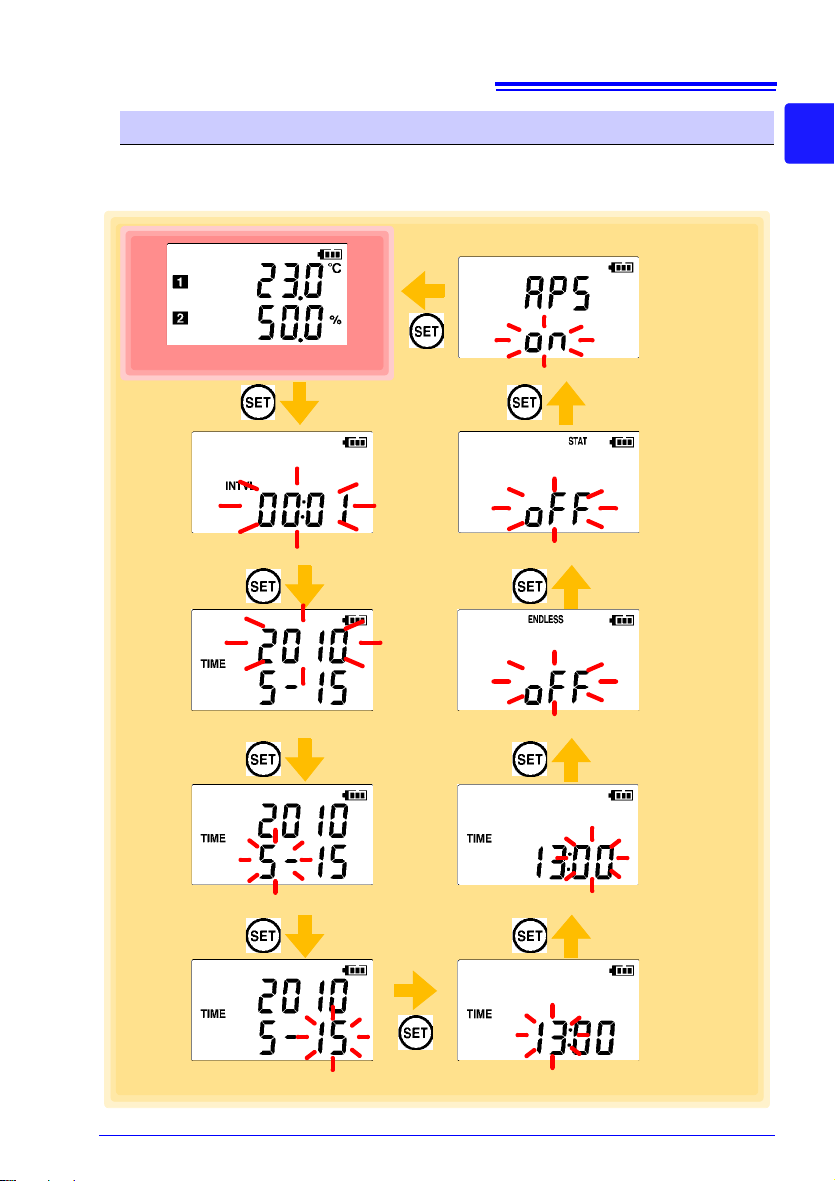

Recording Interval Setting

(p.29)

Year Setting (p.29)

Month Setting (p.29)

Day Setting (p.29)

Power Save Setting (p.31)

Recording Mode Setting

(p.31)

Stop Method Setting

(p.30)

Minute Setting (p.29)

Hour Setting (p.29)

Measuring display

Battery life is extended when on

(enabled).

(Default is on.)

See:

"Appendix 3 Battery Life Approximation" (p.A2)

When on (statistical recording), instantaneous,

maximum, minimum, and average values are

recorded at each

interval. Battery

life is shorter.

(Default is off.)

(Record instantaneous values)

Select what happens when memory becomes full.

When on, the oldest data is overwritten, and when

off, recording

stops.

(Default is on.)

1.3 Display Organization

Setting display

Select the display with the SET button. Press (+) and (-) to change a setting.

Press the REC/STOP button to switch to the Measurement display from any other.

1

Chapter 1 Overview

3

Page 22

16

1.3 Display Organization

• When no operation occurs for 30 seconds with the Settings display,

automatically switches to Measurement display.

• When the battery indicator appears, settings cannot be changed

(although they can still be displayed).

• Settings cannot be changed while recording. However, settings can

still be displayed by pressing the SET button from the Measurement

display.

Page 23

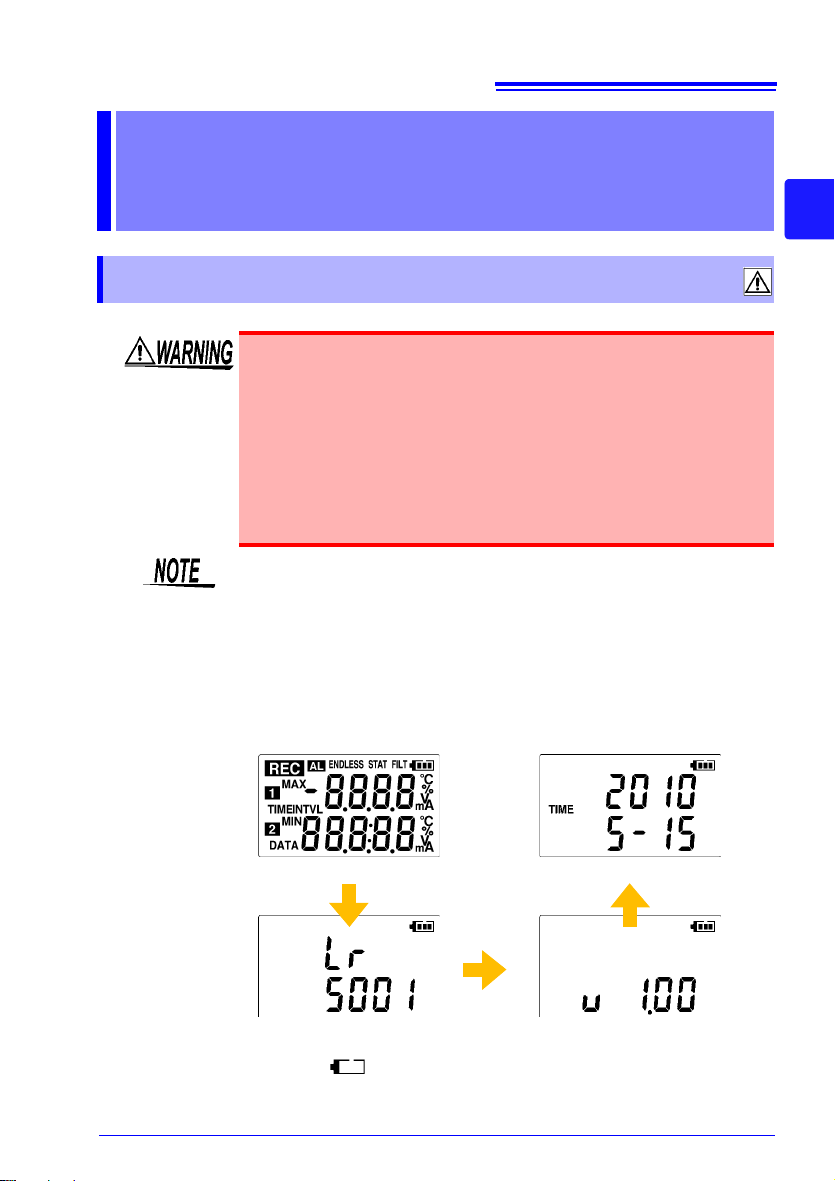

Measurement

1. All segments

2. Model name 3. Firmware version

4. Year Setting display

17

2.1 Installing (or Replacing) the Battery

Preparations Chapter 2

2.1 Installing (or Replacing) the Battery

• After replacing the battery, replace the cover before using the

instrument.

• Be sure to insert them wit

performance or damage from battery leakage could result.

Replace batteries only with the specified type.

• Battery may explode if mistreated. Do no

disassemble or dispose of in fire.

• Handle and dispose of batteries in accordance with local regulations.

• Data and settings stored in the logger are retained even when the battery is depleted, and during battery replacement.

• Testing monitor batteries installed in the unit may possibly be weak.

Replace batteries before extended measurement usage.

• Use only LR6 Alkaline batteries. Using manganese batteries may not

result in accurate measurements or proper communication with the

LR5091 Communication Adapter and LR5092-20 Data Collector.

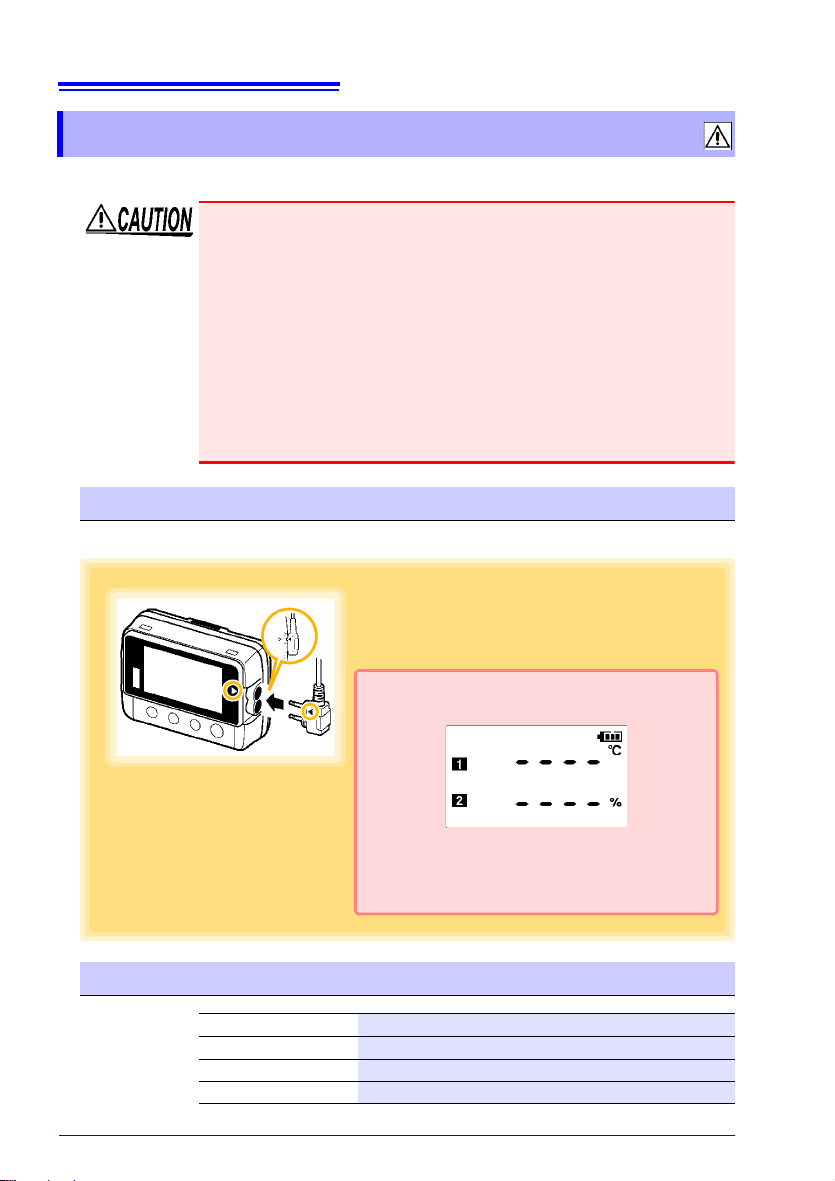

• After installing the batteries, the following displays appear, and the

d

ate and time need to be set. (p.29)

h the correct polarity. Otherwise, poor

t short-circuit, recharge,

2

Chapter 2 Measurement Preparations

3

• When the battery indicator appears, settings cannot be changed

(although they can still be displayed).

Page 24

18

2.1 Installing (or Replacing) the Battery

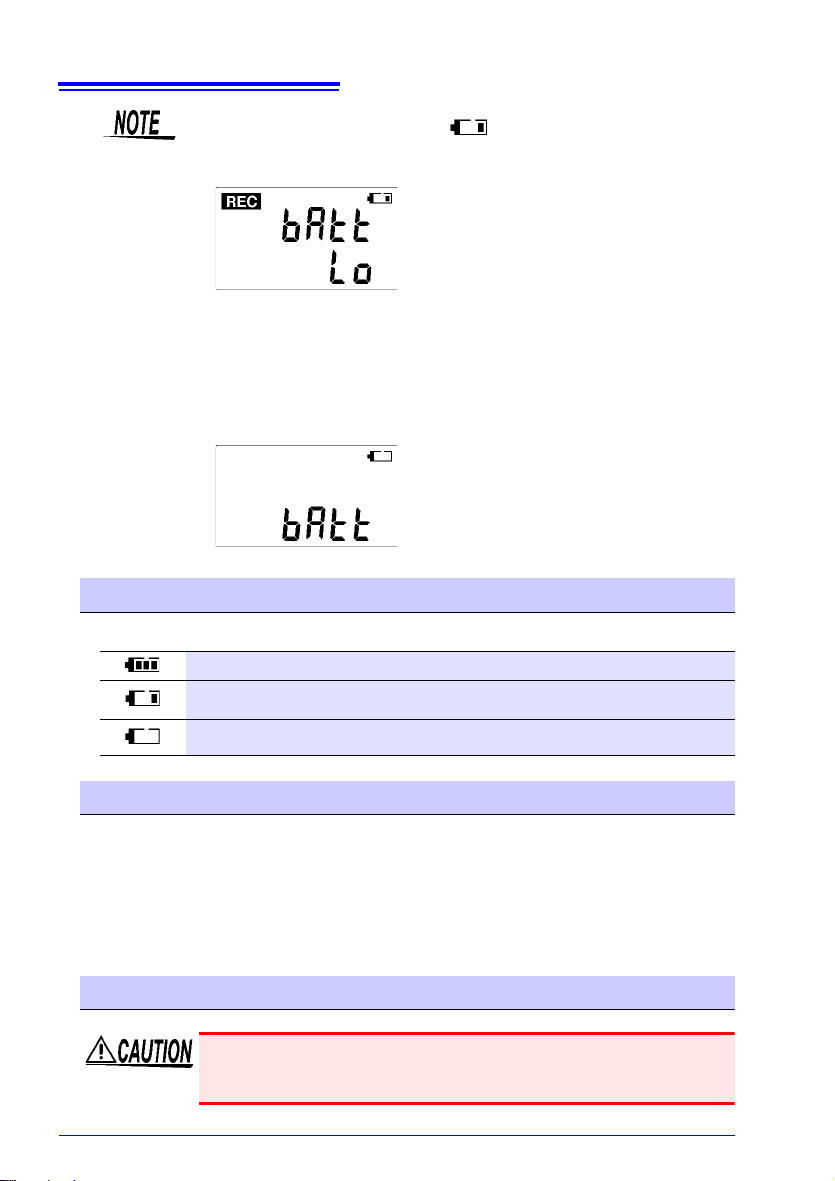

• When the battery indicator is , [bAtt Lo] is displayed on the

screen if the battery is removed during a recording operation. (See the

figur

e below.)

Recording is not performed while [b

period will be missing when the data is imported to a computer.) However, if you insert a new battery within approximately 30 seconds,

re

cording will be resumed after the logger has waited for temperature/

humidity sensor output to stabilize (approximately 30 seconds).

• When battery voltage is too low to operate the logger, the following

app

ears. Replace the battery to restore normal operation.

Att Lo] is displayed. (Data for this

Battery Status Indicator

This indicator is displayed at the top right corner.

Battery charge remains. Fewer blocks within the indicator signify weaker battery charge.

Replace the discharged battery as soon as possible. (Even when the battery is removed

during recording, operation can continue for about 30 seconds.)

In this state, recording and communication with the LR5091 Communication Adapterr

and LR5092-20 Data Collector are not possible.

Using a NiMH Battery

The battery status indicator does not accurately show the remaining battery capacity

wh

en using a NiMH battery. Moreover, the battery life will vary greatly with the capacity, charging conditions and repeated uses. Please take note of these points when

using it.

The device's battery status display and battery life are based on the usage of a brandnew alkaline battery.

When the logger will not be used for long time

To avoid corrosion and damage to this instrument from battery leakage,

remove the batteries from the instrument if it is to be stored for a long

time (1 week).

Page 25

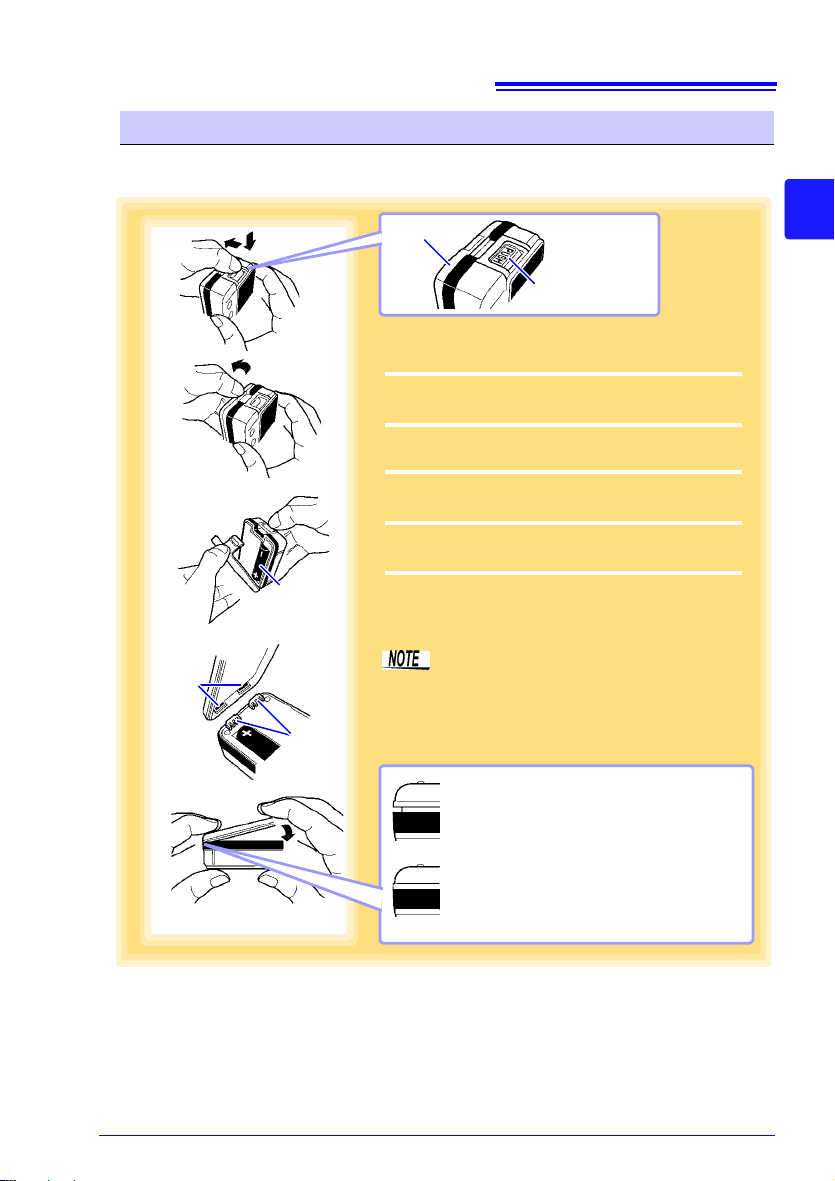

Battery Replacement

1

3

The cover will not close correctly if

there are any gaps.

Never attempt to force the battery

cover closed when not aligned

properly. Doing so could cause

damage.

NG

Battery

4

Projections

Holes

OK

Push the tab

Battery cover

2

5

1

Press the PUSH tab as shown, and pull the

battery cover back.

2

Hold the battery cover while separating it from

the logger.

3

Install the battery as shown.

4

Align the holes in the battery cover with the

projections on the back of the logger.

5

While confirming that there are no gaps, press

with your fingers to close the battery cover.

When the battery is installed, the logger turns

on.

(there is no power switch)

Note that the battery cover is designed to

seal tightly to preserve dust- and dripresistance.

When the holes in the battery cover are

properly aligned with the projections, the

battery cover should close smoothly.

Required Items: LR6 alkaline battery (1)

19

2.1 Installing (or Replacing) the Battery

2

Chapter 2 Measurement Preparations

3

Page 26

20

Align the triangle on the plug with the one in front of

the sensor jacks, and insert the plug securely.

Values are not displayed correctly if the sensor

plug is inserted incorrectly or not inserted far

enough.

If values are not displayed correctly even when the

plug is inserted properly, the logger or sensor may

be damaged. Repair may be necessary.

See: "Requesting repairs" (p.91)

2.2 Connecting a Temperature/Humidity Sensor

2.2 Connecting a Temperature/Humidity Sensor

Connect a temperature/humidity sensor to the logger's sensor jacks.

• A temperature/humidity sensor is precision machined. Applying an

excessively high voltage pulse or static electricity may damage the

sensor.

• Avoid subjecting the temperature/humidity sensor tip to physical

shoc

k, and avoid sharp bends in the leads. These may damage the

probe or break a wire.

• Take care that the temperature/humidity sensor does not exceed the

spec

ified temperature range.

• To avoid breaking the sensor, do not bend or pull it.

• Avoid stepping on or pinching cables, which could damage the cable

tion.

insula

• To avoid damage to the instrument, do not apply voltage to sensor jacks.

Connection Method

Required Items: Hioki LR9501 to LR9504 Temp/Humidity Sensor

Compatible Sensors

LR9501 Humidity Sensor

LR9502 Humidity Sensor

LR9503 Humidity Sensor

LR9504 Humidity Sensor

Approx. length 1 m

Approx. length 5 m

Approx. length 10 m

Approx. length 40 m

Page 27

21

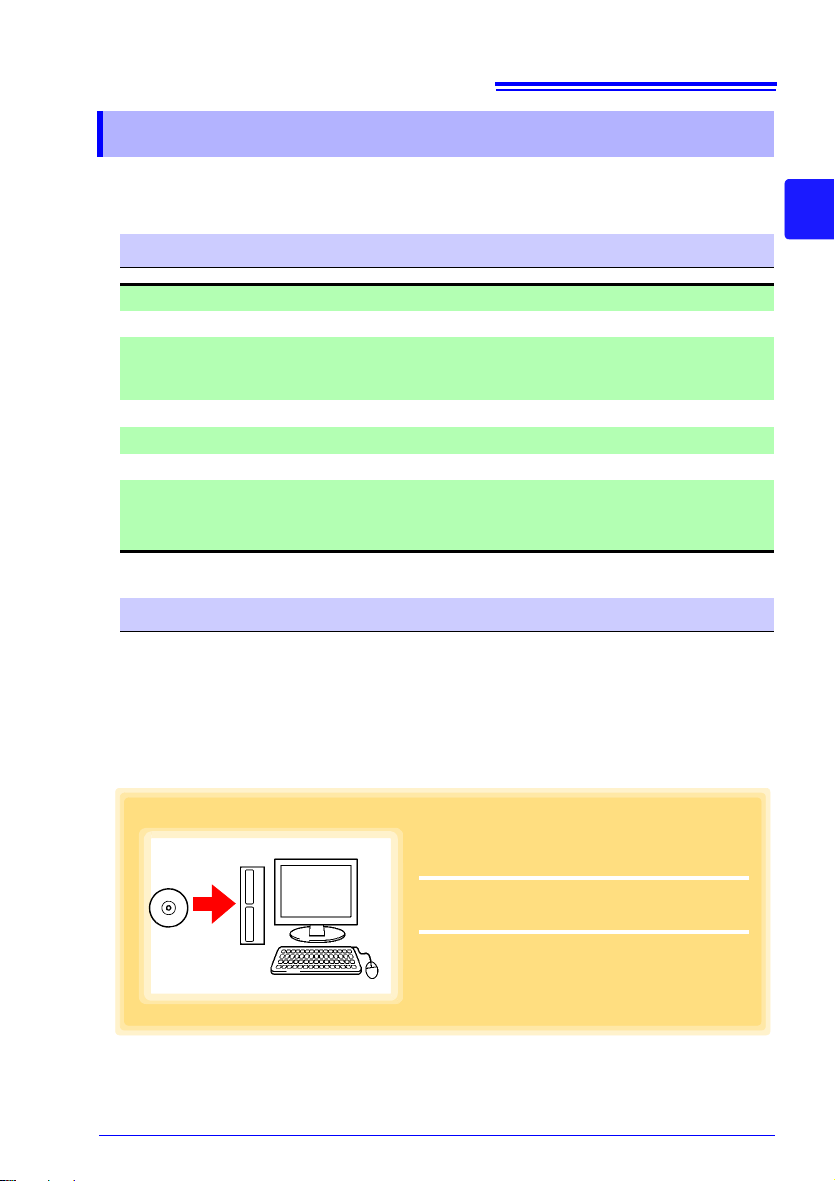

1

Load the CD in the computer's CD-ROM

drive.

The computer's Auto Play function should display the html file on the CD in a web browser.

1

2.3 Installing the PC Application Program

2.3 Inst alling the PC Application Program

To save, browse, or print data, or to make logger settings from a computer, first

install the "LR5000 Utility Program".

LR5000 Utility Program Operating Requirements

CPU 1 GHz or faster processor clock

RAM At least 512 MB

Windows XP SP2 or later

OS

Library .NET Framework 2.0/3.5

Interface USB

Monitor Resolution 1024×768 or higher

Hard Disk

Installation Procedure

Windows Vista SP1 or later

Windows 7

At least 30 MB free space

(Additional space is required for storing recorded data.

Another 500 MB may be required if .NET Framework 2.0 or 3.5 is not yet

installed.)

2

Chapter 2 Measurement Preparations

3

Log in with an Administrator account.

Before installing, close any applications running on the computer.

Required Items: Supplied CD

(for Windows XP) LR5091 Communication Adapter, USB cable

Page 28

22

2

Click [Simple Installation] or [Advanced Installation] on the screen.

Installation of the LR5000 Utility Program and device driver begins.

3

When the security warning window appears, click [Run].

4

After installation, start the program by selecting [Programs]-[Hioki]-[LR5000 Util-

ity Software]-[LR5000 Utility] from the Windows [Start] menu.

The main screen (p.24) appears.

How to start the program?

The program starts automatically from the next Windows logon. (The icon

appears in the task tray (notification area) (p.32).)

Click the icon and click [Show Main Screen].

If the installation screen does not appear?

• Execute X:\English\Setup.exe, where X is the CD-ROM drive letter.

After starting setup.exe, follow the on-screen instructions to complete installation. (If .NET FrameWork 2.0 or 3.5 is not already installed, it is installed first.)

• You may be prompted to reboot during installation.

If installation does not resume after rebooting, execute setup.exe again.

2

3

2.3 Installing the PC Application Program

For setting and importing recorded data from loggers other than the

LR5000 series, use the Communication Utility program supplied with

the model 3911 or 3912 Communication Base. You can browse the

recorded data by using LR5000 Utility Program also.

Page 29

Settings and recorded data are not de leted when uninstalling or upgrad-

1. Click [Start]-[Control Panel].

(The [Control Panel] dialog box appears.)

2. Click [

Programs and Features].

(The [Programs and Features] screen appears.)

3. Select the [LR5000 Utility Program], and click the [Uninstall/

Change] button.

(The [File Delete Confirmation] dialog box appears.)

4. Click [Yes].

(The program is uninstalled.)

3

Follow the procedure on the download page to install the latest version. (The old version is uninstalled automatically.)

ing the program.

Uninstall Procedure

Follow this procedure to uninstall the LR5000 Utility Program.

23

2.3 Installing the PC Application Program

2

Chapter 2 Measurement Preparations

3

Version Upgrading

Download the latest version of the LR5000 Utility Program from our website (ht

www.hioki.com).

tp://

Page 30

24

Main Screen (p.32)

Displays Setting Screens:

Logger settings

Displays the data import screens:

Logger data import

Display Data

Viewing screens

Display Data

Sorting screens

Displays Option

screens

Displays

Help.

Setting Screens (p.33)

Make and export logger settings.

Example: Logger settings

2.3 Installing the PC Application Program

LR5000 Utility Program Screens

Page 31

Data Viewing Screens (p.58)

View imported data on these screens.

Select a file to view, as a graph or table.

Example: Screens for viewing the latest data

Data Import Screens (p.55)

Import data from the logger with these screens.

Example: Logger import screen

25

2.3 Installing the PC Application Program

2

Chapter 2 Measurement Preparations

3

Page 32

26

Option Screens (p.77)

Make advanced settings on these screens.

You can specify the data importing method.

Example: Import Method Setting screen

Data Sorting Screens (p.71)

Sort imported data on these screens.

You can copy, delete, move, combine, and extract data.

Example: Data Copy screen

2.3 Installing the PC Application Program

Page 33

27

3.1 Settings List

Settings Chapter 3

Configure measurement settings before starting to record.

Logger settings can also be made from a PC running the LR5000 Utility Program.

(p.32)

3.1 Settings List

Following is a list of all settings.

Although all settings are available from t

are limited when made from the logger.

Setting Item Setting Options Logger Refer To

Recording Interval Sets the recording interval. Yes (p.29) Yes (p.35)

Set the current year, month,

day

Current Date and

Ti

me

Stop Method

Recording Mode

Power Save

Model Comment

Channel Comment

Recording Start

Method

, hour, and minute. (The

LR5000 Utility Program can

set the logger's clock to

match the computer’s.)

Select the processing

method when memory

becomes full.

Selects instantaneous or

st

atistical value recording

(measurements are taken

once per second, and

instantaneous, maximum,

minimum, and average values are saved at each

r

ecording interval).

Battery life is extended

when on (enabled).

Enter a comment for the

speci

fied logger.

Enter a comment for the

specified measurement

channel.

Select the recording start

m

ethod. (The start time can

be specified.)

he LR5000 Utility Program, some settings

LR5000

Ut

Program

Yes (p.29) Yes

Yes (p.30) Yes

Yes (p.31) Yes

Yes (p.31) Yes (p.34)

No - Yes

No - Yes (p.34)

No - Yes (p.35)

ility

Refer To

(p.38)

Included

in the

recording

stop

method

(p.35)

(p.34)

3

Chapter 3 Settings

3

Page 34

28

3.1 Settings List

Setting Item Setting Options Logger Refer To

Recording Stop

Method

Scaling

Alarm Thresholds

Select the recording stop

method. (The stop time can

be specified.)

Use to scale measured values to display as adjusted

ues.

val

Set upper and lower thresh-

old values to display the

alarm indicator [AL] on the

logger.

No - Yes (p.35)

No - Yes (p.36)

No - Yes (p.37)

LR5

000

Utility

Program

Refer To

Page 35

29

1

Press the SET button to display the interval setting.

(The [INTVL] indicator appears,

and the setting blinks.)

2

Press the (+) and (-) buttons to change

the recording interval.

Example of configuration

1 second: 00:01 / 1 minute: 01:00

3

Press the SET button to accept the setting.

(The year setting is displayed.)

1

Press the SET button to display the time

settings.

([TIME] is displayed, and the year

setting blinks.)

2

Press the (+) and (-) buttons to change

the year.

3

Press the SET button to accept the year

setting.

(The month setting starts blinking.)

4

Repeat this procedure to set the month,

day, hour, and minute.

5

Press the SET button to accept the setting.

(The stop method setting is displayed.)

Year Setting display

3.2 Making Settings on the Logger

3.2 Making Settings on the Logger

To return to the Measurement display from any Settings display, press the REC/

STOP button.

• When the battery indicator appears, settings cannot be changed

(although they can still be displayed).

• When no operation occurs for 30 seconds with Settings displayed,

automatically switches to Measurement display.

• Settings cannot be changed while recording. However, settings can

still be displayed by pressing the SET button from the Measurement

display.

Recording Interval Setting

3

Chapter 3 Settings

3

Recording Interval 1(Default)/2/5/10/15/20/30 sec., 1/2 /5/10/15/20/30/60 min

Real-Time Clock Setting

Page 36

30

1

Press the SET button to display the stop

method setting.

(The [ENDLESS] indicator

appears, and the setting blinks.)

2

Press the (+) and (-) buttons to select

[ON] or [OFF].

3

Press the SET button to accept the setting.

(The recording mode setting is displayed.)

(the Measurement display shows channel measurement value and recorded data count)

(instantaneous value recording display)

(statistical value recording display)

3.2 Making Settings on the Logger

Setting Range 01/01/2010, 00:00 to 12/31/2039, 23:59

Note: Seconds are not settable. However, seconds are set to zero at the instant the display is switched

way from the minute setting.

a

After the battery has been removed for a long time, or if the clock is

incorrect, reset it.

Stop Method Setting (for when memory becomes full)

Setting Options

OFF Recording stops when memory becomes full (One-Time Recording).

ON(Default) The oldest data is overwritten when memory is full (Endless Recording).

Description

When memory becomes full during one-time recording, the recorded

data count appears as follows.

When memory becomes full during endless recording, the recorded

data count (equal to the memory capacity) remains constant.

Page 37

Recording Mode Setting

1

Press the SET button to display the

recording mode setting.

(The [STAT] indica-

tor appears, and the setting blinks.)

2

Press the (+) and (-) buttons to select

[ON] or [OFF].

3

Press the SET button to accept the setting.

(The power save setting is displayed.)

1

Press the SET button to display the power

save setting

([APS] appears, and the setting

blinks).

2

Press the (+) and (-) buttons to select

[ON] or [OFF].

3

Press the SET button to accept the setting.

(The measurement display appears.)

31

3.2 Making Settings on the Logger

3

Chapter 3 Settings

3

Setting Options

OFF (Default)

ON

Description

The instantaneous value is recorded at each recording interval (instantaneous

recording).

When on, measurements are taken once per second, and instantaneous, maximum, minimum, and average values are recorded at each recording interval. (statistical recording).

(Up to 15,000 data values can be recorded.)

Statistical recording cannot be selected when the recording interval is

set to one second.

Power Save Setting

The power save function turns off the display 30 seconds after the last button is

pressed, except when the recording interval setting is displayed. The display reappears upon the next button press.

Setting Options

ON (Default) Power save is enabled.

OFF Power save is disabled (the display remains visible).

Description

The Auto Power Save feature consumes a small amount of current

See: "Appendix 3 Battery Life Approximation" (p.A2)

Page 38

32

1

Plug the USB cable into the USB port on

the LR5091 (or LR5092-20), and into a

USB port on the computer.

2

Dock the logger in the LR5091 (or

LR5092-20).

(When docking, be sure that the infrared ports

are aligned.)

The main display appears automatically (by

default).

When the logger contains recorded data, the

import confirmation dialog appears.

Click [Yes] to import the data automatically.(p.45)

1

2

1

If the main screen is not displayed on the

computer, click the icon in the task tray

(notification area), and click [Show Main

Screen].

The main screen appears.

1

Click

Click

3.3 Making Settings from the LR5000 Utility Program

3.3 Making Settings from the LR5000 Utility

Program

Logger settings can be made with the LR5000 Utility Program supplied with the

LR5091 Communication Adapter and the LR5092-20 Data Collector.

Install the Utility Program on the computer before connecting. (p.21)

Connecting the Logger, LR5091, and Computer

Connect to the computer using the supplied USB cable.

quired Items: Logger, LR5091 Communication Adapter, USB cable, Computer

Re

Logger Settings

Page 39

2

For the [Setting], click the [Logger] button.

The Logger Settings screen appears.

(If the logger is not connected, you are

prompted to connect it. Connect the logger.)

3

Select the logger from the device list*,

and edit the settings. (p.34)

4

Click the [Send Settings] button.

4

How can current settings be imported from the connected logger?

1. Click the [Import Settings] bu tton at the upper right of screen.

(A dialog appears.)

2. Click the [Import Settings to Computer] button. (The logger's settings

are now reflected in the program.)

2

Click to select.

The currently selected logger's background is a different color.

3

Setting Options

Note: The displayed settings are those previously made

from the LR5000 Utility Program, which may be different from the current settings within the logger itself.

* About the Device List

• Up to ten loggers can be displayed when connected to the computer.

• When [Show disconnected loggers ] is sele cte d, discon nected logge rs that had settings previously saved appear in the list.

• The list can be sorted in ascending order ([Sort List]).

Returns to the

main screen.

Settings from other loggers can

be applied. (p.34)

3.3 Making Settings from the LR5000 Utility Program

33

3

Chapter 3 Settings

3

Page 40

34

How can the settings from one logger be copied to another?

1. From the device list, select a logger with settings to be copied, and click

the [Copy Settings] button.

2. From the device list, select a logger as the destination for the settings, and

click the [Paste Settings] button. (A dialog appears.)

3. Click the [Paste] button in the dialog box. (The settings are copied.)

How can I learn more about changing settings?

1 Setting the [Basic Settings]

2 Settings on the [Recording Method] tab

Model

comment

Enter a comment to describe the logger as needed.

Power save

setting

Enable or disable the power save setting (p.31).

See:

"Appendix 3 Battery Life Approximation" (p.A2)

CH1 comment

CH2 comment

Enter a comment to describe the measurement channel as needed.

Note: Comments may consist

of up to 20 characters.

The following characters are not allowed: \, /, :, *, ?, ", <, >, and |.

1

2

Click a tab.

3.3 Making Settings from the LR5000 Utility Program

The Auto Power Save feature consumes a small amount of current

Page 41

3.3 Making Settings from the LR5000 Utility Program

Rec interval

Sets the recording interval.

1/2/5/10/15/20/30 sec., 1/2 /5/10/15/20/30/60 mi

Start Method

Select the recording start method.

When [Scheduled Time] is selected, specify the start date and time.

Setting Options

Button Operation Starts recording by pressing the button on the logger.

Start After Sent Starts recording by pressing the [Send Settings] button.

Scheduled Time

Description

Starts recording at the scheduled time after pressing the [Send Settings] button.

35

3

Chapter 3 Settings

3

Valid setting time

range

01/01/2010, 00:00 to 12/31/2039, 23:59

When the [Scheduled Time] start method is enabled, th e [REC] indicator on the logger display blinks until the specified start time.

Stop Method

Select the recording stop method.

When [Scheduled Time (Endless)] or [Scheduled Time (On e-Time)] is selected,

the date and time need to be set.

Setting Options

Button Operation

(endless)

Button Operation

(one-time)

Scheduled Time

(Endless)

Scheduled Time

(One-Time)

Hold Data at Sched-

uled Time

Description

Stops recording by pressing the button on the logger.

The oldest data is overwritten when memory is full.

Stops recording by pressing the button on the logger.

Recording also stops when memory becomes full.

Stops recording at the scheduled time.

The oldest data is overwritten when memory is full.

Stops recording at the scheduled time.

Recording also stops when memory becomes full.

Specify when setting [Scheduled Time (Endless)].

Select this check box to record the data at the scheduled time and stop recording.

Rec Mode

Select the recording mode.

Setting Options

instantaneous The instantaneous value is recorded at each recording interval.

Statistical

See:Statistical recording results in shorter battery life. "Appendix 3 Battery Life Approxima-

tion" (p.A2)

Description

Measurements are taken once per second, and instantaneous, maximum, minimum, and average values are recorded at each recording interval. (Up to

15,000 data values can be recorded.)

Statistical recording cannot be selected when the recording interval is

set to one second.

Page 42

36

Click a tab.

3 Settings on the [Measurement Method] tab

Click the [E

dit] button to display the setting dialog box.

3

See: "What is Scaling?" (p.38)

Enable scaling

Select this check box to enable scaling.

Clicking this tab

changes the setting

options. Make settings on either tab.

(The settings are applied to the other

tab.)

Specify by example, or Specify by A/B

3.3 Making Settings from the LR5000 Utility Program

Scaling (set as needed)

The following scaling calculation is applied to measured values.

Scaled Result = Raw data (measured value) × A + B × SI prefix (multiplier)

The scaled result is displayed on the logger.

Page 43

3.3 Making Settings from the LR5000 Utility Program

Upper and lower thresholds

Enter numerical values between -9999 and 9999 (up to six digits).

When scaling is enabled, enter these values as scaled results.

Enable alarm judgment

Select this check box to enable the alarm.

1. Set the following options.

Setting Options

Specify by

example

Specify by A/B Enter the scaling coefficients (A and B, up to ten digits each).

Scaled units

Display digits

Description

Enter two known conversion points (up to ten digits each).

• Select the [SI Prefix].

]=1E-12, [n]=1E-9, []=1E-6, [m]=1E-3, blank =1E0, [k]=1E3, [M]=1E6,

([p

[G]=1E9, [T]=1E12)

• Enter the [Ch

(Up to five characters, except \, /, :, *, ?, ", <, >, and |.)

•Select [Fixed decimal point] and specify the [Decimal digits] to be dis-

played to the right of the decimal point. Valid settings are 0 to 3.

(Examples: selecting 0 displays values in the form 0000, and selecting 3 displays values in the form 0.000)

• When [Fi

its (0.000 to 999

ar. String] to identify the scaled units.

xed decimal point] is not selected, values are displayed as four dig-

9) with automatic decimal positioning.

2. Confirm settings.

Setting

confirmation

Confirm that scaling is performed properly.

Enter any numerical value as raw data, and click the [Calc

scaled result.

37

3

Chapter 3 Settings

3

] button to display the

3. Click the [Save

] button.

(Scaling settings are saved, and the display returns to the Logger Settings screen.)

Note: If you click the [Cancel] button without saving the settings, the display still returns to

the Logger Settings screen.

Alarm Thresholds (set as needed)

Set the upper and lower alarm threshold values.

When a measurement is outside of the specified area, the [AL] (alarm) indicator is

displayed on the logger.

Click the [Save] button to save your settings.

(The display returns to the Logger Settings screen.)

Note: If you click the [Cancel] button without saving the settings, the display still returns to the

Logger Settings screen.

Note: Alarm judgment is performed at every recording interval during instantaneous recording,

and once per second during statistical recording.

Note: Alarm judgment is performed using measurement values with a larger number of digi ts

Note: The [AL] indicator appears when the measured value is out of range (OF/UF dis-

than the values (4 digits) indicated in the LR5001 display.

played), and when a sensor anomaly occurs (- - - - displayed).

Page 44

38

Delete Data

Deletes recorded data in the selected logger

(only while connected).

Send PC Clock Time

Set the logger's clock to match the computer's clock (after confirming the computer's

clock is correct).

Copy and Paste Settings

Settings can be copied from another logger. (p.34)

Save Settings *

Saves settings to a computer

file. In the dialog box that appears, specify the location

and name of the destination

file (extension .conf).

Open Settings *

Loads settings from a computer file. In the dialog box

that appears, specify the location and name of the

saved settings file (extension .conf).

* Appears only when [Show the set-

tings of the [Save Settings] and

[Open Settings] buttons.] is selected

on the Options screen.

50.0

0.0

0.2 50.4

[C]

Actual measured value (raw data)

(Scaled result)

[C]

-0.2 Offset (coefficient B)

1

Slope (coefficient A)

[C]

[C]

Since only one point is known, set the slope to "1" and enter the offset only.

3.3 Making Settings from the LR5000 Utility Program

Other Settings on the Logger Settings Screen

What is Scaling?

Scaling converts actual measurement values to their corresponding values in arbitrarily determined units for display. It is useful for reconciling the difference between

values measured with the logger and those of a reference device.

For example, when two points of correspondence are known between values measured with the logger and those of the reference device, select [S pecify by exa mple].

(1) When the logger measures 0.2C the reference device measures 0.0C, and (2)

when the logger measures 50.4C the reference device measures 50.0C

Alternatively, when one point of correspondence is known between the logg er and refe

rence device, select [specify by A/B].

(1) The logger measures 0.2C and the reference device measures 0.0C.

Page 45

Measurement

1

2

3

4

5

Is any damage to the logger or sensor evident?

No damage

Damaged

Request repair.

See: "Requesting repairs" (p.91)

Is the infrared port damaged or dirty?

No damage or dirt

Damaged

or dirty

Communication with LR5091 or

LR5092-20 may not be possible.

Clean the infrared port.

See: "9.1 Cleaning" (p.91)

If significant damage is evident,

request repair.

See: "Requesting repairs" (p.91)

Does the display appear

when the battery is

installed?

Display visible

No

display

Request repair.

See: "Requesting repairs" (p.91)

Is the logger clock

correct?

Correct

Incorrect

Set the clock to the current time.

See: "Real-Time Clock Setting"

(p.29)

Does the battery status

indicator appear as ( )?

It does

Replace the battery.

See: "2.1 Installing (or Replacing)

the Battery" (p.17)

It does not

Inspection complete!

6

Are temperature and

humidity values displayed?

Displayed

Not

displayed

Plug in the sensor securely.

See: "2.2 Connecting a Tempera-

ture/Humidity Sensor" (p.20)

If not displayed even when the

connection cable is securely

plugged in, request repairs.

See: "Requesting repairs" (p.91)

39

4.1 Pre-Measurement Inspection

and Analysis

4.1 Pre-Measurement Inspection

Inspect the following items before starting measurement.

Chapter 4

3

4

Chapter 4 Measurement and Analysis

Page 46

40

1

Attach the stand to the strap/stand attachment

hole.

2

Stand up the logger.

1

2

Strap/stand attachment hole

4.2 Installing the Logger

4.2 Installing the Logger

After inspection, install the logger at the measurement site.

Be sure to read the “"Installation Precautions" (p.5) before installing.

Install the logger as necessary according to the following procedure.

Persons wearing electronic medical devices such as a pacemaker

should not use the Z5004 strap with magnet. Such persons should

avoid even proximity to the Z5004, as it may be dangerous. Medical device operation could be compromise

to human life.

Do not apply heavy downward pressure with the stand extended. The

stand could be damaged.

• Avoid shocking the Z5004, such as by dropping. Shock can cause it to

be chipped or cracked.

• Do not use the Z5004 where it may be subject to rain, dust, or condensation. Use in such conditions may cause corrosion or deterioration of

the

magnet.

• If the Z5004 is brought near a magnetic memory device such as a

floppy disk, credit/debit card, or pre-paid card or ticket, th e device m ay

become unusable due to data corruption. It can also cause damage if

brought near a precision electronic device such as a computer, TV, or

electronic wristwatch.

d, presenting a hazard

Using the St and

Required Items: Stand(Accessory)

Page 47

41

1

Mount the LR9901 to the wall using the two

screws.

2

Insert the logger into the LR9901.

1

2

The logger can also be attached to a wall or

other surface by hanging the strap or attachment hole on a screw. (Supported screw head

dimensions: up to approx. 6.8 mm in diameter

and approx. 2.5 mm in thickness)

1

Attach the Z5004 to the strap/stand attachment hole.

(feed the strap through a, b, and c)

2

Attach the magnet to the wall (ferrous material).

2

1

a

b

c

Magnet

4.2 Installing the Logger

Wall Mounting with the LR9901 Wall-Mounted Holder

Required Items: LR9901 (Option), 2 screws (supplied with the LR9901) screwdriver,

etc. (as needed)

3

4

Chapter 4 Measurement and Analysis

Wall Mounting with the Z5004 Magnetic Strap

Required Items: Z5004 (Option)

Page 48

42

Start

From the Measurement display, hold the

REC/STOP button for two seconds.

The [REC] indicator and the data count blink.

Note: Continue pressing the button until the

[REC] indicator changes from a blink-

ing to on state.

When the blinking stops and the data count is

zeroed, recording starts.

Logger memory contains the data for two

recording sessions. (Be aware that old data is

erased when starting recording after two

recording sessions.)

After one second, the measurement display

reappears.

Stop Hold the REC/STOP button for two se c-

onds while recording (while [REC] is displayed).

[REC] blinks.

Note: Continue pressing the button until the

[REC] indicator changes from a blink-

ing to off state.

[REC] disappears when recording stops.

Start

Stop

If the stop method is set to [OFF] (one-time

recording), recording stops automatically

when memory becomes full.(p.30)

Data can be imported to a computer without

stopping recording.

See: "4.5 Automatically Importing (Saving)

Recorded Data to a Computer, and Graph

Display" (p.45)

4.3 Starting and Stopping Recording

4.3 Starting and Stopping Recording

Start recording after installing the logger.

Page 49

43

Screen Display Recording Interval Power Supply

OFF

30 seconds or

less

Always

OFF 1 minute or more

Starts from approximately 30 seconds before the recording timing.

ON Any of the above Always

Screen Display Power Supply

OFF None

ON Always

12:00:00

Recording Start

Operation

12:00:30

Actual Recording Start

Power Control

(Approx. 30

Seconds)

12:00:00

Recording Start Operation

12:01:00

Actual Recording Start

Power Control

(Approx. 30 Seconds)

12:00:00

Recording Start Operation

12:10:00

Actual Recording Start

Power Control

(Approx. 30

Seconds)

4.3 Starting and Stopping Recording

Recording cannot start when the battery is depleted. When the battery

becomes exhausted during recording, recording stops.

See: "2.1 Installing (or Replacing) the Battery" (p.17)

Control of Power to Temperature/Humidity Sensor

The logger supplies power to the temperature/humidity sensor for measuring humidity but control is performed so that the power is supplied

approximately 30 seconds before the recording timing in order to

increase the battery life and enable stable measurement.

Therefore, the operation is as follows depending on the setting state of

the logg

When recording is started ([RE

er.

C] indicator is on)

3

4

Chapter 4 Measurement and Analysis

When recording is stopped ([RE

About the Recording Start Time

Since the power to the temperature/humidity sensor is controlled (for

approximately 30 seconds), if the recording start operation is performed or

a scheduled time is set immediately before the recording timing (within

approximately 1 minute), the first measurement data will not be recorded

and recording will be performed from the next recording timing.

Example:

If the recording interval is 1 second and recording is st a rted at 12:00:00,

the fir

st data will be from 12:00:30.

If the recording interval is 1 minute and recording is started at 12:00:00,

the fir

st data will be from 12:01:00.

If the recording interval is 10 minute and recording is started at

12:00:

00, the first data will be from 12:10:00.

C] indicator is off)

Page 50

44

At 12:01:00, you press the REC button.

The [REC] indicator in the display turns on,

but recording does not start yet.

At 12:10:00

Recording starts.

In the case of instantaneous value recording,

the number of data soon becomes 1.

In the case of statistical value recording, the

number of data becomes 1 at 12:20:00.

Example: When the button is pushed to start recording at 12:01:00, and

the recording interval is 10 minutes

12:01:00

Recording Start Operation

12:10:00

Actual Recording Start

If you try starting at 12:00 but are one minute late.

Actual recording starts at 12:10, which is considered the

next convenient time.

4.3 Starting and Stopping Recording

About Humidity Indications

To obtain correct humidity measurement values, the lo gger needs to wait

approximately 30 seconds for the measurement values to stabilize after

the screen display is turned on.

When using the logger for humidity monitoring or when calibrating the

logger, set the recording conditions so that the recording interval is 30

seconds or less, or turn off (disable) power saving.

Automatic Recording Start at Convenient Times

Depending on the selected recording interval, recording start is automatically delayed

until the next convenient clock time.

Recording Interval Recording Start Time

1sec 00 to 59 s (1-second interval)

2sec 00 to 58 s (2-seconds interval)

5sec 00 to 55 s (5-seconds interval)

10sec 00 to 50 s (10-seconds interval)

15sec 00 to 45 s (15-seconds interval)

20sec 00 to 40 s (20-seconds interval)

30sec 00 to 30 s (30-seconds interval)

1 min 00 min, 00 s to 59 min, 00 s (1-minute interval)

2 min 00 min, 00 s to 58 min, 00 s (2-minutes interval)

5 min 00 min, 00 s to 55 min, 00 s (5-minutes interval)

10 min 00 min, 00 s to 50 min, 00 s (10-minutes interval)

15 min 00 min, 00 s to 45 min, 00 s (15-minutes interval)

20 min 00 min, 00 s to 40 min, 00 s (20-minutes interval)

30 min 00 min, 00 s to 30 min, 00 s (30-minutes interval)

60 min 00 h, 00 min, 00 s to 23 h, 00 min, 00 s (1-hour interval)

Page 51

45

How to switch from a Setting display to Measurement display?

To switch to the Measurement display from any other display, press REC/STOP.

1

Plug the USB cable into the USB port on

the LR5091 (or LR5092-20), and into a

USB port on the computer.

2

Dock the logger in the LR5091 (or

LR5092-20).

(When docking, be sure that the infrared ports

are aligned.)

or

4.4 Confirming Currently Measured Values and Data Recording

4.4 Confirming Currently Measured Values and

Data Recording

Confirm data recording on the Measurement display (p.14).

You can browse current measurement values (instantaneous), the count of

recorded data items, and maximum and minimum values.

The (+) and (-) buttons select the type of value displayed.

• When power saving (p.31) is enabled, the display blanks after no

operation occurs for 30 seconds. To browse measurement values

(

instantaneous) and verify each recorded data value , press any button

to turn on the Measurement display.

• The currently displayed instantaneous measurement value is

refreshed about once per second, regardless of the recording interval

setting.

3

4

Chapter 4 Measurement and Analysis

4.5 Automatically Importing (Saving) Recorded Data to a Computer, and Graph Display

Data recorded in the logger can be imported to the comput

Utility Program on the computer beforehand. (p.21)

Required Items: LR5001, LR5091 Communica

lector), USB cable, Computer

tion Adapter (or LR5092-20 Data Col-

er. Install the LR5000

Page 52

46

The main screen appears automatically.

If newly recorded data exists, the import confirmation dialog appears.

If the data import screen is displayed before connecting the logger, the import confirmation dialog does not appear. Import manually. (p.55)

3

Click [Yes].

The viewer opens to display the

graph (Auto Graph Display).

Note: By default, [Automatically dis-

play graph when data is

imported] (on the Options

screen) is enabled. (p.78)

The data recorded in the logger is

imported to the computer automatically.

Imported data is saved to a file

(Auto Import).

Note: By default, [Automatically

import and store data when

the logger is connected to a

computer] (on the Options

screen) is enabled. (p.78)

How is recorded data saved?

Recorded data is automatically saved when imported to a computer.

The save destination and file name are specified as a basic setting on the

Options screen.

3

4.5 Automatically Importing (Saving) Recorded Data to a Computer, and Graph Display

Page 53

47

Items to be

displayed are

selectable.

(p.54)

Displayed graphs

and tables can be

printed. (p.60)

The displayed

time span can

be specified.

Reloads and refreshes recorded

data from a file.

Displays the [Statistical In-

formation and Item Settings] dialog box when a

graph is displayed. (p.52)

Click the buttons to

switch between graph

and table displays.

Displays the [Graph Set-

tings] dialog box when a

graph is displayed. (p.50)

The graph or table is displayed.

See: "Menu Bar Items" (p.54)

Opens a file containing

recorded data.

4.5 Automatically Importing (Saving) Recorded Data to a Computer, and Graph Display

Viewer Screen

The viewer screen appears as follows.

3

4

Chapter 4 Measurement and Analysis

Page 54

48

4.5 Automatically Importing (Saving) Recorded Data to a Computer, and Graph Display

Menu Bar Items

Menu Item Contents

Open Opens a file containing recorded data.

File

Process

Data

Help

Recently opened recording files

Save recording file as

Print graph

Paste to Microsoft Excel Pastes displayed data into Microsoft Excel.

Export CSV file

Exit Closes the program.

Scaling

Power Calculation

Energy Cost

Operating Rate

Integration

Dew Point Performs dew-point temperature calculation. (p.68)

Two-Data-Item Ari thmetic

OVER Data Revision

Help

Version

Opens recently used file s.

Currently displayed recording data is saved as a

new file.

Prints data in graphic format. (p.60)

Exports displayed data as a CSV file.

Applies scaling to data on one channel. (p.63)

Performs approximate electric power calculation.

(p.64)

Performs approximate energy cost calculation.

(p.65)

Performs approximate operating rate calculation.

(p.66)

Performs data integration. (p.67)

Performs approximate two-data-item arithmetic calculation. (p.69)

Converts data outside of the upper and lower thr eshold settings to specified values, and saves as new

data. (p.70)

Displays the help file.

Displays LR5000 Utility Program version informa-

tion.

Page 55

49

Displays the [Statistical Information and Item Settings] dialog box. (p.52)

Displays the [Graph Settings]

dialog box. (p.50)

A/B cursors

Scroll Bar (scrolls the graph)

When there are two or

more axes, select the

one displayed closest to

the graph.

Click the buttons to

switch between graph

and table displays.

How can the displayed area be magnified?

Dotted

Box

Click

2

1

Drag over the area to be enlarged to enclose it in a dotted box.

2

Right click to open the pop-up menu, and click [Magnify selected area].

How can graph details be set?

Detailed settings are available in the [Graph Settings] dialog box. (p.50)

How can graph line color and display be switched?

Change settings on the [Item settings] tab in the [Statistical Information and

Item Settings] dialog box (p.52)

4.5 Automatically Importing (Saving) Recorded Data to a Computer, and Graph Display

Main Graph Features

The main graph features are shown below.

3

4

Chapter 4 Measurement and Analysis

Page 56

50

[Common] tab

1

Automatically sets the time axis and Yaxis to the optimum scale.

2

Select to display the grid.

3

Changes the graph background color.

4

Copies the graph to the clipboard. The

graph can then be pasted into Microsoft

Word etc .

1

2

3

4

[Time axis] tab

1

Automatically sets the time axis to the

optimum scale.

2

Zooms the display to show only the time

span between A/B cursors.

3

Changes the time base scale.

4

Specifies the displayed time span on the

time axis. Click [Execute] to apply the

settings.

5

Specifies cursor positions. Click [Exe-

cute] to apply the settings.

6

Specifies the graph start position (time).

Click [Execute] to apply the settings.

1

2

3

4

5

6

4.5 Automatically Importing (Saving) Recorded Data to a Computer, and Graph Display

[Graph Settings] dialog box

Graph details can be set as follows. Click each tab to access various settings.

Page 57

51

[Y axis] tab

1

Automatically sets all Y-axes to the optimum scale.

2

When the Y-axis is different for each item,

set the number of axes to a value other

than one. The axes can be set to the

number of displayed items (up to 16).

3

Displays all axes.

4

A comment can be entered for each axis.

5

Select the item assigned to each axis.

6

Sets the Y-axis scale for each axis.

7

Automatically sets the currently selected

Y-axis to the optimum scale.

8

Specifies the display span on the Y-axis.

Click [Execute] to apply the settings.

9

Sets the Y-axis grid spacing.

10

Display the items selected in [Display

item] on an integrated graph.

11

Upper and lower thresholds can be displayed as solid lines on the graph, or outof-range areas can be filled with a solid

color.

1

2

4

5

6

7

3

8

9

11

10

4.5 Automatically Importing (Saving) Recorded Data to a Computer, and Graph Display

3

4

Chapter 4 Measurement and Analysis

Page 58

52

[Statistical information] tab

Times at A/B cursors

Select to calculate and display maximum,

minimum, average, and integration values

between A/B cursors. Integration values are

displayed only for integrable items.

[Item settings] tab

4.5 Automatically Importing (Saving) Recorded Data to a Computer, and Graph Display

[Statistical Information and Item Settings] dialog box