Page 1

X-FCM & X-FCP Grating & Checkerplate 3.6

h

h

nom

h

NVS

h

h

nom

h

NVS

DX 750DX750

R

4321

30

NVS

26.5

23

16

L

7

21.5

18

20

L

2

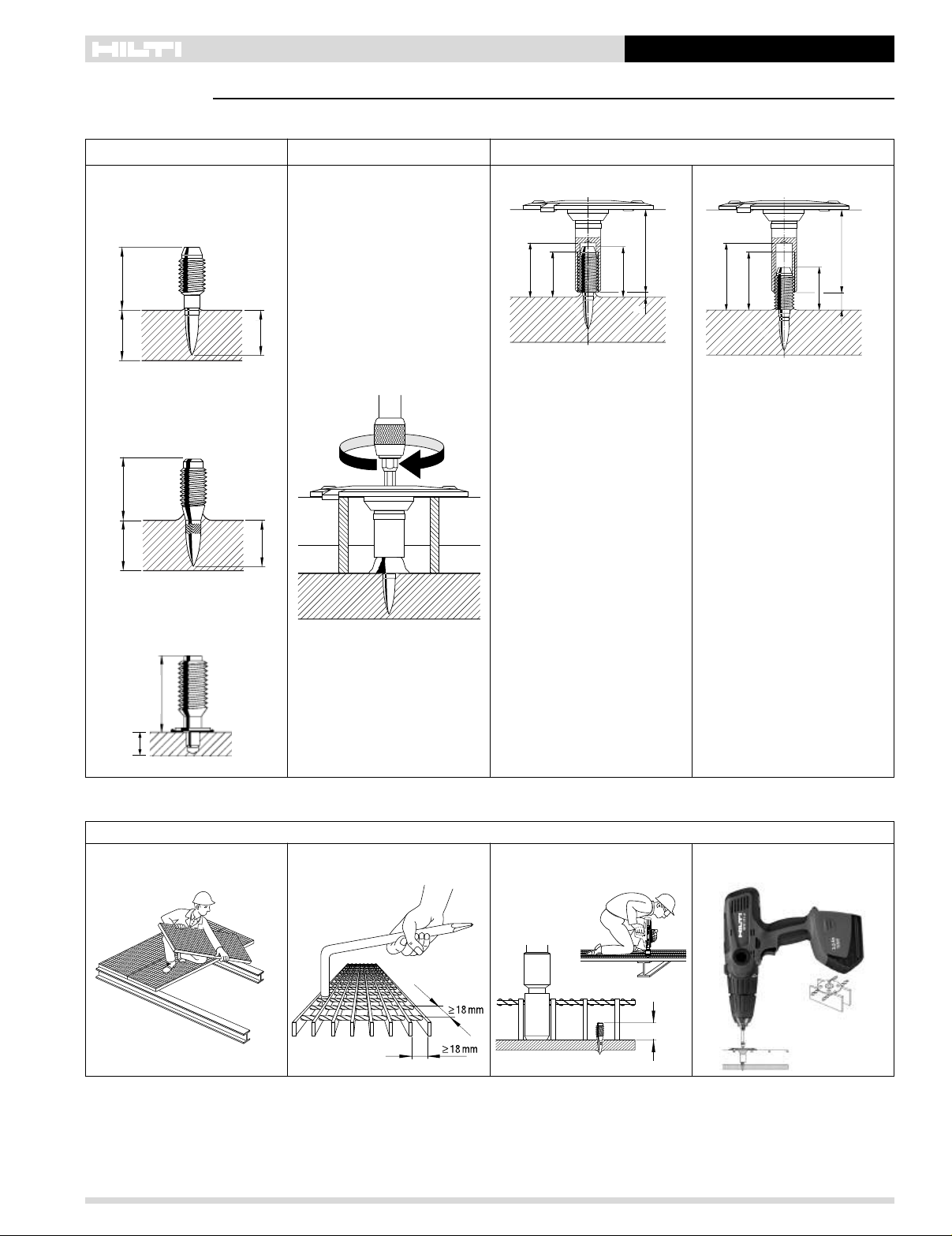

3.6.4 Installation Instructions

D

irect Fastening Systems

Threaded stud placing

X-CRM8-15-12

= 12 ± 2 mm

h

T

E

h

= 18 ± 2 mm

NVS

t

≥ 6 mm

II

NVS

h

II

t

EM8-15-14

= 14 ± 2 mm

h

om

n

= 18 ± 2 mm

h

NVS

t

≥ 6 mm

II

NVS

h

II

t

X-BT M8-15-6 SNR12

h

= 15.7 - 16.8 mm

NVS

t

≥ 8 mm

II

Tightening torque

4.5 ft-lb (6.1 N-m) for

T

=

max

X-CRM8 and EM8 studs.

T

= 5.9 ft-lb (8 N-m) for

max

X-BT M8 studs.

Tightening tool:

Hilti screwdriver SF 121-A

SF 150-A or SF 180-A with 5 mm

orx Bit (Item no. 00087904)

T

ET

h

Set clutch to appropriate setting to

obtain desired torque.

ET

h

Fitting tolerances/height of grating (dimensions in mm)

Min. grating height = L + 2

1

Max. grating height = L + 7

Governing requirement:

• Minimum 2 mm clearance

between X-FCM and surface

of base steel to allow for

deflections

Example:

X-FCM 25/30

Min. grating ht. = 23 + 2 = 25 mm

Max. grating ht. = 23 + 7 = 30mm

Grating height of 32 can be

accommodated if h

≥ 18 mm

NVS

Governing requirement:

• Minimum 5 mm thread

engagement at the minimum

allowable standoff, h

.

VS

N

Note:

• The maximum grating height

for an X-FCM type can be

extended if h

is tightly con-

NVS

trolled, e.g. at 18 mm instead

of 16 mm.

NVS

h

II

t

Installation procedure for bar grating

1. Place the grating sections 2. Widen opening at fastening 3. Place the threaded stud 4. Tighten the disk, without exceeding maximum tightening torque

h

NVS

1 Reference Section 3.5.4 for more details on proper installaton of X-BT fasteners.

Hilti, Inc. (US) 1-800-879-8000 | www

.us.hilti.com

I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www

.ca.hilti.com

I Pr

echnical Guide 2006 47

oduct T

Loading...

Loading...