Page 1

SF 180-A

*375007*

375007

Operating instructions 9–16

en

Page 2

1

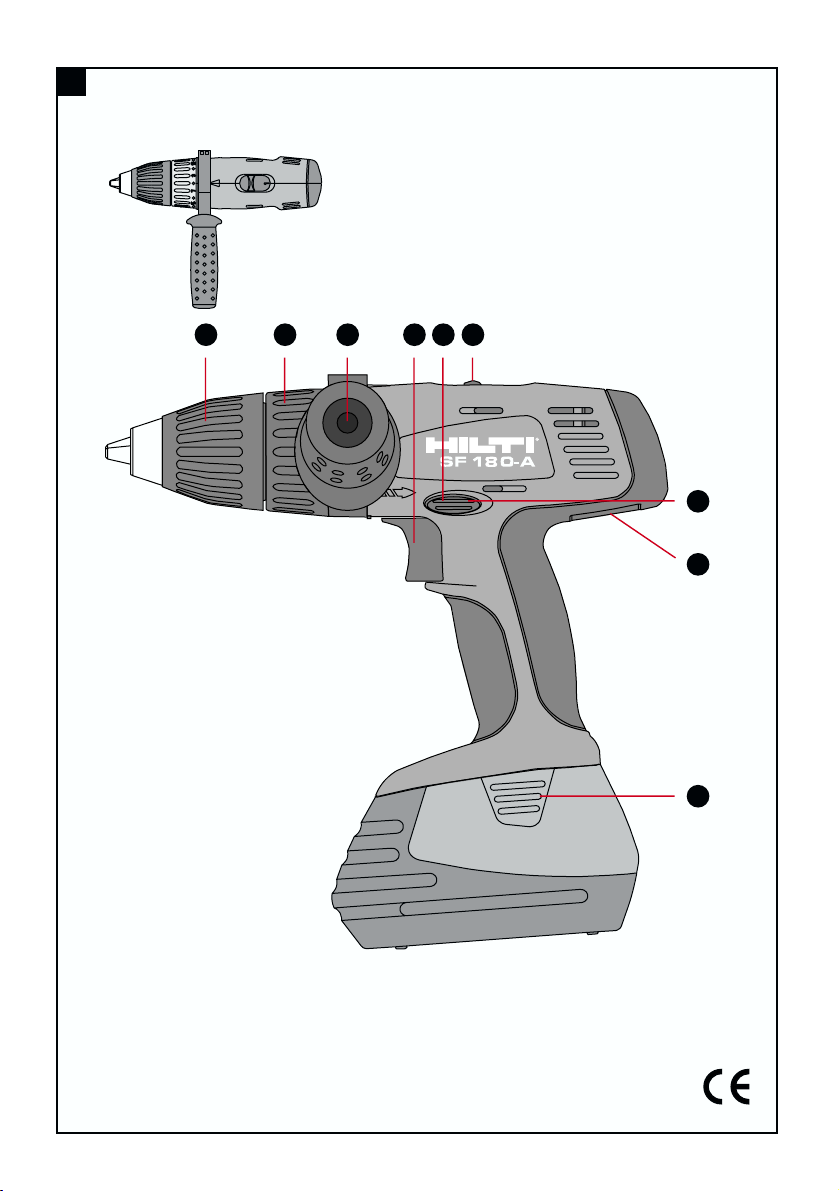

7 4 8 1 5 3

2

9

6

Page 3

2

3

4

5

1-13

13

57911

L

STOP

R

2

1

Page 4

6

7

Page 5

9

It is essential that the operating

instructions are read before the

tool is operated for the first time.

Always keep these operating

instructions together with the tool.

Ensure that the operating instructions are with the tool when it is

given to other persons.

SF180-A hammer drill driver

1. General information

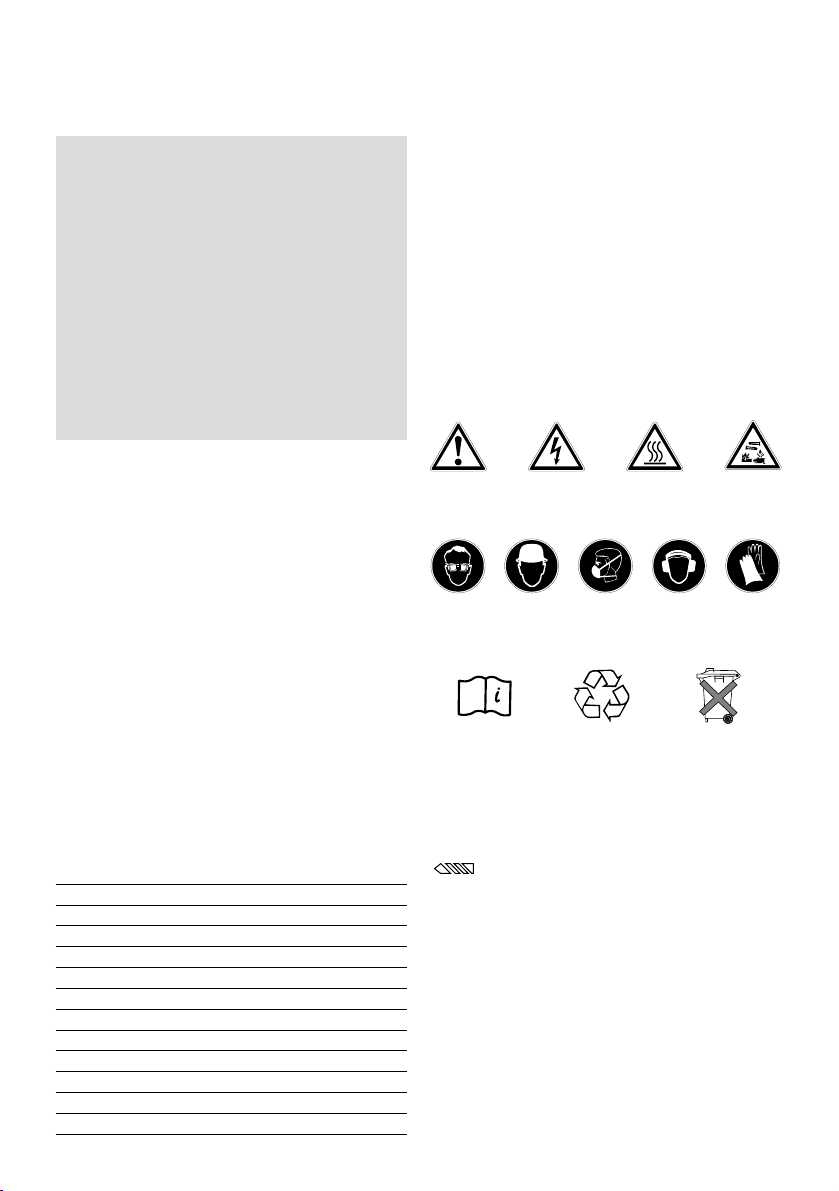

1.1 Indication of danger

-CAUTION-

Used to draw attention to a potentially dangerous situation which could lead to minor personal injury or damage to the equipment or other property.

-NOTE-

Used to draw attention to an instruction or other useful

information. Not used for dangerous situations or where

damage to the equipment or property could occur.

1.2 Pictograms

Contents Page

1. General information 9

2. Description 10

3. Tools and accessories 10

4. Technical data 10

5. Safety precautions 11

6. Before use 12

7. Operation 13

8. Care and maintenance 14

9. Troubleshooting 15

10. Disposal 16

11. Warranty 16

12. Declaration of conformity See cover

Operating controls and parts

Control switch

(with electronic speed control)

Forward / reverse switch

Gear selector switch

Torque clutch setting ring

Motor brake

Battery release buttons (2)

Quick release clutch

Side handle

Rating plate

Warning signs

General

warning

Warning:

electricity

Warning:

hot surface

Obligation signs

Symbols

Wear

eye

protection

Wear

ear protection

Read the operating

instructions before use.

Wear

breathing

protection

Warning:

caustic

substances

Wear

a safety

helmet

Wear

protective

gloves

Return waste material

for recycling.

Do not dispose of

batteries with general

refuse.

These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out cover pages. Keep these pages open while studying the operating instructions. In these operating instructions, the

SF180-A hammer drill driver with battery fitted is referred

to as "the tool".

Location of identification data on the tool

The type designation, item number, year of manufacture

and technical status can be found on the rating plate on

the tool. The serial number is located on the left side of

the motor housing. Make a note of this data in your operating instructions and always refer to it when making an

V = volts

–––

- - -

= direct current

n

o = no load speed

/min = revolutions per minute

j = hammer drilling

= rotation only

Page 6

4. T echnical data

Tool SF180-A

Rated voltage 18 V

–––

- - -

Weight of tool including battery and chuck 2.6 kg

Dimensions (L×H×W) 251×274×83 mm

Speed 1

st

gear: 0– 460 r.p.m.

2ndgear: 0–1600 r.p.m.

Chuck / clamping dia. range (Quick-release chuck) 1.6–13 mm

Torque Max. 31 Nm (at drilling setting)

Torque adjustment 2–12 Nm (in 13 increments)

Speed control Electronic control switch

Forward / reverse Electrical switch with interlock to prevent activation

when running

Spindle lock When control switch is in the “off” position

Motor brake By way of the control switch

Gearing section sealed to prevent entry of dust and with permanent lubrication (maintenance-free)

Noise and vibration information (measured in accordance with EN 50260):

Typical A-weighted noise power level: 99.7 dB(A)

Typical A-weighted noise pressure level: 88.7 dB(A)

Typical weighted vibration at the grips: 9.2 m/s

2

Battery SFB180 SFB185

Rated voltage 18 V

–––

- - -

18 V

–––

- - -

Battery capacity 18 V×2.0 Ah = 36 Wh 18 V×3.0 Ah = 54 Wh

Weight 1.15 kg 1.22 kg

Temperature monitoring yes yes

Type of cell Nickel-cadmium Nickel-metal hydride

SUB C type SUB C type

No. of cells 15 15

Right of technical changes reserved

10

enquiry to your Hilti representative or service department.

Type: Serial no.:

2. Description

The SF180-A is a battery-powered hammer drill driver

for professional use. The tool is suitable for use by right

or left-handed persons. The ergonomically designed rubber-padded grip reduces fatigue and is designed to provide a secure hold.

The items supplied include: Electric tool with side handle,

two SFB180 or SFB185 batteries, SFC7/18H or SFC7/18

charger, rigid carrying case.

Important features of the tool

– Vibration-absorbing grip (rubber-padded)

– Smooth speed control

– Gearing and clutch with permanent lubrication

(grease)

– Automatic cut-out carbon brushes

– Forward / reverse rotation

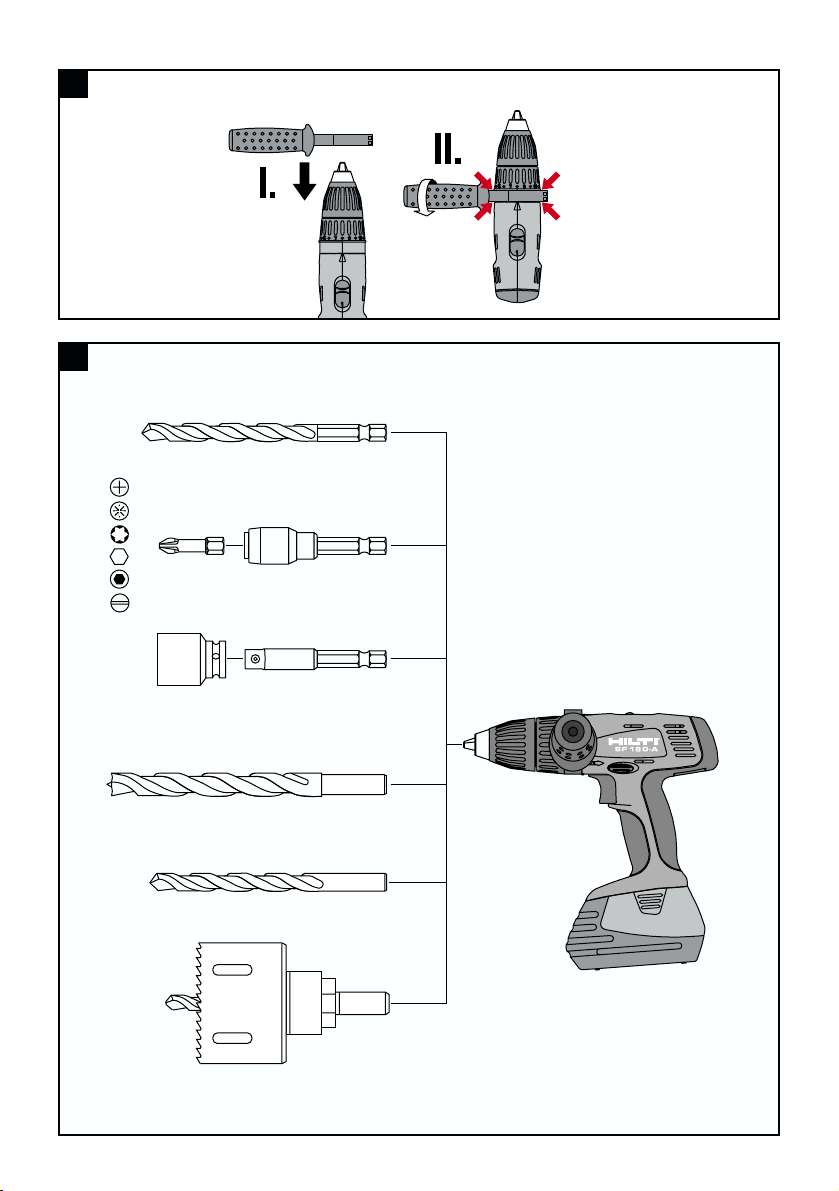

3. Accessories

Magnetic bit holder, long S-BHP 75M

Philips bit Phillips Nr. 2

Charger SFC 7/18

Charger SFC 7/18 H

Charger TCU 7/36

Battery SFB 180 or SFB 185

Toolbox

Belt adaptor

Page 7

11

5. Safety precautions

5.1 Basic information concerning safety

In addition to the information relevant to safety given in

each of the sections of these operating instructions, the

following points must be strictly observed at all times.

CAUTION!

To reduce the risk of fire, battery leakage and personal

injury, the following basic safety precautions must be

observed when battery-powered tools are used:

Read all these instructions before operating this product

and save these instructions.

5.2 Correct use

The SF 180-A is a battery-powered hammer drill driver

for the following applications:

– Driving and removing screws

– Drilling in steel and wood

– Hammer drilling in masonry and light concrete

The working environment may be on a construction site

or in a workshop and may consist of renovation, conversion or new building work.

Main applications

Spax screws in softwood /

chipboard 10×80 mm *

Screws in plastic anchors HRD-U 10/50 120 *

Self-drilling screws S-MD 01 5.5×19 mm **

Drilling in softwood /

chipboard 30 mm diameter **

Hole saws 102 mm diameter *

HSS drill bits 13 mm diameter **

* Speed 1 (low), ** Speed 2 (high)

● Modification or manipulation of the tool other than

described in these operating instructions is not permissible.

●To avoid the risk of injury, use only original Hilti acces sories and additional equipment.

●Observe the information printed in the operating instructions concerning operation, care and maintenance.

●The tool and its ancillary equipment may present hazards when used incorrectly by untrained personnel or

when used not as directed.

5.3 Take the necessary precautions to make the workplace safe

●Wear non-slip shoes or boots and always ensure that

you have a secure stance.

●Avoid unfavorable body positions.

●Ensure that the workplace is well lit.

●Ensure that the workplace is well ventilated.

●Objects which could cause injury should be removed

from the working area.

●When working, keep other persons, particularly children, outside the range of the tool.

●Do not wear loose clothing, loose long hair or jewelry as these can become caught up in moving parts. Wear

suitable headgear if you have long hair.

●Concealed electric cables or gas and water pipes present a serious hazard if damaged while you are working.

Accordingly, check the area in which you are working

beforehand (e.g. using a metal detector). Avoid contact

between your body and earthed / grounded objects, such

as pipes or radiators. External metal parts of the tool may

become live, for example, when an electric cable is drilled

into inadvertently.

●Do not expose the tool to rain or snow and do not use

it in damp or wet areas or where there is a risk of explosion. It is safer than using your hand and it frees both

hands to operate the tool.

●Use a vice or clamp to secure loose workpieces.

●The tool is for hand-held use only.

5.4 General safety precautions

● Operate the tool only as directed and only when it is

in faultless condition.

●Use only insert tools which are approved for use with

the electric tool.

●Keep the grips dry, clean and free from oil and grease.

●Do not touch the chuck while it is rotating.

●Never leave the tool unsupervised.

●Avoid unintentional starting. Do not carry the tool with

your finger on the on/off switch. Switch the tool off completely before transporting it (forward / reverse switch

in middle position).

● Switch the tool on only after bringing it into position

at the workpiece.

● Use only the original accessories or ancillary equipment listed in the operating instructions. Use of other

insert tools or accessories may present a risk of personal

injury.

●Do not overload the tool. It will work more efficiently

and more safely within its intended performance range.

● Disconnect the tool from its battery pack when the

tool is not in use, during pauses between work, before

maintenance, when changing bits and during transport.

● When not in use, the tool and battery pack must be

stored separately in a dry place, locked up or out or reach

of children.

●Take care of your insert tools. You will be able to work

more efficiently and more safely if the insert tools are

kept sharp and clean. Observe instructions on care and

maintenance and on changing insert tools.

● Do not insert wires or other similar objects into the

ventilation slots.

Page 8

12

5.4.1 Mechanical hazards

●Follow the instructions concerning care and maintenance.

● Check that the insert tools used are compatible with

the chuck system and that they are secured in the chuck

or gear housing correctly.

● Check that moving parts function faultlessly and that

they are not sticking or damaged. All parts must be correctly fitted and fulfil all requirements in order to ensure

that the tool operates faultlessly.

● Use only original Hilti insert tools.

5.4.2 Electrical hazards

●Check the condition of the tool. Do not operate the tool

if it is found to be damaged, if it is not complete or if its

controls cannot be operated faultlessly.

●Damaged switches must be replaced at a Hilti service

center. Do not use the tool if it cannot be switched off

and on properly.

●The tool may be repaired by trained electrical specialists only (Hilti service) using original Hilti spare parts.

Failure to observe this point may present considerable

risk to the user.

●Never operate the tool when it is dirty or wet.

●Ensure that the outer surfaces of the battery are clean

and dry before inserting it in the corresponding charger.

●Use only the batteries listed in these operating instructions (see section 6).

● Avoid short circuiting the battery terminals. A short

circuit may cause a fire.

●Check that the battery is securely attached to the tool.

A falling battery could injure you or other persons.

●Batteries that have reached the end of their life must

be disposed of safely (see section 10).

● Ensure that batteries are charged using the correct

charger recommended by the manufacturer . Incorrect

use may result in a risk of electric shock, overheating or

leaking of corrosive liquid from the battery.

5.4.3 Thermal hazards

●The insert tool may become hot during use. You should

therefore wear protective gloves when changing insert

tools.

5.4.3 Liquids

●A caustic liquid may leak from defective batteries. Avoid

contact with this liquid. In the event of contact with the

skin, wash the area affected with soap and plenty of water .

Should the liquid come into contact with the eyes, flush

the eyes with water immediately and subsequently consult a doctor.

5.5 Requirements to be met by users

●The tool is intended for professional use.

●The tool may be operated, serviced and repaired only

by authorized, trained personnel. This personnel must

be informed of any special hazards that may be encountered.

● Always concentrate on the job you are doing. Proceed

carefully and do not use the tool if your full attention is

not on the job.

5.6 Personal protective equipment

● The operator and other persons in the immediate vicinity must always wear eye protection, ear protection and

breathing protection while the tool is in use.

6. Before use

1. It is essential that the safety precautions printed in

these operating instructions are read and observed.

2. A new battery must be charged correctly for the first

time before use:

– charged normally for 24 hours with the SFC 7/8 H

charger, or

– charged for 12 hours using the conditioning func-

tion of the SFC 7/18 or TCU 7/36 charger

This will ensure that the cells form correctly. Incorrect

initial charging may have a permanent, negative effect

on battery capacity.

-NOTE-

– The tool may be used only with SFB 180 or SFB 185

batteries.

– Battery performance drops at low temperatures.

– Batteries should be stored at room temperature.

– Never store batteries where they are exposed to the

heat of the sun, on a radiator, behind a motor vehicle

windscreen or at a window.

– Never use the battery until the cells become fully dis-

charged. Change to the second battery as soon as a

drop in performance is noticed and recharge the bat-

tery immediately so that it is ready for re-use.

– Use bits with a standard

1

/4″ hex. shank.

6.1 Fitting the side handle

1. Open the side handle clamping band by turning the

handle.

Page 9

7.4 Hammer drilling

Turn the torque clutch setting ring to the hammer drilling

symbol.

7.5 Drilling

Turn the torque clutch setting ring to the drilling sym bol.

-CAUTION-

A high torque is experienced if the insert tool sticks while

drilling with large-diameter drill bits and hole saws.

Accordingly, use the side handle and hold the tool with

both hands (one hand on the grip and one hand on the

side handle).

7.6 Switching on and off

Should a sticking drill bit cause the motor to stall for

longer than 2–3 seconds, the tool must be switched off

in order to avoid damage to it.

1. Use the forward / reverse switch to select the direc-

tion of rotation.

2. The speed of the tool can be controlled smoothly

between zero and maximum by pressing the on / off

switch slowly.

7.7 Removing the battery (2-finger operation)

1. Press in both release buttons.

2. Pull the battery downwards out of the tool.

7.8 Fitting the battery

Use only Hilti SFB 180 or SFB 185 batteries.

Push the battery into the tool from below until it is heard

to engage.

7.9 Charging the battery

The battery cannot be charged through the belt adaptor.

Use only the Hilti SFC7/18H, SFC7/18 or TCU7/36 charger.

Incorrect use may lead to electric shocks, overheating

of the battery or leakage of a caustic liquid from the battery.

Read the operating instructions for the charger before

beginning charging.

7.10 Changing the bit

13

-CAUTION-

■ Noise is emitted by the tool and the

screwdriving / drilling / hammer

drilling procedure.

■ Excessive noise may damage the

hearing.

■ Wear ear protection.

2. Slide the side handle clamping band over the chuck

and onto the tool.

3. Pivot the side handle into the desired position.

4. Secure the side handle by turning the handle.

7. Operation

-CAUTION-

■ The screwdriving procedure may

cause the material to splinter .

■ Splintering material may cause injury

to the body, respiratory passages

and the eyes.

■ Wear eye protection, breathing protection and a safety helmet.

7.1 Setting forwards or reverse rotation

The direction of rotation of the driving spindle can be

selected by operating the forward / reverse push switch.

An interlock prevents operation of the switch while the

motor is running. When in the middle position, the on /

off switch is locked.

– Push the forward / reverse switch to the right (tool in

the working position) = reverse.

– Push the forward / reverse switch to the left (tool in

the working position) = forwards.

7.2 Setting the speed

(2-speed gear selector switch)

-CAUTION-

Operate the gear selector switch only when rotation has

stopped.

Select position 1 for a speed range of 0–460 r .p.m. or

position 2 for a speed range of 0–1600 r.p.m.

7.3 Screwdriving

Set the desired direction of rotation by way of the forward / reverse switch.

7.3.1 Torque setting

Set the torque by turning the torque clutch setting ring

to the desired torque setting (1–13).

-CAUTION-

■ The insert tool may become hot during use.

■ There is a risk of burning the hands.

■ Wear protective gloves when chang-

ing insert tools.

Page 10

14

8. Care and maintenance

8.1 Care of insert tools

Remove any dirt adhering to the surface of the insert

tools and protect them from corrosion by rubbing them

with an oily cloth from time to time.

8.2 Care of the tool

Before cleaning, remove the battery from the tool in order

to prevent inadvertent starting.

The outer casing of the tool is manufactured from impactresistant plastic. The grip comprises a synthetic rubber

section.

The ventilation slots must be unobstructed and kept clean

at all times. Use a dry brush to clean the ventilation slots

carefully. Do not permit foreign objects to enter the inte rior of the tool. Use a slightly damp cloth to clean the outside of the tool at regular intervals. Do not use a spray,

steam-cleaning system or running water for cleaning.

This may negatively affect the electrical safety of the tool.

Always keep the grip sections of the tool free from oil

and grease. Do not use cleaning agents or polishes, etc.

containing silicone.

8.3 Maintenance

Check all external parts of the tool for damage at regular

intervals and check that all controls operate faultlessly.

Do not operate the tool when parts are damaged or when

the controls do not operate faultlessly. If necessary , have

the tool repaired at a Hilti service center.

Electrical parts of the tool may be repaired only by trained

electrical specialists.

8.4 Care of the battery

Keep the electrical contacts free from dust, oil and grease.

If necessary, use a clean cloth to clean the contact surfaces.

Do not continue to operate the tool until the battery is

completely discharged as this may damage the battery

cells. Recharge the battery as soon as a drop in performance is noticed.

At monthly intervals or, at the latest, when battery capacity drops significantly, the battery should be conditioned

as follows:

– by charging with the SFC 7/8 H charger for 24 hours

in normal charging mode, or

– by charging with the SFC 7/18 or TCU 7/36 charger for

12 hours in conditioning mode.

If, after conditioning, battery capacity is still unsatisfactory, we recommend returning the battery to Hilti for diagnosis.

8.5 Checking the tool after care and maintenance

After carrying out care and maintenance work on the tool,

check that all protective and safety devices are fitted and

that they function faultlessly.

Page 11

15

9. T roubleshooting

Fault Possible cause Remedy

Tool doesn‘t run Battery is discharged or not correctly Refit the battery. It must be heard

fitted to engage with an audible "click".

Charge the battery if necessary.

Electrical fault Remove the battery and contact

your nearest Hilti service center.

Tool runs too fast / too slow Speed selector in wrong position Move the speed selector switch to

the desired position.

No hammering action Tool set to the wrong mode Set the tool to hammering

mode.

Clutch releases while drilling Tool set to screwdriving mode Set the tool to drilling mode.

On / off switch cannot be pressed Forward / reverse switch is set to Move the forward / reverse switch

middle position to the left/right.

Speed suddenly drops The battery is almost exhausted. Stop working with the exhausted

battery and charge it fully.

Battery becomes discharged Battery condition is not optimal. Charge the battery using condi-

faster than usual tioning mode (see battery charger

operating instructions).

Battery does not engage with an Dirt on battery locking mechanism Clean battery locking mechanism

audible "click" and refit the battery. Contact your

nearest Hilti service center if the

problem persists.

Tool or battery overheats Electrical fault Switch off the tool immediately.

Remove the battery and contact

your nearest Hilti service center.

Overload due to exceeding application Select the right tool for the applilimit cation.

Drill bit or screw gets stuck Release the drill bit or screw .

Drill bit or screwdriving bit slips Chuck not tightened correctly Tighten the chuck securely by

in the chuck applying reasonable force.

Page 12

16

11. Warranty

Hilti warrants that the tool supplied is free of defects in

material and workmanship. This warranty is valid as long

as the tool is operated and handled correctly, cleaned

and serviced properly and in accordance with the Hilti

Operating Instructions, all warranty claims are made

within 12 months from the date of the sale (invoice date),

and the technical system is maintained. This means that

only original Hilti consumables, components and spare

parts may be used in the tool.

This warranty provides the free-of-charge repair or

replacement of defective parts only. Parts requiring repair

or replacement as a result of normal wear and tear are

not covered by this warranty.

Additional claims are excluded, unless stringent

national rules prohibit such exclusion. In particular,

Hilti is not obligated for direct, indirect, incidental or

10. Disposal

Return waste material for recycling.

Most of the materials from which Hilti power tools are manufactured can be recycled. The materials must be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for taking back

your old electric tools for recycling. Please ask your Hilti customer service department or Hilti sales representative

for further information.

Should you wish to return the electric tool yourself to a disposal facility for recycling, proceed as follows: Dismantle the tool as far as possible without the need for special tools. Use absorbent paper to wipe greasy parts clean and

collect any grease that runs out. This paper should also be disposed of correctly. On no account should grease be

allowed to enter the waste water system or find its way into the ground.

Separate the individual parts as follows:

Part / assembly Main material Recycling

Toolbox Plastic Plastics recycling

Outer casing Plastic / synthetic rubber Plastics recycling

Electronic switch Various Electronics scrap

Motor Steel, copper Scrap metal

Gearing parts Steel Scrap metal

Battery Nickel-cadmium *

Nickel-metal hydride

Screws, small parts Steel Scrap metal

* Dispose of the battery in accordance with national regulations or return used batteries to Hilti for recycling.

consequential damages, losses or expenses in connection with, or by reason of, the use of, or inability

to use the tool for any purpose. Implied warranties of

merchantability or fitness for a particular purpose are

specifically excluded.

For repair or replacement, send tool and/or related parts

immediately upon discovery of the defect to the address

of the local Hilti marketing organization provided.

This constitutes Hilti’s entire obligation with regard to

warranty and supersedes all prior or contemporaneous

comments and oral or written agreements concerning

warranties.

Page 13

12. EC declaration of conformity

Designation: Hammer drill driver

Type designation: SF 180-A

Year of design: 2002

We declare, on our sole responsibility, that this product

complies with the following directives and standards:

98/37/EC, 89/336/EEC, 91/157/EEC, 93/86/EEC, EN

50260-1, EN 50260-2, EN 55014-1, EN 55014-2

12. Konformitätserklärung

Bezeichnung: Schlagbohrschrauber

Typenbezeichnung: SF180-A

Konstruktionsjahr: 2002

Wir erklären in alleiniger Verantwortung, dass dieses

Produkt mit den folgenden Richtlinien und Normen

übereinstimmt: 98/37/EG, 89/336/EWG, 91/157/EWG,

93/86/EWG, EN 50260-1, EN 50260-2, EN 55014-1,

EN 55014-2

12. Déclaration de conformité CE

Désignation: Visseuse-perceuse à percussion

Modèle: SF 180-A

Année de conception: 2002

Nous déclarons sous notre seule et unique responsabilité que ce produit est conforme aux directives et

normes suivantes: 98/37/CE, 89/336/CEE, 91/157/CEE,

93/86/CEE, EN 50260-1, EN 50260-2, EN 55014-1, EN

55014-2

12. EG-conformiteitsverklaring

Product: Slagboorschroefmachine

Type: SF 180-A

Bouwjaar: 2002

Wij verklaren, op onze eigen verantwoording, dat dit

product voldoet aan de volgende richtlijnen en normen:

98/37/EG, 89/336/EEG, 91/157/EEG, 93/86/EEG, EN

50260-1, EN 50260-2, EN 55014-1, EN 55014-2

12. EU konformitetserklæring

Betegnelse: Bore-/skruemaskine

Typebetegnelse: SF180-A

Konstruktionsår: 2002

Vi påtager os det fulde ansvar for, at dette produkt er i

overensstemmelse med følgende normer eller

98/37/EF, 89/336/EØF, 91/157/EØF, 93/86/EØF, EN

50260-1, EN 50260-2, EN 55014-1, EN 55014-2

12. Declaración de conformidad de la UE

Denominación: Taladro atornillador de percusión

Identificación de tipo: SF180-A

Año de construcción: 2002

Declaramos, bajo nuestra exclusiva responsabilidad,

que este producto cumple las siguientes normas y

directrices: 98/37/EG, 89/336/EWG, 91/157/EWG,

93/86/EWG, EN 50260-1, EN 50260-2, EN 55014-1,

EN 55014-2

12. Dichiarazione di conformità CE

Denominazione: Trapano avvitatore a percussione

Denominazione del tipo: SF180-A

Anno di costruzione: 2002

Sotto la nostra piena responsabilità dichiariamo che

questo prodotto è conforme alle seguenti direttive e

norme: 98/37/CE, 89/336/CEE, 91/157/CEE,

93/86/CEE, EN 50260-1, EN 50260-2, EN 55014-1, EN

55014-2

12. Declaração de conformidade CE

Designação: Aparafusadora com percussão

Tipo: SF180-A

Ano de fabrico: 2002

Declaramos sob nossa exclusiva responsabilidade que

este produto cumpre as seguintes normas ou documentos normativos: 98/37/EG, 89/336/EEG,

91/157/EEG, 93/86/EEG, EN 50260-1, EN 50260-2, EN

55014-1, EN 55014-2

Page 14

Hilti Corporation

Dr. Joachim Schneider Josef Obermeier

Head Business Unit Head Development

Cutting and Sanding / Screw Fastening Screw Fastening

September 2002 September 2002

12. Försäkran om EU-överensstämmelse

Beteckning: Batteridriven borrskruvdragare med slag

Typ: SF180-A

Konstruktionsår: 2002

Vi intygar på eget ansvar att denna produkt överensstämmer med följande direktiv och standarder:

98/37/EG, 89/336/EWG, 91/157/EWG, 93/86/EWG, EN

50260-1, EN 50260-2, EN 55014-1, EN 55014-2

12. Vaatimustenmukaisuusvakuutus

Merkintä: Akkuporakone/-ruuvain

Tyyppi: SF180-A

Suunnitteluvuosi: 2002

Vakuutamme omalla vastuullamme, että tässä käyttöohjeessa kuvattu tuote täyttää seuraavien direktiivien ja normien vaatimukset: 98/37/EG, 89/336/EWG,

91/157/EWG, 93/86/EWG, EN 50260-1, EN 50260-2,

EN 55014-1, EN 55014-2

12. Samsvarserklæring

Betegnelse: Batteridrill med slag

Modell / type: SF180-A

Konstruksjons år: 2002

Vi garanterer at dette produktet overensstemmer med

følgende stander og standeriseringer: 98/37/EG,

89/336/EWG, 91/157/EWG, 93/86/EWG, EN 50260-1,

EN 50260-2, EN 55014-1, EN 55014-2

12.

∆ήλωση συµβαττητας

Ονοµασία: κρουστικ δραπανοκατσάβιδο

µπαταρίας

Τύπος:

SF180-A

Έτος σχεδιασµού:

2002

∆ηλώνουµε υπεύθυνα τι το συγκεκριµένο προϊν

συµµορφώνεται µε τα ακλουθα κριτήρια ή έγγραφα

προδιαγραφών:

98/37/EG, 89/336/EWG, 91/157/EWG,

93/86/EWG, EN 50260-1, EN 50260-2, EN 55014-1,

EN 55014-2

12. EN-i vastavusdeklaratsioon

Tähis: Lööktrell-kruvikeeraja

Tüübitähis: SF 180-A

Konstrueerimise aasta: 2002

Me deklareerime oma ainuvastutusel, et see toode

vastab järgmistele standarditele ja standardiseerimisdokumentidele: 98/37/EC, 89/336/EEC, 91/157/EEC,

93/86/EEC, EN 50260-1, EN 50260-2, EN 55014-1, EN

55014-2

12. ES – atbilstîbas deklaråcija

Nosaukums: Akumulatora triecienurbmaßîna

Instrumenta kods: SF 180-A

Gads: 2002 atbilst

Més, uzñemoties pilnu atbildîbu, deklaréjam, ka ßis

produkts atbilst sekojoßiem standartiem vai standartu

dokumentiem. EC vadlînijai 98/37/EC, 89/336/EEC,

91/157/EEC, 93/86/EEC, EN 50260-1, EN 50260-2, EN

55014-1, EN 55014-2

12. ES atitikties deklaracija

R‰is: Plaktukinis perforatorius-atsuktuvas

Îymòjimas: SF 180-A

Suprojektavimo metai: 2002

Prisiimdami sau atsakomyb´, parei‰kiame, kad ‰is

gaminys atitinka Ïemiau nurodytas direktyvas ir

standartus: 98/37/EC, 89/336/EEC, 91/157/EEC,

93/86/EEC, EN 50260-1, EN 50260-2, EN 55014-1, EN

55014-2

Page 15

Hilti = registered trademark of Hilti Corp., Schaan W 2729 0103 10-Pos. 1 1 Printed in Liechtenstein © 2003

Right of technical and programme changes reserved S. E. & O.

375007/B

Hilti Corporation

FL-9494 Schaan

Tel.:+423 / 2342111

Fax: +423 /234 2965

www.hilti.com

Loading...

Loading...