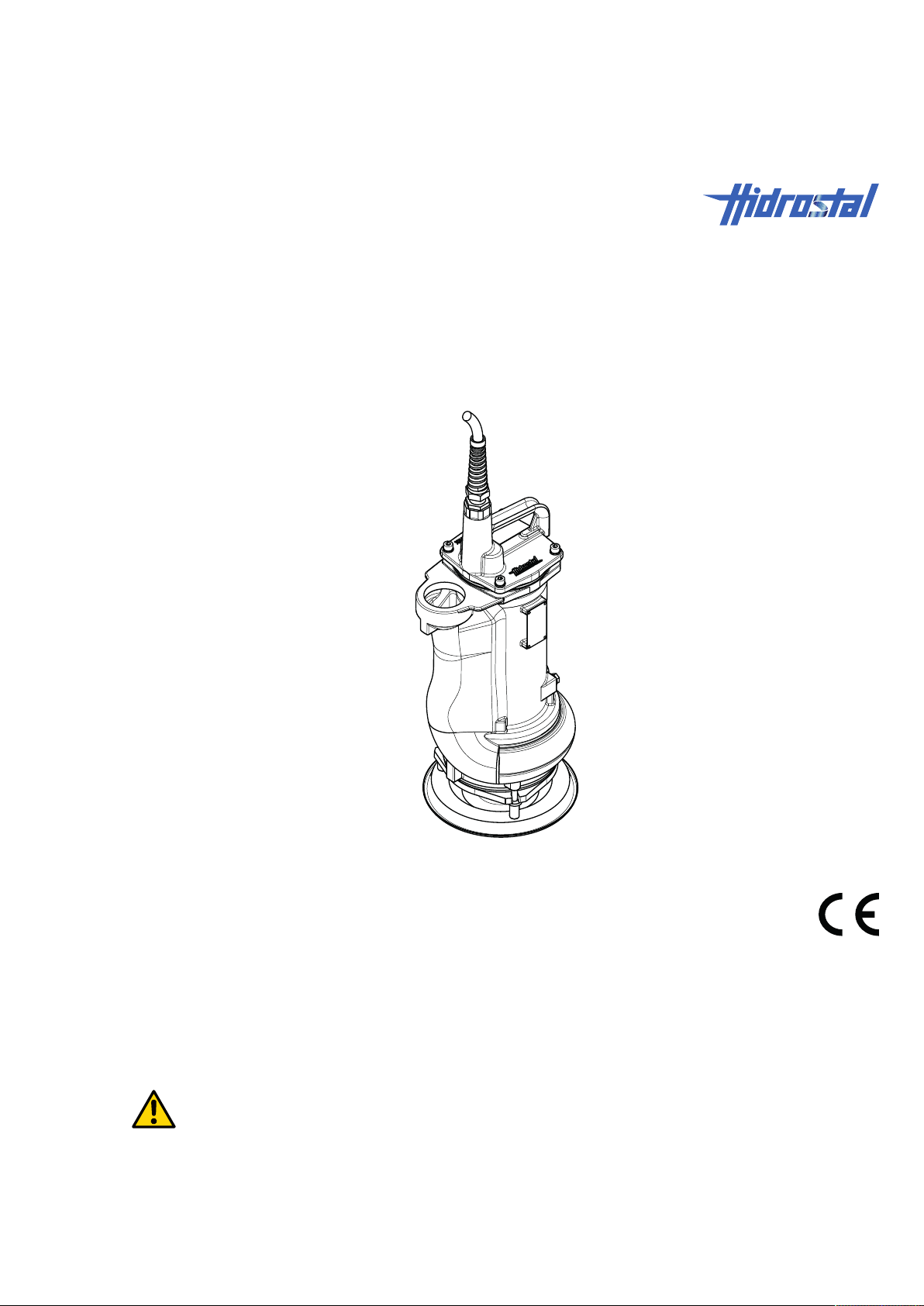

Hidrostal A2Q, BN2, BE2, BN3, BK3 Instructions Manual

Instructions

Compact pump A2Q, BN2, BE2, BN3, BK3

13-BA8057 EN

Translation of the original instructions

Before starting work, read these instructions!

Hidrostal AG

Gigering 27

8213 Neunkirch

Switzerland

T +41 (0) 52 687 06 87

F +41 (0) 52 681 20 84

info@hidrostal.ch

www.hidrostal.ch

Revision status151130

This manual is protected by copyright and is exclusively for internal

purposes.Transfer of this manual to third parties, reproductions in any

manner and form – in full or in part – as well as exploitation and/or

communication of content without written permission from the manufacturer,

except for internal purposes, is prohibited.

Table of contents

Table of contents

1 General information .................................................................................................................................5

1.1 Information about these instructions................................................................................................... 5

1.2 Explanation of symbols....................................................................................................................... 5

1.3 Disclaimer ........................................................................................................................................... 6

1.4 Terms of warranty............................................................................................................................... 7

1.5 Customer service and product monitoring .......................................................................................... 7

1.6 Spare parts ......................................................................................................................................... 7

2 Safety requirements ..................................................................................................................................8

2.1 Introduction ......................................................................................................................................... 8

2.2 Responsibility of the operating company ............................................................................................ 8

2.3 Personnel requirements...................................................................................................................... 9

2.4 Intended use ..................................................................................................................................... 10

2.4.1 Application limits ....................................................................................................................10

2.5 Personal protective equipment ......................................................................................................... 10

2.6 Special hazards ................................................................................................................................ 11

2.6.1 Mechanical hazards ...............................................................................................................11

2.6.2 Biohazards .............................................................................................................................12

2.6.3 Hazards from electric energy .................................................................................................12

2.6.4 Hazards in the working area ..................................................................................................13

2.7 Safety mechanisms and devices, protection against restart, emergency shutdown, what to do in the

event of danger or accidents ............................................................................................................ 13

3 Technical Data .........................................................................................................................................15

3.1 Intended purpose.............................................................................................................................. 15

3.2 General information .......................................................................................................................... 15

3.3 Operating conditions......................................................................................................................... 15

3.4 Consumables.................................................................................................................................... 16

3.4.1 Overview of hydraulic cooling oil............................................................................................ 16

3.5 Type plate ......................................................................................................................................... 16

4 Design and functions ..............................................................................................................................18

4.1 Overview........................................................................................................................................... 18

4.2 Electric motors .................................................................................................................................. 19

4.3 Operational safety components ........................................................................................................ 19

4.4 Hydraulics ......................................................................................................................................... 21

4.5 Connections...................................................................................................................................... 21

4.6 Controls ............................................................................................................................................ 22

5 Transport and storage ............................................................................................................................23

5.1 Transport .......................................................................................................................................... 23

5.1.1 Symbols and information on packaging .................................................................................23

5.1.2 Packages with anchor points .................................................................................................24

5.1.3 Pallet transport by forklift .......................................................................................................24

5.1.4 Pallet transport by crane ........................................................................................................25

Hidrostal AG iii / 49

Table of contents

5.1.5 Crane transport of unpacked pump .......................................................................................25

5.2 Storage ............................................................................................................................................. 25

6 Installation and initial commissioning ..................................................................................................27

7 Operation and special operation............................................................................................................28

7.1 Pumping the sump dry...................................................................................................................... 28

8 Maintenance.............................................................................................................................................29

8.1 Maintenance schedule...................................................................................................................... 29

8.2 Service connections and inspection openings.................................................................................. 30

8.3 Tightening torque for greased screw thread ..................................................................................... 31

8.4 Maintenance work............................................................................................................................. 31

8.4.1 Preparation tasks for maintenance ........................................................................................31

8.4.2 Visual inspection ....................................................................................................................31

8.4.3 Check/readjust impeller clearance......................................................................................... 32

8.4.4 Checking the oil .....................................................................................................................35

8.4.5 Replacing the pump ...............................................................................................................37

8.5 Measures after completion of work................................................................................................... 40

9 Faults ........................................................................................................................................................41

9.1 Safety................................................................................................................................................ 41

9.2 Fault table ......................................................................................................................................... 42

9.3 Measures after completion of work................................................................................................... 45

10 Disassembly.............................................................................................................................................47

10.1 Safety................................................................................................................................................ 47

10.2 Disassembly ..................................................................................................................................... 47

10.3 Disposal ............................................................................................................................................ 48

11 Appendix ..................................................................................................................................................49

iv / 49 Hidrostal AG

General information | 1

1 General information

1.1 Information about these instructions

Target group The target group of these operating instructions is the pump operating

company once the system, in which the pump is fitted, has been handed

over by the system manufacturer to the operating company in ready-for-use

condition.

The selection of the suitable pump, the safe and correct integration into the

system, the description of the operation, the installation and commissioning

are the system manufacturer's responsibility and are NOT covered in these

operating instructions.

How to use these operating

instructions

Reading obligation Before starting any task, personnel must carefully read and understand this

Storage location These instructions are part of the machine and must be stored in an easily

Resale If the machine is sold or transferred, the operating instructions must also be

Other applicable

documents, regulations

and directives

Illustrations in these

instructions

Loss of the operating

instructions

These operating instructions contribute to the safe and efficient handling of

the machine. The fundamental prerequisite for safe working is the

adherence to all safety information, warnings and operating instructions

given in the manual.

manual.

accessible location for personnel to consult before starting work.

passed on to the new owner.

Besides these operating instructions, the instructions and information as well

as the signs on the machine also apply. Any advice on technical

modifications must be attached to these instructions. Furthermore, the local

accident prevention regulations and general safety regulations for the

application range of the machine apply.

Illustrations in these instructions are provided for general understanding and

may differ from the actual design of the machine.

If these operating instructions are lost, please order replacement

immediately (delivery against a nominal charge). Contact data see Imprint

[▶2].

1.2 Explanation of symbols

Symbols are used to denote safety notes and warning messages in these

instructions. Signal words are found at the start of the safety notes and

warning messages and are used to express the severity of the hazard.

Safety instructions must be observed and proper care must be taken to

avoid accidents or injury and damage to property.

DANGER

... indicates an imminent dangerous situation that will result in death or

serious injuries if not prevented.

Hidrostal AG 5 / 49

1 | General information

WARNING

... indicates a potentially dangerous situation that could result in death or

serious injuries.

CAUTION

... indicates a potentially dangerous situation that could result in minor

injuries.

NOTICE

... indicates a potentially dangerous situation that could result in damage to

property.

NOTE

... indicates helpful advise and recommendations as well as information for

efficient and trouble-free operation.

1.3 Disclaimer

Information in these

instructions

Supply, delivery Beyond the contractually negotiated obligations, the General Terms &

Technical changes The publication date of these operating instructions applies. Hidrostal AG

Disclaimer The manufacturer excludes liability for damage and accidents related to the

The information and safety warnings in these instructions of use have been

composed with regard to the applicable standards, directives and

regulations, the state of technology and our years of experience.

Due to the optional equipment, production of custom models or technical

changes reflecting technological improvements, the scope of delivery and

the execution of the machine can deviate from the descriptions and

depictions contained herein.

Conditions and delivery terms of the supplier also apply. These are subject

to the applicable laws at the time of signing of the contract.

reserves the right to make technical changes to the machine as part of

redevelopment to improve its safety and functionality.

following points:

• Non-intended use of the machine

• Non-compliance with the information and warnings given in these

operating instructions

• Work on, or with the machine, by unqualified or unauthorised personnel

• Installation of non-genuine spare parts

• Unauthorised modifications without the written approval from the

manufacturer

• Use of unauthorised operating materials

6 / 49 Hidrostal AG

General information | 1

1.4 Terms of warranty

Location The terms and conditions can be found in the purchase agreement and the

supplier's General Terms & Conditions.

Fundamentals The supplier will make final decisions on claims following the return or return

shipment of all defective components, or following an on-sight inspection if

necessary. The replacement of defective parts does not extend the warranty

period of the machine. Modifications or significant repairs by the operating

company or third parties undertaken without the written consent of the

supplier void the warranty.

1.5 Customer service and product monitoring

Customer service Our customer service department is available in the event of problems or if

questions arise that cannot be resolved solely through this user manual, as

well as for technical queries. For contact data, see Imprint [▶2].

Product monitoring In our efforts to constantly improve our product, we in the Customer Service

department are interested in hearing about your experiences in working with

the machine.

Please inform us of any problems or errors that you may have encountered

while handling the machine. Please notify the manufacturer of any accidents

or hazardous incidents.

1.6 Spare parts

Spare parts shall be obtained from an authorised dealer or directly from

manufacturer. Contact data see Imprint [▶2].

When using non-approved spare parts, all claims concerning warranty,

service, damage and/or liability against manufacturer or his agents, dealers

and representatives will be forfeited.

NOTE

When making spare parts enquiries or placing spare parts orders, complete

information must be provided such as Type designation in the contract. The

spare parts list can be found in Appendix [▶49].

Hidrostal AG 7 / 49

2 | Safety requirements

2 Safety requirements

2.1 Introduction

This section provides an overview of all key safety aspects for optimum

safety of personnel, as well as safe and highly reliable operation.

Non-compliance with the operating instructions as well as the safety

information and warnings listed in this manual can result in considerable

risks.

These operating instructions can only include the risks that have been

identified on the basis of a risk assessment. Risks that occur due to working

conditions, the location of the machine and the interfaces with external

components must be determined and the safety instructions amended

accordingly.

2.2 Responsibility of the operating company

Definition of terms The term “operating company” as used in these instructions refers to the

company or its management that procures the machine (purchase, lease,

rent, etc.) and assigns personnel with the task of handling the machine

(transportation, installation, operation, maintenance, etc.).

Fundamentals Since the machine is intended for use in a commercial environment, the

operating company is strictly subject to the statutory requirements governing

safety at the workplace. In addition to the safety warnings in these operating

instructions, the safety, accident prevention and environmental protection

regulations governing the location where the machine is to be used are also

applicable.

Risk assessment The operating company must inform themselves about the applicable

occupational safety regulations. A risk assessment must also be carried out

to identify additional risks resulting from the specific working conditions at

the location of operation.

Operating Instructions According to the results of the risk assessment of the workplace, the

operating company must initiate, implement and document the operating

instructions. The operating company is responsible for ensuring that these

operating instructions are kept up to date with the current legal requirements

for the entire service life of the machine.

Responsibilities The operating company must manage the responsibilities for work on or with

the machine, including naming a party to be responsible for the safe

operation of the machine and coordinating all tasks.

Information flow The operating company must ensure that all personnel who carry out work

on or with the machine have read and understood these and other

supplementary operating instructions.

Personal protective

equipment

The operating company must provide operating personnel with the

necessary personal protective equipment.

8 / 49 Hidrostal AG

Safety requirements | 2

Safety requirements Where applicable, before commissioning, the operating company must make

sure that the machine into which this product is to be installed, or of which it

represents a component, corresponds to the fundamental safety

requirements and stipulations of all relevant directives.

Technically flawless

condition

To keep the machine in a technically flawless condition at all times, the

operating company must ensure that the maintenance intervals prescribed in

these operating instructions are complied with. The operating company must

furthermore ensure that all necessary safety mechanisms and devices are

properly installed on the machine. The safety mechanisms and devices must

be inspected regularly to check that they are all present and functioning

properly.

2.3 Personnel requirements

General information As personnel, the only authorised persons are those who carry out their task

reliably and whose responses are not impaired, e.g. by drugs, alcohol or

medication.

When selecting personnel, observe the applicable job-specific age

regulations applicable at the location of operation of the machine.

WARNING

Incorrect operation because of insufficient qualifications and knowledge.

Unauthorised persons who do not satisfy the conditions stated here are

unable to recognise the risks in the areas of operation.

Risk of severe injury!

• All tasks may only be carried out by suitably qualified personnel.

• Keep unauthorised personnel away from the danger areas.

In the operating instructions, the qualifications for the various tasks are

specified as follows:

Trained personnel Trained personnel have the technical education, know-how and experience

as well as the knowledge of applicable standards and regulations that allow

them to execute the work assigned to them and to independently recognise

and avoid potential dangers.

Trained personnel are also trained by Hidrostal or a Hidrostal sales partner

in how to operate the pump. The completion of training programs must be

documented.

Manufacturer (service

centre)

Qualified electricians Qualified electricians possess the technical education, knowledge and

Only trained Hidrostal personnel or trained personnel of a Hidrostal sales

partner are allowed to carry out service work. Nobody else is allowed to

perform this work. To have the required work performed, please contact our

Service department, see Imprint [▶2].

experience as well as knowledge of applicable standards and regulations

that allow them to execute work on electrical equipment and to

independently recognise and avoid potential dangers.

Qualified electricians are trained for the specific site where they work and

know the relevant directives, standards and specifications.

Hidrostal AG 9 / 49

2 | Safety requirements

Forklift drivers Forklift drivers must be at least 18years old and their physical, mental state

and personal characteristics must be such that they are capable of driving a

forklift either in seated or standing position.

Furthermore, forklift drivers must have received training in how to operate a

forklift in seated or standing position.

Forklift drivers must have demonstrated to the operating company their

ability to operate a forklift in a seated or standing position and have been

instructed in writing by the operator to do so.

Hoisting equipment

operators

Instructed persons

(operators)

Hoisting equipment operators have been trained and authorised to perform

this work.

Instructed persons have been informed by trained personnel about the

assigned tasks and possible hazards in case of incorrect behaviour. The

completion of training programs should be documented.

2.4 Intended use

The pump is exclusively intended for pumping liquids and viscous, noncombustible media.

If extremely abrasive or aggressive media are circulated, the pump must be

designed in resistant material.

Pumps of the types A2QR2, A2QR4, A2QS2, A2QS4, A2QE4, BE2, and

BK3 can be operated when they are immersed or when they are

permanently outside the liquid. The types A2QE2, BN2, and BN3 must

always be immersed during operation (exception see chapter Pumping the

sump dry [▶28]).

The pump must be kept in a clean and sound condition and its construction

may not be altered from its delivered state.

Intended use also includes compliance with all information contained in

these operating instructions.

Any use beyond the one intended, or other use of the machine is regarded

as misuse and can result in dangerous situations.

2.4.1 Application limits

No potentially explosive atmosphere

WARNING

Potentially explosive atmospheres.

Risk of fatal injury!

• Potentially explosive atmospheres in the pump interior or the ambient

environment are NOT permissible.

2.5 Personal protective equipment

Some tasks require personal protective equipment to be worn.

10 / 49 Hidrostal AG

In addition to the personal protective equipment specified in these operating

instructions, also observe the warnings located in the work area.

2.6 Special hazards

The following section indicates residual risks determined by a risk

assessment.

• The safety instructions listed here and the warnings in the following

chapters of these instructions must be observed in order to reduce health

hazards and avoid dangerous situations.

2.6.1 Mechanical hazards

WARNING

Suspended loads.

Suspension points weakened by corrosion and/or mechanical stress.

Risk of fatal injury!

• Use suitable, undamaged hoisting equipment only.

• If there is a suspicion of weakened suspension points, secure the load

with suitable sling gear.

• Only move loads under supervision.

• Never stand below suspended loads.

• Before leaving the work area: bring the load to the ground.

Safety requirements | 2

WARNING

Tipping loads.

Risk of severe injury!

• Always sufficiently secure components against tipping.

• Use suitable, undamaged hoisting equipment only.

• Only move loads under supervision.

CAUTION

Sharp edges on the edge and inside the pump chamber.

Risk of injury!

• Proceed carefully when working in the vicinity of sharp edges.

• Wear safety gloves.

Hidrostal AG 11 / 49

2 | Safety requirements

WARNING

Flying parts when cleaning with a high-pressure cleaner.

Risk of severe injury!

• Wear safety goggles.

CAUTION

Wood splinters and nails on packaging material.

Risk of injury!

• Wear safety gloves.

2.6.2 Biohazards

WARNING

Contact with infectious substances.

Risk of severe illness!

• Obtain binding information about the hazards relating to the medium from

the operator of the plant.

• Wear personal protective equipment.

• Thoroughly clean the pump.

• Carefully dispose of liquid drained from the oil chamber.

• Thoroughly clean tools after use.

2.6.3 Hazards from electric energy

DANGER

Contact with live parts.

Damaged cable insulation

Risk of fatal injury!

• In case of damaged insulation, disconnect the power supply immediately

and have it repaired.

• Before connecting the machine to the power supply, compare the

specifications Type plate [▶16] with those of the grid and only connect

if they are identical.

• Any work on the electrical system must be performed by authorised

electricians.

12 / 49 Hidrostal AG

2.6.4 Hazards in the working area

WARNING

Dirt and items left lying around represent tripping hazards.

Risk of severe injury!

• Always keep the work area clean.

• Remove objects that are no longer required.

• Use black/yellow tape to mark areas where there is a risk of tripping.

For pumps that are operated outside the liquid (A2QR2, A2QR4, A2QS2,

A2QS4, A2QE4, BE2, BK3):

WARNING

Work at the pump location, noise from neighbouring pumps, tank

overflowing.

Risk of injury!

Risk of permanent health damage!

• Always wear hearing protection near running pumps.

• Before entering a tank, make sure at the control console that the tank will

not be flooded during the work.

Safety requirements | 2

CAUTION

Insufficient lighting in the work area.

Risk of injury!

• Provide adequate lighting at the workplace.

• Immediately replace defective lighting components.

2.7 Safety mechanisms and devices, protection against restart, emergency shutdown, what to do in the event of danger or accidents

The system manufacturer is responsible for ensuring the safety of the

system in which the pump is installed. This aspect is not covered in these

operating instructions.

The system must be fitted with at least a lockable mains switch, to ensure

that all the conductors connected to the pump is voltage free and to prevent

an unintentional restart.

Hidrostal AG 13 / 49

2 | Safety requirements

See chapter Operational safety components [▶19] for information on

operational safety components that are either included as standard in the

pump or that are optionally available from the system manufacturer.

14 / 49 Hidrostal AG

Technical Data | 3

3 Technical Data

3.1 Intended purpose

No potentially explosive atmosphere

WARNING

Potentially explosive atmospheres.

Risk of fatal injury!

• Potentially explosive atmospheres in the pump interior or the ambient

environment are NOT permissible.

Permissible media The pump is exclusively intended for pumping liquids and viscous, non-

combustible media.

If extremely abrasive or aggressive media are circulated, the pump must be

designed in resistant material.

Pumps of the types A2QR2, A2QR4, A2QS2, A2QS4, A2QE4, BE2, and

BK3 can be operated when they are immersed or when they are

permanently outside the liquid. The types A2QE2, BN2, and BN3 must

always be immersed during operation (exception see chapter Pumping the

sump dry [▶28]).

Temperature

3.2 General information

NOTE

For contract-related technical data (dimensions, weights, performance,

connected loads, etc.) refer to enclosed delivery drawings and data sheets,

see chapter Appendix [▶49].

3.3 Operating conditions

NOTICE

Frozen medium inside the pump.

Risk of failure of the pump housing!

• Make sure that the medium inside the pump and the connected hose

lines does not freeze.

• It is particularly important to make sure that the volume behind the

impeller is drained on pumps that are subject to frost (e.g. by blowing out

with compressed air).

Declaration Value

Temperature of medium max. 40°C

Hidrostal AG 15 / 49

Loading...

Loading...