Page 1

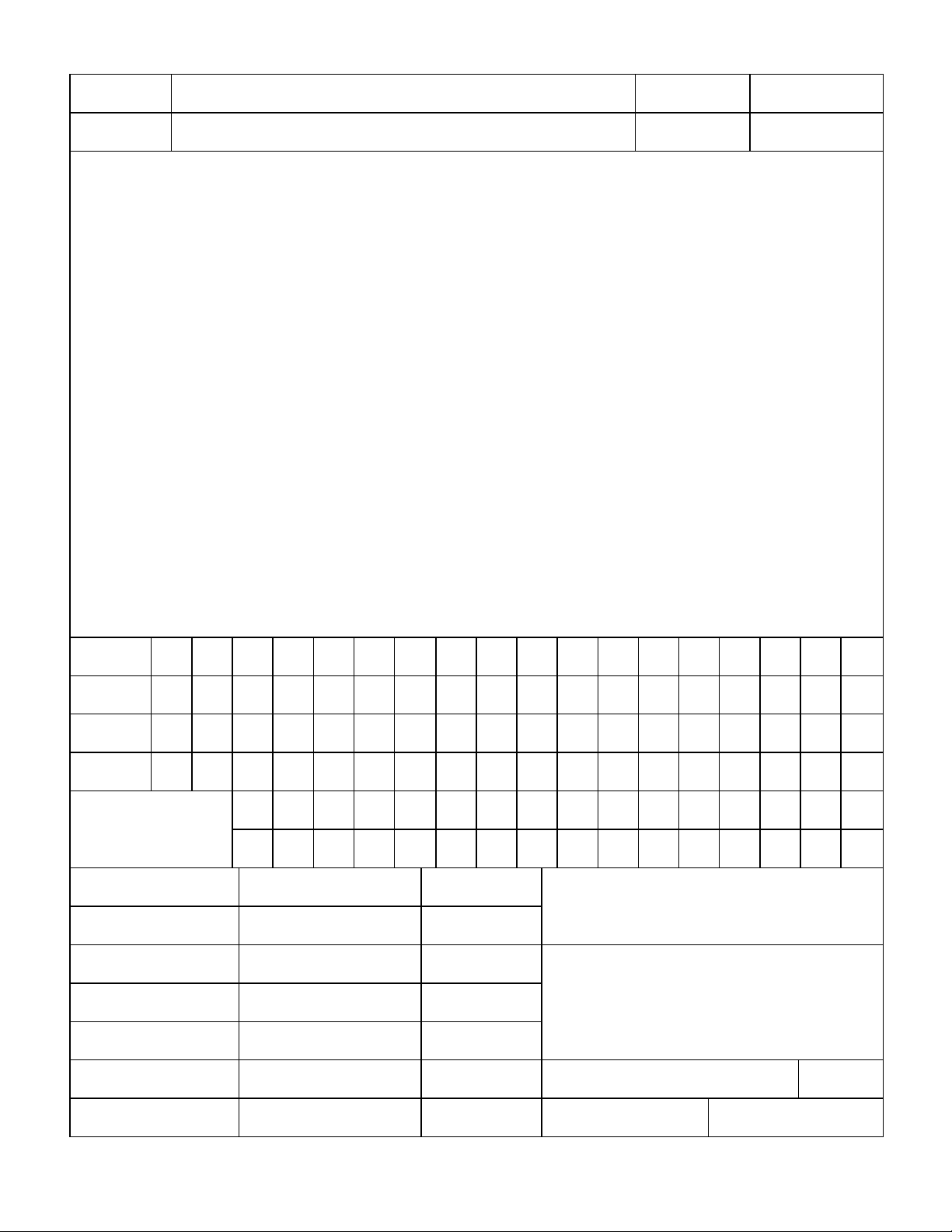

REV DESCRIPTION DATE APPROVED

F REVISED PER ECO #E5352-13

NOTE: Cover sheet is for Revision Control only, and is not to be sent with document.

REV

SHEET 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

REV

SHEET 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

REV STATUS F F F F F F F F F F

OF SHEETS 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

TOLERANCES APPROVALS DATE HID CORPORATION

.XX = +/- .03” DWN J.PENDLETON 053095 IRVINE, CALIFORNIA

.XXX = +/- .010” CHK G. FOSSEN 053195 Installation Manual

ANGLES = +/- 1°

APVD J.GRIFFIN 110195 Serial ProxPro Reader

MATERIAL N/A APVD R.HANAMOTO 110195

FINISH N/A P/N 5352-900 REV F

SCALE N/A SIZE A SHEET 0 OF 9

Page 2

Installation Manual - 5352-900 Rev F

Serial ProxPro Reader - 5352A

________________________________________________________________________________________________

HID Corporation 9292 Jeronimo Road Irvine, CA 92618-1905 USA TEL (949) 598-1600 (800) 237-7769 FAX (949) 598-1690

http://www.prox.com Serial ProxPro Reader Installation Manual 5352-900 Rev F 1 of 9

Page 3

Serial ProxPro Reader™ Installation Manual

System Overview

The Serial ProxPro reader is a s elf c ontained proxim ity reader. T he two piece polycarbonate enclosure has an

rubber gasket that seals the pieces together and a cable fitting that seals the c able entry. The water resistant

unit is approved for outdoor use. The enclos ure is designed to fit on a single gang electric al box. A Bi-color

LED and audible tone enhance user feedback. A tamper switch feature is available that will alert the Host

when the enclosure is opened. An internal DIP switch configures the unit for a RS232, RS422 or RS485

interface. The DIP switch is also used for enabling/disabling the audible tone. A keypad version is available.

Installation of the Serial ProxPro reader c onsists of m ounting, ver ifying the DIP switch settings, setting a tuning

jumper and connecting the cable to the Host.

Operation

Access Cards m ay be presented to either the front or the bac k of the reader. Optimum read range is achieved

when the access card is presented par allel to the front reader face. The LED is normally controlled by the

internal reader firm ware. The LED nor mal s tate is red and indicates that the reader is ready to read an access

card. The LED flashes green when the access card is read and the message is transmitted to the Host

system. When the reader is ready for another access card, the LED returns to red (about 250 milliseconds).

Parts List

1. Serial ProxPro Reader qty 1 (included)

2. #6-32 x 1 self tapping screws, Type T or 23 qty 2 (included)

3. Installation Manual qty 1 (included)

4. Cable Fitting qty 1 (included)

5. Cable, 3,4 or 5 conductor, 22AWG as required (50 to 4000 feet)

(Alpha 1295 C or equivalent) See cable notes.

6. DC Power Supply 12V/120mA or 24V/150mA 1 (Installer supplied)

7. In the E.U. the recommended power supply is the Micro State Electronics Model PS-5.

Installation Procedure

1. Determine an appropriate mounting position for the reader . The reader drawing below is actual size and

may be used as a template. Install a single or

for #6 fas teners. If mounting to a m etal surface, drill two 7/64 (.109) inch holes and use the enclosed self

tapping screws for mounting.

2. Route the interface cable from the reader and/or power supply to the Host.

3. Prepare the cab le by cutting the cable jacket back 2 ( two) inches and strip the wires 1/4 inch. Tinning the

wires is not required.

4. Pry off the center face plate by placing a thin blade into the grove that outlines the f ace of the r eader. Use

care to avoid scratching t he surface of the reader. The f ace plate is attached to the reader by friction

only. The screws that hold the enclosure pieces together will be exposed. Loosen the four screws to open

the enclosure (the enclosure screws are captive in the cover).

5. Install th e cable fitt ing on the rear of the reader. F eed the cable through the cable fitting, tighten the fitting

nut so the cable j acket is flush with the printed c ircuit board. Dress the cable conduc tors and connect the

reader to the Host according to the term inal des c riptions in the dim ens ion diagram. The descriptions are on

the PCB guard in the r eader. Connect the drain line of the shield to terminal 2 (Power Supply Ground).

Terminal 5, Data Return, is to be connected to the ground of the Host if the power supply ground is not

common with the Host. The opposite end of the drain line should be cut flush with the jacket and left

disconnected.

6. If the tamper feature is available on the Host, connect the tamper switch using the connections

recommended by the Host docum entation. The switch is a single pole, double throw. When the inner reader

cover is removed, the tamper switch is released. The TB1 connections to the tamper switch are pins 10 and

11. Pin 10 is the common c ontac t of the s witch and pin 11 is either the normally open or closed. Jumper P3

selects the contact of the tamper switch, either the normally closed or the normally open contact. The

default position is P3 across pins 1 and 2. This selects the nor mally open contact on TB1 pin 11. If the

double gang electrical box or drill the appropriate m ounting

________________________________________________________________________________________________

HID Corporation 9292 Jeronimo Road Irvine, CA 92618-1905 USA TEL (949) 598-1600 (800) 237-7769 FAX (949) 598-1690

http://www.prox.com Serial ProxPro Reader Installation Manual 5352-900 Rev F 2 of 9

Page 4

normally closed contact is required, m ove P3 across pins 2 and 3. (Note - “normally open and normally

closed” refer to the Pin 11 status while the cover is removed.) The contacts are rated for 100m A at 35

VDC.

7. M ount the base of the reader that holds the electronic s to the gang box or surface using the two holes

located on the center axis of the reader. T wo #6-32 x 1 inch screws are provided f or mounting to a gang

box or metal surface.

8. Set the DIP switches according to the table in the section, DIP Switch Settings.

9. Place the jumper on P1 between pins 1 and 2 when mounting to a metallic surface or to a junction box

with a metal cover plate. Otherwise, the jumper should be between pins 2 and 3, the default position.

10. After wiring the Reader and power supply, the Reader is ready to be tested. Pow er up th e Read er and the

LED and Beeper will flash and beep 3 times in a sequence of two short delays and one long delay. This

indicates that the m icro-controller unit is work ing properly. Present an ID card to the Reader and the LED

should momentarily turn green, indicating a read of the card.

11. Replace the top cover and face plate.

Cable Notes

1. The ProxPro Ser ial reader internally connects GROUND to SIG G ND. As a res ult, the power supply used to

power the reader and Host must have a common ground (voltage reference).

2. RS232 (DTE) - A 5 conductor cable (Alpha 1295 C or equivalent) is required when using the RS232

interface. It is recom mended that the RD line be connec ted for com patibility with future firmware upgrades.

The DTR/DSR hardware handshake lines do not need to be connected to the host. T he maximum cable

length for the RS232 interface is 50 - 200 f eet. Connec t TB1- 1 (DC+) and TB1--2 (Gr ound) for power supply

and TB1-6 (TD output)), TB1-7 (RD input) and TB1-3 (Signal Ground) for RS232.

3. RS422 - A 7 conduc tor cable ( Alpha 1297 C or equivalent) is required when using the RS422 interf ace. It is

recommended that the RX+ and RX- lines be connected for compatibility with future upgrades. The

maximum cable length f or the RS422 interf ace is 4000 feet. Connect T B1-1 (DC+) and TB1-2 (Gr ound) to

power supply and TB1-4 (TX+), TB1-5 (TX-), TB1-6 (RX+), TB1-7 (RX-) and TB1-3 (Signal Ground) for

RS422.

4. RS485 - A 5 conduc tor cable (Alpha 1295c or equivalent) is required when using the RS485 interface. The

maximum cable length for the RS485 interface is 4000 f eet. Connect TB1-1 (DC+) and TB1-2 (Ground) to

power supply and TB1-4 (485+), TB1- 5 (485-) and TB1-3 (signal ground) for RS485. Multi-drop protocols

are not currently supported. Contact HID Corporation customer service to inquire about specifying a

particular software protocol.

5. Tamp er Switch Feature - A 22 AW G twisted pair, shielded, s tranded cable (Belden 9330 or equivalent) is

often required for the tam per switch. Follow the recom m endations of the manuf acturer of the Host system.

If the tamper input is a super vised input, the "end of line" resistors may be mounted in the enclosure. Use

extreme care and shield any bare wire from the printed circuit assembly and its components.

6. Cable fitting - The inner diameter of the cable fitting will accom modate a cable with an outer diameter of

.300 inches (nominally). If larger diameter (or two cables) must be accommodated, do not use the fitting.

7. Shield - Connect cable shield by connecting drain wire to TB1-2 ground. Leave foil and drain wire

disconnected at host end of cable by cutting them off at the end of the cable jacket .

RS232/RS422/RS485 Interface Considerations

1. The ProxPro Serial reader operates in a send only mode. However, it is r ecommended that the interface

receive line(s) be connected for compatibility with future firmware upgrades.

2. The RS232 interface includes connections for DTR/DSR hardware handshake lines. However, the

ProxPro Serial reader does not support hardware handshake at this time.

4. The message format for RS232, RS422 and RS485 are identical. There are no provisions for node

addresses in the message.

________________________________________________________________________________________________

HID Corporation 9292 Jeronimo Road Irvine, CA 92618-1905 USA TEL (949) 598-1600 (800) 237-7769 FAX (949) 598-1690

http://www.prox.com Serial ProxPro Reader Installation Manual 5352-900 Rev F 3 of 9

Page 5

RS232/RS422/RS485 Card Message Specification

When Access Cards (transponders) are presented to the ProxPro reader, the reader sends a message. The

message is in the following format:

CCDDDDDDDDDDXX<CR><LF>

^ First character sent

1. All characters C, D and X are ASCII encoded, hexadecimal digits.

(i.e. The hex value 7 is sent as an ASCII character 7 or the hex value E is sent as an ASCII character E)

2. The CC field is reserved for use by HID Corporation. The valid values are 00 through 7F.

3. The DDDDDDDDDD field is the transponders (Access Card) data. The valid values are 0000000000

through 1FFFFFFFFF (ASCII).

4. The XX field is a computed c heck sum. T he check sum is calculated by first grouping the message data into

the pairs CC DD DD DD DD DD. Each pair of characters represents one byte of data. Then each pair of

characters is converted from ASCII to their respective hex values. At this point, the 6 bytes are added

together. The checksum is equal to the least significant 8 bits of the result.

5. <CR> is the ASCII code for a carriage return. (0D hex)

6. <LF> is the ASCII code for a line feed. (0A hex)

7. For example, if the ProxPro reads a transponder (Access Card) that contains the value CC=00 and

DDDDDDDDDD=01234ABCDE, the reader will report the ASCII message 0001234ABCDE08<CR><LF>.

Note that each of the charac ters is ASCII encoded. The actual bytes (hex value) that are sent to the host

are <30><30><30><31><32><33><34><41><42><43><44><45><30><38><0D><0A>. The check sum was

computed by adding 00 + 01 + 23 + 4A + BC + DE = 208 hex. The checksum is the least significant 8 bits of

this result or 08 hex.

8. The communications settings are 9600 BAUD, 8 bits, 1 stop bit, no parity.

DIP Switch Settings

There are two switches on the ProxPro Serial reader that are used to select several different modes of

operation. The following is a diagram detailing the default switch settings.

SWITCH 2SWITCH 1

on

1234567 8on1234567 8

________________________________________________________________________________________________

HID Corporation 9292 Jeronimo Road Irvine, CA 92618-1905 USA TEL (949) 598-1600 (800) 237-7769 FAX (949) 598-1690

http://www.prox.com Serial ProxPro Reader Installation Manual 5352-900 Rev F 4 of 9

Page 6

DIP Switch Settings, continued

SW1-1, 2 and 3 Not used.

SW1-4 Keypad Operation. The keyboard data can be processed by the reader or m ay be connected directly

to the Host. When Switch 1-4 is in the "off" position, the host is expected to

process any key presses (2 of 7 or 3 x 4 form ats). W hen Switch 1-4 is in the "on"

position, the reader scans the keyboard and outputs the keyboard entries over the

selected interface. The message is the ASCII representation of the key that is

pressed. For example, if the “4” is pressed, the reader will output a <34 hex>

(ASCII encoded “4”).

SW1-5 Beeper Operation. The Beeper may be enabled or disabled. If enabled, the reader will issue a beep

while flashing a green LED af ter a card is read. Switch 1-5 in the "on" position

enables the audible tone. Switch 1-5 in the "off" position disables the audible tone.

SW1-6 Terminating Resistor. Some RS422/RS485 connections require that the RX- line be ter minated with a

resistor to RX+. If SW1-6 is in the "off" position, there is no term inating resistor on

RX-. If SW 1-6 is in the "on", then a 120 ohm resistor is connec ted between RX+

and RX-.

SW1-7 Line Setting. SW1-7 is us ed to conf igure the reader's inter face conf iguration. SW1-7 should be

in the "off" position for RS232 and RS422 operation and “on” for RS485 operation.

SW1-8 Line Setting. SW1-8 is us ed to conf igure the reader's inter face conf iguration. SW1-8 should be

in the "off" position for RS232 and RS422 operation and “on” for RS485 operation.

SW2-1 Reader Interface. SW2-1, SW2-2 and SW2-3 are used to select the reader's interface

SW2-2 Reader Interface. configuration. Currently there are 3 options available. They are:

SW2-3 Reader Interface. 1. SW2-1 "on", SW2-2 "on" and SW2-3 "on" selects the RS232 interface.

2. SW2-1 "on", SW2-2 "on" and SW2-3 "off" selects the RS422 interface.

3. SW2-1 “on”, SW2-2 “off” and SW2-3 “off” selects the RS485 interface.

SW2-4, 5, 6, 7 and 8 Not used.

Product Configuration/Ordering Options

5352

A G N 00 -XXXX Y

Customer Custom Artwork or Firmware Number

1 through 9, A through Z

Customer Custom Number

Configuration Options - (00 standard)

Standard Hardware Options - N = None, K = Standard Keypad (internal or

2 of 7), S = Direct Connect Keypad (3 x 4 type)

Color - G = Gray, B = Beige

Current Revision Letter - may change without notice

Model Number 5352 = Serial ProxPro

________________________________________________________________________________________________

HID Corporation 9292 Jeronimo Road Irvine, CA 92618-1905 USA TEL (949) 598-1600 (800) 237-7769 FAX (949) 598-1690

http://www.prox.com Serial ProxPro Reader Installation Manual 5352-900 Rev F 5 of 9

Page 7

)

P1

TB1

1 - DC +

O

2 - GROUND

O

3 - SIG GND

O

4 - TX+/485+

O

5 - TX-/485-

O

6 - RX+/TD

O

7 - RX-/RD

O

O

8 - DTR

O

9 - DSR

O

10 - TAMPER COMMON

11 - TAMPER SELECT

O

1

P3

2

3

321

5.00" (127mm)

3.28" (83.3mm)

SW1

SW2

P2

5.00" (127mm)

mounting holes (2 places)

1.00" (25.4mm)

Dimension Drawing (Actual Size

________________________________________________________________________________________________

HID Corporation 9292 Jeronimo Road Irvine, CA 92618-1905 USA TEL (949) 598-1600 (800) 237-7769 FAX (949) 598-1690

http://www.prox.com Serial ProxPro Reader Installation Manual 5352-900 Rev F 6 of 9

Page 8

Keypad Option Notes:

This section of this doc um ent desc ribes the k eypad interface. T he k eypad has twelve keys, four rows by three

columns. The characters 0 to 9, # and * are arranged the same as a standard telephone keypad. There are two

methods for interfacing to the Keypad.

The first configuration (K version, internal keypad) processes the keypad entries in the reader and then

transmits the data to the host system via the RS232/422 data lines . The reader outputs eac h key as an ASCII

encoded hexadecimal digit. The dec oding of the message sent through the RS232/422 interface is the only

processing required of the host s ystem. The user inter face has been implem ented in the most generic fashion

to give the integrator the most flexibility.

The Second conf iguration (S version, direct connec t keypad), the Host must scan the k eypad directly using a

separate cable.

K Version - Internal keypad processing

Length (Buffer keys) Option

The length option chooses the num ber of key entries that will be buffered before the m essage is sent to the

host. The maximum number of entries is 11. When the option is set for multiple entries the reader has a five (5)

second timer that will clear all entries after five seconds has expired between entries. The length option

requires the user to enter the program med number of key entries. Upon completion of the last key entry, the

message is assem bled and sent. T his requires the system integrator to c onfigure the reader for the num ber of

key entries before installation.

User Interface

The user is able to press k eys at any time. Card reads and k ey entries are independent of each other, the user

is not required to follow any sequence, unless specified by the system integrator. The reader is equipped to

beep, flash the LED and give tactile feedback when a key is pressed. The amount of time is 5 (five) seconds

between key entries when the multiple key entry option is used. If the time expires between key entries, all keys

entered are cleared and the user must start the sequence from the beginning.

Keypad Messages

The keypad message follows a bas ic form at. The reader outputs each key as an ASCII encoded hexadecim al

digit. For an example, if the user presses the:

five key, the host receives ASCII 5 <35 hex>

eight key, the host receives ASCII 8 <38 hex>

star key “*”, the host receives ASCII A <2A hex>

number key “#”, the host receives ASCII B <23 hex>

If the ProxPro has been factory configured for buffering, the reader will buffer the correct number of keys

before transmitting the serial ASCII message.

For an example, if the buffer length equals 3 keys, and the user presses keys 4, 5 and 6, The host will receive

(ASCII) 4,5,6, CR,LF, or <34H 35H 36H 0DH 0AH>

.

The communications settings are 9600 BAUD, 8 bits, 1 stop bit, no parity. The internal keypad processing

mode is available on the Serial ProxPro 5352XXKXX versions.

Keypad Scanning 2 of 7 (K version)

This mode requires a separate cable to be supplied that connec ts to the Keypad board, inside the ProxPro, to

the Host via P2. P2 is a 7 position terminal st rip. Switch 1-4 (SW 1-4) should be switched to the “off” position.

The reader will then NOT process the keypad data, and it will be decoded by the host in 2 of 7 format..

The keypad has a matrix of contacts corresponding with the matrix of keys. The contact outputs are wired to

the seven terminals of P2. T he seven term inals are c alled P2-1 thru P2-7 and provide the 2 of 7 decode of the

buttons. When a k ey is pressed, the button closes two contacts that pull 2 lines to ground. This results of the

key entries are in the table below. The reader and the host that is scanning the k eypad will require a common

signal ground. The connection is to be made on either pin 2 (power supply ground) or 5 (Data Return) of TB1 of

the Serial ProxPro.

________________________________________________________________________________________________

HID Corporation 9292 Jeronimo Road Irvine, CA 92618-1905 USA TEL (949) 598-1600 (800) 237-7769 FAX (949) 598-1690

http://www.prox.com Serial ProxPro Reader Installation Manual 5352-900 Rev F 7 of 9

Page 9

This method of interfacing the keypad requires additional processing by the host. These include the debouncing of the keys, decoding of the keypad, timing between key entries, as well as others depending on the

Host. The 2 of 7 format is available on the Serial ProxPro 5352XXKXX versions.

Key Pad Data Table - 2 of 7

Key #

P2-1 P2-2 P2-3 P2-4 P2-5 P2-6 P2-7

Terminal Number

1 LO HI HI HI HI HI LO

2 LO HI HI HI HI LO HI

3 LO HI HI HI LO HI HI

4 HI LO HI HI HI HI LO

5 HI LO HI HI HI LO HI

6 HI LO HI HI LO HI HI

7 HI HI LO HI HI HI LO

8 HI HI LO HI HI LO HI

9 HI HI LO HI LO HI HI

* HI HI HI LO HI HI LO

0 HI HI HI LO HI LO HI

# HI HI HI LO LO HI HI

HI represents a voltage of +5 volts in reference to the Serial ProxPro ground.

LO represents the Serial ProxPro ground.

Note: The Keypad/Reader is to be used on a single point ground system.

S Version - Direct connect keypad Scanning - 3 X 4 Matrix format

The Serial ProxPr o reader is available with a 3 x 4 m atrix keypad. The keypad is independent of the Serial

ProxPro reader and only provides the connections to the keypad. This mode requir es a separate cable to be

supplied that connects to the Keypad board, inside the ProxPro, to the Host via P2. P2 is a 7 position terminal

strip. The following is the table for the contact closures.

This table indicates the connection between the connector pins when a key is pressed. For example, if key 3 is

pressed P2-5 is connected (shorted) to P2-1. This is available on the Serial ProxPro 5352XXSXX versions.

Rows

P2-5 P2-6 P2-7

Columns

P2-1 3 2 1

P2-2 6 5 4

P2-3 9 8 7

P2-4 # 0

*

________________________________________________________________________________________________

HID Corporation 9292 Jeronimo Road Irvine, CA 92618-1905 USA TEL (949) 598-1600 (800) 237-7769 FAX (949) 598-1690

http://www.prox.com Serial ProxPro Reader Installation Manual 5352-900 Rev F 8 of 9

Page 10

Serial ProxPro Reader™ Specifications

Read Distance - using ProxCard II

Over all Operating Limits, minimum (@12VDC)) 5.0 inches (12.5 cm)

Non-Metallic Mounting, typical (@12VDC) 7.0 inches (17.6 cm)

Mounted on Metal, typical (@12VDC) 5.0 inches (12.5 cm)

Overall Operating Limits, minimum (@24VDC) 5.0 inches (12.5 cm)

Non-Metallic Mounting, typical (@24VDC) 7.5 inches (19 cm)

Mounted on Metal, typical (@24VDC) 5.5 inches (15.2 cm)

Regulatory Approvals and Certifications

Underwriters Laboratories listing under UL 294, Access Control Unit Accessory, Indoor and Outdoor

UK Type Approval

German General License Type Approval per RTP letter, Vfg 70/1998, dated 30 June 1998

CE Mark - See declaration of conformity

FCC Certification

FCC Compliance Statement : This device complies with part 15 of the FCC rules. Operation is subject

to the following two conditions : 1) This device may not cause harmful interference, 2) This device must

accept any interference received, including interference that may cause undesired operation.

The reader is intended to be powered from a limited power source output of a previously certified

power supply.

Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

Environmental Characteristics

Designed for listing under UL 294 “Standard for Access Control System Units”

Operating Temperature Range -30

Storage Temperature Range -40

Operating Humidity Range 5% to 95% non-condensing

Operating Vibration Limit .04 g

Operating Shock Limit 30g, 11mS, Half Sine

Enclosure Material UL Recognized Lexan Polycarbonate

Weight 11.3oz (310gms)

o

C to 65oC (-22oF to 150oF)

o

C to 85oC (-40oF to 185oF)

2

/Hz 20-2000Hz

Power Requirements

Power supply Linear type recommended

Operating Voltage Range (+DC) 10VDC -28.5VDC

Absolute Maximum (+DC non-operating) 31.4VDC

Maximum Average Current 12V/24V 120mA/150mA

Transient Protection (all terminals) 8,000 volts

Reverse Voltage Protection YES

Input Voltage (maximum data-0/1 lines) 28.5VDC

Input Voltage (maximum interface lines) 28.5VDC

Operating Parameters

Excitation Frequency 125KHz

Duty Cycle (alternate power level rate) 20% @ 60mS period

Read and Report Speed (26 bit Card) 100mS

RS232 - Maximum Cable Distance to Host 50 - 200 feet (61 meters)

RS422 - Maximum Cable Distance to Host 4000 feet (1230 meters)

RS485 - Maximum Cable Distance to Host 4000 feet (1230 meters)

LED Type Bi-colored Red/Green

LED Control (default) internal control enabled

Beeper Control (default) internal control enabled

Anti-Pass Back Delay (default) 1 second

NOTES: THE ABOVE ARE RECOMMENDED INSTALLATION PROCEDURES. ALL LOCAL, STATE AND

NATIONAL ELECTRICAL CODES TAKE PRECEDENCE.

________________________________________________________________________________________________

HID Corporation 9292 Jeronimo Road Irvine, CA 92618-1905 USA TEL (949) 598-1600 (800) 237-7769 FAX (949) 598-1690

http://www.prox.com Serial ProxPro Reader Installation Manual 5352-900 Rev F 9 of 9

Loading...

Loading...