Page 1

9292 Jeronimo Road

Irvine, CA 92618-1905

ProxPro® Wiegand/Clock-and-Data

© 2007 HID Global Corporation. All rights reserved.

5355/8A

INSTALLATION GUIDE

5355A-900, Rev N.1

February 22, 2007

Page 2

®

Part No. 5355-900, Rev N.1 ProxPro

Installation Guide

Contents

1 System Overview............................................................................................................................3

1.1 Operation.............................................................................................................................3

1.2 Parts List..............................................................................................................................3

2 Installation Procedure....................................................................................................................4

3 Wiring...............................................................................................................................................5

3.1 Standard Wire Connections.................................................................................................5

3.2 Buffered Direct Wire Connections – Option D.....................................................................5

3.3 Direct Wire Connections – Option S....................................................................................5

4 Switch Configuration......................................................................................................................6

4.1 Switch 1-1 Hardware Identity...............................................................................................6

4.2 Switch 1-2 Audible Tone Control.........................................................................................7

4.3 Switch 1-3 Green LED Control............................................................................................7

4.4 Switch 1-4 Keypad Operation..............................................................................................7

4.5 Switch 1-5 Single / Dual LED Control..................................................................................7

4.6 Switch 1-6 and 1-7 Data Output Biasing.............................................................................7

5 K Version - Internal keypad processing.......................................................................................8

5.1 Parity Option........................................................................................................................8

5.2 Length Buffer Keys Option ..................................................................................................8

5.3 User Interface......................................................................................................................8

5.4 Keypad Message.................................................................................................................8

5.5 Keypad Scanning 2 of 7 ......................................................................................................9

5.6 Key Pad Data Table - 2 of 7................................................................................................9

6 S Version - Direct connect keypad scanning ............................................................................10

7 D Version – Buffered direct connect keypad scanning............................................................11

8 Specifications ...............................................................................................................................12

8.1 Read Distance - using PROXCARD II®............................................................................12

8.2 Environmental Characteristics...........................................................................................12

8.3 Power Requirements.........................................................................................................12

8.4 Option D – Buffered Direct Connect Keypad.....................................................................12

8.5 Operating Parameters.......................................................................................................12

9 Product Configuration/Ordering Options...................................................................................13

Page 2 of 14 February 22, 2007

© 2007 HID Global Corporation. All rights reserved.

Page 3

ProxPro® Installation Guide Part No. 5355-900, Rev N.1

1 System Overview

The ProxPro® reader is a self-contained proximity reader. The two-piece polycarbonate enclosure has

an rubber Gasket that seals the pieces together and a cable fitting that seals the cable entry. The water

resistant unit is approved for outdoor use. The enclosure is designed to fit on a single gang electrical

box. A Bi-color LED and audible tone enhance user feedback. A tamper switch feature is available that

will alert the Host when the enclosure is opened. An internal DIP switch makes the configuration of the

outputs, audible tone, keypad and LED control options simple.

Installation of the ProxPro reader consists of mounting, verifying the DIP switch settings, setting a

tuning jumper and connecting the cable to the Host.

1.1 Operation

Access Cards may be presented to either the front or the back of the reader. Optimum read range is

achieved when the access card is presented face on, and parallel to the reader face. The LED is

normally controlled by the internal reader firmware. Alternatively, the LED can be controlled by the

access control host panel. When the LED is controlled directly by the reader, the LED normal state is

red, and indicates that the reader is ready to read an access card. The LED turns green when the

access card is read and the message is transmitted to the Host system. When the reader is ready for

another access card, the LED returns to red. The typical time the LED is green is 250 milliseconds .

The reader only controls the green state of the LED, there is no amber LED state. The operation of the

LED may be controlled by the Host. When the LED is host system controlled, the LED and beeper

operation may vary depending on the particular host software. The LED may then exhibit a red, green

or “amber” color for certain status conditions as controlled by that host’s software.

1.2 Parts List

1 ProxPro Reader qty 1 (included)

2 #6-32 x 1 self tapping screws, Type T or 23 qty 2 (included)

3 Installation Manual qty 1 (included)

4 Cable Fitting qty 1 (included)

5 Cable, 5 conductor, 22awg

(Alpha 1295 C or equivalent)

6 Cable, 20 conductor, 22awg

(Alpha 1299/20C or equivalent)

7 DC Power Supply 12V/100mA or 24V/120mA 1 (Installer supplied)

8 Recommended power supply in the E.U. is the Micro State Electronics Model PS-5

as required (max. 500 feet)

See cable notes

as required (max. 500 feet)

See cable notes

February 22, 2007 Page 3 of 14

© 2007 HID Global Corporation. All rights reserved.

Page 4

®

Part No. 5355-900, Rev N.1 ProxPro

Installation Guide

2 Installation Procedure

1. Determine an appropriate mounting position for the reader. The reader drawing below is actual

size and may be used as a template. Install a single or

appropriate mounting for #6 fasteners. If mounting to a metal surface, drill two 7/64 (.109) inch holes

and use the enclosed self-tapping screws for mounting.

2. Route the interface cable from the reader and/or power supply to the Host.

3. Prepare the cable by cutting the cable jacket back 2 (two) inches and strip the wires 1/4 inch.

Tinning the wires is not required.

4. Pry off the center faceplate by placing a thin blade into the grove that outlines the face of the reader.

Use care to avoid scratching the surface of the reader. The faceplate is attached to the reader

by friction only. The screws that hold the enclosure pieces together will be exposed. Loosen the

four screws to open the enclosure (the enclosure screws are captive to the cover).

5. Install the cable fitting on the rear of the reader. Feed the cable through the cable fitting; tighten the

fitting nut so the cable jacket is flush with the printed circuit board. Dress the cable conductors and

connect the reader to the Host according to the terminal descriptions in the dimension diagram and

wiring table. The descriptions are on the PCB guard in the reader. Connect the drain line of the

shield to terminal 2 (Power Supply Ground). Terminal 5, Data Return, is to be connected to the

ground of the Host if the power supply ground is not common with the Host. The opposite end of the

drain line should be cut flush with the jacket and left disconnected.

double gang electrical box or drill the

6. If the tamper feature is available on the Host, connect the tamper switch using the connections

recommended by the Host documentation. The switch is a single pole, double throw. When the inner

reader cover is removed, the tamper switch is released. The TB1 connections to the tamper switch

are pins 10 and 11. Pin 10 is the common contact of the switch and pin 11 is either the normally

open or closed. Jumper P3 selects the contact of the tamper switch, either the normally closed or the

normally open contact. The default position is P3 across pins 1 and 2. This selects the normally

open contact on TB1 pin 11. If the normally closed contact is required, move P3 across pins 2 and 3.

(Note - “normally open and normally closed refer to the Pin 11 status while the cover is removed.)

The contacts are rated for 100mA at 35 VDC.

7. Mount the base of the reader that holds the electronics to the gang box or surface using the two

holes located on the center axis of the reader. Two #6-32 x 1 inch screws are provided for mounting

to a gang box or metal surface.

8. Set the DIP switches according to the table in the section, DIP Switch Settings.

9. Place the jumper on P1 between pins 1 and 2 when mounting to a metallic surface or to a junction

box with a metal cover plate. Otherwise, the jumper should be between pins 2 and 3, the default

position.

10. After wiring the Reader and power supply, the Reader is ready to be tested. Power up the Reader

and the LED and Beeper will flash and beep 3 times in a sequence of two short delays and one long

delay. This indicates that the micro-controller unit is working properly. If the switches have been set

for external control only, the Reader will 3 shorts and a long. Present an ID card to the Reader and

the LED should momentarily turn green, indicating a read of the card. If the Reader LED is

controlled by the Host refer to the Host description of the LED operation.

11. Replace the top cover and faceplate.

Page 4 of 14 February 22, 2007

© 2007 HID Global Corporation. All rights reserved.

Page 5

ProxPro® Installation Guide Part No. 5355-900, Rev N.1

3 Wiring

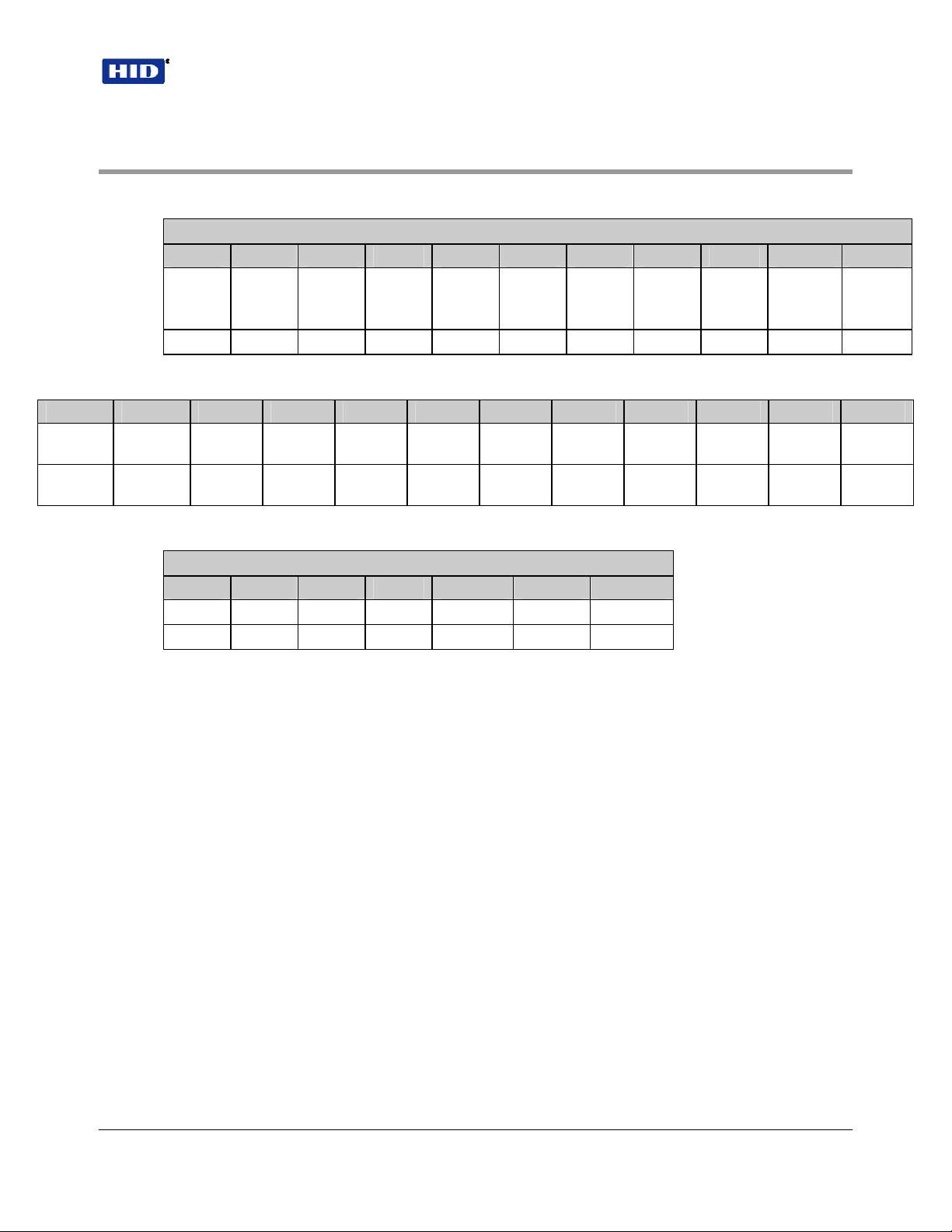

3.1 Standard Wire Connections

TB1

1 2 3 4 5 6 7 8 9 10 11

+DC Ground Data0/

Data

Red Black Green White Violet Orange Brown Yellow Blue -- --

3.2 Buffered Direct Wire Connections – Option D

10 11 E1 E2 E3 E4 E5 E6 E7 E8 E9 E10

Tamper

Common

Red /

Black

Tamper

Select

Red /

Green

+DC Ground Row 1 Row 2 Row 3 Row 4 Column 1 Column 2 Column 3 Select

White /

Red

White /

Black

Data1/

Clock

Gray Violet Red /

Shield

Ground

Green

LED

Yellow

Red

LED

Pink Tan White /

Beeper Hold/

Card

Present

Blue

Tamper

Common

White /

Green

Tamper

Select

Low

White /

Yellow

3.3 Direct Wire Connections – Option S

TB2

1 2 3 4 5 6 7

Row 1 Row 2 Row 3 Row 4 Column 3 Column 2 Column 1

Red Black Green White Drain Orange Brown

Notes:

1. When using 5 conductor cable, the power supply and Host must have a common ground (voltage

reference).

2. 6 conductor cable is required when controlling the red and green LED. (Alpha 1296 C or

equivalent)

3. 7 conductor cable is required when both green and red LED’s are controlled by the Host and the

power supply and Host "ground" are separate. (Alpha 1297 C or equivalent)

4. A 22 AWG twisted pair, shielded, stranded cable is often required for the tamper switch. Follow the

recommendations of the manufacturer of the Host system. If the tamper input is a supervised input

the "end of line" resistors may be mounted in the enclosure. Use extreme care and shield any bare

wire from the printed circuit assembly and its components.

5. The inner diameter of the cable fitting will accommodate a cable with an outer diameter of .300

inches (nominally).

6. Connect cable shield by connecting drain wire to TB1-2 ground. Leave foil and drain wire

disconnected at host end of cable by cutting them off at the end of the cable jacket.

7. When using the Buffered Direct Connect ProxPro with a 20 conductor cable, DC+ and Power (Red

and White / Red wires) must have a common connection to the host +DC power supply. The two

ground wires (Black and White / Black) must have a common ground connection to the host +DC

power supply.

February 22, 2007 Page 5 of 14

© 2007 HID Global Corporation. All rights reserved.

Page 6

Part No. 5355-900, Rev N.1 ProxPro

)

4 Switch Configuration

P1

TB1

1 - DC +

O

2 - GND

O

3 - DATA "0"

O

4 - DATA "1"

O

O

5 - DATA RTN

O

6 - Green LED

O

7 - Red LED

8 - Beeper

O

9 - Hold

O

O

10 - COM

O 11 - Tamper

TAMPER SW

123

1 - n/o

3 - n/c

3.28" (83.3mm)

SW1

P2

®

Installation Guide

5.00" (127mm)

5.00" (127mm)

Dimension Drawing (Actual Size

Figure 1 DIP Switch Settings - Switch 1

4.1 Switch 1-1 Hardware Identity

When set in the "on" position the unit is configured for "Wiegand" interface. The "off" position

configures the unit for "Clock-and-data" interface.

mounting holes (2 places)

1.00" (25.4mm)

Page 6 of 14 February 22, 2007

© 2007 HID Global Corporation. All rights reserved.

Page 7

ProxPro® Installation Guide Part No. 5355-900, Rev N.1

4.2 Switch 1-2 Audible Tone Control

The Audible Tone (Beeper) may be enabled or disabled to sound when an access card is read. When

enabled, the audible tone is sounded when a card is successfully read. When the Beeper is disabled,

the only method to activate the Beeper is to use the external Beeper control line. The Beeper will turn

on when the control line is switched to ground. Switch 2 in the "on" position enables the audible tone

(the default).

4.3 Switch 1-3 Green LED Control

The Green LED can be configured to turn on, or not turn on when an access card is read. Switch 3 in

the “off” position selects the Green LED to be turned on (the default).

4.4 Switch 1-4 Keypad Operation

The keypad inputs may be processed by the reader or may be connected directly to the Host. When

the keypad inputs are processed by the reader, the reader scans the keypad and outputs the keypad

entries over the "Wiegand" interface. When the keypad is connected to the Host, the Host determines

which key is being entered. Switch 4 is in the "on" position for the default mode (the keypad inputs are

processed by the reader).

4.5 Switch 1-5 Single / Dual LED Control

In Single LED Control the LED is Red. When an access card is read, the LED toggles Green, and then

back to Red. Grounding the Green LED Control line will change the LED from Red to Green. The

reader maybe configured so the Green LED is externally controlled independently from the Red LED.

This is referred to as Dual LED Control. When the Red or Green LED Control line is switched to

ground, the respective LED is turned on. If both LED’s are on, the LED appears to glow amber.

Switch 5 in the “off” position selects Single LED Control (the default).

4.6 Switch 1-6 and 1-7 Data Output Biasing

The data outputs may be configured as open collector or biased at 5VDC through 1k Ohm resistors by

the reader. The default (standard) configuration is output biasing, with switches 6 and 7 "on" .

Note: When the outputs are configured as open collector, the host panel should provide bias voltage at

the panel inputs.

on

12345678

Not used

Wiegand Data 0 Bias

Wiegand Data 1 Bias

Single/Dual LED CNTL

KeyPad

Green LED Control

Beeper Control

Hardware Identity

Notes:

This section of this document describes the keypad interface. The keypad has twelve keys, four rows

by three columns. The characters 0 to 9, # and * are arranged the same as a standard telephone

keypad. There are two methods for interfacing to the Keypad.

Default Setting

on

on

(The Wiegand data outputs are pulled up to +5VDC

on

through a 1kOhm resistor)

(Single Line LED Control)

off

(The keypad data is sent on data lines), N/A for D version

on

off

(The green LED is enabled when a card is read)

on

( The beeper is enabled when a card is read)

on

(Identifies the unit to be "Wiegand")

February 22, 2007 Page 7 of 14

© 2007 HID Global Corporation. All rights reserved.

Page 8

Part No. 5355-900, Rev N.1 ProxPro

The first configuration (K version, internal keypad) processes the keypad entries in the reader and then

transmits the data to the host system via the Wiegand data lines. The reader outputs each key as an

ASCII encoded hexadecimal digit. The decoding of the message sent through the Wiegand interface is

the only processing required of the host system. The user interface has been implemented in the most

generic fashion to give the integrator the most flexibility.

The Second configuration (S version, direct connect keypad), the host must scan the keypad directly

using a separate cable.

5 K Version – Internal keypad processing

Parity and Length options must be factory configured. Contact customer service to enable these

options.

5.1 Parity Option

The default does not included parity in the data message. When the parity option is enabled, parity is

added to the total message independent of length. The parity coverage is diagrammed below. Each

parity bit covers exactly one half of the message.

P XXXXXXXX......XXXXXXXXP

EXXXXXXXX...

...XXXXXXXXP

®

Installation Guide

5.2 Length Buffer Keys Option

The length option chooses the number of key entries that will be buffered before the message is sent to

the host. The maximum number of entries is 10 with parity and 11 without parity. When the option is

set for multiple entries the reader has a five (5) second timer that will clear all entries after five seconds

has expired between entries. The length option requires the user to enter the programmed number of

key entries. Upon completion of the last key entry, the message is assembled and sent. Parity is

added if the option is set. This requires the system integrator to configure the reader for the number of

key entries before installation.

5.3 User Interface

The user is able to press keys at any time. Card reads and key entries are independent of each other,

the user is not required to follow any sequence, unless specified by the system integrator. The reader

is equipped to give the user audible, visual and tactile feedback when a key is pressed. The amount of

time is 5 (five) seconds between key entries when the multiple key entry option is used. If the time

expires between key entries, all keys entered are cleared and the user must start the sequence from

the beginning.

5.4 Keypad Message

The keypad message follows a basic format. The entries are transmitted in the hexadecimal

representation. When parity is added, the message format mimics the "standard 26 bit Wiegand

format”. The key that is pressed is represented in Hexadecimal with * represented by A (HEX) and #

represented by B (HEX).

0 = 0000 4 = 0100 8 = 1000

1 = 0001 5 = 0101 9 = 1001

2 = 0010 6 = 0110 * = 1010

3 = 0011 7 = 0111 # = 1011

Page 8 of 14 February 22, 2007

© 2007 HID Global Corporation. All rights reserved.

Page 9

ProxPro® Installation Guide Part No. 5355-900, Rev N.1

Example without parity:

AAAA BBBB CCCC DDDD ..... KKKK

AAAA = The first key entered

BBBB = Second key entered

KKKK = Eleventh key entered (the maximum)

Example with parity:

A message that has a fixed number of key entries set to 4 and the parity option included.

P AAAA BBBB CCCC DDDD P

A - First key entered

B - Second key entered

C - Third key entered

D - Fourth key entered

P - Parity Bits

The whole message is similar to the "Standard 26 Bit Wiegand" formatted message. The format

consists of two parity bits at the opposite ends, one odd and the other even. Each parity bit covering

exactly one-half of the message.

P XXXXXXXX......XXXXXXXXP

EXXXXXXXX...

...XXXXXXXXP

5.5 Keypad Scanning 2 of 7

This mode requires a separate cable to be supplied that connects to the Keypad board, inside the

ProxPro, to the Host via P2. P2 is a 7 position terminal strip. Switch 1-4 (SW1-4) should be switched to

the “off” position. The reader will then NOT process the keypad data, and it will be decoded by the host

in 2 of 7 format.

The keypad has a matrix of contacts corresponding with the matrix of keys. The contact outputs are

wired to the seven terminals of P2. The seven terminals are called P2-1 thru P2-7 and provide the 2 of

7 decode of the buttons. When a key is pressed, the button closes two contacts that pull 2 lines to

ground. This results of the key entries are in the table below. The reader and the host that is scanning

the keypad will require a common signal ground. The connection is to be made on either pin 2 (power

supply ground) or 5 (Data Return) of TB1 of the ProxPro.

This method of interfacing the keypad requires additional processing by the host. These include the debouncing of the keys, decoding of the keypad, and timing between key entries, as well as others

depending on the Host. The 2 of 7 format is available on the ProxPro 5355XXKXX versions.

5.6 Key Pad Data Table 2 of 7

Key #

P2-1 P2-2 P2-3 P2-4 P2-5 P2-6 P2-7

1 LO HI HI HI HI HI LO

2 LO HI HI HI HI LO HI

3 LO HI HI HI LO HI HI

4 HI LO HI HI HI HI LO

Terminal Number

February 22, 2007 Page 9 of 14

© 2007 HID Global Corporation. All rights reserved.

Page 10

Part No. 5355-900, Rev N.1 ProxPro

®

Installation Guide

Key #

P2-1 P2-2 P2-3 P2-4 P2-5 P2-6 P2-7

5 HI LO HI HI HI LO HI

6 HI LO HI HI LO HI HI

7 HI HI LO HI HI HI LO

8 HI HI LO HI HI LO HI

9 HI HI LO HI LO HI HI

* HI HI HI LO HI HI LO

0 HI HI HI LO HI LO HI

# HI HI HI LO LO HI HI

Terminal Number

HI represents a voltage of +5 volts in reference to the ProxPro ground.

LO represents the ProxPro ground.

Note: The system is to be used on a single point ground system.

6 S Version – Direct connect keypad scanning

The ProxPro reader is available with a 3 x 4 matrix keypad. The keypad is independent of the ProxPro

reader and only provides the connections to the keypad. This mode requires a separate cable to be

supplied that connects to the Keypad board, inside the ProxPro, to the Host via P2. P2 is a 7 position

terminal strip. The following is the table for the contact closures.

This table indicates the connection between the connector pins when a key is pressed. For example, if

key 3 is pressed P2-5 is connected (shorted) to P2-1. This is available on the Serial ProxPro

5355XXSXX versions.

Rows

P2-5 P2-6 P2-7

P2-1 3 2 1

P2-2 6 5 4

P2-3 9 8 7

P2-4 # 0 *

Columns

Page 10 of 14 February 22, 2007

© 2007 HID Global Corporation. All rights reserved.

Page 11

ProxPro® Installation Guide Part No. 5355-900, Rev N.1

7 D Version – Buffered direct connect keypad scanning

The ProxPro reader is available with a 3 x 4 matrix keypad. The keypad is independent of the ProxPro

reader and only provides a voltage output from the keypad. This mode requires a separate cable to be

supplied that connects to the Keypad wiring to the host. This method of interfacing the keypad requires

additional processing by the host. This includes toggling the select low line to ground to enable the

keypad, debouncing of the keys, decoding of the keypad voltages, timing between key entries, as well

as others depending on the host.

This table indicates the voltage on the keypad wires when a key is pressed. This is available on the

Buffered Direct Connect ProxPro 5355XXDXX versions.

Table 1 Buffered Direct Connect KeyPad Data

Key #

Gray Violet

1 LO HI HI HI LO HI HI

2 LO HI HI HI HI LO HI

3 LO HI HI HI HI HI LO

4 HI LO HI HI LO HI HI

5 HI LO HI HI HI LO HI

6 HI LO HI HI HI HI LO

7 HI HI LO HI LO HI HI

8 HI HI LO HI HI LO HI

9 HI HI LO HI HI HI LO

* HI HI HI LO LO HI HI

0 HI HI HI LO HI LO HI

# HI HI HI LO HI HI LO

Red /

Yellow

Wire Colors

Pink Tan

White /

Blue

White /

Green

HI represents a voltage of +5 volts in reference to the ProxPro ground.

LO represents the ProxPro ground.

Notes:

1. The system is to be used on a single point ground system.

2. On the Buffered Direct Connect toggle Select Low (White/Yellow) wire to ground to enable the above

keypad outputs.

February 22, 2007 Page 11 of 14

© 2007 HID Global Corporation. All rights reserved.

Page 12

Part No. 5355-900, Rev N.1 ProxPro

8 Specifications

8.1 Read Distance – using PROXCARD II®

¾ Over all Operating Limits, minimum (@12VDC)) 5.0 inches (12.7 cm)

¾ Non-Metallic Mounting, typical (@12VDC) 8.0 inches (20.3 cm)

¾ Mounted on Metal, typical (@12VDC) 5.5 inches (14 cm)

¾ Overall Operating Limits, minimum (@24VDC) 5.5 inches (14 cm)

¾ Non-Metallic Mounting, typical (@24VDC) 9.0 inches (23 cm)

¾ Mounted on Metal, typical (@24VDC) 6.0 inches (15.2 cm)

8.2 Environmental Characteristics

®

Installation Guide

¾ Designed for listing under UL 294 “Standard for Access Control System Units”

¾ Operating Temperature Range -30

¾ Storage Temperature Range -40

¾ Operating Humidity Range 5% to 95% non-condensing

¾ Operating Vibration Limit .04 g

¾ Operating Shock Limit 30g, 11mS, Half Sine

¾ Enclosure Material UL Recognized Lexan® Polycarbonate

¾ Weight 11.3oz (310gms)

8.3 Power Requirements

¾ Power supply Linear type recommended

¾ Operating Voltage Range (+DC) 10VDC -28.5VDC

¾ Maximum Average Current 12V/24V 90mA/155mA

¾ Transient Protection (all terminals) UL 294

¾ Reverse Voltage Protection YES

¾ Input Voltage (maximum data-0/1 lines) 28.5VDC

¾ Input Voltage (maximum interface lines) 28.5VDC

8.4 Option D – Buffered Direct Connect Keypad

¾ Operating Voltage Range (+DC) 10VDC -26VDC

¾ Input Voltage (Maximum Data – 0/1 Lines) 14VDC

¾ Input Voltage (Maximum Interface Lines) 14VDC

o

C to 65oC (-22oF to 150oF)

o

C to 85oC (-40oF to 185oF)

2

/Hz 20-2000Hz

8.5 Operating Parameters

¾ Excitation Frequency 125KHz

¾ Duty Cycle (alternate power level rate) 20% @ 60mS period

¾ Read and Report Speed (26 bit Wiegand Card) 175mS

¾ Maximum Cable Distance to Host 500 feet (152 meters)

¾ LED Type Bi-colored Red/Green

¾ LED Operation (host control of red/green)

¾ Beeper Operation (host control)

¾ LED Control (default) internal/single

¾ Beeper Control (default) Beeper enabled

¾ Anti-Pass Back Delay (default) 1 second

¾ Wiegand Data Pulse Widths (default) 40uS

¾ Wiegand Data Interval (default) 2mS

Page 12 of 14 February 22, 2007

© 2007 HID Global Corporation. All rights reserved.

<

.5V on LED control line

<

.5V on beeper line

Page 13

ProxPro® Installation Guide Part No. 5355-900, Rev N.1

¾ Clock/Data bit time 1.5ms (default)

¾ Clock/Data strobe width bit time/3 (33% of bit time), default = 500us

¾ Clock/Data clock/strobe is valid 1.5ms (one clock cycle, min) after card

present is

Asserted data is valid 10us (min) before the

negative edge of clock/strobe card present

returns to the high level 50 ms (max) after

the last clock/strobe.

9 Product Configuration/Ordering Options

5355 A G N 00 -XXXX Y

Customer Custom Artwork or Firmware Number

1 through 9, A through Z

Customer Custom Number

Configuration Options - (00 standard)

Standard Hardware Options - N = None, K = Standard Keypad

(internal or 2 of 7), S = Direct Connect Keypad (3 x 4 type), D =

Buffered Direct Connect Keypad (3 x 4 type)

Color - G = Gray, B = Beige

Model Number Suffix

Model Number 5355 = ProxPro Wiegand

Model Number 5358 = ProxPro Clock/Data

Final Assembly Number = 5355-300-XX Changes with Revisions

• FCC Compliance Statement: This device complies with part 15 of the FCC rules. Operation is

subject to the following two conditions: 1) This device may not cause harmful interference. 2) This

device must accept any interference received, including interference that may cause undesired

operation.

• For proper regulatory compliance, the drain wire should be disconnected at the power supply end

of the cable.

• The Reader is intended to be powered from a limited source output of a previously certified power

supply.

• Changes of modifications not expressly approved by the responsible for compliance could void the

user’s authority to operate the equipment.

Note: The above are recommended installation procedures. All Local, State and National Electrical

Codes take precedence.

February 22, 2007 Page 13 of 14

© 2007 HID Global Corporation. All rights reserved.

Page 14

HID Global (California, USA)

support: tech@hidcorp.com

main: (949) 598-1600

support: 1-800-237-7769

fax number: (949) 598-1690

HID Corporation, Ltd. (Haverhill, UK)

support: eusupport@hidcorp.com

main: +44 (0) 1440 714 850

support: +44 (0) 1440 711 822

fax number: +44 (0) 1440 714 840

HID Asia Pacific Ltd. (Hong Kong)

support: asiasupport@hidcorp.com

main: (852) 3160 9800

support: (852) 3160 9802

fax number: (852) 3160 4809

www.hidcorp.com

An ASSA ABLOY Group company

Loading...

Loading...