Page 1

15370 Barranca Parkway

Irvine, CA 92618

iCLASS OEM75

INTEGRATION GUIDE

3141-907, Rev. B.0

January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or

proprietary information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose,

without the written consent of HID Global Corporation. If you are an unintended recipient of this information or are

unwilling to accept the above restrictions, please immediately return this document to HID Global Corporation, 15370

Barranca Pkwy, Irvine, CA 92618-3106.

Page 2

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

Contents

1 Overview ................................................................................................................................... 5

1.1 Introduction ........................................................................................................................................ 5

1.2 References ........................................................................................................................................ 5

1.3 Ordering ............................................................................................................................................. 5

2 Getting Started ......................................................................................................................... 6

2.1 Theory of Operation ........................................................................................................................... 6

2.2 Peripheral Circuits ............................................................................................................................. 7

2.2.1 External Noise Filter ...............................................................................................................................7

2.2.2 Adding External LEDs or Beeper ............................................................................................................7

2.2.3 Adding External Resistors ......................................................................................................................7

2.3 Transitioning from HID’s OEM50 or eProx Lock modules .................................................................. 7

2.3.1 OEM50 ...................................................................................................................................................8

2.3.2 eProx Lock Module .................................................................................................................................8

3 Software Integration Recommendations ............................................................................... 9

4 Mechanical Specifications .................................................................................................... 11

4.1 OEM75 Module – 3141Axx .............................................................................................................. 12

4.2 OEM75 Module – 3141ADx ............................................................................................................. 13

4.3 Antennas ......................................................................................................................................... 14

4.3.1 Antenna Model 3142 ............................................................................................................................ 15

4.3.2 Antenna Model 3144 ............................................................................................................................ 15

4.3.3 Antenna Model 3146 ............................................................................................................................ 16

4.3.4 Antenna Model 3148 ............................................................................................................................ 16

4.3.5 Antenna Model 3153 ............................................................................................................................ 17

4.4 Antenna Interfacing.......................................................................................................................... 17

5 Electrical Specifications ........................................................................................................ 18

5.1 Power Supply .................................................................................................................................. 18

5.2 Electrical Connections ..................................................................................................................... 18

5.3 I/O Specifications ............................................................................................................................. 20

5.4 P1 connector Ping Mode Static States ............................................................................................ 22

5.5 Electrical Application Hints .............................................................................................................. 22

6 Firmware ................................................................................................................................. 23

6.1 Applications ..................................................................................................................................... 23

6.2 Feature Bundles and Configuration ................................................................................................. 23

6.3 Updates ........................................................................................................................................... 23

6.4 Communication ................................................................................................................................ 23

6.5 SPI Implementation ......................................................................................................................... 23

6.6 General Recommendations ............................................................................................................. 24

6.7 SPI Message Transmission ............................................................................................................. 27

6.7.1 Host SPI Master Write Function ........................................................................................................... 27

6.7.2 Host SPI Master Read Function ........................................................................................................... 27

6.7.3 Peripheral Processor SPI Slave Interrupt Processing ........................................................................... 27

6.7.4 Sample Source Code ........................................................................................................................... 28

6.8 I²C Implementation .......................................................................................................................... 32

6.8.1 General Recommendations .................................................................................................................. 32

6.8.2 I²C Baud Rates and Clock Stretching ................................................................................................... 32

6.8.3 I²C Message Transmission ................................................................................................................... 32

Page 2 of 49 January 2014

6.8.4 Sample Source Code - I²C ................................................................................................................... 34

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 3

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

6.8.5 Wiegand ............................................................................................................................................... 43

6.8.6 Serial .................................................................................................................................................... 43

6.8.7 Timing .................................................................................................................................................. 44

7 OEM75 Module Configuration ............................................................................................... 45

7.1 Configuration Options ...................................................................................................................... 45

7.2 Configuration Card Availability ......................................................................................................... 45

7.3 Custom Configurations for High Volume Manufacturing Availability ................................................ 45

7.4 Reconfiguring the OEM75 in Normal Power Mode .......................................................................... 45

7.5 Reconfiguring the OEM75 in Ultra Low Power Mode....................................................................... 45

7.6 Regulatory ....................................................................................................................................... 47

8 Additional Tools ..................................................................................................................... 48

January 2014 Page 3 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 4

03/2011

First Release

A.0

Fax: 949 732 2120

Phoenix Road

Fax: 852 3160 4809

Copyright

© 2010-2014 HID Global Corporation/ASSA ABLOY AB. All rights reserved.

Trademarks

HID GLOBAL, HID, the HID logo, iCLASS, OEM 75, and eProx are the trademarks or registered

trademarks of HID Global Corporation, or its licensors, in the U.S. and other countries.

MIFARE is a registered trademarks of NXP B.V. and are used under license.

Disclaimer

This guide presents suggestions for proper usage and integration. Good Mechanical and

Electrical Engineering practices are required to insure a quality final product.

Revision History

Date Description Version

01/14/2014 Update Module Dimensions B.0

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

Contacts

North America

15370 Barranca Parkway

Irvine, CA 92618

USA

Phone: 800 237 7769

Europe, Middle East and Africa

Haverhill, Suffolk CB9 7AE

England

Phone: +44 1440 714 850

Fax: +44 1440 714 840

Asia Pacific

19/F 625 King’s Road

North Point, Island East

Hong Kong

Phone: 852 3160 9800

support.hidglobal.com

Page 4 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 5

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

HID

3141-901

OEM75 User Manual

1 Overview

1.1 Introduction

The OEM75® is designed to offer iCLASS® and MIFARE® technology to a wide variety of service

providers using applications such as vending machines, biometric readers, card printers, time and

attendance terminals, and alarm panels and more. The OEM75 is a third generation iCLASS

module, offers ultra-low power consumption (configuration dependent), on-board voltage regulation,

versatile ISO polling configuration, and various data outputs to enable a variety of hardware

communication protocols. The UART, SPI, I2C and Wiegand communications allow for an OEM to

have the power of iCLASS at their fingertips.

The OEM75 is designed to be a component in an upper level assembly and can operate with one of

several antenna sizes. This Integration Guide provides recommendations which improve the

integrator’s experience. This guide addresses Electrical, Mechanical, Software Interface and

Antenna integration issues.

1.2 References

Source Part Number Description

HID 1356_MHz HTOG How to Order Guide (HTOG)

http://www.hidcorp.com > documents > 13.56 MHz How to

Order Guide

Security Industry

Association

HID 3141-905 OEM75 Interface Protocol

SIA AC-01 (1996.10) Wiegand Card Reader Interface Standard

1.3 Ordering

See the iCLASS OEM75 User Manual for ordering considerations. This document assumes that

OEM75 hardware and the Development Kit are in the user’s possession.

January 2014 Page 5 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 6

Ultra Low Power

OEM75 Module

OEM75

Antenna

iCLASS

Card

/RESET

/HOLD

/GREEN_LED_

CARD_PRESENT

Host Hardware/Application

Wiegand Data 0

Wiegand Data 1

/BEEPER

/RED_LED

UART RX

UART TX

I

2

C SCLK / SPI_ CLK

SPI_CS

SPI_MISO

I

2

C CSDA / SPI_MOSI

4

4

5

2 Getting Started

2.1 Theory of Operation

Configurable operation modes include:

• Autonomous – In this mode, the module polls for a card constantly and will not accept

serial commands unless a card is in the field. Autonomous is the default operation of the

OEM75.

• API – The module acts the same as in Autonomous operation except the module is always

ready to receive a command from the host. When an RF or Serial command is received,

the module will wait a configurable amount of time before it returns to polling for a card.

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

Page 6 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Figure 2-1: OEM75 Operation

Power Modes Include:

• Ultra Low Power – The module is in Ultra Low Power mode as it polls for a card. When a

card is detected in the RF field, the module wakes up, reads the card data, changes the

Card Present line, outputs the card data, and goes back to sleep within a configured period

of time to conserve power. Use this mode with battery power.

• Standard – The module is constantly powered on and polling for cards. The module is

never asleep in this mode. Use this mode with an external power supply.

Power Autonomous Mode Remote Mode Autonomous Remote Mode

Standard Power

Page 7

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

2.2 Peripheral Circuits

The following section details recommended peripheral circuitry.

2.2.1 External Noise Filter

If false card detections occur in Ultra Low Power Mode, or the host has spectral noise, a line filter

designed to block frequencies in the 10 KHz to 50 KHz range is beneficial when inlined with the

power line.

2.2.2 Adding External LEDs or Beeper

Connect external LEDs to the OEM75 by connecting wires to the P2 connector The LEDs are

connected to an external +3.3VDC supply with an external series current limit resistor.

See Table 5-5: P2 I/O Electrical Specifications.

The Cathodes are connected through an external resistor to the RED or GREEN LED connector

port signals. The OEM supplies current limiting resistors for modules.

The value of these resistors will depend on how much current is provided for the LEDs. The

combined voltage drop of the resistor and output low voltage of the OEM75 on these signal lines

should be factored in when selecting the LED brightness.

2.2.3 Adding External Resistors

For I2C Mode operation, external 10k pull-up resistors are required on the SCLK signals.

Note: There is already an internal pull-up resistor on the I2C SDA signal.

2.3 Transitioning from HID’s OEM50 or eProx Lock modules

Provided are suggestions for transitioning from the HID OEM50 and HID eProx Lock modules to the

OEM75.

January 2014 Page 7 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 8

P2 Connector

Pin 1

Exc Supply

No signal on the OEM75

Pin 3

Serial Transmit

Same as OEM75 P1 pin 8 - UART Transmit

Pin 4

Serial Receive

Same as OEM75 P1 pin 7 - UART Receive

and 5VDC is a good supply voltage

P1 Connector

Pin 1

Open Output

OEM75 does not have a similar signal

Pin 2

Ground

Same as OEM75 P1 pin 2, signal Ground

OEM50 is inverted logic

2.3.1 OEM50

If transitioning from an OEM50 – here are the differences.

The OEM50 connector is a 2 X 6 0.1" space pin header or PWB hole pattern.

The OEM50 has a two-wire interface to the antenna and the OEM75 has a four-wire interface.

Therefore, the OEM50 antenna will not work with the OEM75, and vice versa.

The harness and signal changes to adapt the signals from the OEM50 2 X 6 pattern to an

OEM75 1 x 9 1.25mm pattern are the following.

Note: The additional P2 for HSI and SPI interfaces are 1 x 8 1.25mm pattern.

OEM50 OEM75

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

Pin 2

Exc Return is not

used

Pin 5 Vdd Return Same as OEM75 P2 pin 2 - Battery Minus

Pin 6 Vdd +5VDC

Pin 3 Wiegand Data1

Pin 4 Wiegand Data0

2.3.2 eProx Lock Module

The eProx® Lock connector is mechanically the same as the OEM75’s connector P2. Be aware

however, that the connections between the OEM75 module and the eProx Lock module are

reversed. This implies that a straight-thru cable will not work. A 180 degree twist of the cable is

required to insure that Pin 1 on one of the modules correctly mates with Pin 1 on the other module.

No signal on the OEM75

Same as OEM75 P2 pin 1 - Battery Positive

Wiegand data output is per the SIA AC-01 (1996.10)

specification, except Voh is 3.3VDC max, and not 4.0

to 5.5 VDC

Wiegand data output is per the SIA AC-01 (1996.10)

specification, except Voh is 3.3VDC max, and not 4.0

to 5.5 VDC

OEM50 is inverted logic

The two-wire 125 kHz antenna for the eProx Lock is not interchangeable with an OEM75 antenna.

Page 8 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 9

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

3 Software Integration Recommendations

The following section details recommended software operational interfacing. The reader of this

guide should use this information in conjunction with the OEM75 Interface Protocol Manual.

Previously it has been shown how the OEM75 reader module interacts with the processor in the

OEM75 Development Kit.

This discourse applies to a Host based application communicating/controlling/querying the OEM75

based reader firmware. The explanation of the operation is independent of type of hardware used to

communicate with the OEM75. This information applies whether a UART, SPI or I2C serial

connection is used. A user application must first update the data structure Application Protocol Data

Unit APDB

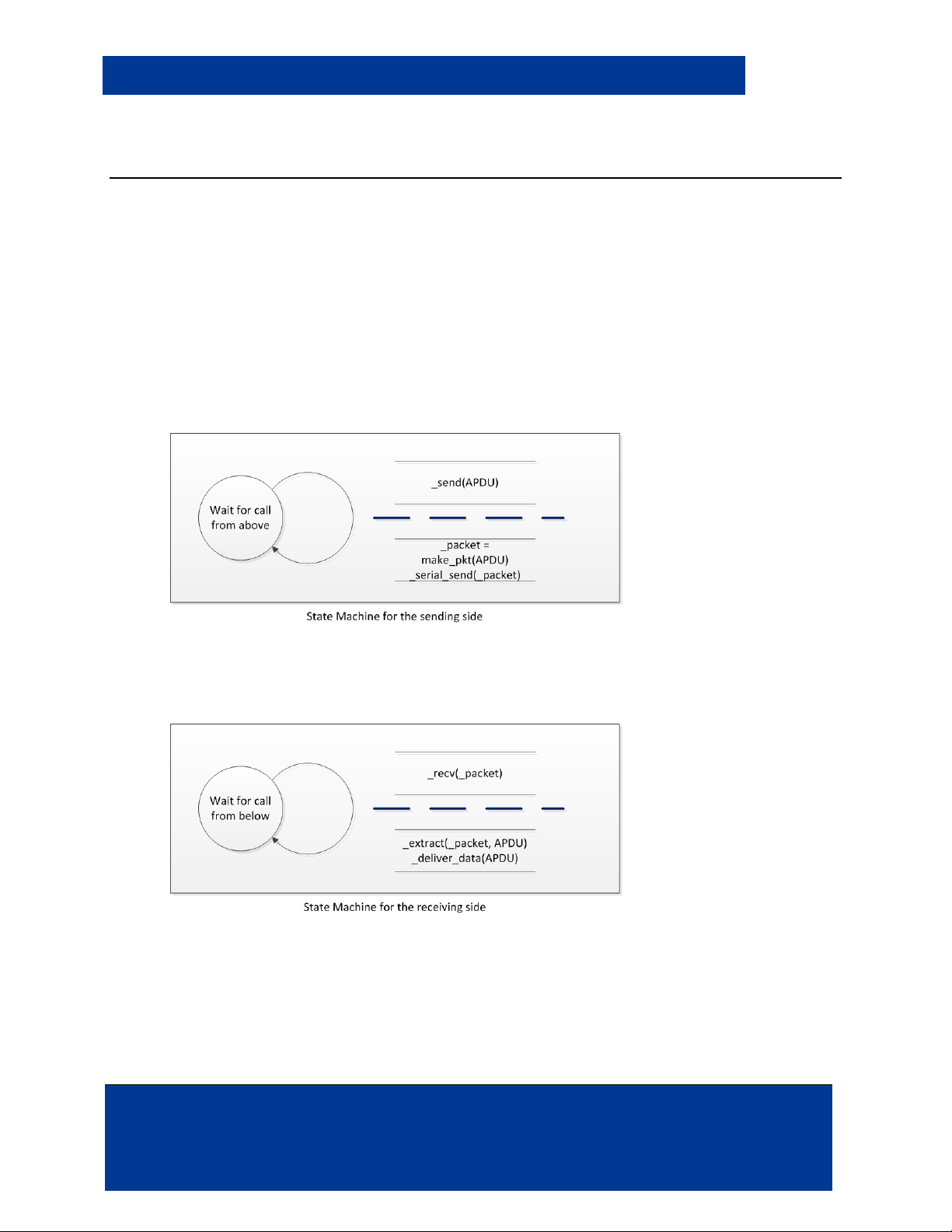

Consider initially the transmission of a command to the OEM75 from a host. The state machine

representation indicates the state of the task, the event that transitions the task is indicated above

the dotted line and the action taken is indicated below the dotted line in the figure below.

When the host application has properly initialized an APDU, it raises the event _send(APDU). This

event triggers a call to make_pkt(APDU) which encapsulates the control block into a serial packet

and then calls _serial_send(_packet) which places the _packet on the serial output lines. The state

machine then reverts back to a “Wait for call from above” state.

When the OEM75 recognizes the receipt of a packet by means of the event _recv(_packet), it

makes a call to _extract(_packet, APDU) in order to extract the APDU from the packet and then call

_deliver_data(APDU) which passes the APDU up to the higher layers for evaluation. The state

machine returns to a state of “Wait for call from below”.

The above state machines represent the transmission of a command from the host to the reader at

its most simplistic level. The operations also assume a perfect world in which no transmission line

bit corruption occurs. In actuality the state machines must be a bit more complicated than initially

January 2014 Page 9 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 10

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

presented in order to recover from potential errors. It must be kept in mind that a similar set of state

machines apply to the communication from the OEM75 to the host computer. The protocol

operating in the OEM75 expects the delay between the stop bit of the preceding byte and the start

bit of the next byte to be less than 500 milliseconds. This implies that a complete APDU is

transmitted.

Let us now take into account the potential of sending the packet over an extended distance. Let us

assume a maximum packet size of 263 bytes. For the most basic UART transmission at 57.6 Kbps

with 2 stop bits and even parity. The recommended length of cable for proper operation is no longer

than 50 feet and smaller lengths are specified for higher speed connections. The speed of an

electrical signal is approximately 3 nsecs. per foot. A signal change on one end of the cable will be

recognized approximately 3 nsecs/ft. *50 ft = 150 nsecs later on the other end of the cable. The bit

time, that is the time to generate a bit is 1.0 / 57.6 Kbps = 17.36 microseconds per bit. Since this

time is much greater than the transmission time of any change we can effectively ignore the transit

time or the time it takes an electron to move from the source side to the destination side. The time it

takes to transmit an entire byte including the start, stop and parity bits is then just 12 * 17.36

microseconds = 208 microseconds per byte. The time it takes to transmit a maximum length APDU

is 208 * 263 = 54.79 milliseconds. The time to transmit back a 2 byte status is 416 microseconds, or

0.000416 milliseconds. If we assume no processing delays in the OEM75 the time from

transmission to complete reception of an acknowledgement is then 55.206 milliseconds. The above

analysis indicates that any timeout value used must be at least this large independent of the time it

takes to process a command. The time it takes to execute each of the commands is command

dependent.

This protocol cannot recover from multiple bit errors. A single bit error per byte can be detected, in

which case either the host or the reader should ignore the entire message. A timeout should occur

and the communication can be re-initiated. It is possible for an APDU to be corrupted when

transmitting it to the OEM75 if the unit is connected to the host by means of a very long cable and

that cable is routed near sources of electromagnetic interference. It is possible with the above

conditions that bit corruption modifies the command field of an APDU resulting in an invalid

execution. It is not recommended that the OEM75 be operated in this manner. In the scenarios

depicted in section 2 of this document, the serial cable had a length of 6 feet.

Ultra-Low power applications must create a host interface which recognizes the CP (Card Present)

signal generated by the constantly energized processor receiving antenna signals. This signal has a

dual purpose, it is used not only to indicate a Card Present Event to the Host Processor but it also

wakes up the OEM75 main processor. The host interface must keep in mind that the OEM75 main

processor requires some time to power up and initialize before it can respond to either card or host

requests. It is recommended that the CP signal be used as an interrupt signal to the Host

processor. The Host processor should respond to this interrupt by setting a flag indicating that the

CP event has been recognized and then return to the main processing task which should use the

flag as an indication that Card Data needs to be read from the OEM75. The Host Application should

delay a set period of time allowing the OEM75 main processor time to wake-up and initialize itself.

After this time period the Host can request the card information.

Page 10 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 11

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

4 Mechanical Specifications

The following section details all mechanical specifications for the OEM75 module, antennas and

interfaces.

The connectors recommended are:

• P1 – An 8-position pin socket header.

Molex Part Number: 53048-0810

Tyco Part Number: 1734829-8

• P2 – A 9-position pin socket header

Molex Part Number: 53048-0910

Tyco Part Number: 1734829-9

• P3 – A 4 Pin right-angle zero-insertion-force connector.

Molex Part Number: 39-53-2044

Note: On OEM 75 part number 3141AD models the form-factor of the circuit board is so small as to

prohibit the use of Molex Part Number: 39-53-2044 on the board. You should investigate other

methods of connecting to an antenna.

The following are the recommend cables that should be used with the OEM 75 modules.

The cable connecting P3 to the antenna connection is called JUDD wire. It is manufactured by both

Judd Corporation and Sumitomo Corporation. This cable is somewhat brittle and the repeated

bending of the cable should be avoided to minimize breakage. User implementations should strive

to limit the length of this interconnection cable.

P1 is an 8-pin connector socket which accepts an 8-pin connector plug MOLEX Part Number:

51021-0800. The wire used is an AWG #28, 8 conductor flat cable

P2 is a 9-pin connector socket which accepts a 9-pin connector plug MOLEX Part Number:

51021-0900. The wire used is an AWG #28, 9 conductor flat cable

Antenna and module form factor specifications are discussed within this section.

January 2014 Page 11 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 12

Angular

±1º Bend

±1º

.XX

±.01 [.3]

Note: In the following mechanical drawings, unless otherwise specified the dimensions are in

inches and [millimeters]. Tolerances are as follows:

Tolerances Definition

.XXX ±.005 [.13]

4.1 OEM75 Module – 3141Axx

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

Figure 4-1: OEM75 – 3141Axx

Note: The 20mil P1, P2 and P3 holes can accept 26 AWG (0.41 mm, 0.13 mm

mm, 0.08 mm

Page 12 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

2

) wires.

2

) or 28 AWG (0.33

Page 13

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

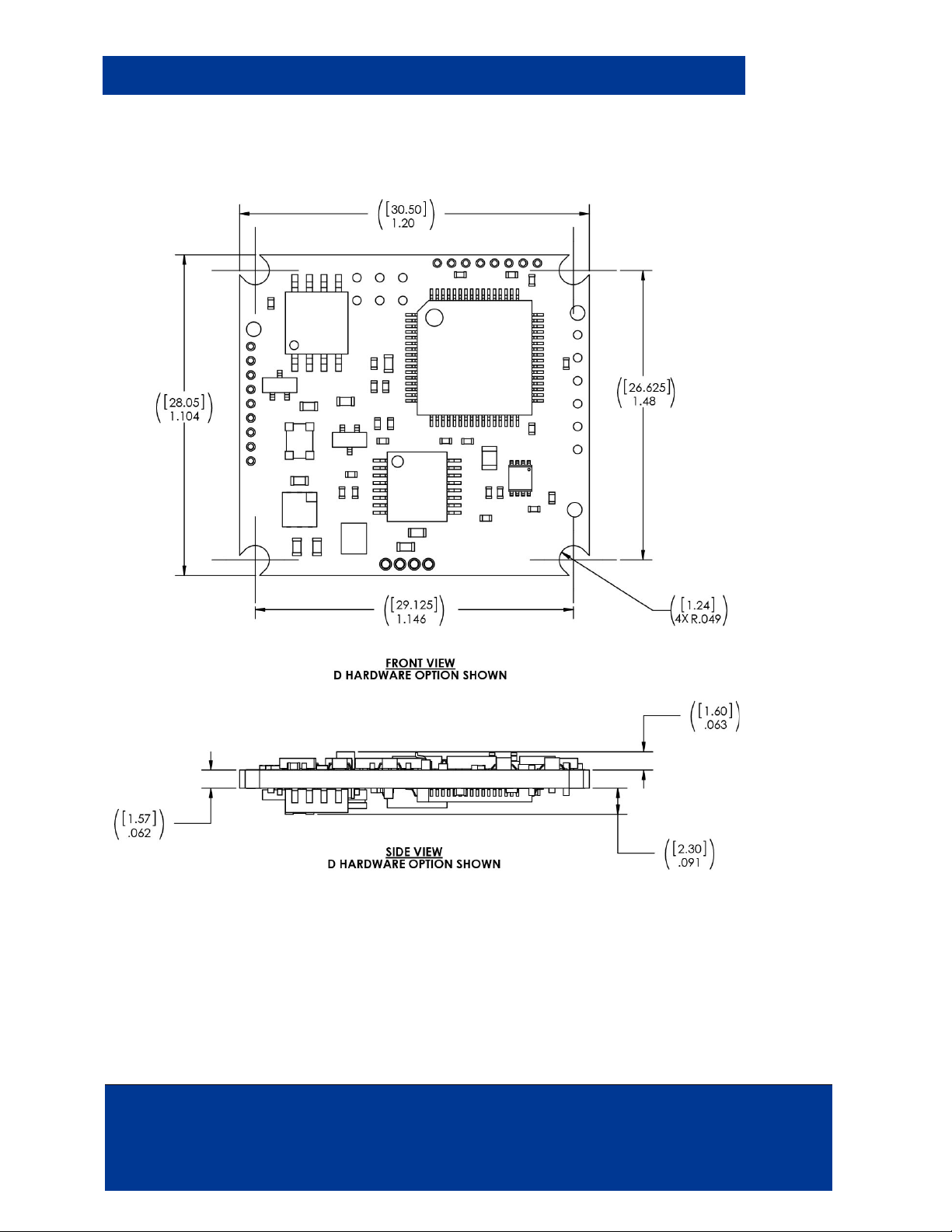

4.2 OEM75 Module – 3141ADx

Figure 4-2: OEM75 – 3141ADx

The OEM75 – 3141ADx was designed to be the smallest form factor possible. This module offering

was designed to be header mounted on a host board utilizing the P1 and P2 connectors.

Note: The 20mil P1 and P2 holes can accept 26 AWG (0.41 mm, 0.13 mm

0.08 mm

2

) wires.

2

) or 28 AWG (0.33 mm,

January 2014 Page 13 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 14

3.0 in

[78 mm]

2.3 in

[60 mm]

Read Range

1.5 in

[40 mm]

4.0 in

[101 mm]

6.0 in

[160 mm]

Cable Length

S

t

a

n

d

a

r

d

P

o

w

e

r

Ultra Low

Power Mode

2.7 in

[70 mm]

4.3 Antennas

Basic Antenna Operation

Credentials obtain their power from the magnetic field generated by the antenna of the reader. At

the operating frequency of the reader this interaction is similar to the operation of an air core

transformer. When an antenna is energized by an alternating current the induced magnetic field is

directly proportional to the area enclosed by the antenna loop. The larger the loop, the more

excitation current is required to produce the same level of magnetic flux. That flux covers a larger

area and so the read range is extended. Other external factors can affect the magnitude of this

induced magnetic field. Magnetic lines of flux when generated by a loop antenna are oriented

perpendicular to the plane of the loop. This is known as the right-hand rule, the magnetic field wraps

around the wire in the direction of current flow.

The antennas for the OEM75 are available in two different configurations.

• Non-tuned

Non-tuned antennas do not have tuning components loaded. OEM customers must stuff

parallel and series capacitance in order to custom-tune non-tuned antennas to their specific

environment. There are many factors involved with antenna tuning regarding proximity to

metal and electronics. HID Global can provide assistance with tuning antennas for custom

OEM environments. Contact your local HID Connect Technical Support for details.

• Air-tuned

Air-tuned antennas do have tuning components loaded. The antenna is pre-tuned for open

air conditions (for example, not near metal). When an air-tuned antenna is placed near

metal, its tuning is affected causing it to perform with a slightly smaller read range. More

importantly, communication errors become more frequent when large data transfers are

involved. All air-tuned antennas are pre-tuned for a 4.0 in (101 mm) cable length. For cable

lengths of differing sizes, reference the following graph for read range impacts.

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

Figure 4-3: Power Modes and Air-tuned Antenna (3142)

Match the signal and ground connections from the antenna to the OEM75 module with a ribbon

cable (1.25mm spacing).

Due to power requirements, applications requiring PIV smart card support require a larger antenna.

The environment where the antenna is placed and tuning also affect the performance. Consult

Connect Technical Support for assistance in choosing an antenna for your environment.

Page 14 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 15

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

It should be recognized that mounting the loop antenna in close proximity to a metallic ground plane

reduces the effective range of the card reader. If such a mounting is required it is recommended

that the metallic ground plane have slots cut in it to reduce the generation of eddy loop currents.

• The following diagrams provide examples of Air-tuned Antenna’s.

4.3.1 Antenna Model 3142

Figure 4-4: 3142 A16 Antenna

4.3.2 Antenna Model 3144

Figure 4-5: 3144 A9 Antenna

January 2014 Page 15 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 16

4.3.3 Antenna Model 3146

Figure 4-6: 3146 A12 Antenna

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

4.3.4 Antenna Model 3148

Figure 4-7: 3148 A17 Antenna

Page 16 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 17

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

P1 Connector

Additional COM methods for SPI, UART or I2C functions

P2 Connector

Standard reader interfaces

P3 Connector

Four through holes labeled antenna drive, feedback, ground 1, and ground 2.

4.3.5 Antenna Model 3153

Figure 4-8: 3153 A15 Antenna

4.4 Antenna Interfacing

The following table summarizes mounting for these antennas and the associated connectors.

Use this table in conjunction with the OEM75 mechanical specifications in order to determine the

physical location of pins.

January 2014 Page 17 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 18

Nominal

current

5 Electrical Specifications

5.1 Power Supply

The following table specifies necessary power supply specifications.

Table 5-1: I/O Electrical Specifications

Pin Name Parameters Notes

Voltage Current

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

40mA +/- 3mA

Reader mode (no card)

Battery Positive

to

Ground

4.0 VDC

to

10.0 VDC

Note: If implementing the OEM75 in a UL listed product, UL requires voltage range tolerances

of -15% to +10%.

5.2 Electrical Connections

The OEM75 is designed for a host with 3.3 VDC or 5.0 VDC I/O interfacing. All input signals to the

OEM75 are 5 VDC tolerant. All output signals are open collector; except the Wiegand lines have a

1K pull up to a diode isolated +3.3 VDC.

For the P1 connector signals, the input interface logic levels are the following specifications for

output logic levels.

< 0.5 VDC for Vil

> 2.0 VDC for Vih

< 0.4 VDC for Vol

> 2.4 VDC for Voh

External LED’s can be added to the board by connecting the LED pins located next to the beeper

on the upper left portion of the board (see Figure 4-1 – OEM75 – 3141Axx). The LEDs can be

controlled with serial commands or using the LED control lines listed in the following table.

80mA +/- 5mA

Peak

12uA +/-3uA Ultra-Low Power Mode (no

Card reading current

card) current

CAUTION: Install a 1K Ohm serial resistor on the SPI lines in SPI communication mode to

eliminate negative voltage spikes.

Page 18 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 19

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

P1 3 SPI Clock / (I2C SCLK)

Clock signal for either SPI or I2C

P1 7 UART Receive

Serial Input Line

P2 1 Supply Voltage

Positive (V+)

Input

Power Supply Positive Voltage

Negative (V-)

antenna.

P2 6 Wiegand Data 0

Output

Internal 1K to +3.3VDC & Collector

P2 7 Wiegand Data 1

Output

Internal 1K to +3.3VDC & Collector

P2 8 /Beeper

Output

Active Low signal which enables off

board signaling

enable an off board Red LED

P3 3 Ground 1

P3 4 Ground 2

Table 5-2: P1 Connector I/O Functionality

Connection Pin #` Signal Name Function

P1 1 +3.3 VDC 0.1W max Power sourced output

P1 2 Ground Logic level reference

P1 4 /SPI Chip Select Active Low signal to select the SPI

chip

P1 5 SPI Data In (I2C_SDA) SPI Data Line valid when clock signal

transitions.

P1 6 SPI Data Out SPI Data Line valid when clock signal

transitions

P1 8 UART Transmit Serial Output Line

Table 5-3: P2 Connector I/O Functionality

Connection Pin #` Signal Name I/O Function

P2 2 Supply Voltage

Input Power Supply Ground

P2 3 /Reset Input Active Low signal which resets the OEM

75.

P2 4 /Hold Input Active Low signal which holds off

presentation of card data. When

asserted, this line either buffers a card or

disables a card read until released, as

configured.

P2 5 /Green LED and

Card Present

Output The signal on this pin, reflects the

recognition of a card in the vicinity of the

P2 9 /Red LED Output Active Low signal which can be used to

Table 5-4: P3 Connector I/O Functionality

Connection Pin #` Pin Name

P3 1 Antenna

P3 2 Antenna Feedback

January 2014 Page 19 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 20

of -15% to +10%.

3.3VDC rail.

Input.

/Hold

0V to 3.3V (+/–

-0mA

Internal limit of 10K series to DTL

/Green LED and

0V to 3.3V (+/–

+0mA

To an Open Collector NPN

5.3 I/O Specifications

Table 5-5: P2 I/O Electrical Specifications

Pin Name Parameters Notes

Voltage Current

Supply Voltage

Positive (V+)

Supply Voltage

Negative (V-)

+4.0 VDC to

10.0 VDC

0VDC or Ground

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

+40mA nominal

+80mA max

40mA is Polling, 80mA is Reading.

The power supply current draw is

normalized from 4.0 to

10 VDC in. The Battery+ has

reverse voltage protection.

Note: If implementing the OEM75 in

a UL listed product, UL requires

voltage range tolerances

Wiegand Data0 0V to 3.3V (+/–

0.3V)

Wiegand Data1 0V to 3.3V (+/–

0.3V)

/Reset 0V to 3.3V (+/–

0.3V)

0.3V)

Card Present

0.3V)

/Beeper 0V to 3.3V (+/–

0.3V)

/Red LED 0V to 3.3V (+/–

0.3V)

+3mADCmax

-25mADC max

+3mADCmax

-25mADC max

+0.33mADC

-5mADC max

+0.33mA nominal

-25mADC max

+0mA

-50mADC max

+0mA

-25mADC max

The module has 3.3VDC regulation.

The Interface circuit is a NPN

transistor with a 1K Collector to a

There is no protection against

reverse voltage or exceeding the

limits specified on Data 0/1.

The minimum VDD rise time for the

processor is 0.050V/mS. There is an

internal 10K Pull up to a continuous

3.3VDC rail. For this reason the

/RESET is best left unconnected, if

not needed. The OEM may control

this by an open drain or collector

signal to control a reset or power-on

reset. Avoid leakage currents on this

signal. Low Active, TTL 0-3.3VDC

circuit, an internal diode blocks the

in

max limit specified. Low Active

10V

DTL 0-5 VDC input.

transistor; this signal does not

source current, nor voltage. Low

Active Open Collector.

To an Open Collector NPN

transistor; this signal does not

source current, nor voltage. Low

Active Open Collector.

To an Open Collector NPN

transistor; this signal does not

source current, nor voltage. Low

Active Open Collector.

Page 20 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 21

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

SPI / I2C Clock

0V to 5.0V

+/-5mADC

* This pin connects directly to Port D6 of the

/SPI_CS

0V to 5.0V

+/-5mADC

* This pin connects directly to Port D0 and

SPI Data In

0V to 5.0V

+/-5mADC

* This pin connects directly to Port D5 of the

UART RX

0V to 5.0V

(+/– 0.3V)

+/-5mADC

* This pin connects directly to Port C7 of the

main microcontroller. TTL 0-5.0VDC Output

Table 5-6: P1 I/O Electrical Specifications

Pin Name Parameters Notes

Voltage Current

+3.3 VDC 3.3V +/- 5%

sourced

Ground 0.0VDC N/A Return for +3.3VDC

+20mADC This pin taps off an internal 3.3 VDC linear

regulator. The internal regulator has current

and thermal overload protection.

(+/– 0.3V)

(+/– 0.3V)

I2C SDA

(+/– 0.3V)

/SPI Data Out 0V to 3.3V

(+/– 0.3V)

UART TX 0V to 3.3V

(+/– 0.3V)

main microcontroller. For I2C operation an

external 10k Pull-up resistor is required. TTL

0-5.0 VDC Input (O.C.Output).

D7 of the main microcontroller TTL 0-5.0

VDC Input (O.C.Output).

main microcontroller. For I2C operation

OEM75 already contains an internal pull-up

resistor. TTL 0-5.0 VDC Input (O.C.Output).

+/-5mADC * This pin connects directly to Port D4 of the

main microcontroller. TTL 0-3.3VDC Output

+/-5mADC * This pin connects directly to Port C6 of the

main microcontroller. TTL 0-3.3VDC Output

January 2014 Page 21 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 22

switched off 3.3V

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

5.4 P1 connector Ping Mode Static States

For Ultra Low Power mode to operate optimally at the lowest power, the following levels are

recommended for the Host Circuitry static signal states.

Pin Name Signal Levels in Ultra Low

Power

OEM75

Host Circuit

Circuit

+3.3 VDC 0.0 VDC 0.0 VDC The +3.3 VDC read is shut off in this mode

Ground 0.0 VDC Ground or

0.0VDC

SPI Clock Input Output - low

/SPI_CS Input Output - low OEM75 has 10K Pull-Up resistor to

/SPI Data In Input Output - low OEM75 has 10K Pull-Up resistor to

/SPI Data Out Output – low /

Input Host must have State set low for meta-

float

UART RX Input Output - low OEM75 has 10K Pull-Down resistor

UART TX Output – low /

Input Host has State set low for meta-stability

float

5.5 Electrical Application Hints

The following provides hints for antenna applications.

• The pins are pre-soldered into the antenna holes and strain relieved by an adhesive.

• The ribbon should not be folded with a hard crease (radius defined at < 3mm) like a piece

of paper more than once; for example if creased at 1mm never unfold it.

• The ribbon performs best as placed in free space. To avoid detuning the antenna from

optimal Ultra-Low Power performance, do not attach the ribbon to a metal surface. Observe

capacitive couplings near proximity to metallic surfaces within 10mm.

• If a ribbon cable is damaged it can only be field replaced by the exact type and length item.

®

• The SUMI-CARD

• The electrical connection between the antenna and connector is not air-tight. It is

recommended that the connector or entire module be sealed to avoid oxidation.

• Linear power supply is recommended to reduce input noise.

ribbon used has a 0.1mm copper thickness for better signal conduction.

Application Comments

This signal is required for all relative

voltages

switched off 3.3V

stability protection

protection

Page 22 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 23

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

6 Firmware

6.1 Applications

The OEM75 has different firmware applications available. Some examples include reading an

iCLASS, and MIFARE, or Ultra Low Power mode.

6.2 Feature Bundles and Configuration

A combination of applications and hardware options can be combined into a bundle. Currently

supported bundles are iCLASS, MIFARE, iCLASS + PIV II, or MIFARE + PIV II.

For a given bundle, there are unique customized configuration options available. See the How to

Order Guide > iCLASS OEM75 Module Part Numbers > Optional Config Suffix column. To

request a custom configuration contact HID Connect.

6.3 Updates

The OEM has the ability to update firmware through the serial interface and a utility, or a smart card

provided by HID using encrypted firmware files.

Contact HID Technical Support for information regarding field upgrades of readers.

6.4 Communication

Read only and Read/Write communications can be established with the OEM75 module. SPI,

UART or I

data from the OEM75. The Wiegand output port is from the reader to the host.

2

C communication ports enable a host to send serial commands and accept responses or

6.5 SPI Implementation

If I²C communications have been enabled, present the SPI_ENABLE configuration card to the

OEM75 in order to switch to SPI communications.

For the OEM75 product, use the Serial Peripheral Interface (SPI) as the underlying protocol for

message transfers. SPI is a full duplex master/slave serial data link. The master uses four logic

signals to control the data frame and slave device selection. The four logic signals are SCLK

(clock), MOSI (master output, slave input), MISO (master input, slave output), and SS (slave

select).

The OEM75 processor is the SPI slave. Any host communicating with the OEM75 must operate as

an SPI master. Four industry defined standard modes of operation for SPI exist. The OEM75

platform uses Mode 3. For a complete description of Mode 3 SPI communications including clock

polarity and data edge activity, see the following URL:

http://en.wikipedia.org/wiki/Serial_Peripheral_Interface_Bus.

In summary, the SPI on the OEM75 platform functions as follows:

• Input data sampled at the middle of data output time

• Transmit occurs on transition from Idle to active clock state

• Idle state for clock is a high level

January 2014 Page 23 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 24

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

6.6 General Recommendations

The OEM 75 contains internal 10k pull-up resistors on the MOSI, and /SS inputs. Do not use

additional external pull-up resistors on these inputs.

External series resistors (100Ω to 1kΩ ) on all SPI signals (/SS, SCLK, MOSI, and MISO) may be

required to eliminate negative spikes on the interface lines.

The OEM75 SPI Slave input was tested to work at a maximum bit rate of 230 kbps and a maximum

byte rate of 150 us/byte.

CAUTION: The pull-up resistors voltage source (+3.3V Read) on the SPI inputs is switched OFF

during Ultra Low Power Mode. Do not hold SPI input signals high during Ultra Low Power Mode.

Doing so causes erratic operation.

The reader serial communication default settings are 57.6 KBaud, 8, even 1 (57.6, 8, E, 1).

Communications from the host to the OEM75 module must insure that the asynchronous data bytes

have no more than 500 ms between the previous stop bit and the next start bit. Violation of this

timing causes the reader software to recognize a timeout condition and ignore the entire data

stream.

The following dialogue illustrates the timing improvements that can be realized when the 16-block

PICO-READ_BLOCKS command is used in place of the 4-block TRANSMIT command.

** Example of Timing Improvement **

** Summary **

Comparison of 16 block read (128 bytes), using one authentication, using 0xC2 4-block

transmit versus 0x76 16-block pico-read-blocks command

0x76 start: (02.39.52.637.909)

0x76 end: (02.39.52.771.088) = 133.179ms

0xC2 start: (02.39.52.882.073)

0xC2 end: (02.39.53.059.508) = 177.435ms

difference = 44ms per 16 blocks (128 bytes) read

this includes minimal additional overhead in-between 0xC2 commands (~1.1ms per 0xC2)

1.1ms x 4 0xC2 commands = 4.4ms

difference about 40ms per 16 blocks (128 bytes) read

Minimum Firmware required:

USB: 6300-502-08

RS232: 6300-501-10

Core: 6300-512-05

** Detail **

************************************************************************

Serial Port 2 open attempt at baud rate 57600, even parity = success

************************************************************************

Get iClass reader firmware = Success

Rdr firmware = UiR0207, 6300-501-15, 6300-512-34

rdr: response code (hex) = 42 00

(02.39.48.819.691) --> 80 F2 00 00 01 (0.059 ms)

(02.39.48.830.473) <-- F2 55 90 00 (10.568 ms)

(02.39.48.830.786) --> 80 F2 00 01 01 (0.052 ms)

(02.39.48.839.789) <-- F2 69 90 00 (8.793 ms)

(02.39.48.840.093) --> 80 F2 00 02 01 (0.052 ms)

(02.39.48.849.147) <-- F2 52 90 00 (8.846 ms)

(02.39.48.849.452) --> 80 F2 00 03 01 (0.050 ms)

Page 24 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 25

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

(02.39.48.858.504) <-- F2 02 90 00 (8.844 ms)

(02.39.48.858.806) --> 80 F2 00 04 01 (0.051 ms)

(02.39.48.867.865) <-- F2 00 90 00 (8.850 ms)

(02.39.48.868.163) --> 80 F2 00 05 01 (0.052 ms)

(02.39.48.877.182) <-- F2 00 90 00 (8.811 ms)

(02.39.48.877.483) --> 80 F2 00 06 01 (0.053 ms)

(02.39.48.896.289) <-- F2 00 90 00 (18.596 ms)

(02.39.48.896.586) --> 80 F2 00 07 01 (0.051 ms)

(02.39.48.905.679) <-- F2 07 90 00 (8.885 ms)

(02.39.48.918.555) --> 42 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00 00 00 00 00 00 00 (11.532 ms)

(02.39.49.169.949) <-- 42 36 33 30 30 2D 35 30 31 2D 31 35 00 36 33 30 30 2D 35 31 32

2D 33 34 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00 00 00 00 00 00 00 (0.039 ms)

************************************************************************

Directory: C:\working\timing

File: 00. Read 16 blocks (128 bytes) using various methods.xml

************************************************************************

(02.39.52.529.367) --> 80 F4 40 00 00 (0.063 ms)

(02.39.52.558.453) <-- 90 00 (28.590 ms)

(02.39.52.559.441) --> 80 52 00 01 08 (0.053 ms)

(02.39.52.562.262) <-- 52 (2.484 ms)

(02.39.52.562.901) --> 00 00 00 00 00 00 00 00 (0.057 ms)

(02.39.52.574.965) <-- 90 00 (11.598 ms)

(02.39.52.575.756) --> 80 A4 30 02 09 (0.053 ms)

(02.39.52.636.949) <-- A4 02 99 F6 20 00 F6 FF 12 E0 90 00 (60.617 ms)

(02.39.52.637.909) --> 80 76 06 15 01 (0.052 ms)

(02.39.52.640.723) <-- 76 (2.438 ms)

(02.39.52.641.218) --> 01 (0.047 ms)

(02.39.52.771.088) <-- 76 AA BB CC DD EE FF 11 3B AA BB CC DD EE FF 11 3C AA BB CC DD

EE FF 11 3D AA BB CC DD EE FF 11 3E AA BB CC DD EE FF 11 3F AA BB CC DD EE FF 11 40 AA

BB CC DD EE FF 11 41 AA BB CC DD EE FF 11 42 AA BB CC DD EE FF 11 43 AA BB CC DD EE FF

11 44 AA BB CC DD EE FF 11 45 AA BB CC DD EE FF 11 46 AA BB CC DD EE FF 11 47 AA BB CC

DD EE FF 11 48 AA BB CC DD EE FF 11 49 AA BB CC DD EE FF 11 4A 90 00 (127.044 ms)

(02.39.52.773.454) --> 80 F4 40 00 00 (0.244 ms)

(02.39.52.801.614) <-- 90 00 (27.647 ms)

(02.39.52.802.510) --> 80 52 00 01 08 (0.053 ms)

(02.39.52.805.348) <-- 52 (2.387 ms)

(02.39.52.806.100) --> 00 00 00 00 00 00 00 00 (0.056 ms)

(02.39.52.818.204) <-- 90 00 (11.631 ms)

(02.39.52.819.082) --> 80 A4 30 02 09 (0.052 ms)

(02.39.52.880.994) <-- A4 02 99 F6 20 00 F6 FF 12 E0 90 00 (61.239 ms)

(02.39.52.882.073) --> 80 C2 F5 20 02 (0.053 ms)

(02.39.52.884.897) <-- C2 (2.371 ms)

(02.39.52.885.493) --> 06 06 (0.049 ms)

(02.39.52.924.522) <-- C2 AA BB CC DD EE FF 11 3B AA BB CC DD EE FF 11 3C AA BB CC DD

EE FF 11 3D AA BB CC DD EE FF 11 3E 90 00 (37.837 ms)

(02.39.52.925.674) --> 80 C2 F5 20 02 (0.053 ms)

(02.39.52.928.618) <-- C2 (2.514 ms)

(02.39.52.929.189) --> 06 0A (0.050 ms)

(02.39.52.969.467) <-- C2 AA BB CC DD EE FF 11 3F AA BB CC DD EE FF 11 40 AA BB CC DD

EE FF 11 41 AA BB CC DD EE FF 11 42 90 00 (39.196 ms)

(02.39.52.970.616) --> 80 C2 F5 20 02 (0.054 ms)

(02.39.52.973.522) <-- C2 (2.470 ms)

(02.39.52.974.160) --> 06 0E (0.108 ms)

January 2014 Page 25 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 26

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

(02.39.53.014.454) <-- C2 AA BB CC DD EE FF 11 43 AA BB CC DD EE FF 11 44 AA BB CC DD

EE FF 11 45 AA BB CC DD EE FF 11 46 90 00 (39.222 ms)

(02.39.53.015.598) --> 80 C2 F5 20 02 (0.053 ms)

(02.39.53.018.515) <-- C2 (2.479 ms)

(02.39.53.019.094) --> 06 12 (0.049 ms)

(02.39.53.059.508) <-- C2 AA BB CC DD EE FF 11 47 AA BB CC DD EE FF 11 48 AA BB CC DD

EE FF 11 49 AA BB CC DD EE FF 11 4A 90 00 (39.340 ms)

Page 26 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 27

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

6.7 SPI Message Transmission

SPI Write Function is the external host master SPI sends a message to the OEM75 slave SPI. SPI

Read Function is the external host master SPI queries for a message from the OEM75 slave SPI. In

both cases, transferred are two bytes over the SPI to set up a message transfer. The first SPI byte

transmitted indicates write or read. The next byte transferred exchanges a number indicating the

message size in bytes.

6.7.1 Host SPI Master Write Function

1. Assert the Slave Select (SS) for the OEM 75.

2. Send an SPI Write (0x08) command byte to the OEM75, then delay approximately 50

microseconds to allow the OEM75 processor to process an SPI interrupt and determine the

SPI state.

3. Send a byte to the OEM75 indicating the number of bytes in the message about to be sent

and delay approximately 50 microseconds to allow the OEM75 processor to process an

SPI interrupt and store the message size byte.

4. Send all message bytes with a 50 microsecond delay between each byte.

6.7.2 Host SPI Master Read Function

1. Assert the Slave Select (SS) for the OEM 75.

2. Send an SPI Read (0x00) command byte to the OEM75, then delay approximately 50

microseconds to allow the OEM75 processor to process an SPI interrupt and determine the

SPI state.

3. Send a dummy byte (0x00) to the OEM75 to drive a return value from the OEM75

indicating the number of bytes available for transfer.

4. If the returned number of bytes is non-zero, then send that number of dummy bytes to the

OEM 75 and collect all the message data after each transfer. Remember to send all bytes

with a 50 microsecond delay between each byte.

6.7.3 Peripheral Processor SPI Slave Interrupt Processing

1. Before any SPI transmission, the slave SPI is in the IDLE state.

2. The first SPI interrupt occurs after a complete transmission of a byte from the host. If the

first byte is an SPI Write (0x08) byte, the SPI state changes to WAITING FOR MESSAGE

BYTE from the core processor. If it is an SPI Read (0x00) byte, then, the SPI state changes

to MESSAGE BYTE REQUESTED and the number of available bytes is loaded into the

SPI register. Otherwise, a null (0x00) byte is loaded into the SPI register.

3. The next SPI interrupt occurs after a complete transmission of a byte from the core

processor. If the peripheral processor’s SPI state is WAITING FOR MESSAGE BYTE, the

byte just transferred is stored in the circular receive buffer for incoming messages. If the

peripheral processor’s SPI state is MESSAGE BYTE REQUESTED, then the next available

byte is stored in the SPI register.

January 2014 Page 27 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 28

6.7.4 Sample Source Code

The following is sample code for implementing a Master SPI driver to talk to the OEM75.

/*============================================================

**

** FILE NAME: masterSpi.c

**

** DESCRIPTION: This file contains functions to manage the SPI message transfers.

**

** PUBLIC FUNCTIONS:

** InitSpi

** WriteSpi

** ReadSpi

**

** PRIVATE FUNCTIONS:

** sendSpiByte

**

**

**===========================================================*/

/********** Project Specific Includes **********/

#include "main.h"

#include "masterSpi.h"

/***************** Private Function Prototypes ***********************/

static void sendSpiByte(UBYTE dataOut, UBYTE *pDataIn);

#define SSPSTAT_MASTER 0x00

#define SSPCON1_MASTER 0x32

#define SPI_READ 0x00

#define SPI_WRITE 0x08

#define OEM75_SS RA5

#define SPI_DELAY 50

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

Page 28 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 29

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

/**********************************************************************/

/************************** Public functions *************************/

/**********************************************************************/

/***********************************************************************

** NAME:

** InitSpi

**

** INPUTS:

** None

**

** OUTPUTS:

** None

**

** RETURN:

** None

**

** DESCRIPTION:

** This function sets up the MSSP to be a master SPI device.

**

** NOTES: This is code for a Microchip PIC18F2520. This initialization code will

** be different for other SPI drivers on other processors.

**

**********************************************************************/

void InitSpi(void)

{

// Enable SPI as a master device, Mode 3

SSPSTAT = SSPSTAT_MASTER;

SSPCON1 = SSPCON1_MASTER;

}

/***********************************************************************

** NAME:

** WriteSpi

**

** INPUTS:

** pData - points to the data to send to the slave SPI

** numBytes – number of bytes in the message

**

** OUTPUTS:

** None

**

** RETURN:

** None

**

** DESCRIPTION:

** This function transmits a message to a slave SPI device.

**

** NOTES:

**

***********************************************************************/

void WriteSpi(UBYTE *pData, UBYTE numBytes)

{

UBYTE returnByte, cnt;

// Select the SPI slave device.

OEM75_SS = 0;

January 2014 Page 29 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 30

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

// Send the WRITE SPI byte.

sendSpiByte(SPI_WRITE, &returnByte);

// Send the number of bytes in this transfer.

sendSpiByte(numBytes, &returnByte);

// Send the data.

for (cnt=0; cnt<numBytes; cnt++)

{

sendSpiByte(pData[cnt], &returnByte);

}

// De-Select the SPI slave device.

OEM75_SS = 1;

}

/***********************************************************************

** NAME:

** ReadSpi

**

** INPUTS:

** None

**

** OUTPUTS:

** pData - points to location to store incoming message data

** pNumBytes – points to location to store number of bytes in the message

**

** RETURN:

** None

**

** DESCRIPTION:

** This function receives a message from a slave SPI.

**

** NOTES:

**

***********************************************************************/

void ReadSpi(UBYTE *pData, UBYTE *pNumBytes)

{

UBYTE cnt;

// Select the SPI slave device.

OEM75_SS = 0;

// Send the Read command.

sendSpiByte(SPI_READ, pNumBytes);

// Send a dummy data byte and store the number of

// available bytes that is returned.

sendSpiByte(SPI_READ, pNumBytes);

for (cnt=0; cnt<=*pNumBytes; cnt++)

{

sendSpiByte(0, &pData[cnt]);

}

// De-Select the SPI slave devices.

OEM75_SS = 1;

Page 30 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 31

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

}

/**********************************************************************/

/************************** Private Functions ************************/

/**********************************************************************/

/***********************************************************************

** NAME:

** sendSpiByte

**

** INPUTS:

** dataOut - the byte to send

**

** OUTPUTS:

** pDataIn - points to the location to store the returned data byte.

**

** RETURN:

** None

**

** DESCRIPTION:

** This function assumes the SPI slave select pin is already driven low.

**

** NOTES: This is code for a Microchip PIC18F2520. This code will

** be different for other SPI drivers on other processors.

**

***********************************************************************/

static void sendSpiByte(UBYTE dataOut, UBYTE *pDataIn)

{

// Send the byte.

SSPBUF = dataOut;

while (0 == (SSPSTAT & BIT_0)) ; // wait for transmission to complete

// Read the byte returned by the slave SPI device.

*pDataIn = SSPBUF; // Clears BF

// Delay a short time to allow the slave device to act.

DelayuS(SPI_DELAY);

}

January 2014 Page 31 of 49

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 32

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

6.8 I²C Implementation

To enable I²C operation and set a Slave Address, first present a configuration card to the OEM75.

For the OEM75, use the Inter-Integrated Circuit (I²C) as the underlying protocol for message

transfers. I²C is a master/slave multi-drop serial data link invented by Philips. It uses two signal

lines, SDA (Serial Data) and SCL (clock). SCL is driven by the master to control transfers.

The OEM75 processor is the I²C slave. Any host communicating with the OEM75 must operate as

an I²C master and use the 7 bit address space reference design. For details on this communication

method, see the following URL:

6.8.1 General Recommendations

For I²C operation, an external 10k pull-up resistor is required on the I²C-SCK signal.

Note: The OEM75 already contains internal 10k pull-up resistors on the I²C SDA signal.

CAUTION: The pull-up resistors voltage source (+3.3V Read) on the I²C inputs is switched OFF

during Ultra Low Power Mode. Do not hold I²C input signals high during Ultra Low Power Mode.

Doing so causes erratic operation.

6.8.2 I²C Baud Rates and Clock Stretching

http://en.wikipedia.org/wiki/I²C.

I²C Write Function is when the external host master I²C is sending messages to the OEM75 slave

I²C. I²C Read Function is when the external host master I²C is querying for messages from the

OEM75 slave I²C.

The OEM75 slave I²C is tested with a master CPU driving the clock, resulting in a clock rate of

115.2 K Baud. The OEM75 has a crystal frequency of over 27 MHz, and therefore significantly

higher baud rates (230.4 K Baud, 460.6 K Baud) are attainable. However, these higher baud rates

have not been tested.

Clock stretching is implemented on the OEM75. This allows the OEM75 to stop the transmission

clock while processing the I²C interrupt. While higher burst speeds of greater than 115.2 K Baud are

possible for individual bytes, there may be clock-stretching activity occurring on the OEM75 that

slows down the overall effective baud rate of a multi-byte transmission.

6.8.3 I²C Message Transmission

An I²C Write Function is when the external host master I²C is sending messages to the OEM75

slave I²C. I²C Read Function is when the external host master I²C is querying for messages from

the OEM75 slave I²C.

Host I²C Master Write Function

1. The master CPU issues an I²C bus Start.

2. The master CPU sends the OEM75 address with the least significant bit set to zero. This

indicates the address is a write address.

3. Send a byte to the OEM75 indicating the number of bytes in the pending message.

4. Send all message bytes.

5. The master CPU issues an I²C bus Stop.

Page 32 of 49 January 2014

HID GLOBAL CONFIDENTIAL AND/OR PROPRIETARY INFORMATION. This document contains confidential and/or proprietary

information, which may not be duplicated, published, disseminated or disclosed, or used for any purpose, without the written

consent of HID Global Corporation. If you are an unintended recipient of this information or are unwilling to accept the above

restrictions, please immediately return this document to HID Global Corporation, 15370 Barranca Pkwy, Irvine, CA 92618-3106.

Page 33

iCLASS OEM75 Integration Guide, 3141-907, Rev. B.0

Host I²C Master Read Function

1. The master CPU issues an I²C bus Start.

2. The master CPU sends the address of the OEM75 with the least significant bit set to one.

This indicates the address is a read address.

3. Read one byte from the OEM75. This is the number of bytes available to read from

theOEM75.

4. Read all available bytes from the OEM75.

5. The master CPU issues an I²C bus Stop.