Page 1

© 2012 HID Global Corporation. All rights reserved.

Printing and Encoding Solutions

FARGO® HDP8500

Industrial Card Printer/Encoder

User Guide

© 2012 HID Global Corporation. All rights reserved.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

1

Page 2

© 2012 HID Global Corporation. All rights reserved.

Section 1: Specifications_____________________________________________________________ 8

Regulatory Compliance _____________________________________________________________________ 8

Agency Listings ____________________________________________________________________________ 8

United States _____________________________________________________________________________ 9

Canada __________________________________________________________________________________ 9

Environmental Protection (China-RoHS) _____________________________________________________ 10

Traditional Chinese RF Emissions and Safety Statements _______________________________________ 11

Taiwan Traditional Chinese _______________________________________________________________ 12

China Simplified Chinese _________________________________________________________________ 12

Japan ________________________________________________________________________________ 14

Korean _______________________________________________________________________________ 14

Technical Specifications ____________________________________________________________________ 15

Functional Specifications ___________________________________________________________________ 19

Section 2: Graphical Display _________________________________________________________ 21

Home Screen ____________________________________________________________________________ 21

System Information Screen Option _________________________________________________________ 26

Process Status _________________________________________________________________________ 27

Main Menu ______________________________________________________________________________ 28

Hopper Selection _______________________________________________________________________ 29

Tools –Diagnostic Self Test Options ________________________________________________________ 30

Tools –Diagnostic Mechanical Test Options __________________________________________________ 31

Sensor Calibration Options _______________________________________________________________ 32

Sleep and Lock Settings __________________________________________________________________ 33

Case Open ____________________________________________________________________________ 33

Station Error ___________________________________________________________________________ 34

Boolean Setting ________________________________________________________________________ 35

Settings Keypad ________________________________________________________________________ 35

Pin Keypad ____________________________________________________________________________ 36

Security Keypad ________________________________________________________________________ 37

Text Button Select ______________________________________________________________________ 37

Notification List ________________________________________________________________________ 38

Menu Detail List ________________________________________________________________________ 38

Consumable Status _____________________________________________________________________ 39

Integer Selection _______________________________________________________________________ 39

Confirmation __________________________________________________________________________ 40

Card Counter __________________________________________________________________________ 40

Help Screen ___________________________________________________________________________ 41

Section 3: Setup and Installation Procedures___________________________________________ 42

Inspection – HDP8500 _____________________________________________________________________ 42

Unpacking the Printer. ___________________________________________________________________ 42

Choosing a Good Location ________________________________________________________________ 42

About Moisture Condensation ____________________________________________________________ 42

Loading the HDP Transfer Film ____________________________________________________________ 43

Loading the Ribbon _____________________________________________________________________ 45

Loading the Card Cleaning Roller __________________________________________________________ 47

Loading the Overlaminate ________________________________________________________________ 49

Loading the Blank Cards _________________________________________________________________ 51

Installing the Card Output Hopper _________________________________________________________ 53

Connecting Power to HDP8500 Printer and/or Lamination Module _______________________________ 53

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

2

Page 3

© 2012 HID Global Corporation. All rights reserved.

Printer Driver Installation Procedures _________________________________________________________ 54

Section 4: Printer Driver Operations _________________________________________________ 55

Using the Card tab ________________________________________________________________________ 55

Selecting the Card Size ___________________________________________________________________ 56

Selecting the Card Type __________________________________________________________________ 57

Printing on Alternate Card Stocks __________________________________________________________ 59

Conducting the Tape Adhesion Test ________________________________________________________ 60

Using the Card Hopper Selection __________________________________________________________ 62

Setting the Orientation __________________________________________________________________ 63

Specifying the number of Copies __________________________________________________________ 64

Selecting the Diagnostics button ___________________________________________________________ 64

Printing a Test Print Image _______________________________________________________________ 65

Selecting the About button _______________________________________________________________ 66

Selecting the Toolbox button _____________________________________________________________ 66

Using the Device Options tab _______________________________________________________________ 67

Detecting Supplies at Print Time Function ___________________________________________________ 68

Adjusting the Ribbon Type _______________________________________________________________ 69

Adjusting the Film Type __________________________________________________________________ 70

Using the Dual Sided Group Functions ______________________________________________________ 70

Using the Dual Sided - Print Both Sides option ________________________________________________ 71

Using the Print Both Sides - Split 1 Set of Ribbon Panels option __________________________________ 71

Using the Print Both Sides - Print Back Image on Front of Card option _____________________________ 72

Using the Dual Sided - Print Back Side Only option ____________________________________________ 72

Using the Print Quality___________________________________________________________________ 73

Using the Options Group _________________________________________________________________ 74

Using the Rotate Front 180 Degrees or Rotate Back 180 Degrees options __________________________ 74

Using the Disable Printing option __________________________________________________________ 75

Using the Dual Pass and Invert F-Panel Image options _________________________________________ 76

Using the Secure Resin Erase _____________________________________________________________ 76

Using the Encrypt Job Data _______________________________________________________________ 77

Using the Use Substitute Panel Data________________________________________________________ 77

Using the Image Color tab __________________________________________________________________ 79

Using the Image Quality – Color Matching dropdown __________________________________________ 80

Adjusting for the Resin Dither _____________________________________________________________ 82

Using the Advanced Image Color window ___________________________________________________ 83

Using the Image Transfer tab ________________________________________________________________ 86

Adjusting the Image Position controls ______________________________________________________ 87

Adjusting the Transfer Dwell Time and Temperature __________________________________________ 89

Using the Flattener Settings ______________________________________________________________ 90

Using the Default button _________________________________________________________________ 91

Using the Magnetic Encoding tab ____________________________________________________________ 92

Using the Encoding Mode dropdown list ____________________________________________________ 93

Selecting the Coercivity/Magnetic Track ____________________________________________________ 95

Reviewing the Shift Data Left Function ______________________________________________________ 96

Using the Character Size buttons __________________________________________________________ 96

Using the ASCII Offset dropdown list _______________________________________________________ 97

Using the Bit Density dropdown list ________________________________________________________ 97

Using the LRC Generation dropdown list ____________________________________________________ 98

Using the Character Parity Mode dropdown list ______________________________________________ 99

Reviewing the ISO Track Locations ________________________________________________________ 100

Sending the Track Information ___________________________________________________________ 101

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

3

Page 4

© 2012 HID Global Corporation. All rights reserved.

Reviewing the Sample String _____________________________________________________________ 102

Reviewing the ASCII Code and Character Table ______________________________________________ 103

Using the Default button ________________________________________________________________ 104

Using the Lamination tab __________________________________________________________________ 105

Selecting the Lamination Position _________________________________________________________ 106

Adjusting the Lamination Speed - Transfer Dwell Time ________________________________________ 106

Selecting the Lamination Side dropdown menu ______________________________________________ 106

Selecting the Lamination Type ___________________________________________________________ 107

Using the K Panel Resin tab ________________________________________________________________ 108

Using the Click and Drag capability ________________________________________________________ 109

Selecting “inches or mm” radio button ____________________________________________________ 109

Using the Add and Delete buttons ________________________________________________________ 109

Selecting the Full Card __________________________________________________________________ 110

Selecting the Defined Area and Undefined Area _____________________________________________ 110

Selecting the Print YMC under the K and Print K Only options __________________________________ 111

Using the Printer Supplies tab ______________________________________________________________ 112

Reviewing Information on the Supplies tab _________________________________________________ 113

Section 5: Accessing the Toolbox ____________________________________________________ 114

Selecting the Configuration tab _____________________________________________________________ 115

Using the Optional Printer Features Group Box ______________________________________________ 116

Using the Event Monitoring Group Box ____________________________________________________ 116

Reviewing the Ribbon Low message _______________________________________________________ 117

Reviewing the Laminate Low Message _____________________________________________________ 117

Using the Film Low message _____________________________________________________________ 117

Selecting the LCD Display Language _______________________________________________________ 118

Using the Printer LCD Display to set the language ___________________________________________ 118

Using the Driver to set the language_______________________________________________________ 119

Selecting the Calibrate Laminator tab ________________________________________________________ 120

Selecting the Calibrate Film tab _____________________________________________________________ 121

Selecting the Calibrate Ribbon tab __________________________________________________________ 122

Selecting the Clean Printer tab _____________________________________________________________ 123

Selecting the Advanced Settings tab _________________________________________________________ 125

Setting the Printhead Resistance _________________________________________________________ 126

Using the Print LOF (Left of Form) Option __________________________________________________ 126

Using the Image Darkness Option _________________________________________________________ 127

Using the Print TOF (Top of Form) Option __________________________________________________ 128

Using the Mag Top of Form Option________________________________________________________ 129

Using the Transfer TOF (Top of Form) Option _______________________________________________ 130

Using the Transfer EOF (End of Form) Option _______________________________________________ 131

Using the Transfer Temp Offset Option ____________________________________________________ 131

Using the Encoder Flip Angle Option ______________________________________________________ 132

Using the Print Flip Angle Option _________________________________________________________ 132

Using the Ribbon Print Take-up Tension Option _____________________________________________ 132

Using the Ribbon Print Supply Tension Option _______________________________________________ 132

Using the Film Print Take-up Tension Option ________________________________________________ 133

Using the Resin Heat Adjust Option _______________________________________________________ 133

Using the Sleep Time Option _____________________________________________________________ 133

Using the Blush Point Option ____________________________________________________________ 134

Using the LCD Contrast Option ___________________________________________________________ 134

Using the Film Supply Transfer Tension Option ______________________________________________ 134

Using the Film Take-up Transfer Tension Option _____________________________________________ 134

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

4

Page 5

© 2012 HID Global Corporation. All rights reserved.

Using the Film Print Supply Tension Option _________________________________________________ 135

Using the Cleaning rate Option ___________________________________________________________ 135

Using the Film Print Cooling Level Option __________________________________________________ 135

Using the Film Transfer Cooling Level Option ________________________________________________ 135

Using the EAT Disable Option ____________________________________________________________ 136

Using the Enable Ribbon Wrinkle Compensation Option_______________________________________ 136

Using the Standby Time Option __________________________________________________________ 136

Using the BEEP disable Option ___________________________________________________________ 136

Using the I Panel Heat Offset Option ______________________________________________________ 136

Using the Holo Transfer Offset Option _____________________________________________________ 136

Using the Standby Temp Option __________________________________________________________ 136

Using the Mag Hi-Co Voltage Offset Option _________________________________________________ 137

Using the Mag Lo-Co Voltage Offset Option _________________________________________________ 137

Using the Mag Flipper Angle Offset Option _________________________________________________ 137

Using the Fluorescent (F) Panel Heat Offset _________________________________________________ 137

Using the Lamination End of Form Option __________________________________________________ 137

Using the Lamination Temp Offset Option _________________________________________________ 137

Using the Lamination Bottom Takeup Option _______________________________________________ 137

Using the Lamination Top Takeup Option __________________________________________________ 137

Using the Lamination Card Backup Option __________________________________________________ 138

Using the Lamination Card Length Option __________________________________________________ 138

Using the Lamination Fan Speed Option____________________________________________________ 138

Using the Lamination Peel Off Delay Option ________________________________________________ 138

Reviewing the No Printer Connected error message __________________________________________ 138

Warming Time Delay ___________________________________________________________________ 139

Power On Ribbon Film Skip ______________________________________________________________ 139

Flipper Reject Angle ____________________________________________________________________ 139

Input Hopper Home Offset ______________________________________________________________ 139

Input Hopper Mag Offset _______________________________________________________________ 139

Transfer Image Length __________________________________________________________________ 139

Transfer Cooling Delay __________________________________________________________________ 139

Ribbon Factory Take-up _________________________________________________________________ 140

Ribbon Factory Supply __________________________________________________________________ 140

Film Factory Take-up ___________________________________________________________________ 140

Film Factory Supply ____________________________________________________________________ 140

Reviewing the Value outside the Range error message ________________________________________ 140

Section 6: Fluorescent Panel Usage __________________________________________________ 141

Configuring Fluorescent Data (F-Panel for YMCFK Ribbon) using the Workbench _____________________ 141

Configuring Fluorescent Data (F-Panel for YMCFK Ribbon) using the Application _____________________ 147

Section 7: Inhibit Panel Usage ______________________________________________________ 149

Using Inhibit Panel (via the Fargo Workbench Printer Utility) _____________________________________ 149

Using Inhibit Panel with an Application _______________________________________________________ 151

Generating Text Objects ________________________________________________________________ 151

Rendering Print Jobs ___________________________________________________________________ 152

Using the Test Print ____________________________________________________________________ 157

Troubleshooting the Inhibit Panel _________________________________________________________ 158

Section 8: General Troubleshooting _________________________________________________ 159

Troubleshooting - LCD and Printer Error Message Tables. ________________________________________ 159

How to use the LCD Error Message Table (example provided) __________________________________ 160

Troubleshooting with the LCD Error Message Table ____________________________________________ 161

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

5

Page 6

© 2012 HID Global Corporation. All rights reserved.

Troubleshooting the Printer Error Message Table ______________________________________________ 172

Communications Errors ___________________________________________________________________ 182

Resolving the Communication Errors ______________________________________________________ 182

Printing a Test Image using the Workbench Diagnostic ________________________________________ 184

Reviewing the Alignment Self Test Card ____________________________________________________ 185

Reviewing the Magnetic Self Test _________________________________________________________ 185

Reviewing the YMCK Self Test ____________________________________________________________ 186

Reviewing the Color Bars Self Test ________________________________________________________ 186

Reviewing the Device Settings Self Test ____________________________________________________ 187

Reviewing the Resin Self Test ____________________________________________________________ 187

Using the Test Print ______________________________________________________________________ 188

Section 9: Packing the Card Printer __________________________________________________ 189

Section 10: Firmware Updates _____________________________________________________ 190

Upgrading the Main Firmware with the Workbench Printer Utility _________________________________ 190

Section 11: HID Global Technical Support _____________________________________________ 192

Contacting Technical Support ____________________________________________________________ 192

Finding out when a Fargo Card Printer was manufactured _____________________________________ 192

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

6

Page 7

© 2012 HID Global Corporation. All rights reserved.

Date

Description

Document Version

05//2012

HDP8500 Industrial Card Printer/Encoder User Guide

1.0

9/2012

HDP8500 Industrial Card Printer/Encoder User Guide

Corrected Clean Card Part Number to 082139

1.1

North America

Europe, Middle East and Africa

15370 Barranca Parkway

Irvine, CA 92618

USA

Phone: 800 237 7769

Fax: 949 732 2120

Phoenix Road

Haverhill, Suffolk CB9 7AE

England

Phone: +44 1440 714 850

Fax: +44 1440 714 840

Asia Pacific

19/F 625 King‟s Road

North Point, Island East

Hong Kong

Phone: 852 3160 9800

Fax: 852 3160 4809

support.hidglobal.com

Trademarks

HID GLOBAL, HID, the HID logo, iCLASS and SIO are the trademarks or registered trademarks of

HID Global Corporation, or its licensors, in the U.S. and other countries.

Revision History

Contacts

Any questions regarding changes, corrections, updates or enhancements to this document

should be forwarded to:

Hid Global

Support Services

6533 Flying Cloud Drive

Eden Prairie, MN 55344 (USA)

(866)607-7339 Ext #6

FAX: (952) 946-8492

www.hidglobal.com

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

7

Page 8

© 2012 HID Global Corporation. All rights reserved.

UL

The Card Printer is listed under UL 60950-1 (2nd edition)

INFORMATION TECHNOLOGY EQUIPMENT

Note: This product is intended to be supplied by a Listed Power

Unit marked Class 2 and rated for 24 V dc, 3.3A minimum

CSA

The Printer manufacturer has been authorized by UL to

represent the Card Printer as CSA Certified under CSA

Standard C22.2 No. 60950-1-07 2nd edition

File Number: E145118

FCC

The Card Printer complies with the requirements in Part 15 of

the FCC rules for a Class A digital device.

CE The Card Printer has been tested and complies with EN300330-1, EN300-330-2, EN301-489-1, EN60950-1:2006 +

A11:2009

(Note: Based on the above testing, the Printer manufacturer

certifies that the Card Printer complies with the following of the

European Community and has placed the CE mark on the Card

Printer.)

LVD 2006/95/EC, EMC 2004/108/EC, R&TTE 1999/5/EC,

ROHS 2002/95/EC

Environmental

Power supply Efficiency level V minimum, RoHS, China RoHS

Emissions Standards

FCC Part 15 Class A, RSS-GEN, RSS 210 ,CNS 13438, EMC

2004/108/EC, R&TTE 1999/5/EC,GB9254-2008, GB 17625

Safety Standards

UL IEC 60950-1 (2nd edition), CSA C22.2 No. 60950-1-07 2nd edition,

LVD 2006/95/EC,GB4943, CNS14336

Section 1: Specifications

The purpose of this section is to provide you with specific information on the Regulatory

Compliances, Agency Listings, Technical Specifications and Functional Specifications for the

HDP8500 Card Printer User Guide.

Regulatory Compliance

Agency Listings

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

8

Page 9

© 2012 HID Global Corporation. All rights reserved.

United States

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may cause

undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference; in which case, you is required to correct the interference at his

own expense.

The user‟s manual or instruction manual for an intentional or unintentional radiator shall caution

the user that changes or modifications not expressly approved by the party responsible for

compliance could void the user‟s authority to operate the equipment. In cases where the

manual is provided only in a form other than paper, such as on a computer disk or over the

Internet, the information required by this section may be included in the manual in that

alternative form, provided the user can reasonably be expected to have the capability to access

information in that form.

Canada

This device complies with Industry Canada license-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this device may not cause interference, and (2) this

device must accept any interference, including interference that may cause undesired operation

of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio

exempts de licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne

doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

Caution: Changes or modifications not expressly approved by the party responsible

for compliance could void the user‟s authority to operate the equipment.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

9

Page 10

© 2012 HID Global Corporation. All rights reserved.

Environmental Protection (China-RoHS)

Environmental Protection Use Period is based on the product being used in an office

environment.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

10

Page 11

© 2012 HID Global Corporation. All rights reserved.

Traditional Chinese RF Emissions and Safety Statements

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

11

Page 12

© 2012 HID Global Corporation. All rights reserved.

符号

涉及安全的重要过程

危险:

如果不遵循这些安装指南进行操作,可能会导致重伤,甚

至死亡。

可能引发安全问题的信息由警告符号(如左图所示)来表

示。

为了确保人身安全,在执行前面带有此符号的操作之

前,请先阅读下面的安全消息。

为了确保人身安全,除非另有规定,否则在执行维修过

Taiwan Traditional Chinese

經型式認證合格之低功率射頻電機,非經許可,公司、商號或使用者均不得

擅自變

更頻率、加大功率或變更原設計之特性及功能。低功率射頻電機之使用不得

影響飛

航安全及干擾合法通信;經發現有干擾現象時,應立即停用,並改善至無干

擾時方

得繼續使用。前項合法通信,指依電信法規定作業之無線電通信。低功率射

頻電機

須忍受合法通信或工業、科學及醫療用電波輻射性電機設備之干擾。

China Simplified Chinese

安全消息(请仔细阅读)

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

12

Page 13

© 2012 HID Global Corporation. All rights reserved.

程前,始终应断开电源。

小心:

此设备为静电敏感设备。如果暴露在静电电流下,可能会

损坏设备。

可能引发静电安全问题的信息由警告符号(如左图所示)

来表示。

为了防止设备或介质受损,在执行前面带有此符号的操

作之前,请先阅读下面的安全消息。

为了防止设备或介质受损,请在处理电路板和打印头部

件中或附近的电缆时,遵守所有规定的静电放电 (ESD)

过程。

为了防止设备或介质受损,请始终佩带适当的个人接地

设备(例如,已接地避免出现潜在损坏的高质量腕

带)。

为了防止设备或介质受损,除非另有规定,否则在执行

任何维修过程前,始终应将色带和证卡与打印机分离。

为了防止设备或介质受损,在操作打印机前,请取下手

指和手上的珠宝饰物,并将手上的油渍和污渍彻底清洗

干净。

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

13

Page 14

© 2012 HID Global Corporation. All rights reserved.

Japan

この装置は総務省の型式指定を受けています。"

(総務省指定番号は第 AC-xxxxx号です)

本製品は電波を使用した RFID 機器の読み取り・書き込み装置です。

そのため使用する用途・場所によっては、医療機器に影響を与える恐れが

あります

Korean

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

14

Page 15

© 2012 HID Global Corporation. All rights reserved.

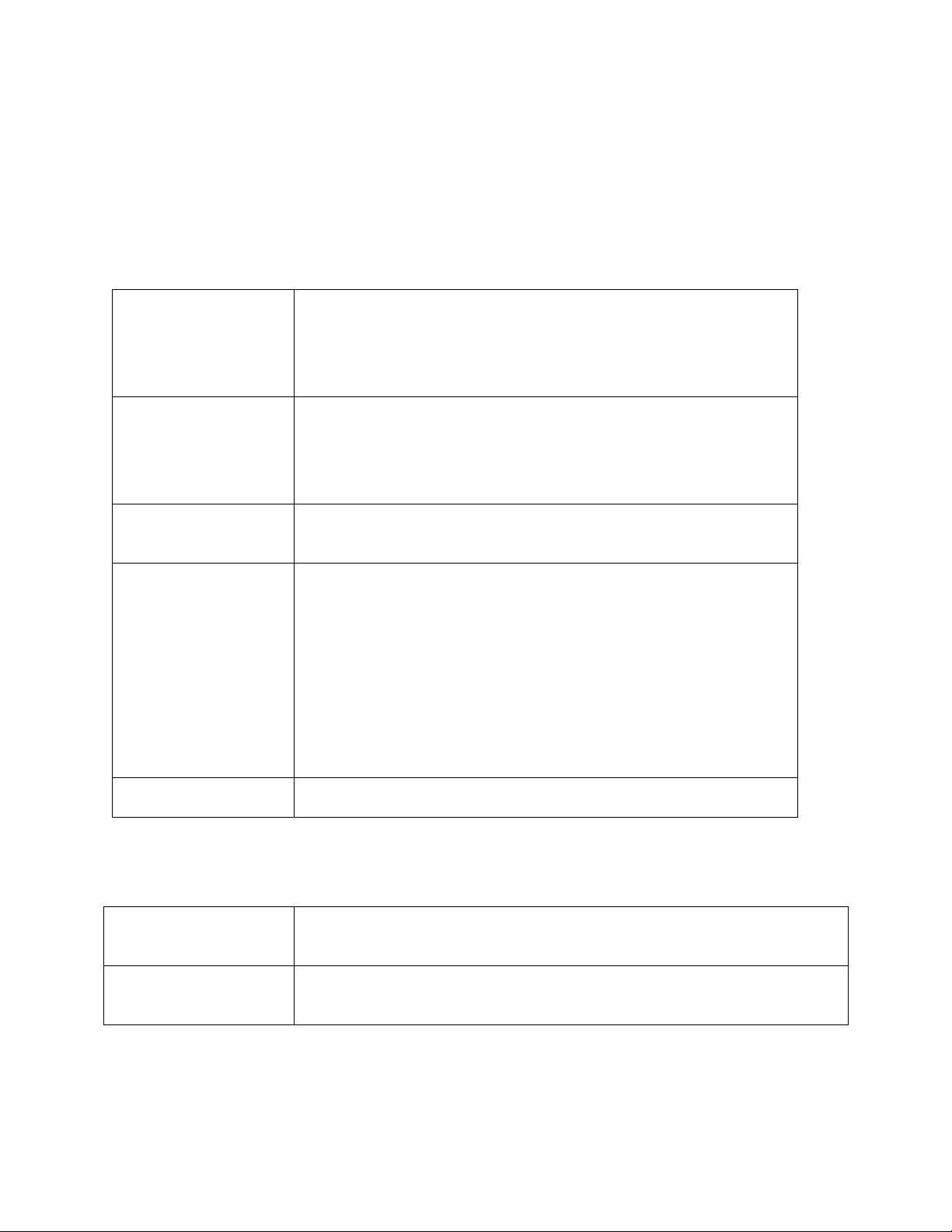

Print Method

HDP Dye-Sublimation/ Resin Thermal Transfer

Print Resolution

300 dpi (11.8 dots per mm)

Print Colors

Up to 16.7 million and 256 shades per pixel

Print Ribbon Options

HDP8500 (prints or images):

Full-color, YMC*, 750 prints

Full-color with resin black, YMCK*, 500 prints

Full-color with two resin black panels, YMCKK*, 500 prints

Full-Color – Half Panel YMCK*, 1000 prints

Full-color with resin black and heat seal panel for difficult-

to-print surfaces, YMCKH*, 500 prints

Full-color with resin black and inhibit panel for signature or

other non-printing areas, YMCKI*, 500 prints

Full-color with fluorescing and resin black, YMCFK*, 500

prints

Resin black, K, 3000 prints

* Indicates the Ribbon type and the number of Ribbon panels

printed where Y=Yellow, M=Magenta, C=Cyan, K=Resin

Black, H=Heat Seal , I= Inhibit, and F=Fluorescing

HDP Film Options

System Capability - HDP Film Options:

Clear (1,500 prints)

Standard Holographic (500 prints)

Custom Holographic, special order (500 prints)

Overlaminate Options

Overlaminate options:

Thermal Transfer Overlaminate, .25 mil thick, 500 prints

PolyGuard® Overlaminate, 1.0 mil and .6 mil thick, 250

prints (PolyGuard available in a CR-80 patch size)

All overlaminates available in clear, standard holographic

design or custom holographic design

Print Speed in Batch

Mode-Normal mode

Batch Mode:

Performance

Normal

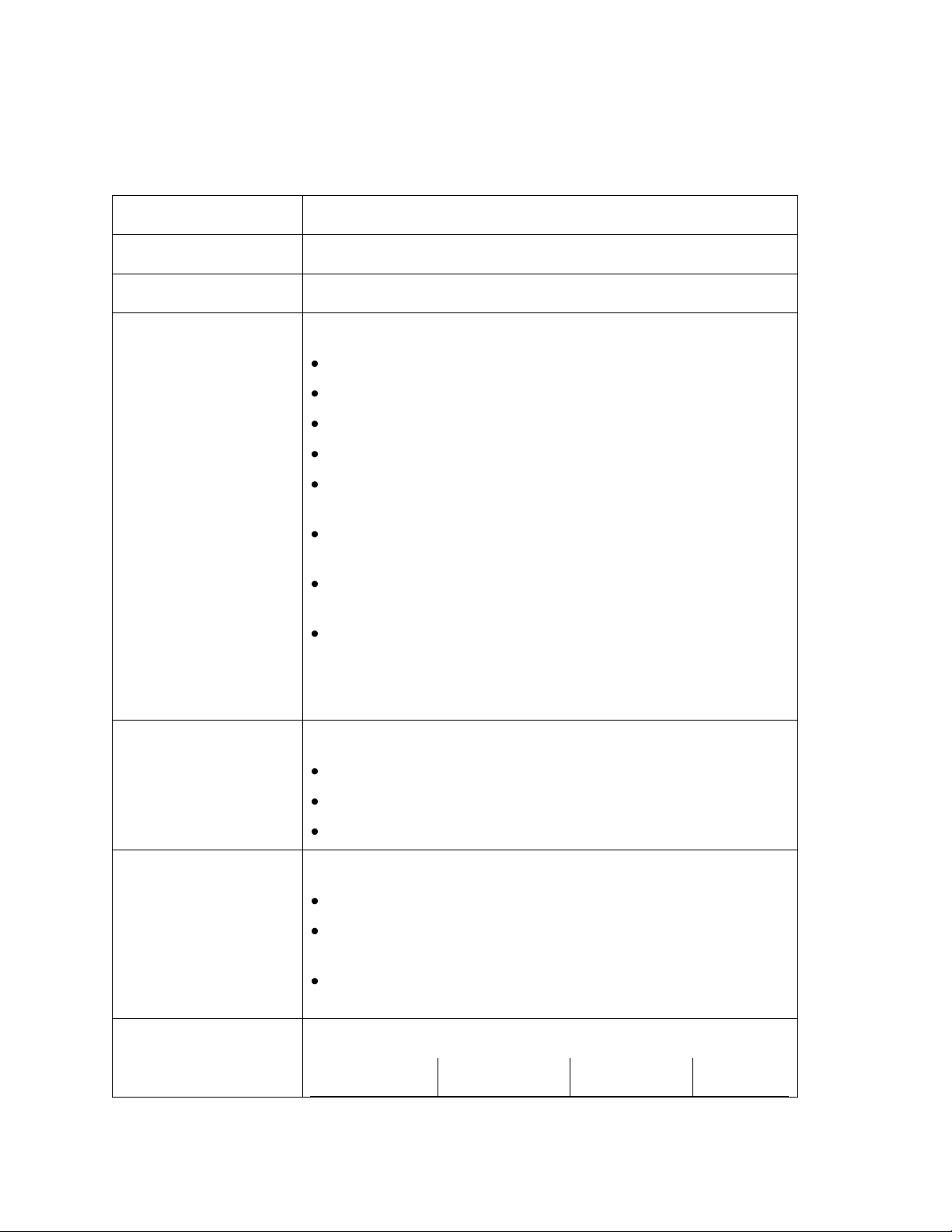

Technical Specifications

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

15

Page 16

© 2012 HID Global Corporation. All rights reserved.

Print Mode

Mode

YMC

24 seconds

per card/ 150

cards per hour

29 seconds

per card/ 124

cards per

hour

YMCK

29 seconds

per card/ 124

cards per hour

35 seconds

per card/ 103

cards per

hour

YMCKK

40 seconds

per card/ 90

cards per hour

49 seconds

per card/ 73

cards per

hour

YMCK+Lam

34 seconds

per card/ 106

cards per hour

40 seconds

per card/ 90

cards per

hour

YMCKK+Lam

48 seconds

per card/ 75

cards per hour

55 seconds

per card/ 65

cards per

hour

Power Source

Voltage, Amp &

Frequency

Supply Voltage/Amp:

100-240 VAC, 3.5 A MAX

Supply Frequency:

50 Hz and 60 Hz

Power Supply

Printer- two (2) internal heavy duty power supplies

Laminator- one (1) internal heavy duty power supply

Dual Input Hopper

Two (2) Input Hoppers included:

Input Hopper supports 200 count card each

Card Exception Feed

standard

Card Input Capacity

400 – (.030” / .762 mm) cards

(Dual input Hoppers with 200 cards each)

Card Output Capacity

Concealed/tinted output bin, lockable access and attachment

to printer , 200 card minimum

.030” ( 30 mil) to .050” (50 mil) (.762 mm to 1.27 mm)

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

16

Page 17

© 2012 HID Global Corporation. All rights reserved.

Reject Area Capacity

15 cards capacity, lockable (.030” and .762mm)

Card Materials and

Types

ABS

Laminated PVC

PET

PETG

Proximity

Smart Cards

Mag Stripe cards

Optical memory cards

Polycarbonate

Card Thickness

System will be compatible with card thicknesses from 20-

50 mil

Print only: .020” (20 mil) to .050” (50 mil) / .762mm to

1.27mm

Print/Lamination: .030” (30 mil) to .050” (50 mil) / .762mm

to 1.27mm

Card Sizes Supported

CR-80 (3.452”L x 2.204”W and 87.7mmL x 56mmW).

Memory

32 MB RAM

Card Cleaning Roller

Automatically cleans cards for higher print quality.

Replaceable biodegradable cleaning roller

Card Cleaning

Printer will use 2 integrated cleaning stations.

Laminator will use 3 integrated cleaning station.

Cleaning Prompt

3000 cards default. Interval is adjustable.

Display

3.2 “ Touchscreen Graphical Display

MS Windows

Compatibility

Windows XP

Server 2003

Vista (32 & 64 bit)

Windows Server (32 & 64 bit)

Windows 7 (32 & 64 bit)

Windows 2008 R1 R2

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

17

Page 18

© 2012 HID Global Corporation. All rights reserved.

Magnetic Stripe

Encoding (Options)

Dual high- and low-Coercivity

Tracks 1, 2 and 3

ISO Mag Encoding

JIS 2 Mag Encoding

Custom Encoding

Raw Binary Encoding

E card

Omnikey 5125 Proximity Encoder

Omnikey 5121 Encoder

Magnetic Encoder

Contact Encoder

Single Wire Encryption

Options

Contactless Smart Card Encoder (HID iCLASS and

MIFARE)

Contact Smart Card Encoder reads from and writes to all

ISO7816-1 and 2 and 3 and 4 memory and microprocessor

smart cards (T=0, T=1) as well as synchronous cards

Prox Card Reader (HID read-only)

Encryption

AES-256 data

USB Connection

USB 2.0 standard

Ethernet Connection

Ethernet standard

System Requirements

x86 based PC or compatible, Windows XP, Windows 2003,

Windows Vista, Windows 2008, or Windows 7

500MHz computer with 256MB of RAM or higher,

500MB free hard disk space or higher

Operating Conditions

Operating Temperature: 65° to 90° F and 18° to 32° C

Humidity: 20 - 80% non-condensing

Dimensions

28.2 “ width x 14.0 “ depth x 15.5” height –Printer only

Ship Weight

Printer: 61 lbs. Laminator: 30 lbs.

Warranty

Printer- 3 years

Printhead Lifetime ; unlimited passes

Extended Warranty available

No On-Call Express offered

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

18

Page 19

© 2012 HID Global Corporation. All rights reserved.

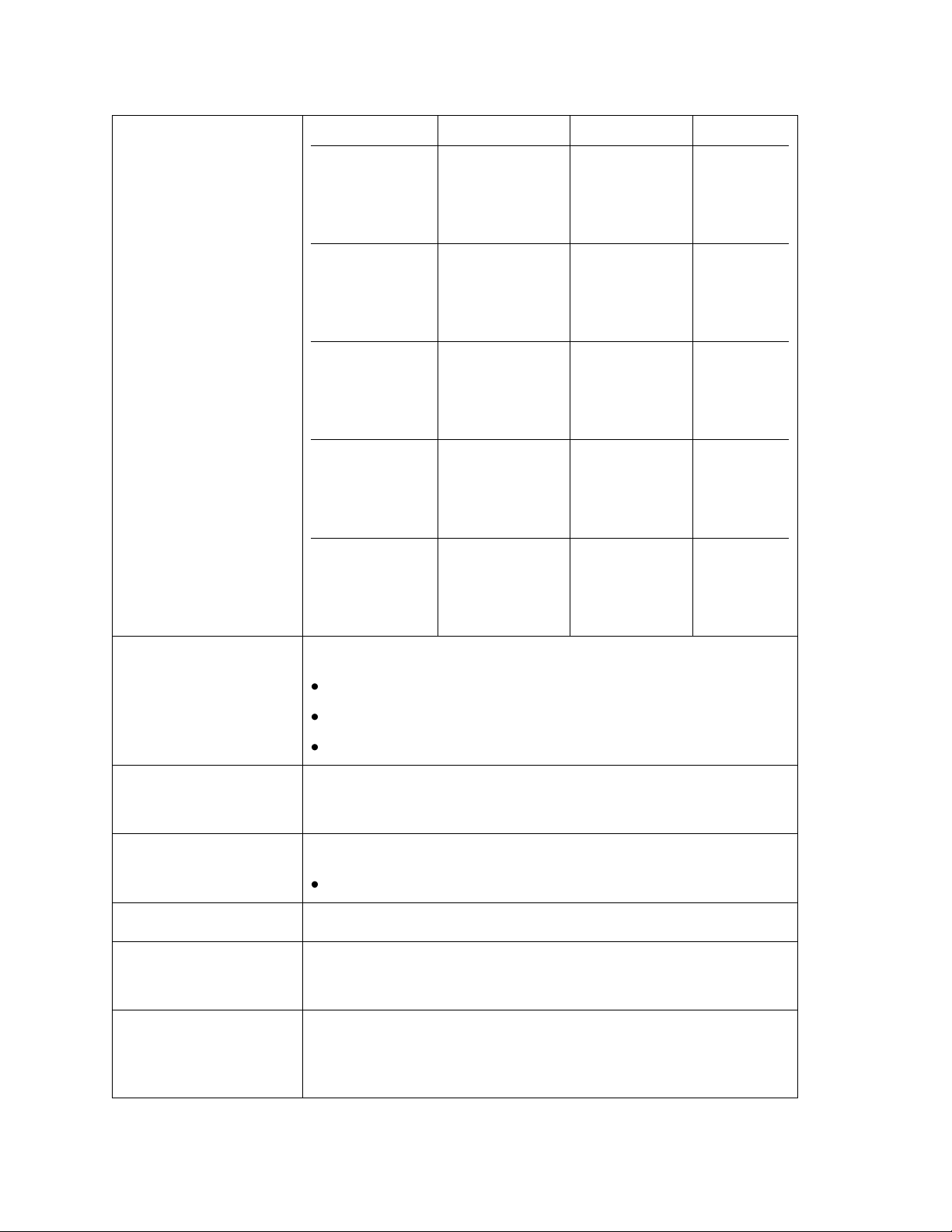

Component

Description

Card Cartridge

Load blank cards into this Cartridge.

Card Output

Hopper

Stores 200 cards.

Card

Lamination

Module

Works in conjunction with the Printer to apply a variety of different

overlaminates to printed cards, providing increased card durability

and security.

Will laminate in either the single or dual side (simultaneous) process

(Note: When printing a batch of cards, the Printer can be encoding

and printing one card while the Lamination Module laminates another

card.)

Display

3.2” AVGA TFT LCD w/ Resistive Touch Overlay

Printhead

The component of the Printer that actually does the printing.

USB Interface

Connect to the Windows PC USB port

Hardware

Accessories &

Connectivity

Each model has multiple cords and connectors.

US power cord

EU power cord

USB cable (2.0)

Ethernet

Print Modes

There are two print modes (Performance and Normal )

Normal print mode (default)

Performance print mode is faster with lower image quality and is

most suitable for minimal color with mostly resin text.

Resin Scramble

(OPTIONAL)

The system can hide any information printed with the resin panel.

Edge-to-Edge

Printing

Prints over the edge on CR-80 cards.

Color Profile

System Color Management & None

Functional Specifications

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

19

Page 20

© 2012 HID Global Corporation. All rights reserved.

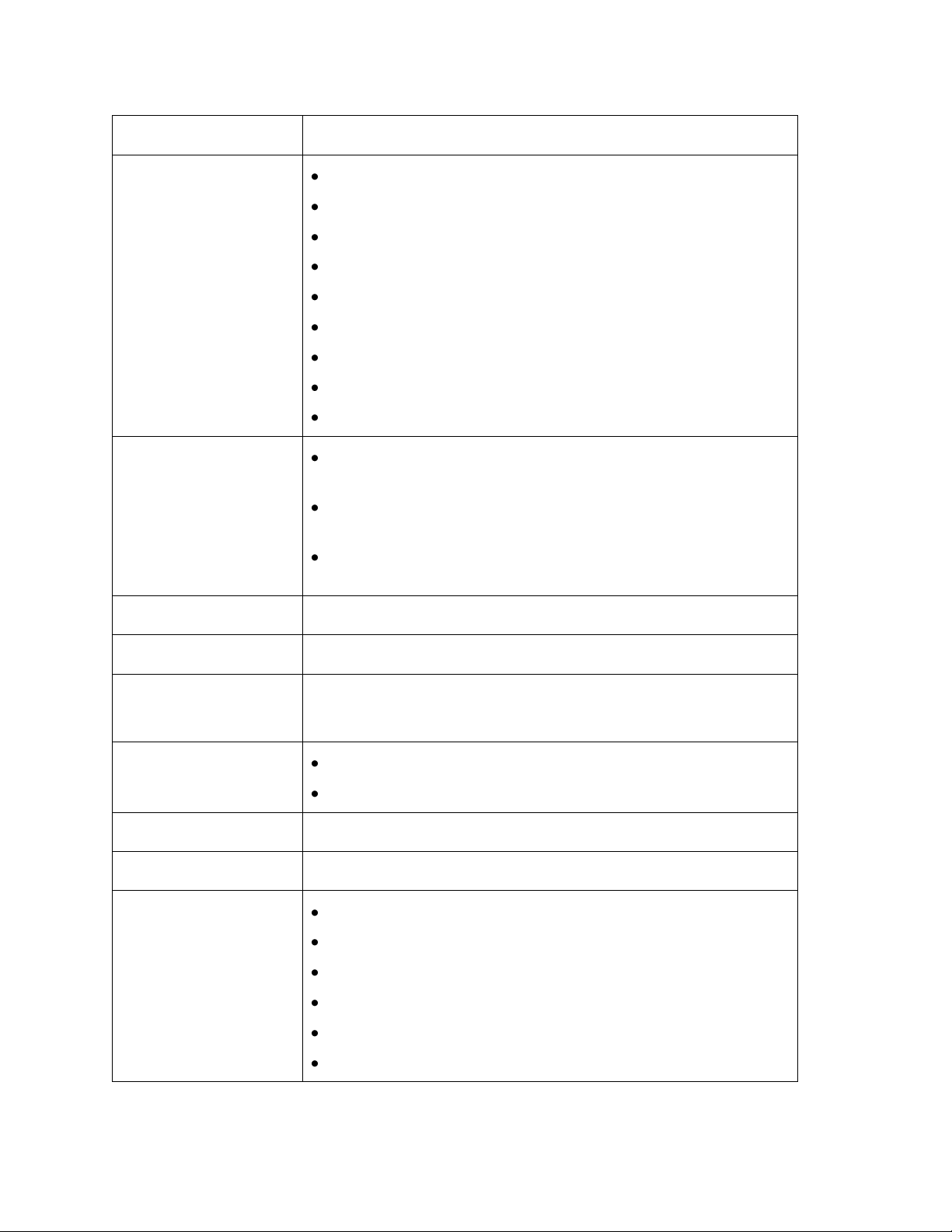

Card Flattener

(OPTIONAL)

Fully adjustable temp dwell

The card flattening routine occurs after the card is transferred but

before lamination.

The card flattener has an adjustable temp and dwell.

You can select from different offset values from the default temp.

You can select from different offset values from the default dwell.

The card flattener has a 0 to 15 second adjustable delay before

the flattening routine will run.

The driver can disable the card flattener, if a dual sided job is

sent.

Recommended for heat sensitive PVC cards.

Locks

Hardware locks are a standard feature.

Mechanical and key locks are used to secure the doors on the

input card cartridges, the access door to the printer, the access

door to the Laminator and the output card Hopper.

The input card cartridges are manually secured to the printer

mechanism via toggle latch located inside the access door of the

printer.

The Printer and Laminator include a compatible hole with a

Kensington lock.

The printer and Laminator include threaded hardware.

Andon Light

(OPTIONAL)

4-Color Andon Light option. Each color is controlled separately. The

four colors indicate the following:

Red: A printer error has occurred or operator intervention is

needed.

Blue: Printer has run out of materials (film, ribbon or cards)

Green: Normal Printer operation.

Orange: User intervention is needed soon. Printer materials are

low or the printer needs to be cleaned.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

20

Page 21

© 2012 HID Global Corporation. All rights reserved.

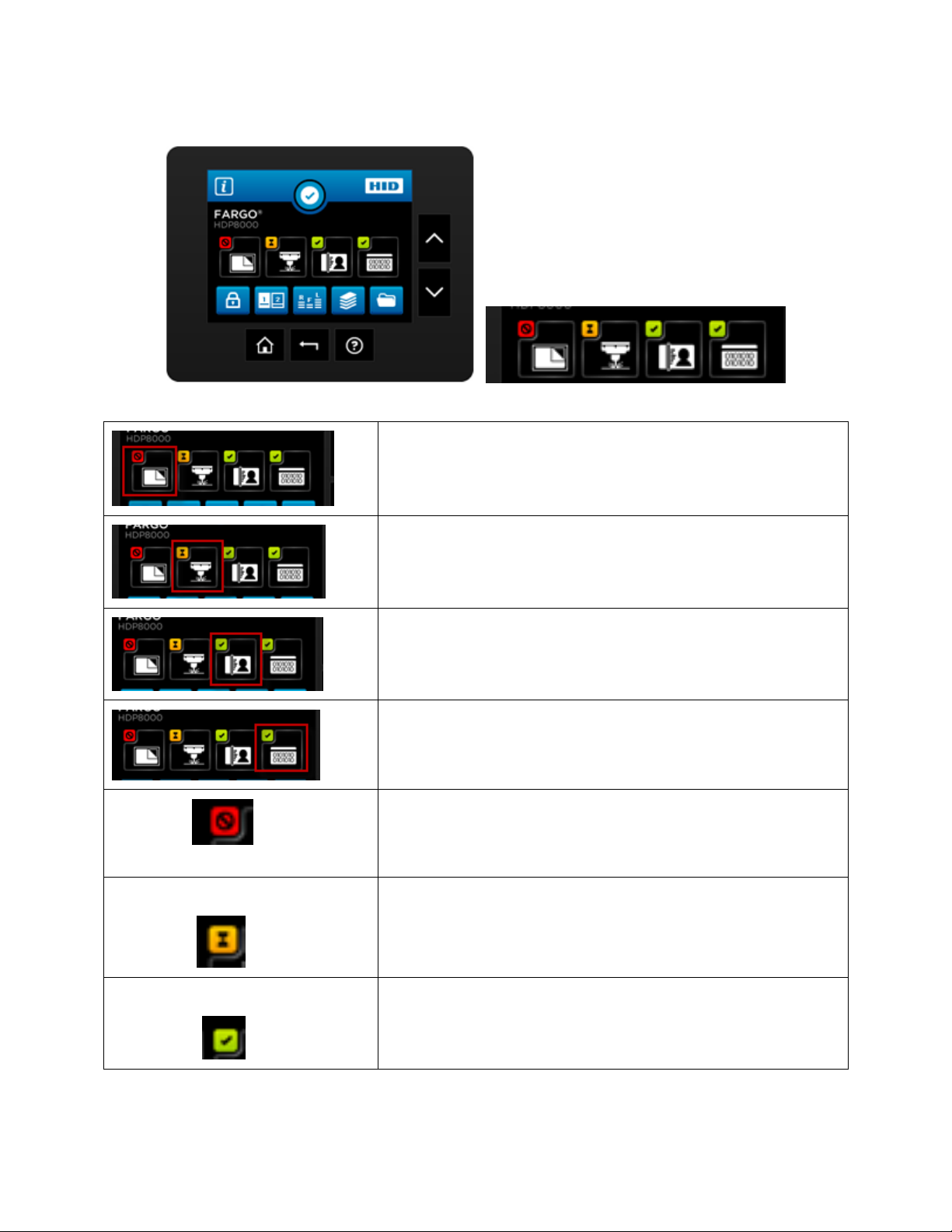

Click this icon to get to the System Information Screen

System Information Screen Option.

This is the Notification Icon which shows status and error

messages

Notification Icons

These are the icons displayed in the notification area.

Section 2: Graphical Display

Home Screen

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

21

Page 22

© 2012 HID Global Corporation. All rights reserved.

22

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

Page 23

© 2012 HID Global Corporation. All rights reserved.

Laminator configuration (if displayed is installed)

Laser Engraver (if displayed is installed)

HID Printer

Encoder (if displayed is installed)

Icon shows status is PROBLEM

Press the Station icon to open the Station Details screen,

which provides more detail about the station status.

Icon shows status is BUSY

Press the Station icon to open the Station Details screen,

which provides more detail about the station status.

Icon shows status is READY

Press the Station icon to open the Station Details screen,

which provides more detail about the station status.

Home Screen ( continued)

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

23

Page 24

© 2012 HID Global Corporation. All rights reserved.

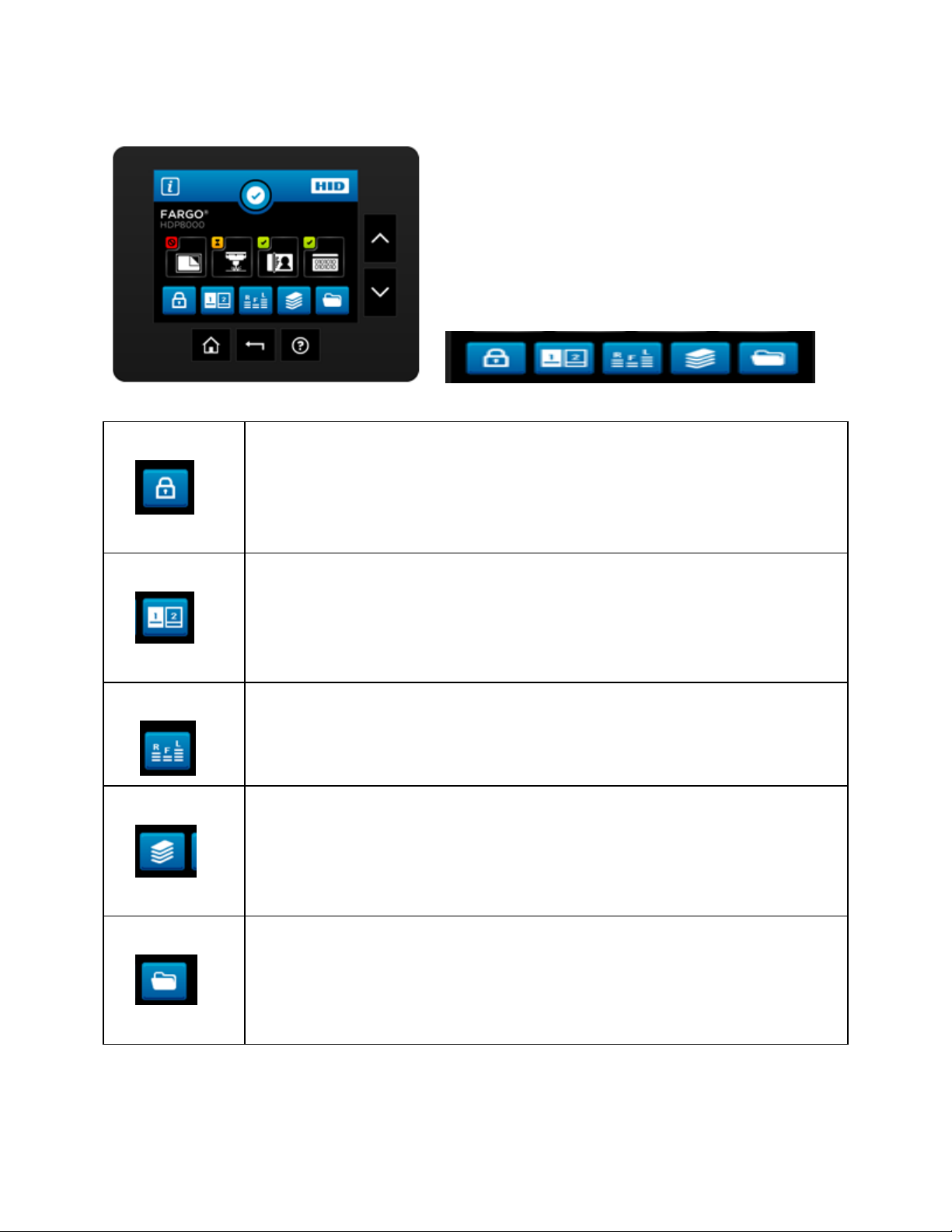

Printer lock

Hopper Select

Ribbon Film Laminate levels shown

Card Count

Setup Menu

Home Screen ( continued)

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

24

Page 25

© 2012 HID Global Corporation. All rights reserved.

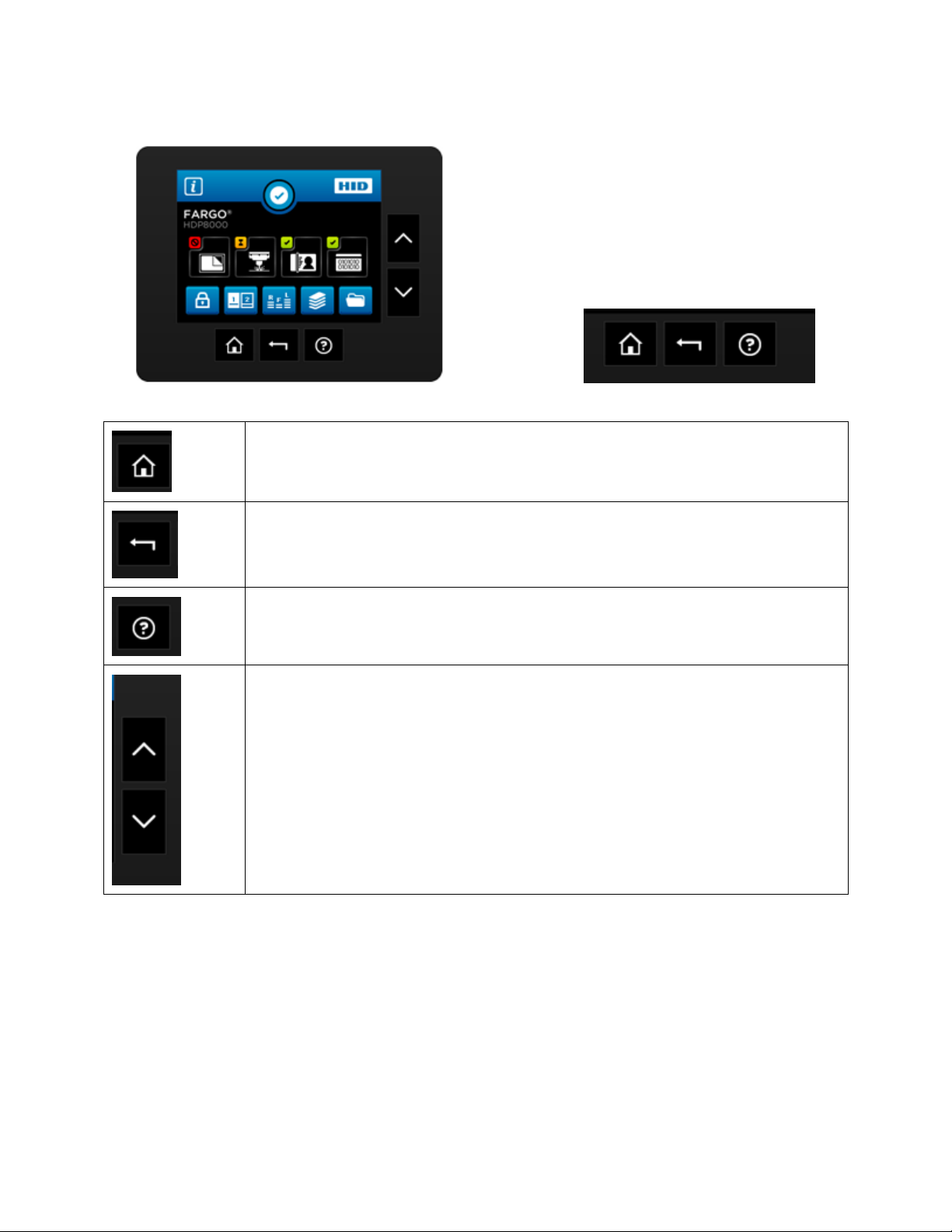

Home Screen

Back one level

HELP

The side buttons allow vertical scrolling when the current screen

accommodates multiple lines.

Home Screen ( continued)

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

25

Page 26

© 2012 HID Global Corporation. All rights reserved.

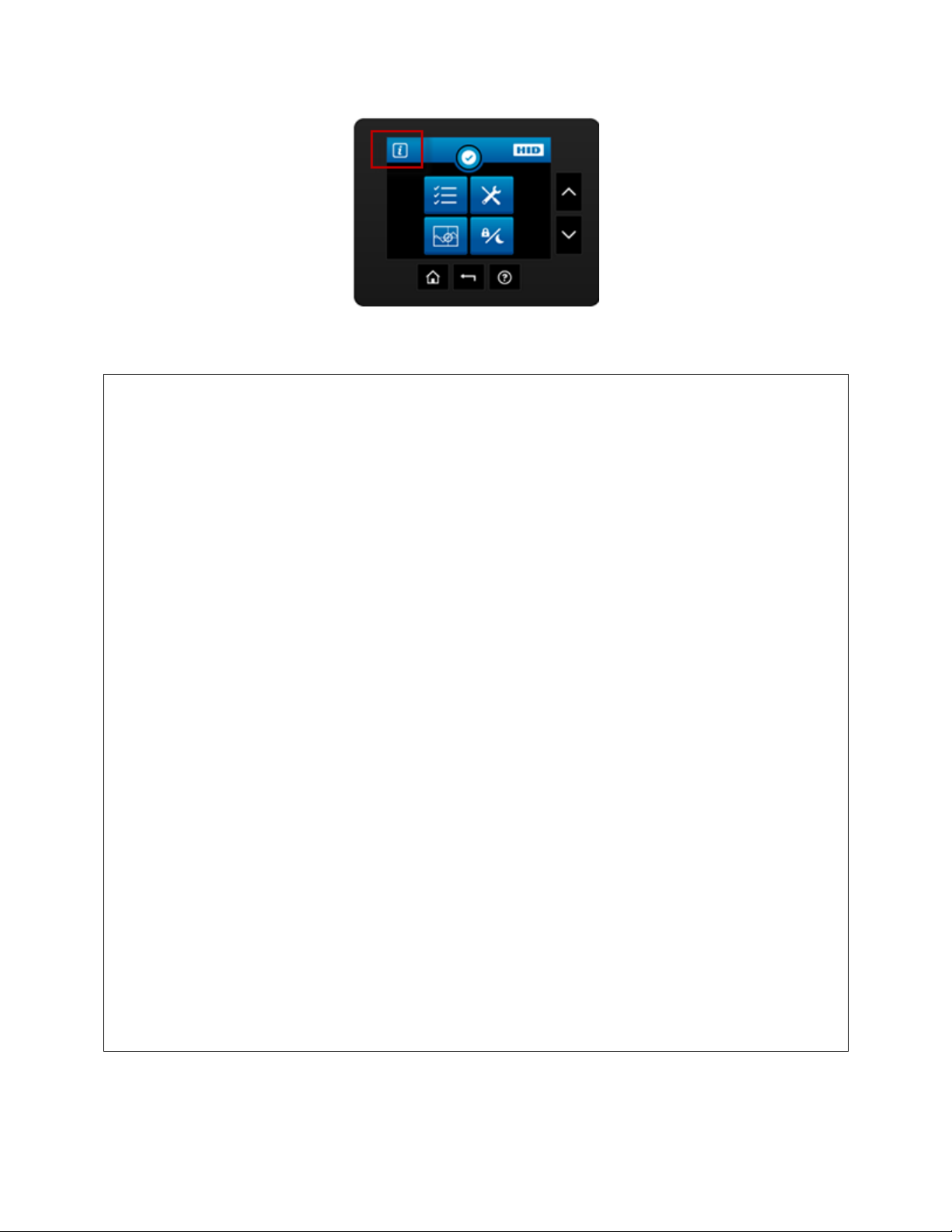

Note: Select the desired option to view information

Serial Number

Model Name

Printer Firmware

Laminator Firmware

Display Firmware

MAC Address

IP Address

Ribbon Type

Film Type

Lam 1 Type

Lam 2 Type

Mag Encoder

Smart Encoder

Prox Encoder

Mifare Encoder

iCLASS Encoder

Laminator

Flipper

Card Count

Pass Count

Transfer Count

System Information Screen Option

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

26

Page 27

© 2012 HID Global Corporation. All rights reserved.

While the printer is working, the Notification icon shows a moving gear .

Each Station icon shows a progress bar with its current progress

in the job

A global pause button is shown.

Process Status

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

27

Page 28

© 2012 HID Global Corporation. All rights reserved.

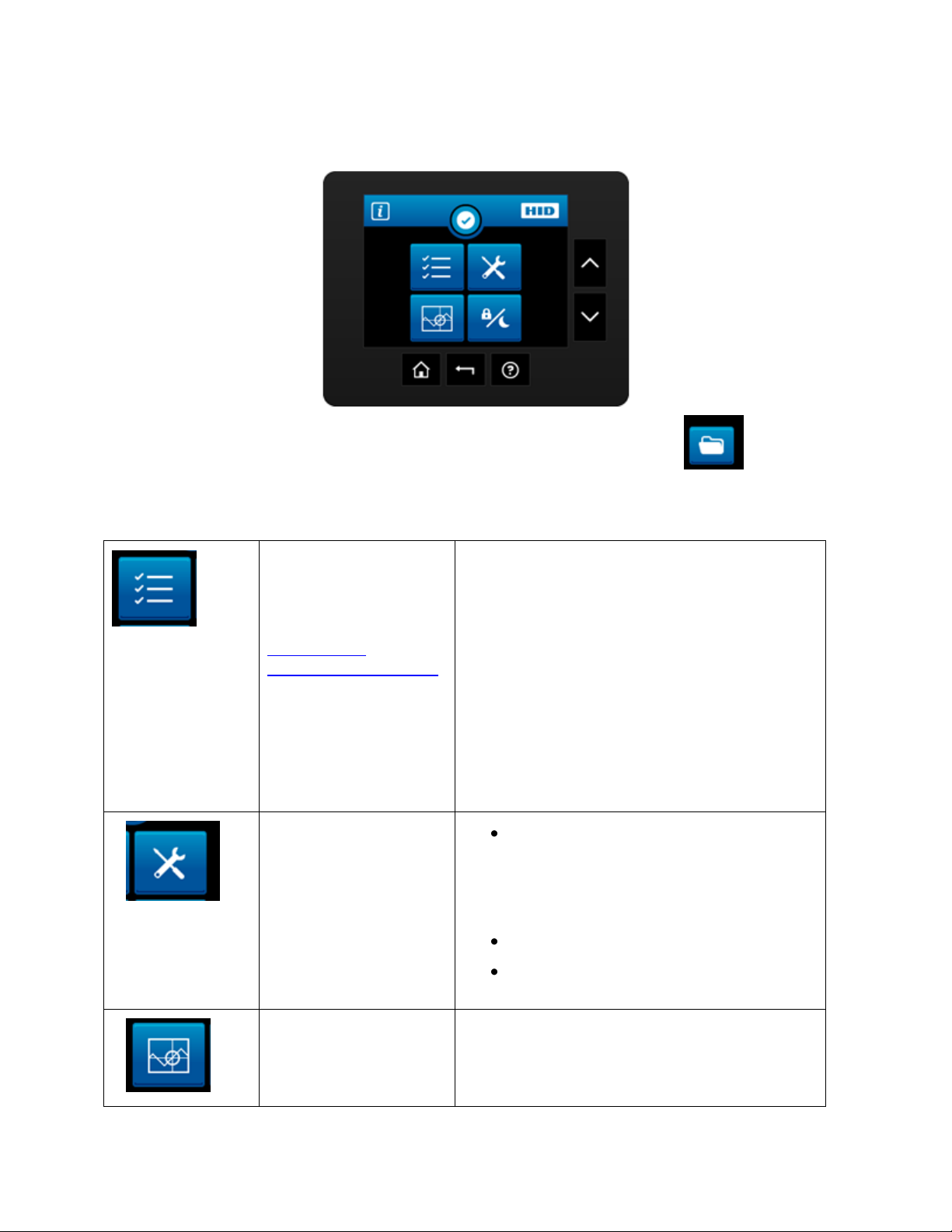

Printer Settings

For details see:

Selecting the

Advanced Settings tab

Printer

Transfer

Laminator

Mag Encoding

Flipper

Hopper (see Display A below for details)

Display

Network

Language

Tools

Diagnostics

Self Test (see Display B below for details)

Mechanical Test (see Display C below for

details)

Cleaning the Printer

Firmware Upgrade (use the

Workbench Utility Program)

Sensor Calibration

Calibration ( see Display D below for details)

Ribbon Sensor

Main Menu

Press the Setup Menu Icon on the Home Screen to access the Main Menu

Icon Name Options Included

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

28

Page 29

© 2012 HID Global Corporation. All rights reserved.

Film Sensor

Mag Sensor

Lamination Sensor

Lock and Sleep

settings

See Display E below for details

Sleep Time

Stand-by Time

Stand-by Temp

Display Sleep Time

Change password

Hopper selection screen allows the user to change the hopper where cards are fed from.

Green indicates the selected hopper, also shows cancel and save buttons.

Main Menu (continued)

Hopper Selection

Display A

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

29

Page 30

© 2012 HID Global Corporation. All rights reserved.

Alignment Test

YMC Color Bar Test

Magnetic Test

YMCK Test

Standard Resin Test

Printer Settings card

Color Photo Test

Main Menu (continued)

Display B

Tools –Diagnostic Self Test Options

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

30

Page 31

© 2012 HID Global Corporation. All rights reserved.

When selected the printer will perform the test to verify mechanical options are working

correctly

Lower Printhead

Raise Printhead

Home Flipper Table

Run ribbon take-up motor

Run ribbon supply motor

Run Printhead lift motor

Cycle transfer head lift motor

Run film supply motor

Run film take-up motor

Main Menu (continued)

Display C

Tools –Diagnostic Mechanical Test Options

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

31

Page 32

© 2012 HID Global Corporation. All rights reserved.

NOTE: Calibrating sensors may be done through the Driver Printing Preferences Toolbox OR

through the LCD DISPLAY. Both options use the same printer setup information.

Ribbon Sensor Calibration

Film Sensor Calibration

Magnetic TOF ( Top of Form)

Lamination Sensor Calibration

Main Menu (continued)

Display D

Sensor Calibration Options

32

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

Page 33

© 2012 HID Global Corporation. All rights reserved.

Select to desired option and use the + and – button to adjust the number.

Cancel revert save buttons

Sleep Time

Standby Time

Standby Temp

Display Sleep Time

Change Password

Main Menu (continued)

Display E

Sleep and Lock Settings

Case Open

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

33

Page 34

© 2012 HID Global Corporation. All rights reserved.

When the cover is opened, this screen is presented.

The arrows ( ) allow card shuttle from 1 to 2

The arrows() ) move the rollers back and forth. This is used if a card jam occurs.

When an error occurs a details screen appears, containing details about the specific error that

occurred.

The keys to the right are:

Job Cancel

Station Error

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

34

Page 35

© 2012 HID Global Corporation. All rights reserved.

Retry

Help

While adjusting settings in the setting menu, the Boolean setting can be set by pressing the

desired value.

Green indicates the selected setting.

Boolean Setting

Settings Keypad

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

35

Page 36

© 2012 HID Global Corporation. All rights reserved.

While setting a value in the settings menu that requires numeric input, a keypad will be

presented.

Current value is displayed in blue font.

Cancel and save buttons

Blue instructions says: "Enter Current PIN" Button says: "Next >"

Blue instructions says: "Enter New PIN" Button says: "Next >"

Blue instructions says: "Confirm New PIN" Button says: "Enter"

Pin Keypad

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

36

Page 37

© 2012 HID Global Corporation. All rights reserved.

When the printer is to be locked or unlocked the Security Keypad is presented.

Enter the PIN and press Enter.

While setting a value in the settings menu that requires a selection, this screen will be

presented.

Current value is highlighted in green.

Cancel and save buttons

Security Keypad

Text Button Select

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

37

Page 38

© 2012 HID Global Corporation. All rights reserved.

Navigate to the Notification list by pressing on the Notification Icon.

This will show the notification detail and allow navigation to further details.

Navigate to a printer settings menu, a list of all settings will be displayed.

Scroll up and down using the side buttons, make selections by pressing the specific setting‟s

button.

Notification List

Menu Detail List

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

38

Page 39

© 2012 HID Global Corporation. All rights reserved.

Consumables status screen shows current levels for :

Laminate supply

Film supply

Ribbon supply

While setting a value in the settings menu that requires an integer input, this screen will be

presented.

Current value is displayed and can be incremented or decremented by the + or – keys

respectively.

Consumable Status

Integer Selection

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

39

Page 40

© 2012 HID Global Corporation. All rights reserved.

Cancel revert save buttons

Some settings require a confirmation.

to Decline or to Accept.

Card counter screen allows the user to view the total number of cards printed as well as the

Current count for a particular batch.

Confirmation

Card Counter

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

40

Page 41

© 2012 HID Global Corporation. All rights reserved.

The current count can be reset to zero by pressing the reset key.

Help screen (in the future) will provide detailed information for recovering from common errors.

Help Screen

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

41

Page 42

© 2012 HID Global Corporation. All rights reserved.

Section 3: Setup and Installation Procedures

Inspection – HDP8500

While unpacking your Printer, inspect the carton to ensure that no damage has occurred during

shipping. Make sure that all supplied accessories are included with your unit.

Unpacking the Printer.

The following items are included with your Printer:

Software Installation CD (includes Printer Driver, Online User‟s Guide and Printer Diagnostic

Tool)

Power Cord

Card Cleaning Roller (x2)

Card Cartridge (x2)

Card Output Bin

Ribbon Cartridge

Film Cartridge

Warranty Statement

This is included with the HDP8500-LC Only:

Card Lamination Module

(Important: Please use the original packaging when shipping the HDP8500 Printer/Laminator.

This will require the Laminator Module to be detached from the Printer prior to shipping.)

Choosing a Good Location

Follow these guidelines:

Place the unit in a location with adequate air circulation to prevent internal heat build-up.

Use the Printer's dimensions as a guideline for the minimum clearances to the unit. (Note:

Allow for adequate clearance above the unit to accommodate the height of the unit with its

Covers open.)

Do not install unit near heat sources such as radiators or air ducts or in a place subject to

direct sunlight, excessive dust, mechanical vibration or shock.

About Moisture Condensation

If the unit is brought directly from a cold to a warm location or is placed in a very damp room,

moisture may condense inside the unit. Should this occur, print quality may not be optimum.

Leave the unit turned OFF in a warm, dry room for several hours before using. This will allow

the moisture to evaporate.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

42

Page 43

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Unlock and open the Printer cover .

2

Remove the HDP Film Cartridge.

Loading the HDP Transfer Film

Note: Fargo Card Printers require highly specialized supplies to function properly.

To maximize Printer life, reliability, printed card quality and durability, you must use only

Fargo Certified Supplies.

For this reason, your Fargo warranty is void, where not prohibited by law, if you use non-

Fargo Certified Supplies.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

43

Page 44

© 2012 HID Global Corporation. All rights reserved.

3

Load the HDP Film into the Film Cartridge and click into place.

The green take-up spool goes on the left side, the full roll goes on the right

side. 4

Tighten the HDP Film.

5

Insert the HDP Film cartridge back into the printer and click into place.

44

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

Page 45

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Unlock and open the Printer cover .

2

Remove the HDP Ribbon Cartridge.

3

Load the HDP Ribbon into the Cartridge and click into place.

The blue take-up spool goes on the left side, the full roll goes on the right side.

Loading the Ribbon

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

45

Page 46

© 2012 HID Global Corporation. All rights reserved.

4

Tighten the Ribbon .

5

Insert the HDP Ribbon cartridge back into the printer and click into place.

6

Insert the HDP Ribbon cartridge back into the printer and click into place.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

46

Page 47

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Unlock and open the Printer cover .

2

Remove the Card Cleaning Roller from the Print Ribbon packaging and insert

the Cleaning Roller into the gray handle.

3

Remove the protective sleeve from the Card Cleaning Roller.

Loading the Card Cleaning Roller

The HDP8500 contains 2 card cleaning assemblies in the Printer and 1 cleaning assembly in

the Lamination Module. Use the same procedure for both.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

47

Page 48

© 2012 HID Global Corporation. All rights reserved.

4

Insert the Card Cleaning Roller assembly into the card cleaning slot.

5

Follow the same procedure for the second cleaning assembly.

6

Follow the same procedures for the Lamination Module assembly.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

48

Page 49

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Unlock and open the Printer cover .

2

Remove the HDP Lamination Cartridge from the Printer.

3

Load the HDP Lamination into the Cartridge and click into place.

4

Tighten the HDP Laminate.

Loading the Overlaminate

(Note: This procedure only applies to the HDP8500-LC.)

The loading process for both the Thermal Transfer Overlaminate and the PolyGuard™

Overlaminate material is the same. Refer to the following steps to load either type of

overlaminate into the Printer.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

49

Page 50

© 2012 HID Global Corporation. All rights reserved.

5

Insert the HDP cartridge back into the printer and click into place.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

50

Page 51

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Unlock and open the Card Input Cartridge.

Leave the cartridge in the Printer, There is no need to completely remove the

cartridge to load cards.

2

Load the cards into the cartridge.

Important: The front of the card must face DOWN. The back of the card

or the magnetic stripe on the card must face UP. The Smart Chip is

loaded on the bottom.

3

Place the Card Weight on top of each stack of cards.

Loading the Blank Cards

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

51

Page 52

© 2012 HID Global Corporation. All rights reserved.

4

Close and lock the Card Input Cartridge.

5

To completely remove the Card Input Hopper unlock the Printer Top Cover

and release the BLUE lever to unlock the individual hopper.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

52

Page 53

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Unlock and place the card output hopper onto the output side ( left) of the

printer and push down until it clicks into place.

Step

Procedure

1

Insert the power cord into the Printer as shown below.

2

Use the ON/Off switch to power up and down. This powers up both the Printer and the

Lamination Module.

Installing the Card Output Hopper

Connecting Power to HDP8500 Printer and/or Lamination

Module

Important! Do not plug in the USB cable until prompted to do so during the installation of the

HDP8500 Printer Driver. Refer to the Driver installation procedure below.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

53

Page 54

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Close down all programs.

Insert the Software Installation CD into your computer‟s CD drive. After a few

seconds, the CD‟s installer program will automatically open.

Follow the CD‟s on-screen Procedures to complete installation.

(Note: If the CD does not automatically open, use “My Computer” or

“Windows Explorer” to view the contents of the CD. Then, double-click on the

Setup.exe file listed on the CD.)

2

Click NEXT and follow the screen prompts to complete the driver installation.

Printer Driver Installation Procedures

(For MAC OS X and Linux Driver and User Guide see www.hidglobal.com

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

54

Page 55

© 2012 HID Global Corporation. All rights reserved.

Section 4: Printer Driver Operations

See this section for printer adjustments.

Using the Card tab

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

55

Page 56

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Select the appropriate card option:

These Card Printers accept standard CR80 sized cards

(3.452L x 2.204W / 87.7 mmL x 56 mmW)

CR-80: This selection is the default form size for the HDP8500

Custom: This selection is used to create a custom form size from 1.0 x

3.0 to 2.204 to 3.452 (25.4 X 76.2 mm to 56 X 87.7 mm).

The dimensions of the total print area for each card size will appear in the Print

Width and Print Length boxes.

These print area dimensions are .04" (1mm) larger than the actual card

size. This is so the Printer can overprint images to ensure they will appear

Edge-to-Edge when transferred to the card.

For this reason, when designing a card format, always set the card size or

page size within the card design program to the exact Print Length and

Width dimensions listed in the Printer Driver.)

Card

Thickness

System will be compatible with card thicknesses from 20-50 mil

Print only: .020” (20 mil) to .050” (50 mil) / .762mm to 1.27mm

Print/Lamination: .030” (30 mil) to .050” (50 mil) / .762mm to 1.27mm

Selecting the Card Size

Important! Never run cards with a contaminated, dull or uneven surface through the Printer.

Printing onto such cards will ultimately lead to poor print quality. Always store the card stock in

its original packaging or in a clean, dust-free container. Do not print onto cards that have been

dropped or soiled.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

56

Page 57

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

Card Type

You have these selections (to choose from):

Fargo UltraCard Premium III (Default Card Type) = 180˚ and 2

sec

Fargo Ultracard = 175˚and 2.0 sec

HID Tech Card Composite = 190˚ and 2 sec

HID Tech Card PVC =180˚and 2.0 sec

Indala FlexISO – Standard (FPISO) = 185˚and 2.0 sec

Indala FLexISO XT-Composite (FPIXT) 190˚ and 2 sec

Custom 1 = 175˚and 2.0 sec

Custom 2 = 175˚and 2.0 sec

Defaults: The HDP Printer Driver software has default Transfer

Temperature and Dwell Time settings that deliver the best

transfer for these card types. These defaults automatically

configure based on the card type, Ribbon type and whether

printing single- or dual-sided.

Card Type Selection: Before printing, if using these standard

Fargo card types, check to make sure that the appropriate card

type option selected from the Card tab of the HDP Printer

Driver:

Proper Settings: It is very important to note that not all card

types will be accommodated by these default settings. In some

cases, experimentation may be needed to find the proper

settings.

IMPORTANT: If the appropriate option is not selected, the wrong

Dwell Time and temperature may be used during the image transfer

process, which may result in poor adhesion of the HDP Film or

warping of the card.)

Card Design

The Printer will print onto any card with a clean, level and polished

PVC surface. (Important: Composite PVC is recommended over

straight PVC for the best results and for ISO card specification

compliance. Single-side straight PVC does not conform to ISO

compliance at this time.)

Card Surface

Suitable cards must have a polished PVC surface free of

fingerprints, dust or any other types of embedded contaminants.

Selecting the Card Type

Select the appropriate card type according to the composition of the card stock.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

57

Page 58

© 2012 HID Global Corporation. All rights reserved.

In addition, cards must have a completely smooth, level surface

in order for the Printer to achieve consistent color

CoverageSome types of Proximity cards, for example, have an

uneven surface which will inhibit consistent color transfer.

Likewise, some smart card chips are raised slightly above the

cards surface, which also results in poor color transfer.

UltraCard stock

Due to the importance of using high-quality blank cards, a factoryapproved card stock called UltraCard™ is available and

recommended for best results.

UltraCard stock has a glossy PVC laminate on top and bottom

and is optically inspected to provide the cleanest, most scratch

and debris-reduced cards possible.

Two types of these cards are available: UltraCard and UltraCard

Premium III.

UltraCard stock has a PVC core and offers medium card

durability.

Recommended: UltraCard Premium III stock has a 40%

polyester core and offers high durability.

Both types of UltraCards produce printed images with a glossy,

photo-quality finish.

Custom

If using a card stock other than listed, use the Custom 1options to

save custom Dwell Time and dwell temperature controls on the

Image Transfer tab.

a. Click on the Custom options and enter a name for the card

stock.

b. Click on the Image Transfer tab to adjust the Dwell Time and

temperature sliders to the appropriate settings. See the Display

A below. page. (Note: These settings will be saved for the

custom card type when the Printer Driver setup window is

closed.)

c. Custom Card stock: To determine the proper settings for

custom card stock, apply the Tape adhesion Test. Conducting

the Tape Adhesion Test.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

58

Page 59

© 2012 HID Global Corporation. All rights reserved.

Display A

Printing on Alternate Card Stocks

In order to optimize the HDP Card Printer‟s capabilities for cards with hard-to-print surfaces, we

recommend evaluating the card stock selection before installation of the Printer. The variability

in cards based on:

Different surface textures and different sources of raw materials: This may require

different HDP Film transfer parameters.

Varied methods of assembling IC smart cards and proximity cards: These particular

adhesives used to glue a smart chip to a plastic card may react differently to a Transfer

Roller‟s pressure and temperature.

Cleanliness of card stock: The HDP process does not eliminate the need to use clean

card stock. The best-looking card always starts with the cleanest card surface. Dirt and

debris on a card can show up as blemishes on the card surface and may reduce the life of

the image itself.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

59

Page 60

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Test the adhesion quality of the HDP Film to the card by printing sample cards

and completing an adhesive tape test.

2

Select the UltraCard IIIs-Glossy PVC if the card is glossy and print a test card.

3

a. Apply a strip of ½ (12mm) wide Scotch-type clear adhesive tape (such as

3M brand 600), at least 2” (50mm) long, firmly across the surface of the

card, pressing out all air bubbles with a fingertip.

b. Remove the tape by smoothly and rapidly (approximately 2 inches/second

(50mm/sec)) pulling it up at a perpendicular (90 degree) angle to the card.

(Note: The IPC recommends a minimum of three tests for each card type

evaluation.)

4

Visually examine the card and the strip of tape pulled from the card, to see if

any portion of the HDP Film was removed from the card.

If any residue (e.g., oil or grease from fingertips) is present on the card

surface, the evaluation results may be affected.

If the printed, transferred HDP Film particles (a) pull away from the card

and (b) adhere to the tape, this indicates that inadequate adhesion of the

HDP Film to the card. Increased heat and Dwell Times are necessary to

resolve this problem.

Samples 1, 2 and 3 show a representation of the adhesion level you can

expect.

Result 1: Sample 1 shows a significant transfer to the tape and is an

absolute failure.

Result 2: Sample 2 shows that very slight transfer to the tape can be

acceptable without sacrificing overall image durability on matte finish cards.

Result 3: Sample 3 shows no transfer to the Tape and is an Absolute

Pass.

5

If the tape test indicates inadequate adhesion, increase the heat setting by 5

degrees, print another card and try the tape test again.

Conducting the Tape Adhesion Test

It is important to conduct tape adhesion tests because Fargo cannot be certain which transfer

temperature and Dwell Time will work best (when printing cards other than UltraCard III). (Note:

The optimal transfer settings may vary from card type to card type.)

Important! Inadequate time and temperature could produce cards that are more vulnerable to

accelerated wear and dye migration. Use sufficient time and temperature to transfer HDP Film

to the card to ensure a long lasting, durable card.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

60

Page 61

© 2012 HID Global Corporation. All rights reserved.

Once the temperature has been increased 4 times (20 degrees), reset

temperature to default and increase the Dwell Time by .5 second.

Repeat this process until adequate adhesion is achieved.

Ensure that the cards (in use) have a surface roughness (Ra) of 60 micro

inches or less.

This information should be available from the card manufacturer.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

61

Page 62

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

From the Printer Driver select the desired hopper from which to feed the

card.

2

From the Printer Ready screen select the HOPPER icon

3

Cycle between Hopper 1 and Hopper 2 by selecting 1 or 2 from the

Printers Display Control Panel.

Click to save

Using the Card Hopper Selection

Use this option to select the Card Input Hopper. There are 2 options for setting the Hopper.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

62

Page 63

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Select Portrait to cause the card to print in a vertical orientation.

OR

Select Landscape to cause the card to print in a horizontal orientation.

Setting the Orientation

Select either the Portrait or Landscape radio buttons for Orientation.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

63

Page 64

© 2012 HID Global Corporation. All rights reserved.

Specifying the number of Copies

Specifies the number of copies to be printed.

The upper limit is 10000 and the lower limit is 1.

Selecting the Diagnostics button

This will launch the Diagnostic tool (if installed). The Workbench Utility Program is included on

the driver CD. Also see the Workbench Utility Program User Guide located on the driver CD..

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

64

Page 65

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Install a HDP8500 compatible ribbon in the Printer for the Test Print.

The ribbon installed determines the Test Print PRN file sent to the printer.

2

Open the Driver settings.

a. From your computer‟s startup menu, select Settings > Printers and Faxes.

b. Double click on the HDP8500 Card Printer under the Printer‟s window.

c. Select Printing Preferences under the Printer drop-down menu. (Note: This

will bring up the HDP8500 Printing Preferences window.)

3

a. Select the Card tab, and then click on the Test Print button, as shown in

Display A on the next page.

b. When the Test Print button is selected, an image is copied to the Printer.

Printing a Test Print Image

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

65

Page 66

© 2012 HID Global Corporation. All rights reserved.

Selecting the About button

Select the About button to open a dialog box containing the copyright information as well as the

Driver‟s version number and date code.

Selecting the Toolbox button

Select the Toolbox button. See the Section 5: Accessing the Toolbox HELP section for more

information and procedures.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

66

Page 67

© 2012 HID Global Corporation. All rights reserved.

Using the Device Options tab

This section describes the use of the Device Options tab.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

67

Page 68

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Use the Supplies checkbox for auto detection of the consumables, which are

the Ribbon and, Film. See below.

In the Firmware, the values (representing the installed Ribbon, installed

Transfer Film) are updated on initialization (including each time the

cover is closed).

The Firmware compares the Ribbon and, Film values in the PRN file to

the values (it holds regarding the currently installed consumables).

If the values do not match, the LCD displays Wrong Ribbon Error or Wrong

Film Error the Driver returns the corresponding error message. See below.

3

When the Supplies checkbox is checked, the following takes place:

Ribbon and Film Type dropdown boxes are inactive and populated with

values of installed supplies. Dual Sided and Options are set to defaults

for detected supplies.

Before the Driver initiates each job, it retrieves the consumables values

from the Firmware.

If no Printer is found or no Ribbon is installed, the checkbox is allowed to

be checked. (Note: The previously-chosen Ribbon and Film values will

remain. You will see an error message.)

Activating the Device Options tab automatically repopulates the Ribbon

and Film types. (Note: You will see an error message if no Printer found

when activating the Device Options tab.)

4

When the Supplies checkbox is not checked or it is de-selected (cleared)

from a selected state, the Ribbon and Film dropdown boxes become active

and auto selected Ribbon and Film types remain (until manually changed).

Detecting Supplies at Print Time Function

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

68

Page 69

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Adjust to match the Ribbon Type selection with the Ribbon type that is

loaded in the Printer.

YMC (Full Color): Yellow, Magenta, Cyan

OR

YMCK (Full Color/Resin Black): Yellow, Magenta, Cyan, Resin Black

OR

YMCKK (Full Color/2 Resin Black): Yellow, Magenta, Cyan, Resin

Black, Resin Black

OR

YMCKH (Full Color/Resin Black/Heat Seal): Yellow, Magenta, Cyan,

Resin Black, and Heat Seal

OR

YMCFK (Full Color/ Fluorescing /Resin Black): Yellow, Magenta,

Cyan, UV Fluorescing, and Resin Black

YMCKI (Full Color/Resin Black/Inhibit): Yellow, Magenta, Cyan, Resin

Black, Inhibit

K Resin Black: Resin Black

Adjusting the Ribbon Type

Use the Ribbon Type dropdown menu to match Ribbon type.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

69

Page 70

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Allows you to select the film type option that is appropriate for the type of

HDP film currently loaded in the Printer.

Select the Clear option to automatically adjust the appropriate transfer

time and temperature to pre-determined defaults. (Note: Select this

option to automatically adjust the transfer temperature and the dwell

times to defaults when non-custom card type is chosen on Card tab.)

OR

Select the Holographic option to change appropriate internal Printer

settings needed to make the holographic film work. (Note: Select this

option to automatically adjust the transfer temperature and the dwell

times to defaults when non-custom card type is chosen on Card tab.)

(Note: It will also adjust the necessary transfer temperature and the

dwell settings in the Driver to provide the optimal holographic InTM

performance.)

Adjusting the Film Type

Using the Dual Sided Group Functions

The Dual Sided group checkboxes (shown below) are grayed out if no Flipper is automatically

found or if the Dual Sided is manually turned off. See the procedures in this section for more

instructions.

HDP8500 Industrial Card Printer/Encoder User Guide L001617 rev 1.1

70

Page 71

© 2012 HID Global Corporation. All rights reserved.

Step

Procedure

1

Select this option in conjunction with any application program that supports a

multiple-page document, duplex printing. (Note: The program must be able

to send down two or more separate pages to be printed within the same

document.)

2

Page 1 will be transferred to the front side of the card.

Page 2 will be transferred to the backside of the card.

The Printer Driver will always place all odd numbered pages on the front

side of the card and all even numbered pages on the back side with this

option selected.

Step

Procedure

1

Select this option to automatically print full-color on the front of a card and

resin black on the back of a card (using YMCKK Print Ribbons

If using a YMCKK Ribbon, the front of the card is printed with the YMCK

Panels and the back is printed with the second K Panel.

(Note #1: This option is automatically enabled when a YMCKK Ribbon type

is selected.)

Using the Dual Sided - Print Both Sides option

Use this option to automatically print on both the front and backside of a card.

Using the Print Both Sides - Split 1 Set of Ribbon Panels

option