Page 1

FARGO® DTC®1500

DIRECT-TO-CARD PRINTER

MODEL X001800

U

SER GUIDE

PLT-03159, Rev A.0

September 2017

hidglobal.com

Page 2

Copyright

© 2017 HID Global Corporation/ASSA ABLOY AB. All rights reserved.

This document may not be reproduced, disseminated or republished in any form without the prior

written permission of HID Global Corporation.

Trademarks

HID GLOBAL, HID, the HID Brick Logo, DTC, ICLASS, ULTRACARD, FARGO WORKBENCH, and FARGO

are the trademarks or registered trademarks of HID Global Corporation, or its licensors, in the U.S. and

other countries. All other trademarks, service marks, and product or service names are trademarks or

registered trademarks of their respective owners.

MIFARE, MIFARE DESFire, and MIFARE DESFire EV1 are registered trademarks of NXP B.V. and are

used under license.

Revision History

Date Description Version

September 2017 Initial release. A.0

Contacts

For additional offices around the world, see www.hidglobal.com/contact/corporate-offices.

Americas and Corporate Asia Pacific

611 Center Ridge Drive

Austin, TX 78753

USA

Phone: 866 607 7339

Fax: 949 732 2120

Europe, Middle East and Africa (EMEA) Brazil

Haverhill Business Park Phoenix Road

Haverhill, Suffolk CB9 7AE

England

Phone: 44 (0) 1440 711 822

Fax: 44 (0) 1440 714 840

HID Global Customer Support: www.hidglobal.com/support

19/F 625 King’s Road

North Point, Island East

Hong Kong

Phone: 852 3160 9833

Fax: 852 3160 4809

Condomínio Business Center

Av. Ermano Marchetti, 1435

Galpão A2 - CEP 05038-001

Lapa - São Paulo / SP

Brazil

Phone: +55 11 5514-7100

2 September 2017

Page 3

Contents

Chapter 1: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.1 United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.2 Canada. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.3 Taiwan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.4 Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.5 Korea . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 Safety Messages—United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.2 Safety Messages—French . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.3 Safety Messages—Taiwan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.4 Safety Messages—China . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5 Printer Components: Print Ribbons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.1 Ribbon Types and Print Counts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.6 Printer Components: Blank Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2: Setup and Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.1 Choosing a Good Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.1 About Moisture Condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 Installing the Print Ribbon Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4 Installing Blank Cards into the Input Card Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5 Card Size Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.6 Connecting the Printer Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 3: Print Driver Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Driver Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Chapter 4: Printer Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1 Card Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1.1 Toolbox Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1.1.1 Configuration Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1.1.2 Calibrate Laminator Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1.1.3 Calibrate Ribbon Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.1.4 Clean Printer Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

September 2017 3

Page 4

PLT-03159, Rev A.0

4.1.1.5 Safety Messages (Review Carefully). . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1.1.6 Cleaning Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.1.1.7 Printhead Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.1.1.8 Cleaning the Platen and the Card Feed Rollers . . . . . . . . . . . . . . . . . . 36

4.1.1.9 Cleaning the Exterior of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.1.1.10 Advanced Settings Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2 Device Options Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3 Image Color Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.3.1 Advanced Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.4 Image Calibrate Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.5 Magnetic Encoding Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.5.1 Magnetic Track Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.5.1.1 Reviewing the Sample String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.5.1.2 Sending the Track Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.6 Lamination Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.7 Overlay / Print Area Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.7.1 Defining an Overlay or Print Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.8 K Panel Resin Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.8.1 Defined Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.8.1.1 Method for Defining a Single Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.8.1.2 Method for Defining Multiple Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.9 Printer Info Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Chapter 5: System Overview—Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.1 Sequence of Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.2 Printer Error Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.3 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.4 Troubleshooting with the Error Message Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Chapter 6: Firmware Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

6.1 Upgrade Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Chapter 7: HID Global Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.1 Reading the Serial Numbers on a Fargo Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4 September 2017

Page 5

Specifications

The purpose of this section is to provide you with specific information on the regulatory compliances,

agency listings, technical specifications, and functional specifications for the DTC1500 printer.

1.1 Regulatory Compliance

UL The card printer is listed under UL 60950-1 (2nd edition) Information Technology

Equipment.

File Number: E145118

Note: This product is intended to be supplied by a listed power unit marked Class 2

and rated for 24 VDC, 3.3A minimum.

Chapter

1

CSA The printer manufacturer has been authorized by UL to represent the card printer

as CSA Certified under CSA Standard C22.2 No. 60950-1-07 2

File Number: E145118

FCC The card printer complies with the requirements in Part 15 of the FCC rules for a

Class A digital device.

CE The card printer has been tested and complies with EN300-330, EN301-489,

EN60950-1:2006 + A11:2009 + A1:2010 + A12:2011 + A2:2013, EN50581, EN62479.

Note: Based on testing, the printer manufacturer certifies that the card printer

complies with the following European Council Directives and has placed the CE

mark on the card printer.

LVD 2014/35/EU, RED 2014/53/EU, ROHS2 2011/65/EC

Emissions and

Immunity

Standards

Safety Standards

Additional

Agency Listings

Environmental

FCC Part 15 Class A, RSS-GEN, RSS 210, CNS 13438, EN55032 Class A, EN55024,

EN6100-3-2, EN6100-3-3, EN300-330, EN301-489, GB9254, GB17625

UL IEC 60950-1 (2nd edition), CSA C22.2 No. 60950-1-07 (2nd edition), EN60950-1,

GB4943, CNS14336

CCC, BSMI, KC, EAC, BIS, MIC, RCM, S-mark

GreenCircle Certified Energy Savings.

Power supply efficiency level VI minimum.

nd

edition.

September 2017 5

Page 6

1.1.1 United States

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause

undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and if not

installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference; in which case, you are required to correct the interference at your expense.

IMPORTANT: Changes or modifications to an intentional or unintentional radiator not expressly

approved by the party responsible for compliance could void your authority to operate the

equipment.

1.1.2 Canada

Specifications PLT-03159, Rev A.0

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to

the following two conditions: (1) this device may not cause interference, and (2) this device must

accept any interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio

exempts de licence. L'exploitation est autorisée aux deux conditions suivantes: (1) l'appareil ne doit

pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

1.1.3 Taiwan

䴻✳⺷娵嫱⎰㟤Ỷ≇澯⮬柣暣㨇炻朆䴻姙⎗炻℔⎠ˣ⓮嘇ㆾἧ䓐侭⛯澵⼿㑭冒嬲

潏柣澯ˣ≈⣏≇澯ㆾ嬲潏⍇姕妰䈡⿏⍲≇傥ˤỶ≇澯⮬柣暣㨇ἧ䓐澵⼿⼙枧梃

凒⬱ℐ⍲⸚㒦⎰㱽忂ᾉ烊䴻䘤䎦㚱⸚㒦䎦尉㗪炻ㅱ灅⌛ 䓐炻㓡┬军䃉⸚㒦㗪㕡

⼿两临ἧ䓐ˤ⇵枭⎰㱽忂ᾉ炻㊯ὅ暣ᾉ㱽夷⭂ἄ㤕䃉䶂暣忂ᾉˤỶ≇澯⮬柣暣㨇

枰⽵⍿⎰㱽忂ᾉㆾⶍ㤕ˣ䥹⬠⍲慓瀏䓐暣㲊灕⮬⿏暣㨇姕⁁⸚㒦ˤ

1.1.4 Japan

ɱʌ㻻㖤ʍ㐅ⴷʌශᕅᇐʰɯʄɢʜɷȾ

( 㐅ⴷᇐ⮠ʍㅢ AC-xxxxx ʅɷ )

ᵢ㼳ʍ䴱⌘ʰֵ⭞ɵɽ 5),'ₕಞʌ䃣ʝʨᴮɫ䗲ʝ㻻㖤ʅɷȾ

ɻʌɽʟֵ⭞ɷʩ⭞䙊ᡶʉʦʁʄʍȽⱸₕಞʉᖧ丵ʰфɦʩᚆʪɪɠʨʜɷ

1.1.5 Korea

㧊 ₆₆⓪ 㠛ⶊ㣿 (A ) 㩚㧦䕢 㩗䞿₆₆⪲㍲ 䕦ⰺ㧦 ⡦⓪ ㌂㣿㧦⓪ 㧊 㩦㦚 㭒㦮䞮㔲₎ ⧒Ⳇ , Ṗ㩫 㣎㦮 㰖㡃

㠦㍲ ㌂㣿䞮⓪ ộ㦚 ⳿㩗㦒⪲ 䞿┞┺ .

6 September 2017

Page 7

PLT-03159, Rev A.0 Specifications

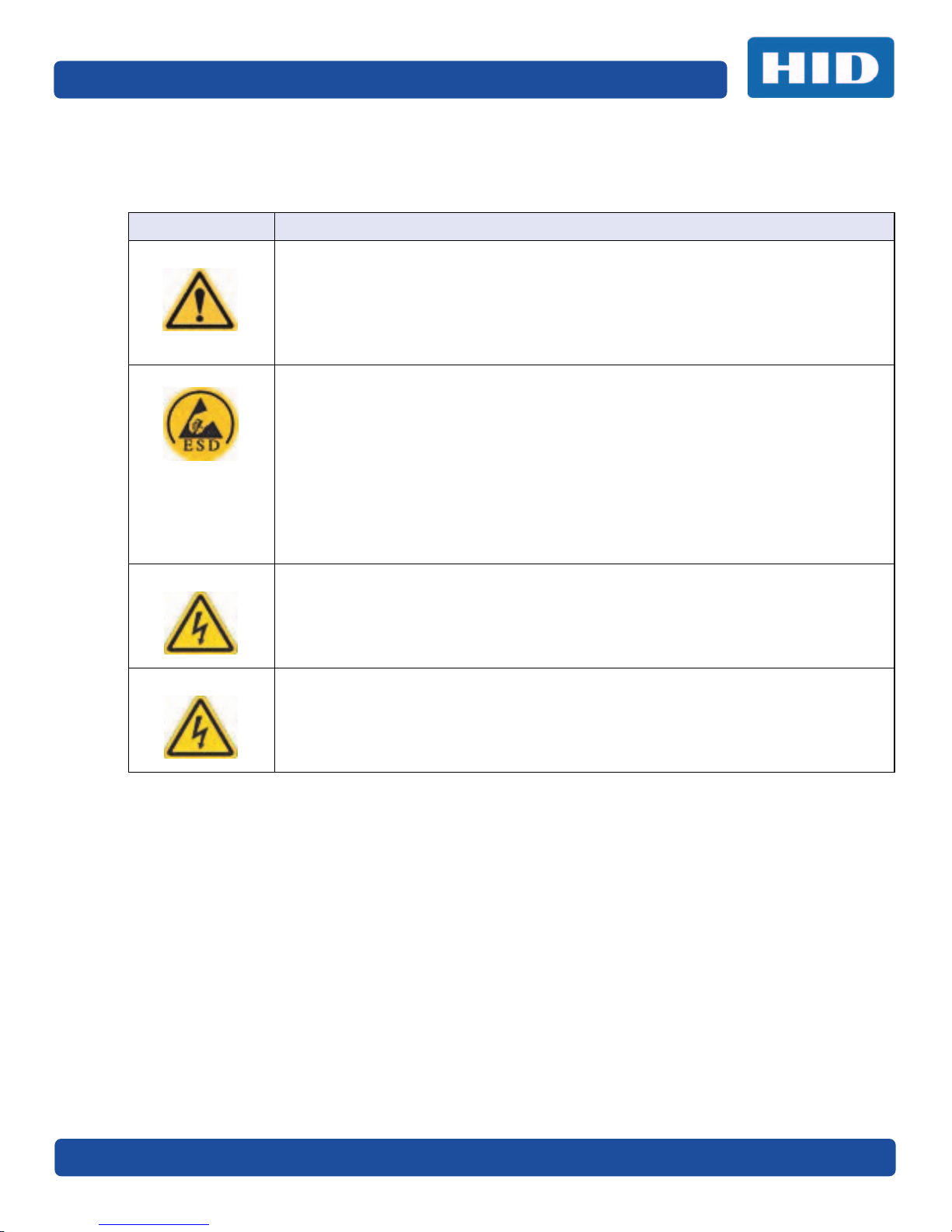

1.2 Safety Messages

1.2.1 Safety Messages—United States

Symbol Critical Instructions for Safety Purposes

Danger: Failure to follow these guidelines results in personal injury or death.

To prevent personal injury or death:

Reference the safety messages before performing an operation.

Always remove the power cord prior to performing repair procedures, unless

otherwise specified.

Ensure only qualified personnel perform these procedures.

ESD: This device is electrostatically sensitive. You may damage the device if exposing it to

static electricity discharges.

To prevent damage:

Reference the safety messages before performing an operation.

Observe all established electrostatic discharge (ESD) procedures while handling

cables in or near the circuit board and printhead assemblies.

Always wear an appropriate personal grounding device.

Always remove the ribbon and cards from the printer before making any repairs,

unless otherwise specified.

Remove jewelry and thoroughly clean hands before working on the printer.

Caution: This symbol warns of an electrical hazard that could result in personal injury or death.

Caution: For safety purposes, do not use Ethernet for a direct connection outside of the building.

September 2017 7

Page 8

Specifications PLT-03159, Rev A.0

1.2.2 Safety Messages—French

Symbole Instructions critiques visant la Sécurité

Danger: Si ces directives ne sont pas suivies les résultats peuvent être des lésions corporelles ou

la mort.

Pour éviter des lésions corporelles ou la mort:

Rapportez-vous aux avis suivants de sécurité avant de procéder à une opération.

Retirez toujours le câble d’alimentation avant d’effectuer des procédures de

réparation, sauf spécification contraire.

Assurez-vous qu’uniquement des personnes qualifiées réalisent des procédures.

ESD: Ce dispositif est sensible à l’électricité statique. Il peut souffrir des dommages s’il est

exposé à des décharges électrostatiques.

Pour éviter des dommages:

Rapportez-vous aux messages suivants avant de procéder à une opération.

Suivez toutes les procédures de Décharges Electrostatiques (ESD) en vigueur

durant le maniement des câbles dans ou à proximité des Ensembles de Cartes de

Circuit Imprimé et Tête d’Impression.

Portez toujours un dispositif de mise à la terre personnelle appropriée.

Retirez toujours le ruban et les Cartes de l’Imprimante avant d’effectuer toute

réparation, sauf spécification contraire.

Retirez tous bijoux et lavez soigneusement vos mains avant de travailler à

l’Imprimante.

Attention: Ce symbole est un avis de péril électrique passible de résulter en lésion corporelle ou

mort.

Attention: Pour des motifs de sécurité, n’utilisez pas Ethernet pour une connexion directe hors du

bâtiment.

8 September 2017

Page 9

PLT-03159, Rev A.0 Specifications

1.2.3 Safety Messages—Taiwan

䷩橼㔯ġ⮬柣䘤⮬⍲⬱ℐ㊯Ẍġ⬱ℐ妲〗 炷⮷⽫㩊㞍炸

㧁姀 慵天䘬⬱ℐḳ枭婒㖶

⌙晒Ļ 㛒㊱䄏婒㖶⬱墅⎗傥忈ㆸṢ⒉ ṉˤ

⛐⎗傥䓊䓇㼃⛐⬱ℐ⓷柴䘬⛘㕡㚱嬎䣢㧁姀ˤ

炷⤪ⶎ⚾䣢炸ˤ

䁢Ḯ性Ṣ⒉ ⭛炻⛐忚埴㚱㬌嬎䣢㧁姀䘬㑵ἄ⇵炻婳⍫侫⬱ℐ屯妲㍸䣢ˤ

䁢Ḯ性Ṣ⒉ ⭛炻⛐㰺㚱䈡⇍婒㖶䘬ね㱩ᶳ炻ᾖ䎮⇵婳斄㌱暣㸸攳斄ˤ

⮷⽫Ļ 㬌姕⁁⮵朄暣⼰㓷デˤ⤪㝄⍿⇘朄暣㓦暣炻姕⁁㚫㎵⢆ˤ

⛐⎗傥䓊䓇㼃⛐朄暣⬱ℐ⓷柴䘬⛘㕡㚱嬎䣢㧁姀ˤ

炷⤪ⶎ⚾䣢炸ˤ

䁢Ḯ性㎵⢆姕⁁炻⛐忚埴㚱㬌嬎䣢㧁姀䘬㑵ἄ⇵炻婳⍫侫⬱ℐ屯妲㍸䣢ˤ

䁢Ḯ性㎵⢆姕⁁炻⛐㌺㓦暣嶗㜧⌘⇟柕倗⎰墅伖墉朊ㆾ旬役䘬暣䶂㗪炻婳㲐シ奨⮇

㚱䘬朄暣㓦暣姕⁁ˤ

䁢Ḯ性㎵⢆姕⁁炻婳晐㗪ἑ㇜⎰怑䘬㍍⛘墅伖炷㭼⤪烉ㇳ僽ᶲ㇜ᶨᾳ檀⑩岒䘬㍍⛘ㇳ

僽ⷞẍ⍿⇘⎗傥䘬 ⭛炸ˤ

䁢Ḯ性㎵⢆姕⁁炻⤪㝄㰺㚱䈡㬲婒㖶炻⛐ ảỽᾖ䎮⇵炻婳⍾ᶳ⌘堐㨇ᶲ䘬刚ⷞ⌉ˤ

䁢Ḯ性㎵⢆姕⁁炻⛐ἧ䓐⌘堐㨇⇵炻婳㐀ᶳㆺ㊯ㇳᶲ梦⑩炻Ṽ䳘㶭㲿ㇳᶲ䘬㱡

傪ˤ

September 2017 9

Page 10

Specifications PLT-03159, Rev A.0

1.2.4 Safety Messages—China

ᆹޘ⎸˄䈧Ԅ㓶䰵䈫˅

ㅖ ⎹৺ᆹޘⲴ䟽㾱䗷〻

ড䲙 ྲн䚥ᗚ䘉Ӌᆹ㻵ᤷই䘋㹼ˈ㜭Պሬ㠤䟽Քˈ⭊㠣↫ӑDŽ

㜭ᕅᆹޘ䰞仈Ⲵؑ⭡䆖ㅖ ˄ྲᐖമᡰ⽪˅ᶕ㺘⽪DŽ

ѪҶ⺞؍Ӫ䓛ᆹޘˈ൘ᢗ㹼ࡽ䶒ᑖᴹ↔ㅖⲴѻࡽˈ䈧ݸ䰵䈫л䶒Ⲵᆹޘ⎸DŽ

ѪҶ⺞؍Ӫ䓛ᆹޘˈ䲔䶎ᴹ㿴ᇊˈࡉ൘ᢗ㹼㔤؞䗷〻ࡽˈ㓸ᓄᯝᔰ⭥ⓀDŽ

ሿᗳ ↔䇮༷Ѫ䶉⭥ᝏ䇮༷DŽྲ᳤䵢൘䶉⭥⭥⍱лˈ㜭Պᦏൿ䇮༷DŽ

㜭ᕅ䶉⭥ᆹޘ䰞仈Ⲵؑ⭡䆖ㅖ ˄ྲᐖമᡰ⽪˅ᶕ㺘⽪DŽ

ѪҶ䱢→䇮༷ᡆӻ䍘ᦏˈ൘ᢗ㹼ࡽ䶒ᑖᴹ↔ㅖⲴѻࡽˈ䈧ݸ䰵䈫л䶒Ⲵᆹޘ⎸

DŽ

ѪҶ䱢→䇮༷ᡆӻ䍘ᦏˈ䈧൘༴⨶⭥䐟ᶯ઼ᢃঠཤ䜘Ԧѝᡆ䱴䘁Ⲵ⭥㔶ᰦˈ䚥ᆸᡰᴹ㿴

ᇊⲴ䶉⭥᭮⭥(6'䗷〻DŽ

ѪҶ䱢→䇮༷ᡆӻ䍘ᦏˈ䈧㓸֙ᑖ䘲ᖃⲴњӪ᧕ൠ䇮༷˄ֻྲˈᐢ᧕ൠ䚯ݽࠪ⧠▌

൘ᦏൿⲴ儈䍘䟿㞅ᑖ˅DŽ

ѪҶ䱢→䇮༷ᡆӻ䍘ᦏˈ䲔䶎ᴹ㿴ᇊˈࡉ൘ᢗ㹼ԫօ㔤؞䗷〻ࡽˈ㓸ᓄሶ㢢ᑖ઼

䇱оᢃঠᵪ࠶DŽ

ѪҶ䱢→䇮༷ᡆӻ䍘ᦏˈ൘ᢃঠᵪࡽˈ䈧лᤷ઼кⲴ⨐ᇍ侠⢙ˈᒦሶкⲴ

⋩઼⊑ᖫᓅ⍇ᒢ߰DŽ

ӵ䘲⭘Ҿ⎧ᤄ Pԕлൠᆹޘ֯⭘

Use only at altitudes not more than 2000m above sea level.

ӵ䘲⭘Ҿ䶎✝ᑖ≄ىᶑԦлᆹޘ֯⭘

⧟ຳ؍ᣔ ѝഭ 5R+6

⧟؍֯⭘ᵏᱟสҾᵜӗ૱⭘Ҿ࣎ޜ⧟ຳDŽ

Environmental Protection Use Period is based on the product being used in an office

environment.

10 September 2017

Page 11

PLT-03159, Rev A.0 Specifications

1.3 Technical Specifications

Term Function

Print Method Dye-sublimation / Resin thermal transfer

Print resolution 300 dpi (11.8 dots/mm); continuous tone

Colors Up to 16.7 million colors / 256 shades per pixel

Print Ribbon Options Full-color with resin black and overlay panel, YMCKO* (500 prints)

Full-color with two resin black panels and overlay panel, YMCKOK* (500 prints)

Full-color with two resin black panels, YMCKK* (500 prints)

Full-color (1/2) with resin black overlay panel, YMCKO* (850 prints)

Full-color (1/2) with two resin black overlay panels, YMCKOK* (650 prints)

Full-color (1/2) with two resin black overlay panels, YMCKOKO* (500 prints)

Resin black standard (3000 prints)

* Indicates the ribbon type and the number of ribbon panels printed where:

Y=Yellow, M=Magenta, C=Cyan, K=Resin Black, O=Overlay

Print Speed 6 seconds per card (K*)

8 seconds per card (KO*)

16 seconds per card (YMCKO*)

24 seconds per card (YMCKOK*)

Print speed indicates an approximate batch print speed and is measured from the

time a card feeds into the printer to the time it ejects from the printer.

Print speeds do not include encoding time or the time needed for the PC to process

the image.

Process time is dependent on the size of the file, the CPU, amount of RAM and the

amount of available resources at the time of the print.

* Indicates the ribbon type and the number of ribbon panels printed where:

Y=Yellow, M=Magenta, C=Cyan, K=Resin Black, O=Overlay

Card Size and Types

Supported

Accepted Standard

Card Sizes

Accepted Card

Thickness

Accepted Card

Types

Input Hopper Card

Capacity

Output Hopper Card

Capacity

Reject Hopper Card

Capacity

Card Cleaning Card cleaning roller integrated into the ribbon drawer.

Printer Memory 32MB RAM

September 2017 11

CR-80 3.375"L x 2.125"W (85.6 mmL x 54 mmW)

CR-79 3.313”L x 2.063”W (84.1 mmL x 52.4 mmW)

CR-80 edge-to-edge 3.36"L x 2.11"W (85.3 mmL x 53.7 mmW)

CR-79 3.3”L x 2.04”W (83.8 mmL x 51.8 mmW)

Print only: 0.009˝ - 0.040˝ / 9 mil - 40 mil / 0.229 mm - 1.016 mm; print / lamination:

0.030˝ - 0.040˝ / 30 mil - 40 mil / 0.762 mm - 1.02 mm

PVC or polyester cards with polished PVC finish; monochrome resin required for

100% polyester cards; optical memory cards with PVC finish; rewrite.

100 cards 0.030” (0.762 mm)

100 cards 0.030” (0.762 mm)

100 cards 0.030” (0.762 mm)

A new cleaning roller is included with each ribbon.

Page 12

Specifications PLT-03159, Rev A.0

Term Function

Operating Systems Windows 7 (32- and 64-bit)

Windows 8 (32- and 64-bit)

Windows 10 (32- and 64-bit)

Windows Server 2003 R1 and R2 (32-bit only)

Windows Server 2008 (32- and 64-bit) R2 (64-bit only)

Windows Server 2012 R1 and R2

Interface USB 2.0 and Ethernet with internal print server

Operating

Temperature

Humidity 20-80% non-condensing

Weight Single-Sided: 8 lb (3.63 kg); Dual-Sided: 10 lb (4.54 kg)

Supply Voltage 100-240 V AC, 1.6 A

Supply Frequency 50 Hz/60 Hz

Warranty Printer—Three years; Printhead—Three years, unlimited pass with UltraCard®

Encoding Options

Supported

Options Single wire Ethernet encoding is only available for iCLASS and contact smart card

Diagnostics Fargo Workbench™ utility

Display Color changing status buttons

65°F to 80°F (18°C to 27°C)

125 kHz (HID Prox) reader

13.56 MHz (iCLASS®, MIFARE®, ISO 14443 A/B, ISO 15693) read/write encoder

Contact smart card encoder reads from and writes to all ISO7816 1/2/3/4 memory

and microprocessor smart cards (T=0, T=1) as well as synchronous cards

ISO magnetic stripe encoding, dual high- and low-coercivity, Tracks 1, 2, and 3

encoding

Smart card encoding (contact/contactless)—Upgradable

Magnetic stripe encoding—Upgradable

Card lamination

Printer cleaning kit

12 September 2017

Page 13

PLT-03159, Rev A.0 Specifications

1.4 Functional Specifications

This card printer utilizes two different, yet closely related printing technologies to achieve its

remarkable direct-to-card print quality for dye-sublimation and resin thermal transfer.

1.5 Printer Components: Print Ribbons

The card printer utilizes both dye-sublimation and/or resin thermal transfer methods to print images

directly onto blank cards. Since the dye-sublimation and the resin thermal transfer print methods each

provide their own unique benefits, print ribbons are available in resin-only, dye-sublimation-only and

combination dye-sublimation/resin versions.

To make it easier to remember which print ribbons are which, a letter code has been developed to

indicate the type of ribbon panels found on each ribbon. This letter code is as follows:

= Dye-Sublimation Yellow Panel

= Dye-Sublimation Magenta Panel

= Dye-Sublimation Cyan Panel

= Resin Black Panel (Premium unless otherwise stated)

= Clear Protective Overlay Panel

September 2017 13

Page 14

Specifications PLT-03159, Rev A.0

1.5.1 Ribbon Types and Print Counts

The following table includes the ribbon types and typical print counts.

Ribbon Print Count

YMCKO – Full Color / Resin Black / Overlay 500

YMCKO Half Panel – Full Color (1/2) / Resin Black / Overlay 850

YMCKK - Full Color / 2 Resin Black 500

YMCKOK - Full Color / 2 Resin Black / Overlay 500

YMCKOK Half Panel – Full Color (1/2) / 2 Resin Black / Overlay 650

YMCKOKO Half Panel - Full Color (1/2) / 2 Resin Black / 2 Overlay 500

K – Standard Resin 3000

14 September 2017

Page 15

PLT-03159, Rev A.0 Specifications

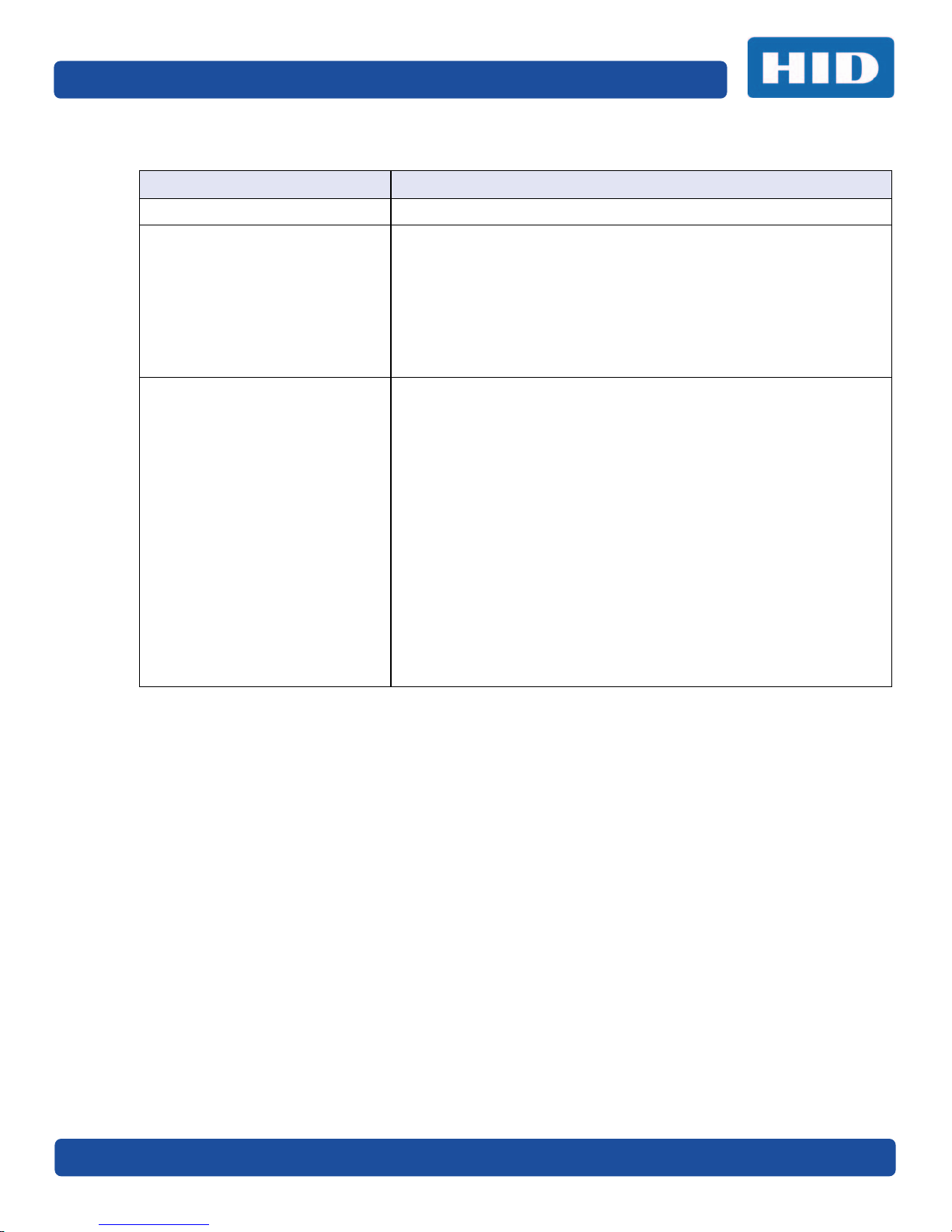

1.6 Printer Components: Blank Cards

Type Description

Card Size The card printer accepts standard CR-79 and CR-80 sized cards.

Card Surface Suitable cards must have a polished PVC surface free of fingerprints,

dust or any other types of embedded contaminants. In addition, cards

must have a completely smooth, level surface for the printer to

achieve consistent color coverage.

Certain types of proximity cards have an uneven surface that inhibit

consistent color transfer.

Certain types of smart card chips are raised slightly above the cards

surface which also results in poor color transfer.

UltraCard Brand Cards The UltraCard product line, available exclusively as part of HID Global

Fargo brand secure card issuance solutions, has a long-standing

reputation among dealers and end users for consistent quality in

construction.

In addition to blank stock, the UltraCard line is available in a

variety of configurations for magnetic stripe, custom hologram,

and other additional anti-counterfeiting features.

UltraCard Premium is the preferred card for Direct-to-Card (DTC)

applications that require a higher quality card. The UltraCard

Premium composite material construction provides for maximum

durability, flexibility, and card life, with optimal resolution print

quality for lamination and fluorescent panel ribbon printing

applications.

UltraCard PVC cards are medium-durability cards for a glossy,

photo quality finish. These cards are manufactured to ensure

clean, scratch-free cards for high-quality prints and extended

printhead life.

September 2017 15

Page 16

Specifications PLT-03159, Rev A.0

This page intentionally left blank.

16 September 2017

Page 17

Chapter

Setup and Installation Procedures

This section describes the setup and installation for the DTC1500 card printer.

2.1 Choosing a Good Location

The following guidelines help to ensure optimal printing performance:

Place the unit in a location with adequate air circulation to prevent internal heat buildup.

Use the dimensions of the printer as a guideline for the minimum clearances to the unit.

Note: Allow for adequate clearance in front of the unit to accommodate the unit with its covers

open.

Do not install the unit near heat sources such as radiators or air ducts or in a place subject to

direct sunlight, excessive dust, mechanical vibration or shock.

2

2.1.1 About Moisture Condensation

If the unit is brought directly from a cold to a warm location or is placed in a very damp room,

moisture may condense inside the unit. Should this occur, print quality may not be optimal.

Leave the unit unplugged in a warm, dry room for several hours before using to evaporate any

moisture.

Caution: For safety purposes, Ethernet is not intended for a direct connection outside of the

building.

Attention: Pour des raisons de sécurité, Ethernet n'est pas conçu pour une connexion

directe à l'extérieur du bâtiment.

September 2017 17

Page 18

Setup and Installation Procedures PLT-03159, Rev A.0

2.2 Unpacking and Inspection

While unpacking your printer, inspect the carton to ensure that damage has not occurred during

shipping. Make sure that all supplied accessories are included with your unit.

Check that the following items are included:

Power supply

US/EU power cable

USB cable (2.0)

Card printer user guide

Warranty statement

Compliance document

18 September 2017

Page 19

PLT-03159, Rev A.0 Setup and Installation Procedures

2.3 Installing the Print Ribbon Cartridge

Fargo Direct-to-Card printers require highly specialized supplies to function properly.

To maximize printer durability, reliability, and printed card quality, you must use only Fargo-certified

supplies. Your Fargo warranty is void, where not prohibited by law, if you use supplies other than

Fargo-certified supplies.

Printer cleaning is recommended with each ribbon change to ensure quality printed cards.

Resin-only print ribbons consist of a continuous roll of a single resin color. No protective overlay

panel (O) is provided because resin images do not require the protection of an overlay.

1. Pull open the drawer.

2. Insert the print ribbon cartridge into the printer drawer.

3. Close the drawer.

For additional help with loading the print ribbon cartridge, see the Fargo Printers videos available at

www.youtube.com/HIDGlobal.

September 2017 19

Page 20

Setup and Installation Procedures PLT-03159, Rev A.0

2.4 Installing Blank Cards into the Input Card Hopper

The Fargo DTC1500 card printer is capable of printing single feed cards and multiple feed cards

(batch mode). To print a single feed card, remove all cards from the input card hopper, leave its door

closed and place a card in the single feed card slot (which can be used repeatedly).

1. Load the cards with the print side down and (if applicable) the magnetic strip up and towards

the front of the printer.

Information: Do not run the cards with a contaminated, dull or uneven surface through the

printer. Printing onto these cards may lead to poor print quality and can greatly reduce the life

of the printhead.

Card types include PVC or PVC finish.

Cards eject into the output hopper or reject hopper.

The input hopper holds 100 cards.

Certain types of smart card chips are raised slightly above the cards surface, which may

result in poor color transfer. Design the card with white space surrounding the chip.

2. Open the input card hopper door.

3. Press the card hopper load lever down until the card tray locks into place.

20 September 2017

Page 21

PLT-03159, Rev A.0 Setup and Installation Procedures

4. Load up to 100 cards into the hopper with the print side down. If using cards with a magnetic

stripe, the magnetic stripe should be loaded with the stripe up and to the front of the printer.

5. Close the input card hopper door to release the lever to the printing position.

September 2017 21

Page 22

Setup and Installation Procedures PLT-03159, Rev A.0

2.5 Card Size Selection

The printer uses standard size CR-79 and CR-80 cards.

Follow this procedure in the printer and in the printer driver to set up the card size.

1. Open the front door and locate the slide bar.

2. If using the CR-79 card, push the slide bar to the LEFT.

3. If using the CR-80 card, push the slide bar to the RIGHT.

22 September 2017

Page 23

PLT-03159, Rev A.0 Setup and Installation Procedures

4. From the Driver Printing Preferences, select the correct card size.

2.6 Connecting the Printer Power

To connect power to the printer, do the following:

Note: Do not connect the printer USB cable until prompted during the printer driver installation.

September 2017 23

Page 24

Setup and Installation Procedures PLT-03159, Rev A.0

1. Plug the AC adapter power cable into the back of the printer.

2. Plug the wall power cable into the AC power adapter.

3. Plug the wall power cable into a standard 100-240 V AC power outlet.

4. Press the printer power button to power on the printer.

Note: The printer powers down during the “sleep time” but automatically powers up when a print

job is sent.

24 September 2017

Page 25

Print Driver Installation

This section describes the printer driver installation requirements and standard procedures.

The DTC1500 Print Driver supports the following:

Windows Server 2003 R1 and R2 (32-bit)

Windows Server 2008 R1 (32- and 64-bit)

Windows Server 2008 R2 (64-bit)

Windows Server 2012 R1 and R2

Windows 7 (32- and 64-bit)

Windows 8 (32- and 64-bit)

Windows 10 (32- and 64-bit)

For more information on supported operating systems, see www.hidglobal.com/support.

Chapter

3

3.1 Driver Installation Instructions

Note: You must be logged in as an administrator to perform the driver installation. After installation,

from Printer & Faxes, select Printer properties. The Security tab must allow you to set the Print,

Manage this printer and Manage documents permissions.

Start by downloading the latest driver file from www.hidglobal.com/drivers. Follow the Installaware

Wizard screen prompts.

1. Select Install the Printer Driver to start the driver installation.

2. Select the Fargo Workbench Utility Program to install the diagnostic program.

3. All versions of Windows require Administrator rights.

4. From the Printer & Faxes, select Printing preferences to set up the printer driver after it has

been installed.

5. Use the drop-down arrows to select the correct options for each printing preference.

September 2017 25

Page 26

Print Driver Installation PLT-03159, Rev A.0

This page intentionally left blank.

26 September 2017

Page 27

Printer Preferences

This section provides an overview of the Printing Preferences tabs.

4.1 Card Tab

The Card tab provides options that define the basic characteristics of a card—the size and orientation.

The Card tab also provides access to helpful utilities and information:

Diagnostics

Test Print

Toolbox

About

Chapter

4

September 2017 27

Page 28

Printer Preferences PLT-03159, Rev A.0

Field Description

Card Size Select CR-80 or CR-79.

Measurement units Select inches or mm (millimeters).

Print Width Displays width dimension of the card.

Print Length Displays length dimension of the card.

Card Thickness (mil) Select the card thickness in mils.

Orientation Select Portrait for vertical orientation or Landscape for horizontal orientation.

Copies Select the number of copies to print using Test Print.

Diagnostics Click Diagnostics to access the Workbench 3 utility. See the Workbench 3 User

Guide or Workbench 3 Help facility for more information.

See Section 4.1.1: Toolbox Window.

Test Print Click Test Print to send one or more self-test prints to the printer.

Toolbox Click the Toolbox button for access to the following options:

Configuration

Calibrate Ribbon

Clean Printer

Advanced Settings

About Displays the About screen.

28 September 2017

Page 29

PLT-03159, Rev A.0 Printer Preferences

4.1.1 Toolbox Window

The Card Toolbox window is displayed with the selection of the Toolbox button on the Card tab.

4.1.1.1 Configuration Tab

The Configuration tab is used to show the currently installed optional printer features, event

monitoring, and to set the printer driver language.

Set Language

To switch between languages, select the preferred language from the Printer Driver drop-down

menu. Click OK twice, and then open the driver in the preferred language.

September 2017 29

Page 30

Printer Preferences PLT-03159, Rev A.0

4.1.1.2 Calibrate Laminator Tab

The Calibrate Laminator tab provides information about Laminator Sensor Calibration.

To calibrate the laminator,

1. Laminate a sample to raise the temperature to the Transfer Temperature displayed on the

Lamination tab.

2. Remove the cartridges from the laminator and close the cover.

3. Click the Calibrate button.

30 September 2017

Page 31

PLT-03159, Rev A.0 Printer Preferences

4.1.1.3 Calibrate Ribbon Tab

The Calibrate Ribbon tab sends the calibrate ribbon command to the printer when you click the

Calibrate button.

Follow the procedure displayed on this window.

September 2017 31

Page 32

Printer Preferences PLT-03159, Rev A.0

4.1.1.4 Clean Printer Tab

The Clean Printer tab launches the cleaning routing when you click the Clean button.

Follow the procedure displayed on this window.

4.1.1.5 Safety Messages (Review Carefully)

Note: All messages are provided in English and French.

Symbol Critical Instructions for Safety Purposes

Danger: Failure to follow these installation guidelines can result in death or serious injury.

Information that raises potential safety issues is indicated by a warning symbol (as shown to

the left).

To prevent personal injury:

Refer to the safety messages before performing an operation preceded by this symbol.

Always remove the power cord prior to performing repair procedures, unless otherwise

specified.

Make sure only qualified personnel perform these procedures.

32 September 2017

Page 33

PLT-03159, Rev A.0 Printer Preferences

Symbol Critical Instructions for Safety Purposes

Attention:

Le non respect de ces consignes d'installation peut entraîner la mort ou des blessures graves.

L'information qui pose des problèmes de sécurité potentiels sont signalées par un symbole

d'avertissement (comme illustré à gauche).

Pour éviter toute blessure:

Consultez les consignes de sécurité suivantes avant d'effectuer une opération précédée

par ce symbole.

Débranchez toujours le cordon d'alimentation avant d'effectuer les procédures de

réparation, sauf indication contraire.

Assurez-vous que seul le personnel qualifié est chargé de ces procédures.

Caution: This device is electrostatically sensitive. It may be damaged if exposed to static electricity

discharges.

Information that raises potential electrostatic safety issues is indicated by a warning symbol

(as shown to the left).

To prevent equipment or media damage,

Refer to the safety messages before performing an operation preceded by this symbol.

Observe all established electrostatic discharge (ESD) procedures while handling cables in

or near the circuit board and printhead assemblies.

Always wear an appropriate personal grounding device (for example, a high quality wrist

strap grounded to avoid potential damage).

Always remove the ribbon and cards from the printer before making any repairs, unless

otherwise specified.

Take jewelery off of fingers and hands, as well as thoroughly clean hands to remove oil

and debris before working on the printer.

Attention:

Ce dispositif est sensibles aux décharges électrostatiques. Il peut être endommagé s'il est

exposé à des décharges d'électricité statique.

Informations qui soulève des questions de sécurité potentiels électrostatiques est indiqué par

un symbole d'avertissement (comme illustré à gauche).

Pour éviter que l'équipement ou les dommages des médias, reportez-vous aux

consignes de sécurité suivantes avant d'effectuer une opération précédée par ce

symbole.

Pour éviter que l'équipement ou des dommages médias, observer tous décharge établie

électrostatique (ESD) des procédures lors de la manipulation des câbles à ou près de la

carte de circuit imprimé et assemblées de la tête d'impression.

Pour éviter que l'appareil ou un support endommagé, portez toujours un dispositif

approprié de mise à la terre personnelle (par exemple, un bracelet de haute qualité à la

terre pour éviter les dommages potentiels).

Pour éviter que l'appareil ou un support endommagé, retirez toujours le ruban et les

cartes de l'imprimante avant d'effectuer des réparations, sauf indication contraire.

Pour éviter que l'équipement ou les dommages des médias, prendre des bijoux hors de

doigts et les mains, ainsi que les mains propres pour enlever l'huile et les débris avant de

travailler sur l'imprimante.

September 2017 33

Page 34

4.1.1.6 Cleaning Kit

As with any electronic device, internal components of the printer, such as the printhead,

may be damaged if exposed to static electrical discharges. To avoid potential damage,

always wear an appropriate personal grounding device, such as a wrist strap (with

integral resistor) connected to an ESD ground.

This cleaning kit provides you with the specialized cleaning supplies and the required cleaning

procedures for you to maintain your card printer/encoder. The following cleaning procedures require

less than ten minutes.

Description Supplies (pictured)

Four (4) Printhead Cleaning Swabs are pre-moistened

with 99.99% isopropyl alcohol for cleaning the

printhead.

Three (3) Alcohol Cards are pre-moistened with

99.99% isopropyl alcohol for cleaning the platen and

card feed rollers.

Printer Preferences PLT-03159, Rev A.0

Ten (10) Cleaning Cards with adhesive backing are

provided for cleaning the platen and card feed rollers.

4.1.1.7 Printhead Cleaning

1. Turn off the printer and unplug the power cord from the printer.

2. Remove the ribbon cartridge.

3. Open the printhead cleaning swabs. Break it to moisten the tip.

4. Swab the tip back and forth across the top of the printhead.

34 September 2017

Page 35

PLT-03159, Rev A.0 Printer Preferences

5. Allow to dry thoroughly before sending a print job.

September 2017 35

Page 36

Printer Preferences PLT-03159, Rev A.0

4.1.1.8 Cleaning the Platen and the Card Feed Rollers

Perform this procedure approximately every 1000 prints to maintain a consistent print quality.

Note: The card feed rollers move the card through the print process. Rollers should be kept clean to

prevent card jams and card contamination. This cleaning process ultimately leads to better print

quality and extended life of the printhead.

1. Remove the ribbon drawer, remove the print ribbon, and reinsert the empty ribbon drawer.

2. Remove all the cards from the input card hopper.

Input Card HopperRibbon Drawer

3. Use the cleaning card from the cleaning kit and remove the adhesive backing from both sides of

the card.

If your printer has a magnetic encoder installed, be sure to leave the small liner strip on top of

the cleaning card in place. This small strip is needed to protect the magnetic head from the

adhesives on the cleaning card.

4. Insert the cleaning card into the single feed card slot until the card stops.

If the printer is equipped with a magnetic encoder, you must insert the cleaning card with the

printed side up and with the small liner strip towards the front of the printer.

36 September 2017

Page 37

PLT-03159, Rev A.0 Printer Preferences

5. From your computer, open the Printer Driver and select Printing Preferences > Card tab >

ToolBox.

6. Select the Clean Printer tab.

September 2017 37

Page 38

Printer Preferences PLT-03159, Rev A.0

7. Click Clean.

The printer pulls in the cleaning card. The printer performs the automated cleaning

procedure.

This procedure is designed to thoroughly clean the platen and the card feed rollers inside

the printer.

4.1.1.9 Cleaning the Exterior of the Printer

Clean the printer with a microfiber cloth only. Do not drip water into the printer. Dry thoroughly

before printing.

Note: The printer has a durable casing that should retain its luster and appearance for many years.

38 September 2017

Page 39

PLT-03159, Rev A.0 Printer Preferences

4.1.1.10 Advanced Settings Tab

Use the Advanced Settings tab to adjust the internal printer settings, which are customized for

every printer at the factory and saved directly within the printer memory.

Note: Select Restore Defaults to restore the internal default settings.

You can change the values for firmware settings by clicking the fields in the Current column.

Field Description

Setting Column Displays label for the setting. See the following Setting Column Fields table.

Default Column Displays default value for setting

Current Column Displays current value for setting

Apply Applies changed values.

Restore Defaults Restores the default values.

Enable Mag Verify Select the check box to verify that the data is written to the tracks correctly.

September 2017 39

Page 40

Printer Preferences PLT-03159, Rev A.0

Setting Column Fields

Field Description

This is factory set. If the main board or the printhead is replaced, then adjust this

Head Resistance

Print Left of Form

Image Darkness

Print Top of Form

number.

Locate the Printhead Setting Number on the bottom of the printhead.

The number reads R=XXXX.

Use this option to adjust the vertical position of the printed image on the card; so

it appears centered.

Maximum Adjustment Range is ±127.

Each increment equals 0.01”.

Use this option to set the overall darkness of the printed image by increasing or

decreasing the amount of heat (used by the printhead when printing).

Note: If the value is set too high, the ribbon may jam or break.

Use this option to adjust the length-wise or horizontal position of the printed

image on the card (so it appears to be centered).

Note: If the negative value is set too high, the print ribbon may break.

Use this option to shift the starting point where the printer begins to encode the

magnetic track data on the card magnetic stripe.

Mag Top of Form

Ribbon Print Tension

Ribbon Calibrate

Green

Resin Heat Adjust

Sleep Time

OLED Contrast

(display contrast)

Ribbon Calibrate Blue

Cleaning Rate

Note: If the negative value is set too high, the printer may start encoding before

the magnetic stripe reaches the encoding head.

Maximum adjustment range is ±80.

Each increment equals 0.01”.

Use the this option to increase or decreases the amount of tension (drag) on the

ribbon during printing.

This is a calibration driven value and should not be adjusted.

Note: This is factory set and should not be changed unless directed by a

technician.

Use this adjustment for black premium resin text and bar codes if they appear

faded, too light or too dark.

Maximum Adjustment Range is ±100.

Note: This control can be helpful for fine-tuning the transfer of resin text and bar

codes.

This setting adjusts the number of minutes of inactivity before the printer enters a

low power sleep state.

Use this option to increase or decrease the contrast of the printer OLED (if

applicable).

This setting is a calibration driven value and should not be adjusted.

It is factory set and should not be changed unless directed by a technician.

Use this option to adjust the number of cards printed before the printer displays a

message indicating cleaning is needed.

The default value is 3000 cards.

Mag HI-Co Voltage

Offset

40 September 2017

This setting is a calibration driven value and should not be adjusted.

It is factory set and should not be changed unless directed by a technician.

Page 41

PLT-03159, Rev A.0 Printer Preferences

Field Description

Mag Lo-Co Voltage

Offset

Ribbon Green LED

Level

Ribbon Blue LED Level

Erase Heat Offset

Write Heat Offset

This setting is a calibration driven value and should not be adjusted.

It is factory set and should not be changed unless directed by a technician.

This setting is a calibration driven value and should not be adjusted.

It is factory set and should not be changed unless directed by a technician.

This setting is a calibration driven value and should not be adjusted.

It is factory set and should not be changed unless directed by a technician.

Adjust the temperature for the rewritable cards as needed.

Increase the current setting to cause more heat to be used in the erasing process.

OR

Decrease the current setting to cause less heat to be used in the erasing process.

Note: This setting provides the ability to control the printhead heat level when the

erase operation is performed. Appropriate heat levels should be applied for the

proper erase process. This setting should be adjusted for proper erasure.

Adjust the temperature for the rewritable cards as needed.

Increase the current setting to cause more heat to be used in the printing process

of a rewritable card.

OR

Decrease the current setting to cause less heat to be used in the printing process

of a rewritable card.

Note: This setting provides the capability to control the printhead heat level when

the write operation is performed. Appropriate heat levels should be applied for the

proper writing process.

Flipper Home Offset

Flipper Eject Height

Offset

Mag Super-Co Voltage

Offset

Mag Medium-Co

Voltage Offset

Head Home Offset

Head Print Offset

This setting is a calibration driven value and should not be adjusted. If the flipper

unit is replaced and has not been calibrated, this value may need to be adjusted.

This setting is factory set and should not be changed unless directed by a

technician.

This setting is a calibration driven value and should not be adjusted. If the flipper

unit is replaced and has not been calibrated, this value may need to be adjusted.

This setting is factory set and should not be changed unless directed by a

technician.

This option changes the voltage going the magnetic head.

This setting is factory set and should not be changed unless directed by a

technician.

This option changes the voltage going the magnetic head.

This setting is factory set and should not be changed unless directed by a

technician.

This setting is a calibration driven value and should not be adjusted. If the

printhead assembly is replaced, then this value may need to be adjusted.

This setting is factory set and should not be changed unless directed by a

technician

This setting is a calibration driven value and should not be adjusted. If the

printhead assembly is replaced, then this value may need to be adjusted.

This setting is factory set and should not be changed unless directed by a

technician.

September 2017 41

Page 42

Printer Preferences PLT-03159, Rev A.0

Field Description

This setting is a calibration driven value and should not be adjusted. If the

Head Contact Offset

Head Queue Offset

printhead assembly is replaced, then this value may need to be adjusted.

This setting is factory set and should not be changed unless directed by a

technician.

This setting is a calibration driven value and should not be adjusted. If the

printhead assembly is replaced, then this value may need to be adjusted.

This setting is factory set and should not be changed unless directed by a

technician.

Head Card Thickness

Offset

Head Smart Card

Engage Offset

Head Mag Offset Adjusts the printhead for magnetic encoding.

Overlay Heat Adjust Adjusts the temperature setting for overlay film.

10 Mil Card Queue

Offset

Erase Speed Adjusts the speed of the erasure process.

Standard Resin Heat

Adjust

Printhead Smart Cue

Offset

Adjusts the card handling path to allow for variances in card thickness.

Adjusts the position of the printhead to allow smart card encoder contact.

Adjusts the input queue for use with thick cards.

Use this adjustment for black standard resin text and bar codes if they appear

faded, too light or too dark.

Maximum Adjustment Range is ±100.

This control can be helpful for fine-tuning the transfer of resin text and bar codes.

Adjusts the card handling path to allow for variances in card thickness.

42 September 2017

Page 43

PLT-03159, Rev A.0 Printer Preferences

4.2 Device Options Tab

Use the Device Options tab to select the Supplies, Dual Sided, and Options areas.

Field Description

Supplies

Automatically detect the

installed Ribbon for every

print job

Ribbon Type

Dual Sided

Print Both Sides

Print Back Side Only Prints only the backside image.

September 2017 43

When this box is checked, the printer always sends the job for the ribbon that is

currently installed in the printer. When this box is cleared, you can select the

ribbon type you want to use to print regardless of what is in the printer.

Indicates the ribbon that is currently installed in your printer or you can select a

ribbon type to create a print job.

Split 1 Set of Ribbon Panels: When using a YMCK ribbon, this selection allows

you to print YMC on the front of the card and K on the back. Normal operation is

to print YMCK on the front and YMCK on the back.

Print Back Image on Front of Card: Reverses the order of printing.

Page 44

Printer Preferences PLT-03159, Rev A.0

Field Description

Options

Rotate Front 180 Degrees Rotates the front print image 180 degrees on the card.

Rotate Back 180 Degrees Rotates the back print image 180 degrees on the card.

Disable Printing Sends a print job without any print data. The printer takes in a card and ejects it

out.

Write Only Disables the erase pass when using rewritable cards.

Invert F-panel Image Inverts the color for the images printed with a fluorescent panel ribbon.

Enable Resin Scramble Makes the data that is left on a used resin panel harder to read.

Encrypt Job Data Encrypts the job data file.

44 September 2017

Page 45

PLT-03159, Rev A.0 Printer Preferences

4.3 Image Color Tab

Use the Image Color tab to improve the quality of the image on the card. Image Color includes two

areas, Image Quality and Heat.

Field Description

Image Quality

Color Matching None: Select this option if any of the following is true:

System Color Management: Select to perform color correction through a complex

color-matching algorithm.

Note: This option shifts colors so the colors more closely match how they appear on

screen.

Algebraic: Select to use the Algebraic color-matching algorithm.

September 2017 45

if interested in print speed rather than print color

if color correcting an image that has been previously printed

if using third-party color matching software

Page 46

Printer Preferences PLT-03159, Rev A.0

Field Description

Resin Dither Select the appropriate dither method according to the type of image to be printed.

Graphics include images such as drawings, clip art, and logos. Photos include images

such as photographs and photo-quality images. This option affects objects printed

with a resin-only ribbon.

Heat

Heat Dye-Sub Intensity (YMC): Control the overall darkness and lightness of the dye-sub

printed image by moving the slider to the left to use less heat in the printing process,

resulting in a lighter print. Move the slider to the right to use more heat, resulting in a

darker print.

Note: This slide only affects those images printed with dye-sublimation ribbon

panels (YMC).

Resin Heat, Front (K): Move the slider to the left to use less heat in the printing

process, resulting in a lighter or less saturated print. Move the slider to the right to

use more heat, resulting in a darker or more saturated print.

Note: This control can be helpful for fine-tuning the sharpness of resin text and bar

codes.

Resin Heat, Back (K): Move the slider to the left to use less heat in the printing

process, resulting in a lighter or less saturated print. Move the slider to the right to

use more heat, resulting in a darker or more saturated print.

Erase Intensity: Move the slider to the left to use less heat in the printing process.

Move the slider to the right to use more heat.

Default Click the Default button to return all options to their factory settings.

Advanced Settings See the following Advanced Settings section.

46 September 2017

Page 47

PLT-03159, Rev A.0 Printer Preferences

4.3.1 Advanced Settings

Click the Advanced Settings button to display the Advanced Image Color window.

Field Description

Image Quality

Sharpness Move the slider to the right to sharpen the image. Move the slider to the left to

decrease sharpness.

Contrast Move the slider to the right to increase contrast in the image. Move the slider to the left

to decrease contrast.

Gamma Move the slider to the right to increase gamma in the image. Move the slider to the left

to decrease gamma.

Balance

Yellow Balance Move the slider to the right to increase the amount of yellow in the image. Move the

slider to the left to decrease the amount of yellow.

Magenta Balance Move the slider to the right to increase the amount of magenta in the image. Move the

slider to the left to decrease the amount of magenta.

Cyan Balance Move the slider to the right to increase the amount of yellow in the cyan. Move the

slider to the left to decrease the amount of cyan.

Default Click the Default button to return all options to their factory settings.

September 2017 47

Page 48

Printer Preferences PLT-03159, Rev A.0

4.4 Image Calibrate Tab

Use the Image Calibrate tab to control the position of the printable area in relation to the card.

Use the Vertical and Horizontal image position controls to adjust the position of the overall print area

to be precisely centered on a card. The maximum value for the Vertical and Horizontal adjustments is

±100 pixels (10 pixels = approx 0.03%, 0.8 mm).

Field Description

Vertical Enter a positive number to move the image toward the rear of the printer, Enter a

negative number to move the image toward the front of the printer.

Horizontal Enter a positive number to move the image toward the rear of the printer. Enter a

negative number to move the image toward the front of the printer.

48 September 2017

Page 49

PLT-03159, Rev A.0 Printer Preferences

4.5 Magnetic Encoding Tab

Select the Magnetic Encoding tab to display options for controlling the magnetic stripe encoding

process. You can use these options only if the printer has an optional magnetic stripe encoding

module installed.

Field Description

Encoding Options

Encoding Mode You can change the encoding mode and coercivity setting or modify the ISO

standards for Tracks 1, 2, and 3. This can be done by correctly modifying these

Magnetic Encoding options.

ISO Encoding The ISO Encoding option sends down a formatted set of characters.

This selection activates the track tabs. However, all functions on the Track tabs are

inactive or gray and display ISO defaults, which are the defaults listed for each track

below. The Shift Data Left check box remains clear and inactive.

Custom Encoding If you select Custom Encoding, all options are active.

The Default is ISO Encoding.

Note: The defaults are the same as the ISO Encoding defaults.

All functions on the Magnetic Track Options tabs are active.

You can change the Magnetic Track options for Tracks 1, 2 and 3.

September 2017 49

Page 50

Printer Preferences PLT-03159, Rev A.0

Field Description

Raw Binary

Encoding

The Raw Binary Encoding option sends down a raw binary string rather than a

formatted set of characters.

The Coercivity drop-down function is active and the Shift Data Left check box is not

active.

All functions on the Magnetic Track Options tabs are inactive except for Bit Density.

JIS II Encoding If you select JIS II Encoding, specific standards are used.

This selection disables all the Magnetic Track Options tabs. It also disables the

Coercivity drop-down function and Shift Data Left check box option.

The default Coercivity is 600 Oe.

Coercivity Select the Coercivity option (Oersted) that matches the card type.

High Coercivity 4000 Oersted

Fargo’s High Coercivity UltraCard IIIs are 2750 Oersted

Medium Coercivity=600 Oersted

Low Coercivity = 300 Oersted

Shift Data Left Select this option to shift the recorded magnetic data to the left side of the card's

Magnetic Stripe.

This is useful in situations that require cards to be readable with insert type readers.

Magnetic Track Options

The magnetic encoding module encodes onto tracks in accordance with an ISO 7811-2 Magnetic Stripe. For

track locations, review the display in Section 4.5.1: Magnetic Track Options. Tabs are available on the

Magnetic Encoding tab with options for encoding data on each track.

Encoding Mode You can change the encoding mode and coercivity setting or modify the ISO

standards for Tracks 1, 2, and 3. This can be done by correctly modifying the Magnetic

Encoding options.

Character Size 4 Bits to change the bits per character to 4 BPC.

5 Bits to change the bits per character to 5 BPC. This is the default for Tracks 2 and 3.

7 Bits to change the bits per character to 7 BPC. This is the default for Track 1.

8 Bits to change the bits per character to 8 BPC.

ASCII Offset NULL to change the ASCII Offset to NULL.

SPACE to change the ASCII Offset to SPACE. This is the default for Track 1.

ZERO to change the ASCII Offset to ZERO. This is the default for Tracks 2 and 3.

Bit Density 75 BPI to change the bits per inch to 75 BPI. This is the default for Track 2.

128 BPI to change the bits per inch to 128 BPI.

210 BPI to change the bits per inch to 210 BPI. This is the default for Tracks 1 and 3.

Custom BPI, which enables the custom BPI text box.

Note: The lower limit is 75 and upper limit is 210.

LRC Generation No LRC to change the LRC Generation to none.

Even Parity to change the LRC Generation to Even Parity. This is the default for all

tracks.

Odd Parity to change the LRC Generation to Odd Parity.

Character Parity No Parity to change the Character Parity to none.

Even Parity to change the Character Parity to Even Parity.

Odd Parity to change the Character Parity to Odd Parity. This is the default for all

tracks.

50 September 2017

Page 51

PLT-03159, Rev A.0 Printer Preferences

Field Description

Reverse Bit Order Reverse Bit Order is used to reverse the character bits and is used for the encryption

of data in specific programs

Add Leading Zeros Add Leading Zeros is used to add a set number of leading zeros to the magnetic

string in order to move the starting point of the encoded data in specific programs for

encryption of data.

Default Click the Default button to return all options to their factory settings.

4.5.1 Magnetic Track Options

The magnetic encoding module encodes onto tracks in accordance with an ISO 7811-2 Magnetic

Stripe. For track locations, review the following display. Tabs are available on the Magnetic Encoding

tab with options for encoding data on each track.

Reviewing the ISO Track Locations

4.5.1.1 Reviewing the Sample String

Track 1: ~1%JULIEANDERSON^1234567890?

Track 2: ~2;1234567890987654321?

Track 3: ~3;1234567890987654321?

Track

Track 1 % ? ^ ASCII 32-95 (See the table in

Track 2 ; ? = ASCII 48-63 (See the table in

Track 3 ; ? = ASCII 48-63 (See the table in

Start

Sentinel

End

Sentinel

Field

Separator

Valid Characters

Section 4.5.1.2: Sending the

Track Data.)

Section 4.5.1.2: Sending the

Track Data.)

Section 4.5.1.2: Sending the

Track Data.)

Maximum

Number of

Characters

78

39

106

September 2017 51

Page 52

Printer Preferences PLT-03159, Rev A.0

4.5.1.2 Sending the Track Data

Magnetic track data is sent in the form of text strings from the application software to the printer

driver.

In order for the printer driver to differentiate between magnetic track data and the rest of the

printable objects, specific characters must be added to the magnetic data to be encoded.

These specify the data that is to be encoded the tracks to encode and mark the start and stop of the

data string. In some cases, these specific characters are automatically added to the string of track

data by ID software applications.

In most cases, the user must carefully add these characters to the string of magnetic track data. If

these characters are not added to the track data, the text intended for the magnetic track appears

as printed text on the card. To avoid this, track information must be entered as described.

When entering track data, the ~ (tilde) character is entered first, followed by the track number (1, 2,

or 3) on which the data should encode. The data to be encoded follows the track number.

The first character of this data string must be the track's specific start sentinel (SS) and the last

character must be the specific end sentinel (ES).

The characters or data in between the SS and ES can include all of the valid characters specific to

each track.

The number of these characters, however, is limited by each track's maximum character capacity.

Note: When segmenting track data, the appropriate field separator (FS) must be used. The

following shows the SS, ES, FS and the valid characters defined for each track.

Reviewing the ASCII Code and Character Table

ASCII Code Character ASCII Code Character ASCII Code Character

32 space 56 8 80 P

33 ! 57 9 81 Q

34 58 : 82 R

35 # 59 ; 83 S

36 $ 60 < 84 T

37 % 61 = 85 U

38 and 62 > 86 V

39 ‘ 63 ? 87 W

40 ( 64 @ 88 X

41 ) 65 A 89 Y

42 * 66 B 90 Z

43 + 67 C 91 [

44 ‘ 68 D 92 \

45 - 69 E 93 ]

46 . 70 F 94 ^

47 / 71 G 95 _

52 September 2017

Page 53

PLT-03159, Rev A.0 Printer Preferences

ASCII Code Character ASCII Code Character ASCII Code Character

48 0 72 H

49 1 73 I

50 2 74 J

51 3 75 K

52 4 76 L

53 5 77 M

54 6 78 N

55 7 79 O

4.6 Lamination Tab

Select the Lamination tab to display options for controlling the lamination process. You can use these

options only if the printer has an optional lamination module installed.

September 2017 53

Page 54

Printer Preferences PLT-03159, Rev A.0

Field Description

Lamination Position

Use this control to adjust the horizontal position of the laminate. Only the

horizontal position needs adjustment.

To adjust the position, click on the horizontal adjustment arrows. (The

adjustment arrows point in the direction the patch will move on the card).

Lamination Position

Lamination Speed

Transfer Dwell Time

Lamination Side

To move the overlaminate more toward the printer output side, enter a

positive number.

To move the overlaminate more toward the printer input side of the printer,

enter a negative number.

The maximum value for the horizontal adjustment is 100 pixels.

(10 pixels = 0.03 [0.8mm]).

Adjust this control for the through-put speed of a card in seconds per inch.

Default is 2.0 seconds per inch

Upper Limit - 5.5 seconds per inch

Lower Limit - 0.8 seconds per inch

Lamination Side

Lamination Type

Lamination Type

To specify the side(s) of the card to laminate select:

No Lamination

Laminate Front Side

Laminate Back Side

Laminate Both Sides

Laminate Opposite Sides

Select No Lamination if the laminator will not be used.

Select one of the lamination type options, according to which type of

lamination media is currently installed. Two types of overlaminates, film, and

PolyGuard are supported by the driver. Custom versions of each type are also

available.

Selections are:

Film Lamination: Select if the thermal transfer film overlaminate type is

installed in the lamination module.

0.6 PolyGuard Lamination: 0.6 is the patch thickness.

1.0 PolyGuard Lamination: 1.0 is the patch thickness.

Note: The two PolyGuard Lamination patches require different heat settings

and lamination speeds. Select the appropriate option according to the thickness

of the PolyGuard material in use.

Registered Film Lamination

Holographic Film Lamination

Transfer Temperature

Automatically detect

installed Laminate for

every print job

54 September 2017

If the check box for auto detection is selected, the temperature is automatically

set. The slider can change the temperature if a different one is required.

Use this check box for auto detection of the lamination installed. In the

firmware, the values are updated on initialization and cover closing.

Page 55

PLT-03159, Rev A.0 Printer Preferences

4.7 Overlay / Print Area Tab

Use the Overlay / Print Area tab to control and customize where the Overlay (O) panel and/or the

print area appear on the card. By default, this option is set to print and overlay the entire card.

The orientation of the card display area is determined by the orientation specified in your template.

September 2017 55

Page 56

Printer Preferences PLT-03159, Rev A.0

4.7.1 Defining an Overlay or Print Area

To define an overlay or print area:

1. Select the Front or Back option to specify the side of the card to apply the area definition.

2. From the Overlay / Print Area drop-down select the option that serves your purpose.

Field Description

Overlay / Print Area

Full Card Select this option to overlay and/or print the entire card.

Defined Area(s) Select this option to overlay and/or print only in the selected and define an area(s).

Undefined Area(s) Select this option to overlay and/or print in the space outside the selected and

defined area.

Omit Smart Chip Area Select this option to overlay and/or print only in the space outside the standard

location of a smart chip.

Omit Mag Strip Area Select this option to overlay and/or print only in the space outside the standard

location of an ISO-standard magnetic stripe.

Omit Signature Area Select this option to overlay and/or print only in the space outside the standard

location of a signature panel.

56 September 2017

Page 57

PLT-03159, Rev A.0 Printer Preferences

3. When an option is selected, a default blackened area appears on the card design area grid.

September 2017 57

Page 58

Printer Preferences PLT-03159, Rev A.0

4. Select and drag to enlarge the area and move it to the preferred location on the card. The size

and coordinates of the area update the number fields (inches or mm).

Field Description

Overlay/Print Area

Full Card Select this option to overlay and/or print the entire card.

Defined Area(s) Select this option to overlay and/or print only in the selected and define an

Undefined Area(s) Select this option to overlay and/or print in the space outside the selected and

Omit Smart Chip Area Select this option to overlay and/or print only in the space outside the

Omit Mag Strip Area Select this option to overlay and/or print only in the space outside the

Omit Signature Area Select this option to overlay and/or print only in the space outside the

For Print and Overlay This option applies the defined area to both the print and overlay processes.

58 September 2017

area(s).

defined area.

standard location of a smart chip.

standard location of an ISO-standard magnetic stripe.

standard location of a signature panel.

Page 59

PLT-03159, Rev A.0 Printer Preferences

Field Description

For Overlay Only The defined are applies only to the overlay process. The entire card prints and

only the overlay is affected.

For Print Only (No

Overlay)

Security Options

Visual Security Solutions Use this field to enable and select a visual security option. When one of the

VeriMark Use this option for VeriMark security.

HoloMark Use this option for hologram security.

Watermark This feature allows for an image to be printed using the overlap panel. Bitmap

The defined are applies only to the print process. Overlay is disabled.

options is selected, the Overlay/Print Area feature is disabled.

This field presents options based on the orientation of the card in the template.

The default value for all cards is No Visual Security.

Landscape designs offer:

A – Upper Left

B – Upper Right

C – Lower Left

D – Lower Right

Portrait designs offer:

E – Upper Left

F – Upper Right

G – Lower Left

files are the only file types accepted and must be 1011 pixels wide and 644

pixels high.

September 2017 59

Page 60

Printer Preferences PLT-03159, Rev A.0

4.8 K Panel Resin Tab

Use the K Panel Resin tab to control where the resin black (K) panel of a full-color ribbon is printed. If

a ribbon without a K resin panel is installed in your printer, these options are grayed out and

unavailable.

Note: Orientation of the card display area is determined by the orientation specified in the template.

See Section 4.7.1: Defining an Overlay or Print Area for information.

Field Description

Print All Black with K Panel

Full Card Select this option to print the resin black (K) panel for all black found within all areas

of the image.

Defined Area(s) Select this option to use resin black (K) panel for all black found only in the selected

and defined area(s).

See Section 4.8.1: Defined Area.

Undefined Area(s) Select this option to omit resin black (K) panel in the selected undefined area(s).

Print YMC under K Select this option to print all black in the designated areas with the yellow (Y),

magenta (M) and cyan (C) ribbon panels directly beneath the resin black (K) panel.

This combination provides a gradual transition between the resin black text or bar

code.

60 September 2017

Page 61

PLT-03159, Rev A.0 Printer Preferences

Field Description

Print K Only Select this option to print using the resin black (K) panel onto a white background to

maximize the sharpness of printed text and bar codes.

Exclude YMC Select this option to stop the printing of the YMC panels.

Resin Threshold

Resin Threshold Changes the level at which the driver moves a pixel to be printed on a resin panel

instead of a YMC.

4.8.1 Defined Area

The Defined Area option can be used with the K Panel Resin or the Overlay / Print Area tabs to

define one or more specific areas.

In the samples, the defined area is indicated by the dashed outline.

September 2017 61

Page 62

Printer Preferences PLT-03159, Rev A.0

4.8.1.1 Method for Defining a Single Area

1. On the Overlay / Print Area or K Panel Resin tab, select Defined Area(s).

2. Print a card and look at it in the same orientation as when it exits the printer.

3. Measure the total size of the area and enter the dimensions into the dimension boxes.

4. Measure from the lower-left corner of the card to the lower-left corner of the defined area and

enter the values into the X and Y boxes.

4.8.1.2 Method for Defining Multiple Areas

1. On the Overlay / Print Area or K Panel Resin tab, select Defined Area(s).

2. Print a card with a defined area and look at it in the same orientation as when it exits the printer.

3. Measure the defined area location based on the printed card.

4. To define another area, click the Defined Area up arrow.

5. Use the Defined Area arrows to navigate back and forth from area to area.

62 September 2017

Page 63

PLT-03159, Rev A.0 Printer Preferences

4.9 Printer Info Tab