Page 1

The HP BladeSystem p-Class 1U power enclosure: hot-plug,

redundant power for a server blade enclosure

technology brief

Abstract.............................................................................................................................................. 3

Introduction......................................................................................................................................... 3

Components of the enclosure ................................................................................................................ 3

Hot-plug, redundant power supplies ................................................................................................... 3

Redundant AC power ....................................................................................................................... 4

Hot-plug power management module ................................................................................................. 5

Features of the enclosure ...................................................................................................................... 5

Bi-directional electronic e-fuse............................................................................................................ 5

Power zones.................................................................................................................................... 5

Firmware in mixed environments .................................................................................................... 6

Dynamic power saver....................................................................................................................... 7

Redundancy with dynamic power saver .......................................................................................... 7

Enabling dynamic power saver ...................................................................................................... 8

Serial port....................................................................................................................................... 8

Remote access to the serial port ................................................................................................... 10

Efficient cabling ............................................................................................................................. 10

Management link cable............................................................................................................... 11

Power distribution unit cables....................................................................................................... 11

Infrastructure configurations ................................................................................................................ 12

Using PDUs with the 1U power enclosure.......................................................................................... 13

Redundancy............................................................................................................................... 13

Maximum rated VA capacity ....................................................................................................... 13

Number of PDU outlets................................................................................................................ 13

Three-phase input ....................................................................................................................... 13

Dynamic power saver and three-phase input PDUs ......................................................................... 13

Standard configurations.................................................................................................................. 15

Using ProLiant BL35p server blades .............................................................................................. 15

Using ProLiant BL30p server blades .............................................................................................. 16

Using ProLiant BL20p server blades .............................................................................................. 17

Risks associated with extreme density ............................................................................................... 18

Supported configurations for the S348 Monitored PDU and S332 Monitored PDU................................. 18

North America/Japan................................................................................................................. 18

Page 2

International .............................................................................................................................. 18

Supported configurations for the 40 A PDU....................................................................................... 18

47U rack................................................................................................................................... 19

800-mm-wide 42U rack .............................................................................................................. 19

Standard 42U rack..................................................................................................................... 20

Using uninterruptible power supplies (UPS) with the 1U power enclosure .............................................. 20

Conclusion........................................................................................................................................ 21

For more information.......................................................................................................................... 22

Page 3

Abstract

The HP BladeSystem p-Class1U power enclosure provides hot-plug, redundant power for a single

enclosure of HP ProLiant BL p-Class server blades from standard single-phase AC inputs. A properly

configured HP BladeSystem p-Class 1U power enclosure is an ideal power solution for small office

and remote site blade deployments. This technology brief explains the 1U power enclosure operation

and features as well as infrastructure configuration considerations. This paper is written with the

assumption that readers are already familiar with the HP BladeSystem.

Introduction

The HP BladeSystem consists of modular components that enable IT administrators to readily modify

and scale their infrastructures to meet changing IT demands. The ability to provide required power to

servers and use it efficiently is a critical IT need. The HP BladeSystem includes two power subsystem

options: a 3U power subsystem and a 1U power subsystem. This paper describes the 1U power

subsystem only. Refer to

subsystem.

The 1U power subsystem includes an HP BladeSystem p-Class 1U power enclosure configured with

embedded power supplies and a power management module. Power supply and AC line cord

redundancy is provided when powering one fully configured HP BladeSystem p-Class server blade

enclosure. The power management module enables IT administrators to efficiently monitor and

manage total enclosure power consumption.

www.hp.com/go/bladesystem for information about the 3U power

Choosing an optimal power solution requires the consideration of many factors, including the number

of server enclosures needed, the type of server blades to be installed, and the type of available

power. The HP BladeSystem p-Class 1U power enclosure is particularly well suited to the following IT

environments:

• Small or mid-size businesses using server blades in their infrastructure

• Remote or branch offices with distributed server blade deployments

• IT environments with single-phase power requirements

Components of the enclosure

The HP BladeSystem 1U power enclosure supports high availability by providing hot-plug, redundant

power supplies; redundant AC inputs; and a hot-plug power management module that operates

independently of the server blades and interconnects.

Hot-plug, redundant power supplies

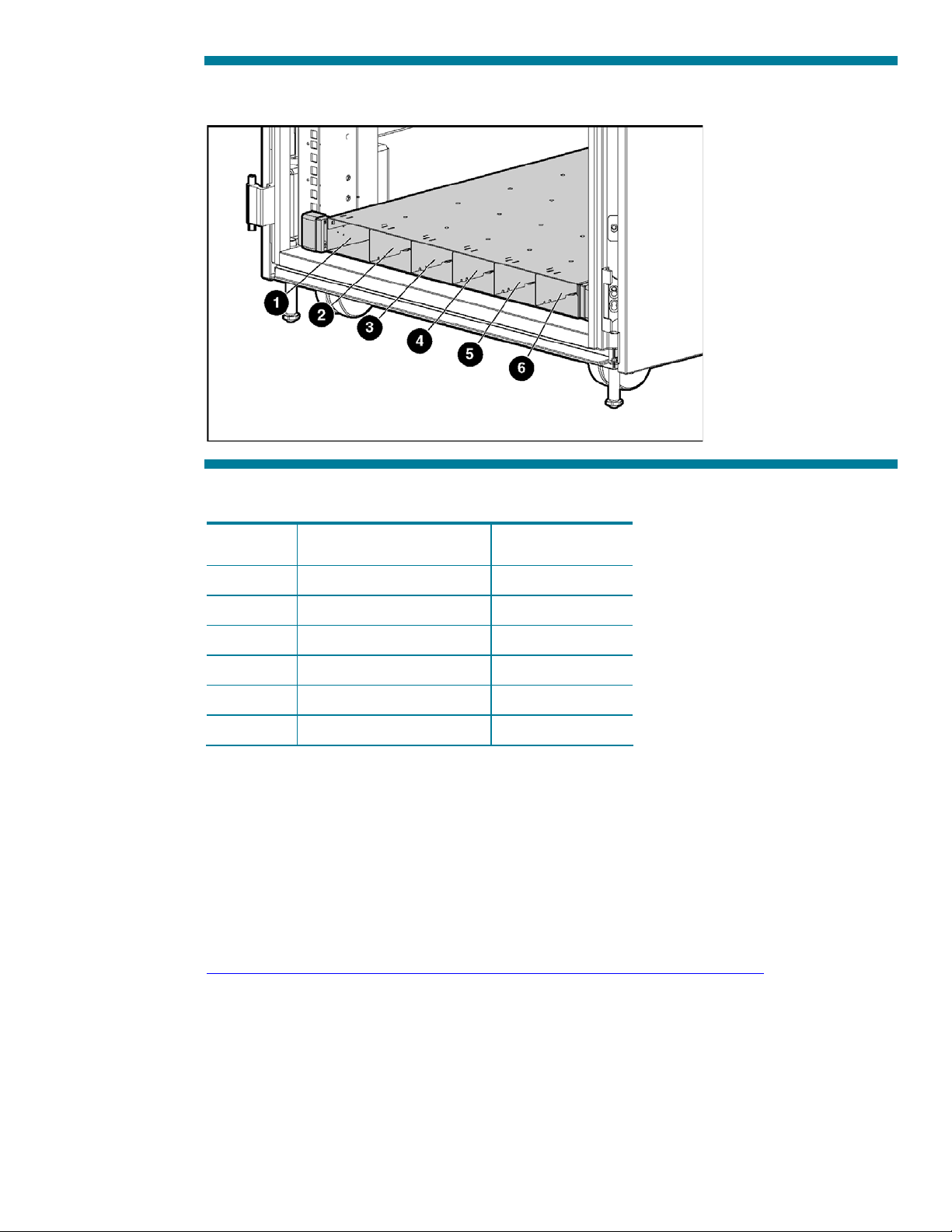

The 1U power enclosure houses up to six hot-plug power supplies, each unit rated at 2,000 W DC

output power. The enclosed six power supply bays are divided into two sides with three bays on bus

A and three bays on bus B (Figure 1 and Table 1).

3

Page 4

Figure 1. HP BladeSystem p-Class 1U power enclosure bays

Table 1. HP BladeSystem p-Class 1U power enclosure bay descriptions

Item Description Configuration

1 Power supply bay 1 Bus A

2 Power supply bay 2 Bus A

3 Power supply bay 3 Bus A

4 Power supply bay 4 Bus B

5 Power supply bay 5 Bus B

6 Power supply bay 6 Bus B

To implement a redundant configuration using power supplies in the 1U power enclosure, one or

more of bays 1 through 3 and an equal number of bays 4 through 6 must be populated with a power

supply.

Redundant AC power

For redundant AC power, bays 1 through 3 must be supplied with AC power from a different branch

circuit than bays 4 through 6. Each bay must be supplied with single-phase AC power according to

the specifications in the QuickSpecs, which are located at

http://h18004.www1.hp.com/products/quickspecs/12330_div/12330_div.html. The branch circuit

should have adequate capacity to handle the peak current demands of a fully populated 1U power

enclosure when attached to a fully populated server blade enclosure.

If only one side of the power enclosure is populated with power supplies, the power subsystem is not

redundant. If AC redundancy is not required, three power supplies located in any three bays can

provide adequate power for a fully loaded server blade enclosure.

4

Page 5

Hot-plug power management module

The hot-plug power management module monitors the power subsystem components and regulates the

power-up sequence of newly installed server blades and interconnect switches. The power

management module is connected with cables to the server blade enclosure management module(s) to

facilitate communication of management information, such as server blade and interconnect location,

power supply budget, and health status.

Features of the enclosure

The HP BladeSystem p-Class 1U power enclosure provides for power subsystem management with the

following features:

• Bi-directional electronic e-fuse provides prompt power up.

• Power zones provide communication and management capabilities between power enclosures and

supported server blade enclosures.

• Dynamic power saver achieves efficient power consumption.

• Serial port allows direct monitoring of the 1U power enclosure status.

• Efficient cabling reduces clutter in the area behind the 1U power enclosure.

Bi-directional electronic e-fuse

The 1U power enclosure has a bi-directional electronic e-fuse switch that connects the -48-V DC

outputs on bus A to the -48-V DC outputs on bus B. Once a single power supply is installed in a bay

on either side of the 1U power enclosure, that side of the power enclosure is immediately powered.

Approximately 3 seconds later, the internal electronic e-fuse switch automatically closes, and the other

side of the 1U power enclosure is powered as a result. In short, both sides of the 1U power enclosure

are powered even if only one power supply is installed, and the 1U power enclosure can operate this

way indefinitely. With only one power supply installed, the built-in power management software

attempts to limit the number of blade servers allowed to power on. An administrator, however, can

override the warning and manually power up the servers.

The only time the electronic switch in the HP BladeSystem p-Class 1U power enclosure opens is when

there is a bus short in the power enclosure. If a bus short occurs in the power enclosure, the electronic

e-fuse switch quickly separates bus A from bus B. The circuitry within the 1U power enclosure

automatically and continuously monitors the faulted side. Once the fault is cleared, the electronic efuse switch resets and closes automatically restoring full power to both sides of the server blade

enclosure. This is a rare situation.

Power zones

Power zones, when set properly, associate server blade enclosures with the power enclosure(s) that

support them. This allows power information and alerts to be sent to the proper power management

module or server blade management module when power conditions change. For example, if an

administrator removes a power supply from the HP BladeSystem p-Class 1U power enclosure,

notification is sent to the affected server blade enclosure in that power zone.

Power zones also define the startup sequence of the server blades when the entire rack needs to be

restarted after a total power outage. The server blade enclosures communicate with the power

enclosures in the rack to ensure that the server blades and enclosures are powered in sequence,

rather than all at once, to prevent overloading the AC infrastructure. The sequence always runs from

the top of the rack (power zone 6), top left-hand blade through the top and bottom row of the blades

in that enclosure (if ProLiant BL30p or BL35p server blades are installed). The sequence then proceeds

5

Page 6

down to the next enclosure and continues until the bottom right blade in the bottom server blade

enclosure is powered.

In a rack that contains many server blade enclosures, the sequencing process may cause a significant

time delay before the last server blade is powered. However, this is preferable to the alternative—the

possibility that the main breakers trip due to the excessive load on the AC infrastructure as all the

server blade enclosures try to power simultaneously.

Firmware in mixed environments

When 1U power enclosures and 3U power enclosures are used in the same rack, the firmware must

be upgraded to the latest version for correct power zone operation. As of firmware release 2.20,

there are important changes in how power zones are managed. In firmware releases prior to 2.20,

there were only two power zones (zone 1 and 2) that were set by a switch on the rear of 3U power

enclosures. Firmware 2.20 provides the capability to have up to six power zones, based on the

absolute maximum hardware that could fit into one rack. The power zone switch on the rear of the 3U

power enclosure only has a setting for zone 1 and 2; new power zones start at 3 to avoid overlap

with existing power zones. The primary difference in setting the new power zones is that they are not

set by a switch on the power enclosure. The switch is still present on HP BladeSystem p-Class 3U

power enclosures for legacy firmware, but firmware version 2.20 and above do not use the switch.

The new power zones (3 and above) are set automatically by the firmware based on rack topology.

Unlike the 3U power enclosure, the 1U power enclosure does not have a power zone switch because

it was released with firmware 2.20.

Every power zone must include a power source (either the 1U power enclosure or the 3U power

enclosure) and at least one server blade enclosure. In the pre-2.20 firmware environment, if a server

blade enclosure were in zone 2 and the power enclosure supporting it were in zone 1, the server

blades and switches in that sever blade enclosure would never power on automatically because the

devices in the server blade enclosure must request power from a power source in their own zone in

order to power on. If the power source is not in the same zone as the server blade enclosure, the

request for power is not answered because power is not available in that zone.

To ensure that all power enclosures and server blade enclosures are configured in the proper zone,

all enclosures in a rack should be upgraded to firmware 2.20. If one enclosure in an infrastructure is

upgraded to firmware 2.20 and the other enclosures are not upgraded:

• The enclosure upgraded to 2.20 is put into power zone 3.

• The enclosures not upgraded are placed in power zone 1 or 2 (depending on the zone in which

the physical switch is set).

Once all the enclosures in a rack are upgraded to firmware 2.20, the switch setting on the rear of the

enclosure no longer serves a functional purpose. After an upgrade to firmware 2.20, power zone 1

and 2 are no longer used since the power zones are set automatically by the firmware based on rack

topology, not switch settings. HP does not support mixed firmware versions within the same

infrastructure. All enclosures should have the same firmware version.

NOTE: For more information on upgrading your firmware, see Chapter 5 of

the “HP ProLiant BL System Best Practices Guide”:

http://h20000.www2.hp.com/bc/docs/support/UCR/SupportM

anual/TPM_351359-001_rev1_us/TPM_351359001_rev1_us.pdf.

6

Page 7

Dynamic power saver

The dynamic power saver feature in the HP BladeSystem p-Class 1U power enclosure provides for

efficient use of power in the server blade enclosure. When this feature is enabled, total power

consumption is monitored in real time. Power supplies are placed in a standby condition when the

power demand from the server blade enclosure is low. As power demand increases, the standby

power supplies activate as necessary to deliver the required power. This enables the power enclosure

to operate at optimum efficiency.

Optimum efficiency can be achieved because of the power supply efficiency curve associated with

any power supply. Power supply efficiency is simply a measure of power in versus power out, so at

50 percent efficiency 2,000 W in would equal 1,000 W out. The difference is wasted energy, which

costs money.

Dynamic power saver recognizes that most power supplies operate less efficiently when lightly loaded

and more efficiently when heavily loaded. A power supply installed in the 1U power enclosure

running with a 10 percent load could have efficiency as low as 50 percent, but with a 50 percent

load, efficiency increases to over 90 percent, providing a significant savings in power consumption.

Dynamic power saver drives power supply efficiency by shifting the load so there is a heavier load on

fewer power supplies as opposed to a lighter load on all the installed power supplies.

Redundancy with dynamic power saver

Redundant power is maintained in dynamic power saver mode. The 1U power enclosure ensures that

at least two power supplies, one from bus A and one from bus B, are active. When dynamic power

saver is enabled on a 1U power enclosure with six power supplies installed, a low load initiates the

following sequence:

1. Initially all power supplies are powered as normal.

2. Power supplies installed in bay 3 and bay 6 are placed in standby.

3. Power supplies installed in bay 2 and bay 5 are placed in standby.

4. Power supplies installed in bay 1 and bay 4 are always powered at 50 percent load or less to

ensure redundancy.

The reverse sequence applies as the load increases. Power supplies that are on standby are activated

in pairs and the load is shared so the maximum load on each feed is 50 percent. Equal distribution of

the load ensures that redundancy is always maintained.

7

Page 8

Enabling dynamic power saver

To configure the dynamic power saver, the power management module must be removed from the 1U

power enclosure and the dynamic power saver feature must be enabled. The module is hot pluggable

and can safely be removed during normal server operation (Figure 2). After enabling the dynamic

power saver, reinstall the power management module.

Figure 2. The 1U power enclosure power management module and location of the dynamic power saver switches

Table 2. Dynamic power saver switch positions and functions

Position Function

1 Dynamic power saver disabled (default)

2 Dynamic power saver enabled

3 Reserved (off = default)

Serial port

The serial port on the back of the HP BladeSystem p-Class 1U power enclosure provides a way for IT

administrators to directly monitor the status of the 1U power enclosure. As shown in Figure 3 and

explained in Table 3, detailed information can be obtained through the serial port.

Table 3. Status information displayed through the serial port

Status information Description

Uptime Shows the amount of time the system has been powered on.

Power supply location (slot number), status,

power usage, input/output temperature

Enclosure backplane temperature Displays the temperature on the enclosure backplane.

Number of fault conditions Shows the number of unresolved faults in the system.

Provides the physical location of power supplies, their fault status, power

usage, and operating temperatures.

Status of unit identification (UID) LED Specifies whether UID LED is active or not.

Status of enclosure link

Management module firmware version Shows revision of the management firmware.

Overall power usage Tabulates total power usage of all the power supplies in the enclosure.

Provides information as to whether the link is connected or not (the enclosure

link connects to the blade enclosure).

8

Page 9

Status information Description

Power supply redundancy (enclosure N+1

redundancy)

AC feed redundancy

Bus balancing

Figure 3. Serial port display

Indicates whether there are sufficient power supplies to take over the load in

the event that one power supply failed without causing an enclosure power

failure.

Specifies whether sufficient power supplies are installed for the enclosure to

remain powered on if an AC feed is lost.

Ensures that the load is balance across the Bus A and Bus B feeds. Only

applies to original p-Class enclosure.

A null modem cable can be used to connect the serial port to a terminal. Terminal software, such as

Microsoft® Windows® HyperTerminal or Minicom for Linux, can be used to access the 1U power

enclosure status display. On the terminal, configure the following settings to allow communication

through the serial port:

• 9,600 bps

• No parity

• 8 data bits

• 1 stop bit

• Software flow control, may also be called XON/XOFF

• VT100 terminal emulation

The serial port on the HP BladeSystem p-Class 1U power enclosure does not support hardware flow

control settings.

9

Page 10

Remote access to the serial port

IT administrators can enable remote access to the serial port in two different ways:

1. Through the HP Serial Console Servers software, which allows serial devices to be accessed

remotely through an IP network, or

2. Through the HP IP Console with the Serial Interface Adapter.

NOTE: HP Serial Console Servers and HP IT Console with Serial Interface

Adapter can also be used for remote access to other devices with a serial

port. For additional information about HP Serial Console Servers and HP

Serial Interface Adapter:

www.hp.com/go/kvm.

Efficient cabling

The HP BladeSystem p-Class 1U power enclosure uses a well-organized cabling system to connect to

the server blade enclosure and any attached Power Distribution Units (PDUs). The 1U power enclosure

provides a direct power connection to the server blade enclosure through two dedicated DC power

cables (Figure 4).

Figure 4. The 1U power enclosure power cables connected to the server blade enclosure

Each server blade enclosure is rated to support up to 6,000 W (3,000 W per side and thus 3,000

W per cable). The individual DC power cables are sized to support the worst-case power tolerances.

At the lowest possible power supply voltage of -48.8 V, the maximum rated sustained output current

would be 61.5 A per side and per cable.

10

Page 11

Management link cable

To provide two-way communication, connect a management link cable from the power management

module of the 1U power enclosure to the server blade enclosure (Figure 5).

Figure 5. Management link cable connected from the 1U power enclosure power management module to the server blade

enclosure

Power distribution unit cables

If PDUs are being used, they must be connected to the 1U power enclosure in three steps. First, before

connecting any PDU power cables, turn off or disconnect facility AC power from the PDUs. Secondly,

connect the PDU power cables to the AC power input connectors on the 1U power enclosure (see

Figure 6). Lastly, once the PDU power cables are connected to the PDUs, power to the PDUs can be

restored.

Figure 6. PDU power cables connected to the 1U power enclosure

11

Page 12

Infrastructure configurations

When using the HP BladeSystem p-Class 1U power enclosure, follow the general guidelines in

Table 4 to install the proper amount of power supplies.

Table 4. General guidelines for power supply installation in the 1U power enclosure

Infrastructure Required power supplies

installed in 1U power enclosure

Server blade enclosure populated with ProLiant BL20p, BL25p, or BL35p server blades 4

Server blade enclosure populated with ProLiant BL35p dual-core server blades 6

Server blade enclosure populated with ProLiant BL30p server blades 6

More than 3,000 W required per enclosure 4

More than 4,000 W required per enclosure 6

To determine power requirements for an enclosure, use the HP Power Calculator available at

www.hp.com/go/bladesystem/powercalculator. The HP BladeSystem p-Class sizing utility is a

Microsoft® Excel workbook with a power calculator; it can be used to help determine the correct

modular components for specific IT environments.

Figure 7. The HP BladeSystem p-Class Sizing utility

12

Page 13

Using PDUs with the 1U power enclosure

When using PDUs within an HP BladeSystem environment, key considerations include redundancy,

volt-ampere (VA) capacity of the PDU, number of PDU outlets, and using PDUs with single-phase or

three-phase inputs.

Redundancy

Planners must consider redundancy when determining how to distribute power using PDUs. The

normal method of delivering AC redundancy is to use two separate feeds to each side of the 1U

power enclosure, referred to as the A feed and the B feed. To ensure that the power subsystem

remains redundant in the event of an AC line feed failure, both feeds and the associated PDUs must

be sized to take the full load of the attached 1U power enclosures.

Maximum rated VA capacity

The key variable to consider when using PDUs with the 1U power enclosure is the maximum rated VA

load capacity for the PDU. The HP Power Calculator allows the calculation of the input VA

requirements of the 1U power enclosure to support any given server blade configuration. Once the

total input VA rating requirement for the 1U power enclosure is obtained, compare this to the rated

load capacity of available PDUs to determine how many 1U power enclosures can be supported.

Number of PDU outlets

Planners must also factor in the number of outlets available on the PDU. For example, the HP 40A NA

PDU (252633-B4) has a maximum capacity of 9,200 VA. Theoretically, in a redundant configuration,

three full server blade enclosures populated with ProLiant BL30p server blades (with 3.06 GHz

processors) rated at 5,300 VA, could be connected to four of these PDUs. However, each PDU has

only four outlets while each enclosure requires six connections at 5,300VA; resulting in 16 available

outlets to accommodate 18 required connections—an impossible configuration.

Three-phase input

Planners should consider whether using a three-phase input PDU is a viable option. Three-phase PDUs

take standard three-phase power input feeds and convert the power to standard single-phase outputs

to power industry-standard IT equipment. One advantage of using three-phase PDUs is that more

power can be delivered to a rack with fewer power drops. For example, at 208 V a 30 A singlephase circuit delivers 4,992 VA, while a three-phase circuit delivers 8,640 VA. Also, when

comparing similar power levels, the size for the wiring and connectors is significantly smaller with

three-phase power.

Phase balance is an important consideration when working with three-phase power. For optimum

efficiency, the load attached to a three-phase source should be balanced across all three phases. It is

possible to balance the load by simply installing six power supplies in the 1U power enclosure;

however, this may not lead to the most efficient use of PDU outlets or power. Manually balancing the

load by plugging in power supplies across phases when using a three-phase PDU may provide for a

more efficient usage of outlets and power.

Dynamic power saver and three-phase input PDUs

Dynamic power saver also affects the phase loads on a three-phase input PDU. The key is to ensure

that the load is balanced as well as possible across all three phases. The determined sequence in

which the power supplies are placed into standby should prevent any single phase from being

excessively loaded. When dynamic power saver is enabled, power supplies one and four are always

powered; power supplies two and five are powered next; and power supplies three and six are

powered last. In a rack with multiple 1U power enclosures, the power supplies installed in bay 1 in

each of the 1U power enclosures should not be plugged into the same phase. Each installed power

supply in bay 1 should be connected to a different phase on the PDU.

13

Page 14

Power supplies installed in bay 2 in each of the 1U power enclosures should also be connected to a

2 4

2 4

different phase on the PDU. Figure 8 illustrates how 1U power enclosures should be connected with

four power supplies installed.

NOTE: The grayscale outlets on the PDU in Figure 8 indicate which phase

the outlet is attached to. The wires are color coded to distinguish the

connections to power supplies installed in bus A and bus B. Power supplies

are numbered in reverse because the view is from the rear of the 1U power

enclosure.

Figure 8. HP BladeSystem p-Class 1U power enclosures connections (rear view)

5 6 3

Phase 1

Phase 2

Phase 3

5 6 3

Phase 1

1

1

Phase 2

Phase 3

14

Page 15

Standard configurations

The following configurations review some common usage scenarios for the HP BladeSystem p-Class

1U power enclosure, including the type of server blades populated and PDU options.

Using ProLiant BL35p server blades

In this configuration, the rack contains three enhanced server blade enclosures, three 1U power

enclosures, and six PDUs (Figure 9). Each enhanced server blade enclosure is populated with ProLiant

BL35p server blades and supported by a 1U power enclosure with four power supplies installed. The

1U power enclosures are attached to two 24 A modular PDUs.

The ProLiant BL35p server blades have two single-core 2.4-GHz processors with 1 MB L2 cache, 4

GB of RAM, and one 60-GB hard drive, resulting in 4,270 VA input. Four power supplies are needed

in the 1U power enclosures for redundant power. The 24 A modular PDU used in this configuration

has a load capacity of 4,992 VA, so it can support one server blade enclosure populated with

ProLiant BL35p server blades.

Figure 9. Rack with enhanced server blade enclosures populated with ProLiant BL30p server blades, three 1U power enclosures

and six 24 A modular PDUs

15

Page 16

Using ProLiant BL30p server blades

In this configuration the rack contains four enhanced server blade enclosures, four 1U power

enclosures and six PDUs (Figure 10). Each enhanced server blade enclosure is populated with

ProLiant BL30p server blades and has a 1U power enclosure with six power supplies installed. The

1U power enclosures are connected to two 40 A modular PDUs.

The ProLiant BL30p server blades have two single-core 3.2-GHz processors with 2 MB L3 cache, 4

GB of RAM, and one 60-GB hard drive, resulting in 5,768 VA input. Six power supplies are needed

in the 1U power enclosures for redundant power. The 40 A modular PDU has a load capacity of

8,320 VA, so it can support one server blade enclosure fully populated with ProLiant BL30p server

blades, with 2,552 VA extra capacity. Each power supply has a load of 1,923 VA; an extra power

supply unit can be connected to each PDU and cross-wired, as shown in Figure 10.

Figure 10. Proposed configuration using four enhanced server blade enclosures populated with ProLiant BL30p server blades,

four 1U power enclosures and six 40 A modular PDUs

16

Page 17

Using ProLiant BL20p server blades

In this configuration, the rack contains six enhanced server blade enclosures, six 1U power

enclosures, and six PDUs. Each enhanced server blade enclosure is populated with ProLiant BL20p

server blades and has a 1U power enclosure with four power supplies installed. The 1U power

enclosures are connected to two 40 A modular PDUs.

The ProLiant BL20p server blades have a single-core 3.6-GHz processor with 2 MB L2 cache, 4 GB of

RAM, and two 18-GB 15,000 RPM SCSI hard drives, resulting in 3,714 VA input. Four power

supplies are needed in the 1U power enclosure for redundant power. The 40 A modular PDU has a

load capacity of 8,320 VA, so it can support two server blade enclosures fully populated with

ProLiant BL20p server blades.

Figure 11. Proposed configuration using six enhanced server blade enclosures populated with ProLiant BL20p server blades, six

1U power enclosures and six 40 A modular PDUs

17

Page 18

Risks associated with extreme density

While it is possible to build a fully populated a rack with server blades and retain power supply and

line cord redundancy using HP BladeSystem p-Class 1U power enclosures, several items should be

considered prior to implementation.

The primary issues associated with extreme density that must be seriously considered include: heat,

weight, PDU placement and PDU breaker and line cord access after the rack is built. Before

deploying these configurations, consider the heat load placed on the data center air-conditioning

system and the weight load placed on the floor.

There are two methods of properly implementing a rack with six 1U power enclosures installed.

1. Install six 40 A modular PDUs in the rack. This PDU setup provides power for up to six 1U power

enclosures, with a maximum of four power supplies in each enclosure. It provides sufficient power

for all ProLiant BL20/25p configurations, ProLiant BL40/45p configurations, and the majority of

ProLiant BL35p configurations. The ProLiant BL30p configuration requires six power supplies per

power enclosure. Some of the dual-core ProLiant BL35p configurations may require six power

supplies, which can risk overloading the PDUs.

2. Use the HP S348 Monitored PDU or S332 Monitored PDU.

NOTE: International configurations can be assembled using the 32 A

modular PDU. This PDU has slightly less power capacity (7,680 VA versus

the 8,320 VA) than the 40 A modular PDU. Always check the power

calculators.

Supported configurations for the S348 Monitored PDU and S332 Monitored PDU

The S348 and S332 PDUs mount in the rear of the rack so there are no issues with access to breakers

or line cords. However, access can be enhanced using a rear extension kit, which adds an extra 155

mm or 6 inches of depth to the rear of the rack. The addition of the rack light kit can also significantly

increase ease of use and access.

North America/Japan

Install four HP 17.3 kVA S348 Monitored PDUs. This provides 24 -four C19 outlets and 34.6 kVA of

power and supports up to six 1U power enclosures of 5.7 kVA each. For 1U power enclosures of 2.8

kVA or less, two S348 Monitored PDUs are sufficient.

International

Install four S332 Monitored PDUs. This provides 42 kVA of power and can support six 1U power

enclosures of any configuration. For 1U power enclosures of 3.52 kVA or less, two S332 Monitored

PDUs are sufficient.

Supported configurations for the 40 A PDU

The 40 A PDUs can be mounted in a 1U configuration, which is recommended for best access, or in

the "0U" space in the side of the rack, which may provide restricted access to the PDU breakers.

The following configurations are potential solutions to provide power for six server blade enclosures

powered by six 1U power enclosures and a 40 A PDU.

18

Page 19

47U rack

Mounting the PDUs in the 1U configuration requires an additional 3U of vertical space in the rack.

Three PDUs must be mounted facing the front of the rack and three PDUs must be mounted facing the

back of the rack (Figure 12). This provides 42U of vertical space for the servers and power enclosures

and 3U additional space for the PDU mounting. This configuration must be assembled onsite, as it is

not available through Factory Express.

Figure 12. Partial diagram of front and back mounted PDUs

Front Back

PDU PDU

PDU PDU

800-mm-wide 42U rack

The 800-mm-wide rack ships standard with vertical blanking panels that block air recirculation back

to the front of the rack. Each side of the rack provides 100mm (approximately 4 inches) of space on

either side of the rack for access to the 0U space. Access to the PDUs from the front of the rack can

be gained by removing the three screws that secure the vertical blanking panels. This configuration

must be assembled onsite, as it is not available through Factory Express.

19

Page 20

Standard 42U rack

This configuration, while possible, may cause issues because of the limited access to the PDUs in the

0U space after all the servers are installed. HP recommends mounting the modular PDU in the 1U

configuration for best access to breaker actuators and receptacles. Otherwise, in the event of a

failure, access to the PDU breakers requires the removal of server blade and power enclosures from

the rack.

This configuration is only recommended in these situations:

• The rack is a stand-alone unit and there is clear access to both sides of the rack by simply removing

side panels.

• There is sufficient space on each side of the rack to provide access to the PDUs for breaker and

receptacle access.

• The rack can be rolled forward away from the row to allow side access to the PDUs.

NOTE: For more information on the PDUs discussed in this section, visit:

http://h18004.www1.hp.com/products/servers/proliantstorage/powerprotection/power-distribution/index.html

Using uninterruptible power supplies (UPS) with the 1U power enclosure

The key factor to consider when sizing a UPS is the supported output wattage for the UPS. The UPS

output wattage must be matched to the total input wattage of the supported 1U power enclosure.

When connecting a UPS it is important to remember that VA and W are not the same.

The HP R5500XR UPS provides the highest level of availability when used with the 1U power

enclosure. In a single-feed environment (Figure 13, top left), the R5500XR can support a single 1U

power enclosure with up to four installed power supplies. This setup can be used to protect the system

from unstable power lines and provide a limited amount of backup time for orderly shut down in the

event of AC failure.

A dual-feed, single-protection setup (Figure 13, top right) can be used to provide an extra level of

availability. If the AC fails and the PDU side has no power, the full load shifts to UPS power to allow

for a controlled shutdown. UPS software can also be used to perform a controlled shutdown.

Using this configuration, a potential problem can occur in the event of a cascading failure where the

UPS side fails first. If the AC power fails, the UPS handles the load on its side, which begins to

discharge the UPS. If the PDU side fails, the whole system can potentially fail without initiating a

controlled shutdown because of the power drain on the UPS.

The ultimate level of availability and protection is provided by the dual-feed, dual-protection

configuration (Figure 13, bottom). This configuration always provides for an orderly shutdown when a

complete loss of utility power occurs.

20

Page 21

,

Figure 13. AC feed redundancy using the HP R5500XR UPS

Single-feed, single protection

Dual feed,-single protection

R5500

Dual-feed

dual-protection

Conclusion

The HP BladeSystem p-Class 1U power enclosure is a vital component of the HP BladeSystem

infrastructure and plays an important role in helping HP customers build an adaptive enterprise. It

provides cost-effective, efficient, hot-plug, redundant power for single server blade enclosure

deployments. IT environments can use this solution for blade evaluation purposes, distributed server

blade deployments to remote locations, and heterogeneous server blade deployments within a single

rack. IT environments with deeply entrenched power distribution environments can leverage the 1U

power enclosure to help accommodate existing PDU strategies. The HP BladeSystem p-Class 1U

power enclosure also has backwards compatibility, allowing IT administrators at small and mediumsized businesses to leverage their previous IT investments by fitting the 1U power enclosure into

existing racks in their infrastructure.

21

Page 22

For more information

For additional information, refer to the resources listed below.

Resource description Web address

HP BladeSystem website

www.hp.com/go/bladesystem

HP BladeSystem p-Class Enclosure

Installation Instructions

HP BladeSystem p-Class 1U Power Supply

Installation Instructions

HP power distribution units website

HP rack-mountable uninterrupted power

supplies website

http://h20000.www2.hp.com/bc/docs/support/SupportManu

al/c00383406/c00383406.pdf

http://h20000.www2.hp.com/bc/docs/support/SupportManu

al/c00383401/c00383401.pdf

http://h18004.www1.hp.com/products/servers/proliantstorag

e/power-protection/power-distribution/index.html

http://h18004.www1.hp.com/products/servers/proliantstorag

e/power-protection/rackups/index.html

© 2005 Hewlett-Packard Development Company, L.P. The information

contained herein is subject to change without notice. The only warranties for

HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed

as constituting an additional warranty. HP shall not be liable for technical or

editorial errors or omissions contained herein.

TC051203TB, 12/2005

Loading...

Loading...