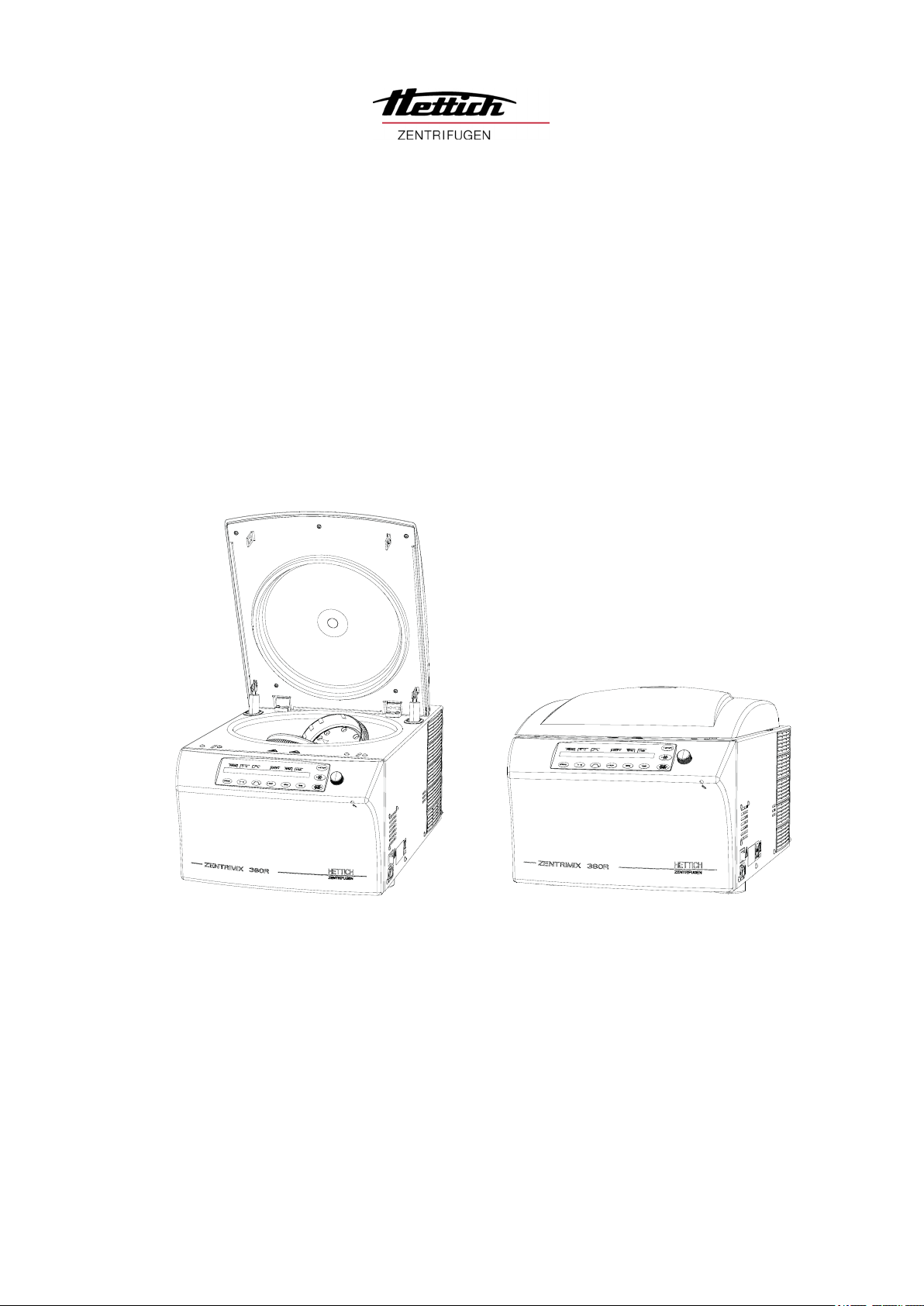

Hettich ZENTRIMIX 380 R Operating Manual

Operating manual

ZENTRIMIX

380 R

Translation of the original operating manual

Read the instructions prior to performing any task!

Andreas Hettich GmbH & Co. KG

Föhrenstraße 12

78532 T

Germany

T

Fax: +49 (0)7461 / 705-1125

Email: info@hettichlab.com

Email: service@hettichlab.com

Internet: www.hettichlab.com

Translation of the original operating manual

ZENTRIMIX, 380 R, en_GB, 2

© 2017

uttlingen

elephone: +49 (0)7461 / 705-0

2

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN

Table of contents

Table of contents

1 Introduction......................................................................... 5

1.1

Symbols........................................................................ 5

1.2 Personal protective equipment..................................... 8

1.3 Personnel qualification.................................................. 8

1.4 Intended use................................................................. 9

1.5 Replacement parts/consumable material................... 10

1.6 Scope of delivery........................................................ 10

1.7 Return shipments........................................................ 11

2 Safety information............................................................ 13

3

Device description

4 Transport and storage...................................................... 23

5 Commissioning................................................................. 25

5.1 Unpacking the device................................................. 25

5.2 Setting up, connecting and switching on the device... 26

6 Operation........................................................................... 31

6.1 Operating elements.................................................... 31

6.2 Opening the lid............................................................ 35

6.3 Closing the lid............................................................. 35

6.4 Quick-stop function..................................................... 35

6.5 Loading the rotor......................................................... 36

6.5.1 Loading a rotor for classical centrifugation.............. 36

6.5.2 Loading a rotor for dual centrifugation..................... 37

6.5.3 Handling of bio-safety systems................................ 38

6.6 Starting centrifugation................................................. 39

6.7 Dual centrifugation: Validating application.................. 41

6.8 Emergency unlocking................................................. 43

6.9 Removing and installing the rotor............................... 45

6.10 Cooling...................................................................... 47

7 Software description........................................................ 49

7.1 Program settings......................................................... 50

7.1.1 Calling up/loading program (RCL 1-99)................... 51

7.1.2 Entering or changing programs (STO 1-99)............ 52

7.1.3 Calling up/loading a program link (RCL A-Z)........... 53

7.1.4 Editing a program link (EDIT A-Z)............................ 54

7.1.5 Saving a program link (STO A-Z)............................. 55

7.2 Centrifugation parameters.......................................... 56

7.2.1 Temperature (t/°C)................................................... 57

7.2.2 Start-up and run-down parameters.......................... 57

7.2.3 RCF and RAD.......................................................... 59

7.2.4 Speed (RPM)........................................................... 61

7.2.5 Runtime (t/hms)....................................................... 62

7.2.6 Precooling of the rotor............................................. 65

............................................................ 21

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 3

Table of contents

7.3 Machine Menu............................................................ 66

7.3.1 Change Lock............................................................ 67

7.3.2 Change PIN............................................................. 68

7.3.3 Info........................................................................... 70

7.3.4 Operating Time........................................................ 71

7.3.5 Settings.................................................................... 74

8 Cleaning, disinfection and maintenance........................ 83

8.1 Cleaning...................................................................... 84

8.2 Disinfection................................................................. 85

8.3 Maintenance............................................................... 86

9 Troubleshooting................................................................ 89

9.1 Performing a mains reset............................................ 91

10 Technical data................................................................... 93

10.1 Type plate................................................................. 94

10.2 Dimensions............................................................... 95

11 Disposal............................................................................. 97

12 Glossary

13 Index................................................................................. 101

Appendix.......................................................................... 105

A Rotors and accessories............................................... 107

............................................................................. 99

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 4

1 Introduction

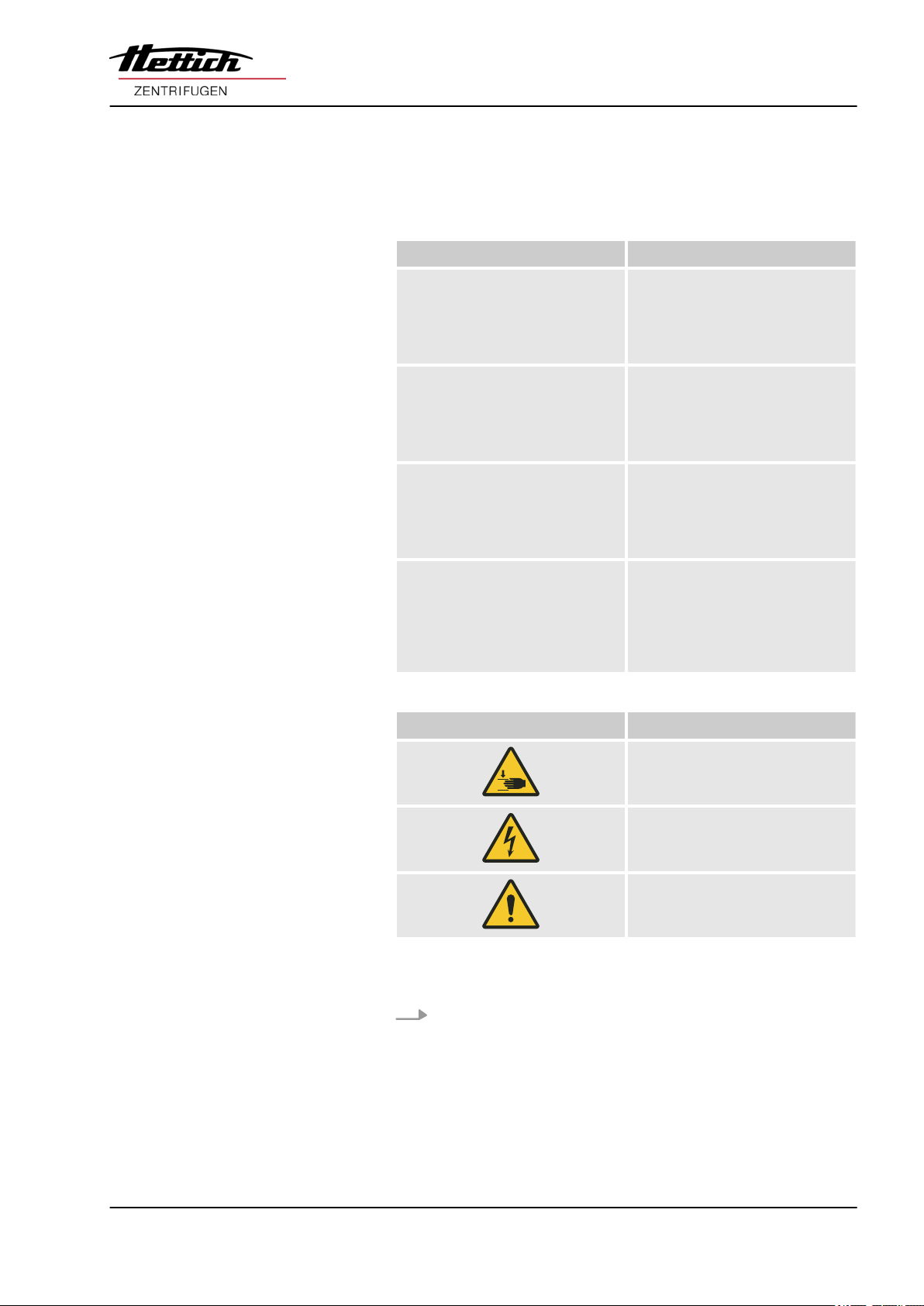

1.1 Symbols

Introduction

Signal words

Signal word Meaning

DANGER! This combination of symbol and

signal word indicates an immediate dangerous situation that

will result in death or serious

injury if it is not avoided.

WARNING! This combination of symbol and

signal word indicates a possible

dangerous situation that can

result in death or serious injury

if it is not avoided.

CAUTION! This combination of symbol and

signal word indicates a possible

dangerous situation that can

result in minor injury if it is not

avoided.

NOTICE! This combination of symbol and

signal word indicates a possible

dangerous situation that can

result in material and environmental damage if it is not

avoided.

arning categories

W

General symbols

Warning signs Type of danger

Warning – hand injuries.

Warning – high-voltage.

Warning – danger zone.

This listing symbol denotes descriptions of tasks that you

must perform.

n This dot is for denoting lists.

– This dash denotes listings of the second level.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 5

Introduction

Cross reference within the document

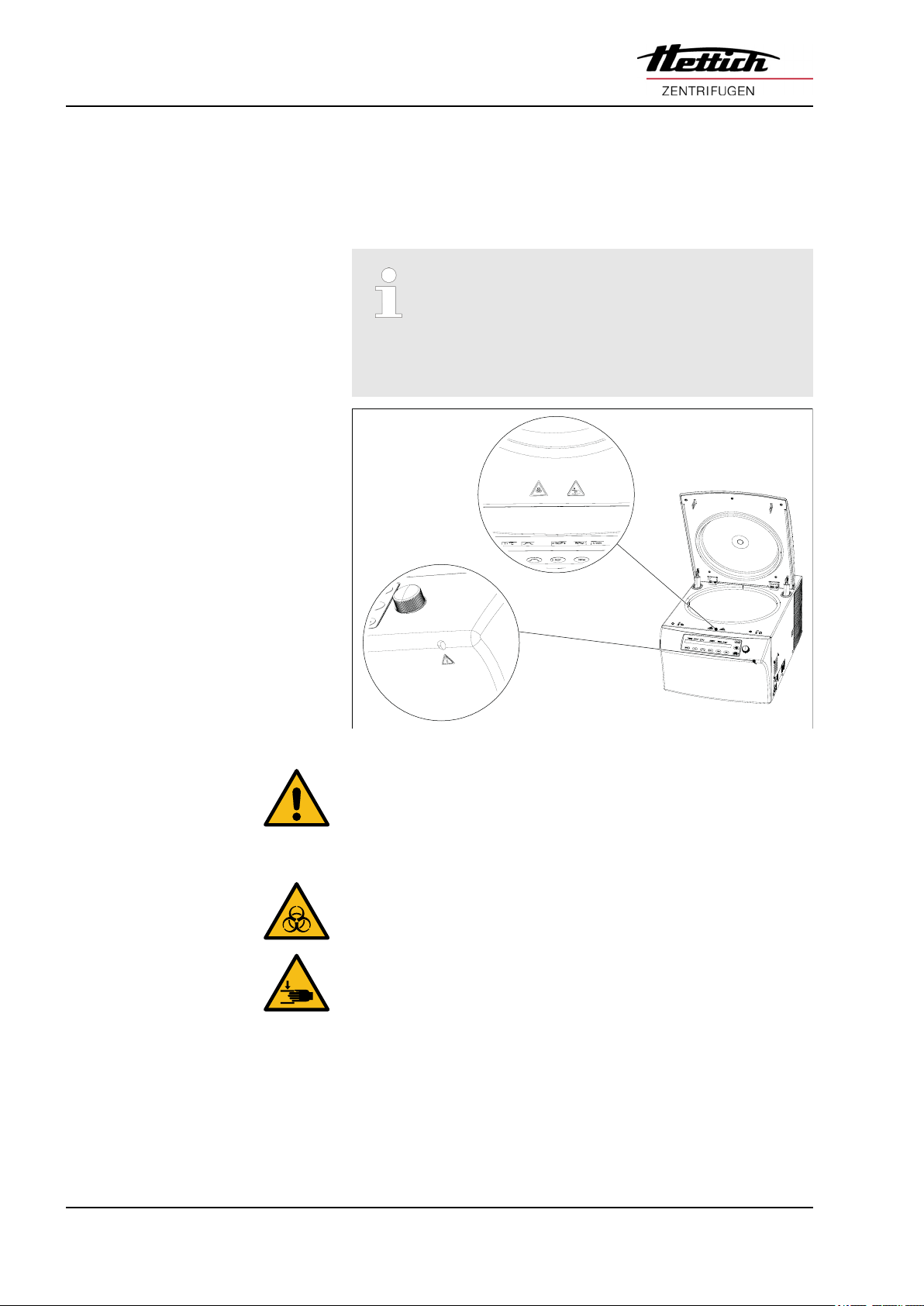

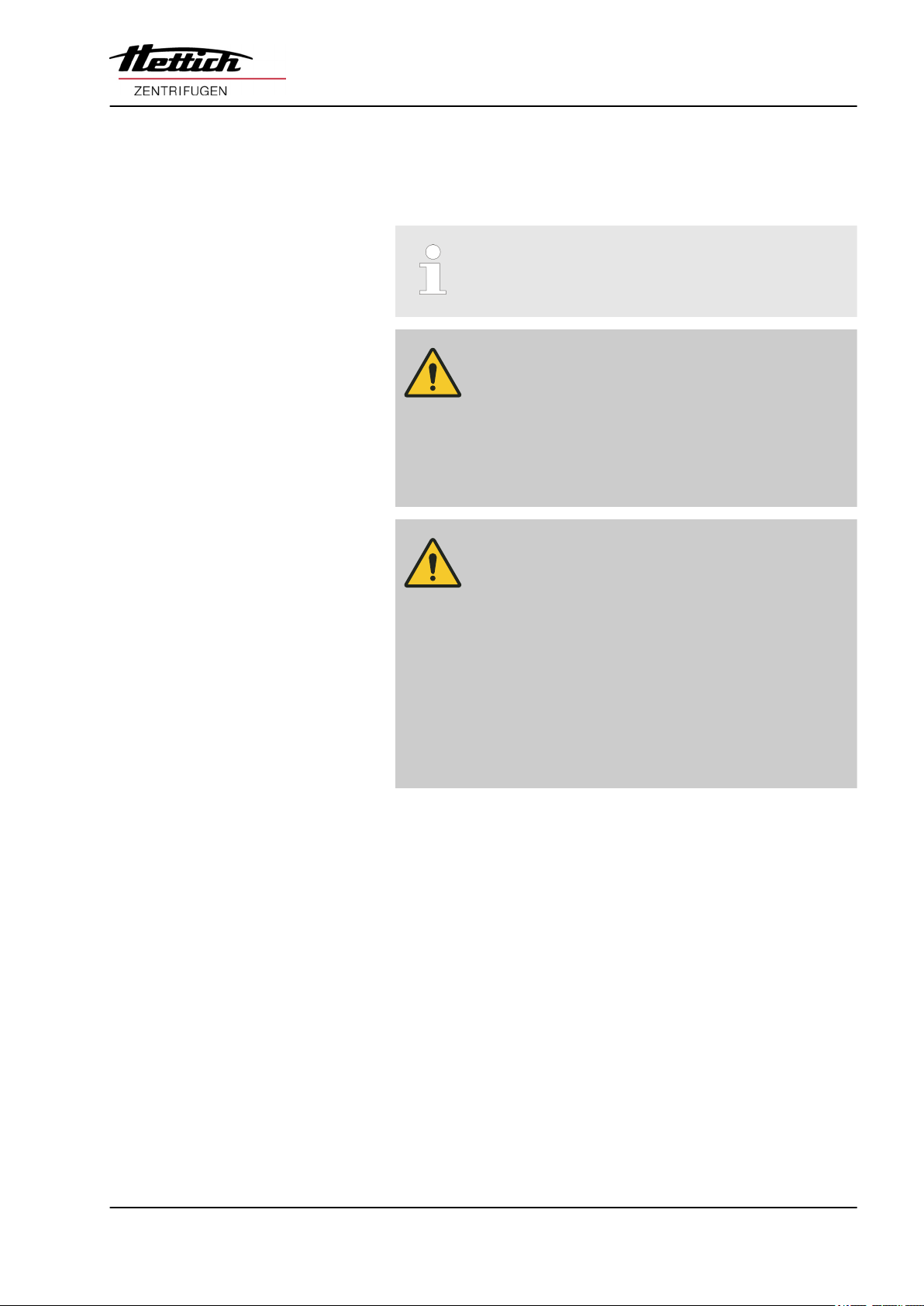

Symbols on the device

Cross references are indicated as follows:

bols’ on page 5

Warnings/symbols on the device which are no

longer recognizable should be immediately

replaced by the operating company.

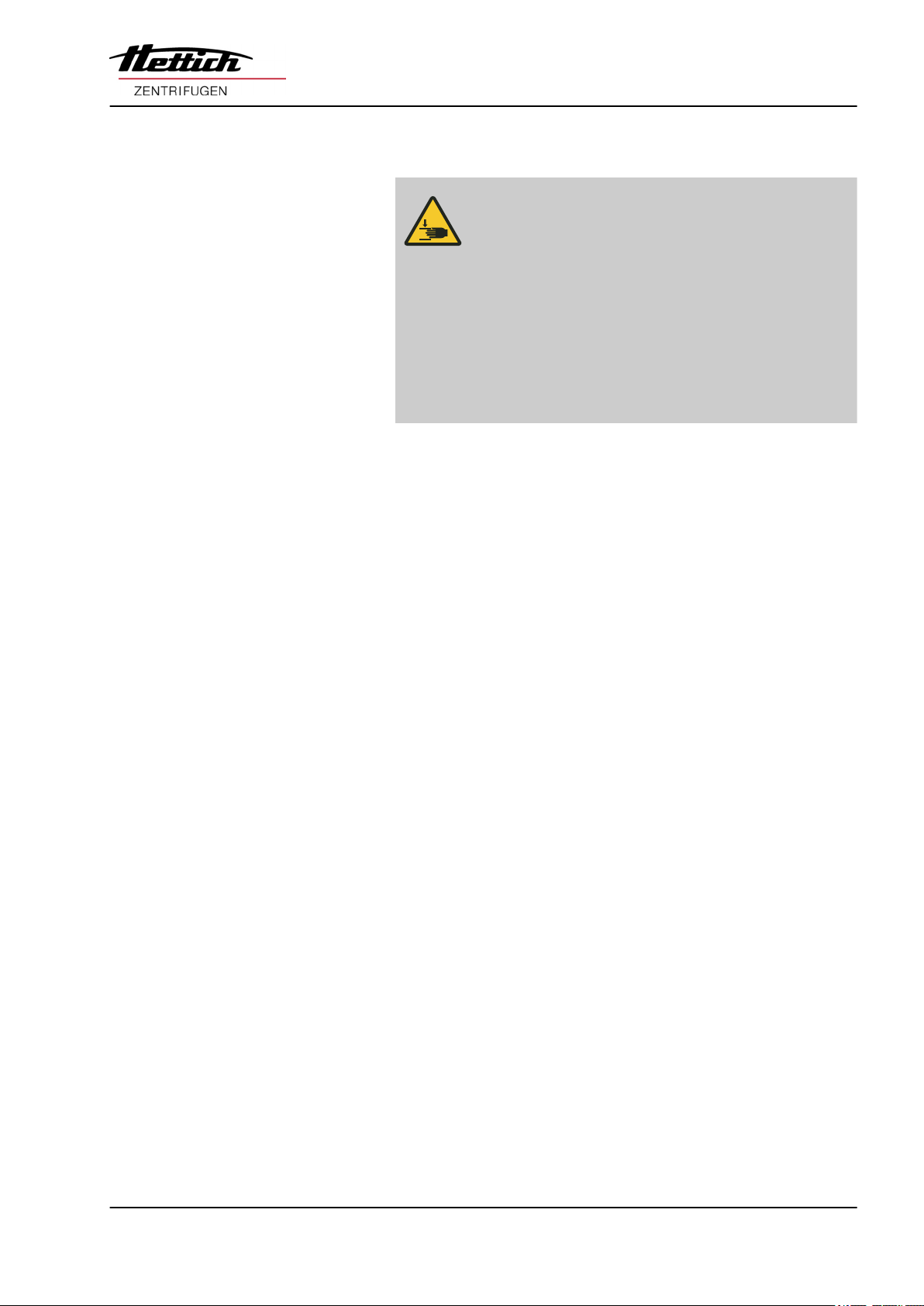

The images shown in the following depict the positions of the warnings and symbols affixed to the

device.

Ä

Chapter 1.1 ‘Sym-

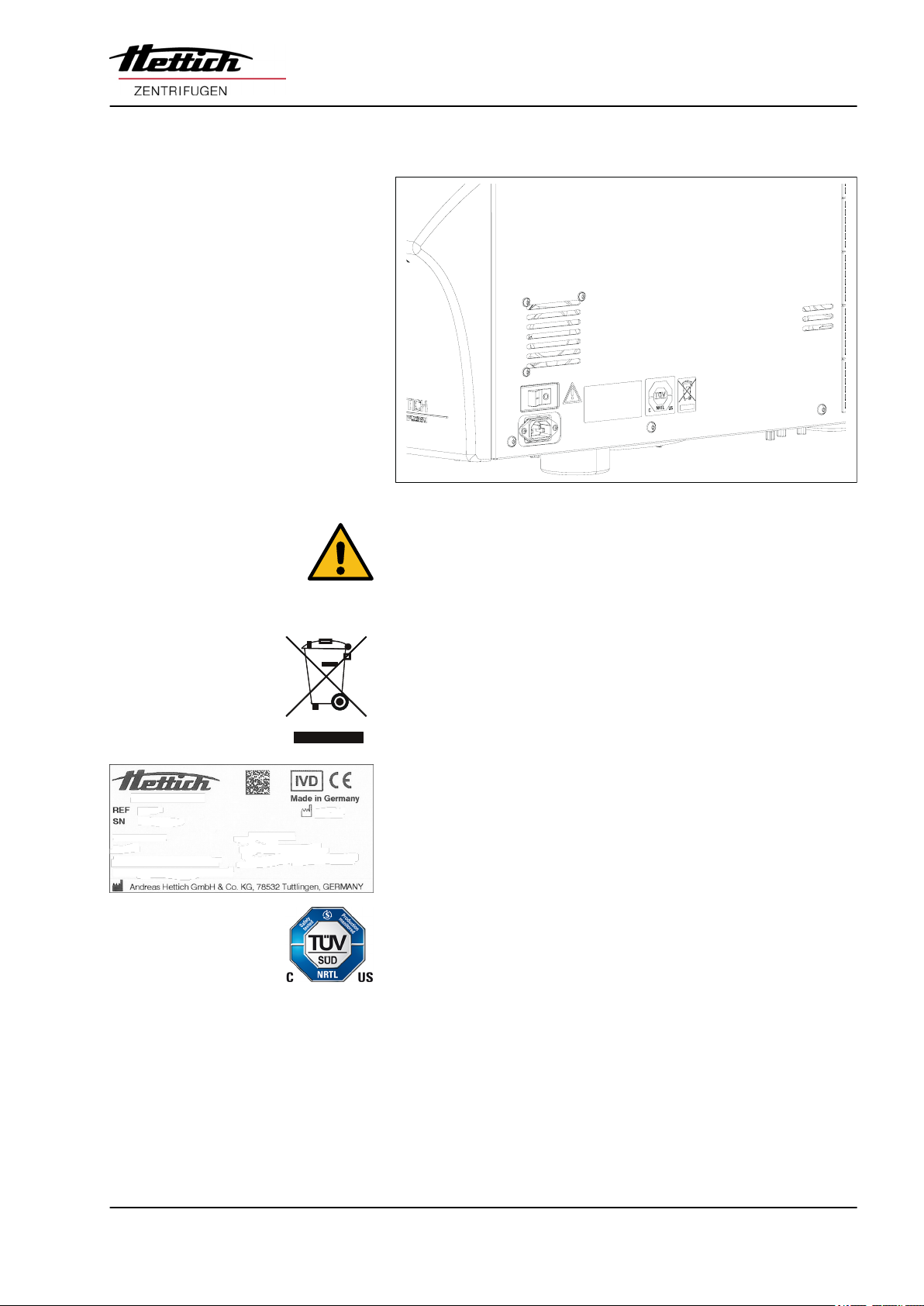

Fig. 1: Warnings on the device

Attention, general danger point

Nonobservance of this warning can lead to material damage and

personal injury.

Before using the device, make sure you read the operating instructions and observe the safety information.

arning - Biological contamination!

W

Before using the device, make sure you read the operating instructions and observe the safety information.

Warning - Hand injury

Nonobservance of this warning can lead to material damage and

personal injury.

Before using the device, make sure you read the operating instructions and observe the safety information.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 6

Introduction

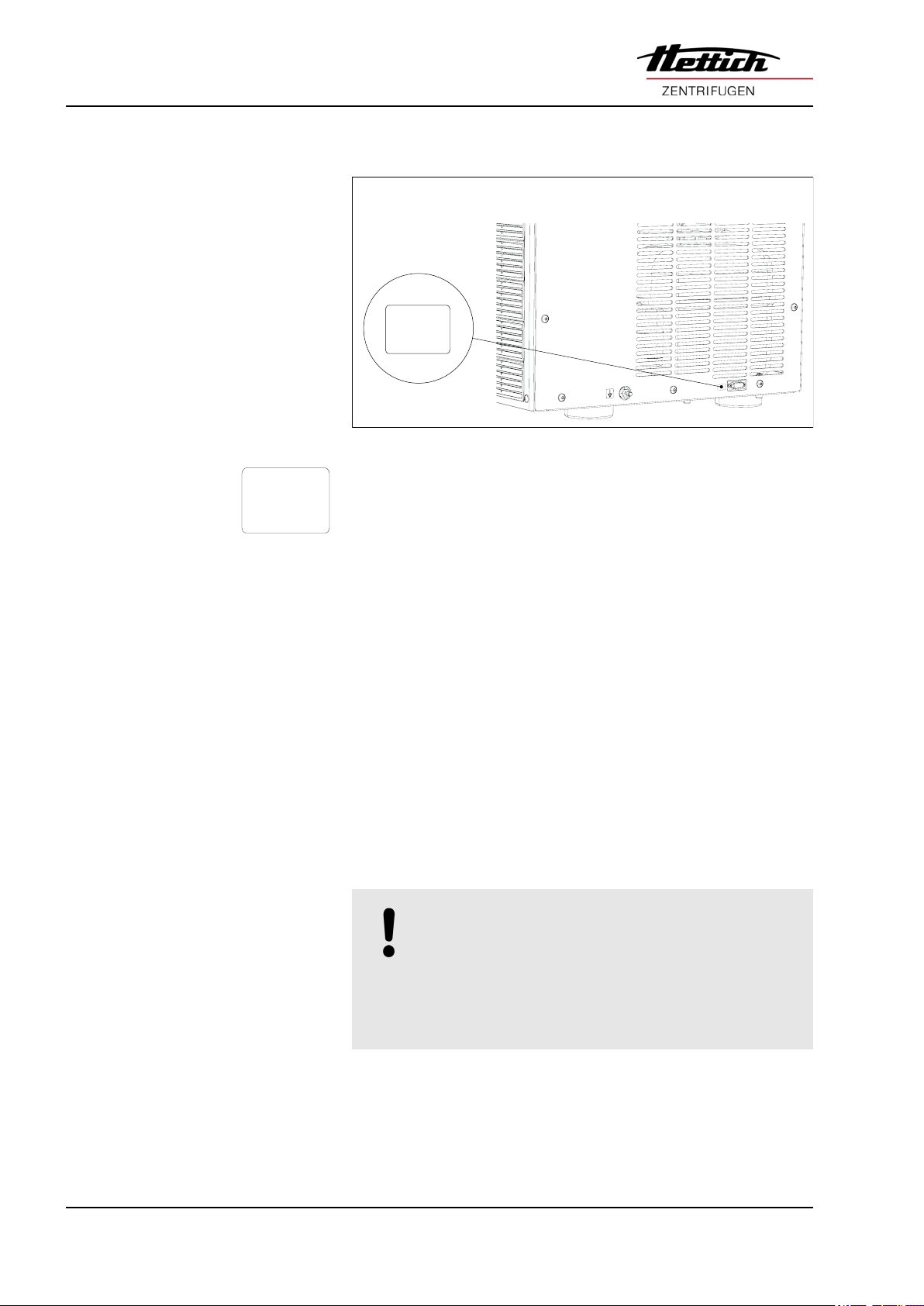

Fig. 2: Warning stickers on the right outer side

Attention, general danger point

Nonobservance of this warning can lead to material damage and

personal injury.

Before using the device, make sure you read the operating instructions and observe the safety information.

Symbol for separate collection of electric and electronic

devices

Symbol according to directive 2002/96/EC (WEEE). Applies in the

countries of the European Union, as well as in Norway and Switzerland.

T

ype plate

Nameplate with technical data specifications.

Symbol for TÜV-inspected device

From TÜV-inspected device.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 7

IOIOI

RS232

I

O

I

OI

RS23

2

IOIOI

RS232

Introduction

Fig. 3: Notice at the RS232 interface

Symbol for RS232 interface

This symbol indicates the RS232 interface (only for device with

RS232 interface).

1.2 Personal protective equipment

The assessment of the personal protective equipment must take

place on site according to the actual risks which are posed by the

used substances, the procedures and the environmental conditions.

The operating company must create a risk assessment according

to the corresponding standards and directives and enact work

instructions which ensure the safe handling of the device and

accessories.

1.3 Personnel qualification

Repairs may only be performed by a person authorized by the

manufacturer.

NOTICE!

Interventions and modifications to devices by persons not authorized by the company Andreas Hettich GmbH & Co. KG will be at one's own risk and

result in the voiding of all warranty claims, as well

as the voiding of liability claims against Andreas

Hettich GmbH & Co. KG.

Authorized skilled personnel with special instruction

Skilled personnel are able to perform the work assigned to them

and independently recognize and avoid potential hazards based on

their specialized education (professionally recognized vocational

training), knowledge and experience as well as knowledge of the

relevant regulations.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 8

Introduction

Personnel have participated in special instruction by the manufacturer of the device or personnel authorized by the manufacturer

and, through this, are authorized to perform the corresponding

task.

Personnel have completely read and understood this documentation.

Service technician

A service technician is someone who, based on his professional

training and advanced practical knowledge, provides expert support (installation, commissioning, maintenance, etc.) for our customers in all things mechanical, on the phone as well as on site,

and is an employee of the company of the manufacturer or was

trained and authorized by the manufacturer to carry out service

work on the device.

1.4 Intended use

Intended use

Improper use

Dual centrifugation: The purpose of the ZentriMix is to process

samples pre-analytically in non-medical laboratories.

This includes the extraction, grinding, mixing and dissolving as well

as homogenizing of samples, so also the decomposition of organic

or inorganic materials.

Another purpose is the creation of nanoparticles through homogenization (e.g. lipid nanoparticles, particularly liposomes) for nonclinical uses.

Classical centrifugation: In its function as a classical centrifuge, it

is used for the separation of materials or material mixtures with a

density of max. 1.2 kg/dm³ in non-medical laboratories.

The device was not designed for use in environmental conditions

that do not meet the manufacturer requirements or in a potentially

explosive, radioactive or biologically or chemically contaminated

atmosphere.

The ZentriMix is only meant for the above-named purposes.

Another use or one which goes beyond this is considered to be

improper. The manufacturer is not liable for damage resulting from

this.

Intended use also includes the observation of all information in the

operating instructions and complying with the inspection and maintenance intervals.

The device was not designed for use under environmental conditions that do not meet the manufacturer requirements or in a potentially explosive, radioactive or biologically or chemically contaminated atmosphere.

The device is not meant for processing toxic, corrosive or infectious samples; such samples must not be processed in the ZentriMix.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 9

Introduction

Foreseeable misuse

The device is built according to the state-of-the-art and the recognized safety regulations. If used and handled improperly, there

could be life-threatening danger to the user or third parties, or the

device could be impaired or there could be other property damage.

The device is only to be used for its intended purpose and only

when it is in safe working condition. Malfunctions which could

fect safety must be corrected immediately.

af

If consumable material approved/sold by the manufacturer is not

used, there is a danger of container damage at high speeds, which

could result in a spontaneously high unbalance and damage to the

device.

Do not operate the device unsupervised.

If used improperly, incorrect input of the parameters can result in

dangerous operating conditions: For example, if the duration of a

run is entered too high, the sample could overheat, which could

cause the sample container to burst, which could result in extreme

unbalance at high speed and damage to the device.

1.5 Replacement parts/consumable material

Only original replacement parts and approved original accessories

of the manufacturer may be used and only original consumable

material or that recommended (approved) by the manufacturer in

its official documentation may be used.

1.6 Scope of delivery

WARNING!

If original replacement parts, consumable material

approved or sold by the manufacturer and original

accessories are not used, any warranty or liability

claims against the company Andreas Hettich

GmbH & Co. KG are void.

n 1 x device with mounted rotor

n 1 x mains cable (power supply)

n 1 x size 5 Allen wrench (for emergency release and mounting/

dismounting the rotor)

n 1 x lubricating grease for lifting lugs

n 1 x operating instructions

Rotor(s) and the corresponding accessories are

included in delivery, depending on the order

.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 10

1.7 Return shipments

Introduction

If the device or its accessories are sent to the manufacturer, this/

these must be decontaminated and cleaned before shipping in

order to protect personnel, the environment and material. Please

contact the Service department of the manufacturer for the return

shipment. You will then receive a clearance certificate and return

material authorization number

ance certificate will not be accepted in order to protect our

employees. We ask for your understanding.

. Devices without a signed clear-

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 11

Introduction

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 12

2 Safety information

Danger due to electrical energy

Safety information

The device and its associated components and

assemblies meet the currently valid safety standards individually and as a whole and meet the CE

directives of the European Union.

The device is safe if used as intended and

observing the descriptions and information given in

this documentation.

WARNING!

W

arning of incorrect voltage on the device pro-

tection switch!

Pay attention to the correct operating voltage in

order to prevent damage to the device.

Only operate the device at the correct oper-

–

ating voltage.

– Refer to the technical data and nameplate for

the value for the correct operating voltage.

– If the operating voltage is too high, the overcur-

rent protection fuse in the device switch can

trip and the device electronics can be

destroyed.

Danger due to kinetic energy

DANGER!

Danger due to rotor moving with high kinetic

energy!

There is a risk of injury if the lid is opened via the

emergency release during device operation.

– Only open the device via the emergency

release when the device is switched off.

Before the emergency release, make sure that

–

the device rotor has stopped.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 13

Safety information

Danger due to insufficient maintenance or maintenance not performed in a timely manner

DANGER!

Danger due to insufficient maintenance or

maintenance not performed in a timely manner!

There is a risk of collision inside the device due to

insufficient maintenance or maintenance not performed in a timely manner

– Have maintenance done at the specified inter-

vals.

– Check the rotor for a firm fit before using the

device. Correctly tighten the fastening screw. If

the rotor has play, it must be replaced.

– Check the device for visible damage or defi-

ciencies before use. If you discover deficiencies or damage, put the device out of operation

and immediately inform an authorized service

technician.

.

Warning of premature program

abort

Warning of hand injury due to rotor

gears

WARNING!

arning of premature program abort!

W

In the event of a premature program abort, such as

a power failure, switching of

run or pulling out the mains plug, the desired effect

on the samples might not be achieved.

– Do not switch off the device during a program

run.

– Do not actuate the emergency release during a

program run.

– Do not pull out the mains plug during a pro-

gram run.

– After a program abort, check whether the sam-

ples can be used.

CAUTION!

Warning of hand injury due to rotor gears!

There is a risk of injury to fingers by the rotor gears

if this is turning. Cuts with possible infections could

result.

Do not grab between the gears of the rotating

–

units and the rotor.

– Avoid rotor rotation with the lid open as much

as possible.

– To prevent injuries to third parties, do not leave

the device unsupervised with the lid open.

f during the program

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 14

Risk of injury due to the device

falling out of the packaging

Warning of hand injury due to

device lid falling closed unbraked

Safety information

WARNING!

Risk of injury due to parts falling out of the

packaging!

When parts fall out of the transport packaging,

there is a risk of crushing injuries to extremities.

– Observe the warnings for opening the pack-

aging.

– Only open the packaging at the specified point.

WARNING!

W

arning of hand injury due to device lid falling

closed unbraked!

If the lid falls closed unbraked, there is a risk of

extremities getting caught.

– Have the device maintained by a service tech-

nician at the specified intervals.

Always open the device lid completely.

–

– If a gas pressure spring of the lid is defective,

have it replaced by a service technician.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 15

Safety information

Danger posed by selection of

unsuitable parameters for dual centrifugation

WARNING!

Danger posed by selection of unsuitable

parameters for dual centrifugation!

The maximum permissible speed (RPM) for ZentriMix applications depends on the sample composition and sample container. Every ZentriMix

sample container can only be used up to a certain

rotational speed depending on the design and

application; this must not be exceeded under any

circumstances! Otherwise, there is a danger that

the sample container will not withstand the stress,

and the device will be damaged due to the

resulting unbalance; the heat that arises cannot be

compensated by the cooling system, resulting in

the sample container becoming very hot. Only

remove such a container after a suf

off time while wearing appropriate protective

clothing.

– ZentriMix applications are to be carried out

according to the protocol authorized by the

manufacturer.

– Every application not yet described by a manu-

facturer protocol must be checked and validated for any hazard potential before its use.

Ä

Further information on page 41.

– The correct parameter input must always be

checked.

– Do not leave the device unsupervised.

ficient cooling-

Damage due to incorrect loading

for dual centrifugation

WARNING!

Damage due to incorrect loading for dual cen-

trifugation!

The two rotor receptacles must be loaded strictly

symmetrically with the same weight.

– Observe the loading rules. Ä Chapter 6.5.2

‘Loading a rotor for dual centrifugation’

on page 37!

– Observe the device as it starts up. If unusually

high unbalance occurs, stop the run immediately by pressing the [Stop/Open] key twice

and check the load. If you cannot determine

that the load is incorrect, put the device out of

operation and inform the Service department.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 16

Danger due to hazardous substances in the sample

Safety information

DANGER!

Danger due to hazardous substances in the

sample

No materials or material mixtures may be processed in a way which poses a risk of fire or explosion.

– Therefore, thoroughly check the intended

process regarding this hazard and take the

appropriate measures to avoid personal injury.

–

Follow the relevant regulations and directives

for handling chemicals and hazardous substances.

– In particular, no aggressive chemicals may be

used (e.g. dangerous, corrosive extracting

agents, such as chloroform, strong acids).

Explosion and fire hazard

WARNING!

Explosion and fire hazard

Do not process any explosive materials or materials which can react together chemically with high

. Substances which could create a haz-

energy

ardous explosive or flammable atmosphere in the

device may not be processed. The estimation of

such risks is the responsibility of the operating

company

user with regard to this.

– Therefore, thoroughly check the intended

– Follow the relevant regulations and directives

– In particular, no aggressive chemicals may be

. The operating company must instruct the

process regarding these hazards and take the

appropriate measures to prevent personal

injury.

for handling chemicals and hazardous substances.

used (e.g. dangerous, corrosive extracting

agents, such as chloroform, strong acids).

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 17

Safety information

Danger due to the penetration of

water or other liquids

Warning - Impermissible ambient

temperature

DANGER!

Danger due to the penetration of water or other

liquids!

When water penetrates into the device, there is a

danger of a short circuit and the user suffering an

electric shock.

–

Prevent water and moisture from penetrating

into the device.

– Do not pour liquids into the device interior.

– The device must not stand in the rain.

– Transport is only allowed with suitable trans-

port protection.

WARNING!

arning - Impermissible ambient temperature!

W

If the ambient temperature is outside of the permissible ambient temperature range for the samples,

these might be compromised.

–

Observe the permissible maximum and min-

imum ambient temperatures for setting up the

device.

– Do not place the device next to heat sources or

devices which radiate heat.

– Check the samples after any device over-

heating to see if they can still be used and take

new samples, if necessary.

– Make sure the device is not exposed to direct

sunlight.

– Make sure the device is not exposed to frost.

– Maintain the minimum clearance around the

device.

– Make sure that the fan is not blocked.

– Never operate the device in a continuous run.

Warning - Position changed due to

vibration

WARNING!

Warning - Position changed due to vibration!

The device might fall down if the set-up surface

vibrates or if it is not flat or stable enough.

Only place the device on a stable, flat surface.

–

– The set-up surface must reliably bear the

weight of the device.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 18

Mechanical emergency release

Safety information

WARNING!

There is a risk of injury if the mechanical emer-

gency release of the device is actuated during

the program run.

If the mechanical emergency release of the lid is

actuated during a program run, the program is

aborted and the rotor runs down unbraked.

– Only actuate the emergency release when the

rotor is stopped.

– Check whether the rotor has stopped before an

emergency release.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 19

Safety information

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 20

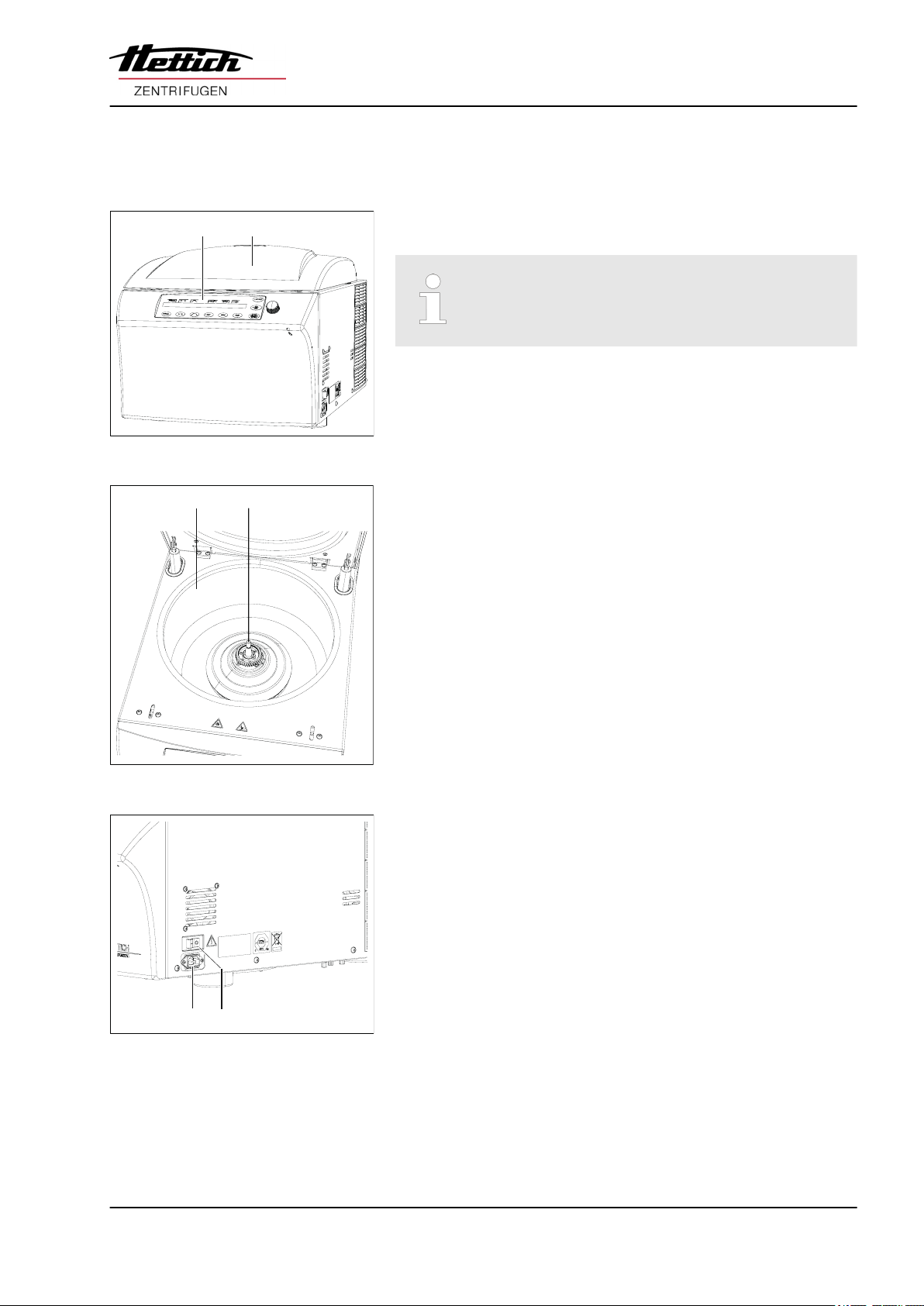

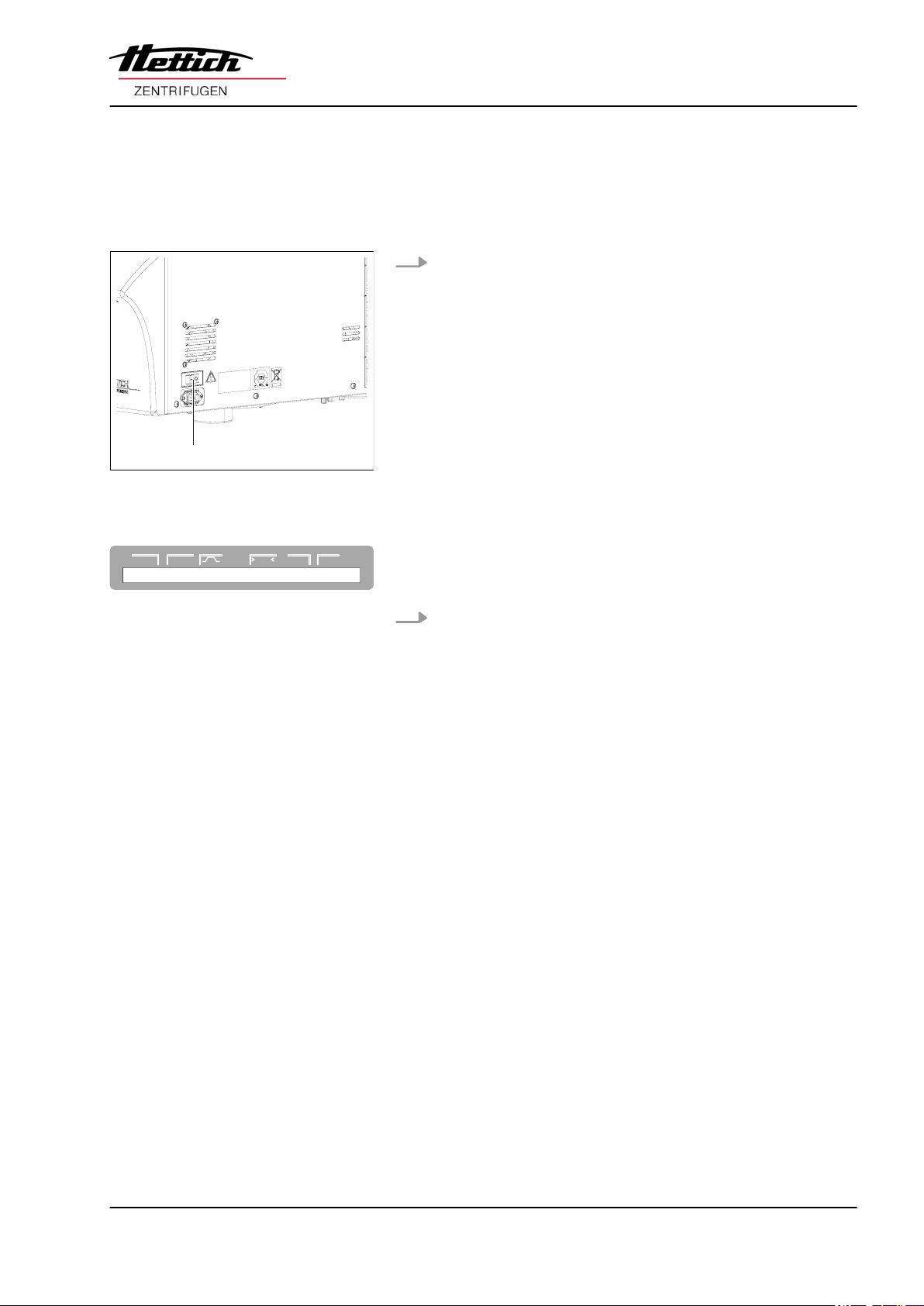

3 Device description

1

2

1

2

1 2

Fig. 4: Operating elements, front side

Device description

1 Control panel

2 Lid

Further information about the control panel can be

found in the Operation chapter Ä Chapter 6 ‘Operation’ on page 31.

1 Centrifuging chamber

2 Rotor cavity

Fig. 5: Device interior

1 Device plug (power supply)

2 Device switch [On/Off]

Fig. 6: Right outer side

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 21

1

Device description

Fig. 7: Rear side

1 RS232 interface

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 22

4 Transport and storage

80

100

ca.925

ca.620

ca.630

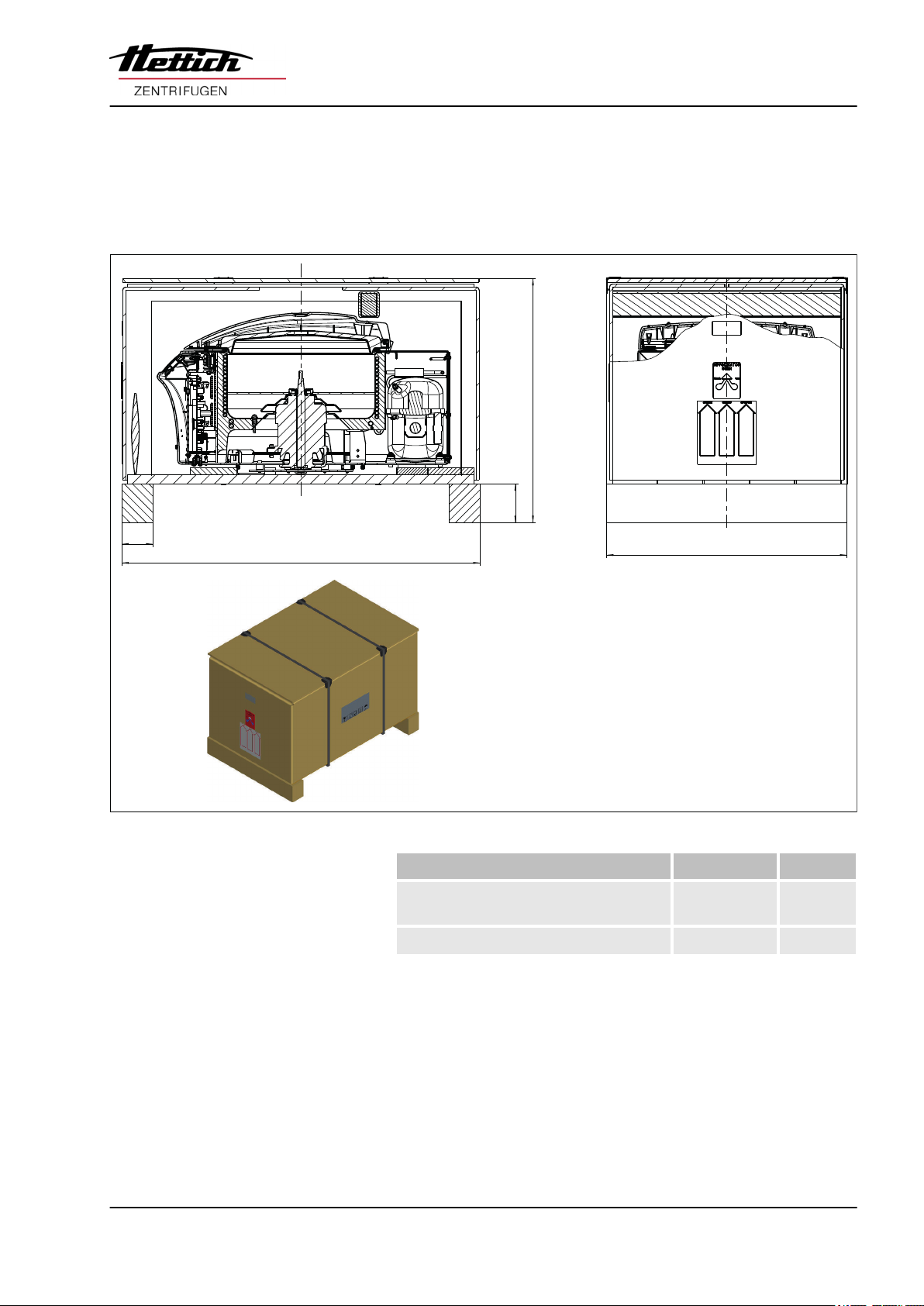

Dimensions and weight with transport packaging

Transport and storage

Fig. 8: Transport packaging dimensions

Data Value Unit

Outer dimensions (L x W x H) 925 x 620 x

mm

630

Weight approx. 105 kg

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 23

Transport and storage

Storage conditions

WARNING!

Warning - Impermissible ambient temperature!

If the ambient temperature is outside of the permissible ambient temperature range for the samples,

these might be compromised.

–

Observe the permissible maximum and min-

imum ambient temperatures for setting up the

device.

– Do not place the device next to heat sources or

devices which radiate heat.

– Check the samples after any device over-

heating to see if they can still be used and take

new samples, if necessary.

– Make sure the device is not exposed to direct

sunlight.

– Make sure the device is not exposed to frost.

– Maintain the minimum clearance around the

device.

Transport

n The device can be stored in the original packaging.

n The device may only be stored in dry rooms.

n The storage temperature must be between - 20 °C and + 60

°C.

n The humidity must be non-condensing and must be between

20 % and 80 %.

n Observe the weight of the device during transport.

n When transporting with a transport aid (e.g. transport cart), this

must be able to bear a weight at least 1.6 times the permissible

transport weight.

n Secure the device against tipping over and falling down during

transport.

n Never transport the device on its side or upside-down.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 24

5 Commissioning

Commissioning

n Set up and level the device at a suitable location so that it is

stable. During setup, the required safety zone of textvar object

does not exist around the device must be complied with in acc.

with textvar object does not exist.

WARNING!

During a centrifugation run, no personnel, hazardous substances or objects may be within a

safety zone of textvar object does not exist around

the device in acc. with textvar object does not

exist.

n Ventilation openings may not be blocked. A distance of textvar

object does not exist to the air slots and ventilation openings

must be complied with.

n Before commissioning, check to make sure the mains voltage

is correct according to the nameplate and that the mains cable

is connected properly

n Only trained and instructed personnel may commission and

use the device.

Every time before the device is used, make sure that

.

Unpacking the device

5.1

n the device is dry (no moist residues from cleaning agents, etc.).

n no objects are lying in the centrifuge chamber under the rotor.

n the rotor position corresponds to the home position.

n the accessories are correctly connected to each other (leak-

proof) and the rotor is correctly inserted.

n the shown displays are correct.

Personnel:

The device is packaged in a box.

When lifting up the device, note the specified

weight and only lift the device with a suitable

number of helpers to avoid injuries.

Authorized skilled personnel with special

n

instruction

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 25

Commissioning

WARNING!

Warning - Position changed due to vibration!

The device might fall down if the set-up surface

vibrates or if it is not flat or stable enough.

–

Only place the device on a stable, flat surface.

– The set-up surface must reliably bear the

weight of the device.

WARNING!

Risk of injury due to parts falling out of the

packaging!

When parts fall out of the transport packaging,

there is a risk of crushing injuries to extremities.

– Observe the warnings for opening the pack-

aging.

Only open the packaging at the specified point.

–

1. Remove the packaging bands.

2. Lift up the box and remove the padding.

3. Remove the accessories.

4. Set up the device on a stable and flat surface with a suitable

number of helpers. Note the weight of the device.

NOTICE!

Check the device for any transport damage before

commissioning. Do not put the device into operation if there is transport damage or if moisture has

penetrated it.

5.2 Setting up, connecting and switching on the device

Setting up the centrifuge

Switching off the device with the device switch

does not disconnect this completely from the

mains. The device is completely disconnected from

the mains by pulling out the mains cable. The

mains cable must be freely accessible at all times

in order to be able to disconnect the device from

the mains at the power socket or device plug.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 26

Commissioning

Personnel:

Authorized skilled personnel with special

n

instruction

When lifting up the device, note the specified

weight and only lift the device with a suitable

number of helpers to avoid injuries.

WARNING!

Warning - Position changed due to vibration

The device might fall down if the set-up surface

vibrates or if it is not flat or stable enough.

–

Only place the device on a stable, flat surface.

– The set-up surface must reliably bear the

weight of the device.

DANGER!

Danger due to the penetration of water or other

liquids

When water penetrates into the device, there is a

danger of a short circuit and the user suffering an

electric shock.

Prevent water and moisture from penetrating

–

into the device.

– Do not pour liquids into the device interior.

– The device must not stand in the rain.

– Transport is only allowed with suitable trans-

port protection.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 27

1

Commissioning

WARNING!

Warning - Impermissible ambient temperature!

If the ambient temperature is outside of the permissible ambient temperature range for the samples,

these might be compromised.

–

Observe the permissible maximum and minimum ambient temperatures for setting up the

device.

– Do not place the device next to heat sources or

devices which radiate heat.

– Check the samples after any device over-

heating to see if they can still be used and take

new samples, if necessary.

– Make sure the device is not exposed to direct

sunlight.

– Make sure the device is not exposed to frost.

– Maintain the minimum clearance around the

device.

– Make sure that the fan is not blocked.

– Never operate the device in a continuous run.

Connecting the device

Fig. 9: Power supply connection

1 Mains cable connection

Set up the device on a stable and flat surface with a suitable

number of helpers. Note the weight of the device.

Personnel:

1.

Make sure the operating voltage is correct,

as specified on the nameplate.

Connect the mains cable included in delivery to the device

plug on the device.

2. Stick the other end in the socket.

Authorized skilled personnel with special

n

instruction

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 28

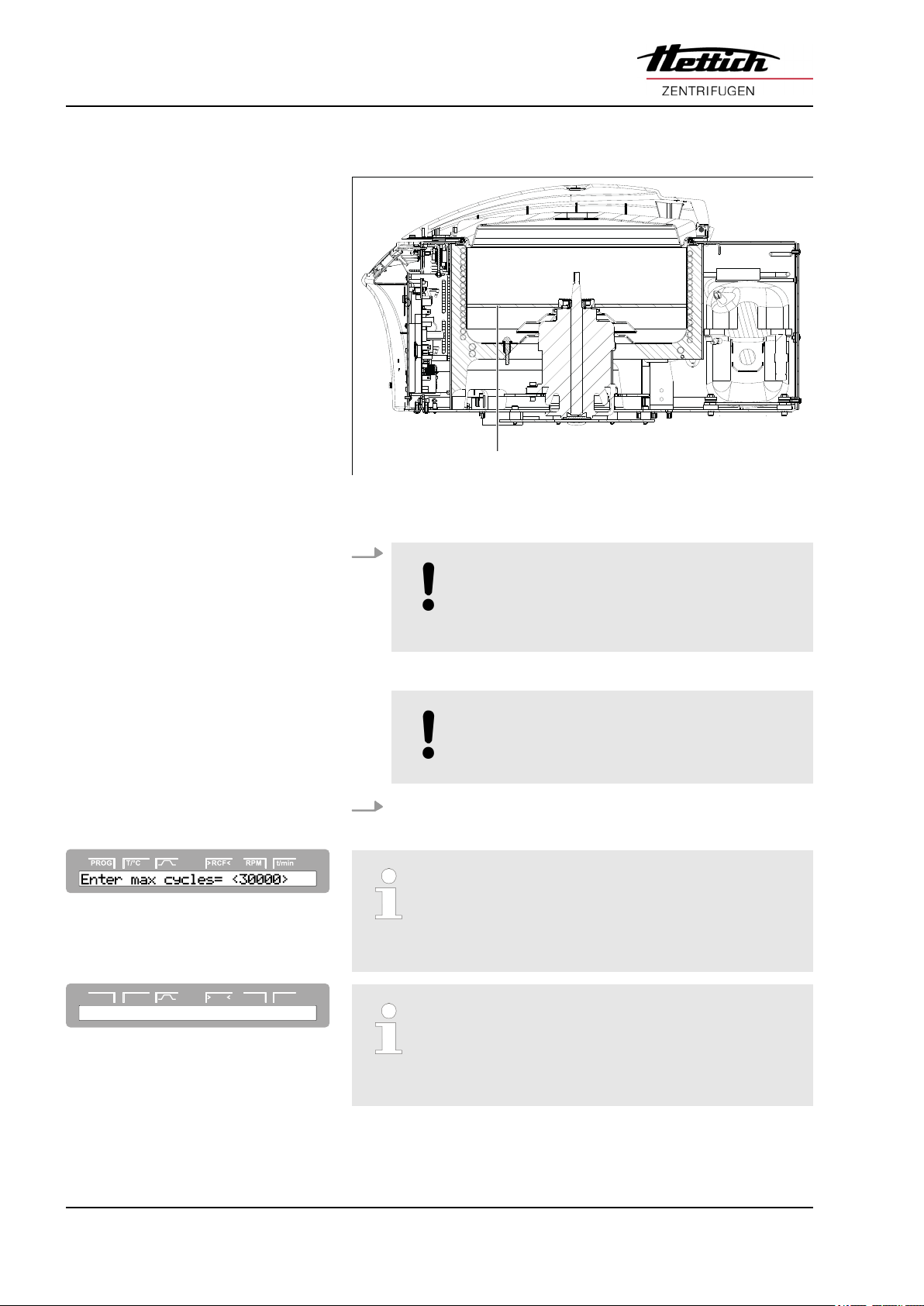

Switching on the device

1

1 20 9/;\9 1500 2:00

PROG T/°C

RCF

RPM

t/min

Commissioning

Fig. 10: Device switch

1 Device switch [ON/OFF]

Fig. 11: Start screen

Personnel:

Authorized skilled personnel with special

n

instruction

1. Switch the device on.

The control will start up. On the display, the device type,

ð

the software version and (depending on the setting) the

last loaded program or program place no. 1 are shown.

2.

Open the lid

Ä

Chapter 6.2 ‘Opening the lid’ on page 35.

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 29

1

N > ROTOR MAX

PROG T/°C

RCF

RPM

t/min

Commissioning

Fig. 12: Transport securing device

1 Transport securing device

3.

NOTICE!

Before commissioning the device, remove

the transport securing device from the interior.

Remove the transport securing device.

NOTICE!

Check to make sure the rotor is mounted correctly before commissioning.

4. The device is now ready for operation.

If ‘Enter max cycles = <30000>’ is displayed after

switching on the device, the maximum permissible

number of running cycles (specified on the rotor)

must first be entered before the centrifugation run

can be restarted.

If the speed in the activated program is higher than

the maximum rotor speed (Nmax), no centrifugation run can be started. ‘N > ROT

Ä

played

Chapter 9 ‘Troubleshooting’

on page 89.

OR MAX’ is dis-

ZENTRIMIX | 380 R | en_GB | 2 | AB3200EN 30

Loading...

Loading...