Hettich Rotina 380R, Rotina 380 Repair instructions

ROTINA 380

ROTINA 380 R

11.08 Andreas Hettich GmbH & Co. KG AR1701EN

Repair instructions

Andreas Hettich GmbH & Co. KG

Föhrenstraße 12, D-78532 Tuttlingen / Germany

Phone (07461) 705-0

Fax (07461) 705-125

info@hettichlab.com, service@hettichlab.com

www.hettichlab.com

© 2008 by Andreas Hettich GmbH & Co. KG

All rights reserved. No part of this publication may be reproduced without the prior

written permission of the copyright owner.

Modifications reserved!

AR1701EN / 11.08

2/98

Contents

1 Introduction ..............................................................................................................6

2 Symbol meanings..................................................................................................... 6

3 Disposal ...................................................................................................................7

4 Description of the centrifuge.....................................................................................8

4.1 Block diagram of the control.............................................................................. 8

4.2 Operating panel (A2).........................................................................................9

4.3 Electronics ROTINA 380 (A1) resp. ROTINA 380 R (A1).................................9

4.4 Special features ..............................................................................................10

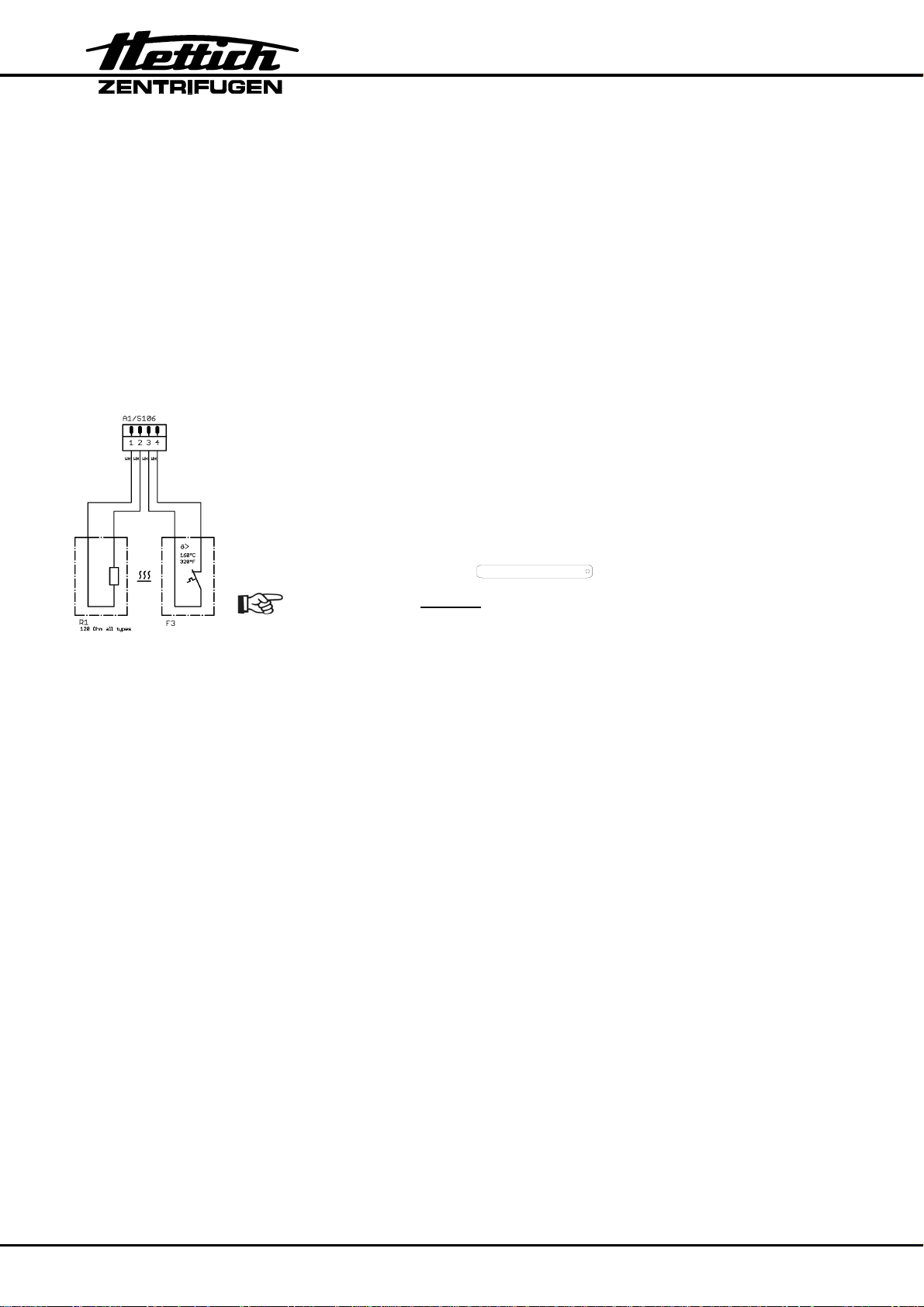

4.5 Brake resistor (R1)..........................................................................................10

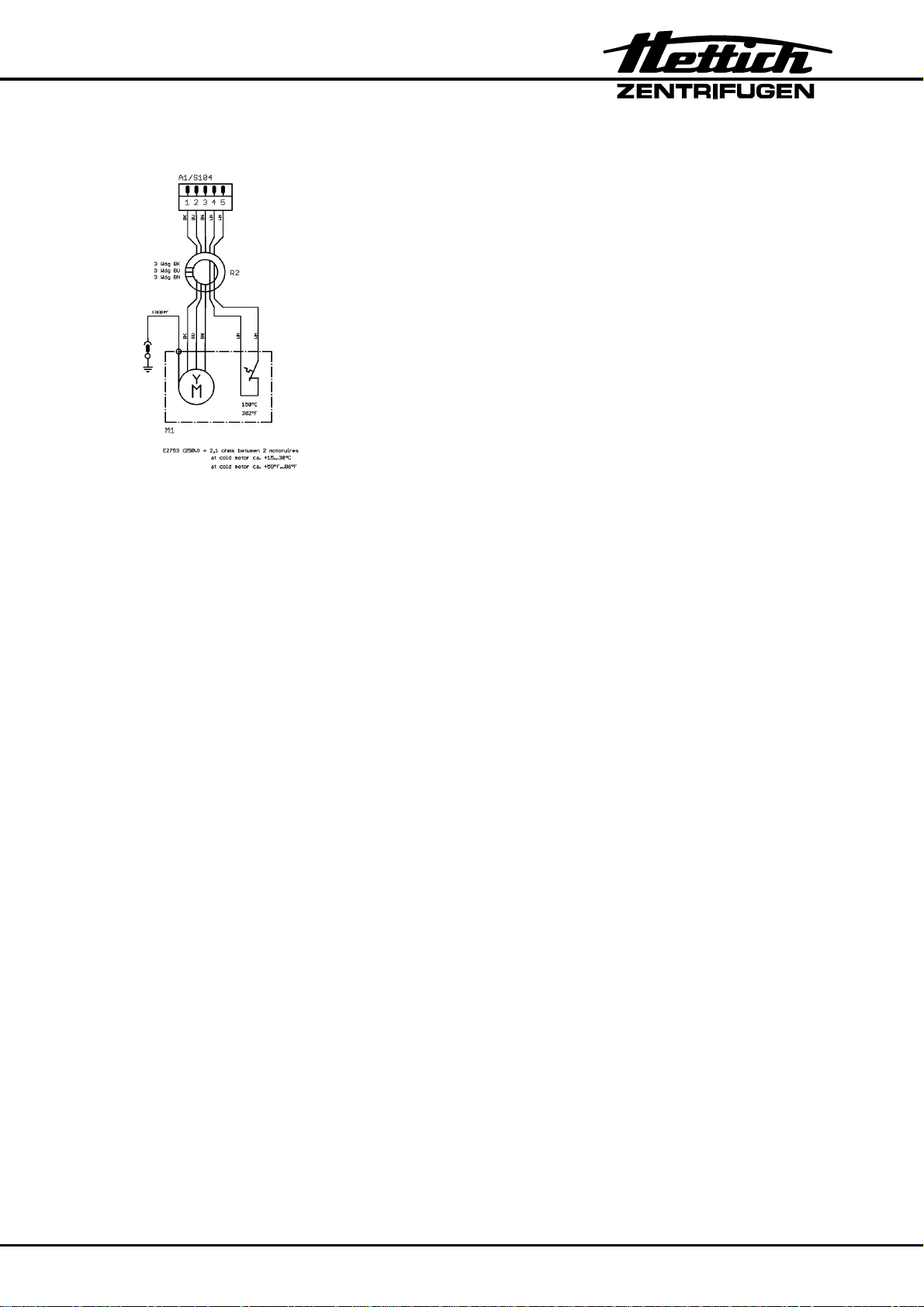

4.6 Motor (M1) / Tacho system (B4, B2.1) ............................................................ 10

4.7 Imbalance sensor (B2.2) .................................................................................11

4.8 Motor-driven lid lock (A3) ................................................................................ 11

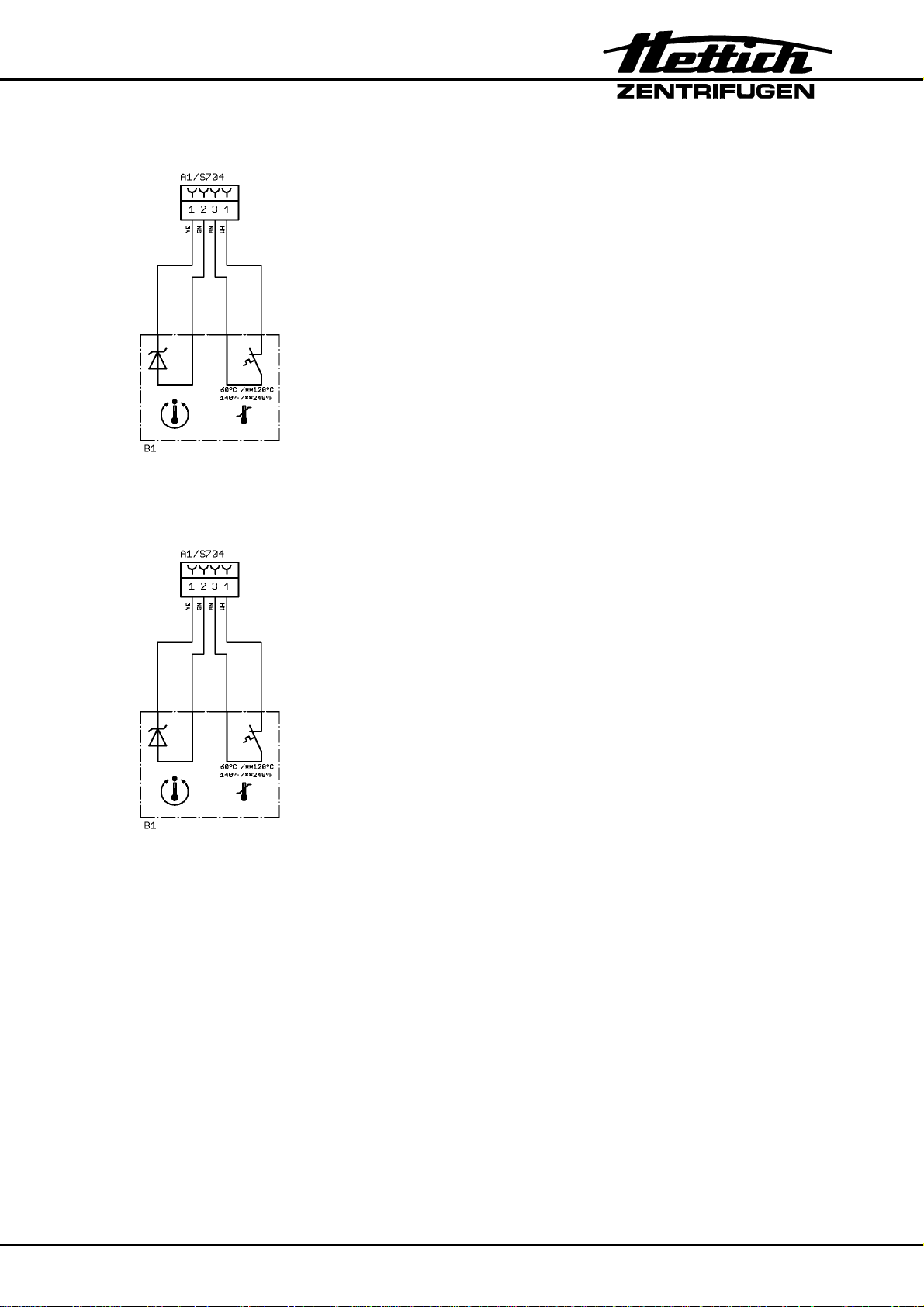

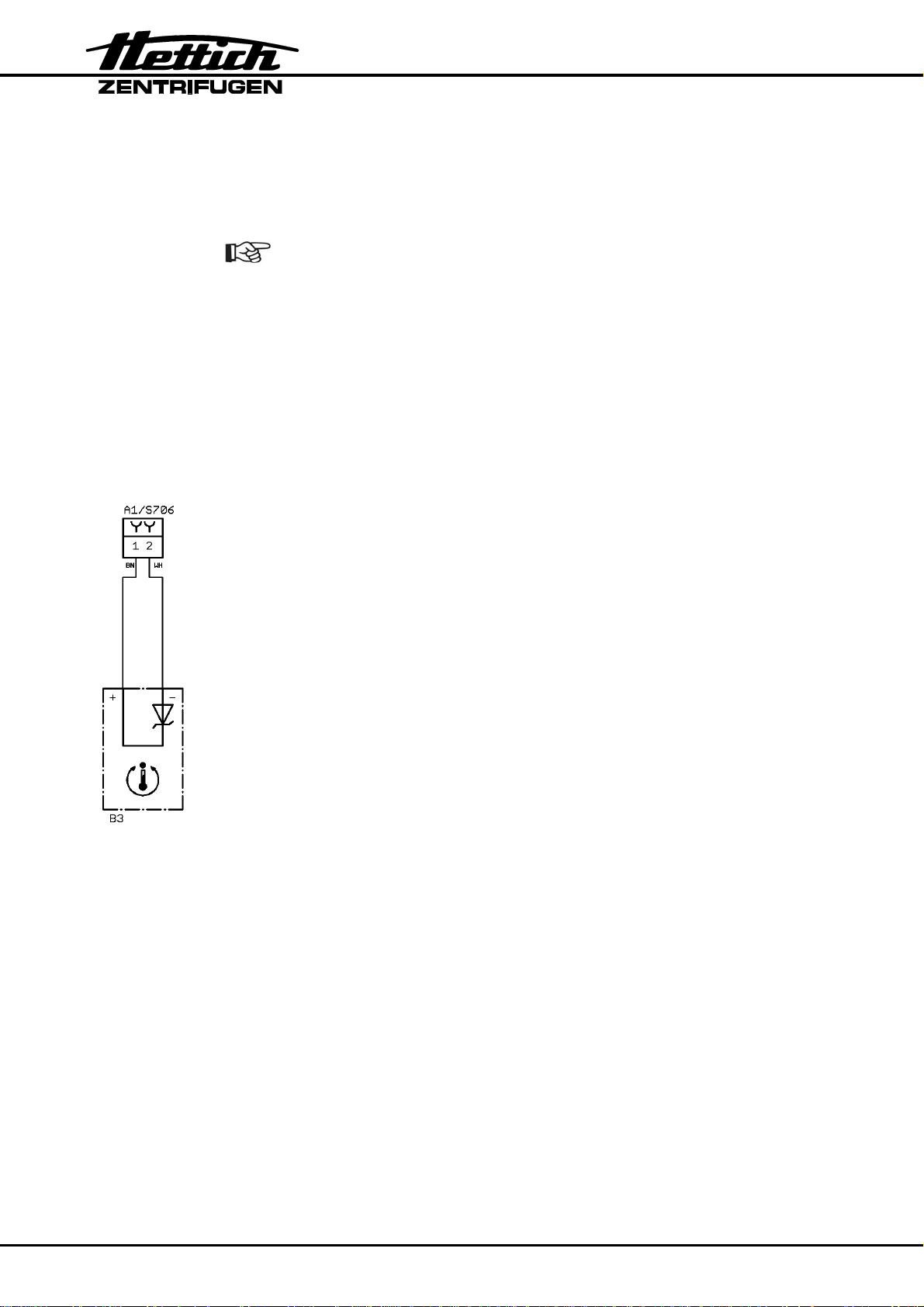

4.9 Cooling system................................................................................................11

4.10 Safety devices.................................................................................................12

5 Troubleshooting procedures...................................................................................12

6 Error messages...................................................................................................... 13

6.1 Perform a MAINS RESET ...............................................................................13

6.2 Brief description ..............................................................................................13

6.3 Description and elimination of errors............................................................... 16

7 Settings and interrogations.....................................................................................36

7.1 Summary of the possible settings and interrogations......................................36

7.2 Inquiry the system information ........................................................................37

7.3 Inquire and change the operating hours and inquire the number of the

centrifugation runs........................................................................................... 38

7.4 Set the acoustic signal .................................................................................... 39

7.5 Set the centrifugation data displayed after switch-on......................................41

7.6 Set the functions Ramp Unit, RCF-Integral, B-Ramp and Multi programs ......42

7.7 Set the address of the centrifuge ....................................................................42

7.8 Logging the occurred faults............................................................................. 43

7.9 Logging of certain procedures (events)........................................................... 46

7.10 Speed values during the centrifugation run..................................................... 48

7.11 Check both speed sensors.............................................................................. 49

7.12 Set the centrifuge model ................................................................................. 50

3/98

7.13 Blank the centrifuge model in the display ....................................................... 51

7.14 Cooling parameters ........................................................................................ 52

7.14.1 Set the temperature unit .......................................................................... 52

7.14.2 Inquire the temperature values ................................................................ 53

7.14.3 Deactivate the temperature sensor (B2) at the top of the

centrifuge chamber.................................................................................. 55

7.14.4 Compensate the temperature sensors .................................................... 56

7.15 Imbalance values............................................................................................ 58

7.15.1 Logging the maximum imbalance values................................................. 58

7.15.2 Inquiry the current and the maximum imbalance values.......................... 59

7.15.3 Setting the imbalance switch-off .............................................................. 60

7.16 Set the transmission rate (baud rate) of the serial interface............................ 62

7.17 Function test ................................................................................................... 63

7.18 Delete programs and program linking............................................................. 69

7.19 Display the contents of the memory cells of the EEPROM ............................. 70

7.20 Initialise the EEPROM .................................................................................... 71

7.21 Automatic repetition of the centrifugation run.................................................. 72

8 Update the software of the control processor ........................................................ 74

8.1 Install the flash-program on the PC ................................................................ 74

8.2 Perform a software update.............................................................................. 74

9 Functional check after a repair............................................................................... 76

10 General arrangement of the components........................................................... 77

11 Mounting and removing components ................................................................. 81

11.1 Removing the front panel................................................................................ 81

11.2 Removing the support sheet of the electronics (A1) ....................................... 81

11.3 Hook in the front panel at the support sheet for electronics (A1) .................... 82

11.4 Removing the upper part of the centrifuge housing ........................................ 82

11.5 Removing Motor (M1) / Rubber-metal bearings / Speed sensor

(B2.1, at the bottom of the motor) / Imbalance sensor (B2.2)......................... 83

11.6 Speed sensor (B4, on top of the motor).......................................................... 83

11.7 Motor-driven lid lock........................................................................................ 84

11.7.1 Removing the motor-driven lid lock ......................................................... 84

11.7.2 Replacing the left lid lock......................................................................... 84

11.7.3 Replacing the right lid lock....................................................................... 84

11.7.4 Replacing the eccentric disc.................................................................... 85

11.7.5 Replacing the sliding blocks .................................................................... 85

4/98

11.8 Electronics (A1)...............................................................................................86

11.9 Operating panel (A2)....................................................................................... 86

11.10 Rotary encoder (S1) .................................................................................... 87

11.11 Brake resistor (R1) with overtemperature switch......................................... 87

11.12 Temperature sensor (B1) at the bottom of the centrifuge chamber

(only in centrifuges with cooling)..................................................................87

11.13 Temperature sensor (B3) at the condenser (only in centrifuges

with cooling) ................................................................................................88

11.14 Fan (M3) at the condenser (only in centrifuges with cooling) ......................88

11.15 Fan (M5) for cooling the electronics (only in centrifuges with cooling)......... 88

11.16 Starting capacitor / starting relay (only in centrifuges with cooling) .............89

11.17 Mains switch (F1) ........................................................................................89

11.18 Appliance plug (A4 resp. A5)....................................................................... 89

11.19 Transformer (T1, only in 120 V version) ...................................................... 90

11.20 Circuit breaker (F2, only in 120 V version) ..................................................90

11.21 Packing ring................................................................................................. 90

11.22 Pneumatic spring.........................................................................................91

12 Technical documents..........................................................................................92

12.1 Tachometer code configuration of the rotors................................................... 92

12.2 Cooling diagram..............................................................................................93

12.3 Connecting diagram ........................................................................................95

12.3.1 Abbreviations of the cable colours ........................................................... 95

12.3.2 Connecting diagram ROTINA 380 / 380 R............................................... 96

12.4 Technical specifications .................................................................................. 98

5/98

1 Introduction

• Repairs must only be carried out by personnel authorised to do so by the

manufacturer.

Interventions and modifications at centrifuges, which have been conducted

by persons not authorized by the Andreas Hettich GmbH & Co. KG

company, are at their own risk and entail the loss off all guarantee and

liability claims. In such an event any guarantee claim or liability claim

against the Andreas Hettich GmbH & Co. KG company expire.

• Only original spare parts and original accessories licensed by the Andreas Hettich

GmbH & Co. KG company are allowed to be utilised.

If no original spare parts or no original accessories are used, any guarantee

claim or liability claim against the Andreas Hettich GmbH & Co. KG

company ceases to exist.

• Information about the operation of the centrifuge please see operating instructions.

• We reserve all rights for these technical documents.

2 Symbol meanings

Symbol on the machine:

Attention, general hazard area.

Before using the centrifuge implicitly read the operating instructions and pay

attention to the safety relevant references!

Symbol in this document:

Attention, general hazard area.

This symbol refers to safety relevant warnings and indicates possibly

dangerous situations.

The non-adherence to these warnings can lead to material damage and injury

to personal.

Symbol in this document:

Warning! Danger for human lives by electric shock.

Symbol on the machine and in this document:

Beware of hot surface.

Symbol on the machine and in this document:

Plastic suspension can only be used in temperatures up to a maximum of

40°C / 104°F.

Symbol on the machine:

Equipotential: Connector (PE connector) for potential equalization (only for

centrifuge with PE connector).

6/98

Symbol in this document:

This symbol refers to important circumstances.

Symbol on the machine and in this document:

Symbol for the separate collection of electric and electronic devices according

to the guideline 2002/96/EG (WEEE). The device belongs to Group 8 (medical

devices).

Applies in the countries of the European Union, as well as in Norway and

Switzerland.

3 Disposal

When you are disposing of the device, the respective statutory rules must be observed.

Pursuant to guideline 2002/96/EC (WEEE), all devices supplied after August 13, 2005

may not be disposed as part of domestic waste. The device belongs to group 8 (medical

devices) and is categorized in the business-to-business field.

The icon of the crossed-out trash can shows that the device may not be

disposed as part of domestic waste.

The waste disposal guidelines of the individual EC countries might vary. If

necessary, contact your supplier.

7/98

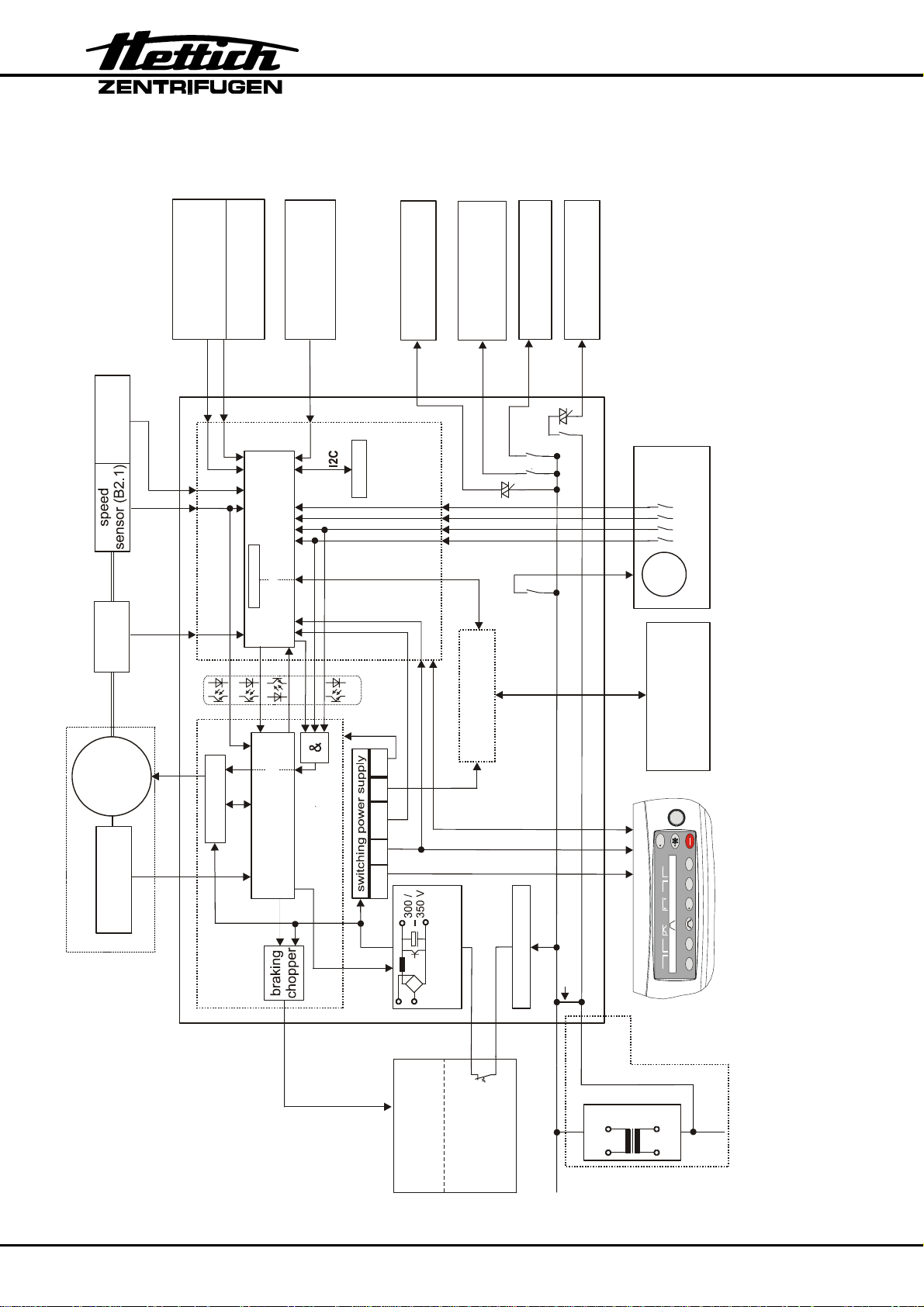

4 Description of the centrifuge

4.1 Block diagram of the control

imbalance

sensor (B2.2)

speed

sensor B4

temperature sensor

S104 S602 S701

(B1) in

1)

centrifuge chamber

S704

1)

switch

overtemperature

Flash-Memory

1)

1)

1)

2)

1)

(B3)

fan (M5)

for cooling

at the condenser

S1001

control

heating (E1)

the motor (M1)

S1000

(M2 / M2.1)

compressor

S900

1) only in centrifuges with cooling

2) only in centrifuges with option

heating/cooling

temperature sensor

S706

fan (M3)

at the condenser

S904

EEPROM

centrifuge-

lid lock

motor-driven

1~

M4

control - processor

3x

S700

RS232

serial interface

RS 232 from / to PC

- programming

- controlling

M 3~

Motor M1

overtemperature

S604 S703S707

START

STOP

12:30450020

9999

OPEN

FC- 3~ driver

S104

switch

drive - processor

frequency converter

(FC)

2.5V 5V

5V

15V 5V

1

line filter

Connection only with

S100

power input 200 - 240 V

S906

S905

power supply

PCF

cutoff

electronics

ROTINA 380 / 380 R

S106

PFC-switching

~

S106

PROG T/°C RCF RPM t/min

electronic operating panel

PROG T/°C RCF RPM TIME

transformer

100 -127 V

(R1)

brake resistor

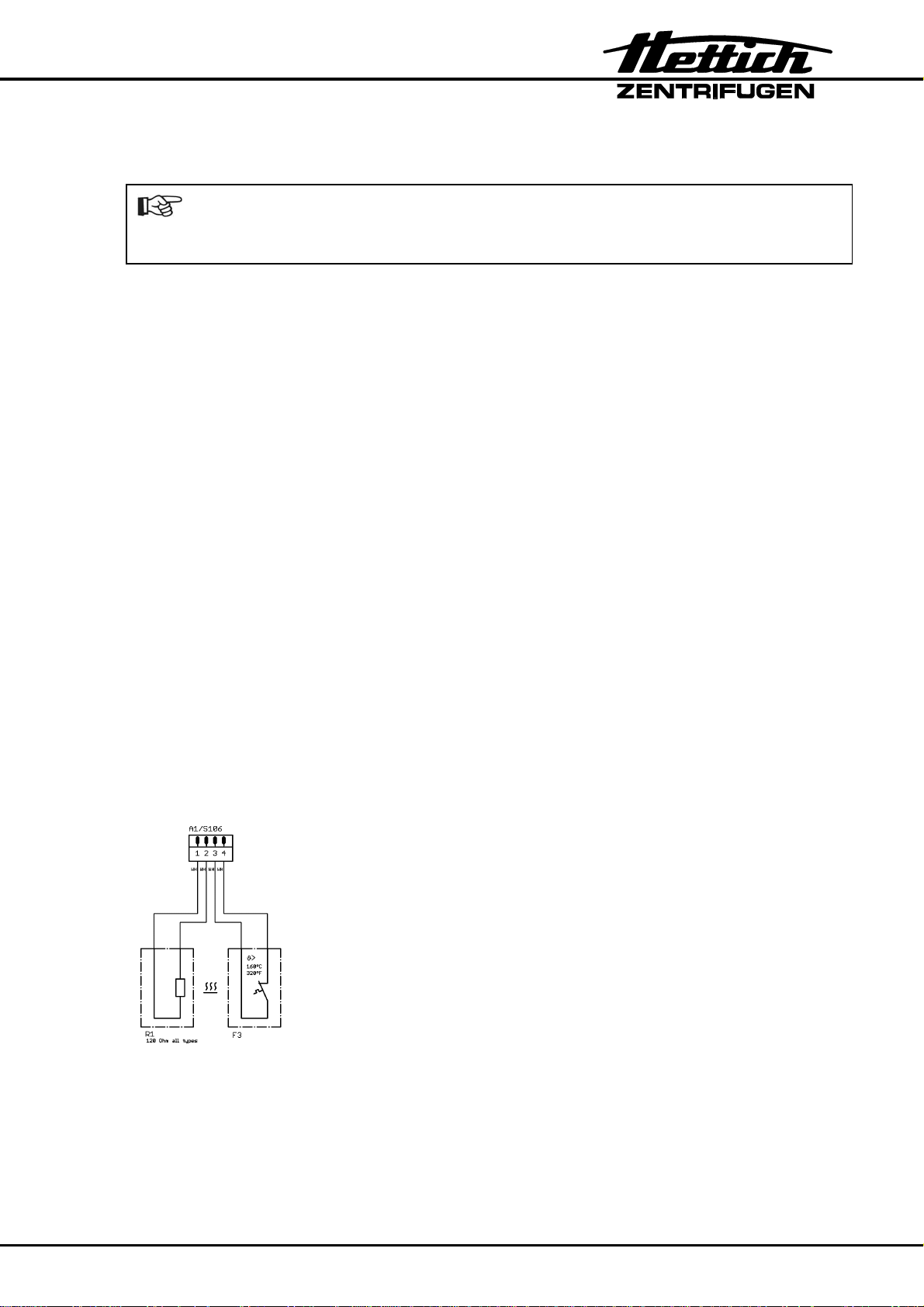

overtemperature

switch (F3)

at the brake

resistor (R1)

~~

power input 200 - 240 V

power input

120 V 230 V

8/98

These microprocessor controlled centrifuges mainly consist of the following electrical

components:

• Operating panel (A2)

• Electronics ROTINA 380 (A1) resp. Electronics ROTINA 380 R (A1)

• Motor (M1) with 2 speed sensors (B2.1, B4) and an imbalance sensor (B2.2)

• Brake resistor (R1)

• Motor-driven lid lock (A3)

• Cooling system

4.2 Operating panel (A2)

The buttons, the LCD display, the status LEDs and the acoustic beeper are located on

the operating panel.

The operating panel is connected with the Electronics (A1) via a 20-pole flat ribbon

cable.

4.3 Electronics ROTINA 380 (A1) resp. ROTINA 380 R (A1)

There are 2 microprocessors on the Electronics. Both processors (control- and driveprocessor) are communicating internal via a serial interface.

The control-processor carries out the following tasks:

• Reading in the buttons and controlling the LCD display and the LEDs.

• Saving of 99 run programs.

• Evaluating the errors recognized by the frequency converter.

• Voltage supply and evaluation of both speed sensors (B2.1, B4, speedometer).

• Voltage supply and evaluation of the imbalance sensor (B2.2).

• Controlling the motor-driven lid lock.

• Voltage supply 15 V DC and 5 V DC for the operating panel.

• Evaluating the temperature sensors T1, T2 (B1, B3) and controlling the cooling.

• Evaluating the overtemperature switch in the centrifuge chamber.

• Status indication with a yellow LED:

All functions are all right: the yellow LED lights up

The frequency converter carries out the following tasks:

• Generating the motor current supply

(three-phase current with variable frequency and voltage)

Functional description: The supply voltage is rectified, smoothened and

chopped into a pulse width pattern in three bridge

elements with a microprocessor.

• Monitoring the motor current.

• Evaluating the overtemperature switch in the motor (M1).

• The braking chopper transfers the electrical energy produced during braking, from a

voltage of approx. 400 Volt, to the brake resistor in a controlled manner.

9/98

• Status indication with a green LED:

Standby: the green LED lights up

Centrifugation run: the green LED lights up

Case of error: the green LED flashes

If the drive-processor detects an error, it switches off the motor.

4.4 Special features

• Multiprocessor concept:

The control- and the drive-processor monitoring one another. If one processor stops

working, the other processor switches off the drive.

• Interface concept:

The information transmission is monitored with an additional check sum.

• Hardware concept:

All safety related switches are break contacts. This also ensures that loose contacts

and cable rupture can be detected.

4.5 Brake resistor (R1)

• An overtemperature switch (F3) protects the brake resistor (R1) against fire. If the

braking chopper has a short circuit, the brake resistor becomes hot due to the high

current, and the overtemperature switch (F3) disconnects the supply voltage of the

centrifuge.

4.6 Motor (M1) / Tacho system (B4, B2.1)

• The motor (M1) is a three-phase asynchronous motor with four pairs of poles.

• A speed sensor (B4, speedometer) which is screwed onto the motor receives

− the rotor code information and

− the speed information (6 pulses per revolution)

from the magnets of the tacho ring attached to the rotor.

• An additional speed sensor (B2.1, speedometer) is together with the imbalance

sensor (B2.2) in one housing. This housing is screwed to the bottom of the motor.

The speed signal (1 pulse per revolution) will be triggered by a magnet fixed at the

motor axle. This signal is used for the release of the motor-driven lid lock.

• The Electronics (A1) monitors and regulates the speed.

− Double safety:

The drive-processor has been programmed in such a way that it

switches off the drive when the speed is higher than the permissible rotor speed. Then error message "FU/CCI-ERROR 61.19

Overspeed" will be displayed.

• The Electronics (A1) monitors the rotor standstill.

10/98

4.7 Imbalance sensor (B2.2)

• An electronic sensor monitors the imbalance.

• The imbalance sensor (B2.2) and the speed sensor (B2.1) are together in one

housing, screwed to the bottom of the motor (M1).

• Imbalance is detected only in running mode (run up, centrifuging and braking).

• If impermissible imbalance is detected, the drive switches off and the rotor slows

down braked until it stops.

4.8 Motor-driven lid lock (A3)

• The lid can be opened only if the Electronics (A1) has detected rotor standstill.

• By pressing the key

STOP / OPEN

the lid opens motor-driven.

• The motor locks the lid only if both lid brackets actuate both lid switches (Ll, Lr), the

position switch (Mo) for position "lid opened" is actuated and the rotor has standstill.

• The centrifuge can only be started when the lid is closed.

4.9 Cooling system

• The cooling system is a hermetical system.

• The cooling system consists of the following components:

− Compressor (M2, M2.1)

− Cooling tubes around the centrifuge chamber (evaporator)

− Condenser

− Dryer

− Fan (M3)

− Temperature sensor T1 (B1) and overtemperature switch in the centrifuge

chamber

− Temperature sensor T3 (B3) on the condenser

• In the housing of the temperature sensor T1 (B1) also the overtemperature switch is

included. With centrifuges with cooling the drive switches off, when the temperature

is > 60°C / > 140°F, and with option Heating/Cooling > 120°C / > 248°F.

• The refrigerant will be cooled down with a fan (M3). The speed of the fan is

controlled dependent to the temperature at the condenser.

• When opening the lid of the centrifuge, the cooling system switches off.

• When the rotor is at standstill and the lid is closed the centrifuge chamber will be

cooled on the preselected temperature, if this is lower than 20°C / 68°F.

During the standby-cooling the compressor is time-cycle controlled (2 minutes ON /

3 minutes OFF).

11/98

4.10 Safety devices

Mains switch

Over voltage protection and

radio interference suppression

filter

Additional radio interference

suppression filter

Frequency converter

Motor

Centrifuge chamber

5 Troubleshooting procedures

• Fuses in installation in which centrifuge is installed are intact.

• Supply voltage present at (see circuit diagram):

− Connecting cable

− Appliance plug

− Mains switch

− Electronics (A1), plug S100

• Look for the displayed error code in the chapter 6, pg. 13.

• Remedy the error according to the instructions.

• Carry out a functional check after every repair and whenever a component is

replaced, see pg. 76, chapter 9.

with thermal overload protection

⇒

on Electronics (A1)

⇒

in mains input circuit (only with 4706-01)

⇒

on Electronics (A1), electrically protected

⇒

Overtemperature switch (> 150 °C / > 302°F)

⇒

Overtemperature switch (> 60 °C / > 140°F,

⇒

with option Heating/Cooling > 120°C / > 248°F)

12/98

6 Error messages

6.1 Perform a MAINS RESET

• Switch off the mains switch (switch position "0").

• Wait at least 10 seconds and then switch on the mains switch again (switch position

"Ι").

6.2 Brief description

Error designation No. Brief description Page

TACHO-ERROR 1 Speed sensor on top of the motor: Speedometer

pulses break down during rotation

TACHO-ERROR 2 After start command no speedometer pulses

from both speed sensors

IMBALANCE (3)* Imbalance on motor axle 18

CONTROL-ERROR 4.1 Lid lock error 18

CONTROL-ERROR 4.2 Lid lock error 19

CONTROL-ERROR 4.3 Lid lock error 19

CONTROL-ERROR 4.4 Lid lock error 19

CONTROL-ERROR 4.5 Lid lock error 20

N > MAX 5 Excessive speed error 20

CONTROL-ERROR 6 Lid lock error 21

ROTORCODE 10.1 No start code recognized 21

ROTORCODE 10.2 Invalid rotor code 21

ROTORCODE 10.3 Error during reading the rotor code 22

MAINS INTERRUPT (11)* Mains interruption. 22

16

17

VERSION ERROR 12 Incorrect machine type and/or cooling version 22

N < MIN 13 Speed error: slippage is too high 23

CONTROL-ERROR 22 Communication error I2C bus 23

CONTROL-ERROR 25.1 EEPROM read error 23

CONTROL-ERROR 25.2 EEPROM write error 24

CONTROL-ERROR 25.3 EEPROM communication error 24

CONTROL-ERROR 25.4 EEPROM storage error 23

* Error number will not be displayed

13/98

Error designation No. Brief description Page

SER I/O-ERROR 31 TIME OUT, communication error with frequency

converter

SER I/O-ERROR 34 Communication error with frequency converter 24

SER I/O-ERROR 36 NAK, communication error with frequency

converter

°C / *-ERROR 51 Overtemperature on condenser 24

°C / *-ERROR 52 Overtemperature in centrifuge chamber 25

°C / *-ERROR 53 Temperature sensor at the bottom of the

centrifuge chamber is defective

°C / *-ERROR 54 Temperature sensor at the top of the centrifuge

chamber is defective (not existing in ROTINA

380 R)

°C / *-ERROR 55 Temperature sensor on condenser is defective 26

FU/CCI-ERROR 60 Faulty release signal to frequency converter

(drive-processor)

FU/CCI-ERROR 61.1 Undervolt, undervoltage frequency converter 27

FU/CCI-ERROR 61.2 Overvolt, overvoltage frequency converter 27

24

24

25

26

27

FU/CCI-ERROR 61.4 OverT FU, Übertemperatur frequency converter 28

FU/CCI-ERROR 61.5 OverT Mot, overtemperature in motor 28

FU/CCI-ERROR 61.9 OverI Peak, peak current error frequency

converter

FU/CCI-ERROR 61.13 Short cir, short circuit cut-off frequency converter 29

FU/CCI-ERROR 61.16 FU Enable, no enabling for frequency converter 29

FU/CCI-ERROR 61.17 Communication error with control-processor 29

FU/CCI-ERROR 61.18 frequency converter receives wrong direction of

rotation command

FU/CCI-ERROR 61.19 Overspeed, frequency converter recognizes

excess speed

FU/CCI-ERROR 61.20 Faulty speed measurement of the frequency

converter

FU/CCI-ERROR 61.128 Internal frequency converter error 31

FU/CCI-ERROR 61.129 System error of the frequency converter 31

FU/CCI-ERROR 61.130 Program memory of the frequency converter

defective

28

30

30

30

31

FU/CCI-ERROR 61.131 Reset by Watchdog of the frequency converter 31

14/98

Error designation No. Brief description Page

SENSOR-ERROR 90 No mains synchronisation 31

SENSOR-ERROR 91 Imbalance sensor – error (x-axis) 32

SENSOR-ERROR 92 Imbalance sensor – error (y-axis) 32

SENSOR-ERROR 93 Imbalance sensor - error: temperature sensor of

the imbalance sensor defective

TACHO-ERROR 96 Speed sensor at the bottom of the motor:

Speedometer pulses break down during

centrifugation run

°C / *-ERROR 97 Temperature sensor on the Electronics defective 33

°C / *-ERROR 98 Temperature sensor on the Electronics detects

overtemperature

PROGRAMM-

ERROR

MULTI PROG

ERROR

NO ROTOR OR

ROTORCODE

ERROR

N > ROTOR MAX --- Speed in the selected program greater than the

FC INIT ERROR --- Initialisation of the frequency converter is faulty 35

100 Ceck sum error with programs (Single programs) 34

101 Ceck sum error with program linking (Multi

programs)

--- No rotor installed or speed sensor on top of the

motor defective

maximum speed of the rotor (Nmax).

32

33

33

34

34

35

FATAL EEPROM

ERROR 1 – 5

--- EEPROM error 35

15/98

6.3 Description and elimination of errors

After occurrence of a fault the cooling / heating switches off. The standby

cooling takes place after the rotor is at standstill and the lid is closed.

During a fault the lid can be opened after the rotor is at standstill.

TACHO - ERROR 1 wait 3:00

During centrifugation the speedometer pulses of the speed sensor

(B4) on top of the motor are interrupted.

The rotor slows down braked until it stops.

No further user operation possible.

After the rotor is at standstill and the 3 minutes have elapsed the

lid lock will be released and the lid can be opened.

• Reset error code:

− Open the lid.

− Switch off the mains switch (switch position "0").

− Wait at least 10 seconds.

− Turn the rotor vigorously by hand.

− Switch on the mains switch again (switch position "Ι").

• Speed sensor (B4) on top of the motor defective or loose

contact on plug.

Check the function of the speed sensor (B4), see pg. 63,

chapter 7.17, item 6.

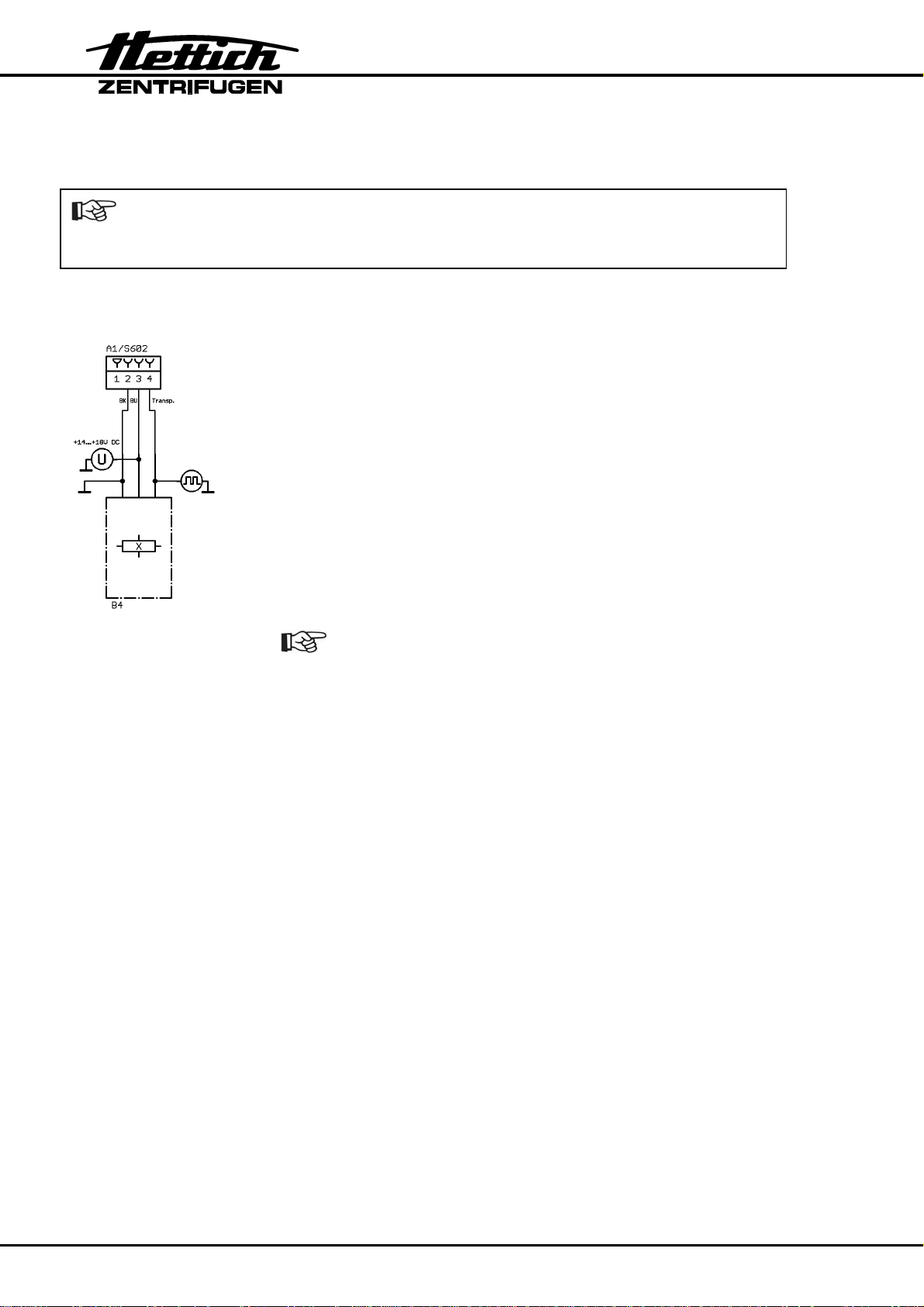

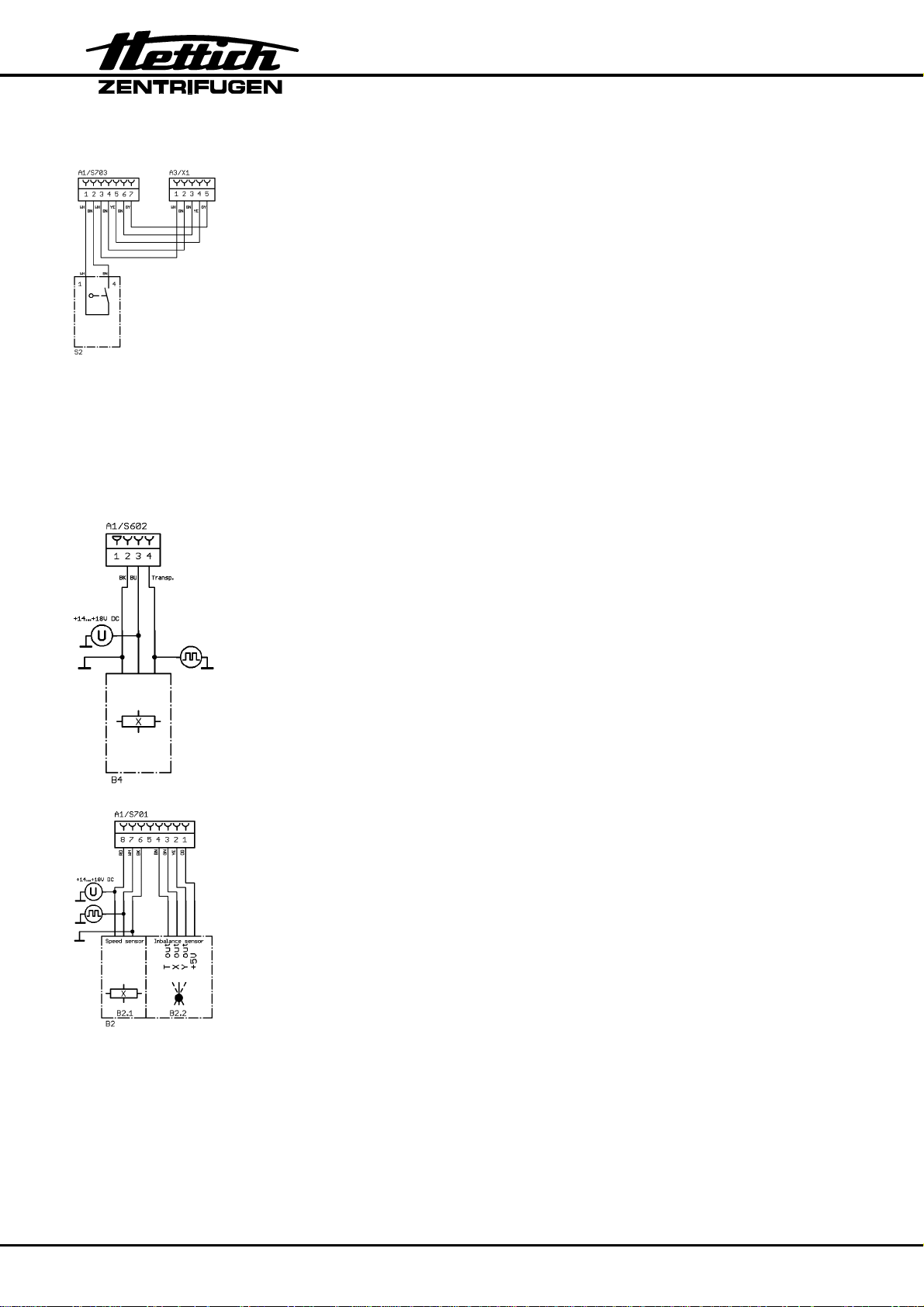

Measure supply voltage on plug S602 / Electronics (A1)

pin 2 – pin 3 (+14-18 VDC).

Measure speedometer pulses on plug S602 / Electronics (A1)

pin 2 - pin 4 (signal).

• Electronics (A1) is defective.

The rotor must turn during switch-on.

16/98

TACHO - ERROR 2 wait 3:00

After start-up no speedometer pulses will be received from both

speed sensors.

The rotor slows down braked until it stops.

No further user operation possible.

After the rotor is at standstill and the 3 minutes have elapsed the lid

lock will be released and the lid can be opened.

• Reset error code:

− Open the lid.

− Switch off the mains switch (switch position "0").

− Wait at least 10 seconds.

− Turn the rotor vigorously by hand.

− Switch on the mains switch again (switch position "Ι").

• Motor is blocked or defective.

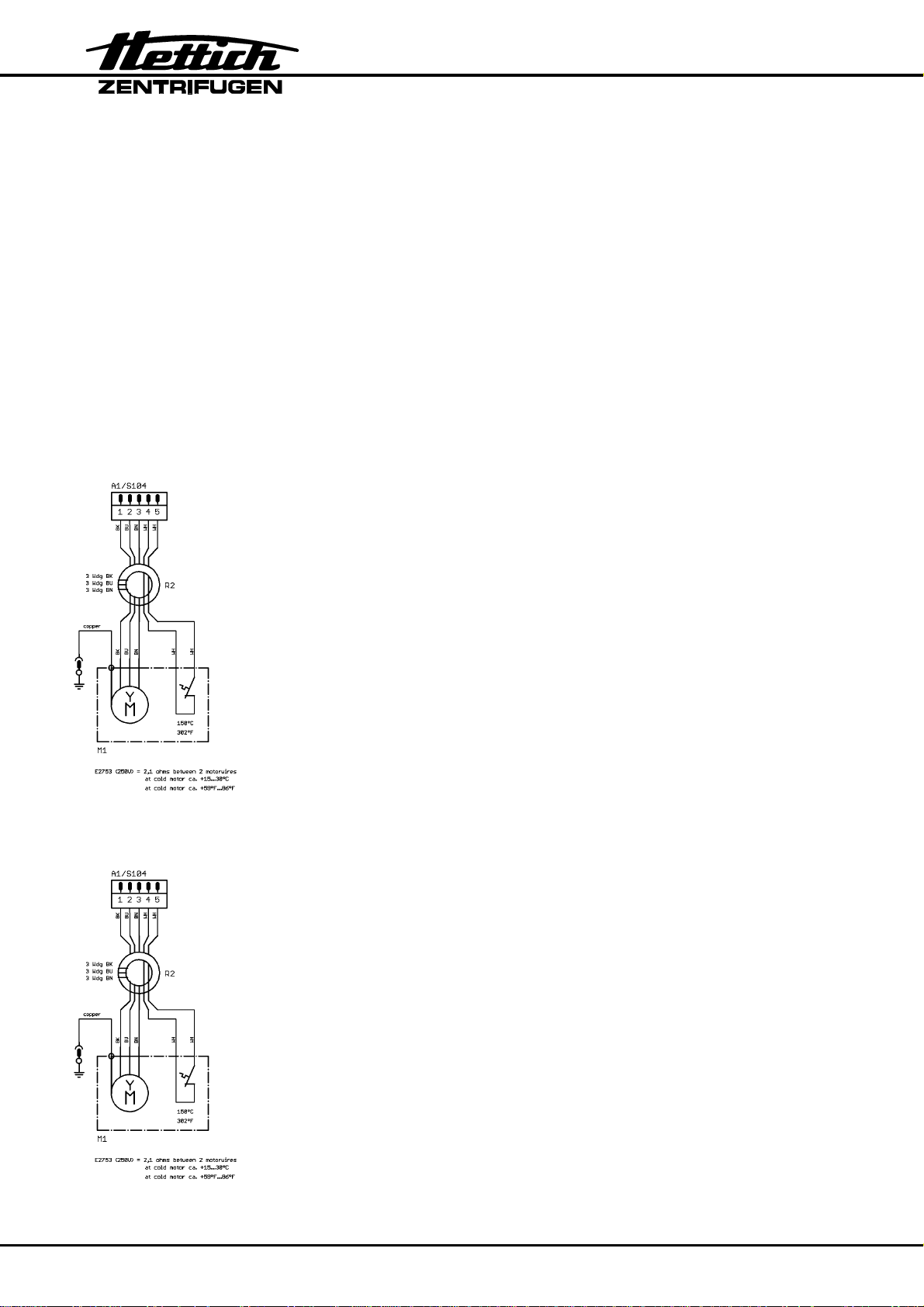

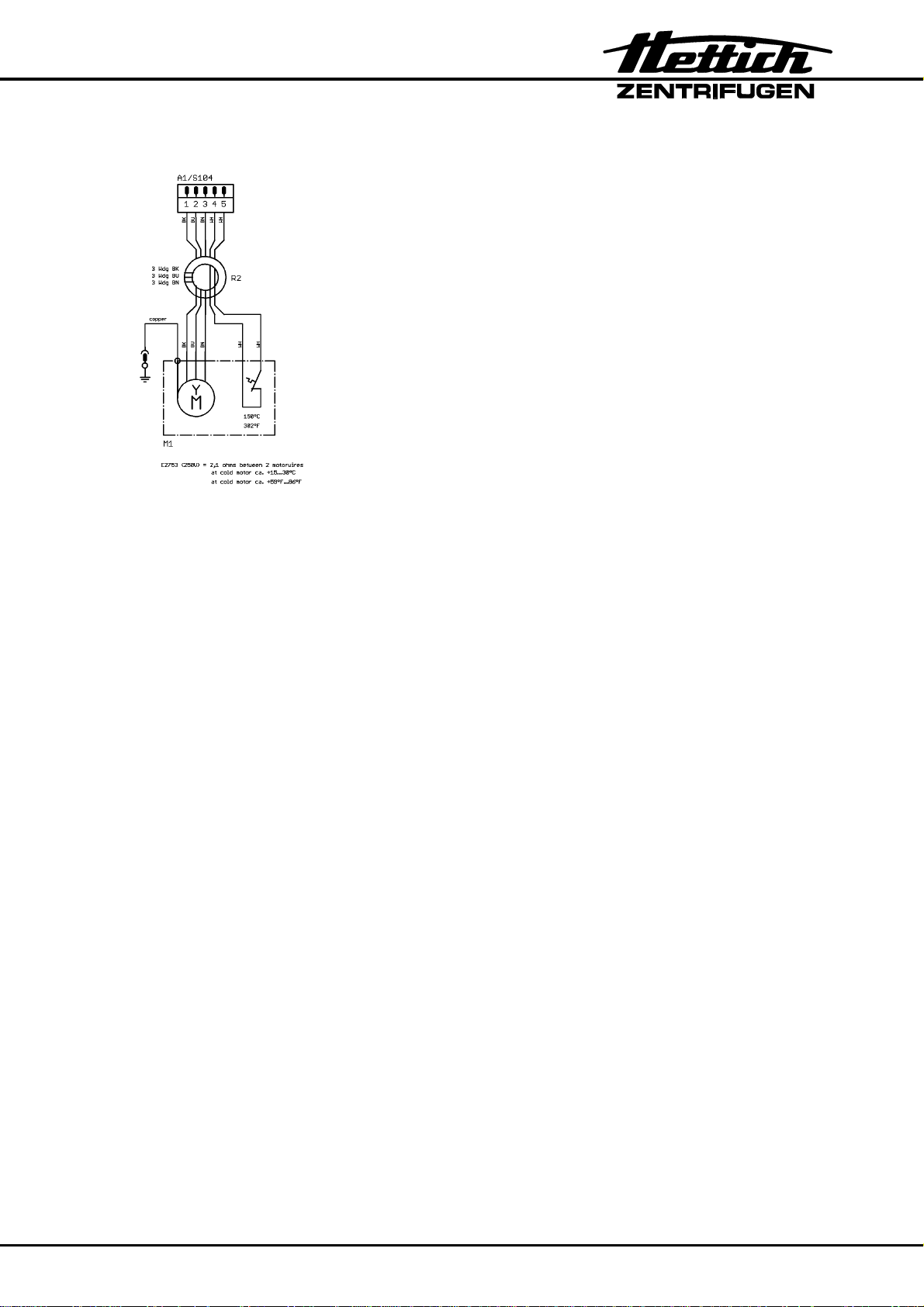

• Loose contact on motor plug S104.

• Both speed sensors (B4, B2.1) defective or loose contact on

plug.

− Check the function of the speed sensors, see pg. 63, chapter

7.17, item 6.

The rotor must turn during switch-on.

− Speed sensor (B4) on top of the motor:

Measure supply voltage on plug S602 / Electronics (A1)

pin 2 – pin 3 (+14-18 VDC).

Measure speedometer pulses on plug S602 / Electronics

(A1)

pin 2 - pin 4 (signal).

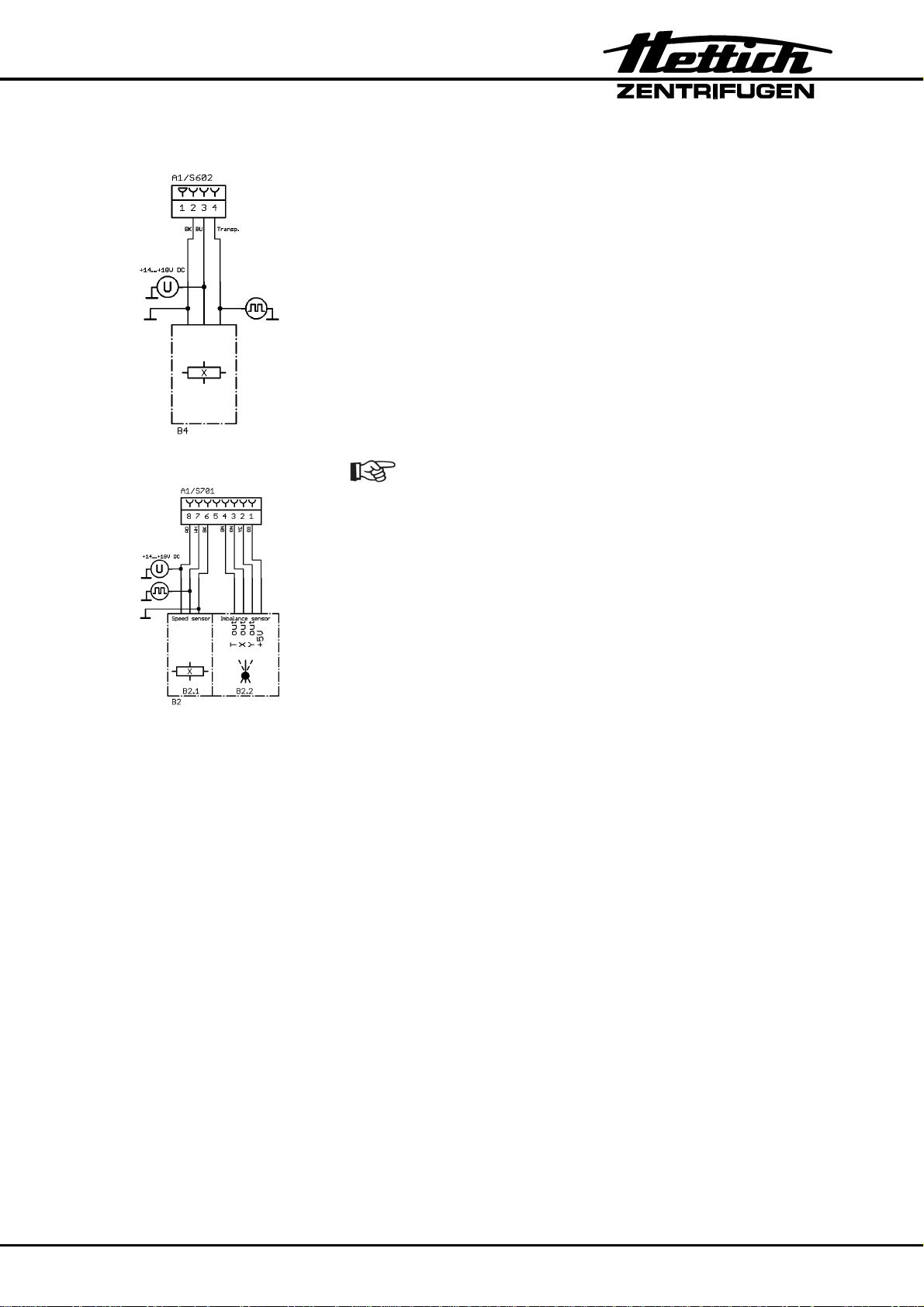

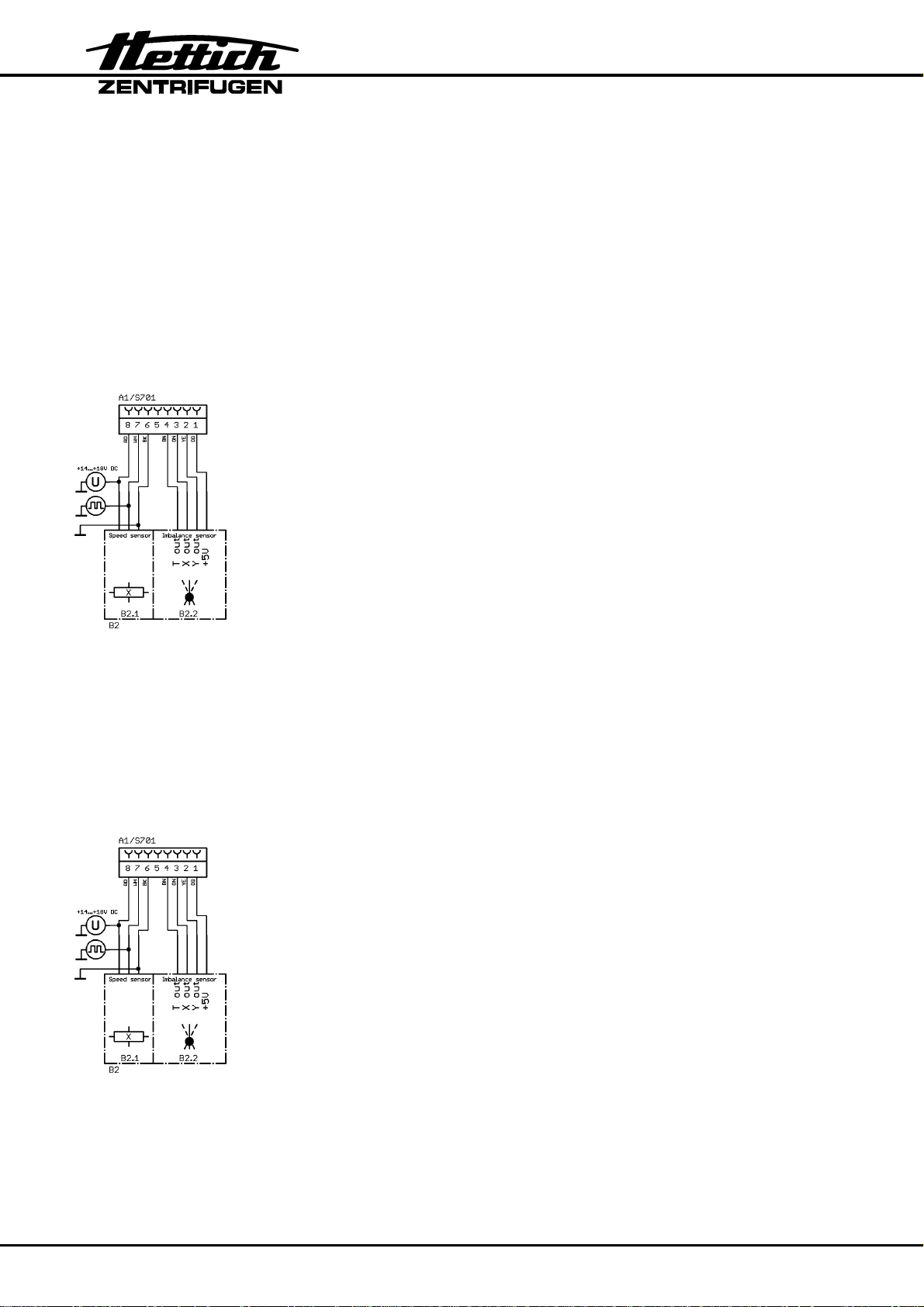

− Speed sensor (B2.1) at the bottom of the motor:

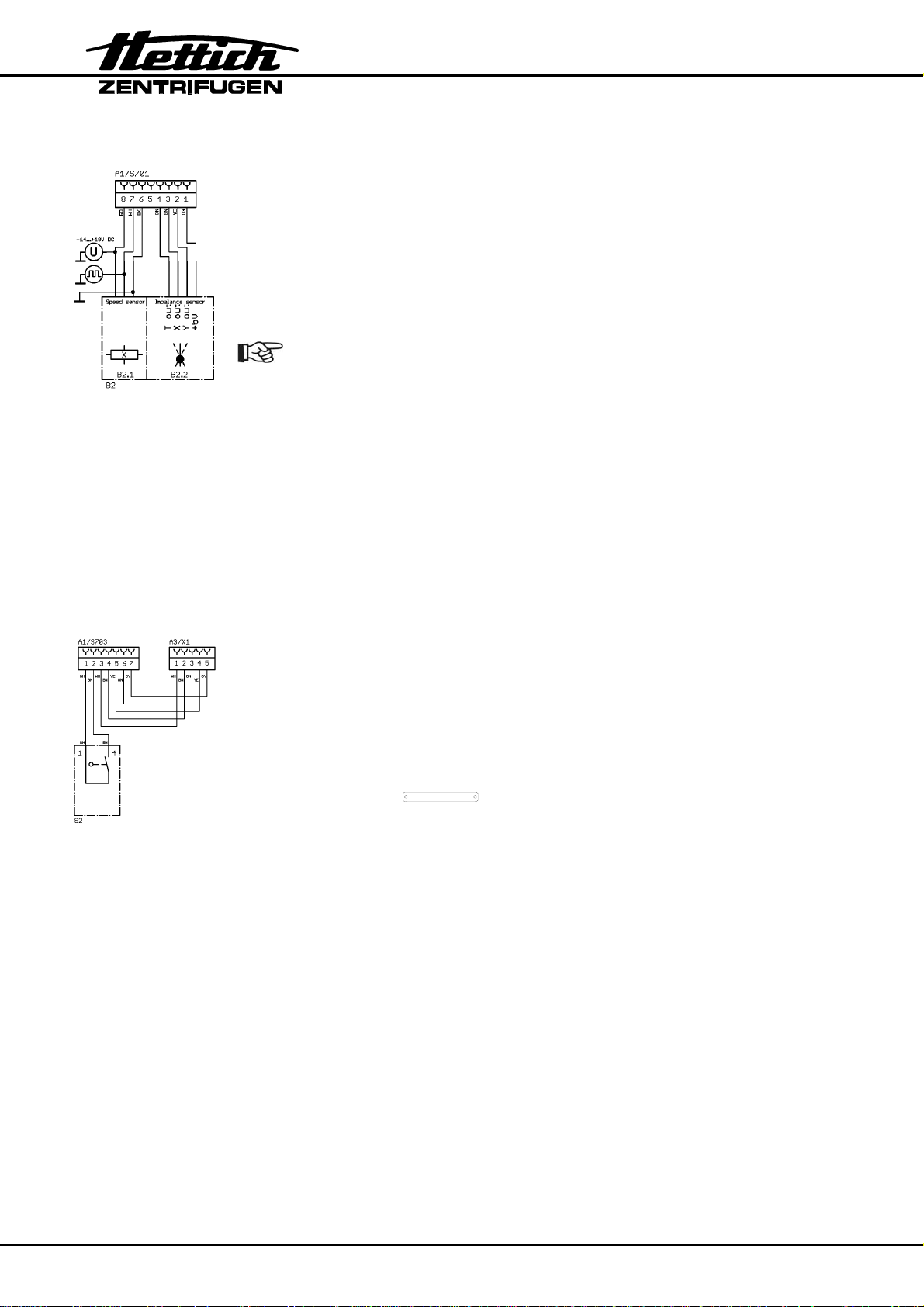

Measure supply voltage on plug S701 / Electronics (A1)

pin 6 – pin 8 (+14-18 VDC).

Measure speedometer pulses on plug S701 / Electronics

(A1)

pin 6 - pin 7 (signal).

• Electronics (A1) is defective.

17/98

IMBALANCE

Imbalance on motor axle.

The rotor slows down braked until it stops.

• Reset error code:

Open the lid or perform a MAINS RESET.

• Weight difference in rotor components.

• The supporting lugs of the rotor are not lubricated.

• Check grounding of the motor.

• Check the maximum permissible imbalance values, see pg. 60,

chapter 7.15.3.

• Imbalance sensor (B2.2) is defective.

Measure supply voltage on plug S701 / Electronics (A1)

pin 6 – pin 1 (+5 VDC).

Measure on Electronics (A1) / plug S701, pin 6 – pin 2 and

pin 6 – pin 3 (square wave signal 5 V /100 Hz).

• Electronics (A1) is defective.

CONTROL - ERROR 4.1

A missing grounding of the motor causes disturbing signals

which can produce the error.

The lid switches for the left and/or right hook have opened during the

centrifugation run.

The rotor slows down without braking until it stops.

No further user operation possible except opening the lid.

• Reset error code:

After the rotor has stopped perform a MAINS RESET. If the left

LED in the button

on again, press this button so that the motor-driven lid locking

STOP / OPEN

is blinking after turning the centrifuge

once again assumes the normal position (opened).

• An emergency unlocking was performed during the centrifugation

run.

• Switches of the lid lock defective.

Check the function of both switches, see pg. 63, chapter 7.17,

item 21.

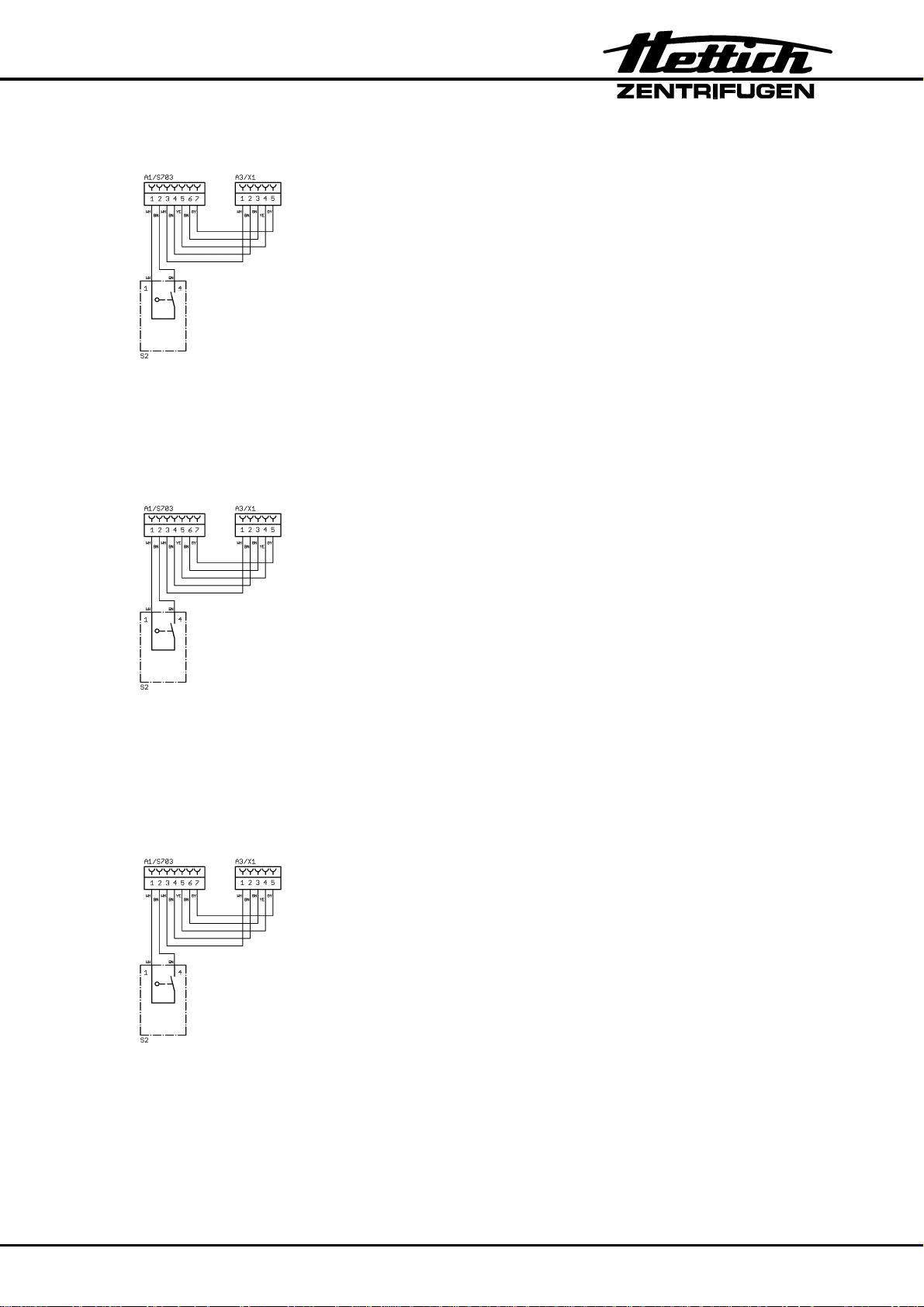

Pull out plug S703 and check the function of the switches at the

plug of the cable between pin 1 - pin 2 (left hook) and

pin 3 - pin 4 (right hook).

• Electronics (A1) is defective.

18/98

CONTROL - ERROR 4.2

Error during testing the lid switches after the start command.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Switches of the lid lock defective.

Check the function of both switches, see pg. 63, chapter 7.17,

item 21.

Pull out plug S703 and check the function of the switches at the

plug of the cable between pin 1 - pin 2 (left hook) and

pin 3 - pin 4 (right hook).

• Electronics (A1) is defective.

CONTROL - ERROR 4.3

Position switch "Mc" of the motor-driven lid lock opens during the

centrifugation run.

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Position switch "Mc" defective.

Check the function of the switch, see pg. 63, chapter 7.17, item

21.

Pull out plug S703 and check the function of the switch at the

plug of the cable between pin 6 - pin 7 (position switch "Mc").

• Electronics (A1) is defective.

CONTROL - ERROR 4.4

The lid can not be locked by motor.

No further user operation possible.

• Reset error code:

Perform a MAINS RESET.

• After opening the lid one of the two lid switches (for the hooks)

remains closed.

• Switches of the lid lock defective.

Check the function of both switches, see pg. 63, chapter 7.17,

item 21.

Pull out plug S703 and check the function of the switches at the

plug of the cable between pin 1 - pin 2 (left hook) and

pin 3 - pin 4 (right hook).

• Electronics (A1) is defective.

19/98

CONTROL - ERROR 4.5

Position switch "Mo" of the motor-driven lid lock closes during the

centrifugation run.

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Position switch "Mo" defective.

Check the function of the switch, see pg. 63, chapter 7.17, item

21.

Pull out plug S703 and check the function of the switch at the

plug of the cable between pin 5 - pin 7 (position switch "Mo").

• Electronics (A1) is defective.

N > MAX 5

Excess speed. The speed measured by the speed sensors B4 or

B2.1 is 250 RPM higher than the maximum speed of the rotor.

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Both speed sensors (B4, B2.1) defective or loose contact on

plug.

− Check the function of the speed sensors, see chapter "7.17,

item 6".

− Speed sensor (B4) on top of the motor:

• Electronics (A1) is defective.

Measure supply voltage on plug S602 / Electronics (A1)

pin 2 – pin 3 (+14-18 VDC).

Measure speedometer pulses on plug S602 / Electronics (A1)

pin 2 - pin 4 (signal).

− Speed sensor (B2.1) at the bottom of the motor:

Measure supply voltage on plug S701 / Electronics (A1)

pin 6 – pin 8 (+14-18 VDC).

Measure speedometer pulses on plug S701 / Electronics (A1)

pin 6 - pin 7 (signal).

20/98

CONTROL - ERROR 6

Lid lock error.

No further user operation possible except opening the lid.

• Reset error code:

• The motor of the lid lock runs too slowly or it is blocked. The

• Position switch "Mc" or "Mo" defective.

• Electronics (A1) is defective.

ROTORCODE 10.1

Start code of the rotor coding not recognized.

Perform a MAINS RESET.

position switch "Mc" or "Mo" must close within 5 seconds.

Check the function of the switch "Mc" or "Mo", see pg. 63,

chapter 7.17, item 21.

Pull out plug S703 and check the function of the switch at the

plug of the cable between pin 6 - pin 7 (position switch "Mc") and

between pin 5 - pin 7 (position switch "Mo").

The rotor slows down braked until it stops.

ROTORCODE 10.2

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Magnetic code on the rotor is defective, see pg. 92, chapter 12.1.

• Electronics (A1) is defective.

An invalid rotor code was read in during start-up.

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Magnetic code on the rotor is defective, see pg. 92, chapter

12.1.

• Motor turns in false direction. Check the motor cables on plug

S104 / Electronics (A1).

• Electronics (A1) is defective.

21/98

ROTORCODE 10.3

Error during reading the rotor code.

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

• Reset error code:

• Magnetic code on the rotor is defective, see pg. 92, chapter 12.1.

• Electronics (A1) is defective.

MAINS INTERRUPT

Interruption of mains supply during centrifugation.

During the interruption of the mains supply the rotor slows down

without braking until it stops.

After the interruption of the mains supply the rotor slows down

braked until it stops.

• Reset error code:

• Power failure.

• Overtemperature switch (F3) on the brake resistor (R1) has

• Loose contact in the electrical wiring.

• Electronics (A1) is defective.

VERSION ERROR 12

Perform a MAINS RESET.

Open the lid and press the

START / IMPULS

key.

The error code cannot be reset by a MAINS RESET.

opened or is defective.

Incorrect machine type and/or cooling version identified.

No further user operation possible except opening the lid.

• Perform an initialisation of the EEPROM, see chapter "7.20".

Then check the machine type and the cooling version (dispaly

after MAINS RESET).

• The installed electronics (A1) does not fit to the centrifuge model.

• Electronics (A1) is defective.

22/98

N < MIN 13

Insufficient speed, motor slippage is too high.

This error is displayed if the rotor speed (ACTUAL speed) is

longer as 30 seconds lower than the SET speed.

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

• Reset error code:

• Motor is labouring (damage to bearings).

• Motor has a short-circuited coil (coil is defective).

• Loose contact in the electrical connections.

• Electronics (A1) is defective.

CONTROL - ERROR 22

Communication error I2C bus.

Perform a MAINS RESET.

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

CONTROL - ERROR 25.1, 25.4

EEPROM: Read or storage error.

The rotor slows down braked until it stops.

• Reset error code:

Perform a MAINS RESET.

• Electronics (A1) is defective.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Delete the programs and the program linking, see pg. 69, chapter

7.18.

• Initialise the EEPROM, see pg. 71, chapter 7.20.

• Electronics (A1) is defective.

23/98

CONTROL - ERROR 25.2, 25.3

EEPROM: Write or communication error.

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

SER I/O - ERROR 31, 34, 36

Communication error with the frequency converter.

The rotor slows down without braking until it stops.

°C / * -ERROR 51

• Reset error code:

Perform a MAINS RESET.

• Electronics (A1) is defective.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Electronics (A1) is defective.

Overtemperature on condenser

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Temperature on condenser ≥ 58°C / 136°F.

• The temperature sensor (B3) on the condenser is defective.

Measure on Electronics (A1) / plug S706, pin 1 – pin 2.

Voltage > 3.31 V = Temperature on condenser > 58°C / 136°F

Voltage at 25°C / 77°F = 2.98 V (± 20 mV)

A temperature change of 1°K causes a voltage change of 10 mV.

• Electronics (A1) is defective.

• Fan (M3) is defective.

24/98

°C / * -ERROR 52

°C / * -ERROR 53

Overtemperature in centrifuge chamber

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Temperature in centrifuge chamber > 60°C / 140°F, with option

heating/cooling > 120°C / 248°F.

• Overtemperature switch in centrifuge chamber is defective.

Measure on Electronics (A1) / plug S704, pin 3 – pin 4

Switch closed: 0 VDC

Switch opened: +15 VDC

• Electronics (A1) is defective.

• Cooling is defective.

The temperature in the centrifuge chamber measured by the

temperature sensor (B1) is out of the valid range.

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• The temperature sensor (B1) in the centrifuge chamber is

defective.

Measure on Electronics (A1) / plug S704, pin 1 – pin 2.

Valid voltage range: 2,24 V up to 3,92 V.

Voltage < 0.5 V = short circuit

Voltage > 4.5 V = disruption

Voltage at 25°C / 77°F = 2.98 V (± 20 mV)

A temperature change of 1°K causes a voltage change of 10 mV.

• Electronics (A1) is defective.

25/98

°C / * -ERROR 54

The temperature in the centrifuge chamber measured by the

No further user operation possible except opening the lid.

temperature sensor (B2) is out of the valid range. The temperature

sensor (B2) does not exist in the ROTINA 380 R.

If the temperature sensor B2 (= T2) is activated in the "Select

Menu", °C / * -ERROR 54 will be displayed.

°C / * -ERROR 55

• Reset error code:

Perform a MAINS RESET.

• Deactivate the temperature sensor B2 (= T2) in the "Select

Menu", see pg. 55, chapter 7.14.3.

• Electronics (A1) is defective.

The temperature on the condenser measured by the temperature

sensor (B3) is out of the valid range.

The rotor slows down braked until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• The temperature sensor (B3) on the condenser is defective.

Measure on Electronics (A1) / plug S706, pin 1 – pin 2.

Valid voltage range: 2,24 V up to 3,92 V.

Voltage < 0.5 V = short circuit

Voltage > 4.5 V = disruption

Voltage at 25°C / 77°F = 2.98 V (±20 mV)

A temperature change of 1°K causes a voltage change of 10 mV.

• Electronics (A1) is defective.

26/98

General notes for FU/CCI-ERROR 60 to FU/CCI-ERROR 61.131

If the drive-processor detects an error, it switches off the motor.

After occurrence of a fault the green LED on the electronics (A1) flashes

quickly.

FU/CCI-ERROR 60

Error when checking the enable signal to frequency converter (drive-

processor).

No further user operation possible except opening the lid.

FU/CCI-ERROR 61.1 Undervolt

• Reset error code:

Perform a MAINS RESET.

• Electronics (A1) is defective.

Frequency converter error. Undervoltage in the intermediate circuit.

The rotor slows down without braking until it stops.

No further user operation possible except opening the lid.

FU/CCI-ERROR 61.2 Overvolt

• Reset error code:

Perform a MAINS RESET.

• Mains voltage is too low. Admissible mains voltage see pg. 98,

chapter 12.4.

• Electronics (A1) is defective.

Frequency converter error. Overvoltage.

The voltage in intermediate circuit is > 426 V DC.

This error normally only occurs when the drive is being braked.

The rotor slows down without braking until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Check the electrical wiring and the plug S106 of the brake

resistor (R1).

• Brake resistor (R1) is defective.

• Electronics (A1) is defective.

27/98

FU/CCI-ERROR 61.4 OverT FU

Overtemperature in the frequency converter.

Temperature ≥ 78°C / 172°F.

The rotor slows down without braking until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• The thermal conduction from the frequency converter to the

supporting sheet of the electronics (A1) is not sufficient.

• Full load operation at an ambient temperature > 35°C / 95°F.

• Electronics (A1) is defective.

FU/CCI-ERROR 61.5 OverT Mot

Overtemperature in the motor. Temperature > 150°C / 302°F.

The rotor slows down without braking until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

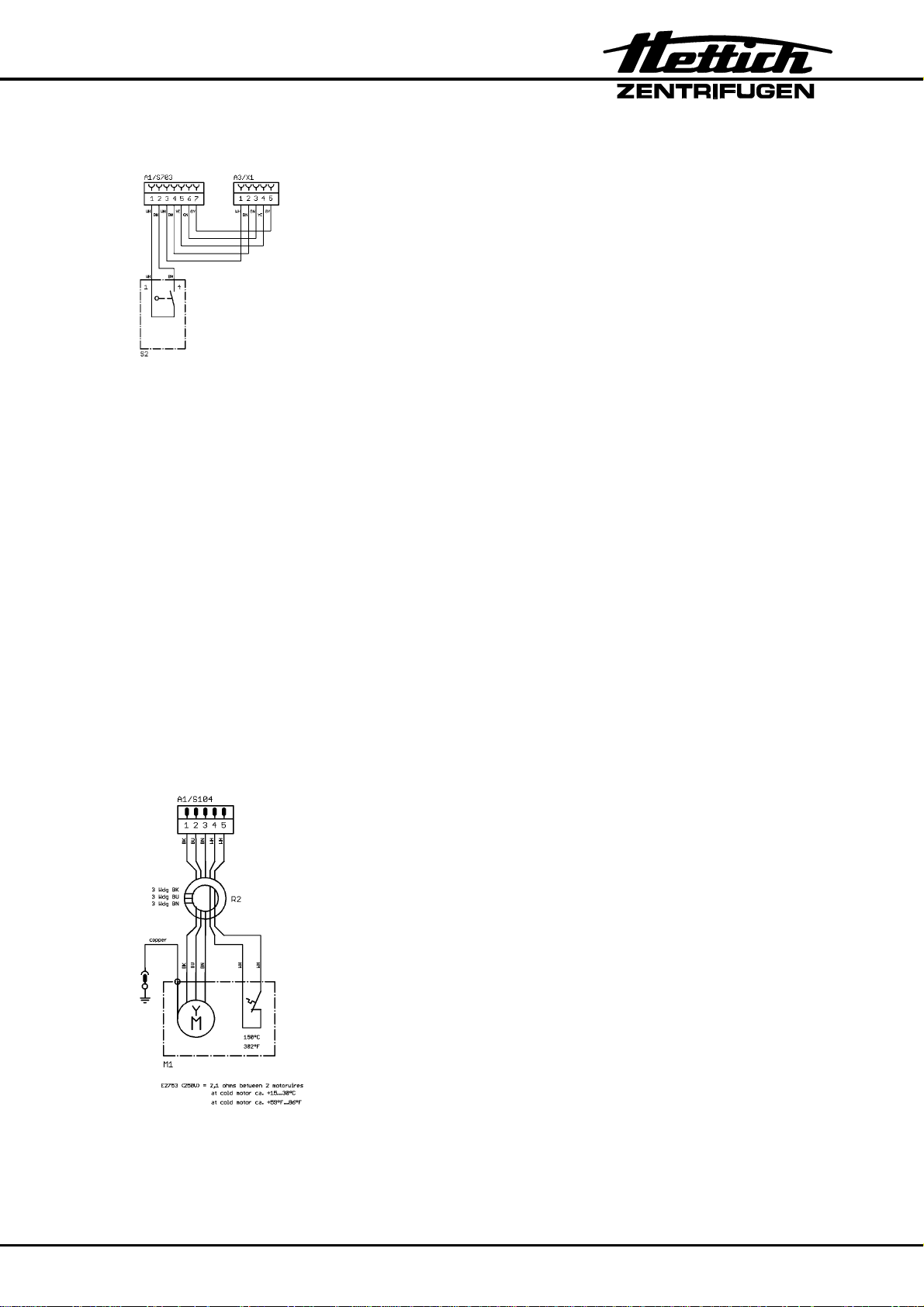

• Overtemperature switch opens because of overtemperature in

the motor.

Remove plug S104 and measure at the plug between pin 4 pin 5:

Switch closed: ≈ 0 Ω

Switch opened: ∞ Ω

• Electronics (A1) is defective.

• Motor is defective.

FU/CCI-ERROR 61.9 Overl Peak

28/98

Overcurrent in the frequency converter (peak current).

The rotor slows down without braking until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Short circuit in the motor.

Remove plug S104 and check at the plug pin 1, pin 2, pin 3

the resistance of the motor coils.

• Electronics (A1) is defective.

FU/CCI-ERROR 61.13 Short cir

Short circuit switch-off of the frequency converter.

The rotor slows down without braking until it stops.

No further user operation possible except opening the lid.

• Reset error code:

Perform a MAINS RESET.

• Short circuit in the motor.

Remove plug S104 and check at the plug pin 1, pin 2, pin 3

the resistance of the motor coils.

• Electronics (A1) is defective.

FU/CCI-ERROR 61.16 FU Enable

No enabling for frequency converter.

The rotor slows down without braking until it stops.

No further user operation possible.

FU/CCI-ERROR 61.17

Communication error with control-processor.

The rotor slows down without braking until it stops.

• Reset error code:

• Switches of the lid lock defective.

• Electronics (A1) is defective.

No further user operation possible.

• Reset error code:

• Electronics (A1) is defective.

Perform a MAINS RESET.

Check the function of both switches, see chapter "7.17, item 21".

Pull out plug S703 and check the function of the switches at the

plug of the cable between pin 1 - pin 2 (left hook) and

pin 3 - pin 4 (right hook).

Perform a MAINS RESET.

29/98

FU/CCI-ERROR 61.18

Frequency converter receives wrong direction of rotation command.

The rotor slows down without braking until it stops.

No further user operation possible.

FU/CCI-ERROR 61.19 Overspeed

FU/CCI-ERROR 61.20

• Reset error code:

Perform a MAINS RESET.

• Electronics (A1) is defective.

The frequency converter recognises excess speed. It evaluates the

signals from the speed sensor (B2.1) at the bottom of the motor.

The error occurs, if the speed measured by the speed sensor

(B2.1) is longer as 0.5 seconds 250 RPM higher than the maximum

speed of the rotor (Nmax).

The rotor slows down without braking until it stops.

No further user operation possible.

• Reset error code:

Perform a MAINS RESET.

• Speed sensor (B2.1) at the bottom of the motor defective or

loose contact on plug.

Measure supply voltage on plug S701 / Electronics (A1)

pin 6 – pin 8 (+14-18 VDC).

Measure speedometer pulses on plug S701 / Electronics (A1)

pin 6 - pin 7 (signal).

• Electronics (A1) is defective.

30/98

Faulty speed measurement of the frequency converter.

The rotor slows down without braking until it stops.

No further user operation possible.

• Reset error code:

Perform a MAINS RESET.

• Speed sensor (B2.1) at the bottom of the motor defective or

loose contact on plug.

Measure supply voltage on plug S701 / Electronics (A1)

pin 6 – pin 8 (+14-18 VDC).

Measure speedometer pulses on plug S701 / Electronics (A1)

pin 6 - pin 7 (signal).

• Electronics (A1) is defective.

Loading...

Loading...