Hettich Rotanta 460 Repair manual

Repair instructions

ROTANTA 460 / 460 R

ROTANTA 460 S / 460 RS

09.06 Andreas Hettich GmbH & Co. KG AR5600EN

Andreas Hettich GmbH & Co. KG

Föhrenstraße 12, D-78532 Tuttlingen / Germany

Phone (07461) 705-0

Fax (07461) 705-125

info@hettichlab.com, service@hettichlab.com

www.hettichlab.com

© 2002 by Andreas Hettich GmbH & Co. KG

All rights reserved. No part of this publication may be reproduced without the written

prior permission of the copyright owner.

Modifications reserved!

AR5600EN / 09.06

2/92

Contents

1 Introduction ...........................................................................................................................6

2 Description of the centrifuge ................................................................................................. 6

2.1 Control panel (A4, A5) .................................................................................................. 6

2.2 Supply board (A1) ......................................................................................................... 7

2.3 Frequency converter (A2) .............................................................................................8

2.4 Special features ............................................................................................................ 9

2.5 Braking chopper (A3) / brake resistor (R1) ................................................................... 9

2.6 Motor / tacho system..................................................................................................... 9

2.7 Motor-driven lid lock....................................................................................................10

2.8 Imbalance switch ........................................................................................................ 10

2.9 Key-operated switch (A7, optionally)........................................................................... 10

2.10 Machine concept.........................................................................................................10

2.11 Cooling system ........................................................................................................... 11

2.11.1 Diagram of the cooling version............................................................................ 12

2.12 Ventilator control ......................................................................................................... 13

2.13 Ventilator.....................................................................................................................13

2.14 Offset compensation ................................................................................................... 13

2.15 Safety devices............................................................................................................. 14

3 Troubleshooting procedures ............................................................................................... 14

4 Error messages ..................................................................................................................15

4.1 MAINS RESET............................................................................................................ 15

4.2 Brief description .......................................................................................................... 15

4.3 Description and elimination of errors........................................................................... 18

5 Settings and interrogations ................................................................................................. 37

5.1 Option: program linkage (only for S-control panel) .....................................................37

5.1.1 Linking programs................................................................................................. 37

5.1.2 Changing program links ...................................................................................... 37

5.1.3 Centrifugation run with program linking............................................................... 38

5.1.4 Deleting program linking .....................................................................................38

5.2 Option: optical interface (only for S-control panel)...................................................... 38

5.3 Option: key-operated switch (only for S-control panel) ............................................... 39

5.4 Setting the lid lock mode............................................................................................. 39

5.5 Setting the machine and cooling version .................................................................... 40

5.6 Function of the additional jumper................................................................................ 41

5.7 Initialization .................................................................................................................41

5.7.1 Prerequisites for the initialization ........................................................................41

5.7.2 Initializing the centrifuge with N-control panel..................................................... 42

5.7.3 Initializing the centrifuge with S-control panel ..................................................... 43

5.8 OFFSET compensation .............................................................................................. 46

5.9 Imbalance Mode ......................................................................................................... 48

5.9.1 Setting the imbalance mode on the supply board ............................................... 48

5.9.2 Setting the imbalance mode in the program .......................................................48

3/92

5.10 Temp. Average Time .................................................................................................. 49

5.11 Leading time ............................................................................................................... 50

5.12 Parameter for error message °C / *ERROR 58 .......................................................... 51

5.12.1 Temperature monitor until reaching the temperature set value ..........................51

5.12.1.1 Setting the temperature monitor with the N-control panel........................... 52

5.12.1.2 Setting the temperature monitor with the S-control panel ........................... 52

5.12.2 Permissible temperature difference after reaching the temperature set value.... 53

5.12.2.1 Setting the permissible temperature difference with the N-control panel.... 53

5.12.2.2 Setting the permissible temperature difference with the S-control panel.... 53

5.13 Parameter interrogation .............................................................................................. 54

5.13.1 Parameter interrogation N-control panel............................................................. 54

5.13.2 Parameter interrogation S-control panel ............................................................. 54

5.14 Acoustic Signal ........................................................................................................... 55

5.14.1 Acoustic Signal N-control panel .......................................................................... 55

5.14.2 Acoustic signal S-control panel........................................................................... 55

5.15 Working hours............................................................................................................. 55

5.15.1 Working hours N-control panel............................................................................ 55

5.15.2 Working hours S-control panel............................................................................ 56

5.16 Checking the motor slippage ...................................................................................... 56

5.16.1 Checking the slippage with the N-control panel.................................................. 56

5.16.2 Checking the slippage with the S-control panel .................................................. 57

5.17 Checking the temperatures......................................................................................... 57

5.17.1 Checking the temperatures with the N-control panel .......................................... 57

5.17.2 Checking the temperatures with the S-control panel ..........................................58

5.18 Setting the date and time (only in S-control panel) ..................................................... 58

5.19 Centrifugation data displayed after switching on (only in S-control) ........................... 59

5.20 Immediate display of the centrifugation data after switching on (only in

S-control panel)........................................................................................................... 59

5.21 Logging (only in S-control panel) ................................................................................ 59

5.21.1 Error messages................................................................................................... 60

5.21.2 Imbalance messages .......................................................................................... 60

5.21.3 Modification logs ................................................................................................. 61

5.21.4 Note on the display of date and time................................................................... 61

5.22 Setting the display contrast......................................................................................... 61

5.23 Imbalance switch-off ................................................................................................... 63

6 Functional check after a repair ...........................................................................................64

7 Mounting and removing components.................................................................................. 64

7.1 Removing the front panel............................................................................................ 64

7.2 Removing the support sheet of the electronic components ........................................ 65

7.3 Removing the upper part of the centrifuge housing .................................................... 65

7.4 Motor (M1) .................................................................................................................. 66

7.5 Rubber-metal bearings ............................................................................................... 67

7.6 Vibration dampers....................................................................................................... 67

7.7 Speed sensor.............................................................................................................. 67

4/92

7.8 Motor-driven lid lock.................................................................................................... 68

7.8.1 Removing the motor-driven lid lock..................................................................... 68

7.8.2 Replacing the motor-lock unit.............................................................................. 69

7.8.3 Replacing the angle support on the left............................................................... 69

7.8.4 Replacing the eccentric disc ...............................................................................70

7.8.5 Replacing the sliding blocks................................................................................ 70

7.8.6 Replacing the plastic rollers and discs ................................................................ 70

7.8.7 Replacing the microswitch ..................................................................................71

7.9 Control panel (A4, A5) ................................................................................................ 71

7.9.1 N-control panel (A4) ............................................................................................ 71

7.9.2 S-control panel (A5) ............................................................................................ 71

7.10 EPROM in the control panel ....................................................................................... 71

7.11 Battery (only in S-control panel).................................................................................. 71

7.12 Supply board (A1) ....................................................................................................... 72

7.13 Frequency converter (A2) ...........................................................................................72

7.14 Braking chopper (A3) .................................................................................................. 73

7.15 Radio interference suppression filter (Z1)................................................................... 73

7.16 Brake resistor (R1)...................................................................................................... 73

7.17 Temperature sensors (only in centrifuges with cooling).............................................. 73

7.17.1 Temperature sensor at the top of the centrifuge chamber (T1) ..........................73

7.17.2 Temperature sensor at the bottom of the centrifuge chamber (T2) ....................74

7.17.3 Temperature sensor on the condenser (T3) .......................................................74

7.18 Imbalance switch (S2)................................................................................................. 74

7.19 Mains switch ............................................................................................................... 75

7.20 Appliance plug with overvoltage protection................................................................. 75

7.21 Gas spring................................................................................................................... 75

7.22 Sealing ring (between the upper part of the centrifuge housing and the lid)............... 76

7.23 Key-operated switch (A7; only in S-control panel) ...................................................... 76

7.24 Optical interface (A6; only in S-control panel)............................................................. 77

8 Designation of the components .......................................................................................... 79

9 Technical documents.......................................................................................................... 82

9.1 Tachometer code configuration of the rotors .............................................................. 82

9.1.1 Centrifuge without cooling................................................................................... 82

9.1.2 Centrifuge with cooling........................................................................................ 83

9.2 Cooling diagram.......................................................................................................... 84

9.3 Connecting diagrams .................................................................................................. 85

9.3.1 Abbreviations of the cable colours ...................................................................... 85

9.3.2 Connecting diagram centrifuge ........................................................................... 86

9.3.3 Transformer connection ...................................................................................... 88

9.3.3.1 Centrifuge without cooling system............................................................... 88

9.3.3.2 Centrifuge with cooling system.................................................................... 88

9.4 Technical specifications .............................................................................................. 89

5/92

1 Introduction

• Repairs must only be carried out by personnel authorised to do so by the

manufacturer.

Interventions and modifications at centrifuges, which have been conducted

by persons not authorized by the HETTICH company, are at their own risk

and entail the loss off all guarantee and liability claims. In such an event any

guarantee claim or liability claim against the HETTICH company expire.

• Only original spare parts and original accessories licensed by the Hettich company

are allowed to be utilised.

If no original spare parts or no original accessories are used, any guarantee

claim or liability claim against the HETTICH company ceases to exist.

• Information about the operation of the centrifuge please see operating instructions.

• We reserve all rights for these technical documents.

2 Description of the centrifuge

These microprocessor controlled centrifuges mainly consist of the following electrical

components:

• Control panel, microprocessor controlled

− N-control panel, (without control knob)

− S-control panel, (with control knob)

• Supply board, microprocessor controlled

− for centrifuges with cooling

− for centrifuges without cooling

• Frequency converter (motor control), microprocessor controlled

• Motor with speed sensor (speedometer) and imbalance switch

• Braking chopper with brake resistor

• Lid lock

2.1 Control panel (A4, A5)

The control panel is the brain or the master of the centrifuge. This MASTER controls its

SLAVES via a serial data bus system. These SLAVES are the following components:

− supply board

− frequency converter

The control panel carries out the following tasks:

• Managing operator entries and controlling the LCD display

• Saving run programs:

− N-control panel: 3 programs

− S- control panel: 89 programs

• Controlling the components:

− supply board via the serial interface

− frequency converter via the release line and the serial interface

• Evaluating the speed sensor (speedometer)

• Evaluating the imbalance switch

6/92

• Evaluating the frequency converter error message line

• Evaluating the message line lid lock open/closed

• Triggering the relay for the voltage supply of the lid lock when the rotor has standstill

• Temperature measurement and evaluation of the temperature sensor at the top of

the centrifuge chamber

• Routine for input, saving and transmitting temperature offset values (offset values

are transmitted to the supply board each time the mains supply is switched on)

• Type of serial interface:

− N-control panel:

5 Volt interface with three wires (16-pole flat ribbon cable, pole 6, 8 and 11)

− S-control panel:

RS 485 interface via two wires (26-pole flat ribbon cable, pole 19 and 20)

• The voltage supply for the control panel is provided by the supply board via the flat

ribbon cable:

− N-control panel: + 15...20 Volt: pole 1, 2 and GND: pole 15, 16

− S-control panel: + 15...20 Volt: pole 1, 2, 25, 26 and GND: pole 15, 16, 17, 18

2.2 Supply board (A1)

The supply board carries out the following tasks:

• Current supply 18 V DC and 5 V DC for the supply board

• Current supply 18 V DC for the control panel

• Temperature measurement and evaluation of the temperature sensor at the bottom

of the centrifuge chamber

• Evaluating the overtemperature switch in the centrifuge chamber

• Temperature measurement and evaluation of the temperature sensor on the

condenser

• Evaluating the overpressure switch (not in ROTANTA 460 series)

• Evaluating the message line lid lock open/closed

• Evaluating the overtemperature switch on the brake resistor (when the overtempera-

ture switch opens, the frequency converter will be switched off)

• Voltage supply for the speed sensor (speedometer)

• Slot for speed sensor cable and transmission of the speed pulses to the control

panel

• Evaluating the speedometer pulses with regard to standstill

• Triggering the relay for the voltage supply of the lid lock when the rotor has standstill

• Slot for imbalance switch and direct transmission of the imbalance signal to the

control panel

• Processing the individual sensor temperatures:

− calculating the ACTUAL temperature

− controlling the cooling units

− controlling the heating

− controlling the solenoid valve

− controlling the condenser ventilator

7/92

• SLAVE behaviour (the requests and commands of the control panel are transmitted

via the serial interface):

− N-control panel:

5 Volt interface with three wires

− S-control panel:

RS 485 interface with two wires

• The 5 Volt interface with three wires is transferred to a RS 485 interface with two

wires.

Interface for the frequency converter: RS 485 interface via two wires

• Transmitting the main enable signal control panel ⇒ frequency converter

• Transmitting the error line frequency converter ⇒ control panel

• Evaluating the switching statuses of the key-operated switch (e.g. LOCK 1) and

transmitting the information to the control panel via the serial interface (only with

centrifuge with key-operated switch)

• Evaluating the jumper assignment and transmitting the information to the control

panel via the serial interface

− Machine version

− Cooling version

− Service mode

If the processor of the supply board detects an error, it switches off automatically. The

control panel continuously checks the status of the supply board via the serial interface.

The control panel defines the SET temperature and OFFSET temperatures via the

serial interface. The control panel inquires the ACTUAL temperature.

2.3 Frequency converter (A2)

The frequency converter carries out the following tasks:

• Generating the motor current supply

(three-phase current with variable frequency and voltage)

Functional description: The supply voltage is rectified, smoothened and

chopped into a pulse width pattern in three bridge

elements with a microprocessor.

• Monitoring the motor current

• Evaluating the overtemperature switch in the motor

• SLAVE behaviour (the requests and commands of the control panel are transmitted

via the serial interface):

RS 485 Volt interface with two wires

(5-pole flat ribbon cable, pole 2 and 3)

• Evaluating the main enable signal for the frequency converter

(5-pole flat ribbon cable, pole 1)

• Evaluating possible errors and handling the error line

(5-pole flat ribbon cable, pole 4)

• The following are defined by the control panel via the serial interface:

− Speed

− Starting and brake levels

− Control commands START, BRAKE, STOP

8/92

• LED status displays:

In the standby status the red LED illuminates

In the run status the green LED illuminates

In the error status the red LED flashes

If the frequency converter processor detects an error, it switches off automatically and

sets the error line. Then the control panel inquires the type of error via the serial

interface.

2.4 Special features

• The voltage supply of the motor-driven lock is switched via a relay on the supply

board.

This relay can pick up only if the control panel and the supply board have detected a

standstill.

• The N-control panel and the S-control panel are interchangeable.

• Multiprocessor concept:

If a processor stops working, the other two processors still continue monitoring their

area.

If there is a control panel failure, the frequency converter automatically switches off

the drive if no inquiries are made via the interface for longer than 60 seconds.

• Interface concept:

The information transmission is monitored with an additional check sum.

• Hardware concept:

All safety related switches are break contacts. This also ensures that loose contacts

and cable rupture can be detected.

2.5 Braking chopper (A3) / brake resistor (R1)

• The braking chopper transfers the electrical energy produced during braking, from a

voltage of approx. 390 Volt, to the brake resistor in a controlled manner.

• An overtemperature switch protects the brake resistor against fire. If the braking

chopper has a short circuit, the brake resistor becomes hot due to the high current,

the overtemperature switch opens the circuit and two relays on the supply board

separate the frequency converter from the mains supply.

2.6 Motor / tacho system

• The motor is a three-phase asynchronous motor with four pairs of poles.

• A speed sensor (speedometer) which is screwed onto the motor receives

− the rotor code information and

− the speed information (6 pulses per revolution)

from the magnets of the tacho ring attached to the rotor.

• The control panel monitors and regulates the ACTUAL speed.

− Double safety:

In addition, the frequency converter has been programmed in

such a way that it is not possible to set a speed value which is

higher than the permissible rotor speed.

• The control panel and the supply board monitor the rotor standstill.

− Double safety:

The lid can be opened only when the control panel and

the

supply board have detected a standstill.

9/92

2.7 Motor-driven lid lock

• The lid can be opened only if the motor of the lid lock is triggered. To do so, press

the key when the rotor is not moving and mains voltage exists. The jumper for the

lid lock must be plugged to the position "Mot" on the supply board.

• The motor locks the lid only if both lid brackets have actuated both switches in the lid

lock.

• You can start the centrifuge only if the lid is closed. A microswitch on the lid lock

detects the lid lock position.

2.8 Imbalance switch

• A switch (break contact) detects imbalance.

• Imbalance is detected only in running mode (starting, centrifuging and braking).

• If imbalance is detected, the drive is brought to a standstill.

2.9 Key-operated switch (A7, optionally)

• With the key-operated switch different program locks can be select, see chapter

"Option: key-operated switch (only for S-control panel)".

The key position will be displayed.

• If the key is removed, the selected program lock is locked and can be changed no

more.

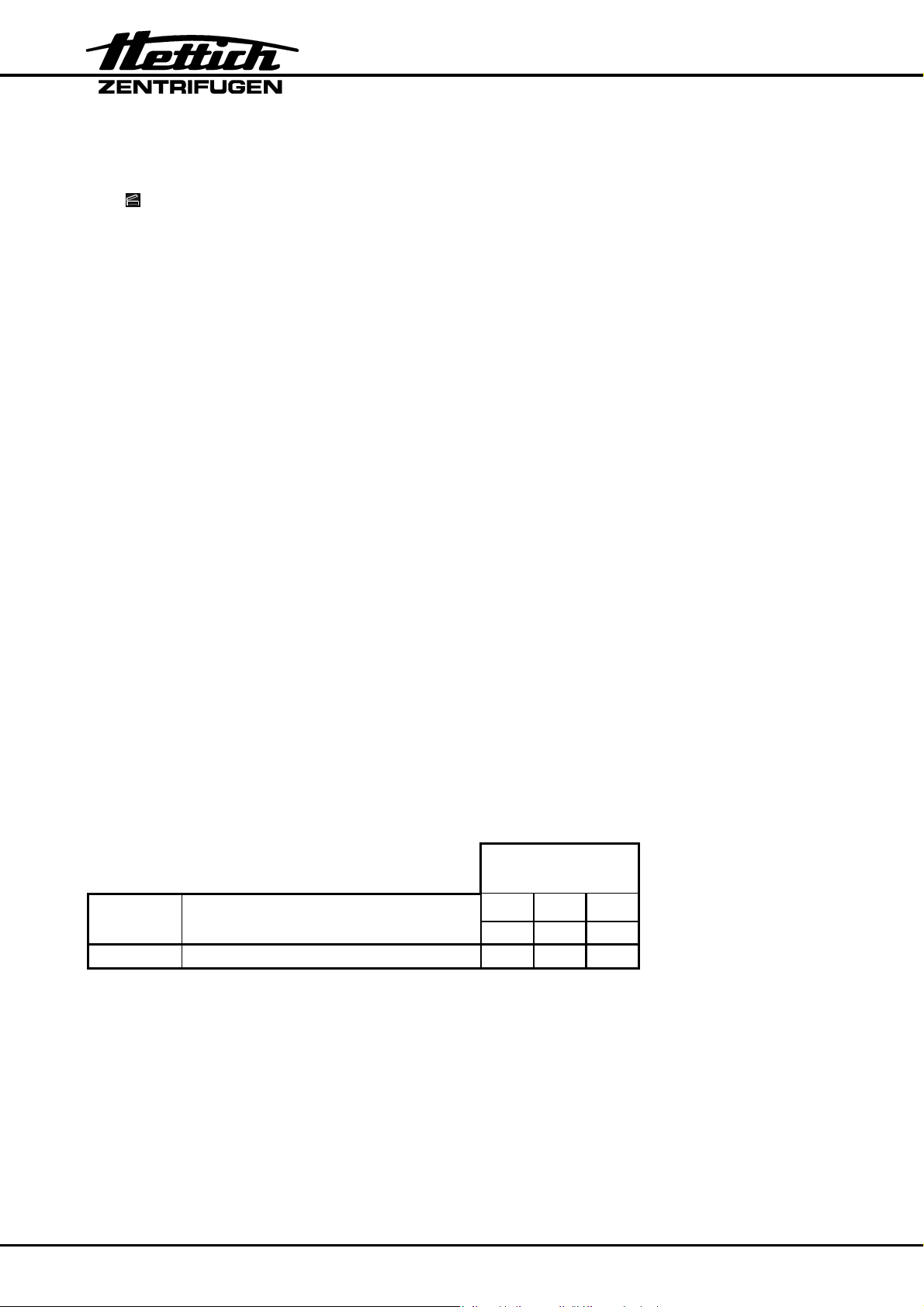

2.10 Machine concept

• The machine version is set with jumper assignment A.4, A.5 and B.7 on the coding

strip of the supply board, see chapter "Setting the machine and cooling version".

• This machine version must comply with the control panel:

− N-control panel: correct EPROM

− S-control panel: correct initialization

• This machine version must comply with the installed and initialized frequency

converter.

• The machine version has a binary code:

Jumper /

Value

Version Machine A.4 A.5 B.7

1 2 16

19 ROTANTA 460 230 V / 115 V X X X

10/92

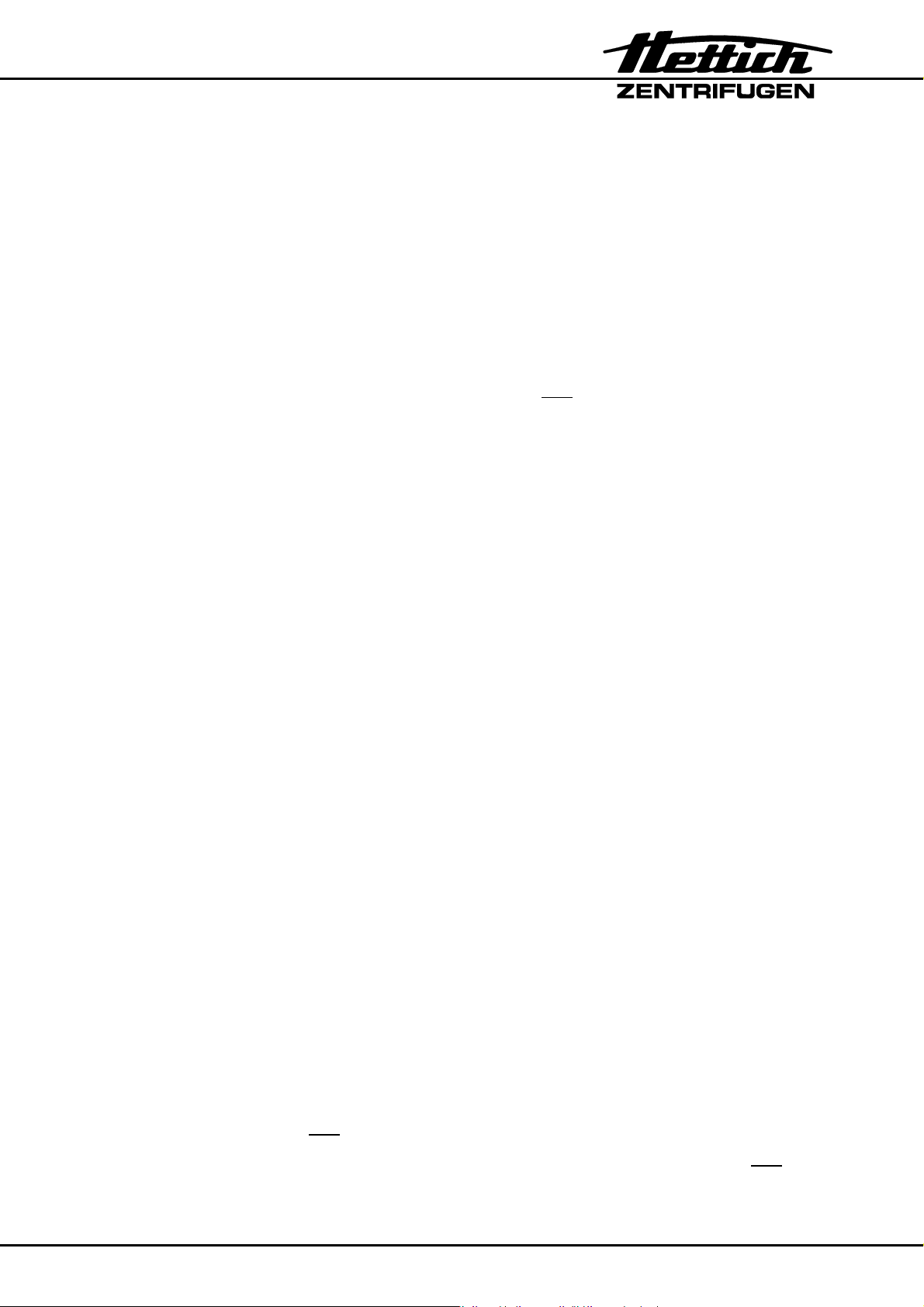

2.11 Cooling system

• The cooling version is set with jumper assignment A.0 to A.2 on the coding strip of

the supply board, see chapter "Setting the machine and cooling version".

• This cooling version must comply with the control panel:

− N-control panel: correct EPROM

− S-control panel: correct initialization

• The cooling version has a binary code:

Jumper /

Value

Version Cooling System A.0 A.1 A.2

1 2 4

0 No cooling system

1 1 compressor X

2 1 compressor, heating/cooling X

7 No cooling system, laboratory thermostat X X X

• Hardware control:

− If the lid is opened, the cooling or heating system switches off.

− If the overtemperature switch is opened, the heating system switches off.

• Software control:

− If the condenser temperature is higher than 58°C, the cooling system switches off.

− The processor on the supply board controls the cooling system.

− The control panel sets the nominal temperature and the temperature of the

temperature sensor T1 on the supply board via the serial interface.

− The control panel inquires the ACTUAL temperature via the serial interface.

− Temperature sensor:

T1 Temperature sensor at the top of the centrifuge chamber

This temperature is processed in the control panel.

T2 Temperature sensor at the bottom of the centrifuge chamber

This temperature is processed on the supply board.

The T2 temperature sensor housing also includes an overtemperature switch.

It switches off the drive in cooling centrifuges when the temperature is > 60°C and

in heating/cooling centrifuges if it is > 80°C.

Temperature determination:

During centrifugation the temperature is determined on the basis of the

relationship between T1 and T2. This occurs in different ways depending on the

speed range (see chapter "Diagram of the cooling version, sensor evaluation").

During standstill, the temperature is determined only with the T2 temperature

sensor.

The switching temperatures depend on the cooling version, see chapter "Diagram

of the cooling version“

T3 Temperature sensor on the condenser

This temperature is used for controlling the ventilator speed.

11/92

∆

g

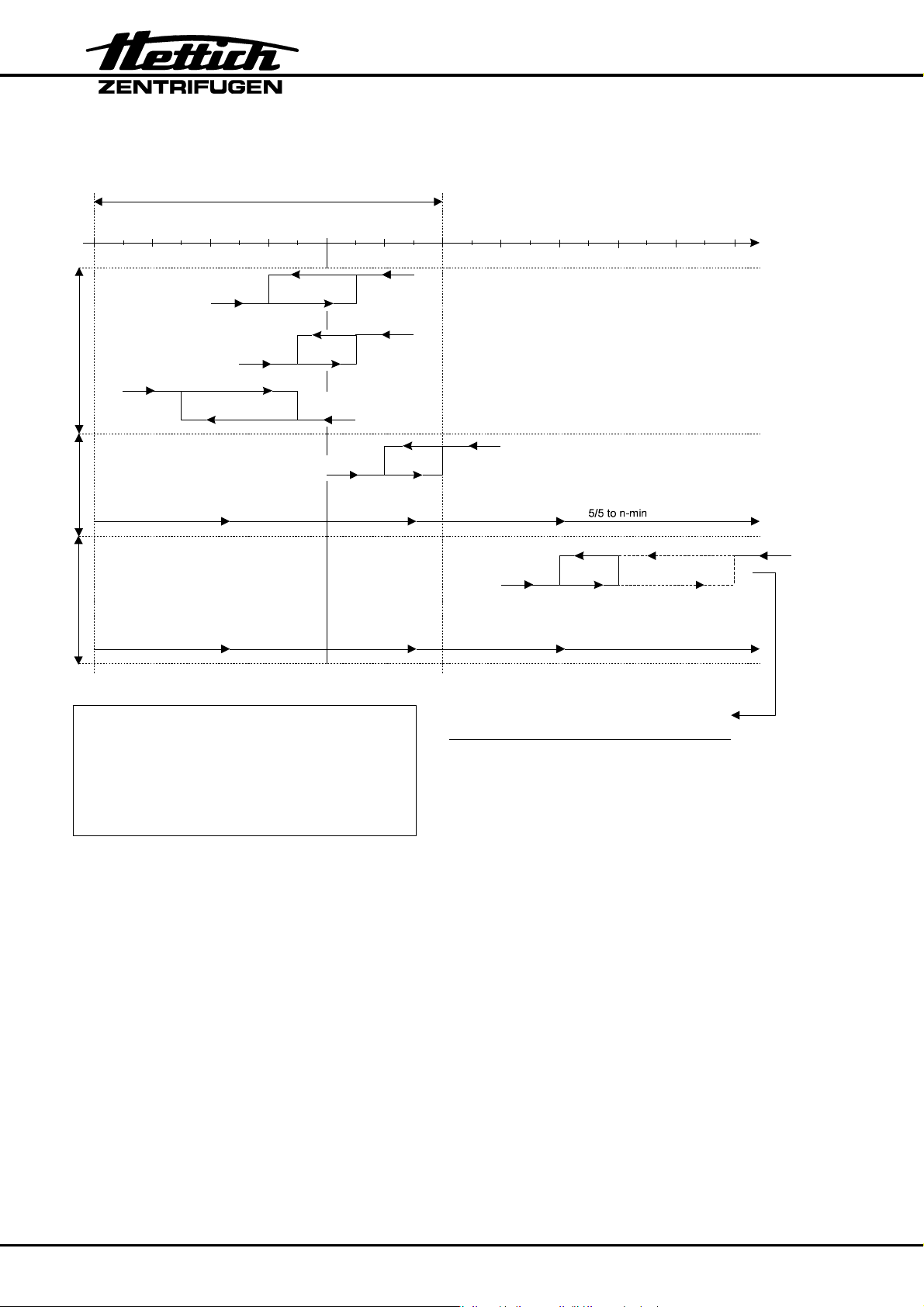

2.11.1 Diagram of the cooling version

-4

centrifugationbrakin

set value -2,5°K

If the set temperature is >= 20° C, the cooling system

standstill

improvement of the displayed temperature

(can b e deac tivated by setting a j umper o n position B.3)

-3

OFF at

set value -1°K

set value -0,5°K

ON at

heating

switched off

remains switched off during standstill!

heating

switched off

heating

-1 +1 +2-2

OFF at

Set value

cooling

cooling

OFF at

set value -0,5°K

OFF at

set value +1°K

ON at

set value +0,5°K

ON at

set value +0,5°K

cooling

+3

ON at

set value +2°K

OFF at

set value +4°K

+4

+5

5/5 to 4/5 of n-max

4/5 to n-min

5/5 to n-min

5/5 to n-min

only sensor T2 only sensor T2

cooling cooling

ON a)

at set value +5°K

+6 +7

at set value +7°K

ON b)

Τ

sensor evaluation

temperature sensor temperature sensor

speed range 5/5 to 4/5 of n-max rotor

speed range 4/5 to 3/5 of n-max rotor

speed range 3/5 to 2/5 of n-max rotor

speed range 2/5 to 1/5 of n-max rotor

speed range 1/5 to n-min

T1 : temperature sensor at the top of the centrifuge chamber

T2 : temperature sensor at the bottom of the centrifuge chamber

T1 : T2

1 : 1

2 : 1

3 : 1

4 : 1

5 : 1

Explanation on:

The cooling will only be switched on 15 s after start

ON a) = cycle time 60 s ON / 6 min OFF

ON b) = cycle time 90 s ON / 6 min OFF

12/92

2.12 Ventilator control

• The ventilator control is a temperature-dependent phase control.

• If the cooling system switches on, the ventilator runs with a fixed start speed.

• When the condenser temperature rises, the ventilator runs faster.

• At 32 °C, or at the latest after 60 seconds, the ventilator speed regulation is

activated and the ventilator speed is regulated to achieve a constant temperature of

34°C at the condenser.

• If the cooling system is switched off and the condenser temperature falls, the

ventilator speed is reduced until minimum speed is achieved.

• If the temperature is lower than 28 °C, the phase control is not triggered, the

ventilator comes to a standstill.

Centrifuge type Start speed Maximum speed Minimum speed

ROTANTA 460 R / RS

230 V / 50 Hz

ROTANTA 460 R / RS

230 V / 60 Hz

• The ventilator runs in a temperature-controlled manner also if the lid is open.

• If there is condenser overtemperature (overpressure in the system) i.e. temperature

sensor T3 indicates a temperature > 58 °C (3.31 V), the cooling system and the

drive are switched off, but the condenser ventilator continues running.

2.13 Ventilator

approx. 2000 RPM approx. 2700 RPM approx. 900 RPM

approx. 1900 RPM approx. 2950 RPM approx. 820 RPM

• The ventilator cools down the refrigerant which flows through the condenser.

• The ventilator speed is controlled with the temperature sensor T3.

• This speed control keeps the pressure in the cooling system constant as far as

possible.

2.14 Offset compensation

• The offset compensation is carried out to balance the tolerances of the temperature

sensors and the electronic system.

After replacing: Offset compensation:

− a temperature sensor

− the supply board

− the control panel

− the control panel EPROM

Compensation of the concerned temperature

sensor.

Compensation of the temperature sensors T2

and T3.

Compensation of the temperature sensor T1

and read out the old offset values of T2 and

T3 and enter them in the new control panel.

Compensation is not required

13/92

2.15 Safety devices

Mains input

Mains switch

Radio interference

suppression filter

Frequency converter

Motor

Cooling system

PE connection

3 Troubleshooting procedures

• Fuses in installation in which centrifuge is installed are intact.

• Supply voltage present at (see circuit diagram):

− Connecting cable

− Appliance plug

− Overvoltage protection (F4)

− Mains switch (Q1)

− Supply board, plugs X21 and X29.

• Look for the displayed error code in the chapter "Error messages".

• Remedy the error according to the instructions.

• Carry out a functional check after every repair and whenever a component is

replaced, see chapter "Functional check after a repair".

overvoltage protection

⇒

with thermal overload protection

⇒

between supply board and frequency converter

⇒

electronically protected

⇒

overtemperature switch > 135 °C

⇒

overtemperature switch in the centrifuge chamber,

⇒

software monitoring of the temperature sensor T3 on the

condenser

additional earthing of the device (only with 115 V model)

⇒

14/92

4 Error messages

4.1 MAINS RESET

• Switch off the mains switch.

• Wait for 10 seconds and then switch on the mains switch again.

4.2 Brief description

Error designation No. Brief description Page

TACHO-ERROR 01 Speedometer pulses break down during rotation 18

TACHO-ERROR 02 No speedometer pulses after start command 18

IMBALANCE (03) Imbalance on motor axle 19

CONTROL-ERROR 04 Lid lock error, lid opened without recognizing that

motor had stopped

N > MAX 05 Excessive speed error, 250 RPM above n-max of

rotor

CONTROL-ERROR 06 Lid lock - error

Message:

from control panel → lid lock open

from supply board → lid lock closed

CONTROL-ERROR 07 Lid lock - error

Message:

from control panel → lid lock closed

from supply board → lid lock open

CONTROL-ERROR 08 Standstill error

Message:

from control panel → standstill

from supply board → no standstill

CONTROL-ERROR 09 Standstill error

Message:

from control panel → no standstill

from supply board → standstill

19

19

20

20

20

20

ROTORCODE 10 Invalid rotor code 21

MAINS INTERRUPT (11) Mains interruption 21

VERSION-ERROR 12 Error in initialization 21

N < MIN 13 Speed error, slippage is too great 22

15/92

Error designation No. Brief description Page

CONTROL-ERROR 21 N-control panel - error: speed 22

CONTROL-ERROR 22 N-control panel - error: I²C-bus 22

CONTROL-ERROR 23 N-control panel - error: display memory 22

CONTROL-ERROR 24 N-control panel - error: clock timeout 22

CONTROL-ERROR 25 N-control panel - error: EEPROM 22

CONTROL-ERROR 27 N-control panel - error: EPROM defective 23

N > ROTOR-MAX --- N-control panel - error: nominal speed is higher

than permitted rotor speed

or nominal RCF is higher

than permitted rotor RCF

CONTROL-ERROR 26 Incorrect feedback, control panel input do not

recognize the expected signal

SER I/O-ERROR 30 No connection between control panel and serial

interface

SER I/O-ERROR 31 No connection between frequency converter and

serial interface

SER I/O-ERROR 32 No connection between supply board and serial

interface

SER I/O-ERROR 33 Data incorrectly transmitted from the componentry 24

SER I/O-ERROR 34 Data incorrectly transmitted between control panel

and frequency converter

SER I/O-ERROR 35 Data incorrectly transmitted between control panel

and supply board

SER I/O-ERROR 36 No acknowledgement (NAK) from frequency

converter to control panel

23

22

23

23

24

24

24

25

SER I/O-ERROR 37 No acknowledgement(NAK) from supply board to

control panel

°C / *-ERROR 50 Overpressure in cooling system 25

°C / *-ERROR 51 Overtemperature on condenser 26

°C / *-ERROR 52 Overtemperature in centrifuge chamber 26

°C / *-ERROR 53 Temperature sensor at the bottom of the centrifuge

chamber is defective

°C / *-ERROR 54 Temperature sensor at the top of the centrifuge

chamber is defective

°C / *-ERROR 55 Temperature sensor on the condenser is defective 28

LOCK-ERROR 57 Program locking is defective 28

°C / *-ERROR 58 Temperature deviation too high 29

16/92

25

27

27

Error designation No. Brief description Page

FU/CCI-ERROR 60 Faulty release signal to frequency converter 29

FU/CCI-ERROR 61 Frequency converter - error: computing section 30

FU/CCI-ERROR 62 Frequency converter - error: undervoltage 30

FU/CCI-ERROR 63 Frequency converter - error: overcurrent 30

FU/CCI-ERROR 64 Frequency converter - error: overvoltage 31

FU/CCI-ERROR 65

FU/CCI-ERROR 66

FU/CCI-ERROR 67 Frequency converter - error: overtemperature in

FU/CCI-ERROR 68 Frequency converter - error: overtemperature in

FU/CCI-ERROR 69 Frequency converter - error: EEPROM 33

CONTROL-ERROR 90 S-control panel - error: EPROM 33

CONTROL-ERROR 91 S-control panel - error: RAM 33

CONTROL-ERROR 92 S-control panel - error: difference between EEPROM

CONTROL-ERROR 94 S-control panel - error: Watchdog 34

CONTROL-ERROR 95 S-control panel - error: inadmissible operative state 34

N > ROTOR - MAX 96 S-control panel - error: nominal speed is higher

Frequency converter - error: I ∗ t switch-off for motor

Frequency converter - error: I ∗ t switch-off of

frequency converter

motor (external)

frequency converter

and RAM

than permitted rotor speed

or nominal RCF is higher

than permitted rotor RCF

31

31

32

32

34

35

CONTROL-ERROR 97 S-control panel - error: EEPROM 35

CONTROL-ERROR 99 S-control panel - error: hardware failure in error

management

INDEFINITE S-control panel - error: not specified error 36

BATT Battery is empty 36

35

17/92

4.3 Description and elimination of errors

TACHO - ERROR 01

Error During centrifugation the speedometer pulses are interrupted.

Consequences

of the error

Cause of error/

measurements

Delete error

code

TACHO - ERROR 02

Error After starting the centrifugation the control panel receives no

The rotor slows down until it stops.

After the rotor stops, there is a DC braking for 30 sec.

A MAINS RESET during slowing-down causes a DC braking for 3

minutes.

After the DC braking, the “open the lid” release takes place.

Further cooling until the SET temperature is achieved.

• Speed sensor (speedometer) is defective or loose contact in the

plug. Measure the speedometer pulses on the supply board (A1) at

plug X5, pin 4 - pin 2.

• Flat ribbon cable to the control panel (A4, A5) or flat ribbon cable to

the frequency converter (A2) is defective.

• Supply board (A1) or control panel (A4, A5) or frequency converter

(A2) is defective.

Open the lid. Turn the rotor by hand and carry out a MAINS RESET

while the rotor is rotating.

− In the S-control panel, CONTROL - ERROR 08 could appear in the

display after TACHO - ERROR 01 is deleted.

speedometer pulses.

Consequences

of the error

Cause of error/

measurements

Delete error

code

The rotor slows down until it stops.

After the rotor stops, there is a DC braking for 30 sec.

A MAINS RESET during slowing-down causes a DC braking for 3 min.

After the DC braking, the “open the lid” release takes place.

Further cooling until the SET temperature is achieved.

• Start implemented without rotor

• Motor is not connected

• Motor is defective

• Speed sensor (speedometer) is defective or loose contact in the

plug. Measure the speedometer pulses on the supply board (A1) at

plug X5, pin 4 - pin 2.

• Flat ribbon cable to the control panel (A4, A5) or flat ribbon cable to

the frequency converter (A2) is defective.

• No enable signal at the frequency converter (A2) (after a start, the

green LED on the frequency converter must illuminate), also refer to

FU / CCI – ERROR 60.

• Supply board (A1) or control panel (A4, A5) or frequency converter

(A2) is defective.

Open the lid. Turn the rotor by hand and carry out a MAINS RESET

while the rotor is rotating.

18/92

IMBALANCE (03)

Error Imbalance on the motor axle.

Consequences

of the error

Cause of error

Delete error

code

CONTROL - ERROR 04

Error Lid lock was opened during centrifugation.

Consequences

of the error

Cause of error

The centrifuge slows down until the “open the lid” release occurs.

Further cooling until the SET temperature is achieved.

• Weight difference in the rotor components

• Supporting lugs are not lubricated

• Wrong IMBALANCE MODE has been set (see chapter "Imbalance

Mode")

• Imbalance switch (S2) is not connected

• Imbalance switch (S2) is defective

• Loose contact in the cable or in the plug

• Flat ribbon cable to the control panel (A4, A5) is defective

• Control panel (A4, A5) or supply board (A1) is defective

Open the lid or carry out a MAINS RESET.

The centrifuge slows down until the “open the lid” release occurs.

Further cooling until the SET temperature is achieved.

• Lid lock (Y1) is defective and can be opened during centrifugation.

• Loose contact in the cable or in the plug

• Flat ribbon cable to the control panel (A4, A5) is defective

• Control panel (A4, A5) or supply board (A1) is defective

Delete error

code

N > MAX 05

Error Overspeed. The speed detected by the speed sensor is 250 RPM

Consequences

of the error

Cause of error

Delete error

code

Open the lid and close it again or carry out a MAINS RESET.

In the S-control panel, CONTROL – ERROR 06 or CONTROL –

ERROR 08 could appear in the display after CONTROL – ERROR 04

is deleted.

higher than the maximum rotor speed (n-max rotor).

The centrifuge slows down until the “open the lid” release occurs.

Further cooling until the SET temperature is achieved.

• The insulation of the speed sensor cable is defective

• Loose contact in the speed sensor cable

• Speed sensor is defective

• Flat ribbon cable to the control panel (A4, A5) is defective

• Control panel (A4, A5) or frequency converter (A2) or supply board

(A1) is defective

Carry out a MAINS RESET.

19/92

CONTROL - ERROR 06

Error Lid lock message is faulty.

Control panel indicates: lid lock open

Supply board indicates: lid lock closed

Consequences

of the error

Cause of error

The centrifuge slows down until the “open the lid” release occurs.

Further cooling until the SET temperature is achieved.

• Flat ribbon cable to the control panel (A4, A5) is defective

• Control panel (A4, A5) or supply board (A1) is defective

Delete error

Carry out a MAINS RESET.

code

CONTROL - ERROR 07

Error Lid lock message is faulty.

Control panel indicates: lid lock closed

Supply board indicates: lid lock open

Consequences

of the error

Cause of error

The centrifuge slows down until the “open the lid” release occurs.

Cooling system is switched off.

• Flat ribbon cable to the control panel (A4, A5) is defective

• Supply board (A1) or control panel (A4, A5) is defective

Delete error

Carry out a MAINS RESET.

code

CONTROL - ERROR 08

Error Standstill message is faulty.

Control panel indicates: standstill

Supply board indicates: no standstill

Consequences

of the error

Cause of error

Braked slow-down.

Further cooling until the SET temperature is achieved.

• Flat ribbon cable to the control panel (A4, A5) is defective

• Control panel (A4, A5) or supply board (A1) is defective

Delete error

Carry out a MAINS RESET.

code

CONTROL - ERROR 09

Error Standstill message is faulty.

Control panel indicates: no standstill

Supply board indicates: standstill

Consequences

of the error

Cause of error

Braked slow-down.

Further cooling until the SET temperature is achieved.

• Flat ribbon cable to the control panel (A4, A5) is defective

• Control panel (A4, A5) or supply board (A1) is defective

Delete error

code

20/92

Carry out a MAINS RESET.

ROTORCODE 10

Error An invalid rotor code was read in during start-up.

Consequences

of the error

Cause of error

The centrifuge slows down until the “open the lid” release occurs.

Further cooling until the SET temperature is achieved.

• Magnetic code on the rotor is defective

• Speedometer system is defective

• Loose contact in speed sensor plug

• Motor is rotating in the wrong direction

Delete error

Open the lid or carry out a MAINS RESET.

code

MAINS INTERRUPT (11)

Error Mains interruption during centrifugation

Consequences

of the error

The centrifuge slows down until the “open the lid” release occurs.

− Switching on the mains during centrifugation causes slowing-down

until the “open the lid” release occurs.

− Switching on the mains when the rotor has stopped brings about

the “open the lid” release

Cause of error

• Power failure

• Loose contact in the electrical connections

• Flat ribbon cable to the control panel (A4, A5) is defective

Delete error

code

Open the lid and press the

− The error cannot be deleted with a MAINS RESET.

START

key

VERSION - ERROR 12

Error Differences in the initialization of supply board (jumper assignment

A.0 – A.7, B.7), control panel (EPROM) or frequency converter.

− In the S-control panel, VERSION – ERROR 12 also appears after

CONTROL – ERROR 92 is displayed

Consequences

Further operation is not possible.

of the error

Cause of error

• Incorrect jumper assignment (A.0 – A.7 and B.7) on the coding strip

of the supply board

Plug the jumper A.0 – A.7 and B.7 as described in chapter "Setting

the machine and cooling version".

• Carry out a MAINS RESET.

• Plug the service jumper at B.1 on the supply board, carry out a

MAINS RESET and re-initialize the machine

• A wrong EPROM is plugged in the control panel

• Supply board (A1) is defective

Delete error

Carry out a MAINS RESET.

code

21/92

N < MIN 13

Error Insufficient speed, motor slippage is too large.

The centrifuge control can readjust the speed by max. 5 % (control

limit).

This error is displayed if the rotor speed (ACTUAL speed) is lower

than the SET speed - 5%.

Consequences

of the error

Cause of error

Delete error

code

CONTROL - ERROR 21 - 25

Error Internal error in the N-control panel

Consequences

of the error

Cause of error

Delete error

code

CONTROL - ERROR 26

The centrifuge slows down until the “open the lid” release occurs.

Further cooling until the SET temperature is achieved.

• Motor is not running smoothly (bearing damage)

• Motor is defective

• Motor has a short-circuited coil (coil is defective)

• Loose contact in the electrical connections

• Frequency converter (A2) is defective

• Enable signal to the frequency converter (A2) was interrupted

during centrifugation (also see FU / CCI - ERROR 60).

Open the lid and carry out a MAINS RESET.

The centrifuge slows down until the “open the lid” release occurs.

• N-control panel (A4) is defective.

Carry out a MAINS RESET.

Error Incorrect feedback, control panel input does not recognize the

expected signal.

Consequences

of the error

Cause of error

Delete error

code

22/92

The centrifuge stops with error message.

• Control panel (A4, A5) is defective.

• Supply board (A1) is defective

• Flat ribbon cable between supply board (A1) and control panel (A4,

A5) is defective.

Carry out a MAINS RESET.

CONTROL - ERROR 27

Error Error in the EPROM of the N-control panel

Consequences

The centrifuge slows down until the “open the lid” release occurs.

of the error

Cause of error

Delete error

• EPROM is defective

Carry out a MAINS RESET.

code

N > ROTOR-MAX

Error Error in the entered program

Consequences

Further operation is not possible.

of the error

Cause of error SET speed or SET RCF is higher than the permissible rotor speed or

permissible rotor RCF.

Delete error

code

Open the lid.

Reduce the speed or RCF in the entered program to the permissible

rotor speed or permissible rotor RCF.

SER I/O - ERROR 30

Error The control panel has no connection to the components supply board

and frequency converter via serial interface.

Consequences

The centrifuge slows down until the “open the lid” release occurs.

of the error

Cause of error

• Flat ribbon cable to the control panel (A4, A5) is defective

• Supply board (A1) or control panel (A4, A5) is defective

Delete error

Carry out a MAINS RESET.

code

SER I/O - ERROR 31

Error The control panel has no connection to the component frequency

converter via the serial interface.

Consequences

of the error

Cause of error

The centrifuge slows down until the “open the lid” release occurs.

Further cooling until the SET temperature is achieved.

• Flat ribbon cable to the frequency converter (A2) is defective

• No voltage at the frequency converter (A2)

• Overtemperature switch (F2) on the brake resistor has opened or is

not connected

• Supply board (A1) or control panel (A4, A5) or frequency converter

(A2) is defective.

• Plug X5 on the frequency converter (A2) is not plugged or plugged

at the wrong position

Delete error

code

Carry out a MAINS RESET.

23/92

SER I/O - ERROR 32

Error The control panel has no connection to the component supply board via

the serial interface.

Consequences

The centrifuge slows down until the “open the lid” release occurs.

of the error

Cause of error

• The false machine or cooling version is set on the supply board (A1).

• Supply board (A1) or control panel (A4, A5) is defective.

Delete error

Carry out a MAINS RESET.

code

SER I/O - ERROR 33

Error The control panel does not receive correct data from the connected

components (supply board, frequency converter).

Consequences

The centrifuge slows down until the “open the lid” release occurs.

of the error

Cause of error

• Flat ribbon cable to the control panel (A4, A5) is defective

• Supply board (A1) or control panel (A4, A5) or frequency converter

(A2) is defective.

Delete error

Carry out a MAINS RESET.

code

SER I/O - ERROR 34

Error The control panel does not receive correct data from the frequency

converter.

Consequences

of the error

Cause of error

The centrifuge slows down until the “open the lid” release occurs.

Further cooling until the SET temperature is achieved.

• Flat ribbon cable to the control panel (A4, A5) is defective

• Flat ribbon cable to the frequency converter (A2) is defective

• Supply board (A1) or control panel (A4, A5) or frequency converter

(A2) is defective.

Delete error

Carry out a MAINS RESET.

code

SER I/O - ERROR 35

Error The control panel does not receive correct data from the supply board.

Consequences

The centrifuge slows down until the “open the lid” release occurs.

of the error

Cause of error

• Flat ribbon cable to the control panel (A4, A5) is defective

• Supply board (A1) or control panel (A4, A5) is defective

Delete error

Carry out a MAINS RESET.

code

24/92

SER I/O - ERROR 36

Error The frequency converter cannot acknowledge a command and sends

the NAK signal to the control panel.

NAK (no acknowledge).

Consequences

of the error

Cause of error

Delete error

code

SER I/O - ERROR 37

Error The supply board cannot acknowledge a command and sends the

Consequences

of the error

Cause of error

Delete error

code

°C / * - ERROR 50

The centrifuge slows down until the “open the lid” release occurs.

Further cooling until the SET temperature is achieved.

• Flat ribbon cable to the control panel (A4, A5) is defective

• Flat ribbon cable to the frequency converter (A2) is defective

• Frequency converter (A2) is defective

• Supply board (A1) or control panel (A4, A5) is defective

Carry out a MAINS RESET.

NAK signal to the control panel. NAK (no acknowledge)

The centrifuge slows down until the “open the lid” release occurs.

• Flat ribbon cable to the control panel (A4, A5) is defective

• Supply board (A1) is defective

• Control panel (A4, A5) or frequency converter (A2) is defective

Carry out a MAINS RESET.

Error Overpressure in the cooling system (only in centrifuges with an

overpressure switch on the plug X11)

No overpressure switch has been integrated in the ROTANTA 460

series. On the supply board, pin 2 and pin 3 on plug X11 are

connected with each other.

Consequences

of the error

Cause of error Plug X11 on the supply board (A1) is not plugged or has a loose

Delete error

code

The centrifuge slows down until the “open the lid” release occurs.

Cooling system is switched off.

contact.

Carry out a MAINS RESET.

25/92

°C / * - ERROR 51

Error Overtemperature in the condenser, temperature > 58 °C.

Consequences

of the error

Cause of error/

measurements

Delete error

code

°C / * - ERROR 52

Error Overtemperature in the centrifuge chamber

Consequences

of the error

Cause of error/

measurements

The centrifuge slows down until the “open the lid” release occurs.

Cooling system is switched off.

• Measurement on the supply board (A1) at plug X1, pin 1 - pin 2

(plug X1 plugged)

Voltage at 25 °C : 2.98 V (± 20 mV)

at 58 °C : 3.31 V (± 20 mV)

• Condenser is dirty

• Ventilator is defective

• Cable of the temperature sensor on the capacitor (T3) is defective

• Loose contact in the plug

• Supply board (A1) is defective

Carry out a MAINS RESET.

The centrifuge slows down until the “open the lid” release occurs.

Cooling system is switched off.

• Measurement on the supply board (A1) at plug X2, pin 1 - pin 2

(plug X2 plugged)

Voltage : 0 V (overtemperature switch closed)

Voltage : 18 V (overtemperature switch open)

• Cable of the overtemperature switch is defective

• Loose contact in the plug

• Supply board (A1) is defective

Delete error

code

26/92

Carry out a MAINS RESET.

°C / * - ERROR 53

Error The temperature sensor at the bottom of the centrifuge chamber has a

short circuit or has opened the circuit.

Voltage < 0.50 V = short circuit

Voltage > 4.50 V = circuit has been opened

Consequences

of the error

Cause of error/

measurements

Delete error

code

°C / * - ERROR 54

Error The temperature sensor at the top of the centrifuge chamber has a

Consequences

of the error

The centrifuge slows down until the “open the lid” release occurs.

Cooling system is switched off.

• Measurement on the supply board (A1) at plug X2, pin 4 - pin 5

(plug X2 plugged)

Voltage at 25 °C : 2.98 V (± 20 mV)

A temperature change of 1 °K causes a voltage change of 10 mV.

• Temperature sensor at the bottom of the centrifuge chamber (T2) is

defective

• Sensor cable is defective

• Loose contact in the plug

• Supply board (A1) is defective

Carry out a MAINS RESET.

short circuit or has opened the circuit.

Permissible range: 2.50 V = -23 °C to 3.77 V = +104 °C

The centrifuge slows down until the “open the lid” release occurs.

Cooling system is switched off.

Cause of error/

measurements

Delete error

code

• Measurement on the control panel (A4, A5) at plug X100 or X2, pin

1 - pin 2 (plug X100 or X2 plugged)

Voltage at 25 °C : 2.98 V (± 20 mV)

A temperature change of 1 °K causes a voltage change of 10 mV.

• Temperature sensor at the top of the centrifuge chamber (T1) is

defective

• Sensor cable is defective

• Loose contact in the plug

• Control panel (A4, A5) is defective

Carry out a MAINS RESET.

27/92

°C / * - ERROR 55

Error The temperature sensor on the condenser has a short circuit or has

opened the circuit.

Voltage < 0.50 V = short circuit

Voltage > 4.50 V = circuit has been opened

Consequences

of the error

Cause of error/

measurements

Delete error

code

LOCK - ERROR 57

Error The analogous value in the program locking plug X27 indicates that

Consequences

of the error

The centrifuge slows down until the “open the lid” release occurs.

Cooling system is switched off.

• Measurement on the supply board (A1) at plug X1, pin 1 - pin 2

(plug X1 plugged)

Voltage at 25 °C : 2.98 V (± 20 mV)

A temperature change of 1 °K causes a voltage change of 10 mV.

• Temperature sensor on the capacitor (T3) is defective

• Sensor cable is defective

• Loose contact in the plug

• Supply board (A1) is defective

Carry out a MAINS RESET.

the voltage is outside the voltage range.

Permissible voltage range: 0.9 V - 3.8 V.

Further operation is not possible.

Cause of error/

measurements

Delete error

code

• Measurement on the supply board at plug X27, pin 1 - pin 2 (plug

X27 plugged)

Key-operated switch position 1 (LOCK1) ≈ 1.4 V

2 (LOCK2) ≈ 2.1 V

3 ≈ 3.3 V

• Key-operated switch board is defective

• Cable to the key-operated switch board is defective

• Loose contact in the wire layout

• Supply board (A1) is defective

Carry out a MAINS RESET.

28/92

Loading...

Loading...