Operating and installation instructions

LegaDrive

2

(Copy of the original)

Operating and installation instructions

under EC Machinery Directive 2006/42/EC,

Annex VI for partly completed machinery

Lifting column system for an electrically

height adjustable workstation

Type: LegaDrive

Manufacturer: Paul Hettich GmbH & Co. KG

Vahrenkampstr. 12-16

32278 Kirchlengern

Year built: 2014

Date / eective: 2018-05 / 03

Foreword

Customer Service

Hettich Marketing- und Vertriebs GmbH & Co. KG

Vahrenkampstr. 12-16

D-32278 Kirchlengern

Please contact the person responsible at the

Hettich Customer Service.

Copyright to these operating and installation instructions

© 2014 held by Paul Hettich GmbH & Co. KG

The copyright to these operating and installation instructions

remains with Paul Hettich GmbH & Co. KG.

These operating and installation instructions are intended for

personnel installing the LegaDrive. It contains regulations and

drawings of a technical nature that must not be duplicated

either in whole or in part, distributed, used without

permission for advertising purposes or communicated to

others.

Warning

Read these operating and installation instruc-

tions carefully in order to obtain a thorough

understanding of the lifting column and how to

install it. Install the lifting column as described

in these instructions so as to avoid injury and

damage to the lifting column. Do not install the

lifting column on the basis of suppositions. Keep

these operating and installation instructions to

hand and consult them if you are in any doubt as

to carrying out any particular procedure.

Before installing the lifting column, settle any

unanswered questions first by consulting Paul

Hettich GmbH & Co. KG.

These operating and installation instructions are

a separate part of the overall documentation. The

overall documentation must be made available

to installation, operating and servicing personnel.

3

6.2.2.2 Replacing the battery 29

6.2.3 Connecting optional components 29

6.2.4 Plugging in power supply cable 30

6.3 Overall configuration (example) 30

7. Operation 31

7.1 Basic functions 31

7.1.1 Upward desk top movement 32

7.1.2 Downward desk top movement 32

7.2. Display functions 33

7.3. Display lock 33

7.4 Extended functions 34

7.4.1 Memorising a desk top position 34

7.4.2 Adjusting desk top to a memorised position 35

7.4.3 Changing desk top position height display 35

7.4.4 Manual reset 36

7.5 Software related functions 36

7.5.1 Low speed areas 36

7.5.2 ON time monitor 36

7.5.3 Safety zone 37

7.5.4 Pedestal stop and shelf stop positions 37

7.5.5 Plug detection 39

7.5.6 Auto detect number of drives 39

7.5.7 Collision detection (Drive back) 39

7.5.8 Changing desk height unit (cm or inch) 40

7.5.9 Returning control unit to factory settings

(S0 menu) 40

7.5.10 Cascading 42

8. Troubleshooting 43

8.1 Safety advice 43

8.2 Malfunctions 44

8.2.1 Potential malfunctions and how to remedy them 44

8.2.2 Faults indicated on the handset display 45

8.2.3 Control click codes 46

9. Servicing and maintenance 47

9.1 Safety advice 47

9.2 Checking safety devices 49

9.3 Labelling, information signs 49

10. Taking out of service 50

11. Disposal 51

11.1 Protecting the environment 51

11.2 Scrapping 52

12. EC Declaration of Incorporation 53

Contents

Subject matter Page

Foreword 2

Contents 3

List of figures 4

1. Introduction 5

1.1 Information on signs, symbols and markings 5

1.2 Information for the owner 6

2. General 7

2.1 Intended use 7

2.2 Foreseeable incorrect use 7

2.3 Package contents 8

2.4 Liability 9

3. Safety 10

3.1 Safety advice for the user company 11

3.2 Safety information for the operating personnel 11

3.3 Safety advice for maintenance work 12

3.4 Noise 12

3.5 Hazards from electrical energy 12

3.6 Particular hazard spots 13

3.7 Residual risk 13

3.8 Training/instruction 14

3.9 Personnel qualification 14

4. Description of the product 15

4.1 Technical specifications 15

4.2 Controls 15

4.2.1 Power supply cable 15

4.2.2 Control unit 16

4.2.3 Handset 16

4.3 Protective guards 18

4.3.1 Mechanical protective guards 18

4.3.2 Software related protective guards 18

5. Transportation and installation 19

5.1 Transportation 19

5.2 Installation 19

5.2.1 Installing lifting column 20

5.2.2 Installing control unit 21

5.2.3 Installing handset 21

5.2.3.1 Installing LegaDrive Basic handset 21

5.2.3.2 Installing LegaDrive Touch Basic handset 22

5.2.3.3 Installing LegaDrive Touch Basic Inlay handset 22

5.2.3.4 Installing LegaDrive Touch Inlay handset 23

5.2.3.5 Installing LegaDrive Touch Comfort handset 24

5.2.3.5.1 Notes on Push to open function 25

5.2.3.5.2 Notes on control panel 25

5.2.3.6 Installing the remote handset Basic 26

6. Start-up 27

6.1 Starting up for the first time 28

6.2 Startup procedure 28

6.2.1 Plugging in drives/lifting columns 28

6.2.2 Plugging in handset 29

6.2.2.1 Programming remote handset 29

4

List of figures

Figure Page

Fig. 1: Example showing overall product 8

Fig. 2: Lifting column (here: moved in and out) 8

Fig. 3: Example of a handset and a control unit 8

Fig. 4: Various power supply cables 15

Fig. 5: Compact-e-2 control unit 16

Fig. 6: Compact-e-3 control unit 16

Fig. 7: LegaDrive Basic handset 16

Fig. 8: LegaDrive Touch Basic handset 16

Fig. 9: LegaDrive Touch Basic Inlay handset 16

Fig. 10: LegaDrive Touch Inlay handset 16

Fig. 11: LegaDrive Touch Comfort handset 17

Fig. 12: Remote handset Basic 17

Fig. 13: Receiver module for remote handsets 17

Fig. 14: Lifting column protective enclosure 18

Fig. 15: Attaching lifting column (viewed from below)

to example skid 20

Fig. 16: Attaching lifting column (viewed from above)

to example desk 20

Fig. 17: Fixing points on control unit 21

Fig. 18: LegaDrive Basic handset 21

Fig. 19: Attaching LegaDrive Basic handset to

example desk 21

Fig. 20: LegaDrive Touch Basic handset 22

Fig. 21: Attaching LegaDrive Touch Basic handset to

example desk 22

Fig. 22: LegaDrive Touch Basic Inlay handset 22

Fig. 23: Cut out for installing LegaDrive Touch Basic Inlay

handset with rubber fins 22

Fig. 24: Attaching LegaDrive Touch Basic Inlay handset to

example desk 22

Fig. 25: LegaDrive Touch Inlay handset 23

Fig. 26: Cut out for installing LegaDrive Touch Inlay handset

with rubber fins 23

Fig. 27: Attaching LegaDrive Touch Inlay handset to

example desk 23

Fig. 28: LegaDrive Touch Comfort handset 23

Fig. 29: Position for installing LegaDrive Touch Comfort handset

24

Fig. 30: Position of screw holes for installing LegaDrive Touch

Comfort handset 24

Fig. 31: Attaching LegaDrive Touch Comfort handset to

example desk 24

Fig. 32: Pressing the control panel to automatically extend it 25

Fig. 33: Lifting and pushing the control panel to retract it 25

Fig. 34: Cable loop of 10 cm min. for the push-to-open feature

25

Fig. 35: Control panel detached from above from its anchorage

25

Fig. 36: Spring end hooked into the lug below the slide 25

Fig. 37: Pushing the control panel into the slide 25

Fig. 38: Remote handset Basic 26

Fig. 39: Inserting / replacing the battery Button cell CR 2032 26

Fig. 40: Installing the remote handset Basic 26

Fig. 41: Sockets on control unit 27

Fig. 42: Sockets on control unit 28

Fig. 43: Sockets on control unit 29

Fig. 44: Remote receiver 29

Fig. 45: Battery change 29

Fig. 46: Sockets on control unit 29

Fig. 47: Example configuration 30

Fig. 48: Display on LegaDrive Touch handset 33

Fig. 49: The key symbol indicates activated

display lock 33

Fig. 50: The LegaDrive Touch Comfort handset lock is activated

and deactivated by swiping to the left or right 33

Fig. 51: The LegaDrive Touch Inlay handset lock is activated and

deactivated by swiping to the left or right 33

Fig. 52: Container-Stop- / Shelf-Stop-Position 37

5

1.1 Information on signs, symbols and markings

The safety advice in the operating and installation instructions is

structured as follows:

These operating and installation instructions are intended to

make it easier for you to become familiarised with the lifting

column system and use its capabilities in the proper manner.

These operating and installation instructions contain impor-

tant information on installing the lifting column system safely

and in the proper manner. Following them will help to avoid

hazards, repair costs and down times, enhance reliability and

prolong service life.

Existing national regulations on preventing accidents and on

protecting the environment are also applicable.

These operating and installation instructions must be read

and applied by all persons instructed to carry out work on the

system's components, e.g.:

· Installation

· Operation

· including troubleshooting while working, care, disposal

· Maintenance

· Servicing, inspection, repair and

· Transportation.

1. Introduction

Danger

Danger!

This danger note draws attention to an immedi-

ately dangerous situation that will lead to death

or serious injuries if the safety measures are not

followed.

Warning

Warning!

This danger note draws attention to a potentially

dangerous situation that may lead to death or

serious injuries if the safety measures are not

followed.

Caution

Caution!

This danger note draws attention to a potenti-

ally dangerous situation that may lead to minor

or slight injuries if the safety measures are not

followed.

i

Note

This advice draws attention to potential damage

to property or to a process of particular interest /

importance that may occur if the safety measu-

res are not followed.

6

1. Introduction

1.2 Information for the owner

In addition to these operating and installation instructions and

the accident prevention regulations in force in the country of use

or at the place of application, it is also necessary to follow the

recognised code of safe and proper working practice.

Without the manufacturer's consent, the owner of the lifting

column system must not make any changes, additions or modifi-

cations to it that may aect safety.

Components used must meet the technical requirements defined

by the manufacturer.

Only ever deploy trained or instructed personnel and clearly de-

fine personnel responsibilities with regard to operating, servicing

and repair.

i

Note

Always perform a hazard analysis of your fini-

shed product (height adjustable workstation)

so you are able to respond to potential residual

hazards (e.g. in the form of structural measures

or warnings in the

operating instructions and/or safety warnings on

your product).

7

2.2 Foreseeable incorrect use

The situations above describe some of the residual hazards which,

despite being impermissible, may occur and harm the health of

sta.

The owner must observe the safety requirements defined in the

German Ordinance on Industrial Safety and Health (Betriebssi-

cherheitsverordnung).

2.1 Intended use

This lifting column system is only intended for installing and then

being used as an electrically height adjustable sitting / standing

workstation in accordance with EN 527 in indoor commercial en-

vironments. This means the lifting column system is only intended

for this purpose.

Any other use beyond this, e.g. outside the technical specifica-

tions (see Section 4.1), is deemed to be incorrect use.

In this context, always follow Section 3 "Safety".

Intended use also includes following the operating, servicing and

maintenance conditions prescribed by the manufacturer.

Unauthorised changes to the lifting column system will result in

the loss of product liability and liability on the part of the manu-

facturer for resultant damage.

Any other use beyond this is deemed to be non-intended use. The

manufacturer shall not be liable for any damage this causes, with

the risk involved being borne solely by the user.

2. General

Warning

Warning!

This danger note draws attention to a potentially

dangerous situation that may lead to death or

serious injuries if the safety measures are not

followed.

i

Note

Do not use the lifting column system in a private

environment but only in commercial premises.

Warning

Hazards may occur if the system is used incor-

rectly!

The following situations in particular are

deemed to be foreseeable hazardous situations:

· Persons may manipulate protective guards.

· Persons may remove separating protective

guards and then put the lifting column system

into operation.

· Persons may use the desk support in private

envirionments.

· Persons may use the desk support for lifting

persons or loads.

· Persons could incorrectly install the LegaDrive

lifting column and use it in pull direction.

· Persons may perform servicing or troubleshoo-

ting work etc. on the desk support without

disconnecting the lifting column system from

the power supply.

· Persons may make adjustments to the desk

support despite the presence of other persons

in the hazard zone.

· Persons may ignore the desk support's maxi-

mum loading capacity.

· Persons may open, remove or damage enclosu-

res of system components.

8

i

Note

Further variants can be found in the Hettich

catalogue

If used, the following components are part of the

overall system:

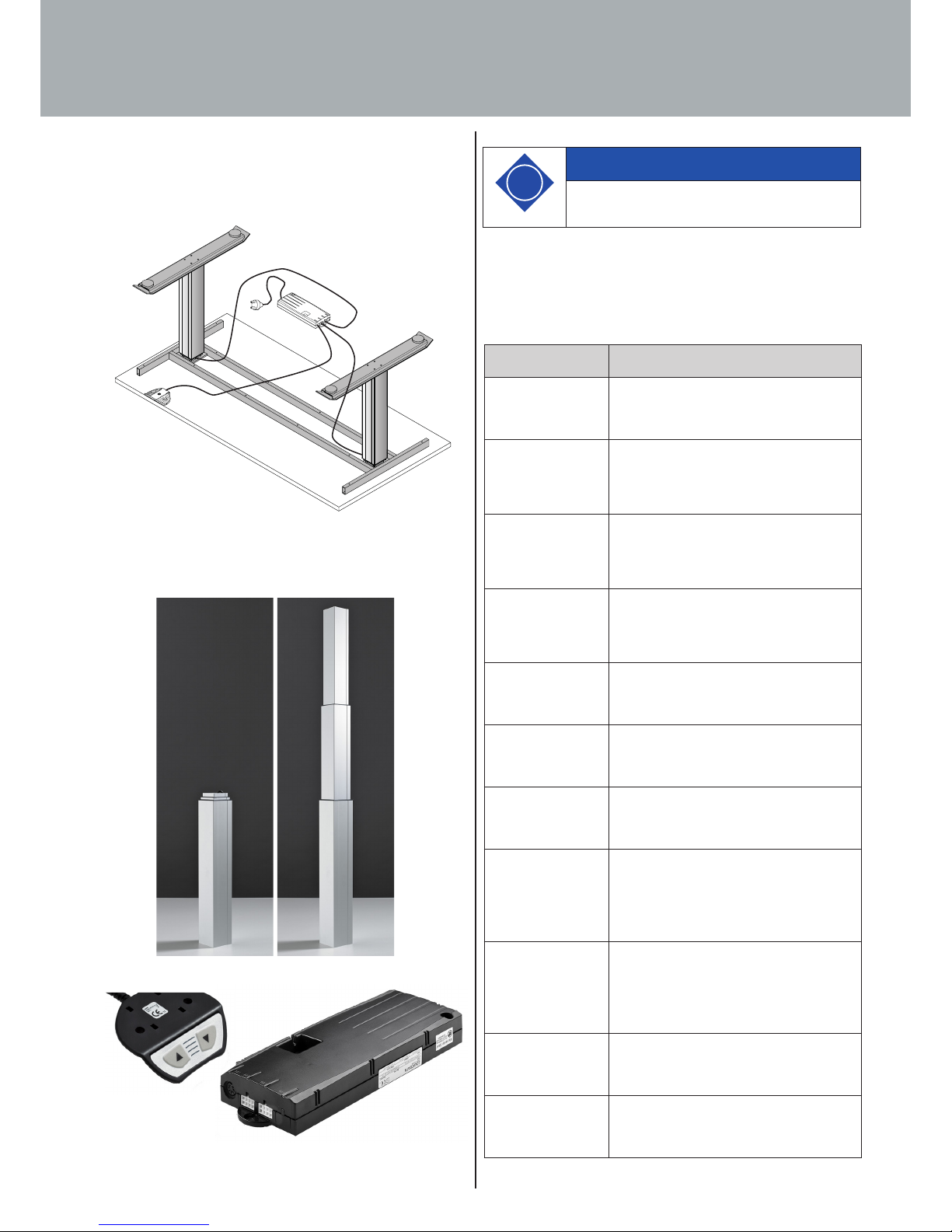

2.3 Package contents

Depending on requirements, the following components may be

used for installing an electrically height adjustable workstation.

Fig. 1: Example showing overall product

The following components (including cabling) are available for

the system:

Fig. 2: Lifting column (here: moved in and out)

Fig. 3: Example of a handset and a control unit

2. General

Component Description

Lifting column

LegaDrive Q 90 A

LegaDrive power-assisted lifting column.

Square 90 mm x 90 mm.

Anodised aluminium.

Control unit

LegaDrive

Compact-e-2-EU

Compact-e-2-EU control unit for

LegaDrive.

For 2 LegaDrive lifting columns and mains

voltage 230V/50Hz.

Control unit

LegaDrive

Compact-e-3-EU

Compact-e-3-EU control unit for

LegaDrive.

For up to 3 LegaDrive lifting columns and

mains voltage 230V/50Hz.

Control unit

LegaDrive

Compact-e-3-US

Compact-e-3-US control unit for

LegaDrive.

For up to 3 LegaDrive lifting columns and

mains voltage 120V/60Hz.

Handset

LegaDrive Basic

Handset Basic for LegaDrive.

With up and down buttons.

Installation under desk top.

Handset

LegaDrive Touch

Basic

Handset Touch Basic for LegaDrive.

With up and down buttons.

Installation under desk top.

Handset

LegaDrive Touch

Basic Inlay

Handset Touch Basic Inlay for LegaDrive.

With up and down buttons.

Recessed in desk top.

Handset

LegaDrive Touch

Inlay

Handset Touch Inlay for LegaDrive.

With up and down buttons and memory

function.

With digital display for height setting.

Recessed in desk top.

Handset

LegaDrive Touch

Comfort

Handset Touch Comfort for LegaDrive.

With up and down buttons and memory

function.

With digital display for height setting.

Installation under desk top.

Power supply cable

LegaDrive CH

Power supply cable for LegaDrive type J.

Mainly used in Switzerland.

Power supply cable

LegaDrive DK

Power supply cable for LegaDrive type K.

Mainly used in Denmark.

M1

HS

M2

M3

9

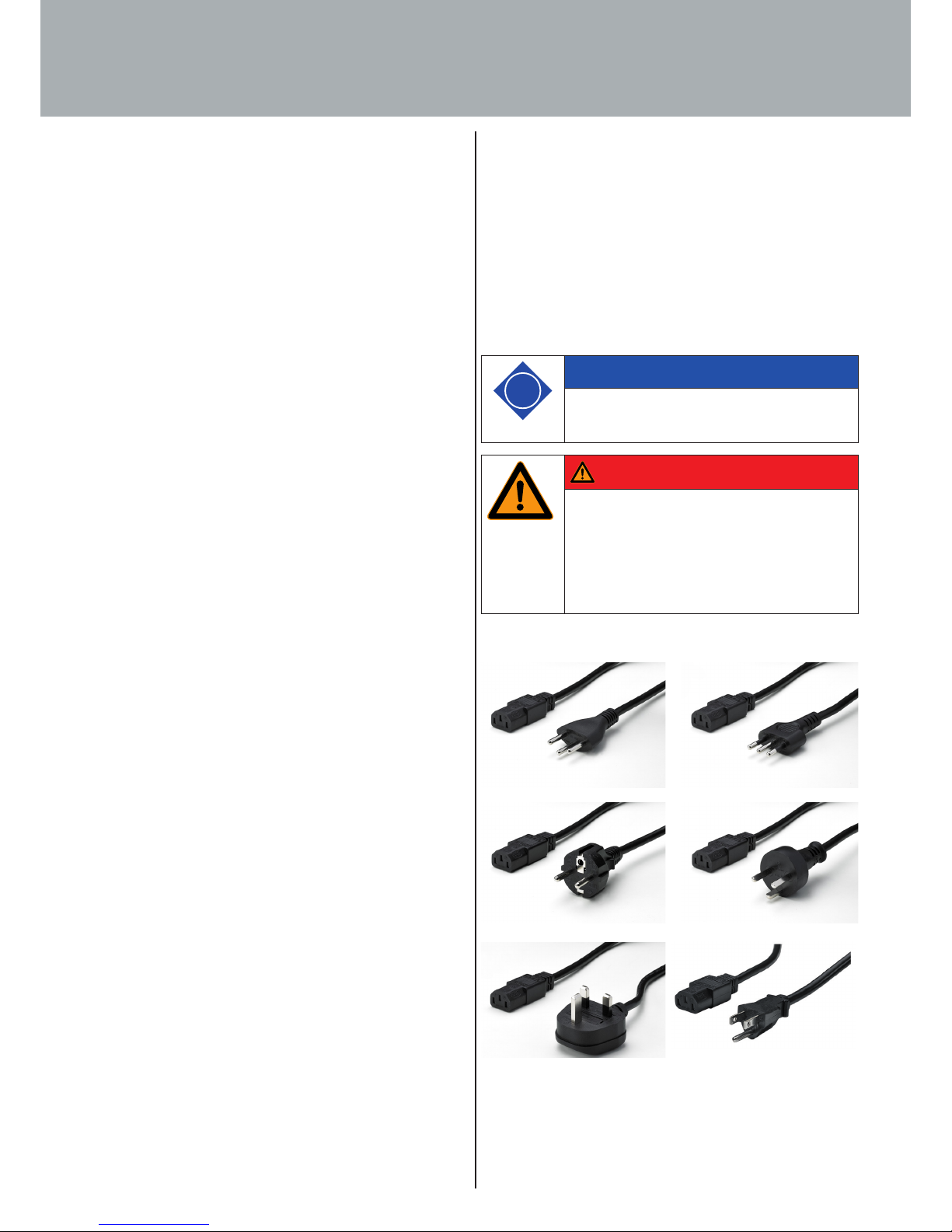

Power supply cable

LegaDrive EU

Power supply cable for LegaDrive type F.

"SchuKo" plug, mainly used in

Germany, Austria, BeNeLux, France,

Spain, Sweden, Norway, Finland etc.

Power supply cable

LegaDrive IT

Power supply cable for LegaDrive type L.

Mainly used in Italy.

Power supply cable

LegaDrive UK

Power supply cable for LegaDrive type G.

Mainly used in the United Kingdom.

Power supply cable

LegaDrive NA

Power supply cable for LegaDrive type B.

Mainly used in the USA, Canada, Mexico

etc.

2.4 Liability

Defects must only be rectified by competent personnel.

The manufacturer's liability is restricted to damage caused

while using the system in the intended manner. The

manufacturer shall not be liable for safety defects not yet

identifiable on the basis of the current state of the art.

Failure to observe

· safety advice for operating personnel

· advice on particular hazards

· the ban on unauthorised modifications and changes

· ban on using components not approved by the

manufacturer

shall rule out any liability on the part of the manufacturer for the

consequences.

2. General

10

The following hazard markings must be axed directly to the

desk where they are visible:

The following hazard zone markings are used in the operating

and installation instructions (in accordance with Technical Rule

for Working Places ASR A1.3):

3. Safety

Danger

Danger from electric shock!

Working on live components in the improper

manner presents a danger to life!

Work on electrical equipment must only be car-

ried out by authorised electricians!

Warning

Risk of injury!

The lifting columns pose a risk of injury when

they are moving. Before attempting any work,

disconnect the lifting column system from power

supply and take action to prevent the power

supply cable from being plugged back in unin-

tentionally!

Caution

Tripping hazard!

The desk support and power supply cable pose of

risk of injury from tripping over.

Caution

Hand injuries!

Hand could be crushed or otherwise injured.

Never reach into moving parts!

Only set the desk support in motion when there

is nobody in the hazard zone!

Warning

Danger of crushing!

Do not position any objects of parts of the body

below the desk support or between the cross

members. Failure to observe this warning may

result in serious injuries or death!

max.

KG

Warning

Danger of crushing!

Do not overload!

Only load the desk support up to the maximum

intended load. Overloading may result in breaka-

ge and serious injuries!

11

3.2 Safety advice for operating personnel

The desk support must only be put into operation in a fully ins-

talled and operational state.

The generally recognised code of occupational health and safety

as well as accident prevention regulations must be observed.

The desk support must only be operated if all protective guards

and safety-related equipment, e.g. protective claddings or enclo-

sures, are in working order and undamaged.

On putting the system into operation, the operator must make

sure that all safety equipment and protective guards as well as

the controls are in correct working order and free of damage.

Work on the desk support must only be carried out by instruc-

ted, skilled personnel. Only skilled personnel who have received

training or instruction must be deployed.

Immediately leave the area around the desk if it starts moving

unintentionally. Immediately disconnect the lifting column

system LegaDrive from the power supply. Have the desk support

repaired by a specialised company. Only put the desk support

back into operation after it has been repaired.

Immediately take the desk support out of operation if you notice

anything unusual (noises, fumes, smoke etc.) at the desk support.

Immediately disconnect the lifting column system LegaDrive from

the power supply. Have the desk support repaired by a specialised

company. Only put the desk support back into operation after it

has been repaired.

Immediately take the desk support out of operation if the safety

devices (e.g. up/down switch) are not working properly.

Only operate the desk support in a commercial environment.

Do not use the desk support on an uneven standing surface. It

could tip over.

3.1 Safety advice for the user company

All persons entrusted with operating the lifting column system

LegaDrive (include line managers) must familiarise themselves

with the section on "Safety". The safety advice must be followed.

The lifting column system LegaDrive must only be operated if

it is in proper working order. The user company will issue clear

responsibilities, e.g. for servicing, cleaning or repair, and ensure

that the persons carrying out this type of work have received the

training necessary for it.

The safety regulations and employers' liability insurance associ-

ation regulations applicable in the owner's country must also be

observed. Refrain from any work that adversely aects operating

safety.

The operating personnel will check the desk support for changes

or malfunctions, report such to the safety ocer responsible and,

if necessary, take this product out of operation.

Only appropriate tools must be used for the work that needs to

be done; remove tools after completing work.

3. Safety

Warning

Never

· operate the desk support if there is anyone in

the hazard zone.

· operate the desk support in a private environ-

ment.

· remove covers or enclosures and take protective

guards out of operation.

· continue operating the desk support if changes

occur that adversely aect safety.

· manipulate or circumvent protective guards.

· use for normal operation without protective

guards in place.

12

Do not make any structural changes to the lifting column system.

Observe the lifting column system‘s maximum ON time.

Only replace faulty components with new, genuine parts from

the manufacturer. When doing so, follow these operating and

installation instructions.

Make sure operating consumables and auxiliary substances as

well as replaced parts are disposed of safely and in an environ-

ment-friendly manner.

3.4 Noise

The lifting column system‘s A-weighted equivalent continuous

sound level is less than 60 dB (A).

3.5 Hazards from electrical energy

Only connect the lifting column system to the power supply after

it has been completely installed.

Regularly check the desk support‘s electrical equipment in ac-

cordance with national regulations (in Germany, the regulations

on preventing accidents).

No not use any cable with damaged insulation. You could get

an electric shock. Immediately instruct a specialised company to

replace damaged cables with undamaged ones.

Do not route the power supply cables near sources of heat. Ex-

posure to heat could damage the cable. A fire could be started or

you could get an electric shock.

Disconnect the lifting column system from the power supply if

it is to be left unused for a prolonged period or when it is not in

use.

Observe the lifting column system's ON time

of 10 %. This means, for example, that 1 minute of continuous

operation must be followed by a pause of 9 minutes or that

operation for a maximum of 2 minutes must be followed by an

18 minute pause.

No not load the desk support beyond the permissible weight limit

(see "Technical Specifications" in Section 4.1).

Allow a distance of at least 25 mm for adjacent elements moving

in relation to each other. This applies to the entire range of travel.

3.3 Safety advice for maintenance work

Please make sure that the product is always in perfect condition

and, if necessary, have it checked at regular intervals by skilled

personnel.

Do not perform any repairs to the desk or components yourself.

Maintenance work must only be performed by the manufacturer‘s

skilled personnel or under the manufacturer‘s supervision.

If the lifting column system is completely shut down for servicing

and repair work, it must be prevented from switching back on

unexpectedly.

For maintenance measures use tools that are appropriate for the

work involved.

Servicing and repair work must only be carried out by the owner‘s

skilled personnel.

Work on electrical components must only be carried out by a

qualified electrician or by instructed persons under the direction

and supervision of a qualified electrician in accordance with the

rules of electrical engineering.

If safety devices need removing for servicing and repair work,

they must be refitted and checked as soon the work has been

completed.

Always tighten screw connections that have come loose during

servicing and repair work.

3. Safety

13

3.6 Particular hazard spots

When adjusting the desk support, make sure there is nobody in

the vicinity. They could be injured.

When setting up the desk support, make sure it is unable to col-

lide with anything (e.g. sloping roofs, structural situation, mobile

pedestals, wastepaper baskets etc.) in any position to which is

can be moved.

Also make sure it cannot collide with objects

(e.g. IT equipment) on the desk either.

Allow a safety distance at the side of at least 25 mm to any other

item of furniture.

Make sure that cables employed are of sucient length for safe

use throughout the entire range of travel.

3.7 Residual risk

The lifting column system reflects the state of the art and is built

in accordance with recognised safety regulations. All the same,

the user or third parties may still be exposed to hazards.

It must only be used:

· for the intended purpose and

· in an absolutely safe state.

3. Safety

Warning

Risk of injury!

Never remove safety devices or render them inef-

fective by making changes to the desk support!

Malfunctions presenting a safety risk must be

rectified without delay!

Before attempting any servicing and cleaning

work, switch the lifting column system o and

prevent it from switching back on again!

Caution

Residual hazards!

Handling the lifting column system involves resi-

dual hazards that could not be limited by design

measures.

Pay attention to the residual hazards described

in these operating and installation instructions

as well as in the end product's documentation!

i

Note

Always perform a hazard analysis of your fini-

shed product (height adjustable workstation)

so you are able to respond to potential residual

hazards (e.g. in the form of structural measures

or warnings in the operating instructions and/or

safety warnings on

your product).

Warning

Risk of injury!

Make sure that no unauthorised persons (e.g.

small children, persons under the influence of

medication etc.) play with or handle your pro-

duct and the lifting column system.

14

3.8 Training/instruction

As owner, you are obliged to inform and instruct the

operating personnel in respect of applicable legal and

accident prevention regulations as well as the safety devices

fitted. In this context, bear in mind the varying specialised quali-

fications of your sta.

3.9 Personnel qualification

Only persons over the age of 16 are allowed to set up and work

on the desk support.

The fitters must have read and understood the operating and

installation instructions.

3. Safety

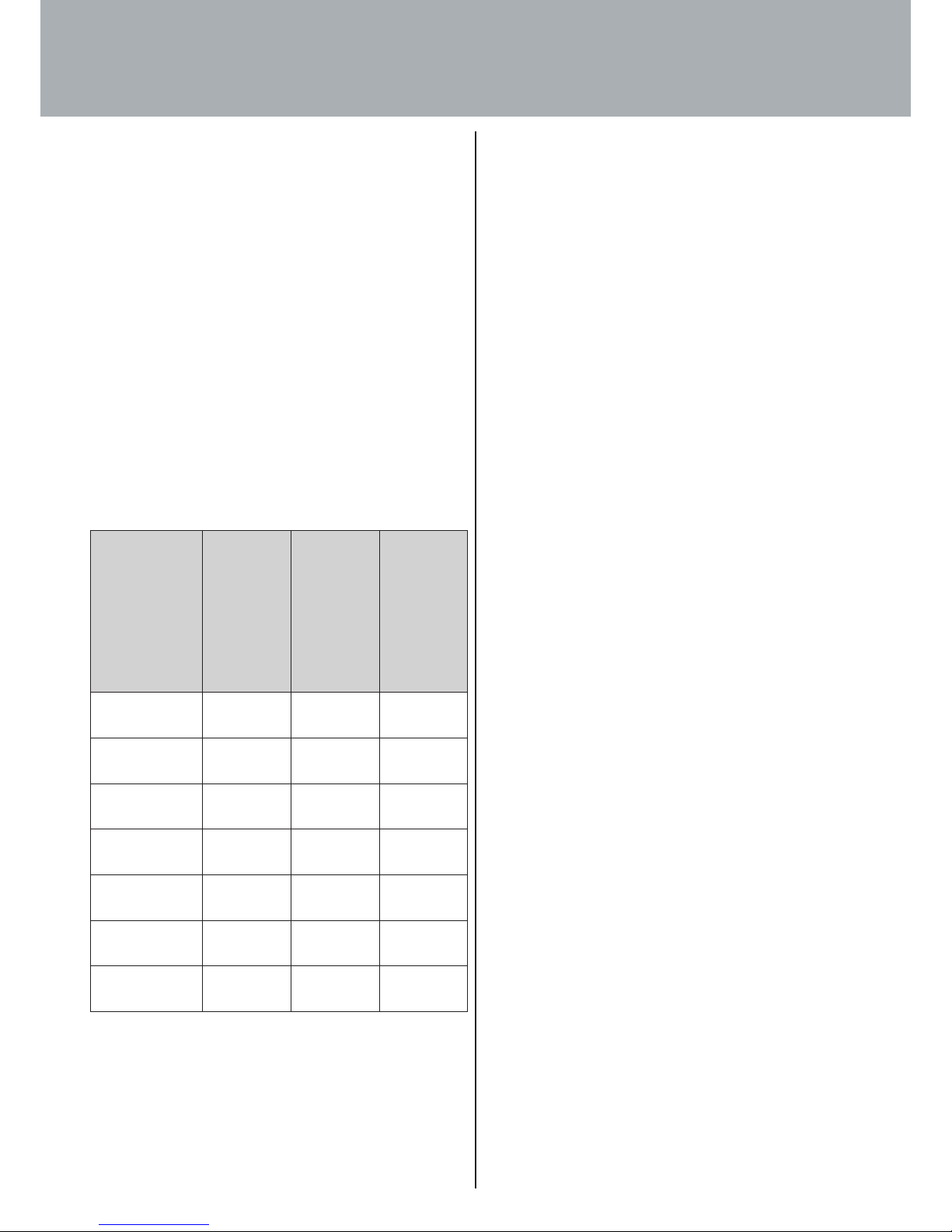

Persons

Activity

Specially

trained

personnel

Instructed

operating

personnel

Instructed

persons with

specialised

training

(mechanical /

electrical

engineering)

Handling

X

Start-up

X

Setting up,

setting

X X

Operation

X

Servicing

X

Troubleshooting

X X

Destruction/

recycling

X

15

4.2 Controls

The lifting column system's controls are described below.

4.2.1 Power supply cable

Depending on place of use, the power supply cables are available

in dierent versions.

Fig. 4: Various power supply cables

4.1 Technical specifications

Designation: Lifting column system for an electri-

cally height adjustable workstation

Type: LegaDrive

Place of installation: Indoors (commercial)

Power supply: 230 V; 50 Hz / 120 V; 60 Hz

(depending on the control unit used)

Minimum height: approx. 575 mm

Maximum height: approx. 1250 mm

max. Loading capacity

per column: 80 kg, dynamic

Desk use: - for

2 columns, dynamic load of

120 kg,

- for 3 columns, dynamic load of

120 kg

- for each additional column +40 kg

(Example: Desk with 5 columns

120 kg + 40 kg + 40 kg = 200 kg)

(in each at the centre above the desk

columns)

Number of lifting columns for

Compact-e-2 control unit:

2 columns

Compact-e-3 control unit:

1, 2 or 3 columns

Max. speed: 40 mm/s

Usage cycle: 10 %

(2 min. of continuous operation /

18 min. out of operation)

Ambient temperature

during operation: 5 °C to 40 °C

Storage /

transportation temperature: -40 °C to 70 °C

Air humidity

during operation

(non condensing): 5 % to 85 %

Max. noise level: 60 dB (A)

Protection class: IP 20

Unauthorised changes and modifications to the lifting column

system are not permitted for safety reasons and rule out any

liability on the part of the manufacturer for any resultant

damage.

4. Description of the product

Danger

Danger from electric shock!

Working on live components in the improper

manner presents a danger to life!

Work on electrical equipment must only be car-

ried out by authorised electricians!

i

Note

Please pay attention to the information under

"Package contents".

16

4.2.3 Handset

The handset is used for controlling the lifting column system.

Depending on the scope of functions, the handsets are available

in dierent versions.

Fig. 7: LegaDrive Basic handset

Fig. 8: LegaDrive Touch Basic handset

Fig. 9: LegaDrive Touch Basic Inlay handset

Fig. 10: LegaDrive Touch Inlay handset

4.2.2 Control unit

Depending on the number of lifting columns needed and the

desired mains voltage, the control units are available in dierent

versions.

Fig. 5: Compact-e-2 control unit

Fig. 6: Compact-e-3 control unit

i

Note

Please pay attention to the information under

"Package contents".

4. Description of the product

i

Note

Please pay attention to the information under

"Package contents".

17

Fig. 11: LegaDrive Touch Comfort handset

Remote handsets:

Fig. 12. Remote handset Basic

Fig. 13. Receiver module for remote handsets

4. Description of the product

i

Note

Refer to the following sections for a detailed

description of the functions.

i

Note

Remote handsets muss be firmly attached and

used within sight of the furniture.

Loading...

Loading...