Hettich HettInfo II Operating Manual

A

e

G

E

I

a

A

5

Hett

nfo II

Rev.

01 / 10.19

ndr

as Hettich

N

Oper

mbH & Co.

ting Manual

KG

B095

EN

3

n

xinfww

2

wMo

B

h

7

7

b

b

e

e

s

v

o

u

c

m

e

b

G

o

o

dreas Hettic

A

Fö

hrenstraße 1

Ph

one +49 (0)

Fa

+49 (0)

o@hettichla

w.hettichla

019 by Andr

©

All

rights reserv

o

ner.

GmbH & C

2, D-78532 T

461 / 705-0

461 / 705-11

.com, servi

.com

as Hettich G

d. No part of

. KG

ttlingen / G

25

e@hettichla

bH & Co. K

this publicati

rmany

.com

n may be rep

roduced with

ut the prior written permiss

ion of the copyright

difications re

A

0955EN / Re

erved!

. 01 / 10.19

2/

0

Contents

1

How to use these operating instructions ................................................................................................................. 4

2 Symbol meanings ................................................................................................................................................... 4

3 Intended use ........................................................................................................................................................... 5

4 Notes on safety ....................................................................................................................................................... 6

5 Scope of delivery .................................................................................................................................................... 6

6 Commissioning the barcode unit ............................................................................................................................. 7

7 Operation of the barcode scanner .......................................................................................................................... 7

7.1 Installing the barcode scanner ......................................................................................................................... 7

7.2 Testing the barcode scanner ........................................................................................................................... 7

7.3 Scanning the barcode ...................................................................................................................................... 8

7.4 Scanning at the centrifuge ............................................................................................................................... 8

7.5 Workflow .......................................................................................................................................................... 8

7.6 Barcode scanner does not work ...................................................................................................................... 8

8 Barcodes ................................................................................................................................................................. 9

8.1 Usable Barcodes ............................................................................................................................................. 9

8.2 Explanation of the barcodes used for control purposes ................................................................................... 9

9 Use of HettInfo II ................................................................................................................................................... 10

9.1 Switch on ....................................................................................................................................................... 10

9.2 Functions and display elements in the main screen ...................................................................................... 10

9.3 Scanning procedure ...................................................................................................................................... 11

9.3.1 Prerequisite for starting the procedure ................................................................................................... 11

9.3.2 Scanning the barcode sets ..................................................................................................................... 11

9.3.3 Detailed view .......................................................................................................................................... 13

9.4 Start and sequence of centrifugation ............................................................................................................. 13

9.5 Setup menu ................................................................................................................................................... 14

9.5.1 Settings .................................................................................................................................................. 15

9.5.1.1 HettInfo Application ......................................................................................................................... 15

9.5.1.2 HettInfo Settings .............................................................................................................................. 16

9.5.1.3 Process Data Setup ........................................................................................................................ 18

9.5.1.4 CSV-File Setup ................................................................................................................................ 18

9.5.1.5 Automatic Database Backup ........................................................................................................... 19

9.5.1.6 Automatic Process Data Export ....................................................................................................... 19

9.5.1.7 Centrifuge Name ............................................................................................................................. 20

9.5.2 Data Management .................................................................................................................................. 20

9.5.2.1 Export .............................................................................................................................................. 21

9.5.2.2 Import .............................................................................................................................................. 22

9.5.3 Blood Bag History ................................................................................................................................... 24

9.5.4 Error Logbook ......................................................................................................................................... 26

9.5.5 System Information ................................................................................................................................. 27

9.5.6 Open Source Licences ........................................................................................................................... 28

10 Creation of the list of operator IDs ..................................................................................................................... 29

11 Free and Open Source Software ....................................................................................................................... 30

3/30

3

e

g

n

e

e

m

e

s

u

m

mCon

m

s

mSym

2Use

m

m

mCan

m

u

m

u

m

e

m

t

m

o

m

g

m

a

r

s

a

c

e

e

d

e

e

c

e

a

E

i

m

t

a

f

a

e

c

h

a

n

o

o

r

a

s

n

a

r

a

o

c

e

e

d

N

e

p

e

a

c

w

e

i

i

n

e

1

•

Before usin

•

The operati

•

If the devic

2

How to us

Symbol m

Sy

Att

Thi

Fail

Sy

Wa

Sy

Sy

Thi

Sy

200

Sy

Wai

Sy

Suc

Sy

Sy

Vol

Sy

Vol

Sy

Dat

Sy

Set

Sy

Err

Sy

Bri

Sy

Hist

these oper

the device,

g instruction

is set up at

anings

bol in this do

ntion, genera

symbol indic

re to observ

bol on the d

rning laser ra

bol on the d

nection for th

bol in this do

symbol indic

bol on the d

bol for separ

/96/EG (WE

in the countr

bol HettInfo I

ting for action

bol HettInfo I

cessful Scan

bol HettInfo I

cel

bol HettInfo I

me muted

bol HettInfo I

me

bol HettInfo I

bol HettInfo I

ings (Setup

bol HettInfo I

r

bol HettInfo I

htness

bol HettInfo I

ory

ting instruc

ead the oper

are a part o

different loc

ument:

l danger zone

ates safety-r

these instru

vice and in t

iation.

vice:

barcode sc

ument:

ates importa

vice:

te collection

E). The devi

es of the Eur

I:

I:

Process

I:

I:

I:

I:

I:

enu)

I:

I:

I:

ions

ting instructi

the device. T

tion, the ope

.

levant inform

tions may re

is document:

nner.

t facts.

of electrical a

e belongs to

pean Union

ns and obse

hey must alw

ating instructi

tion and indi

ult in damag

nd electronic

group 8 (me

s well as in

ve them.

ys be kept r

ns must be

ates possibl

to property

quipment, a

ical devices).

orway and S

adily availabl

rovided with

dangerous s

nd personal i

cording to th

itzerland.

e.

t.

ituations.

njury.

Directive

4/

0

I

p

h

r

o

o

V

o

o

r

o

c

o

p

o

o

o

o

o

o

o

o

e

e

e

b

m

d

f

b

e

n

i

s

m

t

s

t

n

e

t

r

o

5

m

s

3

The

for thi

Anot

& Co.

Obse

part

Symb

Detail

Symb

Move l

Symb

Move

Symb

OK/Ac

Symb

Backs

Symb

Time

Symb

Back

Symb

Switch

Symb

Switch

Symb

Safely

Symb

Detect

Symb

Export

Symb

Import

ntended us

rogram pres

s purpose.

er use or on

KG is not lia

ving all infor

f the intende

l HettInfo II:

iew

l HettInfo II:

eft …

l HettInfo II:

ight…

l HettInfo II:

ept

l HettInfo II:

ace

l HettInfo II:

l HettInfo II:

l HettInfo II:

is switched o

l HettInfo II:

is switched o

l HettInfo II:

remove USB

l HettInfo II:

USB stick (M

l HettInfo II:

data

l HettInfo II:

data

nted here is

which goes

le for damag

ation in the

use.

f

n

stick (Unmou

ount)

or document

eyond this, i

resulting fro

operating ins

nt)

ing the proce

considered

m this.

ructions and

s data of ce

o be non-int

complying wi

trifuge runs,

nded. The co

h the measu

and is theref

mpany Andre

res described

re only inten

as Hettich G

therein is al

ded

bH

o a

/30

4 Notes on safet y

No claim of warranty will be considered by the manufacturer unless ALL instructions in this manual

have been followed.

• Before commissioning the data documentation system HettInfo II, the operating instructions are to be

read and observed. Only persons who have read and understood the operating instructions may use the

data documentation system HettInfo II.

• Alon g with the oper ating instructions and the lega l regulati ons on accident prevention, you should also follo w the

recognised professional regulations for working in a safe and professional manner. These operating instructions

should be read in conjunction with any other instructions concerning accident prevention and environmental

protection based on the national regulations of the country where the device is to be used.

• The barcode unit is built according to the state of the art and is safe to operate. However, it may pose a risk to

the user or third parties if it is not used by tr ained personnel or improperly or for purposes other tha n those for

which it is intended.

• The barcode u nit must not be operated with highly corrosive substances t hat can im pair the mecha nical strength

of accessories.

• Repairs must only be carried out by personnel authorised to do so by the manufacturer.

• Only original spare parts and approved original accessories from Andreas Hettich GmbH & Co. KG may be used.

• The following safety regulations apply:

EN / IEC 61010-1 and EN / IEC 61010-2-020 and their national deviations.

• The security and reliability of the barcode unit is only guaranteed if:

− the barcode unit is operated according to the operating instructions.

− the electrical installation, at the installation site of the barcode unit, meets the requirements of EN / IEC

specifications.

• Meeting the country-specific requirements concerning occupational safety with regard t o the use of laboratory

centrifuges at the workplaces provided for this purpose by the user is the responsibility of the user.

• HettInfo II only supports SMB protocol version 1.0 for network communication.

• The HettInfo II system can buffer up to 3000 runs. The data must be transferred to a server at least once a week.

5 Scope of delivery

The following accessories are supplied with the barcode unit.

1 Hand Barcode Scanner

1 Holding device for the Hand Barcode Scanner

1 Operating Instructions HettInfo II

6/30

C

t

O

P• A

c

o

o

h

e

o

a

o

e

s

b

c

a

a

v

r

e

o

u

s

s

e

n

.

k

p

c

g

u

o

d

s

g

7

S

g

6

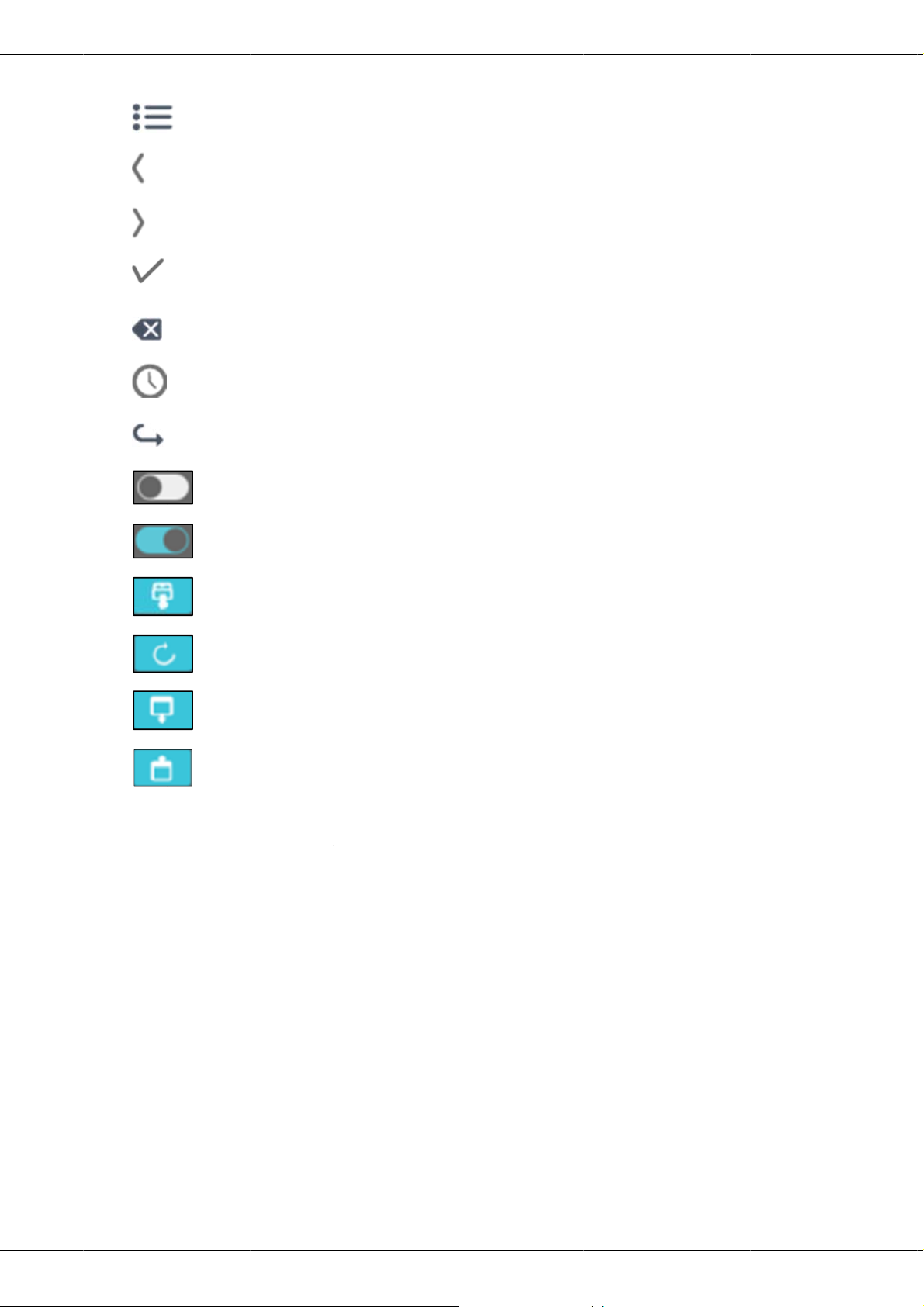

Plug

7

7.1

ommission

he barcode s

peration of

Do not lo

Do not p

Installing t

ing the barc

anner into th

the barcode

k into the la

int the laser

e barcode s

de unit

USB port p

scanner

er beam. Las

eam at pers

anner

1

ovided for thi

r class 2.

ns.

2

purpose usi

g USB.

1. Inse

2. Atta

rt the USB pl

et [1] provide

soc

pur

ose.

h the cable t

usin

g the supplie

Make

trippin

g into the U

d for this

the centrifu

clamps [2].

ure that no

hazard occu

B

e

rs.

7.2

•

Testing th

oint the barc

red laser be

barcode sc

de scanner

m becomes

nner

t a straight s

isible on the

rface and pr

urface.

ss the trigger

/30

3

3

4

aopeposbag

n"Re

5

6

h

g

z

h

a

a

e

d

g

o

e

o

r

s

d

h

h

s

s

w

i

h

n

r

i

c

p

c

T

e

a

e

c

e

s

r

t

g

r

t

g

e

t

e

a

r

e

h

e

t

c

d

n

n

g

c

h

e

b

s

i

e

s

A

e

e

r

n

e

c

c

c

u

n

h

h

c

h

e

o

s

o

n

e

w

g

c

a

l

w

a

p

e

e

b

p

h

c

f

m

u

d

d

r

s

b

p

d

s

d

e

c

u

h

c

p

n

G

H

d

t

g

n

e

D

a

2

b

p

d

e

d

d

s

u

r

h

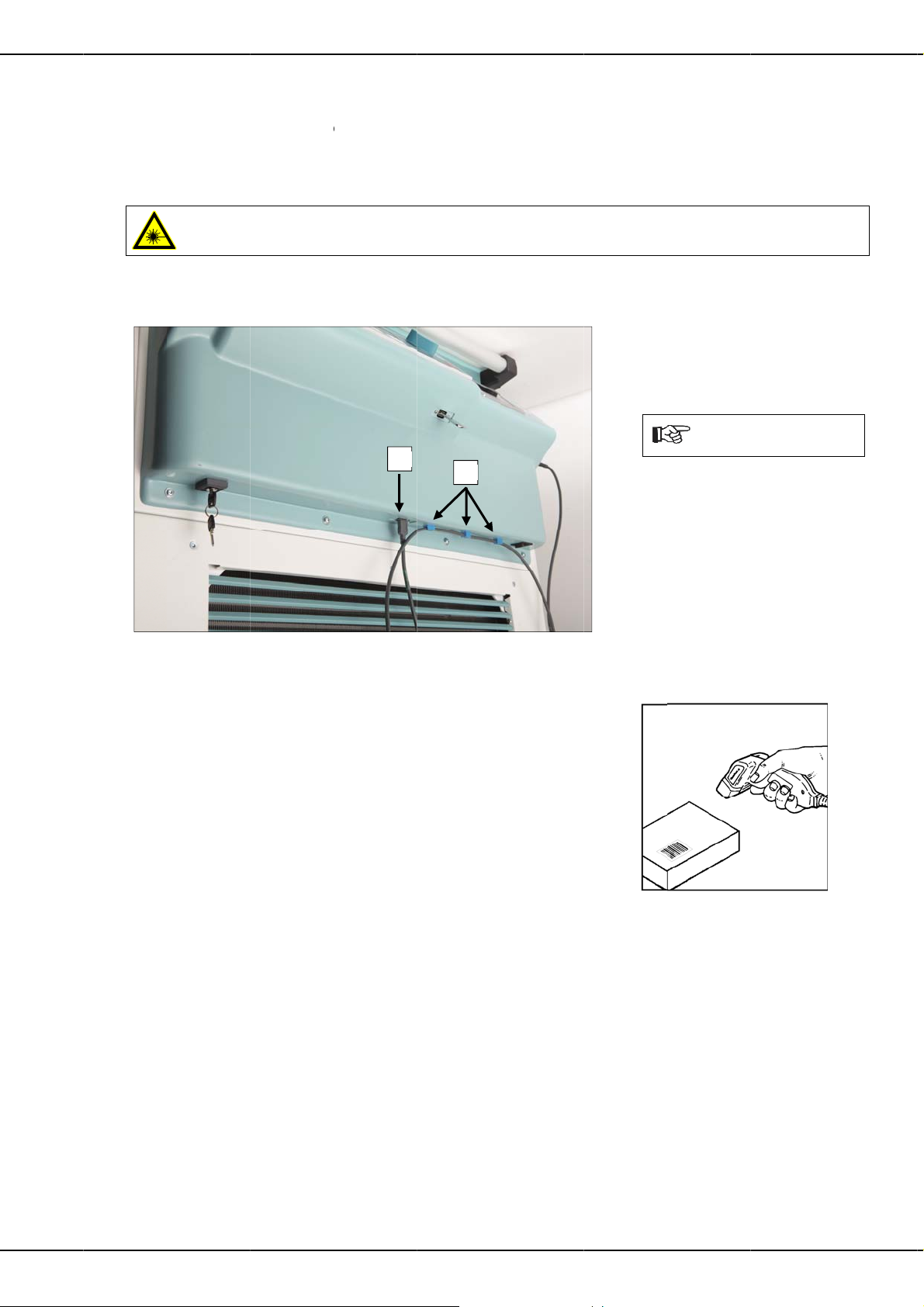

7.

Scannin

the barcod

•

Point the b

press the tri

Direct the l

•

The laser b

•

If the barco

signal soun

Scannin

7.

Sc

n the start c

rator and th

ition. The pr

barcodes a

Do no

The si

Hold t

Finally

the in

slight

t hold the b

e of the las

e barcode s

rcode scann

gger.

ser beam ho

am must ext

de scanner h

s and the la

at the cent

de. It is loca

desired pro

gram is prog

e located on

, after loadin

ide of the c

elay, confirm

rcode scan

r beam cha

anner at a sli

er at the bar

rizontally to t

nd over the

as read the

er beam goe

ifuge

ed on the ins

ram number

ammed at th

he blood bag

the blood ba

ntrifuge lid.

ing the data

er directly o

ges due to t

ht angle to t

ode to be s

e centre of t

ntire barcod

arcode, a sh

out automati

de of the cen

can also be

centrifuge c

. The scanni

gs into the c

fter scanning

xchange.

the barcod

e distance

e barcode..

anned and

e barcode.

.

ort acoustic

cally.

trifuge lid. O

canned. The

ntrol. Next, t

g sequence

ntrifuge, the

the end cod

(keep a di

etween the

tionally, an o

se two barco

e blood bag

an be varied

inal code mu

, the secon

tance of ap

arcode scan

RICHTI

FALSC

erator barco

es can be a

arcodes are

after scannin

t be scanned

acoustic sig

prox. 10 to

er and the

e for the res

tached at a

scanned. Th

the start co

. It is also loc

nal is emitte

0 cm).

arcode.

ective

esired

blood

e.

ated on

with a

Aft

er scanning t

be

closed and t

ru

, the proces

port" appear

7.

Workflo

1.

At the centr

Switch on t

not yet bee

2.

With the ba

Scan all req

3.

At the centr

Load the ce

Press the

7.

Barcode

If t

e barcode s

•

Check the

•

Check the

•

Make sure t

•

Make sure t

e end code,

e centrifugat

data is qu

on the displ

fuge

e centrifuge.

assigned.

code scanne

uired barcod

fuge

ntrifuge with t

S

ART

key on t

scanner do

anner does n

ower supply.

onnection of

hat the corre

hat the barco

he display of

ion run starte

ried from th

y of the cent

Enter the ce

s.

he plastic ins

e centrifuge

s not work

ot work corre

he interface

t barcode is

es are not di

the HMI sho

by pressin

centrifuge

ifuge control.

trifugation p

rts and the b

ontrol.

tly, the follo

able on the b

sed (see cha

ty or damag

s (“Data co

START

the b

ontrol and t

rameters an

ood bags an

ing error sou

rcode scann

pter 8).

d.

plete -> Clos

tton on the

ransferred to

save them

then close t

ces must be

er and on the

lid). The ce

entrifuge. Aft

HettInfo II.

nder a progr

e lid.

hecked:

barcode unit.

trifuge lid mu

r the centrif

uring this p

m number t

t then

gation

ocess,

at has

8/

0

8 Barcodes

8.1 Usable Barcodes

The barcode scanner recognizes the following barcodes with the factory setting:

• Code 128 (with check digit)

Barcodes must not contain diacritics. The scanning of diacritics leads to data manipulation of the scanned data. If a

diacritic is scanned, the device beeps 4x and the red lamp lights up. The operator must then delete all scan data. ->

Scan StartCode and start scanning again.

It is forbidden to create operator ID barcodes that begin with the character strings (HET#; HET!; HET%; HB$).

Each barcode that is used for an operator ID can be used only once.

If this barcode is deleted, it may no longer be used.

HettInfo II only uses the assignment barcode -> name of the operator for the operator ID.

If an operator name is changed, a new barcode must be used.

Should it happen that two or more employees have identical first and last names, the customer must consider an

identification possibility when entering the operator name.

Example: BC1 -> J.Mayer_No1

BC2 -> J.Mayer_No2

8.2 Explanation of the barcodes used for control pu rposes

Startcode: This code must be affixed to the centrifuge lid.

It informs the barcode unit that a barcode set is about to begin.

Endcode: This code must be affixed to the centrifuge lid.

It informs the barcode unit that the barcode set has now been completed.

Operator ID It informs the barcode unit which operator is currently working.

Program number

barcode:

Blood bag code: This code is attached to the blood bag.

Tells the barcode unit which centrifuge program is to be used. If no centrifuge program is

stored on the program position in the centrifuge control or if no program is scanned, an error

message appears.

9/30

Loading...

Loading...