EBA 20S

03.08 Andreas Hettich GmbH & Co. KG AR2080EN

Repair instructions

Andreas Hettich GmbH & Co. KG

Föhrenstraße 12, D-78532 Tuttlingen / Germany

Phone (07461) 705-0

Fax (07461) 705-125

info@hettichlab.com, service@hettichlab.com

www.hettichlab.com

© 2007 by Andreas Hettich GmbH & Co. KG

All rights reserved. No part of this publication may be reproduced without the prior

written permission of the copyright owner.

Änderungen vorbehalten!

AR2080EN / 03.08

2/34

Contents

1 Introduction ..............................................................................................................5

2 Symbol meanings.....................................................................................................5

3 Description of the centrifuge.....................................................................................6

3.1 Control panel A3 ...............................................................................................7

3.2 Power board A1 ................................................................................................7

3.3 Motor M1...........................................................................................................8

3.4 Speed sensor B3...............................................................................................8

3.5 Brake resistor R1 and Overtemperature fuse F3...............................................8

3.6 Lid lock Y1 ........................................................................................................8

3.7 Imbalance switch S 2........................................................................................8

4 Troubleshooting procedures.....................................................................................9

5 Error messages......................................................................................................10

5.1 MAINS RESET................................................................................................10

5.2 Brief description ..............................................................................................10

5.3 Description and elimination of errors...............................................................11

5.4 Defects without Error indications.....................................................................16

6 Settings and enquiries............................................................................................18

6.1 Setting the machine version............................................................................18

6.2 Enquiry the machine version...........................................................................19

6.3 Enquiry the programme versions ....................................................................20

6.4 Brake adjustment............................................................................................20

6.5 Lid lock control................................................................................................21

6.6 Imbalance switch-off .......................................................................................21

7 Change mains input fuse........................................................................................22

8 Functional check after a repair...............................................................................22

9 Assembling and disassembling components..........................................................23

9.1 Motor M1 / speed sensor B3 / Rubber-metal bearing......................................24

9.2 Power board A1 ..............................................................................................24

9.3 Control panel A3 ............................................................................................24

9.4 Brake resistor R1 ............................................................................................25

9.5 Overtemperature fuse F3................................................................................25

9.6 Flat ribbon cable..............................................................................................25

9.7 Appliance plug with mains switch....................................................................25

9.8 Imbalance switch S2.......................................................................................25

9.9 Lid lock Y1 ......................................................................................................25

3/34

10 Circuit diagrams .................................................................................................26

10.1 Circuit diagram and plug assignment..............................................................27

10.2 Signals and test results................................................................................... 28

10.2.1 Speed sensor B3 (Tacho)........................................................................28

10.2.2 Motor ....................................................................................................... 28

10.2.3 Brake resistor R1 and overtemperature fuse F3......................................29

10.2.4 Lid lock Y1............................................................................................... 29

10.2.5 Imbalance switch..................................................................................... 30

10.2.6 Intermediate voltage on power board A1................................................. 30

11 Technical specification....................................................................................... 31

12 Skeleton construction of EBA 20S...................................................................... 32

13 Index .................................................................................................................. 33

4/34

1 Introduction

• Repairs must only be carried out by personnel authorised to do so by the

manufacturer.

Interventions and modifications at centrifuges, which have been conducted

by persons not authorized by the Andreas Hettich GmbH & Co. KG

company, are at their own risk and entail the loss off all guarantee and

liability claims. In such an event any guarantee claim or liability claim

against the Andreas Hettich GmbH & Co. KG company expire.

• Only original spare parts and original accessories licensed by the Andreas Hettich

GmbH & Co. KG company are allowed to be utilised.

If no original spare parts or no original accessories are used, any guarantee

claim or liability claim against the Andreas Hettich GmbH & Co. KG

company ceases to exist.

• Information about the operation of the centrifuge please see operating instructions.

• We reserve all rights for these technical documents.

2 Symbol meanings

Symbol on the machine:

Attention, general hazard area.

Before using the centrifuge implicitly read the operating instructions and pay

attention to the safety relevant references!

Symbol in this document:

Attention, general hazard area.

This symbol refers to safety relevant warnings and indicates possibly

dangerous situations.

The non-adherence to these warnings can lead to material damage and injury

to personal.

Symbol in this document:

Warning! Danger for human lives by electric shock.

Symbol in this document:

This symbol refers to important circumstances.

Symbol on the machine and in this document:

Symbol for the separate collection of electric and electronic devices according

to the guideline 2002/96/EG (WEEE). The device belongs to Group 8 (medical

devices).

Applies in the countries of the European Union, as well as in Norway and

Switzerland.

5/34

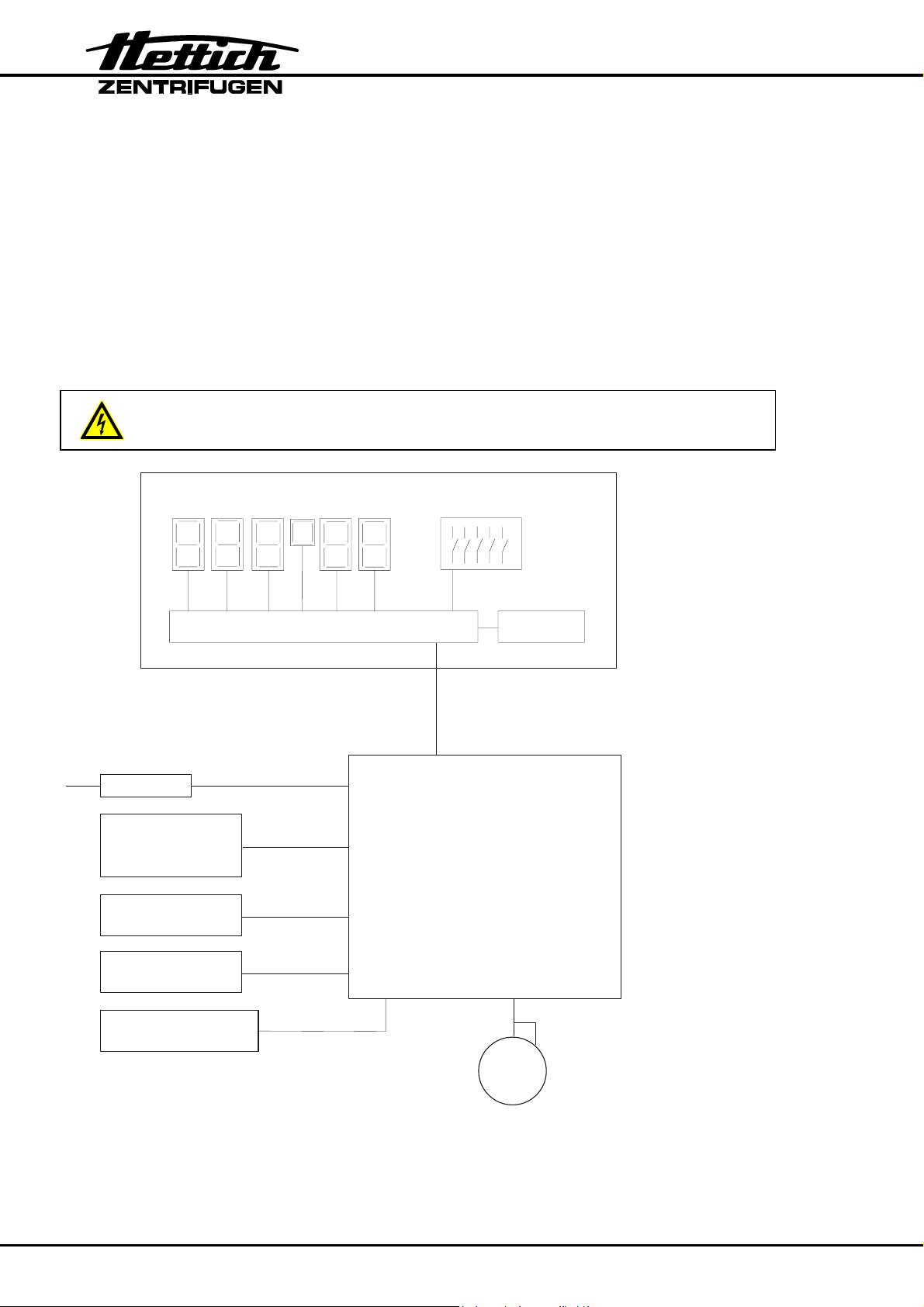

3 Description of the centrifuge

The EBA 20S is a microprocessor-controlled centrifuge which is comprised of the

following electrical components:

• Control panel

• Power board

• Motor

• Speed sensor (Tacho)

• Brake resistor with overtemperature fuse

• Lid lock system

• Imbalance switch

All electronic components are on mains, due to the DC-coupling

Steuerteil LED / Control panel LED

Netz / Mains

Verschluß / Lid lock

Deckelschalter

Lid switch

Uwuchtschalter

Imbalance switch

Bremswiderstand

Brake resistor

Drehzahlsensor (Tacho)

Speed sensor (tacho)

EEPROMSchnittstelle / Interface

Leistungsteil

Power board

mit Mikroprozessorsteuerung

und Frequenzumrichterteil

With Micoprocessor control

and frequency control

Motor

6/34

3.1 Control panel A3

The control panel have only restricted control tasks, it disposes of the following

characteristics:

• Input panel for operation parameters

• Indication elements

• Transmission of the signals to the power board via the interface.

• Storing of centrifuge version

• Storing the machine version and the brake setting.

By means of the machine version the power board is informed which kind of

centrifuge has to be controlled. Then the power board takes the corresponding

values from the ROM.

e.g. Max. Speed

Acceleration and deceleration ramps

• Communication with the power board via TTL interface.

The power supply for the control panel is transmitted via the flat ribbon cable:

Pin 1 GND

Pin 4 +5V

3.2 Power board A1

The power board is an combination of:

• Control panel

• Voltage supply

• Frequency converter

The power board carries out the following tasks:

• Power supply 15 V, DC for imbalance switch

• Power supply 5 V, DC for control panel

• Generating the motor power supply.

(three-phase current with variable frequency and voltage)

Functional description: The mains supply is rectified, smoothened and chopped

into a pulse width pattern in three bridge elements with a

microprocessor.

• Slot for motor with integrated overtemperature switch

• Monitoring the motor current

• Evaluating the overtemperature switch in the motor

• Slot for imbalance switch

• Evaluating the imbalance switch

• Slot for brake resistor

• Triggering the brake resistor

• Slot for speed sensor

• Evaluating the speed sensor pulses (2 pulses per revolution)

• Slot for lid lock

• Triggering the lid lock magnet at standstill of the rotor

• Evaluating the message line lid lock open/closed

• Communication with the control panel via TTL interface

• Error evaluation

7/34

3.3 Motor M1

• The motor is a three- phase asynchronous motor with two pairs of poles.

• The motor is protected against overheating by an overtemperature switch.

• The power board evaluates the overtemperature switch.

• The motor is controlled by the power board with a three-phase current with variable

frequency and voltage.

3.4 Speed sensor B3

• The speed sensor (speedometer) is located at the bottom of the motor.

• The speed signal (2 pulses per revolution) will be triggered by two magnets fixed at

the motor axle.

• The speed of the rotor is monitored and controlled by the power board.

3.5 Brake resistor R1 and Overtemperature fuse F3

• The braking copper which is integrated on the power board transfers the electrical

energy produced during braking, from a voltage of 380 V with the 230 V version and

203 V with the 120 V version, to the brake resistor in a controlled manner.

• An overtemperature fuse protects the brake resistor against overheating. When the

overtemperature fuse (F3) blows, the power board will be separated from the power

supply.

3.6 Lid lock Y1

• Opening of the lid lock is prevented by a latch. The lid lock can only be opened when

the relay REL 602 on the power board is energised. This occurs when the rotor is at

standstill, mains power is applied and the key

gized for three seconds and releases the latch.

• The centrifuge can only be started when the lid is closed. A microswitch on the lid

lock detects the position of the lid lock (open/closed) and report it to the power

board.

3.7 Imbalance switch S 2

• A switch detects any imbalance.

• Imbalance can only be detected in running mode (starting, centrifuging and braking).

• If any imbalance is detected, the drive is changed over to braking.

is pressed. The solenoid is ener-

8/34

4 Troubleshooting procedures

• Fuses in installation in which centrifuge is installed are intact.

• Mains input fuses of centrifuge are intact.

• Supply voltage present at (see circuit diagram):

− Connecting cable

− Appliance plug

− Mains switch

− Power board A1, plug S402L and S402N

• Look for the displayed error code in the chapter "Error messages".

• Remedy the error according to the instructions.

• Carry out a functional check after every repair and whenever a component is

replaced, see chapter "Functional check after a repair".

9/34

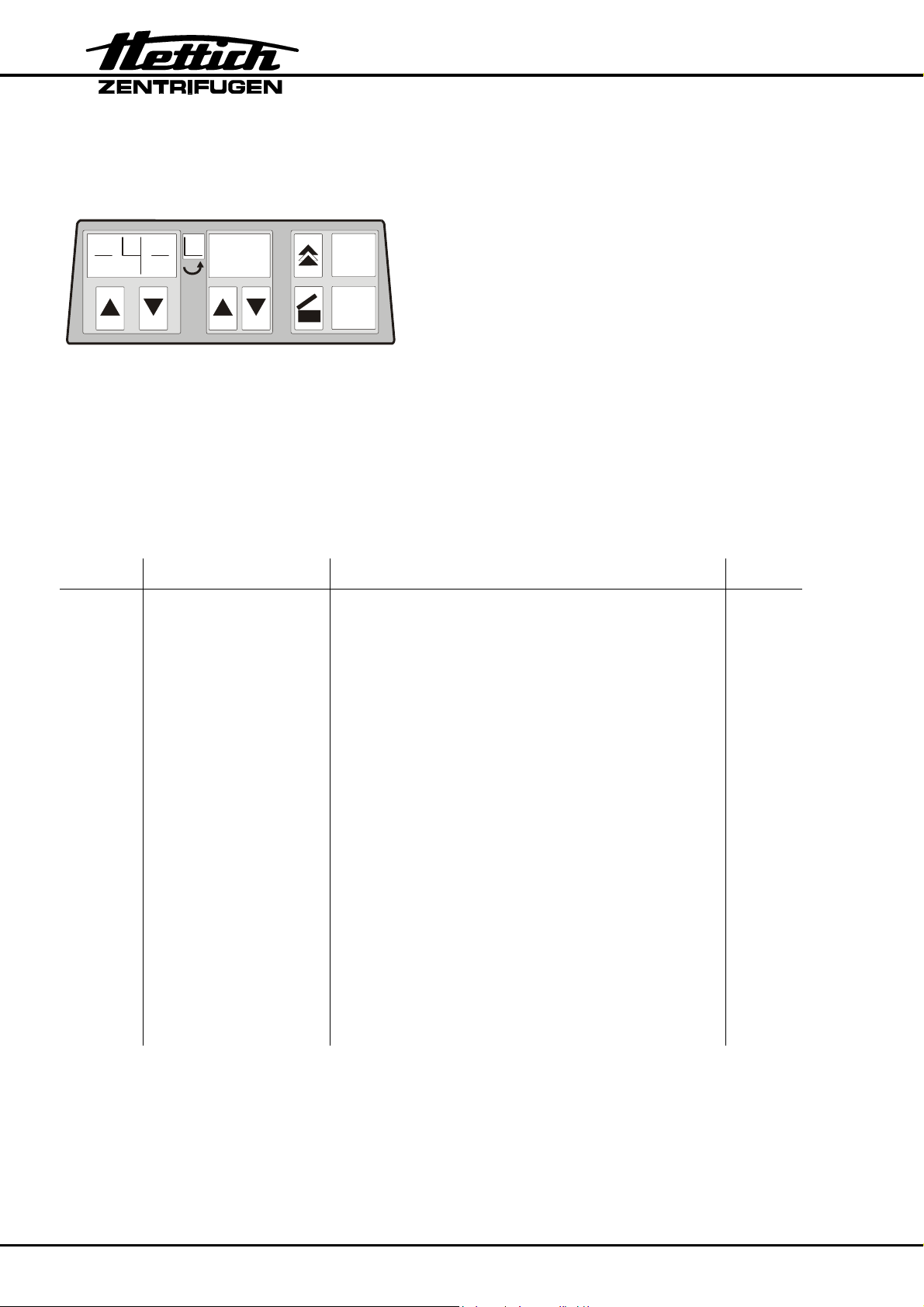

5 Error messages

The error message will be indicated in the speed display of the front panel

e.g. :

START

RPM x 100

t

STOP

5.1 MAINS RESET

• Switch off the mains switch.

• Wait at least for 10 seconds and then switch on the mains switch again.

5.2 Brief description

Display. Fault Brief description Page

- 1 - Tacho error Tacho pulses break down during the run 11

- 2 - System reset Mains interrupt 11

- 3 - Imbalance Imbalance on the motor axis 11

- 4 - Communication Communication error 12

- 5 - Overload Fault in the motor or the motor control 12

- 6 - Overvoltage Mains is out of the tolerance 13

- 7 - Overspeed Overspeed detected 13

- 8 - Undervoltage Mains is out of the tolerance 13

- 9 - Overtemperature Overtemperature switch in the motor release 14

Versions Error No indication in the speed display

Wrong machine version setting

- c - Controller-Watchdog Fault in power board 14

- d - Lid lock error Fault in lid lock system 15

- E - Short circuit Short circuit in power board 15

- F - No Rotor code Wrong machine version 15

16

10/34

5.3 Description and elimination of errors

– 1 – Tacho error

Error Tacho pulses break down during the run.

Error

Drive switch off and brakes with the adjusted brake level.

consequence

Error cause

• Speed sensor (tacho) defective

• Power board (A1) defective

• Loosen contact in plug S502

Measurement 1. A1 / S502 pin 2 (GND) to pin 3 (+UB)

2. Speed sensor plug S502 , pin 4 – pin 2 GND (2 pulses per

revolution). See also section 10.2

Error code reset Wait for a time duration of 120 sec. and after this perform a MAINS

RESET.

– 2 – System reset

Error Mains interrupt during a run

Error

Drive switch off and brakes with the adjusted brake level.

consequence

Error cause

• Power supply has failed

• Loosen contact in electrical connections

Error code reset 1. Wait for rotor standstill

2. Open the lid and press key

or

perform a MAINS RESET

ST ART

11/34

Loading...

Loading...