Hestan GFDSR241, GRGR24, GRFR24 Use and Care Manual

INDOOR / OUTDOOR

UNDERCOUNTER REFRIGERATION

Refrigerators, Freezers, & Beer Dispensers

Use & Care Manual

EN

Message from Hestan:Message from Hestan:

Outdoor cooking is a perfectionist’s pursuit, and with your new investment,

you’ve now taken the ultimate step forward. We sincerely welcome you to

the Hestan Family. We’ve engineered and built our products so that your

guests will rave about your meal, but deep down, our customers know it

could’ve been just a little more tender, juicier – a pinch more salt in the rub

or a few seconds less on the flame. Yes, we’ve taken the time to know our

Hestan customer and we’re excited to be on this journey with you. Hestan

Outdoor was born from this same perfectionist passion. Our engineers

experimented, innovated, tweaked and tinkered until they created the most

powerful, versatile and reliable outdoor products available.

We pride ourselves on restless innovation, superior engineering and

purpose-built designs, but also our in-depth understanding of our target

consumer and the interests and needs of the ultimate end-users we serve

and covet. For many consumers, cooking outdoors is much more than an

act of food preparation. It’s a lifestyle activity that encompasses culinary,

leisure and social pursuits among others.

We are thankful and proud that you have chosen Hestan, and we yearn to

have you as a customer for life. We take your decision to choose Hestan

most seriously, and we promise to deliver the very best to you.

Welcome to Hestan OutdoorWelcome to Hestan Outdoor

2

©2021 Hestan Commercial Corporation

TABLE OF CONTENTS

DANGER

DANGER

NOTICE

3 SAFETY DEFINITIONS

4 MODEL NUMBERS

5 RATING LABEL

5 REGULATORY/CODE REQUIREMENTS

5 IMPORTANT CHILD SAFETY

5 PRECAUTIONS BEFORE YOU USE YOUR APPLIANCE

7 OPERATION

7 DIGITAL TEMPERATURE CONTROL

10 MAINTENANCE - OUTDOOR MODEL / WINTERIZING

10 LED REPLACEMENT

11 CLEANING

13 DISPOSAL

14 TROUBLESHOOTING

15 PARTS LIST / SERVICE

16 WARRANTY

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY

BEFORE INSTALLING OR USING YOUR APPLIANCE TO REDUCE

THE RISK OF FIRE, SHOCK HAZARD, OR OTHER INJURY. KEEP

THIS MANUAL FOR FUTURE REFERENCE.

IMPORTANT! IMPORTANT! Read and understand all information in this manual before

attempting the installation. All plumbing and electrical work must be

performed by a qualified technician and conform to all applicable state and

local codes.

EN

INSTALLER: LEAVE THIS MANUAL WITH THE OWNER OF THE APPLIANCE.

HOMEOWNER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

SAFETY DEFINITIONS

THIS INDICATES A HAZARD THAT WILL RESULT IN SERIOUS

INJURY OR DEATH IF PRECAUTIONS ARE NOT FOLLOWED.

THIS INDICATES A HAZARD THAT MAY RESULT IN SERIOUS

INJURY OR DEATH IF PRECAUTIONS ARE NOT FOLLOWED.

THIS INDICATES A HAZARD WHERE MINOR INJURY

OR PRODUCT OR PROPERTY DAMAGE MAY OCCUR IF

PRECAUTIONS ARE NOT FOLLOWED.

THIS INDICATES THAT PRODUCT OR PROPERTY DAMAGE MAY

OCCUR IF PRECAUTIONS ARE NOT FOLLOWED.

RISK OF FIRE OR EXPLOSION - FLAMMABLE REFRIGERANT USED. Consult

repair manual/owners guide before attempting to service this product. All

safety precautions must be followed. To be repaired by trained service personnel only. Use caution

when handling, moving and using the product to avoid damaging the refrigerant tubing or increasing

the risk of a leak.

All service work shall be performed by factory authorized service personnel and

all component parts shall be replaced with like components to minimize the risk

of possible ignition due to incorrect parts or improper service.

If service is necessary, repair work must be performed by a Hestan authorized

servicer. Work done by unqualified individuals could potentially be dangerous

and will void the warranty.

©2021 Hestan Commercial Corporation

3

SAFETY DEFINITIONS

NOTICE

This product contains blown foam insulation using blowing agent R-611 (Methyl

Formate). The foam in this product does not contain HFC’s, CFC’s, or HCFC’s.

(continued)

EN

All models covered in this manual are manufactured using refrigerant R600a (Isobutane). R600a is

a hydrocarbon. This refrigerant is flammable and is only allowed for use in appliances which fulfill

the requirements of UL/IEC 60335-1 and UL/IEC 60335-2-24 (To cover potential risk originated from

the use of flammable refrigerants). Consequently, R600a is only allowed to be used in refrigerating

appliances which are designed for this refrigerant and fulfill the above-mentioned standard.

• R600a is heavier than air. The concentration will always be highest at the floor level.

• The explosion limits are as follows:

o Lower Limit: 1.8% by volume

o Upper Limit: 8.4% by volume

o Ignition Temperature: 860ºF [460°C]

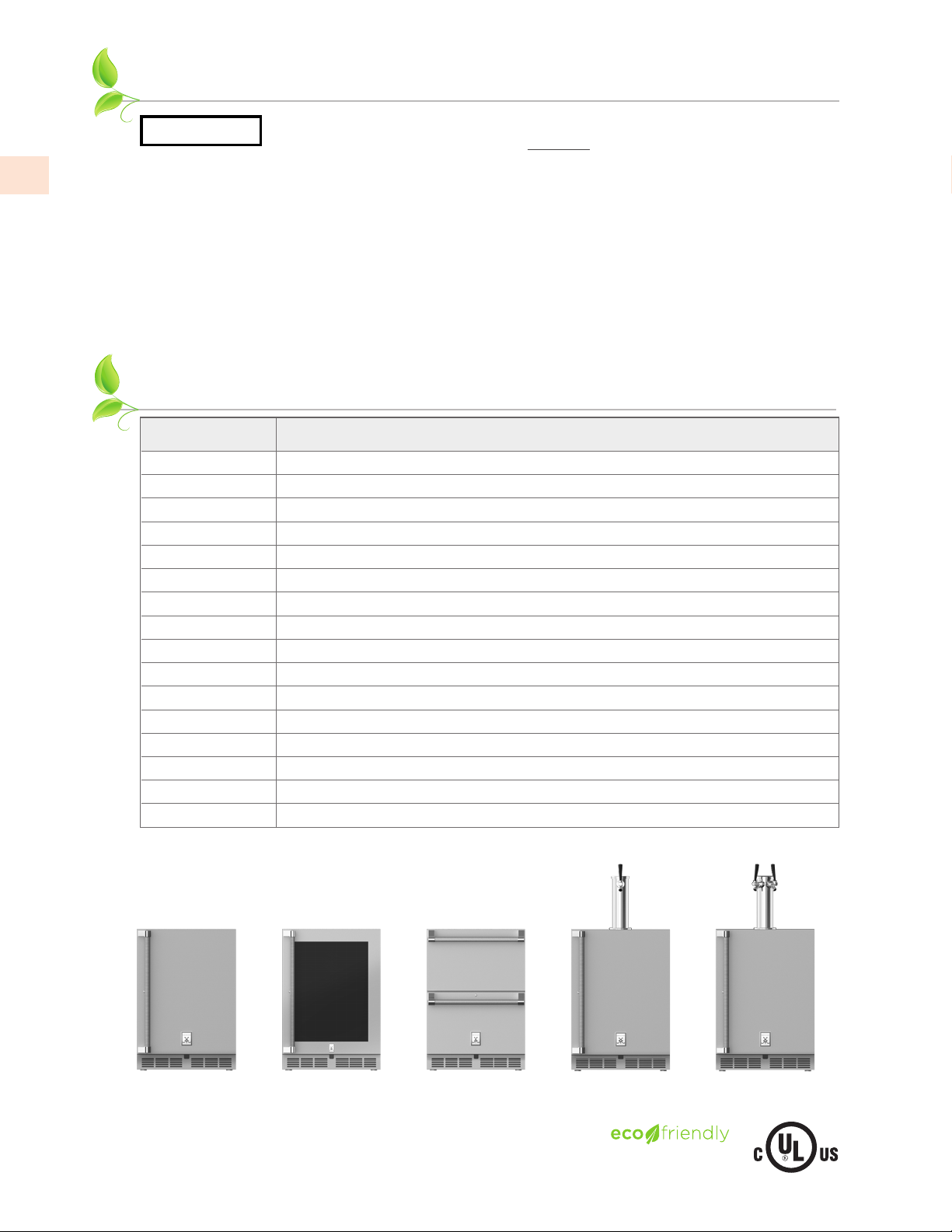

MODEL NUMBERS

Model No. Description

GRS_24 INDOOR / OUTDOOR REFRIGERATOR, SOLID DOOR, 24”

GRS_24-XX INDOOR / OUTDOOR REFRIGERATOR, SOLID DOOR, COLOR, 24”

GRG_24 INDOOR / OUTDOOR REFRIGERATOR, GLASS DOOR, 24”

GRG_24-XX INDOOR / OUTDOOR REFRIGERATOR, GLASS DOOR, COLOR, 24”

GRR24 INDOOR / OUTDOOR REFRIGERATOR DRAWERS, 24”

GRR24-XX INDOOR / OUTDOOR REFRIGERATOR DRAWERS, COLOR, 24”

GRFR24 INDOOR / OUTDOOR REFRIGERATOR DRAWER AND FREEZER DRAWER, 24”

GRFR24-XX INDOOR / OUTDOOR REFRIGERATOR DRAWER AND FREEZER DRAWER, COLOR, 24”

GRWS_24 INDOOR / OUTDOOR DUAL ZONE REFRIGERATOR WITH WINE, SOLID DOOR, 24”

GRWS_24-XX INDOOR / OUTDOOR DUAL ZONE REFRIGERATOR WITH WINE, SOLID DOOR, COLOR, 24”

GRWG_24 INDOOR / OUTDOOR DUAL ZONE REFRIGERATOR WITH WINE, GLASS DOOR, 24”

GRWG_24-XX INDOOR / OUTDOOR DUAL ZONE REFRIGERATOR WITH WINE, GLASS DOOR, COLOR, 24”

GFDS_241 INDOOR / OUTDOOR SINGLE FAUCET BEER DISPENSER, SOLID DOOR, 24”

GFDS_241-XX INDOOR / OUTDOOR SINGLE FAUCET BEER DISPENSER, SOLID DOOR, COLOR, 24”

GFDS_242 INDOOR / OUTDOOR DOUBLE FAUCET BEER DISPENSER, SOLID DOOR, 24”

GFDS_242-XX INDOOR / OUTDOOR DOUBLE FAUCET BEER DISPENSER, SOLID DOOR, COLOR, 24”

4

GRSR24 shown GRR24 shownGRWGR24

shown

©2021 Hestan Commercial Corporation

_ = Right (R) or Left (L) Hinged Model

GFDSR241

shown

R600a Refrigerant

GFDSR242

shown

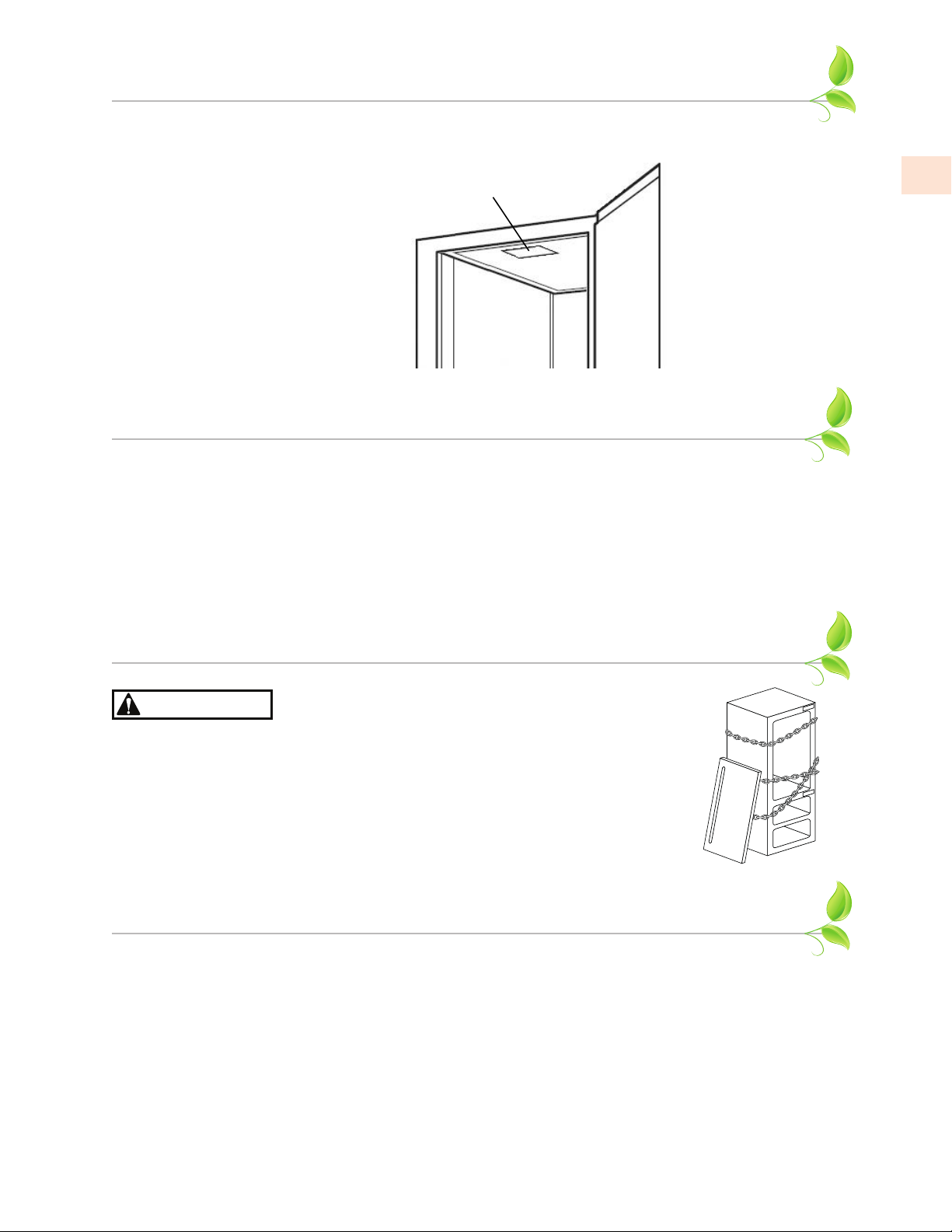

RATING LABEL

DANGER

The rating label contains important information about your Hestan appliance such as the model and

serial number, and refrigerant information if service is required.

RATING LABEL

The rating label is attached to the

inside top of the cabinet.

REGULATORY / CODE REQUIREMENTS

Installation of this appliance must be made in accordance with local codes. In the absence of

local codes, this unit should be installed in accordance with the National Electrical Code and local

codes.

This appliance must be electrically grounded in accordance with local codes or in the absence of

local codes with the National Electrical Code

C22.1

.

ANSI/NFPA 70

, or Canadian Electrical code

CSA

EN

IMPORTANT CHILD SAFETY

Risk of child entrapment. Before you throw away your old refrigerator or freezer:

• Take off the doors

• Leave the shelves in place so that children may not easily climb inside.

NEVER allow children to play inside the appliance.

PRECAUTIONS - BEFORE YOU USE YOUR APPLIANCE

When properly cared for, your Hestan undercounter refrigeration product will provide safe, reliable

service for many years. When using this appliance, basic safety practices must be followed as

outlined below.

IMPORTANT: Save these instructions for the local Utility Inspector’s use if needed.

INSTALLER: Please leave these instructions with the owner.

OWNER: Please retain these instructions for future reference.

This appliance is NOT designed for installation in manufactured (mobile) homes or recreational

park trailers.

©2021 Hestan Commercial Corporation

5

EN

DANGER

NOTICE

DANGER

DANGER

PRECAUTIONS - BEFORE YOU USE YOUR APPLIANCE

(continued)

PRIOR TO INSTALLATIONPRIOR TO INSTALLATION

PLEASE CONSULT THE INSTALLATION MANUAL PROVIDED. Carefully inspect appliance for

hidden damage. If damage is discovered, file your claim immediately with the transport company.

Hestan is not responsible for damage in transit. Remove any packaging materials before operating.

RISK OF FIRE OR EXPLOSION - FLAMMABLE REFRIGERANT USED.

Use caution when handling, moving and using the product to avoid damaging

the refrigerant tubing or increasing the risk of a leak.

When moving the unit, be sure to protect finished flooring with appropriate

material to avoid damage from moving the unit. Do not lift unit by drawer,

shelving or door handles, as damage to the unit could occur if not moved as instructed.

To prevent personal injury, a minimum of two people are required to lift the

unit. Larger units may require additional personnel.

Before moving the unit, secure the door shut with tape to prevent door from swinging open while

being moved. Carefully move unit to installation site and place in front of opening.

If unit has been laid on its back or sides, place unit upright and allow a

minimum of 24 hours before connecting power.

The unit must NOT be totally enclosed or damage may occur. Air circulation must

not be restricted. The condenser at the cabinet front must be provided with a

minimum of 2” [5 cm] air space. Be sure to provide access so the front cover can be removed to

clean the condenser.

Do not store flammable liquids (i.e. Gasoline or Lighter Fluid) or vapors near

the appliance to avoid a fire.

ELECTRICAL SHOCK HAZARDELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing appliance. Failure to

do so can result in death or electrical shock.

ELECTRICAL GROUNDINGELECTRICAL GROUNDING

• This appliance must be grounded. Grounding reduces the

risk of electric shock in the event of a short circuit. Read the

ELECTRICAL CONNECTIONS section of the Installation Manual

for complete instructions.

• DO NOT ground to a gas pipe.

• DO NOT use an extension cord with this appliance.

• DO NOT have a fuse in the NEUTRAL or GROUNDING circuit. A fuse in the NEUTRAL or

GROUNDING circuit could result in an electrical shock.

Appliances equipped with a flexible electrical supply cord are provided with a three-prong

grounding plug. It is imperative that this plug be connected to a properly grounded three-prong

receptacle. If the receptacle is not the proper grounding type, contact an electrician.

• Never remove the grounding prong from this plug.

• Never use a 2-prong adapter.

• If a 2-prong receptacle is encountered, or a longer power cord is required, contract a qualified

electrician to have it replaced in accordance with applicable electrical codes.

• The unit is designed for 115 volt AC power and must be plugged into a Ground Fault Circuit

Interrupter (GFCI) protected circuit when installed outdoors.

6

©2021 Hestan Commercial Corporation

OPERATION

Programming Button Definitions:

MASTER SWITCHMASTER SWITCH

Hestan refrigeration products come equipped with a master power switch located behind the

louvered toe kick. Remove the toe kick/grille to turn power on or off to the unit.

INTERIOR LIGHTINTERIOR LIGHT

Door units are equipped with an interior light that illuminate when the door is opened. All models

come standard with adjustable blue and white LED lighting. The cabinet also comes equipped with a

manual light switch for displaying the products through a glass door.

Always ensure that the manual light switch is in the OFF position before closing a solid wood or

stainless steel door. If manual light switch is left on for an extended period of time, it will increase

energy usage and decrease LED life.

LOADING PRODUCTLOADING PRODUCT

Before storing perishables, turn unit on and allow it to operate for a minimum of 24 hours to allow

temperatures to stabilize. When loading items into the unit, do not block internal louvers and fan

guard openings or performance will be decreased.

CHECKING PRODUCT TEMPERATURECHECKING PRODUCT TEMPERATURE

1. To accurately check the temperature of product stored in the refrigerated compartment, insert

an accurate thermometer into a plastic unbreakable bottle, partially filled with water. Tighten

bottle cap securely.

EN

2. Place the bottle in the desired area for 24 hours. Refrain from opening the unit during the testing

period. After 24 hours, check the temperature of the water. Adjust the temperature accordingly

using the following procedures:

DIGITAL TEMPERATURE CONTROL

Figure 1. Digital Temperature Controller

DUAL ZONE CONTROL INSTRUCTIONSDUAL ZONE CONTROL INSTRUCTIONS

ON / OFF

Press the ON/OFF button to turn the unit on or off.

SET button

DEFROST button (melting snowflake)

UP arrow

DOWN arrow

ON/OFF button

Upper Compartment:

To view the upper compartment temperature, press and release the DEFROST button (melting

snowflake).

Lower Compartment (Must be coldest zone):

Display reading always shows the lower compartment temperature.

©2021 Hestan Commercial Corporation

7

EN

DIGITAL TEMPERATURE CONTROL

Setpoint Display:

Press and release the SET button; display will read St1. Press SET again and the LOWER

compartment setpoint will be displayed.

Press SET again; the display will read St2. Press SET again and the UPPER compartment temperature

will be displayed.

Changing the Lower Compartment Temperature:

1. Press and hold the SET button until the display shows St1 with “F” flashing.

2. Press SET again to display the lower compartment’s current temperature (“F” will continue to

flash).

3. Use the UP or DOWN arrow key to scroll to the desired temperature. The controller will

memorize the new emperature.

Changing the Upper Compartment Temperature:

1. Press and hold the SET button until the display shows St1 with “F” flashing. Press the DOWN

arrow once; the display will read St2.

2. Press SET again to display the upper compartment’s current temperature (”F” will continue to

flash).

3. Use the UP or DOWN arrow key to scroll to the desired temperature. The controller will

memorize the new temperature.

(continued)

NOTE: Dependent on the model and configuration, the controllers have been programmed to only

allow a lower compartment temperature adjustment range as specified within the chart below. The

upper compartment range is not limited, but should always be kept within the specified range shown

in the table for the upper compartment. See the chart below for the specified range allowed for your

unit.

Dual-Zone Units

MODEL TEMPERATURE RANGE

GRFR24 Upper 30°to 42°F [-1 to +6°C] / Lower -10°to 10°F [-23 to -12°C]

GRWS_24 / GRWG_24 Upper 45°to 65°F [+7 to +18°C] / Lower 30°to 42°F [-1 to +6°C]

Dual-Zone Temperature Scale

To change F to C, press and hold the down arrow for 3 seconds.

To Start A Manual Defrost (GRFR24 Only)

Press and hold the DEFROST button (melting snowflake) for 3-5 seconds. Melting snowflake will

illuminate.

SINGLESINGLE ZONE CONTROL INSTRUCTIONS ZONE CONTROL INSTRUCTIONS

ON / OFF

Press the ON/OFF button to turn the unit on or off.

To Set Target Temperature

Press and release the SET button. Display will show the current temperature setpoint.

8

©2021 Hestan Commercial Corporation

DIGITAL TEMPERATURE CONTROL

NOTICE

To Change Setpoint Temperature

1. Press and hold the SET button until the display shows the current setpoint temperature with the

“F” flashing.

2. Use the UP and DOWN arrow button to scroll to the desired temperature.

To Start A Manual Defrost (Freezer Models Only)

Press the DEFROST button (melting snowflake)

To See Maximum Stored Temperature

Press the UP arrow button to see the maximum stored temperature.

To reset the maximum stored temperature, while displayed, press and hold the SET button until ‘rst’

flashes in the display.

To See Minimum Stored Temperature

Press the DOWN arrow button to see the minimum stored temperature.

To reset the minimum stored temperature, while displayed, press and hold the SET button until ‘rst’

flashes in the display.

NOTE: Dependent on the model and configuration, the controllers have been programmed to only

allow a temperature adjustment within the specified range. See the chart below for the specified

range allowed for your unit.

(continued)

EN

Single-Zone Units

MODEL MIN. TEMP. SET MAX. TEMP. SET

GRS_24 33°F [+1°C] 42°F [+6°C]

LED Functions

The following table describes the LED functions.

LED Mode Function

ON Compressor is on

Flashing Anti-short cycle

delay is on

ON Defrost is on

ON Alarm is on

Flashing You are in the process of

Audible alarm will sound if the door is left ajar for longer than 1 minute. Fully

closing the door will clear the alarm condition. Prolonged time spent with the door

open can damage the equipment.

programming the unit

©2021 Hestan Commercial Corporation

9

MAINTENANCE

DANGER

SEASONAL MAINTENANCE FOR UL-APPROVED OUTDOOR MODELSSEASONAL MAINTENANCE FOR UL-APPROVED OUTDOOR MODELS

EN

WINTERIZINGWINTERIZING

This process should occur when the daily low temperatures is at or below the temperatures stated

below:

Refrigerator models: 38°F [+3°C] Beverage Center/Beer: 42°F [+6°C]

Freezer models: 32°F [0°C] Wine Reserve: 45°F [+7°C]

It is best to winterize your unit before the low temperatures listed above.

1. Turn the unit to OFF position by pressing the OFF button on the controller. The controller

displays the word “OFF” and turn the master switch located behind the grille off (if the power

cord is accessible, unplug the power cord. If not, turn off the circuit breaker to the electrical

receptacle the cabinet is plugged into).

2. Remove all contents from the unit.

3. Remove the front grille.

4. Clean the condenser by using a vacuum cleaner to remove loose debris (leaves, dirt, etc.) that

may have accumulated inside the grille.

5. Reinstall the front grille.

6. Clean the interior of the unit using stainless steel cleaner and polish (see page 11).

7. Clean the exterior of the unit using stainless steel cleaner and polish (see page 11).

NOTE: Do not place a cover over the unit. While not required, you may choose to remove the unit

from the outdoor location and store indoors.

Operating the unit at temperatures lower than those recommended will void the warranty.

SPRING START-UPSPRING START-UP

This process should occur after the daily low temperatures is above the temperatures stated below:

Refrigerator models: 38°F [+3°C] Beverage Center/Beer: 42°F [+6°C]

Freezer models: 32°F [0°C] Wine Reserve: 45°F [+7°C]

1. Remove the grille.

2. Check the condensing unit to ensure it is clear of loose debris, and clean as necessary with a

vacuum cleaner.

3. Reattach front grille to the unit.

4. Clean the interior of the unit using stainless steel cleaner and polish (see page 11).

5. Clean the exterior of the unit using stainless steel cleaner and polish (see page 11).

6. Plug the unit into the electrical receptacle or turn on the circuit breaker.

7. Turn on the master switch located behind the grille. Press the OFF button one time to turn the

unit on. The controller display will show the actual temperature inside the cabinet.

8. The cooling process will begin to bring the unit to the set temperature. It is recommended you

run the unit for 24 hours to stabilize the operating temperature before using.

Never attempt to repair or perform maintenance on the unit until the main electrical power has

been disconnected!

10

©2021 Hestan Commercial Corporation

LED REPLACEMENTLED REPLACEMENT

To receive parts and/or service and the name and telephone number of the nearest Hestan

authorized service representative, please contact your Hestan dealer or distributor, or Hestan’s

Customer Service Department by calling 888-905-7463 or e-mailing outdoorwarranty@hestan.com

CLEANING

STAINLESS STEEL CARESTAINLESS STEEL CARE

Stainless Steel is widely used for catering and residential kitchen equipment because of its strength,

its ability to resist corrosion, and its ease of cleaning. Unfortunately, the metal is often taken

for granted and it is assumed that no problems will arise during its usage. However, some care is

required to ensure a long service life of the appliance.

Stainless steel is a “passive” metal because it contains other metals like chromium, nickel and

manganese that stabilize the atoms. Chromium provides an invisible passive film that covers the steel

surface, acting as a shield against corrosion. As long as the film is intact and not contaminated, the

metal is passive and stainless. If the passive film of stainless steel has been broken, equipment can

start to corrode and rust.

Three materials or processes can break down stainless steel’s passive layer and allow corrosion to

occur:

• Mechanical abrasion

• Deposits and water

• Chlorides

Mechanical abrasion refers to items that will scratch a steel surface. Steel pads, wire brushes and

scrapers are prime examples.

Water comes out of the faucet in varying degrees of hardness. Hard water may leave spots. When

allowed to sit, these deposits will break down the passive chromium layer and rust stainless steel.

Other deposits from food preparation must be promptly removed with an appropriate cleaning

agent.

Chlorides are found nearly everywhere. They are in water, food and table salt. Household and

industrial cleaners are the worst offenders. Examples of products containing chlorides are bleach,

and pool chlorine. Outdoor locations near a swimming pool, or near areas where liquid fertilizers are

used can also contribute to corrosion of your Hestan products.

EN

PREVENTING STAINLESS STEEL RUSTPREVENTING STAINLESS STEEL RUST

Use non-abrasive tools to clean stainless steel products. Soft cloths and plastic scouring pads will

not harm the steel’s passive layer. Clean with polish lines. Some stainless steels have visible polishing

lines or “grain”. When visible lines are present, always scrub in a motion parallel to the lines. When

the grain cannot be seen, polish in a consistent straight pattern and not in a circular motion.

Use alkaline, alkaline-chlorinated or non-chloride containing cleaners. While many traditional

cleaners are loaded with chlorides, the industry is providing an ever-increasing choice of non-chloride

cleaners. If you are not sure of chloride content in the cleaner being used, contact your cleaner

supplier. If your present cleaner contains chlorides, ask your supplier for an alternative. Avoid

cleaners containing quaternary salt; it also can attack stainless steel and cause pitting and rusting.

Keep food equipment clean. Use alkaline, alkaline-chlorinated or non-chloride cleaners at

recommended strength. Clean frequently to avoid build-up of hard, stubborn stains. The single most

likely cause of damage is chlorides in the water. Remember, adding heat to cleaners that contain

chlorides dramatically increases their effect on stainless steel.

If chlorinated cleaners are used, immediately rinse and wipe equipment and supplies dry. The sooner

you wipe standing water, especially when it contains cleaning agents, the better. After wiping

equipment down, allow it to air dry. Oxygen helps maintain the stainless steel passive film.

CLEANING THE CABINET INTERIOR / EXTERIORCLEANING THE CABINET INTERIOR / EXTERIOR

NEVER use hydrochloric acid (muriatic acid) on stainless steel. Do not use abrasive cleansers or

cloths on any interior or exterior surfaces or removeable parts.

Glass panels may be cleaned using any standard glass cleaner available on the market.

To clean interior and exterior non-metallic surfaces and removable parts, wash with mild solution of

soap and lukewarm water with a little baking soda. Rinse and dry thoroughly. Avoid getting water

on the lights, controllers, fan motors and unfinished wood wine rack faces.

©2021 Hestan Commercial Corporation

11

Loading...

Loading...