Hestan AEB121NGSS, AEB122NG, AEB122LPSS, AEB121LPSS Installation Manual

LP PORTABLE TANK

CONNECTION KIT

AGCKLPT

IMPORTANT - READ ALL INSTRUCTIONS BEFORE YOU BEGIN

THE INSTRUCTIONS HEREIN SHOULD BE PERFORMED BY A QUALIFIED SERVICE TECHNICIAN.

THE APPLIANCE MUST BE COMPLETELY COOL AND THE PREVIOUS GAS SOURCE MUST BE SHUT

OFF OR REMOVED BEFORE ATTEMPTING INSTALLATION.

Some parts inside your appliance have sharp edges. Care must be taken when handling the various

components to avoid personal injury. Wear gloves when handling.

TOOLS REQUIRED:

Work gloves

Safety glasses

Phillips screwdriver

Pipe wrench or large slip-joint pliers

Thread sealant

Power drill with masonry bit

SS fasteners and/or masonry anchor bolts

EN

DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your gas

supplier or your fire department.

IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH.

Flammable Gas - disconnect all propane or natural gas supplies to this

unit before servicing.

Electrical Parts & Components – disconnect all power supplies and

batteries before servicing.

1. Do not store or use gasoline or

other flammable liquids or vapors

in the vicinity of this or any other

appliance.

2. An LP cylinder not connected for

use shall not be stored in the vicinity

of this or any other appliance.

DANGER

READ THIS MANUAL CAREFULLY AND COMPLETELY BEFORE USING YOUR

APPLIANCE TO REDUCE THE RISK OF FIRE, BURN HAZARD, OR OTHER

INJURY. KEEP THIS MANUAL FOR FUTURE REFERENCE.

©2017 Hestan Commercial Corporation

1

EN

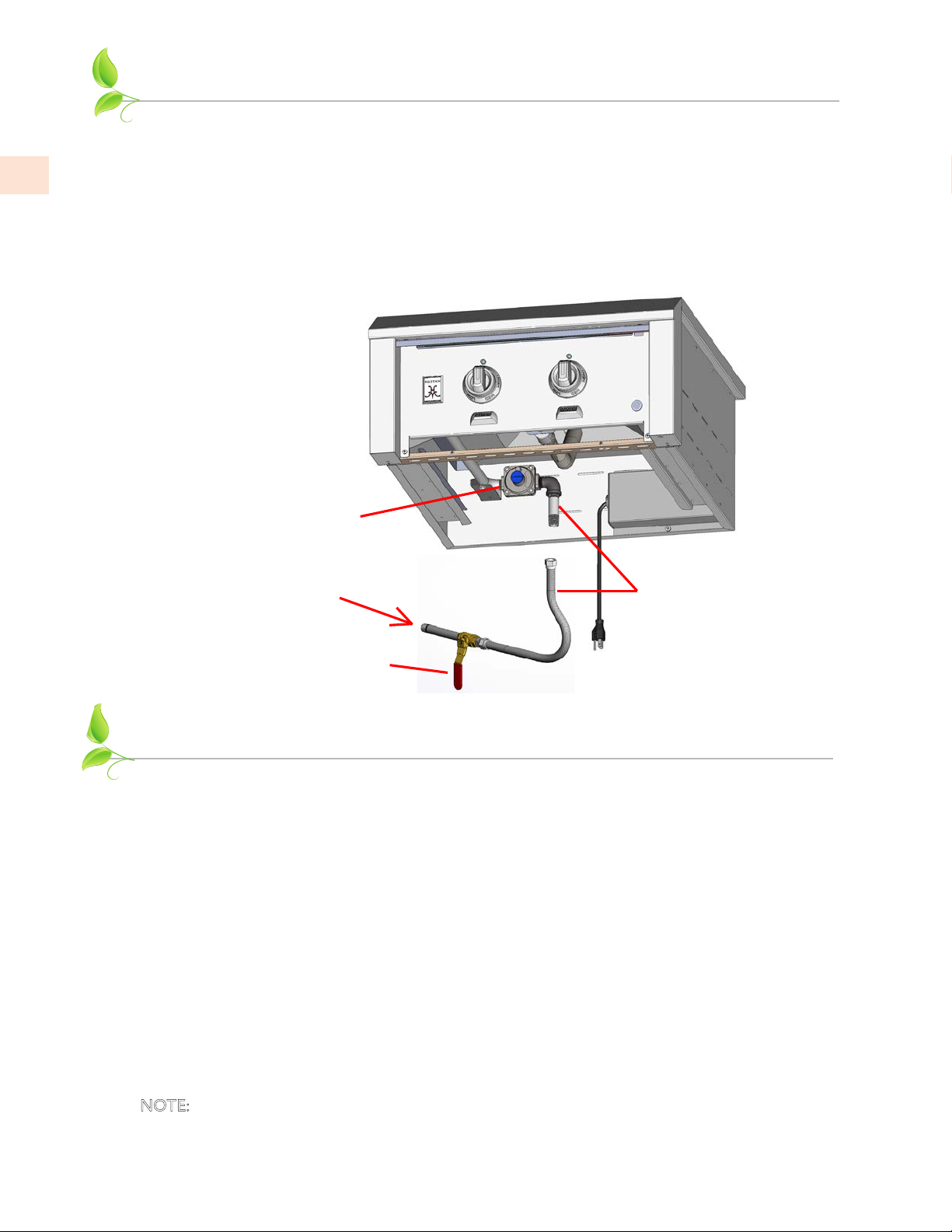

REMOVING THE OLD REGULATOR

NOTE: If you are converting your appliance from an existing regulator as seen below, it must be

removed before you can use the new regulator/hose assembly in this kit. If your existing regulator

was for a Natural Gas (NG) appliance, you will also need a Gas Conversion Kit to change all your

orifices from NG to LP. Please contact your Hestan dealer to order the appropriate kit.

HESTAN POWER BURNER

(MODEL AGPB24-LP shown)

REMOVE THIS

REGULATOR

INCOMING

LP GAS SUPPLY

SHUTOFF VALVE

(SUPPLIED BY

CUSTOMER)

1/2” ID FLEX HOSE,

ELBOW & NIPPLE

(SUPPLIED BY

CUSTOMER)

GAS CONNECTIONS

GAS SUPPLY

Gas connections should be made by a qualified plumber, or your professional outdoor appliance

installer.

Make certain new piping and connections have been made in a clean manner and have been purged

so that piping compound, chips, etc. will not clog regulators, valves, orifices, or burners. Use pipe

joint compound / thread sealant approved for natural and LP gases.

NEVER CONNECT THE APPLIANCE TO AN UNREGULATED GAS SUPPLY. Before proceeding,

ensure the appliance is fitted for Natural or Liquid Propane gas. Connecting to an improper gas type

will result in poor performance and increased risk of damage or injury. Gas type and gas consumption

(BTU per hour) for each burner type is shown on the rating label affixed to the underside of the drip

tray.

Installation of this cooking appliance must be made in accordance with local codes. In the absence of

local codes, this unit should be installed in accordance with the National Fuel Gas Code No.

NFPA 54

Code

, Natural Gas and Propane Installation code

B149.2.

CSA B149-1,

or Propane Storage and Handling

Z223.1/

NOTE: See rating label for manifold pressure for the type of gas of your appliance. To ensure proper

heating performance of this appliance, verify that the supply pressure is adequate (11.0” WC supply

pressure is preferred) to maintain 10.0” WC manifold pressure.

2

©2017 Hestan Commercial Corporation

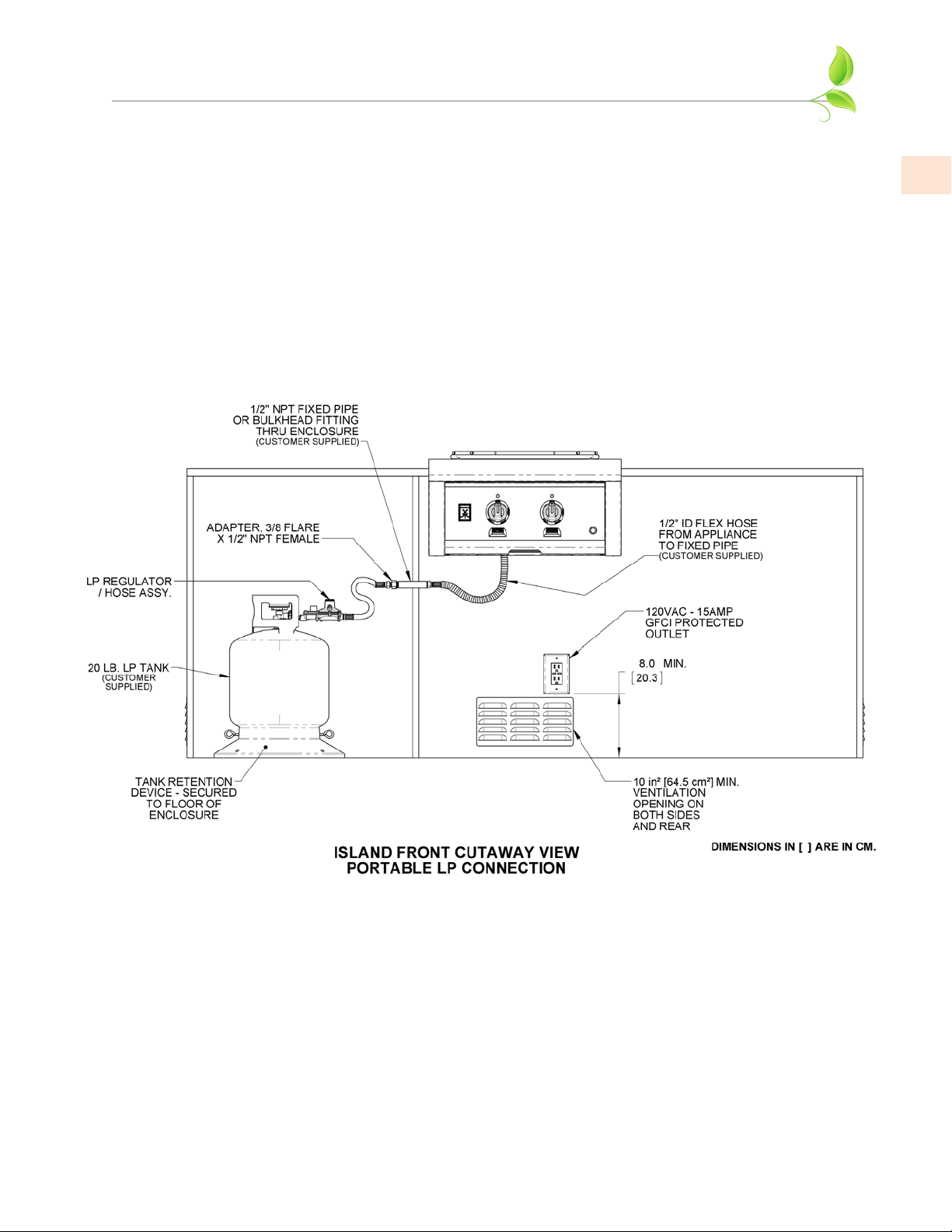

INSTALLATION OF NEW REGULATOR

1. The gas connection at the appliance must use a minimum 1/2” diameter flexible (semi-rigid)

stainless steel gas hose up to the fixed pipe / bulkhead fitting as shown below. The gas line

connectors must comply with the

Manufactured Homes, ANSI Z21.75 • CSA 6.27

stainless steel gas connection shall be 6 feet (1.82 m) or less.

2. Connect the regulator/hose assembly to the 3/8” Flare (compression flare fitting) X 1/2” NPT

female adapter as shown. Use appropriate thread sealant on all connections. The hose as well as

the connectors must comply with the

Manufactured Homes, ANSI Z21.75 • CSA 6.27

NOTE: Locate the pipe and regulator assembly in such a way that the regulator cannot touch

the floor of the enclosure when disconnected from the LP cylinder. This is important so that no

contaminants can get into the large connection end. Also be sure all hoses are away from heat

sources and away from sharp edges which may cut into the hose and cause a leak.

Standard for Connectors for Outdoor Gas Appliances and

, and suitable for outdoor installation. This

Standard for Connectors for Outdoor Gas Appliances and

, and suitable for outdoor installation.

EN

3. Place the tank retention device on the floor of your island (enclosure). Temporarily place a

standard 20 lb. LP cylinder in the retention device and connect the regulator/hose assembly to

the cylinder. DO NOT OPEN THE GAS VALVE. Move the retention device to a convenient

location which allows for easy access to the cylinder shutoff valve, and does not stretch or kink

the hose. When you believe you have the device located correctly, mark the floor around the

device, disconnect the regulator and remove the cylinder from the island.

4. Using the holes provided in the retention device, secure it to the floor with screws (not included).

Use of stainless-steel screws is highly recommended.

5. Re-install the LP cylinder in the retention device and re-connect the regulator/hose assembly.

6. Proceed to LEAK TESTING section.

©2017 Hestan Commercial Corporation

3

EN

LEAK TESTING

GENERAL

A complete gas tightness check must be performed of all gas-carrying components due to possible

movement during installation, or excessive pressure unknowingly being applied to parts of the unit.

BEFORE TESTING

• Do not smoke while leak testing.

• Never leak test with an open flame.

• Make a soap solution of one part liquid detergent and one part water for leak testing purposes.

• Apply the solution to the gas fittings by using a spray bottle or a brush.

• For LP units, always check with a full LP cylinder.

TO TEST

• Make sure all control valves are in the “OFF” position.

• Apply the soap solution described above to all fittings.

• Turn the gas supply on.

• Check all connections from the supply line, or LP cylinder up to and including the manifold pipe

assembly.

• Soap bubbles will appear where a leak is present. If a leak is present, immediately turn off gas

supply, tighten any leaking fittings, turn the gas supply back on, and recheck.

• If you cannot stop a gas leak, turn off the gas supply and call the dealer where you purchased

your appliance.

• Do not use the appliancel until all connections have been checked and do not leak.

IMPORTANT NOTE - ALWAYS CHECK FOR LEAKS AFTER EVERY LP CYLINDER CHANGE.

ADDITIONAL WARNINGS

1. The appliance shall be used only outdoors and shall not be used in buildings, garages, sheds,

breezeways, or any enclosed areas. Do not operate the appliance under unprotected,

combustible construction. Use only in well-ventilated areas. See the INSTALLATION section of

the manual that came with your appliance for more details.

2. Portable LP cylinders - Always shut off the main valve on the liquid propane (LP) cylinder after

each use. Never use a dented or rusted LP cylinder. Never attach or disconnect an LP cylinder, or

move or alter gas fittings when the appliance is in operation or is hot.

3. Inspect LP gas supply hose prior to each use of the appliance. The hose must be kept away from

heated areas of the appliance. If there is evidence of excessive abrasion or wear, or the hose is

cut, it must be replaced before using the appliance. The hose and LP regulator are supplied as a

complete assembly and must be replaced together. Do not attempt to repair or replace the hose

itself. Contact your Hestan dealer for genuine replacement P/N 014309.

4

©2017 Hestan Commercial Corporation