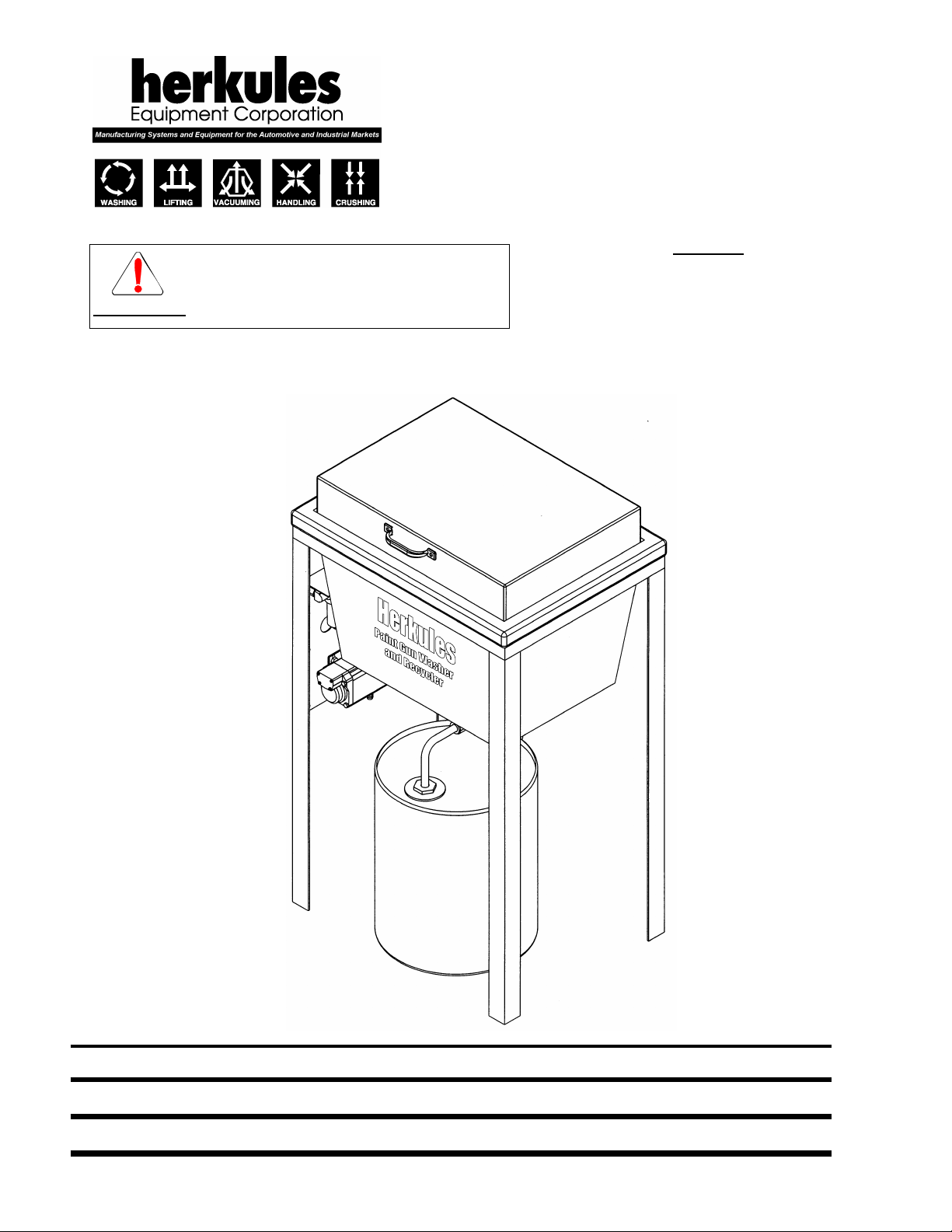

Herkules O505, O500 User Manual

OWNER’S

Part# 1000692

7/12/99 tn

This manual contains important information

concerning the installation and operation of the gun

washers listed at the right. Read manual thoroughly

INSTRUCTIONS and keep for future reference.

MANUAL

Models:

O500 O505

Herkules Equipment Corporation 2760 Ridgeway Court Walled Lake, MI 48390-1662 USA

248-960-7100

1-800-444-4351 Fax 248-960-7109

01980973(200)

Table of Contents

Warnings …………………………………………………………………………………………………………….. 3-4

Model Information …………………………………………………………………………………………. ……….. 5

Installation …………………………………………………………………………………………………………… 5

Operation ……………………………………………………………………………………………………………. 6-7

Preventive Maintenance …………………………………………………………………………………………… 8

Troubleshooting …………………………………………………………………………………………………….. 9

Notes …………………………………………………………………………………………………………………. 10

Drawings with part lists

318 Diaphragm Pump Port Connections ………………………………………………………………………… 11

O500 …………………………………………………………………………………………………………………. 12-13

O505 …………………………………………………………………………………………………………………. 14-15

Warning Symbol Caution Symbol

WARNING

This symbol alerts you to the possibility of

serious injury or death if you do not follow

the instructions.

Serial Number

Purchase Date

Model Number

Distributor

This symbol alerts you to the possibility of

damage to or destruction of equipment if

you do not follow the instructions.

CAUTION

2 of 15

WARNING

INSTRUCTIONS

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly

and result in serious injury.

•

This equipment is for professional use only.

•

Read all instruction manuals, tags, and labels before operating the equipment.

•

Use the equipment only for its intended use.

•

Do not alter or modify this equipment.

•

Do not exceed the maximum working pressure of the lowest rated system component.

•

Do not operate the gun washer at a pressure above the maximum working pressure rating of the

gun(s) being cleaned.

•

Route the hoses away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not use the hoses to pull the equipment.

• Do not move pressurized equipment.

• Use fluids or solvents that are compatible with the equipment wetted parts. Read the fluid and

solvent manufactures warnings.

• Comply with all applicable local, state and national fire, electrical and other safety regulation.

PRESSURIZED EQUIPMENT HAZARD

Spray from hose leaks, ruptured components, or from operating the gun washer with an open

lid can splash fluid in the eyes or on the skin and cause serious injury.

• A safety device has been installed to shut off the pump when the gun washer lid is opened. Do not

tamper with or alter this device.

• Open the gun washer lid slowly.

• Do not prop the gun washer lid open with an object or by any other means.

• Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

• Tighten all fluid connections before operating the equipment.

• Replace worn, damaged, or loose parts immediately.

3 of 15

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous

condition and result in fire or explosion and serious injury.

•

Ground the equipment. See Installation for grounding procedure.

•

Provide fresh air ventilation to avoid the build up of flammable fumes from the solvent.

•

Extinguish all open flames or pilot lights in gun washer area.

•

Electrically disconnect all equipment in the gun washer area.

•

Keep the gun washer area free of debris, including solvent, rags, and gasoline.

•

Do not turn on any light switch in the gun washer area while operating or if fumes are present.

•

Do not smoke in the gun washer area.

•

Do not operate a gasoline engine in the gun washer area.

•

Follow the gun manufactures solvent and other cleaning recommendations.

•

Use solvent with the highest possible flash point.

•

If there is any static sparking while using the equipment, stop operation immediately. Identify

and correct the problem.

•

Drain the solvent into a proper storage container when gun washer(s) is not in use.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in eyes or on

the skin, swallowed, or inhaled.

•

Know the specific hazards of the fluid you are using. Read the fluid manufactures warnings.

•

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

•

Wear the appropriate protective clothing, gloves, eyewear and respirator.

•

Pipe and dispose of the exhaust air safely. If diaphragm fails, the fluid may be exhausted along

with the air.

4 of 15

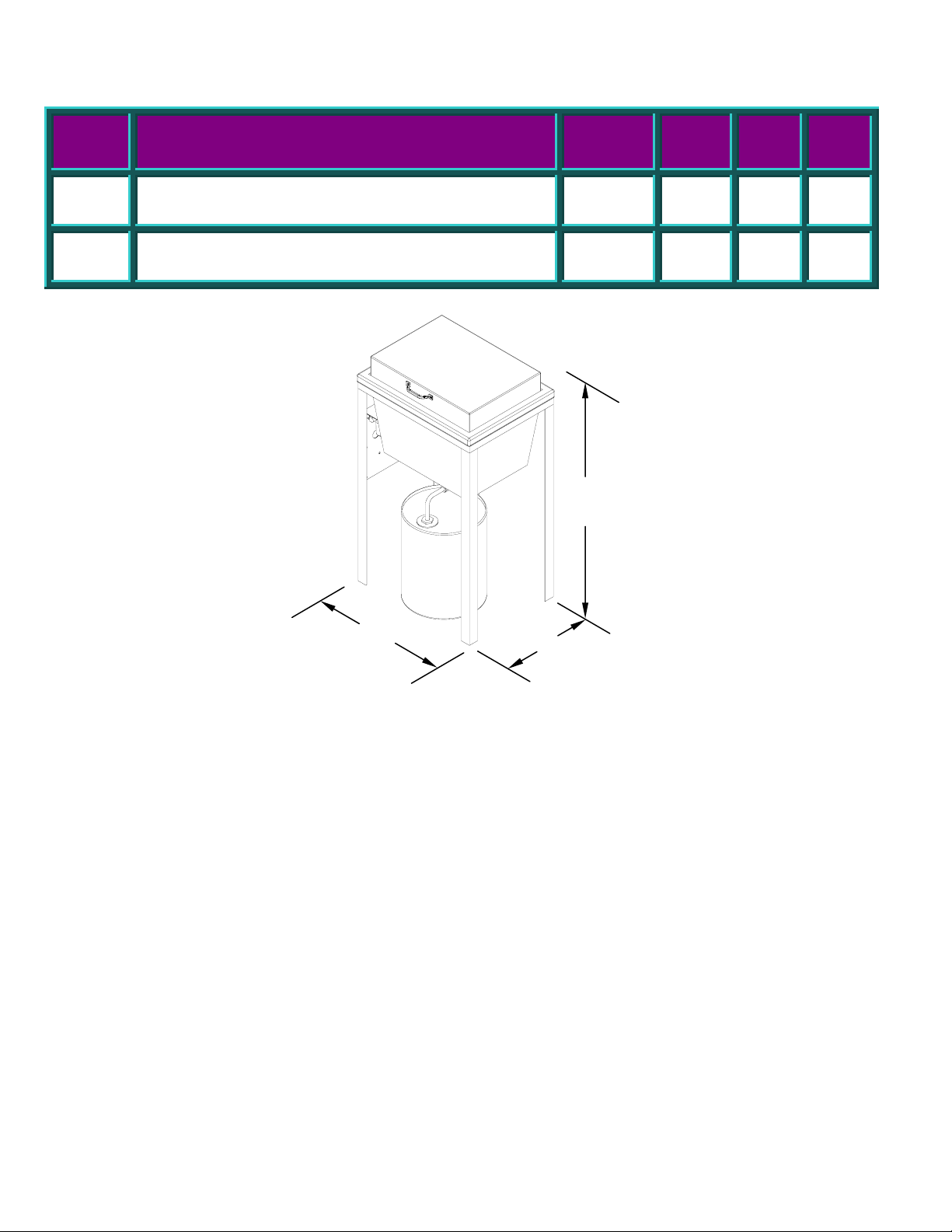

Model Information

Model Description

O500 One gun, one cup paint gun washer / recycler with

diaphragm pump, filter-regulator, and timer.

O505 O500 for use with water based cleaning solutions or

standard lacquer thinner solvents.

Model shown: O500

01980973(200)

Weight

(kg.)

45

(20)

48

(22)

Dim. A

(mm.)

20.5

(521)

20.5

(521)

Dim. B

(mm.)

15.625

(397)

15.625

(397)

Dim. C

(mm.)

35

(889)

35

(889)

C

A

Installing the Gun Washer

1. Place gun washer on a level surface in a

properly ventilated paint mixing room.

Grounding the Gun Washer

1. Connect the ground wire on the gun washer to a

true earth ground.

2. Ground all equipment used or located in the gun

washer area.

Connecting the Air Line

1. Install a 1/4 in. npt male coupler into the air inlet

at the left front of the housing. Hand tighten the

1/4 in. npt coupler into the inlet. Then, wrench

tighten 1/4 turn.

B

Installation

2. Connect a permanent shop air line of 65-120

psi. Filter/regulator is preset. Do not adjust

Connecting the Solvent to the Washer

1. Insert the white, plastic siphon plug into a fresh

5

gallon solvent can. The can must contain at

least 4 gallons of solvent to pump properly. Use

a high quality, slow evaporating solvent, such as

DuPont's 3661S or equivalent.

2. Place the siphon tube into the 5-gallon can

through the white plastic plug. Attach the flare

nut end of the siphon tube to the flare fitting on

the underside of the mini gun washer. Tighten

the flare nut by hand and snug with wrench.

IMPORTANT: Do not over tighten.

5 of 15

Loading...

Loading...