Herkules 11981 INSTALLATION INSTRUCTIONS

Part# 1002389

Y

7/13/2005

INSTALLATION INSTRUCTIONS

11981 TIMED DIAPHRAGM PUMP CONVERSION ASSEMBL

FOR CONVERTING A TIMED GUN WASHER FROM

A PISTON PUMP TO A DIAPHRAGM PUMP

Plastic Bag Contents Assembling Diaphragm Pump Housing onto

Gun Washer

• Installation Instructions

• 2 nuts, 2 flat washers, 2 lock washers, and 1) Loosely mount the 11981 diaphragm pump

2 nylon spacers assembly onto the gun washer stand.

• Solvent intake filter

• 2 steel tubes with flare nuts. Note: The timer knob is at the front of the

• Operating instructions decal for washer lid housing assembly and the filter and air

• Owner's Manual: GW/R-T-OM tubing lines are at the rear.

Removal of Gun Washer's Piston Pump

2) Place the two nylon spacers over the housing

Assembly bolts and insert into the gun washer frame

holes. Place flat washer, then lock washer,

1) Disconnect shop air line from Gun Washer. then nut onto the 1" bolt. Finger tighten only.

2) Drain and clean inside of tub.

3) Remove filter from inside tub. 3) Connect the steel tubes between the pump and

4) Disconnect ground wire from pump. the tub. Use finger force to engage threads on

5) Disconnect the solvent tube fittings at the tub flare nuts.

inlet and outlet locations.

6) Cut or disconnect the ties holding the grey a) Connect the shorter, 3/8" diameter tube

timer tube to the Gun Washer frame. between the "Material Outlet" of the pump

7) Remove the two plastic air lines on the safety and the upper bulkhead of the tub. Finger

shut-off switch at the lid. tighten.

Note: To remove air lines use a fingernail or

b) Connect the longer, 1/2" diameter tube

screw driver to press in brass collar on the between the "Material Inlet" of the pump to

roller switch, then pull on tubing to remove. the lower bulkhead of the tub. Finger

tighten.

8) Remove piston pump saddle clamp from Gun

Washer frame. Dispose of the entire piston

c) When the housing and solvent tubes are

pump assembly, including the timer tube. aligned, tighten the four flare nuts

4) Tighten the diaphragm pump housing's two

1/4-20 x 1" hex head bolts, washers, and nuts

as loosely assembled in step 1.

Herkules Equipment Corporation 2760 Ridgeway Court Walled Lake, MI 48390-1662 USA

248-960-7100

1-800-444-4351 Fax 248-960-7109

www.herkulesequipment.com

■ info@herkules.us

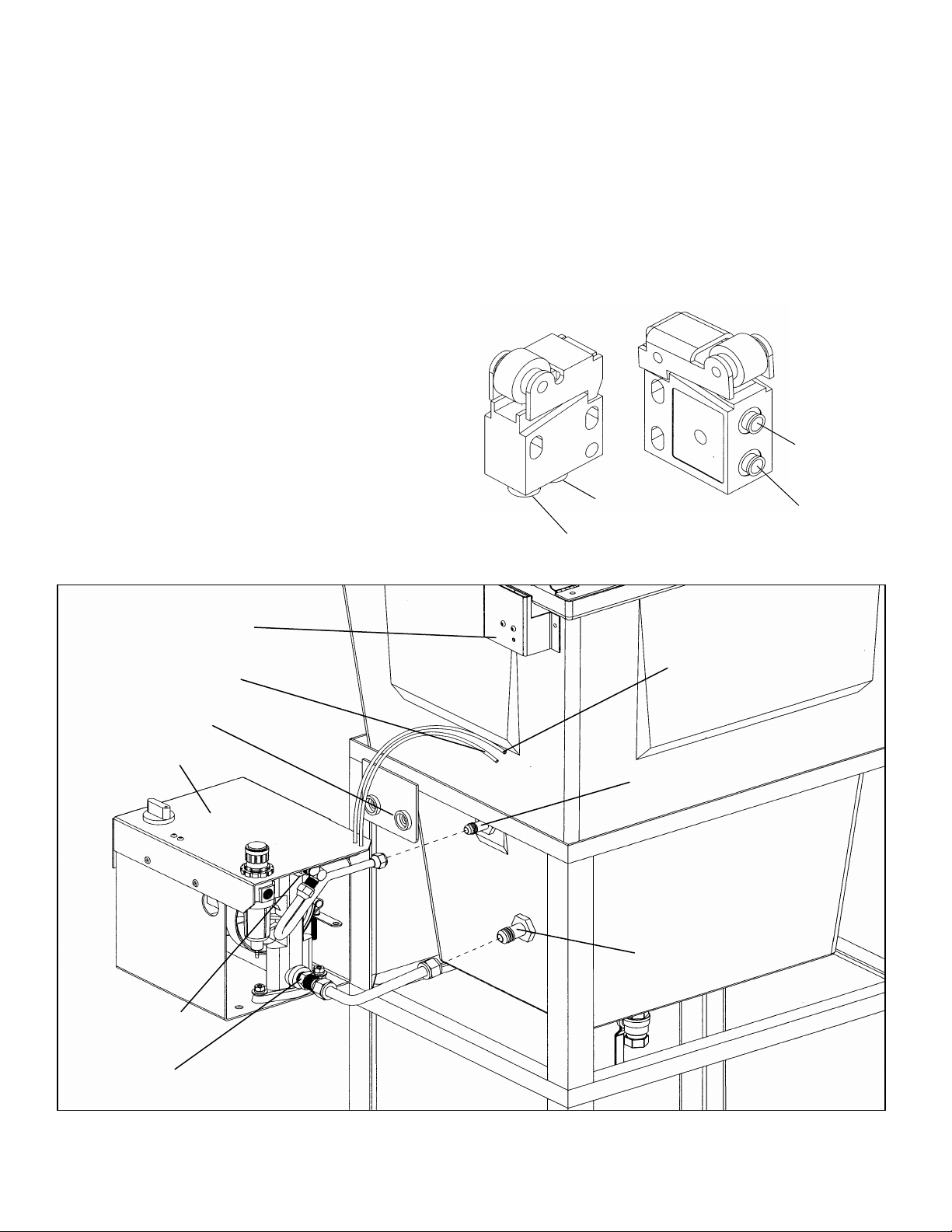

5) Connect the blue plastic air tubing running from 7) Connect a shop air line of 65-120 psi. The paint

the housing (timer cut off switch) to the in port gun washer's filter-regulator is factory preset

of the safety shut-off switch at the lid. The and locked at 65 psi. DO NOT ATTEMPT TO

switch is shielded by an aluminum panel. See CHANGE THIS SETTING.

drawings. Press tubing in through the collar

until seated in the black, roller safety shut-off

8) Connect the coiled ground wire attached at the

switch. The hose must bottom out in the front of the pump to the shop's ground. Route

switch. Then, pull firmly to test for a tight the wire through the housing and out the back.

connection.

In the same way, connect the black plastic air

tubing line running from housing (pump) to the

out port of the safety shut-off switch at the lid.

Again press tubing in through the collar until

seated in the roller safety shut-off switch. The

hose must bottom out in the switch. Then, pull

firmly to test for a tight connection.

6) Install your own 1/4" male connector into the

filter-regulator inlet at the back of the pump

housing. IMPORTANT: Hand tighten your air

coupler male connector into the filter-regulator

inlet. Then, wrench tighten it 1/4 turn only.

Safety shut off switch

Black air tubing

Nylon spacer

#M1C

IN PORT

OUT PORT

#M1

OUT PORT

IN PORT

Blue air tubing

Pump housing

Material outlet

Material inlet

Upper bulkhead

Lower bulkhead

Loading...

Loading...