Herkules 10792 INSTALLATION INSTRUCTIONS

V

Equipment Corporation

Manufacturing Systems and Equipment for the Automotive and Industrial Markets

Part# 1001483

6-21-01 TN

TM

CRUSHING

HANDLING

LIFTINGCURING

WASHING

ACUUMING

This manual contains important information

concerning the installation and operation of the

equipment listed below. Read manual

INSTRUCTIONS thoroughly and keep for future reference.

Herkules Equipment Corporation 2760 Ridgeway Court Walled Lake, MI 48390-1662 USA

248-960-7100 1-800-444-4351 Fax 248-960-7109

9

8

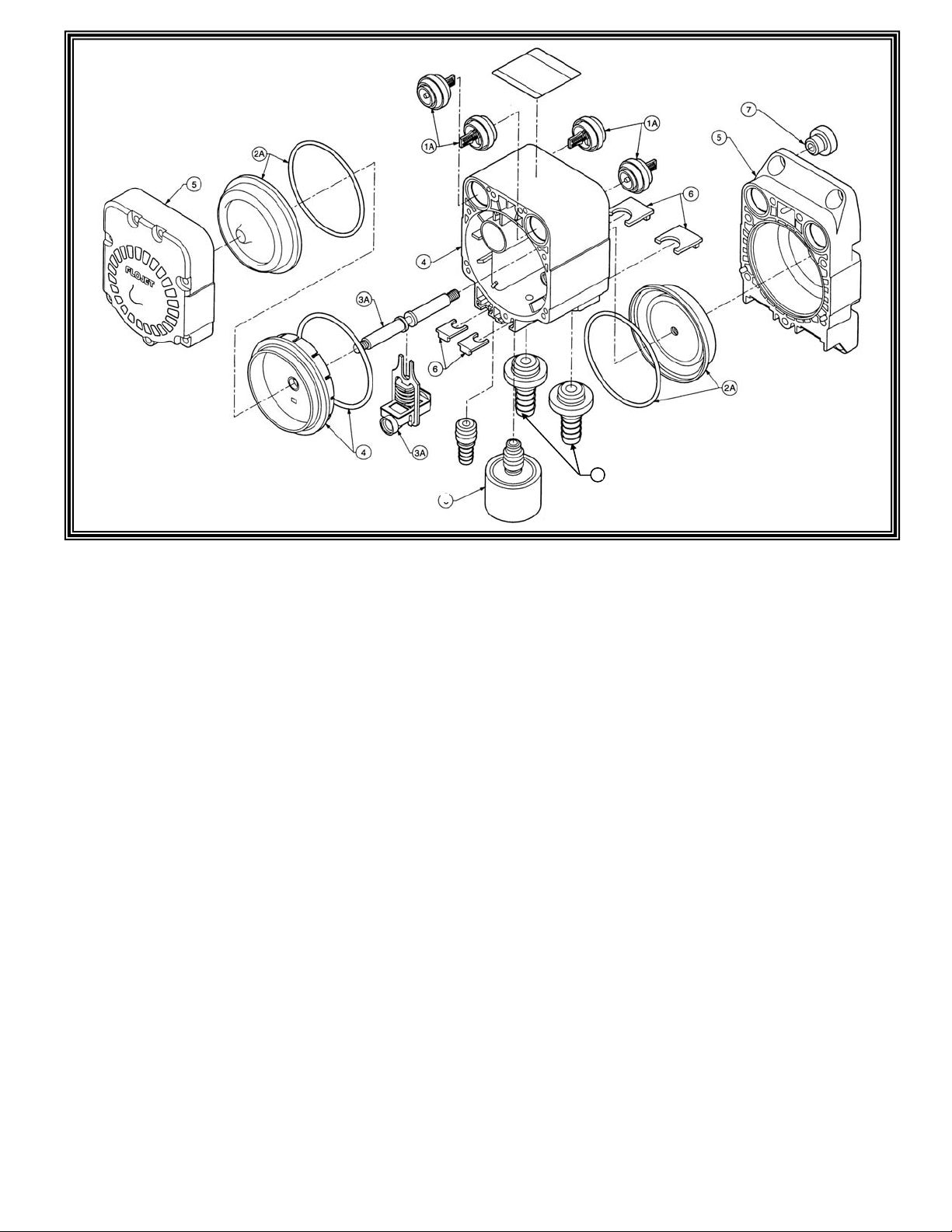

Item Description

1A. Check Valve

2A. Diaphragm & O-ring

3A. Slide Valve Assembly

4. Flange & O-ring

5. End Caps

6. Retaining Clips

7. Rubber Grommet

8. Muffler

9. Suction/Discharge Fitting

Disassemble Procedure

First remove all air in lines and suction/discharge

fittings from the pump. This is accomplished by using

a flat bladed screwdriver to slide the retaining clip

away from the air in and suction/discharge fittings and

pulling the fittings away from the pump body. Now

remove the

muffler by sliding the retaining clip away from the

muffler base and pulling the muffler out of the pump

body.

Using a Phillips screwdriver remove the seven screws

from the front-end cap followed by the seven screws

from the rear end cap. With the front end facing up

and the rear end facing down on the workbench,

position a flat bladed screwdriver into the slot located

above the muffler port and just below the pad marked

Air/CO

can be removed by placing the flat bladed screwdriver

under the fully opened port retaining clip and lifting off.

Note the position of the suction and discharge valves

before removing them from the pump body. The first

diaphragm is removed from the pump shaft by

unscrewing in a counter clockwise direction. The

second diaphragm is removed by the flat tip of a

screwdriver into he exposed slot at the end of the shaft

and unscrewing the diaphragm from the shaft. To

remove the flange housing, place the tip of a flat

bladed screwdriver into the air bleed hole on the lower

side of the flange housing and lift up the lower end

separating the flange housing from the pump body.

The slide valve assembly and the pump shaft can be

removed by simply pulling them from the pump body.

The pump shaft then can be removed from the slide

valve yoke assembly.

2 and lift off the front end cap. The rear end cap

Reassemble Procedure

Assemble the slide valve and the pump shaft with the

yoke placed between the two bumpers on the pump

shaft. Install the slide valve/pump shaft assembly into

the pump body making sure the o-rings in the slide

valve are in place. To install the flange housing,

prelube the o-ring with Parker Super “O” Lube and

install on flange housing and place housing over the

pump body aligning the flange housing with the pump

body ribs pressing it into place.

Install the first diaphragm and o-ring onto the pump

shaft threading it onto the shaft using a flat blade

screwdriver to hold the pump shaft until the diaphragm

is tight. Install the second diaphragm and o-ring onto

he pump shaft turning clockwise until tight.

Install the suction valves with springs facing into the

pump body and the discharge valves with the springs

facing out. See arrows on pump rear end cap below

suction and discharge ports.

Install the port retaining clips (large) into the pump end

cap (mounting base) and install the seven Phillips

screws into the pump body and cross tighten until

snug and the cross torque to 22-24 inch pounds.

Install port retaining clips (small) into the pump body,

tabs facing out, position the front end cap and install

the seven Phillips screws into the pump body and

cross tighten until snug and the cross torque to 22-24

inch pounds.

Install the muffler in the center port by pushing it in

and sliding the retaining clip into place. Install the

suction and discharge and the air in port fitting and

slide the retaining clips into place. Check for leaks.

Loading...

Loading...