Henny Penny CM-5, CM-7, CMT-5, CMT-7, HM-3 General Manual

...

Henny Penny

Heated Merchandiser

Model CM-5/7

Model CMT-5/7

Model HM-3/5/7

Model HMT-3/5/7

Model HS/HST-3

SERVICE MANUAL

TABLE OF CONTENTS

Section

Page

Section 1 INTRODUCTION 1-1

1-1 Heated Merchandiser 1-1

1-2 Features 1-1

1-3 Assistance 1-1

1-4 Model Variations 1-2

1-5 Safety 1-2

Section 2 INSTALLATION 2-1

2-1 Introduction 2-1

2-2 Unpacking 2-1

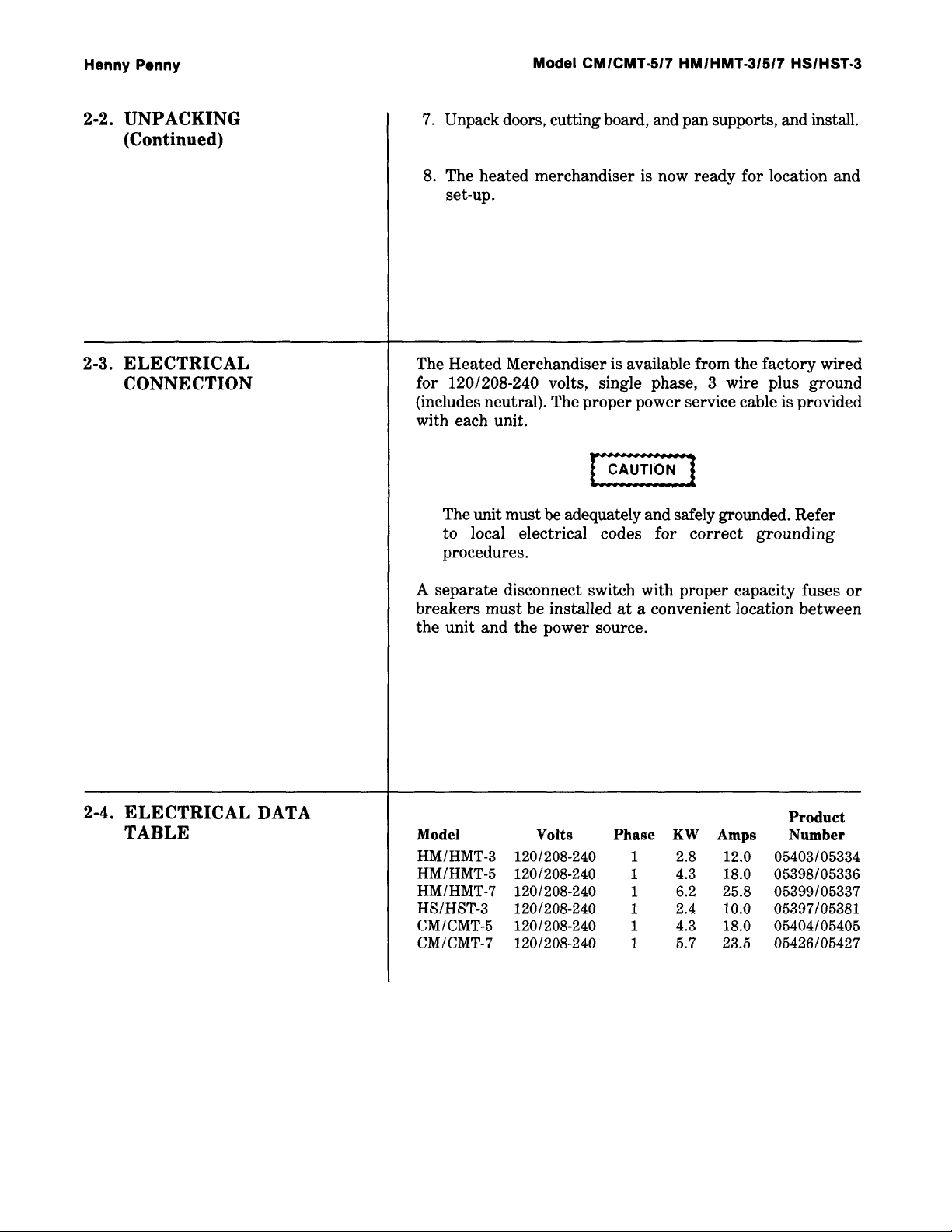

2-3 Electrical Connection 2-2

2-4 Electrical Data Table 2-2

2-5 Cabinet Dimensions 2-3

Section 3 OPERATION 3-1

3-1 Operating Controls 3-1

3-2 Start-Up 3-4

3-3 Operation With Product 3-5

3-4 Recommended Settings for Heated Merchandiser 3-6

3-5 Shut Down and Clean Up 3-6

Section 4 PROGRAMMING 4-1

4-1 Entering Program Mode 4-1

4-2 Programming Upper Heat 4-1

4-3 Programming Water Heat 4-1

4-4 Programming Air Temperature 4-1

4-5 Special Program Mode 4-1

4-6 Error Codes 4-2

Section 5 MAINTENANCE 5-1

5-1 Introduction 5-1

5-2 Removing Front Glass 5-1

5-3 Radiant Heaters 5-3

5-4 Light Socket 5-3

5-5 Water Heater 5-4

5-6 Base Heaters 5-5

5-7 Air Blowers 5-6

5-8 Heat Probe (Air) 5-6

5-9 Transformer 5-7

5-10 Product Probe Outlet 5-7

5-11 Heat Relay 5-8

TABLE OF CONTENTS (Continued)

Section

Page

Section 5 MAINTENANCE (Continued) 5-8

5-12 Cooling Fan 5-8

5-13 Printed Circuit Board 5-9

5-14 Gas Shocks 5-9

5-15 Fuse and Fuse Holder 5-10

5-16 Power and Light Switch 5-11

5-17 Wiring Diagrams 5-12

Section 6 TROUBLESHOOTING 6-1

6-1 Introduction 6-1

6-2 Troubleshooting 6-1

Section 7 PARTS INFORMATION 7-1

SECTION 1. INTRODUCTION

1-1. HEATED The Henny Penny Heated Merchandiser is a basic unit of food

MERCHANDISER processing equipment used to display the food product and

maintain the temperature of hot foods in a commercial food

service operation. Using a combination of precise heat,

humidity and slowly circulating air, Henny Penny's even heat

process creates the ideal environment to maintain the taste

and quality of freshly-cooked foods for hours.

1-2. FEATURES • Unique THERMA-VEC even heat process re-circulates

heated air, keeping temperature precise and stable

throughout the case.

• Contemporary curved glass cases present 100 per cent

product visibility.

• Individually controlled radiant heaters over each well.

• Air heating elements under pans.

• Humidity controlled with heated water pan.

• Touch pad electronic controls and LED readouts.

• Incandescent lighting for attractive food presentation.

• Fold-down cutting board.

1-3. ASSISTANCE Should you require outside assistance, just call your local,

independent Henny Penny distributor maintained by Henny

Penny Corporation. In addition, feel free to contact our

corporate headquarters in Eaton, Ohio. Dial 1-800-543-6243

toll free, except in Ohio, dial 1-800-762-2964.

Henny Penny Model CM/CIVIT- 5/7 HM/HMT- 3/5/7 HS/HST- 3 2-5

CABINET DIMENSIONS

Henny Penny Model CM/CMT-5/7 HM/HMT-3/5/7 HS/HST-3

Henny Penny Model CM/CMT - 5/7 HM/HMT- 3/5/7 HS/HST-3

SECTION 3. OPERATION

3-1. OPERATING CONTROLS

This section describes the functions of all operating controls.

Item

Description Function

No.

1 Increase Switch The increase switch is used during programming to increase

2 Decrease Switch The decrease switch is used during programming to decrease

3 Air Heat Switch This switch is depressed to set the air heat temperature set

4 Water Heat Switch This switch is depressed to set the water heat.

5 Upper Heat - 1, 2, 3, 4, These switches are depressed to set the radiant heaters.

and 5.

6 Temperature Display The temperature display is a three-digit red LED display. The

7

Ready LED product. It turns on to indicate the air temperature is near

8 Display Air Temp LED This LED turns on when the merchandiser air temperature

the displayed value by one setting. It is also used to enter

special program mode.

the displayed value by one setting. It is also used to enter

special program mode.

point.

NOTE

HM-3 will have 1, 2, and 3.

HM-7 will have 1 through 7.

display is used to show the air and product temperatures. It

is also used to display control error messages, and during

programming to show the parameter being programmed.

This LED turns on when the merchandiser is ready to hold

the set point.

is shown in the display.

9 Display Probe Temp LED This LED turns on when the product probe temperature is

10 UPPER HEAT 1, 2, 3, 4, These LED's turn on during operation when the associated

and 5 LED's radiant heater turns on.

shown in the display.

NOTE

The HM-3 has three LED's.

The HM-7 has seven LED's.

Henny Penny Model CM/CMT-5/7 HM/HMT-3/5/7 HS/HST-3

Item

Description Function

No.

11 Water Heat LED This LED turns on during operation when the water heater

is on.

12 Air Heat LED This LED turns on during operation when the air heater is on.

13 Power Switch The power switch is a two-position switch used to switch

electrical current to the unit.

14 Light Switch The light switch is a two-position switch that turns the lights

off and on.

15 Fuse The fuse (2) is a protective device for the PCB control, motor,

and lights circuit. The fuses are a 15 amp rating and must be

replaced by a fuse of the same size and rating.

Henny Penny Model CM/CMT-5/7 HM/HMT-3/5/7 HS/HST-3

Henny Penny Model CM/CMT.5/7 HM/HMT.3/5/7 HS/HST-3

3-2. START-UP Normal Operation

1. Turn POWER and LIGHTS to the ON position.

2. Fill water pan with approximately one quart of water (1

inch in water pan).

3. Allow approximately 30 minutes preheat time.

4. Check air temperature setting by depressing switch

marked AIR HEAT.

5. Check water temperature setting by depressing switch

marked WATER HEAT.

NOTE

Water heat settings read 1, 2, 3, etc. One meaning the

heat is on 10% of the time, and ON meaning the heat

is on 100% of the time. Refer to programming section

for correct setting changes. If you wish to operate unit

with no humidity, program water heat to OFF.

6. Check upper heat settings by depressing numbered switch

corresponding to each well.

NOTE

HM-3 is numbered 1 through 3; HM-5 is number 1

through 5; HM-7 is numbered 1 through 7. Refer to

"Recommended Settings for HM-3, HM-5, and HM-7."

7. As a rule, a lower upper heat setting, such as 3 or 4, holds

dense foods like macaroni and cheese or cherry cobbler.

Use higher upper heat settings for less dense foods, such

as fried chicken.

8. If using a probe to check product temperature, plug probe

into probe outlet (just left of the control panel) and place

probe into the product you are testing.

9. Depress switch marked PROBE TEMP DISPLAY.

Henny Penny Model CM/CMT-5/7 HM/HMT-3/5/7 HS/HST-3

3-3. OPERATION WITH 1. Rotate food from front to back.

PRODUCT

2. Food in half-full pans does not hold as well as food in full

pans. Rotate pan to back of merchandiser where it is

directly under upper heating elements or move food to a

smaller pan that has been preheated.

3. When "freshening" foods such as macaroni and cheese

with added water, heat the water in a clean container until

is it 10 to 20 degrees above the desired holding

temperature of the food. This will keep food at a safe

serving temperature. Depending on the amount of water,

the temperature can drop 10 to 20 degrees in as little as

five minutes.

4. When transferring hot foods in the heated merchandiser

to clean pans, preheat the clean pan. Transferring hot

foods to room temperature pans can cause the temperature

of the food to drop 20 degrees or more, thus causing food

to be at an unsafe serving temperature.

5. To keep hot foods from drying too fast, keep a clean

misting bottle (such as you find in a garden supply store)

with a mixture of 1/3 vegetable oil and 2/3 water on hand.

Set the nozzle for a fine mist. Shake the vegetable oil and

water mixture well. Spray surface of food immediately,

shaking the bottle between each entree. Frequency foods

need to be misted will depend upon the unique

characteristics of the food, the water heat setting in the

case and atmospheric conditions. Do not use this mixture

on foods with a pastry crust or crumb toppings where a

dry surface is desirable.

6. If prepackaging foods, place containers directly under

upper heating elements (in back of the case) for maximum

holding time. Upper heat may need to be increased slightly.

Henny Penny Model CM/CMT-5/7 HM/HMT-3/5/7 HS/HST-3

SECTION 4. PROGRAMMING

4-1. ENTERING PROGRAM

MODE

Program mode is entered by depressing and holding a

parameter switch. Parameter switches are AIR HEAT,

WATER HEAT, and the UPPER HEAT switches.

4-2. PROGRAMMING UPPER

HEAT

Depress and hold switch marked UPPER HEAT.

Using the INCREASE or DECREASE switches, program the

desired percentage on time of the radiant heater. The display

will be numbered 1 through 9. One meaning 10%; 2 meaning

20%, etc. "OFF" means the heater is always off- "ON" means

the heater is always on. Repeat procedures until all radiant

heaters are programmed.

4-3. PROGRAMMING

WATER HEAT

The procedure for programming the water heat is identical

to that of programming the radiant heat, except that the

WATER HEAT LED flashes.

4-4. PROGRAMMING AIR

TEMPERATURE

Depress switch marked AIR HEAT.

Using the INCREASE or DECREASE button, program

desired air temperature. Air temperature can be programmed

between 120°F and 175°F.

4-5. SPECIAL PROGRAM

MODE

Special program mode is used to perform the following

functions:

• Calibrating the air and product temperature probes.

• Initializing the program.

• Changing the control for Fahrenheit 0 /Celsius".

To enter the special program mode, depress and hold the

INCREASE switch and turn the power switch to the "ON"

position. Display will read "SP" for special program. To

exit special program, turn the power switch to "OFF".

To calibrate air temperature, depress and hold the

DISPLAY AIR TEMP switch. Display will show the actual

air temperature seen by the probe. Use your

INCREASEDECREASE switch to adjust the displayed

temperature. Temperature can be adjusted plus or minus 15

degrees.

Henny Penny Model CM/CMT-5/7 HM/HMT-3/5/7 HS/HST-3

Henny Penny Model CM/CMT- 5/7 HM/HMT-3/5/7 HS/HST-3

SECTION 8. MAINTENANCE

Henny Penny Model CM/CMT- 5/7 HM/HMT - 3/5/7

HS/HST-3

Henny Penny Model CM/CMT-5/7 HM/HMT-3/5/7 HS/HST-3

Henny Penny Model CM/CMT-5/7 HM/HMT-3/5/7 HS/HST-3

Henny Penny Model CM/CMT-5/7 HM/HMT-3/5/7 HS/HST-3

Loading...

Loading...