Henny Penny HMR-103 Service Manual

Henny Penny

Heated Merchandisers

Model HMR-103

Model HMR-104

Model HMR-105

Model HMR-106

Model HMR-107

TECHNICAL MANUAL

Model HMR-103,104,105,106,107

TABLE OF CONTENTS

Section Page

Section 1. TROUBLESHOOTING.................................................................................................... 1-1

1-1 Introduction ........................................................................................................... 1-1

1-2 Safety.................................................................................................................... 1-1

1-3. Troubleshooting ..................................................................................................... 1-1

1-4. Error Codes and Warnings.................................................................................... 1-4

Section 2. MAINTENANCE ............................................................................................................. 2-1

2-1. Introduction ........................................................................................................... 2-1

2-2. Maintenance Hints ................................................................................................ 2-1

2-3. Front Glass Replacement...................................................................................... 2-1

2-4. Radiant Heater Replacement ............................................................................... 2-3

2-5. Light Socket Replacement .................................................................................... 2-4

2-6. Water Heater Replacement .................................................................................. 2-5

2-7. Water Probe Replacement.................................................................................... 2-7

2-8. Base Heater Replacement .................................................................................... 2-10

2-9. Blower Motor Replacement ................................................................................. 2-11

2-10. Air Probe Replacement ........................................................................................ 2-12

2-11. Transformer Replacement .................................................................................... 2-15

2-12. Food Probe Receptacle Replacement .................................................................. 2-16

2-13. Relay Replacement............................................................................................... 2-17

2-14. Cooling Fan Replacement ..................................................................................... 2-18

2-15. Fuse and Fuse Holder Replacement..................................................................... 2-20

2-16. High Limit Replacement - Automatic Reset......................................................... 2-21

2-17. High Limit Replacement - Manual Reset ............................................................. 2-22

2-18. Power Switch Replacement ................................................................................. 2-23

2-19. Contactor Replacement ........................................................................................ 2-24

2-20. PC Board Replacement........................................................................................ 2-25

2-21. Light Bulb Replacement ....................................................................................... 2-26

2-21. Wiring Diagrams ................................................................................................... 2-27

Section 3. P AR TS INFORMATION.................................................................................................. 3-1

3-1. Introduction ........................................................................................................... 3-1

3-2. Genuine Parts ....................................................................................................... 3-1

3-3. How to Order ....................................................................................................... 3-1

3-4. Prices .................................................................................................................... 3-1

3-5. Delivery ................................................................................................................ 3-1

3-6. Warranty ............................................................................................................... 3-1

3-7. Recommended Spare Parts for Distributors ......................................................... 3-1

106 FM06-010 i

Revised 02-14-2014

Model HMR-103,104,105,106,107

SECTION 1. TROUBLESHOOTING

1-1. INTRODUCTION This section provides troubleshooting information in the form of an

easy to read table.

If a problem occurs during the first operation of a new unit,

recheck the Installation Section of the Operator’s Manual.

Before troubleshooting, always recheck the operating

procedure per the Operation Section of the Operator’s Manual.

1-2. SAFETY

Where information is of particular importance or is safety related,

the words, NOTICE, CAUTION, or WARNING are used.

Their usage is described below .

SAFETY ALER T SYMBOL is used with DANGER, W ARNING,

or CAUTION which indicates a personal injury type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

W ARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury .

1-3. TROUBLESHOOTING T o isolate a malfunction, proceed as follows:

1. Clearly define the problem (or symptom) and when it

occurs.

2. Locate the problem in the troubleshooting table.

3. Review all possible causes. Then, one-at-a-time work

through the list of corrections until the problem is solved.

203 1-1

Model HMR-103,104,105,106,107

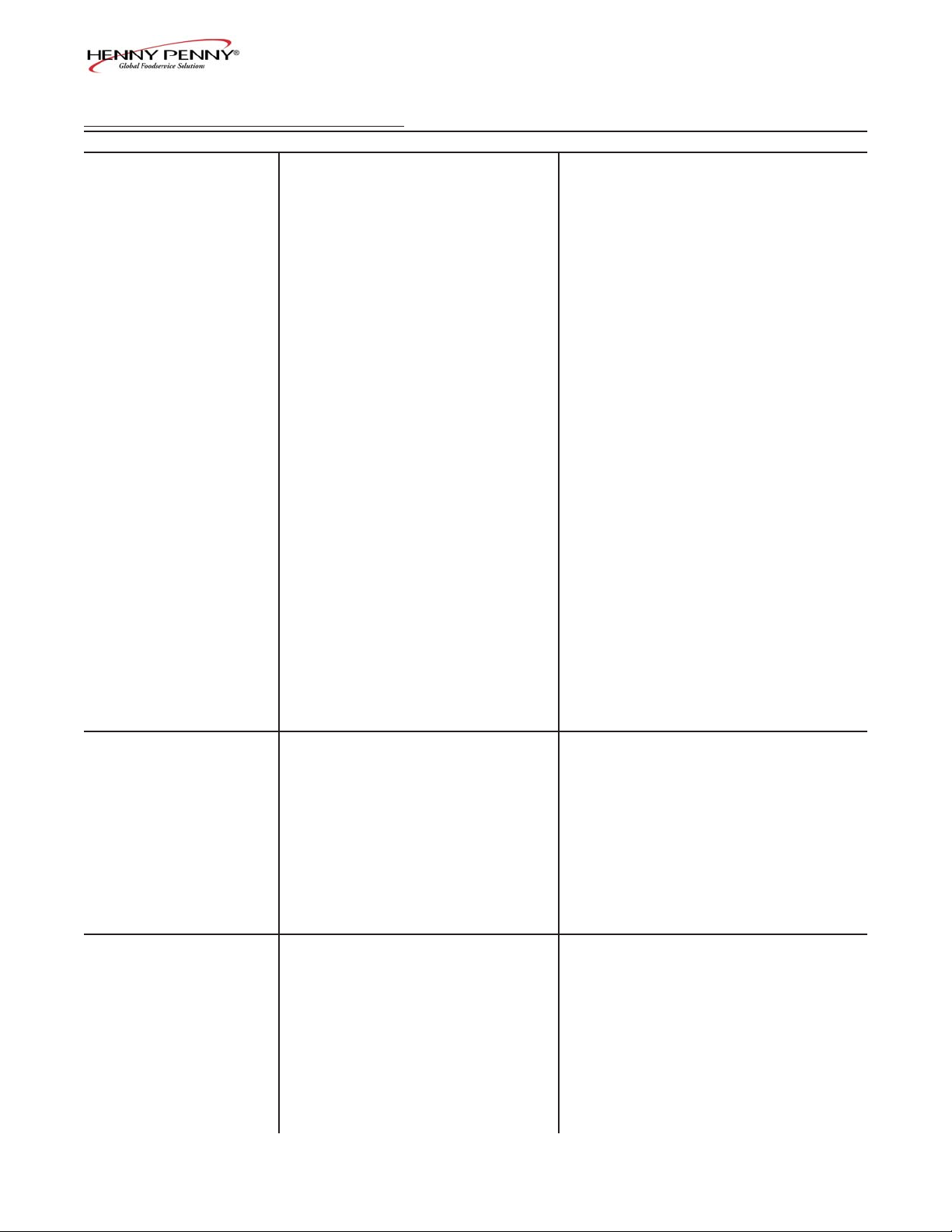

1-3. TROUBLESHOOTING (Continued)

PROBLEM CAUSE CORRECTION

With power switch in • Open circuit • Check to see that unit is

POWER position, unit plugged in

is completely

inoperative (no power) • Check breaker or fuse at

supply box

• Check control panel fuses per Fuse

and Fuse Holder Replacement Section

• Check voltage at wall

receptacle

• Check POWER switch;

replace if defective

• Check cord and plug for loose

connections

• Control board defective • Check for 12 volt input from

transformer; replace if

defective

• Transformer defective • Check input and output voltage;

replace if defective

Unit will not heat • Control board not calling • Check set point reading; if unit

for heat below setpoint and not calling

for heat, control board

defective

• Power on, board has • Hi limit tripped; check for

no display defective hi limit, or defective

blower motor

No air heat • Faulty heat relay • Check and replace

• Faulty air heater • Check and replace

• Unit not preheated • Preheat unit with pans in

place before loading product

• Faulty radiant/air heat PC board • Replace PC Board

1-2 803

Model HMR-103,104,105,106,107

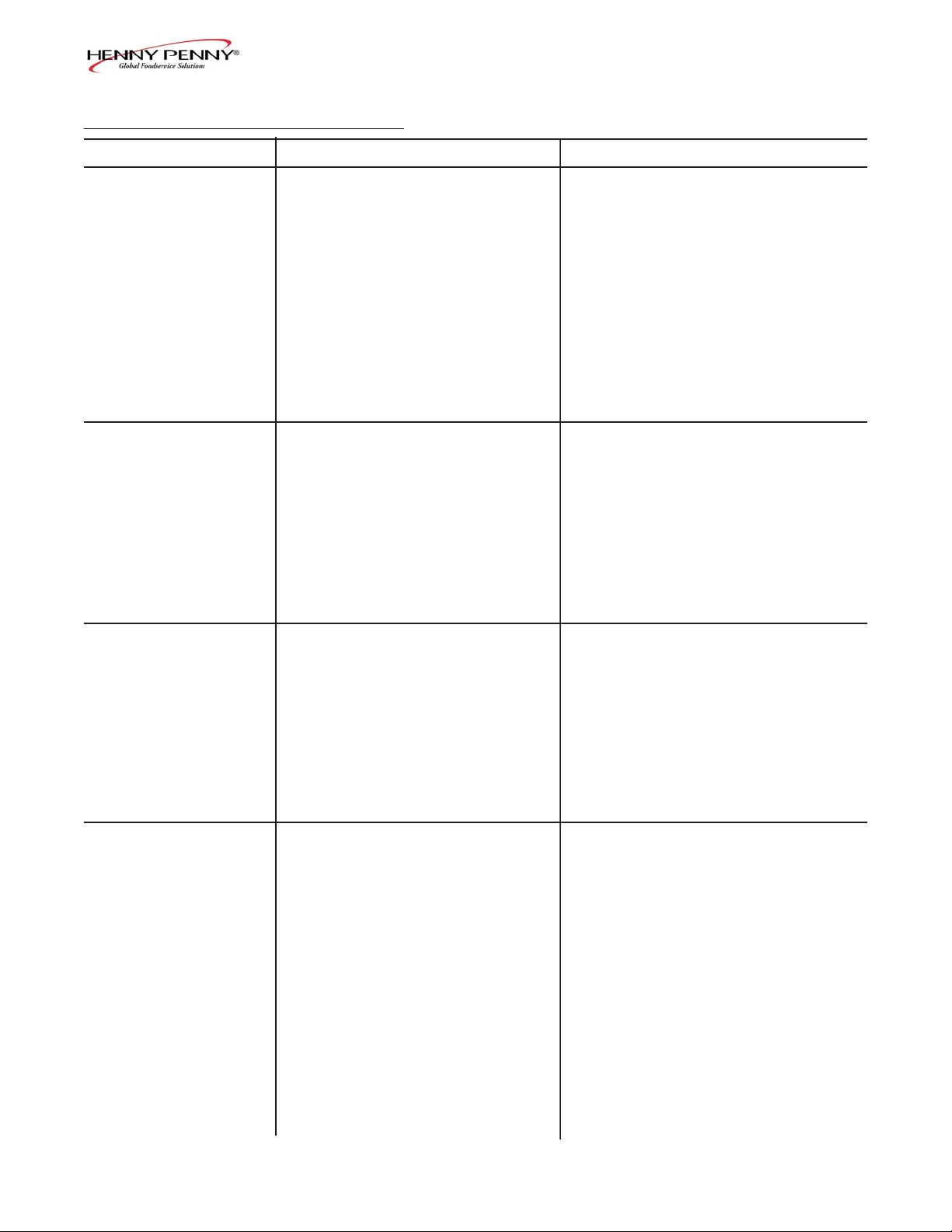

1-3. TROUBLESHOOTING (Continued)

PROBLEM CAUSE CORRECTION

No radiant heat • Faulty control • Replace the appropriate PC Board;

PC board each well has its own control board

• Faulty radiant heater • Replace radiant heater

No water heat • Faulty radiant/water heat • Replace PC board

PC board

• Faulty water heater • Replace water heater

No lights • Light switch defective • Replace light switch

• Light relay defective • Replace relay (same as heat relay)

• Light socket shorted • Replace light socket

• Light bulb blown • Replace light bulb

Canopy glass fogging • Air blowers not circulating • Replace blower motor

heated air across glass

• W ater heat setting too high • Lower water heat setting

• Radiant heat setting too low • Raise radiant heat setting

Product not holding • Doors are left open • Keep doors closed except to

temperature load and unload product

• Heat settings too low • Adjust heat settings

• Low or improper voltage • Using met er , compare receptacle

voltage to data plate voltage

• Product held too long • Hold product for recommended time

• Product not placed correctly in unit • Place product in unit as per Operation

with Product Section of Operator’s

Manual

803 1-3

Model HMR-103,104,105,106,107

1-4. ERROR CODES AND The display shows the following error codes and warnings when a

WARNINGS fault is detected, along with an alarm sound. Both the heat and

humidity systems shut down, except when specified otherwise.

DISPLAY

LO

HI

“E-4”

“E-6”

CAUSE

• Food probe or actual temperature

o

is below 50

F (10o C) in Calibra-

tion Mode only

• Food probe temperature above

o

500

F (260o C) or lower air

o

temperature 275

F (135o C), or

above

• Control board temperature above

o

140

F (60o C)

• Air probe error; displayed if the

probe resistance falls below 930

ohms or rises above 2036 ohms;

the exception is on the upper heat

control; any high resistance appears as if no food probe is

plugged in

CORRECTION

• Allow unit to heat-up, or remove food

from unit

• Check the probes and heating circuit

• Check or clean cooling fans; if “E-4”

persists, replace PC board

• Check probe and connection at PC

board

“E-41”

“E-56”

• Scrambled PC board memory

• Setpoint storage error

• Press UP button to clear “E-41”; if

“E-41” persists, replace PC board

• Press UP button to clear “E-56”, then

turn unit off and back on; if “E-56”

persists, replace PC board

1-4 803

Model HMR-103,104,105,106,107

SECTION 2. MAINTENANCE

2-1. INTRODUCTION This section provides procedures for the checkout and re-

placement of the various parts used within the heated merchandiser. Before replacing any parts, refer to the Troubleshooting Section. It will aid you in determining the cause of

the malfunction.

2-2. MAINTENANCE HINTS 1. Y ou may want to use a multimeter to check the electric

components.

2. When the manual refers to the circuit being closed, the

multimeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open, the multimeter reads infinity .

2-3. FRONT GLASS

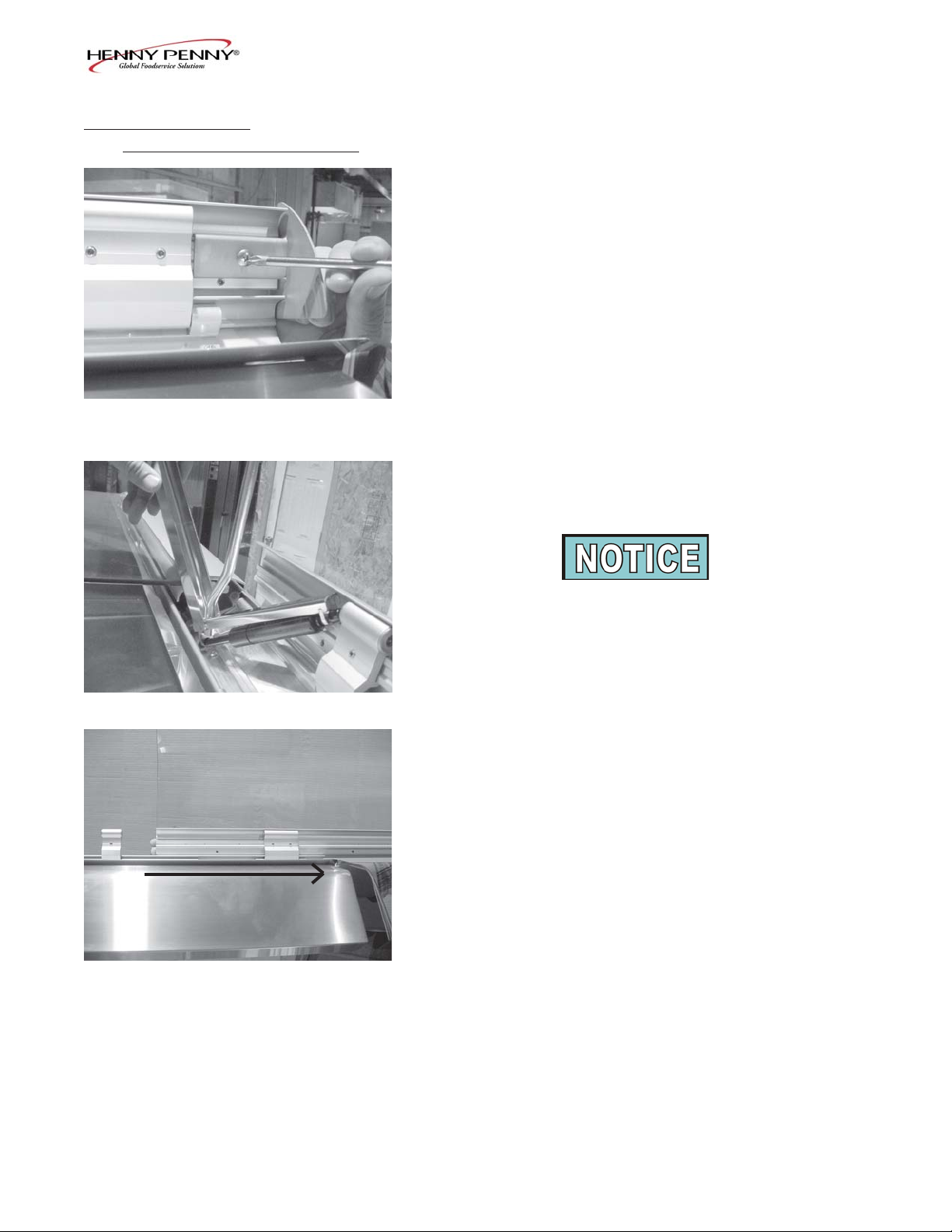

REPLACEMENT 1. Raise the front glass to expose the gas shocks.

2. Using a 3 mm Allen wrench, loosen the set screws on

the shock bracket armature (Figure 2-1).

Figure 2-1

3. Using a Phillips head screwdriver, remove the screws

securing the exterior end cap and remove end cap

(Figure 2-2).

Figure 2-2

203 2-1

2-3. FRONT GLASS

REPLACEMENT (Continued)

Figure 2-3

Model HMR-103,104,105,106,107

4. Using a Phillips head screwdriver, remove the screws

securing the interior end cap and remove cap

(Figure 2-3).

5. Hold glass upright, then use the gas shock tool (part no.

56878), to release the shock from the brackets (Figure

2-4). Place tool on shock as shown and squeeze handle.

Be sure to hold onto glass to prevent glass from breaking.

Figure 2-4

Figure 2-5

Note location and strength (N) of shock before

removing.

6. Slide glass assembly off end of unit (Figure 2-5).

2-2 1202

Model HMR-103,104,105,106,107

2-3. FRONT GLASS

REPLACEMENT (Continued)

Figure 2-6

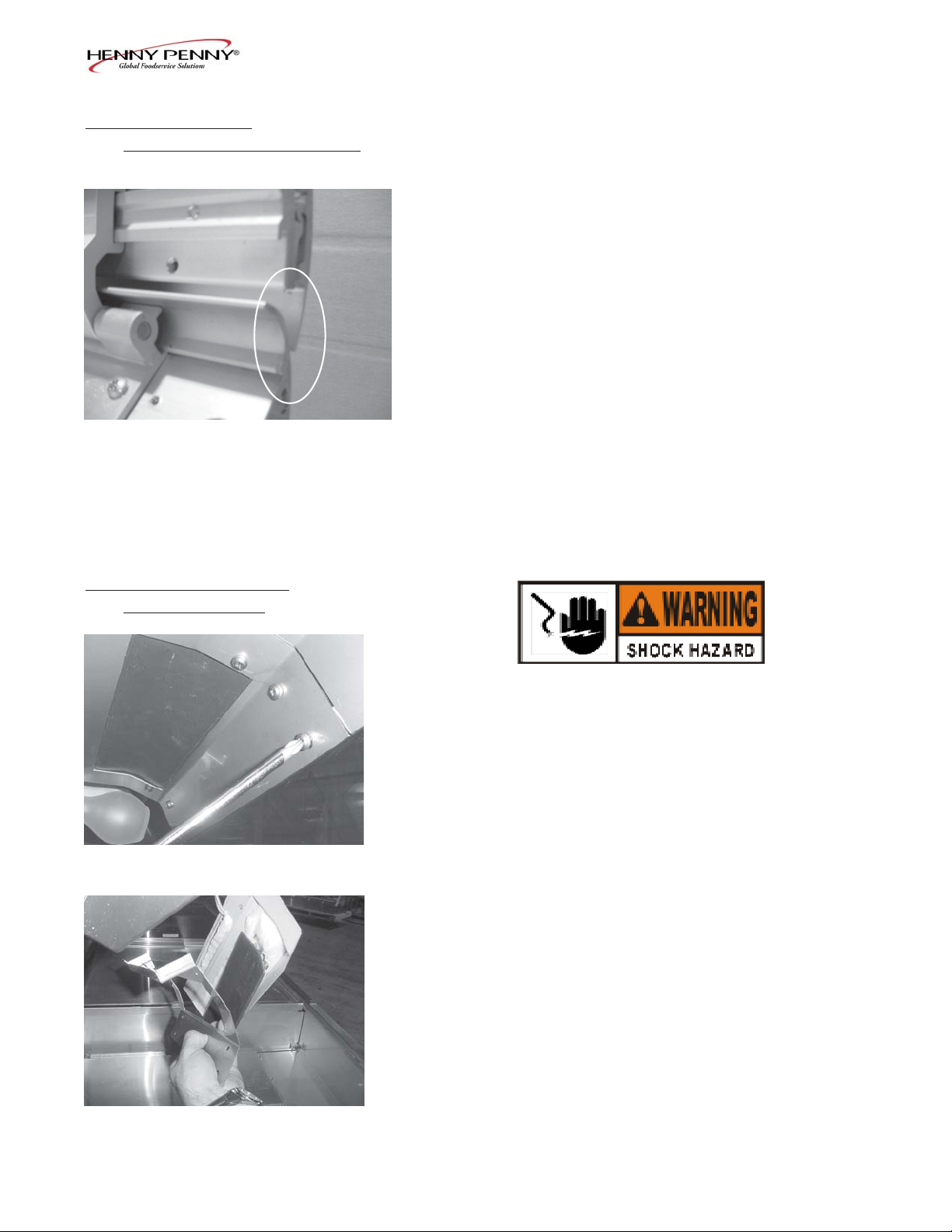

7. Slide new glass assembly into place, aligning outside edge

of glass clamp to the outside edge of the canopy

(Figure 2-6).

8. Tighten set screws on shock bracket armatures

(Figure 2-1).

9. Using the gas shock tool, reinstall the gas shocks, placing

the bottom end of shock in place first.

10. Replace interior end cap, with it being completely flush with

glass clamp.

11. Replace the exterior end caps. Make sure spacers are

between the end cap and the canopy .

2-4. RADIANT HEA TER

REPLACEMENT

Figure 2-7

T o avoid electrical shock or pr operty damage, move

the POWER switch to OFF and disconnect main

circuit breaker, or unplug cord at wall receptacle.

1. Remove sliding doors.

2. Using a Phillips head screwdriver, remove 3 screws

around the heater, leaving the top right screw .

3. Using a Phillips head screwdriver , remove the 4 screws

securing the heater housing and allow housing to hinge

down (Figure 2-7).

4. Remove fourth screw from around heater and remove

outer housing (Figure 2-8).

Figure 2-8

1202 2-3

Model HMR-103,104,105,106,107

2-4. RADIANT HEA TER

REPLACEMENT (Continued)

Figure 2-9

2-5. LIGHT SOCKET REPLACEMENT

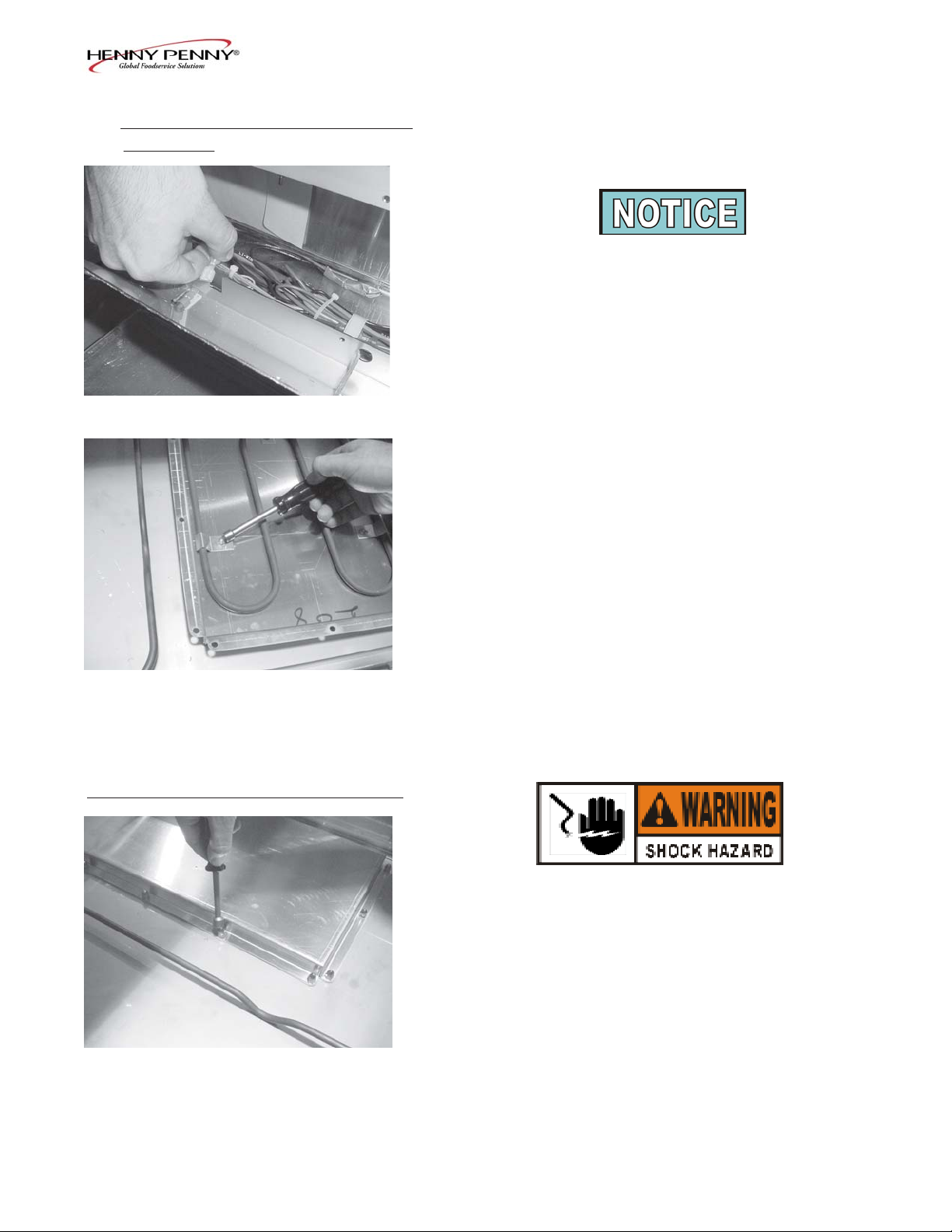

5. Using a 3/8” socket, remove the wires from the back

of the radiant heater (Figure 2-9).

Using a multimeter, or ohmmeter , check ohm rating without the wires connected. The Ohm ratings:

208V - Hot - 84.8 ohms; Cold - 72.7 - 88.9 ohms

230V - Hot - 103.7 ohms; Cold - 88.9 - 108.7 ohms

240V - Hot - 221.5 ohms; Cold - 189.9 - 232.1 ohms

6. Install new radiant heater in reverse order .

When re-attatching the heater wires to the heater the

bottom nut must be held in place while the top nut is

tightened down on the heater wires.

Figure 2-10

T o avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker , or unplug cord at wall receptacle.

1. Raise canopy glass and remove light bulb.

2. Using 3/8” socket, remove the 2 keps nuts securing the

light socket assembly (Figure 2-10).

3. Pull socket assembly from studs.

4. Using a Phillips head screwdriver, remove the wires from

the socket (Figure 2-11).

Figure 2-11

2-4 506

2-5. LIGHT SOCKET REPLACEMENT

(Continued)

Figure 2-12

Model HMR-103,104,105,106,107

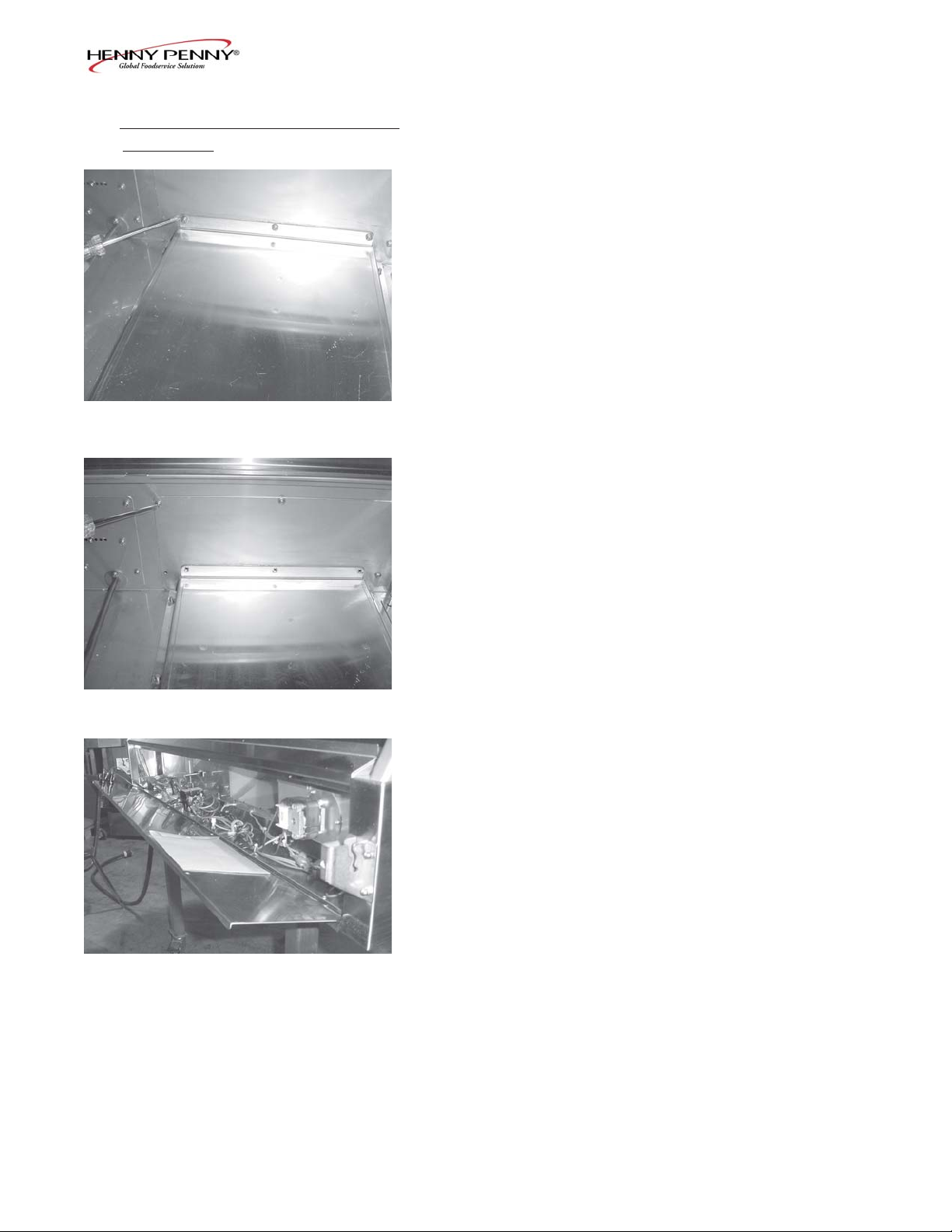

5. Squeeze the brackets and pull socket from housing

(Figure 2-12).

6. Install new socket in reverse order .

2-6. WATER HEATER REPLACEMENT

Figure 2-13

T o avoid electrical shock or pr operty damage,

move the POWER switch to OFF and disconnect

main circuit breaker , or unplug cord at wall

receptacle.

1. Remove pans and pan supports from unit.

2. Using a 3/8” socket, remove the acorn nuts securing the

heater cover (Figure 2-13).

3. Remove the 3 Phillips head screws securing the rear of

the heater cover (Figure 2-14).

4. Cut the silicone seal around the rear of the cover .

Figure 2-14

203 2-5

Model HMR-103,104,105,106,107

2-6. WATER HEATER REPLACEMENT 5. Remove the 5 Phillips head screws securing side mount-

(Continued) ing plate (Figure 2-15).

Figure 2-15

6. Remove the Phillips head screws securing the bottom,

rear cover and let hinge down (Figure 2-16).

Figure 2-16

Figure 2-17

7. Cut wire ties to probe wires (Figure 2-17).

2-6 1202

Model HMR-103,104,105,106,107

2-6. WATER HEATER REPLACEMENT

(Continued)

Figure 2-18

8. Disconnect wires from heater (Figure 2-18).

Using a multimeter, or ohmmeter , check ohm rating without the wires connected. The ohm ratings:

208V - Hot - 108.1 ohms; Cold - 97.8 - 1 13.3 ohms

230V - Hot - 132.2 ohms; Cold - 1 19.6 - 138.5 ohms

9. Pull heater cover from side mounting plate.

10. Flip heater cover to expose heater .

11. Using 5/16” socket, remove keps nuts securing the

heater clips, and pull heater from heater cover

(Figure 2-19).

Figure 2-19

2-7. WATER PROBE REPLACEMENT

Figure 2-20

12. Replace new heater in reverse order.

T o avoid electrical shock or pr operty damage,

move the POWER switch to OFF and disconnect

main circuit breaker , or unplug cord at wall receptacle.

1. Remove pans and pan supports from unit.

2. Using a 3/8” socket, remove the acorn nuts securing

th e heater cover (Figure 2-20).

803 2-7

Model HMR-103,104,105,106,107

2-7. WATER PROBE REPLACEMENT 3. Remove the 3 Phillips head screws securing the rear of

(Continued) the heater cover (Figure 2-21).

4. Cut the silicone seal around the rear of the cover .

Figure 2-21

Figure 2-22

Figure 2-23

5. Remove the 5 Phillips head screws securing side mounting plate (Figure 2-22).

6. Remove the Phillips head screws securing the bottom,

rear cover and let hinge down (Figure 2-23).

2-8 1202

Model HMR-103,104,105,106,107

2-7. WATER PROBE REPLACEMENT 7. Cut wire ties to probe wires (Figure 2-24).

(Continued)

\

Figure 2-24

8. Unplug probe from wiring harness (Figure 2-25).

Figure 2-25

Figure 2-26

9. Using 5/16” socket, loosen keps nut on probe clip and

pull probe from unit.

10. Install new probe in reverse order.

Extend probe 1-1/2” (38 mm), from clip (Figure 2-26).

1202 2-9

2-8. BASE HEA TER REPLACEMENT

Figure 2-27

Model HMR-103,104,105,106,107

T o avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker, or unplug cord at wall receptacle.

1. Remove pans and pan supports from unit.

2. Remove Phillips head screws from heater bracket

(Figure 2-27).

Figure 2-28

Figure 2-29

3. Using a 3/8” wrench or socket, remove the acorn nut

securing the heater brace and remove brace.

4. Remove the Phillips head screws securing the bottom,

rear cover and let hinge down (Figure 2-28).

5. Pull wires from heater and pull heater from unit

(Figure 2-29).

Using a multimeter, or ohm meter , check ohm rating

without the wires connected. The ohm ratings:

208V - Hot - 66.5 ohms; Cold - 60.2 - 89.7 ohms

240V - Hot - 88.6 ohms; Cold - 80.1 - 92.8 ohms

6. Install new heater in reverse order .

2-10 506

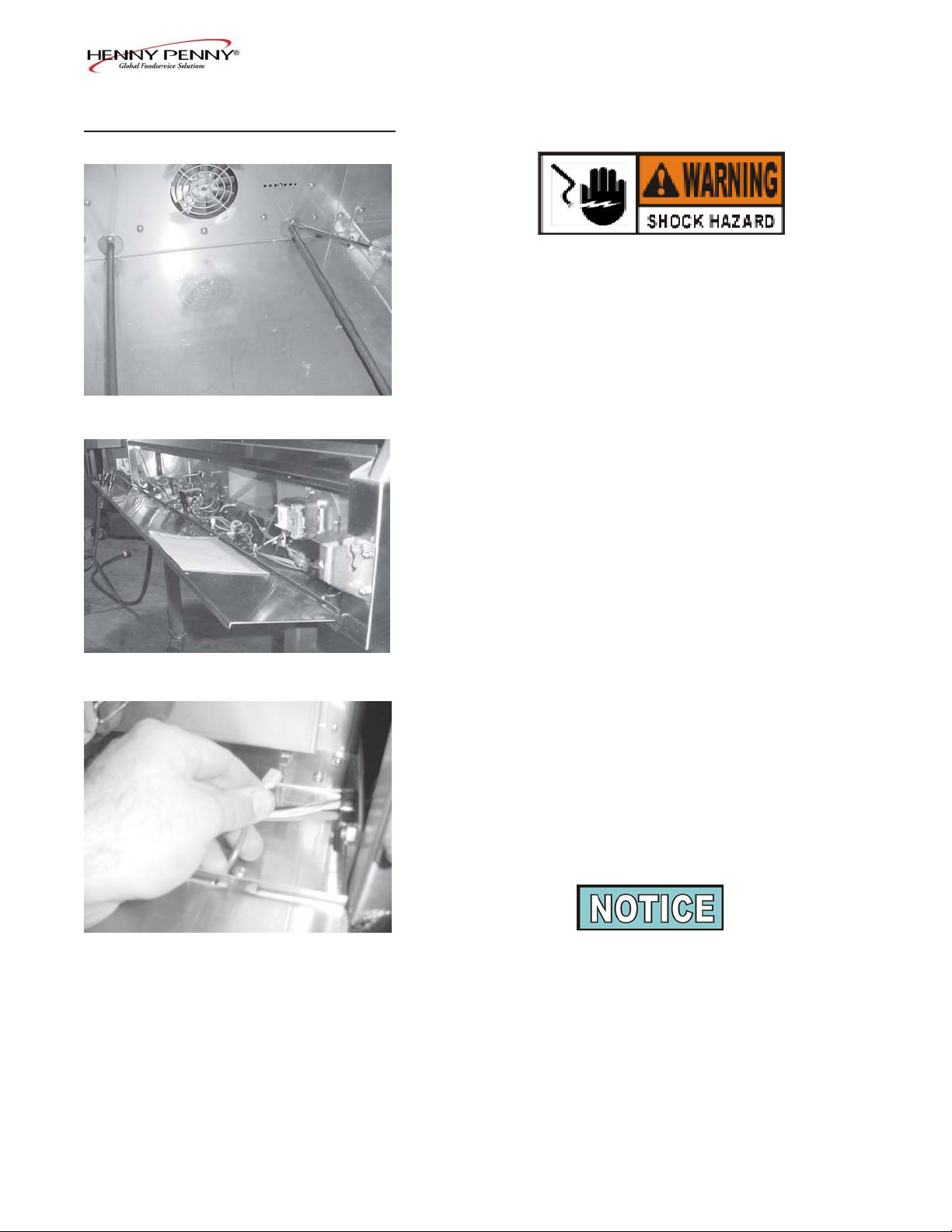

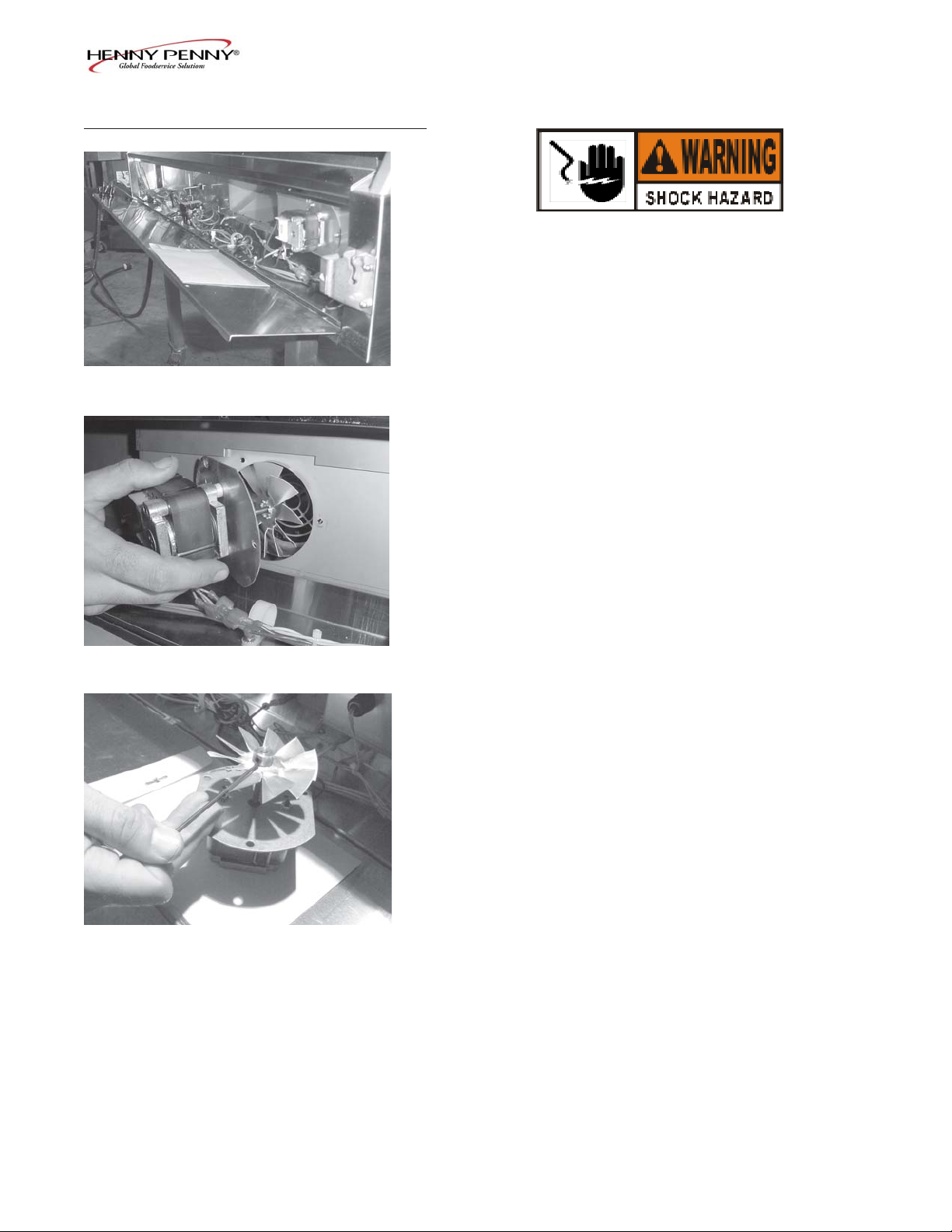

2-9. BLOWER MOTOR REPLACEMENT

Figure 2-30

Model HMR-103,104,105,106,107

T o avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker, or unplug cord at wall receptacle.

1. Remove the Phillips head screws securing the bottom,

rear cover and let hinge down (Figure 2-30).

Figure 2-31

Figure 2-32

2. Remove the 3 screws from the blower bracket and pull

blower motor assembly from housing (Figure 2-31).

3. Using an Allen wrench, loosen the set screw securing

the fan blade to the blower motor and pull fan blade from

motor (Figure 2-32).

4. Cut wires to blower motor and pull motor from unit.

5. Strip back the cut wires, and connect new blower motor

wires to these wires, using wire splicers or wire nuts.

6. Install new blower motor in reverse order.

203 2-11

Loading...

Loading...