Page 1

Model OFE- 290

SECTION 3. OPERA TION

3-1. OPERA TING COMPONENTS

POWER/PUMP Switch A three way switch with center OFF position; move the switch to

the position marked POWER to operate the fryer; move the switch

to the position marked PUMP to operate the filter pump; certain

conditions must be met prior to operation of the filter pump; these

conditions are covered later in this section

Frypot This reservoir holds the cooking shortening, and is designed to

accommodate the heat exchanger, 6 head of product and an

adequate cold zone for collection of cracklings

Carrier This stainless steel carrier consists of five racks which contain

the food product during and after frying

Drain V alve A two-way ball valve, normally in the closed position; turn the

handle to drain the shortening from the frypot into the filter drain

pan

Drain Interlock Switch A microswitch that provides protection for the frypot in the event an

operator inadvertently drains the shortening from the frypot while

the main switch is in the POWER position; the switch is designed to

automatically shut off the heat when the drain valve is opened

Shortening Mixing System A shortening mixing capability to help ensure shortening is properly

mixed to prevent an accumulation of moisture and hence boiling

action in the pot; the filter pump is activated by the controls, at

preset intervals, to mix the shortening

Lid Latch A mechanical catch on the front of the lid which engages a bracket

on the front of the frypot, when lid is lowered

Air V alve Pumps air into the shortening, periodically , to keep the shortening at

a uniform temperature; this only functions when the unit has been

sitting idle for a period of time, and when heating upfrom a cold

start

403 3-1

Page 2

Model OFE- 290

3-1. OPERA TING COMPONENTS

(Continued)

High Limit This high temperature control senses the temperature of the

shortening; if the temperature of the shortening exceeds

450°F (230°C), this control will open and shut off the heat

to the frypot; when the temperature of the shortening drops

to a safe operation limit, the control must be manually reset by

pressing the red reset button, located under the control panel, in the

right, front of the fryer

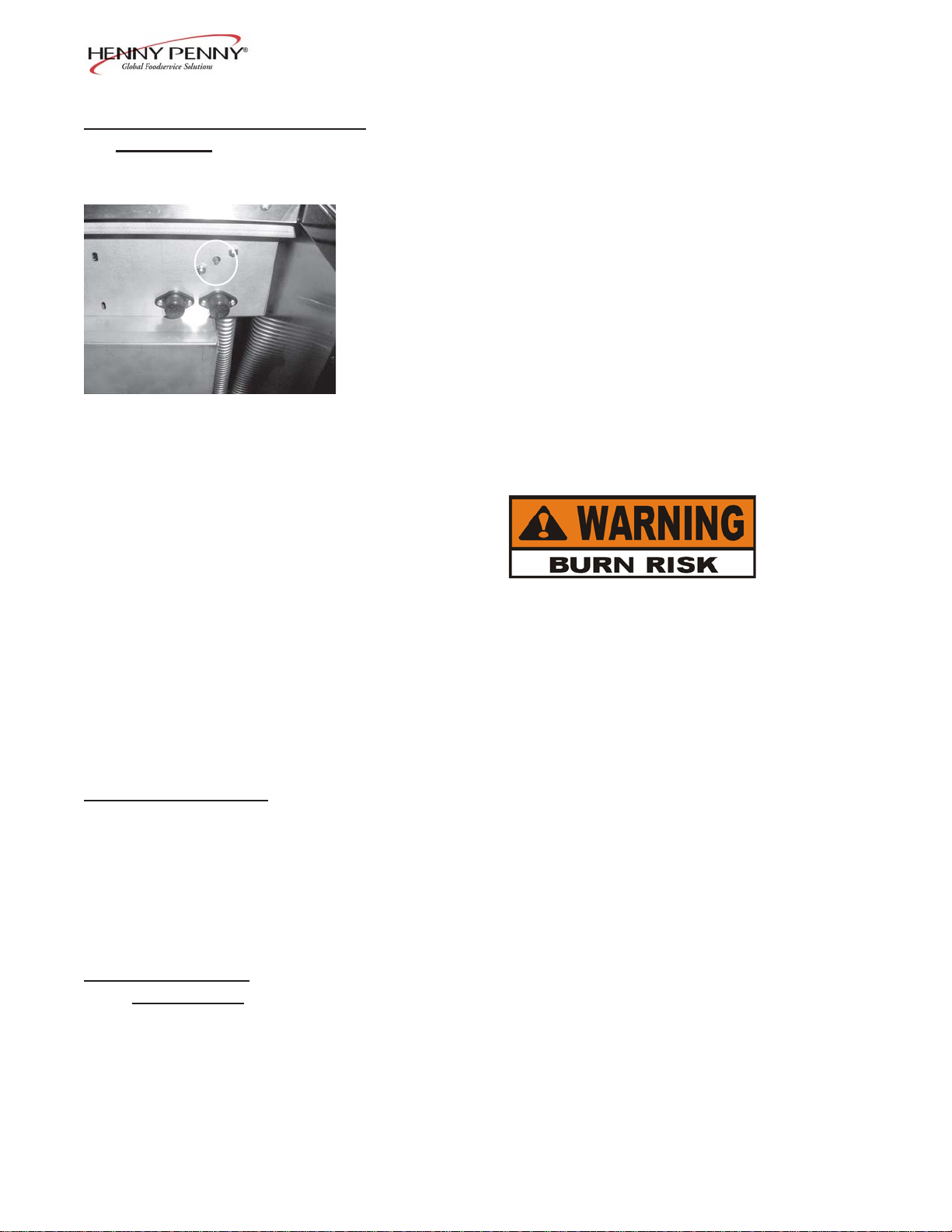

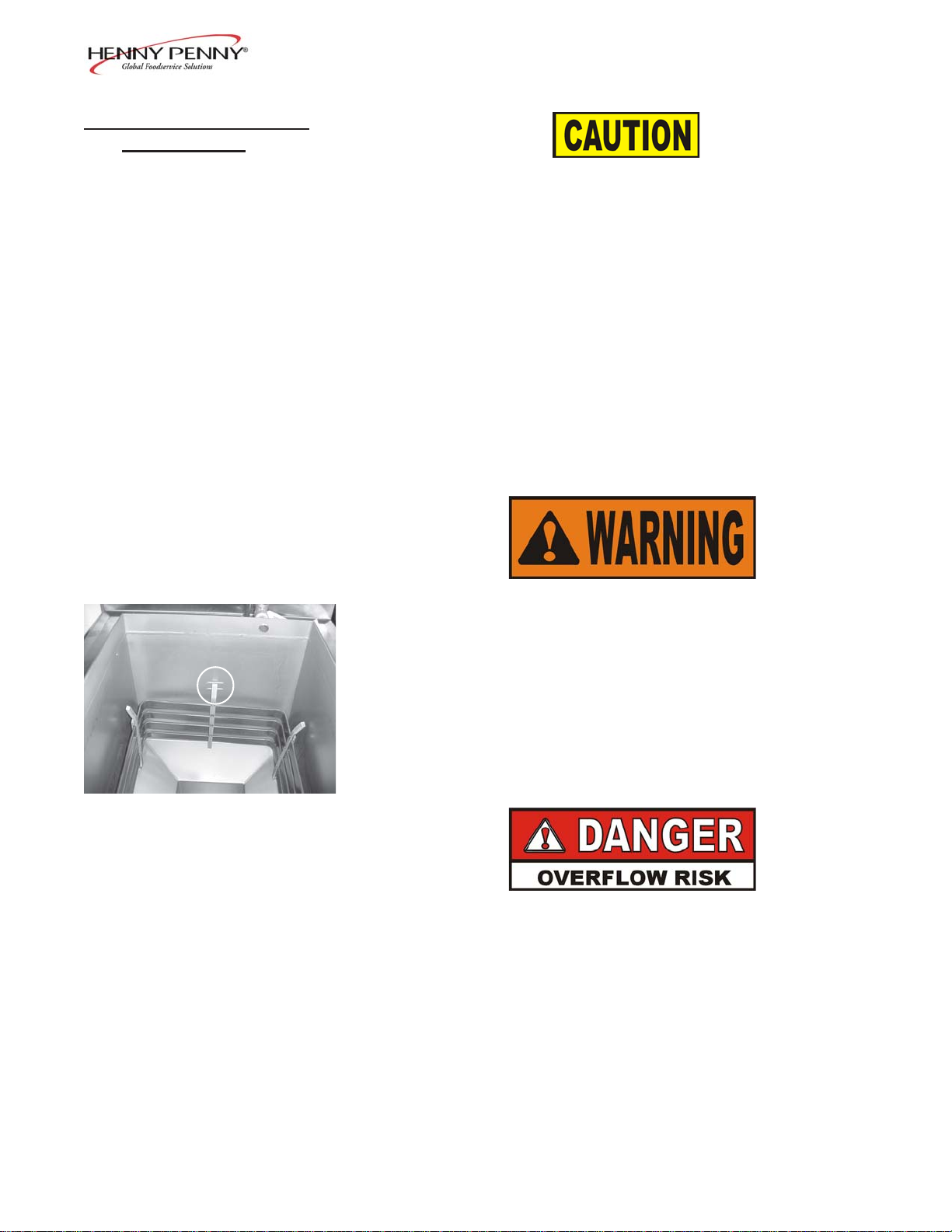

Figure 3-1

Filter Drain Pan The removable pan that houses the filter and catches the shortening

when it is drained from the frypot; also used to remove anddiscard

old shortening

When hot shortening is in this pan, use extreme care to

avoid burns.

Filter Union Connects the filter to the filter pump, and allows easy removal of the

filter and drain pan

Fuses A protective device which breaks the circuit when the current

exceeds the rated value

3-2. LID OPERA TION T o close lid:

1. Lower the lid until latch comes into contact with the pot.

T o open lid:

1. Unlatch the front lid latch.

2. Lift up on handle to raise lid.

3-3. MEL T CYCLE If the shortening is below 185°F (77°-85°C) with the POWER/

OPERATION PUMP switch in the POWER position, the fryer enters the Melt

Cycle. The shortening is heated slowly to prevent scorching of the

shortening. The heat cycles on and off to ensure slow melting of

shortening. At 185°F (85°C) the heat stays on until the Cool Mode

is reached, which is 250°F (121°C). The controls maintains this

temperature until the COOL button is pressed.

3-2 703

See Filling and Adding Shortening Section.

Page 3

Model OFE- 290

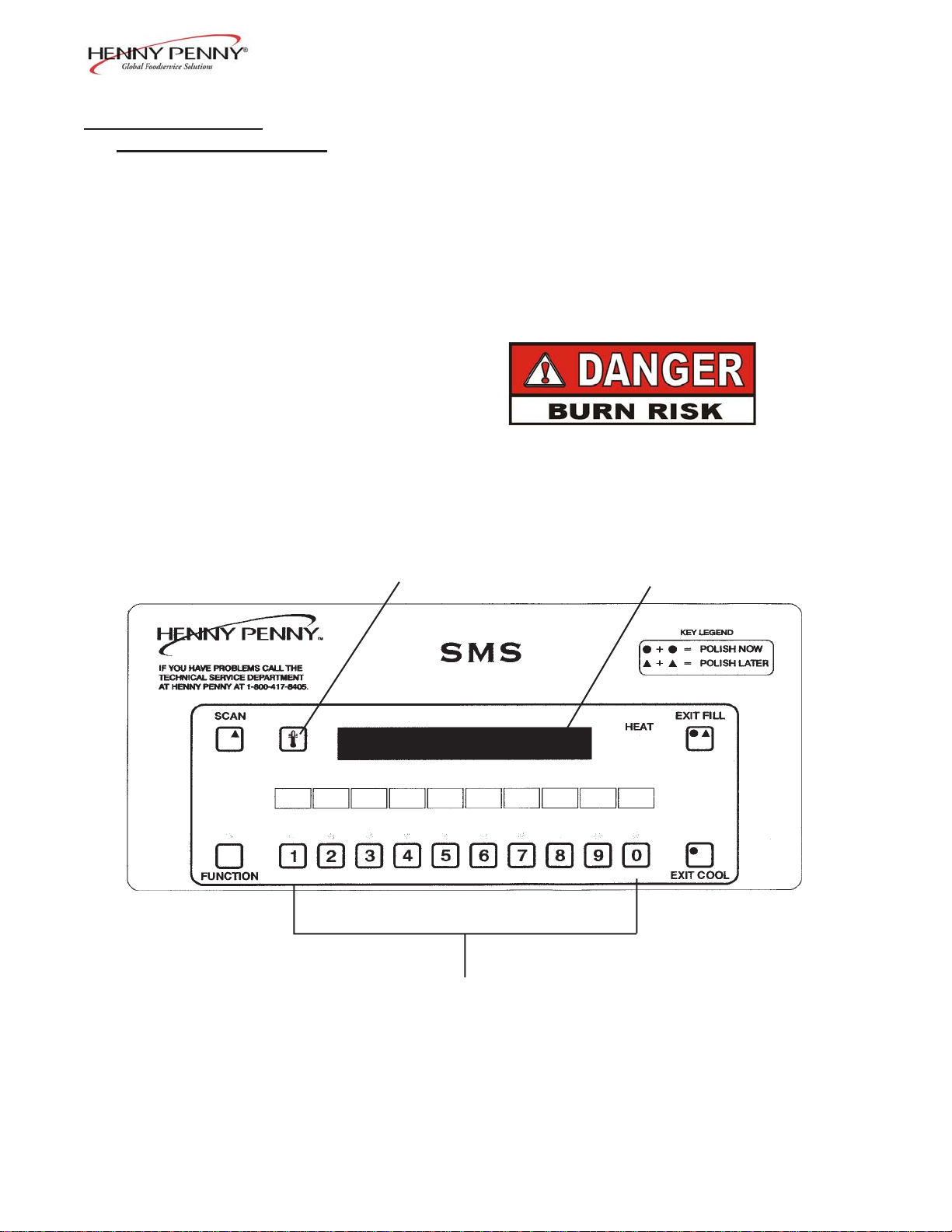

3-4. SWITCHES AND Refer to image at end of this section.

INDICATORS

Product Selection Buttons Select the number of heads, or product, to be cooked by pressing

the button below the menued item; shortening will then heat to

drop temperature of that item

Pressing the same button again begins the Cook Cycle; the display

changes from “DROP” to counting down the cook time in minutes

and seconds

At the end of the Cook Cycle, the alarm sounds and the display

reads “DONE”; press the cycle button that is flashing, to stop the

alarm ; the fryer then resets to the Cool Mode

A Cook Cycle can be aborted at any time by pressing and

holding the product button.

Time/T emperature Display A four digit LED type display which shows the remaining cook time

during Cook Cycles and also the shortening temperature on

demand from the operator

Heat Indicator Illuminates whenever the control calls for heat; when shortening

temperature has been reached, the heat light goes off

HI T emperature Indicator The display reads “HI” if the shortening temperature is 40° F above

the setpoint

Drop Indicator The display reads “DROP” when the shortening has reached

the setpoint temperature (will read “DROP” 2° before setpoint and

4° above setpoint )

Done Indicator The display reads “DONE” at the end of the Cook Cycle

T emperature Button Press this button to read the temperature of the shortening during a

Cook Cycle

SCAN Button Pressing this button toggles through the items being programmed

FUNCTION Button Used in the programming of the controls

EXIT FILL Button After filtering the fryer, if in the filter lockout mode, the display reads

“FILL”, and the EXIT FILL button must be pressed.

504 3-3

Page 4

Model OFE- 290

3-4. SWITCHES AND

INDICATORS Continued)

EXIT COOL Button After cooking, or filtering the shortening, the temperature automati-

cally goes into the Cool Mode, which keeps shortening at a lower

temperature; this temperature extends the shortening life and

minimizes the time to heat the shortening for the next Cook Cycle;

EXIT COOL button must be pressed to heat up to setpoint temperature

AL THOUGH THE DISPLA Y WILL READ “COOL”

DURING THE ST ANDBY MODE, THE SHORTENING IS HOT AND WILL CAUSE BURNS.

TEMPERA TURE BUTTON DIGIT AL DISPLAY

Figure 3-2

3-4 504

Page 5

3-5. FILLING OR ADDING

SHORTENING

Model OFE- 290

The shortening level must always be above the heating

elements when the fryer is heating and at the frypot level

indicators on the rear of the frypot (Figure 3-3). Failure

to follow these instructions could result in a fire and/or

damage to the fryer.

When using solid shortening, it is recommended to melt

the shortening on an outside heating source befor e placing it in the frypots. The burner tubes must be completely

submerged in shortening. Fire or damage to the frypot

could result.

1. It is recommended that a high quality frying shortening

be used in the open fryer . Some low grade shortenings have a

high moisture content and will cause foaming and boiling over .

Figure 3-3

T o avoid severe burns when pouring hot shortening

into frypot, wear gloves and take care to avoid

splashing.

2. The electric model requires 100 lbs. (45 Kg.) of shortening.

The frypot has 2 level indicator lines inscribed on the rear

wall of the frypot which show when the heated shortening is at

the proper level. Figure 3-3.

3. Cold shortening should be filled to the lower indicator .

BE CERT AIN THE SHORTENING IS NEVER

ABOVE THE UPPER LEVEL INDICA TOR LINE.

FAILURE TO FOLLOW THESE INSTRUCTIONS

CAN RESUL T IN SHOR TENING OVERFLOWING

THE FRYPOT CAUSING SERIOUS BURNS, PERSONAL INJUR Y , FIRE AND/OR PROPERTY

DAMAGE.

For complete instructions, refer to KFC’s S tandards Library .

703 3-5

Page 6

Model OFE- 290

3-6. BASIC OPERA TION Follow the procedure below on the initial start-up of the fryer, and

each time the fryer is brought from a cold, or shut down condition,

back into operation. These are basic, general instructions. Be sure

to follow KFC’ s Standards Library when operating the fryer.

1. Make sure the shortening is filled to the proper level in

the frypot; to the lower indicator.

DO NOT OVERLOAD, OR PLACE PRODUCT WITH

EXTREME MOISTURE CONTENT INTO THE

RACKS. 21 LBS. (9.5 KG.) IS THE MAXIMUM

AMOUNT OF PRODUCT PER FRYPOT . FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN RE

SUL T IN SHOR TENING OVERFLOWING THE

FRYPOT WHICH COULD CAUSE SERIOUS

BURNS, PERSONAL INJUR Y , FIRE AND/OR

PROPERTY DAMAGE.

2. Turn the POWER/PUMP switch to the POWER position and

press the appropriate product button to select the amount

of product to be cooked.

3. Stir the shortening as it’ s heating up from a cold start.

Be sure to stir down into the cold zone.

DO NOT STIR THE SHORTENING AT ANY OTHER

TIME EXCEPT A T MORNING ST ART-UP. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

RESUL T IN SHOR TENING OVERFLOWING THE

FRYPOT WHICH COULD CAUSE SERIOUS

BURNS, PERSONAL INJUR Y , FIRE, AND/OR

PROPERTY DAMAGE.

3-6 703

Page 7

Model OFE- 290

3-6. BASIC OPERA TION 4. Allow fryer to heat until digital display shows “DROP”.

(Continued) (Press the EXIT COOL button if the display shows COOL”)

The heat cycles on and off approximately 10 degrees before

the setpoint temperature, to help prevent overshooting the

setpoint temperature. (proportional control)

5. Slide racks of breaded product into carrier on the lid,

starting with the bottom rack, to prevent damaged product.

Before loading product onto the racks, lower the racks

into the hot shortening to prevent the product sticking to

the racks.

6. Lower and latch the lid down and press the appropriate

product button.

7. At the end of the cycle, an alarm sounds, and the display

shows “DONE”. At this time, press the appropriate product

button.

8. Unlatch and raise the lid cautiously.

9. Using the rack handles, remove the racks of product from

the carrier, starting with the top rack to prevent damaged

product.

703 3-7

Page 8

3-7. CARE OF THE

SHORTENING

Model OFE- 290

FOLLOW THE INSTRUCTIONS BELOW TO A V OID

SHORTENING OVERFLOWING THE FR YPOT ,

WHICH COULD RESUL T IN SERIOUS BURNS,

PERSONAL INJUR Y , FIRE, AND/OR PROPERTY

DAMAGE.

1. T o protect the shortening when the fryer is not in immediate

use, the fryer should be put into the Cool Mode.

2. Frying breaded products requires filtering to keep the

shortening clean. The shortening should be filtered at

least twice a day; after lunch rush and at the end of the day .

3. Maintain the shortening at the proper cooking level. Add

fresh shortening as needed.

4. Do not overload the racks with product (21 lbs. (9.5 kgs.)

maximum), or place product with extreme moisture content

into racks.

WITH PROLONGED USE, THE FLASHPOINT OF

SHORTENING IS REDUCED. DISCARD SHORTENING IF IT SHOWS SIGNS OF EXCESSIVE

SMOKING OR FOAMING. SERIOUS BURNS,

PERSONAL INJUR Y , FIRE, AND/OR PROPERTY

DAMAGE COULD RESUL T .

3-8. FIL TERING The Henny Penny gas 6 head open fryer, Model 290, must be

INSTRUCTIONS cleaned and the shortening must be cleaned and polished at

least twice daily; after lunch rush and at the end of the day .

Refer to KFC’s S tandards Library .

Filter shortening immediately following a Cook Cycle when the

shortening temperature is in the Cool Mode; 250° F

(121° C) or less.

Drain the shortening at 250° F (121° C) or less. The

higher temperatures cause cracklings to burn on the

steel frypot surfaces after the shortening has drained.

3-8 703

Page 9

3-8. FIL TERING

INSTRUCTIONS

(continued)

Model OFE- 290

ONLY FILTER WHEN “COOL” IS DISPLAYED.

FAILURE TO DO SO CAN RESULT IN SHORTENING

OVERFLOWING THE FRYPOT, CAUSING SERIOUS

BURNS, PERSONAL INJURY, FIRE,AND/OR

PROPERTY DAMAGE.

High volume cooking could cause the cold zone to fill quicker with

cracklings and cleaning may be required more often. Part of the process involves removing cracklings from the cold zone of the frypot.

1. Turn POWER/PUMP switch to OFF position.

2. Make sure filter drain pan is under fryer and the filter union

is fastened to the filter standpipe, coming out of the pan.

Shortening Stirrer

Drain Cleanout Small White

Rod Brush

The filter drain pan must be as far back under fryer as

it will go, and the cover in place. Be sure the hole in the

cover lines up with the drain before opening the drain.

Failure to follow these instructions causes splashing of

shortening and could result in personal injury.

Surfaces of fryer and racks will be hot. Use care when

filtering to avoid getting burned.

3. Remove cooking racks, carrier and wipe bottom of lid. Tilt

lid out of the way to clean frypot.

4. Pull drain handle towards you to open drain valve. The handle

should point straight out to the front of the fryer. Use large

white brush to clean cracklings from the elements and from

sides and bottom of frypot as shortening drains. Use the drain

cleanout rod to push cracklings through drain opening in bottom

of frypot if necessary . Using the small straight white brush,

clean between the elements and the frypot wall.

BRUSH ALL CRACKLINGS FROM FRYPOT SURFACES AND THE COLD ZONE DURING THE FILTE

TERING PROCESS. FAILURE TO DO SO CAN

RESULT IN SHORTENING OVERFLOWING THE

FRYPOT, WHICH COULD CAUSE SERIOUS BURNS,

PERSONAL INJURY, FIRE AND/OR PROPERTY

403 3-9

DAMAGE.

Page 10

Model OFE- 290

3-8. FIL TERING 5. Scrape cracklings and crackling ring from frypot and discard.

INSTRUCTIONS Do not let cracklings drain into filter drain pan. These crack-

(Continued) lings can cause a burned taste in gravy . Wipe all surfaces with

a clean damp towel. If water drops into cold zone, dry with

towel before pumping shortening back into the frypot.

6. Return drain handle to the closed position to close the drain.

7. Turn POWER/PUMP switch to PUMP , and when all shortening has been pumped into frypot swing drain handle to

the closed position to close the drain.

IF THERE ARE AIR BUBBLES COMING UP IN THE

SHORTENING, IT’S POSSIBLE THA T THE FILTER

CONNECTION A T THE UNION ON THE FILTER

TUBE IS NOT TIGHTENED PROPERL Y. IF SO,

TURN OFF THE PUMP AND USE PROTECTIVE

CLOTH OR GLOVE WHEN TIGHTENING THE

UNION. THIS UNION WILL BE HOT AND SEVERE

BURNS WILL RESULT .

3-9. CHANGING THE FILTER The filter envelope should be changed after 10-12 filterings, or

ENVELOPE whenever it becomes clogged with crumbs. Refer to KFC’s

Standards Library.

Use protective cloth or glove when disconnecting the

filter union or severe burns could result.

If the filter pan is moved while full of shortening, use

care to prevent splashing, or severe burns could result.

Be sure that the filter screens, crumb catcher, filter clips

and the standpipe are thoroughly dry before assembly of

the filter envelope or water will dissolve the filter paper.

3-10 703

Page 11

Model OFE- 290

3-10. CLEANING THE FRYPOT After the initial installation of the fryer, as well as before every

change of shortening, the frypot should be thoroughly cleaned as

follows:

1. Turn the POWER/PUMP switch to OFF positioin, and unplug

unit from wall receptacle.

Moving the fryer or filter drain pan while containing

hot shortening is not recommended. Hot shortening can

splash out and severe burns could result.

The filter drain pan must be as far back under fryer as

it will go, and the cover in place. Be sure the hole in the

cover lines up with the drain before opening the drain.

Failure to follow these instructions causes splashing

of shortening and could result in personal injury .

2. If hot shortening is present in the frypot, it must be

drained by slowly pulling the drain handle out towards you.

3. Close the drain valve and discard the shortening.

4. Raise lid, remove the racks and carrier from lid, and tilt lid

back, so that the lid won’t interfere with cleaning.

5. Refer to KFC’ s Standard’s Library on cleaning instructions.

If the cleaning solution in the frypot starts to foam and

boil over,

immediately turn the POWER Switch to OFF

or damage to components could result.

Do not use steel wool, other abrasive cleaners or cleaners/

sanitizers containing chlorine, bromine, iodine or ammonia

chemicals, as these will deteriorate the stainless steel

material and shorten the life of the unit.

Do not use a water jet (pressure sprayer) to clean the

unit, or component damage could result.

Make sure the inside of the frypot, the drain valve opening,

and all parts that come in contact with the new shortening are

as dry as possible.

703 3-11

Page 12

Model OFE- 290

3-11. FIL TER PUMP MOTOR The filter pump motor is equipped with a manual reset button,

PROTECTOR-MANUAL located on the rear of the motor, in case the motor overheats. If

RESET motor won’t run, wait about 5 minutes before attempting to reset this

protective device to allow motor to cool. Remove the access panel

on the left side panel of the unit to reset the button. It takes some

effort to reset, and a screwdriver can be used to help reset the

button.

To prevent burns caused by splashing shortening, turn

the unit’s main power switch to the OFF position before

resetting the filter pump motor’ s manual r eset

protection device.

3-12. REGULAR MAINTENANCE The Henny Penny open fryer does require care and proper mainte-

nance. The table below provides a summary of scheduled maintenance. The following paragraphs provide step-by-step preventive

maintenance procedures to be performed by the operator .

Procedure Frequency

Filtering of shortening See KFC’s S tandards Library

Changing of shortening See KFC’s S tandards Library

Changing the filter envelope See KFC’s S tandards Library

Cleaning the frypot See KFC’s S tandards Library

Cleaning Nylattrons Monthly-see below

Lubricate lid rollers Annually-see below

3-13. PREVENTIVE Cleaning Nylatrons

MAINTENANCE

1. Spray Henny Penny biodegradable, food safe, foaming

degreaser (part no. 12226) on Nylatrons.

2. Raise lid up and down several times to spread the degreaser .

3. Wipe Nylatrons to remove food soil, grease, and degreaser

residue.

Lubricating Lid Rollers

The lid rollers, in the back of the fryer, should be lubricated at

least once a year, to allow the lid easy movement.

1. Remove the back shroud of the fryer .

2. Using spindle lube, part number 12124, place a small amount

of lube on both top and bottom rollers. Make sure to lube

both left and right rollers.

3-12 810

Page 13

Model OFE- 290

3-14. PROGRAMMING 1. Press and hold the FUNCTION button for two seconds.

“REG PROGRAM” shows in the display , followed by

“CODE”.

2. Press the code1-2-3. “SELECT PRODUCT” scrolls

across the display .

If no buttons are pressed, within approximately 1 minute

while in the Program Mode, the controls will revert back

to the Cook Mode.

3. Press the appropriate product button, (1-0), to identify

what product you want to program.

4. “INT1” and “TIME” flashes on the left side of the display .

The right side shows the starting time of the Cook Cycle and

can be changed by pressing the appropriate numbers. Ex:

Press 1,0,0,0 and 10:00 flashes on the right side of the

display , setting the start time at 10 minutes.

5. After setting the time, press and release the FUNCTION

button and “INT1” and “TEMP” flashes on the left side of the

display . The right side shows the starting temperature and can

be changed by pressing the appropriate numbers. Ex: Press

2,5,0 and “250° F” shows onthe right side of the display ,

setting the start temperature at 250° Fahrenheit.

6. After setting the temperature, press and release the FUNCTION button and “INTI”, “LOAD”, and “COMP” flashes on

the left side of the display . The factory preset load compensation value shows in the right side of the display .

703 3-13

Page 14

Model OFE- 290

3-14. PROGRAMMING

(Continued)

7. After the load compensation, press and release the FUNCTION button. “PROP” and “CONTROL” shows on the

left side of the display and the factory preset proportional

control temperature shows on the right side of the display .

8. After the proportional control, press and release the

FUNCTION button. “ALM 1” and “TIME” flashes in the left

side of the display , and the first alarm time shows on the right

side of the display . T o change the time the alarm sounds,

press the appropriate product buttons to set the time. Ex:

Press 1,0,0,0. 10:00 flashes on the right side of the display ,

which means when the timer counts down to 10 minutes, an

alarm sounds.

9. After alarm is set, press and release the FUNCTION button.

“ALM 1”, “SELF-’ ’, and “CANCEL” flashes in the left side

of the display and “YES” or “NO” shows on the right side of

the display . The yes and no can be toggled by pressing any of

the product buttons, (l -0). “YES” means the alarm tone

automatically stops after several beeps. “NO” means some

one must manually press the appropriate product button to

stop the alarm tone.

10. Repeat steps 9 and 10 for alarms 2 and 3.

11. After alarm 3 is set, press and release the FUNCTION

button. “FIL TER” and “CYCLES” show on the left side of

the display and the Filter Cycle value is on the right side of the

display . The value is the number of Cook Cycles that must

completed before the control signals the operator that the

shortening needs filtered.

12. After the filter value is set, press and release the

FUNCTION button. “EOC” and “EXIT” flashes on the left

side of the display and “COOL” shows on the right side of

the display . The end-of-cycle, (EOC), exit point can be set

to COOL, SETP , or FLTR, by pressing any of the product

buttons (EOC). At the end of a Cook Cycle the controls can

be set to return to Cool Mode, the setpoint temperature, or to

signal the operator to filter the shortening.

3-14 703

Page 15

Model OFE- 290

3-14. PROGRAMMING

(continued)

13. After the end-of-cycle point is set, press and release the

FUNCTION button. “HEAD” flashes on the left side of the

display and a number shows on the right side of the display .

The number on the right, is the number of head of chicken to

be cooked at one time, when that product button is pressed.

The number can be changed by pressing the appropriate

product button. The control can then accumulate the head

count (usage) of that product,based on counting the number

of Cook Cycles.

Another product can be programmed while in the program

mode by following these procedures:

Press and hold the SCAN button at any time while in the

Program Mode and the display will scroll “SELECT PRODUCT”. Then press any of theproduct buttons, (1-0), and

now that product can be programmed.

14. T o program second interval, press and release the

SCAN button while in the Time Mode of the first mode.

“INT2” and “TIME” will flash on the left side of the display .

Then follow the steps above, starting with step 4.

3-15. SPECIAL PROGRAM MODE

Review Usage

1. Press and hold the FUNCTION button for two seconds until

“REG PROGRAM” shows in the display . As soon as

“REG PROGRAM” shows in the display , press and release

the FUNCTION button 1 time until “REVIEW USE” shows

in the display .

2. “DAIL Y” shows in the display . Press any of the product

buttons to view the usage of that product. Press and hold the

FUNCTION button to exit Special Program mode.

Reset Usage

1. Press and hold the FUNCTION button for two seconds until

“REG PROGRAM” shows in the display . As soon as “REG

PROGRAM” shows in the display , press and release the

FUNCTION button 2 times until “RESET USE” shows in

display .

2. When “CODE” shows in the display , press 1-3-5. “DAIL Y

will show in the display , and press any of the Product buttons

to reset them to 0.

703 3-15

Page 16

Model OFE- 290

3-15. SPECIAL PROGRAM MODE

(Continued) Factory Presets (F/C, Gas/Electric, Speaker Volume,

Speaker Frequency , Codes, Initialize System)

1. Press and hold the FUNCTION button for two seconds until

“REG PROGRAM” shows in the display . As soon as

“REG PROGRAM” shows in the display , press and release

the FUNCTION button 3 times until “F AC PRESET” shows

in the display .

2. When “CODE” shows on the display , enter 2957. “DEG”

and “MODE” flashes in the display . Press any of the product

buttons to toggle from ºF to ºC, and vice versa.

3. Press and release the FUNCTION button and “TYPE”

and “FR YR” flashes in the display. Press any of the product

buttons to toggle from “GAS” to “ELEC”, or vice versa.

4. Press and release the FUNCTION button twice, and

“SPKR” and “VOL” flashes in the display . The volume can

be changed from 01 to 10, 10 being the loudest.

5. Press and release the FUNCTION button 3 times, and

“SPKR” and “FREQ” will flash in the display . The frequency

can be set from 100 to 2000.

6. Press and release the FUNCTION button 10 times, and

“INITIALIZE SYSTEM” scrolls across the display . Press

and hold any of the product buttons and the display will count

down from 5. Once the display counts down, release the

product button, and the control will set factory preset parameters into the controls.

Before attempting to change the other modes in the Factory

Preset Mode, please call the Henny Penny T echnical Service

Department at 1-800-417-8405, or 1-937-456-8405.

3-16 703

Page 17

3-15. SPECIAL PROGRAM MODE

(Continued) Tech I/O Mode

Model OFE- 290

1. Press and hold the FUNCTION button for two seconds until

“REG PROGRAM” shows in the display . As soon as

“REG PROGRAM” shows in the display , press and release

the FUNCTION button 4 times until “TECH I-O” shows in

the display .

2. When “CODE” shows in the display , press 2-4-6 (1-7-7-6

for CE units). “HEA T’, and “PUMP”shows alternately in the

display . Also, the LEDs over 1 and 3 flashes alternately .

3. T o test the heat circuit, press and hold the 1 button.

4. T o test the pump system, press and hold the 3 button.

Appliance T est

Press and hold the FUNCTION button for two seconds until

“REG PROGRAM” shows in the display . As soon as

“REG PROGRAM” shows in the display , press and release

the FUNCTION button 5 times until “APPL TEST” shows

in the display .

With the power switch on, the display will show “CURR=”,

along with the time it took the unit to heat from 250º to

300º F (121º to 149º C) . This is normally recorded from the

initial heat up in the morning.

504 3-17

Page 18

Model OFE- 290

3-16. SPECIAL PROGRAM Heat Control

MODE (Continued) 1. Press and hold the FUNCTION button for two seconds until

“REG PROGRAM” shows in the display . As soon as

“REG PROGRAM” shows in the display , press and release

the FUNCTION button 6 times until “HEA T CNTRL” shows

in the display .

2. When “CODE” shows in the display , press 1-2-3-4.

“MEL T”, “EXIT”, and “TEMP” flashes in the display , along

with the shortening temperature at which the unit will exit the

melt cycle. This should be set at 180º F (82º C), and should

not be changed until the factory is consulted.

3. Press and release the FUNCTION button and ”MEL T”,

“CYCLE”, and “100s” shows alternately in the display , along

with the period (pulse) length of 4000. This should not be

changed until the factory is consulted.

4. Press and release the FUNCTION button twice and

“MEL T”, “ON-”, “TIME”, and “100s”, shows alternately in

the display , along with the length of time the heat is on. This

should be set at 1700, and should not be changed until the

factory is consulted.

5. Press and release the FUNCTION button three times and

“COOL”, “SET -”, and “POINT” shows alternately in the

display , along with the temperature at which the control exits

the melt cycle. This is set at 250º F (121º C), and should not

be changed until the factory is consulted.

6. Press and release the FUNCTION button four times and

“AUTO”, and “IDLE” shows alternately in the display , along

with “OFF”. This should not be changed until the factory is

consulted.

7. Press and release the FUNCITON button five times and

“AUTO”, “IDLE”, and “MMSS” shows alternately in the

display , along with “0:00”. This should not be changed until

the factory is consulted.

8. The last 3 functions in the Heat Control Mode are used by the

factory only , and should not be changed.

3-18 703

Loading...

Loading...