Planning and installation instructions

Combisteamer (gas)

SizeType no.

(ClassicCombi)

Type no.

(SmartCombi)

615GCC61XXXXGSC61XXXX

620GCC62XXXXGSC62XXXX

115GCC11XXXXGSC11XXXX

120GCC12XXXXGSC12XXXX

215GCC21XXXXGSC21XXXX

220GCC22XXXXGSC22XXXX

*FM07-187B* en-US

Smart Combi

™

Global Foodservice Solutions

Classic Combi

™

306174---0AIAE-- / 14.12.2009 / TAG-MaBr

Planning and installation instructions

Smart Combi

™

Classic Combi

™

5Planning ..............................................................1

5Standards and regulations ............................................1.1

5Ensure conformity with standards ............................................1.1.1

5Water ........................................................................................1.1.2

5Waste water .............................................................................1.1.3

6Electricity ..................................................................................1.1.4

6Gas ..........................................................................................1.1.5

8Room air ..................................................................................1.1.6

8Safety .......................................................................................1.1.7

8Food hygiene ...........................................................................1.1.8

9Relevant laws, institutions and authorities ...............................1.1.9

9Package dimensions and weights ................................1.2

10Weight ..............................................................................1.3

10Scale drawings ...............................................................1.4

10Abbreviations, installation dimensions .....................................1.4.1

11Installation dimensions .............................................................1.4.2

13Unit dimensions .......................................................................1.4.3

17Specifications, water ......................................................1.5

17Specifications, soft water .........................................................1.5.1

17Specifications, hard water ........................................................1.5.2

17Specifications, waste water ......................................................1.5.3

18Specifications, gas .........................................................1.6

18Specification Natural Gas E/H - 20/20 mbar ............................1.6.1

18Specification Natural Gas LL/L - 25/20 mbar ...........................1.6.2

18Specification, liquid gas B/P - 30/50 mbar ...............................1.6.3

19Specifications, power supply ........................................1.7

19Supply line, gas ..............................................................1.8

19Heat loss .........................................................................1.9

20Ambient atmosphere and noise level ...........................1.10

21Transport .............................................................2

21Transporting the unit ......................................................2.1

22Installation ..........................................................3

22Installation information ..................................................3.1

23Mounting the suspension frame in the base frame .....3.2

25Installing tabletop units .................................................3.3

25Installing floor standing units .......................................3.4

3Planning and installation instructions

Global Foodservice Solutions

Contents

Smart Combi

™

Classic Combi

™

25Aligning the rack trolley ...................................................3.5

26Aligning the rack trolley with slide in system EasyIn ....3.6

28Electricity ..............................................................4

28Power cable requirements ...............................................4.1

28Opening and closing the switch cover ...........................4.2

29Description of the terminal strip ......................................4.3

29Connecting the power supply ..........................................4.4

30RS485/RS422 interface .....................................................4.5

31Water ......................................................................5

31Water supply ......................................................................5.1

33Information about the soft water supply ......................................5.1.1

33Information about the hard water supply ....................................5.1.2

34Fitting the T-piece (accessory) ....................................................5.1.3

35Waste water connection ...................................................5.2

35Waste water connection for units with WaveClean .....................5.2.1

36Waste water connection for units without WaveClean ................5.2.2

38Gas .........................................................................6

38Gas supply .........................................................................6.1

40Converting to a different type of gas ..............................6.2

41Hose connection ...............................................................6.3

42Testing for leaks ................................................................6.4

42Checking the connection pressure .................................6.5

43Checking CO2/CO values (ClassicCombi) ......................6.6

44Start CO2 calibration ..................................................................6.6.1

45Measure CO2 values ..................................................................6.6.2

47Display burner status and cooking chamber temperature ..........6.6.3

48Checking CO2/CO values (SmartCombi) ........................6.7

48Starting CO2 calibration .............................................................6.7.1

49Measuring CO2 values ...............................................................6.7.2

51Setting the CO2 content manually ...................................6.8

52Exhaust gas routing .............................................7

54Air outlet connection ............................................8

54Installation under an extraction hood .............................8.1

54Connection to an air outlet duct ......................................8.2

Global Foodservice Solutions

Planning and installation instructions4

Smart Combi

™

Classic Combi

™

Contents

1 Planning

1.1 Standards and regulations

1.1.1 Ensure conformity with standards

→

Ensure that your plans conform to the standards and regulations

applying at the installation location.

NOTICE

The following overviews assist with orientation. They make no claim

to be complete.

1.1.2 Water

DescriptionRelates toStandard

Drinking water protection, preservation of the drinking water

quality

Drinking water supplyDIN 1988-4

Table 1: Standards/regulations relevant to water

1.1.3 Waste water

DescriptionRelates toStandard

Additional specifications to

DIN EN 752 and

DIN EN 12056: Drainage systems on private ground

Waste water qualityDIN 1986-100

Table 2: Standards/regulations relevant to waste water

5Planning and installation instructions

Global Foodservice Solutions

Planning

Smart Combi

™

Classic Combi

™

1.1.4 Electricity

DescriptionRelates toStandard

Provisions for the erection of

high-voltage current systems

with nominal voltages up to

1000 V

Requirements for electronic

components

DIN VDE

0100 ff.

Erection of low-voltage systems

part 5-54: Selection and erection

of electrical equipment – Earthing arrangements, protective

conductors and protective potential equalisation conductors

Potential equalisationDIN VDE

0100-540

Erection of low-voltage systems

part 4-43: Protection for safety

– Protection against overcurrent

Potential equalisation of the

location

DIN VDE

0100-430

Table 3: Standards/regulations relevant to electricity

1.1.5 Gas

DVGW regulations

DescriptionRelates toStandard

Technical regulations for gas

installations (DVGW-TRGI)

Gas supplyG 600

Technical regulations for liquid

gas (TRF)

Gas supply

Installation of the unit

TRF

Gas qualityGas quality

Conditions for supply

G 260/I

Gas quality – Supplementary

rules for 2nd family gases

G 260/II

Installation of gas appliances in

commercial kitchens

Gas supply

Installation of the unit

G 634

Mechanical extraction of flue

gas for gas-fired appliances

without fans

Exhaust gas routingG 660

Table 4: DVWG regulatory standards/provisions relevant for gas

Global Foodservice Solutions

Planning and installation instructions6

Smart Combi

™

Classic Combi

™

Planning

DIN standards/provisions

DescriptionRelates toStandard

Gas-fired catering appliances

– Part 1: General safety requirements

Basic requirementsDIN EN 203-1

Test gases – test pressures –

appliance categories

Types of gasDIN EN 437

Hose assemblies and connection valves for gas; safety hose

assemblies, safety valves with

quick connecting devices

Flexible connectionsDIN 3383,

Par t 1

Hose assemblies and connection valves for gas ; hose assemblies for rigid connection

Flexible connectionsDIN 3383,

Par t 2

Hose assemblies of stainless

steel for gas (draft)

Flexible connectionsDIN 3384

Table 5: DIN standards/provisions relevant for gas

BG Construction standards/provisions

DescriptionRelates toStandard

Regulations for the prevention

of accidents with the use of liquid gas

Scope of the provision: 1. Use

of liquid gas for burning purposes 2. Liquid gas systems

for burning purposes, insofar

as supplied by pressurised

gas containers 3. Liquid gas

systems with gas consuming

appliances for burning purposes, insofar as supplied by

pressurised gas containers.

Gas supply

Appliance installation (formerly

ZH 1/455)

BGV D 34

(formerly VBG

21)

Table 6: BG construction standards/provisions relevant for gas

7Planning and installation instructions

Global Foodservice Solutions

Planning

Smart Combi

™

Classic Combi

™

1.1.6 Room air

DescriptionRelates toStandard

Ventilation equipment for kitchen, basis for planning the

ventilation of commercial kitchens as well as for calculating

the size and construction of

ventilation systems. It applies

in connection with the complete

reference work of DIN 1946.

Priority circuit room ventilation

system

VDI 2052

General conditions for working

environments in kitchens with

regard to the planning of kitchen ventilation systems.

Emissions and comfortASR 5

Table 7: Standards/regulations relevant to room air

1.1.7 Safety

DescriptionRelates toStandard

Safety regulations for kitchens,

kitchen safety equipment (fire

extinguishers...)

Hazards in kitchens (formerly

ZH 1/37)

BGR 111

Table 8: Standards/regulations relevant to safety

1.1.8 Food hygiene

DescriptionRelates toStandard

Regulation about food hygieneDocumentation of heating temperatures according to HACCP

principles

Regulation

(EG) Nr.

852/2004

Table 9: Standards/regulations relevant to hygiene

Global Foodservice Solutions

Planning and installation instructions8

Smart Combi

™

Classic Combi

™

Planning

1.1.9 Relevant laws, institutions and authorities

Name of the institute/authority

Relates toStandard

Regional gas or energy supplier (GVU) or network operator

Gas supply

Installation of the unit

TAB (Technical

Connection

Conditions)

GAS (Low

Pressure Gas

Supply

(NDAV))

Building inspection authoritiesGas supply

Installation of the unit

BauO (Building

Regulations);

LBO (Regional

Building Regulations)

Trading standards officeInstallation of the unitGewO (Trade,

Commerce and

Industry regulations)

Responsible district chim-

ney/heating inspector

Gas supply

Installation of the unit, emissions

BauO (Building

Regulations);

FeuVo (Ordinance on Firing

Installations),

BISchV (Federal Emission

Control Ordinance)

Water/waste water association

or authority

Installation of the unit

Water/waste water connections

AbwV (Waste

Water Ordinance)

ATV information sheets

(Association of

Waste Water

Technicians)

Technical connection condi-

tions for connecting to the low

voltage mains network, require-

ments applying to the installa-

tion location

Mains network operators,

power suppliers

Installation of the unit

Mains connection

TAB (Technical

Connection

Conditions)

POWER (NAV

- Ordinance on

Low-Voltage

Connections)

Table 10: Relevant laws, institutions, authorities

1.2 Package dimensions and weights

NOTICE

These specifications may be modified for technical reasons.

9Planning and installation instructions

Global Foodservice Solutions

Planning

Smart Combi

™

Classic Combi

™

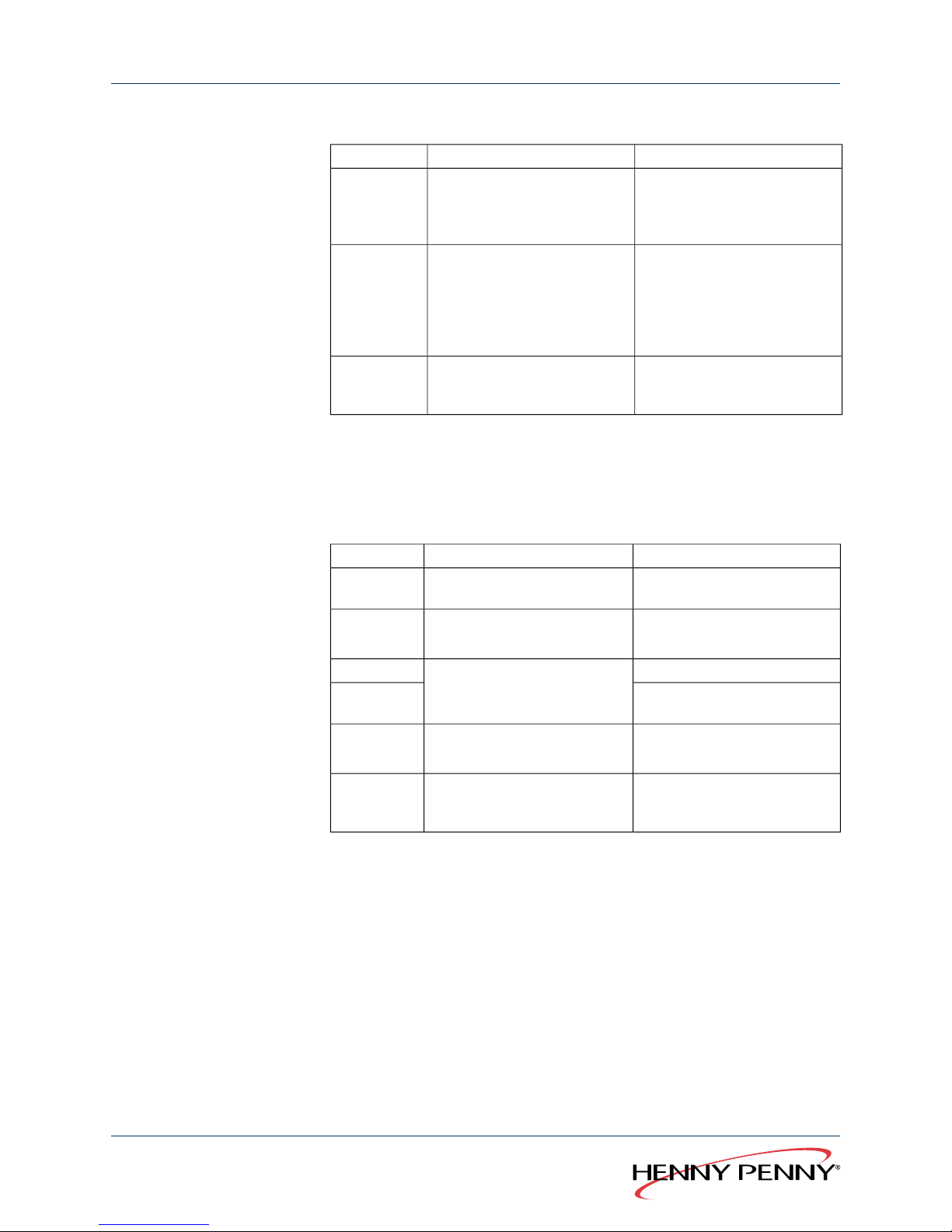

Gross weight (lb.)Package dimensions (in.)

Depth x width x height

Size

374.842.5 x 37.8 x 40.2615/620

429.942.5 x 37.8 x 50.4115/120

826.745.7 x 37.8 x 86.6215/220

Table 11: Package dimensions and weights

1.3 Weight

NOTICE

These specifications may be modified for technical reasons.

Weight (lb.)Size

302.0615

313.1620

368.2115

412.3120

782.6215

782.6220

Table 12: Weight

1.4 Scale drawings

1.4.1 Abbreviations, installation dimensions

MeaningAbbreviation

WidthB

Width, distance from wall to the left of the unitBL

Width, distance from wall to the right of the unitBR

HeightH

Height, distance from the ceilingHD

Height, unit feetHF

Height, overallHG

Height, tableHT

DepthT

Depth, distance to wall behind the unitTH

Table 13: Abbreviations, installation dimensions

Global Foodservice Solutions

Planning and installation instructions10

Smart Combi

™

Classic Combi

™

Planning

1.4.2 Installation dimensions

B

BR

TH

H

HG

HF

HT

BL

T

Figure 1: Installation dimensions of combisteamers 615/620 and 115/120

B

BR

TH

H

HG

HF

BL T

Figure 2: Installation dimensions, combisteamer 215/220

THTHTHGHFHBRBLBSize

5079985016401006905050997615/620

5079958016401009605050997115/120

50813 1960238172250501075215/220

Table 14: Installation dimensions in mm

11Planning and installation instructions

Global Foodservice Solutions

Planning

Smart Combi

™

Classic Combi

™

NOTICE

A clearance of at least 50 mm from walls must be maintained to the

right and the left of the unit as well as behind it.

A minimum distance of 500 mm to the left is recommended for servicing.

When using rack trolleys, the distance to the left of the unit should be

at least 800 mm to allow the trolley to be positioned at the side.

Global Foodservice Solutions

Planning and installation instructions12

Smart Combi

™

Classic Combi

™

Planning

1.4.3 Unit dimensions

MeaningAbbreviation

Drain (waste water)A

Flue outletAG

Air outletAL

Electrical connectionEA

Soft water, coldEW

Gas supplyCM

InterfaceKE

Cold water, hardKW

Performance optimisation systemLOA

Potential equalisation connectionPA

Centre of gravityS

Control lead, externalSTL

13Planning and installation instructions

Global Foodservice Solutions

Planning

Smart Combi

™

Classic Combi

™

72

PA

EW

KW

760

223

163

138

93

61

38

140

97

73

52

EA

GA

STL

50

50

100

278

73 897

A

53

100

+20

0

790

849

AL Ø53

50

165

1020

52

799

100 535

76

Figure 3: Combisteamer 615/620, unit dimensions in mm

Global Foodservice Solutions

Planning and installation instructions14

Smart Combi

™

Classic Combi

™

Planning

KE

140

71

100

97

73

52

LOA

EA

STL

50

50

73

278

897

+20

0

100

PA

EW

KW

760

223

163

138

93

61

38

54

1060

113 8

1020

AL Ø53

52

799

100

535

76

50

Figure 4: Combisteamer 115/120, unit dimensions in mm

15Planning and installation instructions

Global Foodservice Solutions

Planning

Smart Combi

™

Classic Combi

™

KE

67

EA

EW

KW

759

303

243

139

133

75

52

141

118

103

90

52

PA

GA

STL

50

50

39

233

996

187

238±20

1960

2009

AL Ø73

50

170

1075

50

813

93 609

76

100

Figure 5: Combisteamer 215/220, unit dimensions in mm

Global Foodservice Solutions

Planning and installation instructions16

Smart Combi

™

Classic Combi

™

Planning

1.5 Specifications, water

1.5.1 Specifications, soft water

ValueParameters

Drinking water, coldType

2–6 bar/200–600 kPaSupply pressure

< 1.5 mmol/l, < 5 °dH (soft water)Hardness

¾" outside threadThread

DN 15 hose with ¾" union nutConnection

Table 15: Specifications, soft water

1.5.2 Specifications, hard water

ValueParameters

Drinking water, coldType

Up to 50 °C (122 °F)Temperature

2–6 bar/200–600 kPaSupply pressure

0–4 mmol/l, 0–25 °dHHardness

¾" outside threadThread

DN 15 hose with ¾" union nutConnection

Table 16: Specifications, hard water

1.5.3 Specifications, waste water

ValueParameters

Up to 80 °C (176 °F)

For adjusting the waster water temperature, see chapter “Standard settings”

in the operating manual.

Temperature

DN 50 direct connectionConnection

Table 17: Specifications, waste water

17Planning and installation instructions

Global Foodservice Solutions

Planning

Smart Combi

™

Classic Combi

™

1.6 Specifications, gas

1.6.1 Specification Natural Gas E/H - 20/20 mbar

ValueParameters

A3, B23Model EN 203-1:2005

15–25 mbarConnection pressure EN 437:2003-09

45.67 MJ/m

3

Wobbe index W

i

34.02 MJ/m

3

Heating value H

i

50.72 MJ/m

3

Wobbe index W

s

37.78 MJ/m

3

Calorific value H

s

¾" outside threadThread

Table 18: Specification Natural Gas E/H - 20/20 mbar

1.6.2 Specification Natural Gas LL/L - 25/20 mbar

ValueParameters

A3, B23Model EN 203-1:2005

15–30 mbarConnection pressure EN 437:2003-09

37.38 MJ/m

3

Wobbe index W

i

29.25 MJ/m

3

Heating value H

i

41.52 MJ/m

3

Wobbe index W

s

32.49 MJ/m

3

Calorific value H

s

¾" outside threadThread

Table 19: Specification Natural Gas LL/L - 25/20 mbar

1.6.3 Specification, liquid gas B/P - 30/50 mbar

ValueParameters

A3, B23Model EN 203-1:2005

15–57.5 mbarConnection pressure EN 437:2003-09

80.58 / 70.69 MJ/m

3

Wobbe index W

i

116.09 / 88.00 MJ/m

3

Heating value Hi per m

3

45.65 / 46.34 MJ/kgHeating value Hi per kg

87.33 / 76.84 MJ/m

3

Wobbe index W

s

Global Foodservice Solutions

Planning and installation instructions18

Smart Combi

™

Classic Combi

™

Planning

ValueParameters

125.81 / 95.65 MJ/m

3

Calorific value Hs pro m

3

49.47 / 50.37 MJ/kgCalorific value Hs pro kg

¾" outside threadThread

Table 20: Specification, liquid gas B/P - 30/50 mbar

1.7 Specifications, power supply

SizeParameters

220215120115620615

1 N PE/AC 50 HzMains type

230 VVoltage

1.5 kW0.8 kWConnected load

IP X5Protection type

1 x 16 AFuses

Table 21: Specifications, power supply

1.8 Supply line, gas

Connected load (kW)Size

11615

17620

18115

26120

36215

52220

Table 22: Supply line, gas

1.9 Heat loss

Latent (kW)Sensible (kW)Size

2,201,70615

3,402,60620

3,602,70115

5,203,90120

7,205,40215

10,407,80220

Table 23: Heat loss

19Planning and installation instructions

Global Foodservice Solutions

Planning

Smart Combi

™

Classic Combi

™

1.10 Ambient atmosphere and noise level

ValueParameters

5 °C (41 °F)–40 °C (104 °F),

95% relative humidity, non condensing

Ambient atmosphere

< 70 dB (A)Noise level

Table 24: Ambient atmosphere and noise level

Global Foodservice Solutions

Planning and installation instructions20

Smart Combi

™

Classic Combi

™

Planning

2 Transport

2.1 Transporting the unit

L

H

B

NOTICE

The units are delivered on pallets in cardboard casing. Packed in this

way, the units cannot be stacked and are not protected from moisture.

Packed units can be transported lengthways or crossways with a

pallet truck.

Unpacked floor standing units can be lifted at the guiding rails.

CAUTION

Damage due to incorrect transportation

→

Do not position a fork lift in the cooking chamber.

→

When using a fork lift truck, make sure that the siphon, which

protrudes downwards, and the waste water pipe are not damaged.

→

Do not lift tabletop units by the chamber door or the operation

panel.

→

Always transport units upright, do not tip or stack.

1. Consider the package dimensions and weight when choosing a

method of transport (see Chapter “Package dimensions and

weights”, Page 9).

2. Always transport units upright, do not tip or stack.

3. Secure palettes against slipping and tipping over.

21Planning and installation instructions

Global Foodservice Solutions

Transport

Smart Combi

™

Classic Combi

™

3 Installation

3.1 Installation information

Before installing

NOTICE

Examine the unit for transportation damage. Do not install or use

damaged units.

Remove the protective film from the external panels before using for

the first time.

Remove foam transport protection from the chamber.

Fire prevention regulations

NOTICE

Observe the local fire prevention regulations when installing near to

materials that are heat sensitive or endangered by fire.

Covers on top of the unit must be fire-proof.

Units may only be installed on or against fire-proof surfaces and in

compliance with fire prevention regulations.

Installation in buildings The floor or table must be able to bear the weight of the unit (see Chapter

“Weight”, Page 10).

If there is a drainage grating in front of the unit, the customer should fit a

ramp to enable the rack trolley or loading trolley to be pushed across.

Installing below ground

level

NOTICE

When installing the unit in rooms below ground level (cellars), the current

local provisions for liquid gas, in particular, are to be observed when

connecting and operating the gas combisteamer.

Minimum clearances A minimum clearance of 50 mm (2") must be maintained from walls to

the sides and behind the unit and at least 0.5 m (1.6 ft.) above the unit

for servicing.

Global Foodservice Solutions

Planning and installation instructions22

Smart Combi

™

Classic Combi

™

Installation

When using rack trolleys, there should be a minimum distance of at

least 0.8 m (2.6 ft.) to allow the trolley to be positioned at the side.

Heat sources, such as ovens (2) must be at least 0.5 m (1.6 ft.) away

so that the cooling air drawn in under the base is not warmed.

WARNING

Possible danger

→

Non-compliance may pose a threat of death or serious injury.

Fryers or deep fat fryers must be positioned outside of the splash zone

(3) of the hand shower. Splashes of water in hot grease can lead to

serious burns.

Air intake and blow out

vents

NOTICE

The unit's air intake and blow out vents must not be blocked or

covered!

Avoid sources of heat and steam at the sides or behind the unit.

If this is not possible, use shields to prevent warm or damp air from

being drawn into the unit.

The air intake and blow out vents are situated underneath the unit.

Affix “Risk of scalding”

warning

A warning notice must be mounted on the door of the cooking chamber

if units are installed in such a way that the upper slide-in rails exceed

a height of 1.60 m (5.3 ft.).

The warning “Risk of scalding” warns about the danger of scalding that

exists when the contents of a container being pulled out cannot be

seen.

3.2 Mounting the suspension frame in the

base frame

Depending on the version, the base frame can be equipped with

suspension frames for taking GN containers, trays and racks.

Bolts on the vertical supports indicate that it is possible to fit suspension

frames.

NOTICE

The following illustrations show 4 suspension frames (2 sets).

23Planning and installation instructions

Global Foodservice Solutions

Installation

Smart Combi

™

Classic Combi

™

1. Mount the inner suspension frames.

2. Push the rear stop profiles (right/left) onto the bolts.

3. Mount the outer suspension frames (right/left).

Global Foodservice Solutions

Planning and installation instructions24

Smart Combi

™

Classic Combi

™

Installation

3.3 Installing tabletop units

NOTICE

A warning notice must be mounted on the door of the cooking chamber

if tabletop units are installed in such a way that the upper slide-in rails

exceed a height of 1.60 m (5.3 ft.).

The label warns about the danger of scalding that exists when the

contents of a container being pulled out cannot be seen.

1. Observe the instructions for installation (see Chapter “Installation

information”, Page 22).

2. Make sure that the table is able to bear the weight of the unit.

3. Position the unit horizontally level. Correct the alignment using the

feet, if necessary.

4. Remove moisture and grease from the area for affixing the warning

notice.

5. Attach the warning notice on the door of the cooking chamber.

3.4 Installing floor standing units

1. Observe the instructions for installation (see Chapter “Installation

information”, Page 22).

2. Make sure that the floor is able to bear the weight of the unit.

3. Position the unit horizontally level. Correct the alignment using the

feet, if necessary.

3.5 Aligning the rack trolley

NOTICE

Floor standing units may only be operated with a rack trolley. The

rack trolley forms part of the seal of the cooking chamber.

If the rack trolley is not correctly aligned the cooking chamber will not

be sealed properly. Water can escape during cooking and the food

will not be cooked evenly.

1. Check whether the floor underneath and in front of the unit is level.

2. Level out small differences with the unit's feet.

25Planning and installation instructions

Global Foodservice Solutions

Installation

Smart Combi

™

Classic Combi

™

3. Place spacer plates in the frame of the rack trolley if the condition of

the floor is unsuitable.

4. Check the alignment of the rack trolley and correct it if necessary.

The rails in the unit are horizontal.

There is no gap between the sealing plate on the rack trolley and the door

seal.

3.6 Aligning the rack trolley with slide in

system “EasyIn”

Floor standing units in sizes 215 and 220 are equipped with the “EasyIn”

slide-in system. With the “EasyIn” slide-in system, the rack trolley is lifted

and slides into the unit on rails.

Irregularities of up to 10 mm (0.4") in the floor can be evened out in this

way.

WARNING

Risk of damage or personal injury

There is at least 1100 lbs (500 kg) = 4 load points of 275 lbs (125 kg)

on the adjustable legs.

→

To prevent damage or personal injury, ensure that the floor is strong

enough.

CAUTION

Damage to equipment due to incorrect height adjustment

If the minimum distance (y) is not observed, rails and rollers can be

damaged.

→

Set up the unit horizontally, adjust alignment using the feet, if

necessary.

→

Observe a minimum clearance of 1 mm in the take-up area.

NOTICE

Floor standing units may only be operated with a rack trolley. The rack

trolley forms part of the seal of the cooking chamber.

If the rack trolley is not correctly aligned the cooking chamber will not

be sealed properly. Water can escape during cooking and the food will

not be cooked evenly.

Global Foodservice Solutions

Planning and installation instructions26

Smart Combi

™

Classic Combi

™

Installation

1. Push the rack trolley into the take-up area.

x

y

2. In the take-up area (x), there must be a clearance (y) of at least

1 mm between the rollers and the rails.

The clearance (y) should not exceed 5 m.

Correct the clearance (y) using the feet, if necessary.

3. Check whether the rails are horizontal.

Correct the alignment using the feet, if necessary.

k

4. Push the rack trolley further onto the lifting bevel (k) into the unit.

The rack trolley will be lifted up.

5. Push the trolley into the unit as far as it will go.

The wheels should no longer touch the floor when the unit is fully

pushed in. The rack trolley is only supported by the carrying rollers.

27Planning and installation instructions

Global Foodservice Solutions

Installation

Smart Combi

™

Classic Combi

™

4 Electricity

4.1 Power cable requirements

LK

The unit is delivered as standard without a connection cable. A H07RN-F

cable complying with EN standards or, respectively, with the locally

applying provisions, must be used for connecting the unit. The table shows

the length of cable required inside the unit.

Cable length (LK) (cm)Size

80615/620

80115/120

100215/220

4.2 Opening and closing the switch cover

DANGER

Danger due to high voltage

There are voltage-carrying components behind the switch cover.

→

Disconnect the unit from the power supply before opening the switch

cover.

→

Do not operate the unit when the switch cover is open.

1. Pull the hand shower out approx 20 cm.

2. Screw in the hexagonal socket screw (size 5) on the underside of

the switch cover as far as it will go.

3. Press the switch cover lightly and lift approx 20 mm upwards.

4. Raise the switch cover approx 20 mm and lower it again

5. Open the switch cover fully.

6. Check that the seal around the switch cover fits properly and that it

is not damaged.

7. Replace a damaged seal, if necessary.

8. Close the switch cover carefully.

When doing so, ensure that cables are not trapped and that the

cooling fan cannot be obstructed by any cables.

9. Press the switch cover lightly and lift approx 20 mm upwards.

10. Close the switch cover fully and lower it again pressing lightly.

11. Check that the seal around the switch cover fits properly.

Global Foodservice Solutions

Planning and installation instructions28

Smart Combi

™

Classic Combi

™

Electricity

12. If necessary, open the switch cover and correct the position of the

seal.

13. Screw out the hexagonal socket screw (size 5) on the underside

of the switch cover.

4.3 Description of the terminal strip

A1/X5.11

A1/X5.12

K1/A2

X3

PE PE PE13 N 11 12 12 3 4

A_TXD+

B_TXD-

B_RXD-

A_RXD+

YE

GN

BN

WH

H13/A1

R = 150 Ω

Figure 6: Terminal strip

DescriptionTerminalTerminal

strip

External buzzer

External signalling device activated via an auxiliary

relay.

13X3

N

PE

Extraction hood, potential-free11

12

PE

RS485/RS422 interface1

2

3

4

PE

4.4 Connecting the power supply

The unit may only be connected and serviced by an authorised electrical

technician, according to the provisions of the German Association of

29Planning and installation instructions

Global Foodservice Solutions

Electricity

Smart Combi

™

Classic Combi

™

Electrical Technicians, the power supply company and the information

on the nameplate.

Have damaged power cables replaced by customer service to avoid risks

of damage or injury.

The connection can be made either with a plug or by connecting directly.

Isolator with direct connections

The power supply must be fitted with an all pole isolator (e.g. automatic

cutout) with a minimum contact opening of 3 mm, so that the unit can be

removed from the mains at any time.

Plug connection

The plug socket must be adequately protected.

Potential equalisation

The unit can be included in a potential equalisation system (grounding).

The connection terminal is underneath the information plate.

1. Prepare the connection cable (see Chapter “Power cable

requirements”, Page 28).

2. Remove the left side panel.

3. Pass the connection cable through the strain relief screws into the

unit.

4. Connect the connection cable with the connecting terminals according

to the connection diagram.

5. Sizes 115 and 120: Secure the connection cable additionally with

cable clips.

6. Secure the left side panel.

4.5 RS485/RS422 interface

SmartCombi units are equipped as standard with a four-pin RS485

interface; this is optional with ClassicCombi. The interface can be reduced

to a two-pin RS422 interface.

1. Bridge the terminals to reduce the interface to a two-pole RS422

interface.

- X3/1 to X3/3

- X3/2 to X3/4

2. Use twisted wires (e. g. LiYY (TP) 2x2x0.5) for the connection.

3.

Close the last unit with a 150 Ω terminating bus resistor.

Global Foodservice Solutions

Planning and installation instructions30

Smart Combi

™

Classic Combi

™

Electricity

5 Water

5.1 Water supply

The unit is equipped with two water connections:

●

a soft water connection for producing steam

●

a hard water connection for cooling waste water, for operating the

hand shower and for the automatic cleaning system “WaveClean”

For units that are equipped with the “WaveClean” automatic cleaning

system, use of “WaveClean” is not possible without a hard water

connection.

NOTICE

Both water supplies must always be connected.

Hard and soft water connections can be made via a hose with a

T-piece (accessory) in the event that only soft water is available on

site (see Chapter “Fitting the T-piece (accessory)”, Page 34).

NOTICE

When using the stacking kit (accessory), the upper and lower units

must be connected independently so that the other unit can still be

used in the event that one unit fails.

1. Observe information about the hard water supply (see Chapter

“Information about the hard water supply”, Page 33).

2. Observe information about the soft water supply (see Chapter

“Information about the soft water supply”, Page 33).

3. Ensure that customer-supplied water hoses fulfil the requirements

for the hard and soft water supplies (see Chapter “Specifications,

soft water”, Page 17 and Chapter “Specifications, hard water”,

Page 17).

4. Make sure that the provisions for the supply of drinking water are

complied with (see Chapter “Water”, Page 5).

5. Ensure that the water stop-cock is fitted with a backflow preventer.

6. Use ½" hoses with an R ¾" thread permitted for connecting drinking

water for the connection.

NOTICE

Use DVGW-tested hoses, or hoses conforming to the local regulations,

according to IEC 61770.

31Planning and installation instructions

Global Foodservice Solutions

Water

Smart Combi

™

Classic Combi

™

7. When preparing the hoses, calculate the length to allow 0.8 m to be

pulled out from the unit after connection, for later servicing.

8. Rinse out customer-supplied hoses for the hard and soft water

connections.

9. Make sure that the filters fitted as standard to the unit's water inlets

are present.

CAUTION

Damages caused by incorrect water supply

→

Do not confuse the hard water and the soft water connections.

NOTICE

The connections for hard and soft water are located on the floor of the

unit on the left.

2

1

Figure 7: Water connections, tabletop units

1

2

Figure 8: Water connections, floor standing units

Global Foodservice Solutions

Planning and installation instructions32

Smart Combi

™

Classic Combi

™

Water

10. Connect the hose for the hard water supply to the hard water

connection (1).

11. Connect the hose for the soft water supply to the soft water

connection (2).

5.1.1 Information about the soft water supply

Cl/Fe content If the Cl content is greater than 150 mg/l, Fe content greater

than 0.1 mg/l or Cl

2

content greater than 0.1 mg/l, corrosion can occur

in the cooking chamber.The Cl content can be reduced with an

activated charcoal filter.

Supply pressure If the supply pressure is not within the given limits (see Chapter

“Specifications, soft water”, Page 17), the cooking art “Steaming” will

fail to produce any steam.

Contamination of the water If the water is heavily contaminated, a sedimentation filter (grit size

0.08 mm) must be installed upstream.

Water hardness Scale deposits may form if the total water hardness or carbonate

hardness exceeds 5 °dH (0.89 mmol/l). For values smaller than this,

the scale formation is correspondingly less. A total water hardness or

carbonate hardness of 1 °dH is ideal. Certain water components (Na

+

ions and silicates) can cause the windows to become cloudy.This effect

depends on the quality of the water and how the unit is used.

Decarbonisation or full desalination systems can prevent the formation

of scale deposits.

A water softening system should be installed upstream if the water is

very hard.

Water softening systems based on electromagnetic fields do not provide

protection against scale deposits with combisteamers.

Pipes from galvanized steel or other corrosive material may not be

used downstream from water softening systems.

Systems with phosphate and silicate dosing may not be used. Deposits

may form in the cooking chamber with such systems.

SmartCombi units can show the service intervals of a connected water

softening system on the multi-function display.You will find further

information in the operating instructions.

5.1.2 Information about the hard water supply

Cooling waste steam Cold water that has not been softened can be used for cooling waste

steam.

33Planning and installation instructions

Global Foodservice Solutions

Water

Smart Combi

™

Classic Combi

™

Warm water leads to increased water consumption and should not be

used.

The water temperature must not exceed 50 °C (122 °F).

Automatic cleaning system

“WaveClean”

Units that are equipped with the “WaveClean” automatic cleaning system

must always be connected to a hard water and a soft water supply.

Otherwise, cleaning with “WaveClean” is not possible.

5.1.3 Fitting the T-piece (accessory)

Hard and soft water connections can be made via a hose with a T-piece

(accessory) in the event that only soft water is available on site.

Figure 9: Position of the T-piece

Global Foodservice Solutions

Planning and installation instructions34

Smart Combi

™

Classic Combi

™

Water

1

2

3

Figure 10: Parts of the T-piece

1 Sealing ring

2 Threaded connector

3 Metal ring

1. Check that both sealing rings (1) are lying flat in the threaded

connectors (2).

2. Screw the threaded connectors (2) evenly onto the hard and soft

water connections and tighten securely. Avoid cross-threading.

CAUTION

Damage to the unit caused by water

→

Check that the metal rings are positioned correctly.

3. Check that both metals rings (3) are lying on the respective plastic

sprocket in the threaded connector (2).

If not, open the threaded connector (2) and repeat the process.

5.2 Waste water connection

5.2.1 Waste water connection for units with WaveClean

The unit is equipped with a siphon (odour trap) with an overflow and

can be connected to the waste water system without taking additional

action. Customer-supplied siphons should be avoided.

35Planning and installation instructions

Global Foodservice Solutions

Water

Smart Combi

™

Classic Combi

™

1

2

3

If the waste water outlet is connected to a customer-supplied siphon (1),

counter pressure may cause the siphon in the unit (3) to overflow.

Therefore, the waste water pipe must be fitted with an aerator in this case.

A PA-I 1818 DIN 19560 HT pipe is recommended for the connection to

the waste water system.

The diameter of the waste water pipe must not be reduced.

CAUTION

Damage caused by an incorrect water connection

→

Do not operate the unit without an aerator in the waste water pipe.

1. Make sure that customer-supplied pipes meet the requirements for

the waste water connection (see Chapter “Specifications, waste

water”, Page 17).

2. Observe the provisions for the disposal of waste water (see Chapter

“Waste water”, Page 5).

3. Connect the unit to the waste water system using a heat-proof pipe

(DN 50).

4. With customer-supplied siphons: connect aerator to a waste water

pipe.

5. With customer-supplied siphons: pour 2 quarts (2 l) of drinking water

into the siphon.

This ensures the siphon will work properly.

5.2.2 Waste water connection for units without WaveClean

CAUTION

Risk of damage by waste steam

→

To protect the unit from damage caused by waste steam, the funnel

must not be positioned below the unit.

NOTICE

Units without WaveClean are supplied without a built-in overflow.

Therefore, they may only be connected to the waste water system via

an open drain in a funnel.

Global Foodservice Solutions

Planning and installation instructions36

Smart Combi

™

Classic Combi

™

Water

DN 50

DN 50

5% (3°)

1. Make sure that customer-supplied pipes meet the requirements

for the waste water connection (see Chapter “Specifications, waste

water”, Page 17).

2. Observe the provisions for the disposal of waste water (see Chapter

“Waste water”, Page 5).

3. Connect the unit to the waste water system using a heat-proof pipe

(DN 50) and a funnel.

37Planning and installation instructions

Global Foodservice Solutions

Water

Smart Combi

™

Classic Combi

™

6 Gas

6.1 Gas supply

Requirements The following conditions must be met before the gas pipeline is connected

to the unit:

●

All gas connection parts (also those supplied by the customer) must

be tested according to DIN-DVGW (German Association for Gas and

Water).

●

The central gas supply must not be located within the safety distances

and must be freely accessible.

●

The supply pipeline must have a diameter of at least ¾“.

WARNING

Risk of fire

Unintended moving of the appliance results in damage to gas line and

possible fire.

→

Do not equip this appliance with casters or with stands with casters.

→

Do not equip this appliance with stands with casters.

CAUTION

Material damage due to insuffient aeration

The amount of fresh air needed for proper combustion is dependent

upon the input power (BTU/hr) of the appliance. In rooms in which the

nominal heat loading caused by all gas appliances is less than 170,721

BTU/hr (50 kW), air supply via external joints or openings into the open

air is permissible.

→

Ensure sufficient supply of combustion air.

Global Foodservice Solutions

Planning and installation instructions38

Smart Combi

™

Classic Combi

™

Gas

CAUTION

Damage caused by incorrect gas connection

→

Do not confuse the gas connection with the water connection.

→

Contact customer service in the event that the gas connection is

confused with the water connection.

NOTICE

The unit is intended for a fixed connection by the customer. The gas

connection can be made via a gas socket.

The unit may only be installed by an authorised installation company

contracted by the respective gas supplier.

The regulations of the local gas supply company must be complied

with (see Chapter “Standards and regulations”, Page 5).

1. Check whether the type of gas available corresponds to that given

on the nameplate.

2. Convert the unit to the type of gas available if this differs from that

given on the name plate (see Chapter “Converting to a different

type of gas”, Page 40).

3. Observe the information about the hose connection (see Chapter

“Hose connection”, Page 41).

1

4. Attach the gas hose to the ¾" steel pipe outlet under the floor of

the unit (1).

5. Test for leaks (see Chapter “Testing for leaks”, Page 42).

6. Test the connection pressure (see Chapter “Checking the

connection pressure”, Page 42).

7. Check CO

2

/CO values in the exhaust gas.

39Planning and installation instructions

Global Foodservice Solutions

Gas

Smart Combi

™

Classic Combi

™

6.2 Converting to a different type of gas

NOTICE

When converting to a different type of gas, the burner orifice must be

changed. The orifices, together with an orifice table, are in a plastic bag

located in the connection compartment.

1

1

1

1. Switch the unit off at the mains (switch off circuit breakers or remove

the plug) and shut off the central gas supply.

2. Remove the fixing screws at the bottom of the unit on the left.

3. Remove the side panel.

With floor standing units: remove one screw at the top and one at the

bottom.

With tabletop units: remove two screws at the bottom and two in the

middle.

4. Remove the fixing screws for the gas valve.

5. Remove the gas valve.

1

2

6. Remove gas orifice with seal (1).

7. Select orifice according to the orifice table and refit it using an

undamaged seal (2).

8. Mount the gas valve and screw it tightly.

9. Reopen the central gas supply.

10. Start the unit.

11. Switch the power supply back on.

After the type of gas has been converted, you can proceed with the leak

test, the connection pressure test and the calibration of the CO

2

/CO

values.

Global Foodservice Solutions

Planning and installation instructions40

Smart Combi

™

Classic Combi

™

Gas

6.3 Hose connection

Gas hose and fitting

connections in the same

plane

Left: correct; Right: incorrect

If the connection points are laterally offset, this will cause additional

torsional stress and heavy strain on the hose.This leads to premature

failure.

Connection with a metal

hose

Left: correct; Right: incorrect

Make sure that the hose has only one bend. A strained or twisted metal

hose can lead to early failure of the connection.

Minimum bending

diameter

Left: correct; Right: incorrect

41Planning and installation instructions

Global Foodservice Solutions

Gas

Smart Combi

™

Classic Combi

™

If the separation between the two connection points is less than the

minimum bending diameter, it results in the hose ends bending in opposite

directions. This leads to fatigue fractures.

6.4 Testing for leaks

NOTICE

Use only DVGW-approved foam forming agents or those that have been

tested according to locally applying regulations!

Do not spray leak spray onto the wires of the ignition electronics.

Electronic gas detectors also react to exhaust gas (CO).Therefore, the

null calibration of an electronic gas detector should be done outdoors.

→

Test all connections inside and outside the unit for leaks according

to the “technical provisions for the gas installation” , using a gas

detector or leak spray.

6.5 Checking the connection pressure

Requirements All connections inside and outside the unit are free of leaks (see Chapter

“Testing for leaks”, Page 42).

NOTICE

The manometer should be accurate to at least 0.1 mbar.

1. Switch the unit off at the mains (switch off circuit breakers or remove

the plug) and shut off the central gas supply.

2. Unscrew the side panel.

With tabletop units: remove one screw at the top and one at the

bottom.

With floor standing units, remove two screws at the bottom and two

in the middle.

Global Foodservice Solutions

Planning and installation instructions42

Smart Combi

™

Classic Combi

™

Gas

3. Unscrew the sealing screw from the pressure measurement

connection on the gas valve.

4. Connect the manometer.

5. Reopen the central gas supply.

6. Switch on the unit.

7. Measure the connection pressure.

The connection pressure should be within the range given in the

following table.

Action to be

taken

Measured connection pressure

Nominal connection pressure

Type of gas

None, no operating restrictions

15.0–25.0 mbar20 mbarNatural gas E, LL

None, no operating restrictions

15.0–57.5 mbar50 mbarLiquid gas B, P

Table 25: Connection pressures

NOTICE

Deviations in connection pressure

The appliance may not be used if the connection pressure is above

the range given above (max. 60 mbar). The gas supplier must be

informed that the supply pressure is too high.

Reliable operation cannot be guaranteed if the connection pressure

is below the range given above, (less than 15 mbar). Calculate the

gas supply to ensure that connection pressure during operation is at

least 15 mbar, even when several gas-consuming appliances are

used simultaneously.

8. Close the pressure measuring points tightly while the shut-off valve

is still closed.

9. Check pressure measuring points for leaks.

10. Refit the side panel.

6.6 Checking CO2/CO values (ClassicCombi)

NOTICE

Open the front cover of the operating manual to see the controls.

43Planning and installation instructions

Global Foodservice Solutions

Gas

Smart Combi

™

Classic Combi

™

6.6.1 Start CO2 calibration

WARNING

Possible danger

→

Non-compliance may pose a threat of death or serious injury.

NOTICE

If there is still air in the gas pipeline, display (8) will show the error “71”

(no gas). Repeat the start procedure if this happens.

1. Switch on the unit.

CL

2. Press FL E X I (2).

Display (9) flashes and shows “CL”.

PAr

3. Rotate the set button (6), to select “PAr”.

0PAS

4. Press St a r t / St op (5).

Display (9) shows “PAS” for password.

Display (8) shows “0”.

5. Rotate the set button (7) to select “999”.

CO2 Hi

6. Press St a r t / St op (5) to confirm the entry.

Display (9) shows “CO2”.

With tabletop units: Display (8) flashes and shows “Hi”.

With floor standing units: Display (8) flashes and shows “Hi1” for the first

chamber.

NOTICE

With the set button (7) you can switch between high power “Hi” (“Hi1”

and “Hi2” with floor standing units) and lower power “Lo” (“Lo1” and

“Lo2” with floor standing units).

With floor standing units, you can switch between the upper and the

lower chambers with FLE XI (2).

The CO

2

content is measured at high power.

7. Set high power with the set button (7). “Hi” (“Hi1” or “Hi2” for floor

standing units).

CO2 Hi

8. Press St a r t / St op (5) to start CO2 calibration.

St a r t / St op LEDs (5) flash.

Global Foodservice Solutions

Planning and installation instructions44

Smart Combi

™

Classic Combi

™

Gas

Display (9) shows “CO2”.

Display (8) flashes and shows “Hi” (“Hi1” or “Hi2” for floor standing

units).

6.6.2 Measure CO2 values

Requirements The following conditions must be met in order to measure CO2 values

in the cooking chamber:

●

cooking chamber door is closed

●

150 Hi

Display (9) shows a cooking chamber temperature of 150 °C (302

°F).

●

burner is at high power “Hi” (“Hi1” or “Hi2” for floor standing units)

●

Display (8) shows the fan speed at high power “Hi” ( “Hi1” or “Hi2”

with floor standing units) according to the following table.

WARNING

Risk of suffocation due to carbon monoxide

Safe operation cannot be guaranteed if the CO

2

content is not within

the recommended limits.

→

Make sure that the CO2 content at low power is 0.5–1% lower

than at high power.

→

Keep within the recommended limits for CO

2

content (see Ta bl e

27, Page 46).

NOTICE

Do not insert the probe during ignition; the CO2 values measured will

be especially high due to the ignition process.

Lo (Lo1 or Lo2 for floor standing units)

Hi (Hi1 or Hi2 for floor standing

units)

Size

48005050615

48006700620

28005050115

28006700120

28005050215

28006700220

Table 26: Fan speed (rpm) at high power (Hi) and low power (Lo) for natural

and liquid gas

45Planning and installation instructions

Global Foodservice Solutions

Gas

Smart Combi

™

Classic Combi

™

NOTICE

Turn the set button (7) to switch between the upper and lower

chambers with floor standing units.

Hi1

Display (8) shows the selected chamber

“Hi1” or “Hi2” and “Lo1” or “Lo2”.

1. Hold the probe in the exhaust outlet to measure the CO2 value.

- Left exhaust outlet: lower chamber

- Right exhaust outlet: upper chamber

Carry out measuring quickly to prevent the cooking chamber from

overheating due to the high temperature of 150 °C (302 °F).

The CO

2

content must be within the limits given in the following table.

CO2 content at low

power

CO2 content at high

power

Type of gas

0.5–1.0% lower as with

maximum output Hi/Hi1 or

Hi2

8,6–9,6 %Natural gas

10,0–11,0 %Liquid gas, propane

11,7–12,7 %Liquid gas, butane

Table 27: CO

2

content for max./min. burner output

Lo

2. With the set button (7), select low power “Lo” (“Lo1” or “Lo2” with

floor standing units).

CO2

Display (9) shows “CO2”.

Lo

Display (8) shows “Lo” ( “Lo1” or “Lo2” with floor standing units).

The CO2 content measured by the probe must be 0.5–1.0% lower as the

value measured at high power. “Hi”(“Hi1” or “Hi2” for floor standing units).

3. Set the CO

2

content manually (see Chapter “Setting the CO2 content

manually”, Page 51) if the values differ from those given in the table.

NOTICE

The CO2 value must be under 100 ppm during burning, 0–10 ppm is

normal.

4. Contact customer service if the CO

2

values are over 100 ppm.

Global Foodservice Solutions

Planning and installation instructions46

Smart Combi

™

Classic Combi

™

Gas

6.6.3 Display burner status and cooking chamber

temperature

1. Press Preheat (10).

With tabletop units: Display (9) shows “GF”.

With floor standing units: Display (9) shows “GF1” or “GF2”.

With error-free burner ignition: Display (8) shows “00”, “10”, “11”.

MeaningDisplay

Burner gas valve, flame sensor

6F

Chamber 1: Burner gas valve, flame sensor

6F1

Chamber 2: Burner gas valve, flame sensor

6F2

Gas valve closed, no flame

00

Gas valve open, no flame (ignition)

10

Gas valve open, flame present (burner ignited)

11

If the gas supply is interrupted the ignition procedure will be aborted.

Display (9) flashes “Err” for errors.

Display (8) flashes the error number.

The Step (13) LEDs flash.

47Planning and installation instructions

Global Foodservice Solutions

Gas

Smart Combi

™

Classic Combi

™

RemedyPossible causesFault

- Open gas tap.

- Repeat the ignition

process.

“No gas”: Gas tap is

closed or there is air in

the gas pipeline

ErR 71

- Contact customer

service.

“Gas fan”: Power supply to the gas fan is interrupted or there is a

fault in the controls

ErR 72

- Contact customer

service.

“General gas fault”: Incorrect gas quality

ErR 73

2. After the burner has ignited, press Preheat (10) to display the

cooking chamber temperature and the fan speed.

130 280

Display (9) shows the current temperature of the cooking chamber in °C

(°F).

Display (8) shows the first three digits of the four-digit fan speed, e.g.

“280” for 2800 rpm.

6.7 Checking CO2/CO values (SmartCombi)

NOTICE

Open the front cover of the operating manual to see the controls.

6.7.1 Starting CO2 calibration

WARNING

Possible danger

→

Non-compliance may pose a threat of death or serious injury.

NOTICE

If there is still air in the gas pipeline, the multi-function display (4) will

show the error “No gas” at the initial start-up. Repeat the start procedure

if this happens.

1. Switch on the unit.

2. Press the select button (13) to open the menu.

3. Press Co m b i Dial (9) to select the “Settings” menu.

Global Foodservice Solutions

Planning and installation instructions48

Smart Combi

™

Classic Combi

™

Gas

4. PressCo m b i Dial (9) to open the menu.

The multi-function display (4) shows „Password“ and „000“ .

5. Press Co m b i Dial (9) to enter the password “999”.

6. PressCo m b i Dial (9) to confirm the selection.

The multi-function display (4) shows “Calibr. gas CO2”.

7. Press St a r t / Stop (8) to start the CO

2

calibration.

The multi-function display (4) shows “High power”, the fan speed and

the cooking chamber temperature.

NOTICE

With floor standing units, you can switch between the upper and the

lower chambers with the select button (13)“Change chamber”.

The multi-function display (4) indicates the selected chamber with an

arrow next to the fan speed.

The CO

2

content is measured at high power.

6.7.2 Measuring CO2 values

Requirements The following conditions must be met in order to measure CO2 values

in the cooking chamber:

●

Cooking chamber door is closed

●

Burner is at high power

●

The multi-function display (4) shows a cooking chamber

temperature of 150 °C (302 °F)

●

The multi-function display (4) shows the fan speed at full power

according to the following table.

WARNING

Risk of suffocation due to carbon monoxide

Safe operation cannot be guaranteed if the CO

2

content is not within

the recommended limits.

→

Make sure that the CO2 content at low power is 0.5–1 % lower

than at high power.

→

Keep within the recommended limits for CO

2

content (see Ta bl e

29, Page 50).

NOTICE

Do not insert the probe during ignition; the CO2 values measured will

be especially high due to the ignition process.

49Planning and installation instructions

Global Foodservice Solutions

Gas

Smart Combi

™

Classic Combi

™

Lo (Lo1 or Lo2 for units with two

chambers)

Hi (Hi1 or Hi2 for units with two

chambers)

Size

48005050615

48006700620

28005050115

28006700120

28005050215

28006700220

Table 28: Fan speed (rpm) at high power (Hi) and low power (Lo) for natural and

liquid gas

NOTICE

With floor standing units, you can switch between the upper and the

lower chambers with the select button (13)“Change chamber”.

The chamber selected is indicated by an arrow next to the fan speed

in the multi-function display (4).

1. Hold the probe in the exhaust outlet to measure the CO2 value.

- Left exhaust outlet: lower chamber

- Right exhaust outlet: upper chamber

Carry out measuring quickly to prevent the cooking chamber from

overheating due to the high temperature of 150 °C (302 °F).

The CO

2

content must be within the limits given in the following table.

CO2 content at low

power

CO2 content at high

power

Type of gas

0,5–1,0 % lower than with

maximum power Hi/Hi1 or

Hi2

8.6– 9.6 %Natural gas

10.0– 11.0 %Liquid gas, propane

11.7– 12.7 %Liquid gas, butane

Table 29: CO

2

content for max./min. burner output

2. Switch the burner to low power.

The multi-function display (4) shows “Low power”, the fan speed and the

cooking chamber temperature.

The CO

2

content measured by the probe must be 0,5–1,0 % lower than

the value measured at high power.

3. Set the CO

2

content manually (see Chapter “Setting the CO2 content

manually”, Page 51) if the values differ from those given in the table.

Global Foodservice Solutions

Planning and installation instructions50

Smart Combi

™

Classic Combi

™

Gas

NOTICE

The CO2 value must be under 100 ppm during burning, 0–10 ppm is

normal.

4. Contact customer service if the CO

2

values are over 100 ppm.

6.8 Setting the CO2 content manually

The CO2 content must be set manually if the values differ from those

given in the table.

NOTICE

When the CO2 content has been set for low power, the CO2 content

must subsequently be remeasured at high power.

Both settings interact with each other.

1

2

1. If the CO2 content at low power is too high or too low:

- Unscrew the cap (1) from the gas valve.

- Adjust the CO

2

content using the hexagonal socket screw

underneath the cap (1). When doing this, only adjust the socket

screw by a maximum of ¼ of a turn.

- Check CO

2

content at low power.

- Replace the cap (1) on the gas valve.

2. If the CO

2

content at high power is too low:

- Remove the gas orifice.

- Screw in the adjusting screw (2) by approx. 10 mm.

- Set the CO

2

content.

3. If the CO

2

content at high power is too high:

- Screw in the adjusting screw (2) by approx. 10 mm.

- Set the CO

2

content.

4. Check CO

2

content at low and at high power.

51Planning and installation instructions

Global Foodservice Solutions

Gas

Smart Combi

™

Classic Combi

™

7 Exhaust gas routing

WARNING

Risk of fire due to combustion gases and hot surfaces

The exhaust flue connection and its covering can become extremely

hot and cause burns in cases of direct contact.

→

The temperature of the exhaust gas can reach 400 °C (752 °F).

Plan and carry out the installation of the unit in such a way as to

avoid contact with flammable surfaces.

→

Do not place any objects close to or on the unit.

→

Maintain sufficient distance to fat filters in customer supplied

extraction hoods.

→

Use a ventilation cover (accessory) to reduce exhaust temperatures.

→

Only allow gas supply to the burners when the extraction system

is working.

WARNING

Danger of poisoning by exhaust fumes

→

Ensure, during planning and installation, that exhaust fumes are

transported to the open air.

→

Install extraction systems such as extraction hoods, chimneys and

ventilation covers.

→

Ensure that all users know the fire prevention regulations.

NOTICE

In order to prevent an unacceptable build-up of harmful combustion

products, the units must be installed under extraction systems (room

ventilation system with safety switch). When installing the appliance

beneath a ventilation cover or an extractor hood system, safety devices

must be in place that allow gas supply to the burners only when the

extraction system is working.

The following exhaust gas evacuation paths are possible (according to

DVGW worksheet G634):

B23A3

Extractor hood

●

For units of type A3 (size 615)

●

For units of type B23 (all other sizes)

Global Foodservice Solutions

Planning and installation instructions52

Smart Combi

™

Classic Combi

™

Exhaust gas routing

B13B13

Chimney

For units of type B13 (optional, possible for all versions).

When connecting appliances to a chimney, all exhaust gas paths must

be cleaned regularly.

Ventilation cover

For units of type B13 (optional, possible for all versions).

1. Observe the regulations for room ventilation systems (see Chapter

“Room air”, Page 8).

2. Observe country-specific regulations.

3. Exhaust gas systems are to be agreed with the district

chimney/heating inspector and documented.

4. Make sure that the pipes have leak-proof connections and lay them

according to the technical regulations governing liquid gas and gas

installations (see Chapter “Gas”, Page 6).

5. Secure the unit against being moved.

53Planning and installation instructions

Global Foodservice Solutions

Exhaust gas routing

Smart Combi

™

Classic Combi

™

8 Air outlet connection

Waste steam and vapours are cooled by the built-in cooling system and

extracted via the drain; an air extraction system is therefore not essential.

Installation under an extraction hood is recommended.

8.1 Installation under an extraction hood

→

Observe the regulations for room ventilation systems (see Chapter

“Room air”, Page 8).

8.2 Connection to an air outlet duct

Requirements Connection with a pipe

●

Do not use galvanized pipes.

●

Heat-proof and non-corrosive pipe (e.g. PA-I 1818 DIN 19560 HT

pipe)

Connection with a hose

●

Do not use aluminium tubes because tube corrosion might occur.

●

Heat-proof to at least 180 °C (356 °F)

●

Hose diameter

With tabletop units: 53 mm

With floor standing units: 73 mm

●

Hose length max. 2.5 m

The end of the hose must not be connected directly to an air-outlet duct

(e.g. extraction hood). Counter-pressure will cause steam to be drawn

off from the cooking chamber; this will impair the cooking results. The

end of the hose should end below (outside) the air-outlet duct.

1. Connect the unit to an air-outlet duct using a pipe or a hose.

2. Take care not to create a “water pocket” (sagging when laid

horizontally), and that the cross-section is not restricted.

Global Foodservice Solutions

Planning and installation instructions54

Smart Combi

™

Classic Combi

™

Air outlet connection

Planning and installation instructions

Smart Combi

™

Classic Combi

™

Global Foodservice Solutions

Henny Penny Corporation

P.O. Box 60

Eaton, OH 45320

1-937-456-8400

1-937-456-8402 Fax

Toll free in USA

1-800-417-8417

1-800-417-8434 Fax

www.hennypenny.com

Planning and installation instructions

Smart Combi

™

Classic Combi

™

Loading...

Loading...