Henny Penny FSDE 610.610 Installation Manual

Installation

Manual

FM08-639-A • 9/18/2018

FM08-639-A

en-US

FlexFusion® ELECTRIC

SPACE$AVER (PLUS) TEAM

Read the operating instructions prior to commissioning

Model

FSDE 610.610FSDE

SPACE$AVER PLUS

FUSION

FLEX

SPACE$AVER

FUSION

FLEX

Henny Penny Corporation

P.O.Box 60

Eaton,OH 45320

USA

Phone +1 937 456-8400

Fax +1 937 456-8402

Toll free in USA

Phone +1 937 417-8417

Fax +1 937 417-8434

www.hennypenny.com

2 Installation instructions

Directory of contents

3Installation instructions

1Introduction......................................................................... 5

1.1About this manual ............................................................................ 5

1.1.1Explanation of signs .................................................................................. 6

1.2Personnel qualifications.................................................................. 7

1.3Use of the unit................................................................................... 7

1.4Warranty............................................................................................ 7

2Safety instructions ............................................................. 8

3Description of the unit ..................................................... 10

3.1Overview of the unit ....................................................................... 10

3.2Unit and connection data............................................................... 10

4Transporting the unit ....................................................... 15

4.1Transporting the unit to the installation site ............................... 15

4.2Unpacking the unit ......................................................................... 15

5Installing the unit.............................................................. 17

5.1Minimum clearances ...................................................................... 17

5.2Lifting the unit off the pallet .......................................................... 18

5.3Installing the unit on the unit legs ................................................ 18

5.4Aligning the unit ............................................................................. 18

6Connecting the unit.......................................................... 19

6.1Opening and closing the housing................................................. 19

6.1.1Removing and attaching the rear panel .................................................. 19

6.2Making the electrical connection.................................................. 20

6.2.1Connecting the electrical connection line ................................................ 22

6.2.2Connecting the power optimization system............................................. 22

6.2.3Connecting the potential equalization ..................................................... 24

6.3Connecting the kitchen guiding system ...................................... 24

6.4Performing the basic setting of the control................................. 26

6.4.1Changing the basic setting of the control ................................................ 26

6.5Making the water connection ........................................................ 27

6.5.1Connecting the drinking water connection line........................................ 28

6.5.2Connecting softened drinking water to both connections........................ 29

6.6Making the waste water connection ............................................. 29

6.6.1Connecting the waste water line to a permanent connection.................. 30

7Testing the function ......................................................... 31

7.1Checking recirculation hood......................................................... 31

7.2Checking the controls.................................................................... 31

7.3Checking the inspection of the cooking chamber door ............. 31

7.4Heating and rinsing the unit.......................................................... 32

FM08-639-A

Directory of contents

4 Installation instructions

8Putting the unit into service ............................................ 33

8.1Filling out the Start-up operation report ...................................... 33

FM08-639-A

Introduction

5Installation instructions

1 Introduction

1.1 About this manual

The installation instructions are part of the unit and contain

information on safe installation of the unit.

Observe the following notes and adhere to them:

• Read the installation instructions completely prior to installation.

• Make the installation instructions available to the installation fitter

at the operating site at all times.

• Preserve the installation instructions throughout the service life of

the unit.

• Insert any additions from the manufacturer.

• Pass on the installation instructions to any subsequent operator of

the unit.

Target group The target group of the installation instructions is trained qualified

personnel that is familiar with installing and operating the unit.

Figures All figures in this manual are intended as examples. Discrepancies

can arise between this and the actual unit.

FM08-639-A

Introduction

6 Installation instructions

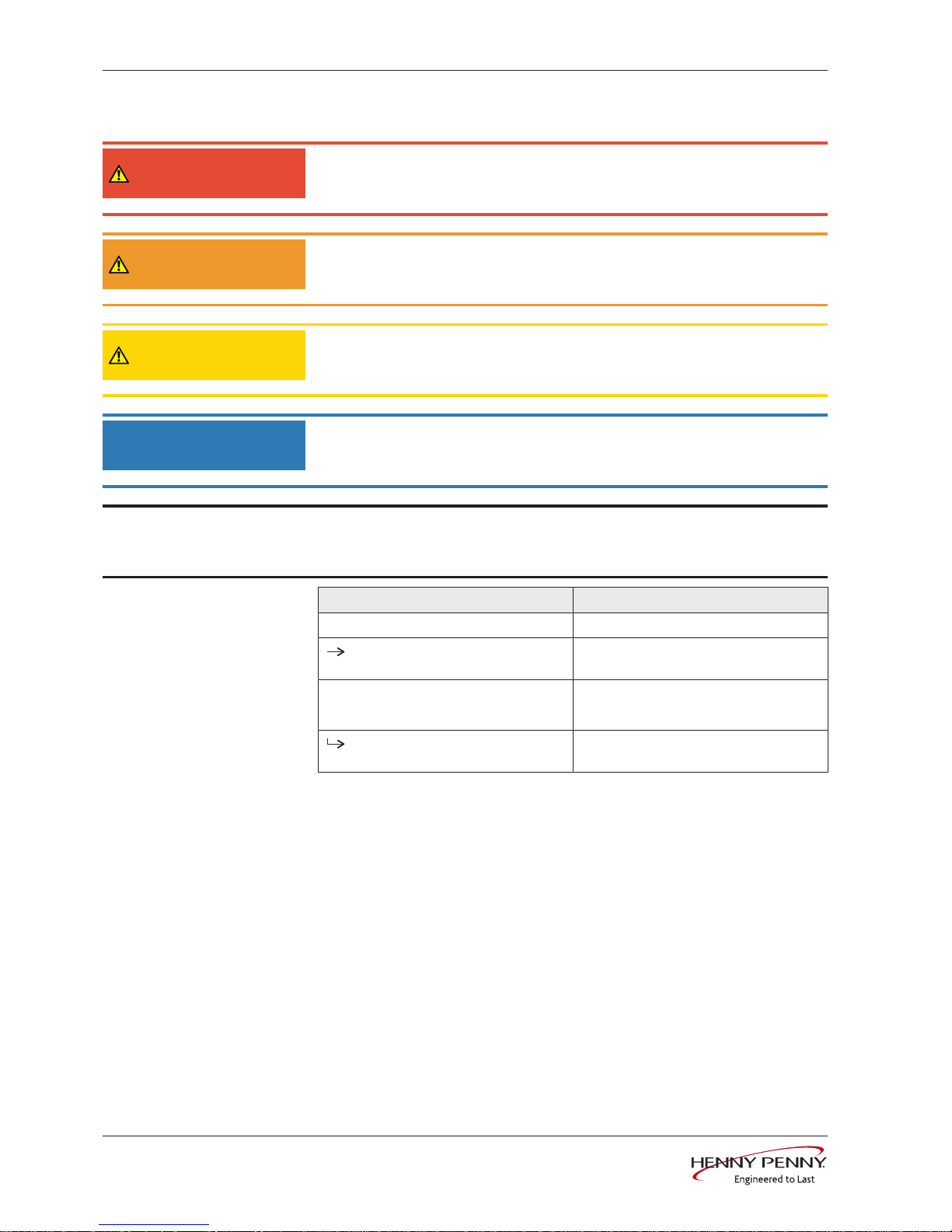

1.1.1 Explanation of signs

DANGER

Imminent danger

Failure to comply will lead to death or very severe injuries.

WARNING

Potential danger

Failure to comply can lead to death or very severe injuries.

CAUTION

Dangerous situation

Failure to comply can lead do slight to moderately severe injuries.

NOTICE

Property damage

Failure to comply can cause property damage.

INFORMATION

Information

Notes for better understanding and operation of the unit.

Symbol / sign Meaning

• Listing of information.

Action steps which can be performed in

any sequence.

1.

2.

Action steps which must be performed

in the specified sequence.

Result of an action performed or

additional information relating to it.

FM08-639-A

Introduction

7Installation instructions

1.2 Personnel qualifications

Explanation of qualification

Skilled personnel • A skilled person is someone who, on the basis of

their technical training, knowledge and experience

as well as familiarity with the applicable standards,

can assess the assigned work and recognize possible dangers.

Type of activity Qualification

Electrical connection • Electrician

• Specialized training

• Employee of the responsible technical company

Water connection • Water specialist

• Specialized training

• Employee of the responsible technical company

Waste water connection • Waste water specialist

• Specialized training

• Employee of the responsible technical company

1.3 Use of the unit

This unit is intended to be used solely for commercial purposes,

particularly in commercial kitchens.

1.4 Warranty

The warranty is void and safety is no longer assured in the event of:

• Improper conversion or technical modifications of the unit,

• Improper use,

• Improper startup, operation or maintenance of the unit,

• Problems resulting from failure to observe these instructions.

FM08-639-A

Safety instructions

8 Installation instructions

2 Safety instructions

The unit complies with applicable safety standards. Residual risks

associated with operation or risks resulting from incorrect operation

cannot be ruled out and are mentioned specifically in the safety

instructions and warnings.

The installation fitter must be familiar with regional regulations and

observe them.

The installation fitter must observe the safety instructions in these

installation instructions and in the "Safety information" chapter of the

operating instructions.

Ensuring conformity with

standards

Observe applicable international, European and national laws,

regulations, standards and directives for the unit when transporting,

setting up and connecting it.

Improper installation Risk of property damage and personal injury from improper

installation

• Install the unit only as specified in these installation instructions.

• Do not add anything to the unit or modify the unit.

• Use only original spare parts.

Transportation and storage Risk of personal injury and property damage from improper

transportation and improper storage

• Store the unit in a dry, frost-free environment.

• Observe the safety regulations for the lifting gear used.

• Attach the unit to the lifting gear securely during transport and

installation, and prevent it from dropping.

• Transport the unit in an upright position, do not tilt or stack.

• Pay attention to protruding parts when transporting the unit

without packaging.

Fire prevention Risk of fire from combustible surfaces

• Observe general fire prevention regulations.

Organizational measures Risk of property damage and personal injury from lack of

organizational measures

• Identify danger zones when transporting, installing and connecting

the unit.

• Prior to starting the installation tasks, notify any operator present

about the procedure.

• Prior to starting the installation task, discuss how to behave in an

emergency.

• Use equipment and protective gear suitable for the activity.

• Brace housing components to prevent them from falling over and

dropping.

FM08-639-A

Safety instructions

9Installation instructions

Installation Risk of property damage and personal injury from improper

installation

• Ensure that the installation area has adequate load-bearing

capacity.

• Wear safety shoes and protective gloves.

Electrical connection Risk of fire from improper connection

• Observe applicable regional regulations of the electric supplier.

• Ensure that only electricians licensed by the electric supplier

connect the unit.

• Ensure that the electrical system is earthed by a protective

earthing conductor.

• Note the information on the nameplate.

Danger of electric shock from live components.

• Prior to working on the electrical system, switch off the unit,

disconnect the electrical system from the mains and prevent

power from being switched on again. Check to ensure the system

is dead.

• Use only insulated tools.

Commissioning Risk of property damage and personal injury from improper

commissioning

• Read the operating instructions prior to commissioning. Observe

the safety instructions in these installation instructions and in the

"Safety information" chapter of the operating instructions.

• Only put the unit into service after a successful function test in its

assembled state.

• Put the unit into service only after it has reached room

temperature.

• Observe the units during operation.

FM08-639-A

Description of the unit

10 Installation instructions

3 Description of the unit

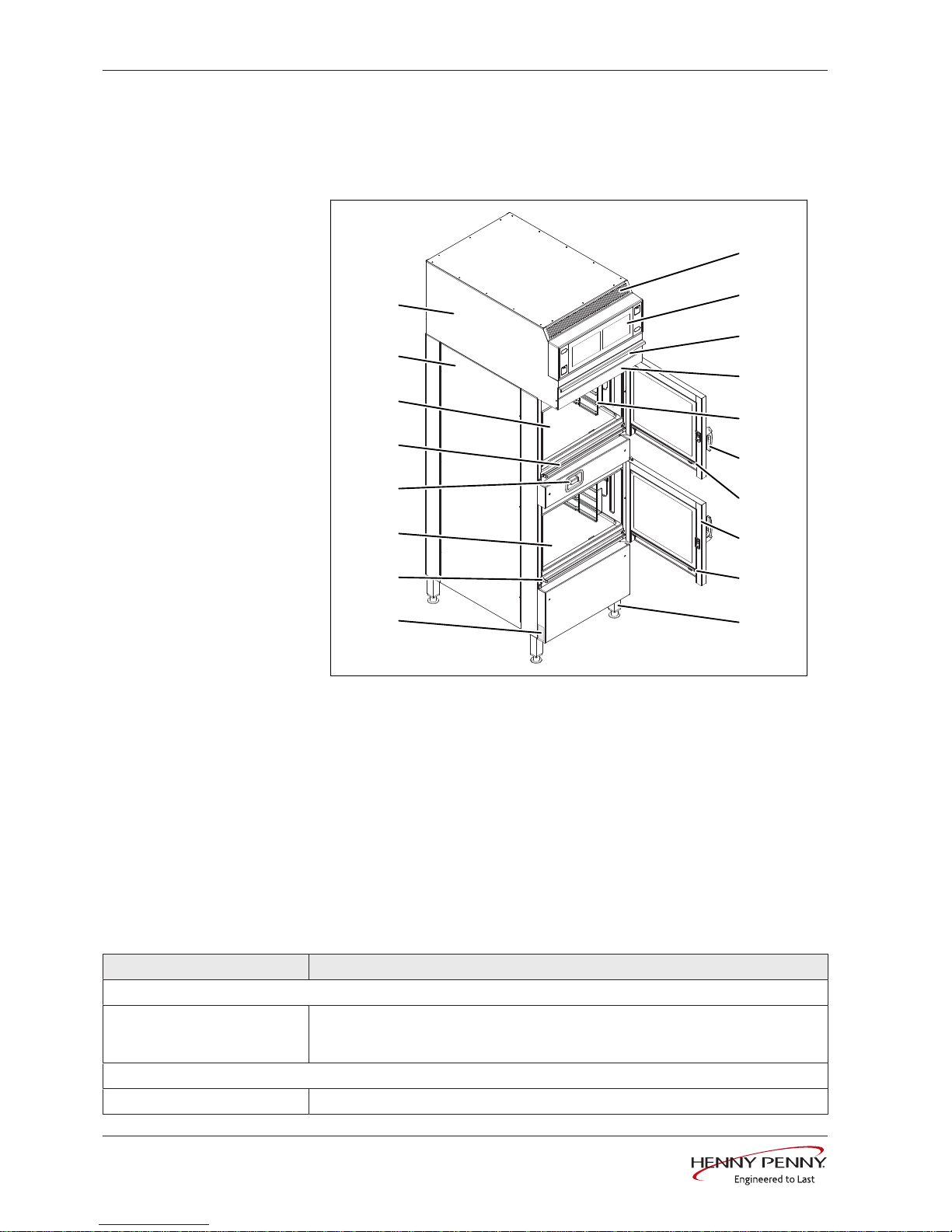

3.1 Overview of the unit

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

q

r

Image: Floor-standing unit

a Air outlet j Unit leg

b Operating unit k Nameplate

c Filter drawer l Discharge channel for bottom unit

d Condensate baffle m Cooking chamber in bottom unit

e Hang-in frame n Hand shower (optional)

f Door handle o Discharge channel for top unit

g Discharge channel for top door p Cooking chamber in top unit

h Cooking chamber door q Housing

i Discharge channel for bottom

door

r Recirculation hood

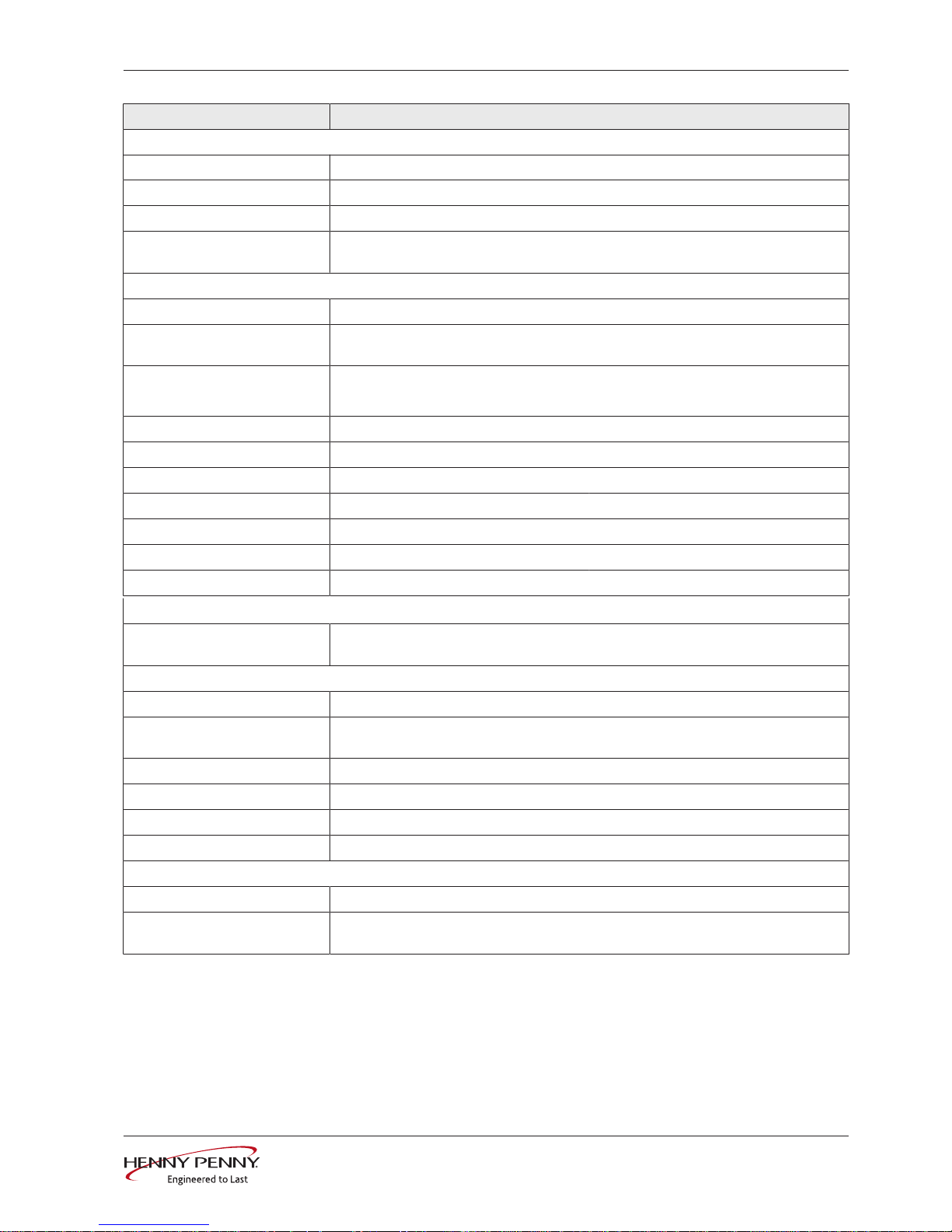

3.2 Unit and connection data

Size 610

Dimensions

Unit

Length x Width x Height (mm

(in))

550 (21,65) x 880 (34,65) x 1908 (75,12)

Weight

Unit (kg (lb)) 220 (485,1)

FM08-639-A

Description of the unit

11Installation instructions

Size 610

Emissions

Noise level (db(A)) < 65

Operating environment

Temperature (°C (°F)) 5 (41 ) — 40 (104 )

Relative air moisture (%)

non-condensing

95

Electrical connection

Protection class IPX5

Connection terminal (mm²

(sqin))

16 (0,0248)

Connection line One connection line

Type of connection 3PE AC 50/60 Hz, 3NPE AC 50/60 Hz

Voltage (V) 208

Connected load (kW) 14,8

Fuse (A) 50

Voltage (V) 240

Connected load (kW) 19,6

Fuse (A) 50

Power optimization system

Connection terminal (mm²

(sqin))

2,5 (0,0039)

Softened drinking water connection

Type of water Softened drinking water, cold

Carbonate hardness CaCO

3

(mmol/l (ppm))

< 0,9 (90 ppm)

Chloride Cl (mg/l) < 100

Iron Fe (mg/l) < 0.2

Connection pressure (kPa (psi)) 200 (29) — 600 (87)

Connection (") R 3/4 male thread

Drinking water connection

Type of water Drinking water, cold

Carbonate hardness CaCO

3

(mmol/l (ppm))

< 4 (400 ppm)

FM08-639-A

Description of the unit

12 Installation instructions

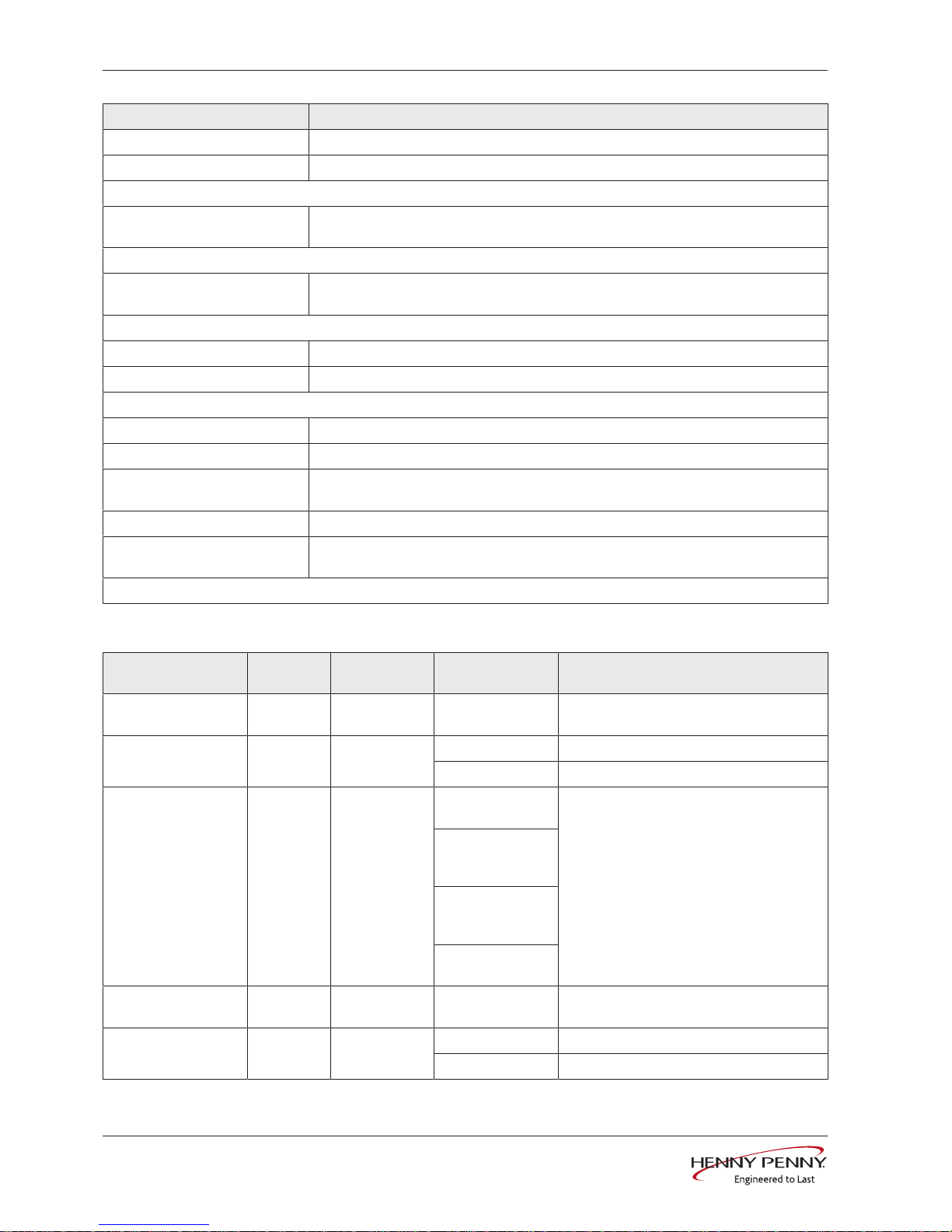

Size 610

Connection pressure (kPa (psi)) 200 (29) — 600 (87)

Connection (") R 3/4 male thread

Water consumption for steaming *

Softened drinking water (l/h

(gal/h))

20 (5,28)

Water consumption for combisteaming *

Softened drinking water (l/h

(gal/h))

4,4 (1,16)

Water consumption for WaveClean cleaning program *

Softened drinking water (l (gal)) 2,5 l (0,66)

Drinking water (l (gal)) 35 l (9,25)

Waste water connection

Waste water type Dirty water

Maximum length (m (ft)) 1 (3,3) with a drop of at least 5% or 3°

Temperature-resistant to (°C

(°F))

95 (203 )

Connection (mm (in)) 50 (1,97)

Maximum flow rate (l/min (gal/

min))

10 (2,64)

* Applies to both cooking chambers together

Basic setting of the control

Basic setting ParametersStandard

value

Range of

adjustment

Explanation

Supply voltage 14 400 100 — 500 V Enter the local, mean voltage between the

line conductors.

Date / time yyyy - mm - dd Year - Month - Day

hh : mm Hour : Minute

Altitude 2 0—999 0—999 m (3277

ft)

Request the altitude above sea level from

the local weather station. If the altitude is

unknown, enter 0—999 m (3277 ft).

1000 m (3280

ft)—1999 m

(6557 ft)

2000 m (6560

ft)—2499 m

(8197 ft)

2500 m (8200 ft)

or higher

Volume of audible

signal

Medium Individual Sets the volume.

Temperature unit

setting

1 °C °C Celsius (°C)

°F Fahrenheit (°F)

FM08-639-A

Loading...

Loading...