Henny Penny FPG-615, FPG-215, FPG-221, FPG-621, FPG-115 Operating Manual

...

Read the operating instructions prior to commissioning

PLATINUM

FUSION

FLEX

FlexFusion® GAS

PLATINUM COMBI

Operating

manual

Model

FPG-615

FPG-621

FPG-115

FPG-121

FPG-215

FPG-221

FM05-118-D • 11/20/2018

FM05-118-D

en-US

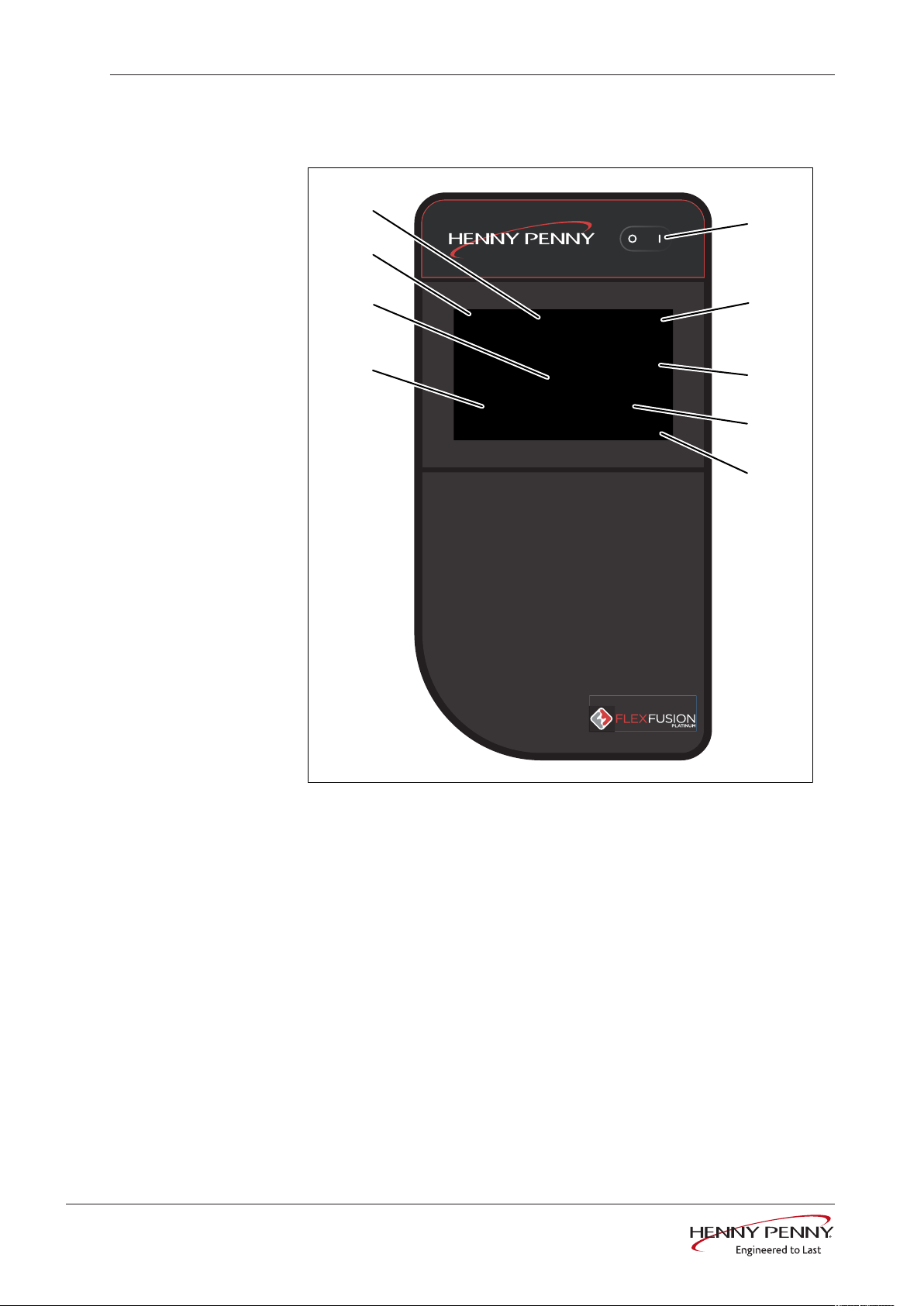

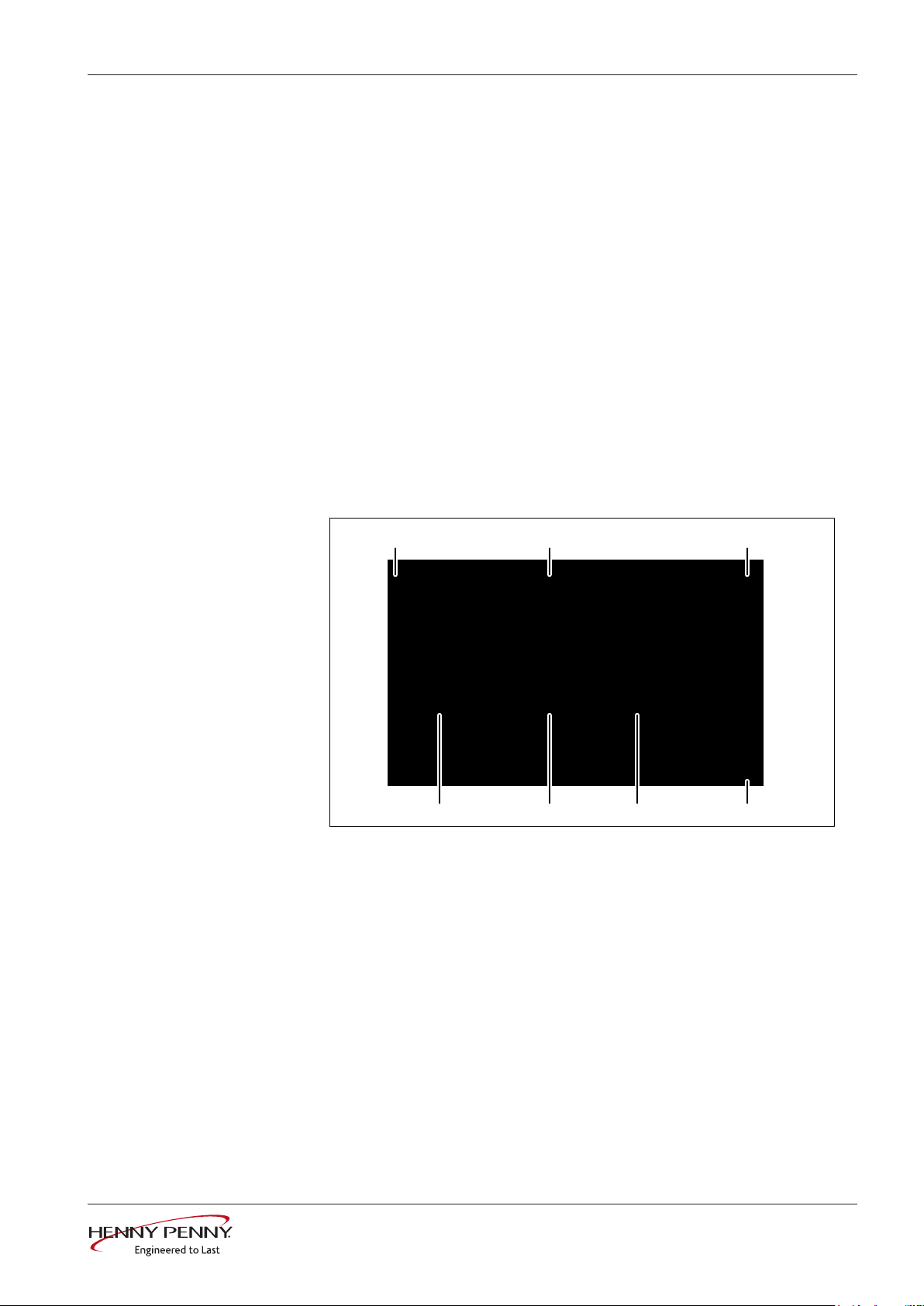

Operating and display elements

a

b

c

d

e

f

g

h

i

a

On Off

button f "Automatic cooking" button

b

Help

button g "Unit functions" button

c Operating element with

touchscreen

d "Manual cooking" button i Information strip

e

Language selection

h

Back

button

button

2 Operating instructions

FM05-118-D

Henny Penny Corporation

P.O.Box 60

Eaton,OH 45320

USA

Phone +1 937 456-8400

Fax +1 937 456-8402

Toll free in USA

Phone +1 937 417-8417

Fax +1 937 417-8434

www.hennypenny.com

3Operating instructions

Directory of contents

1Introduction......................................................................... 9

1.1About this manual ............................................................................ 9

1.1.1Explanation of signs ................................................................................ 10

1.2Intended use ................................................................................... 11

1.3Warranty.......................................................................................... 11

2Safety instructions ........................................................... 12

3Rules of conduct when the smell of gas is detected .... 15

4Description of the unit ..................................................... 16

4.1Overview of the unit ....................................................................... 16

4.1.1Tabletop unit............................................................................................ 16

4.1.2Pedestal unit............................................................................................ 17

4.2Features .......................................................................................... 17

4.2.1Characteristics......................................................................................... 17

4.2.2Barcode Scanner..................................................................................... 18

4.2.3USB port.................................................................................................. 18

4.2.4HACCP logging ....................................................................................... 18

4.2.5WaveClean automatic cleaning............................................................... 18

4.2.6CombiDoctor (self-diagnostic program)................................................... 18

4.2.7VideoAssist.............................................................................................. 18

4.2.8Preheat bridge for the models FPG 215 and FPG 221...................................... 19

4.3Operating and cooking modes...................................................... 19

4.3.1Operating modes..................................................................................... 19

4.3.2Cooking modes ....................................................................................... 19

4.3.3Expanded cooking functions ................................................................... 20

4.3.4Core temperature measurement ............................................................. 23

4.4Chef´s touch unit controls ............................................................ 23

4.4.1Touchscreen operation............................................................................ 25

4.4.2Operating, control and display element functions ................................... 26

4.4.3Display elements ..................................................................................... 27

4.5Loading capacities ......................................................................... 29

4.5.1Plate capacity during regeneration.......................................................... 29

4.5.2Loading capacity ..................................................................................... 29

4.6Standard settings ........................................................................... 29

4.6.1Core temperature standard setting.......................................................... 29

4.6.2Temperature standard setting ................................................................. 30

5Quick introduction............................................................ 31

6Operating the unit............................................................. 32

6.1Environmentally friendly operation .............................................. 32

6.2Switching the unit on and off ........................................................ 32

6.2.1Switching on ............................................................................................ 32

4 Operating instructions

FM05-118-D

Directory of contents

6.2.2Switching off ............................................................................................ 32

6.3Opening and closing the cooking chamber door........................ 32

6.3.1Opening the 1-step door lock .................................................................. 33

6.3.2Closing the 1-step door lock.................................................................... 33

6.3.3Opening the 2-step door lock .................................................................. 33

6.3.4Closing the 2-step door lock.................................................................... 34

6.4Loading and emptying the unit ..................................................... 34

6.4.1Loading and emptying ............................................................................. 35

6.4.2Loading and emptying with a tray rack trolley ......................................... 35

6.4.3Loading and emptying with a tray trolley ................................................. 36

6.5Unit functions menu....................................................................... 37

6.5.1Opening the Unit functions menu ............................................................ 38

6.5.2Changing the basic settings .................................................................... 38

6.5.3Retrieving unit information....................................................................... 40

6.5.4Setting the date and time ........................................................................ 40

6.5.5Presetting the language selection ........................................................... 41

6.5.6Setting favorites....................................................................................... 41

6.5.7Activating and canceling inhibit operation ............................................... 42

6.5.8Setting the background lighting ............................................................... 43

6.5.9Setting the water filter maintenance ........................................................ 43

6.5.10Possible settings in the parameter level................................................ 44

6.5.11Importing video...................................................................................... 46

6.5.12Importing images................................................................................... 46

6.5.13Importing recipes................................................................................... 47

6.6Basic functions............................................................................... 47

6.6.1Setting the cooking temperature ............................................................. 47

6.6.2Setting the cooking time and continuous operation................................. 49

6.6.3Setting the core temperature................................................................... 51

6.6.4Setting the fan speed and direction of rotation........................................ 52

6.6.5Exporting the HACCP log........................................................................ 52

6.6.6Using Perfection (regeneration) .............................................................. 53

6.6.7Using PerfectHold ................................................................................... 54

6.6.8Ready2CookSetting ............................................................................... 55

6.6.9Using start time selection ........................................................................ 56

6.6.10Steam Exhaust System (SES) .............................................................. 57

6.6.11RackControlUsing 2 .............................................................................. 58

6.6.12FamilyMixUsing .................................................................................... 61

6.6.13Using continue cooking ......................................................................... 62

6.6.14Setting manual steaming....................................................................... 63

6.6.15Setting a resting step............................................................................. 64

6.6.16QualityControlUsing ............................................................................. 65

6.6.17Using LT cooking................................................................................... 66

6.6.18Using Delta-T cooking ........................................................................... 67

6.6.19Using the barcode scanner ................................................................... 68

FM05-118-D

5Operating instructions

Directory of contents

6.6.20Preparing a USB stick for importing and exporting ............................... 68

6.6.21Inserting and removing the USB stick ................................................... 69

6.7Using the core temperature sensor.............................................. 69

6.7.1Measuring with a 4-point core temperature sensor ................................. 70

6.7.2Measuring the core temperature when cooking frozen food ................... 70

6.7.3Core temperature display with time-controlled cooking process ............. 71

6.7.4Core temperature display outside the cooking process .......................... 71

6.8Manual cooking .............................................................................. 71

6.8.1Opening the Manual cooking menu......................................................... 72

6.8.2Creating a cooking program step ............................................................ 72

6.9Creating and managing your own cooking programs ................ 74

6.9.1Creating a cooking program .................................................................... 74

6.9.2Saving the cooking program.................................................................... 75

6.9.3Exporting a cooking program .................................................................. 79

6.10Automatic cooking (autoChef) .................................................... 79

6.10.1Opening the Automatic cooking menu .................................................. 80

6.10.2Finding and opening a cooking program ............................................... 80

6.10.3Starting the cooking program ................................................................ 81

6.10.4Ending the cooking program ................................................................. 81

6.10.5Modifying the cooking program ............................................................. 82

6.10.6Deleting a cooking program .................................................................. 83

6.10.7Exporting and importing a cooking program.......................................... 84

6.11VideoAssist................................................................................... 85

6.11.1Watching a video................................................................................... 85

6.11.2Deleting a video..................................................................................... 86

6.12Pausing and ending operation.................................................... 86

7Cleaning and caring for the unit ..................................... 87

7.1Preventing corrosion ..................................................................... 87

7.2Removing rust spots...................................................................... 87

7.3Cleaning the housing..................................................................... 88

7.4Cleaning the handle, operating elements and operating panel

membrane ............................................................................................. 88

7.5Cleaning the touchscreen ............................................................. 88

7.6Cleaning the door seal................................................................... 89

7.7Cleaning the cooking chamber door ............................................ 89

7.8Cleaning the steam outlet.............................................................. 90

7.9Cleaning the condensation hood (optional) ................................ 90

7.10Removing calcium deposits from the unit................................. 91

7.11Cleaning the cooking chamber automatically with WaveClean.....

91

7.11.1Preparing for cleaning ........................................................................... 93

7.11.2Selecting the cleaning level................................................................... 93

7.11.3Inserting the cleaning cartridge ............................................................. 94

FM05-118-D

6 Operating instructions

Directory of contents

7.11.4Starting automatic cleaning ................................................................... 95

7.11.5Canceling automatic cleaning ............................................................... 95

7.11.6Ending automatic cleaning .................................................................... 95

7.12Cleaning the cooking chamber manually .................................. 96

7.12.1Preparing the cooking chamber ............................................................ 96

7.12.2Starting the cleaning program ............................................................... 96

7.12.3Spraying the cleaner ............................................................................. 96

7.12.4Allowing the cleaner to act .................................................................... 96

7.12.5Starting cleaning.................................................................................... 97

7.12.6Rinsing the cooking chamber ................................................................ 97

7.12.7Drying the cooking chamber.................................................................. 97

7.13Swinging the air diverter open and closed ................................ 97

7.14Inspecting the unit........................................................................ 98

7.14.1Performing a visual inspection .............................................................. 98

7.14.2Running CombiDoctor (self-diagnostic program) .................................. 99

8Troubleshooting ............................................................. 101

8.1Emergency operation................................................................... 101

8.2Cause of error and remedy.......................................................... 101

8.3Nameplate ..................................................................................... 101

9Disposing of unit in an environmentally responsible

manner ............................................................................... 102

Keyword index.................................................................. 103

FM05-118-D

7Operating instructions

Directory of contents

8 Operating instructions

FM05-118-D

1 Introduction

1.1 About this manual

Introduction

The operating instructions are part of the unit and contain information:

• on safe operation,

• on cleaning and care

• on remedial actions in case of faults.

Observe the following notes and adhere to them:

• Read the operating instructions completely before operating the

unit for the first time.

• Make the operating instructions available to the operator at all

times at the operating site of the unit.

• Insert any supplements from the manufacturer.

• Keep the operating instructions throughout the service life of the

unit.

• Pass on the operating instructions to any subsequent operator of

the unit.

Target group The target group of the instruction manual is the operator, who is

entrusted with the operation, cleaning and care of the unit.

Figures All figures in this manual are intended as examples. Discrepancies

can arise between this and the actual unit.

FM05-118-D

9Operating instructions

Introduction

1.1.1 Explanation of signs

DANGER

WARNING

CAUTION

NOTICE

INFORMATION

Imminent danger

Failure to comply will lead to death or very severe injuries.

Potential danger

Failure to comply can lead to death or very severe injuries.

Dangerous situation

Failure to comply can lead do slight to moderately severe injuries.

Property damage

Failure to comply can cause property damage.

Information

Notes for better understanding and operation of the unit.

Symbol / sign Meaning

• Listing of information.

Action steps which can be performed in

any sequence.

1.

2.

Action steps which must be performed

in the specified sequence.

Result of an action performed or

additional information relating to it.

10 Operating instructions

FM05-118-D

1.2 Intended use

Introduction

This unit is intended to be used solely for commercial purposes,

particularly in commercial kitchens.

This unit may only be used with suitable accessories and for the

cooking of food.

It is forbidden to use the unit for other purposes, which include the

following:

• Washing dishes

• Storing supplies

• Drying cloths, paper or dishes

• Heating acids, alkaline solutions or other chemicals

• Heating preserved food

• Heating combustible liquids

• Heating rooms

1.3 Warranty

• Cleaning air filters

The warranty is void and safety is no longer assured in the event of:

• Improper conversion or technical modifications of the unit,

• Improper use,

• Improper startup, operation or maintenance of the unit,

• Problems resulting from failure to observe these instructions.

FM05-118-D

11Operating instructions

Safety instructions

2 Safety instructions

The unit complies with applicable safety standards. Residual risks

associated with operation or risks resulting from incorrect operation

cannot be ruled out and are mentioned specifically in the safety

instructions and warnings.

The operator must be familiar with regional regulations and observe

them.

Operation During operation, the following group of individuals must be

supervised by an individual who is responsible for safety:

• Individuals with physical, sensory, or mental handicaps, or who

The supervising individual must be familiar with the unit and the risks

associated with it.

Hot surfaces Risk of burns from hot surfaces

• Protect arms and hands by wearing suitable protective gloves.

lack the knowledge and experience to operate the unit properly.

• Allow surfaces to cool prior to cleaning.

• Remove hot utensils only with suitable protective gloves or

potholders.

• Remove containers and baking sheets only with suitable

protective gloves or potholders.

Hot liquids Risk of scalding from hot liquids

• Protect arms and hands by wearing suitable protective gloves.

• Remove, transport and empty containers carefully.

Risk of chemical burns from evaporating cleaners

• Follow the instructions of the cleaning agent manufacturer.

• Allow the cooking chamber to cool to a temperature below 60 °C

(140°F) and then clean.

Risk of scalding from steam

• Protect arms and hands by wearing protective gloves.

• Do not hold hands in front of the extractor hood.

• First open the cooking chamber door slightly and allow the steam

to escape. Then open the cooking chamber door completely.

• Dry unit completely after cleaning it.

Defective unit Risk of injury from a defective unit

• Disconnect a defective unit from the electrical supply mains.

• Defektes Gerät mit Gas-Absperrhahn von Gaszufuhr trennen.

• Do not operate a defective unit.

• Allow only qualified personnel to repair the unit.

12 Operating instructions

FM05-118-D

Safety instructions

Escaping gas or exhaust

gas

Fire prevention Risk of fire from dirt and grease deposits

Risk of asphyxiation and explosion from escaping gas

• Follow the rules of conduct when the smell of gas is detected (see

"Rules of conduct when the smell of gas is detected").

Risk of asphyxiation and poisoning from exhaust gases

• Ensure that air inlet openings are free and that a sufficient amount

of the necessary combustion air is supplied.

• Ensure that the exhaust gas outlet openings are free and that the

exhaust gases are discharged properly.

• Clean the unit when finished using it.

• Do not use the unit as a deep fat fryer.

• Do not store any combustible objects or plastic containers in the

cooking chamber.

Risk of fire from objects

• Do not obstruct the exhaust gas duct.

Firefighting

• In the event of a fire, disconnect the unit from the electrical supply

mains.

• Im Brandfall Gerät mit Gas-Absperrhahn von Gaszufuhr

trennen.In the event of a fire, use the gas shut-off valve to isolate

the unit from the gas supply.

• Use a Fire Class F fire extinguisher, never water, to extinguish

grease fires. Other fires, for instance, can be extinguished with fire

extinguishers suitable for Fire Classes A, B, C, CO2 fire

extinguishers or extinguishing media suitable for the fire class

confronted.

Unit on casters Risk of injury from a unit on casters

• Lock casters during operation.

• Only move an empty unit.

Danger of a line breaking if subjected to high tensile load

• Secure the unit with a chain as a strain relief for the connection

line at the installation site so that no tensile load is applied to the

connection line if the unit is moved.

Improper cleaning Risk of chemical burns from cleaning agent

FM05-118-D

• Follow the instructions of the cleaning agent manufacturer.

• Take appropriate protective measures when handling aggressive

cleaning agents.

Risk of falling on smooth floors

• Keep the floor in front of the unit clean and dry.

13Operating instructions

Safety instructions

Risk of injury from improper cleaning

• Clean the cooking chamber carefully. The cooking chamber

sensor protrudes into the cooking chamber.

Risk of property damage from improper cleaning

• Clean the unit after using it.

• Do not clean the unit with a high-pressure cleaner.

• Do not clean the housing with highly abrasive or chemically

aggressive cleaning agents.

• Do not clean the housing with highly abrasive sponges.

• Follow the instructions of the cleaning agent manufacturer.

• Do not shock the unit by cooling it abruptly.

• Clean the cooking chamber carefully. The cooking chamber

sensor protrudes into the cooking chamber.

• Do not use any bleaching or chlorine-containing cleaners.

• Remove rust spots with an abrasive.

• Keep the unit free of calcium deposits.

Hygiene Health risk from insufficient hygiene

• Observe applicable regional hygiene regulations.

Core temperature

measurement

Risk of injury from overheated core temperature sensor

• Do not heat the core temperature sensor over an open flame.

Improper use Risk of property damage from improper use

• Use only original accessories.

• Train operators regularly.

• Do not heat food warmer plates or cans of preserved food.

• Do not cover air inlet and outlet openings.

• Do not operate the unit at temperatures below 4°C (32°F).

• Remove the core temperature sensor before the cooked food is

removed.

• Insert the core temperature sensor back into the holder after use.

14 Operating instructions

FM05-118-D

Rules of conduct when the smell of gas is detected

3 Rules of conduct when the smell of gas is detected

DANGER

Risk of asphyxiation and explosion from escaping gas

Rules of conduct when the smell of gas is detected.

• Remain calm.

• Open windows and doors and ventilate rooms.

• Avoid rooms with the smell of gas.

• Do not smoke.

• Do not ignite any flames. Extinguish flames.

• Do not create any sparks. Do not operate any switches, electrical

devices or use telephones.

• Remove mobile phones and radio-controlled devices from the

hazard area.

• Close gas shut-off valves at the gas meter, at the main supply and,

if possible, at the units.

• Warn other individuals in the building. Call out and knock, do not

ring doorbells.

• Leave the building and prevent entry by others.

• Observe the safety instructions of the gas utility.

• Once outside the building, notify the responsible parties:

– If the smell of gas comes from the unit, notify Customer service.

– If the source of the gas smell can not be localised immediately,

notify the gas utility.

– If the escaping gas is audible, leave the building immediately,

prevent others from entering and notify the fire brigade, police

and gas utility.

– If the smell of gas comes from inaccessible rooms, notify the fire

brigade, police and gas utility.

FM05-118-D

15Operating instructions

Description of the unit

q

p

o

n

m

l

k

j

i h g f

e

d

c

b

a

r

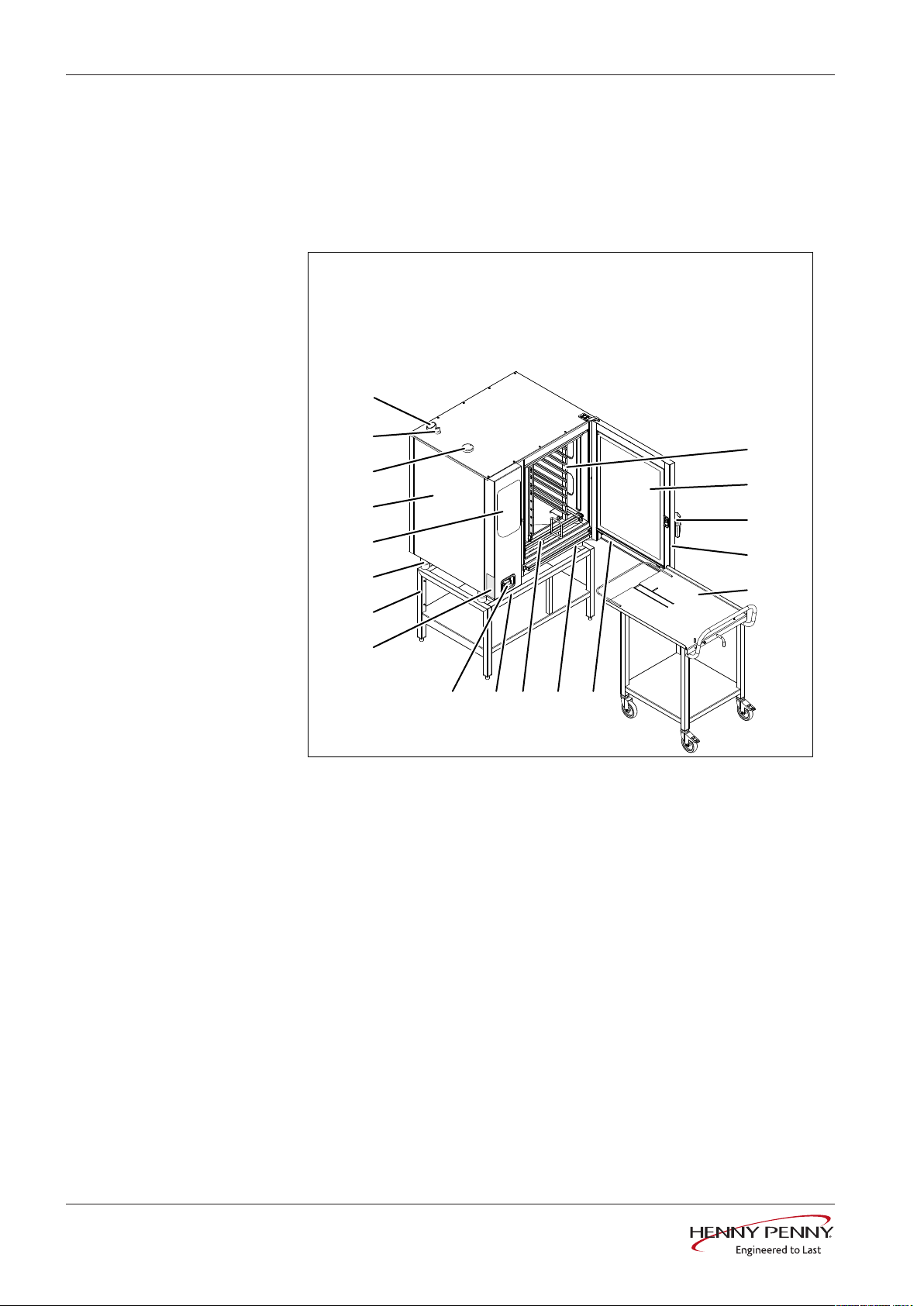

4 Description of the unit

4.1 Overview of the unit

4.1.1 Tabletop unit

Image: Unit with tray rack trolley

a Tray rack j Hand shower

b Insulating disk k Nameplate

c Door handle l Base frame (optional)

d Cooking chamber door m Unit leg

e Tray rack trolley (optional) n Operating unit

f Vapor drainage channel, door o Housing

g Vapor drainage channel, unit p Air inlet nozzle

h Guide rail for tray rack (optional) q Waste gas connection

i USB port (covered) r Steam outlet nozzle

FM05-118-D

16 Operating instructions

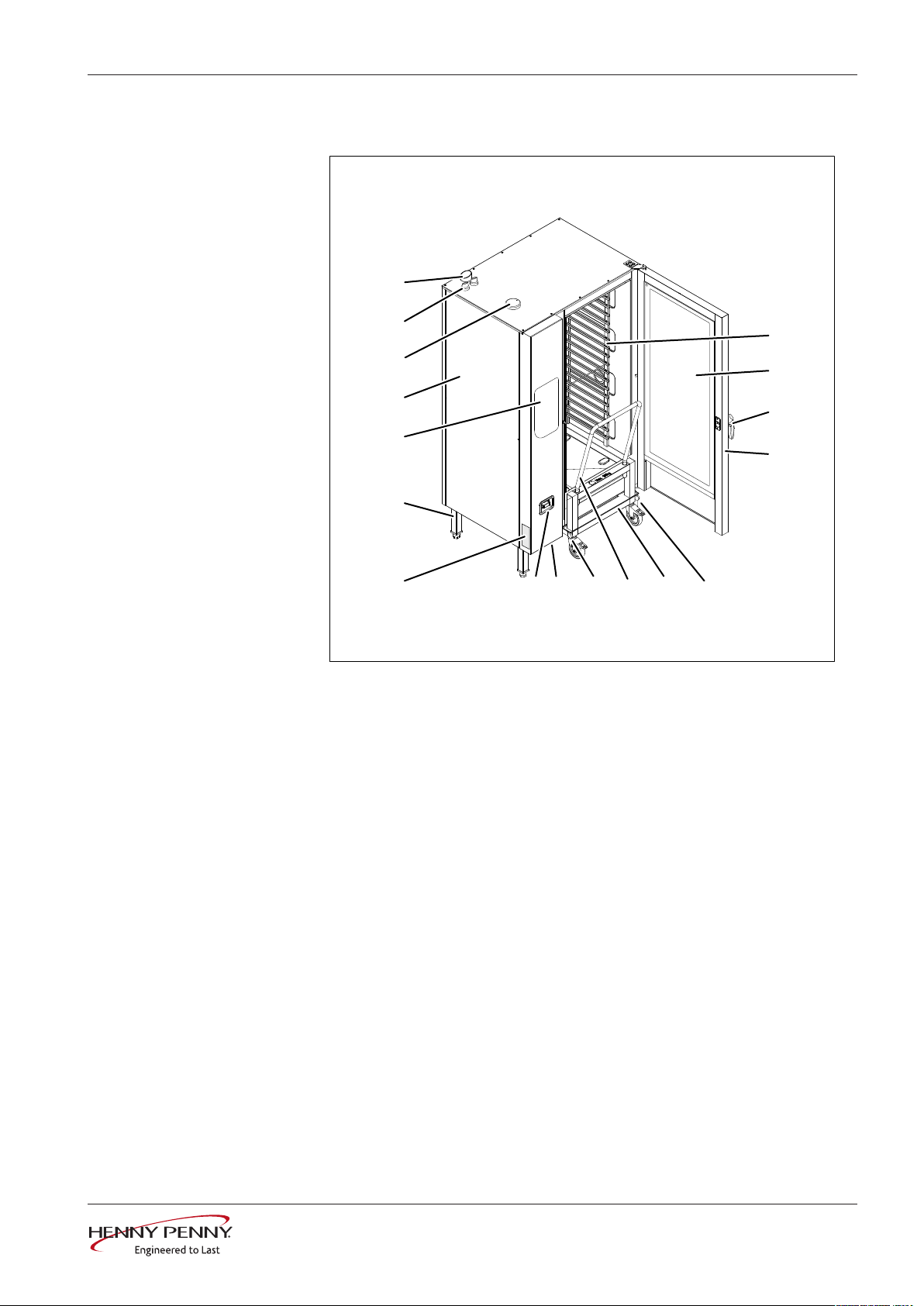

4.1.2 Pedestal unit

q

p

o

n

m

l

k

i

j

h g f e

d

c

b

a

Description of the unit

4.2 Features

4.2.1 Characteristics

Image: Unit with tray trolley

a Tray rack j Hand shower

b Insulating disk k Nameplate

c Door handle l Unit leg

d Cooking chamber door m Operating unit

e Guide rail (right) n Housing

f Tray trolley o Air inlet nozzle

g Handle bar p Waste gas connection

h Guide rail (left) q Steam outlet nozzle

i USB port (covered)

• 4-point core temperature sensor

• Sous-vide core temperature sensor or a second 4-point core

temperature sensor (optional)

• Hand shower

• Cooking chamber door with hygienic glazing

FM05-118-D

• 1-step door lock

17Operating instructions

Description of the unit

4.2.2 Barcode Scanner

• Two-step door lock (optional); this feature is standard on size 20

units

• Power optimization system (optional)

• Ethernet connection (optional)

• Cooking chamber door hinged at right

• Cooking chamber door hinged at left (optional), not on size 20

floor-standing units

• WaveClean

• Barcode scanner (optional)

• Steam Exhaust System (SES)

Use the barcode scanner to scan the barcode, for instance, on the

packaging of the food to be cooked, and transfer it to the unit. The

unit then searches for the appropriate cooking program. If several

cooking programs are found, they are all listed.

A prerequisite for using the barcode scanner is correct connection of

the barcode scanner and a cooking program with the appropriate

recognition capability.

4.2.3 USB port

The unit is equipped with a USB port (USB 2.0).

HACCP logs can be exported via the USB port.

A wireless or corded barcode scanner (optional) can be connected to

the USB port.

4.2.4 HACCP logging

All cooling programs run are recorded in the HACCP log.

The data are exported via the USB port.

4.2.5 WaveClean automatic cleaning

With WaveClean automatic cleaning, the cooking chamber is cleaned

with the aid of a cleaning cartridge intended specifically for the

program and then rinsed clean.

4.2.6 CombiDoctor (self-diagnostic program)

CombiDoctor uses a selectable self-diagnostic program to check the

components used for climate control and cleaning.

4.2.7 VideoAssist

VideoAssist can be used to display videos with additional

explanations regarding operation.

18 Operating instructions

FM05-118-D

4.2.8 Preheat bridge for the models FPG 215 and FPG 221

Image: Preheat bridge

The preheat bridge is placed on the lower edge of the cooking

chamber opening on combisteamer models FPG 215 and FPG 221 when

the cooking chamber is heating up or WaveClean is running and

there is no tray trolley in the combisteamer.

Description of the unit

4.3 Operating and cooking modes

4.3.1 Operating modes

Manual cooking

In the Manual cooking mode, individual cooking modes and

equipment functions can be actuated directly. The various types of

cooking and equipment functions can be adapted individually.

Automatic cooking (autoChef)

In the Automatic cooking mode, stored cooking programs can be

actuated and adapted as necessary.

4.3.2 Cooking modes

Steaming

Steaming is a cooking mode, in which the food to be cooked is

cooked gently by means of steam in a temperature range of 30 °C (86

°F) to 130 °C (266 °F)..

Combisteaming

Combisteaming is a cooking mode in which the steaming and hot air

cooking modes are combined. The temperature range extends from

30 °C (86 °F) to 250 °C (482 °F).

FM05-118-D

Hot air

Hot air is a cooking mode, in which the food to be cooked is cooked

without additional moisture in a temperature range of 30 °C (86 °F) to

250 °C (482 °F).

19Operating instructions

Description of the unit

Perfection (regeneration)

Perfection is a cooking mode, in which cooled food to be cooked can

be kept warm and prepared in a short time in a temperature range of

30 °C (86 °F) to 180 °C (356 °F).

Delta-T cooking

Delta-T cooking is a cooking mode, in which the cooking temperature

depends on the core temperature of the food being cooked.

The cooking temperature is always higher than the current core

temperature by the set value (Delta-T value, cooking temperature

difference). The resulting cooking time is longer than with other

cooking modes.

Delta-T cooking is especially well-suited for general cooking. The

food being cooked remains tender and juicy with little weight loss.

Low-temperature cooking

Low-temperature cooking is a cooking mode, in which the food to be

cooked is cooked particularly gently in a temperature range of 30 °C

(86 °F) to 100 °C (212 °F).

The cooking time is considerably longer than at higher temperatures,

but no supervision is required and the cooking time can be extended

considerably without any loss in quality.

The food being cooked remains tender and juicy with little weight

loss.

Baking

Baking is a cooking mode in which the texture of the food to be

cooked is loosened and then cooked and browned by hot air in a

temperature range of 30 °C (86 °F) to 220 °C (428 °F). Before baking

takes place, a humidifying process with its associated acting time can

be performed.

4.3.3 Expanded cooking functions

Expanded cooking functions can be used to adapt individual cooking

steps to the particular food being cooked.

The following expanded cooking functions are available:

PerfectHold

PerfectHOLD is a cooking function, in which the food to be cooked is

kept warm in the unit at a temperature range of 50 °C (122 °F) to 100

°C (212 °F) after the actual cooking process, until it is ready to be

served.

Ready2Cook (preheating)

For many cooking programs such as baking, for instance, the correct

starting temperature is important.

20 Operating instructions

FM05-118-D

INFORMATION

Description of the unit

With Ready2Cook, the cooking chamber can automatically be heated

or cooled to the correct starting temperature.

A screen-filling display gives information during the procedure about

the status.

Start-time selection

When using start time selection, temperatures that promote the growth of

harmful microorganisms on the food being cooked can occur in the cooking

chamber. Observe food processing regulations.

Start time selection can be used to set a waiting period until the

program starts.

In this way, bottlenecks in production and preparation can be avoided.

The prepared food can be loaded into the unit and the desired cooking

program selected.

Steam Exhaust System (SES)

This function is activated by default for all cooking programs that have

a cooking time longer than 6 minutes.

The Steam Exhaust System (SES) is activated automatically shortly

before the end of cooking.

After the cooking time, the Steam Exhaust System (SES) extracts the

steam from the cooking chamber. It is then possible to open the

cooking chamber door without risk of injury.

RackControl2

RackControl is ideal for rolling cooking.

With the extended RackControl2 cooking function, different foods

such as potatoes, cauliflower, peas, carrots and meat can be cooked

simultaneously for different times.

RackControl2 monitors the various cooking times in one process.

When one cooking time has elapsed, a signal sounds and the food

being cooked can be removed.

The set temperature can be changed during an active cooking

process, without the process having to be stopped.

FM05-118-D

ChefsHelp

With the ChefsHelp advanced cooking program, it is possible to insert

a cooking step that assists the user further with Information in the

form of text and images at a certain time.

FlexiRack

With the FlexiRack advanced cooking function, it is possible to set a

cooking program for each shelf individually.

21Operating instructions

Description of the unit

FamilyMix

With the expanded cooking function FamilyMix, the appropriate

cooking programs are displayed in the

Automatic cooking (autoChef)

menu for the currently set cooking mode. The cooking programs

displayed have the same cooking climate and an identical or shorter

cooking time. Tapping the individual suggestions transfers the

cooking times for the individual products to the RackControl function

and these can then be started when desired during the cooking

process.

Manual steaming

Manual steaming allows the cooking chamber humidity to be

increased during operation.

Manual steaming can only be used in the Hot air and Delta T hot air

cooking modes.

The remaining time for this procedure is displayed during steaming.

After the Drop symbol has been touched, the set value is displayed

for 3 seconds.

Idle time

With the idle time expanded cooking function, a cooking step can be

inserted during which the heating and the fans are programmed to

switch off for a certain period of time.

QualityControl

With the expanded QualityControl cooking function, the control

senses the amount loaded automatically and adjusts the individual

cooking parameters in autoChef. This ensures first-class quality

consistently.

Continue cooking button

The Continue cooking button lets you continue the cooking process

for a predefined period of time after the cooking program has ended.

Time2Serve

With the Time2Serve advanced cooking function, different products

are ready to be served at the same time.

The serving time is specified. The combisteamer signals when it has

reached a remaining cooking time for a product. A signal sounds and

the food to be cooked is loaded successively during an active cooking

process. The cooking time is shortened, conserving resources.

ClimaSelect plus

The ClimaSelect plus advanced cooking function optimizes the

atmosphere in the cooking chamber. Steam is added in small

amounts; the atmosphere can be controlled individually.

22 Operating instructions

FM05-118-D

4.3.4 Core temperature measurement

When using core temperature measurement, the temperature inside

the food being cooked is measured by means of a core temperature

sensor.

As soon as the target core temperature is reached, the cooking

process is ended automatically or, in the case of a multi-step cooking

program, the next cooking step starts.

The use of core temperature measurement offers the following

benefits:

• Reduced energy and water consumption

• No overcooking

• Less weight lost by the food being cooked

• High HACCP safety

4.4 Chef´s touch unit controls

Description of the unit

a b c

Image: Main menu

Back

a

b Information strip f "Unit functions" button

c

d

button e "Manual cooking" button

Help

button g "Automatic cooking" button

Language selection

button

defg

FM05-118-D

23Operating instructions

Description of the unit

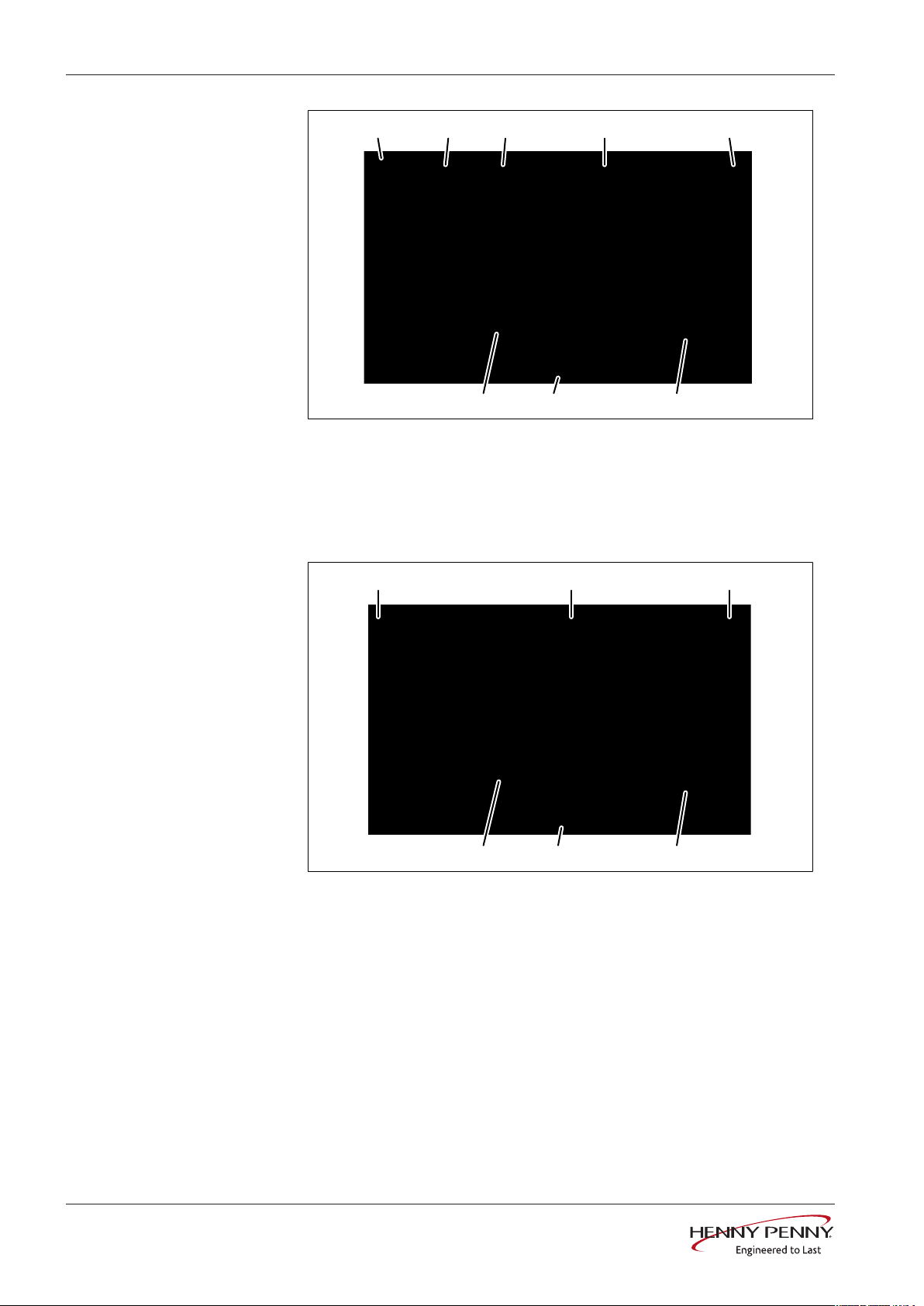

a b c d e

fgh

a b c

def

Image: Automatic cooking menu, autoChef

a

Back

button e

b "autoChef" button f

c

Barcode scanner

d Information strip h Separating bar

button g

Help

Category

Next page

button

field

arrow symbol

Image: Manual cooking menu

a

Back

button d "Hot air" field

b Information strip e

c

Help

button f Separating bar

24 Operating instructions

Next page

arrow symbol

FM05-118-D

a b c

d

e

f

Image: Unit functions menu

a

Back

button d Window

b Information strip e

c

Help

button f

Description of the unit

Manual cleaning

Next page

field

arrow symbol

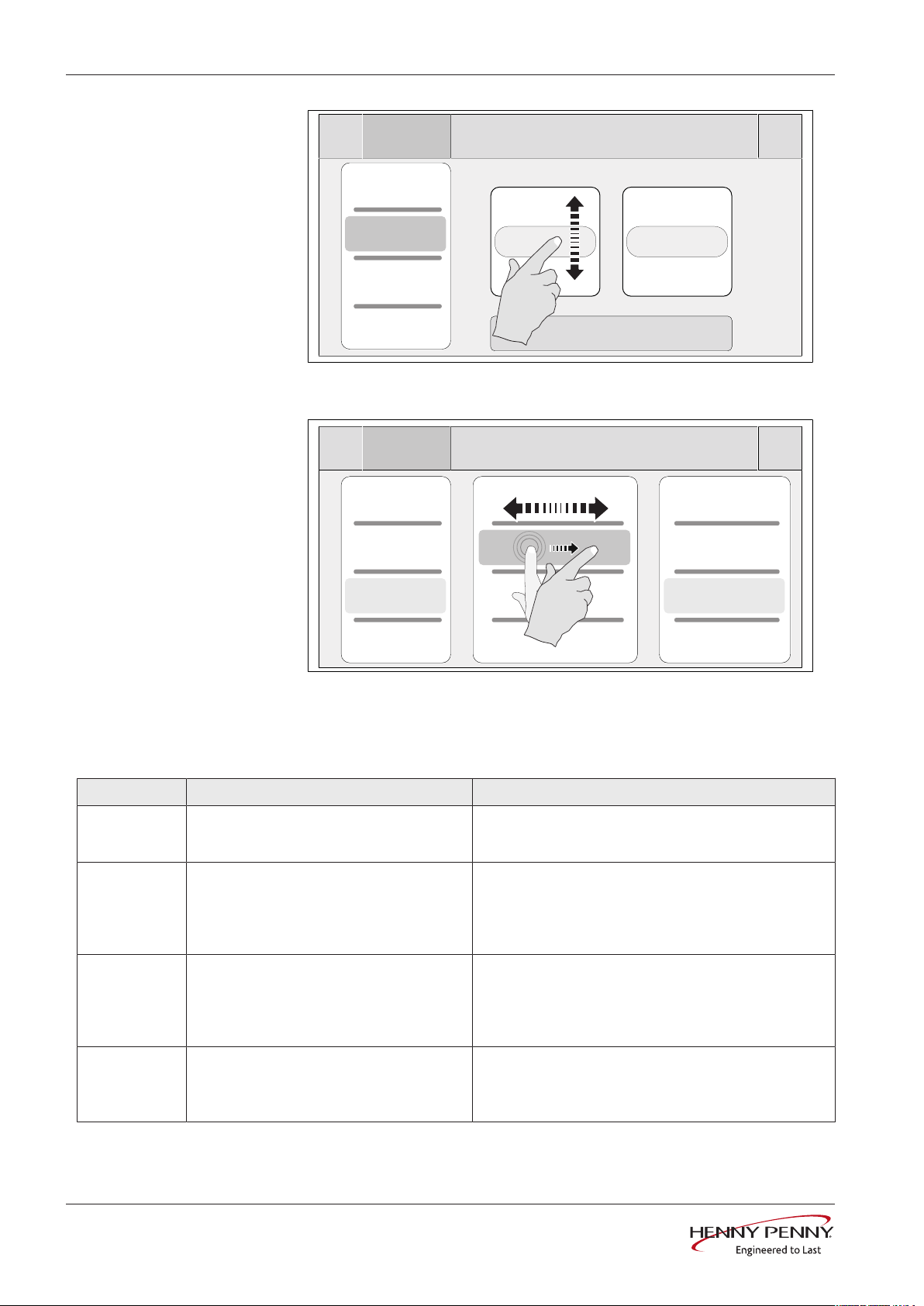

4.4.1 Touchscreen operation

The touchscreen can be operated with latex gloves.

INFORMATION

Tapping

Display elements such as buttons, fields or tabs are selected or

activated by tapping them. They appear to the right of the currently

displayed roller.

FM05-118-D

25Operating instructions

Description of the unit

Scrolling

Swiping

The rollers are used to scroll up or down to display additional content.

You use the swipe gesture to access fields to the right and left of the

current display.

4.4.2 Operating, control and display element functions

Symbol Operating and display element Function

On Off "I O"

"Automatic cooking" button • Opens the

"Manual cooking" button • Opens the

"Unit functions" button • Opens the

button • "I" switches on the unit

• "O" switches off the unit

programs

cooking modes

ing and settings

Automatic cooking

Manual cooking

Unit function

menu for selection of the

menu for selection of clean-

menu for selection of

26 Operating instructions

FM05-118-D

Symbol Operating and display element Function

Description of the unit

Language selection

Back

button • Tapping once returns the user to the previous menu

Help

button • Displays the help texts for the active menu or win-

button • Indicates that the operating language for the unit can

be selected here by tapping a country's flag

Selection and the number of selectable languages can

be specified in the

"Languages" settings field.

• Tapping twice returns the user directly to the main

menu

dow.

4.4.3 Display elements

The following table lists the basic display elements of the unit's

control system with examples.

Symbol Display element Function

Information strip The information strip is the uppermost bar on the

touchscreen and visible at all times.

The information strip is used to display current

information, for instance, categories or cooking

programs.

Unit functions

menu in the

Menu Menus have a colored border that identifies the

associated subject.

• Blue for unit functions

and

• Violet for cooking functions.

Menus frequently contain vertical separating bars

to simplify swipe gestures.

Menus represent central entry points and provide

an overview of the selectable functions and

submenus.

Page Pages are the areas with content in windows and

menus. Several pages can follow one another in

sequence.

An arrow symbol displays further pages. Changing

to the next or the previous page is accomplished

by swiping up or down.

Window Windows have a colored border and are opened

from menus or higher-level windows.

Functions are executed and settings displayed in

windows.

Depending on the function, there are several

window types, for instance, Find.

FM05-118-D

27Operating instructions

Description of the unit

Symbol Display element Function

Field Fields are areas in windows or menus defined by

separating bars.

Tapping fields opens functions and settings.

Button Buttons are areas enclosed by borders in windows

or menus.

Tapping buttons confirms settings. Buttons control

functions and are used to navigate in menus and

windows.

Tab A

Display Displays are information-containing areas in

Symbol Symbols are graphical elements in windows and in

Roller Rollers are areas where settings can be made by

blue

and a

green

tab are located on the left side

of the touchscreen. The tabs are available only in

the cooking step display.

Tapping the tabs offers quick access to unit

functions and cooking program functions.

windows.

Displays show entries and current information

some of which may be operated by tapping.

the toolbar.

Symbols indicate current states and possible

functions some of which may be operated by

tapping.

means of swipe gestures.

Lock This symbol indicates that screen lock has been

activated. Only the lock symbol is active.

If the operator taps on the lock symbol, a numeric

keypad appears. The touchscreen is unlocked by

entering a specific combination of numbers.

28 Operating instructions

FM05-118-D

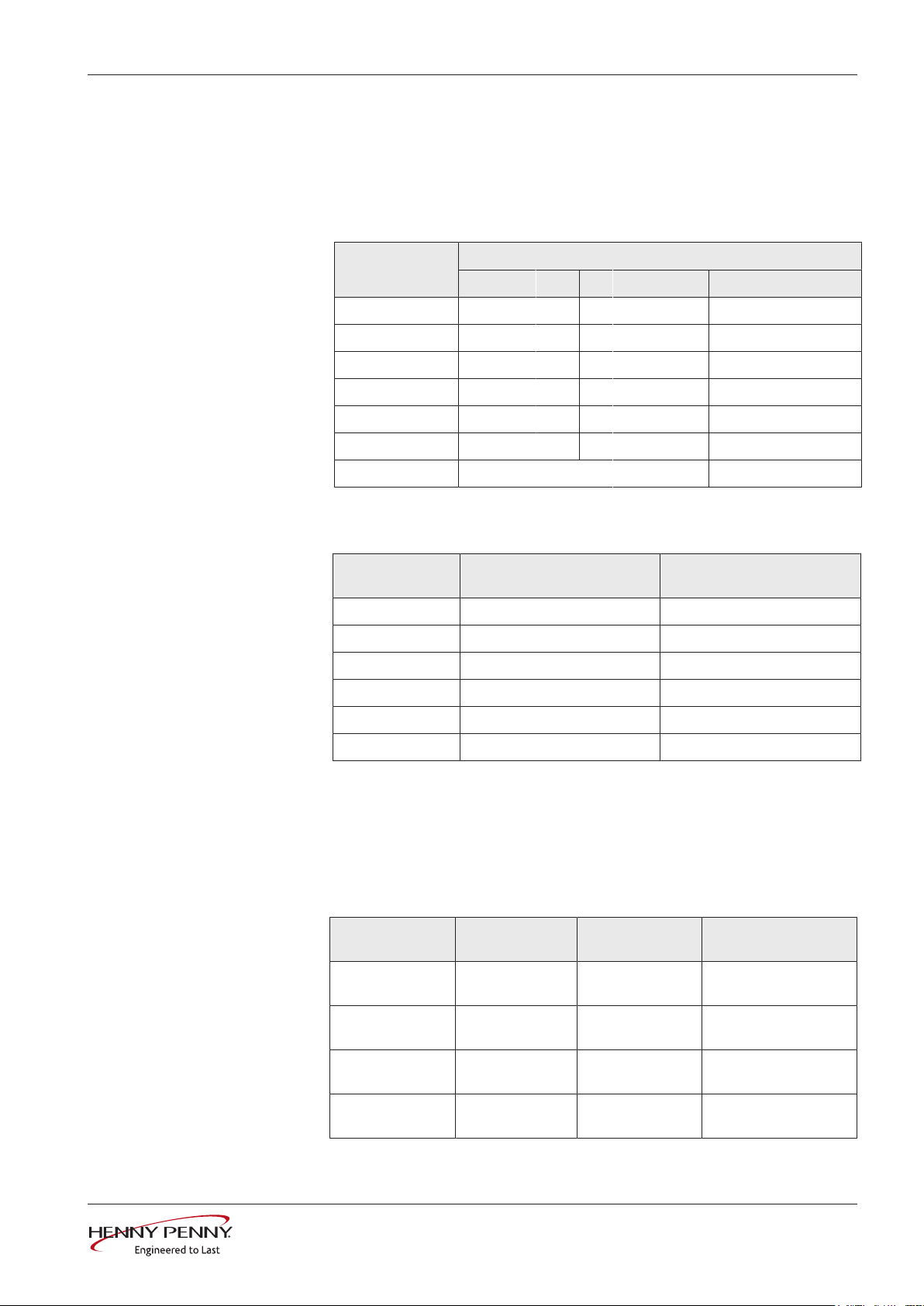

4.5 Loading capacities

4.5.1 Plate capacity during regeneration

Cooking time and cooking temperature depend on the number of

plates.

Version Plate diameter

FPG-615 30 24 22

FPG-621 30 24 22

FPG-115 50 40 40

FPG-121 50 40 40

FPG-215 100 80 80

FPG-221 120 120 80

on 1/1 GN grate Tray rack or tray trolley

Description of the unit

26 cm (10,24 inch) 28 cm (11,02 inch) 32 cm (12,56 inch)

4.5.2 Loading capacity

Tray rack trolley and tray trolley

Version Per shelf maximum (kg

FPG-615 15 (33,1) 50 (110,3)

FPG-621 15 (33,1) 50 (110,3)

FPG-115 15 (33,1) 80 (176,4)

FPG-121 15 (33,1) 80 (176,4)

FPG-215 15 (33,1) 150 (330,8)

FPG-221 15 (33,1) 150 (330,8)

4.6 Standard settings

4.6.1 Core temperature standard setting

The adjustment range for the core temperature depends on the

cooking mode.

Cooking mode Standard value

(lb))

(°C (°F))

Setting range

(°C (°F))

Per unit maximum (kg (lb))

Change increments

(°C (°F))

FM05-118-D

Steaming 70 (158 ) 0 (32 ) - 99

(210,2 )

Combisteaming 70 (158 ) 0 (32 ) - 99

(210,2 )

Hot air 70 (158 ) 0 (32 ) - 99

(210,2 )

Regeneration 50 (122 ) 0 (32 ) - 99

(210,2 )

1 (33,8 )

1 (33,8 )

1 (33,8 )

1 (33,8 )

29Operating instructions

Description of the unit

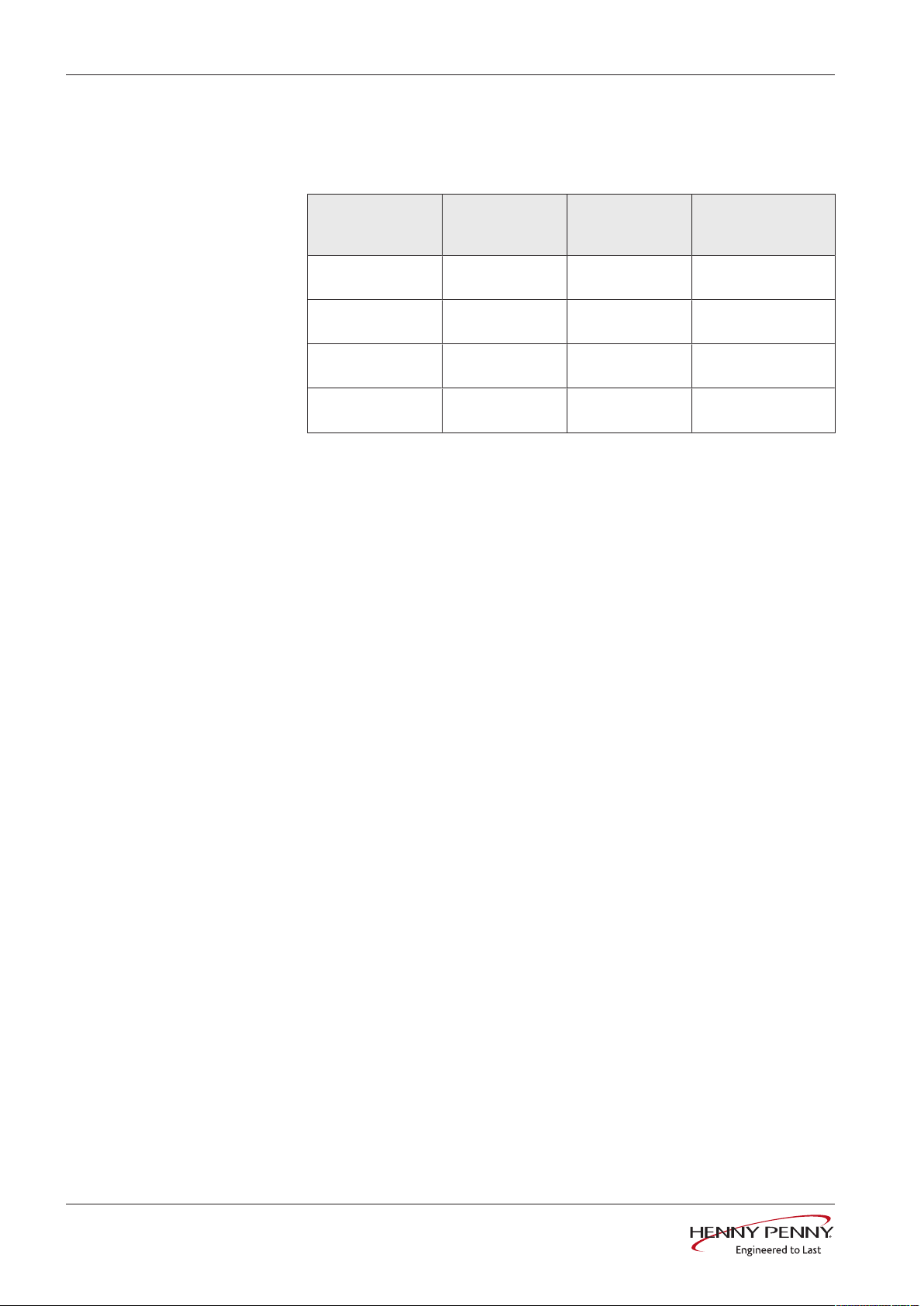

4.6.2 Temperature standard setting

The setting range for the cooking zone temperature depends on the

type of cooking.

Cooking mode Standard value

(°C (°F))

Steaming 100 (212 ) 30 (86 ) 130

Combisteaming 150 (302) 30 (86 ) 250

Hot air 180 (356) 30 (86 ) 250

Regeneration 50 (122 ) 30 (86 ) 180

Setting range

(°C (°F))

(266)-

(482)-

(482)-

(356)-

Change

increments (°C

(°F))

1 (33,8 )

1 (33,8 )

1 (33,8 )

1 (33,8 )

30 Operating instructions

FM05-118-D

Loading...

Loading...