Henny Penny FPG-615, FPG-121, FPE-121, FPE-215, FPG-215 Service Instructions Manual

...

FlexFusion® ELECTRIC

& GAS PLATINUM

COMBI

Service instructions

Model

FPE-615 FPG-615

FPE-621 FPG-621

FPE-115 FPG-115

FPE-121 FPG-121

FPE-215 FPG-215

FPE-221 FPG-221

Translation from the original document • FM06-101A DE • 8/26/2019

FM06-101A

en-US

Henny Penny Corporation

P.O.Box 60

Eaton,OH 45320

USA

Phone +1 937 456-8400

Fax +1 937 456-8402

Toll free in USA

Phone +1 937 417-8417

Fax +1 937 417-8434

www.hennypenny.com

2 Service instructions

Directory of contents

1Password overview ............................................................ 7

2Introduction......................................................................... 8

2.1About this manual ............................................................................ 8

2.2Warranty............................................................................................ 8

3Safety instructions ............................................................. 9

4Description of operation.................................................. 10

4.1DynaSteam...................................................................................... 10

4.2WaveClean ...................................................................................... 11

5Opening and closing the unit.......................................... 13

5.1Control panel .................................................................................. 13

5.1.1Opening the control panel ....................................................................... 13

5.1.2Closing the control panel......................................................................... 13

5.2Side wall .......................................................................................... 14

5.2.1Removing the side wall ........................................................................... 14

5.2.2Attaching the side wall............................................................................. 14

6Component overview ....................................................... 15

6.1Platinum operating panel / control ............................................... 15

6.2Gold operating panel / control ...................................................... 16

6.3FGE/ FPE 6xx 1xx Electric, left side ............................................. 17

6.4FGE/ FPE 2xx Electric, left side .................................................... 19

6.5FGG/ FPG 6xx 1xx Gas, left side................................................... 20

6.6FGG / FPG 2xx Gas, left side......................................................... 22

6.7FGG/ FPG 6xx 1xx, right side ........................................................ 24

6.8FGG/ FPG 2xx, right side ............................................................... 25

7Service menu - appliance test......................................... 26

7.1Service menu .................................................................................. 26

7.1.1Calling up the service level...................................................................... 26

7.1.2Service menu overview ........................................................................... 26

7.2Appliance information.................................................................... 27

7.3Status information.......................................................................... 28

7.4CombiDoctor................................................................................... 31

7.5Relay test ........................................................................................ 34

7.6WaveClean Test.............................................................................. 36

7.7100°C + core temperature calibration........................................... 37

7.7.1Checking the calibration - single-chamber appliance 6.x / 10.x .............. 38

7.7.2Checking the calibration - two-chamber appliance 20.x.......................... 39

7.7.3Calibrating the cooking chamber sensor - single-chamber appliance 6.x /

10.x................................................................................................................... 40

7.7.4Calibrating the cooking chamber sensor - two-chamber appliance 20.x. 41

FM05-16--

3Service instructions

Directory of contents

7.8DynaSteam test .............................................................................. 42

7.9Emptying the water ........................................................................ 43

7.10Data and time................................................................................ 43

7.11Installation height......................................................................... 44

7.12Audio settings .............................................................................. 44

7.13Select signal tones....................................................................... 45

7.14POS activation (only for electric energy type)........................... 45

7.15Exporting log data........................................................................ 45

7.16Software update ........................................................................... 46

7.17Importing additional content....................................................... 46

7.18Restoring data .............................................................................. 47

7.19Backing up data............................................................................ 47

7.20Water filter maintenance.............................................................. 48

7.21Importing contact data................................................................. 48

7.22Setting units.................................................................................. 49

7.23Backup relay ................................................................................. 49

7.24Settings parameters..................................................................... 51

7.24.1Selecting and changing parameters...................................................... 51

7.24.2Parameter overview .............................................................................. 51

7.25Backing up the SD card ............................................................... 53

7.26Restoring the SD card.................................................................. 53

7.27Background lighting..................................................................... 54

7.28Hour meter .................................................................................... 54

7.29Status overview direct access .................................................... 54

8Software ............................................................................ 55

8.1Software update ............................................................................. 55

8.2Importing additional content......................................................... 57

8.3Importing the manufacturer's cookbook...................................... 59

9Trade show mode............................................................. 61

10Electronics ...................................................................... 62

10.1Overview of the controller ........................................................... 62

10.2Layout of the control board......................................................... 63

10.3Configuration of the control board............................................. 64

10.4 Safety overview ........................................................................... 66

11Gas technology .............................................................. 68

11.1Basic principles............................................................................ 68

11.2CO2 setting ................................................................................... 69

11.2.1Opening the Setting menu..................................................................... 69

11.2.2Adjusting the settings (CO2 calibration) ................................................ 70

11.3Converting the gas type .............................................................. 76

4 Service instructions

FM05-16--

Directory of contents

11.4Checking the connection pressure ............................................ 78

11.5Checking the offset pressure...................................................... 80

12Gas orifices and C02 values up to S/N 16212355........ 82

13Gas orifices and C02 values after S/N 16212356......... 83

14Fault messages & troubleshooting............................... 84

14.1Overview ....................................................................................... 84

14.2Symbols for errors ....................................................................... 85

14.3Emergency operation................................................................... 87

14.4Temperature sensor area ............................................................ 88

14.4.1Cooking chamber sensor defective (694, 695)...................................... 88

14.4.2Top cooking chamber sensor defective (696, 728) ............................... 89

14.4.3Bottom cooking chamber sensor defective (697, 729) ......................... 90

14.4.4Core temperature sensor defective (699, 700)...................................... 91

14.4.5Internal core temperature sensor defective (714, 716) ......................... 92

14.4.6External core temperature sensor defective (715, 717) ........................ 92

14.4.7Water vapor sensor defective (710) ...................................................... 93

14.4.8Siphon temperature very high (SOF_ID20, ID21) ................................. 94

14.4.9Risk of frost (TMP_ID72, MMI_ID51)..................................................... 94

14.4.10Excess temperature in the cooking chamber (ID18, ID73).................. 95

14.5Motor area ..................................................................................... 96

14.5.1Overview ............................................................................................... 96

14.5.2Fan defective or temperature limiter triggered (702) ............................. 98

14.5.3Fan defective. Cooking program was cancelled (701) ........................ 100

14.5.4Top fan defective. Automatic switching to emergency operation (703, 705)

....................................................................................................................... 100

14.5.5Bottom fan defective. Automatic switching to emergency operation (704,

706) ................................................................................................................ 101

14.5.6FAN_ID23: Fan error: Attempt to restart ............................................. 103

14.5.7FAN_ID24: Upper fan fault: Attempt to restart..................................... 103

14.5.8FAN_ID25: Lower fan fault: Attempt to restart..................................... 103

14.6Water area ................................................................................... 105

14.6.1Water pressure too low (709) .............................................................. 105

14.6.2Water pressure during WaveClean too low......................................... 107

14.7Electronics / control area .......................................................... 108

14.7.1Overtemperature control (TMP_ID2) ................................................... 108

14.7.2Critical temperature in the electronics (MMI_ID50) ............................. 109

14.7.3Failure to access external EEPROM (SOF_ID12)............................... 110

14.7.4Faulty CAN connection........................................................................ 110

14.7.55007: Not enough storage space for software update ........................ 110

14.7.65008: No new version found................................................................ 110

14.7.75009: The application could not be started. Application is restarting. . 111

FM05-16--

5Service instructions

Directory of contents

14.7.85010: The application could not be started. Restore configuration

backup?.......................................................................................................... 111

14.7.95013: Application could not be restored! Restore to factory settings with

OK. ................................................................................................................. 111

14.7.10Unit was restarted after power failure................................................ 112

14.7.11Door is open - cooking program was stopped................................... 112

14.8Gas area ...................................................................................... 114

14.8.1No gas (OTH_ID1)............................................................................... 114

14.8.2No gas (top)(OTH_ID2) ....................................................................... 116

14.8.3No gas (bottom)(OTH_ID3) ................................................................. 116

14.8.4No flame (OTH_ID4)............................................................................ 116

14.8.5No flame (top)(OTH_ID5) .................................................................... 116

14.8.6No flame (bottom)(OTH_ID6) .............................................................. 117

14.8.7Communication fault between I/O and ignition electronics (OTH_ID25) .....

117

14.8.8Communication fault between I/O and ignition electronics (top)

(OTH_ID26) .................................................................................................... 118

14.8.9Communication fault between I/O and ignition electronics (bottom)

(OTH_ID27) .................................................................................................... 118

14.8.10GAS_ID13: Flame fault during operation........................................... 119

14.9Testing the gas components..................................................... 119

14.9.1Checking the electrodes...................................................................... 119

14.9.2Inspection of the gas solenoid valve ................................................... 120

14.9.3Testing the heat exchanger................................................................. 121

6 Service instructions

FM05-16--

1 Password overview

Range Password Description Described in

Password overview

Installation /

commissioning

CO2 gas calibration 999 Verification and calibration of

Network settings 2000 Input network addressing. Only

Basic settings / user 111 Setting of basic values for the

Lockscreen 369 Deactivating the lockscreen in

Trade show mode 888 Activation / deactivation for

Service menu with

CO2 gas calibration

2100 Setting all basic parameters (for

example time / date).

exhaust emissions. Only for

energy type - gas.

for units with touchscreen control.

user, functions, software update.

cooking mode. Only for units with

touchscreen control.

exhibition mode.

1967 Service range for authorized

service technicians.

Installation instructions

Installation instructions

Installation instructions

Operating instructions

Operating instructions

Service instructions

Service instructions

FM05-16--

7Service instructions

Introduction

2 Introduction

2.1 About this manual

Target group Target group for this service manual is qualified personnel who are

Figures All figures in this service manual are intended as examples.

Spare parts To ensure the reliability of the unit and the individual components, it is

This service manual contains information needed by the service

technician for professional and correct fault isolation, repair and

maintenance of the unit. The service technician must also observe

the contents of the installation instructions and the user manual.

familiar with the technical functioning and operation of the unit.

Discrepancies can arise between this and the actual unit.

essential that only genuine OEM parts be used.

Spare parts can be identified exactly with the aid of the online

database.

2.2 Warranty

The warranty is void and safety is no longer assured in the event of:

• Modifications or technical changes to the unit,

• Improper use,

• Incorrect startup, operation or maintenance of the unit,

• Problems resulting from failure to observe these instructions.

8 Service instructions

FM05-16--

3 Safety instructions

For servicing tasks, the service technician must be familiar with and

observe regional regulations.

In addition, the notes in the service manual must be observed.

Safety instructions

DANGER

DANGER

Danger to life due to electric current

ü Disconnect power prior to performing gas and electrical work.

• Disconnect unit from the mains supply and secure it against restart.

• Check to ensure absence of voltage.

Risk of fatal injury from gas

ü Disconnect the unit from gas supply prior to performing gas installation

tasks.

• Lock site gas supply and secure it against restart.

FM05-16--

9Service instructions

Description of operation

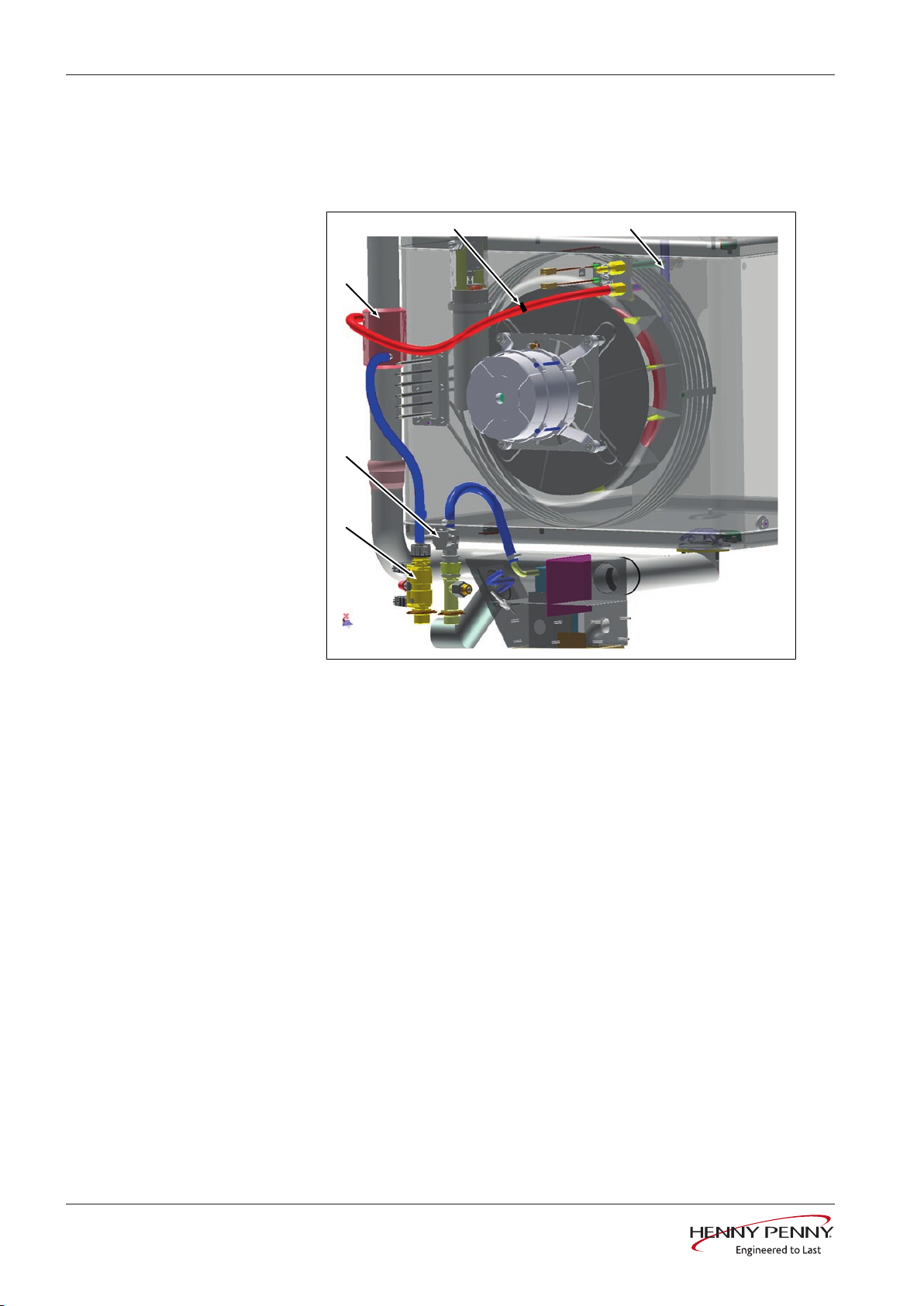

a

b

c

d

e

4 Description of operation

4.1 DynaSteam

Overview

a Steaming appliance with pressure

switch

b Magnetic valve water vapor

elimination

c Heat exchanger (up to approx.

50°degrees)

d Reduction

e Water supply pipe

Description • The electronics control the DynaSteam steaming appliance. They

regulate the water quantity for generating steam. DynaSteam

guarantees, regardless of the water pressure, the precise supply

of the required quantity of water. The prerequisite for this is a

customer-supplied water flow pressure between 2 and 6 bar. The

water pressure is monitored using a pressure switch.

• The DynaSteam steaming appliance cannot be calibrated and is

completely electronically controlled.

• The heat exchange heats the water in advance up to 50°C. The

heat from the exhaust pipe is used for this.

• The water comes through the water supply pipe to the fan impeller

in the cooking chamber. The fan impeller creates small water

drops, which evaporate in the hot oven atmosphere. The water

evaporates in the cooking chamber and on the fan impeller. The

tapering of the hose stabilizes the water flow of the pulsing

steaming unit.

10 Service instructions

FM05-16--

4.2 WaveClean

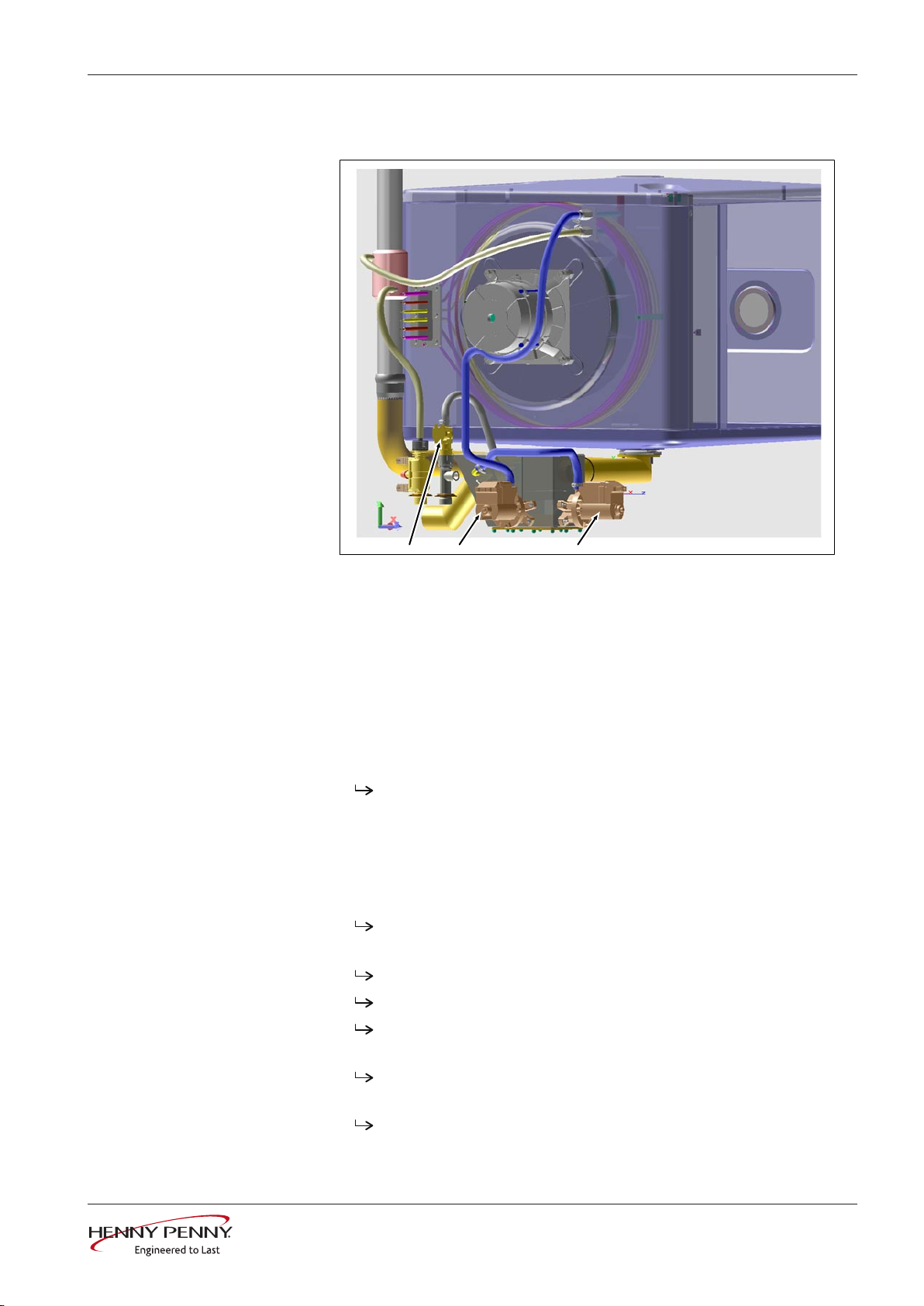

a b c

Functional overview

Description of operation

a Magnetic valve K12 c Pump G24

b Pump G16

The following purification stages are available on the fully automatic

cleaning WaveClean:

• Short: duration of about one hour

• Normal: duration about two hours

• Extra: duration approximately three hours

Description 1. Testing the cooking chamber temperature.

Automatic cooling of the cooking chamber, if > 55°C.

2. Inserting the WaveClean cartridge.

3. Water exchange of siphon content by the siphon pump G24 and

solenoid valve K12.

4. Circulation of water by means of pump G16. Thus pre-cleaning of

the cooking chamber. Then anew siphon water exchange.

The heater heats the oven to 55°C.

5. Start cleaning.

Fan motor and WaveClean pump G16 active.

Heating active. Heating the cooking chamber to about 70°C.

FM05-16--

The first layer of wax melts in the WaveClean cartridge. The

cleaner falls into the cooking chamber and mixes with water.

The fan motor operates in both directions of rotation and at

different speeds.

The cleaning phase duration depends on the selected

program.

11Service instructions

Description of operation

INFORMATION

6. A new water exchange of siphon content by means of the siphon

pump G24 and solenoid valve K12.

7. Start of rinsing.

Identical to step 5 (cleaning).

Differences: Heating of the cooking chamber to 92°C. The

second layer of wax melts in the WaveClean cartridge. The

rinse agent drops into the cooking chamber and mixes with

water.

Final rinse to bring the pH value to the normal level.

8. In the programs "normal" and "extra" additional drying of the

interior occurs by means of hot air.

9. Finally, an indicator for withdrawing the WaveClean cartridge

appears, and has to be confirmed.

Despite different cleaning durations, all cleaning steps require the same

amount of water.

During the cleaning process about 3 liters of water are provided by the steam-

WaveClean termination

INFORMATION

ing unit into the oven.

WaveClean forced rinsing

The WaveClean forced rinse is automatically started by the operator in case of

failure or premature termination. The duration is 12 minutes. An entry is made

into the HACCP and in the diagnostic memory.

12 Service instructions

FM05-16--

5 Opening and closing the unit

a

c

b

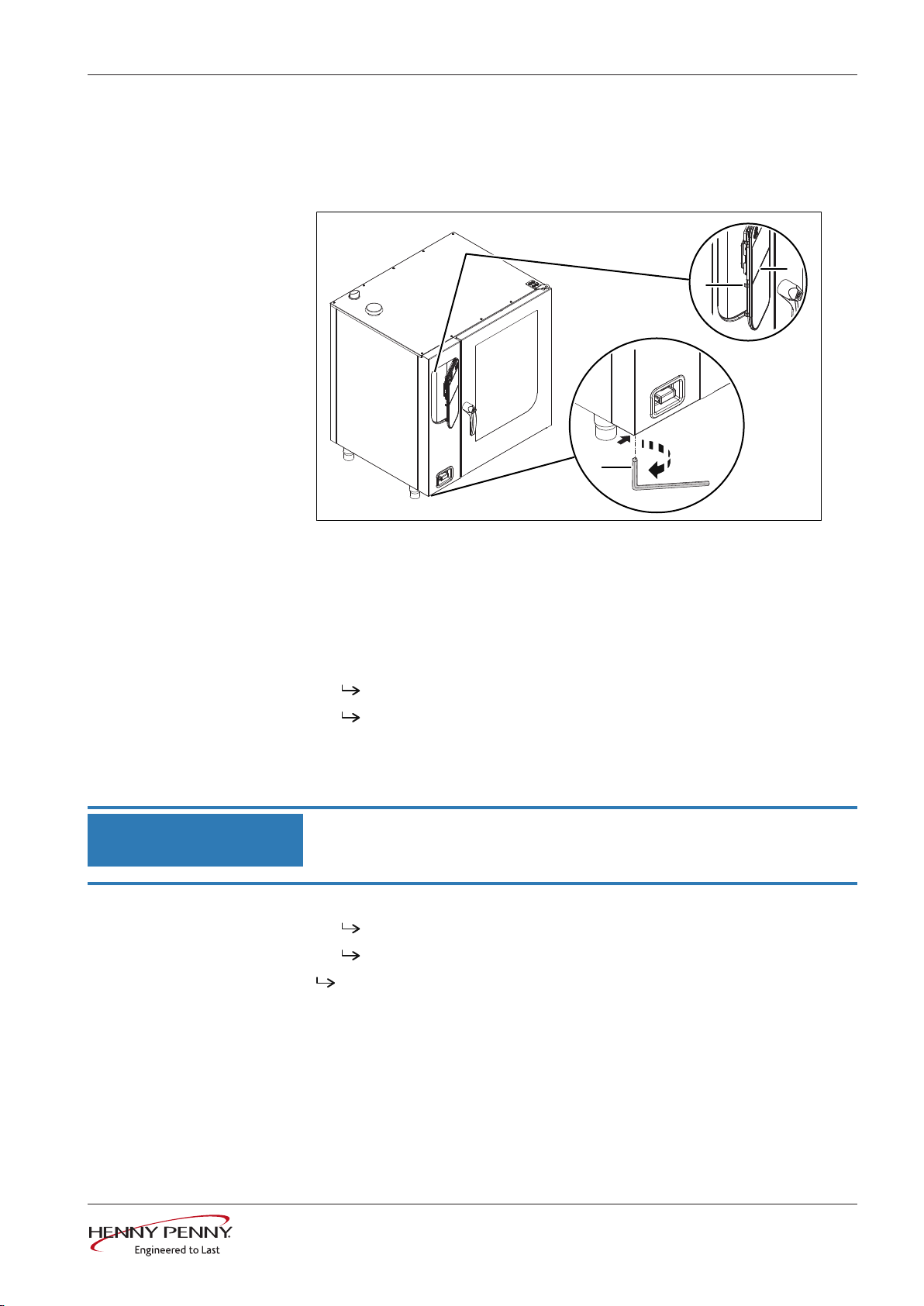

5.1 Control panel

Opening and closing the unit

Image: Opening the control panel

a Lock (cam) b Operating panel

c Hex key

5.1.1 Opening the control panel

1. Insert hex key (5 mm ) into screw and turn it clockwise.

2. Withdraw the hex key.

5.1.2 Closing the control panel

Damage due to vapor / moisture

NOTICE

There should be no gap between the control panel and housing.

1. Press and hold operating panel on the left.

The operating panel is secured against unauthorized opening.

The operating panel is now unlocked.

The operating panel pops up automatically.

Repeat as many times as necessary.

The operating panel snaps in audibly.

FM05-16--

13Service instructions

Opening and closing the unit

BA

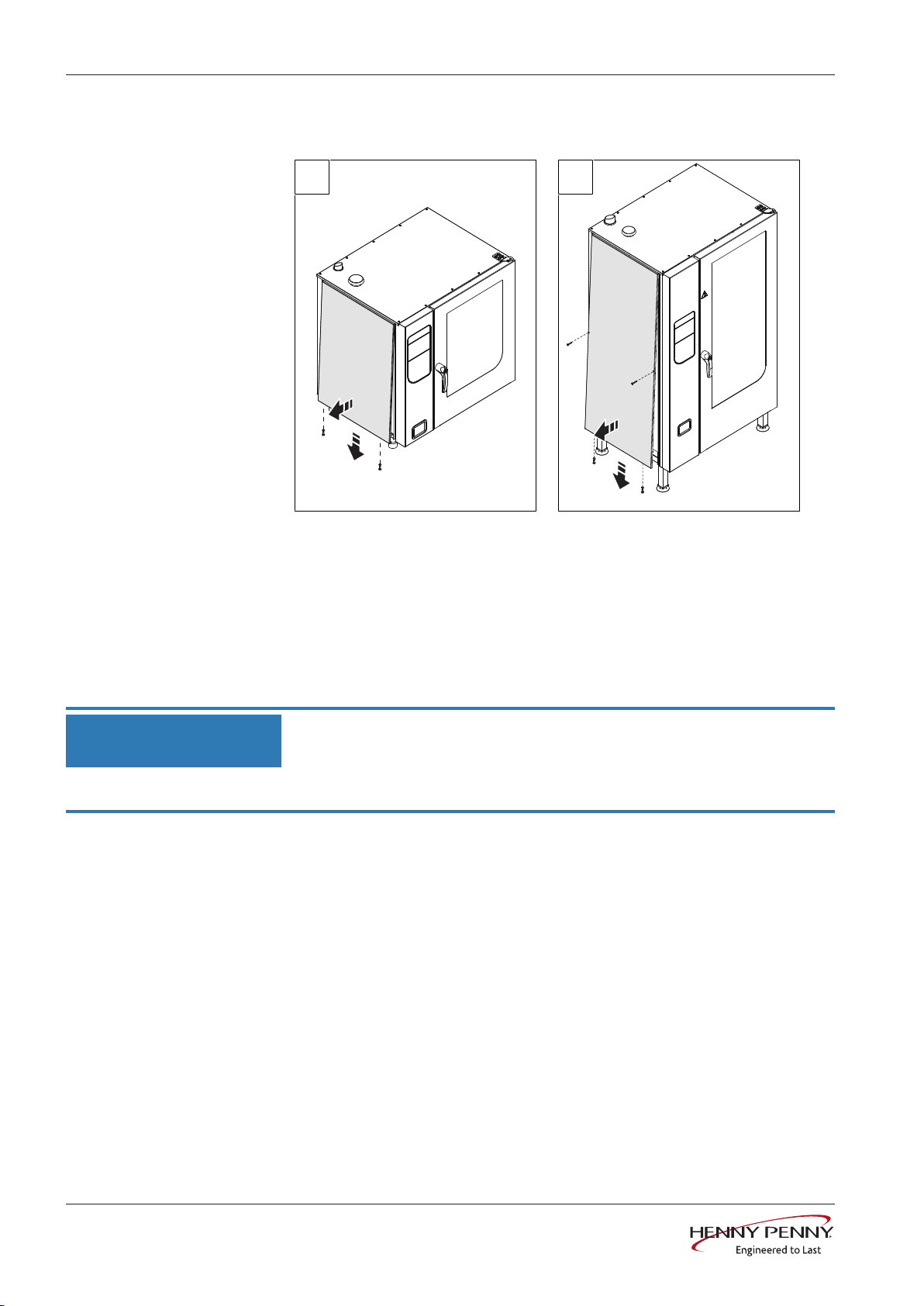

5.2 Side wall

Image: A Sizes 6.x and 10.x; B Size 20.x

5.2.1 Removing the side wall

1. Unscrew the screws in the side wall.

2. Pull the bottom edge of the side wall forwards.

3. Remove the side wall.

5.2.2 Attaching the side wall

NOTICE

Risk of property damage from leaky housing

• Check seals when attaching the housing parts.

• Replace damaged seals.

1. Insert top edge of side wall.

2. Carefully push the bottom of the side wall inward.

3. Secure the bottom of the side panel with screws.

4. Check that the side wall is in contact with the unit on all sides.

14 Service instructions

FM05-16--

6 Component overview

A2

S0

A3

B1

B15

A1

B20

E1

SD

6.1 Platinum operating panel / control

Component overview

Image: Touch operating panel area - FKE/ FKG

A1 Control board A2 Operating panel

A3 Digital memory B1 Core temperature sensor

B15 Reed contact switch B20 Loudspeaker

E1 Insert with LED lighting S0 On / Off switch

SD SD card

FM05-16--

15Service instructions

Component overview

A2

S0

A3

B1

B15

A1

B20

6.2 Gold operating panel / control

Image: Classic operating panel area - FKE/FKG

A1 Control board A2 Operating panel

A3 Digital memory B1 Core temperature sensor

B15Reed contact switch B20Loudspeaker

S0 On / Off switch

16 Service instructions

FM05-16--

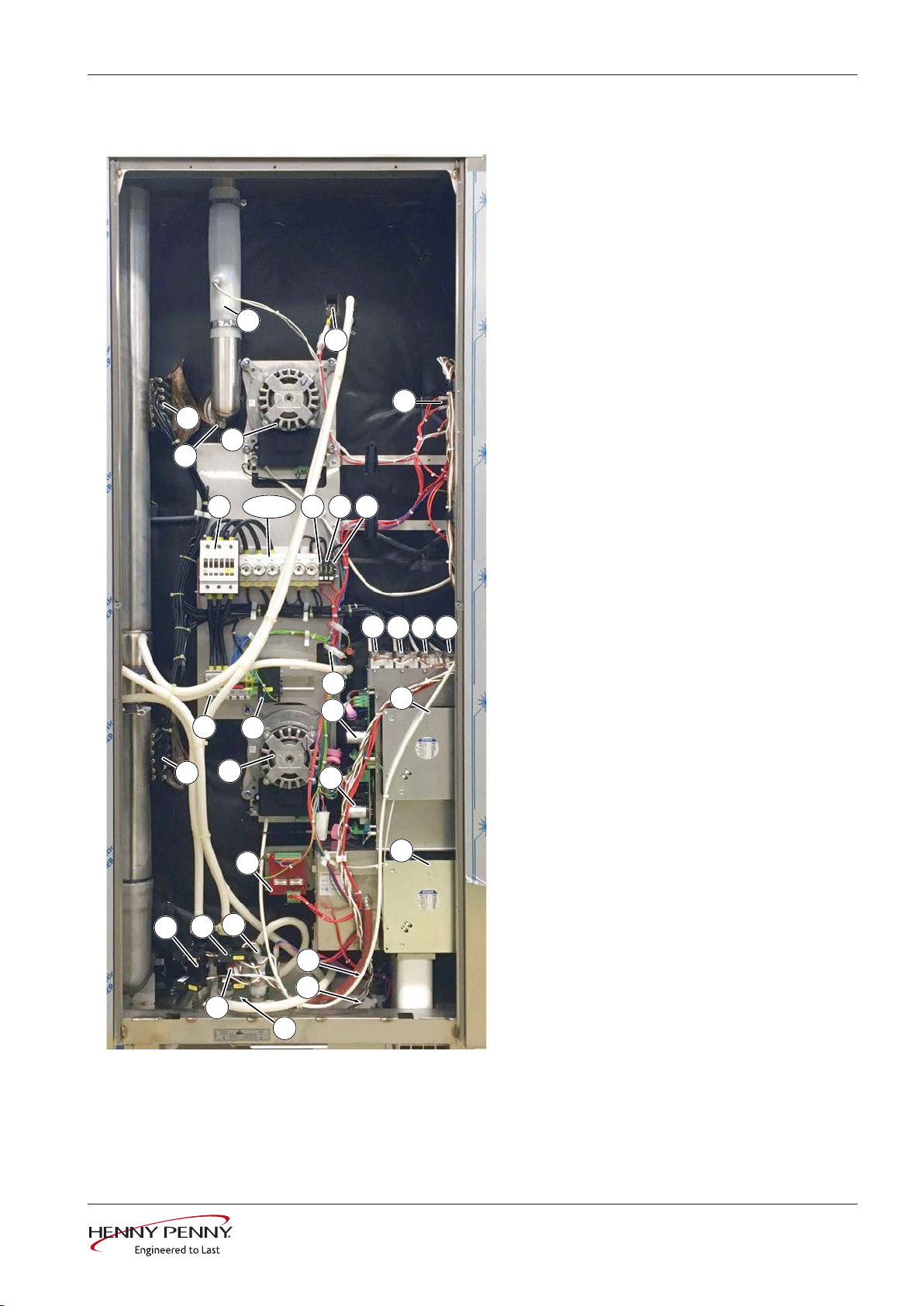

6.3 FGE/ FPE 6xx 1xx Electric, left side

Q1 F1

F4

X1

K12

G16

G24

T1

B5

B4

B11

E1

M10

K20

B14

T10

M8

G7

B13

F1

F1.1

F21

F22

F23

F24

Q2

Q3

Component overview

Image: FGE/ FPE UL - left side

FM05-16--

17Service instructions

Component overview

B4 Vapor sensor B5 Moisture sensor

B11Safety temperature limiter B13Thermal switch 50°C

B14Pressure switch F1 Fuse, 6A, slow-blow

F1.1Fuse, 6A, slow-blow F4 Fuse, 6A, slow-blow

F21 Fuse, 60A (only on 220) F22 Fuse, 60A (only on 220)

F23 Fuse, 60A (only on 220) F24 Fuse, 60A (only on 220)

G7 Cooling fan G16Circulation pump

G24Drain pump K12Solenoid valve (steam)

K20DynaSteam unit M8 Solenoid

M10Fan motor Q1 Main contactor

Q2 Solid-state relay (SSR), 100 A Q3 Solid-state relay (SSR), 100 A

T1 Transformer (supply) T10 Power pack for fan motor

X1 Power connection terminal

18 Service instructions

FM05-16--

6.4 FGE/ FPE 2xx Electric, left side

B11

E1

M10

B5

R1

X1

F1Q1

M8

B13

G8

T1

B4

T10

B14

K20

K12

G24

G16

E2

K21

G7

M20

F2 F4

T20

Q2

F21-F23

B12

Q3 Q4 Q5

Component overview

B4 = Steam sensor

B5 = Moisture sensor

B11 = Safety temperature limiter

B12 = Safety temperature limiter

B13 = Thermal switch 50°C

B14 = Pressure switch

F1 = Fuse, 10A, slow-blow

F2 = Fuse, 10A, slow-blow

F4 = Fuse, 6.3A, slow-blow

F21-F23 = Fuse

G7 = Cooling fan (180 x 180 mm)

G8 = Cooling fan 180 x 180 mm)

G16 = Recirculation pump

G24 = Emptying pump

K12 = Solenoid valve (steam)

K20 = DynaSteam unit with pressure switch

K21 = DynaSteam unit without pressure switch

M8 = Solenoid

M10 = Fan motor

M20 = Fan motor

Q1 = Main contactor

Q2 = Solid-state relay (SSR), top

Q3 = Solid-state relay (SSR), top

Q4 = Solid-state relay (SSR), bottom

Q5 = Solid-state relay (SSR), bottom

R1 = Filter

T1 = Transformer (supply)

T10 = Power pack for fan motor (top)

T20 = Power pack for fan motor (bottom)

X1 = Mains connection terminal

FKG – View of left side

FM05-16--

19Service instructions

Component overview

Q1 F1 F4

X1

G10

K12

G16

G24

T1

R1B5

B4

B11

A10

RC1

B100

T2

M10

E10

K20

B14

T10

M8

G7

K30

B13

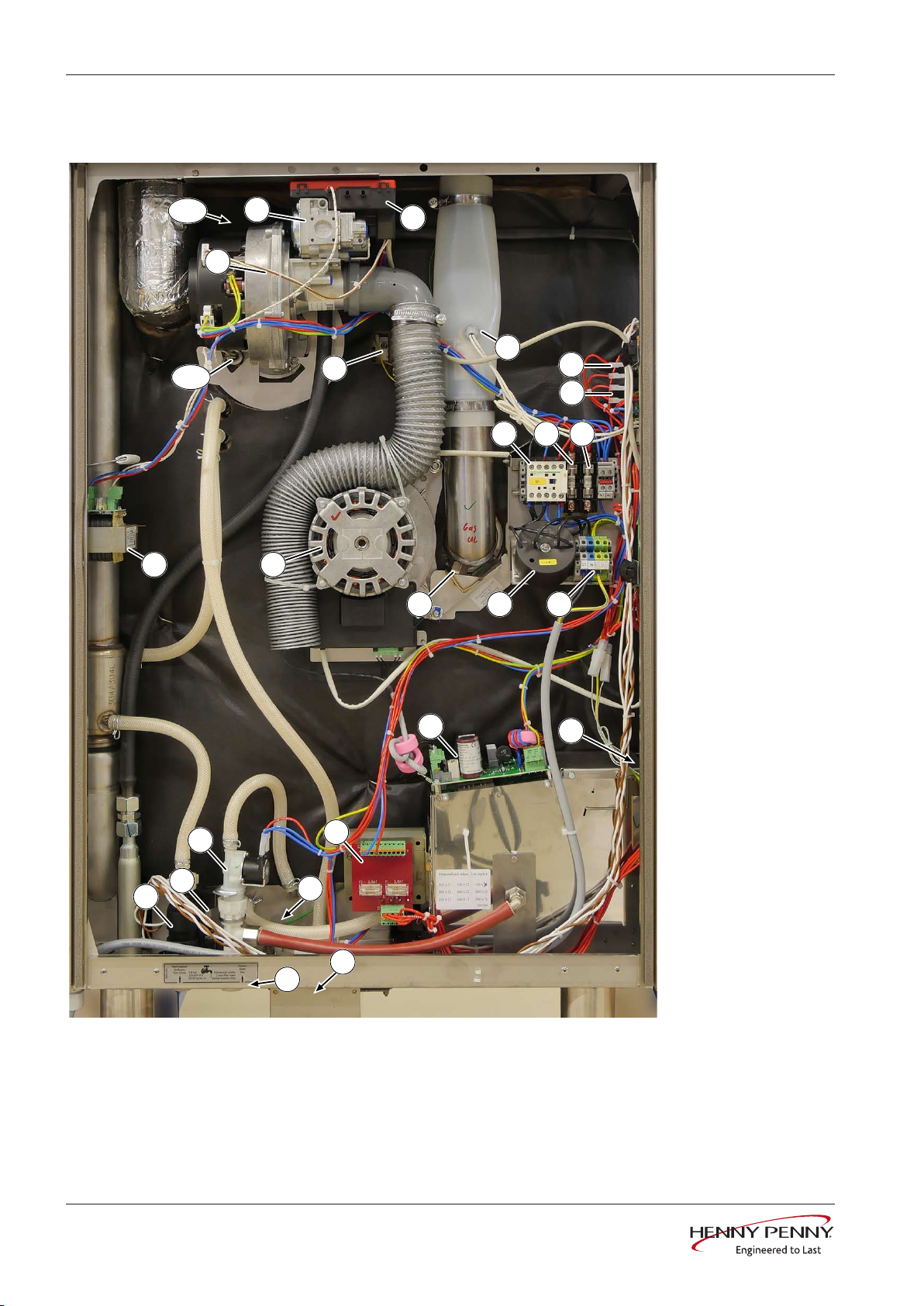

6.5 FGG/ FPG 6xx 1xx Gas, left side

Image: FGG/ FPG CSA - left side

20 Service instructions

FM05-16--

Component overview

A10 Ignition electronics B4 Vapor sensor

B5 Moisture sensor B11 Safety temperature limiter

B13 Thermal switch 50°C B14 Pressure switch

B100 Glow electrode E10 Ionization electrode

F1 Fuse 10A, slow-blow F4 Fuse 6A, slow-blow

G7 Cooling fan G10 Gas fan

G16 Circulation pump G24 Drain pump

K12 Solenoid valve (steam) K20 DynaSteam unit

K30 Gas magnetic valve M8 Solenoid

M10 Fan motor Q1 Main contactor

R1 Filter RC1 RC combination

T1 Transformer (supply) T2 Transformer for glow electrode

T10 Power pack for fan motor X1 Power connection terminal

FM05-16--

21Service instructions

Component overview

Q1 F1 F4

X1

G10

K12

G16

G24

T1

R1B5

B4

B11

A10

RC1

B100

T2

M10

E10

K20

B14

T10

M8

G7

K30

B13

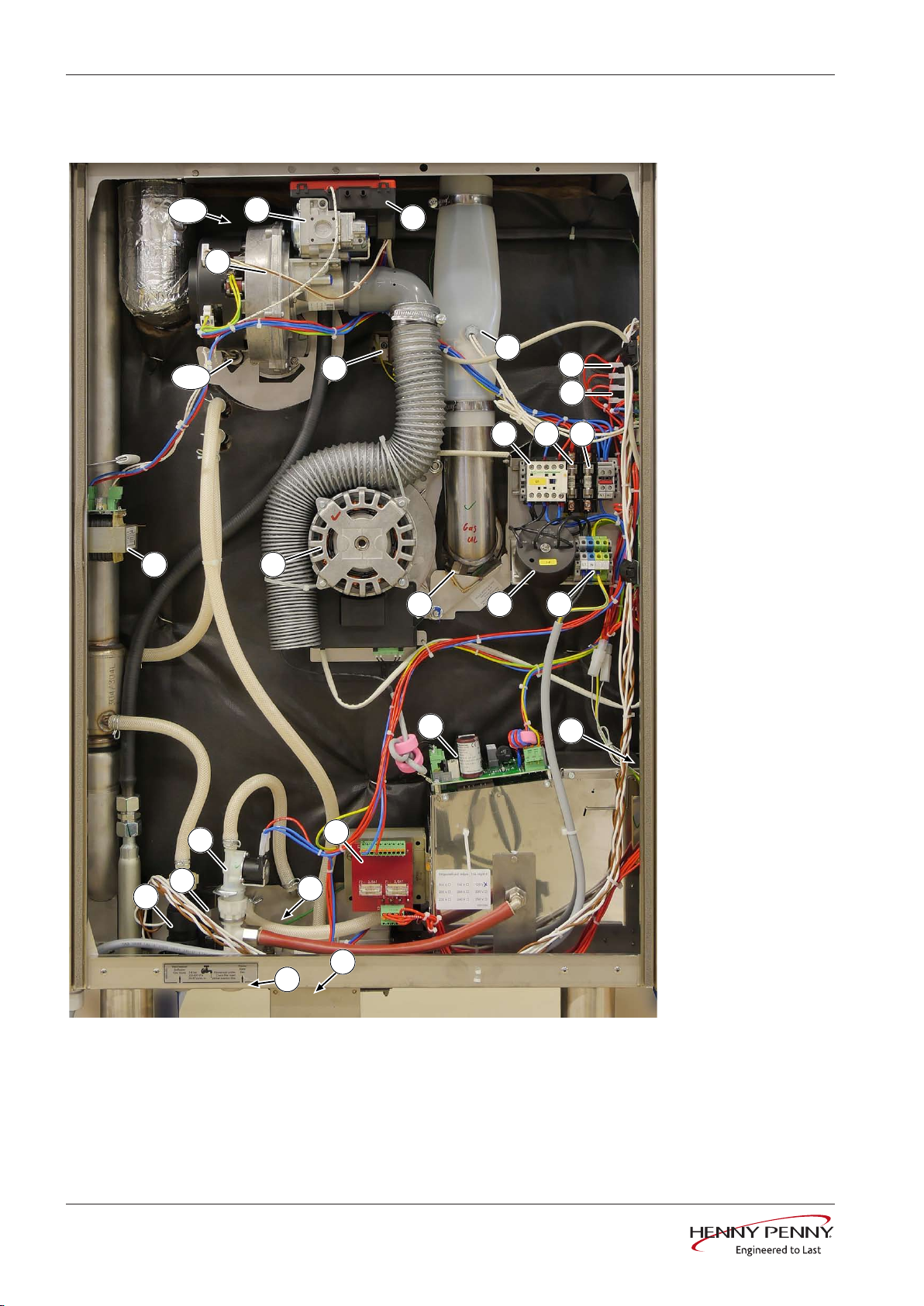

6.6 FGG / FPG 2xx Gas, left side

Image: FGG/ FPG CSA - left side

22 Service instructions

FM05-16--

Component overview

A10 Ignition electronics B4 Vapor sensor

B5 Moisture sensor B11 Safety temperature limiter

B13 Thermal switch 50°C B14 Pressure switch

B100 Glow electrode E10 Ionization electrode

F1 Fuse 10A, slow-blow F4 Fuse 6A, slow-blow

G7 Cooling fan G10 Gas fan

G16 Circulation pump G24 Drain pump

K12 Solenoid valve (steam) K20 DynaSteam unit

K30 Gas magnetic valve M8 Solenoid

M10 Fan motor Q1 Main contactor

R1 Filter RC1 RC combination

T1 Transformer (supply) T2 Transformer for glow electrode

T10 Power pack for fan motor X1 Power connection terminal

FM05-16--

23Service instructions

Component overview

E3

B2

6.7 FGG/ FPG 6xx 1xx, right side

Image: FKE/ FKG – View of right side

B2 Cooking chamber sensors E3 Cooking chamber light

24 Service instructions

FM05-16--

6.8 FGG/ FPG 2xx, right side

E3

B2

B3

E4

Component overview

B2 = To cooking chamber sensor

B3 = Bottom cooking chamber sensor

E3 = Cooking chamber light

E4 = Cooking chamber light

FKE/ FKG – View of right side

FM05-16--

25Service instructions

Service menu - appliance test

7 Service menu - appliance test

7.1 Service menu

Description • Functional testing of individual components

• Error analysis

• Maintenance

• Change basic settings

• Software update

The graphics shown may deviate due to changes and different

software versions.

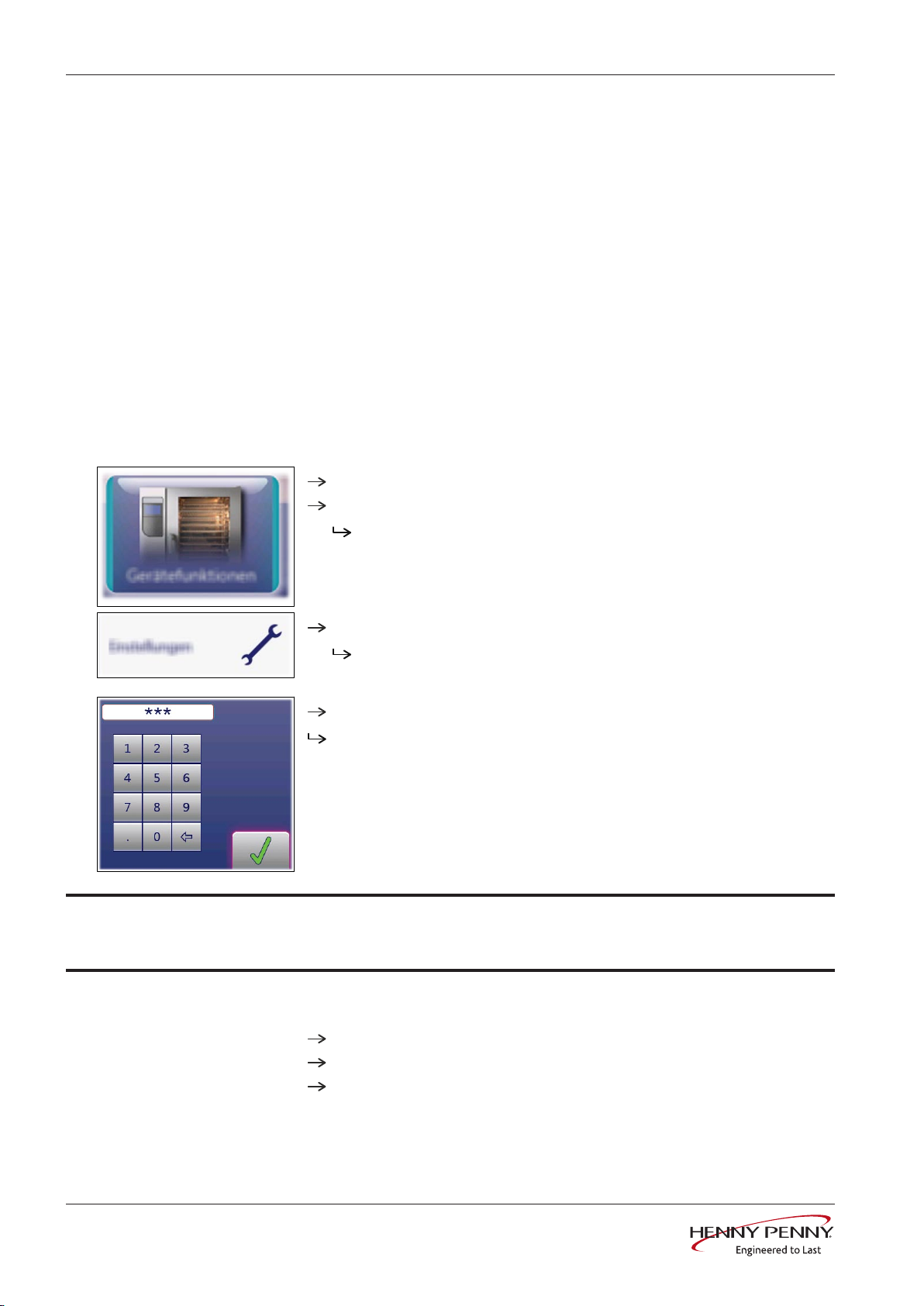

7.1.1 Calling up the service level

Calling up the Service menu

Switch the appliance on.

Touch the "Appliance functions" field.

INFORMATION

Display of

Touch "Settings" field.

Display of

Enter password and touch

Display of menu

The password for the service menu is 1967

Appliance functions

PIN

window.

Confirmation

Appliance test (Service menu)

menu.

field.

.

7.1.2 Service menu overview

Selecting a menu element

26 Service instructions

Display of the menu elements in the left area.

Page change by swiping upward/downward.

Select menu element by touching.

FM05-16--

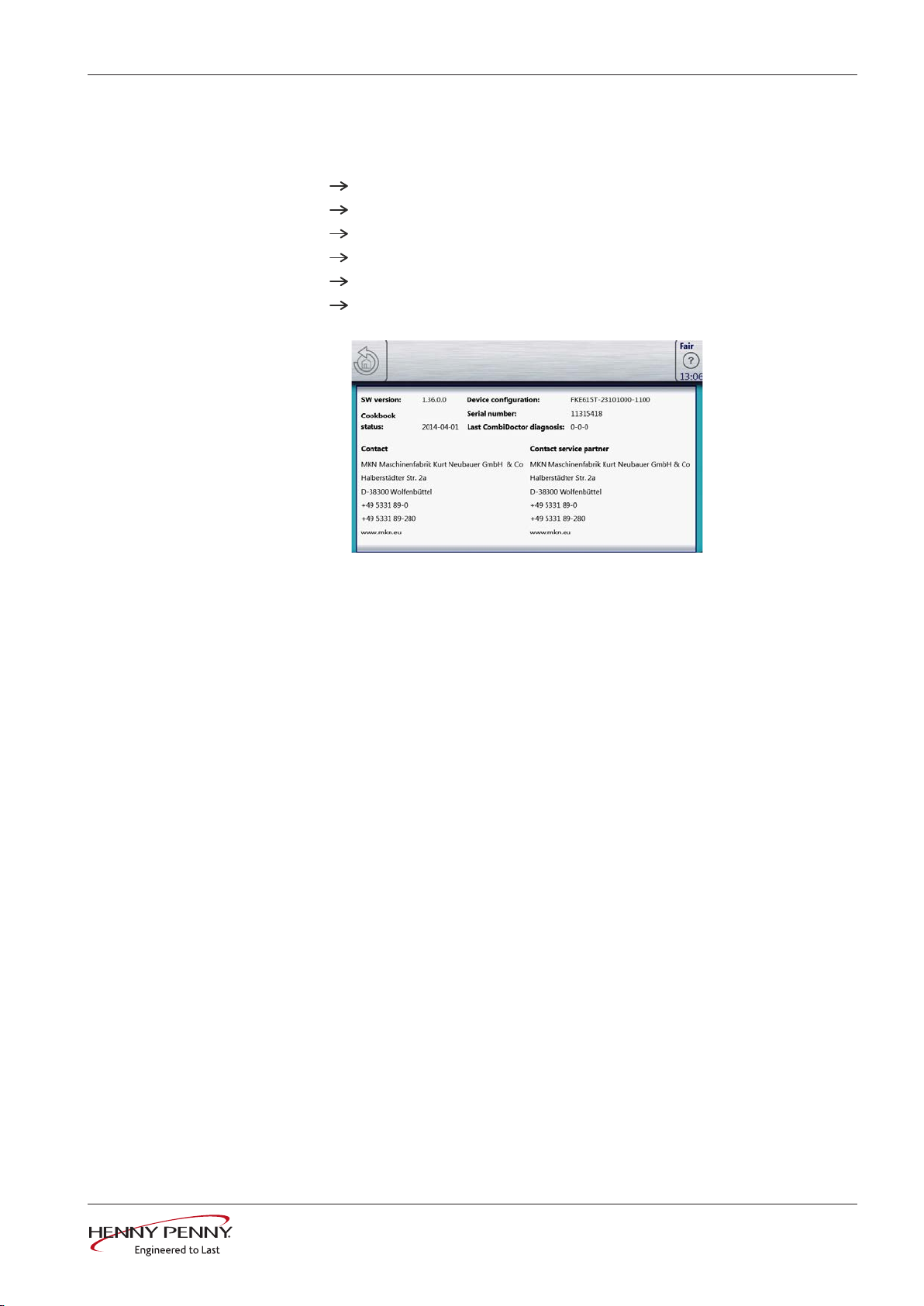

7.2 Appliance information

Description Display of the appliance-specific information

Overview

Service menu - appliance test

Software version

Cookbook version

Unit configuration

Serial number

Date of last CombiDoctor diagnosis.

Contact data

Exiting the appliance

information

Touch the

Back

field.

FM05-16--

27Service instructions

Service menu - appliance test

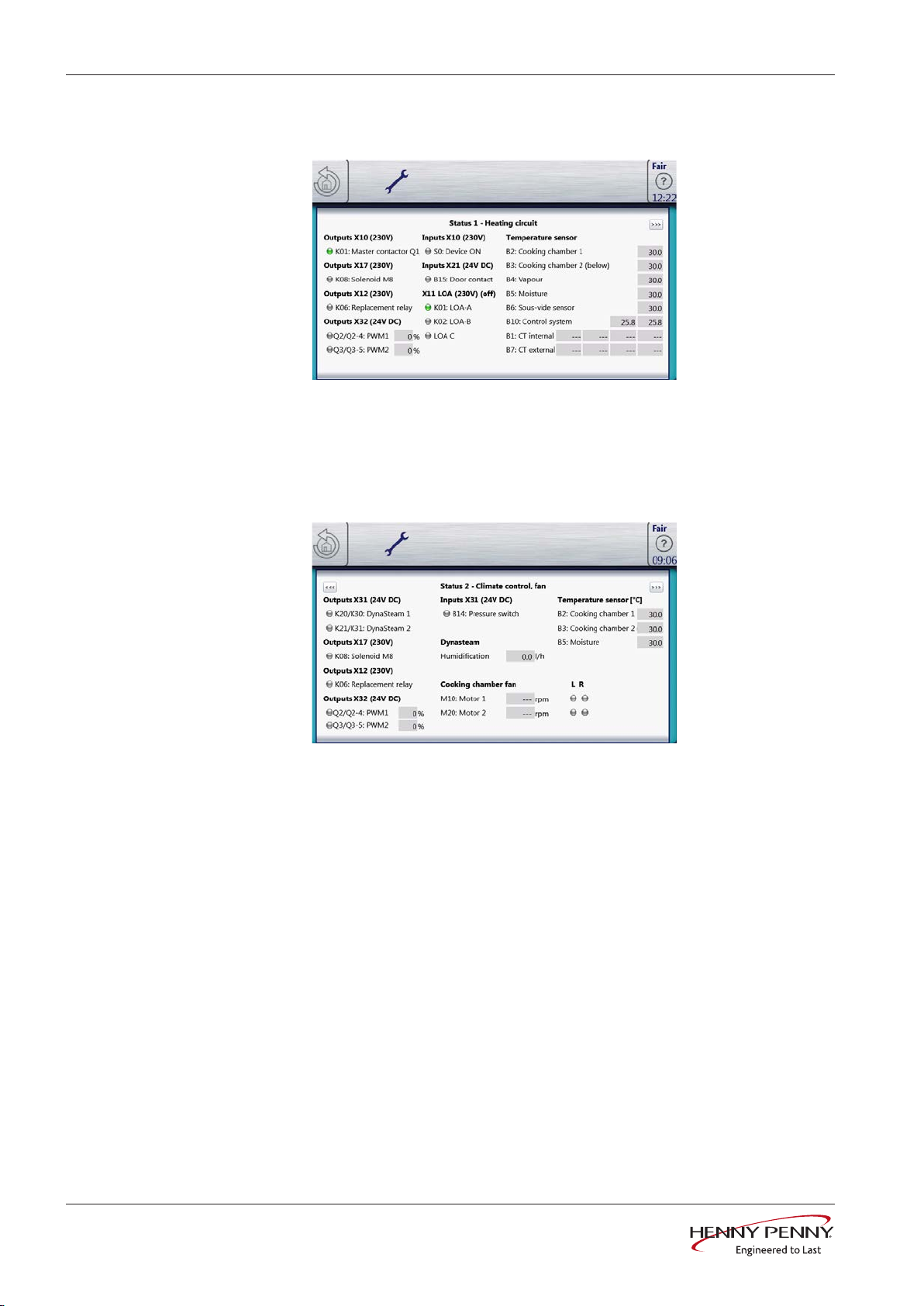

7.3 Status information

Status 1

Heating circuit

PWM Heat requirement in %.

POS Performance optimization system (option).

B3 Lower chamber sensor. Only present in 20.x floor-mounted

appliances.

Status 2

Climate control, fan

B14 Pressure switch on the DynaSteam unit

PWM Heat requirement in %.

M20 Bottom fan motor. Only present in 20.x floor-mounted appliances.

B3 Bottom cooking chamber sensor. Only present in 20.x floor-mounted

appliances.

28 Service instructions

FM05-16--

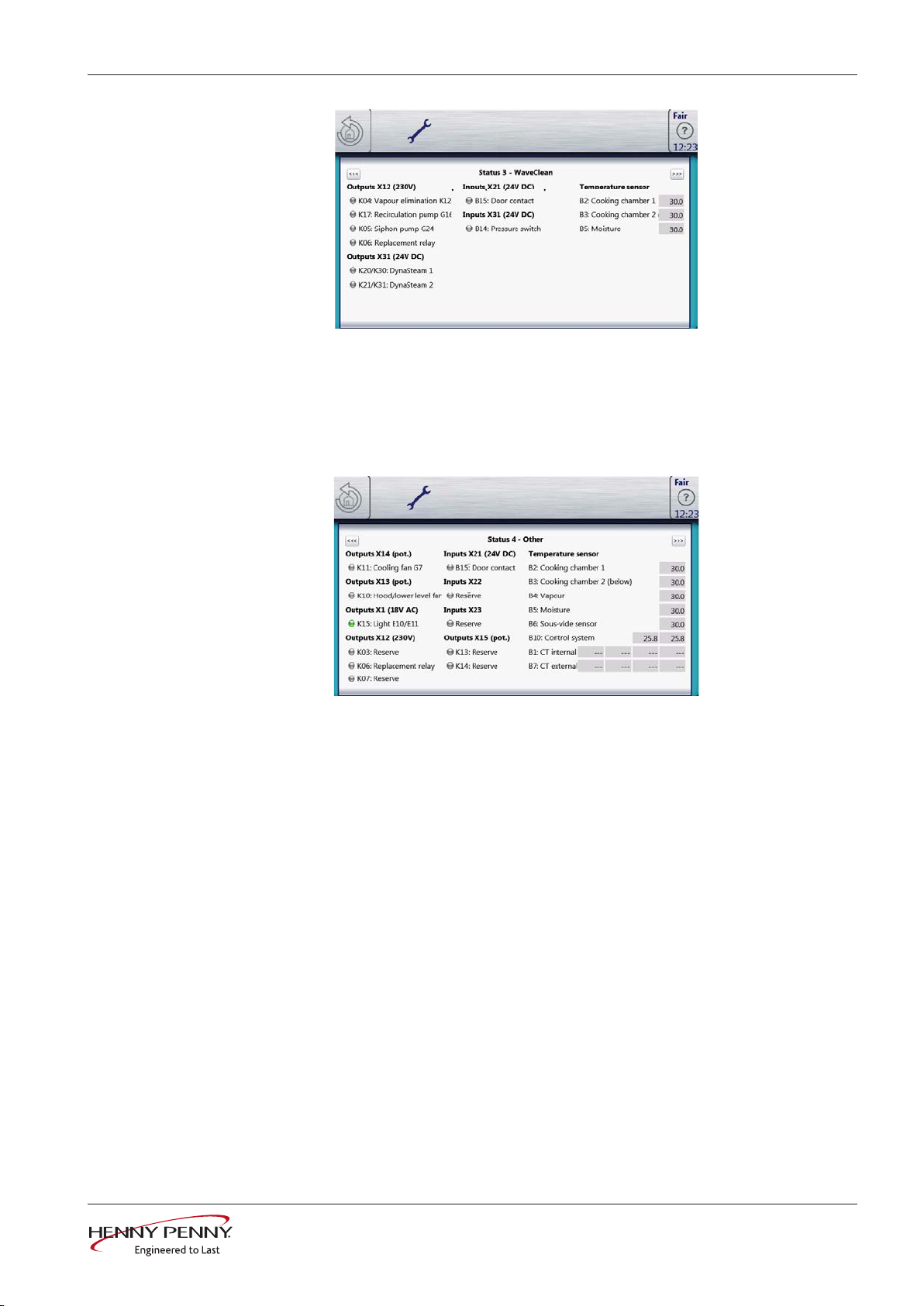

Status 3

WaveClean

Status 4

Service menu - appliance test

K04 Magnetic valve for water vapor elimination & siphon filling

B15 Reed contact switch

B14 Pressure switch on the DynaSteam unit

B3 Bottom cooking chamber sensor. Only present in 20.x pedestal unit

Miscellaneous

K10 Activation for optional condensation hood

B15 Reed contact switch

K03, K07 Not in use

K13, K14 Not in use

B3 Bottom cooking chamber sensor. Only present in 20.x pedestal unit

FM05-16--

29Service instructions

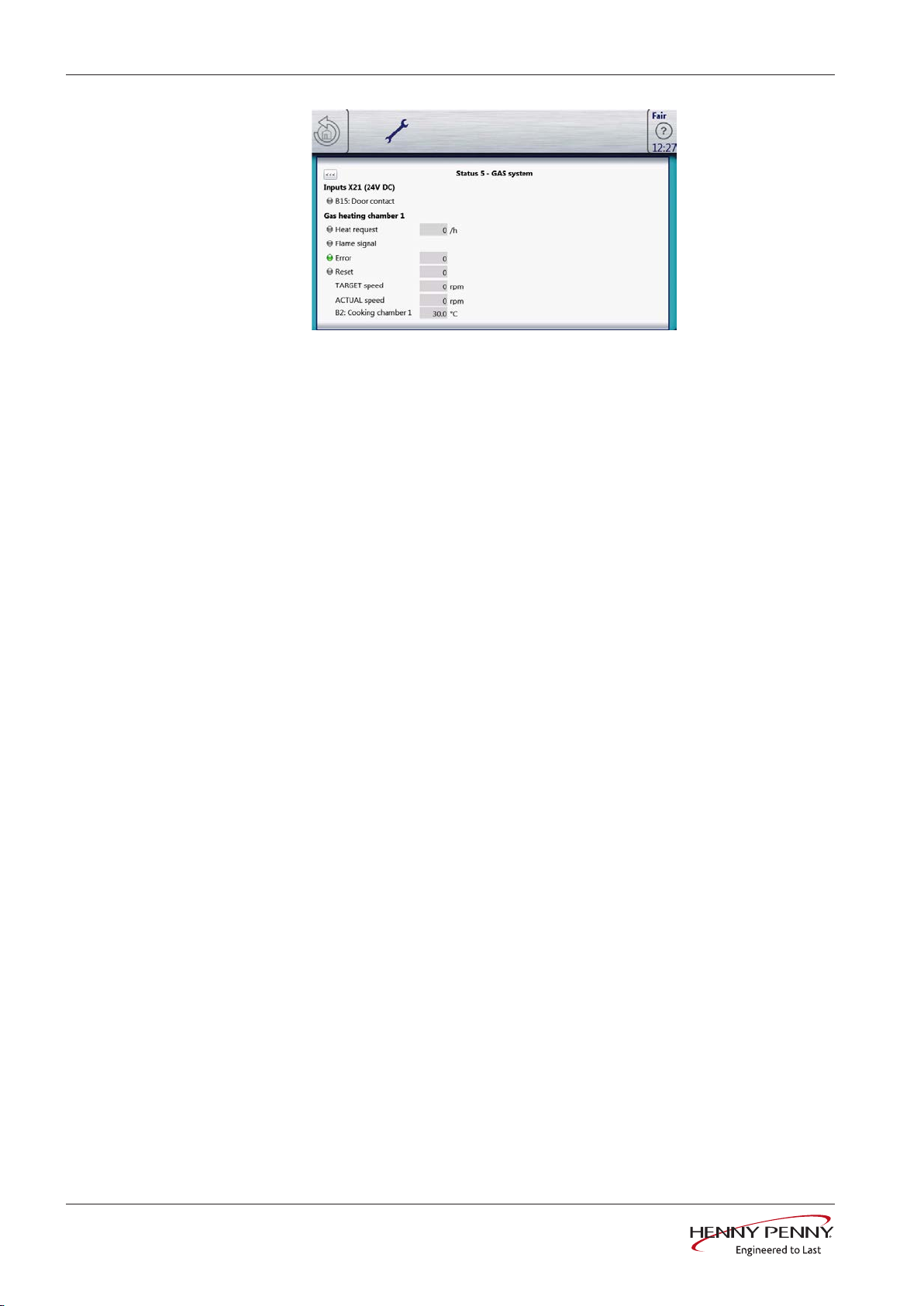

Service menu - appliance test

Status 5

Gas system

B15 Reed contact switch

Chamber 1 Top heating system

Chamber 2 Bottom heating system. Only present in 20.x pedestal unit

Flame signal Flame was detected by ionization electrode / ignition

electronics.

Error LED green if error was reported by the ignition electronics and

error number in the last hour.

Reset LED green if reset signal is sent by the I/O board to the ignition

electronics and error number in the last hour.

30 Service instructions

FM05-16--

Loading...

Loading...