Page 1

Page 2

This excerpt for the Model 500 and 600 Pressure Fryer service manual provides additional

information related to product numbers 02213, 01208, and 02502 Computron 7000. This excerpt

covers the programming, operation, and troubleshooting for the computer control. All other

information not related to the computer control is contained in the pressure fryer service manual.

Revised 7-96

Page 3

Henny Penny

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten

(10) days after installation.

REPLACEMENT PARTS:

be defective in material or workmanship within ninety (90) days from date of original installation will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a

new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal

sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves to

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE

AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE

LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Page 4

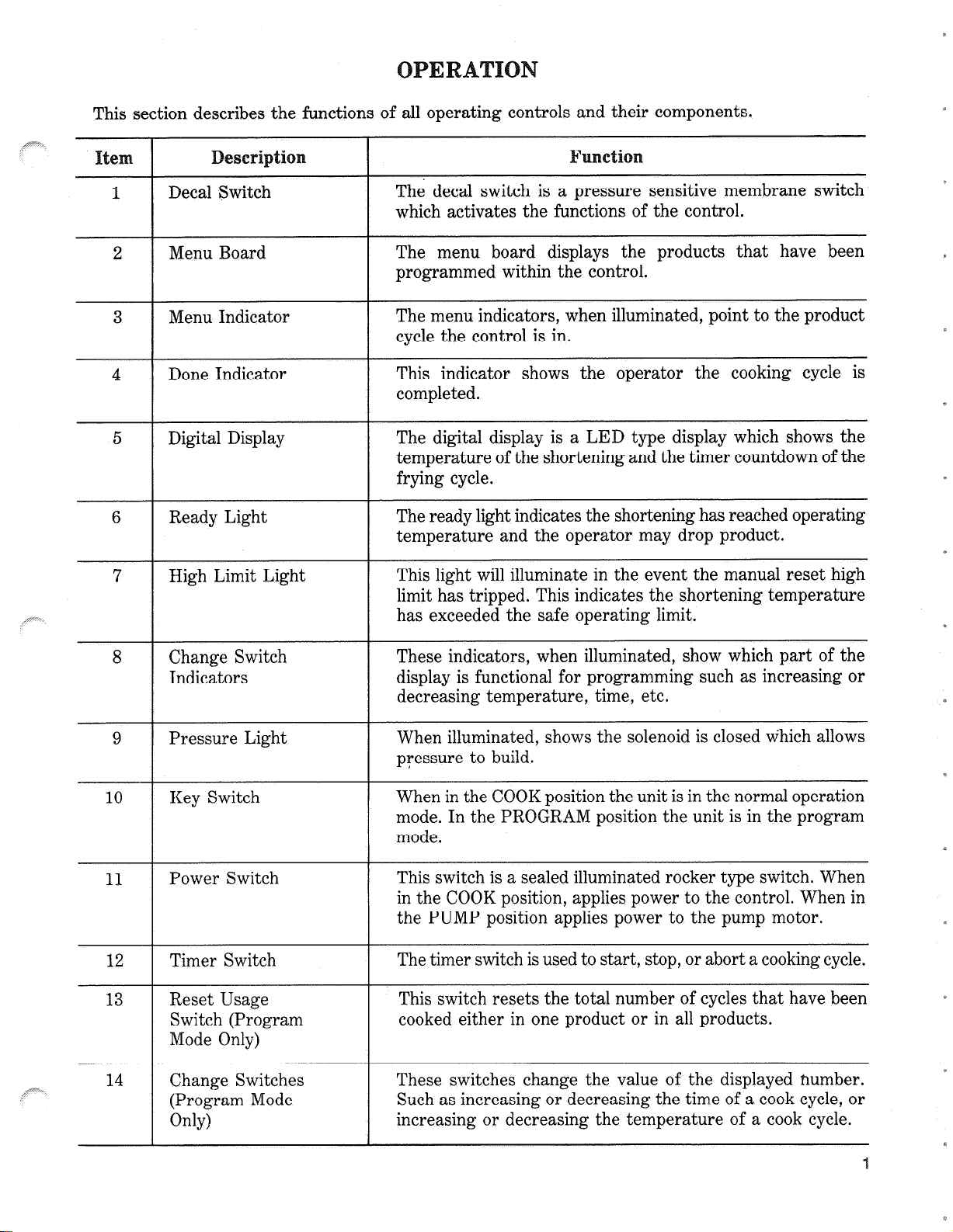

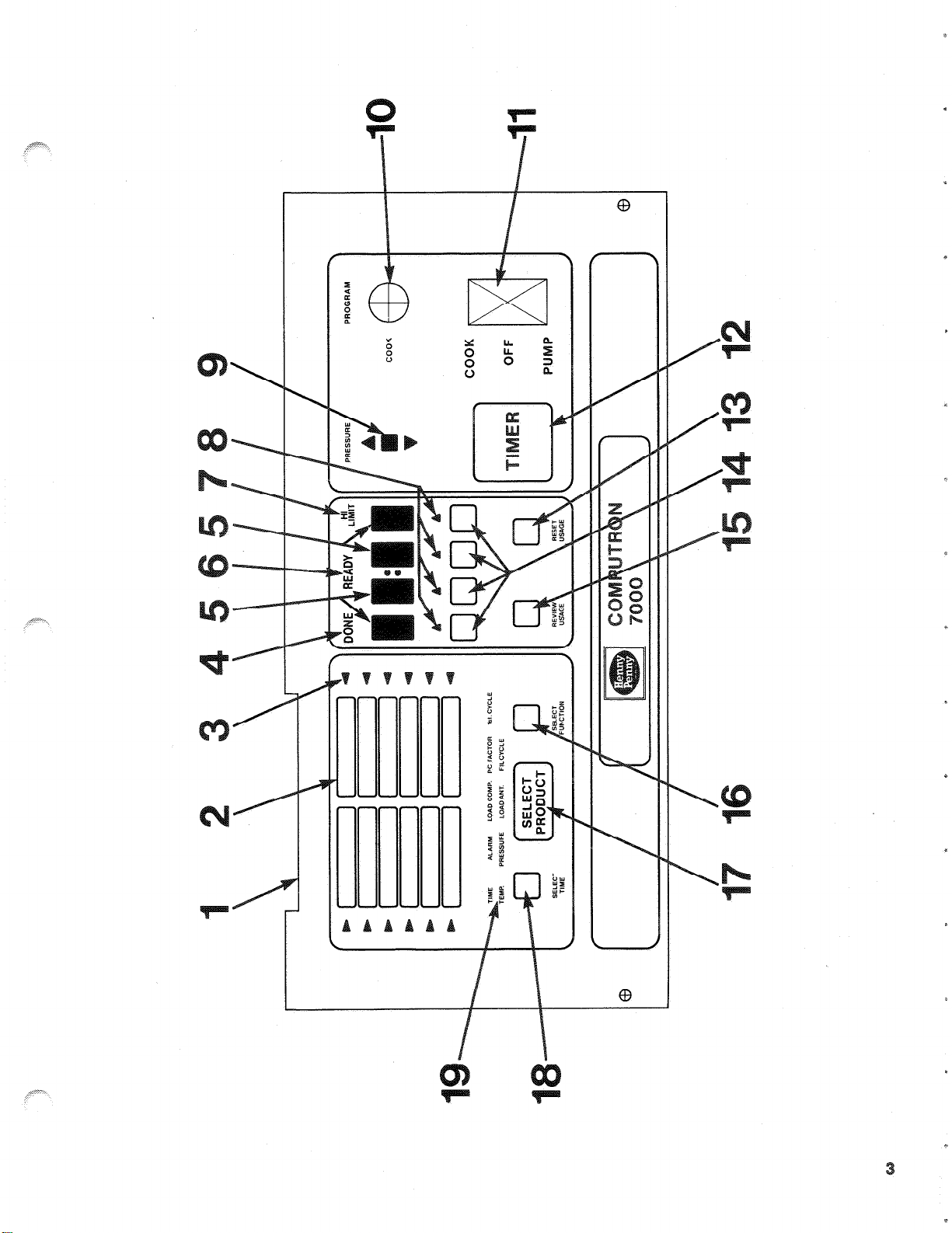

This section describes the functions of all operating controls and their components.

i’--

escri

Decal Switch

The decal switch is a pressure sensitive membrane switch

eti

which activates the functions of the control.

2 Menu Board

The menu board displays the products that have been

programmed within the control.

3

Menu Indicator

The menu indicators, when illuminated, point to the product

cycle the control is in.

4

Done Indicator

This indicator shows the operator the cooking cycle is

completed.

5 Digital Display The digital display is a LED type display which shows the

temperature of the shortening and the timer countdown of the

frying cycle.

6 Ready Light

The ready light indicates the shortening has reached operating

temperature and the operator may drop product.

7

High Limit Light

This light will illuminate in the event the manual reset high

limit has tripped. This indicates the shortening temperature

has exceeded the safe operating limit.

~>.dT . .

8

9

10

11

12

13

14

Change Switch

Indicators

Pressure Light

Key Switch

Power Switch

Timer Switch

Reset Usage

Switch (Program

Mode Only)

Change Switches

(Program Mode

Only)

These indicators, when illuminated, show which part of the

display is functional for programming such as increasing or

decreasing temperature, time, etc.

When illuminated, shows the solenoid is closed which allows

pressure to build.

When in the COOK position the unit is in the normal operation

mode. In the PROGRAM position the unit is in the program

mode.

This switch is a sealed illuminated rocker type switch. When

in the COOK position, applies power to the control. When in

the PUMP position applies power to the pump motor.

The timer switch is used to start, stop, or abort a cooking cycle.

This switch resets the total number of cycles that have been

cooked either in one product or in all products.

These switches change the value of the displayed number.

Such as increasing or decreasing the time of a cook cycle, or

increasing or decreasing the temperature of a cook cycle.

Page 5

of cook cycles that have been cooked for a particular product.

16

Select Function

Switch (Program

Mode Only)

17

Select Product

Switch

18

Select Time

Switch

19

Function Display

(Program Mode

Only)

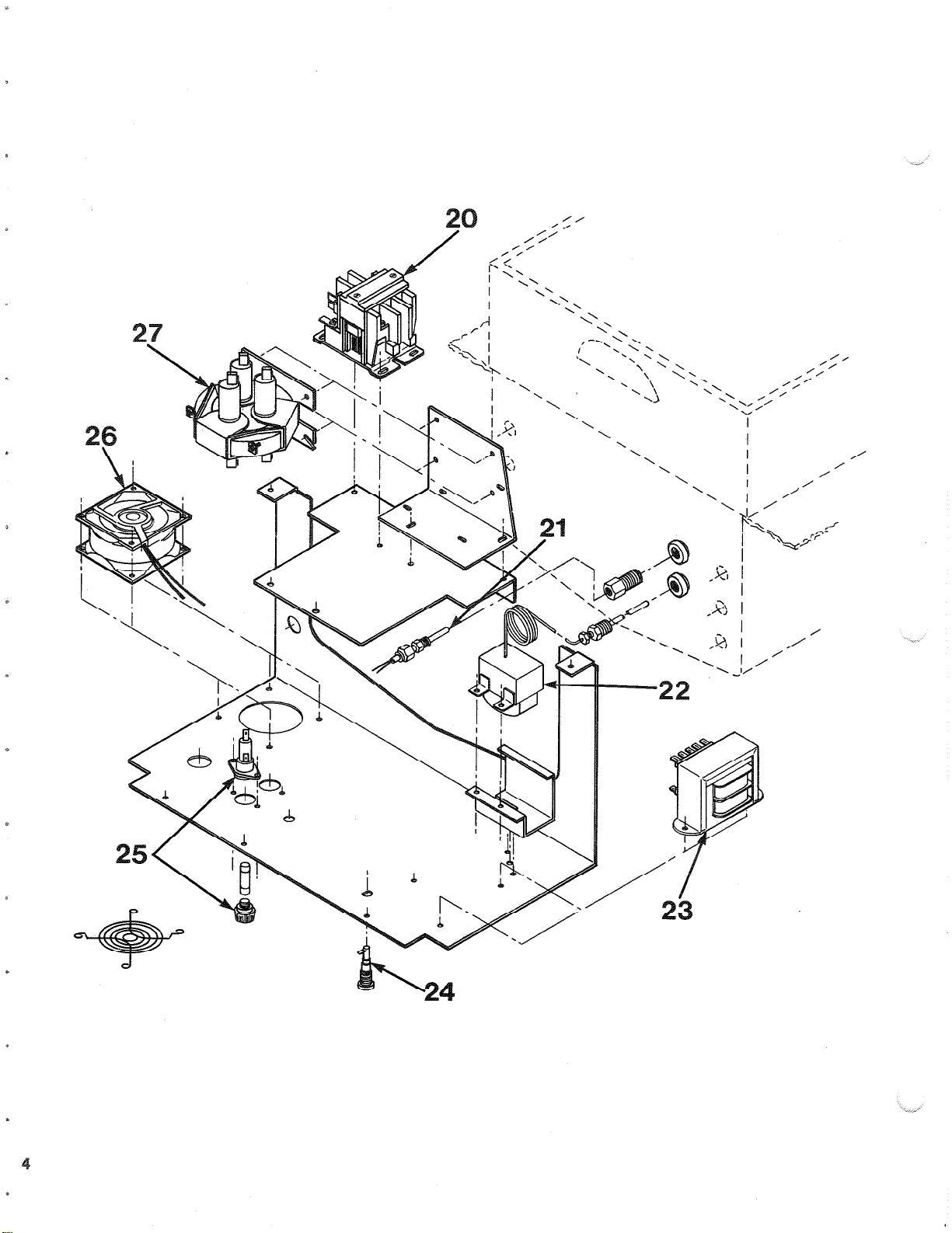

20127 Primary and

Secondary

Contactor

21

22

Thermal Sensor

High Limit

Thermostat

This switch will change the function that is being programmed

such as time, temperature, alarm, etc.

This switch selects the product you wish to cook or program.

The select time switch selects the interval within a product.

There are ten intervals per product.

The function display will show you the function you are in

when programming.

The contactors are relays that route power to the heating

elements. The primary relay coil is in series with the high

temperature control and the secondary relay coil is in series

with the heat control circuit.

The thermal sensor determines the shortening temperature.

The high limit thermostat is a manual reset control that senses

the shortening temperature in the event the temperature

exceeds the safe operating limit.

23

Transformer The transformer is a step down type transformer. It converts

24125 I Fuses

26

Fan

Back-Up High

Limit Thermostat

(Not Shown)

high voltage to lower voltage.

The fuses provide an overload protection for the control panel.

I

The fan’s function is to eliminate any heat build up inside the

control panel area.

This is a back-up high limit thermostat in the event the

temperature exceeds the safe operating limit.

Page 6

. . . . SF--.‘

Page 7

/

Page 8

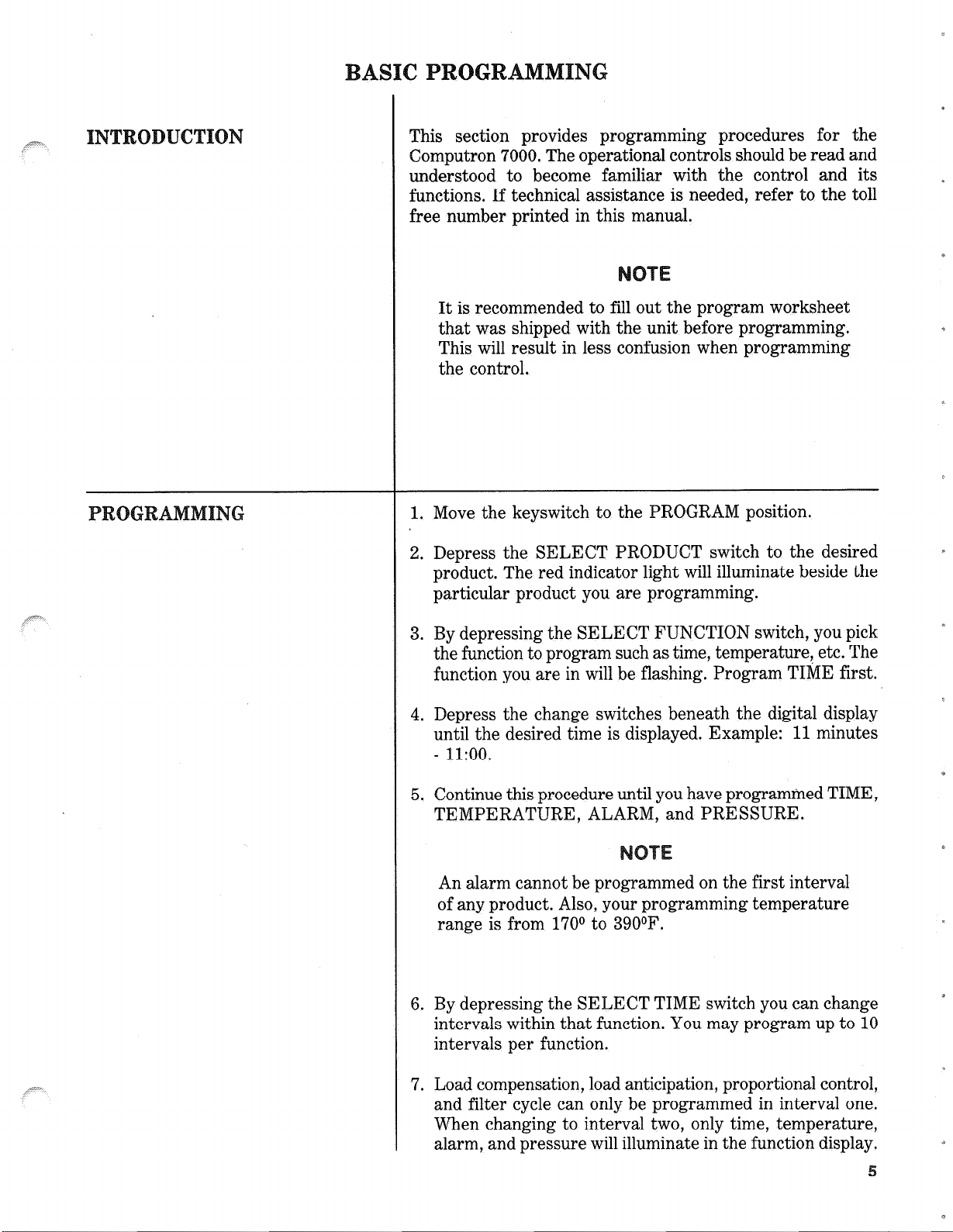

This section provides programming procedures for the

Computron 7000. The operational controls should be read and

understood to become familiar with the control and its

functions. If technical assistance is needed, refer to the toll

free number printed in this manual.

It is recommended to fill out the program worksheet

that was shipped with the unit before programming.

This will result in less confusion when programming

the control.

1. Move the keyswitch to the PROGRAM position.

2. Depress the SELECT PRODUCT switch to the desired

product. The red indicator light will illuminate beside the

particular product you are programming.

3. By depressing the SELECT FUNCTION switch, you pick

the function to program such as time, temperature, etc. The

function you are in will be flashing. Program TIME first.

4. Depress the change switches beneath the digital display

until the desired time is displayed. Example: 11 minutes

- 11:oo.

5. Continue this procedure until you have programmed TIME,

TEMPERATURE, ALARM, and PRESSURE.

An alarm cannot be programmed on the first interval

of any product. Also, your programming temperature

range is from 170° to 390OF.

6. By depressing the SELECT TIME switch you can change

intervals within that function. You may program up to 10

intervals per function.

7. Load compensation, load anticipation, proportional control,

and filter cycle can only be programmed in interval one.

When changing to interval two, only time, temperature,

alarm, and pressure will illuminate in the function display.

Page 9

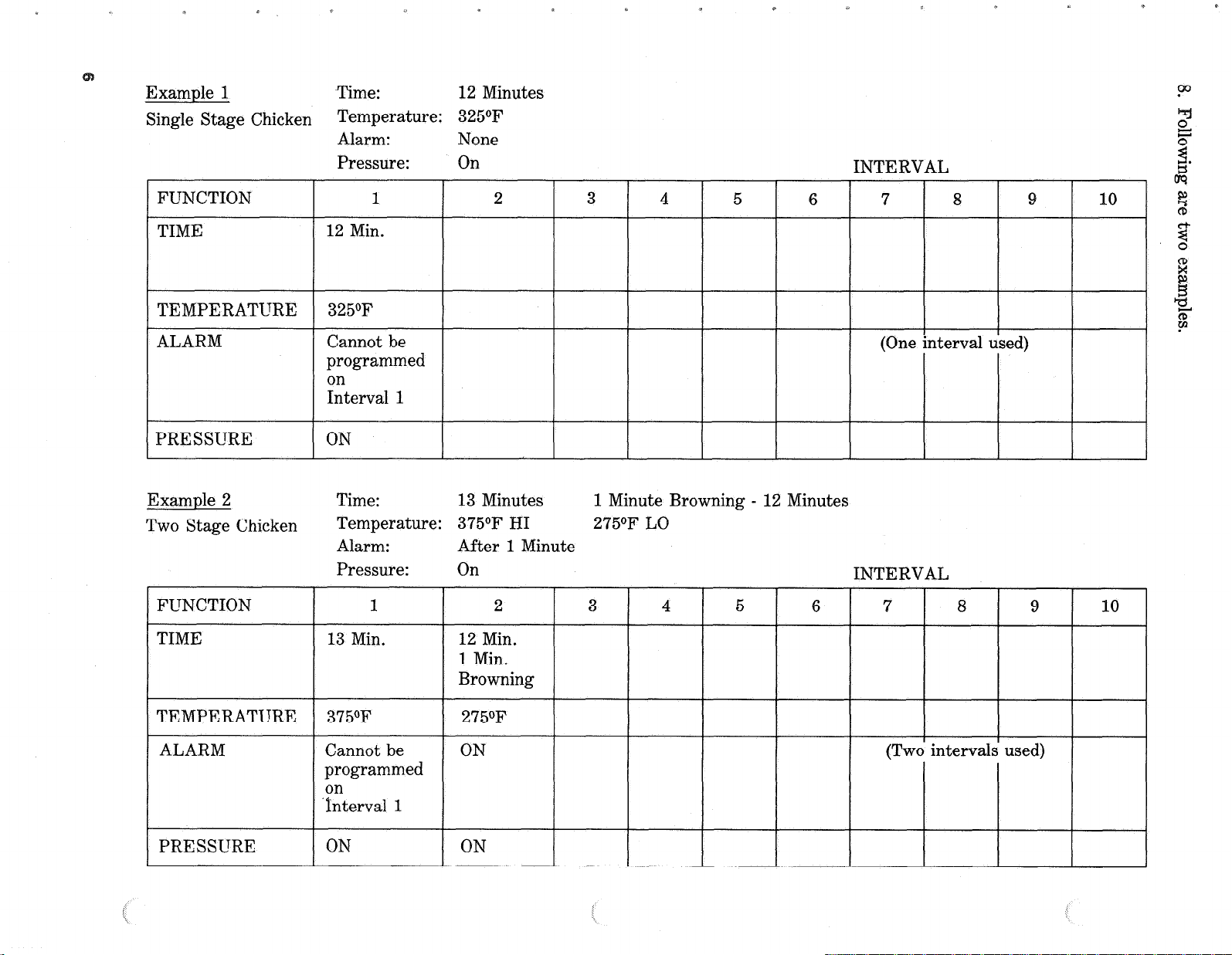

Example 1

Time:

12 Minutes

Single Stage Chicken Temperature: 325’F

Alarm: None

Pressure: On

INTERVAL

FUNCTION FUNCTION 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 9 9 10 10

TIME TIME 12 Min. 12 Min.

TEMPERATURE TEMPERATURE 325OF 325OF

ALARM ALARM

PRESSURE PRESSURE

Example 2

Two Stage Chicken

FUNCTION

TIME

TEMPERATURE

ALARM

Cannot be Cannot be

(One interval used) (One interval used)

programmed programmed

;)iYterval ;)iYterval 1 1

ON ON

Time: 13 Minutes 1 Minute Browning - 12 Minutes

Temperature: 375OF HI 275OF LO

Alarm: After 1 Minute

Pressure: On

INTERVAL

1 2 3 4 5 6 7 8 9 10

13 Min. 12 Min.

1 Min.

Browning

375OF

275OF

Cannot be ON (Two intervals used)

programmed

PRESSURE

Gerval 1

ON

ON

Page 10

NS

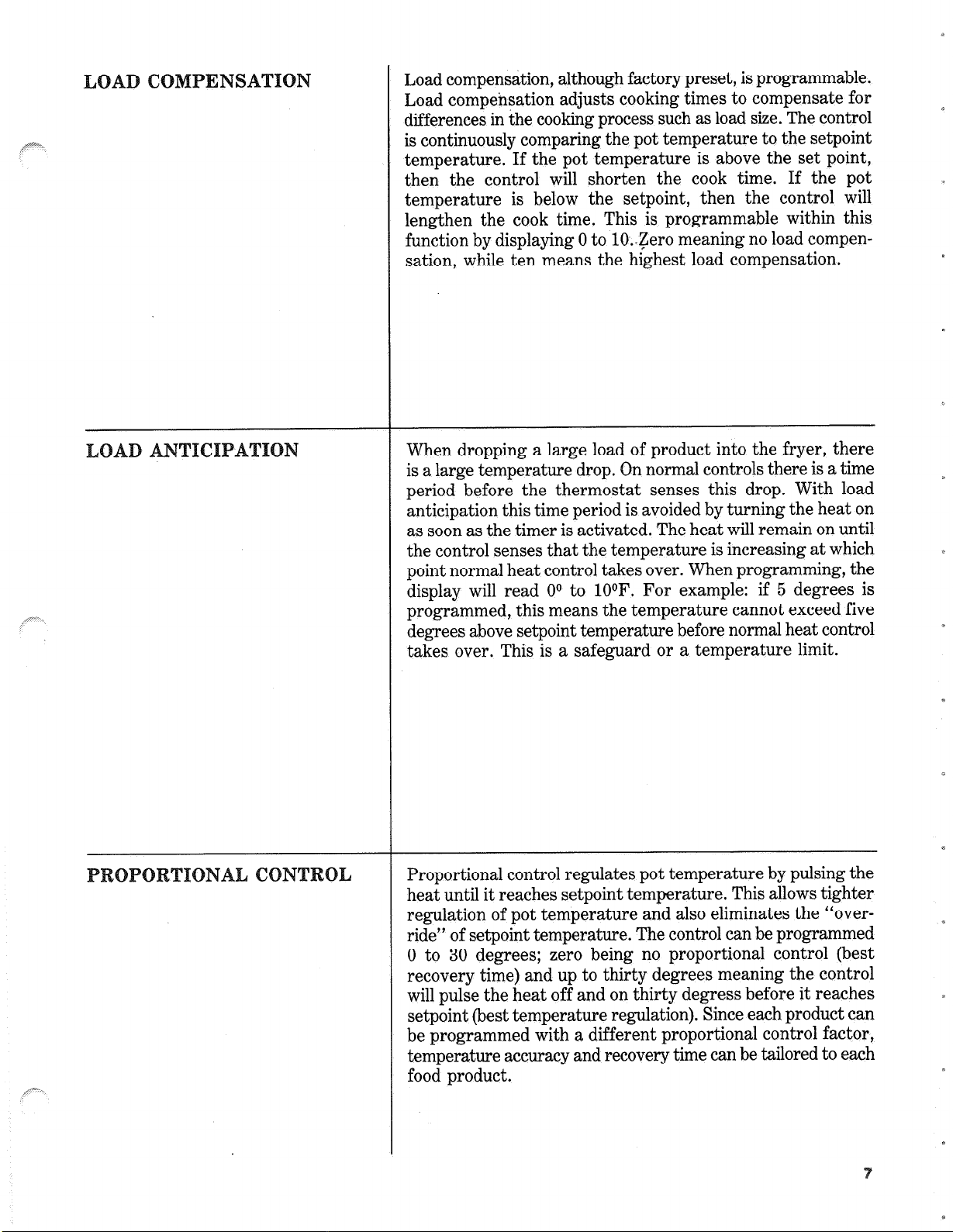

Load compensation, although factory preset, is programmable.

Load compensation adjusts cooking times to compensate for

differences in the cooking process such as load size. The control

is continuously comparing the pot temperature to the setpoint

temperature. If the pot temperature is above the set point,

then the control will shorten the cook time. If the pot

temperature is below the setpoint, then the control will

lengthen the cook time. This is programmable within this

function by displaying 0 to lO..qero meaning no load compensation, while ten means the highest load compensation.

When dropping a large load of product into the fryer, there

is a large temperature drop. On normal controls there is a time

period before the thermostat senses this drop. With load

anticipation this time period is avoided by turning the heat on

as soon as the timer is activated. The heat will remain on until

the control senses that the temperature is increasing at which

point normal heat control takes over. When programming, the

display will read 00 to lOOF. For example: if 5 degrees is

programmed, this means the temperature cannot exceed five

degrees above setpoint temperature before normal heat control

takes over. This is a safeguard or a temperature limit.

Proportional control regulates pot temperature by pulsing the

heat until it reaches setpoint temperature. This allows tighter

regulation of pot temperature and also eliminates the “override” of setpoint temperature. The control can be programmed

0 to 30 degrees; zero being no proportional control (best

recovery time) and up to thirty degrees meaning the control

will pulse the heat off and on thirty degress before it reaches

setpoint (best temperature regulation). Since each product can

be programmed with a different proportional control factor,

temperature accuracy and recovery time can be tailored to each

food product.

c

Page 11

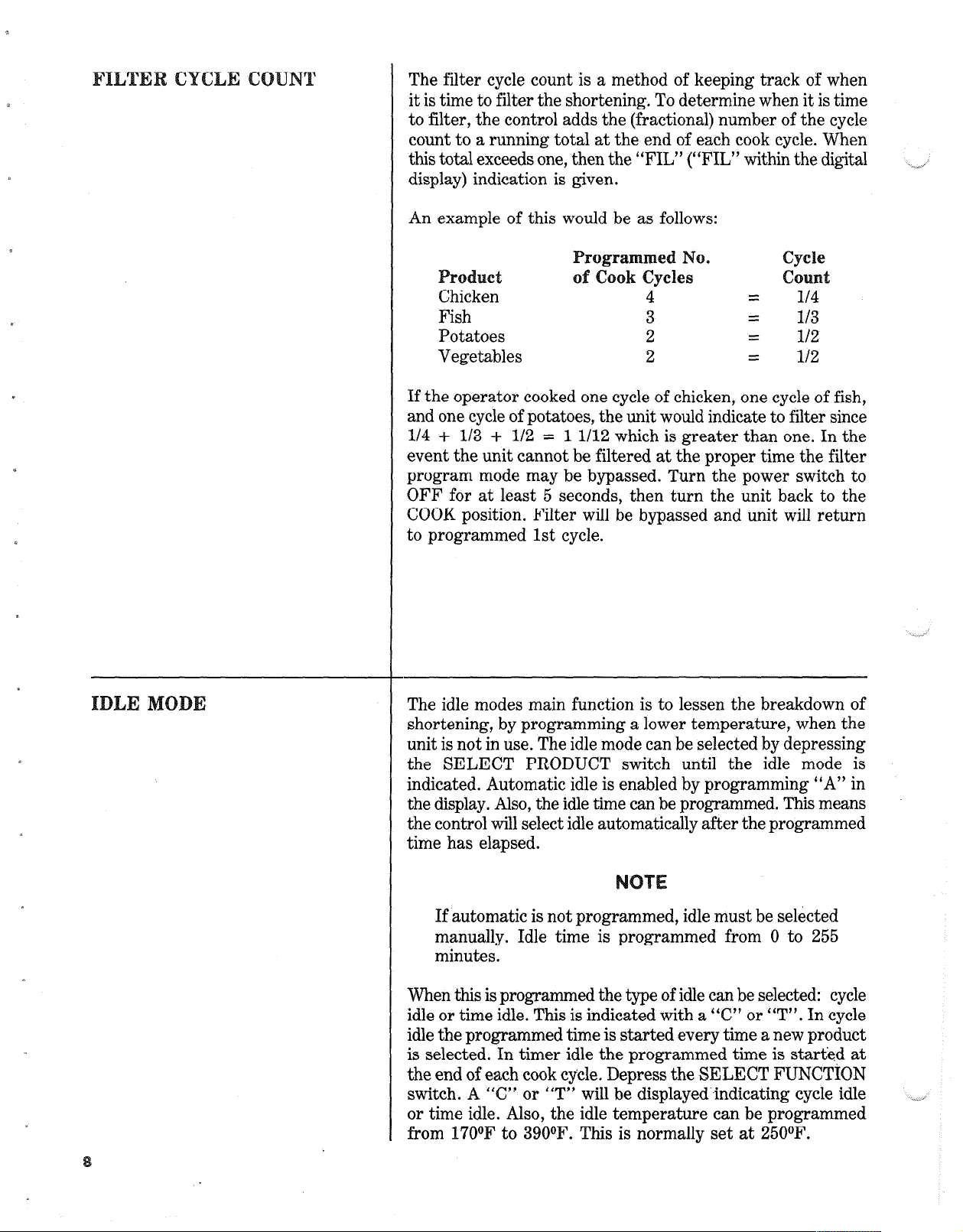

The filter cycle count is a method of keeping track of when

N

it is time to filter the shortening. To determine when it is time

to filter, the control adds the (fractional) number of the cycle

count to a running total at the end of each cook cycle. When

this total exceeds one, then the “FIL” (“FIL” within the digital

_,

display) indication is given.

An example of this would be as follows:

et

Chicken

Fish

Potatoes

Vegetables

If the operator cooked one cycle of chicken, one cycle of fish,

and one cycle of potatoes, the unit would indicate to filter since

114 I- l/3 + l/2

= 1 l/12 which is greater than one. In the

event the unit cannot be filtered at the proper time the filter

program mode may be bypassed. Turn the power switch to

OFF for at least 5 seconds, then turn the unit back to the

COOK position. Filter will be bypassed and unit will return

to programmed 1st cycle.

The idle modes main function is to lessen the breakdown of

shortening, by programming a lower temperature, when the

unit is not in use. The idle mode can be selected by depressing

the SELECT PRODUCT switch until the idle mode is

indicated. Automatic idle is enabled by programming “A” in

the display. Also, the idle time can be programmed. This means

the control will select idle automatically after the programmed

time has elapsed.

If automatic is not programmed, idle must be selected

manually. Idle time is programmed from 0 to 255

minutes.

When this is programmed the type of idle can be selected:

cycle

idle or time idle. This is indicated with a “6” or “T”. In cycle

idle the programmed time is started every time a new product

is selected. In timer idle the programmed time is started at

the end of each cook cycle. Depress the SELECT FUNCTION

switch. A “C” or “T” will be displayed’indicating cycle idle

or time idle. Also, the idle temperature can be programmed

from 170°F to 3900F. This is normally set at 250OF.

__

Page 12

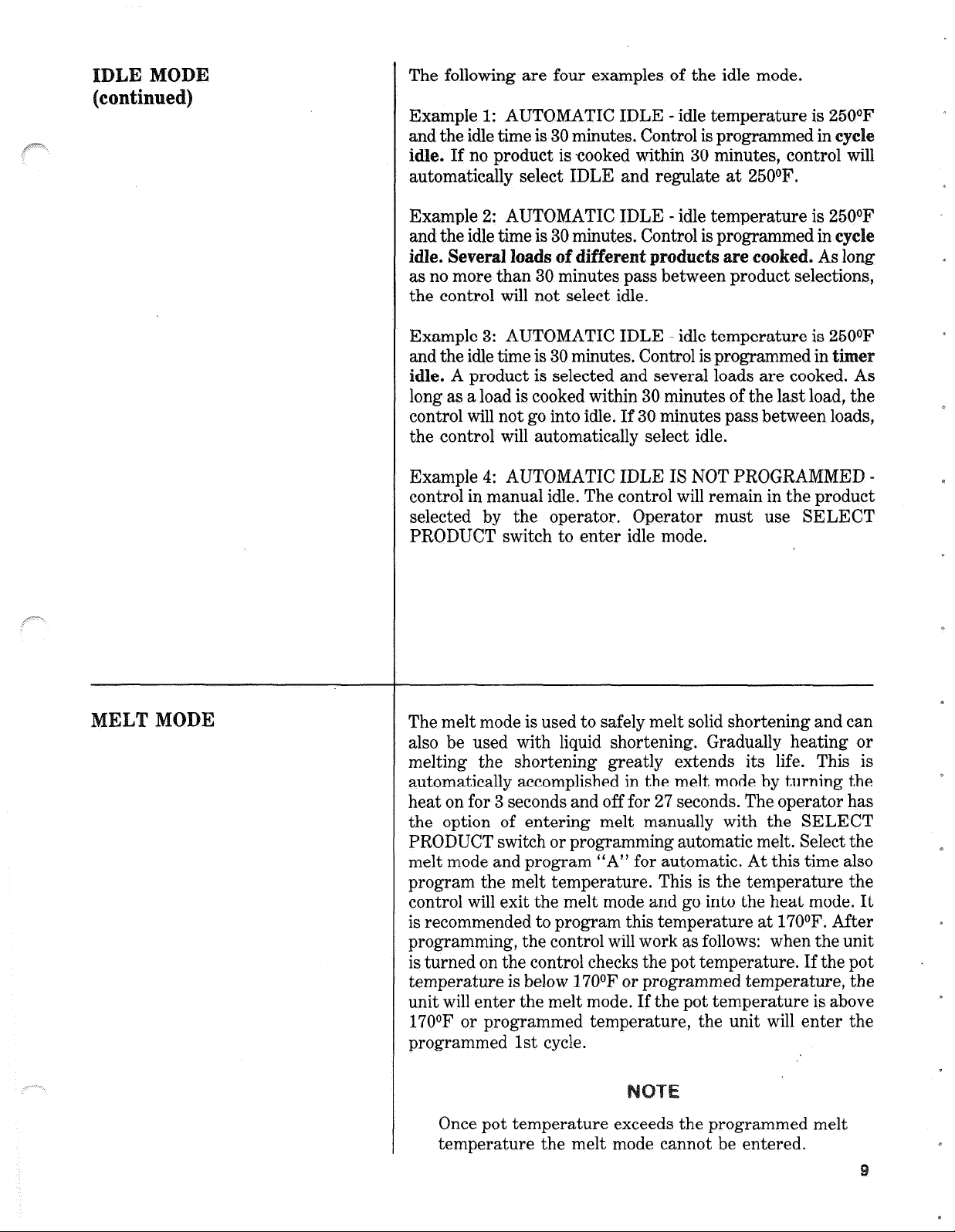

The following are four examples of the idle mode.

Example 1: AUTOMATIC IDLE - idle temperature is 250’JF

and the idle time is 30 minutes. Control is programmed in eye

idle. If no product is cooked within 30 minutes, control will

automatically select IDLE and regulate at 250OF.

Example 2: AUTOMATIC IDLE - idle temperature is 250°F

and the idle time is 30 minutes. in

idle. Several loads of differen

A

as no more than 30 minutes pass between product selections,

the control will not select idle.

Example 3: AUTOMATIC IDLE - idle temperature is 250°F

and the idle time is 30 minutes. Control is programmed in time

le. A product is selected and several loads are cooked. As

long as a load is cooked within 30 minutes of the last load, the

control will not go into idle. If 30 minutes pass between loads,

the control will automatically select idle.

Example 4: AUTOMATIC IDLE IS NOT PROGRAMMED control in manual idle. The control will remain in the product

selected by the operator. Operator must use SELECT

PRODUCT switch to enter idle mode.

The melt mode is used to safely melt solid shortening and can

also be used with liquid shortening. Gradually heating or

melting the shortening greatly extends its life. This is

automatically accomplished in the melt mode by turning the

heat on for 3 seconds and off for 27 seconds. The operator has

the option of entering melt manually with the SELECT

PRODUCT switch or programming automatic melt. Select the

melt mode and program “A” for automatic. At this time also

program the melt temperature. This is the temperature the

control will exit the melt mode and go into the heat mode. It

is recommended to program this temperature at 170OF. After

programming, the control will work as follows: when the unit

is turned on the control checks the pot temperature. If the pot

temperature is below 1 70°F or programmed temperature, the

unit will enter the melt mode. If the pot temperature is above

1700F or programmed temperature, the unit will enter the

programmed 1 st cycle.

Once pot temperature exceeds the programmed melt

temperature the melt mode cannot be entered.

Page 13

While in the melt mode, the first cycle can also be pro

This is the cycle the control will automatically select when in

COOK upon exiting the melt mode. It is programmed

ing the melt mode and depressing the SELECT FU

switch. The green 1st cycle light will flash and the temperature

light in the function display will be on. The left half of the

product display are numbered from top to botto

right half are numbered 7 to 10. Melt and

numbered. However, idle can be selected as th

number one of the product display is desired as first cycle,

program a number one. If number eight of the product display

is desired, program number eight.

An unprogrammed product cycle cannot be selected as

the first cycle.

The one button programming feature is a simple way for the

operator to place Henny Penny’s cooking parameters into the

control’s memory. These programmed cooking cycles are

matched with the menu item cards sent with each unit. To

achieve this one button programming, follow these steps:

1. Turn the COOK/PROGRAM keyswitch to the PROGRAM

position.

2. Depress the TIMER switch. This will put you into the

Special Program Mode. The display will read “SP”.

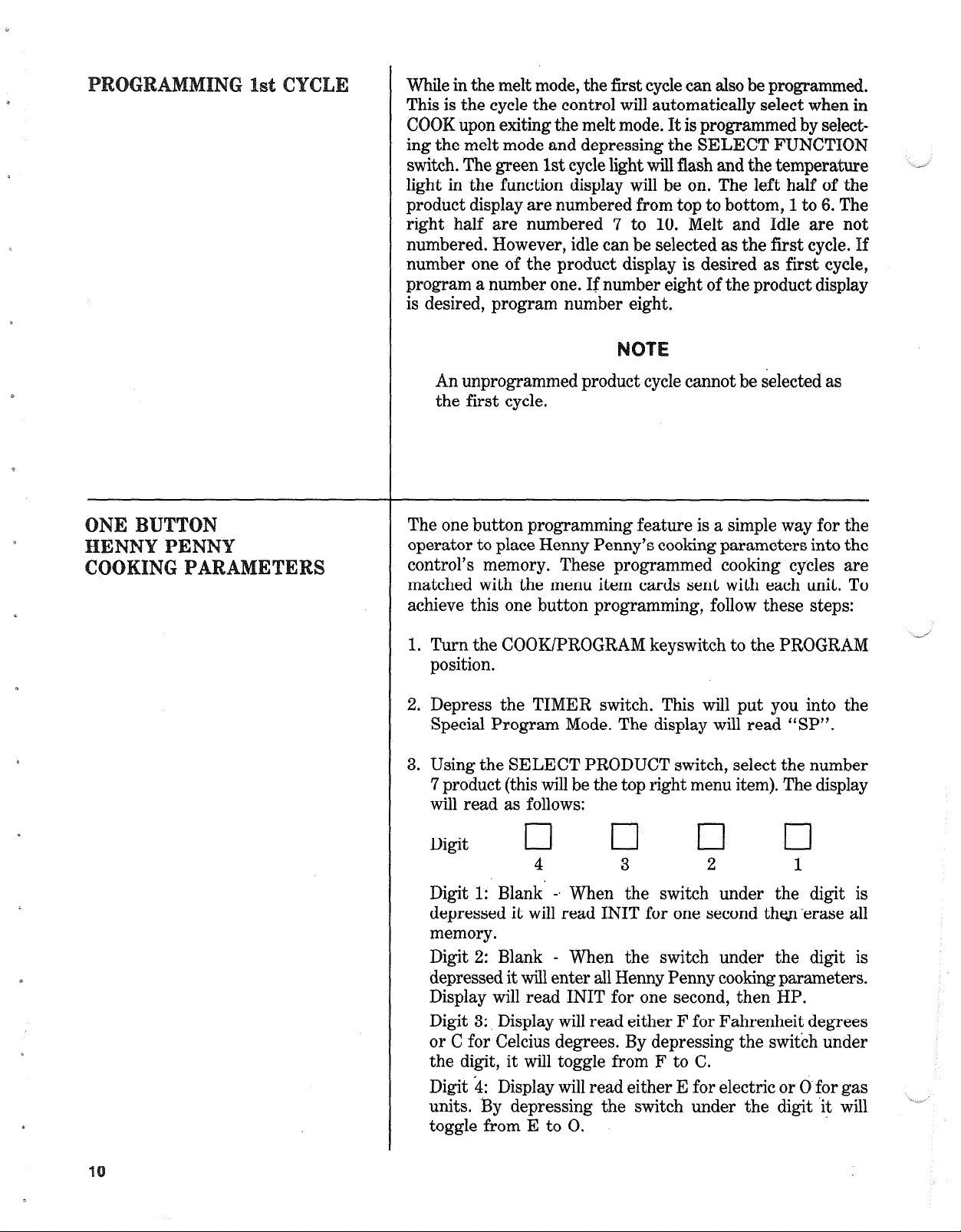

3. Using the SELECT PRODUCT switch, select the number

7 product (this will be the top right menu item). The display

will read as follows:

Digit

Digit 1: Blank’ -’ When the switch under the digit is

depressed it will read INIT for one second then ‘erase all

memory.

Digit 2: Blank - When the switch under the digit is

depressed it will enter all Henny Penny cooking parameters.

Display will read INIT for one second, then HP.

Digit 3: Display will read either F for Fahrenheit degrees

or C for Celcius degrees. By depressing the switch under

the digit, it will toggle from F to C.

Digit ‘4: Display will read either E for electric or 0 for gas

units. By depressing the switch under the digit ‘it will

toggle from E to 0.

q q q 0

4 3

2

1

Page 14

This feature will aid the operator in the event there is a power

outage. If the control is timing down and the power supply

is interrupted for any reason, the control will not reset to the

original cook cycle time, When power is restored, the control

will resume timing at the point the power was interrupted,

allowing the operator to know what time is needed to finish

cooking that particular’ load of product.

The unit has a boil out mode which is factory pre-programmed.

To enter the boil out mode, follow the instructions below.

1. Place keyswitch in the COOK position.

2. Depress the SELECT PRODUCT switch and select either

IDLE or MELT.

3. Depress the TIMER switch.

4. Display will read Y for yes or N for no.

5. If you desire to enter the boil out mode, depress the switch

below Y. Control will heat to factory’s pre-programmed boil

out temperature.

6. If, for any reason, you do not wish to enter boil out

mode, depress the switch under N.

7. After boil out is complete, turn power switch to the OFF

position and drain contents from unit.

R TO CLEAN. Leave

lid open. Water under pressure is super heated and will

cause severe burns if it comes in contact with skin.

Page 15

1 1. Be sure keyswitch is in the CO

~ 2. Turn the power switch to the cook position.

3. Select desired product using the SELECT P

switch. The red indicator will be illuminated beside

product.

4. Be sure ready light is illuminated indicating pot

temperature is up to setpoint temperature.

5. Place the empty basket into the shortening.

6. Place the product into the submerged basket, large pieces

first.

7. Lift the basket slightly out of the shortening and shake

it. This will cause the pieces to separate, eliminating white

spots.

8. Remove basket handle. Close and latch the lid.

9. Tighten spindle in clockwise rotation aligning red ball on

the spindle with red ball on lid latch.

-..*

10. Depress timer switch. This will start the cook cycle and

countdown of timer.

11. At the end of the cook cycle the DONE light will illuminate

and the buzzer will sound.

12. Depress timer switch to turn buzzer off.

13. After all pressure has been released, (pressure gauge reads

0) turn lid spindle counterclockwise as faras possible and

open lid.

14. Insert basket handle, lift basket out of shortening and rest

the basket on the side of pot rim to allow product to drain.

15. Place product on bun pan and place in holding cabinet.

, --_

Page 16

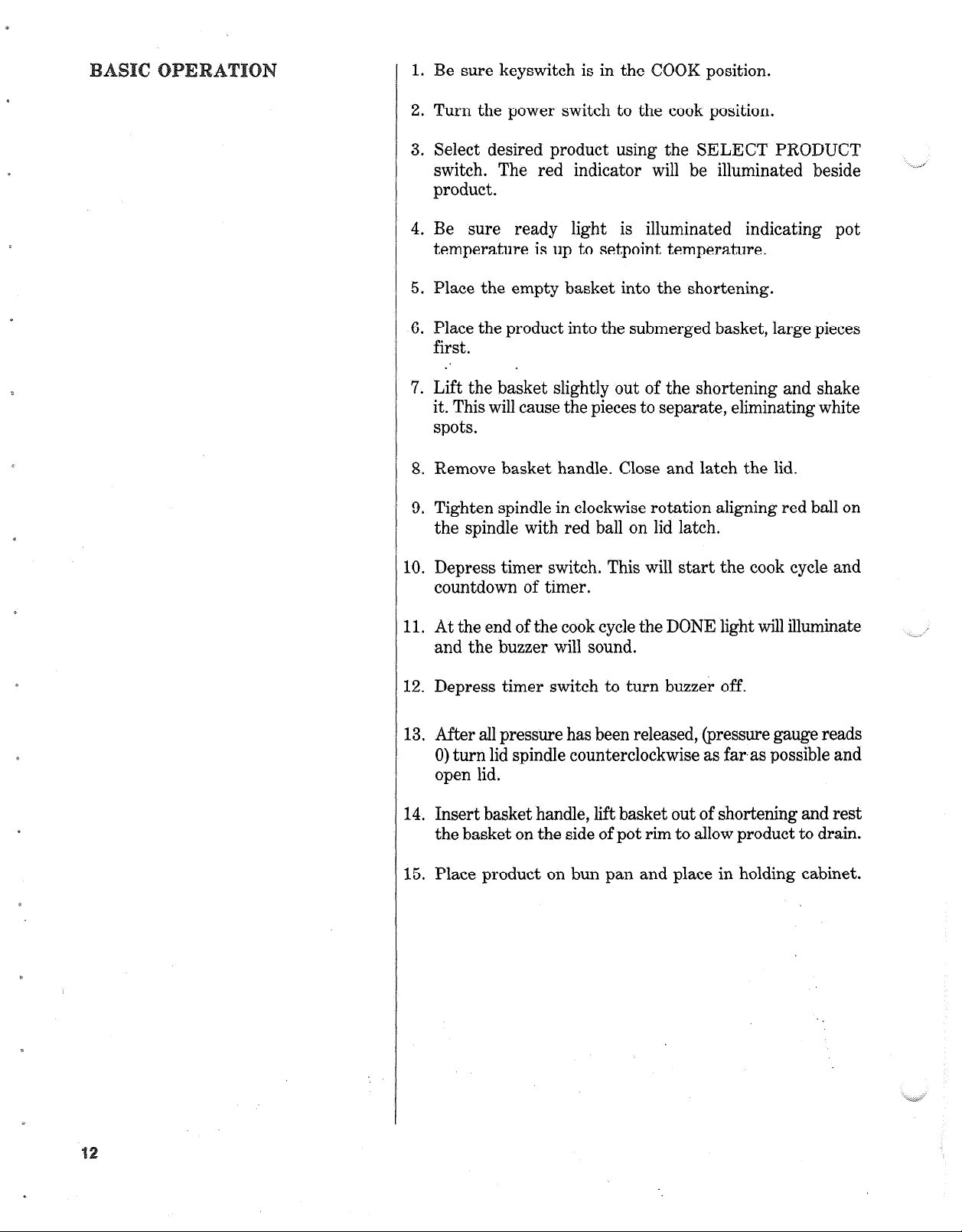

he food preparation procedures, cooking times, temperatures and other parameter settings provided

d

are suggestions to be used as starting points when establishing your specific cooking procedures.

Parameter settings for time, temperature, alarm, pressure, load compensation, load anticipation, PC factor

and filter cycle may need to be adjusted to produce food products more suitable for your application.

:

Chicken, 8 or 9 piece cut.

314 pounds each:.

: 2 - 14 pounds, approximately 1 - 4 head of chicken.

Please refer to section on cut-up fried chicken.

*Increase time to 11:30 or load

Do not exceed 4 head.

: Chicken nuggets (frozen).

- 6 pounds*.

:2

*Do not cook larger loads as nuggets will tend to stick together.

compensation to 9 or 10 if

INTERVALS

NOTES: Set load compensation from 7 - 10 if individual size of

chickens varies or if total weight of loads varies from 2 -

14 pounds (l-

if total weight of load and individual size of chickens is

. consistent or seldom varies.

frying

4 head). Set load compensation at 5 or less

2-314

- 3 pound chickens.

FUNCTION

TIME

TEMP.

ALARM

PRESSURE

1 LOAD COMP. 1 7 1

1

4:oo

325

ON

ILOADANT.1

2

INTERVALS

3 4 5

NOTES:

6 7 8

9

10

Page 17

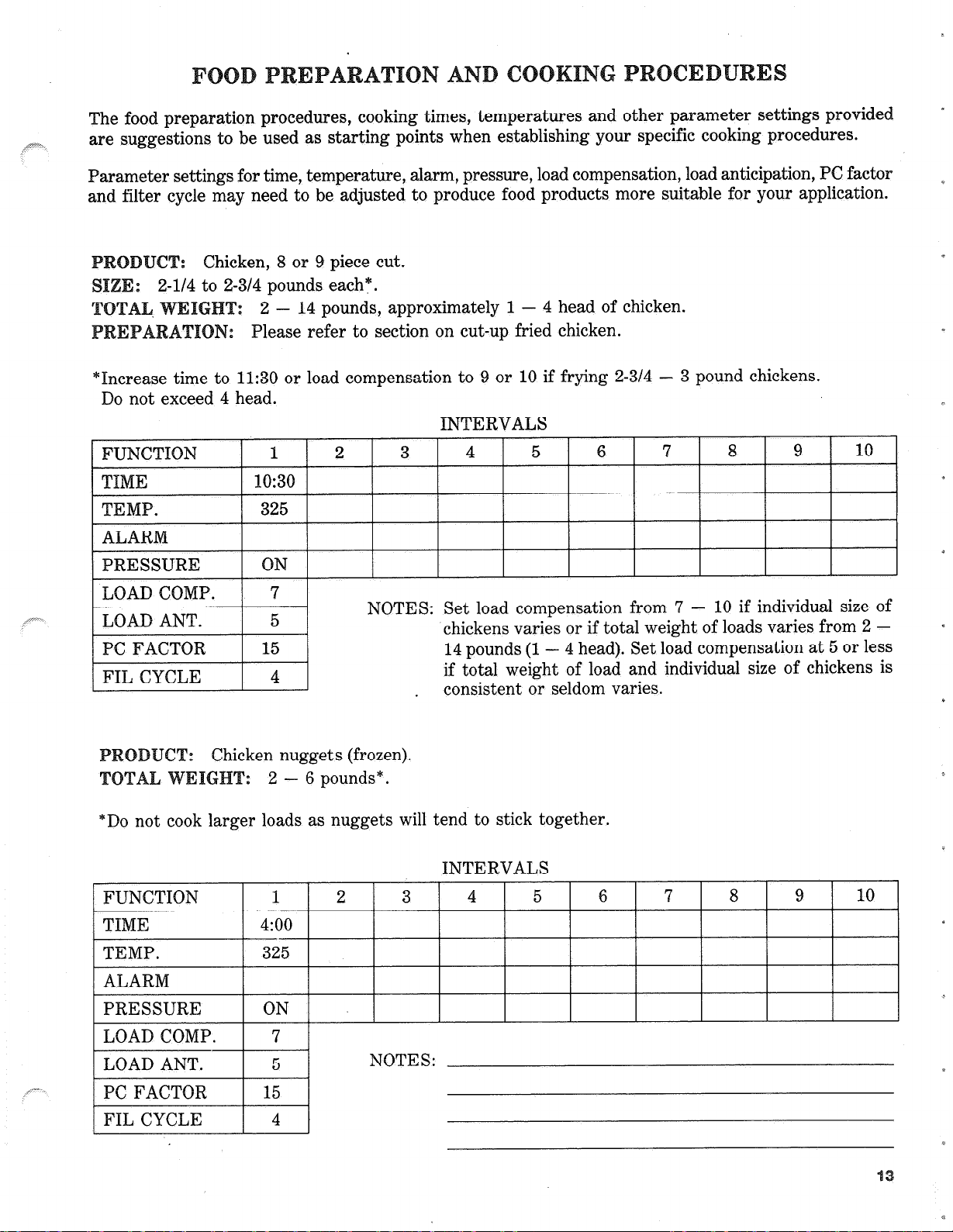

: Chicken breast fillets.

- 4 ounces each.

- 22 fillets.

1.’ Wash and drain.

:

2. Bread with Henny Penny Fryer Mix or marinate and bread.

INTERVALS

: Chicken gizzards.

* 2 .

- 3 pounds.

FUNCTION

1 2

TIME 12:oo 11:oo

TEMP.

ALARM

PRESSURE

LOAD COMP.

LOAD ANT,

PC FACTOR

FIL CYCLE

330 ‘255

OFF

ON ON

5

5

15

1

3

NOTES:

INTERVALS

4

5 6

7

8 9

IO

Page 18

: 5 - 10 pounds.

2. Bread with Henny Penny Fryer Mix or marinate and bread.

INTERVALS

,, I ,

PRESSURE

LOAD COMP.

ON

5

1 LOAD ANT. 5

1 PC FACTOR 1 15 1

1 FIL CYCLE

1 1

ken livers.

: 2 - 6 pounds.

1. Wash and drain.

2. Bread with Henny Penny Fryer Mix or marinate and bread.

NOTES:

INTERVALS

Page 19

: Chicken livers.

: 10 pounds.

INTERVALS

NOTES: Make sure pieces are well separated when returning basket

to shortening. Frying 2 five pound loads may produce a

better product.

FUNCTION

TIME

TEMP.

: Potatoes - U.S. No. 1 Grade Idaho

1 - 10 pounds.

1. Wash, and remove any sprouts. Do not peel.

:

2. Cut into 8 wedges.

3. Bread with Henny Penny fryer mix.

INTERVALS

1 2

3 4

7:oo

325

5 6

7 8

._.,

,

9 10

Page 20

1. Clean, wash and drain.

2. Bread with Henny Penny fryer mix or marinate and bread.

r-

:

Cauliflower.

: 1 - 5 large heads.

: 1. Clean, rinse

2. Slice into 1

and drain.

inch pieces.

3. Bread.

INTERVALS

LOAD ANT.

I

5

NOTES:

1 PC FACTOR 1 15 1

FIL CYCLE 4

Page 21

Wash and drain.

Slice large mushrooms in half.

Leave medium and small mushrooms whole.

Bread.

INTERVALS

: Polish sausage or kielbasa.

FUNCTION

TIME

TEMP.

ALARM

PRESSURE

LOAD COMP.

: 1 - 5 pounds.

Slice into 2 inch chunks.

N:

1

2:oo

315

2

ON

5

INTERVALS

3 4

5 6

7

8

9

10

Page 22

RQDUCT: Corn dogs (frozen).

TOTAL WEIG

“?“-

T:

5 pounds or approximately 27 corn dogs.

INTERVALS

I I

PRESSURE ON

c^”

LOAD; COMP.

5

LOAD ANT. 5

PC FACTOk 20

FIL CYCLE

3

Egg rolls (fully cooked, frozen).

: 1.5 ounces each.

T:

2.5 - 6.5 pounds or approximately

:

1. Thaw if frozen.

2. Fry at 315 or 320OF.

FUNCTION

1 2

NOTES: If cooking a thawed or fresh corn dog, fry for 3-l/2 minutes

at 315-325OF.

24

- 72

egg

rolls.

INTERVALS

3 4

5 6

7 8

9 10

,^..

TIME

TEMP.

ALARM

PRESSURE

LOAD COMP.

LOAD ANT.

PC FACTOR

FIL CYCLE

3:oo

320

ON

7

5

15

2

NOTES:

Page 23

This section provides troubleshooting information in the form of an easy to read guide. Clearly define

the problem and review all possible causes.

The following guide requires voltage to be present when troubleshooting the control. When the

guide refers to connecting pins on the power connector, unplug the power connector from the

bo

of

and refer to the attached illustration. These are numbered 1 through 9. Using a strand

gauge wire, connect the pins as numbered in the troubleshooting guide. Extreme caution

must be taken when connecting these pins to avoid control board damage or electrical shock.

rr

With switch in COOK position, the fryer is

completely inoperative (no power switch light).

With switch in COOK position, the fryer is

completely inoperative (power switch light on,

pump works)

Control operative - all lights on - primary contactor engages - no heat or pressure

Control operative - all lights on - no heat or

pressure - primary contactor does NOT engage

Control operative - all lights on - has pressure

Check to see if unit has voltage

Check fuses

Defective power switch

Check voltage on pins 1 and 7 on power

connector, 10 VAC

If voltage is present, check fuse on control board

If fuse is defective, replace fuse

If fuse is good, replace control board

Drain Valve Open

Defective Drain Switch

Check 5 amp fuse located on heat shroud

- fuse OK

Check voltage from center of fuse to ground 24 VAC

Defective transformer

Connect pins 4 and 6 on the power connector

If contactor eng

If contactor does

- replace control board

engage, replace contactor

Control operative - all lights on - heat on - no

pressure - pressure light ON.

Control operative - all lights on - heat on - no

pressure - pressure light OFF

Connect pins 3 and 6 on the power connector

If solenoid eng - defective control board

If solenoid does engage - defective solenoid

coil - 24 VAC

Check programming

Page 24

rror message E-5 display reads HI

-

shortening down

d display temperature - if display

temperature reads HI, unplug power connector

from control board. If secondary contactor stays

engaged, change contactor - if secondary

contactor disengages, change control board

If shortening temperature reads normal defective thermal sensor - replace

Replace thermal sensor

_,

Page 25

C363’

FUSES

15 AMP

C 16

I

I

MODEL 500 PRESSURE FRY

COMPUTRON 7000

240 VOLT, 3 PHASE

Page 26

24 201

Page 27

,

1lOJ I++

36 1.

ODEL 500 PRESSURE FRYER

COMPUTRON 7000

208 VOLT. 3 PHASE

Page 28

,

(90)

(50)

46)

(46)

c901

-J

?

C36ft-

1’

(37)

MODEL 500 PRESSURE FRYER

COMPUTRON 7000

208 VOLT. 1 PHASE

I

29617

Page 29

201 27

Page 30

L3 L2 Ll -

N-

49

48

45

1

MODEL 500 COMPUTRON 7000

220/380 OR 240/415 VAC 3PH

SO/60 HZ

4 POLE, 5 WIRE

L

Page 31

201 29

Page 32

(53)

L (52)

r

:46)

FIELD WIRING

JUNCTION BOX

r

L‘tYJ -

m

I f

I I

c35y [341

II I

ECOl-015

PLUG ,

I

-%G-

3

38

13)

220 VOLT.

PRESSURE FRYER

7000

1 PHASE

29658

Page 33

, -

Y

HI-LIMIT

THERMOSTAT

-

GAS VALVE

-

TEMP.

PROBE

FAN

MOTOR

MODEL 600 PRESSURE FRYER

COMPUTRON 7000

120 VOLT 50160 Hz

-

-

-

CONTROL

BOARD

-

CONNECTOR

Page 34

r

i

341

FAN

MOTOR

MODEL 600 PRESSURE FRYER

,COMPUTRON 7000

208 VOLT SO-60 Hz

I

GAS VALVE

CONNECTOR

temp.

29701

Page 35

-

-

-

-

-

19

SAFETY VALVE

27

GA5 VALVE

VALVE

l-

temp.

probe

MODEL 600 PRESSURE FRYER

COMPUTRON 7000

2201240 VOLT 50160 Hz

c

-

CONNECTOR

Page 36

I

I

I

I I

I

15

FILTER

unTnn

VI” I “l-l

PUMP

SAFETY VALVE

I

I

[S

-

I ‘:

32

11

I

\

:

.

3.

I

2

z

3

4 -

DRAIN SWITCH

12

11

-

-

POWER

SWITCH

= FIELD CONNECTION

2A

mV14A

t

25A' hl5*

NOTE: THIS WIRING DIAGRAM MUST BE

USED IN CONJUNCTION WITH THE

WIRING DIAGRAM ORIGINALLY

SUPPLIED WITH THE FRYER.

MODEL RG-600 GAS FRYER

1OOV - 208V - 220V - 240V

SO/60 HZ WITH GAS SAFETY VALVE

I

34436

Page 37

201 35

Page 38

36 201

Page 39

201 37

Page 40

38 201

Page 41

PARTS LIST

The following are replaceable parts for the gas and electric Computron.

(Refer to drawing in operation section)

Model 500/600 and 561 after Nov . 2000

Item Part

Number Number Description Qty

26 16684 Fan - 120 V 1

26 16688 Fan - 208/240 V 1

18402* Back-Up High Limit Thermostat 1

19440RB* Control Board 1

27 29510 Heat Contactor 24 V 1

20 29509 Primary Contactor 24 V 1

23 29521 Transformer 1

21 55167 Thermal Sensor Assembly (Electric) 3" 1

10 29524 Key switch Assembly 1

21 55168 Thermal Sensor Assembly (Gas) 6" 1

24 30090 Fuse Holder - 5 AMP 1

11 30261 Power Switch 1

1 31268 Decal Membrane Switch 1

1 61442 Decal Membrane Switch - Pollo 1

24 FA53-005 Fuse - 5 AMP 1

FH51-300* Control Board Fuse - 3 AMP 1

21 30094 Compression Fitting 1

22 16738 High Limit Thermostat 1

36097* Probe guard (Gas) 1

25 18364 Fuse Holder Assembly 1

29698* Solenoid - 24 Volt-50 Hz 1

29515* Solenoid V alve - 24 Volt-60 Hz 1

Model 561 and RE-500/600 Parts

1 44082 Decal-561 1

1 38384 Decal-RE-500 1

1 38370 Decal-RE-600 1

27 29942 Mercury Contactor-208/240 V 1

20 19405 Primary Contactor-208/240 V 1

23 28979 Transformer-208/240 V 1

21 55167 Thermal Sensor Assembly (Electric) 3" 1

31900* Switch Board 1

28980* Relay-120 V 1

ME90-007* Relay-240 V 1

TS22-006* Transformer- 120 V 1

ME90-006* Relay-120 V 1

*not shown

201 39

Page 42

BLE CORE DISC ASSEhABLY

ROUNDED EDGE OF

TOWARD DISC SPRING GUIDE (ITE

SEAT IN ANY WAY

as a ectric

Page 43

SOLENOID VALVE ASSEMBLY

KIT, Solenoid Valve Repair

RETAINER, Spring

CORE, Disc Assembly

GUIDE, Disc Spring

RING, Spring Retainer

SEAT, O-Ring Seal

PLATE, Solenoid Name

COVER, Coil Housing

15 17104 WASHER, Coil 2

16 17105 YOKE, Coil 1

17 29547 COIL, 24 Volt, 50/60 Hz 1

17 18706 COIL, 208/240 Volt, 60 Cycle 1

17 18726 COIL, 208/240 Volt, 50 Cycle 1

18 17123 HOUSING, Coil 1

19 17108 BONNET, Solenoid 1

20 17113 BODY, Solenoid Valve 1

21 17118 ADAPTER, Pipe 1

22 17119 SCREW, Adapter 2

Page 44

Page 45

FIGURE

& ITEM

NO.

1A

1B

2

2

3

4

5

6

PART

NUMBER

GAS CONTROL VALVE .........................

(Gas Model)

29614 VALVE, Control, Natural Gas, 24 Volt

29728

29688

29729

16253 REGULATOR, Gas Valve, Natural Gas

16352 REGULATOR, Gas Valve, Propane Gas

16267 DIAL,GasCock .................................

38468 SOLENOID, Gas, 24 Volt, (not shown)

3 8467 SOLENOID, Gas, 240 Volt, (not shown)

VALVE, Control, Propane Gas, 24 Volt

OPERATOR, Gas Valve, 24 Volt, Natural

OPERATOR, Gas Valve, 24 Volt, Propane

DESCRIPTION

UNITS

PER

ASSY.

...............

..............

.............

............

..............

..............

...............

..............

Page 46

The following is to be used as a quick reference for the cooking and programming of the Computron 7000 control. If more detail is needed, refer to

the Computron 7000 excerpt in this manual.

, -*

Cooking Operation

1. Make sure that the keyswitch is in the “COOK” position. Push the power switch to the “COOK” position.

2. If the red MELT light is on, wait for it to turn off.

3. Push the grey SELECT PRODUCT switch to pick the product to cook. This switch will keep selecting products until released. If.you go past your

product, keep pushing the switch, you will come back to it.

4. Drop the product when the green READY light stays on and does not flash. Close the lid. Push TIMER to start the cooking timer. The display

will show the time remaining.

5. The product is done when the buzzer beeps and the yellow DONE light flashes. Push TIMER to stop the buzzer. Open the lid and remove the product.

6. To cook more of the same product, go to Step 4. To cook a different product, go to Step 3.

If the display shows “Fil”, then it is time to filter the shortening. You can either filter, or bypass filtering:

TO FILTER: Push power switch to “OFF”; filter as usual; go to Step 1. Pump runs with power switch in “PUMP” position.

TO BYPASS FILTERING: Push power switch to “OFF” for about 3 seconds, then back to “COOK”. Go to Step 3.

Cooking alarms may occur while the timer is running. The display will flash “AL 1” for the first alarm,

will beep 3 times, then stop. DO NOT PUSH THE TIMER SWITCH DURING THE ALARMS!

The meaning of the alarms depends on your cooking process. They can be used as “stir” or “almost done” messages to the frycook.

The green PRESSURE light will turn on during the cook cycle if the control calls for pressure. Pressure gauge shows the actual pot pressure.

Use idle mode to conserve energy and shortening life. It can be entered manually or automatically. Put the fryer into Idle mode by pushing SELECT

PRODUCT until the red IDLE light (in the menu area) turns on.

If the control automatically goes into Idle, the IDLE light will turn on. To resume cooking, go to Step 3.

“AL 2” for the second, and so on. The buzzer

r

’

*

*

e-w

If the timer is accidentally started, push the TIMER switch to stop it.

If an error in the fryer occurs, the buzzer will sound until you push the TIMER switch. The display will show an error code:

E 5 Pot temperature is too high.

E 1:

E 41 Memory lost - reprogram complete unit.

The display will continue to flash the error code until the error is fixed. You cannot cook until the error is fixed.

rogramming Products

Move the keyswitch to the “Program” position to set cooking times and temperatures. When done, move it back to “COOK,”

You push switches to program. Switches are black or grey squares with white boarders. Don’t push on the lighted words on the front panel!

Example: “push SELECT PRODUCT: means push the switch above the red SELECT PRODUCT light.

Push SELECT PRODUCT to pick the product to program. The red light in the menu area shows the selected product.

Push SELECT FUNCTION to pick the item to program: time, temperature, etc. The flashing light is the item you

show what can be set.

Push SELECT TIME to see the times set for the product. You can set up to 10 times in each product. These are called interval times.

You can push SELECT TIME with an item displayed to see that item at all times in the program. Example: with TEMP flashing, push SELECT

TIME to see all temperatures.

4.

Push the change switches under the display to change the number displayed. Push the change switch under a number to increase that number by

one. If a change switch can be used, the red light above that switch is on.

For example: if the time 13:25 is displayed, change it to 13:35 by pushing the switch under the “2”.

Temperature probe has failed.

High limit has tripped; also flashes red HI LIMIT light.

e setting, the other lights

/

u

e Product times can be set from 0O:OO (minutes:seconds) to 99:59. To add a new time, push SELECT TIME until 0O:OO is displayed, then set the

new time. To change a time, push SELECT TIME until the desired time is shown, then push the change switches to set the new time. To remove

a time, push SELECT TIME until the desired time is shown, then push the change switches until the display shows 0O:OO

Page 47

Temperatures can be programmed from 1’70 to 390 degrees F. If you try to go beyond these limits, the buzzer will sound and the display will

blank, then go to 170 or 390.

0 Alarms and pressures can be turned on or off using any change switch. The display will show “on” or “off”.

Four times affect the whole cook cycle. There are:

* LOAD COMP: This is load compensation. Set from 1 to 10. 0 is no load compensation, 10 is full load compensation.

LOAD ANT: This is load anticipation. Set from 0 to 10. 0 is no anticipation, 10 is full anticipation.

PC FACTOR: This is the proportional control factor. Set from 0 to 30. 0 is no proportional control (best recovery time), 30 is full proportional control

8’ (best temperature regulation).

FIL CYCLE: This is the number of filter cycles. Set to the number of loads to cook this product before filtering.

5. You can push SELECT PRODUCT whenever you are done with a product. This will take you to the next product.

amming

1.

Put keyswitch in “Program” position. Push SELECT PRODUCT until red Melt light turns on. Push SELECT FUNCTION to set the melt temperature

elt

or 1st cycle.

2.

When the melt temperature is displayed, an “A” in the display means that auto melt is turned on. Example: if the melt temperature is 200 and

auto melt is on, the display will show “A200”. If auto melt is off, the display will show “200”. Push the change switch under the “A” to turn it on or off.

If auto melt is on, the control will pulse the heating elements until the pot temperature reaches the melt temperature, then automatically select

tm

the 1st cycle.

3.

The 1st Cycle is the product the control will select on power-up. Products are numbered from 1 to 10; the upper left product is 1, the product below

that is 2, etc. Set with change switches.

m

rogramming Idle

1. Put keyswitch in “Program” position. Push SELECT PRODUCT until red Idle light turns on. Push SELECT FUNCTION to set the idle clock

time or the idle temperature.

* 2. When the idle time is shown, the first digit indicates that auto idle is on with an “A”.

Push the change switch under the “A” to turn it on or off.

The idle time is shown in minutes. It is set from 0 to 255. If auto idle is off, the idle time is irrelevant.

3. When the idle temp is shown, the type of auto idle is shown with a “C” or a “T” in the first digit. “C” means cycle idle, “T” means times idle.

n

Cycle idle starts the idle clock each time a new product is selected. Timer idle starts the idle clock at the end of each load cooked. Idle is entered

automatically when the idle clock times out.

To See The

r

1. With keyswitch in PROGRAM position, push REVIEW USAGE switch. Push SELECT PRODUCT to see the number of loads of each product cooked.

oduct Usage

All product lights turn on when the total count of all products is shown.

2. Push RESET USAGE switch to set a count to zero. Pushing RESET USAGE when all LED’s are lit will set the total count and all individual counts

to zero. Pushing RESET USAGE when only one product LED is lit will reset only that count, not the grand total.

* 3. Push REVIEW USAGE when done to return to programming.

The maximum product cycle count is 255. The grand total count maximum is 9,999. If a count reaches the maximum without being reset, it will remain

at the maximum until you reset it.

ro~amming Notes

The change switches, SELECT PRODUCT and SELECT TIME will auto-repeat when held down: SELECT FUNCTION does not.

You cannot turn the alarm on in the first time of a cook cycle.

Pushing SELECT TIME when the LOAD COMP, LOAD ANT, PC FACTOR, or FIL CYCLE lights are on will not take you to the next interval

time in a product, because these items can only be set in the first interval time.

m~o~ant Note

After programming a product (or melt or idle), you should review all settings for all times. Verify that you have deleted any times that you do not

want, and that all settings are programmed as required.

Page 48

Page 49

For Sales or Service Please Contact

The Nearest Henny Penny Distributor

1. General Services

100 Hicks Ave.

Medford, MA 02155

(800) 233-1033

2. Art Cole Associates

Golden Street

Industrial Park

Meriden, CT 06450

(203) 237-7177

3. Globe-Monte Metro, Inc.

47-02 Metropolitan Avenue

Ridgewood, NY 11385

(718) 786-5760

4. Guertin Dist. Inc.

5 Technology Drive

East Syracuse, NY 13057-9713

(315) 437-4928

(800) 468-6336

5. Kreiser Distributing Co.

13800 Lincoln Highway

N. Huntington, PA 16652

(724) 863-3360

6. AFS Equipment Company

9130-X Red Branch Road

Columbia, MD 21045

(410) 964-3770

(800) 969-3770

7. HP Sales & Service Co.

200 Rittenhouse Circle, 4-East

Bristol, PA 19007

(215) 785-3250

NJ Watts (800) 477-4379

8. Astro Food Equipment

7901 Old Rockside Rd.)

Independence, OH 44131

(216) 619-8821

(800) 367-4237

9. Carlisle Food Systems, Inc.

11020 Lakeridge Pkwy.

Ashland, VA 23005

(804) 550-2169

10. Price-Davis, Inc.

Route 1, Highway 27

Iron Station, NC 28080

(509) 928-8815

(704) 732-2236

(800) 456-1014

11. Big A Distributors, Inc.

P.O. Box 1283

Forest Park, GA 30051

(404) 366-6510

(800) 222-0298

12. W.H. Reynolds

Distributors, Inc.

4817 Westshore Blvd.

Tampa, FL 33609

(813) 873-2402

Miami-(954) 845-0841

Jacksonville-(904) 781-9054

FL Watts (800) 282-2733

13. Ber-Vel Distributing Co. Inc.

P.O. Box 9943

Birmingham, AL 35220

(205) 681-1855

14 . Barnett Supply

2089 York Ave.

Memphis, TN 38104

(901) 278-0440

Nashville, TN

(615) 242-6451

Scotsman Supply

516 5th Ave., South

Nashville, TN 37203

(615) 242-6451

15. St. Clair Supply Company

231 East Main Street

Eaton, OH 45320

(937) 456-5500

(800) 762-2968

16. Dine Equipment Co.

3110 Preston Hwy.

P.O. Box 34038 zip 40232

Louisville, KY 40213

(502) 637-3232

FAX (502) 637-5177

17. United Marketing Assoc.

11877 Belden Court

Livonia, MI 48150

(734) 261-5380

18 . T&H Distributors

1235 Parkview

Green Bay, WI 54304

(920) 339-9838

19. Food Service Solutions, Inc.

1682 Barclay Blvd.

Buffalo Grove, IL 60089

(847) 459-8040

(847) 459-7942

20. MEC

2511 Cassens Dr.

Fenton, MO 63026-2547

(636) 343-0664

(800) 397-1515

21. Delta Supply Co., Inc.

3315 W. Roosevelt Rd.

Little Rock, AR 72204

(501) 664-4326

22. Dixie Supply

490 Julianne St.

Bldg. A-2

Jackson, MS 39201

(601) 354-3025

23. Beaullieu Refrigeration Inc.

200 North Luke St.

Lafayette, LA 70506

(337) 235-9755

24. S.L.E. Corporation

1110 Avenue H East

Arlington, TX 76011

(817) 640-7999

25. Brooks Industries

4420 S.W. 29th St.

Oklahoma City, OK 73119

(405) 685-7200

26 . B & D Dist.

19915 W. 161st St.

Suite D

Olathe, KS 66062

(913) 768-8588

FAX 913-768-8855

27 . PHT Systems

1801 Highway 8

Suite 120

New Brighton, MN 55112

(651) 639-0368

28. Mid-Nebraska Restaurant

Supply Co.

1415 S. Webb Road

Grand Island, NE 68802

(308) 384-5780

29. Robert G. Wood & Co.

2080 W. Cornell Ave.

Englewood, CO 80110

(303) 761-0500

(800) 358-3061

30. Open Territory

31 . CPE-USALCO

1310 West Drivers Way

Tempe, AZ 85284

(480) 496-6995

32. National Equipment Corp.

242 West-3680 South

Salt Lake City, UT 84115

(800) 266-5824

(800) 955-9202

33. The Nicewonger Co.

19219 West Valley Hwy

Suite M103

Kent, WA 98032

(800) 426-5972

(425) 656-0907 FAX

34. Tri-State Market Supply

11115 E. Montgomery, Suite A

Spokane, WA 99206

(509) 928-8815

(877) 828-4268

36. Western Pacific

Distributors, Inc.

19422 Cabot Boulevard

Haywood, CA 94545

(510) 732-0100

37. Don Walters Company

2121 S. Susan Street

Suite A

Santa Ana, CA 92704

(714) 979-5863

38 . Troyer Foods, Inc.

17141 State Route 4

Goshen, IN 46526

(219) 533-0302

39. Tri-City HP, Inc.

527 West Fourth St.

Davenport, IA 52801

(319) 322-5382

40. Certified Commercial Service &

Equipment (CCSE)

6031-A Industrial Heights Drive

Knoxville, TN 37909

(865)-546-8778

41 . Gower Distributors, Inc.

P.O. Box 4804

Box 216K Rt. -4

Victoria, TX 77903

(361) 573-9777

42 . Top-Line Distributors

1501 College Ave.

Houston, TX 77585

(713) 946-6008

43. DSL Inc., Canada

14520 128th Ave.

Edmonton, Alberta

Canada T5L3H6

(403) 452-7580

(Alberta, British Columbia,

Manitoba, Saskatchewan,

Yukon, & N.W. Territories)

44. Taylor Freezers, Inc.

52 Armthorpe Rd.

Brampton, Ontario

Canada L6T5M4

(905) 790-2211

(Ontario, Montreal, and

Maritime Provinces)

45. Bazinet Taylor Ltee.

4750 Rue Bourg

Ville St. Laurent

Quebec, Canada H5T 1J2

(514) 735-3627

(Quebec only)

If Further Assistance Is Needed Please Contact: Henny Penny Corporation

1219 U. S. Route 35 West

Eaton, Ohio 45320

1-800-417-8417

Fax 1-800-417-8402

Revised 4-01

Page 50

Page 51

Henny Penny International Distributor Network

U.S. Headquarters

Henny Penny Corporation

1219 U.S. Route 35 West

Eaton, OH 45320 USA

Telephone: 937-456-8417

Fax: 937-456-1860

Representative Office

1 . Henny Penny Corporation

Representative Office

Parc dEntreprises de

IEsplanade

2bis Rue Paul Henri Speak

Saint Thibault des Vignes

77462 Lagny sur Mame Cedex,

France

Telephone: 33 (1) 60075600

Fax: 33 (1) 60071489

U.S. Export Centers

2. Feco International Company

20 North San Mateo Drive,

Suite 9

San Mateo, CA 94401 USA

Telephone: 415-348-3499

Fax: 415-348-3575

3. Caribbean Islands & Central

America (excluding Puerto Rico)

Total Equipment Suppliers

9550 NW 41

Miami, FL 33178

Telephone: 305-718-9550

Fax: 305-718-9505

Algeria

4. SOMAB

Y1 Rue Mahmoud Boudjatit

(Oasis) Ager, Algeria

Tel: 213-21-23-3051/3052

Fax: 213-21-23-3161

Argentina

5. Oditec S.A.

Augstin Alvarez 2128

1602 Florida

Buenos Aires, Argentina

Telephone: (541) 796-0820

Fax: (541) 796-2009

6. Australia

J.L. Lennard Pty. Ltd.

937-941 Victoria Rd.

West Ryde NSW 2114

Sydney, Australia

Telephone: 617-3272-4744

Fax: 617-3272-4799

Bahrain

7. Mohammed Jalal Catering

Old Palace Road

P.O. Box 1335

Manama, State of Bahrain

Telephone: 973-53-45-39

Fax: 973 53-14-78

Bangladesh

8. Puffin International Ltd.

3691B Elephant Rd.

Swarankika Plaza

4th Floor-Dhaka 1205

Dhaka, Bangladesh

Telephone: 8802-863117

Fax: 880-2-867563

Belgium

9. Engelen-Heere N.V.

Industrialpark Terbekehof

Fotografielaan 14

B-2610 Antwerpen (Wilrijk)

Telephone: 323-825-5577

Fax: 323-825-3702

st

St.

Brazil

10. Pesin Equipment Food Service

R. Olavo Bilac 188/198

Sao Caetano Do Sul - SP

Brazil

Telephone:55-11-7690-1470

Fax: 55-11-7690-1466

Bulgaria

11. E.C.E. - CAIX

23A Rue Oborichte

Sofia 1604, Bulgaria

Telephone: 19-359-2-946-1479

Fax: 19-359-2-946-1669

Chile

12. IMAHE

Manuel Montt 1154 Providencia

Santiago, Chile

Tel: 562-341-4953/5707

Fax: 562-274-8567

China

13. Bonny Foodservice Products

Flat C, 8/F, Yeung Yiu Chung

Industrial Bldg., No. 20

Wang Hoi Rd.

Kowloon Bay, Kowloon Hong Kong

Telephone: 852-796-5616

Fax: 852-799-8490

Colombia

14. Industrial Taylor Ltda.

Transversal 93, Numero 64-24

Apartado Aereo 95075

Bogota D.E., Colombia

Telephone: 57 (1) 4340016

Fax: 571-223-2642

Crotia

15. New Rok

Opatija M. Tita 15

51410 Opatija, Crotia

Telephohe: 385-51-701-251

Fax: 385-51-701-251

Cyprus

16. AMF Chistofides Ltd.

104A Prodromos Str.

P.O. Box 25100

Nicosia, Cyprus

Telephone: 357-2-454-380

Fax: 357-2-454-088

Czech Republic

17. Citus

Argentinska 20

CZ 4170 00 Pragues 7

CZECH REPUBLIC

Telephone: 420-2-667-10-561

Fax: 420-2-667-10-557

Denmark

18. Inter-Gastro A.S.

Midtager 18

2605 Brondby

Denmark DK2605

Telephone: 45-43292000

Fax: 45-43292001

Ecuador

19. Equindeca Cia. Ltda.

Hotel El Conquistador

Gran Colombia 6-65

Cuenca, Ecuador

Telephone: 593-7-831788

Fax: 593-7-843221

Egypt

20. Con Trade Centre

3A Ramsis Street

Maaroof Building #83 & #62

Cairo, Egypt

Telephone: 20 (2) 770642/762551

Fax: 20 (2) 756258

Estonia

21. Sisustaja As

Tihniku 5

11625 Tallinn, Estonia

Telephone: 372-6502300

Fax: 372-6502301

Finland

22. Monilaite Oy

P.O. Box 27

Salpakuja 6

SF-01200 Vantaa, Finland

Telephone: 358-9-877-0100

Fax: 358-9-877-01099

France

23. Diffusion International de

Materiel (DIM)

Parc dactivite Clemenceau

Chemin du Chateau dEau

B.P. 4009

59704 Marcq-En-Baroeuil

Cedex, France

Telephone: (33) 20890000

Fax: (33) 20727355

Germany

24. Sesjak KG

Wullener Feld 9a

D-58454 Witten

Germany

Telephone: 49-2302-697077

Fax: 49-2302-698451

Ghana

25. DRT Ghana

E6619 Ablade Road

Kanda Estate

P.O. Box C2074

Accra-Cantonments, Ghana

Telephone: 233-2123-3949

Fax: 233-2123-1380

Greece

26. Domestica S.A.

65 Stournara Str.

Athens 10432, Greece

Telephone: 30-15-24-30-14/15

Fax: 30-15-22-91-58

Guam

27. Pacific Technical Service, Inc.

New Commercial Building

#979 Rt. 16, Suite B-3

Barrigada, Guam 96913

Telephone: 6710632-5000

Fax: 671-632-3333

Holland

28. Englelen-Heere B.V.

Straatveg 85, Postbus 35020

3005 DA Rotterdam, Holland

Telephone: 311-042-23077

Fax: 311-042-23435

Hong Kong

29. Bonny Foodservice Products

Flat C, 8/F, Yeung Yiu Chung

Industrial Building #20

Wang Hoi Road

Kowloon Bay, Kowloon,

Hong Kong

Telephone: 852-796-5616

Fax: 852-799-8490

Hungary

30. Hotex Service

H-2094 Nagykovacsi

Kossith Lajos u. 1.

Hungary

Telephone: 36-263-56653/89463

Fax: 36-26389463

Iceland

31. A. Karlsson H. F.

Brautarholti 28

105 Reykjavik, PO Box 167

Iceland

Telephone: 354-560-0900

Fax: 354-560-0901

India

32.

AISHWARYA

Trust Complex, 10 OVG Rd

Basavanagudi

Bangalore 560004, India

Telephone: 91-80-667-7576

Fax: 91-80-667-7576

Intl. Refrigeration Corp

7 Netaji Subhash Marg

Darya Ganj

New Delhi 110002, India

Telephone: 91-11-3275651

Fax: 91-11-6221827

Indonesia

33. P.T. Gema

JL. Raya Bloulevard Raya

Block IOA 2 No. 27

Kelapa Gading Permai

Jakarta 14240, Indonesia

Telephone: 62-21-4532077

62-21-4508910

Fax: 62-21-4532586/4530777

Ireland

34. Martin Food Equipment Ltd.

Gaskin Business Park

Coes Road

Dundalk, Louth County

Ireland

Telephone: 353-42-30366

Fax: 353-42-30370

Italy

35. Allegra SRL

Corso Matteotti, 5 - 10121

Torino, Italy

Telephone: 39-011-540264

Fax: 39-011-533779

Japan

36. Toei Kogyo Co. Ltd.

4F, Nissay Nishi-Gotanda

Building 24-5

Nishi-Gatanda 7-Chome

Shinagawa-ku, Tokyo 141-0031

Japan

Telephone: 813-3779-1081

Fax: 813-3779-1638

Jordan

37. Awar Trading Est

PO Box 962227

Amman 11196, Jordan

Telephone: 962-6-55-19-610

Fax: 962-6-55-19-605

Korea

38. Ohjin Corporation

3rd Floor, Hee Jung Building

1635-0 Seocho-dong

Seocho-ku

C.P.O. Box 3252

Seoul 137-070, Korea

Telephone: 82-2-5850441

Fax: 82-2-5874197

Kuwait

39. Mabrook Hotel Supplies Co.

PO Box 43832 Hawalli

32053 Kuwait

Telephone: 965-481-8242

965-483-01648

Fax: 965-483-4314

Revised 5/01

Page 52

Lebanon

40. Pro Kitchen

Cahlfoun Building

Kaslik - Main Road

PO Box 1066 Jounieh

Lebanon

Telephone: 961-9-635-077

Fax: 961-9-635-059

Lithuania

41. Master Group Baltic Master

Dariaus Ir Girena 175

2038 Vilnius, Lithuania

Telephone: 3702-306-528/529

Fax: 3702-306-533

Malaysia

42. SCC Corp. Sdn. Bhd.

19-21 Jalan Hujan

Taman Overseas Union

58200 Kuala Lumpur,

Malaysia

Telephone: 60-3-77828384

Fax: 60-3-77818561

Malta

43. C & H Bartoli Ltd.

232 The Strand

Gzira Gzros, Malta

Telephone: 356-342-584

Fax: 356-342-569

Mauritius Island

44. (Mauritius, Reunion Island,

Seychelles)

Hassam Moussa Rawat

10 Bourbon Street

P.O. Box 492

Port Louis, Mauritius Island

Telephone: 160 (230) 2080024

Fax: 160-230-2080147

Mexico

45.

Central Mexico Metro Mexico City

Cavimex S.A. de C.V.

Revillagigedo No. 61 Col Centro

Mexico, D.F. 06070

Mexico

Telephone: 525-521-4200

Fax: 525-510-2791

Pacific

Micro Herros De Occidente,

S.A. de C.V.

Av. Juan Palamar y Arias

#83 Col. Jardines Vallarta

Zapopan, Jalisco, Mexico

C.P.45020

Telephone: 52-3-629-54-05

Fax: 52-3-673-29-43

Southeast

Equipo Para El Mercado

S.A. de C.V

Calle 55 No. 501-B por 60 y 62

Merida, Yucatan,

Mexico C.P. 97000

Telephone: 52-99-236500

Fax: 52-99-286649

Morocco

46. Electra

Boulevard AHL Loghlam

BP 25698

Sidi Bernoussi - Ain-Sebaa

Casablanca Morocco

Telephone: 212-22-753-531

Fax: 212-22-753-554

New Zealand

47. Taylor Equipment Limited

4 Ponuz Place

Mt. Wellington

Auckland, New Zealand

Telephone: 64 (9) 5733377

Fax: 64 (9) 5730841

Norway

48. Grillfagmannen A.S.

Ostensjoveien 44

N-0667 Oslo 6, Norway

Telephone: 47 (2) 651410

Fax: 47 (2) 720017

Oman

49. Mohsin Haider Darwish LLC

P.O. Box 880

Ruwi, Code 112

SULTANATE OF OMAN

Telephone: 968-703411

Fax: (968) 789927

Pakistan

50. The Equipment Company

Ground Floor, Dadabhoy Centre

Sharea Faisai, Karachi 75530

Pakistan

Telephone: 922-1-778-1778/2778

Fax: 922-1-587-0456/778-2777

Peru

51. Importadora Tecnica

Comercial C.R. Ltda.

Jr. Marcos de Aramburu #595

Lima 17, Peru

Telephone: 51-1-226-2124

Fax: 51-1-275-2689

Philippines

52. HKR Equipment Corp.

2nd Floor, THC Bldg.

2176 Primo Rivera St.

La Paz, Makati City, Philippines

Telephone: 632-899-4511

Fax: 632-899-4541

Poland

53. I. F. E.

Rydygiera 12

01 793 Warsaw, Poland

Telephone: 48-3912-3373

42-22-663-4820/4069

Fax: 48-3912-3373

Portugal

54. Restaurotel

AV Da Republica

83 C 1050

243 Lisboa

Portugal

Telephone: 351 7967116/7/8/9

FAX: 351 7933982

Puerto Rico

55. Progressive Sales and Service

PO Box 10876

Caparra Heights Station

San Juan, Puerto Rico 009220876

Telephone: 787-782-7474

Fax: 787-793-6479

Qatar

56. Tristar Group

C.R. No. 6778

P.O. Box 4746

Doha, Qatar

Telephone: 974-4664433

Fax: 974-4365365

Romania

57. Delta Technologies Romani S.A.

Sector 6, 20 Constructorilor Blvd.

Bloc 20 A, sc. B 7th Floor

Apt. 64

Bucharest, D599 Romania

Telephone: 401-220-4261

Fax: 401-220-3990

US Address:

115 Main St.

Mishawaka, In. 46544

Telephone: 219-256-3783

Fax: 219-256-7130

Saudi Arabia

58. Commercial Center

Development & Economy

P.O. Box 1210

Jeddah 21431, Saudi Arabia

Telephone: 966 (2) 629-1857

Fax: 966 (2) 629-1860

Senegal

59. Breading Systems Co.

C/ Ripoche,14

35007 Las Palmas

Spain

Telephone: 34-9-28-22-43-86

Fax: 34-9-28-27-56-90

Singapore

Simplex Pte. Ltd.

60.

Block 1, Lorong 8

Toa Payoh Industrial Park 01-1383

Singapore 319053

Telephone: 65-251-6241

Fax: 65-253-8814

Shopfit (S) Pte. Ltd.

Blk 623 Aljunied Industrial Complex

Unit 02-09

Singapore 389835

Telephone: 65-7410911

Fax: 65-7438911

South Africa

61. Foodserv CC

PO Box 55269

Northlands 2116,

Republic of South Africa

Telephone: 27 (11) 616-5183,

Fax: 27 (11) 616-8287

Spain

62. Adisa

Tuset, 8-10

08006 Barcelona, Spain

Telephone: 34-93-415-0018

Fax: 34-93-218-1782

Sri Lanka

63. Sperrys Commercial Equipment

1014 Parliament Road

Etul Kotte

Kotte/Colombo, Sri Lanka

Telephone:941-873-0561

Fax: 941-863-8361

Suriname

64. Tessco N.V.

Oude Charlesburgweg #47

Paramaribo Suriname

Telephone: 597-473366/477388

Fax: 597-473366

Sweden

65. Eurospice AB

Box 5050

Hejargatan 6

632 29 Eskilstuna, Sweden

Telephone: 46 (16) 125600

Fax: 46 (16) 131390

Switzerland

66. Stuppen Fast Food GmbH

Oberneuhofstrasse 8

CH-6340 Baar, Switzerland

Telephone: 41-41-761-5052

Fax: 41-41 761-7210

Syria

67. Lahham Trading & Contracting

Hamra Str. Omyad Building

P.O. Box 2960

Damascus Syria

Telephone: 963-11-331-2251

Fax: 963-11-331-2252

Taiwan

68. Feco Corporation

420, 11 F Keelung Rd.

Sec. 1 Postal Code 110

Taipei, Taiwan

Republic of China

Telephone:886-2-2758-2288

Fax: 886 (2) 2758-2297

Thailand

69. Fieco Company Ltd.

43/524-526 Amarinnivej 1

Anusaovari Laksi

Phaholoyothin Road

Bangkok 10220

Thailand

Telephone: 66-2-521-3824/3878

Fax: 66-2-552-0833

Tunisia

70. Semci

16, Rue Aziz Taj

1101 Tunis RP, Tunisia

Telephone: 216 -133-1501

Fax: 216-133-0698

Turkey

71. Klimatek

Inonu Caddesi, Opera Palas 73/5

80090 Gumussuyu

Istanbul, Turkey

Telephone: 90-212-245-1812

90-212-293-7892

Fax: 90-212-293-3903

United Arab Emirates

72. Habtoor International

P.O. Box 55332

Dubai, United Arab Emirates

Telephone: 971-4-272-1212

Fax: 971-4-272-2255

United Kingdom

73. Servequip Products Ltd.

214 Purley Way

GB-Croyden CRO 4XG, England

Telephone: 44-208-6868855

Fax: 44-208-6817509

Uruguay

74. Tecnoland S.A.

Dr. José Scorsería 2740

CP 11300 Montevideo, Uruguay

Telephone: 598-2-7105900

Fax: 598-2-7105900

Venezuela

75. Prefer, C.A.

Avenida Presidente Medina

Edificio Prefer, Local No. 44

Entre Calles Chile y Progreso

urb. Los Acacias

Caracas 1040, Venezuela

Telephone: 58-212-633-6933/2801

Fax: 58-212-632-6711

Vietnam

76. Cao Sinh Pte

Block 1, Lorong 8

Toa Payoh Industrial

Estate #01-1383

Singapore 319053

Telephone: 65-2516241

Fax: 84-2538814

Yemen

77. Mukiriani Sanaa

PO Box 8150 Sanaa

Yem e n

Telephone: 967-1-230-675

Fax: 967-1-230-929

Revised 4/01

Loading...

Loading...