Page 1

Quality

Comes First

Page 2

A Recipe

For Success

Henny Penny pioneered the rst commercial pressure fryer in

1957 and quickly became known for delicious fried chicken.

Across America, diners and restaurants began taking orders

for moist and crispy chicken cooked

next y years, that same spirit of

customers’ businesses has made Henny Penny a global leader

in foodservice solutions.

While pressure fryers continue to be a cornerstone of the

company, our business has expanded to include the

best-engineered, best-built and best-tested cooking, holding

and merchandising equipment in the foodservice industry.

Henny Penny open fryers, rotisseries, heated merchandisers,

combi-ovens, blast chillers, warming cabinets and breading

products are found in the world’s most successful QSR and

restaurant chains, as well as in independent restaurant,

supermarket, c-store and noncommercial operations around

the corner and around the globe.

in our fryers. Over the

innovation and focus on our

At Henny Penny, we aren’t satis ed with simply making the

best products, we make sure those products are backed by the

best people. at’s why you’ll nd our level of service and

commitment to your foodservice operation unmatched by

anyone in the industry — on any continent. Bringing a half

century of experience to the table, we are resolute in helping you

deal with the most important issues a ecting your bottom line:

■

Food quality, consistency and safety

■

Labor and economic savings

■

Productivity

Page 3

Our Legacy

Page 4

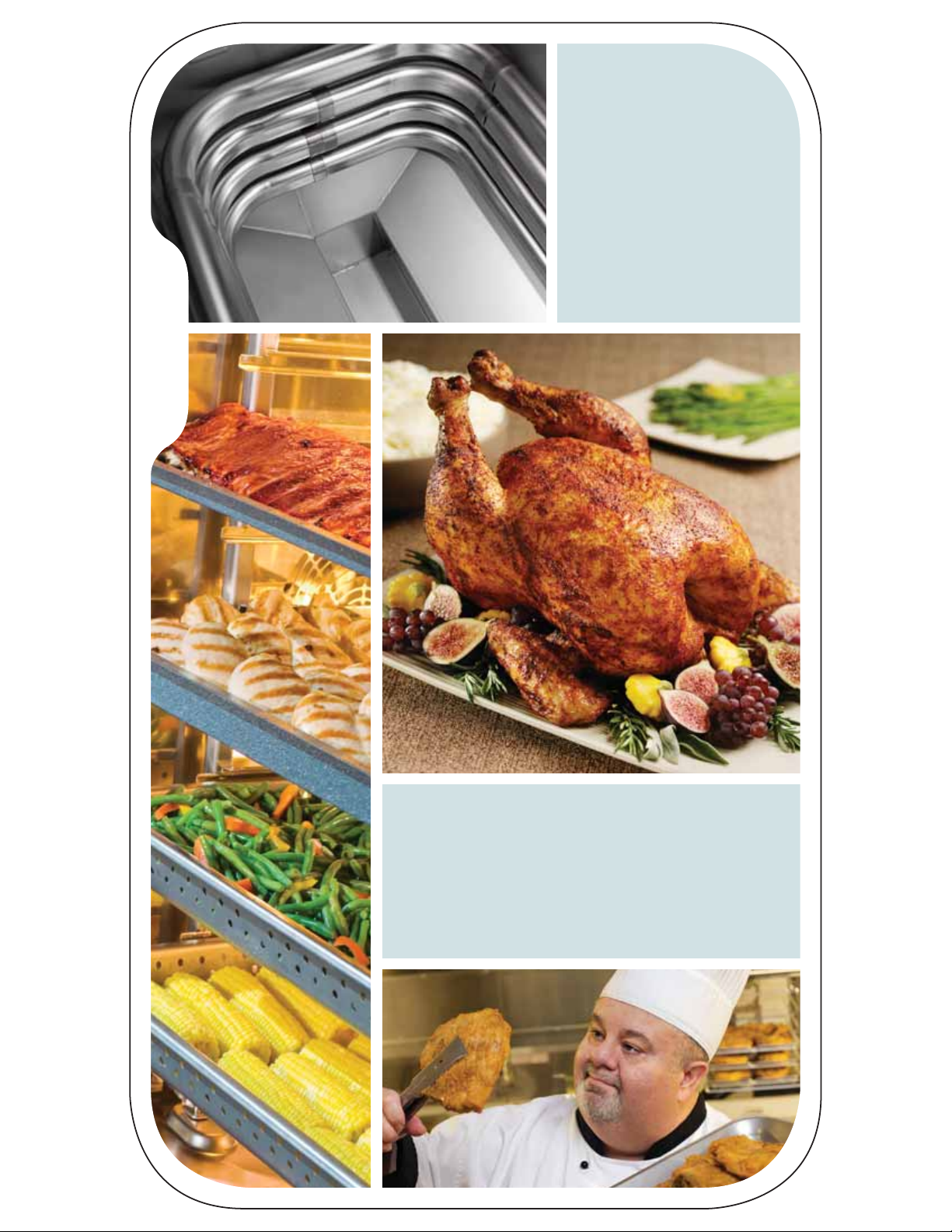

Food Quality

Fryers are precision

engineered with rectangular

fry pots and cold zones below

the heating elements to reduce

cracklings and greatly improve

shortening quality, food fl avor

and consistency.

Ensuring food is evenly cooked,

uniformly browned, moist, crisp

and fresh until served, Henny Penny

rotisseries, heated merchandisers

and holding cabinets use our

patented THERMA-VEC

®

technology,

letting you easily control radiant

heat and humidity.

Moving beyond traditional boiler and boilerless designs,

Henny Penny SmartCombi

Steam Technology

™

ovens use our patented Advanced

™

which lets you cook with both dry and

steam heat to better control the moistness of the food while

minimizing maintenance costs.

New products, in concert with equipment usage and shortening

management, are being explored at our Food Quality Institute by

in-house chefs and in fully equipped test kitchens around the world.

Page 5

Designed to Delight You

and Your Customers

e success of your business is, and always will be,

based on food quality. Today, your customers have

more meal options and they demand meals that are

better looking, better tasting and the best possible

value. ey also seek variety and meals that t

their lifestyles, which includes nutrition as well as

convenience. Our operations, equipment and many

of our patented technologies have been speci cally

designed with this in mind. We have devoted years

to nding the best solutions, so you and your

customers can be con dent that the food is cooked

and held properly each and every time. We have

honed our expertise across many di erent types of

foods, ensuring you the most delicious products

and the most satis ed customers.

Page 6

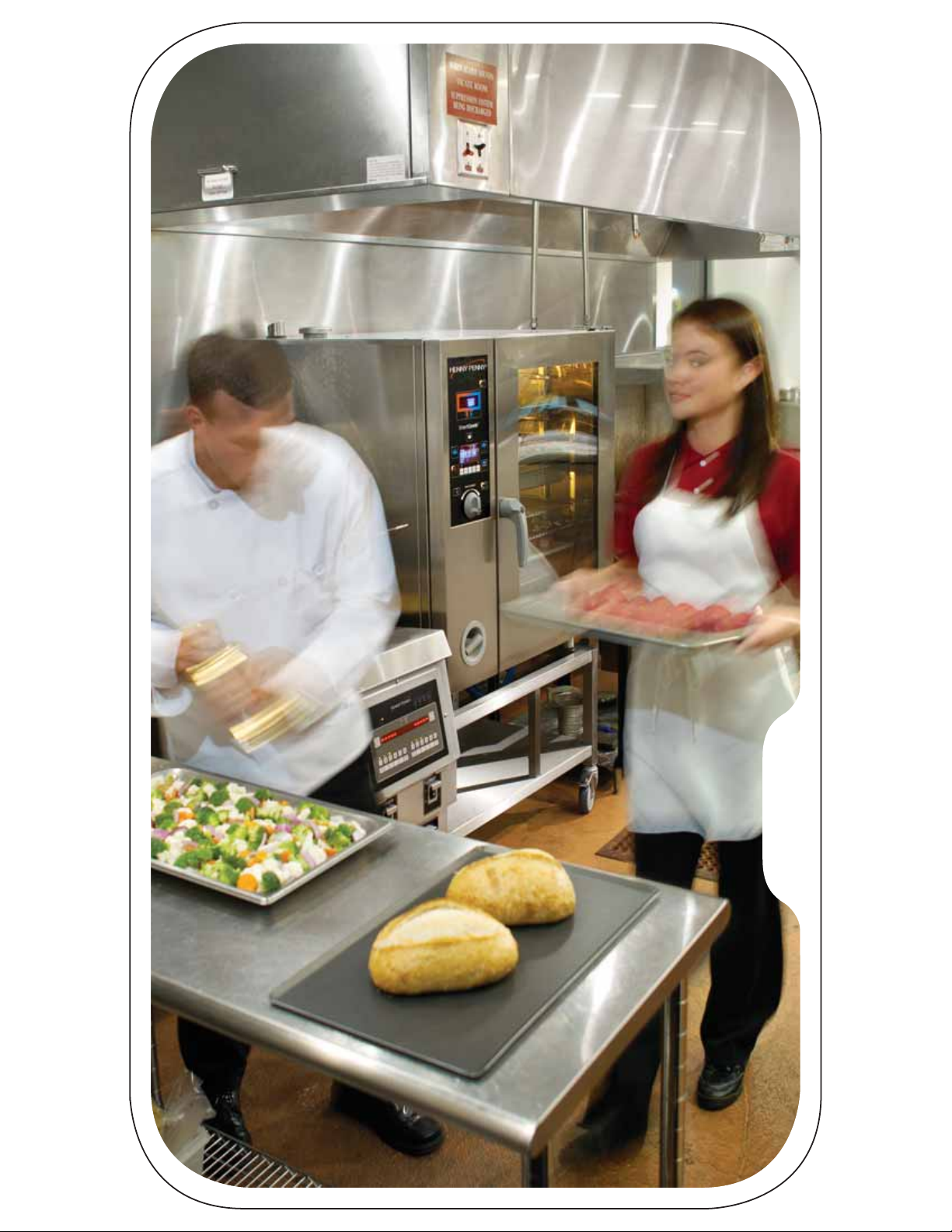

Buying You More Time

In foodservice, productivity means pro ts, and we

help protect your pro ts with equipment speci cally

engineered to be easy to use and easy to maintain.

Our products o er a wide range of features that

translate into genuine labor savings and increased

productivity. Easy-to-learn controls mean you spend

less time training employees — a big advantage in a

high employee turnover world. And incorporation of

the best automation technology means preparation

and cleaning tasks are shortened and simpli ed.

e goal is to save you time and labor, without

sacri cing food quality. Ultimately, the true test of

our equipment is its ability to deliver a consistent,

great-tasting product to your customers, regardless

of who prepares it.

10

Page 7

While proper shortening

management protects the fl avor

of your food and extends the life of

your shortening,

built-in shortening fi ltration

this once laborious, time-consuming

process quick, safe and easy.

Henny Penny’s

makes

Henny Penny’s in-house

Controls Division designs and

manufactures electronic

controls to our own rigid

standards and specifi cations,

giving you programmable

computer controls that allow

you to create custom settings

and protect the quality of

your product.

With our integrated cook/chill systems

and accompanying holding cabinets,

bulk food operations can dramatically

decrease their reliance on labor,

even streamlining kitchen production

to a single fi ve-day, eight-hour work

schedule instead of the traditional

12-hour shifts, seven days per week.

Equipment upkeep can keep your employees

from other important duties. That’s why our fryers,

rotisseries, combi-ovens and cook/chill systems

are designed for maximum ease of cleaning.

For instance, the WaveClean

cleans SmartCombi

of a button, requiring no supervision.

™

™

ovens with a simple push

system thoroughly

Labor

Page 8

Economics

Guaranteed performance no matter what conditions

you work in, thanks to full lifecycle testing in labs

that can simulate any climate or humidity. And

100 percent of equipment is tested for operational

integrity before shipping.

Attention to details, such as corner radius welds,

give Henny Penny products added strength and

durability, and our certifi ed welders are reviewed

daily for quality assurance. This meticulous attention

to detail means enhanced durability, and an overall

lower cost of ownership.

With the versatility of equipment

built to cook a wide variety of

foods, you have fewer pieces to

buy and the added freedom to

market new menu items without

incurring additional costs.

Page 9

Quality Pays Off

While the rst thing you’ll notice when you choose

Henny Penny is an unmatched level of cra smanship,

the full value of our equipment goes much deeper

than high-grade stainless steel and polished corners.

e precision engineering behind our products

is more than just a matter of pride, it stems from

an unwavering commitment to increasing your

pro tability and decreasing operational costs. For

instance, faster recovery times allow you to prepare

more food in less time, while more energy-e cient

designs lead to full lifecycle payback in 1-2 years.

And with an average tenure of over 18 years, our

engineers’ experience and attention to detail make

Henny Penny equipment stand apart. is focus on

quality and the long-term bene ts of a better-made

product extends from our company president to our

workers on the factory oor — all of which makes

Henny Penny a sound long-term investment in your

company’s success.

Page 10

With regional corporate offi ces in the United States, Mexico,

France, Russia, Lebanon, China and Singapore, as well as a

distributor network reaching over 100 countries, Henny Penny

offers quick problem resolution anywhere in the world.

Shining Service

From initial design to a er-sales support, Henny Penny

works tirelessly to be a partner in your company’s success.

We treat your purchase as the beginning of a mutually bene cial

relationship, and go out of our way to respond quickly to

your needs as they arise. We also

take an active role in identifying

and implementing the most

useful technology, and nding the

best solutions to the foodservice

challenges that you face every day.

With Henny Penny, you can be

con dent that you’ll receive not only

the best products, but also a level of

ongoing service that lives up to the

same high standards. O ering global

scope and personal attention, we’re

behind you every step of the way.

Convenience

Henny Penny’s dedicated

service parts assembly area

ensures parts requests and

repairs are handled quickly

to minimize downtime and

lost revenue.

Page 11

Page 12

Pressure Fryers

Open Fryers

Rotisseries

SmartCombi

™

Ovens

Holding Cabinets

Heated Display Cases

Blast Chillers/Freezers

Island and Express Merchandisers

Breading Systems

Breadings, Seasonings and Supplies

Technical Service and Training

To learn more about Henny Penny’s

comprehensive products, programs and services,

contact your nearest Henny Penny distributor.

P.O. Box 60 ■ Eaton, Ohio 45320

www.hennypenny.com

1 937 456.8400

80 0 417. 8417

FM03 -670 Litho in U. S.A. © 2007 H enny Penny Corp oration, Pr inted 12-06

■

FAX 1 937 456.8434

Toll-free in USA:

■

FAX 800 417.8434

Loading...

Loading...