Henny Penny CMC-103 Owner’s Manual

Henny Penny

Cold Tops

Model CMC/CMR-103

Model CMC/CMR-104

Model CMC/CMR-105

Model CMC/CMR-106

Model CMC/CMR-107

OPERA TOR’S MANUAL

Model CMC/CMR-103,104,105,106,107

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT: Any part of a new appliance, except lamps and fuses, which proves to be defective

in material or workmanship within two (2) years from date of original installation, will be repaired or replaced

without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To validate this warranty, the

registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

REPLACEMENT PARTS: Any appliance replacement part, except lamps and fuses, which proves to be

defective in material or workmanship within ninety (90) days from date of original installation will be repaired

or replaced without charge F.O.B. factory, Eaton, Ohio, or F .O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY: Henny Penny will replace any frypot that fails due to manufacturing or

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new

frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for the frypot only . Any freight charges and labor costs to install

the new frypot as well as the cost of any other parts replaced, such as insulation, thermal sensors,

high limits, fittings, and hardware, will be the responsibility of the owner.

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If

damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse;

(b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE EXCLUDED. HENNY

PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY OTHER OBLIGATION OR LIABILITY.

FM01-878-C

Revised 02-09-06

Model CMC/CMR-103,104,105,106,107

T ABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION ...................................................................................................................1-1

1-1. Henny Penny Cold Tops ..............................................................................................1-1

1-2. Features .......................................................................................................................1-1

1-3. Proper Care .................................................................................................................1-1

1-4. Assistance.................................................................................................................... 1-1

1-5. Safety........................................................................................................................... 1-2

Section 2. INSTALLATION......................................................................................................................2-1

2-1. Introduction ..................................................................................................................2-1

2-2. Unpacking .................................................................................................................... 2-1

2-3. Electrical ...................................................................................................................... 2-2

2-4. Location .......................................................................................................................2-3

2-5. Refrigerant Information ...............................................................................................2-3

2-6. Drain Connection ......................................................................................................... 2-3

2-7. Compressor Size and Load ..........................................................................................2-4

2-8. Foot Print Drawing ...................................................................................................... 2-4

2-9. Cut Out Dimensions for Dry Base or T able Installation.............................................. 2-5

2-10. Flourescent Lighting and Bulb Replacement ...............................................................2-6

2-11. Hot or Cold Top on a Cold Base Installation Instructions............................................ 2-7

Section 3. OPERATION............................................................................................................................ 3-1

3-1. Introduction ..................................................................................................................3-1

3-2. Operating Controls .......................................................................................................3-1

3-3. Basic Operation ........................................................................................................... 3-3

3-4. Cleaning ....................................................................................................................... 3-3

3-5. Programming ................................................................................................................3-5

3-6. Fluorescent Bulb Replacement ....................................................................................3-7

Wiring Diagram .........................................................................................................................3-8

Section 4. PAR TS INFORMATION .........................................................................................................4-1

4-1. Introdution ....................................................................................................................4-1

4-2. Genuine Parts ..............................................................................................................4-1

4-3. How to Order ..............................................................................................................4-1

4-4. Prices ........................................................................................................................... 4-1

4-5. Delivery .......................................................................................................................4-1

4-6. Warranty......................................................................................................................4-1

4-7. Recommended Spare Parts for Distributors................................................................4-1

206 i

Model CMC/CMR-103,104,105,106,107

SECTION 1. INTRODUCTION

1-1. COLD TOPS The Henny Penny cold tops are full service units, designed to hold

chilled or refrigerated products. The units are electronically

controlled for easy use and for consistent operation.

1-2. FEA TURES • Can be matched with hot or cold merchandisers in all lengths

• Electronic Controls

• Stackable units on top of bases

• Low speed air circulation

• Easily maintained

• Fluorescent lighting with electronic ballast

(CE-magnetic ballast)

• Mirrored or clear side glass

• Full service units

• Remote or self-contained condenser models

• Insulated-well with high pressure injected polyurethane foam

• Automatic defrost cycles

• Fold-down wood or plastic cutting board

• Sliding rear doors with double thermal mirrored glass

• Front glass lifts for easy cleaning

1-3. PROPER CARE As in any unit of food service equipment, the Henny Penny cold top

does require care and maintenance. Requirements for the mainte

nance and cleaning are contained in this manual and must become a

regular part of the operation of the unit at all times.

1-4. ASSISTANCE Should you require outside assistance, just call your local indepen-

dent Henny Penny distributor in your area, or call Henny Penny

Corp. 1-800-417-8405 toll free or 1-937-456-8405.

503 1-1

Model CMC/CMR-103,104,105,106,107

1-5. SAFETY The Henny Penny cold tops have many safety features

incorporated. However, the only way to ensure a safe operation

is to fully understand the proper installation, operation, and

maintenance procedures. The instructions in this manual have

been prepared to aid you in learning the proper procedures.

Where information is of particular importance or safety related,

the words NOTICE, CAUTION, and WARNING , are used. Their

usage is described below .

SAFETY ALER T SYMBOL is used with DANGER,

W ARNING, or CAUTION which indicates a personal injury

type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

W ARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

1-2 303

Model CMC/CMR-103,104,105,106,107

SECTION 2. INSTALLATION

2-1. INTRODUCTION This section provides the installation for Henny Penny cold tops.

Installation of this unit should be performed only by a

qualified service technician.

Do not puncture the unit with any objects such as

drills or screws, or component damage or electrical

shock could result.

2-2. UNP ACKING The Henny Penny Cold T op has been tested, inspected, and

expertly packed to insure arrival at its destination in the best

possible condition. The grids, side glass, and sliding thermal doors

are packed separately inside the unit. The cabinet rests on a

wooden skid and is then packed inside a heavy cardboard carton

with sufficient padding to withstand normal shipping treatment.

To avoid damage to the components, do not lay the unit

on its side. If the unit has been on its side, the unit must

be in an upright position for at least 4 hours before power

is applied to the unit.

Check all components, for signs of being loose or damaged, and make sure the system has refrigerant.

When moving the cold top be careful not to damage the

refriger ent circuit.

Any shipping damage should be noted in the presence

of the delivery agent and signed prior to his or her

departure.

T o remove the Henny Penny cold top from the carton:

1. Carefully cut banding straps.

2. Lift the carton off the unit.

3. Remove bolts securing the cold top to the skid and lift the

unit off the skid.

303 2-1

2-2. UNP ACKING

(Continued)

Model CMC/CMR-103,104,105,106,107

T ake care when moving the fryer to pr event personal

injury or damage to the refrigeration system. The

CMC-107s weigh over 700 lbs. (318 kg).

4. Peel off any protective covering from exterior of the cabinet.

5. Install the grids into unit.

6. Unpack sliding thermal doors and side glass. Install on rear

and side of unit.

7. Y our cold top is now ready for operation.

2-3. ELECTRICAL The Cold T op is available as a 120 VAC, 60 Hz. or 230V AC,

50 Hz., single phase unit, both for domestic and international use.

The data plate, located beside the power cord, specifies the correct

electrical supply . The Cold T ops are shipped with cord and plug,

and requires a grounded receptacle with a separate electrical line

protected by a fuse or circuit breaker of the proper rating. Position

the unit so the power cord receptacle is accessible.

T o avoid electrical shock, this appliance must be

equipped with an external circuit breaker which will

disconnect all ungrounded (unearthed) conductors.

Refer to the table below for electrical ratings:

Model No. Volts Amps Phase Max. Fuse Size

CMC-103 120 7.7 1 15

CMC-103 230 4.5 1 15

CMC-104 120 7.7 1 15

CMC-104 230 4.5 1 15

CMC-105 120 8.6 1 15

CMC-105 230 6.0 1 15

CMC-106 120 8.6 1 15

CMC-106 230 6.0 1 15

CMC-107 120 9.5 1 15

CMC-107 230 7.7 1 15

2-2 303

Model CMC/CMR-103,104,105,106,107

2-4. LOCA TION Place the cold tops in an area where product can be loaded and

unloaded without interruption. For proper operation, level the unit

by adjusting the bolts under the base, and leave 3 feet (91.44 cm)

clearance behind the unit for ventilation and service.

For maximum efficiency , units should be operated in an air-conditioned environment, with maximum air temperature of 75° F

(24° C), and 55% relative humidity .

Wait at least 4 hours before plugging the unit into an

electrical supply. The gases and oils in the r efrigeration

system needs to settle before operating the compressor, or

damage to the compressor could result.

2-5. REFRIGERANT Design Pressure

INFORMATION High Low

CMC-103 R22 1.5 lbs (0.680 kg) 440psig 162 psig

CMC-104 R22 1.5 lbs (0.680 kg) 440psig 162 psig

Refrigerant T ype Amount of Refrig.

(30.3 bar) (1 1.2 bar)

(30.3 bar) (1 1.2 bar)

UL Specs CMC-105 R22 2.5 lbs (1.134 kg) 440psig 162 psig

(30.3 bar) (1 1.2 bar)

CMC-106 R22 2.5 lbs (1.134 kg) 440psig 162 psig

(30.3 bar) (1 1.2 bar)

CMC-107 R22 2.5 lbs (1.134 kg) 440psig 162 psig

(30.3 bar) (1 1.2 bar)

CMC-103 R134A 1.65 lbs (0.750 kg) 440psig 162 psig

(30.3 bar) (1 1.2 bar)

CMC-104 R134A 1.87 lbs (0.850 kg) 440psig 162 psig

(30.3 bar) (1 1.2 bar)

CE Specs CMC-105 R134A 2.65 lbs (1.200 kg) 440psig 162 psig

(30.3 bar) (1 1.2 bar)

CMC-106 R134A 3.09 lbs (1.400 kg) 440psig 162 psig

(30.3 bar) (1 1.2 bar)

CMC-107 R134A 3.53 lbs (1.600 kg) 440psig 162 psig

(30.3 bar) (1 1.2 bar)

2-6. DRAIN CONNECTION The cold tops-remote (CMRs), requires 1-1/2 inch (38.1 mm)

drain connection. CMCs do not require a plumbed drain.

303 2-3

Model CMC/CMR-103,104,105,106,107

2-7. COMPRESSOR SIZE

AND LOAD

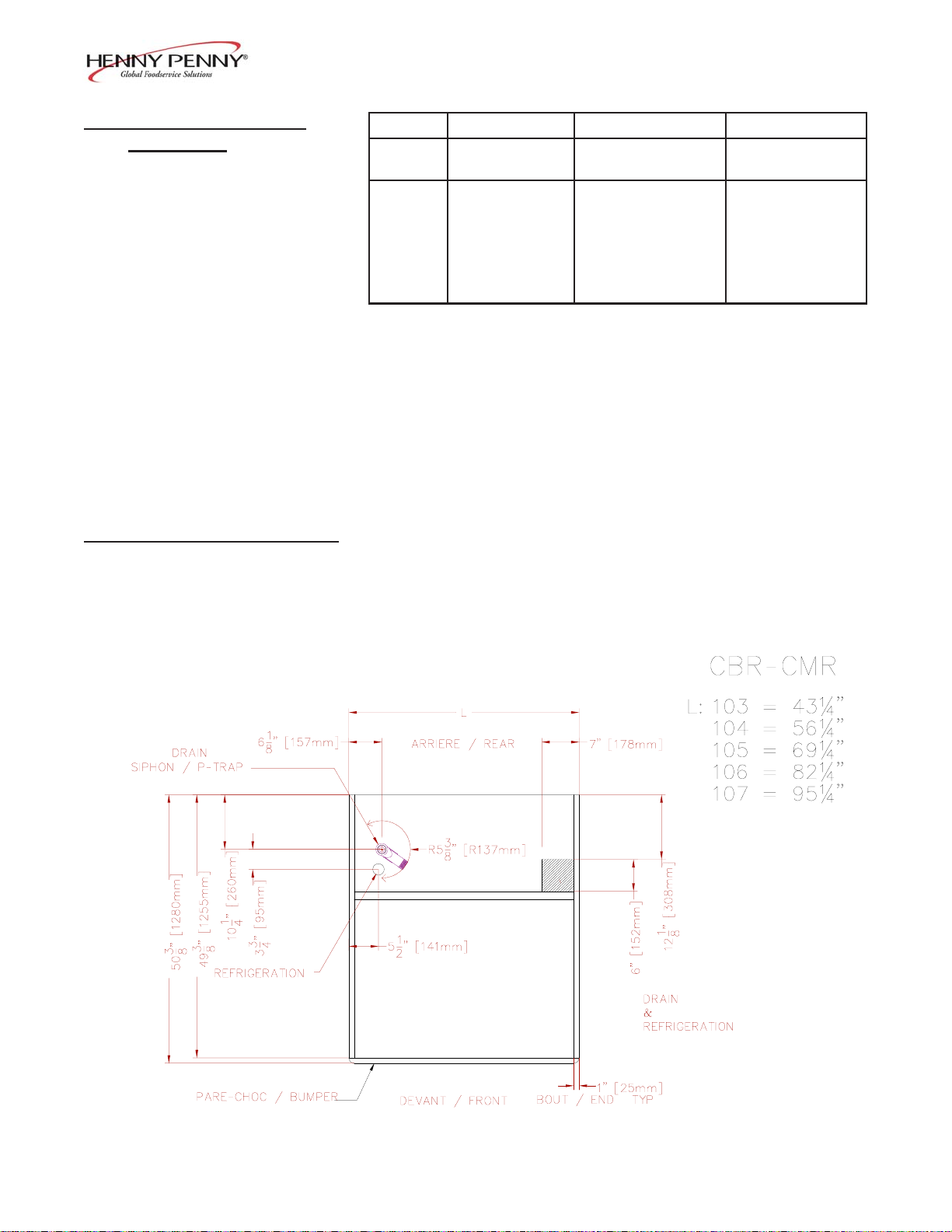

2-8. FOOT PRINT DRAWING

Model CMC Motor HP CMR Motor HP

CMC/ BTU Load U L CE U L CE

CMR R-22 R-134a R-22 R-134a

103 2860 1/4 1/3 Remote

104 2860 1/4 1/3 Compressor

105 2830 1/3 1/2 Supplied

106 2830 1/3 1/2 By Other

107 3840 1/2 1/2

BTU load sized at evaporator temperature + 20 F or -6 C.

CMR MODELS

DRAIN& REFRIGERATION CONNECTIONS

2-4 303

Loading...

Loading...